Page 1

Air Conditioning

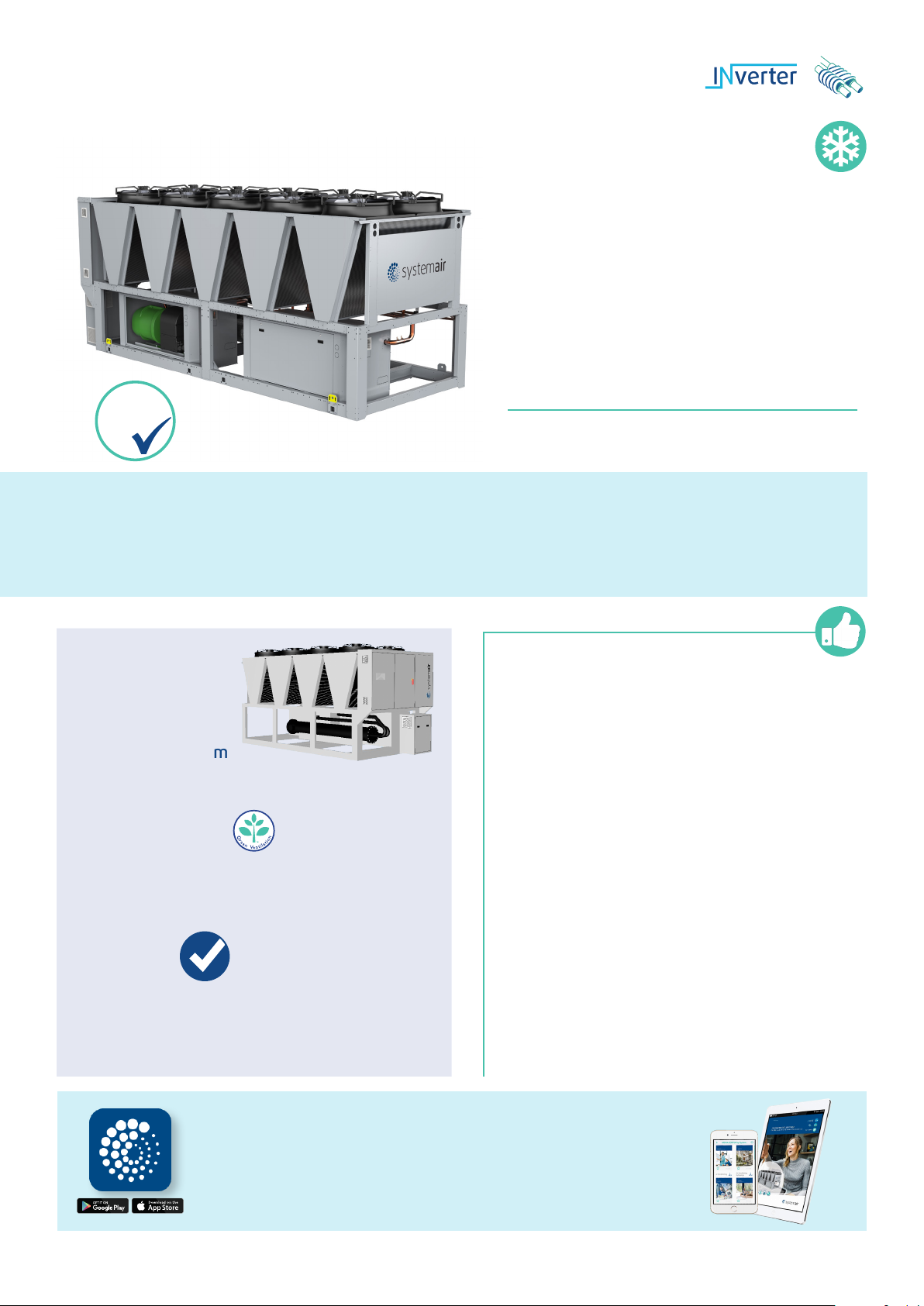

SYSCREW 380-1260 AIR EVO HSE

Air Cooled Water Chillers with Inverter Screw Compressors

366 to 1241 kW

Page 2

SYSCREW 380-1260 AIR EVO HSE

Air Cooled Water Chillers with Inverter Screw Compressors

• Available in 12 sizes

• Three fan versions: Standard, High Temperature & High Pressure Fans

• Two acoustic variants: Standard & Super Low

noise

• R513A and R134a refrigerant

• Cooling capacities from 366 to 1241 kW

• Low energy consumption

• Reduced sound emission

• Robust frame

ErP

2021

SYSCREW 380-1260 AIR EVO HSE is a step ahead in terms of environmental sustainability and guarantees a

rapid investment pay-back. Introducing all-round variable volume ow management thanks to inverter driven

compressor technology, EC fan motors and electronic expansion valve, this solution optimizes seasonal cooling

efciency (SEER) and guarantees extended envelope operation and noise reduction.

BIM

models

available at

www.magicloud.com

EC Driven

The preservation of the environment and energy savings are at

the heart of the Systemair philosophy.

100%

of the units are factory tested

Product advantages

• High seasonal efciency level exceeding Erp 2021

requirements

• High durability painting process for casing and

frame, offering C4 corrosion category in

accordance with ISO 12944

• Compressor metal box, providing basic acoustic

protection and resistance to atmospheric agents

• Side panel on coil ends, protecting from

corrosion and damages

• EC fan motors, improving part load efciency,

extending envelope operation and reducing noise

level in part load operation

• Proprietary software logic, optimizing unit

efciency in accordance with plant needs and

protecting unit operation with preventing actions

• Wide range of connectivity options with Serial /

Ethernet / USB ports standard included

1 systemair

Technical Documentation

Find our complete documentation on the application MEDIA CENTER by Systemair

Also available at: www.systemair.com

Page 3

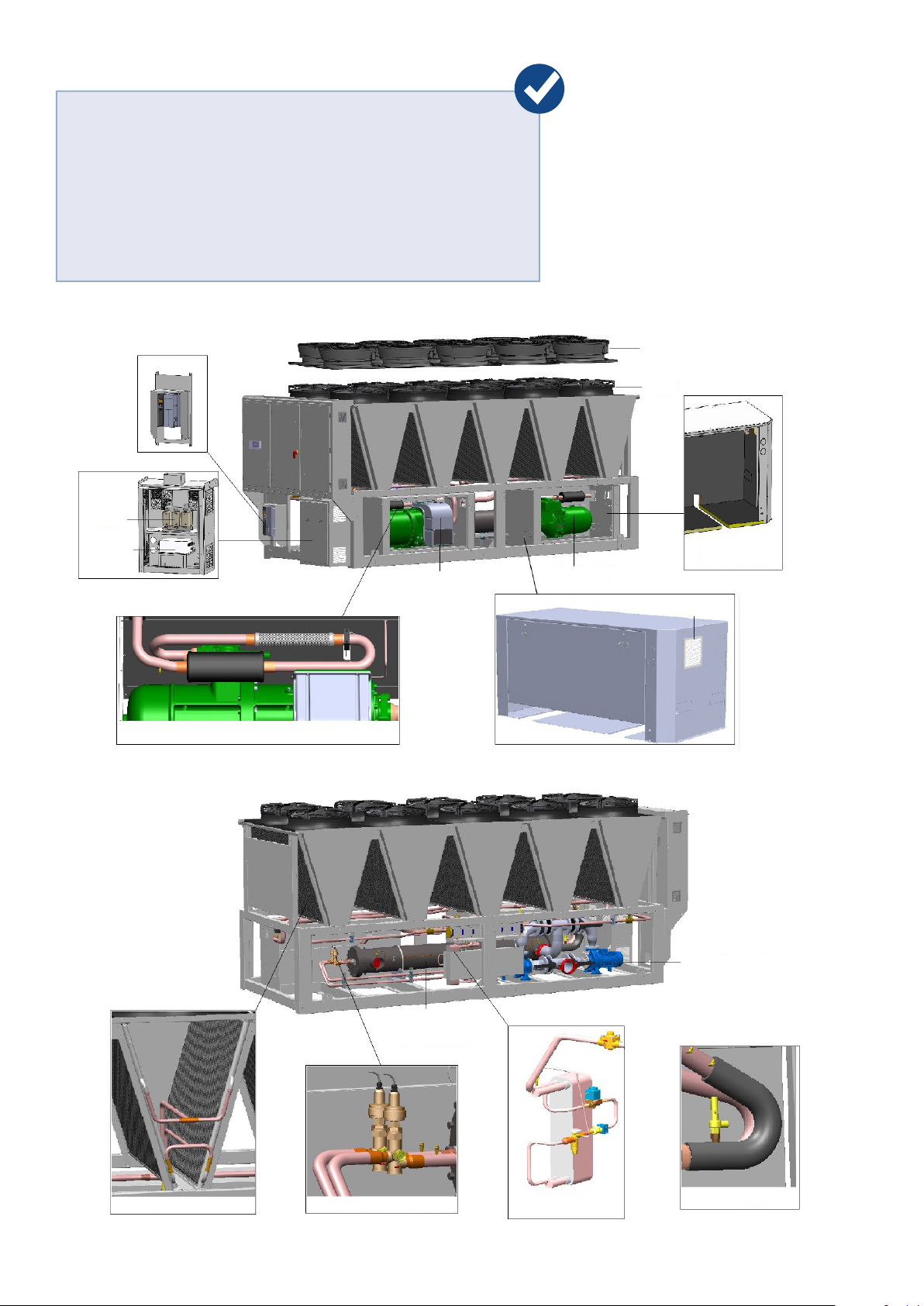

Main features

• Two refrigerant circuits with hybrid combination between

inverter driven and xed speed Screw compressors

• Pure countercurrent shell and tubes direct expansion heat

exchanger

• Axial type EC fan motors

• Micro-channels condensers

• Electronic expansion valve

• Hydronic / heat recovery options

Inverter

Choke

Line

inverter

lter

Pump inverter

Mufer and exible pipe (S version)

Inverter compressor

frequence inverter

driven

Special diffuser

(S version)

EC fans

Box insulation

(S version)

Step compressor

Fan HT version

Compressor box

MCX coils

Counter ow shell &

tube evaporator with

insulation

Electronic expansion valves

Economizer

(where included)

Water pumps

(option)

Pipes insulation

systemair 2

Page 4

Environmental sustainability

Seasonal efciency exceeding Erp 2021 requirements thanks to variable speed technology

ηs,c / Erp 2021 & SYSCREW AIR EVO HSE

200%

195%

190%

185%

180%

175%

η s,c

170%

165%

160%

155%

150%

AVG/190%

250 1000

300 350 400 450 500 550 600 650 700 750 800 850 900 950

COOLING CAPACITY [KW]

1050 1100 1150 1200

1250 1300 1350 1400 1450

R513A, a safe refrigerant reducing environmental impact

ERP 2021 REQUIREMENT

SYSCREW AIR EVO HSE CO

ηs,c

up to

200

SEER

up to

5,07

• A greener solution → Global warming potential 56% lower than R134a

• A safe solution → A1 classication (according ASHRAE ) meaning not toxic / not ammable

• A plug & play solution → Alternative slightly ammable / low GWP refrigerants generate capacity loss with

equivalent components

While limiting CO2 emission within the environment, the combination of variable speed technology with a greener

refrigerant represent a competitive advantage for the customer, meeting environmental protocols and raising the

value of the building.

3 systemair

Page 5

Technologic Innovation

All-round variable volume ow management

Improved part load efciency

Continuous capacity control

Flexible offer in plant integration

�

REFRIGERANT

Inverter driven compressor

technology and electronic

expansion valve

AIR

�

EC brushless fan motor

technology

WATER

�

Inverter driven pump

technology

Robustness

Screw compressor technology, proprietary software logic and heavy construction

Screw compressor operating with low pressure refrigerant

• Ideal combination for heady duty use

• Innovative design adapting internal geometry to the optimal performance

Proprietary software logic

• Optimized load management to boost seasonal efciency

• Active control algorithms to operate safe in borderline conditions

Heavy construction

• Strong design of metal proles to t challenging transportation and lifting

• Double refrigerant circuit an all the sizes

systemair 4

Page 6

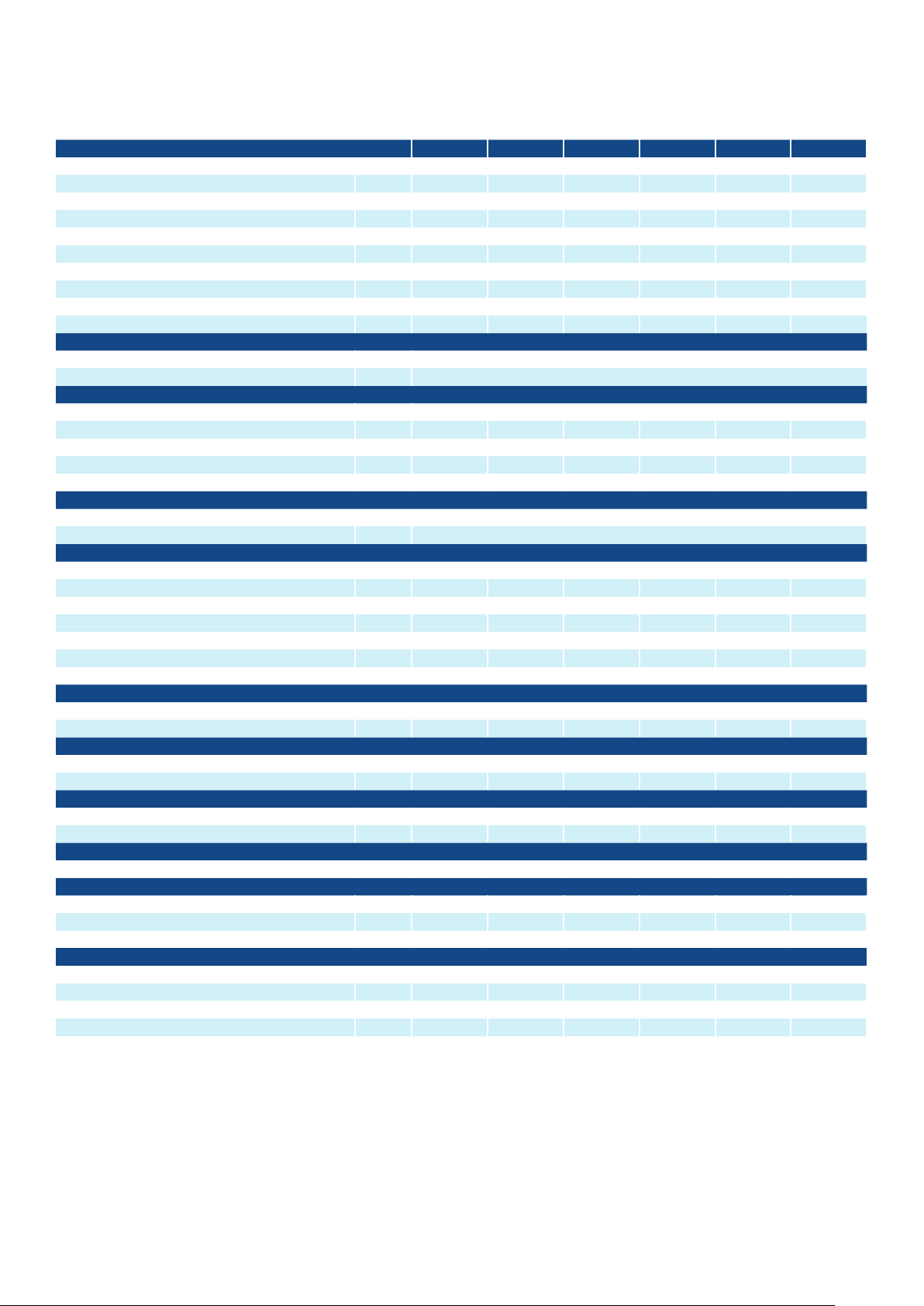

Technical Data

SYSCREW AIR EVO HSE R513A (STD/HT/HPF)

Model 380 440 510 590 660 730

Nominal cooling capacity

Input power

1

1

kW 365,7 443,0 500,2 565,8 643,5 704,3

kW 123,9 142,9 165,6 181,1 206,2 228,6

EER1/ Energy Efciency Class 2,95/B 3,10/A 3,02/B 3,12/A 3,12/A 3,08/B

EER

EER

EER

SEER

η

s,c

(74%) 3,95 4,01 3,99 4,02 3,93 3,95

CONDITION B

(47%) 4,66 4,81 4,81 5,03 4,76 4,66

CONDITION C

(21%) 6,14 6,31 6,33 6,65 6,62 6,23

CONDITION D

2

2

4,53 4,66 4,65 4,80 4,66 4,56

% 178 183 183 189 183 179

Number of refrigerant circuits 2

Total capacity steps

*

% 22%÷100% 18%÷100% 16%÷100% 14%÷100% 13%÷100% 15%÷100%

Compressor

Number/ Type 2 / 1 variable speed + 1 xed speed

N° of loading stages Continuous capacity control

Evaporator

Number/ Type 1/Shell&Tube

Water ow m3/h 63,0 76,4 86,2 97,5 111,0 121,4

Pressure drop kPa 17 24 19 24 31 30

Water volume l 149 142 246 246 228 276

Antifreeze Heater W 200 200 300 300 300 300

Air cooled condenser

Number of coils 8 10 10 12 14 14

Total coil face area per coil m

2

2,3

Fans

Number of fans 8 10 10 12 14 14

Nominal speed rpm 900 900 900 900 900 900

Total airow m3/h 183.960 230.040 230.040 276.120 321.840 321.840

Total input power kW 12,0 15,0 15,0 18,0 21,0 21,0

Total input power

Total input power

External static pressure

**

***

***

kW 20,5 25,6 25,6 30,7 35,8 35,8

kW 24,0 30,0 30,0 36,0 42,0 42,0

Pa 0 - 120 Pa

Water Connections (Evaporator)

Type Victaulic

Inlet Diameter/Outlet Diameter inch 6/6 6/6 8/8 8/8 8/8 8/8

Water Connections (Desuperheater)

Type Male GAS Threaded

Inlet Diameter/Outlet Diameter inch 2”/2” 2”/2” 2”/2” 2”/2” 2”/2” 2”/2”

Weight

Shipping kg 3.747 4.117 4.651 4.995 5.392 5.931

Operating kg 3.896 4.259 4.897 5.241 5.620 6.207

Additional weight

Desuperheater versions kg 76 86 100 100 114 114

Dimensions

Length mm 4.660 5.712 5.712 6.764 7.816 7.816

Width mm 2.192 2.192 2.192 2.192 2.192 2.192

Height mm 2.510 2.510 2.510 2.510 2.510 2.510

Acoustic Data

Sound power level

Sound power level

Sound pressure level at 10 m

Sound pressure level at 10 m

3

3**/***

4

4**/***

dB(A) 97 98 100 100 100 101

dB(A) 102 103 104 104 104 105

dB(A) 65 66 68 68 68 68

dB(A) 70 71 72 72 72 72

1

Data refers to 7°C leaving chilled water temperature and 35°C condenser air temperature, according EN14511 standard

2

According to commission regulation (EU) N° 2281/2016 for comfort chillers

3

Sound levels are at fully loaded conditions. Sound power level values refer to ISO standard 3744

4

Sound pressure levels refer to ISO Standard 3744, parallelepiped shape

*

This value can change for BC version or other special applications

**

High Temperature Units (HT), data with fans at max speed (1100 Rpm)

***

HPF Units, data with fans at max speed (1100 Rpm)

5 systemair

Page 7

Technical Data

SYSCREW AIR EVO HSE R513A (STD/HT/HPF)

Model 810 900 980 1060 1160 1260

Nominal cooling capacity

Input power

1

1

kW 778,1 896,9 983,5 1047,4 1154,0 1240,5

kW 253,4 290,2 322,3 332,0 370,4 408,1

EER1/ Energy Efciency Class 3,07/B 3,09/B 3,05/B 3,15/A 3,12/A 3,04/B

EER

EER

EER

SEER

η

s,c

(74%) 3,89 3,82 3,98 4,10 4,14 4,20

CONDITION B

(47%) 4,72 4,68 4,72 5,10 5,06 5,02

CONDITION C

(21%) 6,62 6,32 6,22 6,69 6,70 6,68

CONDITION D

2

2

4,62 4,56 4,60 4,87 4,86 4,85

% 182 179 181 192 191 191

Number of refrigerant circuits 2

Total capacity steps

*

% 13%÷100% 14%÷100% 13%÷100% 17%÷100% 15%÷100% 14%÷100%

Compressor

Number/ Type 2 / 1 variable speed + 1 xed speed

N° of loading stages Continuous capacity control

Evaporator

Number/ Type 1/Shell&Tube

Water ow m3/h 134,2 154,5 169,5 180,5 199,0 213,9

Pressure drop kPa 36 21 24 27 33 32

Water volume l 276 379 367 356 356 431

Antifreeze Heater W 300 300 300 300 300 300

Air cooled condenser

Number of coils 16 18 20 22 24 24

Total coil face area per coil m

2

2,3

Fans

Number of fans 16 18 20 22 24 24

Nominal speed rpm 900 900 900 900 900 900

Total airow m3/h 367.920 414.000 460.080 506.160 552.240 552.240

Total input power kW 24,0 27,0 30,0 33,0 36,0 36,0

Total input power

Total input power

External static pressure

**

***

***

kW 41,0 46,1 51,2 56,3 61,4 61,4

kW 48,0 54,0 60,0 66,0 72,0 72,0

Pa 0 - 120 Pa

Water Connections (Evaporator)

Type Victaulic

Inlet Diameter/Outlet Diameter inch 8/8 8/8 10/10 10/10 10/10 10/10

Water Connections (Desuperheater)

Type Male GAS Threaded

Inlet Diameter/Outlet Diameter inch 2”/2” 2”/2” 2”/2” 2”/2” 2”/2” 2”/2”

Weight

Shipping kg 6.255 6.947 7.397 8.124 8.508 8.643

Operating kg 6.531 7.326 7.764 8.491 8.875 9.074

Additional weight

Desuperheater versions kg 147 147 180 180 216 216

Dimensions

Length mm 8.868 9.920 10.972 12024 13.076 13.076

Width mm 2.192 2.192 2.192 2.192 2.192 2.192

Height mm 2.510 2.510 2.510 2.510 2.510 2.510

Acoustic Data

Sound power level

Sound power level

Sound pressure level at 10 m

Sound pressure level at 10 m

3

3**/***

4

4**/***

dB(A) 101 102 102 103 103 103

dB(A) 105 106 106 107 108 108

dB(A) 68 69 69 70 70 70

dB(A) 72 73 73 74 75 75

1

Data refers to 7°C leaving chilled water temperature and 35°C condenser air temperature, according EN14511 standard

2

According to commission regulation (EU) N° 2281/2016 for comfort chillers

3

Sound levels are at fully loaded conditions. Sound power level values refer to ISO standard 3744

4

Sound pressure levels refer to ISO Standard 3744, parallelepiped shape

*

This value can change for BC version or other special applications

**

High Temperature Units (HT), data with fans at max speed (1100 Rpm)

***

HPF Units, data with fans at max speed (1100 Rpm)

systemair 6

Page 8

Systemair AC SAS

Route de Verneuil

27570 Tillières-sur-Avre

France

Systemair srl

Via XXV Aprile, 29

20825 Barlassina (MB)

Italy

Tel. +33 02 32 60 61 00

Fax +33 02 32 32 55 13

Tel. +39 0362 680 1

Fax +39 0362 680 693

www.systemair.com

Systemair · LEAF SYSCREW 380-1260 AIR EVO HSE 1GB(12.19)

As part of our ongoing product improvement programme, our products are subject to change without prior notice. Non contractual photos.

Loading...

Loading...