SystemAir TFC 225 P, TFC 355 P, TFC 280 P, TFC 450 P, TFC 500 P Operation And Maintenance

...Page 1

Roof fans

TFC 225-560 S/P

Operation and Maintenance Instructions

Document in original language | 206434 · A006

GB

Page 2

© Copyright Systemair AB

All rights reserved

E&OE

Systemair AB reserves the rights to alter their products without notice.

This also applies to products already ordered, as long as it does not affect the previously agreed specifications.

206434 | A006

Page 3

1 EU Declaration of conformity....... . . . . . ............. . . . . . 1

2 Warnings. . . . . . .............. . . . . . . ............. . . . . . ...........2

3 Product information ....... . . . . . . . ............. . . . . . . ........3

3.1 General....... . . . . . . . ............. . . . . . . ............. . . 3

3.2 Technical data ............ . . . . . . ............. . . . . . . . .4

3.2.1 Dimensions and weight ............. . . 4

3.2.2 Performance ...... . . . . . ............. . . . . . 5

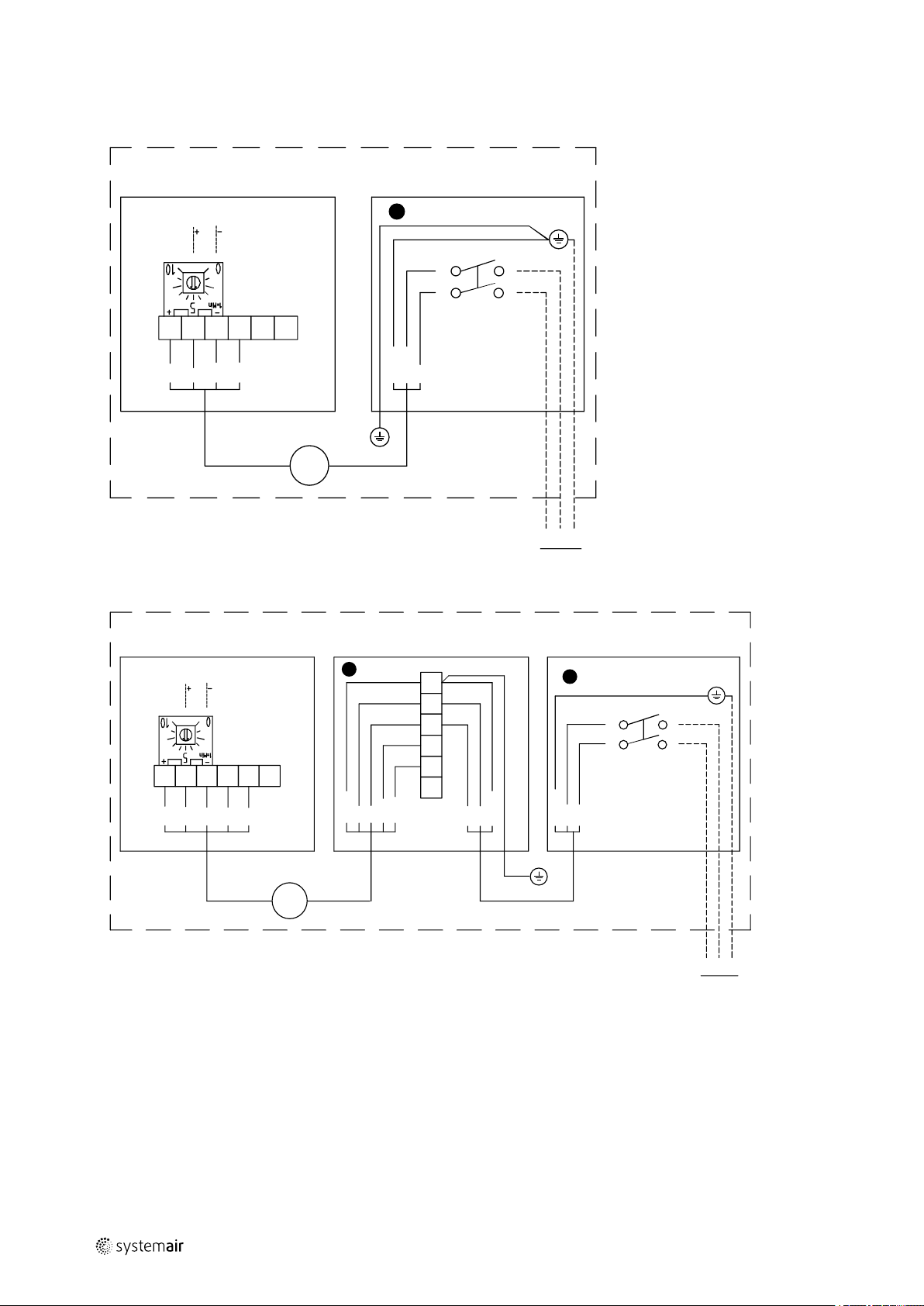

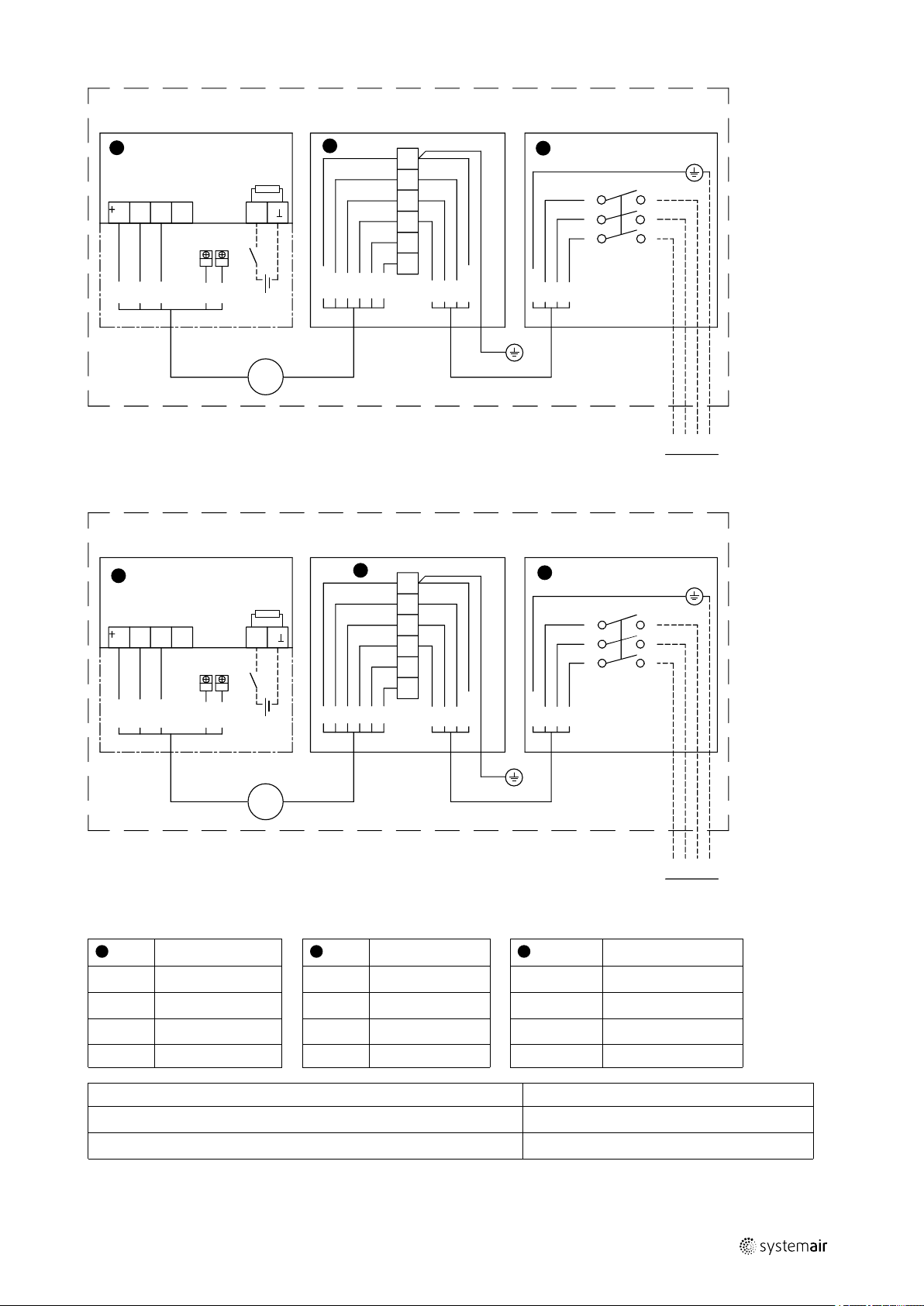

3.2.3 Wiring diagram . . . . . . . . ............ . . . . . .6

3.2.4 Residual current devices . . . ......... 10

3.3 Transportation and storage. . . . ............. . . . . 10

4 Installation.... . . . . . . ............ . . . . . . . .............. . . . . . . .. 10

4.1 Installing the fans ... . . . . . . ............. . . . . . ...... 11

4.2 Change from VAV to CAV ..... . . . . . ............. 13

4.3 K-factor ......... . . . . . . .............. . . . . . . .......... 13

4.4 Commissioning .......... . . . . . . ............. . . . . . . . 14

4.5 Alarm output . . . . . . ............. . . . . . . . ............. 14

5 Control panel......... . . . . . . ............. . . . . . . . ............. 15

5.1 Operating the control panel ............. . . . . . .. 15

6 Maintenance .............. . . . . . . .............. . . . . . ......... 18

6.1 Important ....... . . . . . . .............. . . . . . . .......... 18

6.2 Maintenance intervals ..... . . . . . . ............ . . . . 18

6.3 Cleaning the fan........ . . . . . . . ............. . . . . . .. 18

7 Troubleshooting..... . . . . . . . ............. . . . . . . ............. 19

Contents

206434 | A006

Page 4

Page 5

EU Declaration of conformity |

1 EU Declaration of conformity

Manufacturer

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg SWEDEN

Office: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

hereby confirms that the following products:

Roof fans TFC 225-560 S/P

(The declaration applies only to product in the condition it was delivered in and installed in the facility in accordance with the included

installation instructions. The insurance does not cover components that are added or actions carried out subsequently on the

product)

Comply with all applicable requirements in the following directives and regulations

1

Machinery Directive 2006/42/EC Ecodesign Directive 2009/125/EC

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

The following harmonized standards are applied in applicable parts:

EN ISO 12100:2010

EN 13857

Safety of machinery – General principles for design – Risk assessment and risk reduction.

Safety of machinery – Safety distances to prevent hazard zones being reached by upper

327/2011 Requirements for fans

1253/2014 Requirements for ventilation units

or lower limbs.

EN 60 335-1

EN 60 335-2-80

Household and similar electrical appliances – Safety Part 1: General requirements.

Household and similar electrical appliances – Safety – Part 2-80: Particular requirements

for fans.

EN 62233

Measurement methods for electromagnetic fields of household appliances and similar

apparatus with regard to human exposure.

EN 50 106:2007

Safety of household and similar appliances – Particular rules for routine tests referring to

appliances under the scope of EN 60 335-1 and EN 60967.

EN 60529

EN 60 204-1

EN 61000-6-2

Degrees of protection provided by enclosures (IP Code).

Safety of machinery – Electrical equipment of machines – Part 1: General requirements

Electromagnetic compatibility (EMC) – Part 6-2: Generic standards – Immunity for

industrial environments.

EN 61000-6-3

Electromagnetic compatibility (EMC) – Part 6-3: Generic standards – Emission standards

for residential, commercial and light-industrial environments.

The complete technical documentation is available.

Skinnskatteberg, 09-05-2016

Mats Sándor

Technical Director

206434 | A006

Page 6

Warnings

|

2

2 Warnings

The following admonitions will be presented in the different sections of the document:

Danger

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or

serious injury.

Warning

Indicates a potentially hazardous situation that may result in minor or moderate injuries.

Caution

Indicates a risk of damaging the product or prevent optimal operation.

Important

• This appliance can be used by children aged from 8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and understand the hazards involved.

• Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children

without supervision.

206434 | A006

Page 7

Product information |

3 Product information

3.1 General

This installation manual concerns Roof fans TFC 225, TFC 280, TFC 355, TFC 450, TFC 500 and TFC 560 manufactured

by Systemair Sverige AB.

The S-fans are delivered with potentiometer, 0-10 V. The integrated potentiometer is factory preset to 10 V. This value

can be changed manually to obtain a different motor rpm/fan performance. Fan performance charts for this purpose

are shown in the table by voltage steps (chapter 3.2.2). An external potentiometer can be connected if necessary. If so

the internal potentiometer needs to be disconnected from the connection terminals. It is also possible to use an external pressure meter to set the desired airflow using the K-factor table (chapter 4.3).

The P-fans are regulated with a built in differential pressure and airflow controller. The fans are delivered with VAV control – Variable Air Volume but can be converted to CAV – Constant Air Volume (see chapter 4.2).

This manual consists of basic information and recommendations concerning the design, installation, start-up and operation, to ensure a proper fail-free operation of the unit. The key to proper and safe operating of the unit is to read this

manual thoroughly, use the unit according to given guidelines and follow all safety requirements.

The TFC 225-560 S/P are intended for transportation of air in air handling systems. The fans are meant for use in ducted

systems and should always be duct connected on the inlet side. No moving parts shall be accessible after installation.

TFC 225-560 S/P roof fans are adapted to continuous operation.

Roof fans are exclusively intended for extract air applications.

3

Danger

• The fans are not to be used in hazardous environments or connected to flue ducts.

• The appliance must be connected to a mains circuit breaker in the fixed installation.

• Switch power off (all-pole circuit breaker) before servicing or maintenance, and make sure the impeller

has come to standstill.

• Make sure protection grid has been installed (EN ISO 13857), no moving parts shall be accessible after

installation.

• Do not remove, short-circuit or disconnect safety accessories (i.e. motor protection, safety grille).

Warning

• The fans can have sharp edges and corners which may cause injuries. Be careful when opening the fans,

the motor assembled on the motor bracket is relatively heavy.

Caution

• Take precautions to prevent the back flow of exhaust gases from flues from other appliances installed in

the same room, which are fired by gas or other fuels.

• This appliance can be used by children aged from 8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and understand the hazards involved.

Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children

without supervision.

206434 | A006

Page 8

| Product information

G

F

22

55

A

B

C

D

E

185

øH

4

3.2 Technical data

3.2.1 Dimensions and weight

Model

TFC 225 413 422 281 330 435 266 49 195 12,4

TFC 280 514 523 333 450 535 368 86 245 17,1

TFC 355 618 627 376 535 637 491 150 300 27,5

TFC 450 728 737 417 655 747 602 176 375 35,4

TFC 500 924 934 531 840 946 695 200 400 60,8

TFC 560 924 934 531 840 946 744 279 470 74

□A □B

C

□D

E F G øH

Weight, kg

206434 | A006

Page 9

3.2.2 Performance

0 0.1 0.2 0.3 0.4

0

200

400

600

Q [m³/s]

Ps [Pa]

0 300 600 900 1200 1440

[m³/h]

16738, 16737

4,6V

6,5V

10V

TFC 225

2,6V

0 0.2 0.4 0.6 0.8

0

100

200

300

400

500

Q [m³/s]

Ps [Pa]

0 500 1000 1500 2000 2500

[m³/h]

16853, 16852

5V

7,4V

10V

TFC 280

2,6V

0 0.4 0.8 1.2 1.6

0

250

500

750

1000

Q [m³/s]

Ps [Pa]

0 1000 2000 3000 4000 5000

[m³/h]

16745, 16744

5V

7,3V

10V

TFC 355

2,5V

0 0.5 1 1.5 2

0

200

400

600

800

Q [m³/s]

Ps [Pa]

0 2000 4000 6000

[m³/h]

16888, 16886

4,8V

7V

10V

TFC 450

2,4V

0 1 2 3

0

300

600

900

1200

Q [m³/s]

Ps [Pa]

0 2500 5000 7500 10000

[m³/h]

16894, 16893

4,6V

7V

10V

TFC 500

2,3V

0 1 2 3 4

0

300

600

900

1200

Q [m³/s]

Ps [Pa]

0 4000 8000 12000

[m³/h]

16792, 16791

4,4V

6,7V 10V

TFC 560

2,3V

Product information |

5

206434 | A006

Page 10

| Product information

Tacho

0-10V DC

Ext

RD

YE

BU

WH

1

3

2

4

BU

BN/BK

GN-YE

230V 1~

NLP

E

1

TFC 225-280 S

M

RSA

RSB

0-10V DC

Ext

RD

YE

BU

WH

BN

1

3

2

4

230V 1~

BU

BN

GN-YE

NLPE

GN-YE

WH 2

WH 1

GN-YEBUBK

BN

BU

1

TFC 355-450 S

M

3

6

3.2.3 Wiring diagram

Modbus communication is possible from TFC 355, see wiring diagram.

206434 | A006

Page 11

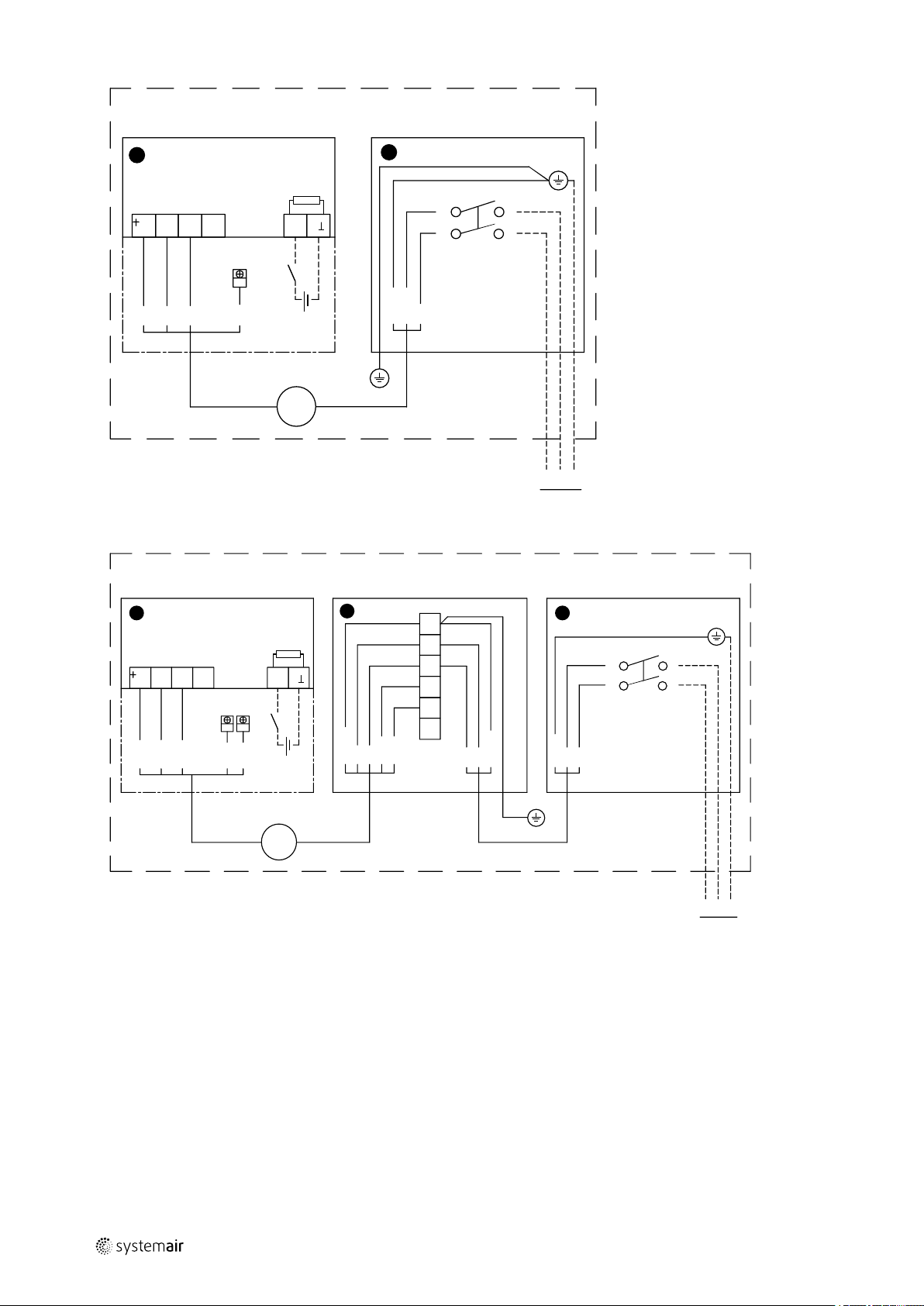

Product information |

1

3

2

4

400V 3~

5

6

BK

BN

GN-YE

GY

L2L1PE

L3

GYBKBN

GN-YE

0-10V DC

Ext

RD

YE

BU

WH

BN

RSA

RSB

WH 2

WH 1

BK 3

BK 2

BK 1

GN-YE

1

TFC 500 S

M

3

1

3

2

4

400V 3~

5

6

BK

BN

GN-YE

GY

C

NC

L3L2L1

PE

L2L1PE

L3

GYBKBN

GN-YE

0-10V DC

Ext

+10V

Ain1U

GND

RSA

RSB

1

TFC 560 S

M

3

7

Ext = External

206434 | A006

Page 12

| Product information

1

3

2

4

230V 1~

RDYEBU

WH

BU

BN/BK

GN-YE

N

L

PE

Tacho

AGNDU

S

GND

1

2

TFC 225-280 P

M

10V DC

-

+

10.. .24 V DC

2( )1(+)

Ri = 4 kΩ

1

3

2

4

230V 1~

RDYEBU

WH

BN

BU

BN

GN-YE

WH 2

WH 1BUBK

GN-YE

NLPE

BUBNGN-YE

RSA

RSB

AGNDU

S

GND

1(+) 2( )

1

2

TFC 355-450 P

M

3

10V D C

10... 24 V DC

-

+

Ri = 4 kΩ

8

206434 | A006

Page 13

Product information |

1

3

2

4

400V 3~

5

6

BKBNGN-YE

GY

WH 2

WH 1

BK 3

BK 2

BK 1

GN-YE

L2L1PE

L3

GYBKBN

GN-YE

RDYEBU

WH

BN

AGNDU

S

GND

RSA

RSB

1

2

TFC 500 P

M

3

10V D C

10... 24 V DC

-

+

2( )1(+)

Ri = 4 kΩ

1

3

2

4

400V 3~

5

6

BKBNGN-YE

GY

C

NC

L3L2L1

PE

L2L1PE

L3

GYBKBN

GN-YE

+10V

Ain1U

GND

RSA

RSB

AGNDU

S

GND

1

2

TFC 560 P

M

3

10V D C

10... 24 V DC

-

+

2( )1(+)

Ri = 4 kΩ

1

2

3

9

Safety switch

RD

YE

BU

WH

Switch-over contact enables:

Voltage off

Red

Yellow

Blue

White

Voltage on

206434 | A006

Fan control

Black

NC/WH1 Alarm output

C/WH2 Normally closed

GN Green

BN Brown

GY Gray

BK

Alarm

Setpoint 1 active

Setpoint 2 active

Page 14

| Installation

10

3.2.4 Residual current devices

Only universal (type B, B+) RCD protective devices are permitted.

Like frequency inverters, RCD protective devices cannot provide personal safety while operating the device, pulse

charge currents from the capacitors in the integrated EMC filter lead to the RCD protective device triggering without

delay.

We recommend residual current devices with a trigger threshold of 300mA and delay triggering. (super-resistant, characteristic K)

3.3 Transportation and storage

All fans are packaged at the factory to withstand normal transport handling. When handling the goods use suitable lifting equipment in order to avoid damage to fans and personnel. Avoid blows and shock loads. Store the fans in a dry

place protected from weather and dirt until final installation.

Warning

• The unit is heavy. Be careful during transport and installation. Risk of injury through pinching. Use

protective clothing.

• Do not lift the fans by the connecting cable, connection box, motor bracket, impeller or inlet cone.

4 Installation

Danger

• Make sure that the mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• All electrical connections must be carried out by an authorized installer and in accordance with local rules

and regulations.

Warning

• The units electrical connection to the mains supply must be preceded by an all pole circuit breaker with a

minimum 3 mm gap.

• Do not lift the fans by the connecting cable, connection box, motor bracket, impeller or inlet cone.

• Do not block or cover the drainage gap around the bottom of the fan.

The fan should be installed horizontally. Make sure the assembly of the fan is firmly fixed and stable. The fans must be

installed to ensure that service and maintenance can be performed easily and safely. Disturbing noise can be reduced

by installing silencers (available as an accessory). Electrical connections are made according to the wiring diagram in

the terminal box, markings on terminal blocks or on cable. All 3 phase fans are delivered from factory in 400 V 3~

connection.

206434 | A006

Page 15

4.1 Installing the fans

Installation |

11

Figure 1

Loosen the screws to open the lid to reach the motor.

Unscrew the two screws to open the lid to the electrical

compartment.

Figure 2

Connect the mains supply to the lockable safety switch

(1). Image show S-controller (2).

The hinges on the hatch to the electrical compartment

prevents the hatch from falling down.

Figure 3

Possible to mount the TFC with suitable roof curb

(optional), using the holes in the bottom of the fan (3).

206434 | A006

Figure 4

TFC mounted on roof curb.

Page 16

| Installation

4

5

12

Figure 5

Mains supply (4) can be run through the cable glands beside the electrical compartment or inside a roof curb, if used.

Note:

Don’t cover this gap (5). It is for drainage if water enters the fan.

206434 | A006

Page 17

Installation |

k ·

q =

p

4.2 Change from VAV to CAV

TFC 225 -TFC 560 are delivered as VAV- fans. The tubing is connected to - (minus) inlet on the controller.

All fans are also prepared with tubing for CAV (Constant air volume). The tubing is attached along the side of the casing

and loosely inserted in the electrical compartment. Change the function to CAV by replacing the connection to the controller, the tubing from the bottom of the fan (1) to + (plus) inlet and the tubing from the cone (2) to - (minus).

The tubing from the cone is labelled with blue tape.

13

In BASE SETUP 5.01 in table 1, set the K-factor (see chapter 4.3). In SETTINGS, adjust the airflow for Setpoint 1, Setpoint

2 and Pband (nominal airflow x 2 recommended).

4.3 K-factor

Use the following equation to calculate the requested setting:

q = airflow [m3/h]

k = k-factor

p= tuning pressure [Pa]

Model K-factor

TFC 225 57

TFC 280 79

TFC 355 134

TFC 450 212

TFC 500 289

TFC 560 554

206434 | A006

Page 18

| Installation

14

4.4 Commissioning

Danger

• All electrical connections must be carried out by an authorized installer and in accordance with local rules

and regulations.

Before initial operation, check the following:

• Electrical connection has been properly completed.

• Protective earth has been connected.

• Safety devices in place (protection grid).

• Leftover installation materials and foreign materials have been removed from the casing.

Testing the installation:

• Adjustment may be required in the electrical compartment during test (i.e. changing of the potentiometer), however

during operation the lid must be closed.

When putting into operation, check the following:

• Connection data corresponds to the specifications on the nameplate: Maximum voltage +6%, -10%, according to IEC

38. Rated current must not be exceeded with more than 5% at rated voltage.

• The direction of rotation should correspond to direction-of-rotation arrow (3 phase).

• Smoothness of motor operation, (no abnormal noises).

Sound levels exceeding 70 dB(A) may occur depending on size (see www.systemair.com for detailed information).

4.5 Alarm output

The fan motor has built in protection for locked rotor, which implies that the motor tries to restart with a pre-programmed interval whenever it senses that the rotor is standing still. When the blockage is removed the fan will start up

by itself without any further measures. At high motor temperatures the current will be cut from the motor. It can then

only be restarted by manually disconnecting the mains supply to the fan for couple of minutes.

TFC 225 and TFC 280 has Tacho output

The tacho output is an open collector output. Connect a pull up resistor to a DC voltage – make sure that the current

does not exceed 10mA.

206434 | A006

Page 19

5 Control panel

5.1 Operating the control panel

Multipurpose LC display and keyboard

Control panel |

15

100 Pa

∆p

P

▼

▲

▼+▲

Messages on the display

!

100 Pa

∆p

Selection of the menu group (e.g. BASE SETUP) to the right through the ▼-key, to the left through the ▲-key. You can

go to the menu items in the menu groups (e.g. mode) by using the P key. Use the arrow keys to move up and down

within the menu group. To make adjustments, press the P key after selecting the menu item. If the previously set value

starts to ash, it can be adjusted with the ▼ + ▲ keys and then saved with the P key. To exit the menu without making

any changes, use the “Esc” short-key, i.e., the originally set values remain.

For more detailed information see table 1.

Display after turning on the voltage supply. Switch over between

actual value display and “INFO” with the key shortcut for Escape

(Esc = ▼+▲)

Display show the actual and desired values

Display show menu text

Program key and open menu

Menu selection, reduce value

Menu selection, increase value

ESC-key combination, Escape = leave menu

Exceeding measuring range

Moon symbol = Adjustment for Setpoint 2 active

Info

INFO

P ↓↑ Esc P ↓↑ Esc P ↓↑ Esc

100 Pa

∆p

▲▼ ▲▼ ▲▼

100 Pa

Setpoint 1

▲▼ ▲▼ ▲▼

▼

▲

SETTINGS

100 Pa

Setpoint 1

100 Pa

Setpoint 2

▼

▲

BASE SETUP

4.01

Mode

1:metric

Units

206434 | A006

Page 20

| Control panel

16

Select operation mode

Marked area indicates factory setting.

Mode

4.00

Function

Pressure sensor output 0...10 V proportional to measuring range.

4.01 Factory preset

Pressure controller (PID): Output 0...10 V depending on adjusted setpoint and

measured actual value.

5.00

Air volume sensor: Output 0...10 V proportional to measuring range

(depending on setting for K-factor).

5.01

Air volume controller (PID): Output 0...10 V depending on adjusted setpoint

and measured actual value

Table 1 Parameter table

Parameter

Display/Factory

setting

Mode

4.00 4.01 5.00 5.01

INFO

∆p

qV

Setpoint 1

Range qV

0 Pa 0 Pa

- -

-

100 Pa

- -

- -

3

0 m

/h 0 m3/h Display actual

-

2371 m

3

/h 2371 m3/h Air volume

1185 m

Uout 0.0 V 9.9 V 0.0 V 9.9 V

UNIcon 1.00 1.00 1.00 1.00

∆p

- -

0 Pa 0 Pa

Function

Mode

Information

Different actual

value for

differential

pressure

value for airflow

3

/h Display active

Setpoint

measuring range

depending on

sensor

measuring range

and K-factor

Magnitude of the

output voltage

0...10 V

Software version

Display actual

value for volume

measurement

206434 | A006

Page 21

Control panel |

17

Setpoint 1

Setpont 2

SETTING 4.01 + 5.01

-

-

100 Pa

200 Pa

-

-

1185 m

1185 m

3

h

3

h

Setting

Setpoint 1

Setpoint 2

(Active if voltage

at terminals 1, 2)

Pband

Min. Uout

-

-

250 Pa

0.0 V

-

-

1185 m

0.0 V Min output

3

h Pband1,

voltage:

0.0...10.0 V

(priority over

“Max. Uout”)

Parameter

Max. Uout

Display/factory setting

-

10.0 V

-

10.0 V Max. output

Function

voltage:

10.0...0.0 V

1

Setting range 4.01: 0...100 % sensor measuring range, 5.01: 0...Max. Range qV (depending on K-factor and sensor measuring

range).

2

Small value = quick regulation, great value = slow regulation, high stability.

BASE SETUP Base setup

Mode

Units

4.00 4.01 5.00 5.01

metric: Pa, m

3

/h, K-factor

Mode

SI units or

Imperial units

(US)

Measuring range 1: 0...1000 Pa

2: 0...500 Pa

3: 0...300 Pa

PCA1000D2

Adjustable

measuring range

4: 0...200 Pa

K-factor

(K-factor US)

- -

75 75

Nozzle

coefficient (Kfactor) see

chapter 4.3

Autozero OFF => ON

Automatic “0”

offset

Offset

0 Pa

Sensor offset

(automatically

when

“Autozero”)

Setting range:

+/- 1000 Pa

1

1

2

,

2

206434 | A006

Page 22

Maintenance

|

18

6 Maintenance

6.1 Important

Danger

• Make sure that the mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• Fan impeller has come to a complete standstill.

• Should the supply cable be damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard

• The unit is heavy. Be careful during transport and installation. Risk of injury through pinching. Use

protective clothing.

• Do not lift the fans by the connecting cable, connection box, motor bracket, impeller or inlet cone.

6.2 Maintenance intervals

The fan should be cleaned when necessary, at least once a year to avoid imbalance and unnecessary damage to the

bearings. The fan bearings are maintenance free and should only be replaced if damaged. Do not use a high-pressure

cleaner (steam jet) when cleaning the fan. Ensure that the fan impeller's balance weights are not moved or the fan impeller distorted. Listen for abnormal operating noise.

6.3 Cleaning the fan

Warning

• Make sure that the mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• Fan impeller has come to a complete standstill.

• The unit is heavy. Make sure that the motor bracket attach to the lock to prevent the motor to fall down

during maintenance.

Danger

• Make sure that the motor does not fall down.

Caution

• Beware of sharp edges during maintenance, use protective gloves. Risk of injury through pinching.

206434 | A006

Page 23

Troubleshooting |

Loosen the M5 screws to open the lid (chapter 4.1.)

Unscrew the motor bracket's two screws. Lift the motor up by holding the motor bracket's handle,

keep fingers away from the back of the hinge. Make sure

that the motor bracket attach to the lock to prevent the

motor from falling down during maintenance.

After maintenance, release the lock, using the handle to

bring the motor down. Fasten the motor bracket with the

screws.

19

Note:

TFC 225 and TFC 280 has no handle, hold the

motor bracket to lift the motor.

7 Troubleshooting

The following applies in case the fan has stopped:

• Try to restart the fan by cutting the power a couple of minutes.

• Ensure that the impeller is not locked. Disconnect the power supply, remove any obstacles. Check that the fan starts

after reconnecting the current. Should the fan not start please contact your place of purchase.

206434 | A006

Page 24

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg, Sweden

Phone +46 222 440 00

Fax +46 222 440 99

www.systemair.com

Roof fans · Operation and Maintenance Instructions · 206434 · en_GB · 21-11-2017 · A006

Loading...

Loading...