SystemAir VSC Series, VSC 700, VSC 700 HW, VSC 1500, VSC 1500 EL Installation Instructions Manual

...Page 1

VSC

Compact Air Handling Unit

Installation instructions GB

V1 (1/2)

Page 2

© Copyright Systemair AB

All rights reserved

E&OE

Systemair AB reserves the rights to alter their products without notice.

This also applies to products already ordered, as long as it does not aect the previously agreed specications.

Operation and Maintenance Instructions

2

Systemair AB

Page 3

Contents

1 Warnings........................................................................................................................................................... 4

2 Product information........................................................................................................................................... 4

2.1 General ..................................................................................................................................... 2

2.2 Technical data ........................................................................................................................... 5

2.2.1 Dimensions and weight ...........................................................................................................5

2.2.2 Space required ........................................................................................................................8

2.2.3 Electrical data VSC .................................................................................................................9

2.3 Transport and storage ...................................................................................................................... 9

3 Installation ........................................................................................................................................................10

3.1 Unpacking .......................................................................................................................................10

3.2 Where/how to install.........................................................................................................................10

3.3 Condensation drain..........................................................................................................................11

3.4 Condensation drain..........................................................................................................................12

3.4.1 Installation procedure ...........................................................................................................13

3.5 Connections.....................................................................................................................................14

3.5.1 Ducting .................................................................................................................................14

3.5.2 Condensation and heat insulation.........................................................................................15

3.5.3 Silencers................................................................................................................................15

3.5.4 Electrical connections, components .....................................................................................15

3.5.5 External connections ............................................................................................................17

3.5.6 BMS Connection...................................................................................................................18

Operation and Maintenance Instructions

3

Systemair AB

Page 4

1 Warnings

The following admonitions will be presented in the dierent sections of the document:

Danger

• Indicates a potentially or imminently hazardous situation which, if not avoided, could result in

death or serious injury.

Warning

• Indicates a potentially hazardous situation that may result in minor or moderate injuries.

Caution

• Indicates a risk of damaging the product or prevent optimal operation.

Important

• This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have

been given supervision

• or instruction concerning use of the appliance in a safe way and understand the hazards

involved.

• Children shall not play with the appliance. Cleaning and user maintenance shall not be made

by children without supervision.

2 Product information

2.1 General

This installation manual concerns air handling unit type Topvex FC manufactured by Systemair Sverige AB. The units

include the following model options:

• Model: VSC 700, VSC 1500, VSC 2000

• Heating coil: EL (Electric), HW (Water coil) or None.

This manual consists of basic information and recommendations concerning the design, installation, start-up and operation, to ensure a proper fail-free operation of the unit.

The key to proper and safe operating of the unit is to read this manual thoroughly, use the unit according to given

guidelines and follow all safety requirements.

Operation and Maintenance Instructions

4

Systemair AB

Page 5

2.2 Technical data

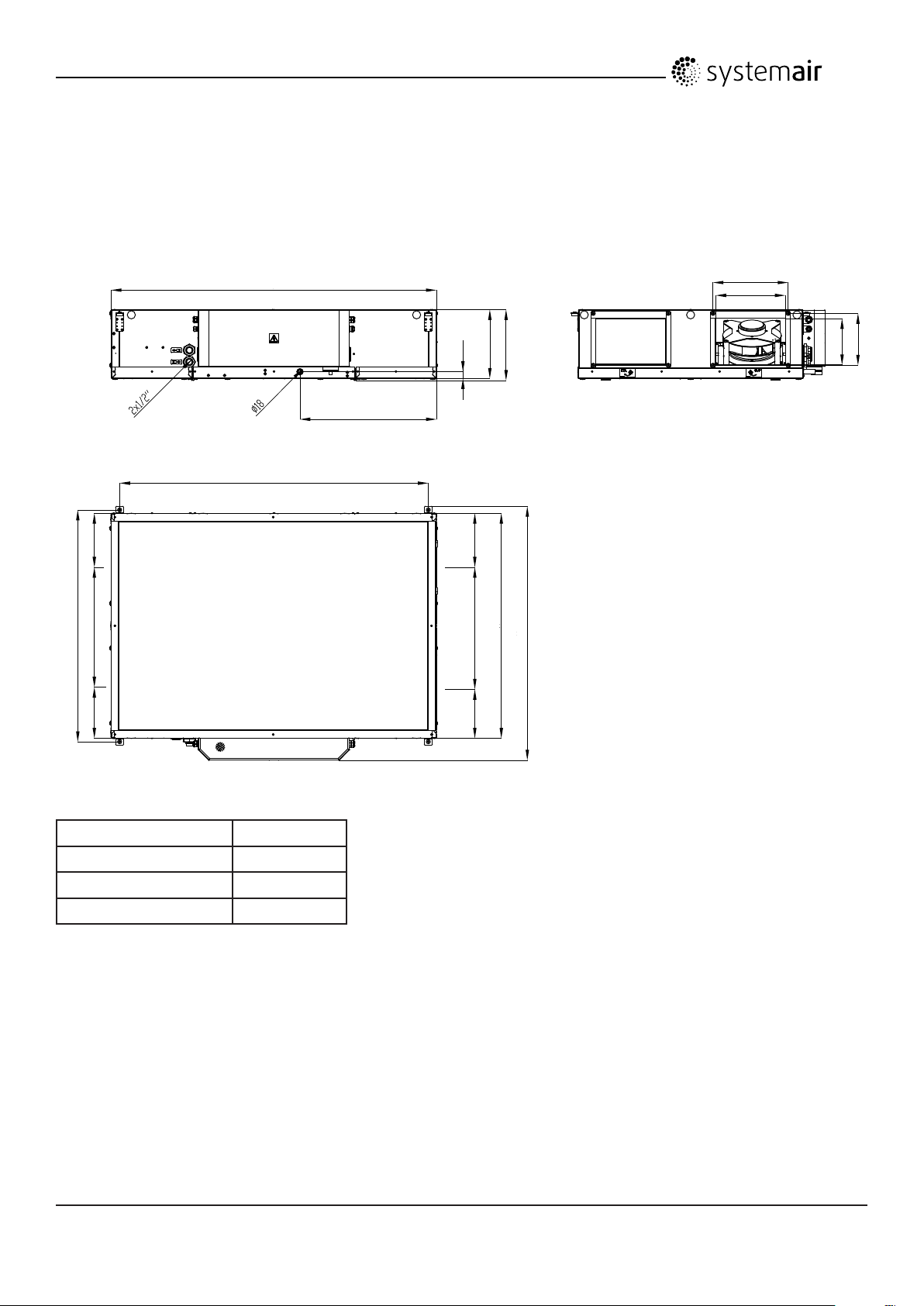

2.2.1 Dimensions and weight

1000

242

517242

1400

1330

590

324

300

224

21

300

310

970

517 242242

1096

200

Model Weight, kg

VSC 700 90

VSC 700 EL 95

VSC 700 HW 95

Operation and Maintenance Instructions

Systemair AB

5

Page 6

323

1700

1630

720

524

500

274

21

380

390

250

1305

625323

Model Weight, kg

VSC 1500 165

VSC 1500 EL 170

VSC 1500 HW 170

625 323323

1270

1400

Operation and Maintenance Instructions

6

Systemair AB

Page 7

433

2000

1630

902

624

600

324

21

460

470

300

1630

735433

Model Weight, kg

VSC 2000 240

VSC 2000 EL 245

VSC 2000 HW 245

735 433433

1600

1728

Operation and Maintenance Instructions

7

Systemair AB

Page 8

2.2.2 Space required

W

Model W (mm)

VSC 700 350

VSC 1500 450

VSC 2000 550

Operation and Maintenance Instructions

8

Systemair AB

Page 9

2.2.3 Electrical data VSC

Model Fans (W tot.) 230V 1~ El Heating battery (kW tot.) Fuse (mains) (A) for 230V 1~ and

400V 3~

VSC 700

EL

VSC 700

None, HW

VSC 1500

EL

VSC 1500

None, HW

VSC 2000

EL

VSC 2000

None, HW

330 1,4 16

330 - 10

910 2,7 25

910 - 10

1000 4,8 3x16

1000 - 10

2.3 Transport and storage

VSC is delivered in one piece on a pallet for easy transportation using a forklift. The unit should be stored

and transported in such a way that it is protected against physical damage that can harm panels, handles, display etc.

It should be covered so that dust, rain and snow cannot enter and damage the unit and its components. The appliance

is delivered complete with all necessary components, wrapped in plastic on a pallet for easy transportation.

At delivery the unit is fastened to the pallet with 4pcs screws. Unscrew the srews from the pallet.

When transporting the VSC units use a forklift.

Fig. 1

Operation and Maintenance Instructions

Systemair AB

9

Page 10

NOTE:

Necessary parts like control panel, supply air sensor, handles, drainage pipe with drain trap are placed

loosely inside the unit. The unit must not be put into operation before the enclosed parts are removed and

installed properly.

Warning

• The unit is heavy. Be careful during transport and mounting. Risk of injury through pinching. Use protective

clothing.

• Be careful so the unit don‘t tip over.

3 Installation

VCS is designed for installation above suspended ceilings.

Fig. 2

3.1 Unpacking

Verify that all ordered equipment are delivered before starting the installation. Any deviation from the ordered equipment must be reported to the supplier of Systemair products.

3.2 Where/how to install

VSC are meant for indoor installation. The electronic components should not be exposed to lower temperature

than 0° C and higher than +50° C.

VSC must always be installed horizontally with the inspection doors downwards.

When choosing the location it should be kept in mind that the unit requires maintenance regularly and that the inspec-

tion doors should be easily accessible. Leave free space for opening the doors and for taking out the main components (chapter 2.2.2.)

NOTE:

If there is not sucient space to open the inspection doors, it is possible to mount rails and use existing doors as

sliding doors (accessory) chapter 4.6.

The outdoor air intake of the building should if possible be put in the northern or eastern side of the building and away

from other exhaust outlets like kitchen fan outcasts or laundry room outlets.

Warning

• The unit must be duct connected or in some other way provided with protection so that it is not possible to come

in contact with the fans through the duct connections

10

Operation and Maintenance Instructions

Systemair AB

Page 11

3.3 Condensation drain

The unit must be connected to the condensation drain.

See table 1 how the height “H” corresponds to dierent maximum negative pressures.

If the unit is mounted in a tight area that makes it dicult to have the appropriate height, a pump is available as an

accessory.

Note:

When installed in a non heated place the drain pipe and trap needs to be insulated well to prevent the water from

freezing.

Fig. 3

H

Fig. 4 - Drainage connection

Table 1

H (mm) Max. Negative pressure (Pa)

65 300

95 600

135 1000

NOTE: It is recommended to use a ball trap siphon

Operation and Maintenance Instructions

Systemair AB

11

Page 12

3.4 Installing the unit

The units are designed for ceiling installation

Fig. 5

SUP

ETA

ODA

ETA

Table 2 Symbol description

Symbol Description

Supply air

Exhaust air

Outdoor air

Extract air

Operation and Maintenance Instructions

Systemair AB

12

Page 13

3.4.1 Installation procedure

The units are designed for ceiling installation

Warning

• Beware of sharp edges during mounting and maintenance. Make sure that a proper lifting

device is used. Use protective clothing.

Warning

• The units electrical connection to the mains power supply must be preceded by an all pole

circuit breaker with a minimum 3 mm gap.

Danger

• Make sure that the mains power supply to the unit is disconnected before performing any

maintenance or electrical work!

• All electrical connections must be carried out by an authorized installer and in accordance

with local rules and regulations.

1)

Prepare the surface where the unit is to be mounted. Make sure that the surface is at, levelled and that it

carries the weight of the unit. Perform the installation in accordance with local rules and regulations.

Install the unit with 0-3° lean towards drainage connections.

2)

Li the unit in place.

3)

Connect the unit electrically to the mains power supply through the all pole circuit breaker (safety switch).

Led the wiring directly to the electrical connection box. Be careful not to cut the wiring.

13

Operation and Maintenance Instructions

Systemair AB

Page 14

3.5 Connections

3.5.1 Ducting

8

1

SUP

4

ETA

Fig. 6 Connections and basic components

7

5

6

3

ODA

2

ETA

Position Description Symbol

A Connection supply air (SUP)

B Connection exhaust air (EHA)

C Connection outdoor air (ODA)

D Connection extract air (ETA)

1 Fan supply air

2 Fan extract air

3 Filter supply air

4 Filter extract air

5 Heat exchanger

6 Electrical connection box

7 Damper by-pass outdoor air

8 Re-heater battery with manual everheat protection

14

Operation and Maintenance Instructions

Systemair AB

Page 15

3.5.2 Condensation and heat insulation

on ducts connected to the unit is especially important. All ducts installed in cold rooms/areas must be well insulated.

Use insulating covering (minimum 100 mm mineral wool) with plastic diusion barrier. In areas with extremely low

outdoor temperatures during the winter, additional insulation must be installed. Total insulation thickness must be at

least 150 mm.

Caution

• If the unit is installed in a cold place make sure that all joints are covered with insulation, and

tape well

• Duct connections/duct ends should be covered during storage and installation

• Do not connect tumble dryers to the ventilation system

3.5.3 Silencers

To avoid fan noise being transferred via the duct system, silencers should be installed both on supply and extract air.

To avoid noise being transferred between rooms via the duct system and also to reduce noise from the duct system

itself, installation of silencers before every inlet diuser is recommended.

3.5.4 Electrical connections, components

Danger

• Make sure that the mains power supply to the unit is disconnected before performing any

maintenance or electrical work!

• All electrical connections must be carried out by an authorized installer and in accordance

with local rules and regulations.

Warning

• The units electrical connection to the mains power supply must be preceded by an all pole

circuit breaker with a minimum 3 mm gap.

All electrical connections are made in the electrical connection box which can be found on the long side of the unit.

The hatch is removed by unscrewing one screw (gure 7).

The unit must not be put into operation before all the electrical safety precautions have been read and understood.

See the enclosed wiring diagram for internal and external wiring.

All external connections to possible accessories are made to terminals inside the electrical connection box (chapter

3.5.5).

15

Operation and Maintenance Instructions

Systemair AB

Page 16

Fig. 7

VSC units are equipped with a built in regulator.

4

7 8

3

Fig. 8 Electric components

Position Description

1 Regulator E-28

2 Transformer 230/24V DC

3 Pressure transmiters (Fans, Filters)

4 SSR relay - EL heater

1 2

9

5

6

5 Terminals for mains supply to the unit and air dumpers control

6 Main switch

7 Safety contactor

8 Terminals for external components

9 Fans fuses

16

Operation and Maintenance Instructions

Systemair AB

Page 17

3.5.5 External connections

Connections to external functions:

Terminal block Description Remark

Main terminals - 1

PE PE Ground

N N Earthed neutral (mains power supply) Used for phase 230V 1~ and

400V 3~

L1 L1 Phase (mains power supply) Used for phase 230V 1~ if the

unit has this mains

400V 3~

L2 L2 Phase (mains power supply) 400V 3~

L3 L3 Phase (mains power supply) 400V 3~

Lfs Lfs Damper supply (230V output) 230V output

Lfe Lfe Damper exhaust (230V output) 230V output

Err 14 - DO4 Error output (230V) 230V Output

Lout Lout Phase for accessories (230V output) 230V output (2A)

Terminals for external components - 2

+C 4 - +C Terminals for external control inputs External control, Fire, Occupancy

0-10V VALVE * 93 - A03 Control signal valve actuator, Water

Heating

+24V +24V Power supply for accesories (AQS,

actuators)

GND GND Ground terminal (AQS, actuators) GND

GDo 10 - GDo Terminal for internal components GDo

0-10V DC

24V DC

Regulator E-28 - 3

DI1 71 - DI1 External control contact NC contact

DI2 72 - DI2 Fire contact NC contact

DI3 73 - DI3 Occupancy contact NC contact

* Avalible only for VSC 700 HW, VSC 1500 HW, VSC 2000 HW

2 3

1

17

Operation and Maintenance Instructions

Systemair AB

Page 18

3.5.6 BMS Connection

Communication possibilities for control unit.

• RS485(Modbus): 50-51-52

• RS485(BACnet): 50-51-52

• RS485(Exoline): 50-51-52-53

• TCP/IP Exoline

• TCP/IP Modbus

• TCP/IP WEB

• TCP/IP BACnet

RS 485 connection:

18

Operation and Maintenance Instructions

Systemair AB

Page 19

Systemair AB reserves the right to make changes and improvements to the contents

of this manual without prior notice.

Systemair AB

Unit 28, Gravelly Industrial Park, Birmingham, B24 8HZ

Tel: +44 (0) 121 322 0200 Fax: +44 (0) 121 322 0201

Emal: info@systemair.co.uk

Loading...

Loading...