Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

4451HT and 4451HTA

I56-0690-005R

Plug-in Fixed Intermediate

Temperature Thermal Detectors

Specifications

Diameter: 4.1 inches (104 mm)

Height: 2.1 inches (53 mm)

Weight: 5 ounces (150 g)

Installation Temperatures: 32° to 150°F (0° to 66°C)

Operating Humidity Range: 10% to 93% Relative Humidity

Latching Alarm: Reset by momentary power interruption

Sensitivity: 190°F (88°C)

Operating Voltage: 15-35 VDC

Standby Current: 100 µA

Before Installing

This detector must be installed in compliance with the control panel installation manual and meet the requirements of

the authority having jurisdiction. In addition, the National

Fire Protection Association has published codes, standards,

and recommended practices for the installation and use of the

above appliances (NFPA 72). For installation in Canada, refer

to CAN/ULC-S524 and CEC Part 1, Sec. 32. Therefore, the installer must be familiar with these requirements, with local

codes, and any special requirements of the authority having

jurisdiction.

NOTICE: This manual should be left with the owner/user of

this equipment.

IMPORTANT: This detector must be tested and maintained

regularly following NFPA 72 requirements. The detector should

be cleaned at least once a year.

General Description

The 4451HT and 4451HTA detectors are fixed intermediate

temperature alarm thermal detectors utilizing a state-of-the-art

dual thermistor sensing circuit. These detectors are designed

to provide open area protection with 50-foot spacing capabil-

ity, and are to be used with compatible control panels only.

This listed spacing is based on a 10′ ceiling height and should

be reduced based on the table in Figure 1 for ceilings higher

than 10′.

Two LEDs on each detector light to provide 360° visibility of

the detector indication. Remote LED annunciator capability is

provided as standard, and the RA400Z remote LED annunciator is available as an optional accessory.

Base Selection And Wiring Guide

Refer to the installation instructions for the plug-in detector

bases for base selection and wiring instructions. System Sensor has available a variety of detector bases for these heat detectors, including 2-wire applications with and without relays

and/or current limiting resistors for use with control panels

that require one. These detectors are only to be used with 400

and 400B series bases.

Install the System Sensor plug-in base to be used with the

detector following the instructions in the base manual.

Installation

NOTE: All wiring must conform to applicable installation

codes and regulations.

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

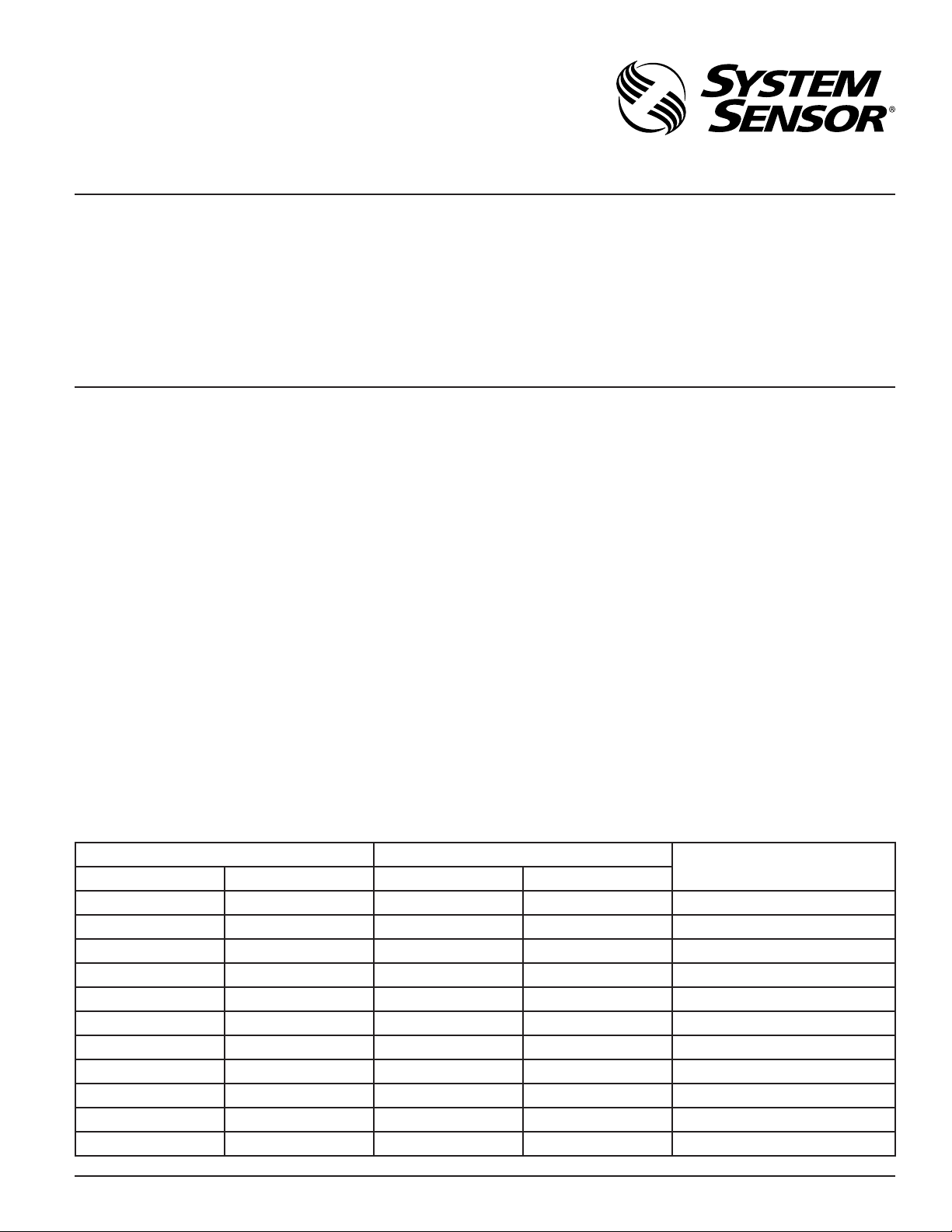

Figure 1. Heat detector spacing reduction based on ceiling height:

Ceiling Height Above Up To And Including

(ft) (m) (ft) (m)

0 0 10 3.05 100

10 3.05 12 3.66 91

12 3.66 14 4.27 84

14 4.27 16 4.88 77

16 4.88 18 5.49 71

18 5.49 20 6.10 64

20 6.10 22 6.71 58

22 6.71 24 7.32 52

24 7.32 26 7.93 46

26 7.93 28 8.54 40

28 8.54 30 9.14 34

D400-54-00 1 I56-0690-005R

Percent Of Listed Spacing

Page 2

NOTE: Verify that all detector bases are installed, that the ini-

CAUTION

CAUTION

TEST

MAGNET

LED

TEST MODULE

SOCKET

LED

tiating-device circuits have been tested, and that the wiring is

correct. (Refer to detector base manual for testing procedure.)

Disconnect the power from initiating-device circuits before installing detectors.

1. Install Detectors:

a. Insert the detector into the detector base.

b. Turn the detector clockwise until the detector drops

into place.

c. Continue turning detector clockwise to lock it in place.

Tamper-Resistance Feature

The detector bases include a feature that, when activated, prevents removal of the detector without the use of a tool. Refer

to the installation instruction manual of the detector base to

make use of this capability.

2. After all detectors have been installed, apply power to the

control unit.

3. Test the detector using the magnet as described under TESTING.

4. Reset the detector at the system control panel.

5. Notify the proper authorities the system is in operation.

Testing

Before testing, notify the proper authorities that the heat detector system is undergoing maintenance, and therefore the

system will temporarily be out of service. Disable the zone or

system undergoing maintenance to prevent unwanted alarms.

Detectors must be tested after installation and periodic maintenance. Test the detector as follows:

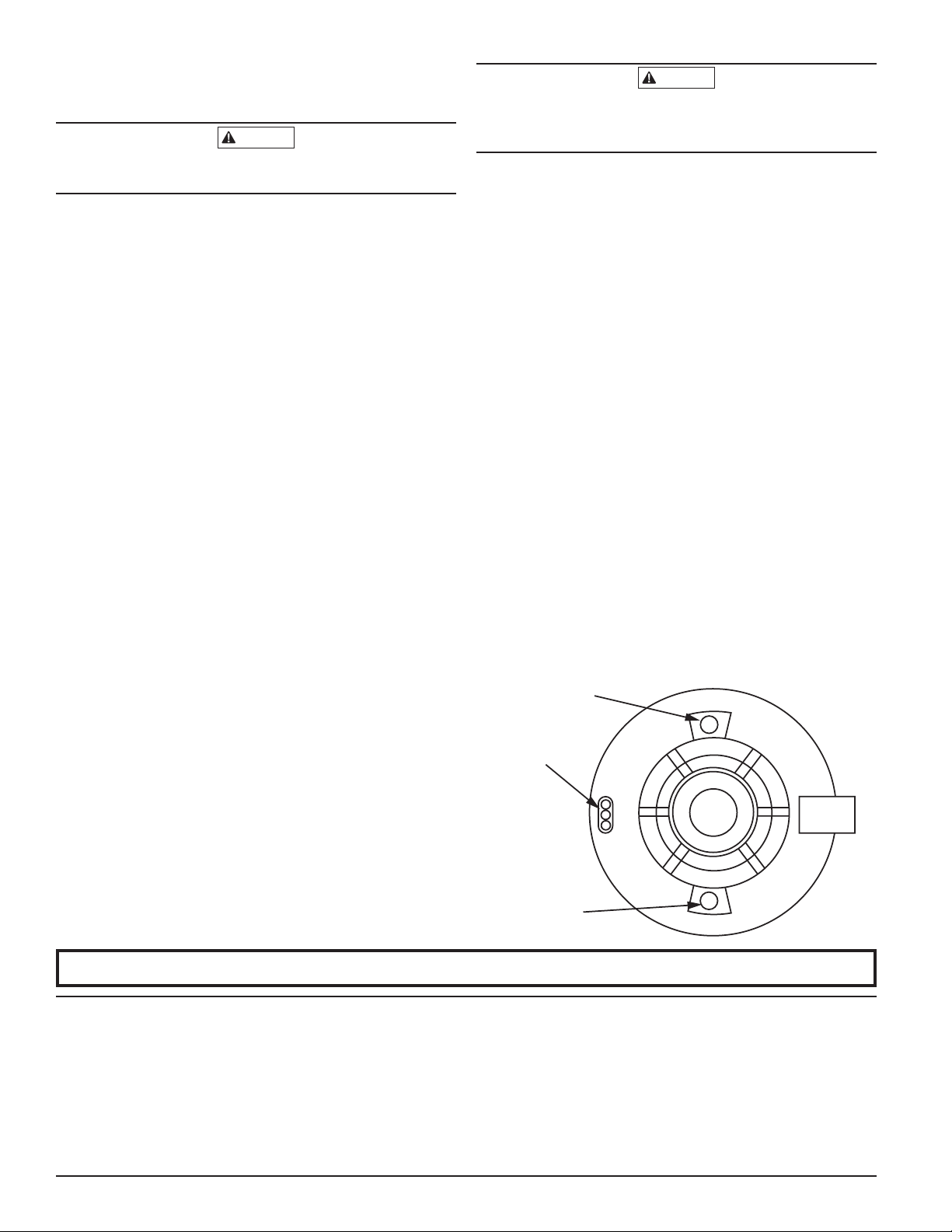

A. Test Magnet (System Sensor Model M02-04)

1. Position the magnet against the cover opposite the test

module socket. (See Figure 2.)

2. The LEDs on the detector should light within 10 sec-

onds. If the LEDs fail to light, check the power to the

detector and the wiring in the detector base.

3. Reset the detector at the system control panel.

B. Test Module (System Sensor Model MOD400R)

The MOD400R is used with a DMM or voltmeter to check the

detector sensitivity as described in the module’s manual.

C. Direct Heat Method (Heat Gun)

1. From the side of the detector, direct the heat toward

the sensor. Hold the heat source about 15 cm away to

prevent damage to the cover during testing.

Avoid exposing the detector cover to the heat source for more

than 15 seconds. Extended periods of extreme heat can melt

the plastic and damage the cover.

NOTE: If a detector goes into alarm, it will reset only if the detector has cooled and if its power is momentarily interrupted.

Check the control panel being used to determine whether the

RESET switch (or some other auxiliary device or control) momentarily cuts off power to the detector loop.

Detectors that fail these tests should be cleaned as described

under MAINTENANCE and retested. If the detectors still fail

these tests they should be returned for repair.

Maintenance

The 4451HT and 4451HTA detectors have been designed to be

as maintenance-free as possible. Normal air-borne dust, however, can accumulate on the detector’s sensing elements and

cause them to become less sensitive. All detectors should be

tested and cleaned at least once a year, and those in dustier

areas should be tested and cleaned more often. Detectors must

also be cleaned and tested immediately after a fire.

Before cleaning, notify the proper authorities that the system

is undergoing maintenance and therefore the system will temporarily be out of service. Disable the loop or system undergoing maintenance to prevent unwanted alarms.

1. Remove detector from mounting base.

2. Use a vacuum cleaner to remove dust from the

sensing chamber.

3. Reinstall the detector.

4. Test the detector as described under TESTING.

Figure 2. Test magnet position:

C0957-00

System Sensor warrants its enclosed heat detector to be free from defects in materials

and workmanship under normal use and service for a period of three years from date

of manufacture. System Sensor makes no other express warranty for this heat detec

tor. No agent, representative, dealer, or employee of the Company has the authority

to increase or alter the obligations or limitations of this Warranty. The Company’s

obligation of this Warranty shall be limited to the repair or replacement of any part

of the heat detector which is found to be defective in materials or workmanship

under normal use and service during the three year period commencing with the

date of manufacture. After phoning System Sensor’s toll free number 800-SENSOR2

(736-7672) for a Return Authorization number, send defective units postage prepaid

to: System Sensor, Returns Department, RA #__________, 3825 Ohio Avenue, St.

D400-54-00 2 I56-0690-005R

©2007 System Sensor

Please refer to insert for the Limitations of Fire Alarm Systems

Three-Year Limited Warranty

Charles, IL 60174. Please include a note describing the malfunction and suspected

cause of failure. The Company shall not be obligated to repair or replace units which

-

are found to be defective because of damage, unreasonable use, modifications, or

alterations occurring after the date of manufacture. In no case shall the Company

be liable for any consequential or incidental damages for breach of this or any other

Warranty, expressed or implied whatsoever, even if the loss or damage is caused by

the Company’s negligence or fault. Some states do not allow the exclusion or limita

tion of incidental or consequential damages, so the above limitation or exclusion

may not apply to you. This Warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

-

Loading...

Loading...