System Cleaners S4 User Manual

Version 3 (02.207. EN)

MANUAL

S4

Version 5 (05.2018. EN) (S4)

Page 2 of 52

General

For safety during installation and later use it is very important that installation, operating and maintenance

instructions are carefully followed.

You are requested to keep this instruction manual at a location where it will be available at all times, and it should be

submitted to the person who is responsible for this product. In the event that the instruction manual is lost, you are

welcome to order a new one from your dealer.

If any doubt should arise with regard to the content of these instructions, please contact the distributor.

Proper use

System Cleaners’ system is exclusively designed to transport and pressure-increase of water to satellite stations. All

other forms of application or use not within the scope of the above are considered to be improper and inconsistent

with the requirements and regulations, and may lead to hazardous situations.

System Cleaners A/S cannot be held liable for consequential damage resulting from improper use of the equipment.

Proper use includes the following:

The instructions, regulations and recommendations concerning the system stated in the instruction manual

Observance of the specified inspection and maintenance intervals

Correct maintenance of good operating condition of the system

Observance of the specified environmental and operating conditions

Proper use also includes observance of all information that is stated in this instruction manual. This applies in

particular to the specified safety instructions.

Liability

Each user must handle and use the system in a responsible manner.

It is therefore of great importance that this instruction manual is available to the sanitation employee concerned at all

times.

Safety

The design of the system complies with generally accepted technical regulations and provisions concerning the working

environment and accident prevention. Despite this, risks can occur during use that can lead to physical inconvenience

for the user or a third party or have an impact on the machine or other equipment.

The system must therefore be in prime technical condition before use and may only be used in accordance with its

purpose and with strict observance of the safety requirements and operating instructions. In particular, malfunctions

and irregularities that can affect safety must be remedied immediately.

Warranty

For a period of 24 months from the date of delivery, your dealer will honor a warranty on parts that do not function

properly due to material defects or manufacturing faults. The warranty does not cover wearing parts. The warranty will

cover replacement or repair of the defective part. Costs with regard to dismantling, forwarding and reassembly are

defrayed by the purchaser. Any return shipments from System Cleaners A/S following completed repairs are defrayed

by System Cleaners A/S. The defective parts remain the property of System Cleaners A/S.

Claims that may be made for legal reasons, ordinary wear and tear, as well as damage to parts that can be attributed

to negligent or improper handling are not covered by the warranty. The warranty will be void if the system has been

exposed to frost. The warranty will also be void if modifications or repairs have been carried out by unauthorized

personnel. Warranty claims will only be accepted if they are reported to System Cleaners A/S immediately after

damage has been discovered. The warranty is terminated if there is a change of ownership of the machine. System

Cleaners A/S and its dealers cannot be held liable for personal injury, damage to equipment, loss of earnings,

including production losses, losses to stock or similar that may have arisen as a result of defects or delayed delivery of

the sold product, irrespective of the cause, including manufacturing faults or material defects. In addition, please refer

to our general terms and conditions of sales and delivery.

Version 5 (05.2018. EN) (S4)

Page 3 of 52

Disposal

Please be aware of the following applicable provisions: the equipment must be disposed of according to its nature and

applicable requirements, e.g. electrical scrap, synthetic material, stainless steel, brass, etc.

Labelling

The system is equipped with a type plate containing technical data.

The type plate is located on a fixed part of the system.

Declaration of conformity

We declare that this product is in conformity with the following directives:

2006/42/EC Directive on Machinery

Per Kjøller

Development Manager

Version 5 (05.2018. EN) (S4)

Page 4 of 52

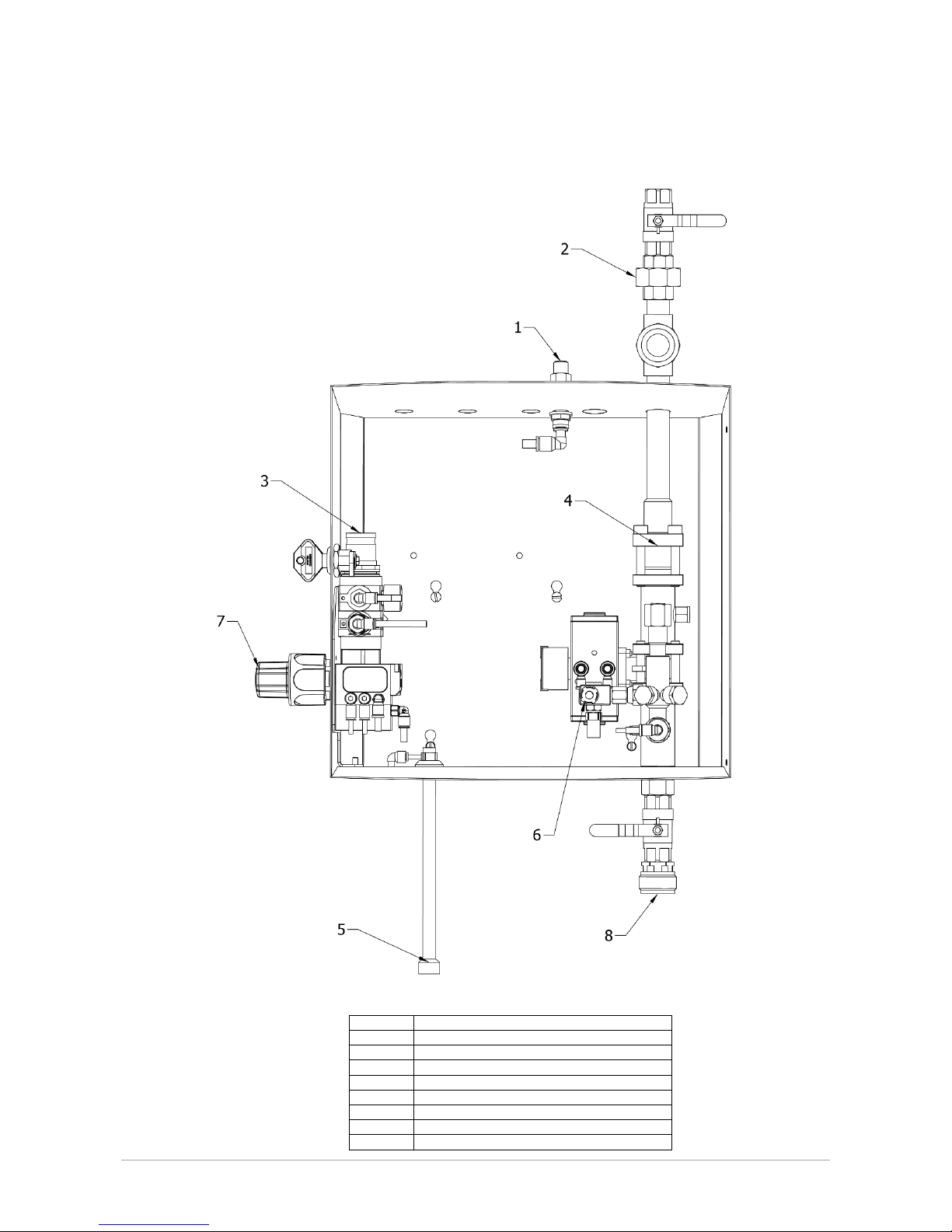

DESCRIPTION

Satellite

A satellite is connected to pressurized water, a number of chemicals and, depending on the model, compressed air.

Using a satellite it is possible for one operator to rinse, foam or disinfect (depending on model).

Pos

Description

1

Inlet air

2

Inlet water

3

Air regulator

4

Injector system

5

Suction tube chemical

6

Dosing valve chemical

7

Function selector

8

Outlet

Version 5 (05.2018. EN) (S4)

Page 5 of 52

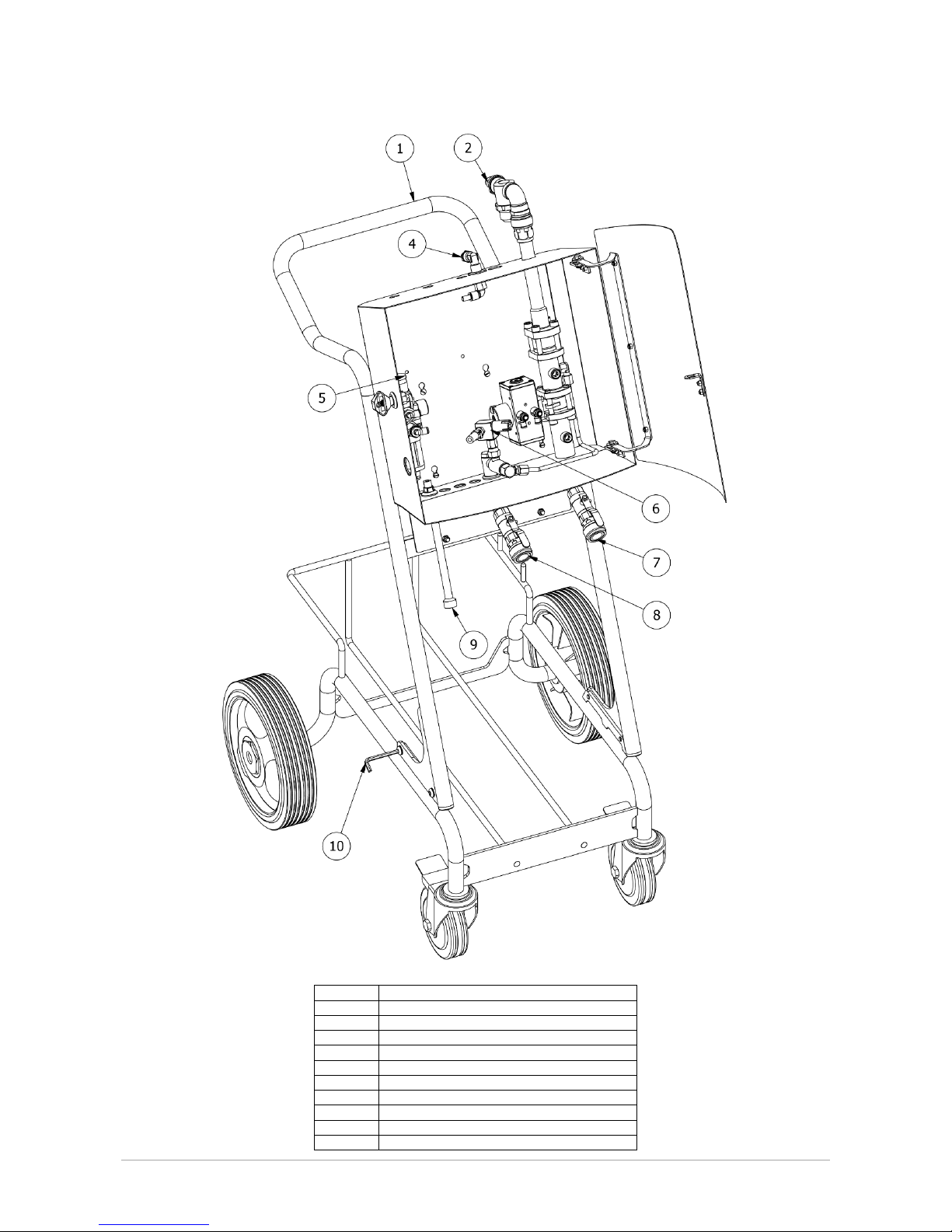

Trolley

Pos

Description

1

Trolley

2

Inlet water

3

Injector system

4

Inlet air

5

Air regulator

6

Dosing valve chemical

7

Outlet

8

Outlet

9

Suction tube chemical

10

Allen key

Version 5 (05.2018. EN) (S4)

Page 6 of 52

INSTALLATION

Storage

The machine must not be exposed to frost unless it has been emptied of water (frost protected). Even brief periods of

exposure to frost may cause damage to the equipment.

Store the equipment in a frost-free room in the original packing.

Installation

Place the equipment in a frost-free room, well protected from the sun and place it on a hard surface.

Make sure that, in the event of failing non-return valves in the air and water supply, there are suitable back-flow

preventers fitted.

Local regulations may require installation of a back-flow protecting device to prevent compressed air or chemicals

getting into the water supply.

Piping

The piping should be made from materials suitable for the media in the pipes, the maximum pressure and

temperature.

It is the fitter’s responsibility to ensure that the piping including all armatures conform to local regulations.

The installation must be performed such that forces from pipes etc. are not transferred to the equipment during and

after fitting, as this may result in leaks or damage the equipment.

Select a pipe size so that the flow velocity in the pipe is up to 3 meters/second (10 feet/second). This gives a normally

accepted pressure loss and low noise from the flow.

In order to facilitate maintenance of the equipment, it is recommended to fit a shut-off valve in the pipelines

immediately at the connections for water.

Pipe supports

Always use pipe supports designed for the pipe size and material and maximum working pressure and temperature.

Version 5 (05.2018. EN) (S4)

Page 7 of 52

COMMISSIONING

Flushing

Pipes etc. must be flushed efficiently before connecting the unit.

Before commencing operation on the unit or following repair work, the unit must be flushed thoroughly to remove any

impurities or foreign bodies.

Disinfection

Local specifications may require disinfection of the wetted parts like internals of pipes and pumps before use to avoid

contamination of newly cleaned surfaces.

Dosing

Adjust the dosing according to the chemical supplier’s recommendations.

Always calibrate and, if required, document the dosing on a regular basis.

Version 5 (05.2018. EN) (S4)

Page 8 of 52

Air

Adjust the air pressure until a satisfactory foam quality is achieved.

Note that good foam quality depends on the mixture of water, chemical and air and getting a perfect result requires

some adjustments of the mixing ratios.

OPERATION

Safety

It is recommended that suitable working clothes be worn. For protection against certain types of detergents, always

use protective goggles, respiratory protective equipment and rubber gloves.

It is recommended that non-slip footwear be worn since the floor can be slippery due to the presence of water and

foam.

This system may only be operated, maintained and – not least - repaired by persons who are familiar with the system

and properly trained to carry out the job concerned.

It is the customer’s responsibility that these installation and operating instructions are supplemented by in-house

instructions concerning inspection and reporting, industrial management, personnel training, etc.

Do not carry out any work if you are unsure of the consequences or are insufficiently skilled to carry it out. If in doubt,

you should contact your superior or your agent in advance.

Never direct the water jet at other persons.

Never direct the water jet at electrical installations.

Check that couplings “lock” when hoses and nozzles are fitted. If possible, practise this procedure before operation.

Always relieve the pressure in the rinsing hose by opening the low-pressure gun or valve after the water supply has

been shut off before dismantling the couplings and removing the hose.

During operation of the system, ensure that the low-pressure gun/valve is closed before releasing the handle.

When the low-pressure gun or valve is opened, the water jet will result in a certain amount of counter-pressure.

Therefore make sure that you hold the handle firmly and have a firm foothold.

System Cleaners low-pressure systems may only be used in conjunction with soaps and chemicals that are approved

for cleaning within the food or transport industries.

Soaps and chemicals that are classified as highly corrosive, toxic or which pose a health risk to humans or animals

may not be used.

The system must not be used together with solvents or volatile liquids that pose a health risk or are inflammable.

In the event that the system is used with non-approved soaps, chemicals or solvents, System Cleaners A/S disclaims

all liability.

If in doubt, please contact your soap or chemical supplier and read the supplier manual.

In the event that you use the system with chemicals that require mandatory labelling, or if the water temperature

exceeds 50°C, a low-pressure gun with an automatic closing device must be used.

In the event that you use the system without a gun with an automatic closing device together with chemicals that

require mandatory labelling, or water with a temperature that exceeds 50°C, System Cleaners A/S disclaims all

liability.

Pressure relief

After use shut the isolating valves over the equipment and relieve air and water pressure in hoses etc.

Flush injector system

After each use flush the injector system with warm water to avoid clogging of the injector.

Version 5 (05.2018. EN) (S4)

Page 9 of 52

MAINTENANCE

Water filter

Depending on the mains water quality it may be necessary to clean the water filter on a regular basis to prevent the

pump from stopping.

Water non-return valve

Water non-return valves are critical wear parts and should be replaced yearly.

Air filter

Depending on the quality of the compressed air it may be necessary to empty condensation collected in the air filter

bowl on a regular basis.

Injector system

The injector system consists of foot strainer, dosing valve, non-return valve and injector.

Chemical residues compromises the function of the injector and flushing with warm water after each use is required to

maintain trouble free operation.

Depending on the water quality it may be necessary to de-scale the water side of the injector on a regular basis

following the chemical supplier’s guidelines.

Version 5 (05.2018. EN) (S4)

Page 10 of 52

TROUBLE SHOOTING

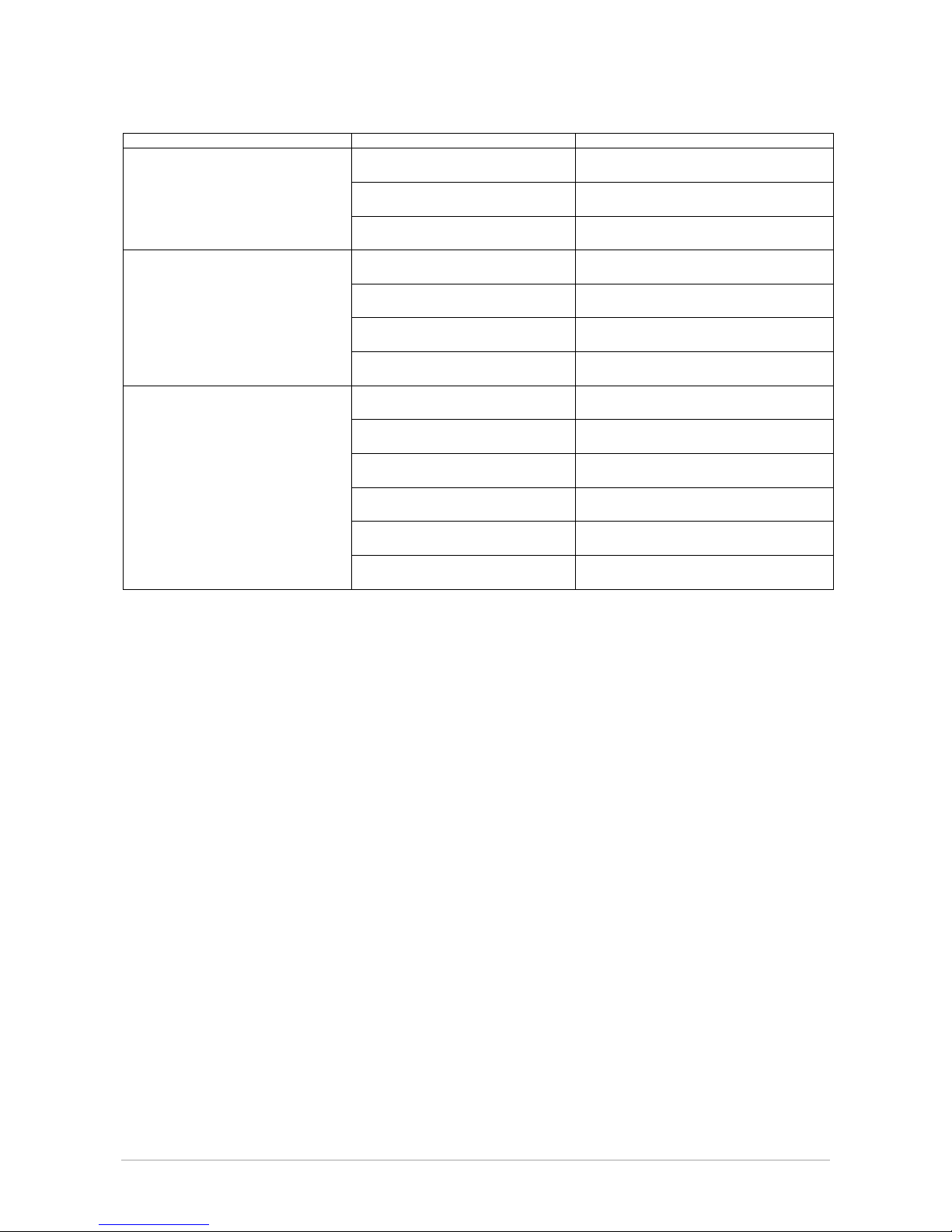

Fault

Cause

Remedy

No water or insufficient water at the

nozzle when rinsing

Function selector is in closed

position

Turn the function selector switch to the

desired function

Insufficient water supply to the unit

Make sure that the water supply is as

described in the technical specifications

Valve at the end of the hose not

open

Open valve

The unit does not suck up detergent

Function selector is not in the

correct position

Turn function selector switch to desired

function

Suction filter or chemical restrictor

are blocked by chemical residue

Clean suction filter or chemical

restrictor

Water pressure is too low

Make sure water supply is as

described in the technical specifications

Suction filter is above the fluid level

in chemical container

Position the suction filter below fluid level

Poor foam quality

Chemical product is not a foaming

product

Change to a foaming chemical

Incorrect dosing

Adjust the dosing according to chemical

supplier’s specifications

Suction filter or chemical restrictor

are blocked by chemical residue

Clean the suction filter or chemical

restrictor

Water pressure is too low

Make sure that the water supply is as

described in the technical specifications

Air pressure too low

Increase air pressure

Non-original foam nozzle fitted

Replace with original white foam nozzle

Version 5 (05.2018. EN) (S4)

Page 11 of 52

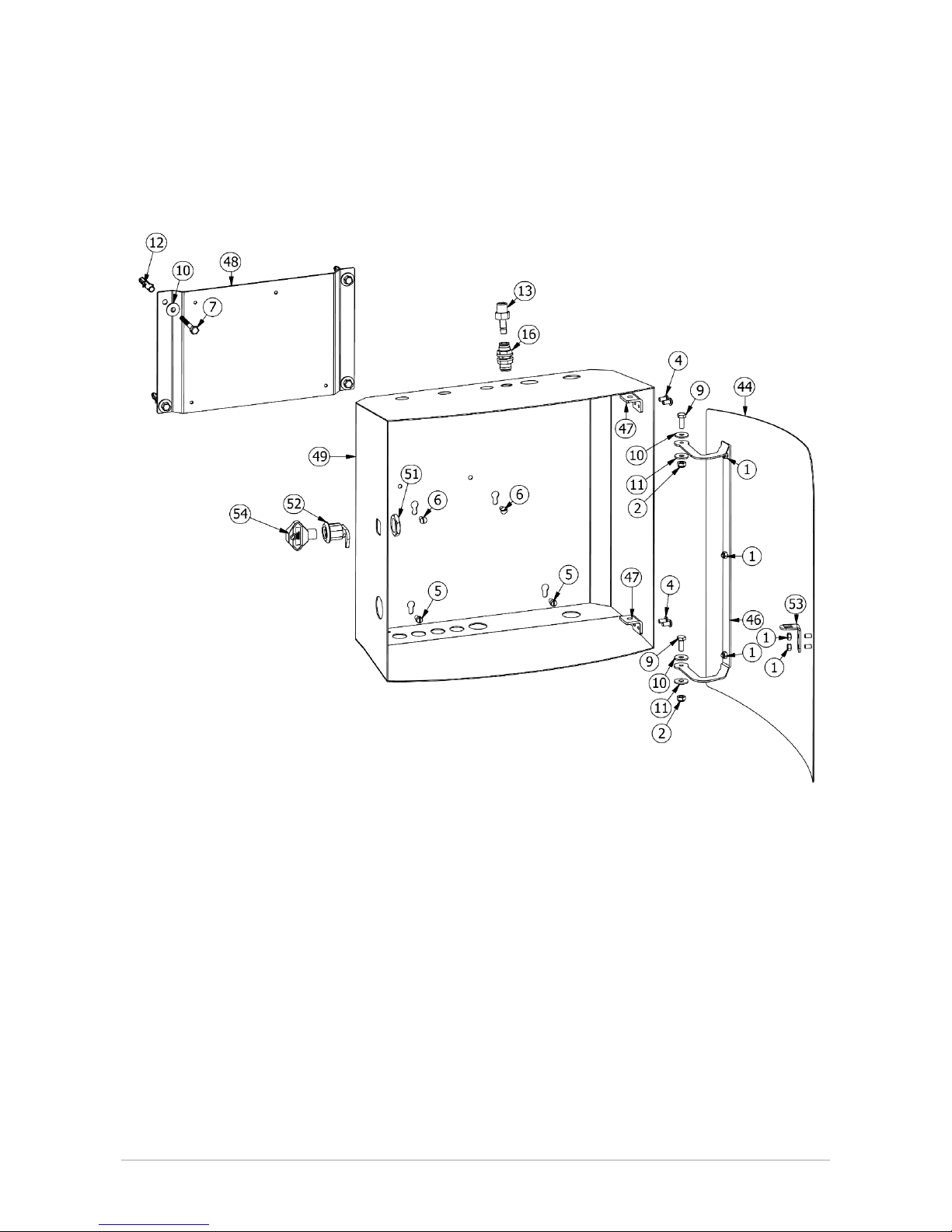

SPARE PARTS

Cabinet

Version 5 (05.2018. EN) (S4)

Page 12 of 52

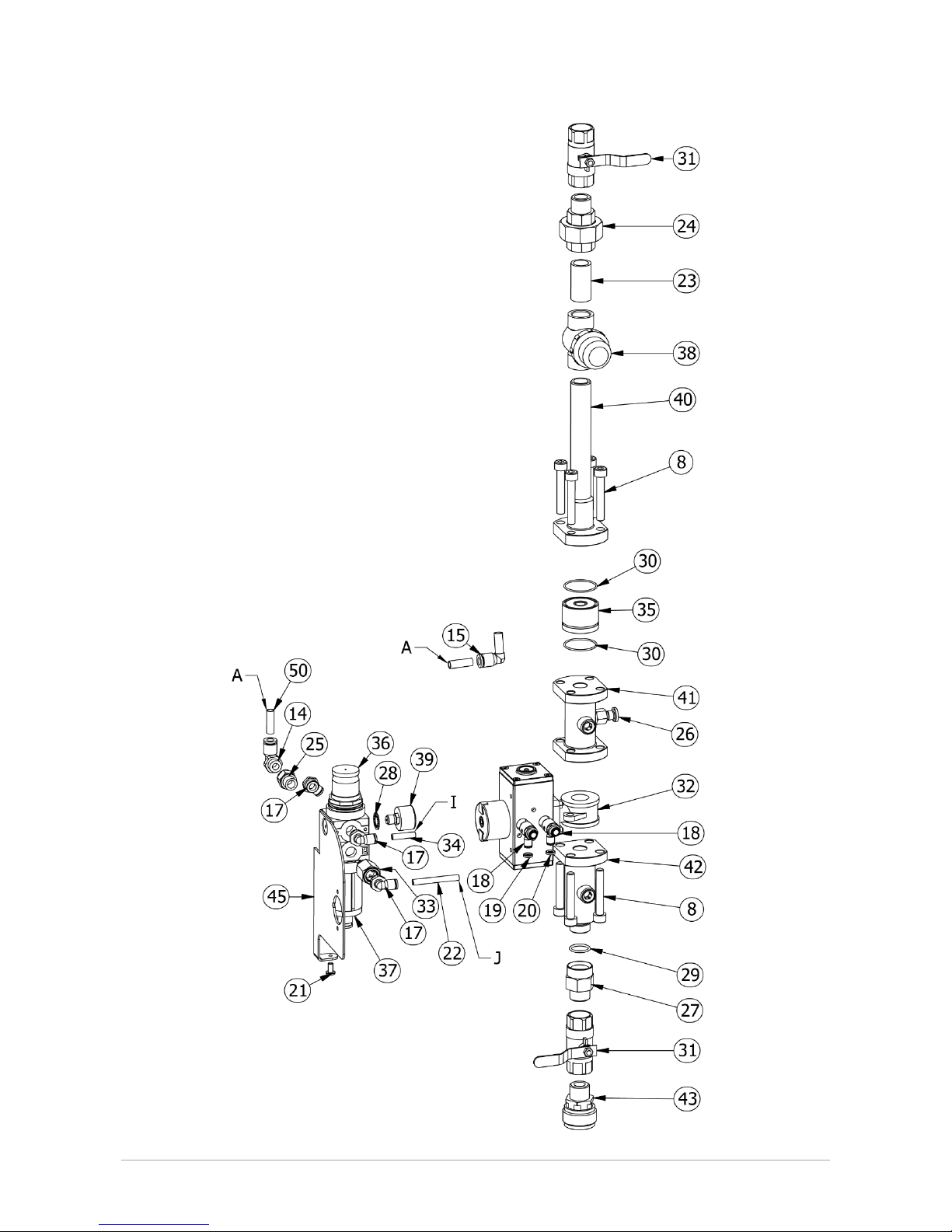

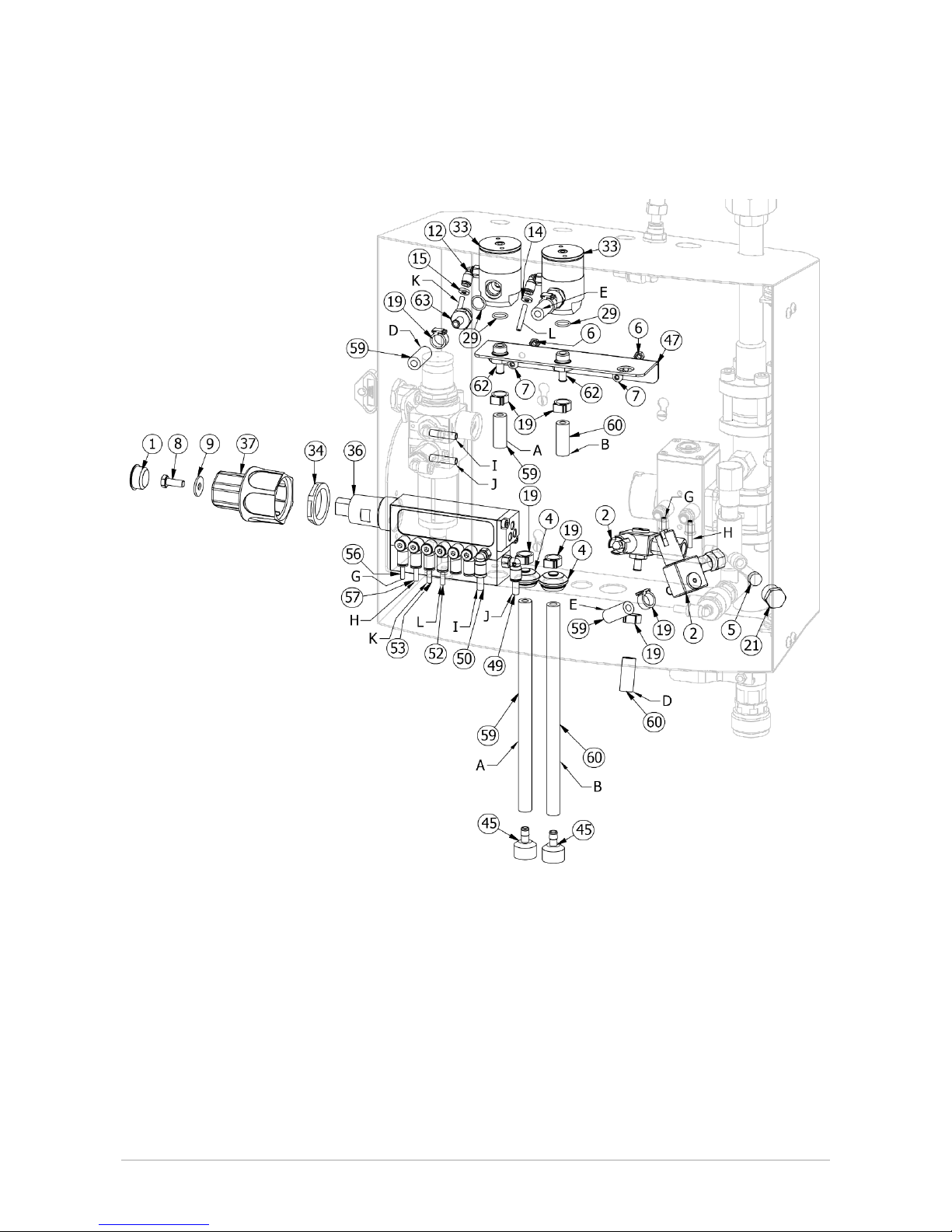

Injector system

Version 5 (05.2018. EN) (S4)

Page 13 of 52

Pos.

Part no.

Description

Material

Version

1

08-000502

Lock nut M5

A2

All

2

08-000602

Lock nut M6

A2

All

4

08-100501

Screw button head M5x10

A2

All

5

08-100505

Screw M5x10 cylinder head

A2

All

6

08-100512

Screw fillister head M5x10

A2

All

7

08-100606

Coach screw M6x50

A2

All

8

08-800807

Cheese-head screw M8x50

A2

All

9

08-200606

Set screw M6x16

A2

All

10

08-300602

Disc washer ø6

A2

All

11

08-300605

Disc washer ø6

Nylon

All

12

08-900008

Rawlplugs S 8

PVC

All

13

15-000010

Adapter ø8x1/4" NPT SS

AISI 304

NPT

14

15-000011

Air fitting 1/4"x8 elbow

Nickel-plated brass/Plastic

All

15

15-000061

Air fitting 8x8 elbow

Plastic

All

16

15-000071

Bulkhead Union air ø8

Plastic

All

17

15-010010

Air fitting 1/4"x6 elbow

Nickel-plated brass/Plastic

All

18

15-020050

Air fitting Elbow with throttle 1/8"x4

Plastic/Brass

All

19

15-090402

Color ring 4mm green

Plastic

All

20

15-090406

Color ring 4mm grey

Plastic

All

21

08-100515

Screw buttonhead M5x10

A2

All

22

55-110040

Air hose ø6mm black

PA12

All

23

15-510121

Nipple pipe 1/2"x40mm

AISI 316

3-8 bar

24

15-800032

Union 1/2" with packing, e/i

AISI 316/PTFE

BSP

24

15-800033

Union 1/2" with packing, NPT

AISI 316/PTFE

NPT

25

16-400040

Extension nipple 1/4"x20

Nickel-plated brass

All

26

16-501802

Plug 1/8"

AISI 316

All

27

16-800060

Outlet nipple 1/2"x37 E/I

AISI 304

All

28

17-000072

Gasket 1/8"

Nylon

All

29

17-020080

O-ring 18x2 70 sh

EPDM

All

30

17-030129

O-ring 32x1,5 Viton 75 sh

Viton

All

31

20-000220

Ball valve 1/2" (blue)

AISI 316

BSP

31

20-000226

Ball valve 1/2"NPT (blue)

AISI 316

NPT

32

20-000283

Ball valve 1/2" with actuator

-

All

33

20-200025

Non-return valve air 1/4"

-

All

34

55-110060

Air hose ø6mm red, m

PA12

All

35

20-200410

Non-return valve 1/2"

AISI 304/NBR

All

36

20-300080

Regulator air without filter

Plastic

All

37

20-300141

Filter air 1/4"

Plastic

All

38

20-500061

Strainer 1/2" brass 300 µm

Nickel-plated brass

3-8 bar

39

22-000071

Gauge ø20 0-10 bar

AISI 304/brass/glycerine

All

40

25-000520

Inlet pipe 1/2" BSP

AISI 304

All

41

25-100420

Intermediate pipe 1/2"

AISI 316

All

42

25-200350

Outlet pipe 1/2"

AISI 316

All

43

30-000050

Outlet coupling 1/2"

Special stainless

All

44

41-230302

Door 300 mm

AISI 304

All

45

42-200120

Bracket for pneumatics G5

AISI 304

All

46

42-600038

Hinge for door 300 mm

AISI 304

All

47

42-600039

Hinge for satellite

AISI 304

All

48

43-100080-01

Wall bracket for satellite

-

All

49

46-400301

Housing 300mm S4

AISI 304

All

50

55-100040

Air hose 8mm black

PA12

All

51

72-000030

Nut for lock

Nylon

All

52

72-000040

Lock with hook

AISI 304/Plastic

All

53

72-000051

Strike plate 300 mm cabinet

-

All

54

72-100010

Key for housing

Plastic

All

Version 5 (05.2018. EN) (S4)

Page 14 of 52

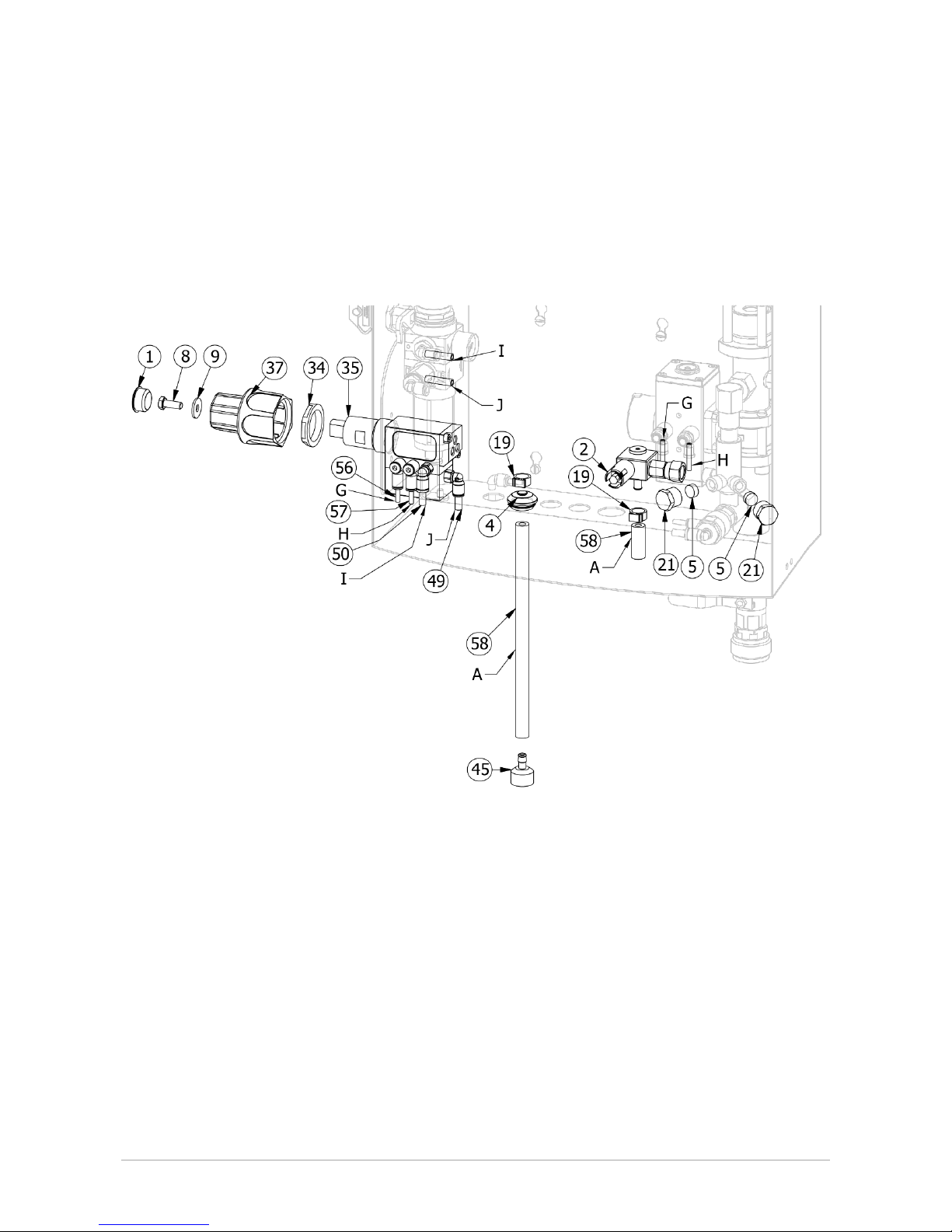

Function F

Version 5 (05.2018. EN) (S4)

Page 15 of 52

Function F D

Version 5 (05.2018. EN) (S4)

Page 16 of 52

Function F F

Loading...

Loading...