System Equine Standard Stall Series, Rockwood Stall Series Assembly And Installation Instructions Manual

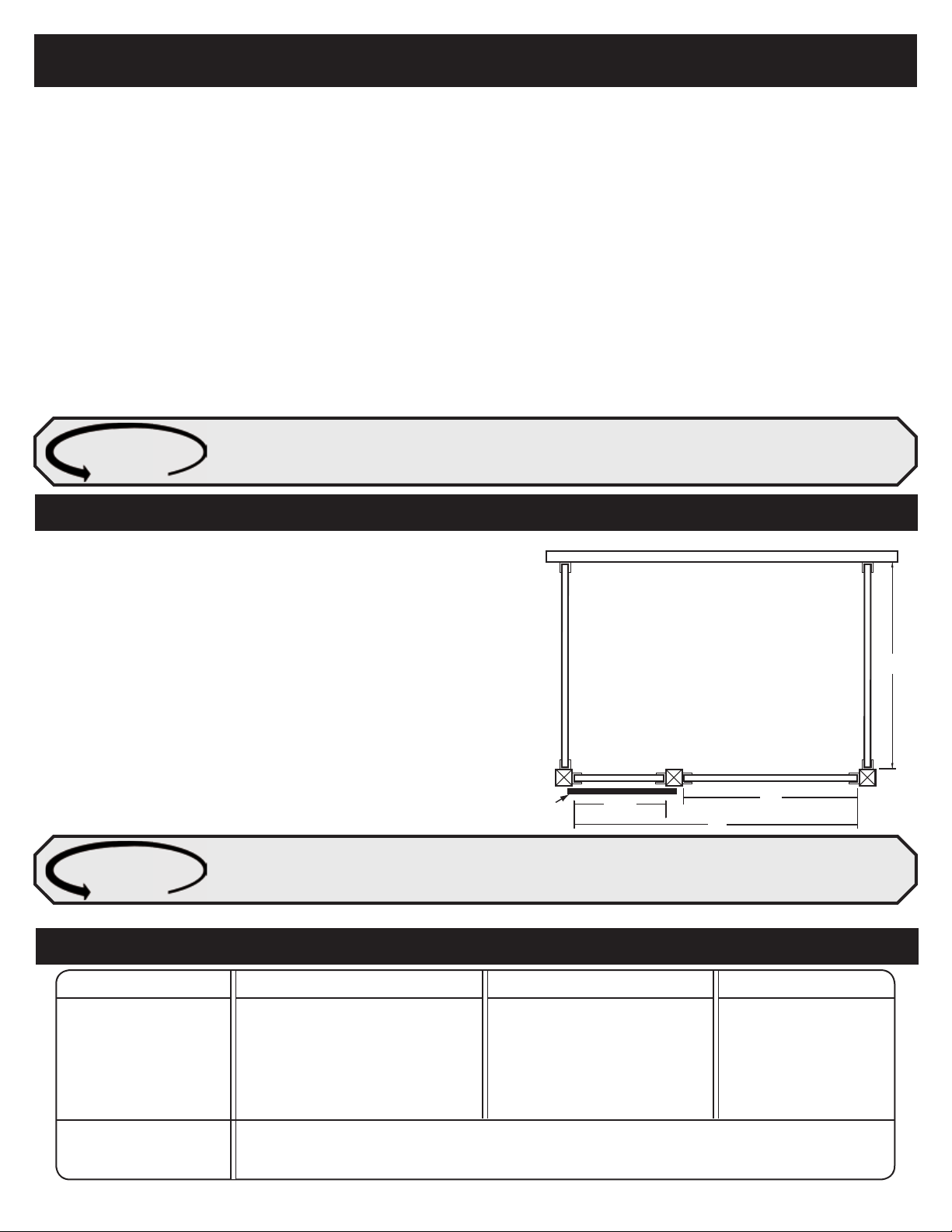

Outside Wall of Building

Door Post

Side Wall

DFig. A

C

A

B

Side Wall

Corner PostCorner Post

Stall Door

BEFORE YOU START

NOTE: All measurements are based on finished wood sizes. Example 2” x 6” finished size is 1 1/2” x 5 1/2”

Questions to Be Answered…

Careful consideration when designing your barn layout will save you time, money and frustration.

Do you want the horses to see one another?

Solid partition walls

Grilled partition walls

Privacy partition walls

Do you want to have the horses look out the front of the

stalls?

Flip down V- doors

Swing out feed doors

Shutter doors

Swing Down doors

Do you want to be able to feed from outside the stall?

Swing out feed doors

Feed Opening

Standard Stall Sizes are 10’x10’, 12’x12’, 10’x12’ Make sure to plan for additions to your stable ahead

SY S T E M TI P

of time. System Standard Stalls feature options such as removable walls, feed doors, V-Doors & more.

ANY SIZE STALL CAN BE BUILT USING THE SYSTEM STALL SYSTEM

What type of latch do you like?

Slide latch

Top latch catch

Horseshoe Latch

What type of wood are you using?

1 1/2" width is the standard thickness of the

U-Channel.

Are you concerned with good ventilation?

Grilled Front Walls

Grilled side walls

Full Grill doors

1. Corner posts can be set 10' or 12' (or any other spacing as

desired) on center to fit building design or special needs. The

Grill length (See C in fig A) of a standard 10’ stall front is 65” and

91” for a 12’ stall front. (See Fig. A). However, grill sections can

be combined to create any size of stall front you desire.

2. The inside distance between the door posts (See B in fig A) must

be 48". Posts used for the installation may be 6X6, 4x4, or 4X6.

If top of posts are not going to be anchored then a sufficient

amount of post should be placed deep enough in the footing to

provide adequate holding power. (We recommend a 3’ depth)

3. Install the corner posts first followed by the door posts. Make

sure all posts are plumb, true and level.

Keep in mind the finished size for 2” x 6” dressed lumber is 1 1/2” x 5 1/2”. If choosing tongue & groove as your

SY S T E M TI P

filler wood take in to account the loss of height due to the tongue & grooves. We recommend you use pressure

treated wood for the bottom two boards of your stall system.

NOTE: Wall sections that span over 12’ long will require a 4” x 4” center support post.

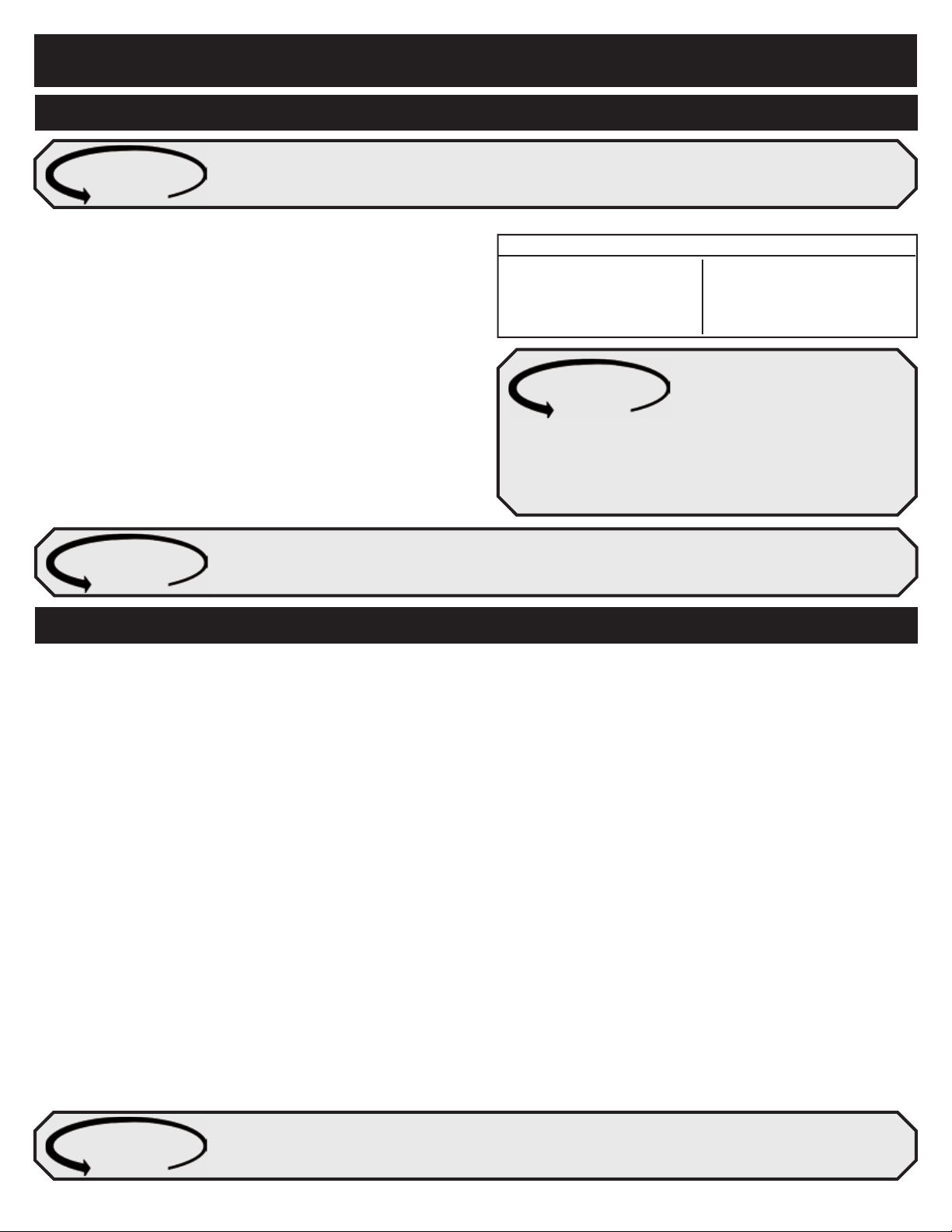

WOOD SPECS FOR SYSTEM STALL SYSTEMS

SECTION 10 FT. STALL 12 FT. STALL 14 FT. STALL

Front walls

(for header channel)

Grill Partitions

Solid Partitions

10 - 2” X 6” X 10’

1 - 2” X 10” X 10’

9 - 2” X 6” X 10’

1 - 2” X 10” X 10’

18 - 2” X 6” X 10’

10 - 2” X 6” X 12’

1 - 2” X 10” X 12’

9 - 2” X 6” X 12’

1 - 2” X 10” X 12’

18 - 2” X 6” X 12’

10 - 2” X 6” X 14’

1 - 2” X 10” X 14’

9 - 2” X 6” X 14’

1 - 2” X 10” X 14’

18 - 2” X 6” X 14’

Posts* 4X4

4X6

6X6

Standard Stall Instructions 2011 - Page 2

3 Needed per stall system except when stalls are added next to each other.

*See Fig. A above.

STEPS TO EASY INSTALLATION...

POST INSTALLATION

When you auger posts, all posts should be installed with the top at least 8’ above the ground. If the

SY S T E M TI P

NOTE: Post can be installed in several ways. The most common is to auger into the ground and using post anchoring plates.

posts are not properly secured at the top, they must be buried to a depth of at least 3’ to provide

adequate stability.

STEP 1

Refer to Fig. A page 2 to determine post locations for the size of stall

that has been selected.

STEP 2

Install the corner posts first, being careful to stay within the distances

A and D as given in the chart.

STEP 3

Install the door post to distance B to a tolerance of + or - 1/4”.

NOTE: Make sure all posts are checked for level on all sides.

STEP 4

Dimension C should be treated as the variable dimension if a problem

with post location should arise. In this event, it may be necessary to

cut some of the grill components.

CHECKING FOR SQUARE: Measure from one corner diagonally to the opposite corner (top left to bottom

SY S T E M TI P

right) and repeat for the other corner, measurements should be the same. If they are not, tap the corner of

the longest measurement until you have two equal measurements. This will ensure your work is square.

FRONT WALL ASSEMBLY

STEP 1 (See Fig. 1B, on page 5)

1a. Install the 46" U-channels on the corner and door posts with the

screws provided. (channels under grillwork)

1b. U-channels should be set back 1/2" from the front face of the posts.

1c. The U-channels should be set + or - 1/2" above the floor.

STEP 2

Cut all necessary lumber to a length 1/4" to 3/8" less than the distance

measured between the inside faces of the U-channel.

STEP 3

Installing the lumber in the U-channels.

3a. Slide the first board down to the bottom of the U-channel ensuring

that it is level. (pressure treated lumber can be used for the bottom

of the stall wall)

3b. Firmly secure the bottom board with the screws provided before

installing the remaining boards.

STEP 4

Install all remaining boards ensuring that they come to a height of 1 1/8"

above the top of the U-channels. It may be required to rip cut a board to

achieve the correct height.

STEP 5

Install the rubber grommets as shown in Detail D on page 5 for both the

bottom and top grill channels.

STEP 6

Install the bottom grill channel flush with the top of the U-channels, secure

STALL ARRANGEMENTS USING 3 1/2”X 3 1/2” POSTS

10’ STALL FRONT

A = 116.5”

B = 48”

C = 65”

D = 120”

12’ STALL FRONT

A = 142.5”

B = 48”

C = 91”

D = 144”

With all posts in place it is time

SY S T E M TI P

to order your lumber and unpack

the stall components. Review the

assembly drawing to familiarize

yourself with the names and locations of the parts. Try not

to mix boxes.

TO AVOID MISTAKES PERFORM EACH STEP IN THE

SEQUENCE SHOWN.

the channel with the screws provided.

STEP 7

At a height 36 3/8" install two 7" header U-channels above the top of the

46” U-channel.

STEP 8

Place the 2” x 10” header board in the 7” U-channels allowing it to extend

1/2” bellow the 7” U-channels. Use a screw at each end to hold the header

board in place for now. Put the top grill channel in position on the bottom

of the header board again hold in place with screws.

STEP 9

Insert the grill bars starting at one end. Place the grill bars in the top grill

channel then lower into the bottom grill channel, repeat until all bars are

in place. When all bars are in place remove the screws used to hold the

header board and top grill channel. Push or pull down on the header board

until it sits evenly on the top of the grill bars. Now secure the header and

top grill channel in place with the screws provided.

STEP 10

THE FOLLOWING IS FOR 12’ FRONTS OR LARGER ONLY. Install the

one wall brace placing it on the inside of the wall.

NOTE:

• 12’ Front walls come with one 46” wall brace.

• Grilled partition walls come with two 46” wall braces, 1 for each

side.

• Solid partition walls come with two 94” wall braces one for each

side.

SY S T E M TI P

There are two 7” header U-Channels provided with each stall door to install an optional 2”x10” lumber

header in the door opening for added strength. Installation instructions for Optional Header are on page 8

of this manual.

Standard Stall Instructions 2011 - Page 3

Loading...

Loading...