Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

I56-3904-001

8251F FAAST

Fire Alarm Aspiration Sensing Technology

SPECIFICATIONS

Electrical Characteristics

External Supply Voltage 18 – 30 VDC

Power Reset 10 sec.

Average Signaling Line Circuit (SLC) Operating Current 700 uA

Average Operating Current 500 mA @ 24 VDC

SLC Voltage Range 15 to 32 VDC

Alarm 650 mA – All relays active, all alarm levels displayed. Voltage @ 24 VDC

Relay Contact Ratings 3.0 A @ 30 VDC, 0.5A @ 125 VAC

Environmental Ratings

Operating Temperature 32°F (0°C) to 100°F (38°C)

Sampled Air Temperature -4°F (-20°C) to 140°F (60°C)

Humidity 10 to 95% (non-condensing)

IP Rating IP30

Coverage Area 8,000 sq. ft. (743.2 sq. m.)

Air Movement 0 – 4,000 ft./min. (0-1,219.2 m/min.)

Mechanical characteristics

Exterior Dimensions

Height 13.25 in. (33.66 cm)

Width 13.0 in. (33 cm)

Depth 5.0 in. (12.7 cm)

Cable Access 4 – 1 in. (2.54 cm) cable entry holes on top and bottom of unit.

Wire Gauge 12 AWG (2.0523 mm) max. to 24 AWG (0.5105 mm) min.

Pipe Network Size Up to 8000 sq. ft. (approx 743 sq. m)

Maximum single pipe length 262 ft. (80 m)

Network outside pipe diameter 1.050 in., IPS (25 mm)

Internal pipe diameter .591 to .827 in. (15-21 mm)

Shipping Weight 11.6 lbs. (5.26 kg), includes packing material

TABLE OF CONTENTS

INTRODUCTION

SCOPE OF THIS MANUAL ...........................................2

DESCRIPTION

FEATURES .......................................................2

ITEMS INCLUDED WITH UNIT .......................................2

INSTALLATION

PIPE INSTALLATION ............................................... 2

PHYSICAL UNIT INSTALLATION ...................................... 2

Securing the Mounting Bracket ................................2

Mounting the Detector to the Bracket ...........................3

Connecting the Air Sampling Pipe ..............................3

Exhaust Pipe ................................................3

WIRING .......................................................3

Power Cables ...............................................3

Conduit Usage ..............................................3

CABLING REQUIREMENTS .......................................... 4

SYSTEM POWERING ...............................................4

USER INTERFACE

USER INTERFACE CARD INSTALLATION ...............................5

PARTICULATE LEVEL DISPLAY .......................................5

ALARM LEVEL DISPLAY ............................................ 5

AIR FLOW/FAULT DISPLAY ..........................................5

Labels .....................................................5

USER INTERFACE BUTTONS ........................................5

MODES OF OPERATION

INITIALIZATION ...................................................6

STARTUP ....................................................... 6

CONFIGURATION ................................................. 6

NORMAL MODE .................................................. 6

TEST MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RESET MODE .................................................... 6

ACCLIMATE ......................................................6

DAY, NIGHT AND WEEKEND MODE ...................................7

ISOLATION .......................................................7

USER BUTTON ALTERNATE FUNCTIONS ...............................7

FAULTS ....................................................... 8

REAL–TIME CLOCK ...............................................8

LOGS .......................................................8

EXTERNAL MONITOR/RESET ........................................8

ETHERNET CONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PIPE NETWORK .................................................. 8

WEB SERVER .................................................... 9

E-MAIL NOTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CANNED SMOKE TESTING ..........................................9

MAINTENANCE ...................................................9

FAAST COMMISSIONING FORM .......................................10

GLOSSARY

KEY TERMS ....................................................12

®

Failure of Configuration Validation ..............................6

Power or Network Loss during Configuration ......................6

Setting Acclimate mode .......................................6

Passcode Access ............................................7

Address Blink Mode ..........................................7

IP Address Blink Mode ........................................7

Event Log ..................................................8

Data Trend Log ..............................................8

Message Log ...............................................8

3825 Ohio Avenue, St. Charles, Illinois 60174

1.800.SENSOR2; Fax: 630.377.6495

www.systemsensor.com

SS-600-000 1 I56-3904-001

Page 2

INTRODUCTION

WARNING

WARNING

Mounting Stud

SCOPE OF THIS MANUAL

This manual is intended as a guide for technicians to install, set up and provide preliminary system checks for the FAAST (Fire Alarm Aspiration Sensing Technology) aspirating smoke detection system. Before installing, please

read the Comprehensive Instruction Manual for the FAAST aspiration detection system (available at SystemSensor.com/faast), which provides detailed information on pipe design and system configuration.

The performance of the system depends on the designed pipe network for

the site. Any alteration to the pipe network will alter the performance of

the system and must be verified by a technician. The PipeIQ® design tool

can be used to verify the suitability of any pipe network design and subsequent alterations. The PipeIQ software program can be downloaded from

systemsensor.com/faast.

DESCRIPTION

The FAAST aspirating smoke detection system is an advanced particulate detection system for use in early warning and very early warning applications.

The system continuously draws air from the controlled environment (up to

8,000 sq. ft.) through a series of sampling holes to monitor the environment

for smoke particulate.

FAAST system conditions are displayed at the user interface and at a fire alarm

control panel. System conditions can also be displayed remotely in two ways

through the network interface: integrated Web server or PipeIQ software. The

display provides a clear indication of the system status, particulate levels,

alarm levels, air flow and faults. Additionally, e-mail notification can be sent

upon status changes. These can all be discerned by monitoring the user interface at either the local or remote display.

FEATURES

• Clip intelligent protocol

• Advanced detection using blue LED and IR laser technology

• Monitors up to 8,000 sq. ft. (dependant on local code and ordinances)

• Wide sensitivity range of 0.00046% to 6.25% obs/ft.

• Programmable alarm thresholds and delays

• Six sets of relay contacts

• Advanced dust discrimination for reduced false alarms

• Air filtration

• Particle separation for increased filter life

• Electronic filter life monitoring

• Ultrasonic air flow sensing

• Field service access door

• Easy access filter maintenance door

• Event, service and trend logs

• Pipe modeling software

• Acclimate mode operation for auto-adjustment of sensitivity

• Remote monitoring via Ethernet/IP

• Multi-lingual support

• E-mail notification of alarm, fault or isolate conditions

ITEMS INCLUDED WITH UNIT

• FAAST unit

• Mounting bracket

• Mounting nuts (2) and washers (2)

• 3-pin Terminal block (6)

• 4-pin Terminal block (2)

• Installation and Maintenance Instructions

• PipeIQ® software, the Comprehensive Instruction Manual, and the Advanced

Networking Guide may be downloaded at systemsensor.com/faast

INSTALLATION

This equipment must be installed in accordance with all local and national

codes and regulations.

PIPE INSTALLATION

The pipe layout is designed using the PipeIQ software package. Refer to the

Comprehensive Instruction Manual available at www.systemsensor.com/faast

to design the pipe network. All pipe must be installed in accordance with local and national codes and regulations. The pipe network should be complete

before proceeding with the physical and electrical system installation.

PHYSICAL UNIT INSTALLATION

Make sure that there are no pipes or electrical wires within the wall before

drilling any mounting holes.

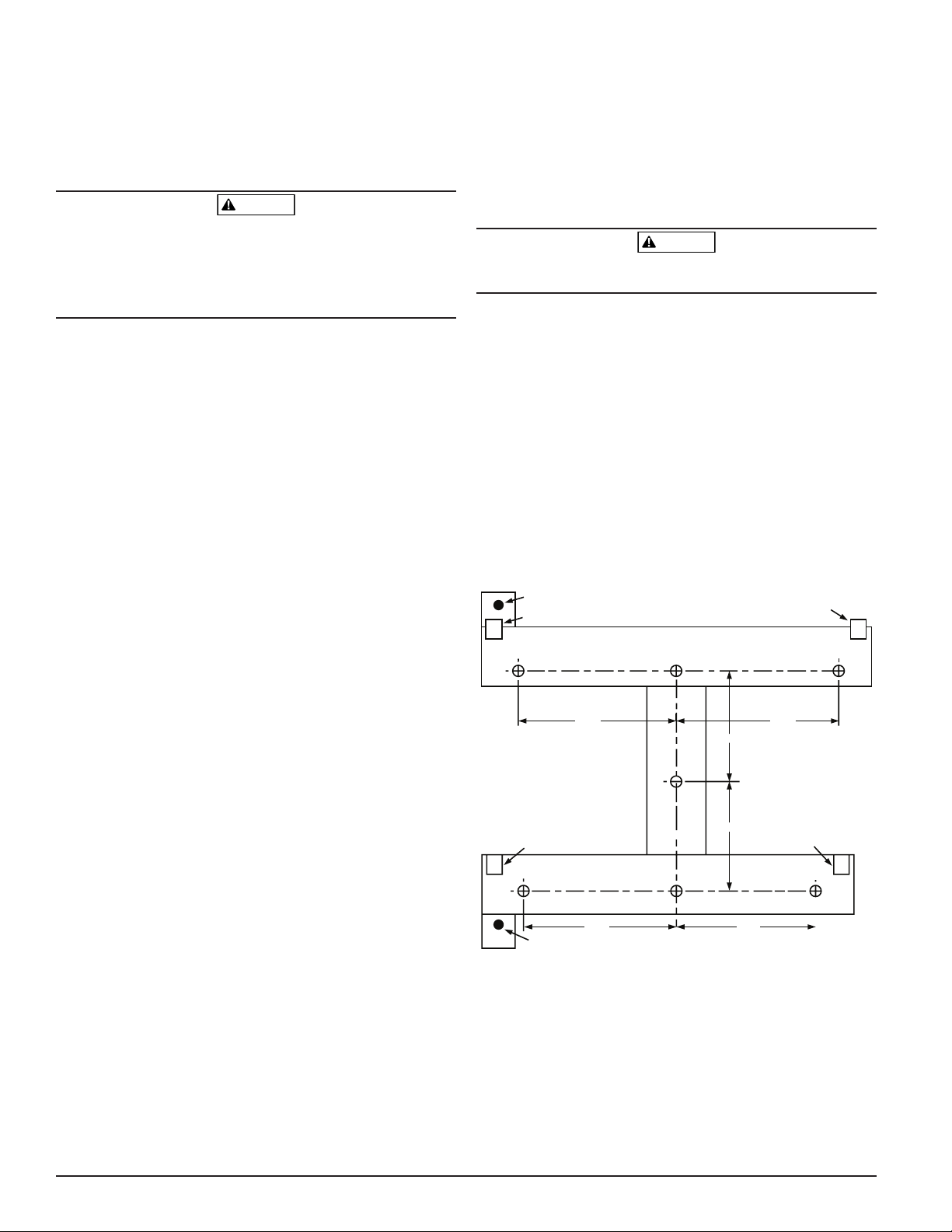

Securing the Mounting Bracket

The typical mounting location for the FAAST unit is on a wall. The unit is

mounted to the wall using the enclosed mounting plate. Figure 1 shows the

wall mounting plate. For easier access to the FAAST unit, it is preferred to

position the mounting plate in an easily accessible location.

1. Place the mounting bracket on the wall in the desired location and use it as

a template to locate the necessary mounting holes.

2. Mark the hole locations and remove the bracket. It is recommended to

secure the bracket using the 4 outer mounting holes.

3. Using a drill and the proper size bit for your mounting hardware, drill the

necessary holes.

4. Use appropriate fasteners to accommodate the mounting surface and

FAAST device weight.

5. Secure the bracket to the wall.

FIGURE 1. WALL MOUNTING PLATE

Mounting Clip

Mounting Clip

Mounting Stud

4.650"

11.811 cm

4.500"

11.430 cm

3.240"/8.230 cm

3.210"/8.153 cm

4.090"

10.389 cm

12.116 cm

Mounting Clip

4.770"

Mounting Clip

ASP-07

SS-600-000 2 I56-3904-001

Page 3

Mounting the Detector to the Bracket

Po

Once the mounting plate is attached, the unit is ready to be mounted onto the

plate. Perform the following procedure to mount the unit.

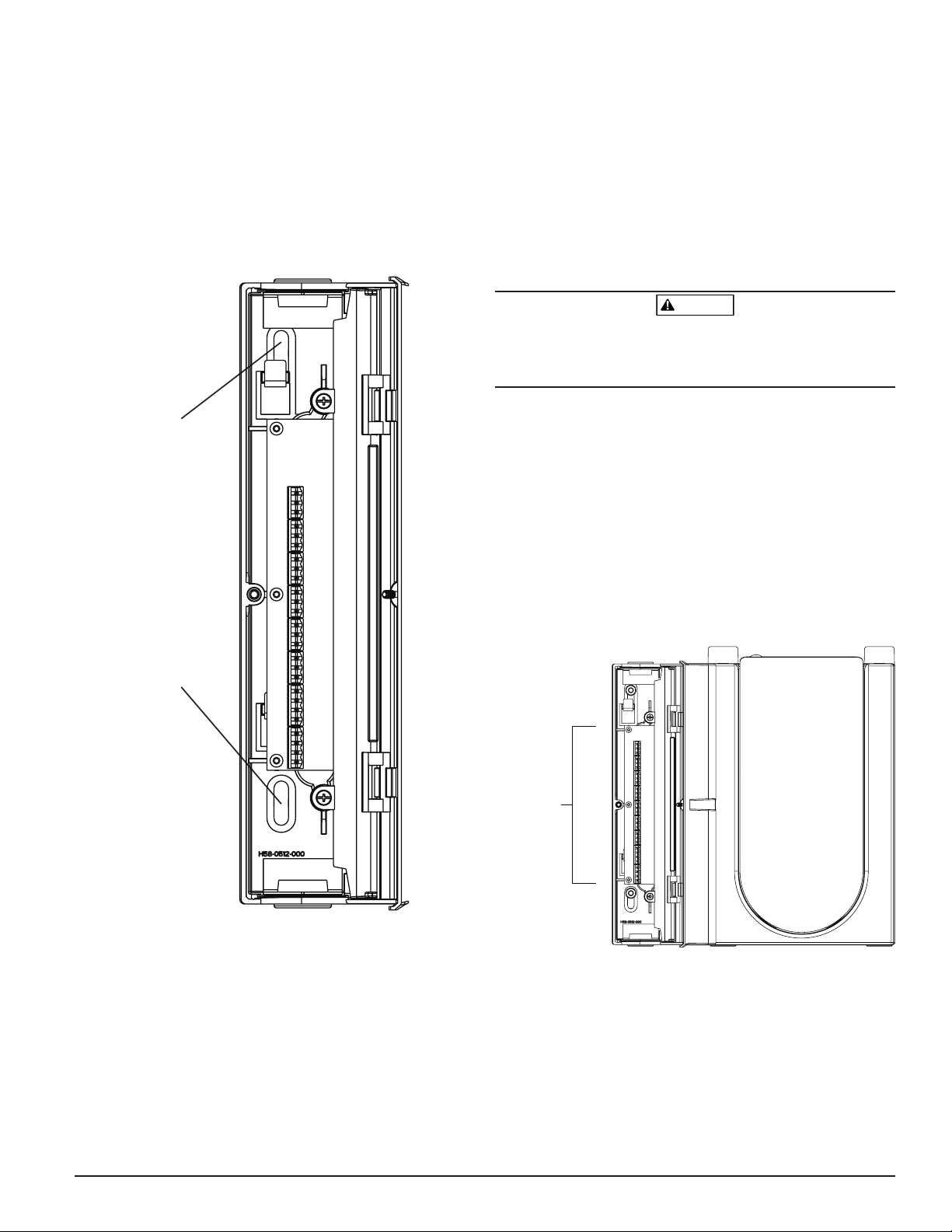

1. Before installing the unit onto the bracket, remove the appropriate conduit cap from the top or bottom-left side of the unit to match the orientation of the wiring. See Figure 14 for location of the wiring access plugs.

2. Line up the unit with the four mounting clips and the mounting studs on

the left side.

3. Push the unit down onto the mounting clips and secure it with the supplied washer and nut on at least one of the two mounting studs protruding through the mounting slots shown in Figure 2.

FIGURE 2. MOUNTING SLOTS FOR MOUNTING STUDS

Mounting

Slot

Mounting

Slot

Exhaust Pipe

The device should always be exhausted into the space that it is monitoring.

There are some circumstances when it may be necessary to connect a pipe to

the exhaust port to divert the exhaust away from the location of the unit. The

output ports are tapered the same as the input ports, to provide fast, easy,

push-fit connection of an exhaust pipe to the unit. Perform the following procedure to connect the exhaust pipe to the unit.

1. Square off and de-burr the end of the exhaust pipe. Ensure that the pipe

is free from any particles that might interfere with the pipe connection.

2. Remove the exhaust plug from the output port being used (either the top

or bottom of the unit).

3. Insert the exhaust pipe into the output port, ensuring a snug fit. DO NOT

glue these pipes.

WIRING

WARNING

Before working on the FAAST system, notify all required authorities that the

system will be temporarily out of service. Make sure all power is removed

from the system before opening the unit. All wiring must be in accordance

with local codes.

Power Cables

Use the power ratings of the unit to determine the required wire sizes for each

connection. Use the power ratings of the connected products to determine

proper wire size.

Conduit Usage

If electrical conduit is used for system wiring, terminate the conduits at the cable

entry ports on the top or bottom of the unit, using the appropriate conduit connectors.

1. Run all wiring, both power and alarm, through the conduit and into the

left side of the unit enclosure, as shown in Figure 3.

2. Attach the appropriate wires to the supplied Euro connector. Follow appropriate local codes and electrical standards for all cabling.

3. Plug the appropriate connector into the mating connector on the unit.

FIGURE 3. POWER AND ALARM CONNECTION CONNECTOR BLOCK

wer and Alarm

Connections

ASP17-01

Connecting the Air Sampling Pipe

The input and output ports are designed to accept standard one inch pipe (25

mm) OD. The input ports are tapered to provide fast, easy, push-fit connection

of the sampling pipe to the unit. Perform the following procedure to connect

the air sampling pipe to the unit.

1. Square off and de-burr the end of the sampling air pipe. Ensure that the pipe

is free from any particles that might interfere with the pipe connection.

2. Remove the input plug from the input port being used (either the top or

bottom of the unit).

3. Insert the sampling air pipe into the input port, ensuring a snug fit.

DO NOT glue these pipes.

SS-600-000 3 I56-3904-001

ASP16-01

Page 4

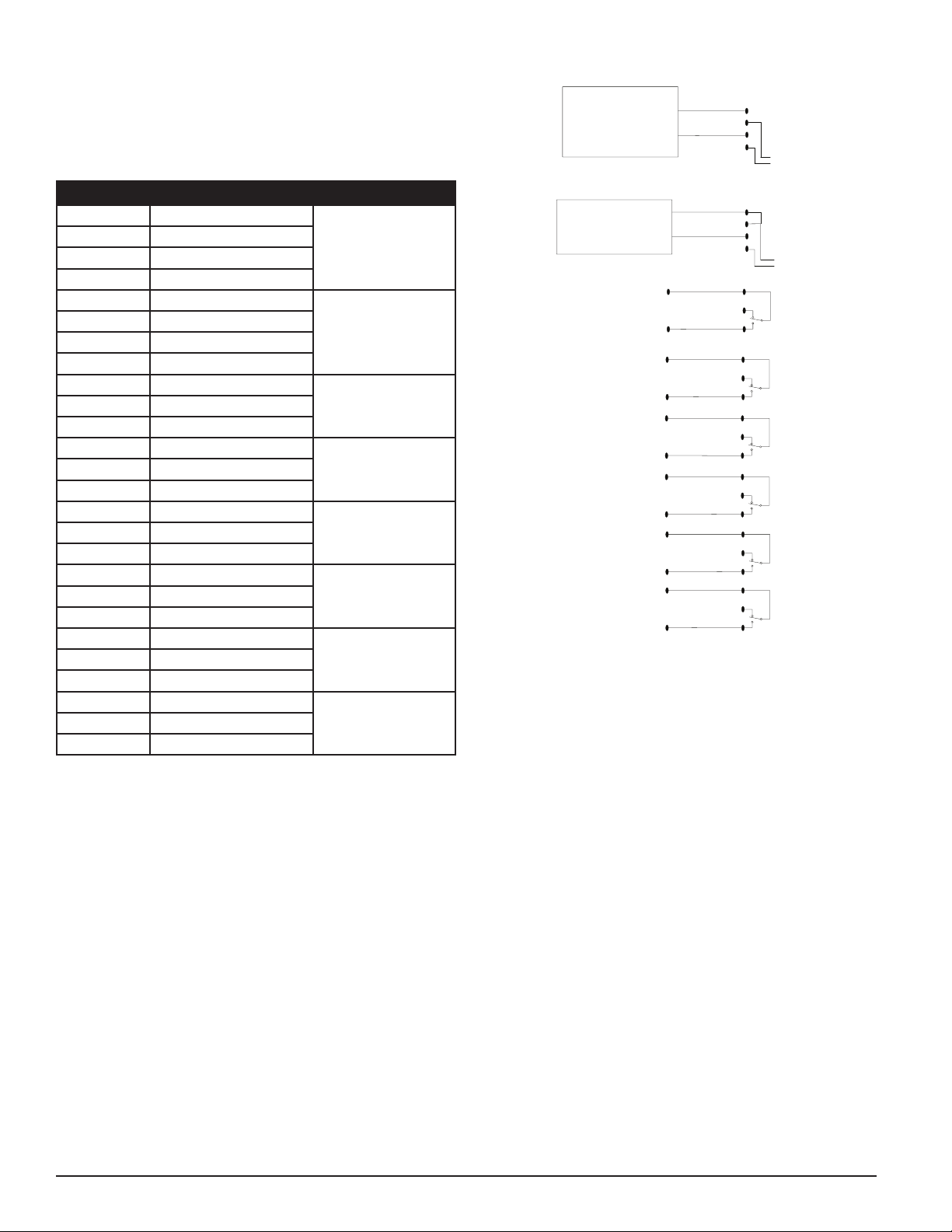

CABLING REQUIREMENTS

The FAAST system provides a series of Euro style pluggable terminals, located

behind the left side door of the unit.

Refer to Table 1 for the proper electrical connections to the unit. Refer to Table

2 for a typical connection for monitoring the FAAST system at a Fire Alarm

Control Panel (FACP).

TABLE 1. TERMINAL DESIGNATIONS

NUMBER NAME TERMINAL BLOCK

T1 External Power -

T2 External Power -

T3 External Power +

1

T4 External Power +

T5 SLC+

T6 SLC+

T7 SLC-

2

T8 SLC-

T9 ALERT NO

T10 ALERT COM

3

T11 ALERT NC

T12 ACTION 1 NO

T13 ACTION 1 COM

4

T14 ACTION 1 NC

T15 ACTION 2 NO

T16 ACTION 2 COM

5

T17 ACTION 2 NC

T18 FIRE 1 NO

T19 FIRE 1 COM

6

T20 FIRE 1 NC

T21 FIRE 1 NO

T22 FIRE 2 COM

7

T23 FIRE 2 NC

T24 FAULT NO

T25 FAULT COM

8

T26 FAULT NC

TABLE 2. FACP WIRING DIAGRAM

N.C.

N.O.

N.C.

N.O.

N.C.

N.O.

N.C.

N.O.

N.C.

N.O.

N.C.

N.O.

-

-

(T1)

+

Ext PWR

+

To next

device

+

+

SLC (T2)

-

To next

C.

C.

C.

C.

C.

C.

device

ALERT

ACTION 1

ACTION 2

FIRE 1

FIRE 2

FAULT

(T3)

(T4)

(T5)

(T6)

(T7)

(T8)

ASP98-00

Power

Supply

24VDC

Fire Panel (FACP) typical connection

for monitoring of device

FACP

+

-

+

-

SYSTEM POWERING

The following procedure describes how to initially power up the FAAST system.

1. Unplug the unit’s power connector to the unit before turning ON the

power.

2. Turn on the power.

3. Check the voltage at the connector. Make sure it is within the required

voltage range.

4. If the voltage is within the proper range, reconnect the power connector

to the unit.

5. Connect the SLC connector to the SLC terminal.

6. Verify the system fan starts up and air begins to flow out of the exhaust port.

USER INTERFACE

The user interface, shown in Figure 4, provides the following information:

• Detector Status: Normal, Alarm, Fault or Isolate

• Alarm Level; Alert, Action 1, Action 2, Fire 1 and Fire 2

• Particulate Levels; 1-10 relative to user programmable scale

• Fault Status

• Flow Level

• Test, Mode and Isolate Buttons

SS-600-000 4 I56-3904-001

Page 5

GREEN LEDs

FIGURE 4. USER INTERFACE DISPLAY

Alarm Level

Indicator

Particulate Level

Indicator

Power

Indicator

ASP08-02

USER INTERFACE CARD INSTALLATION

The user interface card must be installed on the front panel of the FAAST

aspirating smoke detection system. For installation, first slide the card into

the bottom pocket, then beneath each of the mounting tabs. If necessary,

use a flathead screwdriver to gently press the card in place beneath each of

the mounting tabs. The card is moderately flexible to allow for some bending

during installation. The user interface card is available in various languages.

PARTICULATE LEVEL DISPLAY

The particulate level display, shown in Figure 5, consists of ten amber LEDs

that correspond to the current level of the particulate detected. The LEDs illuminate in order from Level 1 to Level 10, starting from the bottom of the

display and moving up as the particulate level increases. Each LED represents

a ten percent increase in the particulate level necessary to reach the user programmable level.

FIGURE 5. PARTICULATE LEVEL DISPLAY

These alarm levels are configured at default levels when shipped. Each of these

alarm levels can control a set of form C relay contacts. When an alarm level threshold is crossed, the corresponding level LED illuminates and the relay activates a

signal. These alarm levels and associated relay outputs can be programmed for

either latching or non-latching operation, in addition to a programmable delay for

each level. The programmable ranges for each level are shown in Table 3.

FIGURE 6. ALARM LEVEL DISPLAY

ASP-10

AIR FLOW/FAULT DISPLAY

The FAAST system uses ultrasonic airflow sensing and displays the status in

real time on the User Interface. The air flow/fault display consists of 10-bicolor LEDs and operates in one of two modes. A default warning occurs when

airflow increases or decreases by 20% or greater. The green segments indicate

how close the current air flow is to either of these thresholds. During normal

operation two adjacent indicators are green and correspond to the current airflow entering the detector. When airflow is at a balanced level the two green

segments are centered on the graph at levels 5 and 6, see Figure 7. As airflow rises and falls, the green segments move right and left accordingly. The

segment on the far left represents a decrease in airflow of 20%. Conversely,

movement to the segment on the far right represents an airflow increase of

20%. A flow fault occurs within 3 minutes of reaching either of these levels

and the minor fault relay is indicated. During a fault condition, the fault LED

as well as the corresponding high or low fault segment is lit in amber.

Labels

Detector faults are labeled adjacent to the indicators on the Air Flow Fault graph.

FIGURE 7. BALANCED AIR FLOW

ASP14-01

USER INTERFACE BUTTONS

The user interface has three buttons, shown in Figure 8, that are used to operate the unit. Functionality of these buttons are locked out by default from

the factory and require a passcode to enable them (refer to Passcode Access

section). The passcode can be programmed from the PipeIQ software tool.

ASP-09

FIGURE 8. USER INTERFACE BUTTONS

ALARM LEVEL DISPLAY

The Alarm Level Display consists of five red LEDs that correspond to the current alarm level, shown in Figure 6. These LEDs are located directly above the

Particulate Level LEDs. They illuminate sequentially upward as the severity of the

ASP11-01

alarm increases.

SS-600-000 5 I56-3904-001

Page 6

TABLE 3. ALARM LEVEL PROGRAMMABLE RANGES

ALARM LEVEL DEFAULT THRESHOLD

%OBS/FT.

Alert 0.012 0.00046 - 6.25 0.0396 0.0015 - 20.5

Action 1 0.050 0.00046 - 6.25 0.165 0.0015 - 20.5

Action 2 0.100 0.00046 - 6.25 0.33 0.0015 - 20.5

Fire 1 0.250 0.00046 - 6.25 0.825 0.0015 - 20.5

Fire 2 0.500 0.00046 - 6.25 1.65 0.0015 - 20.5

NOTE: Installation must be accomplished in accordance with all local codes and regulations.

Product is UL certified to UL268. FAAST is UL approved from 0.00046 %/ft obs. to 4.0%/ft obs. Evacuation via FACP (fire alarm control panel) must not be set

higher than 0.743 %/ft obs. Product UL approved sensitivity range for D(l) classification is from 0.5 to 0.61 %/ft obs. from 300 to 4000 FPM.

PROGRAMMABLE RANGE

%OBS/FT.

DEFAULT THRESHOLD

%OBS/M

PROGRAMMABLE

RANGE %OBS/M

MODES OF OPERATION

INITIALIZATION

(Refer to the Configuration section below for further instructions). Once configuration has started, the device performs an automatic initialization. This

initialization sets the air flow baseline, the filter clogged baseline and the particulate level baseline. It is important that the system is connected properly

and the filter is installed correctly when the device is initialized. These initial

readings are used as a reference baseline to indicate when a fault occurs. Innitialization may take up to five minutes to complete.

STARTUP

Once powered, the FAAST system initializes using its stored configuration.

The device checks and establishes its initial airflow, filter and fan settings.

If all measurements are normal it begins normal operation. If any fault is detected the appropriate fault LED will illuminate.

CONFIGURATION

The FAAST system is configured using the PipeIQ software (available at www.

systemsensor.com/faast). Data is sent via the built-in Ethernet connection.

The device receives the configuration and performs a validation before the

configuration becomes active. After validation of the data, the device performs

an initialization with the new configuration.

ADDRESS ASSIGNMENT

The SLC address for a Clip FAAST unit is set using the PipeIQ software. Each

unit consumes one SLC address.

To assign the device a SLC address, navigate to the ‘Network’ tab in the ‘Configuration’ portion of your PipeIQ project. Use the ‘Identification Number’

drop box at the top of the page to assign the Clip FAAST an address of 1

through 99. Each SLC loop can support a maximum of 99 Clip FAAST devices.

Failure of Configuration Validation

If configuration validation fails, the software configuration tool indicates a

failure and the FAAST system illuminates the amber CONFIGURATION fault

LED on the user interface. The device will not accept any of the data as valid.

If a configuration fault occurs during the initial configuration or the device is

unable to operate due to the configuration, the device must be re-configured

using PipeIQ. If the configuration fault occurs after the initial configuration

has been accepted, a Minor Fault relay will be set and the device reverts back

to its last valid configuration.

Power or Network Loss during Configuration of E-mail

During an upload of configuration data, the FAAST system keeps the last

known valid configuration in memory until a complete validation is completed on the new configuration data. This prevents data corruption in the

event of a power loss or network failure. When power is restored the device

performs a Startup with the last valid configuration. The device also indicates

a CONFIGURATION fault on the user interface. This occurs only once. When

the next Reset or Power On Reset is performed the device continues to use the

last valid configuration.

NORMAL MODE

In Normal operating mode the FAAST system displays the air flow and current

particulate levels on the user interface. The particulate level is compared to

the threshold levels programmed into the device and activates the appropriate

alarm as particulate levels exceed that threshold. If any fault occurs it activates the corresponding fault LED and relay.

TEST MODE

Test mode is initiated through the FACP or by depressing the TEST button on

the user interface, when the button is enabled (refer to passcode access section for activation details).

ACCLIMATE

The FAAST system includes an available Acclimate mode. By allowing the device to operate in Acclimate mode, a device’s susceptibility to nuisance alarms

can be reduced. This provides maximum protection for a device located in

changing environments. The sensitivity of the unit continuously adjusts over

time, within the set limits as the local environment changes. Acclimate mode

must be activated and configured using PipeIQ. In Acclimate mode the device automatically adjusts the alarm point between a specified minimum and

maximum sensitivity, programmed by the user. For the first 24 hours of operation the device monitors its environment. After the initial 24 hour period, the

device adjusts the alarm point based on the particulate levels over a rolling

1 hour period. It then adjusts the alarm level starting from the insensitive

boundary, based on the stability of the environment being monitored.

Setting Acclimate mode

The user chooses the boundaries for each alarm level in the Acclimate mode.

The FAAST system starts from the insensitive boundary and adjusts itself to

stay within the sensitive boundary.

ISOLATE

Isolation mode is initiated by pressing and releasing the ISOLATE button on

the user interface when the button is enabled (refer to the passcode section).

When the ISOLATE button is activated the FAAST system resets the fault and

alarm relays. It then sets the isolation relay and the isolation fault indicator

illuminates on the user interface. In this mode the device operates normally

but will not activate relays for any alarm or fault levels (except the Isolation

relay). Fire and fault events can still be seen on the user interface and the

web server will send e-mail notification of events if enabled. Isolation mode

will be held through resets and power outages. The device will remain in

isolation mode until the isolation mode is removed by pressing the ISOLATE

button. ISOLATE mode may be enabled and disabled using the monitoring

portion of PipeIQ.

DISABLE

Disable mode is initiated by pressing and holding the ISOLATE button on the

user interface for 3 seconds when the button is enabled (refer to the passcode

section). When the ISOLATE button is activated, the FAAST system resets the

fault and alarm relays. It then sets the isolation relay and the isolation fault

indicator illuminates on the user interface. In this mode the fan switches off

and the device does not report any alarm or fault levels on the user interface

or activate any relays (except the Isolation Relay). This mode should only

be used when the system needs to be taken offline. This mode will be held

through resets and power outages. The device will remain in disable mode

until the disable mode is removed by pressing the ISOLATE button. Disable

mode cannot be enabled or disabled using the monitoring portion of PipeIQ.

SS-600-000 6 I56-3904-001

Page 7

USER BUTTON ALTERNATE FUNCTIONS

Passcode Access

The user interface has an option that requires users to enter a security code

before the front panel functions become active. All passcodes must be 4 digits

in length using numbers 1 through 9 (zero cannot be used). Passcodes may

only be changed through the device specific page. In addition, the configuration software tool is capable of locking out buttons individually, so that certain buttons may be accessed without a passcode, if desired.

The default passcode is ‘1111’.

The TEST button enters digits, the MODE button is used to enter the unlock

mode and the ISOLATE button increments the current digit.

FIGURE 9. PASSCODE ACCESS BUTTONS

ASP11-01

To enter the passcode mode, press and hold the MODE button for 8 seconds.

The first segment on the flow indicator first illuminates yellow, then green.

When the segment illuminates green, release the MODE button. The first segment on the airflow display blinks green, indicating the device is ready to

accept the first digit.

To enter the passcode, use the ISOLATE and TEST buttons, shown in Figure 9.

The ISOLATE button is used to increment the current digit. As the current digit

is incremented the segments of the Particulate Bar Graph illuminate accordingly. To complete entry of the digit, press the TEST button. As each digit is

entered the airflow segment illuminates solid green and the next segment begins to flash, indicating the next digit is ready to be entered. After the 4th digit

is entered, the fault indicator illuminates green, if the passcode was accepted

and remains green as long as the detector is “unlocked”. If the passcode was

not accepted, the fault indicator illuminates amber for 3 seconds then the

device returns to its previous state.

Once the passcode is accepted, the locked out button(s) become active. After

45 seconds of inactivity the fault indicator begins to blink green. After an additional 15 seconds the detector re-locks the button(s) and returns to normal

operation.

FIGURE 10. ADDRESS BLINK MODE

in Figure 11. The example shown in Figure 11 shows that the 5th number of the

IP address is 6. The current digit displayed is indicated by the FAULT, FLOW /

FAULT and VOLTAGE indicators (figure 12) starting with the FAULT for the 1st

digit, progressing through the HIGH FLOW, and ending with the LOW VOLTAGE

for the 12th digit. If one of the numbers is zero, then no lights will illuminate for that

number on the particulate graph. The device will return to normal operating mode.

FIGURE 11. IP ADDRESS BLINK MODE

Alarm Level

Indicator

Particulate Level

Indicator

Power

Indicator

ASP15-02

FIGURE 12. IP ADDRESS INDICATOR LIGHTS

ASP12-01

Address Blink Mode

The Clip FAAST can output its’ 3 digit address through the user interface. This

can be accessed from the user interface by pressing and holding the MODE

button for 3 seconds. After 3 seconds the first segment on the airflow display

will turn amber indicating the device is in address blink mode. Release the

MODE button and The device will give the 3 digit address by lighting the

particulate bar graph the appropriate number of segments for each digit. The

current digit displayed is indicated by the 6 left most indicators on the air flow

graph. The first 3 segments will be the loop.

IP Address Blink Mode

If the device IP has been lost or is unavailable, it’s possible to obtain the address

using the IP address blink mode. The IP address can be accessed from the user

interface by pressing and holding the MODE button for 30 seconds. The digits are

displayed using the same method described in the address blink mode, except

that the FAULT and LOW VOLTAGE indicators are used to show the 1st and 12th

digit, respectively. The device gives the 12 digit number by illuminating the particulate bar graph to the appropriate number of segments for each digit, as shown

SS-600-000 7 I56-3904-001

9

1

2

1

6

8

IP ADDRESS: 192.168.1.10

0

1

1

ASP19-01

Page 8

TABLE 5. FAULT DESCRIPTION

NUMBER NAME DESCRIPTION

1 Low Flow Fault Device has decreased airflow

2 Configuration Configuration of device with configuration software has failed.

Device was interrupted with a power loss during configuration. A Reset will

clear this fault and device will revert back to it's last good configuration.

Device is new and has not been configured.

Device has corrupt configuration and is unable to operate.

3 Sensor Fault Device has problem with the particulate sensor and needs

immediate replacement.

N/A N/A Locate LED used for maintenance.

5 Time Fault Internal Time base needs updating.

6 Communication Fault Device has failed to communicate to SLC and cannot function properly.

7 Aspirator Fault Indicates the fan has stopped working and requires immediate attention.

8 Filter Fault Device filter is clogged and requires replacement.

Device filter is clogged and has not been replaced 72 hours after giving the

Filter Fault with Minor Fault Relay set.

9 Isolate Fault Device has been disabled.

10 High Flow Fault Device has Increased airflow.

11 Low Voltage Fault Device Input voltage is low.

12 Isolate Fault Device is in isolate mode

FAULTS

Whenever a fault occurs, the general FAULT indicator illuminates amber and

the flow status bar oscillates between flow status (green) and a detailed fault

status (amber). Table 5 shows the number, name, description and the activated relay for each fault. The fault display on the user interface is shown in

Figure 13.

FIGURE 13. FAULT DISPLAY

ASP13-01

REAL–TIME CLOCK

The unit is equipped with a real-time clock and power supply that allows the

FAAST system to maintain the date and time for up to 72 hours after a loss

of power. Date and time are configured through PipeIQ. The real-time clock

is used to maintain a time base for the device. This time base is used to time

stamp all log entries. If the device loses power for more than 72 hours the

device sets the TIME fault indicating the time needs to be updated.

LOGS

Event Log

The FAAST system is equipped with internal memory that can be configured

to log detector events. Up to 18,000 events can be stored. Events that are

tracked include alarms, faults and user actions. Event tracking data may be

accessed via the network through the PipeIQ software or the Web server interface. Configuration and management of the log are done using the PipeIQ

software.

Data Trend Log

The FAAST system tracks trend data for each 24 hour time period, up to 1

year. The device records the minimum, maximum and average reading of the

sensor for each day.

Message Log

The message log allows the user to enter generic text messages into the system’s memory. Messages may be retrieved for viewing at a later time. These

messages may be used to track service history, configuration changes, etc. A

maximum of 300 messages may be stored.

ETHERNET CONNECTION

The FAAST system is a network capable device that is compatible with standard

Ethernet networking equipment. Connectivity is provided by an onboard RJ-45

connector located on the bottom of the unit, as shown in Figure 14. Once initial

setup is complete, the Ethernet connection provides optional remote access, monitoring and e-mail notification through the unit’s Web server and SMTP client.

PIPE NETWORK

The unit can monitor up to 8,000 sq.ft. (approx. 743 sq. m) with a properly

designed pipe network. The pipe network must be properly configured using

the PipeIQ software. The pipe network accommodates a maximum single pipe

length of 262 ft. (80 m). If two branches are used, the maximum single pipe

length is 165 ft. (50 m). The device is capable of both metric 25 mm and IPS

1.05 in. pipe outside diameters without the use of an adaptor. The internal

pipe diameter can range from .591-.827 inches (15-21mm). Only 1 inlet and 1

outlet pipe are used at a time. Pipe networks may be constructed of various

materials such as ABS, cPVC, PVC, copper or stainless steel pipe. Travel time

from the furthest hole depends on the application of the device, but is limited

to a maximum of 120 seconds by the PipeIQ software. Refer to local agency

requirements and PipeIQ software for proper configuration.

SS-600-000 8 I56-3904-001

Page 9

WEB SERVER

The FAAST system contains an integrated Web server which is used to observe detector configuration and may be used to remotely monitor the unit.

The Web server features include:

• Intuitive interface for remote monitoring of faults, relays, particulate

level, air flow, and power supply

• Facility location and contact information

• Configuration settings display

• Event log viewer

E-MAIL NOTIFICATION

The FAAST system has the ability to send e-mail notifications to an individual

or organization. Up to 6 different email addresses may be stored for notification. Each email address can be configured to be notified of a specific alarm

level, fault level or isolate condition through the PipeIQ software. E-mails from

the device indicate a device’s ID, location and alarm or fault type. A comprehensive networking guide may be downloaded at systemsensor.com/faast.

CANNED SMOKE TESTING

All FAAST systems must be tested after installation and periodically thereafter.

Testing methods must statisfy the authority having jurisdiction. Systems offer maximum performance when tested and maintained in compliance with

NFPA 72 and/or CAN/ULC S536 depending upon your national regulations..

UL Tested and approved aerosol smoke products are listed in Table 6.

TABLE 6. CANNED SMOKE TESTING

UL

LISTED

MAINTENANCE

The only periodic maintenance required is to replace the filter assembly when

the filter light is illuminated. Perform the following procedure to replace the

filter assembly.

1. Remove power from the system.

2. Open the door on the right side of the device that covers the LED system

3. Remove the plastic name card over the LEDs.

4. Remove the two screws holding the filter assembly into the device.

5. Remove the filter assembly and replace it with a new assembly.

6. Torque the two philips head screws to 6in-lb (0.7 N-M) or ¼ turn past

7. Replace the plastic name card over the LEDs.

8. Close the door and return power to the system.

Other system checks may need to be performed in accordance with local or

national codes and regulations.

COMPANY AEROSOL

Home

Safeguard

SDI LLC

indicators.

“lightly snug.” PLEASE DO NOT OVERTIGHTEN.

25S

CHEK02,

CHEK06

SOLOA3

SMOKE

SABRE-01

ULC

LISTED

COMPANY AEROSOL

Home

Safeguard

No Climb

25S

SOLOA4

SMOKE

SABRE-01

FIGURE 14. BOTTOM VIEW OF UNIT

Wiring

Access

Plugs

Sampled

Air Inlet

Network

Connection

Sampled

Air Outlet

ASP-03

SS-600-000 9 I56-3904-001

Page 10

FAAST System Validation Form

Customer Name:

Project Name:

Site Address:

Installer Name/Contact information: Date:

Commissioning Agent/Contact information: Date:

Client Representative/Contact information: Date:

Witness/Contact information: Date:

Wiring Checked: Date: Yes / No

Detector Settings Checked: Date: Yes / No

Test Relays: Date: Yes / No

REQUIRED DOCUMENTS

Copy of Commissioning Form Yes / No

FAAST system Bill of Material Yes / No

Commissioning Form for each system Yes / No

Smoke Test results (optional) Yes / No

Locally required forms Yes / No

Customer’s Signature: Date:

Commissioning Agent Signature: Date:

SS-600-000 10 I56-3904-001

Page 11

FAAST System Validation Form (CONT.)

Air Handling Yes / No Duct Sampling Yes / No

Number of Sample points: Number of Cabinets:

Temperature:

Conditions:

As-Built Installation

Drawings Available?

Is the power supply

installed properly?

Describe any Variations:

Sensitivity: % Obscuration/ft.:

Detector Address: Detector Address:

Day Alert: Predicted: Actual:

Action 1: Predicted: Actual:

Action 2: Predicted: Actual:

Fire 1: Predicted: Actual:

Fire 2:

Night Alert: Alarm Outputs Verified: Yes / No

Action 1: Fault Outputs Verified: Yes / No

Action 2: Isolate Function Verified: Yes / No

Fire 1:

Fire 2:

Weekend Alert:

Action 1:

Action 2:

Fire 1:

Fire 2:

Acclimate Alert:

Action 1:

Action 2:

Fire 1:

Fire 2:

Air Flow Fault

Thresholds

Low:

High:

Yes / No

Yes / No

THRESHOLD TIME DELAY TRANSPORT TIMES

Humidity:

Other:

Is the system installed in

accordance with the design?

Is the pipe network installed

and labeled properly?

Yes / No

Yes / No

Comments:

SS-600-000 11 I56-3904-001

Page 12

GLOSSARY

KEY TERMS

Configure:

To set up a program or computer system for a particular application.

FAAST Fire Alarm Aspirating Sensing Technology®:

High sensitivity aspirating smoke detection system.

IP Address:

An Internet Protocol (IP) address is a numerical label that is assigned to devices participating in a computer network utilizing the Internet Protocol for

communication between its nodes.

PipeIQ®:

A software program designed to work with the FAAST unit for system configuration, monitoring and pipe design.

Web server:

A Web server is a computer program that delivers (serves) content. The device

contains an integrated Web server which is used to observe detector configuration and may be used to remotely monitor the system.

LASER SAFETY INFORMATION

This aspiration detector does not produce any hazardous laser radiation and is certified

as a Class 1 laser product under the U.S. Department of Health and Human Services

(DHHS) Radiation Performance Standard according to the Radiation Control for Health

and Safety Act of 1968. Any radiation emitted inside the smoke detector is completely

within the protective housings and external covers.

System Sensor warrants its enclosed smoke detector to be free from defects in materials

and workmanship under normal use and service for a period of three years from date

of manufacture. System Sensor makes no other express warranty for this smoke detector. No agent, representative, dealer, or employee of the Company has the authority to

increase or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of the smoke

detector which is found to be defective in materials or workmanship under normal use

and service during the three year period commencing with the date of manufacture.

After phoning System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return

Authorization number, send defective units postage prepaid to: System Sensor, Returns

FCC STATEMENT

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used

in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

This Class B digital apparatus complies with Canadian ICES-003.

The laser beam cannot escape from the detector during any phase of operation.

The Center of Devices and Radiological Health (CDRH) of the U. S. Food and Drug

Administration implemented regulations for laser products on August 2, 1976. These

regulations apply to laser products manufactured after August 1, 1976. Compliance is

mandatory for products marketed in the United States.

WARRANTY

Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please include a

note describing the malfunction and suspected cause of failure. The Company shall not

be obligated to repair or replace units which are found to be defective because of damage,

unreasonable use, modifications, or alterations occurring after the date of manufacture.

In no case shall the Company be liable for any consequential or incidental damages for

breach of this or any other warranty, expressed or implied whatsoever, even if the loss

or damage is caused by the Company’s negligence or fault Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you. This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

SS-600-000 12 I56-3904-001

©System Sensor 2013

Loading...

Loading...