SystemAir SAVE VSR 300, SAVE VSR 500, SAVE VTC 700, SAVE VTR 700R, SAVE VTR 700L Installation And Service

Page 1

SAVE VSR 300/500

Installation and Service

Document in original language | 211458 · A002

GB

Page 2

© Copyright Systemair UAB

All rights reserved

E&OE

Systemair UAB reserves the rights to change their products without notice.

This also applies to products already ordered, as long as it does not affect the previously agreed specifications.

Systemair is not liable or bound by the warranty if these instructions are not adhered to during installation or service.

211458 | A002

Page 3

Contents

1 Declaration of Conformity . . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . 1

2 Disposal and recycling .... . ... . .. . ... . .. . .. . . .. . .. . . .. . .. . ..2

3 Warnings. .. . ... . .. . ... . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. 2

4 About this document....... . . .. ... . .. . ... . .. . .. . . .. . .. . . .. . .2

5 Product information ..... . . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . 2

5.1 General.... . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ... . .. . .. . . .2

5.2 Installation recommendation regarding

condensation ..... . ... . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . 3

5.2.1 Condensation inside of the

unit .. .. . .. . ... . .. . ... . .. . .. . . .. . .. . ... . .. . ..3

5.2.2 Condensation outside of the

unit .. .. . .. . ... . .. . ... . .. . .. . . .. . .. . ... . .. . ..3

5.3 Transport and storage . . .. ... . .. . ... . .. . .. . . .. . .. . .3

5.4 Technical Data .... . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. 4

5.4.1 Dimensions and Weight of

VSR 300 .. ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ..4

5.4.2 Dimensions and Weight of

VSR 500 .. ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ..5

5.4.3 Duct connections. . .. . .. . ... . .. . ... . .. . ..5

5.4.4 Power consumption and fuse

size ... . .. . ... . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . 5

6 Installation...... . . .. . .. . . .. ... . .. . ... . .. . .. . . .. . .. . ... . .. . ... . .6

6.1 Unpacking ...... . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . 6

6.2 Where/how to install ... . . .. . .. . ... . .. . ... . .. . .. . . .6

6.3 Installation procedure.... . . .. . . .. ... . .. . ... . .. . ... . 6

6.4 Condensation drainage ....... . .. . . .. . .. . . .. . .. . . .. 7

7 Electrical connections .. .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. ... . 7

7.1 Main board layout ...... . .. . . .. . .. . . .. . .. . . .. . .. . . .. 8

7.2 External connections (Connection

board) ..... . . .. . . .. ... . .. . ... . .. . .. . . .. . .. . ... . .. . ... . .9

8 SAVECair control . . .. . .. . ... . .. . ... . .. . .. . . .. . .. . .. . . .. . .. . . 10

8.1 General.... . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ... . .. . .. . 10

8.2 Startup wizard ... . .. . . .. . .. . .. . . .. . .. . . .. . .. . ... . .. 10

8.3 Common symbols. .. . .. . . .. . .. . . .. ... . .. . ... . .. . .. 10

8.4 Menu overview . . .. . . .. . .. . .. . . .. . .. . . .. . .. . ... . .. 11

8.5 Home screen... . .. . ... . .. . .. . . .. . .. . .. . . .. . .. . . .. . .12

8.5.1 User modes .. . .. . . .. . .. . . .. . .. . . .. . .. . . 12

8.5.2 Temperature settings ....... . . .. . .. . .14

8.5.3 Airflow settings .... . .. . . .. . .. . . .. . .. . .14

8.5.4 Indoor Air Quality ...... . . .. . .. . ... . .. . 15

8.5.5 Status line .. . .. . . .. . .. . . .. . .. . ... . .. . .. . 15

8.6 Description of User function icons ... . . .. . .. . .15

8.7 Main menu .... . . .. . .. . . .. . .. . . .. ... . .. . ... . .. . .. . . .16

8.7.1 Unit Information .. . . .. . .. . ... . .. 16

8.7.2 Alarms .. . .. . ... . .. . ... . .. . .. . . .. . .. . . .. 17

8.7.3 Week Schedule ... . . .. . .. . .. . . .. . .. . .20

8.7.4 Filter .. . .. . ... . .. . ... . .. . .. . . .. . .. . . .. 21

8.7.5 System Preferences ... . ... . .. . .. 22

8.7.6 Service ... . ... . .. . .. . . .. . .. . . .. . .. . .. . 22

8.7.7 Help .... . .. . . .. . .. . . .. . .. . . .. ... . .. . ... . .28

9 Service ... . .. . ... . .. . .. . . .. . .. . ... . .. . ... . .. . .. . . .. . .. . . .. . .. . 29

9.1 Warnings. . .. . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . ... . .. . .. 29

9.2 Internal components ..... . .. . .. . . .. . .. . ... . .. . .. . 30

9.2.1 Component descriptions .. . ... . .. . .. 30

9.3 Replacing rotor drive belt . . .. . .. . . .. . .. . . .. . .. . .32

9.4 Troubleshooting..... . . .. . .. . . .. . .. . . .. . .. . . .. ... . .32

10 Accessories..... . .. . ... . .. . .. . . .. . .. . ... . .. . ... . .. . ... . .. . .. . 34

10.1 Internet Access Module (IAM) . . . .. . .. . . .. ... . .34

10.1.1 Mobile application and

Login . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. ... . .34

10.2 Indoor air quality sensors .. . ... . .. . ... . .. . .. . . .. 34

10.3 Temperature control . .. . .. . . .. . .. . . .. . .. . . .. . .. . .36

10.3.1 Electrical duct pre-

heater ... . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. .36

10.3.2 Duct water heater ..... . . .. . .. . .. . . .. . 37

10.3.3 Duct water cooler... . . .. . .. . ... . .. . .. . 38

10.3.4 Change-over coil (DX) ...... . . .. . .. . .39

10.4 Airflow control..... . ... . .. . .. . . .. . .. . . .. . .. . .. . . .. . 41

10.4.1 VAV/CAV conversion kit.. . . .. . .. . . .. 41

10.5 Installation/Maintenance . .. . .. . . .. . .. . ... . .. . .. 42

10.5.1 Outdoor/Exhaust air

dampers..... . ... . .. . .. . . .. . .. . . .. . .. . .. . 42

10.6 Filters ..... . ... . .. . ... . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . .43

10.7 Passive House function...... . .. . ... . .. . ... . .. . .. 43

211458 | A002

Page 4

Page 5

Declaration of Conformity |

1 Declaration of Conformity

Manufacturer

Systemair UAB

Linų st. 101

LT–20174 Ukmergė, LITHUANIA

Office: +370 340 60165 Fax: +370 340 60166

www.systemair.com

hereby confirms that the following product:

Heat recovery ventilation unit: SAVE VSR 300/500

(The declaration applies only to product in the condition it was delivered in and installed in the facility in accordance

with the included installation instructions. The insurance does not cover components that are added or actions carried

out subsequently on the product).

Comply with all applicable requirements in the following directives:

• Machinery Directive 2006/42/EC

• Low Voltage Directive 2014/35/EU

• EMC Directive 2014/30/EU

• Ecodesign Directive 2009/125/EC

The following regulations are applied in applicable parts:

1

1253/2014 Requirements for ventilation units

1254/2014

327/2011 Requirements for fans above 125 W

The following harmonized standards are applied in applicable parts:

EN ISO 12100:2010

EN 13857

EN 60 335-1

EN 60 335-2-40

EN 62233

EN 50 106:2007

EN 61000-6-2

EN 61000-6-3

Energy labelling of residential ventilation units

Safety of machinery - General principles for design - Risk assessment and risk reduction

Safety of machinery – Safety distances to prevent hazard zones being reached by upper or

lower limbs

Household and similar electrical appliances – Safety Part 1: General requirements

Safety of household and similar electrical appliances – Part 2-40: Particular requirements

for electrical heat pumps, air-conditioners and dehumidifiers

Measurement methods for electromagnetic fields of household appliances and similar

apparatus with regard to human exposure

Safety of household and similar appliances – Particular rules for routine tests referring to

appliances under the scope of EN 60 335-1 and EN 60967

Electromagnetic compatibility (EMC) – Part 6-2: Generic standards – Immunity for industrial

environments

Electromagnetic compatibility (EMC) – Part 6-3: Generic standards – Emission standards for

residential, commercial and light-industrial environments

Skinnskatteberg, 10-08-2017

Mats Sándor

Technical Director

211458 | A002

Page 6

| Disposal and recycling

2

2 Disposal and recycling

This product is compliant to the WEEE directive. When disposing the unit, follow your local rules

and regulations.

This product packing materials are recyclable and can be reused. Do not dispose in household

waste.

3 Warnings

Danger

• Make sure that the mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• All electrical connections and maintenance work must be carried out by an authorized installer and in

accordance with local rules and regulations.

Warning

• This product must only be operated by a person who has suitable knowledge or training within this field

or carried out with the supervision of a suitably qualified person.

• Beware of sharp edges during mounting and maintenance. Use protective gloves.

Warning

• All though the mains supply to the unit has been disconnected there is still risk for injury due to rotating

parts that have not come to a complete standstill.

Important

• The installation of the unit and complete ventilation system must be performed by an authorized installer

and in accordance with local rules and regulations.

• The system should operate continuously, and only be stopped for maintenance/service.

• Do not connect tumble dryers to the ventilation system.

• Duct connections/duct ends must be covered during storage and installation.

• Make sure that filters are mounted before starting the unit.

4 About this document

This installation manual concerns air handling unit type SAVE VSR 300/500 manufactured by Systemair.

The manual consists of basic information and recommendations concerning the design, installation, start-up and operation, to ensure a proper fail-free operation of the unit.

The key to proper and safe operating of the unit is to read this manual thoroughly, use the unit according to given

guidelines and adhere to all safety requirements.

5 Product information

5.1 General

The SAVE VSR 300/500 is a heat recovery ventilation unit, with a built in rotary heat exchanger. The SAVE VSR 300/

500 is suitable for houses with up to 240/360 m

The SAVE VSR 300/500 supplies filtered outdoor air to residential areas and extract air from bathroom, kitchen and wet

rooms.

2

heated living area.

211458 | A002

Page 7

Product information |

5.2 Installation recommendation regarding condensation

5.2.1 Condensation inside of the unit

When the unit is installed in a cold attic (close to outdoor temperature) the unit should run continuously. If the unit is intended to be stopped by the user manually or due to calendar function we recommend to install air tight dampers at extract and supply air ducts. The dampers will ensure that no air circulates from the warm parts of the building through

the unit to outside (chimney effect). If no dampers are installed there is risk of condensation inside the unit and the outdoor ducts during these stop periods. It also might be that cold air from outside could pass the unit and enter into the

building. That could cause condensation outside the supply and extract air ducts and even at the valves in the rooms.

When the unit is not running due to late commissioning in winter time, the supply and extract air ducts should be disconnected and closed due to above mentioned effects until commissioning and regular operation.

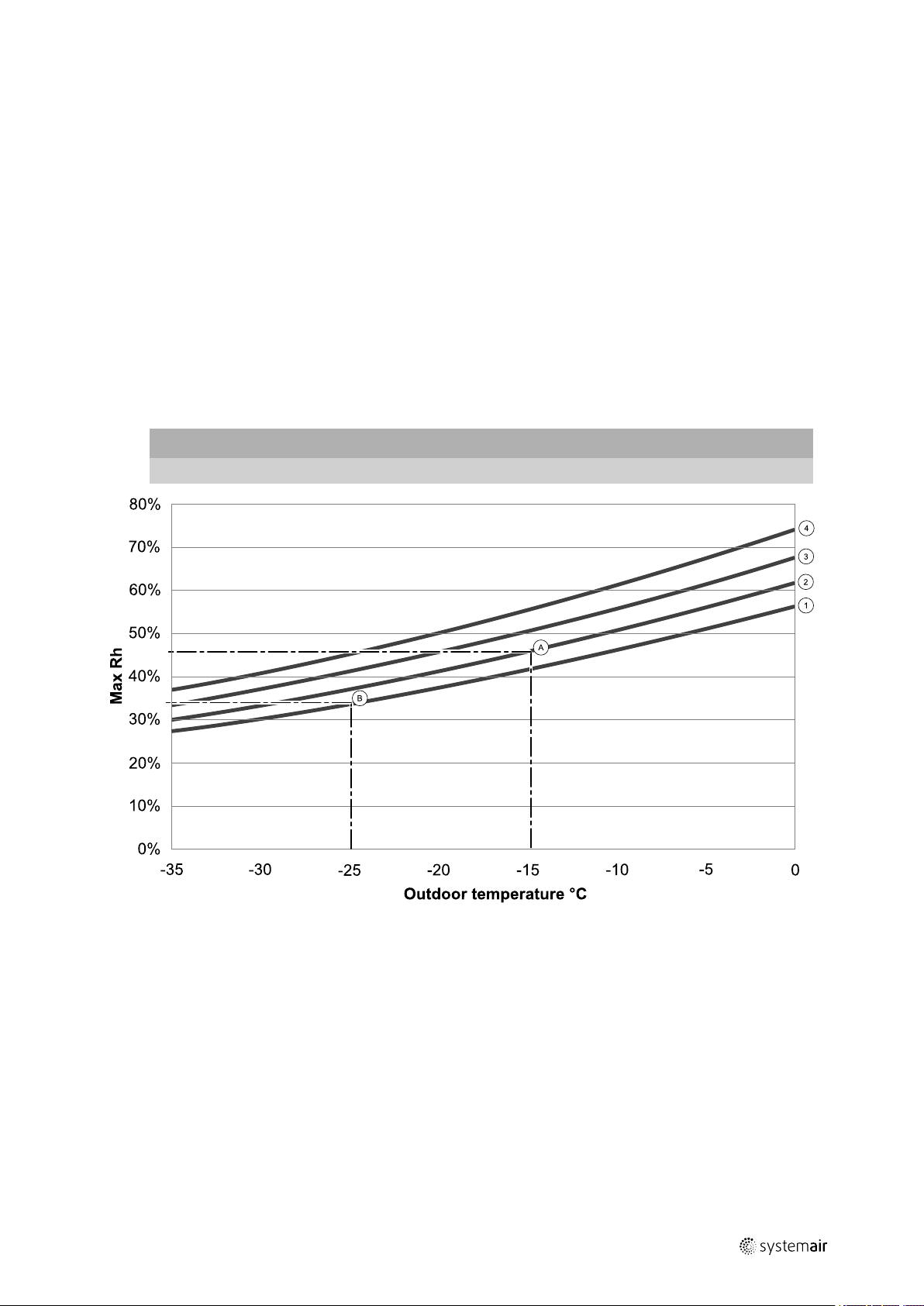

5.2.2 Condensation outside of the unit

When the unit is installed in warm humid areas (like laundry) together with low outdoor temperature there is a certain

point where moisture can condense outside of the casing. The condensation relation to indoor relative humidity, room

and outdoor temperature is shown diagram below. The condensation outside of the unit do not occur in zones bellow

each curve.

Important

Recommendation: If condensation occurs, increase ventilation in area close to the unit.

3

1. Room temperature 20°C

2. Room temperature 22°C

3. Room temperature 24°C

4. Room temperature 26°C

Examples when condensation outside of the unit can occur:

Example A: If the unit is installed in room where temperature is 22°C, outside temperature is –15°C, then dew will start

accumulating when relative humidity is 46% and higher.

Example B: If the unit is installed in room where temperature is 20°C, outside temperature is –25°C, then dew will start

accumulating when relative humidity is 34% and higher.

5.3 Transport and storage

The SAVE VSR 300/500 should be stored and transported in such a way that it is protected against physical damage

that can harm panels etc. It should be covered so dust, rain and snow cannot enter and damage the unit and its

components.

211458 | A002

Page 8

| Product information

4

The appliance is delivered in one piece containing all necessary components, wrapped in plastic on a pallet for easy

transportation.

5.4 Technical Data

5.4.1 Dimensions and Weight of VSR 300

* Drainage

The unit weight is 61 kg.

Fig. 1 Dimensions of VSR 300

211458 | A002

Page 9

5.4.2 Dimensions and Weight of VSR 500

Product information |

5

* Drainage

The unit weight is 72 kg.

5.4.3 Duct connections

Symbol

Description

Supply air

Fig. 2 Dimensions of VSR 500

Fig. 3 Duct connections

Symbol

Description

Outdoor air

Exhaust air

Extract air

5.4.4 Power consumption and fuse size

SAVE VSR 300/500 come with 1670 Winstalled re-heater battery.

Model

Re-heater

211458 | A002

VSR300 VSR500

1670 W

Page 10

| Installation

6

Fans 166 W 338 W

Total power consumption

Fuse 10 A 13 A

1836 W 2008 W

6 Installation

This section describes how to install the unit correctly. To ensure a proper and fail-free operation, it is important that

the unit is installed according to these instructions.

6.1 Unpacking

Verify that all ordered equipment are delivered before starting the installation. Any discrepancies from the ordered

equipment must be reported to the supplier of Systemair products.

6.2 Where/how to install

The SAVE VSR 300/500 should preferably be installed in a separate room (e.g. storeroom, laundry room or similar.), but

can also be installed in the loft space.

When choosing the installation position, consideration must be taken that the unit requires regular maintenance. Flooring boards must be mounted up to and under the unit. Light and mains supply should be installed. Leave free space for

removing of inspection doors and for taking out main components inside the unit.

The SAVE VSR 300/500 are supplied with approximately 1 m cable and plug for 230V, single phase earthed connection.

Recommended installation location for the outdoor air intake is the northern or eastern side of the building and with a

distance to openings for discharge of stale ventilation air, kitchen ventilator, central vacuum system, waist water drainage and other pollution sources like exhaust from traffic etc. Stale discharge air should ideally be led via a roof unit to

the outside and with a good distance to any outdoor air intake, windows etc.

Note:

If the passage to the installation location is narrow, remove the side covers and the side cover support

brackets.

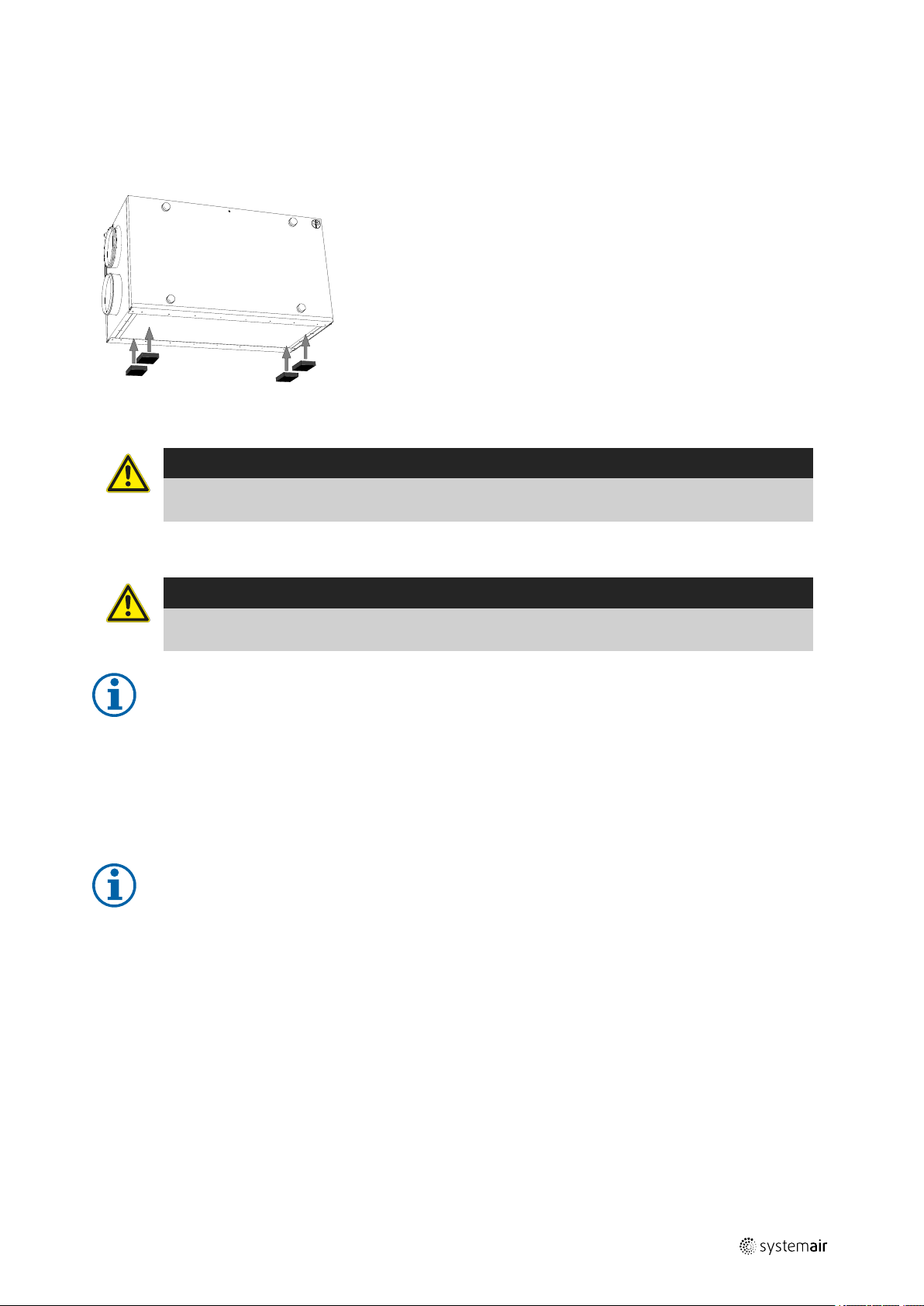

6.3 Installation procedure

A. Upright installation on the floor. Left and right connections are possible.

The enclosed self adhesive vibration dampers must be used.

B. Ceiling installation. Left and right connections are possible.

A ceiling mounting kit is required. Not delivered with the unit. Needs to be ordered separately.

211458 | A002

Page 11

Electrical connections |

C. Upside down installation is NOT allowed.

1. Make sure that the surface is flat and horizontal and that it supports the weight of the unit. Perform the installation in

accordance with local rules and regulations.

2. Fit the enclosed self adhesive vibration dampers on the unit.

Mount according to the enclosed Vibration Damper Quick Guide.

3. Lift the unit in place

Warning

Beware of sharp edges during mounting and maintenance. Use protective gloves.

Consider the unit weight when mounting!

7

4. Connect the unit to the duct system. Make sure that all necessary accessories are used to create a functional ventilation solution.

Warning

The installation of the unit and complete ventilation system must be performed by an authorized installer

and in accordance with local rules and regulations.

Note:

The unit may not be installed with the electrical connection box facing downward due to the fact that the

heat from the re-heater is rising in the unit!

6.4 Condensation drainage

In general no condensation drainage is needed for rotational heat exchangers at dry conditions. However, if a lot of humid air is present in the residence, a condensation drainage might be needed. Drainage connection is available as an accessory and can be ordered separately.

Note:

The drainage connection is plugged in the bottom of the unit at delivery. To use the drainage: elevate the

unit from the floor, remove the rubber seal and connect the water hose. Connect the water hose to the

sewer. The water can not be led straight to the sewer without a water trap.

7 Electrical connections

The SAVE VSR 300/500 is wired internally from factory.

The electrical connection box is on top of the unit behind a cover plate.

211458 | A002

Page 12

| Electrical connections

8

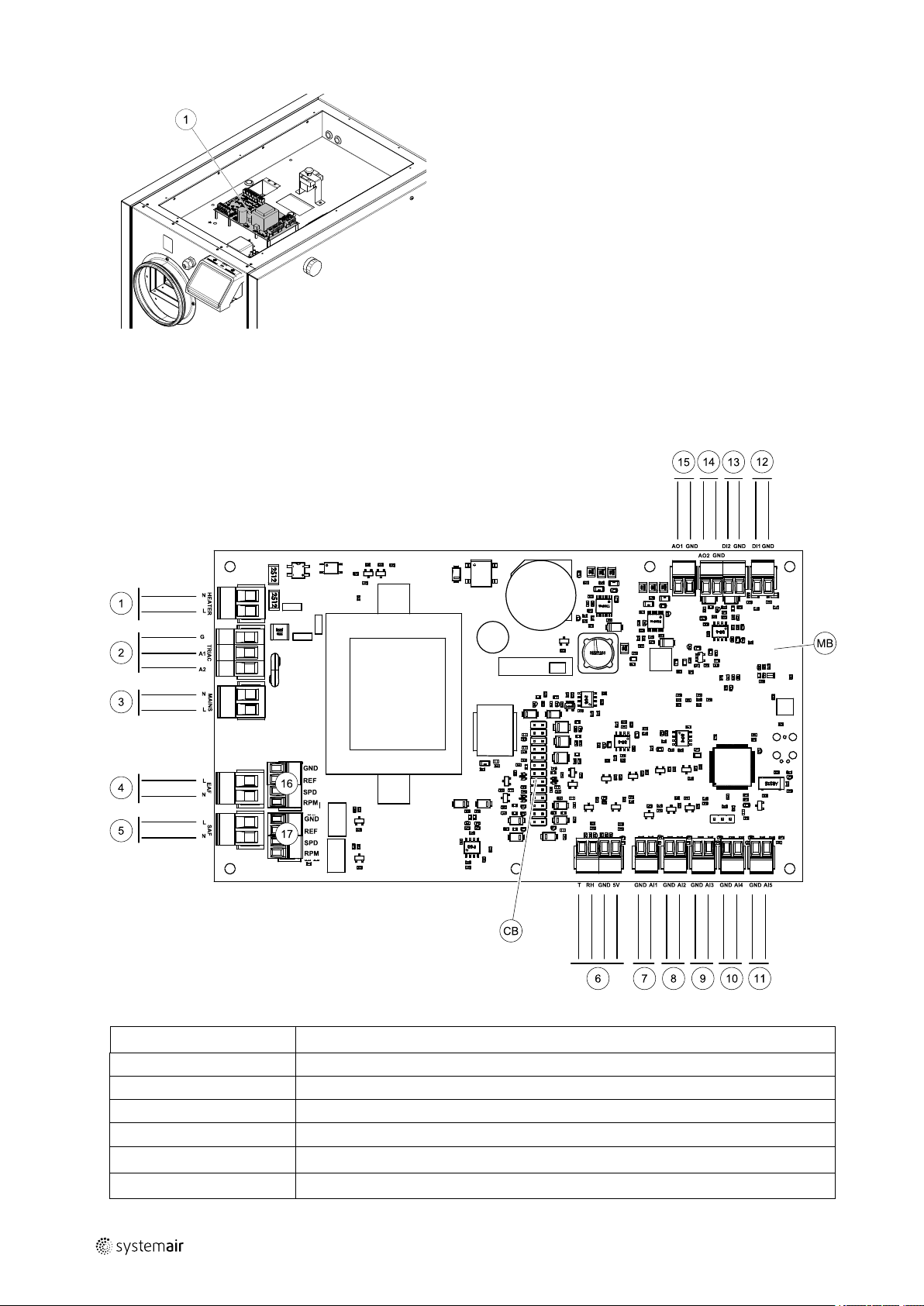

1. Main print card

7.1 Main board layout

The SAVE VSR 300/500 is equipped with built-in regulation and internal wiring.

The figure shows the main circuit board. See wiring diagram for more information.

Position Description

MB

CB

1

2

3

4

Main circuit board

Connection to the external connection box

Terminals for a heater

Terminals for a TRIAC

Terminals for the mains power supply

Terminals for power supply of extract air fan

Fig. 4 Main circuit board connections

211458 | A002

Page 13

Position Description

5

6

7

8

9

10

11

12

13

14

15

16

17

Terminals for power supply of supply air fan

Terminals for internal relative humidity/temperature sensor

Analog input 1 — Outdoor air sensor

Analog input 2 — Supply air sensor

Analog input 3 — Freely configurable

Analog input 4 — Freely configurable / Overheat temperature sensor (units with

heater)

Analog input 5 — Freely configurable

Digital input 1 — Rotor guard sensor (VSR, VTR units)/ Damper signal (VTC units)

Digital input 2 — Freely configurable / Cooker hood (VTR 150/K unit)

Analog output 2 — Freely configurable / Electrical heater controller (VTC 700 unit)

Analog output 1 — Rotor of the heat exchanger (VSR, VTR units) / Damper control

(VTC units)

Terminals for speed control of extract air fan

Terminals for speed control of supply air fan

Electrical connections |

9

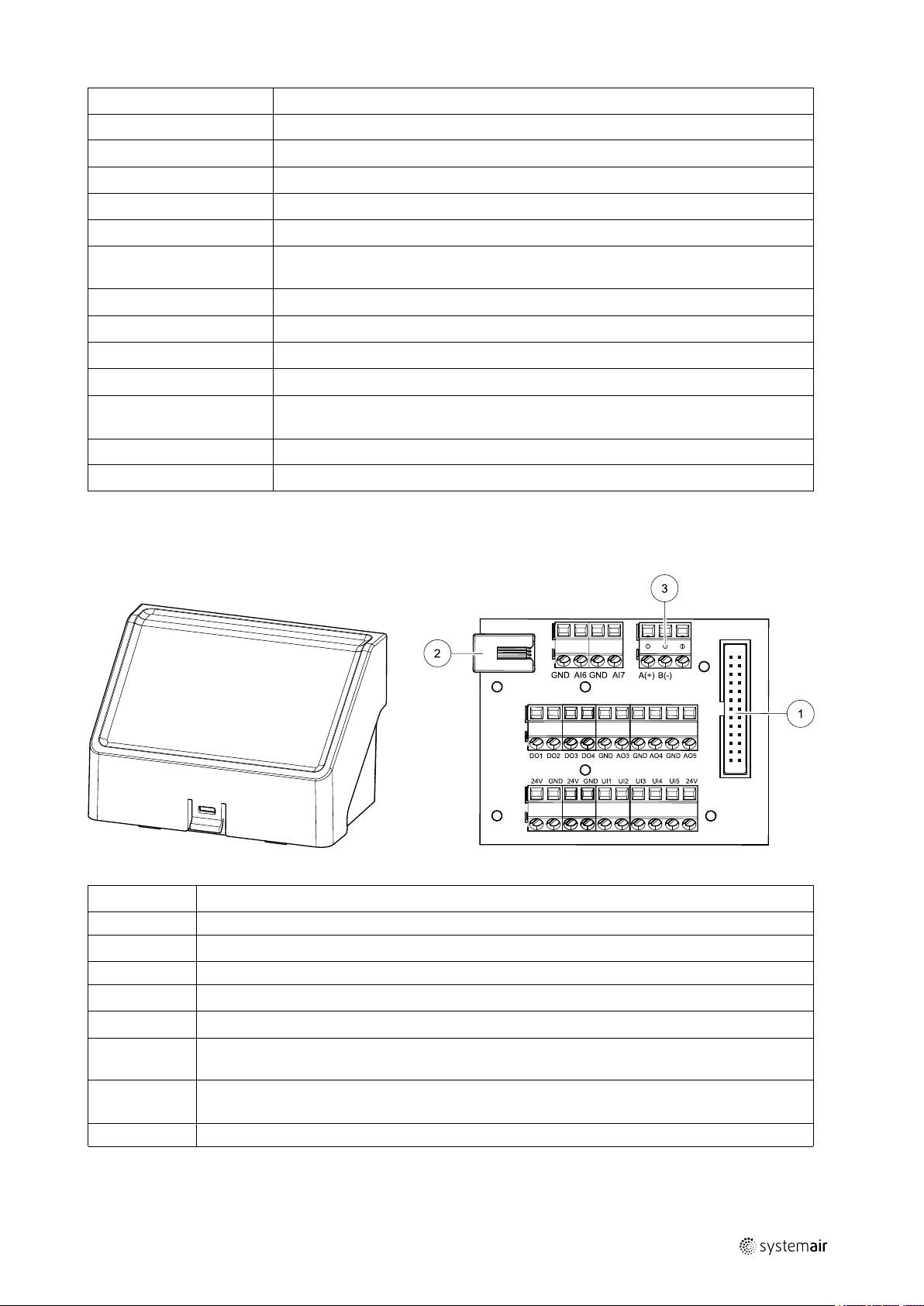

7.2 External connections (Connection board)

External connections to the main circuit board are done via connection board situated outside of the unit.

Fig. 5 External connection box and board

Position Description

1

2

3

AI6–7

DO1–4

AO3–5

UI1–5

24V Maximum current 200mA at 24VDC +-10%.

Connection to the main circuit board

Connection for external control panel (HMI) or Internet access module (IAM)

Modbus RS485 connection

Freely configurable Analog input. None/Input type selection in HMI.

Freely configurable Digital output. None/Output type selection in HMI.

Freely configurable Analog output. None/Output type selection in HMI. Actuator type 0–10V, 10–

0V, 2–10V, 10–2V.

Freely configurable Universal input. Can be configured to act as Analogue input (0–10V) or as

Digital input (24V). None/Input type selection in HMI (NC or NO polarity).

211458 | A002

Page 14

| SAVECair control

10

8 SAVECair control

8.1 General

SAVECair is a modern touchscreen LCD control panel, simply known as HMI — Human Machine Interface. The

touchscreen display provides information about current state of the unit and allows you to control all system functions.

Settings are done by touching the icons or options. The touch screen is sensitive and it is not necessary to press too

hard.

8.2 Startup wizard

During the first power up of the unit, you will be asked to set:

• menu language

• time and date

• airflow control type (Manual/RPM) and airflow level values

• heater type (None/Electrical/Water/Change-over)

If the start-up wizard is cancelled it will start again during next power up of the unit, this will continue until start-up wiz-

ard is successfully finished.

8.3 Common symbols

The following selection symbols are common and are present in most menu pages:

Back button to return to a previous

menu, located at the upper left corner

Up arrow to increase a value CANCEL Button to cancel changes

Down arrow to decrease a value

Many options show up in a form of the pop-up window. Select the option from the displayed list in the pop-up window

and press OK to confirm selection.

SET/OK

On and Off slider to activate or

deactivate a function. White bubble —

function is inactive, green bubble —

function is active.

Buttons to confirm changes

211458 | A002

Page 15

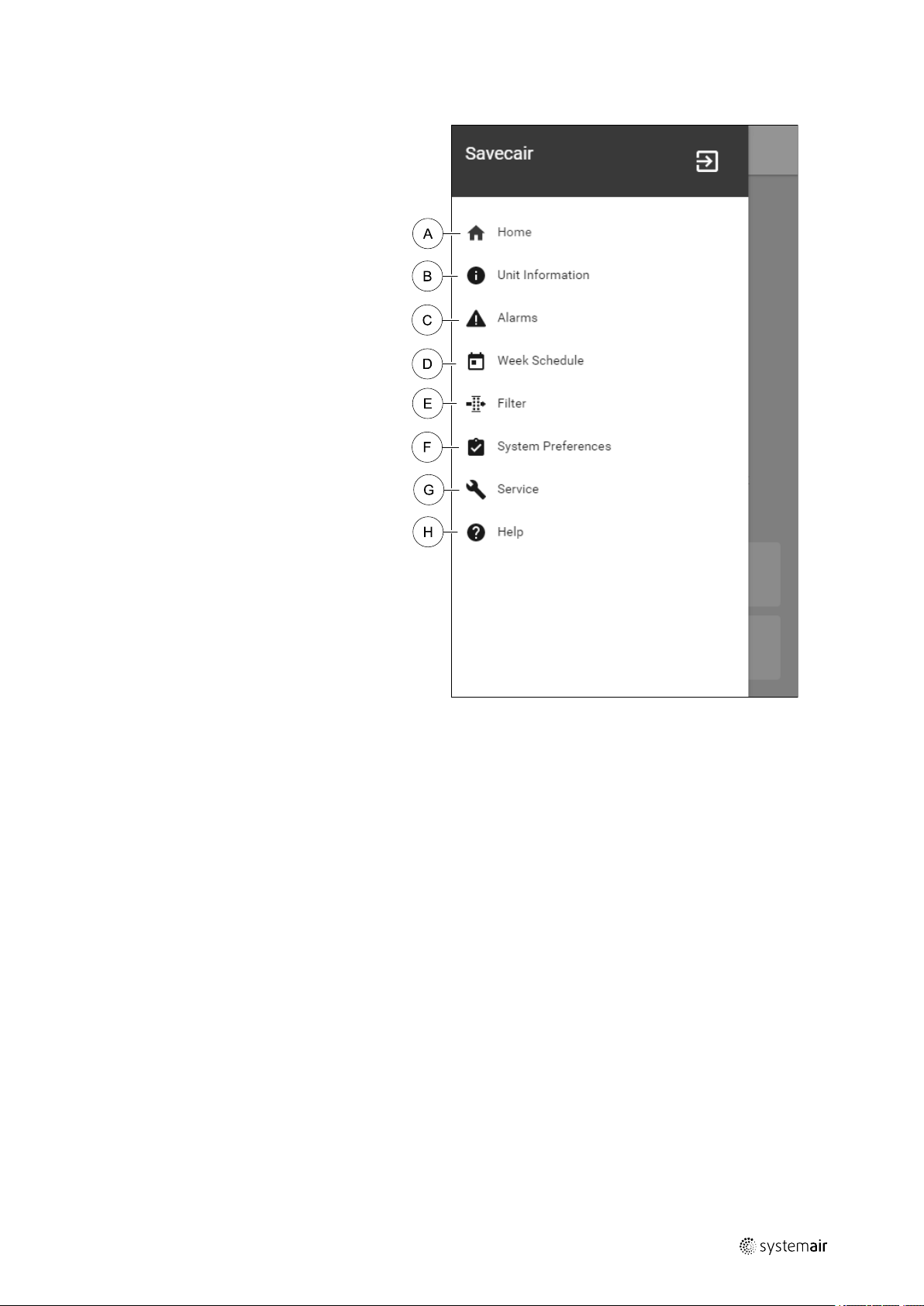

8.4 Menu overview

A.Return to home screen

B. Basic read-only information about the unit

C. Currently active alarms and alarm history

D.Configure and check week schedule

E. Check and change remaining time till filter

change

F. General system preferences

G.Configuration of all system parameters

H.Help and troubleshooting menu

SAVECair control |

11

211458 | A002

Page 16

| SAVECair control

12

8.5 Home screen

Touching home icon (pos. A) in dropdown menu list (pos. 1) will always returns you

to home screen after commissioning.

1. Drop-down menu list

2. Active user mode

3. Airflow settings

4. Temperature settings

5. List of active alarms

6. Icon list of active user functions

8.5.1 User modes

The first icon at the top of home screen shows currently active user mode. To change the user mode, touch the active

user mode icon (pos. 2) and select a new user mode from the list. The unit has 2 permanent and 5 temporary user

modes available for selection. Only one mode can be active at a time.

Settings of all modes can be modified in Service menu.

8.5.1.1 Permanent modes

Permanent modes are always active unless interrupted by temporary modes, activated user functions or alarms:

Icon Text

AUTO

MANUAL

Automatic airflow control. AUTO mode is available for selection when Demand

Control, Week Schedule and/or external fan control functions are configured,

otherwise AUTO mode icon won’t be visible in active user modes menu. AUTO

mode activates Demand Control, Week Schedule and/or external fan control

functions. Demand is available to choose as airflow setting in Week Schedule.

Manual selection of airflow levels. The unit can be set run at one out of four

available airflow speeds: Off/Low/Normal/High.

Note:

The fan can be set to OFF by activating Manual Fan Stop function in

Service menu.

Description

8.5.1.2 Temporary modes

Temporary modes are active only for a set period of time unless interrupted by active user modes, activated user functions or alarms:

211458 | A002

Page 17

SAVECair control |

13

Icon Text

Sets speed of both supply and extract air fans to Low levels when user is away

HOLIDAY

CROWDED

AWAY

REFRESH

FIREPLACE

Settings of all modes can be modified in Service menu.

Temporary modes and user functions are active only for a set period of time after which they are terminated and the

unit changes back to a former AUTO or MANUAL mode, depending on which one was active before temporary mode or

user function was activated.

from home for a long period of time.

ECO mode is active.

Delay in days.

Sets speed of both supply and extract air fans to maximum High levels and

temperature setpoint offset to –3 K when apartment is more crowded than usual.

Default temperature setpoint offset is –3 K.

Delay in hours.

Sets speed of both supply and extract air fans to Low levels when user is away

from home for a short period of time.

ECO mode is active.

Delay in hours.

Sets speed of both supply and extract air fans to maximum High levels to

replace indoor air with a fresh air in a short period of time.

Delay in minutes.

Sets speed of supply air fan to High level and extract air fan to Low level to

increase air pressure within the apartment for better smoke extraction through

the chimney.

Delay in minutes.

Description

8.5.1.3 Digital input functions

Digital input functions always active while digital input is activated.

Icon Text

Central

Vacuum

Cleaner

Cooker Hood

Function sets speed of supply air fan to High level and extract air fan to Low

level to increase air pressure within the apartment for better dust collection

through central vacuum cleaner.

Function can be activated via digital input — Central Vacuum Cleaner

Function.

Sets speed of supply air fan to High level and extract air fan to Low level to

increase air pressure within the apartment for better airborne grease and steam

collection in the kitchen.

Function can be activated via digital input — Cooker Hood Function.

Description

8.5.1.4 Digital input and Mode hierarchy

User modes and functions have a different hierarchy. User functions activated via HMI or mobile APP, such as AWAY,

CROWDED, FIREPLACE, HOLIDAY and REFRESH, are interrupted by manual selection of AUTO and MANUAL fan modes.

A FIREPLACE function has the highest priority between user functions. Other functions activated via HMI/APP can interrupt each other.

If FIREPLACE function is hard-wired on the connection board and configured as digital input (DI) then it has a higher

priority than AUTO and MANUAL mode. Digital input for a FIREPLACE function has also a higher priority than other

hard-wired digital inputs (DI) for: AWAY, CENTRAL VACUUM CLEANER, COOKER HOOD, CROWDED, HOLIDAY or REFRESH.

Digital input and Mode hierarchy:

1. EXTERNAL STOP

2. FIREPLACE function

3. COOKER HOOD, CENTRAL VACUUM CLEANER, CROWDED, REFRESH functions

4. AWAY, CROWDED functions

211458 | A002

Page 18

| SAVECair control

14

8.5.2 Temperature settings

Temperature can be set at SET TEMPERATURE menu accessible from the home screen by touching

TEMPERATURE icon with thermometer. Default temperature value is 18°C (range 12–30°C).

Use up and down arrows or a slider to change the value.

Then touch the SET to confirm changes.

Temperature set point is for room air temperature, supply air temperature or for extract air temperature depending on

which control mode is active. Default setting is Supply air temperature control.

Control mode of the temperature can be changed in Service menu.

8.5.2.1 ECO mode

ECO mode is a power saving function that can be activated in SET TEMPERATURE menu.

While ECO mode is active, a temperature setpoint at which heater is activated is lowered to avoid activation of the heater during cold nighttime.

If the temperature is very low and the heater is activated during the nighttime (even with lowered temperature setpoint), then during the upcoming daytime indoor temperature will be increased using the heat exchanger so that accumulated heat could be used during the next cold nighttime, the lowered setpoint for the heater remains.

ECO mode will have impact for the following user

functions/modes if selected:

• AUTO mode

• MANUAL mode

• AWAY mode

• HOLIDAY mode

• CENTRAL VACUUM CLEANER function

• COOKER HOOD function

• FIREPLACE mode

ECO mode is always activated by the following modes:

• AWAY mode

• HOLIDAY mode

ECO mode is always deactivated by the following user

functions/modes:

• CROWDED mode

• REFRESH mode

• FREE COOLING function

8.5.3 Airflow settings

Airflow settings are available only in MANUAL mode. Click on fan icon on the main screen to enter SET

AIRFLOW menu.

Use up and down arrows or a slider to change the airflow value.

The airflow may be adjusted in these steps: Off/Low/Normal/High. These settings control output signals to the supply and extract fans.

211458 | A002

Page 19

Important

It is not recommended to set fan to Off in standard households. If manual fan stop is activated, the unit

should be provided with dampers in exhaust and fresh air ducts to avoid cold draught and risk of

condensation when the unit has been stopped.

The fan can be set to Off by activating Manual Fan Stop function in Service menu.

8.5.4 Indoor Air Quality

The unit automatically controls indoor humidity and/or CO2levels by adjusting airflow setting. Airflow is

increased if air quality is decreasing.

SAVECair control |

15

Demand Control function is responsible for IAQ (Indoor Air Quality) regulation. Relative humidity (RH) and/or CO

sors are responsible for IAQ monitoring.

Indoor air quality (IAQ) indicator is available if AUTO mode and Demand Control function is activated.

IAQ levels:

• ECONOMIC: Actual IAQ value is below low IAQ set point.

• GOOD: Actual IAQ value is between low and high IAQ limits.

• IMPROVING: Actual IAQ value is above high IAQ set point.

Different airflow settings can be set for IMPROVING and GOOD IAQ levels in Service menu.

Setpoint for relative humidity and CO

level can be set in Service menu.

2

2

sen-

8.5.5 Status line

Status line located at the bottom area of home screen displays information about:

List of active alarms. See

chapter 8.7.2.3 for more

information.

Touching any of these lines will move you to the next page with more detailed list and information about each alarm or

active user function.

List of active user functions.

See chapter 8.6 for more

information.

8.6 Description of User function icons

Icon Text

Heat recovery

211458 | A002

Heating

Cooling

Cooling

recovery

Free cooling

Moisture

transfer

Description

Connected heater or pre-heater is active and air heating is in process.

Heat recovery from apartment is active.

Connected cooler is active and air cooling is in process.

Automatic cooling recovery is active when extract air temperature from

apartment is lower than outdoor air temperature and there is a cooling demand

(temperature setpoint is lower than outdoor air temperature).

No cooling recovery with heating demand. If the outdoor air temperature is

higher than then thee indoor air temperature and there is a heating demand,

function Free heating is activated instead.

Function decreases indoor air temperature by using only cool outdoor air during

nighttime to save energy consumption.

Function controls the rotation speed of the heat exchanger to prevent moisture

transfer to supply air due to high relative humidity in the extract air.

Function is only available for units with Rotating type heat exchanger.

Page 20

| SAVECair control

16

Icon Text

Defrosting

Secondary air

Vacuum

cleaner

Cooker hood

User lock

Description

Function prevents formation of the ice on the heat exchanger during cold

outdoor temperatures.

Warm air from the living space is used to defrost the heat exchanger using a

damper inside the outdoor air duct. The unit switches from outdoor air to

secondary air while the extract air fan stops and warm secondary air increases

the temperature inside the heat exchanger.

Function sets speed of supply air fan to High level and extract air fan to Low

level to increase air pressure within the apartment for better dust collection

through central vacuum cleaner.

Function can be activated via digital input — Central Vacuum Cleaner

Function.

Always active while digital input is activated.

Sets speed of supply air fan to High level and extract air fan to Low level to

increase air pressure within the apartment for better airborne grease and steam

collection in the kitchen.

If a cooker hood with integrated fan is used, then it is recommended to set

airflow levels of both fans to Normal.

Function can be activated via digital input — Cooker Hood Function.

Always active while digital input is activated.

Function indicates that the system is locked with a password and cannot be

edited or settings changed in any way. System must be unlocked first to make

changes.

8.7 Main menu

User settings and advanced settings

8.7.1 Unit Information

A basic read-only information about status of the unit, configured components and inputs/outputs.

211458 | A002

Page 21

SAVECair control |

8.7.1.1 Components

Type and settings of heat exchanger, heater, cooler, extra controller.

8.7.1.2 Sensors

Values from sensors and load of fans (rpm).

8.7.1.3 Input Status

Status of configured analog, digital and universal inputs. Connected component type and raw value (volts) is displayed.

8.7.1.4 Output Status

Status of configured analog, digital and universal outputs. Connected component type and value (volts) is displayed.

8.7.1.5 Unit Version

Unit model name, manufacturer number, serial number and unit software versions for Mainboard, HMI and IAM.

8.7.2 Alarms

A detailed information about active system alarms and alarm log of last 20 events.

17

8.7.2.1 Active Alarms

Alarm screen is empty if there are no active or logged alarms.

Press HELP button on the active alarm to access FAQ and troubleshooting (if available). Press ACKNOWLEDGE on the individual alarm to clear it. Depending on alarm type and the cause, it might be necessary to do a troubleshooting first to

acknowledge active alarm.

It may be not possible to clear the status of alarm if the cause of alarm is still present, as that would immediately trigger

alarm to return.

8.7.2.2 Alarms log

Alarm log allows to view last 20 alarms.

Each alarm contains information:

• Alarm name

• Date/time stamp

• Information if the alarm stops the unit or other note

8.7.2.3 Alarm list

Alarm name Explanation Do the following

Frost protection

Frost protection temperature

sensor

Frost protection of return water in

heating coil.

• Alarm stops the unit and opens

the water valve completely.

Indicates malfunction of water

heater temperature sensor.

• Alarm stops the unit.

The alarm will reset once the water

temperature reaches 13°C.

Check the water fluid temperature in

heating coil.

Check the circulation pump of water

heater. Contact your installation

company or place of purchase.

Check that frost protection

temperature sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

211458 | A002

Page 22

| SAVECair control

18

Alarm name Explanation Do the following

Defrosting error

Supply air fan rpm

Extract air fan rpm

Supply air fan control error

Extract air fan control error

Fire alarm

Emergency thermostat

Bypass damper

Indicates failure of pre-heater to

preheat the incoming outdoor air (in

case Extra controller is configured as

Preheater).

• Alarm stops the unit.

Rotation speed of the supply air fan

is lower than minimum required. Fan

malfunction.

• Alarm stops the unit.

Rotation speed of the extract air fan

is lower than minimum required. Fan

malfunction.

• Alarm stops the unit.

Flow or pressure alarm for supply air.

The pressure is bellow pressure limit.

• Alarm stops the unit.

Flow or pressure alarm for extract

air. The pressure is bellow pressure

limit.

• Alarm stops the unit.

Fire alarm is active.

• Alarm stops the unit.

Indicates triggered overheat

protection (in case of installed

electric re-heater battery).

Indicates malfunction in bypass

damper.

Check the pre-heater reset button.

Check the pre-heater cabling.

Contact your installation company or

place of purchase.

Defrosting error may be caused by

extremely low outdoor air

temperatures or pre-heater failure.

Check quick connectors of the fan.

Contact your installation company or

place of purchase.

Check quick connectors of the fan.

Contact your installation company or

place of purchase.

Check that air tube for pressure

sensor is connected properly and

cable is not damaged.

Contact your installation company or

place of purchase.

Check that air tube for pressure

sensor is connected properly and

cable is not damaged.

Contact your installation company or

place of purchase.

Once the external Fire alarm is

disabled – alarm has to be

acknowledged and unit restarted.

A triggered manual or automatic

overheat protection (EMT) gives an

alarm in the control panel.

In case a manual overheat protection

is triggered, reset it by pushing the

reset button.

If the automatic overheat protection

is triggered, it will reset

automatically once the temperature

has dropped.

If the problem continues contact

your installation company or place of

purchase.

Disconnect the main power supply

for 10 seconds to reset control

function.

Power up the unit, an automatic

bypass damper test will be

performed.

If the alarm occurs again after

approximately 2 minutes – contact

your installation company or place of

purchase.

211458 | A002

Page 23

Alarm name Explanation Do the following

Rotor guard

Secondary air damper

Outdoor air temperature

sensor

Overheat temperature sensor

Supply air temperature

sensor

Room air temperature sensor

Extract air temperature

sensor

Extra controller temperature

sensor

Efficiency temperature

sensor

PDM RH

PDM RH Extract air

temperature

Indicates a rotor malfunction.

No rotation guard signal for 180

seconds.

Secondary air defrosting failed.

Outdoor air temperature sensor

measures < 10°C in 2 sec after

defrosting

OR

Outdoor air temperature sensor

measures < 5°C in 5 min after

defrosting

Indicates outdoor air temperature

sensor malfunction.

Indicates overheat temperature

sensor malfunction.

Indicates supply air temperature

sensor malfunction.

Indicates room air temperature

sensor malfunction.

Indicates extract air temperature

sensor malfunction.

Indicates extra controller

temperature sensor malfunction.

Indicates efficiency temperature

sensor malfunction.

Indicates internal relative humidity

sensor malfunction.

Active: measured humidity = 0%

Returned: measured humidity > 5%

Indicates internal extract air

temperature sensor malfunction.

Active: measured temperature = 0°C

Returned: measured temperature >

5°C

If the rotating heat exchanger has

stopped. Check the rotor belt.

If the heat exchanger is still rotating,

check that the quick connector for

the sensor is connected and that

there is an air gap of 5-10 mm

between the sensor and the magnet.

Adjust the gap if necessary.

If the alarm persists, the rotor sensor

may be faulty. Contact your

installation company or place of

purchase.

Check if secondary air damper is in

correct position.

Check that damper is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

SAVECair control |

19

211458 | A002

Page 24

| SAVECair control

20

Alarm name Explanation Do the following

Filter

Time for filter change. Change the filter.

Change filter according to the

instructions in the User Manual.

Details about filter retailers can be

found in Help menu.

Extra controller alarm

Error from external device. Check if external device is connected

properly and cable is not damaged.

Reset overheat protection on

electrical pre-heater. Contact your

installation company or place of

purchase.

External stop

Unit is stopped by external signal. Operation is stopped by digital signal

from external remote device or

signal from building management

system.

Manual fan stop active

Operation stopped, fans are in

manual mode and selected as OFF.

Select another speed of fans (LOW /

NORMAL / HIGH) or AUTO mode in

HMI home screen.

Overheat temperature

Temperature after reheater is too

high.

Active: (Overheat temperature

sensor measures > 55°C)

Returned: (Overheat temperature

sensor measures < 50°C)

Alarm is possible if supply airflow is

too low when the reheater is

switched on.

Check the supply airflow.

Check that intake grille is not

blocked.

Check that shut off damper for

outdoor air is open in operation.

Contact your installation company or

place of purchase.

Low supply air temperature

Supply air temperature is too low.

Active: (Outdoor air temperature

sensor measures < 0°C) AND (Supply

Check the heat exchanger and reheater or refer to Point 2 in

“Troubleshooting” menu.

air temperature sensor measures <

5°C)

Returned: (Supply air temperature

sensor measures > 10°C)

CO₂

External CO

sensor malfunction. Check that sensor is connected

2

properly and cable is not damaged.

In case sensor wireless – check

RS485 gateway status and sensor

status in HMI.

Contact your installation company or

place of purchase.

RH

External relative humidity sensor

malfunction.

Check that sensor is connected

properly and cable is not damaged.

In case sensor wireless – check

RS485 gateway status and sensor

status in HMI.

Contact your installation company or

place of purchase.

Output in manual mode

One or more of analogue outputs are

in manual mode.

Check Service menu for Output

settings, and check all configured

outputs to be in Auto mode. If any

outputs in Manual - change back to

Auto mode.

8.7.3 Week Schedule

The unit can be configured to operate at set airflow levels up to two time periods (00:00–23:59) on user

selected days.

Week Schedule is active only during AUTO mode.

211458 | A002

Page 25

SAVECair control |

8.7.3.1 Schedule airflow settings

Touch settings icon to go to SCHEDULE AIRFLOW SETTINGS menu. In this menu set airflow level for

scheduled and unscheduled periods. Available levels: Off, Low, Normal, High or Demand.

Set temperature setpoint offset for both periods (-10°C – 0°C).

Demand level is available only if Demand Control or External fan function is active.

8.7.3.2 Edit schedule

Touch icon at the bottom left corner of the screen to add a new schedule or press EDIT button to modify

already added schedule.

To configure the schedule:

1. Set the time. Touch the START TIME or END TIME values to change time. Use arrow buttons

or decrease value. Confirm with OK button.

and to increase

Note:

Scheduled time can start but never end at midnight (00:00). The latest END TIME period is 23:59.

Scheduled time cannot go to the next day.

If necessary, activate second scheduled period and set up time.

2. Once time is set, click on the day(s) when schedule should be active. It is possible to set a separate schedule for each

day.

Already scheduled days are not available for selection for new schedules.

3. Confirm schedule with OK button.

21

Fig. 6 Week schedule example

Scheduled days are highlighted (pos. 1). First time period (pos. 2) and the second time period (pos. 3) are shown on the

right side of each schedule.

Scheduled time period is displayed in blue colour on the clock (pos. 4).

8.7.4 Filter

In this menu the remaining time until filter change is displayed. Editing is locked with a password, use

administrator password. See Password Settings in Service menu for more information.

Set duration of the filter until next change for period of 3–15 months in steps of 1 month. Default setting is 12 months.

If a new filter period is selected and confirmed or filter alarm is acknowledged, the timer resets and starts counting from

the beginning.

Information what filter type is needed for change or where to order a new filter can be found in Help menu.

211458 | A002

Page 26

| SAVECair control

22

8.7.5 System Preferences

Configuration of unit location, language and time.

Change the following information:

• Language (default language is English)

• Country (default country is UK)

• Unit address (address, post code)

• Unit date and time, activate or deactivate summer/winter time switch.

Time will automatically change between summertime and wintertime according to European standard, based on

Greenwich time zone and set unit location.

Switch between 12 and 24 hours time format.

• Contact information: contractor, installer, service, phone, website, e-mail, etc.

• Display settings: screen brightness and screen behavior in standby mode.

8.7.6 Service

All unit parameters and settings can be changed in the Service menu.

The Service menu is locked by default and it is necessary to enter a password (default

password is 1111).

8.7.6.1 Input

Configuration of inputs

Settings for analog, digital and universal input terminals on the main board, configuration of functionality.

Relative humidity and rotation speed signals from fans are already pre-addressed to specific terminals and cannot be

changed, all other inputs are free for configuration by commissioning. Inputs are free to be used for any purpose.

Digital inputs are restricted by signal type and physical number of connections. An input function is only allowed to be

used once.

Universal input (UI) configured as universal analog input (UAI) can be configured for several inputs because multiple

sensors of the same type can be used. Universal analog inputs (UAI) have only selections for RH Sensor (RH), CO₂

Sensor (CO₂), Supply Air Fan Control (SAFC) and Extract Air Fan Control (EAFC) wired configurations.

Analog input (AI) temperature sensors are not allowed to be configured more than once.

Already used and configured input signal type is greyed out and not available for selection. However some user functions related to configuration of digital input (AWAY, CROWDED, FIREPLACE, HOLIDAY or REFRESH) have several possible activation points, via HMI/APP/Wireless/Modbus (BMS).

Digital inputs can be configured to be normally open (Normally Open (NO)) or normally closed (Normally Closed

(NC)). Default setting is Normally Open (NO). Not available for wireless inputs.

PDM (pulse density modulation) input for relative humidity (RH) sensor on the main board is pre-adressed and cannot

be changed.

Table 1 Overview of input configuration

Analog inputs Digital inputs Universal analog inputs Universal digital inputs

Input type

Value

Compensation

Input type

Polarity

Value

Input type

Analog type

Value

Input type

Digital type

Polarity

Value

211458 | A002

Page 27

SAVECair control |

8.7.6.2 Output

Configuration of outputs.

Settings for analog, digital and universal output terminals on the main board and connection board, configuration of

functionality.

Fan output PWM (Pulse-width modulation) signal and triac output are already pre-addressed to specific terminals and

cannot be changed, all other outputs are free for configuration by commissioning. Outputs are free to be used for any

purpose.

Digital outputs are restricted by signal type and physical number of connections.

An output function is only allowed to be used once. Already used and configured terminal is greyed-out in the menu for

output type selection.

Analogue and digital outputs have a selection for Auto/Manual modes and an adjustable value for Manual mode.

Manual mode selection overwrites all system related automatic functions. Analogue output adjustable manual value

range is 0–10V and digital output values On/Off.

Table 2 Overview of output configuration

Analog outputs Digital outputs

Output type

Auto/Manual

Value

Output type

Auto/Manual

Value

23

8.7.6.3 Components

Configuration of connected components.

Heat Exchanger

• Choose heat exchanger type.

Available types: Rotating / Plate

• Activate or deactivate passive house function if heat exchanger type Rotating is selected.

Options: Yes / No.

• Choose bypass damper location if heat exchanger type Plate is selected. Default setting is based on unit type.

Supply / Extract

• Set actuator type. Default setting is based on unit type.

Range: 0–10 V / 2–10 V / 10–0 V / 10–2 V.

Heater

• Choose heater type. Each selection unlocks additional configuration options. Default setting is based on unit type.

Available types: None / Electrical / Water / Change-over.

• Set actuator type. Default value is 0–10 V.

Range: 0–10 V / 2–10 V / 10–0 V / 10–2 V.

• Set circulation pump temperature. Default setting is 10°C. This option is available if Water / Change-over heater

type is selected.

Range: 0–20°C.

• Set circulation pump stop delay. Default setting is 5 minutes. This option is available if Water / Change-over heater type is selected.

Range: Off / 1–60 min.

Cooler

• Choose cooler type. Each selection unlocks additional configuration options. Default setting is None.

Available types: None / Water / Change-over.

211458 | A002

Page 28

| SAVECair control

24

• Set outdoor air temperature interlock. Default setting is 10°C.

Range: 0–20°C.

• Set actuator type. Default value is 0–10 V

Range: 0–10 V / 2–10 V / 10–0 V / 10–2 V.

• Set circulation pump stop delay. Default setting is 5 minutes. This option is available if Water / Change-over heater type is selected.

Range: Off / 1–60 min.

Extra controller

• Choose extra controller type. Each selection unlocks additional configuration options. Default setting is None.

Available types: None / Preheater / Heating / Cooling.

• Set temperature set point of the extra controller. Default value is 0°C.

Range: –30°C — 40°C.

• Set P-band. Default setting is 4°C.

Range: 1-60°C.

• Set I-time. Default setting is Off.

Range: Off / 1–240 sec.

• Set actuator type. Default value is 0–10 V.

Range: 0–10 V / 2–10 V / 10–0 V / 10–2 V.

• Set circulation pump temperature. Default setting is 0°C. This option is available if Preheater / Heating controller

type is selected.

Range: 0–20°C.

• Set circulation pump stop delay. Default setting is 5 minutes.

Range: Off / 1–60 min.

8.7.6.4 Control Regulation

Configure how the system is controlled.

Temperature Control

• Configure temperature controller. Choose control mode:

Available modes: Supply air temperature control / Room temperature control / Extract air temper-

ature control

• Choose temperature unit. Default setting is Celsius.

Available units: Celsius / Fahrenheit

• Set P-band. Default setting is 20°C. Set I-time. Default setting is 100 sec.

• Configure SATC Split for heater (0–20%), heat exchanger (25–60%) and cooler (65–100%) output settings.

Range: 0–100%.

• Configure cascade control setpoint for min/max supply air temperature, P-band, I-time.

Only available for Room temperature control / Extract air temperature control modes.

ECO mode

• Configure ECO mode settings. Set heater offset. Default setting is 10°C.

Range: 0–10°C.

Fan Control

• Configure airflow and fan settings. Select fan control (airflow) type. Default setting is Manual (%).

Available types: Manual (%) / Manual rpm / Flow (CAV) / Pressure (VAV) / External

211458 | A002

Page 29

SAVECair control |

25

Setting

Airflow

Manual RPM Flow (CAV)

%

rpm

l/s, m

3

/h, cfm

Pressure

(VAV)

Pa, inwc %

External

measurement

unit.

P-Band

0–100% 0–3000 rpm 0–500 Pa

0–100%

Default setting: 150 Pa

I-time

Off / 1–240 sec. Off / 1–240 sec.

Default setting:

Off / 1–240 sec.

Default setting: 50 sec.

Off / 1–240 sec.

50 sec.

Airflow level

16-100% 500–5000 rpm

Sensor range (airflow unit)

0–100%

settings for each

level: MAXIMUM

LEVEL, HIGH

LEVEL, NORMAL

LEVEL, LOW

LEVEL,

MINIMUM LEVEL

Manual Fan Stop — turn on or off manual fan stop, this function enables manual fan stop from HMI. Default setting

is OFF.

Pressure

Sensors —

configure sensor

voltage relation

to pressure.

Set value at

which fan alarm

occurs. Default

setting is None

- -

Supply air fan control sensor:

Pressure at 0V: 0-500 Pa, default

setting 0 Pa

Pressure at 10V: 0-2500 Pa, default

setting 500 Pa.

Extract air fan control sensor:

Pressure at 0V: 0-500 Pa, default

setting 0 Pa.

Pressure at 10V: 0-2500 Pa, default

-

setting 500 Pa

Set K factor for

supply air fan

and extract air

fan. Default

- - SAF K-Factor

range: 0–1000

EAF K-Factor

range: 0–1000

- -

settings are

based on unit

type.

Outdoor

Compensation

Compensation is always started at fixed value of 0° C. Set stop compensation for outdoor air

temperature and compensation value for fan speed.

Stop Compensation Temperature range: -25 - 0°C, default setting 0°C

Stop Compensation Value range: -50 to 0%, default setting 0%

Important

Changing the airflow type does not change P-band value automatically. P-band value have to be changed

manually after changing the airflow type.

Demand Control

Configure indoor air quality sensors. Once sensor(s) are configured, Demand Control function is activated by choosing

AUTO mode in home screen.

• Activate or deactivate CO

Set CO

sensor setpoint. Default setting is 800 ppm (parts per million in atmosphere). Normal atmospheric CO2con-

2

centration is 400 ppm. Range: 100–2000 ppm.

Set P-band, default setting is 200 ppm. Range: 50–2000 ppm.

Set I-Time, default setting is Off. Range: Off/1–120 sec.

• Activate or deactivate RH sensor. Default setting is Off.

Set humidity setpoint in summer, default setting is 60%. Range: 1–100%.

Set humidity setpoint in winter, default settting is 50%. Range: 1–100%.

Set P-band, default setting is 10%. Range: 1–100%.

211458 | A002

sensor. Default setting is Off.

2

Page 30

| SAVECair control

26

Set I-time, default setting is Off, Range: Off/1–120 sec.

• Select airflow level for Improving Air Quality. Range: Normal / High / Max.

• Select airflow level for Good Air Quality. Range: Low / Normal.

RH Transfer Control

Note:

Setting is available if heat exchanger type is set as Rotating. It is highly recommended to leave default

values for P-band and I-time. They should be changed only by installer and trained staff.

• Activate or deactivate relative humidity transfer functionality. Default setting is On.

• If RH Transfer Control is activated, configure:

Setpoint, default setting is 45% humidity. Range: 1–100% RH.

Set P-band, default setting is 4g/kg. Range: 1–100g/kg.

Set I-time, default setting is Off. Range: Off/1–120 sec.

Defrosting Control

Note:

Setting is available if heat exchanger type is set as Plate.

The unit is equipped with an automatic defrost function that is activated when there is risk of icing in the area around

the heat exchanger.

• Select defrosting mode. Default setting is Normal.

Soft

Normal Apartments or houses with normal humidity

Hard

1

In newly constructed houses it might be necessary with a higher defrost level during the first winter period.

Dry areas, such as warehouse buildings with few people or industrial

buildings that don’t use water in their production process.

1

Buildings with very high humidity level.

• Set by-pass location. Default setting is based on unit configuration.

Supply / Extract.

• Set preheater setting. Default setting is based on unit configuration.

Auto / Fixed

Fixed pre-heater setting allows user to adjust pre-heater setpoint manually. Auto pre-heater setting sets floating

pre-heater activation setpoint (Stop defrosting temperature +2K).

• Set if secondary air is allowed. Default setting is Off.

Off / On.

Cooling Control

• If the outdoor air is warmer than the extract air and the supply air is above the setpoint, cooling recovery occurs. This

condition blocks the heat regulation process. Activate or deactivate cooling recovery. Default setting is On.

Set cooling limit. Cooling recovery is allowed if extract air temperature is lower than outdoor air temperature by a set

limit (default setting is 2K) and cooling demand is present.

• Configure status, temperature and duration of free cooling. Activate or deactivate free cooling . Default setting is

Off.

Set supply and extract air fan levels during free cooling. Default setting is Normal. Range: Normal / High /

Maximum.

Set start condition. Outdoor daytime temperature for activation, default setting is 22°C. Range: 12–30°C.

Stat stop conditions. Extract/Room temperature, default setting is 18°C. Outdoor high temperature limit, default set-

ting is 23°C. Outdoor low temperature limit is 12°C. Start and stop time.

211458 | A002

Page 31

SAVECair control |

8.7.6.4.1Finding RPM for desired airflow

It is necessary to set fan RPM (revolutions per minute) for each airflow level to control airflow by changing fan speed.

Fan speed differ for each household because of different unit size, duct system and system pressure. In order to find

correct fan speed, external tool must be used at Systemair website.

1. Go to Systemair website and find your unit.

2. Go to Diagram tab and type in desired airflow values in l/s, m

sure drop in duct system (if this value is not know, type in 100 Pa for both supply and extract air)

Fig. 7 Example of airflow and external pressure selection

3. See calculated speed values in revolutions per minute (rpm) for both supply and extract air in the table bellow

diagrams.

3

/h, m3/s or cfm for supply and extract air. Input pres-

27

Fig. 8 Example speed for supply and extract air

4. Use this procedure to find fan speed for all airflow levels: MINIMUM LEVEL, LOW LEVEL, NORMAL LEVEL, HIGH LEV-

EL, MAXIMUM LEVEL.

5. Finally in the control panel go to Service menu, enter the password, then go to Control Regulation → Fan

Control. Choose RPM as airflow type and in sub-menu Airflow Level Settings enter calculated fan speed values for each level.

8.7.6.5 User Modes

Set airflow level, duration and offset for each user mode.

Set supply and extract air fan levels, default duration and temperature offset where available for user modes:

• Away

• Central Vacuum Cleaner

• Cooker Hood

• Crowded

• Fireplace

• Holiday

• Refresh

8.7.6.6 Communication

Configure Modbus and wireless settings

Modbus

• Set Modbus address. Default setting is 1.

• Set baud rate. Default setting is 19200.

• Set parity. Default setting is None. Range: None / Even / Odd.

• Set stop bits. Default setting is 2. Range: 1–2.

• Shows Smartly-Gateway state.

211458 | A002

Page 32

| SAVECair control

28

HMI

• Shows communication information for HMI. Modbus device number (1–10) and Modbus termination: Active/

Inactive.

8.7.6.7 Logs

Information about alarms, fans and parameters are stored in Logs menu.

Fans Levels

• Time counter for each supply air fan level duration is displayed. Counted and total time. Reset counted time.

Level 1: 0%

Level 2: 1–29%

Level 3: 30–44%

Level 4: 45–59%

Level 5: 60–100%

Parameters

• Select parameter type and create a graph based on stored data

button

. (only available in mobile application)

. Export parameters data by touching arrow

8.7.6.8 Unit Backups

In this menu it is possible to save and restore user and factory settings.

User backups

• Touch SAVE button to save current configuration and parameters.

Touch RESTORE button to restore last saved user configuration and parameters

Factory settings

• Touch RESTORE button to restore factory configuration and parameters. This will also overwrite changed password.

Software versions

Displays current version of main circuit board, Internet Access Module and HMI.

• Touch SOFTWARE UPDATE button to update software if there is a newer version.

8.7.6.9 Password Settings

Service level is always locked with a password. Other menu levels have a separate option for locking. If password requirement is activated for different menu levels, these are unlocked with the administrator password.

Choose what menus should be locked or not.

8.7.7 Help

FAQ, troubleshooting of alarms, contact information for support is provided in this menu.

• Service partner — information about service partner.

• Company

• Telephone

• Homepage

• Email

• User modes— detailed description of all user modes.

• Functions— detailed description of different user functions.

211458 | A002

Page 33

• Alarms— detailed description of all alarms.

• Troubleshooting— information about all different possible malfunctions.

9 Service

9.1 Warnings

Danger

• Make sure that the mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• All electrical connections and maintenance work must be carried out by an authorized installer and in

accordance with local rules and regulations.

Warning

• This product must only be operated by a person who has suitable knowledge or training within this field

or carried out with the supervision of a suitably qualified person.

• Beware of sharp edges during mounting and maintenance. Use protective gloves.

Warning

Service

|

29

• All though the mains supply to the unit has been disconnected there is still risk for injury due to rotating

parts that have not come to a complete standstill.

Important

• The installation of the unit and complete ventilation system must be performed by an authorized installer

and in accordance with local rules and regulations.

• The system should operate continuously, and only be stopped for maintenance/service.

• Do not connect tumble dryers to the ventilation system.

• Duct connections/duct ends must be covered during storage and installation.

• Make sure that filters are mounted before starting the unit.

211458 | A002

Page 34

Service

|

30

9.2 Internal components

Fig. 9 Internal components

Position Description

1

2

3

4

5 Rotor sensor

6

7

8

9

10

11 Rotor motor

12

13

14

15

Supply air fan

Overheat protection sensor

Overheat protection reset button

Internal electrical re-heater

Rotating heat exchanger

Outdoor air sensor

Supply air filter

Extract air fan

Drive belt for rotating heat exchanger

Relative humidity/Extract air temperature sensor

Extract air filter

Supply air sensor

External connections

9.2.1 Component descriptions

9.2.1.1 Fans

The fans have external rotor motors of EC type which can be steplessly controlled individually 16–100%. The motor

bearings are life time lubricated and maintenance free. It is possible to remove the fans for cleaning, see “User Manual”

for more information.

211458 | A002

Page 35

Service

|

9.2.1.2 Filters

The factory installed filters are of filter quality F7 for the supply air and G3 for the extract air filter. The filters need to be

replaced when polluted. New sets of filters can be acquired from your installer or wholesaler.

Filter quality G3 can be installed for supply air filtering.

The filter type is labelled on the top of the filter

9.2.1.3 Heat exchanger

SAVE VSR 300/500 is equipped with a highly efficient, rotating heat exchanger. Required supply air temperature is

therefore normally maintained without adding additional heat.

The heat exchanger is removable for cleaning and maintenance, see “User Manual” for more information.

9.2.1.4 Main circuit board

The main circuit board controls all functions and the unit.

It is possible to connect external accessories to a free terminals on the main circuit board.

9.2.1.5 Connection box

Connection box is placed outside of the unit. It contains connection board. All external accessories can be connected to

the unit via connection board with freely configurable terminals.

31

9.2.1.6 Temperature sensors

Four temperature sensors (NTC, 10 kΩ at 25°C) are included in the unit from factory and positioned in the corresponding air chambers.

The sensors are connected to the main print card. See wiring diagram for more information.

9.2.1.7 Humidity sensor

Relative humidity sensor (RHS) is included in the unit from factory and positioned in the extract air chamber.

The sensor is connected to the main print card. See wiring diagram for more information.

9.2.1.8 Electrical Re-heater battery

The re-heater battery is positioned in the supply air chamber.

The re-heater is activated by a relay and switches on if the supply air temperature is lower than the set point and

switches off if one or more of the following conditions are met:

1. If the supply air temperature is above the set point.

2. If the over heat protection is activated or the sensor is malfunctioning.

3. If the emergency thermostat is triggered or broken.

4. If the supply air sensor is in error state.

5. If the supply air fan is not running.

6. If the heater is set to disabled in the menu.

9.2.1.9 Overheat protection reset button

If the supply air temperature is low, it can indicate that the over heat protection is triggered. The overheat protection

can be reset by pressing the reset button .

The button is placed on the top cover.

211458 | A002

Page 36

Service

|

32

1. Reset button

9.3 Replacing rotor drive belt

If the alarm Rotor guard is raised, see chapter 8.7.2.3, the rotor drive belt may be damaged or broken.

Fig. 10 Rotor drive belt

The replacement drive belt (1) is adjustable and delivered with a nipple attached in one end.

1. Stop the unit by disconnecting the mains.

2. Open and remove the side cover.

3. Remove the broken drive belt.

4. Use tape to attach the drive belt to the rotating heat exchanger, and rotate the exchanger by hand to get hold of the

drive belt.

5. Remove the tape and put the ”empty” end on to the nipple. Press the ends firmly towards each other and tighten the

nipple.

6. Pull the drive belt on to the belt pulley and rotate the exchanger by hand. Check that the belt pulley rotates.

Note:

If the drive belt slips, the drive belt may be too long and needs to be shortened. Cut the drive belt 5 mm

and go to step 5.

7. Replace and lock the side cover and connect the unit to mains.

8. Check that the alarm has ceased on the Control Display.

Note:

If the alarm remains, check the rotor sensor.

9.4 Troubleshooting

If problems should occur, please check the items below before calling your service representative.

211458 | A002

Page 37

Service

|

33

Malfunction

Fans do not start

Reduced airflow

Action

1. Check the HMI for alarms.

2. Check that all fuses and fast couplings are connected (main power supply and fast

couplings for supply and extract air fans).

3. Check that the week schedule is ON and running in AUTO mode. The week schedule

might be in OFF mode with the air flow set to OFF (chapter 8.7.3).

1. Check the HMI for alarms. Some alarms can reduce the airflow to LOW if active.

2. The unit could be in defrost mode. This reduces the fan speed and in some cases shuts

down the supply air fan completely during the defrosting cycle. The fans go back to

normal after finished defrosting. There should be a defrosting function icon visible in the

APP or HMI home screen if defrosting is active.

3. If the outdoor air temperature is below 0°C (Outdoor air temperature sensor (OAT)

measures < 0°C) outdoor airflow compensation function can be active (if enabled). Fan

speed (Supply or Supply/Extract air fans) is linearly reduced for decreasing outdoor air

temperature.

4. Check if temporary user mode that reduces airflow is not activated, for example AWAY,

HOLIDAY, etc. Also check digital inputs CENTRAL VACUUM CLEANER and COOKER HOOD.

5. Check setting of airflow in the HMI.

6. Check week schedule settings (chapter 8.7.3).

7. Check filters. Is change of filters required?

8. Check diffusers/louvres. Is cleaning of diffusers/louvres required?

9. Check fans and heat exchange block. Is cleaning required?

10.Check if the buildings air intake and roof unit (exhaust) have been clogged.

11.Check visible duct runs for damage and/or build up of dust/pollution.

12.Check diffuser/louvre openings.

The unit cannot be

controlled (control

functions are stuck)

Low supply air

temperature

Noise/vibrations

1. Reset control functions by pulling out the plug for 10 seconds.

2. Check the modular contact connection between the HMI and the main printed circuit

board.

1. Check the display for alarms.

2. Check the active user functions in HMI screen if Defrosting function is running.

3. Check set supply air temperature in the HMI.

4. Check if ECO mode is activated in HMI (it is a power saving function and prevents the

heater from activating).

5. Check if user modes HOLIDAY, AWAY or CROWDED are activated in the HMI or via a

hardwired switch.

6. Check the analogue inputs in the service menu to verify that the temperature sensors

are functioning correctly.

7. In case of installed electrical/other re-heater battery: Check if the overheat protection

thermostat is still active. If necessary, reset by pressing the red button on the front plate

of the electrical re-heater.

8. Check if the extract filter must be changed.

9. Check if the unit has a re-heater battery connected. At very cold outdoor conditions an

electrical or water heating battery might be necessary. A re-heater battery can be

acquired as an accessory.

1. Clean fan impellers.

2. Check that the screws holding the fans are tightened.

3. Check that the anti vibration lists are fitted to the mounting bracket and to the back of

the unit.

4. Check that the rotor belt is not slipping if the unit has rotating heat exchanger.

211458 | A002

Page 38

Accessories

|

34

10 Accessories

SAVE VSR 300/500 have many available accessories that can be used to expand functionality of the unit and increase

comfort level.

Recommended accessories can be always found at Systemair website www.systemair.com by searching the article

number or the name of the desired accessory.

10.1 Internet Access Module (IAM)

Internet access module is a device that allows to connect

to the unit and control it via a mobile application or

directly from the computer and receive automatic

updates.

The Cloud is a mediator between the user and the unit.

To access your unit via Cloud, it has to be connected to

the internet via Internet Access Module.

The Internet Access Module (IAM) should be connected to the Connection Board (CB) and then via WiFi or Ethernet cable to the internet gateway (router).

For more information read the manual that comes with the accessory.

Component/product — Article number:

• Internet Access Module (IAM) – 211243

10.1.1 Mobile application and Login

A mobile application to access your unit via internet can be downloaded from Google Play or AppStore.

Once application is installed on your smartphone and IAM is connected properly:

1. Launch the application. In the login screen (pos. 1) enter your unique

UNIT ID number which can be found on the back label of IAM.

2. Press LOG IN button (pos. 2).