Page 1

SAVE VTR 300/B

Installation instructions

Document in original language | 229391 · v02

GB

Page 2

© Copyright Systemair UAB

All rights reserved

E&OE

Systemair UAB reserves the rights to alter their products without notice.

This also applies to products already ordered, as long as it does not affect the previously agreed specifications.

Systemair is not liable or bound by warranty if these instructions are not adhered to during installation or service.

229391 | v02

Page 3

1 Overview . .. ....... .... .... .... ......... .... .... .... .... .... ...1

1.1 Warranty.. ............. .... .... .... .... ............. ..1

1.2 Type label.. .... .... .... .... .... ..... ........ .... .... ..1

1.3 Disposal and recycling .... .... .... .... .... .... .....1

2 Important Safety Information ..... .... .... .... .... .... ....1

2.1 Intended Use... ..... .... .... .... .... .... .... ..... ....2

2.2 Admonitions .... .... ............. .... .... .... .... ....2

3 Technical Data .... .... .... .... ......... .... .... .... .... .......2

3.1 Power consumption and fuse size .... .... .... ..2

3.2 Dimensions and Weight .... .... .... .... ...........3

3.3 Connections Left and Right models.. .... .... ...5

3.4 Installation recommendation regarding

condensation .... ........ .... .... .... .... ......... ...5

3.4.1 Condensation inside of the

unit . .... .... .... ......... .... .... .... .... ...5

3.4.2 Condensation outside of the

unit . .... .... .... ......... .... .... .... .... ...6

4 Delivery, Transport, Storage..... .... .... .... .... .... .... ..6

4.1 Transport and storage . .... .... ..... .... .... .... ...6

4.2 Delivery/Unloading. ............. .... .... .... .... ...6

5 Prerequisites for Installation.... .... .... .... .... ......... ..6

5.1 Location and Space Requirements..... .... .... .7

5.2 Wall preparation for mounting

bracket .... ............. .... .... .... .... ............. ..7

5.3 Condensation drainage . .... ..... .... .... .... .... ..7

5.4 Outdoor Air Intake Location

Recommendation.. .... .... ............. .... .... .... 7

5.5 Access to Power supply .... ..... ........ .... .... ..7

6 Installation.. .... .... .... ........ ..... .... .... .... .... .... ......7

6.1 Ventilation Duct Connection and

Insulation .... .... .... .... .... .... ......... .... .... .... 9

6.2 Installation and Configuration of

Accessories............ .... .... .... .... ............. ..9

7 Before Starting the System........ .... .... .... .... ........9

8 Commissioning .... .... .... .... .... ..... .... .... .... .... .... 10

9 Concluding Routines .. .... ..... .... .... .... .... .... .... ... 10

10 EU Declaration of Conformity . .... .... .... ............. . 11

Contents

229391 | v02

Page 4

Page 5

Overview

|

1 Overview

Read the instructions carefully and in its entirety.

For description of advanced settings and installation of accessories see Service and Accessories Installation manual.

All documents can be found in our online catalogue at www.systemair.com.

1.1 Warranty

For the assertion of warranty claims, the products must be correctly connected and operated, and used in accordance

with the data sheets. Further prerequisites are a completed maintenance plan with no gaps and a commissioning report. Systemair will require these in the case of a warranty claim.

1.2 Type label

Before calling your service representative, make a note of the specification and production number from the type label,

which can be found next to the external connections and inside of the unit.

1

Position Description

1

2

3

4

5

6

7

Product code (product specification)

Product item number

Production order number

Serial number

Production date (YY.MM.DD)

QR code for manufacturing order (MO) number and software version

QR code for the spare parts list and documentation

1.3 Disposal and recycling

This product is compliant with the European WEEE Directive and related national waste

legislation. When disposing the unit, follow your local rules and regulations.

This product packing materials are recyclable and can be reused. Do not dispose in household

waste.

Fig. 1 Type label

2 Important Safety Information

• Observe and respect local conditions, regulations and laws.

229391 | v02

Page 6

| Technical Data

2

• Safety elements may not be dismantled, circumvented or deactivated.

• Wear protective equipment during all work in the vicinity of the unit.

• Do not allow children to play with the device.

2.1 Intended Use

• Abide by the system-related conditions and requirements of the system manufacturer or plant constructor.

• Keep all the warning signs on the device and in a legible condition.

• The device is not to be used by persons (including children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given supervision or instruction.

• The system should operate continuously, and only be stopped for maintenance/service.

• Do not connect tumble dryers to the ventilation system.

• Make sure that filters are mounted before starting the unit.

2.2 Admonitions

Danger

• Make sure that the mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• All electrical connections and maintenance work must be carried out by an authorized installer and in

accordance with local rules and regulations.

Warning

• This product is not intended to be used by children or people with reduced physical or mental ability or

lack of experience and knowledge, if no instruction concerning the use has been given by the person

responsible for their safety or that this person is supervising the operation. Children should be supervised

so that they can not play with the product.

• Beware of sharp edges during mounting and maintenance. Use protective gloves.

Warning

• Risk of injury due to rotating parts that have not come to a complete standstill after mains supply to the

unit have been disconnected.

3 Technical Data

3.1 Power consumption and fuse size

Re-heater

Fans 176 W

Total power consumption

Fuse 10 A

1670 W

1846 W

229391 | v02

Page 7

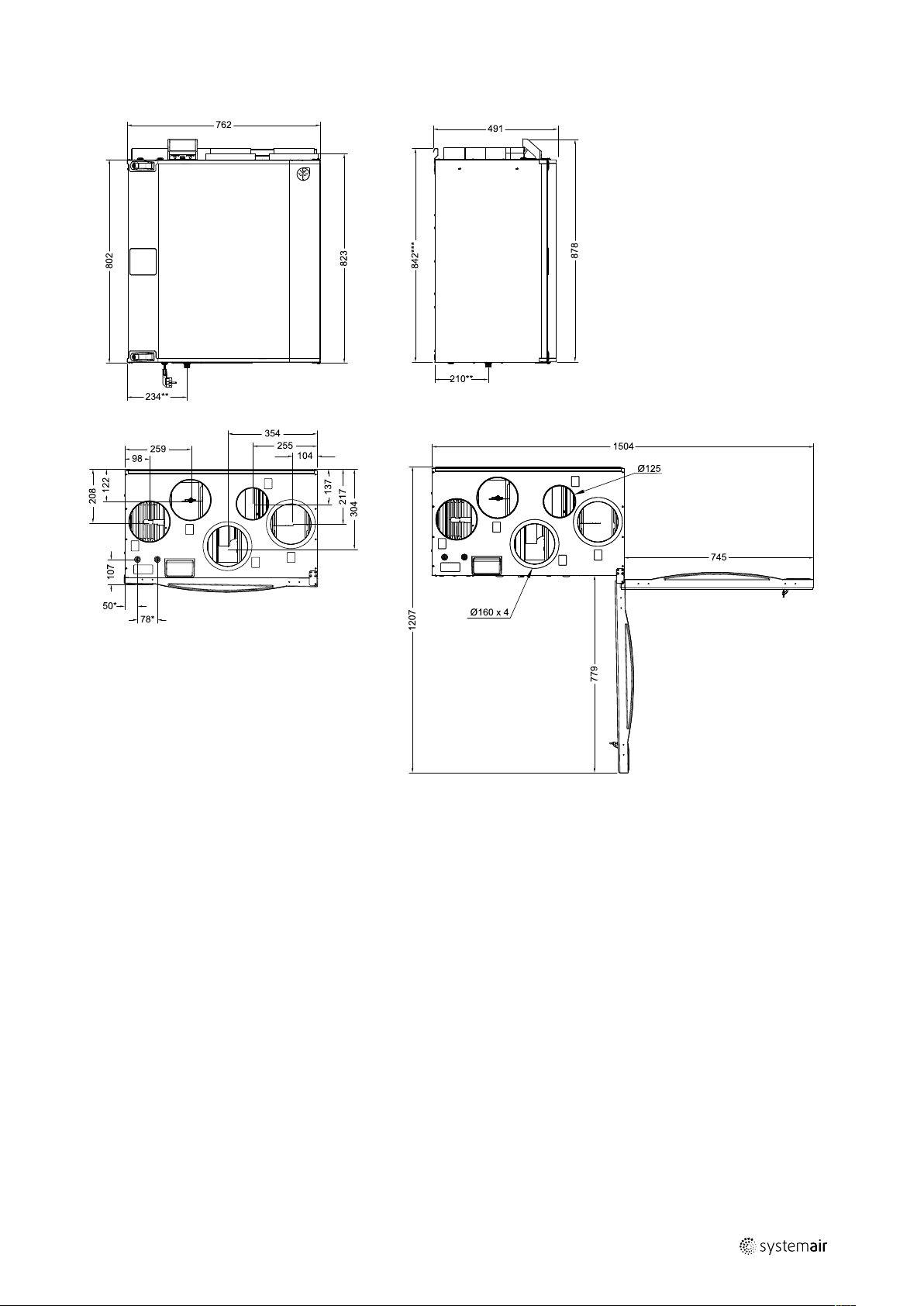

3.2 Dimensions and Weight

Technical Data |

3

Fig. 2 Dimensions of left hand unit

229391 | v02

Page 8

4

| Technical Data

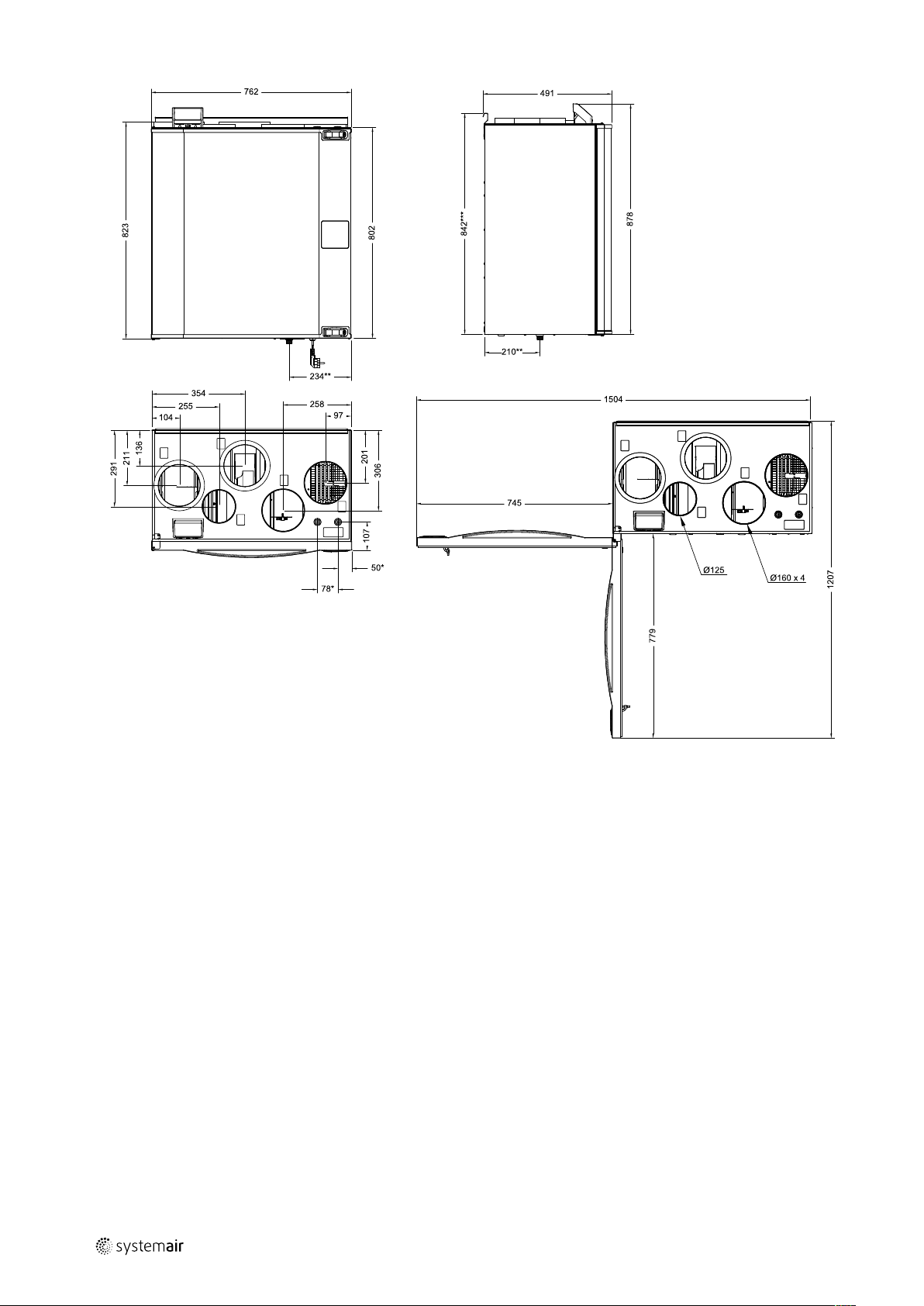

Fig. 3 Dimensions of right hand unit

* Water coil connections.

** Drainage.

*** Height with mounting bracket.

The unit weight is 56 kg.

229391 | v02

Page 9

3.3 Connections Left and Right models

Position Description

R

L

Right hand model (Supply air connection is situated on the right hand side of the unit

viewed from the front)

Left hand model (Supply air connection panel is situated on the left hand side of the unit

viewed from the front)

Technical Data |

5

Symbol

Description

Supply air

Exhaust air

Symbol

Description

Outdoor air Cooker hood air

Extract air

Symbol

Description

3.4 Installation recommendation regarding condensation

3.4.1 Condensation inside of the unit

When the unit is installed in a cold attic (close to outdoor temperature) the unit should run continuously. If the unit is intended to be stopped by the user manually or due to calendar function we recommend to install air tight dampers at extract and supply air ducts. The dampers will ensure that no air circulates from the warm parts of the building through

the unit to outside (chimney effect). If no dampers are installed there is risk of condensation inside the unit and the outdoor ducts during these stop periods. It also might be that cold air from outside could pass the unit and enter into the

building. That could cause condensation outside the supply and extract air ducts and even at the valves in the rooms.

When the unit is not running due to late commissioning in winter time, the supply and extract air ducts should be disconnected and closed due to above mentioned effects until commissioning and regular operation.

229391 | v02

Page 10

| Delivery, Transport, Storage

6

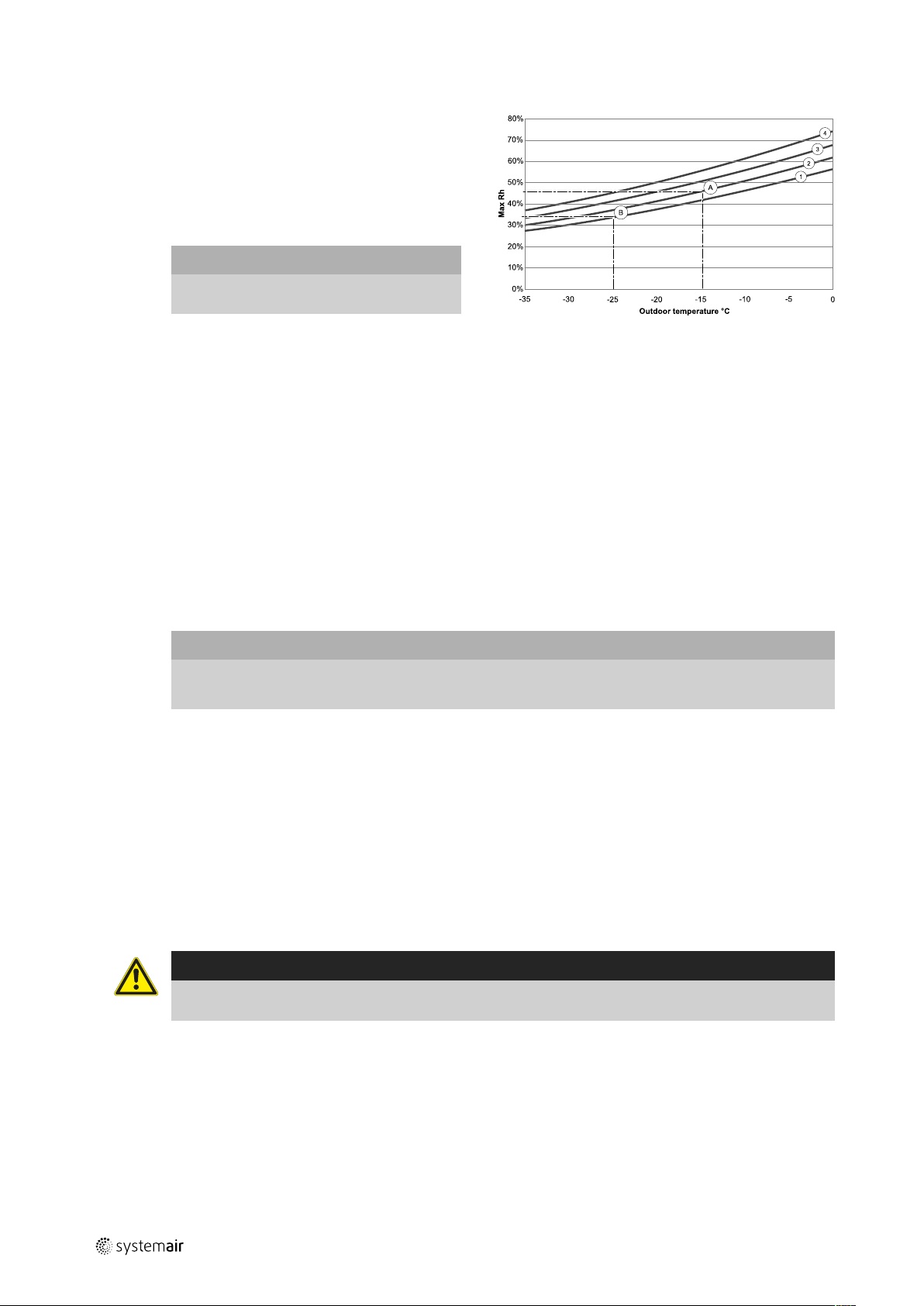

3.4.2 Condensation outside of the unit

When the unit is installed in warm humid areas (like laundry) together with low outdoor temperature there is a

certain point where moisture can condense outside of the

casing. The condensation relation to indoor relative humidity, room and outdoor temperature is shown diagram

below. The condensation outside of the unit do not occur

in zones bellow each curve.

Important

Recommendation: If condensation occurs,

increase ventilation in area close to the unit.

Examples when condensation outside of the unit can

occur:

Example A: If the unit is installed in room where temperature is 22°C, outside temperature is –15°C, then dew will

start accumulating when relative humidity is 46% and

higher.

Example B: If the unit is installed in room where temperature is 20°C, outside temperature is –25°C, then dew will start

accumulating when relative humidity is 34% and higher.

1. Room temperature 20°C

2. Room temperature 22°C

3. Room temperature 24°C

4. Room temperature 26°C

4 Delivery, Transport, Storage

4.1 Transport and storage

The SAVE VTR 300/B should be stored and transported in such a way that it is protected against physical damage. It

should be covered so dust, rain and snow cannot enter and damage the unit and its components.

Important

• Use the packaging exclusively as transport protection and not as a lifting aid.

• Load and unload the air handling unit carefully.

4.2 Delivery/Unloading

The appliance is delivered in one piece containing all necessary components, wrapped in plastic on a pallet for easy

transportation.

Checking delivery

• Check the packaging and the air handling unit for transport damage. Any findings should be noted on the cargo

manifest.

• Check completeness of the delivery.

Verify that all ordered equipment is delivered before starting the installation. Any discrepancies from the ordered

equipment must be reported to the supplier of Systemair products.

Warning

When opening the transport packaging, there is a risk of damage from sharp edges, nails, staples, splinters

etc.

Unpacking

• Check the air handling unit for visible transport damage.

• Only remove the packaging shortly before assembly.

• Beware of sharp edges during mounting and maintenance. Use protective gloves.

5 Prerequisites for Installation

To ensure a proper and fail-free operation, it is important that the unit is installed according to these instructions.

229391 | v02

Page 11

Installation |

5.1 Location and Space Requirements

The SAVE VTR 300/B should preferably be installed in a separate room (e.g. storeroom, laundry room or similar.).

When choosing the location it should be kept in mind that the unit requires maintenance regularly and that the inspection door should be easily accessible. Leave free space for opening the door and for taking out the main components

(figure 3.2).

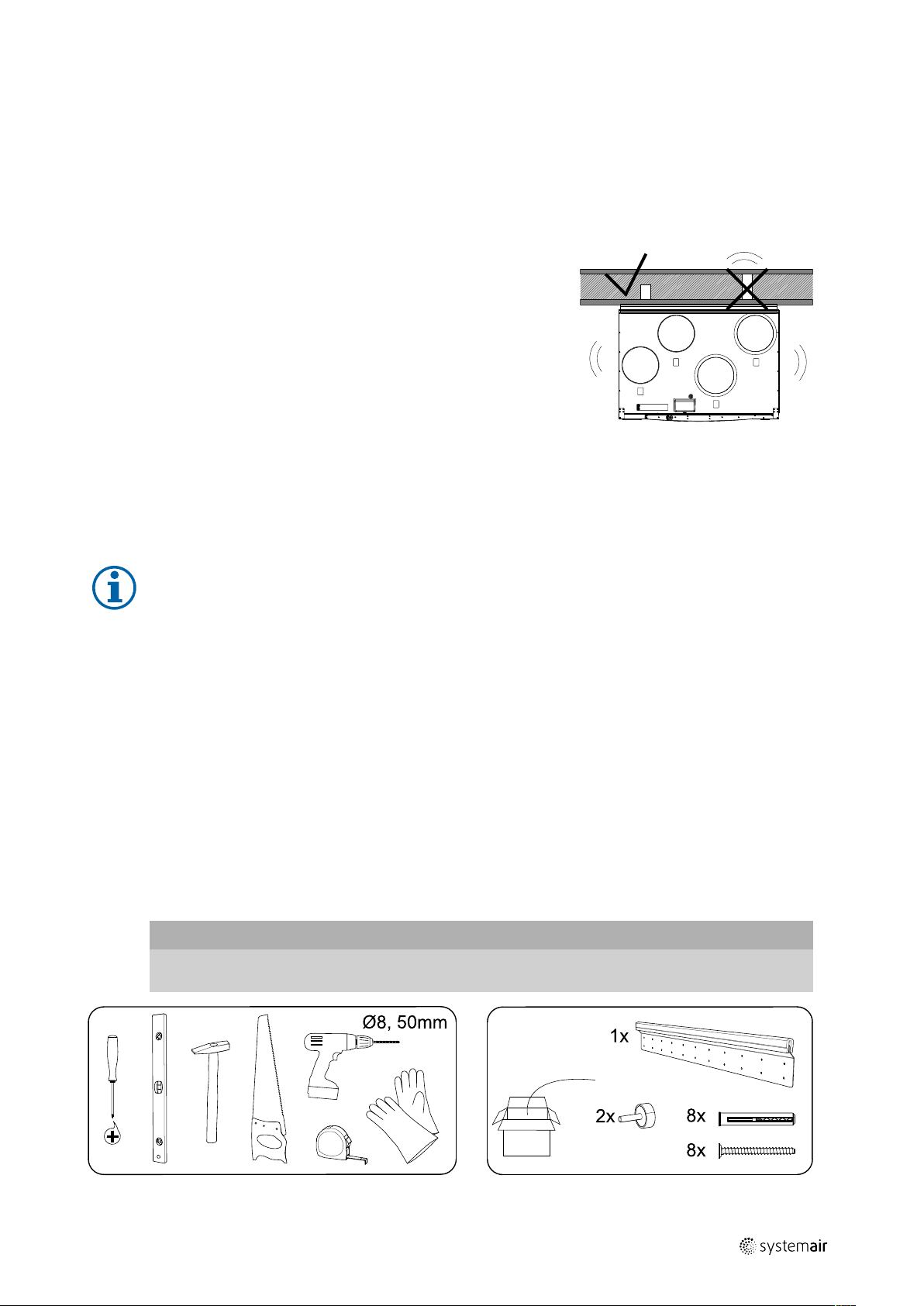

5.2 Wall preparation for mounting bracket

The unit should be installed in such a way that there is no vibration noise

coming from the wall on which the unit is installed.

5.3 Condensation drainage

In general no condensation drainage is needed for rotational heat exchangers at dry conditions. However, if a lot of humid air is present in the residence, a condensation drainage might be needed. Drainage connection is available as an accessory and can be ordered separately. Installation instructions for the drainage are enclosed in the drainage pipes

delivery.

7

Note:

The drainage connection is plugged in the bottom of the unit at delivery. To use the drainage: remove the

rubber seal and connect the drainage pipe. Connect the drainage pipe to the sewer. The water can not be

led straight to the sewer without a water trap.

5.4 Outdoor Air Intake Location Recommendation

Recommended installation location for the outdoor air intake is the northern or eastern side of the building and with a

distance to openings for discharge of stale ventilation air, kitchen ventilator, central vacuum system, waste water drainage and other pollution sources like exhaust from traffic, etc. Exhaust air should ideally be led via a roof cowl to the outside and with a good distance from the outdoor air intake, windows, etc.

5.5 Access to Power supply

The SAVE VTR 300/B is supplied with approximately 1,5 m cable and plug for 230V, single phase earthed connection.

Make sure a power outlet is reachable by the plug.

6 Installation

Important

The device may only be installed by qualified, instructed and trained personnel. The persons must know the

relevant safety directives in order to recognise and to avoid risks.

229391 | v02

Page 12

8

| Installation

C — concrete/bricks, W — wood block, G — gypsum, M — mineral wool

X* — adaptable height according to needs.

Make sure the mounting bracket is completely level.

229391 | v02

Page 13

Follow the ventilation drawing when connecting the unit to the duct system.

Before Starting the System |

9

6.1 Ventilation Duct Connection and Insulation

Important

• Always cover the ventilation ducts during construction period.

• Make sure there are no loose objects or impurities inside the ducts.

Install the ducts, supply air diffusers and air intake grilles as shown in the ventilation drawing.

• Supply air and extract air ducts must be insulated if located in cold places.

• Outdoor air and exhaust air ducts with cold air must be insulated if located in warm places (inside building’s vapour

barrier).

It is very important to insulate cold ducts and joints tightly without any gaps, otherwise there is a risk of condensation

which may result in moisture damage.

Do not install the ducts directly against structural building elements to avoid sound propagation. Use acoustic insulation

and sound attenuators.

Note:

The type of ventilation ducts and insulation differ for each building and climate zone. If the ventilation

drawing is not provided, please contact your installer or place of purchase for recommendations.

6.2 Installation and Configuration of Accessories

Please follow instructions included with the accessory or consult “Service and Accessories Installation” manual which

can be found in our online catalogue.

7 Before Starting the System

When the installation is completed, check that:

• The unit is installed in accordance with the instructions

• Outdoor and exhaust air dampers and silencers are installed and that the duct system is correctly connected to the

unit

• All ducts are sufficiently insulated and installed according to local rules and regulations

• Outdoor air intake is positioned with sufficient distance to pollution sources (kitchen ventilator exhaust, central vacuum system exhaust or similar)

• All external equipment is connected

229391 | v02

Page 14

Commissioning

|

10

• The unit is correctly wired

8 Commissioning

Follow the first startup instructions and fill in the Commissioning record as you go through the settings.

The Startup Wizard cannot be skipped.

Select language, set the time and choose airflow control type. Select revolutions per minute as the type of airflow control only if these values are included with the device.

Set speed of supply and extract air fans for each level. When finished, review your settings. It is possible to go back to

previous menus and make modifications. Finally choose heating type or none. Finish startup wizard with OK button.

All additional changes post-startup wizard must be recorded in the Commissioning record.

9 Concluding Routines

Perform the following procedures before leaving the site:

1. Ensure that the product is operational and that no alarms are active.

2. If applicable, save the configuration backup.

3. Make sure that the Commissioning record is complete.

4. Collect all tools.

5. Inform the appropriate person that work is finished.

6. Follow the procedures for the return and disposal of replacement parts and the disposal of packing.

229391 | v02

Page 15

10 EU Declaration of Conformity

EU Declaration of Conformity |

11

Manufacturer

Systemair UAB

Linų st. 101

LT–20174 Ukmergė, LITHUANIA

Office: +370 340 60165

Fax: +370 340 60166

www.systemair.com

The manufacturer hereby confirms that

SAVE VTR 300/B

comply with all applicable requirements in the following

directives and regulations.

Machinery Directive 2006/42/EC

Ecodesign Directive 2009/125/EC

327/2011 Requirements for fans above 125 W

1253/2014 Requirements for ventilation units

1254/2014 Energy labelling of residential ventilation units

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

RoHS Directive 2011/65/EU, 2015/863/EU

The following harmonized standards are applied in applicable parts:

EN ISO 12100

Safety of machinery - General principles for design - Risk

assessment and risk reduction.

EN 13857

Safety of machinery – Safety distances to prevent hazard

zones being reached by upper or lower limbs.

EN 60529

Degrees of protection provided by enclosures (IP Code).

EN 62233

Measurement methods for electromagnetic fields of

household appliances and similar apparatus with regard

to human exposure.

EN 61000-6-2

Electromagnetic compatibility (EMC) – Part 6-2: Generic

standards – Immunity for industrial environments.

EN 61000-6-3

Electromagnetic compatibility (EMC) – Part 6-3: Generic

standards – Emission standards for residential, commercial and light-industrial environments.

EN 13053

Ventilation for buildings – Air handling units – Rating and

performance for units, components and sections.

EN 13142

Ventilation for buildings. Components/products for residential ventilation. Required and optional performance

characteristics

The declaration applies only to product in the condition it

was delivered in and installed in the facility in accordance

with the included installation instructions. The insurance

does not cover components that are added or actions

carried out subsequently on the product.

The complete technical documentation is available.

Ukmergė, 13-01-2021

EN 60204-1

Safety of machinery – Electrical equipment of machines –

Part 1: General requirements.

EN 60335-1

Household and similar electrical appliances – Safety Part

1: General requirements.

EN 60335-2-40

Safety of household and similar electrical appliances Part 2-40: Particular requirements for electrical heat

pumps, air-conditioners and dehumidifiers.

EN 50106

Safety of household and similar appliances – Particular

rules for routine tests referring to appliances under the

scope of EN 60 335-1.

Nerijus Lapackas

Technical Manager

229391 | v02

Page 16

Systemair UAB

Linų st. 101

LT–20174 Ukmergė, LITHUANIA

Phone +370 340 60165

Fax +370 340 60166

www.systemair.com

SAVE VTR 300/B · Installation instructions · 229391 · en_GB · 2021-02-05 · v02

Loading...

Loading...