Page 1

TCA 150D

part. no. 32186

Control module for temperature

Operating Instructions

Software version: D2033A from Version 1.00

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

english

Page 2

Content

1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Structure of the operating instructions . . . . . . . . . . . . . . . . . . . . 4

1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Exclusion of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Operational area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Disposal / recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Installation location for agriculture . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 Temperature influences during commissioning . . . . . . . . . . . . . . 6

5 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.2 EMC-compatible installation of control lines . . . . . . . . . . . . . . . . 7

5.3 Connection Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.4 Connection of sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.5 Output voltage 0 - 10 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.6 Input for switch over Setpoint 1 / Setpoint 2 . . . . . . . . . . . . . . . . 8

6 Device construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.1 Select operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.2 Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.3 Menues of operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.4 Characteristic curve temperature sensor 2.00 . . . . . . . . . . . . . . 12

7.5 Temperature controller

2.01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operating Instructions TCA 150D

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

2/17

Page 3

9 Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9.2 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

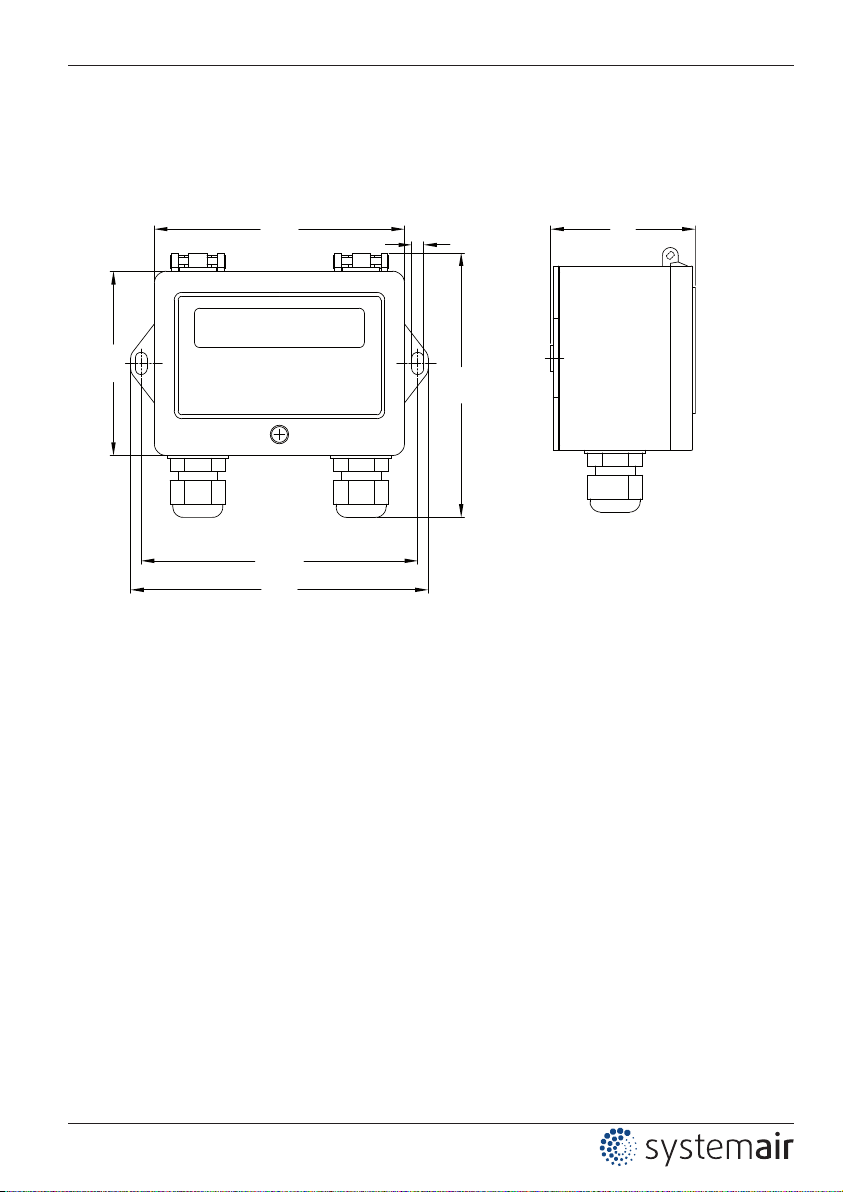

9.3 Dimensions [mm] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.4 Manufacturer reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating Instructions TCA 150D

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

3/17

Page 4

1 General notes

1.1 Structure of the operating instructions

Before installation and start-up, read this manual carefully to ensure correct use!

We emphasize that these operating instructions apply to specific units only, and are in

no way valid for the complete system!

Use these operating instructions to work safely with and on the device. They contain

safety instructions that must be complied with as well as information that is required for

failure-free operation of the device.

Keep these operating insturctions together with the device. It must be ensured that all

persons that are to work on the device can refer to the operating instructions at any time.

1.2 Target group

The operating instructions address persons entrusted with planning, installation, commissioning and maintenance and servicing and who have the corresponding qualifications and skills for their job.

1.3 Exclusion of liability

To allow for future developments, construction methods and technical data given are

subject to alteration. We do not accept any liability for possible errors or omissions in the

information contained in data, illustrations or drawings provided.

We accept no liability for damage caused by misuse, incorrect use, improper use or as a

consequence of unauthorized repairs or modifications.

1.4 Copyright

These operating instructions contain copyright protected information. The operating

instructions may be neither completely nor partially photocopied, reproduced, translated

or put on data medium without previous explicit consent. Infringements are liable for

damages. All rights reserved, including those that arise through patent issue or registration on a utility model.

2 Safety instructions

•

Mounting, electrical connection, and start-up operation may only be carried out by

an electrical specialist in accordance with electrotechnical regulations (e.g. DIN

EN 50110 or DIN EN 60204)!

•

Persons entrusted with the planning, installation, commissioning and maintenance

and servicing in connection with the device must have the corresponding qualifications and skills for these jobs. In addition, they must be knowledgeable about

the safety regulations, EU directives, rules for the prevention of accidents and the

corresponding national as well as regional and in-house regulations.

Operating Instructions TCA 150D General notes

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

4/17

Page 5

•

The equipment is to be used solely for the purposes specified and confirmed in

the order. Other uses which do not coincide with, or which exceed those specified

will be deemed unauthorised unless contractually agreed. Damages resulting

from such unauthorised uses will not be the liability of the manufacturer. The user

will assume sole liability.

•

It is strictly forbidden for work to be carried out on any components while they are

connected to live voltage.

•

The safe isolation from the supply must be checked using a two-pole voltage

detector.

•

The owner is obliged to ensure that the device are operated in perfect working

order only.

•

Inspect electrical equipment periodically: retighten loose connections – immediately replace damaged lines and cables.

•

Never clean electrical equipment with water or similar liquids.

•

A separate fault and performance monitoring-system with an alarm signal function

is necessary in order to prevent personal injuries and material damages during

malfunctions and in case the device fails. Substitute operation must be taken into

consideration!

3 Product overview

3.1 Operational area

Temperature control for e.g.: extraction systems, warm-air heaters, air curtain installations, liquid-cooling, chillers.

Controlled output (0 - 10 V) e.g. for activating a speed controller for fans.

Fans with integrated controller and input 0 - 10 V can be activated directly.

3.2 Function

The measured actual value at the sensor is compared with the adjusted target value.

Output voltage and thus fan speed is controlled automatically depending on the adjusted

parameters.

Alternatively the device can be operated as temperature sensor. Output 0 - 10 V in this

mode proportional to the adjusted measuring range (max. -50...150 °C).

3.3 Storage

•

The device must be stored in its original packaging in a dry and weather-proof

room.

•

Avoid exposure to extreme heat and cold.

•

Avoid over-long storage periods (we recommend a maximum of one year).

3.4 Disposal / recycling

Disposal must be carried out professionally and environmentally friendly in accordance

with the legal stipulations.

Operating Instructions TCA 150D Product overview

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

5/17

Page 6

4 Mounting

4.1 General notes

Attention!

The following points must be complied with during the mechanical installation to avoid

causing a defect in the device due to assembly errors or environmental influences:

•

Before installation remove the device from the packing and check for any possible

shipping damage!

•

Assemble the device on a clean and stable base. Do not distort during assembly!

Use the appropriate mounting devices for proper installation of the unit!

•

Do not mount equipment on vibrating base!

•

When mounted onto lightweight walls, there must be no impermissibly high

vibrations or shock loads. Any banging shut of doors that are integrated into these

lightweight walls, can result in extremely high shock loads. Therefore, we advise

you to decouple the devices from the wall.

•

Do not allow drilling chips, screws and other foreign bodies to reach the device

interior!

•

The device should be installed in a location where it will not be disturbed, but at

the same time can be easily accessed!

•

Any cable ducts openings not used must be sealed!

•

Care must be taken to avoid direct radiation from the sun!

•

The device is designed for vertical installation (cable inlet down). A horizontal or

reclined installation is only permissible after technical release of the manufacturer!

4.2 Installation location for agriculture

In order to avoid damage caused by ammoniac vapours, the controller shall not be

installed in the stable, but rather in an outhouse wherever possible.

4.3 Temperature influences during commissioning

Avoid condensation in the controller and functional faults attributable to condensation by

storing the controller at room temperature!

Operating Instructions TCA 150D Mounting

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

6/17

Page 7

5 Electrical installation

5.1 Safety precautions

Danger due to electric current

•

Work on electric components may only be carried out by trained electricians or by

persons instructed in electricity under the supervision of an electrician in accordance with electrical engineering regulations.

•

The programming of the equipment takes place with switched on supply voltage

by opened cover and voltage for change-over Setpoint 1/2. Use power supplies

which guarantee reliable electrical isolation of the operating voltage as per IEC/DIN EN 60204-1. Consider also the general requirements for PELV circuits in

accordance with IEC/DIN EN 60204-1.

•

Inspect electrical equipment periodically: retighten loose connections – immediately replace damaged lines and cables.

•

Never clean electrical equipment with water or similar liquids.

Information

The respective connections are represented in the enclosure of this manual (

Connection diagram)!

5.2 EMC-compatible installation of control lines

Pay attention to maintain sufficient distance from powerlines and motor wires to prevent

interferences. The control cable may not be longer than 30 m. Screened control cables

must be used when the cable length is longer than 20 m!

5.3 Connection Voltage supply

Connection Voltage supply at terminals: “+Ub” and “GND”. Here, it must be strictly

observed that the mains voltage lies within the allowable tolerance specifications (

Technical data and nameplate affixed to the side).

5.4 Connection of sensor

Connection of temperature sensor for measuring actual value (not in scope of delivery)

to terminals “TF”. It is possible to connect sensors of series “TF..” (KTY81-210) or

PT1000 temperature sensors. It must be paid attention to no polarity.

For a high interference immunity a capacitor must be connected directly to the sensor (1

nF parallel). With temperature sensors type TF.. (KTY81-210) a capacitor is integrated.

Attention!

Never apply line voltage to analog inputs!

Operating Instructions TCA 150D Electrical installation

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

7/17

Page 8

5.5 Output voltage 0 - 10 V

Connection to Terminals “A” - “GND” (I

max

Technical data).

It is not permissible to connect outputs of several devices to each other!

5.6 Input for switch over Setpoint 1 / Setpoint 2

Via voltage at terminals “1” and “2” (10... 24 V DC) a switchover between Setpoint 1 and

Setpoint 2 is possible (note polarity

connection diagram).

20.0 °C

Setpoint 1

None Voltage at terminals “1” and “2” = adjustment for Setpoint1 active.

15.0 °C C

Setpoint 2

Voltage at terminals “1” and “2” = adjustment for Setpoint 2 active.

The active Setpoint is indicated in the menu INFO, an active “Setpoint 2” is signalized by

the moon symbol.

6 Device construction

Screw off the hinged cover to proceed with electrical connection and programming.

Subsequently close carefully!

+Ub

GND A GND

P

05.05.2010

v_ctg_bedien.vsd

!

D

27.5 °C

Actual Value

TF

TF

1

2

D

LC-Display

Moon symbol = Adjustment for Setpoint 2

active

! = Exceeding measuring range (sensor in-

terruption / sensor short-circuit)

+Ub / GND Voltage supply

A / GND Output signal 0 - 10 V

TF / TF

Connection temperature sensor (KTY81210 or PT1000)

1 / 2

Voltage input for switch over Setpoint 1 /

Setpoint 2

Multipurpose LC display and internal keyboard

27.5 °C

Actual Value

Text line 1 with 16 figures for display of actual and desired values

Text line 2 with 16 figures for display of menu text

P ▼ ▲

P Program key and open menu

▼ Menu selection, reduce value

▲ Menu selection, increase value

▼ + ▲ ESC-key combination, Escape = leave menu

Operating Instructions TCA 150D Device construction

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

8/17

Page 9

7 Programming

7.1 Select operation mode

Information

Simple installation is possible through the selection of the preprogrammed mode of

operation.

This determines the basic function of the device, factory set

2.01 .

Mode Function

2.00

Temperature sensor: output 0...10 V proportional to measuring range

2.01

Temperature controller (P): output 0...10 V depending on adjusted Setpoint an measured

actual value (Factory setting)

7.2 Menu structure

27.5 °C

Actual Value

Display after turning on the voltage supply.

Switch over between actual value display and “INFO” with

the key shortcut for Escape (ESC = ▼ + ▲).

INFO

Example for Mode

2.01 (Factory setting)

INFO

▼

▲

SETTING

▼

▲

BASE SETUP

P↓ ↑ ESC P↓ ↑ ESC P↓ ↑ ESC

20.0 °C

Actual Value

20 °C

Setpoint 1

2.01

Mode

▲ ▼ ▲ ▼ ▲ ▼

20 °C

Setpoint 1

15 °C

Setpoint 2

KTY81-210

Sensortype

▲ ▼ ▲ ▼ ▲ ▼

0.0 V

Uout

5.0 K

Pband

0.0 K

Offset

▲ ▼ ▲ ▼ ▲ ▼

2058 Ω

Resistor

0.0 V

Min. Uout

OFF

MSCO

▲ ▼ ▲ ▼ ▲ ▼

0.08

UNIcon

10.0 V

Max. Uout

ON

Value>Set = n+

Selection of the menu group (e.g. BASE SETUP) to the right through the ▼-key, to the

left through the ▲-key.

Operating Instructions TCA 150D Programming

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

9/17

Page 10

You can go to the menu items in the menu groups (e.g. mode) by using the P key. Use

the arrow keys to move up and down within the menu group.

To make adjustments, press the P key after selecting the menu item. If the previously set

value starts to flash, it can be adjusted with the ▼ + ▲ keys and then saved with the P

key. To exit the menu without making any changes, use the “Esc” short-key, i.e., the

originally set values remain.

Reprogramming Mode

2.01 to 2.00 in “BASE SETUP”

1 2 3

4

5 6 7

2.01

Mode

P

«2.01»

Mode

▲

«2.00»

Mode

P

2.00

Mode

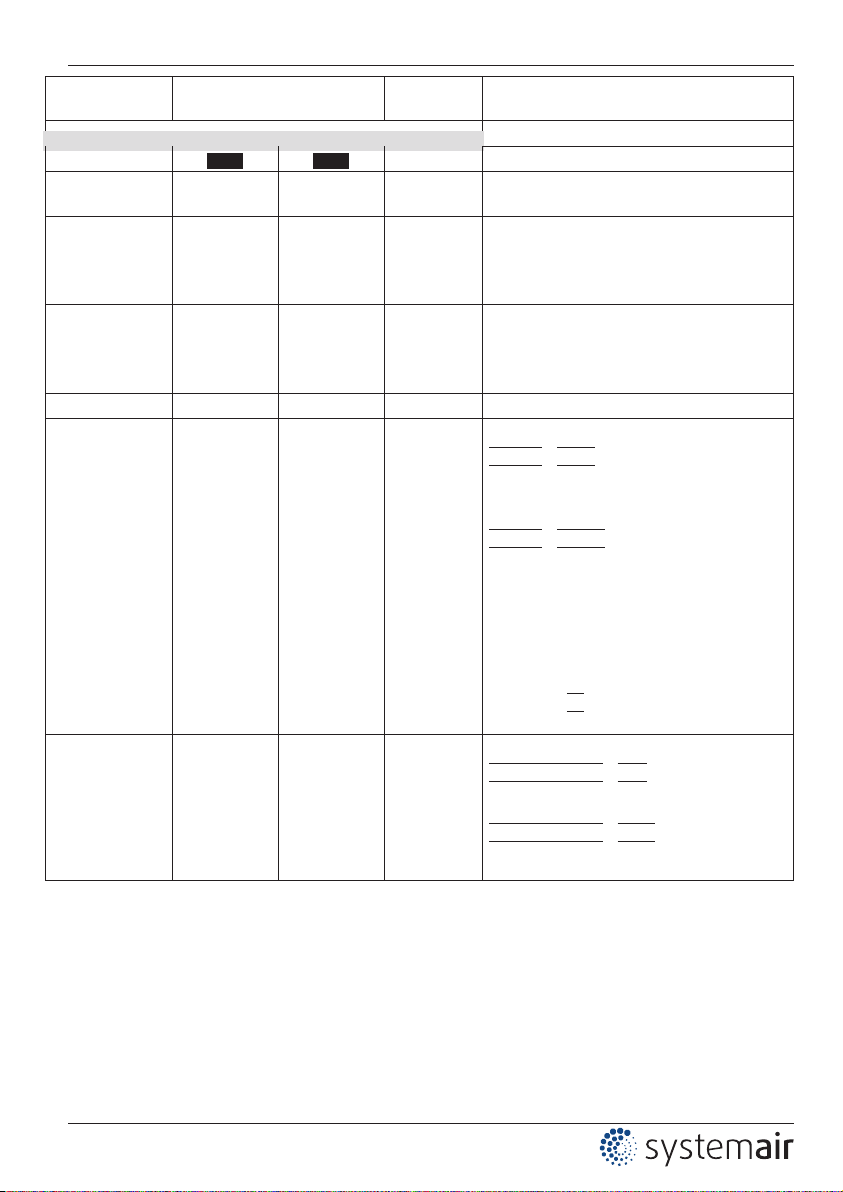

7.3 Menues of operating modes

Parameter Factory setting User Set-

ting

Function

Mode

2.00 2.01 Mode

INFO

Actual Value 27.1 °C 27.1 °C Display actual temperature

Setpoint 1 - 20.0 °C Display active Setpoint

Uout 5.0 V 5.0 V Magnitude of the output voltage 0...10 V

Resistor 2049 Ω 2049 Ω

current resistance value of the temperature

sensor

UNIcon 1.00 1.00 software version

SETTING

Setpoint 1 - 20.0 °C

Setpoint1

Setting range: -50.0...+150.0 °C

Factory setting: 20.0 °C

Setpoint 2 - 15.0 °C

Setpoint 2 active, if voltage at terminals 1, 2

Setting range: -50.0...+150.0 °C

Factory setting: 15.0 °C

Pband -

5.0 K

Pband

Setting range: 1.0...50.0 K

Factory setting: 5.0 K

Min. Uout 0.0 V 0.0 V Setting minimal output voltage

Max. Uout 10.0 V 10.0 V Setting maximal output voltage

Operating Instructions TCA 150D Programming

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

10/17

Page 11

Parameter Factory setting User Set-

ting

Function

BASE SETUP

Mode

2.00 2.01 Mode selection

Sensortype KTY81-210 KTY81-210

Setting type of sensor: KTY81-210 or

PT1000

Range min. Temperature

-50 °C -

Setting measuring range, minimum temperature value

Setting range: -50...150 °C

Factory setting: -50 °C

Range max.

Temperature

150 °C -

Setting measuring range, maximum temperature value

Setting range: 150...-50 °C

Factory setting: 150 °C

Offset 0.0 K 0.0 K Sensor offset

MSCO - OFF

Minimum speed cut off

|

MSCO|: |OFF| (factory setting)

If “Min. Uout” is adjusted (e.g. 2.0 V), than

no diconnection of the output takes place

(does not go under “Min. Uout)”.

|

MSCO|: |-2.0 K| (example)

It takes place a disconnection from Setting

“Min. Uout” to “0”, if the given difference is

reached related to the Setpoint.

At a plus value (+) before reaching the desired value

At a minus value (-) after falling below the

desired value.

Hysteresis

|H|

ON /OFFs: approx. 1 K

Setting range: -10.0 K...+10.0 K

Value>Set = n+ - ON

Controller function

|

Value>Set = n+|: |ON| Cooling = increasing modulation for increasing actual value

over Setpoint.

|

Value>Set = n+|: |OFF| Heating = increasing modulation for decreasing actual value

below Setpoint.

- Parameter for selected mode not available

Operating Instructions TCA 150D Programming

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

11/17

Page 12

7.4 Characteristic curve temperature sensor 2.00

Uout

[V]

10

Actual Value

[°C]

Range min. value -50 °C

Range max. value 150 °C

5

0

50 100

150-50

Range min. value 0 °C

Range max. value 100 °C

05.05.2010

v_kennnl_ctg_temp_sens.vsd

7.5 Temperature controller 2.01

Functional diagrams temperature control

Cooling:

|

Value>Set = n+|: |ON

|

20 °C

Setpoint

05.05.2010

v_temp_cool_ctg.vsd

24 °C

Uout

[V]

5

10

Actual Value

[°C]

Min. Uout = 3.5 V

Max. Uout = 8.5 V

Min. Uout = 0.0 V

Max. Uout = 10.0 V

4 K

Pband

Heating: |Value>Set = n+|: |OFF

|

20 °C

Setpoint

4 K

Pband

05.05.2010

v_temp_heat_ctg.vsd

16 °C

Max. Uout = 10.0 V

Min. Uout = 0.0 V

Max. Uout = 8.5 V

Min. Uout = 3.5 V

Uout

[V]

Actual Value

[°C]

10

5

Operating Instructions TCA 150D Programming

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

12/17

Page 13

Minimum speed cut off

10

Min. Uout = 3.5 V

Max. Uout = 10.0 V

20 °C

Setpoint

7 K

Pband

27 °C

06.05.2010

v_min_luft_abschalt_ctg.vsd

Uout

[V]

Actual Value

[°C]

5

H

Msco. = OFF

Msco. = -2.0 K

8 Start-up

8.1 Procedure

1. You must mount and connect the device in accordance with the operating instructions.

2. Double check that all connections are correct.

3. The supply voltage must match the information on the rating plate.

4. Set the operating Mode in the BASE SETUP (factory settings

2.01 ).

5. When saving the Operating Mode, the factory settings are stored.

Therefore the settings you have made, e.g. in “SETTING” are lost.

Attention, electrostatic sensitive devices!

Be sure to ground the board at a suitable point in order to prevent damage to the

electronic components being caused by electrostatic discharges. Such damage

could occur, e.g., if a metal water pipe or heating line are briefly touched.

Operating Instructions TCA 150D Start-up

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

13/17

Page 14

9 Enclosure

9.1 Technical data

Type TCA 150 D

Part-No. 32168 (320048-42)

Measuring range -50...150 °C (external sensor KTY81-210 or

PT1000)

Voltage supply U

B

10 V...24 V DC

Protected against reverse polarity

@ U

B

10 V DC @ UB 13...24 V DC

Max. load output 0 - 10 V

(short-circuit-proof)

0,3 mA 10 mA

Max. current consumption ca. 6 mA 14 mA

LC-Display double-row (max. 16 digits each)

Housing Cover ABS, bottom Polyamid PA 6.6

Fire protection classification UL 94 HB

Protection class IP54 according EN 60529

Weight approx. 200 g

Permissible ambient temperature -10 °C...50 °C

Permissible rel. humidity 85 % no condensation

Interference emission according EN 61000-6-3 (domestic household

applications)

Interference immunity according 61000-6-2 (industrial applications)

Operating Instructions TCA 150D Enclosure

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

14/17

Page 15

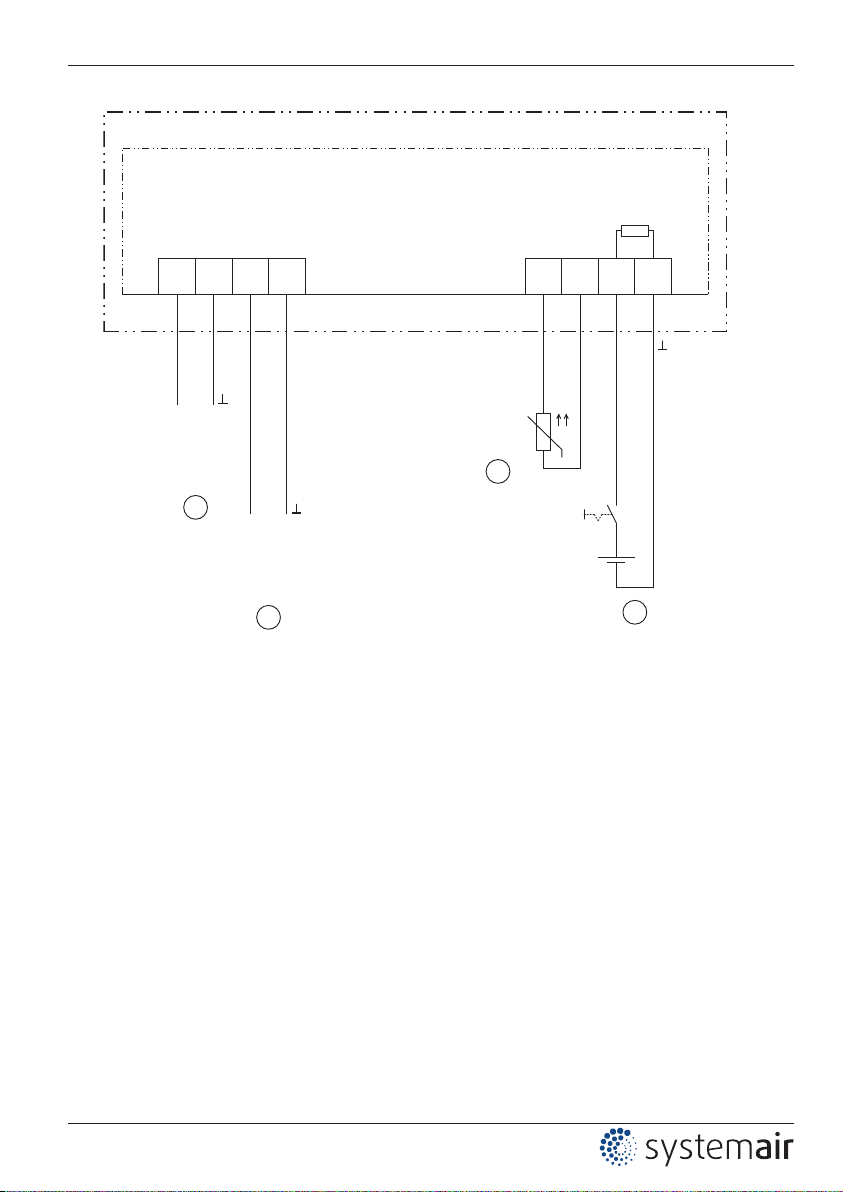

9.2 Connection diagram

GND A GND

1

2+Ub

MCTE03K1

05.10.2010

TCA 150D

Eingang

Input

10...24 V DC

(I

max

= 6 mA)

+

1

Ausgang

Output

0...10 V

(I

max

= 0.3 mA)

+

2

10...24 V DC

+

4

Ri = 4 kΩ

0 1

0 = Setpoint 1

1 = Setpoint 2

q

TF..

TF TF

KTY 81-210

PT 1000

3

+

-

1 Voltage supply 10...24 V DC

2 Output 0...10 V

3 Temperature sensor KTY 81-210 or PT 1000

4 Voltage input for switch over Setpoint 1 / Setpoint 2

Operating Instructions TCA 150D Enclosure

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

15/17

Page 16

9.3 Dimensions [mm]

GM00009A

12.05.2010

104

70

95

4,5

114

108

56

Operating Instructions TCA 150D Enclosure

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

16/17

Page 17

9.4 Manufacturer reference

Our products are manufactured in accordance with the relevant international regulations.

If you have any questions concerning the use of our products or plan special uses,

please contact:

Systemair

Industrievägen 3

73930 Skinnskatteberg

Telefon:+46 (0) 222 440 00

Telefax:+46 (0) 222 440 99

mailbox@systemair.se

www.systemair.se

Operating Instructions TCA 150D Enclosure

L-BAL-E119-GB 1318 Index 002 Part.-No. 00163357-GB

17/17

Loading...

Loading...