Page 1

Fire Safety Products

S-SA2 & S-SA2L

Smoke Control Dampers - AAmulti

User Manual

Page 2

2/40 | User Manual S-SA2 & S-SA2L | 201905

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Conditions . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Methods . . . . . . . . . . . . . . . . . . . . 6

Opening Preparation for S-SA2 Installation . . . . . . . . 8

Standard Distances Between Damper Bodies. . . . . . . 10

Wet Installation . . . . . . . . . . . . . . . . . . . . 11

Installation into a Soft Crossing . . . . . . . . . . . . 14

Connecting S-SA2 to “multi” Ductwork Made of Boards . 16

S-SA2L Installation. . . . . . . . . . . . . . . . . . . . . 20

Installation on the Vertical Duct with a Ledge . . . . 22

Installation Directly on the Vertical Duct . . . . . . . 25

Installation on the Horizontal Duct with a Ledge . . . 27

Installation Directly on the Horizontal Duct . . . . . . 30

Electrical Connections . . . . . . . . . . . . . . . . . . . . . 32

Operation Manual . . . . . . . . . . . . . . . . . . . . . . . 36

Smoke Damper Functionality Check . . . . . . . . . . . . . 36

Smoke Damper Inspection . . . . . . . . . . . . . . . . . . 36

Warranty Conditions . . . . . . . . . . . . . . . . . . . . . . 37

Operating Journal . . . . . . . . . . . . . . . . . . . . . . . 38

Warranty Service . . . . . . . . . . . . . . . . . . . . . . . 40

Good to know

Current information on all re safety

products is available at

design.systemair.com

Page 3

Introduction

These are the original installation, inspection and operating instructions for the S-SA2 and S-SA2L smoke control dampers.

EVERY S-SA2 AND S-SA2L SMOKE DAMPER NEEDS TO BE INSTALLED IN ACCORDANCE WITH THIS DOCUMENT!

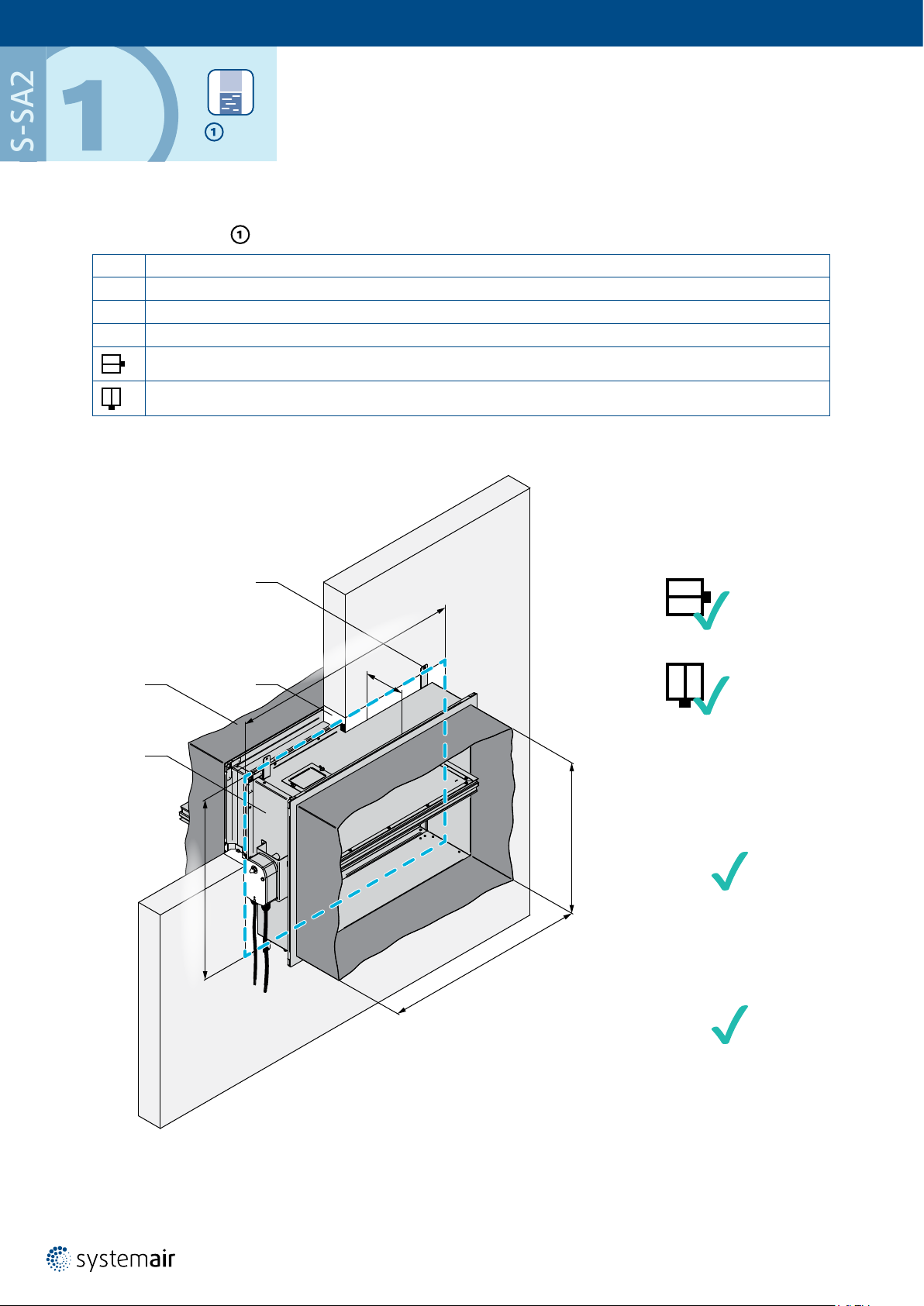

S-SA2

Rectangular smoke control damper

without mesh for wall and ceiling installations.

Dimension range (mm):

W × H = 200 × 200 up to 1600 × 1000

1396-CPR-0112

Wet Installation

Maximum performance up to EI120S

Using concrete lling

Installation into a Soft Crossing

(up to Size 1000 × 800 mm)

S-SA2L

Rectangular smoke control damper

with a mesh-tted extension suited

for vertical or horizontal duct installations.

Dimension range (mm):

W × H = 200 × 200 up to 1600 × 1000

1396-CPR-0147

Installation on the Vertical Duct with a Ledge

Installation Directly on the Vertical Duct

Installation on the Horizontal Duct with a Ledge

Installation Directly on the Horizontal Duct

Maximum performance up to EI90S

Using mineral wool lling

Page 4

4/40 | User Manual S-SA2 & S-SA2L | 201905

Warnings

Some damper parts may have sharp edges; therefore, to protect yourself, please use gloves during damper

installation and manipulation. In order to prevent electric shock, re or any other damage which could result from

incorrect damper usage and operation, it is important to:

1. ensure that installation is performed by a trained person.

2. follow the written and depicted instructions provided within this User Manual closely.

3. perform damper inspection in accordance with this User Manual.

4. check the damper’s functionality as per the

install the smoke damper. This procedure prevents the installation of a damper that has been damaged during

transportation or handling.

IMPORTANT: Do not install non-functioning dampers!

“Smoke Damper Functionality Check” chapter before you

Operating Conditions

S-SA2 and S-SA2L smoke dampers are intended:

• for installation in places which are protected against weather disruptions.

• for ducts, distributing air without any mechanical or chemical contamination.

• for a maximum air ow velocity 12 m/s.

• for a storage temperature range of -20°C to 50°C.

List of Accessories

• D1-S-SA2: Duct Extension with Mesh for S-SA2

• K1-S-SA2L: Kit for Sheet-Metal Duct Installation

Page 5

Installation

• The duct connected to the smoke damper must be supported or hung in such a way that the damper does not

carry its weight. The damper must not support any part of the surrounding construction or wall which could cause

damage and consequent damper failure.

• The damper driving mechanism can be placed on either side of the wall, however, it needs to be situated to ensure

easy access during inspection.

• According to the EN 1366-2 standard, the distance between the smoke damper bodies must be at least 200 mm.

• According to the EN 1366-2 standard, the distance between smoke damper and the adjacent wall/ceiling

and the smoke damper must be at least 75 mm.

• The S-SA2 smoke damper must be installed into a smoke and re partition structure in such a way that the damper

blade is located inside this structure in its closed position. To help you nd the suspension plane, a bendable hinge

is provided on the damper body. This condition does not apply for S-SA2L.

• The gap in the installation opening between the smoke damper and the wall/ceiling can be increased by up to 50%

of the gap area, or decreased to the smallest amount possible that still provides sufcient space for the installation

of the seal.

• The gap between the damper blade in the open position and the self-standing grill (when installed) must be at least

200 mm according to EN 1366-10. Otherwise, the damper must be tested together with the grill.

• The smoke damper must be earthed after being installed into or onto the duct.

• Lists of all permitted installation methods are provided on the following pages. Every method only applies to those

damper types that are listed in the corresponding paragraph’s heading.

Page 6

6/40 | User Manual S-SA2 & S-SA2L | 201905

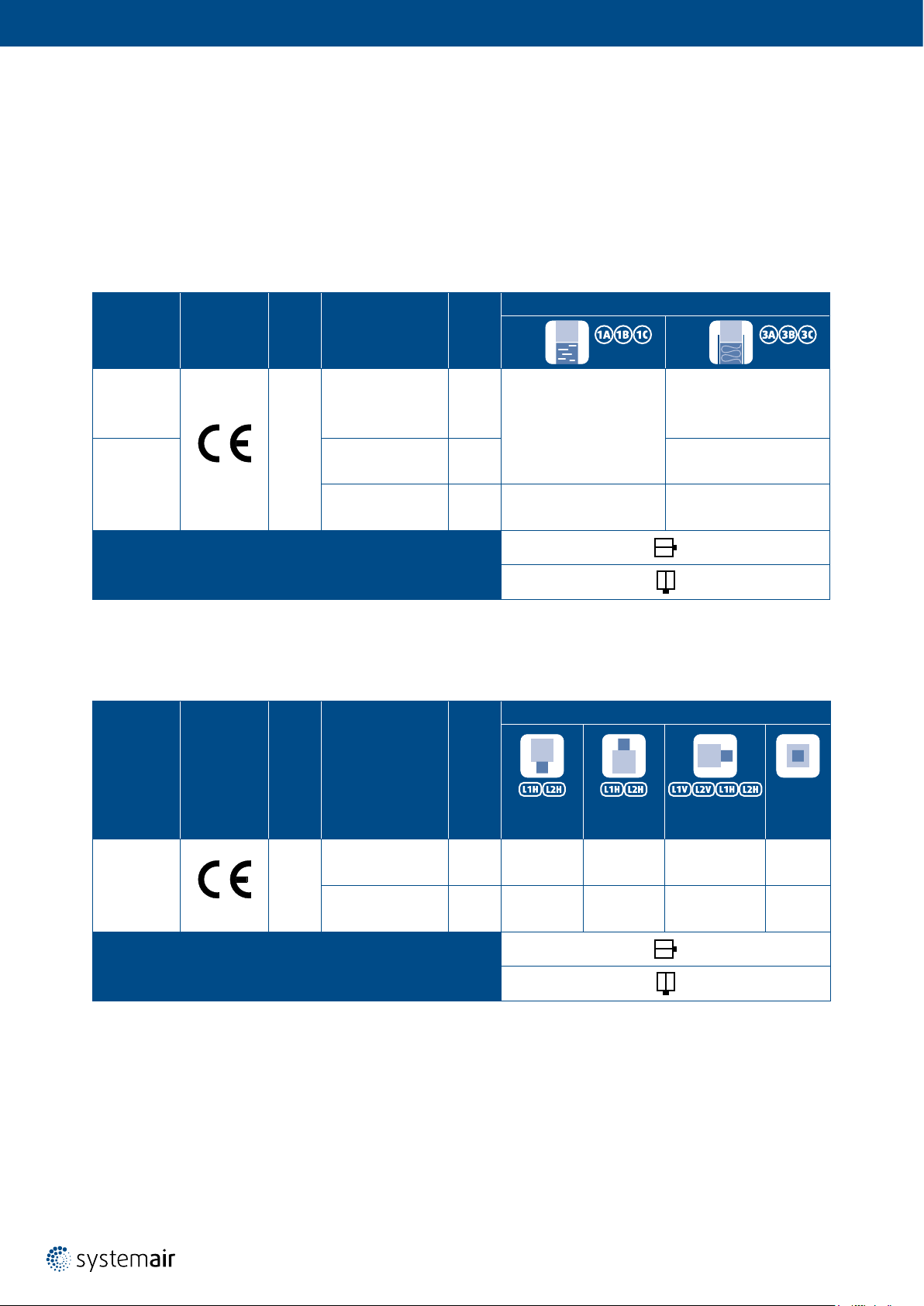

Installation Methods

All S-SA2 and S-SA2L smoke dampers are CE certied according to EN 12101-8:2011, tested according

to EN 1366–10 :2011+A1:2017, and classied according to EN 13501-4:2016.

The smoke damper, together with its installation, form an inseparable part of the re resistivity rating.

Tab. 1: S-SA2 re resistivity

Dimension

Range

Certicate

(mm)

200 × 200

up to

1000 × 800

200 × 200

1396 - CPR - 0112

up to

1600 × 1000

Tab. 2: S-SA2L re resistivity

Product

No.

Type

EI90 (v

S-SA2

EI120 (v

EI120 (h

Allowed Blade Axis Orientation

Classication

i ↔ o) S1500

ew

AAmulti

C

mod

i ↔ o) S1500

ew

AAmulti

C

mod

i ↔ o) S1500

ow

AAmulti

C

mod

Construction Type/Minimal Thickness (mm)

Supporting

Construction

ve

Wet Soft

Rigid/150

Rigid/150

Flexible/150

Flexible/150

ve -

ho Rigid/150 -

Applicable Duct Tested per Standard

Dimension

Range

(mm)

200 × 200

up to

1600 × 1000

Certicate

No.

Product

Type

S-SA2L

1396 - CPR - 0147

Allowed Blade Axis Orientation

Classication

EI120 (v

EI120 (h

i ↔ o) S1500

ed

AAmulti

C

mod

i ↔ o) S1500

od

AAmulti

C

mod

Supporting

ve

Construction

On the Duct/

Bottom Mounted

EN 1366-9,

EN 1366-8

On the Duct/

Top Mounted

EN 1366-9,

EN 1366-8

ho - -

On the Duct/

Side Mounted

EN 1366-9,

EN 1366-8

EN 1366-9,

EN 1366-8

In the Duct/

Horizontal

Axis

-

-

Page 7

Legend

ve Vertical supporting construction (wall, horizontal duct)

ho Horizontal supporting construction (oor/ceiling, vertical duct)

Wet Installation

Installation into a soft crossing

Damper placed on duct surface, bottom side of the duct

Damper placed on duct surface, top side of the duct

Damper placed on duct surface, left and right side of the duct

Damper placed within the duct canal, outside of supporting construction

Installation of S-SA2L on the vertical duct with a ledge

Installation of S-SA2L directly on the vertical duct

Installation of S-SA2L on the horizontal duct with a ledge

Installation of S-SA2L directly on the horizontal duct

Damper‘s horizontal blade axis orientation

- mechanism can be placed on either side

Damper‘s vertical blade axis orientation

- mechanism can be placed on top and bottom.

Page 8

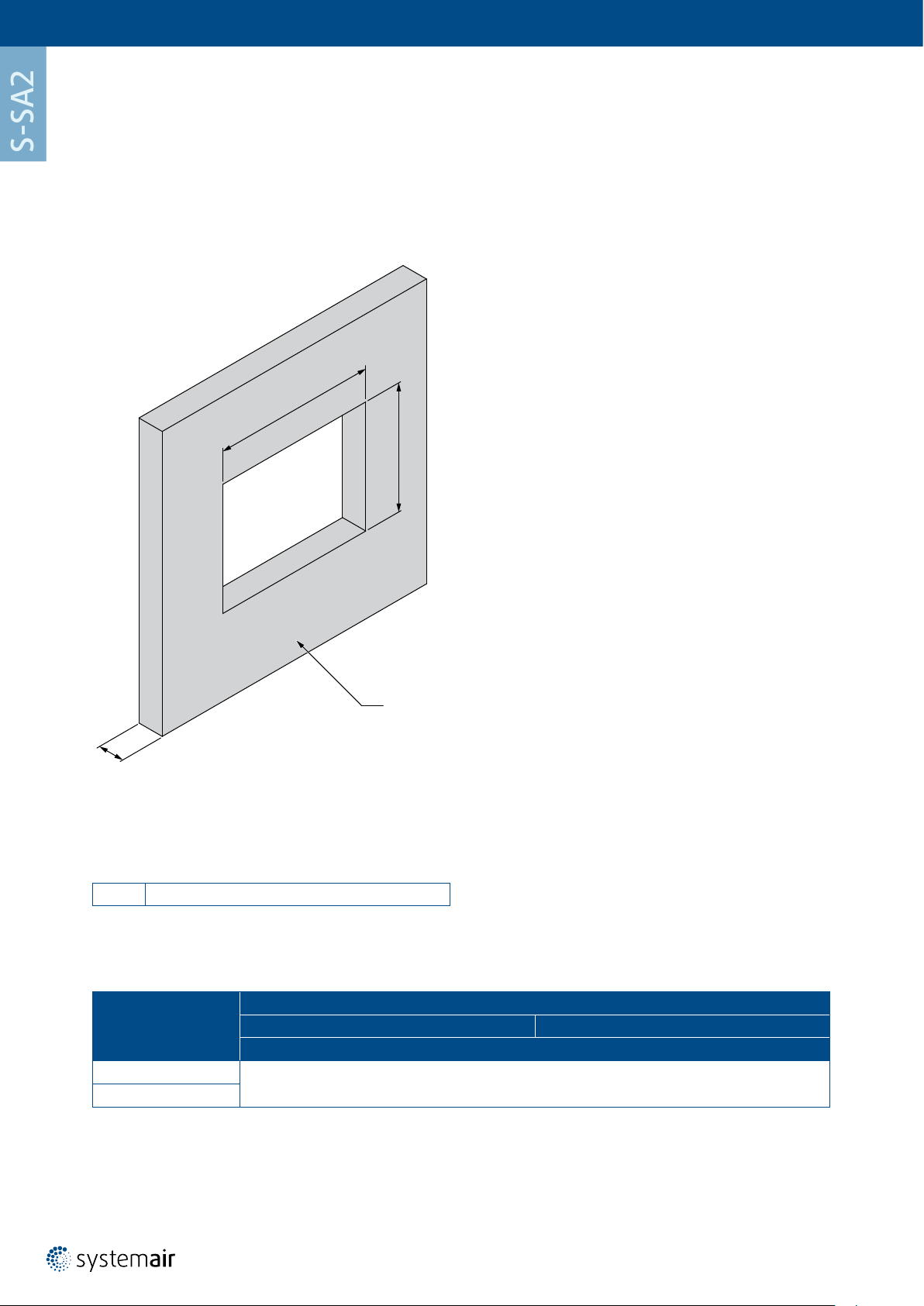

S-SA2

8/40 | User Manual S-SA2 & S-SA2L | 201905

Opening Preparation for S-SA2 Installation

The S-SA2 smoke damper can be installed in a wall or ceiling between zones classied as “multi-multi”,

“multi-single” and “single-multi”.

Opening Preparation for a Rigid Wall

1

W

H

1

s

Fig. 1: Rigid wall/ceiling with a rectangular opening

NOTE: Dimensions W

and H1 are dened in every installation

1

Legend

1 Concrete/Masonry/Cellular Concrete

Tab. 3: Thickness of tested wall

Fire Resistivity

90

120

1

Minimum s (mm)

Wall Ceiling

Concrete/Masonry/Cellular Concrete

150 ± 10

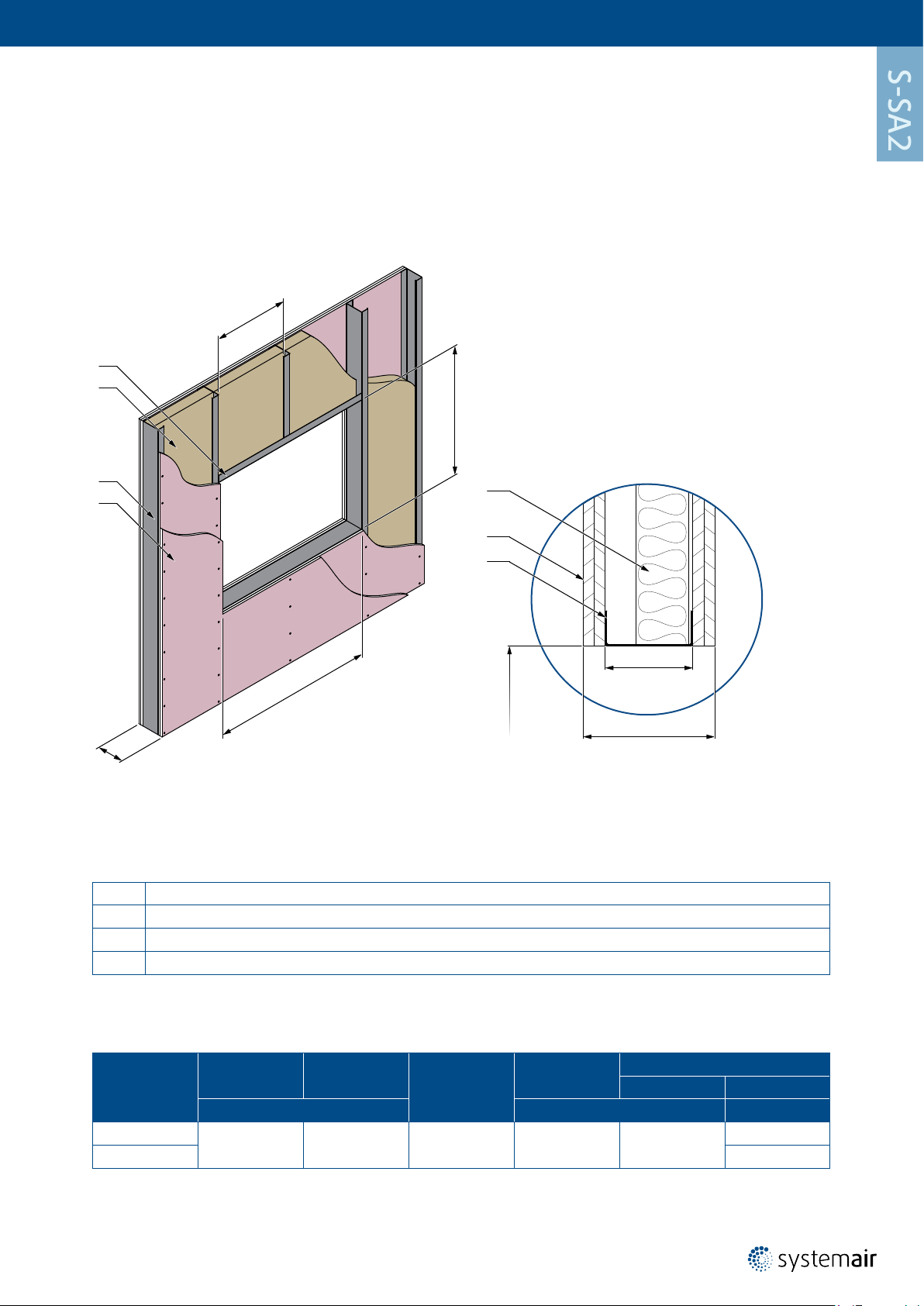

Page 9

S-SA2

Opening Preparation for a Flexible Wall

25

6

.

x

ma

3

4

H

1

2

1

4

1

3

W

1

× W

H

1

1

s

Fig. 2: Flexible (plasterboard) wall with a rectangular opening and vertical cross-section (right)

Legend

1 On each side - 2 layers of plasterboard reproof plate type F, EN 520 (thickness see Tab. 4)

2 Vertical CW-proles (proles with s

3 Horizontal CW-proles (prole with s

4 Mineral wool; thickness/cubic density see Tab. 4)

based on re resistivity, see Tab. 4)

CW

based on re resistivity, see Tab. 4)

CW

s

CW

s

Tab. 4: Thickness of tested wall

Fire Resistivity

90

120 85 ... 115

Minimum s Minimum s

(mm) (mm) (kg/m

150 100 C 12,5 60 ... 70

CW

Allowed Metal

Stud Group

Thickness

of Plasterboards

Thickness Cubic Density

Insulation

80 ... 115

3

)

Page 10

10/40 | User Manual S-SA2 & S-SA2L | 201905

S-SA2

10/40 | User Manual S-SA2 & S-SA2L | 201905

Standard Distances Between Damper Bodies

According to the EN 1366-2 standard, the minimum distance from the wall or ceiling to the damper body is 75 mm.

For multiple crossings through a re resistive wall, the minimum distance between two damper bodies is 200 mm.

This applies for distances between the damper body and a nearby foreign object crossing the re resistive wall.

Damper clearances vary from the type of mechanism and their rotation (please see Fig. 3 and see Tab. 5).

≥75

≥210

≥75A

Fig. 3: Installation distances between damper bodies

Tab. 5: Installation distances for minimal clearance to the actuator in Fig. 3

Clearance

200

250

300

350

400

450

500

200

250

300

350

400

450

H

(mm)

500 -

600 -

700 - -

800 - - -

900 - - - -

1000 - - - - -

B230, G230, B24, G24; A = 240 mm

B230-ST, G24-ST; A = 380 mm

-

-

-

-

A = 240 mm

-

-

≥210

≥200 A

W (mm)

600

700

800

900

1000

-

- - - - - - - -

-

- - - - - - -

-

A = 270 mm

≥210

1100

1200

1300

1400

1500

- - - - - -

- -

- - - -

-

- - -

-

A = 430 mm

- -

-

1600

-

-

Page 11

S-SA2

Wet Installation

Using Concrete Filling

Wet

1. The supporting construction opening must be prepared in a way depicted in the “Opening preparation” section

(as per Fig. 1 – Fig. 2). Opening surfaces must be even and cleaned. The exible wall opening must be reinforced

as per the standards for plasterboard walls. The opening dimensions are driven by the nominal dimensions of the

damper with added clearance. The opening will be made with dimensions W

and H1 ( Fig. 4 ).

1

2. Insert the closed damper into the middle of the opening so that the damper blade is in the wall. Use the bendable

hanger to secure the damper against the wall by using a suitable screw (3; recommended screw diameter 5,5;

e.g. DIN7981).

For damper widths greater than 600 mm, it is recommended to use a duct support inside the damper during

installation to avoid any damage to the damper housing from the weight of the lling.

3. Fill in the area between the wall and the damper with gypsum plaster, or mortar or concrete lling (2), while

paying attention to prevent the fouling of the damper’s functional parts, which could limit its correct functionality.

The best way is to cover the functional parts during installation. To prevent seepage of the lling material, the use

of boards is recommended.

First let the plaster, mortar or concrete lling harden and then perform the next steps.

4. After the lling hardens, remove the duct support from inside of the damper.

5. If needed, uncover and clean the damper after installation.

6. Check the damper’s functionality.

Product Type Dimension Range (mm) Classication Supporting Construction

S-SA2 200 × 200 up to 1600 × 1000

EI120 (v

EI120 (h

i ↔ o) S1500 C

ew

i ↔ o) S1500 C

ow

AAmulti Wall

mod

AAmulti Ceiling/Floor

mod

Page 12

S-SA2

12/40 | User Manual S-SA2 & S-SA2L | 201905

Wet

Legend for Figures of Wet Instalation

1 Smoke damper S-SA2 (actuator side)

2 Accessory LEAS/Connected ductwork tested according to EN 1366-9

3 Screw 5,5 DIN 7981 xing the Damper through bendable hangers

4 Gypsum plaster; Mortar; Concrete lling - minimal category M2.5, EN 998-2

Damper‘s horizontal blade axis orientation

Damper‘s vertical blade axis orientation

3

)

0

4

±

(

0

= W + 12

1

2

4

W

1

7

5

1

H

= H + 120 (±40)

1

H

W

Fig. 4: Wet installation of the S-SA2 smoke damper

Page 13

S-SA2

Wet

≥150

3

1

4

2

175

Fig. 5: (EI120S) Cross-section of a wet installation in rigid wall

≥150

× W

H

H1 × W

1

1

175

1

≥150

1

3

4

2

Fig. 7: (EI120S) Cross-section of a wet installation in rigid ceiling/oor

(actuator above)

42

3

1

4

2

175

× W

H

Fig. 6: (EI120S) Cross-section of a wet installation in exible wall

3

≥150

1

1

175

1

H1 × W

1

Fig. 8: (EI120S) Cross-section of a wet installation in rigid ceiling/oor

(actuator below)

Page 14

S-SA2

14/40 | User Manual S-SA2 & S-SA2L | 201905

Installation into a Soft Crossing (up to Size 1000 × 800 mm)

Soft

EI90 - Using Mineral Wool Filling

1. The supporting construction opening must be prepared in a way described in the “Opening Preparation for

S-SA2 Installation” section (as per

Fig. 1, Fig. 2). Opening surfaces must be even and cleaned.

The exible wall opening must be reinforced as per the standards for plasterboard walls.

2. The opening dimensions are driven by the nominal dimensions of the damper with added clearance.

The opening will be made with dimensions W

3. Prepare mineral wool installation segments (4; with cubic weight of 150 kg/m

and H1 ( Fig. 9).

1

3

, thickness as opening gap).

First apply a suitable re resistive coating (5; CFS-CT {HILTI}) onto the damper at the place of its future placement,

assemble and glue the lling of the future installation with the same re resistive coating.

After the re resistive coating has dried, the damper along with the lling are ready for installation.

4. Apply the same re resistive coating (5) onto the internal surface of the wall opening. Also apply the re resistive

coating to the external surface of the lling glued to the damper surface. Immediately after applying the re

resistive coating, place the damper into the wall opening. The damper blade must be located in the supporting

structure. Then x the damper using the bendable bracket.

5. After inserting the damper into the opening and xing it using the bendable hangers and suitable screws

(3; recommended screw diameter 5,5 - e.g. DIN7981), apply the same re resistive coating (5), at least 2 mm

thick and 100 mm wide, to the opening lling and wall edges evenly from both sides. Do not apply this layer

in the place where the mechanism is located, inspection openings and manufacturer labels.

6. Before the re resistive coating dries, remove the unwanted remnants of the coating.

7. If needed, uncover and clean the damper after installation.

8. Check the damper’s functionality.

Product Type Dimension Range (mm) Classication Supporting Construction

S-SA2

200 × 200

up to 1000 × 800

EI90 (v

i ↔ o) S1500 C

ew

AAmulti Wall

mod

Legend for Figures of Instalation into a Soft Crossing

1 Smoke damper S-SA2 (actuator side)

2 Accessory LEAS/Connected ductwork tested according to EN 1366-9

3 Screw 5,5 DIN 7981 xing the Damper through bendable hangers

3

4 Mineral wool lling 150 kg/m

5 Fire resistive coating CFS-CT (HILTI)

Damper‘s horizontal blade axis orientation

Damper‘s vertical blade axis orientation

Page 15

Soft

S-SA2

)

40

±

4

= W + 120 (

1

W

1

7

5

2

1

H

W

= H + 120 (±40)

1

H

Fig. 9: Wet installation of the S-SA2 smoke damper

≥150

175

≥150

3

175

3

100

5

1

2

1

× H

1

W

4

Fig. 10: (EI90S) Cross-section of a soft cross installation in a exible wall Fig. 11: (EI90S) Cross-section of a soft cross installation in a rigid wall

5

1

2

1

× H

1

W

4

100

Page 16

S-SA2

16/40 | User Manual S-SA2 & S-SA2L | 201905

Connecting S-SA2 to “multi” Ductwork Made of Boards

The S-SA2 smoke damper can be connected to “multi” ductwork made of calcium silicate boards tested according

to EN 1366-8. If mounted on a duct classied with lower re resistivity, the re resistivity of the S-SA2 smoke damper

will be decreased to the duct level.

This section does not depict duct hanger rules as those are dependent on the weight of the duct itself and must be

statically approved.

IMPORTANT: The interior of the S-SA2 smoke damper must remain accessible for maintenance.

Depending on the installation conguration, it may be necessary to create additional inspection panels

in the connecting ducts.

Connection Possibilities:

•

•

•

Multi-Single

Single-Multi

Multi-Multi

Legend for Figures of Connections to “Multi” Classied Ducts

1 Smoke damper S-SA2 (actuator side)

2 Accessory LEAS/Connected ductwork classied according EN 1366-9

3 Screw 5,5 DIN 7981 xing the damper through bendable hangers

When the damper is installed using

4

5 Cover plates thickness 10 mm placed on the opening circumference made of Promatect H (Promat)

6 Ductwork made of Promatect-L500 boards (Promat). Thickness of boards (P

7 Fire resistive coating Promat K84 (Promat)

Gypsum plaster; mortar; concrete lling minimal category

M2.5, EN 998-2

Damper‘s horizontal blade axis orientation

Damper‘s vertical blade axis orientation

wet method: When the damper is installed using soft crossing method:

Mineral wool lling 150 kg/m

CFS-CT (HILTI)

) depends on the desired re resistivity.

t

3

and re resistive coating

Page 17

S-SA2

Multi-Single

≥150

175

175

≥150

Fig. 12: Connection of the S-SA2 smoke damper to multi compartment

ductwork on the damper side without a mechanism

Fig. 14: (EI120S) Cross-section of a

(for board dimensions follow Fig. 13)

≥150

10

5

6

t

P

2

4

Fig. 15: (EI120S) Cross-section of a

Wet installation in a rigid ceiling/oor

175

3

1

1

× H

1

W

Wet installation in a exible wall

≥150

10

5

6

t

P

2

4

Fig. 13: (EI120S) Cross-section of a

175

3

1

1

× H

1

W

Wet installation in a rigid wall

≥150

10

5

6

120

t

P

2

4

Fig. 16: (EI90S) Cross-section of a

175

3

100

17

1

× H

1

W

Soft cros. installation in a exible wall

Page 18

S-SA2

18/40 | User Manual S-SA2 & S-SA2L | 201905

Single-Multi

≥150

175

175

≥150

0

3

≥

≥30

≥3

0

Fig. 17: Connection of the S-SA2 smoke damper to multi compartment

ductwork on the damper side with a mechanism

Fig. 19: (EI120S) Cross-section of a

(for board dimensions follow Fig. 18)

1

× H

1

2

W

4

Fig. 20: (EI120S) Cross-section of a

Wet installation in a rigid ceiling/oor

≥150

175

10

3

1

Wet installation in a exible wall

6

120

t

P

≥150

1

× H

1

2

W

4

Fig. 18: (EI120S) Cross-section of a

175

10

3

6

P

1

Wet installation in a rigid wall

≥150

175

10

3

6

100

120

t

× H

W

1

1

2

17

120

t

P

4

Fig. 21: (EI90S) Cross-section of a

Soft cros. installation in a exible wall

Page 19

S-SA2

Multi-Multi

≥150

175

175

≥150

0

3

≥

≥30

≥

3

0

Fig. 22: Connection of the S-SA2 smoke damper to multi compartment

ductwork on both sides of the damper

Fig. 24: (EI120S) Cross-section of a

(for board dimensions follow Fig. 23)

5

6

t

P

2

4

Fig. 25: (EI120S) Cross-section of a

Wet installation in a rigid ceiling/oor

≥150

175

10

3

1

Wet installation in a exible wall

× H

W

120

1

1

≥150

5

6

t

P

2

4

Fig. 23: (EI120S) Cross-section of a

175

10

3

1

1

× H

1

W

Wet installation in a rigid wall

≥150

175

10

5

3

6

t

120

P

17

2

120

1

× H

1

W

4

Fig. 26: (EI90S) Cross-section of a

Soft cros. installation in a exible wall

Page 20

20/40 | User Manual S-SA2 & S-SA2L | 201905

S-SA2L Installation

S-SA2L

The S-SA2L smoke damper can be installed on “single” (tested according to EN 1366-9) or “multi” (tested according

to EN 1366-9) ductwork. If mounted on a duct classied with lower re resistivity, the re resistivity of the S-SA2L

smoke damper will be decreased to the duct level.

This section does not depict duct hanger rules as those are dependent on the weight of the duct itself and must be

statically approved.

Smoke control dampers can be suspended from solid ceiling slabs using adequately sized threaded rods.

When using anchors in the ceiling, use a re-rated anchor (with suitable a re rating certicate).

IMPORTANT: The suspension of the damper must be loaded only with the weight of the damper.

The connection surfaces must be attened and clean before the re resistive coat is applied.

Suspension systems longer than 1,5 m require re-resistant insulation.

Fixing the S-SA2L Smoke Damper

Each S-SA2L smoke damper has a connection ange with openings in the corners (Fig. 27).

For damper widths greater than 750 mm, another xing point in the middle of the widest side is added and must be

connected as per instructions in

Fig. 28 - Fig. 33.

Legend for Figures of S-SA2L Smoke Damper Fixing

1 Smoke damper S-SA2L (actuator side)

2

3 Combi screw M8

4 Nut M8

5 Bendable hanger (delivered on the damper)

6 Screw 4,8×16 DIN 7982 (delivered on the damper)

7 Screw 4,8×25 DIN 7982

Ductwork made of calcium silicate boards.

Thickness and depth of boards depends on installation type.

2

3

4

1

Fig. 27: Detail of S-SA2L damper's corner xing

Page 21

S-SA2L

Fig. 28: Removing the xing screw

Fig. 29: Hanger bending and rotating ush with suspension plane

Fig. 30: Fixing the bendable hanger in place

6

7

1 2

5

A

Fig. 31: Fixing the damper to the duct boards

B C

Fig. 32: Middle xing to 40 mm thick board

625

1

625

1

Fig. 33: Middle xing to 30 mm thick board

Page 22

22/40 | User Manual S-SA2 & S-SA2L | 201905

L1V

S-SA2L

1. Prepare the duct connection or opening as per Fig. 36 - Fig. 41, clean and atten the connecting surface.

2. Apply a re resistive coat (3) on the connection surfaces as depicted in Fig. 36 - Fig. 41.

3. Connect the damper’s ange (on the blade side) to the duct as per the

4. From boards (4 and 7) create a collar overlapping the connection as depicted in Fig. 36 - Fig. 41.

5. Fix the overlapping collar to the damper with screws (5). Fix the collar to the duct by using screws

IMPORTANT: The opening dimensions must be created according to the details of each type and thickness

of the connected duct.

The re resistivity of the S-SA2L smoke damper must be decreased to the duct performance.

The maximum resistivity for L1V installation is EI120S with pressure level 3 (-1500 Pa … 500 Pa).

Installation on the Vertical Duct with a Ledge

section.

as per instructions of duct system manufacturer.

“Fixing the S-SA2L Smoke Damper”

Legend for Figures of Installation

1 Smoke damper S-SA2L (actuator side)

2 Connected ductwork classied according EN 1366-9

3 Fire resistive coating Promat K84 (Promat)

4 Collar made of Promatect H (Promat) - thickness per detail

5 Screw 5,5×40 DIN 7981 xing the collar with the damper

6 Screws or pins as per duct system manufacturer instructions

7 Cover plates thickness 10 mm placed on the opening circumference made of Promatect H (Promat)

8 Combi screw size 8

9 Accessory K1-S-SA2L-W×H (size of damper = W - nominal width; H - nominal height)

Damper‘s horizontal blade axis orientation

Damper‘s vertical blade axis orientation

Page 23

L1V

S-SA2L

Fig. 34: Installation of S-SA2L on a vertical duct with ledge

240 350

Gd = (≥H/2 + 100)

G

d

40

(240)

Fig. 35: Hanger position for L1V installation

Page 24

24/40 | User Manual S-SA2 & S-SA2L | 201905

24/40 | User Manual S-SA2 & S-SA2L | 201905

L1V

S-SA2L

2 3 58

50

6

7

2

3

20

50

50

6

10

4

20

1

25

(W+10)×(H+10)

Fig. 36: Cross-section of connection to 25 mm thick board duct

2 3 58

30

50

6

W × H

4

1

4

8

W × H

Fig. 39: Cross-section of connection to 50 mm thick board duct

3

2 5 9

20

t

50

W × H

1

20

1M6

Fig. 37: Cross-section of connection to 30 mm thick board duct

2 3 8

40

Fig. 38: Cross-section of connection to 40 mm thick board duct

50

6

W × H

5 7

4

1

Fig. 40: Cross-section of connection to a mineral wool insulated sheet

metal duct with the K1-S-SA2L accessory

5 94

10

10

Fig. 41: Cross-section of connection to a board insulated sheet metal duct

with the K1-S-SA2L accessory

2

50

W × H

20

20

3

1

8

Page 25

S-SA2L

Installation Directly on the Vertical Duct

1. Prepare the duct connection or opening as per Fig. 43, clean and atten the connecting surface.

2. Apply a re resistive coat (8) on the connection surfaces as depicted in the detail in Fig. 43.

3. Connect the damper’s ange (on the blade side) to the duct as per the

section.

4. From boards (4 and 5) create a collar overlapping the connection as depicted in Fig. 43.

5. Fix the overlapping collar to the damper with screws (5). Fix the collar to the duct by using screws

as per instructions of duct system manufacturer.

IMPORTANT: The opening dimensions must be created according to the details of each type

and thickness of the connected duct.

The re resistivity of the S-SA2L smoke damper must be decreased to the duct performance.

The maximum resistivity for L2V installation is EI120S with pressure level 3 (-1500 Pa … 500 Pa).

“Fixing the S-SA2L Smoke Damper”

L2V

Legend for Figures of Installation

1 Smoke damper S-SA2L (actuator side)

2 Connected ductwork classied according EN 1366-9

3 Collar made of Promatect H (Promat) - thickness per detail

4 Cover plates thickness 10 mm placed on the opening circumference made of Promatect H (Promat)

5 Cover plates thickness 10 mm placed on the opening circumference made of Promatect H (Promat)

6 Screw 5,5×40 DIN 7981 xing the collar with the damper

7 Combi screw size 8

8 Fire resistive coating Promat K84 (Promat)

Damper‘s horizontal blade axis orientation

Damper‘s vertical blade axis orientation

Page 26

26/40 | User Manual S-SA2 & S-SA2L | 201905

26/40 | User Manual S-SA2 & S-SA2L | 201905

L2V

S-SA2L

Fig. 42: Installation of S-SA2L, directly on the vertical duct

140 350

7

W × H

2

100 20

5

4

1

6

3

≥ (H/2) + 100

Fig. 43: Hanger position for L2V installation

10

>P

50

Page 27

S-SA2L

Installation on the Horizontal Duct with a Ledge

1. Prepare the duct connection or opening as per

2. Apply a re resistive coat (3) on the connection surfaces as depicted in Fig. 46 - Fig. 51.

3. Connect the damper’s ange (on the blade side) to the duct as per the

section.

4. From boards (4 and 7) create a collar overlapping the connection as depicted in Fig. 46 - Fig. 51.

5. Fix the overlapping collar to the damper with screws (5). Fix the collar to the duct by using screws

as per instructions of duct system manufacturer.

IMPORTANT: The opening dimensions must be created according to the details of each type

and thickness of the connected duct.

The re resistivity of the S-SA2L smoke damper must be decreased to the duct performance.

The maximum resistivity for L2V installation is EI120S with pressure level 3 (-1500 Pa … 500 Pa).

Fig. 46 - Fig. 51, clean and atten the connecting surface.

“Fixing the S-SA2L Smoke Damper”

L1H

Legend for Figures of Installation

1 Smoke damper S-SA2L (actuator side)

2 Connected ductwork classied according EN 1366-9

3 Fire resistive coating Promat K84 (Promat)

4 Collar made of Promatect H (Promat) - thickness per detail

5 Screw 5,5×40 DIN 7981 xing the collar with the damper

6 Screws or pins as per duct system manufacturer instructions

7 Cover plates thickness 10 mm placed on the opening circumference made of Promatect H (Promat)

8 Combi screw size 8

9 Accessory K1-S-SA2L-W×H (size of damper = W - nominal width; H - nominal height)

Damper‘s horizontal blade axis orientation

Damper‘s vertical blade axis orientation

Page 28

28/40 | User Manual S-SA2 & S-SA2L | 201905

L1H

S-SA2L

Fig. 44: Installation of S-SA2L on the vertical duct with a ledge

240 350

Gd = (≥H/2 + 100)

G

d

40

(240)

Fig. 45: Hanger position for L1H installation with detail

Page 29

2 3 58

50

6

S-SA2L

L1H

7

2

3

20

50

50

6

10

4

20

1

25

(W+10)×(H+10)

Fig. 46: Cross-section of connection to 25 mm thick board duct

2 3 58

30

50

6

W × H

4

1

4

8

W × H

Fig. 49: Cross-section of connection to 50 mm thick board duct

3

2 5 9

20

t

50

W × H

1

20

1M6

Fig. 47: Cross-section of connection to 30 mm thick board duct

2 3 8

40

Fig. 48: Cross-section of connection to 40 mm thick board duct

50

6

W × H

5 7

4

1

Fig. 50: Cross-section of connection to a mineral wool insulated sheet

metal duct with the K1-S-SA2L accessory

5 94

10

10

Fig. 51: Cross-section of connection to a board insulated sheet metal duct

with the K1-S-SA2L accessory

2

50

W × H

20

20

3

1

8

Page 30

30/40 | User Manual S-SA2 & S-SA2L | 201905

L2H

S-SA2L

1. Prepare the duct connection or opening as per Fig. 53, clean and atten the connecting surface.

2. Apply a re resistive coat (8) on the connection surfaces as depicted in Fig. 53

3. Connect the damper’s ange (on the blade side) to the duct as per the

section.

4. From boards (4 and 5) create a collar overlapping the connection as depicted in Fig. 53.

5. Fix the overlapping collar to the damper with screws (6). Fix the collar to the duct by using screws

as per instructions of duct system manufacturer.

IMPORTANT: The opening dimensions must be created according to the details of each type and thickness

of the connected duct.

The re resistivity of the S-SA2L smoke damper must be decreased to the duct performance.

The maximum resistivity for L2H installation is EI120S with pressure level 3 (-1500 Pa … 500 Pa).

Installation Directly on the Horizontal Duct

“Fixing the S-SA2L Smoke Damper”

Legend for Figures of L2H Installation

1 Smoke damper S-SA2L (actuator side)

2 Connected ductwork classied according EN 1366-9

3 Collar made of Promatect H (Promat) - thickness per detail

4 Cover plates thickness 10 mm placed on the opening circumference made of Promatect H (Promat)

5 Cover plates thickness 10 mm placed on the opening circumference made of Promatect H (Promat)

6 Screw 5,5×40 DIN 7981 xing the collar with the damper

7 Combi screw size 8

8 Fire resistive coating Promat K84 (Promat)

Damper‘s horizontal blade axis orientation

Damper‘s vertical blade axis orientation

Page 31

L2H

S-SA2L

Fig. 52: Installation of S-SA2L on the vertical duct with a ledge

140 350

≥ (H/2) + 100

7

W × H

2

100 20

5

4

1

6

3

Fig. 53: Hanger position for L1H installation with detail

10

>P

50

Page 32

32/40 | User Manual S-SA2 & S-SA2L | 201905

Electrical Connections

Legend for Tab. 6 and Tab. 7

IMPORTANT: Danger of electric shock!

Switch off the power supply before working

on any electrical equipment.

Only qualied electricians are allowed to work

on the electrical system.

Tab. 6: Electric parameters of Belimo mechanism types (B230; B24) for S-SA2 and S-SA2L based on the size

One actuator per damper

For Belimo „Bxxx-ST“ versions add 4 W and 10 VA

For Gruner „Gxxx-ST“ versions add 2 W and 2 VA

Two actuators per damper

For Belimo „Bxxx-ST“ versions add 8 W and 20 VA

Two actuators per damper

For Gruner „Gxxx-ST“ versions add 4 W and 4 VA

Consumption per: Type/

In Operation/In Rest/

Wire Sizing/Voltage

200

250

300

350

400

H (mm)

Tab. 7: Electric parameters of Gruner mechanism types (G230; G24) for S-SA2 and S-SA2L based on the size

Consumption per: Type/

In Operation/In Rest/

Wire Sizing/Voltage

H (mm)

450

500 -

600 -

700 - -

800 - - -

900 - - - -

1000 - - - - -

200

250

300

350

400

450

500 -

600 -

700 - -

800 - - -

900 - - - -

1000 - - - - -

200 250 300 350 400 450 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600

B24 = 7,5 W/0,5 W/9 VA (AC/DC 24 V)

B230 = 5 W/1 W/12 VA (AC 230 V)

-

-

-

-

200 250 300 350 400 450 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600

G24 = 7,5 W/1,5 W/9 VA (AC/DC 24 V)

G230 = 7 W/1,5 W/12 VA (AC/DC 230 V)

-

-

-

-

Belimo BLE

-

-

Gruner 342-15

-

-

W (mm)

W (mm)

-

- - - - - - - -

-

B24 = 12 W/0,5 W/18 VA (AC/DC 24 V)

B230 = 8 W/0,5 W/15 VA (AC 230 V)

-

- - - - - - - -

-

G24 = 8 W/1,5 W/10 VA (AC/DC 24 V)

G230 = 8,5 W/1,5 W/14 VA (AC/DC 230 V)

- - - - - - -

-

- - - - - -

- -

Belimo BE

B24 = 24 W / 1 W / 36 VA (AC/DC 24 V)

B230 = 16 W / 1 W / 30 VA (AC 230 V)

- - - - - - -

-

- - - - - -

- -

Gruner 362-40

G24 = 16 W/3 W/20 VA (AC/DC 24 V)

G230 = 17 W/3 W/28 VA (AC 230 V)

- - - -

-

2 × Belimo BE

- - - -

-

2 × Gruner 362-40

- - -

-

- -

-

- - -

-

- -

-

-

-

-

-

Page 33

AC 230 V

L1

N

AC/DC 24 V

⊥ ~

+

–

1

2 3

Fig. 54: B230 connection scheme; actuator BELIMO Fig. 55: B24 connection scheme; actuator BELIMO

NOTES:

• Caution! Main power supply voltage!

• Parallel connection of several actuators possible.

• Power consumption and switching thresholds must be observed!

• When power supply is connected to wires 1 and 3,

actuator drives to position OPEN.

• When power supply is connected to wires 1 and 2,

actuator drives to position CLOSED.

• Circuit switch between wires 2 and 3 is not part

of the damper delivery.

AC/DC 24 V (B24)

AC 230 V (B230)

⊥ ~

+

–

S1 S2 S3 S4 S5 S6

<3°

NOTES:

• Caution! Main power supply voltage!

• Supply via isolation transformer.

• Power consumption and switching thresholds

must be observed!

<87°

1

2 3

S1 S2 S3 S4 S5 S6

<3°

NOTES:

• When power supply is connected to wires 1 and 3,

actuator drives to position OPEN.

• When power supply is connected to wires 1 and 2,

actuator drives to position CLOSED.

• Circuit switch between wires 2 and 3 is not part

of the damper delivery.

• When power supply is connected to wires 1 and 3, actuator drives

to position OPEN.

• When power supply is connected to wires 1 and 2, actuator drives

to position CLOSED.

• Circuit switch between wires 2 and 3 is not part of the damper delivery.

<87°

1

2 3

Fig. 56: Parallel connection of two coupled BELIMO actuators on one smoke damper

S1 S2 S3 S4 S5 S6

<3°

<87°

1

2 3

1)

L (+) N (-)

AC 230 V

BKNE230-24

Legend

4 5 6 71 2 3

a

2)

b

NOTES:

• The actuator and the control module are factory wired.

• Connect the supply voltage to the connecting cable (approx. 1 m,

1

2

3

N

L

L

⊥

~

~

-

+

+

S1 S2 S3 S4 S5 S6

<3° <87°

B(L)E 24-12-ST

Fig. 57: BST connection scheme; communication unit wit BELIMO actuator

S1 S2 S3 S4 S5 S6

<3°

1) Supply voltage

2) 2-wire cable

with ferrules). 2-wire cable for signals (terminals 6 and 7).

<87°

Page 34

34/40 | User Manual S-SA2 & S-SA2L | 201905

AC 230 V

LL

N

1

2 3

Fig. 58: G230 connection scheme; actuator GRUNER Fig. 59: G24 connection scheme; actuator GRUNER

NOTES:

• Caution! Main power supply voltage!

• Parallel connection of several actuators possible.

• Power consumption and switching thresholds must be observed!

• Connect power supply to wire 1+2, actuator drives to position OPEN (1).

Is also wire 3 connected to the power supply, actuator drives to position CLOSED (0).

S1 S2 S3 S4 S5 S6

<5°

<85°

AC/DC 24 V

⊥ ~+~

+

–

1

2 3

S1 S2 S3 S4 S5 S6

<5°

<85°

AC 230 V (G230)

LLN

⊥ ~

~

AC/DC 24 V (G24)

+

+

–

1

2 3

Fig. 60: Parallel connection of two coupled GRUNER actuators on one Smoke damper

NOTES:

• Caution! Main power supply voltage!

• Supply via isolation transformer.

• Power consumption and switching thresholds must be observed!

• Connect power supply to wire 1+2, actuator drives to position OPEN (1).

Is also wire 3 connected to the power supply, actuator drives to position CLOSED (0).

S1 S2 S3 S4 S5 S6

<5°

<85°

1

2 3

S1 S2 S3 S4 S5 S6

<5°

<85°

Page 35

P PC C

A1

A1

D1

D1

120 Ω

B

So

Sc

Coms Power In Power Out

R1 C R1 CC B A

DI2 C

2 5 4

6 3 1

S1 S2 S3

DAMPER OUT

1

C 2

Power

CONF

Close

TX

Open

DAMPER OUT

1

Close

S4 S5 S6

RX

Open

ON

1 2 3 4 5 6 7 8

ON

S1 S2 S3

2 5 4

C 2

A2

DI1 C

6 3 1

S4 S5 S6

A2

D2

D2

1 2 3 4 5 6 7 8

Tes t

Button

Fig. 61: GST connection scheme; communication unit with 1 or 2 Gruner actuators

ADDRESS

Tes t

Button

Legend

Analog Application; Digital input for manual override

A1, A2

B Position of line termination 120 ohm if FS-UFC24-2 is last Modbus or BACnet device in line

C RS-485 Coms; Modbus RTU or BACnet MS/TP dip switch selectable

D1, D2 Damper 1, Damper 2; Fire or smoke extraction application

P Main power 24 V AC/DC; Daisy chain from and to other FS-UFC24-2

So Contact open

Sc Contact closed

Can be selected via bus as „Normally Open“ (= standard open) or „Normally Closed“ (= standard closed)

Default: „Normally Open“

Page 36

36/40 | User Manual S-SA2 & S-SA2L | 201905

Operation Manual

After installation, it is necessary to adjust the damper into its operating position “closed”.

In case, that the damper is used for extraction of pollutants, adjust the damper into its operating position “open”.

Connect the actuator to the relevant electric power supply (

The electromotor is activated and adjusts the damper into its operating position.

Fig. 54 - Fig. 61).

Smoke Damper Functionality Check

Switching the damper to the “open” position:

• The blade must come to the fully open position within 60 seconds and must remain locked.

• After reaching the end position of the blade, the appropriate signaling circuit must switch on

– wires S1 and S2 must be connected.

Switching damper to the “closed” position:

• The blade must come up to the fully closed position within 60 seconds and must remain locked.

• After reaching the end position of the blade, the appropriate signaling circuit must switch on

– wires S4 and S6 must be connected.

Smoke Damper Inspection

The actuator keeps the dampers on stand-by during their entire life cycle in accordance with this manual issued by

the manufacturer. It is not permitted to alter the dampers in any way or to perform any changes to their structure

without the manufacturer’s consent.

The operator performs regular checks of the dampers as per established regulations and standards at least once

every 3 months.

The check needs to be performed by an employee who has been specically trained for this purpose by the

manufacturer. The current damper condition evaluated during the inspection must be entered into the

Journal” along with the date of the inspection, the legible name, surname and signature of the employee who

performed the inspection. The Operating Journal includes a copy of the employee’s authorization. If any discrepancies

are discovered, these need to be entered in the Operating Journal along with a proposal for their removal.

The Operating Journal can be found

Immediately after the installation and activation of the damper, it must be checked under the identical conditions

as apply to the above mentioned six-month inspections. On its external side, the damper housing and the actuator

movement are checked. Due to the need to perform a visual check of the damper’s internal parts, it is possible

to dismount the body extension tted with the grille, which will enable access inside the damper or open

the inspection lid if the damper is equipped with one.

The damper’s internal casing, sealings, foaming substance, the damper blade condition and accuracy of its closure

during its leaning against the backstop in the closed position must all be checked. There must not be any strange

objects or a layer of impurities from the air distribution systems inside the damper.

on page 38 of this user manual.

“Operating

NEVER OPEN THE INSPECTION LID WHEN THERE IS AIR FLOWING IN THE DUCT CONNECTED TO THE SMOKE DAMPER.

Page 37

Recommended Course of Action and Inspection Log as per EN 12 101:

1. Identication of damper

2. Date of inspection

3. Check actuator wiring for damage

4. Check the wiring of the end switches for damage

5. Check the damper cleanliness and clean where necessary

6. Check the inspection lid, cover tightness

7. Check the blade and sealings, and correct and record where necessary (where applicable)

8. Check the damper functionality (open and close) as per the

and conrm operation by using the control system, tracking the physical behavior of the damper and signalization

of the end positions, and correct and record where necessary (where applicable).

9. The damper is part of the SHEVS. Therefore, the complete system must be checked as specied in its operational

and maintenance requirements.

10. Set into the operating position – as per the

11. Record the result into the

“Operating Journal” with the name and signature of the Inspection Technician.

“Operation Manual” chapter.

“Smoke Damper Functionality Check” chapter

Warranty Conditions

For warranty conditions, contact your local Systemair representative.

Functionality of every S-SA2 and S-SA2L smoke damper is tested in the production factory before being shipped.

Before you can install the re damper, its functionality must be tested as per the

Check” chapter.

DO NOT INSTALL NON-FUNCTIONING SMOKE DAMPERS.

Changes of smoke damper functionality caused by transport or installation are not reclaimable after installation

(deformation, damages, mechanical damage of the sealing material, foreign objects which may constrain the blade

movement, incorrect handling of the activation mechanism, etc.).

“Smoke Damper Functionality

Page 38

38/40 | User Manual S-SA2 & S-SA2L | 201905

Operating Journal

Activation of the Damper

Mark the Applied Installation Method with a Cross:

Wet Wet Wet Wet

Soft Soft Soft Soft

On a Duct On a Duct On a Duct On a Duct

Date Description of the Discovered Defects and the Date of the Following Inspection

after the Elimination of Deciencies.

Inspection Technician’s Signature

Page 39

Periodic Damper Inspections – at Least Once Every 3 Months

Date Description of the Discovered Defects and the Date of the Following Inspection

after the Elimination of Deciencies

Inspection Technician’s Signature

Page 40

40/40 | User Manual S-SA2 & S-SA2L | 201905

1396

Systemair Production a.s.

15

1396-CPR-0112

EN 12101-8:2011

Smoke control damper

Multi compartment

S-SA2

Nominal activation conditions/sensitivity Automatic activation

- passed

Closure/opening during test at correct time

and in allowable time

Response delay/closure time: Automatic activation

- passed

Operational reliability: 10 000 operations

- passed

Fire resistance:

- Integrity E EI120(v

- Insulation I

- Smoke leakage S

- Mechanical stability (under E)

- Maintenance of cross section (under E)

Durability:

- of response delay Pass

- of operational reliability Pass

i↔o)S1500C

ew ,how

mod

AAmulti

1396

Systemair Production a.s.

19

1396-CPR-0147

EN 12101-8:2011

Smoke control damper

Multi compartment

S-SA2L

Nominal activation conditions/sensitivity Automatic activation

- passed

Closure/opening during test at correct time

and in allowable time

Response delay/closure time: Automatic activation

- passed

Operational reliability: 10 000 operations

- passed

Fire resistance:

- Integrity E EI120(v

- Insulation I

- Smoke leakage S

- Mechanical stability (under E)

- Maintenance of cross section (under E)

Durability:

- of response delay Pass

- of operational reliability Pass

i↔o)S1500C

ed,hod

AAmulti

mod

Damper Identication

Building Object Position No.

Placement Identication

Room No. Signalization

Warranty Service

Date of Warranty

Repair Notication

Systemair Production a.s. · UserManual_S-SA2_S-SA2L_EN_202010

Date of Warranty

Repair Finalization

Description of Warranty Repair Performed Representative of the Manufacturer

(Stamp, Signature)

Loading...

Loading...