Systematics MP140 Owner's Manual

OWNER'S MANUAL

MP140 MIG COMBINATION UNIT

THE MP140

REPRESENTS THE LATEST TECHNOLOGY

IN MIG COMBINATION UNITS. THE MP140 OPERATES

ON 115 VOLT AC SINGLE PHASE CURRENT, AND FEATURES

"SMOOTH ARC" TRANSFORMER DESIGN CONCEPT.

FOR TECH. SERVICE, CALL 1-610-696-9040

FORM WC5342 Rev. 8/00

INSTALLATION

OPERATION

MAINTENANCE

MANUFACTURER’S LIMITED WARRANTY

!

WARNING

This equipment is warranted against defects in materials

and workmanship for a period of two years from the date of

purchase.

EXCEPTION: THE MIG TORCH IS WARRANTED FOR A

PERIOD OF 30 DAYS FROM THE DATE OF PURCHASE.

Should the equipment become defective for such reason,

the Manufacturer will repair it without charge, if it is returned

to the Manufacturer’s factory, freight prepaid. This warranty

does not cover: (1) failure due to normal wear and tear; (2)

consumable parts, such as, but not limited to, torch contact

tips, gas cups and insulating bushings; (3) damage by

accident, force majeure, improper use, neglect, unauthorized repair or alteration; (4) anyone other than the original

purchaser.

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE MANUFACTURER SHALL NOT BE LIABLE FOR ANY INJURY TO

PERSONS, INCLUDING DEATH; OR LOSS OR DAMAGE

TO ANY PROPERTY, DIRECT OR CONSEQUENTIAL,

INCLUDING, BUT NOT LIMITED TO, LOSS OF USE,

ARISING OUT OF THE USE, OR THE INABILITY TO USE,

THE PRODUCT. THE USER ASSUMES ALL RISK AND

LIABILITY WHATSOEVER IN CONNECTION WITH THE

USE OF THE PRODUCT, AND BEFORE DOING SO,

SHALL DETERMINE ITS SUITABILITY FOR HIS INTENDED USE, AND SHALL ASCERTAIN THE PROPER

METHOD OF USING IT.

SOME STATES DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY LASTS, OR THE

EXCLUSIONS OR LIMITATIONS OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES. SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU. THIS

WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND

YOU MAY HAVE OTHER RIGHTS WHICH MAY VARY

FROM STATE TO STATE.

ARC WELDING CAN BE INJURIOUS TO OPERATOR AND PERSONS IN THE WORK AREA -——

CONSULT INSTRUCTION MANUAL BEFORE

OPERATING.

ELECTRIC SHOCK can kill.

• Do not touch electrodes or other electrically live parts.

• Insulate yourself from work and ground.

• Install and ground machine in accordance with the National

Electical Code and local code(s). Read Operating Manual

before installing or operating.

• Do not operate with protective covers, panels, or guard

removed.

• Disconnect input power before servicing.

• Only qualified personnel should install, use, or service this

equipment.

ARC RAYS can injure your eyes and burn

skin.

• Wear correct eye, ear, and body protection while welding.

FUMES AND GASES can be dangerous to your

health.

• Use enough ventilation and/or exhaust at the arc.

• Keep your head out of fumes.

• Do not breathe fumes.

READ AND UNDERSTAND THE

MANUFACTURER’S INSTRUCTIONS AND

YOUR EMPLOYER’S SAFETY PRACTICES.

See American National Standard Z49.1, “Safety in

Welding and Cutting”, published by the American

Welding Society, 2501 N.W. 7th St., Miami, Florida

33125; OSHA Safety and Health Standards, 29 CFR

1910 available from U.S. Dept. of Labor, Wash.,

D.C. 20210.

ELECTRICAL SUPPLY REQUIREMENTS................................... 1

INTRODUCTION ........................................................................... 2

SPECIFICATIONS......................................................................... 3

CHECK LIST (CONTENTS) .......................................................... 4

INSTALLATION ............................................................................. 4

OPERATION ................................................................................. 7

MAINTENANCE ........................................................................... 13

TROUBLE SHOOTING CHART.................................................. 15

CONNECTING TIGIT2 OR MHG7 SPOOL GUN ........................ 20

CONSUMABLE PARTS BREAKDOWN ..................................... 22

PARTS BREAKDOWN - MIG TORCH ........................................ 23

OPTIONS - TIGIT2, MHG7 SPOOL GUN ................................... 24

Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380

TABLE OF CONTENTS

ELECTRICAL SUPPLY REQUIREMENTS FOR THE MP140

Ensure that there is a 115 volt single phase, 20 amp electrical supply within easy reach

of the unit. The input cable supplied is 20 feet long. A 50 foot cable is an optional extra. The

plug which is factory installed is suitable for use up to 120 amps of output. The plug must

be changed if the welder is used above 120 amps of output. Attach a suitable plug

sure the green wire is attached to ground. Refer to boxes below with the WARNING and

NOTE headings for more information. All wiring should be performed by a qualified

electrician.

making

WARNING

To conform to the National Electrical Code, the power input plug must be

changed if this unit is to be operated on a 20 amp circuit or higher.

Never change fuses or circuit breakers to a higher value than the wires and

outlet are designed for.

Breaker size - Wire size

15 Amp 14 Gauge

20 Amp 12 Gauge

30 Amp 10 Gauge

Do not rely on the circuit breaker built into the MP140 to protect your wiring.

This circuit breaker protects the MP140 internal wiring only.

Do not use undersized extension cords. Follow the cord manufacturer's

recommendations as to current carrying capacities.

Make sure all electrical wiring is installed by a qualified electrician.

NOTE

The maximum output of the MP140 will be limited by the size (amp rating) of

the circuit used.

Operation on a 15 amp circuit (14 gauge wire) will limit maximum

output to 100 amps.

Operation on a 20 amp circuit (12 gauge wire) will limit maximum

output to 120 amps.

Operation on a 30 amp circuit (10 gauge wire) will result in maximum

output of 140 amps.

MP140 output will be limited also by low input voltage (less than 120 volts),

long input cords and use of extension cords.

Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380 1

INTRODUCTION

The Systematics MP140 is a com-

bination welding power source,

wire feed unit, MIG torch and

accessory package. It operates on

115 volts AC input current and is

designed to meet the requirements

of auto body repair shops and light

fabrication. The MP140 produces

fusion welds by the Gas Metal Arc

Welding process (GMAW or MIG), on

steel up to 1/4" thick(aluminum 3/

16") , using .023" through .045"

steel wire and 3/64" aluminum

wire(Optional liners and contact

tips must be purchased to cover

given wire sizes). Heavier sec-

tions can be easily welded using

slightly different techniques. Consumable MIG Spot/Stitch Welding on

steel can be performed with the

Optional SSTP-2 module installed.

The number of controls on the

unit have been reduced to assist

inexperienced operators learn MIG

welding. This facilitates rapid

set up for welding different thicknesses of material requiring various heat inputs. The VOLTAGE control adjusts the welding voltage

and the WIRE SPEED control adjusts

the speed of the wire drive motor.

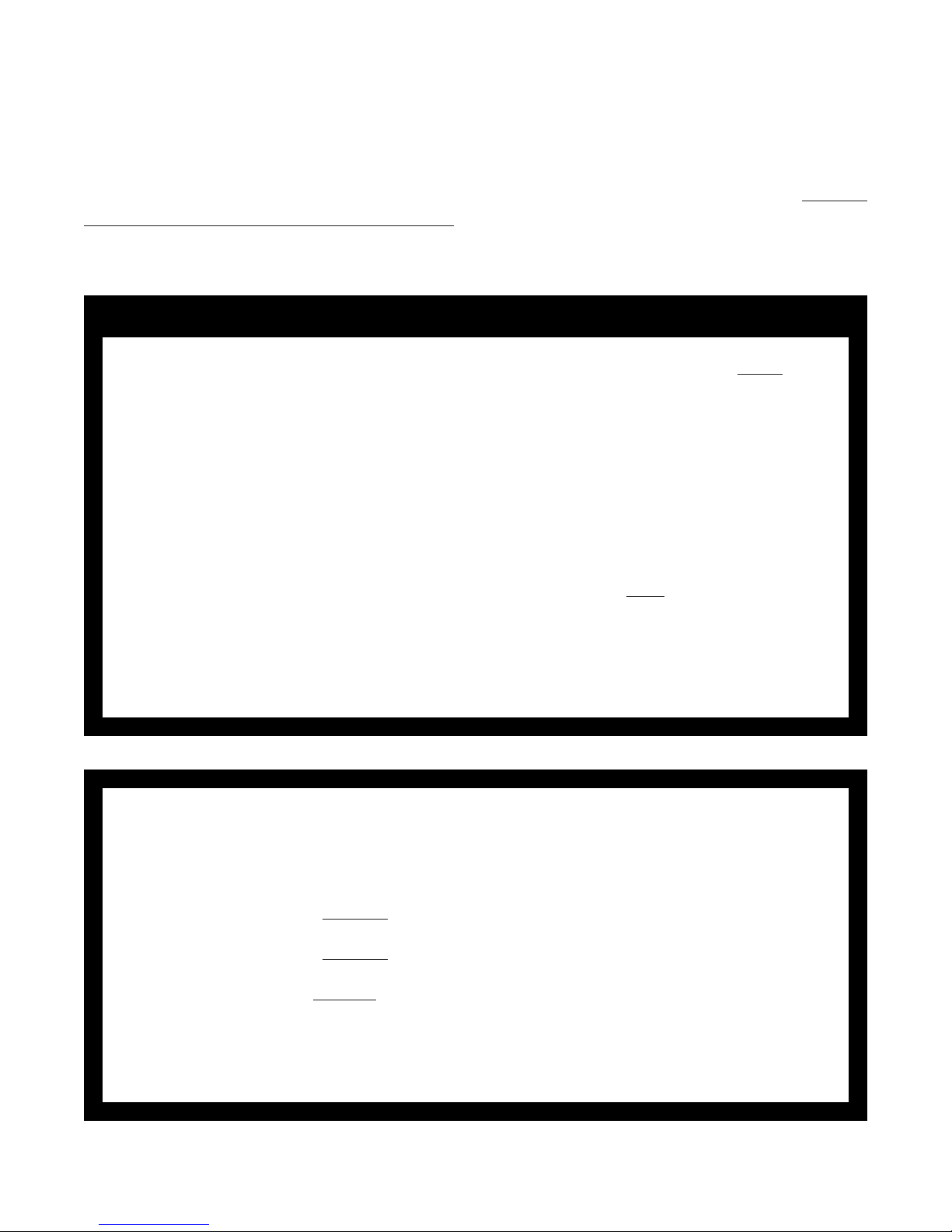

THE MIG PROCESS

AS APPLIED TO THE MP140

WIRE SPOOL

FEED

ROLLS

MIG

TORCH

POWER SOURCE

+

REVERSE

POLARITY

SHIELDING GAS

WORK

FIG. 1. SCHEMATIC OF MIG PROCESS

(STD.)

_

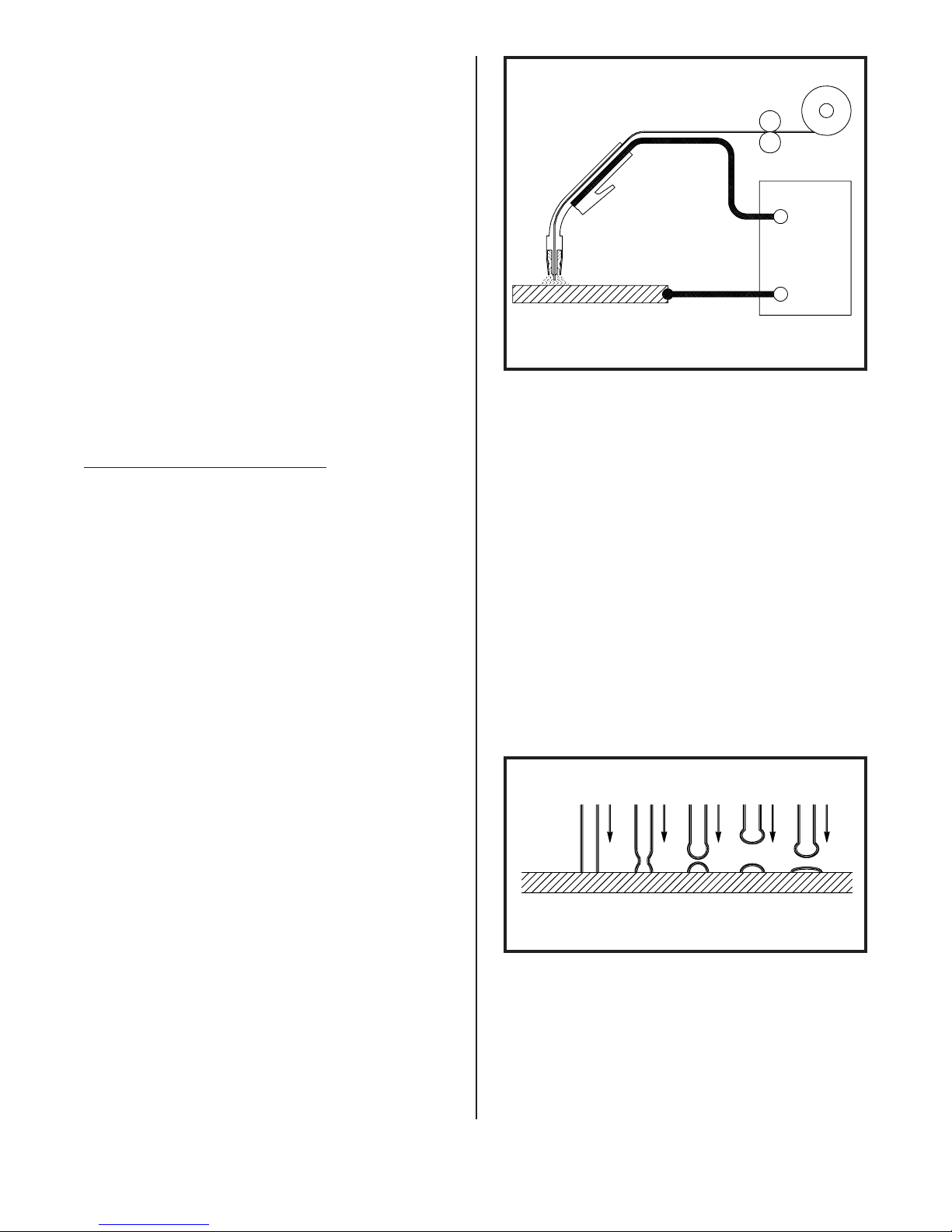

SHORT ARC OR DIP TRANSFER

Short arc transfer occurs at 12

to 22 arc volts (voltage while

welding), depending on wire size.

Welding commences as the arc is

struck and a weld pool is formed.

The tip of the electrode wire dips

into the pool and causes a short

circuit. The short circuit current

flow causes a rapid temperature

rise in the electrode wire and the

end of the wire is melted off. An

arc is immediately formed between

the tip of the wire and the weld

pool, maintaining the electrical

circuit and producing sufficient

heat to keep the weld pool fluid.

The electrode continues to feed and

again dips into the pool.

The MIG process uses a bare,

consumable electrode in the form of

spooled wire, which is fed by a

controllable speed feed unit through

the cable and torch to the weld. The

emerging wire and the weld are

shielded by a stream of CO2, Argon,

ELECTRODE

WORK

or a mixture of the two, which

prevents oxidation of the molten

weld puddle. The gas shield enables

high quality welds to be made

FIGURE 2. SHORT ARC TRANSFER

without the use of flux, eliminating the need for slag or flux

removal after the weld is completed.

This sequence of events is repeated up to 200 times per second.

Short arc transfer is suitable for

positional welding. The heat input

The consumable electrode wire is

melted and transferred to the weld

puddle by the "short arc" or "dip"

transfer mode.

to the workpiece is kept to a

minimum which limits distortion

and makes possible the welding of

thin sheet material.

2 Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380

DESCRIPTION

SPECIFICATIONS (Cont.)

The MP140 consists of a combina-

tion MIG welding power source and

wire feed unit, a MIG torch with 10

foot cable, a ten foot work (ground)

cable with ground clamp, a fifteen

foot power input cable, a gas

regulator/flowmeter, a torch accessory kit, and a built-in cylinder rack and industrial wheel kit.

Welder controls are simple and

clearly marked. The output voltage

is controlled by a six position tap

switch, providing six voltage selections. Voltages can be monitored by the voltmeter on the

control panel. Wire feed speed is

controlled by the wire speed potentiometer.

An OPTIONAL SPOT/STITCH WELD

(SSTP-2)control module with adjustable timer circuit provides

Consumable MIG Spot Welding or

Stitch Welding capabilities of

light gauge steel.

SPECIFICATIONS

PART NUMBER: MP140

INPUT POWER REQUIREMENTS:

Voltage 115 volts AC

Phase single phase

Frequency 50/60 hertz

Current (see OUTPUT POWER)

ARC VOLTAGE: 14 - 24 volts DC

WELD CURRENT RANGE:

30 - 140 amps

WIRE TYPES: mild steel,

stainless steel, aluminum,

bronze, flux cored, flux cored

gasless

WIRE SIZES: .023" - .045" steel,

3/64" aluminum,

(.023" - 3/64" alum. w/ Spool Gun)

.030" - .035" bronze,

.030" - .045" flux cored

(gas shielded or gasless)

WIRE FEED SPEED RANGE:

50 - 500 inches per minute

SHIELDING GASES:

For Steel Argon/CO2 mix or CO2

For Aluminum, Bronze Argon

For Stainless Steel

Argon + 2% Oxygen

For Flux cored Argon/CO2 mix or

CO2

DIMENSIONS:

Height 31 in.

Width 14-1/2 in.

Depth 35-1/2 in.

Weight 175 lbs.

TORCH SPECIFICATIONS

OUTPUT POWER @ 100% Duty Cycle:

15 Amps Input Current = 100 Amps

20 Amps Input Current = 120 Amps

OUTPUT POWER @ 60% Duty Cycle:

30 Amps Input Current = 140 Amps

DUTY CYCLE TIME PERIOD:

OPEN CIRCUIT VOLTAGE:

18 - 33 volts DC

Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380 3

10 minutes

NECK ANGLE: 60 degrees

LEAD LENGTH: 10 feet

OVERALL LENGTH: 10 feet

COOLING METHOD: gas (air)

RATING - 60% DUTY CYCLE:

With Argon/CO2 gas 200 amps

With CO2 gas 225 amps

CHECK LIST

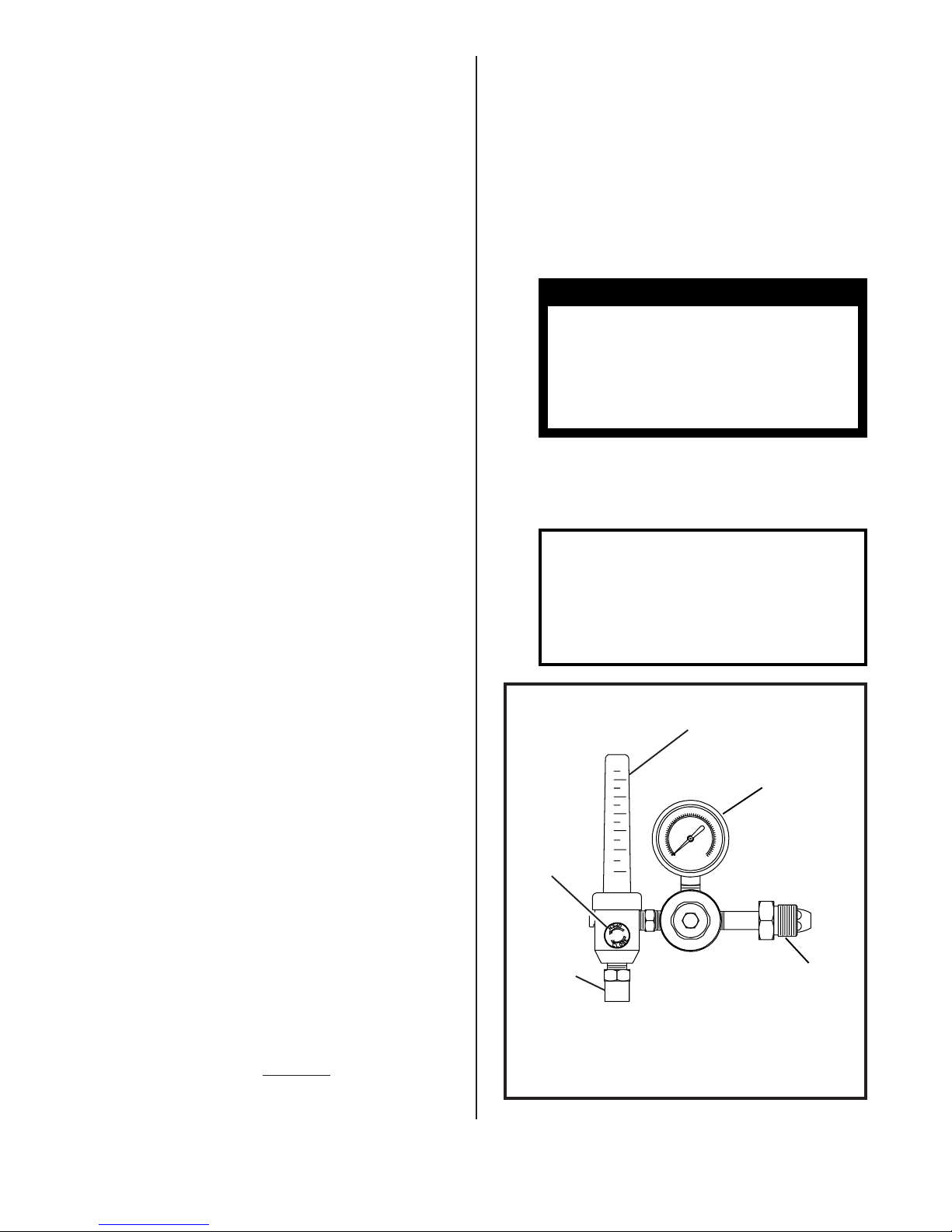

SHIELDING GAS CONNECTIONS

THE SYSTEMATICS MP140 INCLUDES THE

FOLLOWING:

1- Combination Power Source/Wire

Feeder

1- Cylinder Rack/Industrial Wheel

Kit

1- 15TG10 MIG Torch with adjust-

able nozzle

1- 15 foot Power Input Cable with

Plug

1- 10 foot Work(Ground)Cable and

Clamp

1- MP250PK Parts Kit

1- GR-FM Gas Regulator/Flowmeter

1- Nozzle, 1/2 in. orifice (in-

stalled on MIG torch)

1- Contact Tip, for .030 in. wire

(installed on MIG torch)

1- ER70S-6-30-3, Sample Spool of

.030" Steel Wire

ITEMS REQUIRED FOR MIG WELDING

WHICH ARE NOT PROVIDED WITH THE

MP140

1. Full cover welding helmet with

proper colored lens (shade 9 to

11 depending on operator’s pref-

erence).

2. Proper shielding gas and cylin-

der.

1. Place a cylinder of the appropriate shielding gas in the

rack at the rear of the machine

and secure it with the chain

provided.

2. Rapidly open and close the

cylinder valve. This will purge

dust and foreign matter from

the valve.

CAUTION

Take care to point the

valve outlet away from

yourself or other people,

as escaping high pressure

gas may be dangerous.

3. Attach the gas regulator/flowmeter supplied with this unit,

to the cylinder valve using a

suitable wrench.

NOTE

If this unit is to be used

with 100% CO2 shielding

gas, an optional gas regulator coupler is required.

3. Leather welding gloves.

4. 115 volt single phase AC power.

INSTALLATION

POSITIONING THE UNIT

Locate the unit near the welding

area and position it so there is

adequate clearance all around for

ventilation and maintenance.

ELECTRICAL SUPPLY

Follow the Electrical Supply

Requirements on page 1.

GAS FLOW

ADJUSTING

KNOB

OUTLET

FITTING

TO

WELDING

MACHINE

FIG. 3. GAS FLOW ADJUSTMENT

FLOW TUBE

INDICATES

FLOW RATE

IN C.F.H.

GAUGE -

INDICATES

TANK

PRESSURE

INLET

FITTING

TO

TANK

4 Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380

SHIELDING GAS CONNECTIONS(Cont.)

4. Fit the gas hose from the

welding machine to the regulator outlet fitting and tighten

it with a suitable wrench. Open

the cylinder valve.

5. Check that the gas regulator is

properly adjusted. When welding steel, the gas flow rate is

30 CFH. When welding aluminum,

the gas flow rate is 40 CFH.

NOTE

The MP140 must be turned

"ON" and the MIG torch

trigger depressed, before

the gas flow rate can be

adjusted.

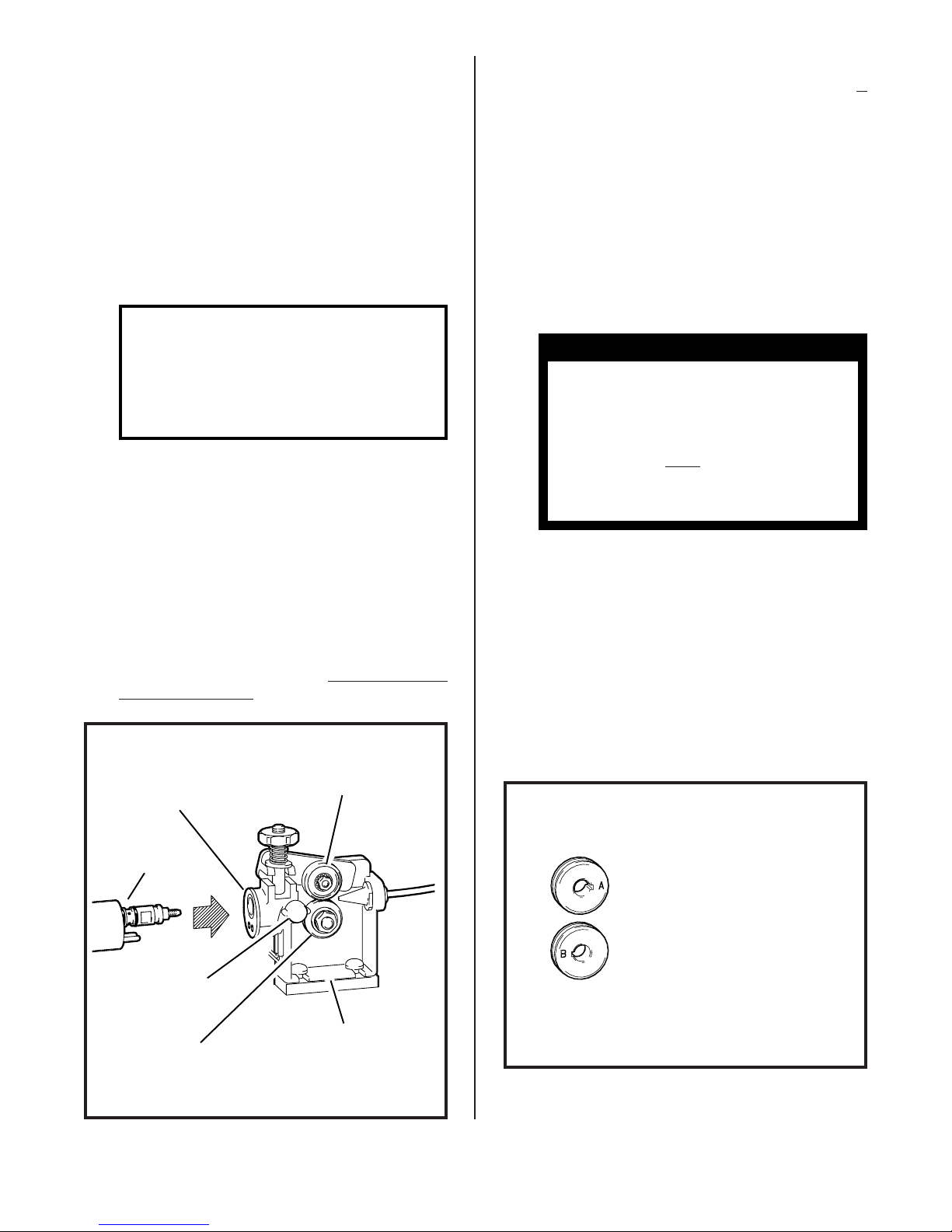

TORCH CONNECTION

FITTING AND THREADING THE ELECTRODE WIRE - ALWAYS USE ER70SWELDING WIRE

1. Remove the wire spool clip from

the spool hub.

2. Unpack the spool of welding

wire from its protective packaging.

3. Place the spool of ER70S-6

welding wire onto the hub. The

wire is fed off the bottom of

the spool.

CAUTION

Look for and remove any

wire protruding from the

center of the spool. The

protruding wire is electrically

ing and must not touch

the machine.

HOT during weld-

6

1. Open the access door of the

machine to its fullest extent.

2. Back out the thumb screw located on the drive assembly

mounting bracket inside the

machine. Insert the MIG torch

into the torch panel mount on

the front panel and TIGHTEN THE

THUMB SCREW.

TORCH PRESSURE

PANEL ROLL

MOUNT

MIG

TORCH

THUMB

SCREW

4. Replace the spool clip on the

hub.

5. Unlatch the pressure roll arm

and swing it open.

6. Make sure the double v-groove

drive roll is installed to

match the wire size. To change

the wire size setting, remove

the drive roll, turn it over and

reinstall it on the shaft.

"A" SIDE FACING IN FOR

.023" - .035" STEEL WIRES

"B" SIDE FACING IN FOR

.040" - .045" STEEL WIRES

AND 3/64" ALUMINUM WIRES

DRIVE DRIVE

ROLL ASSEMBLY

FIGURE 4. TORCH CONNECTION

Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380 5

FIG. 5. DOUBLE GROOVE DRIVE ROLL

(continued on following page)

FITTING AND THREADING THE ELECTRODE WIRE (Continued)

FITTING AND THREADING THE ELECTRODE WIRE (Continued)

7. Release the wire from the spool

and trim off the kinked end with

wire cutters. The wire must be

straight when it enters the

inlet guide.

8. Thread the electrode wire through

the inlet guide, over the feed

roll and into the torch liner.

Ensure that the wire locates in

the feed roll groove. Do not

allow the wire on the spool to

loosen.

9. Close and relatch the pressure

roll arm.

10.Stretch the torch cable straight

out in front of the machine

making sure there are no kinks.

Remove the nozzle and contact

tip from the torch.

11.Turn "ON" the circuit breaker on

the front of the machine. The

cooling fan will start and the

"ON" indicator light will illuminate. Set the VOLTAGE control

switch to "4", the function

switch to "CONTINUOUS WELD" (if

the unit has the optional SSTP2 installed) and the WIRE SPEED

control to "7". Pull the

trigger on the MIG torch. The

wire feed system will start and

wire will be fed through the

cable liner and torch. If the

wire does not feed, or appears

to slip, tighten the pressure

roll arm adjusting nut. Feed

the wire until it protrudes

from the front of the torch

approximately six inches.

CAUTION

12.Install the contact tip over the

protruding wire and tighten it

firmly using a proper size

wrench. Make sure the tip is the

correct size for the wire being

used.

13.Install the nozzle on the torch.

For steel, the contact tip

should be flush or stick out up

to 1/16 inch beyond the end of

the nozzle. For aluminum, the

contact tip should be recessed

1/8 to 1/4 inch inside the

nozzle. Using wire cutters,

trim off the wire so the stickout

is approximately 1/4 inch for

steel or 1 inch for aluminum.

For aluminum, the end of the

wire should be bent over so it

does not JAM into the work. This

is called a "scratch start".

1/4"

STICK-

OUT

FOR STEEL:

CONTACT TIP

FLUSH WITH NOZZLE

FIGURE 6.

WIRE STICKOUT - STEEL, ALUMINUM

1"

STICK-OUT

FOR ALUMINUM:

CONTACT TIP

RECESSED 1/8" - 3/8"

Keep hands and face away

from the front of the

torch and do not allow the

wire to contact ground.

The wire is electrically

HOT when the torch trigger

is actuated.

6 Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380

14.For steel welding only, spray

anti-spatter compound inside

the nozzle and on the outside of

the contact tip. For aluminum

or stainless steel welding, NO

anti-spatter compound can be

used as it will contaminate the

weld.

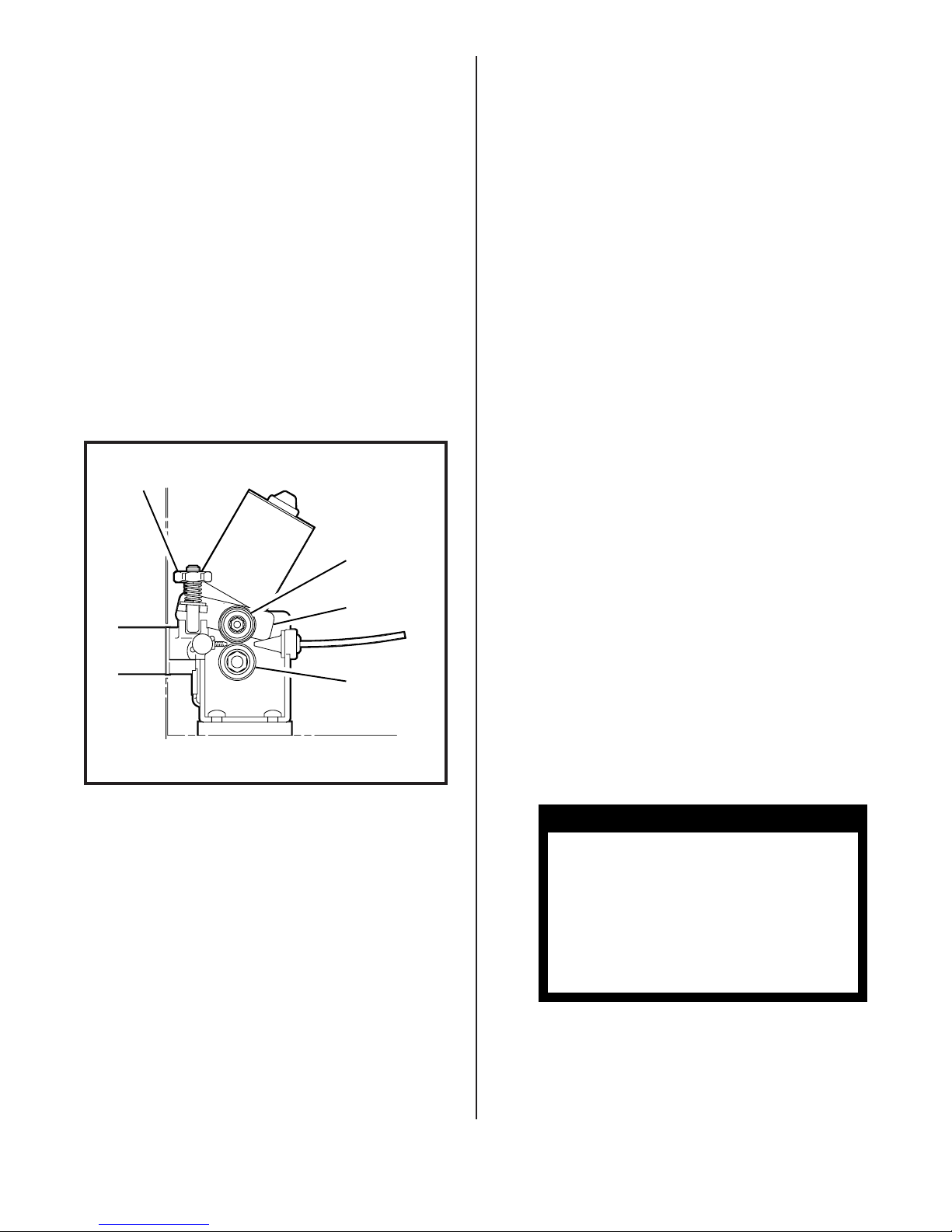

WIRE FEED PRESSURE ROLL ADJUSTMENT

The wire feed pressure roll is

adjusted to the proper setting at

the factory, prior to delivery. It

may be necessary to readjust the

setting as components "seat in" or

when changing to a different diameter wire. To check for proper roll

pressure, hold the torch in one

hand and the wire between two

fingers of the other hand. Pull the

torch trigger. If the wire continues to feed when firm pressure is

applied to the wire, the pressure

roll adjusting nut should be backed

off until the feed rolls start to

slip. If the wire will not feed

with very little pressure applied,

the pressure roll adjusting nut

should be tightened.

PRESSURE ROLL

ADJUSTING NUT

PRESSURE

ROLL

PRESSURE

ROLL ARM

DRIVE

ROLL

FIGURE 7.

PRESSURE ROLL ADJUSTMENT

OPERATION

The following operating instructions and detailed setup procedures enable an operator without

previous experience to produce

quality fusion welds. It is recommended that an operator without

prior experience with this equipment, first practice on scrap metal

of the same type and thickness as

the material to be welded.

OPERATING SEQUENCE

1. Make sure that the pieces of

metal to be welded are free of

grease, dirt, paint and scale.

Use a wire brush to remove paint

and scale. Paint must be completely removed to bare metal.

Grease and oil could burn and

cause a fire or safety hazard.

Failure to clean the metal

properly will result in erratic

and porous welds.

2. Install the unit as directed in

the installation instructions

and make sure the work clamp is

firmly attached to a cleaned

area on the workpiece to be

welded.

3. Open the shielding gas cylinder

valve. Press the torch trigger

and listen for gas flow. Adjust

the gas flow rate to 30 CFH for

steel and 40 CFH for aluminum.

TORCH SELECTOR CABLE

Plug the torch selector cable

into the Positive (+) terminal on

the machine(see "Process Selec-

tion" on page 8 for further details).

WORK (GROUND) CABLE

Uncoil the work cable and plug it

into the negative (-) terminal on

the machine.

Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380 7

CAUTION

The welding wire will feed

when the trigger is actuated. Take care that the

wire is not directed to

hit yourself or anything

that is grounded to the

ground wire on the welder.

Loading...

Loading...