Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

SG6848x1

FEATURES

Green-mode PWM Controller

Low Start-up Current (5uA)

Low Operating Current (3mA)

Programmable PWM Frequency

Peak-current-mode Operation

Leading-edge Blanking

Built-in Synchronized Slope Compensation

Cycle-by-cycle Current Limiting

Constant Output Power Limit

Gate Output Voltage Clamped at 15V

Small SOT-26 Package Available

APPLICATIONS

General-purpose switching mode power supplies and

flyback power converters, such as

Battery chargers

Power adapters

Open-frame SMPS

Replacements for linear transformers and RCC

5V standby power for PC power supply.

DESCRIPTION

This highly integrated PWM controller provides

several special enhancements designed to meet the low

standby-power needs of low-power SMPS. To

minimize standby power consumption, the proprietary

green-mode function provides off-time modulation to

continuously decrease PWM frequency under light-load

conditions. This green-mode function enables the power

supply to easily meet even the strictest power

conservation requirements.

The BiCMOS fabrication process enables reducing

the start-up current to 5uA, and the operating current to

3mA. As a result, a large start-up resistance can be used.

Built-in synchronized slope compensation ensures the

stability of peak-current-mode control. Proprietary

internal compensation provides a constant output power

limit over a universal AC input range (90VAC to

264VAC). Cycle-by-cycle current limiting ensures safe

operation during short-circuits.

To protect the external power MOSFET from being

damaged by supply over voltage, the SG6848x1’s output

driver is clamped at 15V. The SG6848x1’s controllers can

be used to improve the performance and reduce the

production cost of power supplies. The SG6848x1 is the

best choice for replacing linear and RCC power supplies.

It is available in DIP-8 and SOT-26 packages.

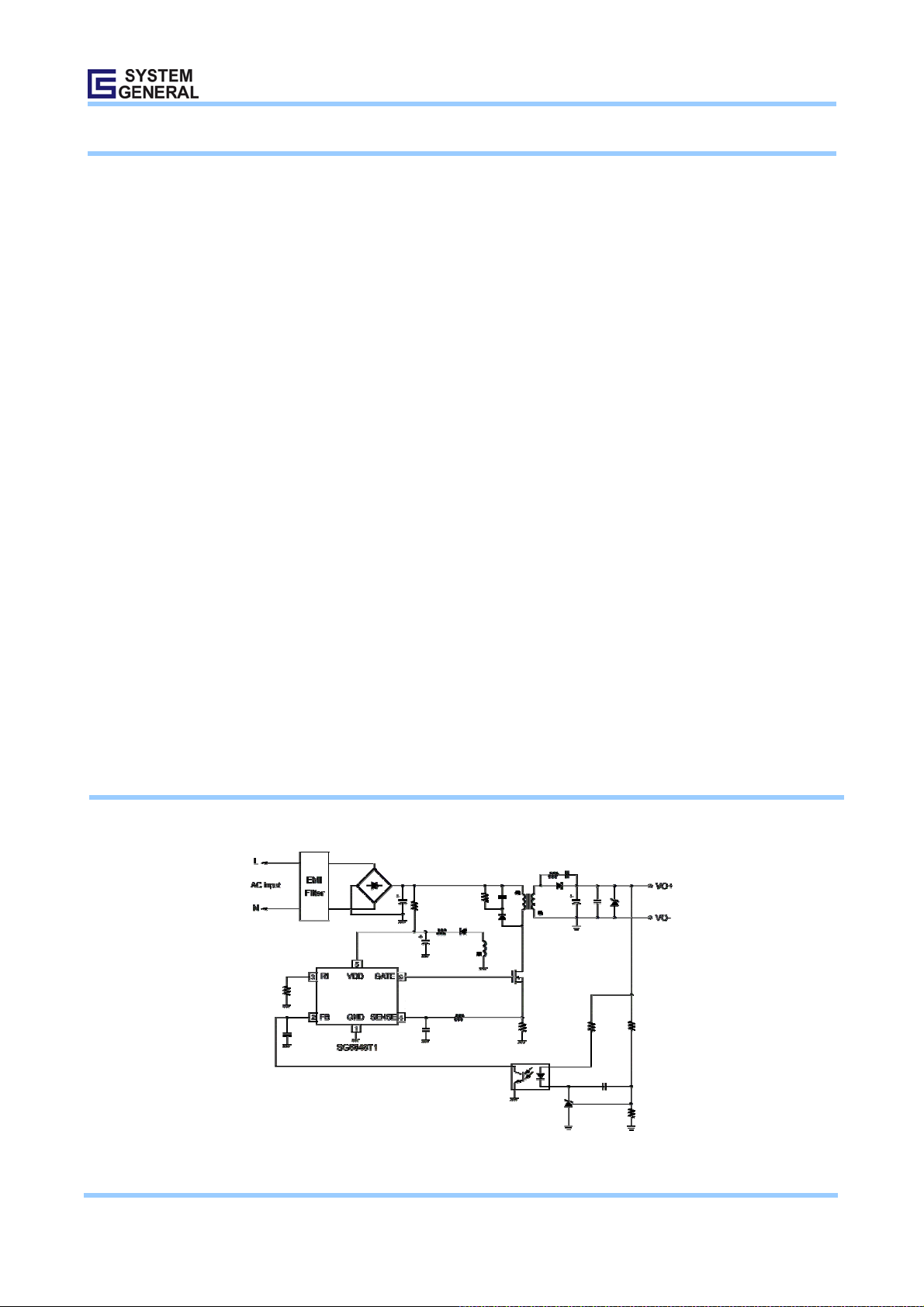

TYPICAL APPLICATION

© System General Corp. - 1 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

1

N

N

y

Low-cost Green-Mode PWM Controller for Flyback Converters

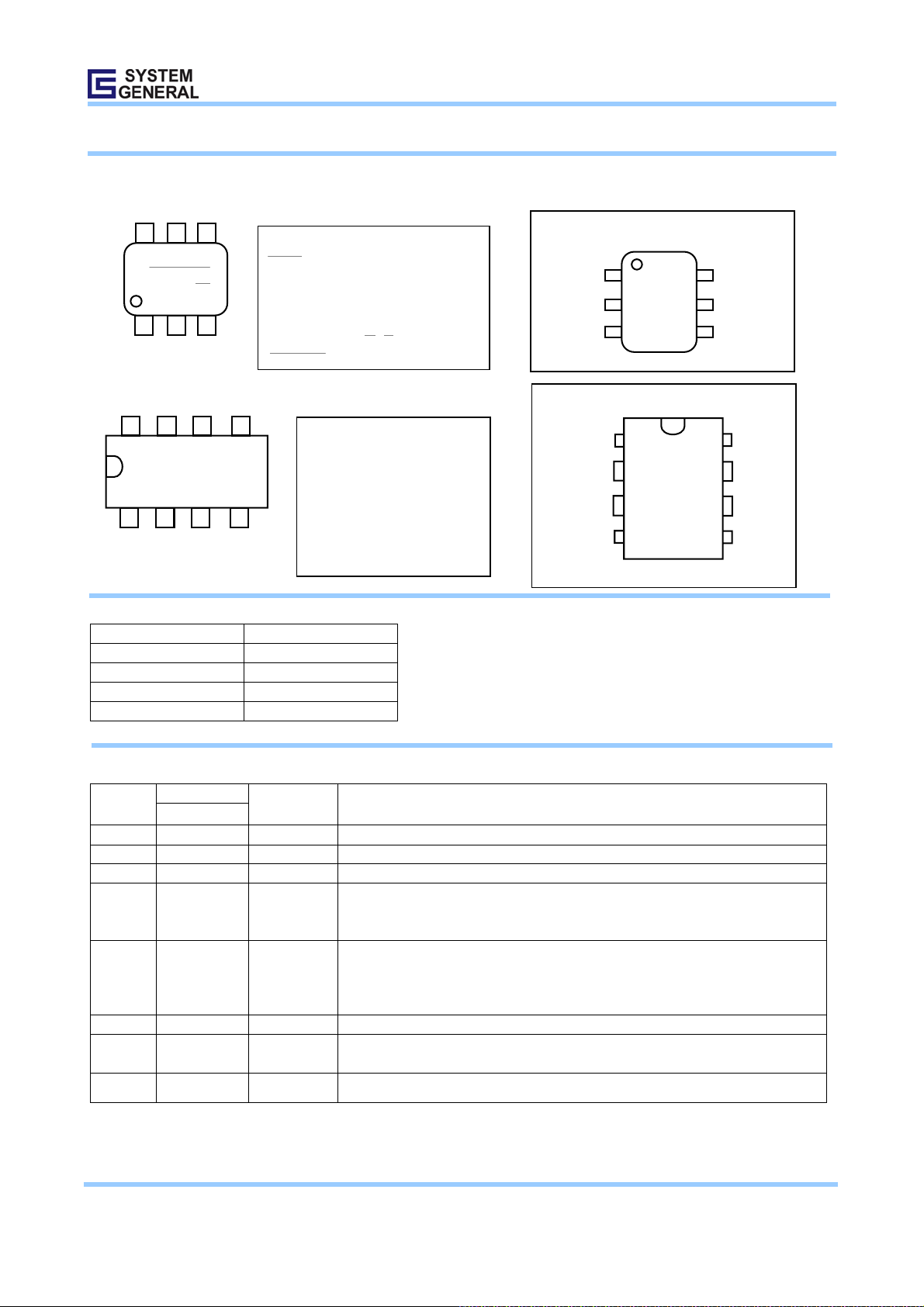

MARKING DIAGRAMS PIN CONFIGURATION

XXXMW

1

XXX:AAH =SG6848T1

XXX:AAH =SG6848TZ1

M: Mask Version

W: Week code A~Z=W1~W26

A

~Z=W27~W52

:Lead free package

GND

FB

RI

SOT-26

2

3

GATE

6

VDD

5

4

SENSE

8

DIP-8

SG6848x1

SG6848DP1

MXXXXXXYYWWV

1

D: D = DIP

P : Z = Lead Free

Null = Regular Package

M: Mask Version

XXXXXX: Wafer Lot

YY: Year; WW: Week

V: Assembl

Location

GATE

VDD

SENSE

C

1

2

3

4

ORDERING INFORMATION

Part Number Package

SG6848T1 SOT-26

SG6848D1 DIP-8

SG6848TZ1 SOT-26 (Lead Free)

SG6848DZ1 DIP-8 (Lead Free)

PIN DESCRIPTIONS

Name

GATE 1 / (6) Driver Output The totem-pole output driver for driving the power MOSFET.

VDD 2 / (5) Supply Power supply.

NC 3 No connection.

SENSE 4 / (4) Analog Input

RI 5 / (3)

NC 6 No connection.

FB 7 / (2) Analog Input

GND 8 / (1) Supply Ground.

Pin No.

DIP-8 / (SOT-26)

Type Function

Current sense. This pin senses the voltage across a resistor for peak-current-mode

control. If the voltage reaches the internal threshold, PWM output is disabled. This

activates cycle-by-cycle current limiting.

A resistor connected from the RI pin to GND pin will generate a constant current source

Analog

Input/Output

for the controller. This current is used to determine PWM frequency. Increasing the

resistance will reduce PWM frequency. A 95kΩ resistor results in a 70kHz PWM

frequency.

Feedback. The FB pin accepts the output voltage regulation signal. It provides feedback

to the internal PWM comparator to adjust the duty cycle.

GND

8

FB

7

6

5

C

RI

© System General Corp. - 2 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

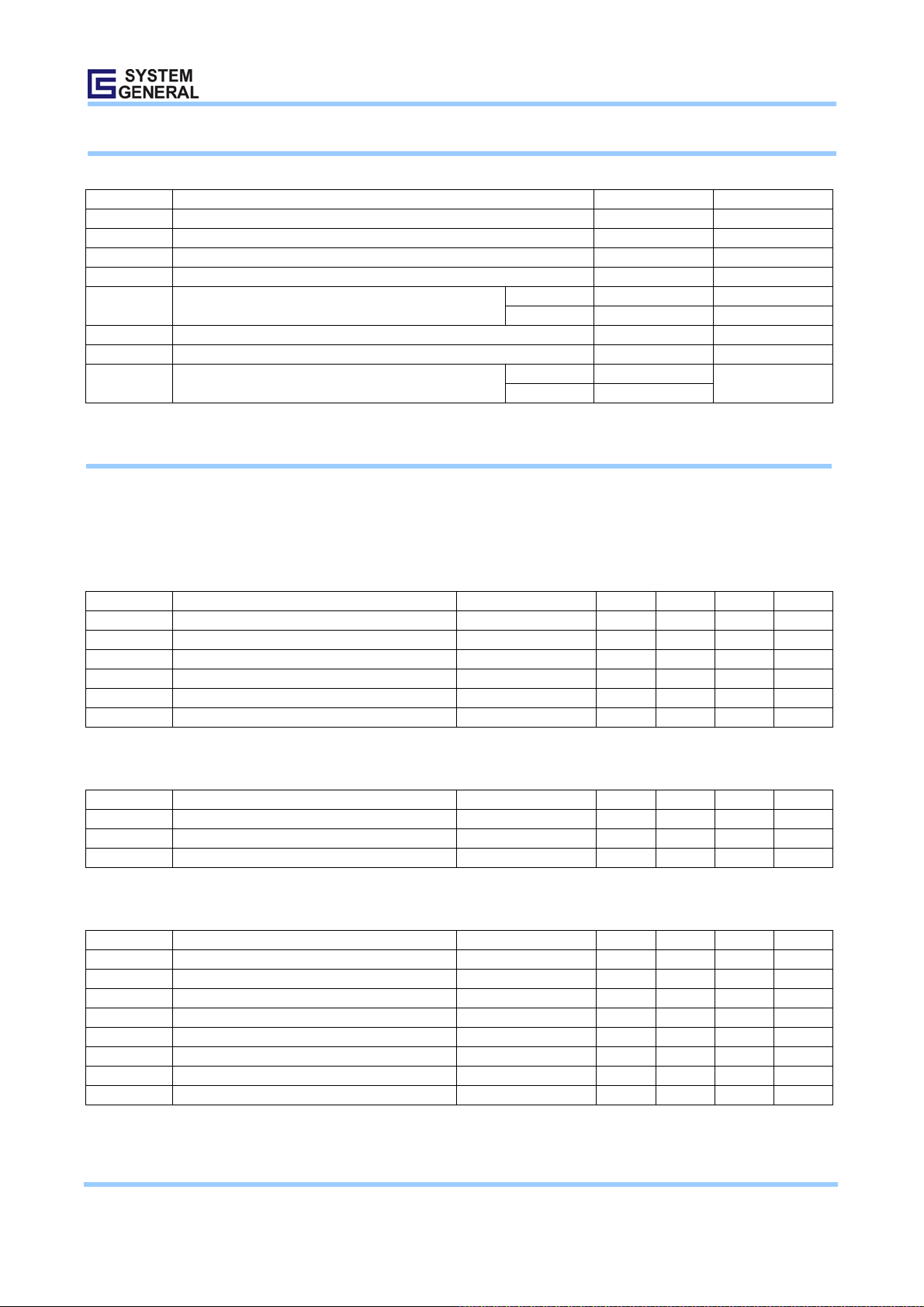

BLOCK DIAGRAM

SG6848x1

© System General Corp. - 3 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

SG6848x1

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

VDD DC Supply Voltage 25 V

VFB Input Voltage to FB Pin -0.3 to 6 V V

V

Input Voltage to Sense Pin -0.3 to 6V V

SENSE

PD Power Dissipation 300 mW

RθJA Thermal Resistance (Junction to Air)

TJ Operating Junction Temperature -40 to +125 °C

T

Storage Temperature Range -55 to +150 °C

STG

TR Peak Reflow Temperature

* All voltage values, except differential voltages, are given with respect to GND pin.

* Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device.

SOT-26 208.4 °C/W

DIP-8 82.5 °C/W

Pb free 260(+5/-0)

Pb 230(+5/-0)

°C

RECOMMENDED OPERATING JUNCTION TEMPERATURE: -30°C ~ 105°C*

*For proper operation

ELECTRICAL CHARACTERISTICS (VDD=15V, TA = 25°C, unless noted)

VDD Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

VOP Continuously Operating Voltage 20 V

V

Start-up Threshold Voltage 15.3 16.3 17.3 V

TH(ON)

V

Min. Operating Voltage 10.9 11.7 12.5 V

DD(MIN)

I

Start-up Current 5 30 uA

DD ST

I

DD OP

V

Over Voltage Protection 22 23.5 25 V

DD-OVP

Operating Supply Current GATE = 1nF 3 5 mA

Feedback Input Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

ZFB Input Impedance 2 kΩ

IOZ Zero-duty-cycle Input Current 1.3 2.0 mA

VOP Open Loop Voltage 4.5 V

Oscillator Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

F

PWM Frequency RI = 95kΩ 65 70 75 kHz

OSC

F

FDY Frequency Variation versus VDD Deviation VDD = 14 to 20V 2 %

FDT Frequency Variation versus Temp. Deviation TA = -30 to 105 ℃ 2 %

IN Green-mode Start Threshold FB Input Current 1 mA

IG Green-mode Min. Freq. FB Input Current 1.16 mA

SG Green-mode Modulation Slope RI = 95kΩ 300 Hz/uA

RI RI pin resistance 66.5 150 kΩ

Green-mode Min. Frequency RI = 95kΩ 15 kHz

OSC-GREEN

© System General Corp. - 4 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

SG6848x1

Current Sense Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

ZCS Input Impedance 10 kΩ

TPD Delay to Output 100 nsec

V

Current Limit Flatten Threshold Voltage 0.96 V

TH,FLT

V

DC

Current Limit Valley Threshold Voltage 0.81 V

TH,VALLEY

Duty Cycle of SAW Limit 45 %

SAW

Gate Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

DC

Maximum Duty Cycle 70 75 80 %

(MAX)

DC

Minimum Duty Cycle 0 %

(MIN)

BNK Leading-edge Blanking Time 200 nsec

VOL Output Voltage Low Sink current = 20mA 1.5 V

VOH Output Voltage High Source current = 20mA 8 V

TR Rising Time GATE = 1nF 250 nsec

TF Falling Time GATE = 1nF 80 nsec

V

Output Clamp Voltage VDD = 20V 15 17 V

CLAMP

© System General Corp. - 5 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

TYPICAL CHARACTERISTICS

SG6848x1

Start-up Threshold Voltage vs Temperature

17

16.8

16.6

(V)

TH(ON)

16.4

V

16.2

16

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (℃)

Min. Operating Voltage vs Temperature

11

10.9

10.8

10.7

10.6

(V)

10.5

10.4

DD(MIN)

V

10.3

10.2

10.1

10

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (℃)

Start-up Current vs Temperature

10.000

8.000

6.000

(uA)

4.000

DD ST

I

2.000

0.000

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (℃)

PWM Fre quency vs Temperature

65.300

65.200

65.100

65.000

(kHz)

64.900

OSC

F

64.800

64.700

64.600

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (℃)

Green-mode min. Frequency vs Temperature

15.0

14.8

(kHz)

14.6

14.4

OSC-GREEN

F

14.2

14.0

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (℃)

80

70

60

50

40

(kHz)

OSC

30

F

20

10

0

0.6 0.7 0.8 0.9 1 1.1 1.2

PWM Frequency vs. FB

FB(mA)

© System General Corp. - 6 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

−

−

Low-cost Green-Mode PWM Controller for Flyback Converters

OPERATION DESCRIPTION

10uF/50V, the power-on delay T

is less than 2.8S for

D_ON

90VAC input.

The SG6848x1 devices integrate many useful

functions into one controller for low-power switching

mode power supplies. The following descriptions

The FB input

highlight some of the features of the SG6848D1.

This pin is designed for feedback control and to

Start-up Circuitry

When the power is turned on, the input rectified

voltage, Vdc, charges the hold-up capacitor C1 via a

start-up resistor R

the start threshold voltage V

activates the entire power supply.

. As the voltage of VDD pin reaches

IN

, the SG6848x1

TH(ON)

V

TH(ON)

Vdc

activate the green-mode function. Figure 2 is a typical

feedback circuit mainly consisting of a shunt regulator

and an opto-coupler. R

and R2 form a voltage divider for

1

the output voltage regulation. R3 and C1 are adjusted for

control-loop compensation. A small-value RC filter (e.g.

= 47ohm, CFB= 1nF) placed from the FB pin to GND

R

FB

can increase stability. The maximum source current on the

FB pin is 2mA. The phototransistor must be capable of

sinking this current to pull the FB level down at no load.

Thus, the value of the biasing resistor Rb is determined as

follows,

SG6848x1

R

SG6848D1

VDD

GND

I

DDST

C1

IN

D1

T

D_ON

Figure 1. Power Circuit

The maximum power-on delay time is determined as

follows,

)(

INDDSTdcONTH

T

1)(

eRIVV (1)

−⋅−=

where

VVV

ZDo

(2)

mAK

2≥⋅

Rb

V

Z

regulator. Typical value is 2.5V;

K is the current transfer rate (CTR) of the opto-coupler.

maximum value of Rb is 650ohm.

OND

_

⋅−1

CR

IN

where V

is the drop voltage of a photodiode, about 1.2V;

D

is the minimum operating voltage of the shunt

For an output voltage Vo=5V, with CTR=100%, the

V

O

R1

FB

R

FB

C

FB

Rb

R3

C1

is the start-up current of SG6848x1;

I

DDST

is the power-on delay time of the power

T

D_ON

R2

supply.

Due to the low start-up current, a large R

such as

IN

1.5Mohm can be used. Also with a hold-up capacitor of

Figure 2. Feedback circuit.

© System General Corp. - 7 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

⋅

=

F

Low-cost Green-Mode PWM Controller for Flyback Converters

SG6848x1

Oscillator & Green Mode Operation

One external resistor, RIi, connected between RI and

GND pins is used to program the PWM frequency of the

SG6848x1. The approximated formula is:

=

6650

I

is from 50 to 100KHz.

OSC

RI

SG6848D 1

GND

(3)

)Kohm(R

OSC

)KHz(F

The recommended F

RI CI

Figure 3. Setting PWM frequency

The patented green-mode function provides off-time

modulation to reduce the PWM frequency at light-load

and no-load conditions. The sink current of the FB pin

determines the green mode operation as shown in Figure 4.

At light load, the sink current of the FB pin will increase.

When the sink current is larger than 1mA, the PWM

frequency decreases in order to reduce the power

consumption of the power supply at light-load and in

no-load conditions.

For lightning surge tests, a small capacitor (not over

50pF) connected from the RI pin to GND is recommended.

This added capacitor also improves stability, especially at

light load and high input line voltage conditions.

Built-in Slope Compensation

A flyback converter can be operated in either

discontinuous current mode (DCM) or continuous current

mode (CCM). There are many advantages to operating the

converter in CCM. With the same output power, a

converter in CCM exhibits smaller peak inductor currents

than one in DCM. Therefore, a small-sized transformer

and a low-rated MOSFET can be applied. On the

secondary side of the transformer, the rms output current

of DCM can be up to twice that of CCM. Larger wire

gauge and output capacitors with larger ripple current

ratings are required. DCM operation also results in higher

output voltage spikes. A large LC filter must also be

added. Therefore, a flyback converter in CCM achieves

better performance with lower component cost.

Despite the above advantages of operating in CCM,

there is one concern–stability. Operating in CCM, the

output power is proportional to the average inductor

current, while the peak current is controlled. This causes

the well-known sub-harmonic oscillation when the PWM

duty cycle exceeds 50%. Adding slope compensation

(reducing the current-loop gain) is an effective way to

prevent this oscillation. The SG6848x1 introduces a

synchronized positive-going ramp (V

switching cycle to stabilize the current loop. The sensed

voltage together with this slope compensation signal

) is fed into the non-inverting input of the PWM

(V

SLOPE

comparator. The resulting voltage is compared with the

FB signal to adjust the PWM duty cycle, such that the

output voltage is regulated. Therefore, users can use the

SG6848x1 to design a cost-effective, highly efficient and

compact sized flyback power supply operating in CCM

without adding any external components.

) in every

SLOPE

)(kHzf

The positive ramp added is,

F

OSC

(4)

DVV

SLSLOPE

where

= 0.33V;

V

F

OSC

5

I

N

I

G

B

SL

D = Duty cycle

Figure 4. PWM frequency vs. FB current.

© System General Corp. - 8 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

Constant Output Power Limit

UVLO level of the SG6848x1, the power supply will

enter hiccup operation mode and hence limit the output

The maximum output power of a flyback converter

can generally be determined from the current-sense

resistor R

. When the load increases, the peak inductor

S

current increases accordingly. When the output current

arrives at the protection value, the OCP comparator

dominates the current control loop. OCP occurs when the

current-sense voltage reaches the threshold value. The

output GATE driver is turned off after a small propagation

delay, td. The delay time results in unequal power-limit

level under universal input. In the SG6848x1, a saw-tooth

power. However, it is possible that the V

remains higher than the UVLO level even if the output is

shorted. This happens when the coupling between the aux

and the primary winding is too good. Therefore, the

construction of the transformer becomes a dominant

factor. The recommended construction layout is to

increase the insulation thickness for the aux winding and

place the primary aux winding in one side of the bobbin.

For low output voltage applications, using a low dropout

voltage diode and a larger secondary winding also helps.

power-limiter is designed to solve the unequal

power-limit problem. As shown in Figure 5, the power

One side

limiter is designed as a positive ramp signal and is fed to

the inverting input of the OCP comparator. This results in

Primary aux winding

a lower current limit at high-line inputs than at low-line

inputs. However, with fixed propagation delay, td, the

peak primary current would be the same for various line

Primary main winding

Secondary winding

input voltages. Therefore the maximum output power can

practically be limited to a constant value within a wide

Primary main winding

input voltage range without adding any external circuitry.

Figure 6. Transformer construction

t

ton

off

V

TH,FLT

SG6848x1

voltage

DD

Increased thickness

Leading-Edge Blanking

A voltage signal proportional to the MOSFET

High line

sense vo ltage

Low line

sense voltage

TH,VALLEY

current develops on the current-sensing resistor, R

time the MOSFET is turned on, a spike, which is induced

. Each

S

V

by the diode reverse recovery and by the output

capacitances of the MOSFET and diode, inevitably

appears on the sensed signal. Inside the SG6848x1, a

leading-edge blanking time of about 200 nsec. is

0

T

1

T2

Figure 5. Constant power limit compensation

introduced to avoid premature termination of the

MOSFET by the spike. Therefore, only a small-value RC

filter (e.g. 100ohm + 470pF) is required between the

SENSE pin and R

is recommended.

R

S

. Still, a non-inductive resistor for the

S

Short Circuit Protection

When the output of a flyback power supply is shorted,

the primary VDD will decrease due to the coupling

polarity between the aux winding and the secondary

winding of a transformer. When V

© System General Corp. - 9 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

drops below the

DD

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

Lab Note

Before reworking or soldering/de-soldering on the

power supply, it is suggested to discharge the primary

SG6848D1

Blanking

Circuit

Gate

Sense

capacitors by an external bleeding resistor. Otherwise the

PWM IC may be destroyed by external high voltage

during soldering or de-soldering.

This device is sensitive to ESD discharge. To

improve the production yield, the production line should

be ESD protected in accordance to ANSI ESD S1.1, ESD

S1.4, ESD S7.1, ESD STM 12.1, and EOS/ESD S6.1.

Printed Circuit Board (PCB) Layout

Figure 7. Turn on spike

Gate Drive

The SG6848x1’s output stage is a fast totem pole

driver that can drive a MOSFET gate directly. It is also

equipped with a voltage clamping Zener diode to protect

the MOSFET from damage caused by undesirable

over-drive voltage. The output voltage is clamped at 15V.

An internal pull-down resistor is used to avoid a floating

state of the gate before startup. A gate drive resistor in the

range of 47 to 100ohm is recommended. This resistor

limits the peak gate drive current and provides damping to

prevent oscillations at the MOSFET gate terminal.

VDD

ON/OFF

Driver

SG6848D1

15V

Gate

Figure 8. Gate drive

High frequency switching current/voltage makes

PCB layout a very important design issue. Good PCB

layout minimizes excessive EMI and helps the power

supply survive during surge/ESD tests. Here, we give

some common guidelines:

In order to get better EMI performance and reduce

line frequency ripples, the output of the bridge rectifier

should be connected to capacitor C1 first, and then to the

switching circuits.

The high frequency current loop is in C1 –

Transformer – MOSFET – R

– C1. The area enclosed

S

by this current loop should be as small as possible. Keep

the traces (especially 4→1) short, direct, and wide. High

voltage traces related to the drain of the MOSFET and the

RCD snubber should be kept far way from control circuits

to prevent unnecessary interference. If a heatsink is used

for the MOSFET, it’s better to connect this heatsink to a

ground.

As indicated by 3, the ground of control circuits

should be connected first before any other circuitry.

As indicated by 2, the area enclosed by the

transformer aux winding, D1, and C2 should also be

kept small. Place C2 close to the SG6848x1 for good

decoupling.

Two suggestions for ground connections, with

different pro and cons, are offered.

SG6848x1

© System General Corp. - 10 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

GND3 → 2 → 4 → 1: This should avoid common

impedance interference for the sense signal.

high frequency impedance and help increase ESD

immunity.

SG6848x1

GND3→2→1→4: This should be better for ESD

tests, where the earth ground is not available on the power

supply. Regarding the ESD discharge path, the charges go

from secondary through the transformer’s stray

capacitance to GND2 first. Then the charge goes from

GND2 to GND1 and back to the mains. It should be noted

that control circuits should not be placed in the discharge

path. Point discharges for common choke can decrease the

Vdc

C1

Common mode

choke

1

R

I

C

R

FB

Should a Y-cap between primary and secondary be

required, it is suggested to connect this Y-cap to the

positive terminal of C1 (Vdc). If this Y-cap is connected

to the primary GND, it should be connected to the

negative terminal of C1 (GND1) directly. The Point

discharge of this Y-cap also helps with ESD. However,

the distance between these two points should be at least

5mm according to safety requirements.

R

IN

VDD

D1

C2

2

Cf

Rg

Rf

R

S

4

RI

I

SG6848D1

FB

C

FB

GND

Gate

Sense

3

Y-cap

5

Figure 9. Layout considerations

© System General Corp. - 11 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

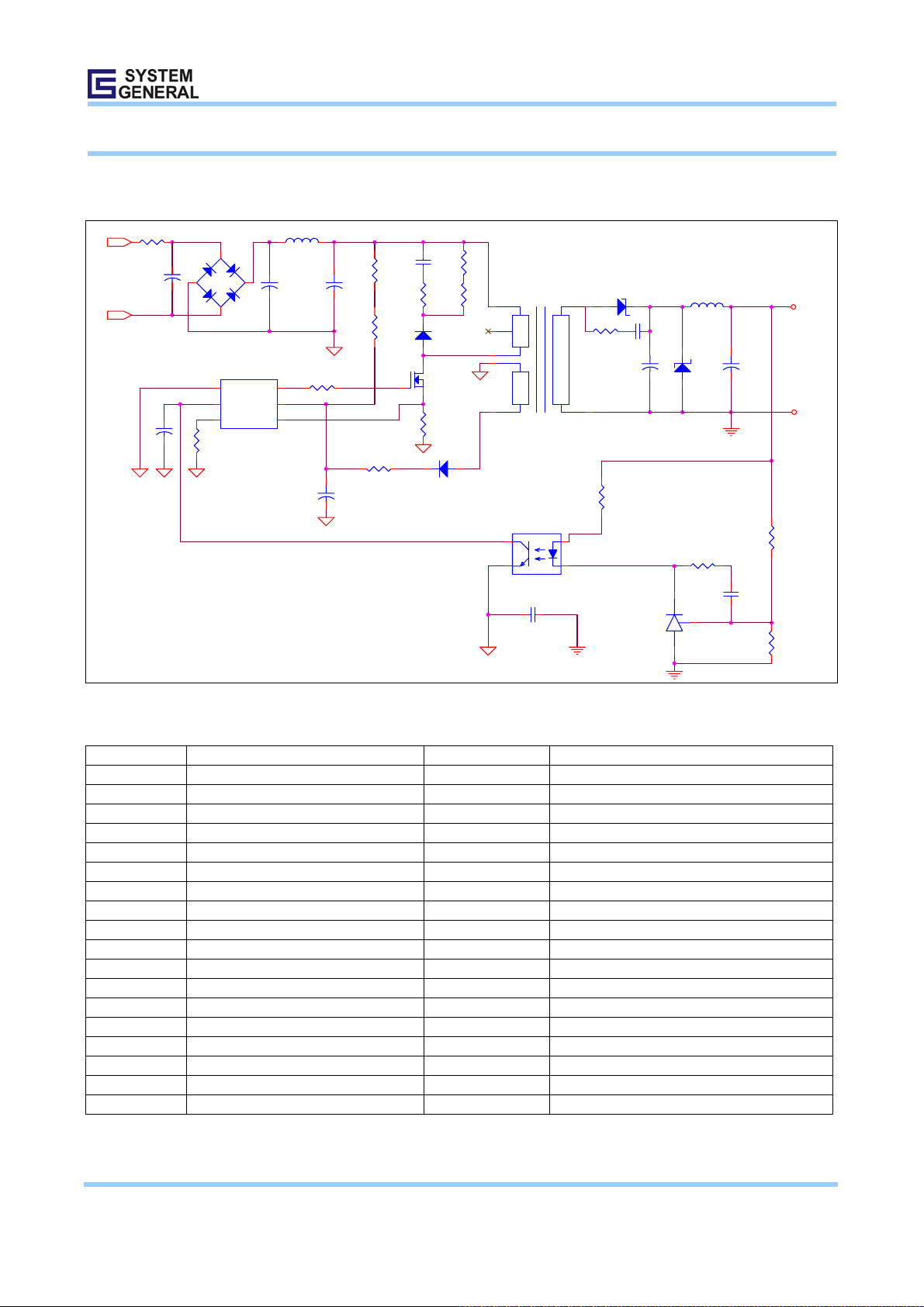

REFERENCE CIRCUIT

Circuit 5V/1A

4

GATE

VDD

L1

1 2

C1

6

5

R7

C3

Q1

R6

R5

D1

D2

R3

R4

21

T1

9

8

5

7 3,4

1,210

2 1

R10

R11

D4

C8

C7

+

L2

1 2

D5

2 1

+

C9

R1

+

C2

R2

2 1

23

1

R8

+

C4

L

N

F1

CX1

C6

1

BD1

-+

2

3

U1

1

GND

2

FB

3 4

RI SENSE

R9

SG6848x1

VO

GND

U2

4

3

1

2

CY1

BOM

Reference Component Reference Component

BD1 BD 1A/500V L2 10uH 6mm

CX1 (Optional) XC 0.1uF Q1 MOSFET 1A/600V

CY1 (Optional) YC 102P/400V (Y1) R1, R2 R 750KΩ 1206

C2 EC 10uF/400V 105℃ R4, R3 R 47KΩ 1206

C1 CC 103P/500V R5 R 47Ω 1206

C3 CC 102P/500V R6 R 4.7Ω 1206

C4 EC 10u/50V R7 R 100Ω 0805

C6 CC 472P 0805 R8 R 10Ω 1206

C7 (Optional) CC 102P/100V 1206 R10 (Optional) R 10Ω 1206

C8 EC 470u/10V 105℃ R9 R 100KΩ 0805

C9 EC 220u/10V 105℃ R11 R 100Ω 1/8W

C10 CC 222P 0805 R12 R 33KΩ 0805

D1 Diode FRI07 R13 R 33KΩ 1/8W

D2 Diode FR102 R14 R 4.7KΩ 0805

D4 Diode SB360 T1 EE-16

D5 (Optional) ZD 6.8V 0.5W U1 IC SG6848D1

F1 R 1Ω/0.5W U2 PC817

L1 20mH 6*8mm U3 TL431

R13

R14

3

U3

2

C10

1

R12

© System General Corp. - 12 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

PACKAGE INFORMATION

8 PINS - DIP (D)

D

°

85

Θ

SG6848x1

Dimensions

E1

41

A2

A1

L

b1

e

b

Symbol

A 5.334 0.210

A1 0.381 0.015

A2 3.175 3.302 3.429 0.125 0.130 0.135

b 1.524 0.060

b1 0.457 0.018

D 9.017 9.271 10.160 0.355 0.365 0.400

E 7.620 0.300

E1 6.223 6.350 6.477 0.245 0.250 0.255

e 2.540 0.100

L 2.921 3.302 3.810 0.115 0.130 0.150

eB 8.509 9.017 9.525 0.335 0.355 0.375

θ˚ 0˚ 7˚ 15˚ 0˚ 7˚ 15˚

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

E

A

eB

© System General Corp. - 13 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

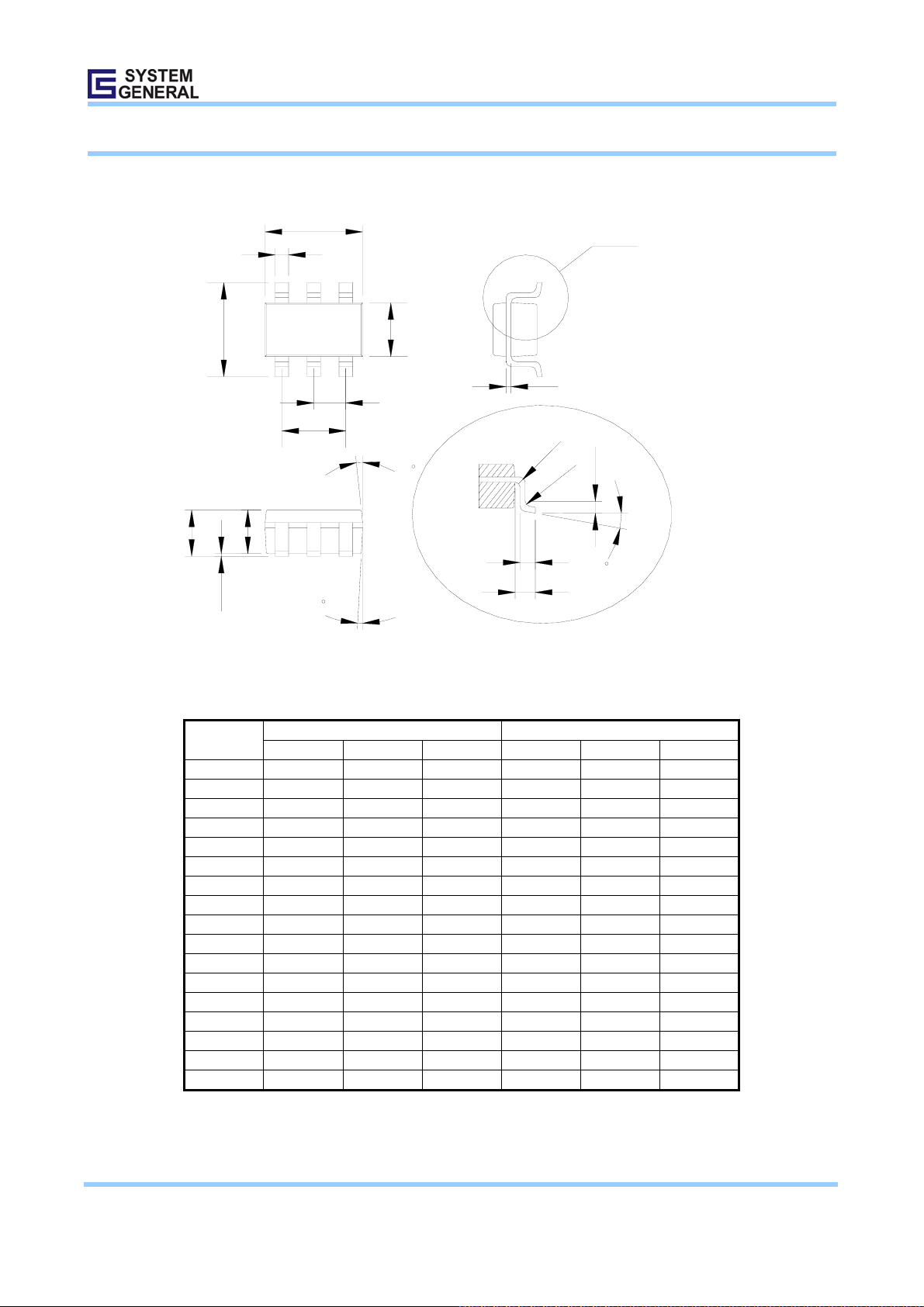

6PINS - SOT (T)

D

b

64

Detail A

SG6848x1

Dimensions

E

1

e

e1

A

Symbol

A 1.45 0.057

A1 0.15 0.006

A2 0.90 1.15 1.30 0.036 0.045 0.051

b 0.30 0.50 0.011 0.020

c 0.08 0.22 0.003 0.009

D 2.90 0.114

E 2.80 0.110

E1 1.60 0.063

e 0.95 0.037

e1 1.90 0.075

L 0.30 0.45 0.60 0.020 0.018 0.024

L1 0.60 0.024

L2 0.25 0.010

R 0.10 0.004

R1 0.10 0.25 0.004 0.010

θ° 0° 4° 8° 0° 4° 8°

θ1° 5° 10° 15° 5° 10° 15°

A1

A2

θ

1

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

E1

3

θ

1

c

1

R

L

L1

Detail A

L2

R

θ

© System General Corp. - 14 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Product Specification

Low-cost Green-Mode PWM Controller for Flyback Converters

SG6848x1

DISCLAIMERS

LIFE SUPPORT

System General’s products are not designed to be used as components in devices intended to support or sustain

human life. Use of System General’s products in components intended for surgical implant into the body, or other

applications in which failure of System General’s products could create a situation where personal death or injury may

occur, is not authorized without the express written approval of System General’s Chief Executive Officer. System

General will not be held liable for any damages or claims resulting from the use of its products in medical applications.

MILITARY

System General's products are not designed for use in military applications. Use of System General’s products in

military applications is not authorized without the express written approval of System General’s Chief Executive Officer.

System General will not be held liable for any damages or claims resulting from the use of its products in military

applications.

RIGHT TO MAKE CHANGES

System General reserves the right to change this document and/or this product without notice. Customers are advised

to consult their System General sales representative before ordering.

© System General Corp. - 15 - www.sg.com.tw

Version 1.3(IAO33.0002.B4) Jan. 27, 2006

Loading...

Loading...