Page 1

ZRS

Smoke gas fan

…………………………….2

…………………………….6

……………………………10

……………………………14

GB

GB

SE

FR

RU

Page 2

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

2 Systemair AB

GB

Manufacturer

Our products are manufactured in compliance with applicable international standards and regulations.

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg SWEDEN

Office: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

The manufacturer hereby confirms that the following products:

Smoke gas fan ZRS

(The declaration applies only to product in the condition it was delivered in and installed in the facility in

accordance with the included installation instructions. The insurance does not cover components that are

added or actions carried out subsequently on the product)

Comply with all applicable requirements in the following directives

Machinery Directive 2006/42/EC

Low Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC

RoHS2 Directive 2011/65/EC

The following harmonized standards are applied in applicable parts:

EN ISO 12100:2010 Safety of machinery – Basic concepts, general principles for design – Risk

assessment and risk reduction

EN 14121-1:2007 Safety of machinery – Risk assessment – Part 1: Principles

EN 13857 Safety of machinery – Safety distances to prevent hazard zones being reached

by upper or lower limbs

EN 60 335-1 Household and similar electrical appliances – Safety Part 1: General requirements

EN 60 335-2-80 Household and similar electrical appliances – Safety – Part 2-80: Particular

requirements for fans

EN 50 106:2007 Safety of household and similar appliances – Particular rules for routine tests

referring to appliances under the scope of EN 60 335-1 and EN 60967

EN 60 034-5 Rotating electrical machines – Part 5: Degrees of protection provided by the

integral design of rotating electrical machines (IP code)

EN 60 204-1 Safety of machinery – Electrical equipment of machines – Part 1: General

requirements

EN 61000-6-2 Electromagnetic compatibility (EMC) – Part 6-2: Generic standards – Immunity for

industrial environments

EN 61000-6-3 Electromagnetic compatibility (EMC) – Part 6-3: Generic standards – Emission

standards for residential, commercial and light-industrial environments

Skinnskattberg 26-11-2012

Mats Sándor

Technical Director

Page 3

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

3 Systemair AB

GB

Introduction

Smoke gas fan ZRS from Systemair is used to prevent insufficient draft from stoves, ovens and fireplaces. The smoke gas fan can be installed without interfering with the chimney pipe.

Transport and storage

All Systemair fans are packaged at the factory to withstand normal transport handling.

When handling the goods use suitable lifting equipment in order to avoid damage to fans or personnel.

The fans do not have any lifting eye bolts.

Avoid blows or shock loads.

Be on the alert for any damage on the packaging or the fan.

The fans should be stored in a dry area protected from the weather and dirt until final installation.

Avoid excessive storage periods (we recommend one year maximum).

Note! Do not lift the fan by the connecting cable, connection box, impeller or inlet cone.

Safety information

Systemair fans are not ready-to-use products and are only to be put into operation after they have been

built into machines, duct systems or if safe operation has been ensured by a contact protection grid.

Installation must be carried out in such a way that direct contact with moving parts is not possible.

Installation has to be performed by authorized personnel only!

The fans must not be used in an explosive atmosphere. Connect to a flue duct, max. temperature 200°C.

The fans must be installed so that safe operation and maintenance is ensured. Safety devices (e.g.

motor protection, contact protection grid etc), must not be dismantled, circumvented or made

inoperative.

Note! Before servicing or maintenance, switch off power, (all-pole circuit breaker), and make sure the

impeller has come to a standstill.

Note! The fans can have sharp edges and corners which may cause injuries.

Note! The smoke gas fan must always be running when the fireplace is being used.

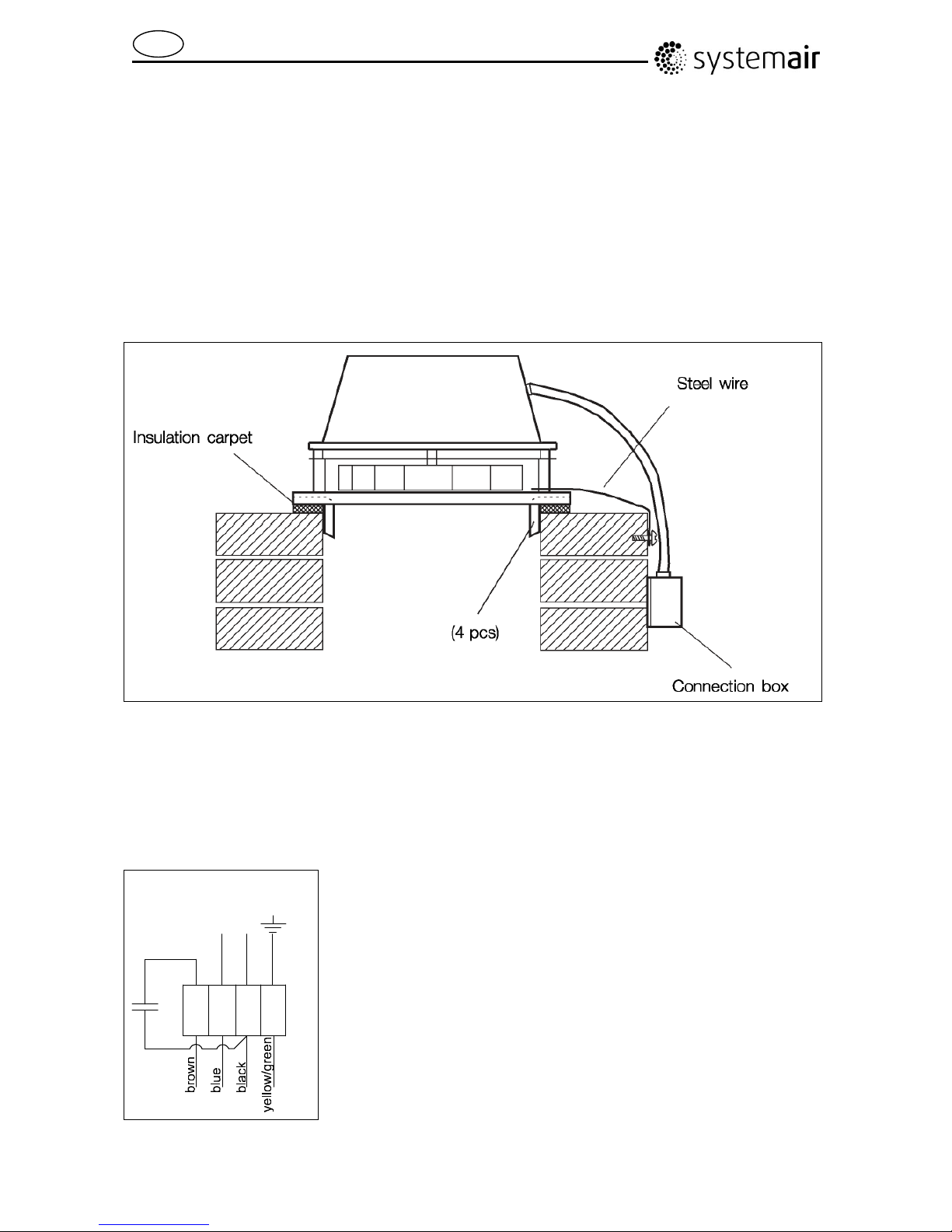

Installation

Put the insulation carpet, supplied with the fan, on top of the chimney and cut out a hole for the fan.

Fixate the four adjustable steering rods which are pushed into the chimney (no need to interfere with the

chimney itself).

The supplied steel wire can be used as extra support during chimney sweeping.

Installation, electrical connection and commissioning are only to be performed by authorized personnel

and in accordance with the requirements of the installation.

Electrical connection according to the wiring diagram in the terminal box, markings on terminal blocks or

on cable.

Use a dummy plug seal for the compression gland fitting as well.

The fan must be installed so that vibrations are not transmitted to duct systems or frame of building.

Make sure the assembly of the fan is firmly fixed and stable.

The fans must be assembled so that service and maintenance can be performed easily and safely.

Page 4

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

4 Systemair AB

GB

How to install

1. Put the insulation carpet, supplied with the fan, on top of the chimney.

2. Make a hole for the smoke gas fan.

3. Secure the four adjustable steering rods to the fan with the supplied screws and nuts.

4. Push the fan and steering rods into the chimney.

5. Attach the steel wire so the fan is secured when lifted away from the chimney during chimney

sweeping etc.

Electrical connection

Note! Electrical installation has to be performed by authorized personnel only and in accordance

with prevailing regulations.

The electrical connections are performed according to below wiring diagram

C

LN

230V 1~

Steering rods

Page 5

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

5 Systemair AB

GB

Operating Conditions

Do not operate the fan in an explosive atmosphere.

Switching frequency:

- The fan is rated for S1 continuous operation.

- Controls must not allow extreme switching operation!

When using speed control with a frequency inverter, note that the voltage peaks at the motor terminals

must be less than 1000V and the voltage rise rate less than 500V/µs (IEC 34-17). If the operational

leakage current exceeds 3,5mA, earthed in compliance with DIN VDE 0160/5.88, Art 6.5.2.1 must be

provided.

When using a long motor lead wire, install an output filter between the frequency inverter and the

motor!

Noise problems can be eliminated by using a silencer.

Operation

Before initial operation, check the following:

Electrical connection has been properly completed.

Protective conductor has been connected.

Motor protection assembled.

Safety devices in place (protection grid)

Leftover installation materials and foreign materials have been removed from the

casing.

When putting into operation, check the following:

Connection data corresponds to the specifications on the nameplate:

Maximum voltage +6%, -10%, according to IEC 38. Rated current must not be exceeded with more

than 5% at rated voltage.

Note! When speed regulating by reducing the voltage the motor current may exceed the rated

current at a lower voltage. In this case the motor windings are protected by the thermal contact. The

minimum static fall of pressure must observed.

Make sure that the air supply is adequate for a proper combustion.

Smoothness of motor operation, (no abnormal noises).

Speed control of the fan is recommended

Maintenance, service and repair

Before maintenance, service or repair, make sure that:

Power supply is interrupted (all-pole circuit breaker).

Fan impeller has come to a complete standstill!

Observe personnel safety regulations!

The fan should be cleaned when necessary, at least 1/year to avoid imbalance an unnecessary damage

to the bearings.

If a surplus of tar is built up during combustion it may be necessary to clean the fan more often.

The fan bearings are maintenance free and should only be replaced if damaged.

Do not use a high-pressure cleaner (steam jet) when cleaning the fan. Make sure the fan impeller's

balance weights are not moved or the fan impeller distorted.

Take note of abnormal operating noise!

Check that the impeller is not hindered or the motor protection triggered.

If the fan does not start after it has been checked, and/or the thermal contact is reset, contact your local

supplier.

Page 6

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

6 Systemair AB

SE

Försäkran om överensstämmelse

Tillverkare

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg SVERIGE

Kontor: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

intygar härmed att följande produkter:

Rökgasfläkt ZRS

Intyget gäller endast för produkten i det skick i vilket den levererats och installerats vid anläggningen i

enlighet med medföljande installationsanvisningar. Intyget omfattar inte komponenter som senare lagts till

eller åtgärder som senare vidtagits på produkten.

uppfyller alla tillämpliga krav i nedanstående direktiv.

Maskindirektivet 2006/42/EG

Lågspänningsdirektivet 2006/95/EG

EMC-direktivet 2004/108/EG

RoHS2 direktivet 2011/65/EC

Tillämpliga delar av nedanstående harmoniserade standarder tillämpas.

EN ISO 12100:2012 Maskinsäkerhet – Allmänna konstruktionsprinciper – Riskbedömning och

riskreducering

EN 14121-1:2007 Maskinsäkerhet – Riskbedömning – Del 1: Principer

EN 13857 Maskinsäkerhet – Skyddsavstånd för att hindra att armar och ben når in i

riskområden

EN 60335-1 Elektriska hushållsapparater och liknande bruksföremål – Säkerhet – Del 1:

Allmänna fordringar

EN 60335-2-80 Elektriska hushållsapparater och liknande bruksföremål – Säkerhet – Del 2-80:

Särskilda fordringar på fläktar

EN 50106:2007 Elektriska hushållsapparater och liknande bruksföremål – Säkerhet – Anvisningar

för tillverkningskontroll av apparater som omfattas av EN 60 335-1 och EN 60967

EN 60034-5 Roterande elektriska maskiner – Del 5: Kapslingsklasser för elektriska maskiner

(IP-beteckning)

EN 60204-1 Maskinsäkerhet – Maskiners elutrustning – Del 1: Allmänna fordringar

EN 61000-6-2 Elektromagnetisk kompatibilitet (EMC) – Del 6-2: Generella fordringar – Immunitet

hos utrustning i industrimiljö

EN 61000-6-3 Elektromagnetisk kompatibilitet (EMC) – Del 6-3: Generella fordringar – Emission

från utrustning i bostäder, kontor, butiker och liknande miljöer

Skinnskatteberg 2012-11-26

Mats Sándor

Teknisk Direktör

Page 7

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

7 Systemair AB

SE

Introduktion

Rökgasfläkt ZRS kan användas för att motverka dåligt drag i kaminer, ugnar och öppna spisar. Den kan

monteras på skorstenen utan att man behöver göra några ingrepp.

Transport och lagring

Samtliga fläktar som levereras från Systemair är emballerade för att klara normal godshantering.

Vid godshantering använd lämplig lyftanordning för att undvika skador på fläktar och personer.

Fläktarna är ej förberedda med särskilda lyftpunkter.

OBS! Lyft ej fläktarna i motorkabel, kopplingsdosa, fläkthjul eller insugningskona.

Undvik slag och stötar.

Var uppmärksam på skador på emballage eller fläktar.

Fläktarna ska lagras torrt och väderskyddat och skyddas från smuts och damm före slutlig

installation.

Undvik extrem värme och kyla.

Undvik att lagra fläktarna under lång tid. (Vi rekommenderar högst 1 år).

Säkerhet

Systemairs fläktar är produkter som ej är färdiga att användas, och är avsedda att tas i bruk endast efter

inbyggnad.

Installationen ska utföras på sådant sätt att beröring av rörliga delar ej är möjlig.

Fläkten ska installeras av behörig installatör.

Fläktarna får ej användas i explosiv miljö. Ansluts till rökgaskanal, max. temp. 200°C.

Fläkten ska installeras så att drift och underhåll kan ske på ett säkert sätt.

Säkerhetsdetaljer (t ex beröringsskydd) får ej demonteras, förbikopplas eller bortkopplas.

OBS! Innan service och underhåll påbörjas måste fläktarna göras spänningslösa, allpolig brytning, och

fläkthjulet ha stannat.

OBS! Fläktarna kan ha vassa kanter och hörn, vilket kan orsaka skärskador.

OBS! Fläkten måste alltid vara i drift när eldstaden används.

Installation

Lägg den medlevererade isoleringsmattan på toppen av skorstenspipan och skär passande hål för

rökgasfläkten. Fixera därefter de fyra justerbara styrpinnarna på fläkten och trä ner allt i skorstenspipan

(inga ingrepp krävs på själva skorstenen).

Stålvajer medlevereras som extra förankring till fläkt vid sotning etc.

Installation, elektrisk anslutning samt idrifttagande ska göras av behörig installatör och utföras i

enlighet med för installationen gällande föreskrifter och krav.

Elektrisk anslutning ska göras enligt kopplingsscheman i kopplingsdosa, märkning på kopplingsplint eller

på kabel.

Täta ev. tomma förskruvningshål med blindplugg.

Fläkten ska monteras så att vibrationer ej kan överföras till kanalsystem och byggnadsstomme.

Fläkten ska monteras på ett stadigt och stabilt sätt.

Fläkten ska monteras så att service och underhåll kan utföras på ett enkelt och säkert sätt.

Page 8

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

8 Systemair AB

SE

Montering av rökgasfläkten

1. Lägg isoleringsmattan, som levereras tillsammans med fläkten, på toppen av skorstenspipan.

2. Skär ut ett hål som passar för rökgasfläkten.

3. Skruva fast de fyra justerbara styrpinnarna på rökgasfläkten. Använd skruvar och muttrar från

skruvsatsen.

4. Trä ner fläkten i skorstenspipan.

5. Fäst stålvajern på lämplig plats så fläkten är väl förankrad när den ska lyftas bort från skorstenspipan

vid sotning etc.

Elektrisk anslutning

Elektrisk installation ska göras av behörig elektriker och enligt gällande föreskrifter

Elektrisk anslutning ska utföras enligt nedan kopplingsschema.

C

LN

230V 1~

Page 9

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

9 Systemair AB

SE

Driftsförhållanden

Fläktarna får ej användas i explosiv miljö.

Switch-frekvens vid frekvensreglering:

Fläktarna är anpassade till kontinuerlig drift

S1.

Styrningen får ej tillåta extrema till- och från slag.

Vid frekvensreglering observera att spänningstoppar vid motorns kopplingsplint inte får överstiga 1 000V

och att spänningsökningen är mindre än 500V/µs (IEC 34-17). Om läckströmmen överstiger 3,5 mA

måste jordledningen uppfylla DIN VDE 0160/5.88 art 6.5.2.1.

Om motorkabeln är lång måste ett utgångsfilter monteras mellan frekvensreglering och motor.

Ljudproblem kan elimineras genom att använda störningsfilter.

Drift

Före idrifttagande kontrollera följande:

Elektrisk anslutning är slutförd.

Skyddsjorden ansluten.

Säkerhetsutrustning monterad (berörings-skydd).

inga främmande föremål finns i fläkten.

Att tilluft till rummet där eldstaden finns är ombesörjd för en riktig förbränning

Vid idrifttagande kontrollera följande:

Att uppmätta data ej överstiger på fläktens typskylt angivna märkdata:

Maximalt tillåten spänning +6%, -10%, enligt IEC 38. Märkströmmen får ej överskridas med mer än

5% vid Märk-spänning. OBS! Vid varvtalsreglering genom spänningssänkning kan strömmen i

motorn vid en lägre spänning överstiga den angivna märkströmmen. I dessa fall skyddas

motorlindningen av termo-kontakten!

Att inga missljud hörs från fläkten.

Varvtalsreglering rekommenderas.

Underhåll, service och reparation

Innan service, underhåll eller reparation påbörjas måste:

Fläkten göras spänningslös (allpolig brytning).

Fläkthjulet stannat.

Gällande säkerhetsföreskrifter beaktats.

Fläkten ska rengöras vid behov, dock minst 1 gång/år för att undvika obalans med onödiga lagerskador

som följd.

Om riklig tjärutfällning sker vid förbränning måste rengöring ske oftare.

Fläktens lager är underhållsfria och ska endast bytas vid behov.

Vid rengöring av fläkten får högtryckstvätt ej användas. Rengöring måste ske försiktigt så att fläkthjulets

balansvikter ej rubbas eller fläkthjulet deformeras.

Kontrollera att inga missljud hörs från fläkten.

Kontrollera att fläkthjulet inte är blockerat eller att motorskyddet har löst ut. Om fläkten efter kontroll ej

startar kontakta er lokala leverantör.

Page 10

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

10 Systemair AB

FR

Déclaration de conformité

Le fabricant

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg, SUÈDE

Téléphone: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

certifie par les présentes que les produits suivants:

(La déclaration s’applique exclusivement au produit dans l’état où il a été livré et installé sur site

conformément aux instructions jointes. L’assurance ne couvre pas les composants ajoutés ou les

interventions effectuées ultérieurement sur le produit.)

Est conforme à l’ensemble des exigences des directives suivantes

Directive machines 2006/42/CE

Directive basse tension 2006/95/CE

Directive CEM 2004/108/CE

Directive RoHS2 2011/65/EC

Les normes harmonisées suivantes sont d’application pour les parties concernées:

EN ISO 12100:2012 Sécurité des machines – notions fondamentales, principes généraux de conception

– évaluation des risques et réduction des risques

EN 14121 1:2007 Sécurité des machines – évaluation des risques – Partie 1: principes

EN 13857 Sécurité des machines – distances de sécurité pour les membres supérieurs ou

inférieurs

EN 60 335-1 Appareils électrodomestiques et analogues – Sécurité – Partie 1: Règles générales

EN 60 335-2-80 Appareils électrodomestiques et analogues – Sécurité – Partie 2-80: Règles

particulières pour les ventilateurs

EN 50 106:2007 Sécurité des appareils électrodomestiques et analogues – Règles particulières pour

les essais de série concernant les appareils dans le domaine d’application des

normes EN 60 335-1 et EN 60967

EN 60 034-5 Machines électriques rotatives – Partie 5: Niveaux de protection procurés par le

design intégré des machines électriques rotatives (code IP)

EN 60 204-1 Sécurité des machines; équipement électrique des machines – Partie 1: Règles

générales.

EN 61000-6-2 Compatibilité électromagnétique (CEM) – Partie 6-2: exigences générales –

Immunité des appareils en environnements industriels

EN 61000-6-3 Compatibilité électromagnétique (CEM), Partie EN 6-3: Normes génériques –

Émissions standards pour les environnements résidentiels, commerciaux et

l'industrie légère

Skinnskattberg 26-11-2012

Mats Sándor

Directeur technique

Page 11

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

11 Systemair AB

FR

Introduction

L’extracteur de fumées Systemair ZRS est destiné à améliorer le tirage des conduits de fumée. Il peut être

installé sans modification du conduit existant.

Transport et stockage

Tous les produits Systemair sont emballés en usine pour supporter des conditions de stockage, de

manutention et de transport normales.

Utilisez des appareils de manutention adéquats afin de ne pas mettre en danger le personnel ou

endommager les produits.

Les ventilateurs ne sont pas munis de crochets de levage. N'utilisez pas la boîte de connexion ou les

câbles électriques pour la manutention ou le levage.

Vérifiez l'état de l'emballage dès réception du matériel.

Stockez-le à l'abri de l'humidité et de la poussière.

Evitez de les stocker pendant une durée supérieure à un an.

Sécurité

Les ventilateurs Systemair doivent être utilisés comme composant d'une installation de ventilation et non

comme des produits finis.

L'installation doit être réalisée de façon à ce que le contact avec les parties en mouvement soit

impossible.

L'installation doit être réalisée uniquement par du personnel qualifié.

Les ventilateurs ne doivent pas être utilisés dans une atmosphère explosive. La température dans le

conduit de cheminée ne doit pas dépasser 200°C.

Les ventilateurs doivent être installés de façon à fonctionner en sécurité. Les systèmes de protection tels

que protection moteur, grille de protection ou autres ne doivent en aucun cas être modifiés, démontés ou

rendus inopérants.

Attention: Avant toute intervention sur les ventilateurs, coupez l'alimentation électrique principale et

attendez l'arrêt complet des pièces en mouvement.

Certaines parties des appareils comportent des coins acérés ou des parties coupantes pouvant

occasionner des blessures durant la manipulation. Le ventilateur ne doit pas être installé en atmosphère

explosive.

NB ! A chaque utilisation de la cheminée, l’extracteur doit être mis en fonctionnement.

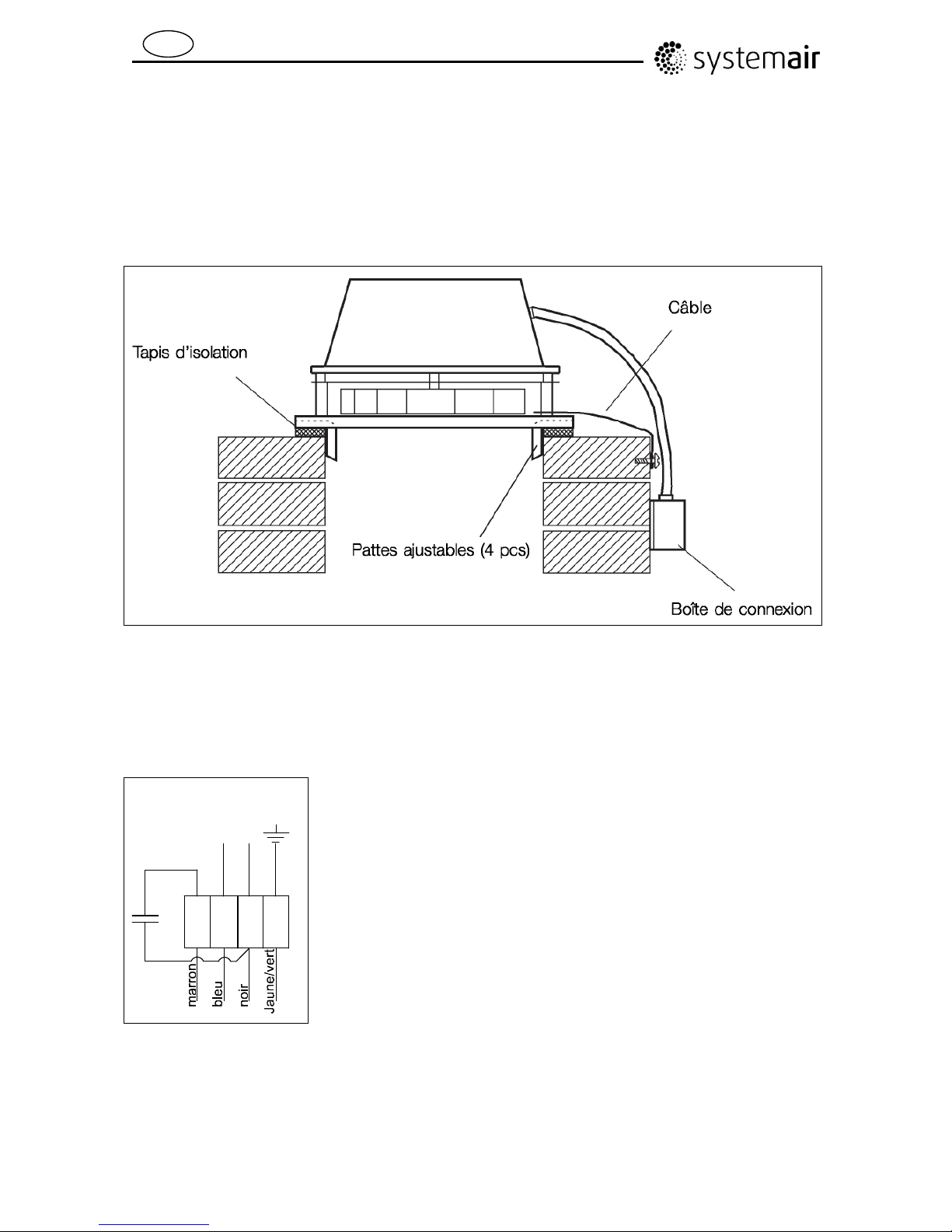

Installation

Poser le tapis d’isolation fourni sur la base de la cheminée et découper un trou pour le passage de l’air.

fixer au moyen des boulons fournis les quatre pattes ajustables au socle du ventilateur et poser

l’ensemble sur la base de la cheminée (aucune modification n’est à faire sur la cheminée elle-même). Le

câble fourni peut être utilisé pour retenir le ventilateur lors des démontages pour l’entretien de la

cheminée.

L'alimentation, le branchement électrique et la mise en route doivent être effectués par un professionnel

qualifié.

Le raccordement électrique doit être effectué conformément aux indications portées dans la boîte de

connexion.

Les ventilateurs doivent être installés de façon à éviter la transmission de vibration dans les réseaux de

gaine ou les structures des bâtiments.

Assurez-vous que le ventilateur est fixé fermement.

Le ventilateur doit être installé de manière à permettre facilement les interventions ultérieures.

de

maintenance.

Installation de l’extracteur de fumées

1. Poser le tapis d’isolation fourni sur la base de la cheminée.

Page 12

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

12 Systemair AB

FR

2. Percer le trou de passage de l’air.

3. Fixer au moyen des boulons fournis les quatre pattes ajustables au socle du ventilateur.

4. Poser l’assemblage sur la base de la cheminée.

5. Fixer le câble afin que le ventilateur soit retenu lors des démontages pour le ramonage.

Installation électrique

NB ! L’installation électrique doit être réalisée par un professionnel et en respect des normes en

vigueur.

Les raccordements électriques sont réalisés conformément au schéma électrique ci-dessous.

C

LN

230V 1~

Conditions de fonctionnement

N'utilisez pas le ventilateur en atmosphère explosive.

Fréquence de commutation:

Page 13

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

13 Systemair AB

FR

Le ventilateur est prévu pour une opération continue.

Ne pas sous-dimensionner les systèmes de variation et de protection.

En cas d'utilisation avec un variateur de fréquence, il faut que les pointes de tension aux bornes du

moteur soient inférieures à 1000V et que l'augmentation de tension soit inférieure à 500V/µs. Si la fuite

de courant opérationnel excède 3,5mA, raccordez l'ensemble à la terre suivant la norme DIN VDE 01

60/5.88 Art 6.5.2.1.

Si le câble de raccordement électrique est long, il faut prévoir un filtre entre le variateur et le ventilateur.

Les problèmes de bruits peuvent être résolus en utilisant un silencieux.

Fonctionnement

Avant la première mise en route vérifiez les points suivants:

Le raccordement électrique doit être fait suivant les règles de l'art.

Les conducteurs électriques doivent être bien isolés.

Les protections mécaniques doivent être en place (ex: grillage de protection).

Les résidus des matériels d'installation ainsi que tous les objets étrangers au ventilateur doivent

être enlevés.

Lors de la mise en route vérifiez les points suivants:

Les caractéristiques électriques doivent correspondre à celles indiquées sur la plaque moteur:

Ecart de tension entre +6% et -10% suivant la norme IEC38. Courant nominal ne dépassant pas

de 5%, la valeur nominale a la tension nominale. (Ceci est toutefois possible en cas de variation

de tension. Dans ce cas les enroulements seront protégés par les thermocontacts). Le sens de

rotation correspond au sens de la flèche.

Absence de bruits anormaux.

Assurez vous que l’entrée d’air neuf est suffisante pour une bonne combustion.

Variateur de vitesse avec ce ventilateur est recommandée.

Maintenance, nettoyage et réparation

Avant de procéder aux opérations ci-

dessus, vérifiez les points suivants:

Coupure de l'alimentation principale.

Arrêt complet de l'hélice.

Respect par le personnel d'entretien des consignes de sécurité.

Le ventilateur doit être nettoyé aussi souvent que nécessaire et au minimum une fois par an afin

d'éviter un déséquilibrage et l'usure des roulements.

S’il existe des résidus de combustion, il peut être nécessaire de nettoyer le ventilateur plus

fréquemment.

Les roulements ne nécessitent ni entretien ni graissage et doivent être remplacés en cas de dommage.

Ne pas utiliser de système à haute pression ou à vapeur pour le nettoyage du ventilateur.

Vérifier que les plots d'équilibrage ne sont pas enlevés et que les pales d'hélice ne sont pas tordues.

Contrôlez la présence de bruits anormaux.

Vérifier que l'hélice n'est pas bloquée et que la protection thermocontact n'est pas activée. Après cette

vérification, si le ventilateur ne repart pas, contactez votre distributeur.

Page 14

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

14 Systemair AB

RU

Декларация о соответствии

Изготовитель

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg ШВЕЦИЯ

Тел.: +46 222 440 00 Факс: +46 222 440 99

www.systemair.com

подтверждает, что следующее оборудование:

(Действие настоящей декларации распространяется только на продукцию, находящуюся в состоянии, в

котором она была доставлена и смонтирована на объекте в соответствии с руководством по монтажу,

входящим в комплект поставки. Гарантия не распространяется на компоненты, установленные отдельно,

и действия, выполненные впоследствии.)

соответствует требованиям указанных ниже нормативных директив

.

Директива по оборудованию 2006/42/EC

Директива по низковольтным устройствам 2006/95/EC

Директива по электромагнитной совместимости 2004/108/EC

Директива по RoHS2 2011/65/EC

Учтены требования указанных ниже гармонизированных стандартов.

EN ISO 12100:2010 Безопасность оборудования. Основные концепции и общие принципы

конструирования. Оценка и снижение риска.

EN 14121-1:2007 Безопасность оборудования. Оценка рисков. Часть 1. Принципы.

EN 13857 Безопасность оборудования. Безопасные расстояния для предотвращения контакта

верхних или нижних конечностей с опасными зонами.

EN 60 335-1 Бытовые и аналогичные электрические приборы. Безопасность. Часть 1.

Общие

требования.

EN 60 335-2-80 Бытовые и аналогичные электрические приборы. Безопасность. Часть 2-80. Особые

требования к вентиляторам.

EN 50 106:2007 Безопасность бытовых и аналогичных электрических приборов. Особые правила

проведения контрольных испытаний, имеющих отношение к приборам, согласно

стандартам EN 60 335-1 и EN 60967.

EN 60 034-5 Машины электрические вращающиеся. Часть 5. Степени защиты, обеспечиваемые

собственной конструкцией вращающихся электрических машин (степени защиты IP).

EN 60 204-1 Безопасность оборудования. Электрооборудование

промышленных машин. Часть 1.

Общие требования.

EN 61000-6-2 Электромагнитная совместимость (ЭМС). Часть 6-2. Общие требования.

Невосприимчивость к промышленной окружающей среде.

EN 61000-6-3 Электромагнитная совместимость (ЭМС). Часть 6-3. Общие стандарты. Стандарты в

области излучения для бытового и торгового оборудования, а также оборудования

для легкой промышленности.

Скиннскаттеберг, 26 ноябрь 2012 г.

Матс Сандор (Mats Sándor),

технический директор

Page 15

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

15 Systemair AB

RU

Введение

Вентиляторы Systemair для вытяжки дымовых газов предназначены для усиления недостаточной

тяги печей, духовых шкафов, каминов. Вентиляторы для вытяжки дымовых газов могут быть

установлены без пересечения с каминной трубой.

Транспортировка и хранение

Все вентиляторы Systemair упаковываются на заводе в соответствии с общепринятыми

стандартами отгрузки.

При обработке грузов используйте подходящее подъемное оборудование, чтобы не повредить груз

и персонал.

Вентиляторы не имеют подъемных болтов с ушками.

Примечание! Не понимайте вентиляторы за кабель, распределительную коробку, рабочее колесо,

входное отверстие.

Избегайте излишней вибрации и ударной нагрузки при транспортировке

.

Осмотрите упаковку вентилятора на предмет отсутствия повреждений упаковки и оборудования.

Храните вентиляторы в заводской упаковке в сухом помещении и предотвращайте попадание грязи

и осадков на вентиляторы до окончательного монтажа.

Избегайте длительных периодов хранения на складе (рекомендуется не более года) и перед

установкой вентиляторов проверьте работоспособность подшипников.

Техника безопасности

Вентиляторы Systemair предназначены для установки в системы вытяжной вентиляции, аппараты,

они не готовы к использованию без дополнительных средств защиты, таких как защитные решетки

или другие приспособления для предотвращения несчастных случаев от попадания во

всасывающее отверстие.

Монтаж необходимо проводить таким образом, чтобы исключить прямой контакт с вращающимися

частями.

Монтаж должен выполнятся квалифицированным персоналом

.

Данные вентиляторы нельзя эксплуатировать во взрывоопасных помещениях. Устанавливаются на

дымоходе, максимальная температура 200°С.

Вентилятор должен быть смонтирован так, чтобы были гарантированы безопасная работа и

обслуживание. Устройства безопасности, такие как защита двигателя, ограждающая решетка,

нельзя удалять или приводить в нерабочее состояние.

Примечание! Перед сервисным обслуживанием отключите питание (всеполюсным прерывателем)

и убедитесь,

что рабочее колесо не вращается.

Примечание! Вентиляторы могут иметь острые углы и края, что может привести к ранениям и

порезам.

Примечание! Вентилятор для вытяжки дымовых газов должен всегда работать при использовании

камина.

Монтаж

Установите изоляционные вставки, поставляемые в комплекте с вентилятором, наверху камина и

вырежьте отверстие для вентилятора. Прикрепите 4-ре регулируемые стержня и втолкните их в

отверстие камина.

Поставляемая стальная проволока может быть использована как дополнительное крепление при

чистке камина.

Монтаж, электрическое подключение и наладка должны выполняться квалифицированным

персоналом в соответствии с местными нормами

.

Электрическое подключение выполняется в соответствии с электрической схемой в

распределительной коробке и меткам на клеммах и кабелях.

Используйте изоляцию для клепаных соединений.

Вентилятор должен быть установлен так, чтобы вибрация не передавалась на воздуховод и опору.

Убедитесь, что вентиляторный узел крепко зафиксирован и неподвижен.

Вентилятор должен быть смонтирован так, чтобы обеспечить

доступ для обслуживания и сервиса.

Page 16

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

16 Systemair AB

RU

Монтаж вентиляторов для вытяжки дымовых газов

1. Установите изоляционные вставки, поставляемые в комплекте с вентилятором, наверху

камина.

2. Сделайте отверстие для вентилятора

3. Прикрепите 4-ре регулируемые стержня при помощи винтов и гаек к вентилятору.

4. Втолкните вентилятор с направляющими стержнями в отверстие камина.

5. Прикрепите стальную проволоку, так чтобы предохранить вентилятор от смещения при

эксплуатации и чистке камина

.

Page 17

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

17 Systemair AB

RU

Электрические подключения

Примечание! Электрическое подключение должно проводиться

квалифицированным персоналом и в соответствии с местными электрическими

нормами.

Схема электроподключений приведена ниже.

Условия эксплуатации

Вентиляторы нельзя эксплуатировать во взрывоопасных помещениях (кроме тех, которые

обозначены ЕХ).

Частота переключения:

- Вентиляторы предназначены для продолжительной эксплуатации S1.

- Используемые регуляторы скорости должны исключать очень частое переключение между

режимами.

При использовании в качестве регулятора скорости частотный преобразователь, соблюдайте

условие - пиковые напряжения на клеммах двигателя должны быть менее 1000 В и скорость

подъема напряжения менее 500 В/мс (IEC 34-17).

При использовании длинного кабеля между двигателем и частотным преобразователем,

установите выходной фильтр.

Если утечки тока составляют более 3,5мА, необходимо предусмотреть заземление в соответствии

с DIN VDE 0160/5.88, параграф 6.5.2.1.

Излишний шум может быть устранен при помощи глушителей.

Page 18

_________________________________________________________________________________________________________

ZRS Installation instructions

200515

18 Systemair AB

RU

Эксплуатация

Перед первоначальным запуском, проверьте следующее:

- Электрическое подключение выполнено верно.

- Защитный кабель подключен.

- Защита двигателя установлена.

- Защитное оборудование (решетка) установлено.

- Остатки материала и другие посторонние предметы убраны из корпуса вентилятора.

При включении, проверьте следующее:

- Рабочие характеристики вентилятора соответствуют спецификации на табличке вентилятора.

Максимальное напряжение +6%, -10% (согласно IEC38). Номинальный ток не

должен

превышать более чем на 5%, чем ток при номинальном напряжении. Примечание! При

регулировании скорости вращения путем снижения напряжения ток в двигателе может

превышать номинальный ток при более низком напряжении. В этом случае защита двигателя

осуществляется при помощи термоконтактов. Минимальное статическое падения давления

должно соблюдаться.

- Заданного расхода воздуха достаточно для горения

.

- Нет нетипичного шума при работе вентилятора.

Мы рекомендуем использование регулятора скорости.

Обслуживание, сервис и ремонт

Перед обслуживанием, сервисом и ремонтом убедитесь, что:

- Отключено питание (всеполюсным выключателем),

- Рабочее колесо вентилятора полностью остановилось,

- Выполняются требования техники безопасности.

Вентилятор необходимо очищать по необходимости, по крайней мере 1 раз в год в целях

обеспечения балансировки рабочего колеса и длительной эксплуатации подшипников.

Если остатки смолы накапливаются при горении, нужно очищать

вентилятор чаще.

Подшипники вентилятора не требуют обслуживания, их необходимо заменить по окончании срока

службы.

Не используйте высоконапорные дутьевые машины для очистки вентиляторов. Удостоверьтесь,

что балансировочные веса на месте и рабочее колесо не деформировано.

Обратите внимание на шум работы вентилятора.

Проверьте, чтобы крыльчатка не была заблокирована и защита двигателя не активирована. Если

вентилятор не работает после подачи питания и проверки и защита двигателя перезапущена,

обратитесь к поставщику.

Page 19

A001

Systemair AB

Industrivägen 3

SE-739 30 Skinnskatteberg, Sweden

Phone +46 222 440 00

Fax +46 222 440 99

www.systemair.com

200515 (27-11-2012)

Loading...

Loading...