Page 1

Topvex SoftCooler SR09, SR11

Access control system

Installation instructions

Document in original language | 208765 · A005

GB

Page 2

208765 | A005

Page 3

1 Declaration of Conformity ......... . . . . . . . ................. 1

2 Warnings. . . . . . . . ................ . . . . . . . . . ................ . . . . . .2

3 Refrigerant Control/Reporting ............ . . . . . . . . ........2

4 Product information ......... . . . . . . . . ................ . . . . . . . .2

4.1 General.......... . . . . . . . ................. . . . . . . . .......2

4.2 Technical data ........ . . . . . . . . . ................ . . . . . . 3

4.3 Components .......... . . . . . . . . . ................ . . . . . . 4

4.4 Electrical cabinet . . . ................ . . . . . . . . .........5

5 Transport and storage . . ................ . . . . . . . . . ...........6

6 Installation..... . . . . . . . . ................. . . . . . . . ................6

6.1 Unpacking ... . . . . . . . . ................. . . . . . . . . ........6

6.2 Where/how to install ... . . . . . . . . ................. . . 6

6.3 Installing the unit............. . . . . . . . . ...............7

6.4 Dividing the Topvex SR air handling

unit .. . . . . . . . . ................ . . . . . . . . ................ . . . 9

6.5 Condensation and Heat Insulation ........ . . . . 11

6.6 Condensation drain . . . . ................ . . . . . . . . . .. 11

6.7 Electrical connection .... . . . . . . . . . ................ 12

7 Function Description . . . . ................ . . . . . . . . . ......... 14

7.1 General.......... . . . . . . . ................. . . . . . . . ..... 14

7.2 Power control....... . . . . . . . . ................ . . . . . . . 14

7.3 Power limitation. . . . . ................. . . . . . . . ...... 14

8 Commissioning protocol..... . . . . . . . . . ................ . . . . 15

8.1 General.......... . . . . . . . ................. . . . . . . . ..... 15

8.2 Installation protocol ..... . . . . . . . . . ................ 15

8.3 Preparing control unit.......... . . . . . . . . .......... 15

8.4 Before compressor start ................. . . . . . . . 16

8.5 Control cooling operation ......... . . . . . . . . ...... 16

Contents

208765 | A005

Page 4

Page 5

1 Declaration of Conformity

Declaration of Conformity |

1

Manufacturer

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg SWEDEN

Office: +46 222 440 00

www.systemair.com

hereby confirms that the following products:

Cooling unit

Topvex SoftCooler SR09

Topvex SoftCooler SR11

(The declaration applies only to product in the condition it

was delivered in and installed in the facility in accordance

with the included installation instructions. The insurance

does not cover components that are added or actions

carried out subsequently on the product).

Comply with all applicable requirements in the following

directives and regulations

Machinery Directive 2006/42/EC

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

Pressure Equipment Directive (PED) 2014/68/EU

Ecodesign Directive 2009/125/EC

327/2011 Requirements for fans

1253/2014 Requirements for ventilation units

The following harmonized standards are applied in applicable parts:

EN ISO 12100

EN 50106

Safety of household and similar electrical appliances –

Particular rules for routine tests referring to appliances

under the scope of EN 60 335-1.

EN 13053

Ventilation for buildings – Air handling units – Rating and

performance for units, components and sections.

EN 60529

Degrees of protection provided by enclosures (IP Code).

EN 62233

Measurement methods for electromagnetic fields of

household appliances and similar apparatus with regard

to human exposure.

EN 61000-6-2

Electromagnetic compatibility (EMC) – Part 6-2: Generic

standards – Immunity for industrial environments.

EN 61000-6-3

Electromagnetic compatibility (EMC) – Part 6-3: Generic

standards – Emission standards for residential, commercial and light-industrial environments.

EN 378-2:2016

Refrigerating systems and heat pumps – Safety and environmental requirements – Part 2: Design, construction,

testing, marking and documentation.

The complete technical documentation is available.

Skinnskatteberg, 27-01-2020

Safety of machinery - General principles for design - Risk

assessment and risk reduction.

EN 13857

Safety of machinery – Safety distances to prevent hazard

zones being reached by upper or lower limbs.

EN 60204-1

Safety of machinery – Electrical equipment of machines –

Part 1: General requirements.

EN 60335-1

Household and similar electrical appliances – Safety Part

1: General requirements.

EN 60335-2-40

Safety of household and similar electrical appliances Part 2-40: Particular requirements for electrical heat

pumps, air-conditioners and dehumidifiers.

Sofia Rask

Managing Director

208765 | A005

Page 6

Warnings

|

2

2 Warnings

The following admonitions will be presented in the different sections of the document:

Danger

• Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or

serious injury.

Warning

• Indicates a potentially hazardous situation that may result in minor or moderate injuries.

Caution

• Indicates a risk of damaging the product or prevent optimal operation.

Important

• This appliance can be used by children aged from 8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and understand the hazards involved.

• Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children

without supervision.

3 Refrigerant Control/Reporting

Topvex SoftCooler SR comes pre-filled with refrigerants and belongs to the group "Piece units containing more than

3kg refrigerants per circuit". Before commissioning shall always a control report in respect of the installation be established by a cooling certified person. Leakage control with record keeping shall be done once per year. The installation of

the Topvex SoftCooler SR is only duty to report if the property/enterprise where the installation occurs, all together

after installation, has a total amount of refrigerants of 10 kg or more ("small Piece units" with refrigerants less than 3

kg, e.g. normal refrigerators/freezers does not includes). Reporting shall in occurring cases be done to major inspection

authority (normally the municipal environmental office).

Different regulations can be valid in different countries. Check with your local government.

4 Product information

4.1 General

This installation manual concerns Topvex SoftCooler SR manufactured by Systemair AB. Topvex SoftCooler SR include

the following model options:

• Model: SR09, SR11.

• Right or left models: R (Right) L (Left). The side of the supply air outlet when viewed from the access side.

This manual consists of basic information and recommendations concerning the design, installation, start-up and operation, to ensure a proper fail-free operation of the unit.

The key to proper and safe operating of the unit is to read this manual thoroughly, use the unit according to given

guidelines and follow all safety requirements.

This instruction is a complement to “Topvex SR 09,11, TR 09-15 Installation instruction” (separate document) and

should also be read prior to installation.

208765 | A005

Page 7

4.2 Technical data

890 890 890

29

29

G

D C

E

A

C

D

A

F B

225

100

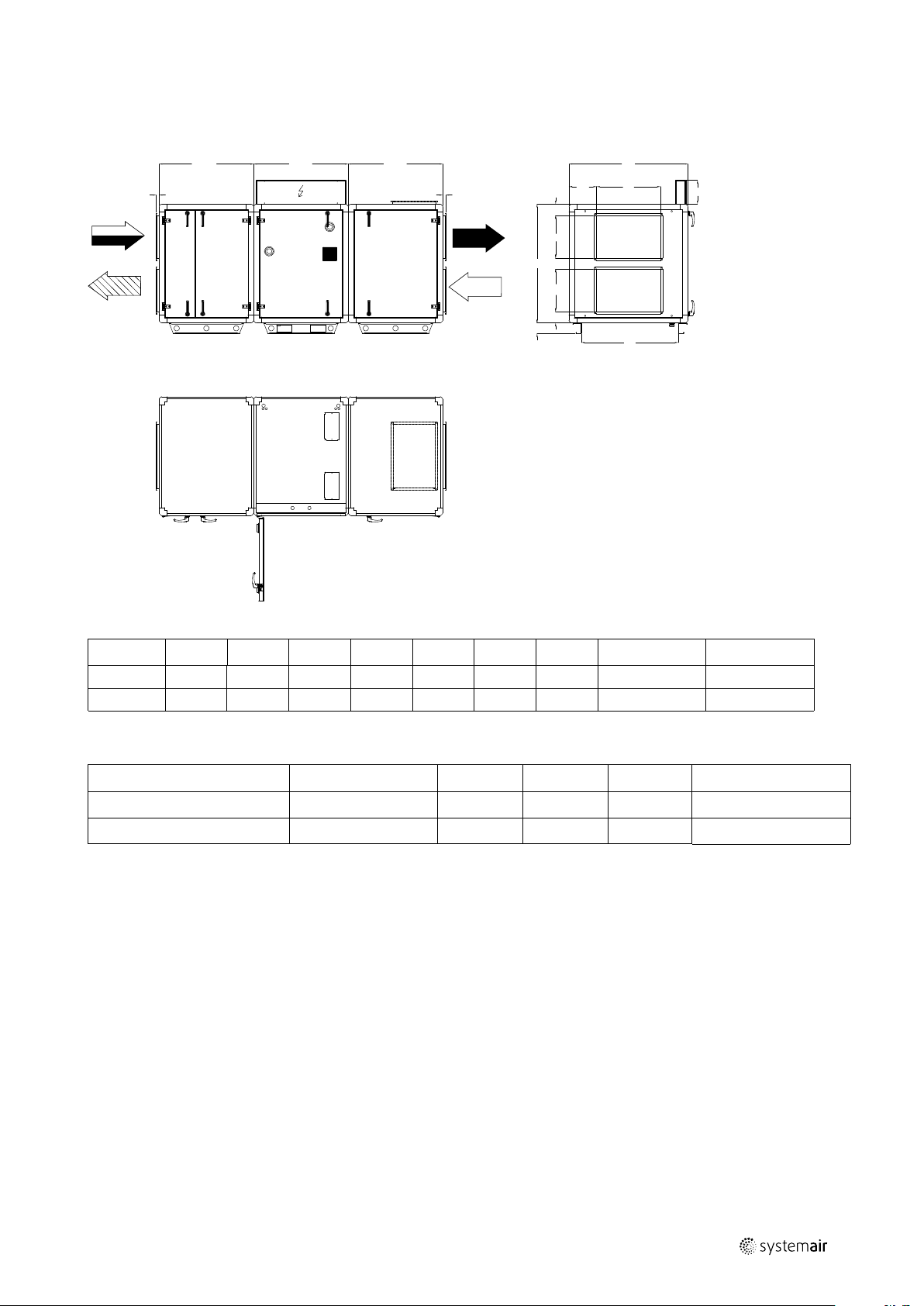

4.2.1 Dimensions and weights Topvex SoftCooler SR09, SR11

Product information |

3

Fig. 1 Dimensions (mm) SR09, SR11 (Drawn as left hand unit)

Model

A B C D E F G

Weight, kg Weight, TOT

SR09 1120 600 400 108 104 260 915 230 665

SR11 1230 800 400 135 165 215 1025 260 695

4.2.2 Technical data

Model Voltage

Topvex SoftCooler SR09

Topvex SoftCooler SR11

Current (A) Power (W)

400V 3N~, 50Hz 15 9230 20 4,1

400V 3N~, 50Hz 15 9230 20 4,8

Fuse, slow Quantity of R410A, kg

208765 | A005

Page 8

| Product information

4

4.3 Components

Fig. 2 Basic components in left hand unit

Position Description

1. Compressor

2.

3.

4.

5.

6.

7.

8.

9.

10. Frequency converter

11.

12.

Condenser coil

Evaporator coil

Filter drier with sight glas

Electronic expansion valve

Drip-tray with drain

Water seal

Cable grommet for external cabling

El. cabinet

Pressure/hot gas switches

Measuring points refrigerant system high/low

208765 | A005

Page 9

4.4 Electrical cabinet

5

4

3

2

1

6

7

8

Product information |

5

Fig. 3 Electrical cabinet

Position Description

1.

2.

3.

4.

5. Frequency converter

6.

7.

8.

Terminal block, mains supply

Circuit breaker (MCB) oil heater

Relays

Terminal block, internal/external connections

DC choke

24V transformer

LCD display

208765 | A005

Page 10

| Transport and storage

6

5 Transport and storage

The Topvex SoftCooler should be stored and transported in such a way that it is protected against physical damage that

can harm panels, handles etc. It should be covered so that dust, rain and snow cannot enter and damage the unit and

its components. The appliance is delivered in one piece containing all necessary components, wrapped in plastic on a

pallet for easy transportation.

When transporting the Topvex SoftCooler use a forklift, but once installed on the floor avoid transfer, the feet can damaged due to lateral loading.

Warning

• The unit is heavy. Be careful during transport and mounting. Risk of injury through pinching. Use

protective clothing.

• Be careful so the unit doesn't tip over.

6 Installation

6.1 Unpacking

Verify that all ordered equipment are delivered before starting the installation. Any discrepancies from the ordered

equipment must be reported to the supplier of Systemair products.

6.2 Where/how to install

Topvex SoftCooler are meant for indoor installation. Place the unit on a horizontal flat surface. It’s important that the

unit is completely levelled before it is put into operation.

The electronic components should not be exposed to lower temperature than 0° C and higher than +50° C.

The following max. temperatures applies for an interference-free operation of the Topvex SoftCooler:

• Outside air max. +33 °C

• Extract air max. +28 °C.

• Ambient temperature max. +28 °C.

When choosing the location it should be kept in mind that the unit requires maintenance regularly and that the inspection doors should be easily accessible. Leave free space for opening the doors and for taking out the main components

(figure 1). General maintenance includes among other things inspection and cleaning of the drip tray and flange coils.

A floor drain must be available in the room so that the condensation water can be drained off (chapter 6.6)

Avoid placing the appliance against a wall, as low frequency noise can cause vibrations in the wall even if the fan

noise-level is acceptable. If this is not possible it is recommended to carefully insulate the wall.

208765 | A005

Page 11

6.3 Installing the unit

6.3.1 Installation

Fig. 4 Installation, left hand unit

Position Description

Supply

Installation |

7

Exhaust

Outdoor

Extract

1.

2.

3.

4.

5.

6.

VAV pressure transmitter supply air (accessories)

VAV pressure transmitter extract air (accessories)

Damper and motor exhaust air (accessories)

Damper and motor outside air (accessories)

Sensor supply air

Topvex SoftCooler SR

6.3.2 Installation procedure

Warning

Beware of sharp edges during mounting and maintenance. Make sure that a proper lifting device is used.

Use protective clothing.

1 Prepare the surface where the unit is to be mounted.

Make sure that the surface is flat, levelled and that it

supports the weight of the unit. Perform the installation in accordance with local rules and regulations.

2 Lift the unit in place.

208765 | A005

Page 12

| Installation

8

3 Level the unit with help of the enclosed mounting

feet

4 Connect the unit electrically to the mains through the

all pole circuit breaker (safety switch), which is enclosed inside the unit on delivery. The wiring between

the safety switch and the unit is led through the top

of the unit casing directly to the electrical connection

box.

See enclosed wiring diagram, and chapter 6.7.1, table

1 for more information.

Warning

The units electrical connection to the mains supply must be preceded by an all pole circuit breaker with a

minimum 3 mm gap.

Danger

• Make sure that the Mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• All electrical connections must be carried out by an authorized installer and in accordance with local rules

and regulations.

208765 | A005

Page 13

6.4 Dividing the Topvex SR air handling unit

Before the installation of Topvex SoftCooler SR the Topvex SR has to be divided (figure 5).

How to split the unit:

Remove the heat exchanger, supply air fan and the extract air filter

A. Loosen the cable connectors in the wall

B. The two halves of the unit are joined using 4 M10 screws, one in each corner

C. Control section

D. Heat recovery section

E. It is possible dismount the gables by removing 6 MRX M6 screws with TH2 bits tool

Reassemble in the reverse order.

Installation |

9

Fig. 5 Left hand version

Note:

When reassembling the pieces make sure they are connected correctly - see cable markings on the side of

the cables.

208765 | A005

Page 14

| Installation

10

6.4.1 Assembley the Topvex SoftCooler SR

Fig. 6 Left hand unit (right hand units are mirrored)

Make sure that the sealing stripes and faces in-between the units halves are undamaged. Place the SoftCooler between

the two air handling units parts and carefully push them completely together. The SoftCooler is joined to the air handling parts by 4 M10 screws, one in each corner.

1. Remove the cover plate on top of Softcooler to access the inner upper mounting screw on the SoftCooler side that

faces the rotary heat exchanger.

2. Remove the exhaust air filter to access the inner upper mounting screw on the Softcooler side that faces the exhaust

air filter.

3. Remove the supply air fan to access the inner upper screw on the Softcooler side that faces the supply air fan.

4. When all 4 screws are in place remount the supply air fan, the exhaust air filter and the cover plate on top of the unit.

208765 | A005

Page 15

Installation |

6.5 Condensation and Heat Insulation

Outdoor air duct and discharge ducts must always be well insulated against condensation. Correct insulation installation

on ducts connected to the unit is especially important. All ducts installed in cold rooms/areas must be well insulated.

Use insulating covering (minimum 100 mm mineral wool) with plastic diffusion barrier. In areas with extremely low outdoor temperatures during the winter, additional insulation must be installed. Total insulation thickness must be at least

150 mm.

Caution

• If the unit is installed in a cold place make sure that all joints are covered with insulation, and tape well

• Duct connections/duct ends should be covered during storage and installation

• Do not connect tumble dryers to the ventilation system

6.6 Condensation drain

Warning

The unit is not to be taken into operation before the included condensation drain and water seal are

connected from the Topvex SoftCooler to the floor drain.

The drain is to be connected to the drain connection under the drip-tray. The drip-tray is located in the bottom of the

Topvex SoftCooler.

11

Use the included plastic connection pipe which is to be cut to the correct height "H" according to the below figure. See

the below table for the relation of hight "H" and maximum under pressure in the unit.

Fig. 7 Dimension and assembly

H (mm) Max. Negative pressure (Pa)

85 500

1

110

135 1000

1

Normal conditions

750

To lead the water from the water seal outlet to the floor drain an extra pipe, not included with the Topvex SoftCooler, is

needed. Connect this pipe and make sure that the slope is at a minimum 1:200 to the floor drain and also that the complete drain installation are in a frost free space.

Fig. 8 Pipe to floor drain

208765 | A005

Page 16

| Installation

12

6.7 Electrical connection

Danger

• Make sure that the Mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• All electrical connections must be carried out by an authorized installer and in accordance with local rules

and regulations.

• Operation in the refrigerant cycle and handling refrigerants must be performed by certified personnel.

Fig. 9 Electrical connection, left hand unit

Cable fastener

Control cable

Power supply

1. Wire the prepared control cable from the Topvex SoftCooler electrical connection box to the Topvex SR electrical cabinet (in the supply air part).

Use the prepared grommet to enter the cabinet and secure the cable along its way on top of the unit using the self

adhesive cable fasteners.

2. Connect the wires to the terminal block in the electrical cabinet according to labeling on the wires and electrical wiring diagram. See also chapter 6.7.1 Internal electrical connections.

3. Connect the cooler unit electrically to the mains (400V 3~, 50 Hz) through the all pole curcuit breaker (safety switch)

which is enclosed inside the unit at delivery. The power cable is led directly into the Topvex SoftCooler electrical connection box. Dimension the wire and fuses according to the electrial data (figure 4.2.2)

4. Do the electrical connections for the Topvex SR air handling unit according to the installation instruction that follows

that unit.

208765 | A005

Page 17

6.7.1 External/Internal connections

See also the enclosed wiring diagram.

Mains supply is the only external connection that should be connected to the Topvex SoftCooler.

Table 1 External connections

Terminal

block

PE

Description

Ground

Remark

Installation |

13

N N

L1 L1

L2 L2

L3 L3

The already prepared operating cable in Topvex SoftCooler is to be drawn to the electrical cabinet in the supply part of

the Topvex air handling unit and connected to the terminal blocks with the same numbers as the cable markings.

Table 2 Internal connections

Terminal

block

G G 24V AC

4

10

15 DO

74 DI

90

94 AO

DI ref Referens

DO ref Referens

AO ref Reference

Earthed neutral (supply voltage)

Phase (supply voltage)

Phase (supply voltage)

Phase (supply voltage)

Description

A signal from control unit for starting Step controller 1 step 1

indicates a cooling demand. The signal controls relay R1 that is

then starting the compressor.

Alarm indication cooling (Malfunction cooling (SEQ-C).

Control signal from control unit for cooling. Controls the frequency

converter "FC".

400V 3N~, 50Hz

supplied via safety

switch

Remark

24V AC, 0.5A

NO

0-10V DC

208765 | A005

Page 18

Function Description

RC

RM

HE

EV

CO

FC

HPS

CPR

EV

CO

FC

HPS

CPR

|

14

7 Function Description

Fig. 10 Left hand unit

Position Description

EF

SF

SS

OS

ETS Temp. sensor extract air

UC

RC

RM Rotor motor

HE

DO

DEH

FC Frequency converter

CPR Compressor

EV Evaporator

CO

HPS

Extract air fan

Supply air fan

Temp. sensor supply air

Temp. sensor outdoor air

Control unit

Rotor control

Exchanger

Damper outdoor air (accessory)

Damper exhaust air (accessory)

Condenser

Condenser pressure sensor

OT/ET Overheating/Max. temp switches

FGS/FGE Air filter pressure switches

7.1 General

Control unit (UC) senses the temperature via the extract temperature sensor (ETS) and then keep the set extract temperature by sequence controlling the compressor (CPR), heat exchanger (HE) and hot water- /electrical heater (HWL/H,

ELH). The temperature sensor in the supply air (SS) is min. and max. limiting the supply air temperature.

7.2 Power control

The compressor (CPR) are step-less controlled between, in the frequency converter (FC), set minimum and maximum

frequency.

7.3 Power limitation

The programmable controller is continuously sensing the condensing pressure via the high pressure sensor (HPS) and

gradually slows down the speed of the compressor (CPR), if the pressure exceeds the set limitation value. This is done

to avoid a high pressure alarm.

Note:

This instruction contains functions for the Topvex SoftCooler SR, for a complete description of functions see

" SR 09,11, TR 09-15 Installation instruction".

208765 | A005

Page 19

8 Commissioning protocol

Company:

Responsible:

8.1 General

Commissioning protocol |

15

Customer: Date:

Object/unit:

Item no:

Model/size Serial no:

8.2 Installation protocol

Moment Done Note

Control report cooling concerning installation established.

(Application shall in some cases be done, see chapter 3,

Refrigerant Control/Reporting).

All unit parts undamaged.

Installation carried out according to instructions (see

chapter 6.4.1, Assembly the Topvex SoftCooler.

Condensation drain connected (see chapter 6.6,

Condensation drain).

Mains supply connected via the Safety switch (see chapter

6.7, Electrical connection).

Internal operating cable connected (see chapter 6.7.1,

External/Internal connections).

Supply and extract airflow adjusted

Installation:

Installation address:

Designation:

8.3 Preparing control unit

To receive correct functions the following settings must be done in the control unit. Log in with service level using password 0612.

Moment Done Note

Select the menu Configuration > Functions >

Function activation > Heating/Cooling

sequence setup:

• Choose Cooling

• Set Type of cooler to DX

• Set Type of feedback to Alarm

Select the menu Configuration > Functions >

Function activation > Heating/Cooling

sequence setup:

• Choose Step controller 1

• Set Step control sequence to Cooling

• Set Number of steps to 1

Select the menu Configuration > Functions >

Function activation:

• Check that Temperature control type is set as

Extract air cascade or Room cascade

Select the menu Configuration > Functions >

Temperature control:

• Set Cooling recovery mode to Off

Select the menu Configuration > I/O allocation

settings > Digital outputs:

Set Signal for Step controller 1 step 1 to DO5

208765 | A005

Page 20

| Commissioning protocol

16

Moment Done Note

Select the menu Configuration > I/O allocation

settings > Digital inputs:

• Set signal for Extended operation normal speed

to Select I/O (or to any other free DI)

• Set signal for Feedback cooling (SEQ-C) to DI4

Select the menu Data & Settings > Temperature

control > Cooling:

Set Min switch time to 1s

Set Step 1 start point to 10%

Set Step 1 stop point to 0%

Set Reduction of min limit supply air if active

DX-cooling to 0°C

Note:

Note: DI4 cannot be used for extended run

when Topvex SoftCooler is used.

8.4 Before compressor start

To avoid damage on the compressor the oil in the compressor crankcase must be heated before the first start.

Moment Done Note

Stop the Supply- and extract fan (via the Topvex air

handling units safety switch)

Turn on the mains supply for the Topvex SoftCooler via the

safety switch, make sure that the voltage is on (the display

in the frequency converter lights up) Wait for minimum 2

hours so that the oil will reach about +30° C!

8.5 Control cooling operation

Moment Done Note

Start the Supply- and extract fan (via the Topvex air

handling units safety switch). Run the unit on dimensioning

airflows.

Start the compressor by establishing a 100% cooling

demand:

• Log in with service level using password 0612

• Select menu Data & Settings > In-/Output

status > Heating/Cooling sequences

• Set Mode for Cooling to Manual

• Set Manual for Cooling to 100%

Run the compressor for at least 10 minutes.

Then read the Extract-, Outdoor- and Supply air

temperature via the display of the control unit (in the menu

Temperature).

Let the compressor run.

Measure the hotgas- and liquid line temperature with a

strap-on temperature detector.

Supply air ________________m3/h

Extract air _______________m

Outdoor air temperature __________°C

Supply air temperature ___________°C

Extract air temperature __________°C

Hotgas temperature ___________°C

Liquid line temperature _________°C

3

/h

208765 | A005

Page 21

Moment Done Note

Keep the compressor running.

Read the below values via the display of the frequency

converter, see section ”Frequency converter, quick guide”,

in Operating and Maintenance Instructions. First set the

parameter for reading, then let the door of the Topvex

SoftCooler be closed for at least 5 minutes before reading:

• Output frequency (Param d001)

• Output current (Param d002)

• Condenser pressure (Param d004)

Output frequency __________________Hz

Output current ____________________Hz

Condenser pressure ______________bar

Note:

Important! Restore the cooling operation to Auto:

• Log in to the control unit as Service (0612)

• Select menu Data & Settings > In-/Output

status > Heating/Cooling Sequences

• Set Mode for Cooling to Auto

Notes:

Commissioning protocol |

17

208765 | A005

Page 22

208765 | A005

Page 23

208765 | A005

Page 24

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg, Sweden

Phone +46 222 440 00

Fax +46 222 440 99

www.systemair.com

Topvex SoftCooler SR09, SR11Access control system · Installation instructions · 208765 · en_GB · 2019-12-19 · A005

Loading...

Loading...