Page 1

SAVE VTR 150/K

GB User Manual................................................2

SV Användarhandbok .....................................26

Document translated from English | 211568 · A003, 29

DE Bedienungsanleitung .................................50

FI Käyttöohje................................................74

Page 2

GB

User Manual

© Copyright Systemair UAB

All rights reserved

E&OE

Systemair UAB reserves the rights to alter their products without notice.

This also applies to products already ordered, as long as it does not affect the previously agreed specifications.

GB

211471 | A003, 29

Page 3

Contents

1 Disposal and recycling ...... ......... ........ ......... . .....5

2 Warnings. ......... ........ . ......... ........ . ........ ......... .5

3 Type label.. . ........ . ........ . ........ ......... ......... .......6

4 Introduction ........ ......... ......... ......... ........ ........6

5 Cooker hood .... ........ . ........ ......... ......... ......... ..6

6 Configuration ...... . ........ . ........ ......... ......... .......7

6.1 General.... . ........ ........ . ......... ........ . ........ 7

6.2 Startup wizard ....... ......... ......... ........ . .....7

6.3 Common symbols. . ........ ......... . ........ .......7

6.4 Menu overview ......... ........ . ........ ......... . .8

6.5 Home screen...... ........ . ........ ......... . ........8

6.5.1 User modes .... ......... ........ . ........ 8

6.5.2 Temperature settings .. . ........ ..... 11

6.5.3 Airflow settings . ........ . ........ . .... 12

6.5.4 Indoor Air Quality . ......... ........ . .. 12

6.5.5 Status line .... ........ . ........ . ........ 12

6.6 Description of User function icons ...... ...... 13

6.7 Week Schedule..... ........ . ........ . ........ . .. 14

6.7.1 Schedule airflow

settings......... ........ . ........ ........14

6.7.2 Edit schedule ........ . ........ . ........ 14

7 Cooker hood maintenance........ ......... ......... ..... 15

7.1 Cleaning cooker hood... . ........ ......... . ...... 15

8 Maintenance of the unit........ . ........ . ........ ........15

8.1 Warnings. ........ . ........ . ........ . ........ ........ 15

8.2 Remove/mount the outer front ...... ......... 16

8.3 Remove/mount the inner front... ......... .... 16

8.4 Changing filters.... . ........ . ........ . ........ ..... 16

8.4.1 Resetting the filter time ........ ..... 17

8.5 Checking and cleaning the heat

exchanger ........ . ........ . ........ ......... ....... 17

8.6 Cleaning the fans ........ . ........ ......... ....... 17

8.7 Replacing rotor drive belt ......... . ........ ..... 17

8.8 Overheat protection reset button . ........ . ... 19

9 Duct system maintenance .. . ........ ......... ......... .. 19

9.1 Cleaning extract louvres and supply air

diffusers........ ........ . ........ ......... ......... .. 19

9.2 Checking the outdoor air intake . ......... ..... 19

9.3 Checking the roof cowl (if fitted). ........ . .... 19

9.4 Checking and cleaning the duct

system ........ ......... ........ . ........ . ........ . .. 19

10 Troubleshooting... ......... . ........ ......... ........ . ..... 19

11 Alarms..... . ........ . ........ ......... ......... ........ . ...... 21

11.1 Alarm list...... . ........ . ........ . ........ ........ . .. 21

211471 | A003, 29

Page 4

Page 5

GB

1 Disposal and recycling

This product is compliant to the WEEE directive. When disposing the unit, follow your local rules

and regulations.

This product packing materials are recyclable and can be reused. Do not dispose in household

waste.

2 Warnings

Danger

• Make sure that the mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• All electrical connections and maintenance work must be carried out by an authorized installer and in

accordance with local rules and regulations.

Warning

Disposal and recycling |

5

• This product must only be operated by a person who has suitable knowledge or training within this field

or carried out with the supervision of a suitably qualified person.

• Beware of sharp edges during mounting and maintenance. Use protective gloves.

Warning

• All though the mains supply to the unit has been disconnected there is still risk for injury due to rotating

parts that have not come to a complete standstill.

Important

• The installation of the unit and complete ventilation system must be performed by an authorized installer

and in accordance with local rules and regulations.

• The system should operate continuously, and only be stopped for maintenance/service.

• Do not connect tumble dryers to the ventilation system.

• Duct connections/duct ends must be covered during storage and installation.

• Make sure that filters are mounted before starting the unit.

211471 | A003, 29

Page 6

| Type label

6

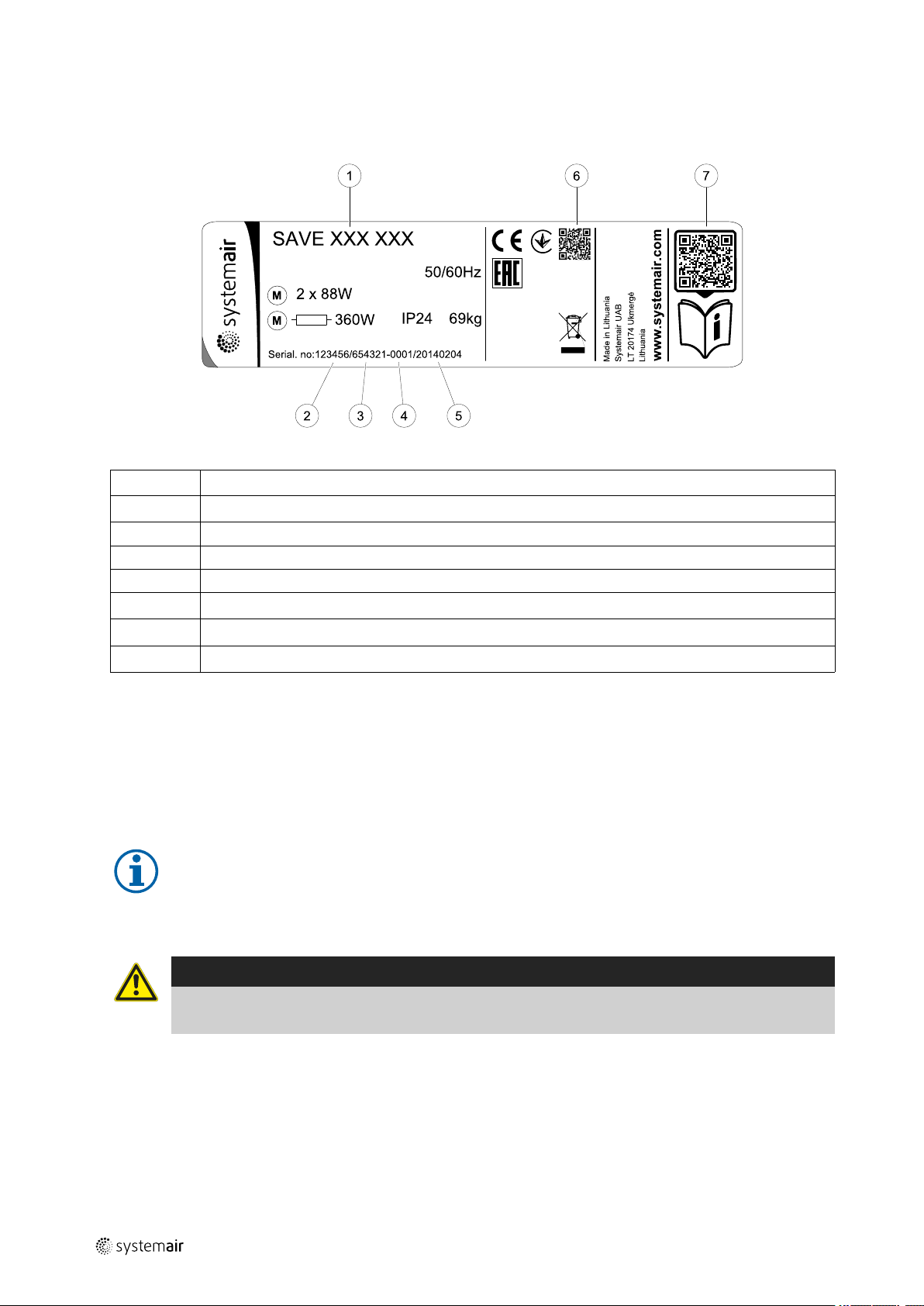

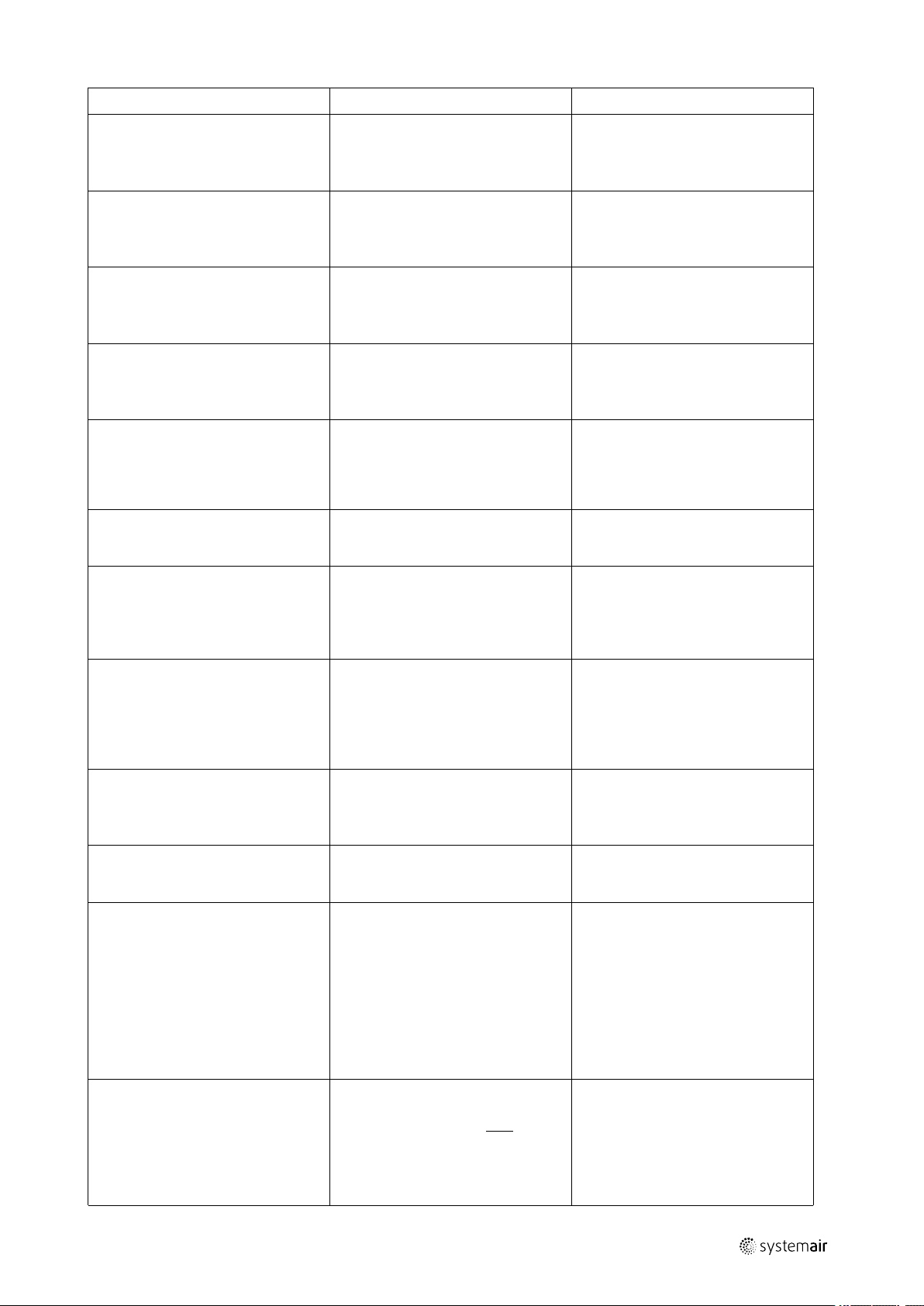

3 Type label

Before calling your service representative, make a note of the specification and production number from the type label,

which can be found on the side of the units, next to the external connections.

Fig. 1 Type label

Position Description

1

2

3

4

5

6

7

Product code (product specification)

Product item number

Production order number

Serial number

Production date (YY.MM.DD)

QR code for manufacturing order (MO) number and software version

QR code for the spare parts list and documentation

GB

4 Introduction

The SAVE VTR 150/K is a heat recovery ventilation unit with a built in rotating highly efficient heat exchanger and cooker hood. The SAVE VTR 150/K is suitable for smaller flats or houses. It supplies filtered outdoor air to residential areas

and extract air from bathroom, kitchen and wet rooms.

There are two model options, right (R) and left (L) model. Both models come with 500 W or 1000 W installed re-heater

battery. The different models are recognized by the placing of the internal components. This manual describes basic information how to operate and perform maintenance on a left (L) unit and the system it is connected to.

Note:

This document describes a left (L) model. The inside of a right (R) model is mirrored.

5 Cooker hood

Danger

• Do NOT flambé beneath the cooker hood when in use.

• Sufficient air flow must be secured to the room when the cooker hood is in use

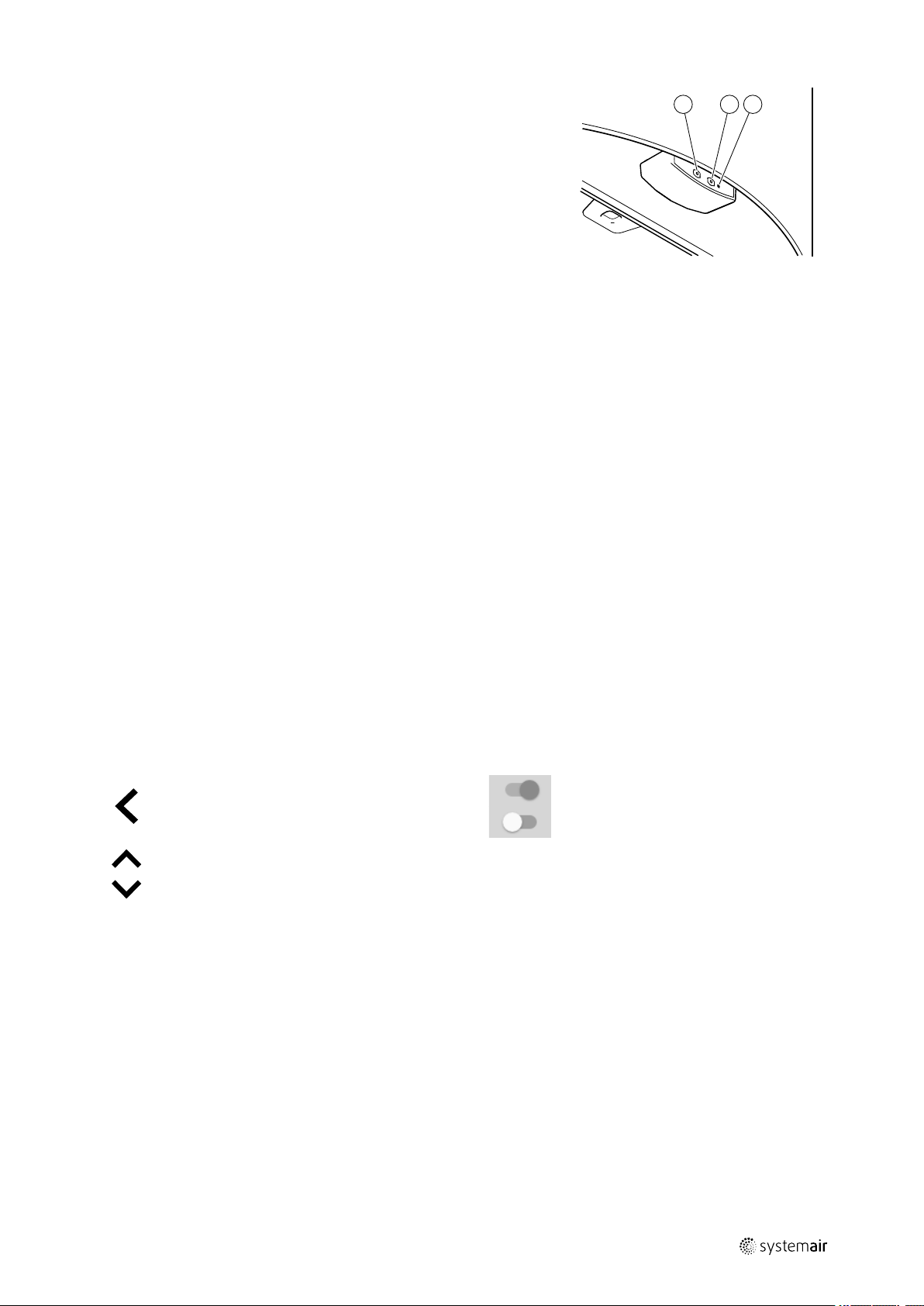

Press button A to turn on the lights.

Press button B once to open the ventilation damper when cooking. The LED indicator (C) is steadily lit.

Press button B again to force the ventilation. The LED indicator is blinking.

211471 | A003, 29

Page 7

GB

A B C

Press button B a third time to close the ventilation damper. The ventilation

fan goes back to nominal speed and the LED indicator goes off.

The damper will automatically close after 60 minutes unless it is manually

closed.

No extract air will go through the cooker hood in "off" mode. Extract air from

the kitchen needs a separate air valve.

Hint: Let the damper be open a while before and after cooking to prevent

smoke from spreading in the room.

Fig. 1 Cooker hood front panel

Configuration |

6 Configuration

6.1 General

SAVE VTR 150/K has a modern touchscreen LCD control panel, simply known as HMI — Human Machine Interface. The

touchscreen display provides information about current state of the unit and allows you to control all system functions.

Settings are done by touching the icons or options. The touch screen is sensitive and it is not necessary to press too

hard.

7

6.2 Startup wizard

During the first power up of the unit, you will be asked to set:

• menu language

• time and date

• import configuration file (if the Internet Access Module (IAM) with configuration file is available)

• airflow control type (Manual/RPM) and airflow level values

• heater type (None/Electrical/Water/Change-over)

The Startup Wizard cannot be skipped.

6.3 Common symbols

The following selection symbols are common and are present in most menu pages:

Back button to return to a previous

menu, located at the upper left corner

Up arrow to increase a value CANCEL Button to cancel changes

Down arrow to decrease a value

Some menus have more than one page. Touch page indicator in the top right corner to go to the next page. The first

number indicates current page number and the second number indicates a total number of pages available.

SET/OK

On and Off slider to activate or

deactivate a function. White bubble —

function is inactive, green bubble —

function is active.

Buttons to confirm changes

Many options show up in a form of the pop-up window. Select the option from the displayed list in the pop-up window

and press OK to confirm selection.

211471 | A003, 29

Page 8

| Configuration

8

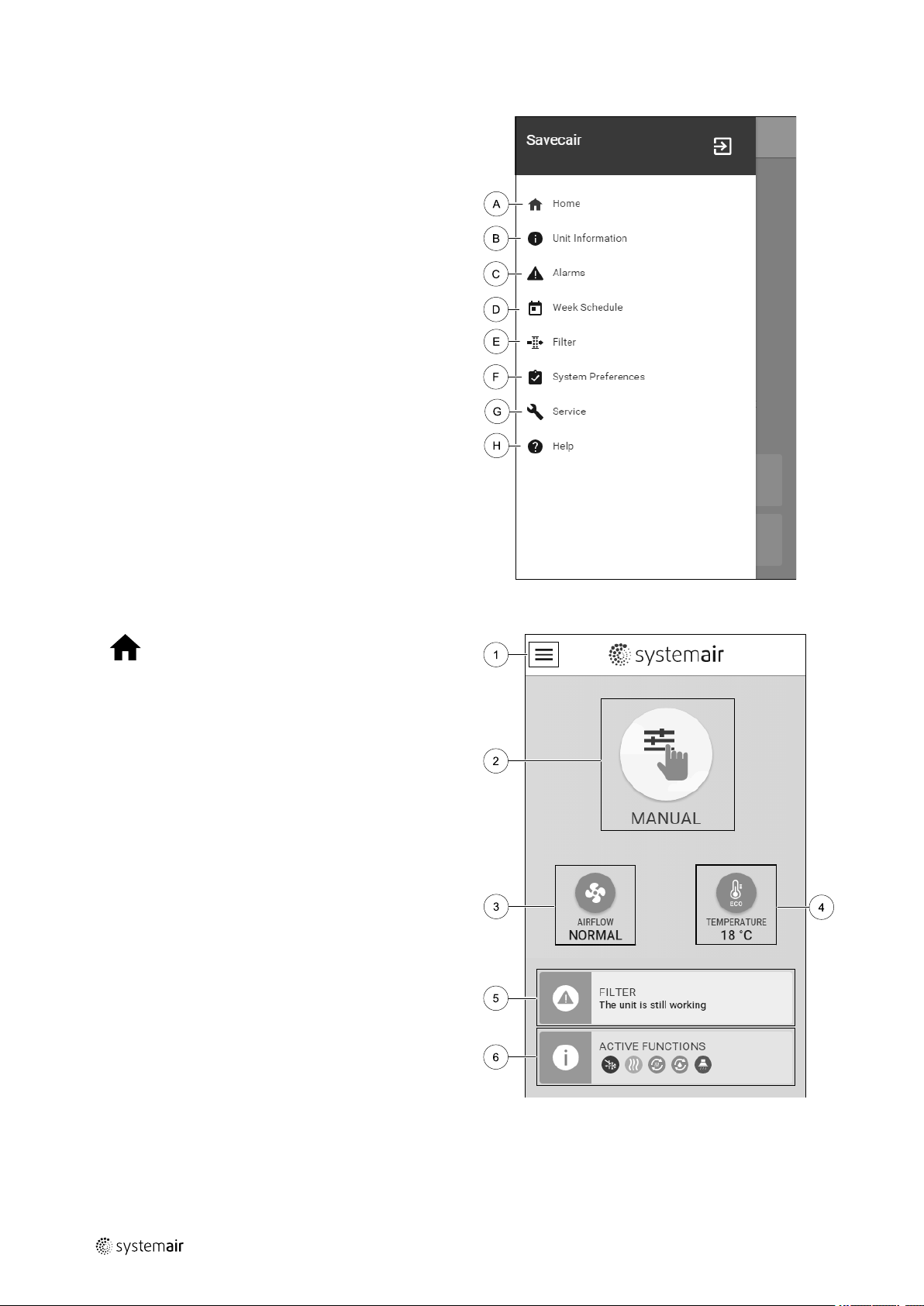

6.4 Menu overview

A.Return to home screen

B. Basic read-only information about the unit

C. Currently active alarms and alarm history

D.Configure and check week schedule

E. Check and change remaining time till filter change

F. General system preferences

G.Configuration of all system parameters

H.Help and troubleshooting menu

GB

6.5 Home screen

Touching home icon (pos. A) in drop-down menu

list (pos. 1) will always returns you to home screen after

commissioning.

1. Drop-down menu list

2. Active user mode

3. Airflow settings

4. Temperature settings

5. List of active alarms

6. Icon list of active user functions

6.5.1 User modes

The first icon at the top of home screen shows currently active user mode. To change the user mode, touch the active

user mode icon (pos. 2) and select a new user mode from the list. The unit has 2 permanent and 5 temporary user

modes available for selection. Only one mode can be active at a time.

211471 | A003, 29

Page 9

GB

Settings of all modes can be modified in Service menu.

Configuration |

6.5.1.1 Permanent modes

Permanent modes are always active unless interrupted by temporary modes, activated user functions or alarms:

9

Icon Text

AUTO

MANUAL

Automatic airflow control. AUTO mode is available for selection when Demand

Control, Week Schedule and/or external fan control functions are configured,

otherwise AUTO mode icon won’t be visible in active user modes menu. AUTO

mode activates Demand Control, Week Schedule and/or external fan control

functions. Demand is available to choose as airflow setting in Week Schedule.

Manual selection of airflow levels. The unit can be set run at one out of four

available airflow speeds: Off/Low/Normal/High.

Note:

The fan can be set to OFF by activating Manual Fan Stop function in

Service menu.

Description

6.5.1.2 Temporary modes

Temporary modes are active only for a set period of time unless interrupted by active user modes, activated user functions or alarms:

Icon Text

HOLIDAY

CROWDED

AWAY

REFRESH

FIREPLACE

Sets speed of both supply and extract air fans to Low levels when user is away

from home for a long period of time.

ECO mode is active.

Set duration in days.

Sets speed of both supply and extract air fans to maximum High levels and

temperature setpoint offset to –3 K when apartment is more crowded than usual.

Default temperature setpoint offset is –3 K.

Set duration in hours.

Sets speed of both supply and extract air fans to Low levels when user is away

from home for a short period of time.

ECO mode is active.

Set duration in hours.

Sets speed of both supply and extract air fans to maximum High levels to

replace indoor air with a fresh air in a short period of time.

Set duration in minutes.

Sets speed of supply air fan to High level and extract air fan to Low level to

increase air pressure within the apartment for better smoke extraction through

the chimney.

Set duration in minutes.

Description

Settings of all modes can be modified in Service menu.

Temporary modes and user functions are active only for a set period of time after which they are terminated and the

unit changes back to a former AUTO or MANUAL mode, depending on which one was active before temporary mode or

user function was activated.

Temporary modes can also be activated via digital input signal triggered by push button, presence detector, etc.

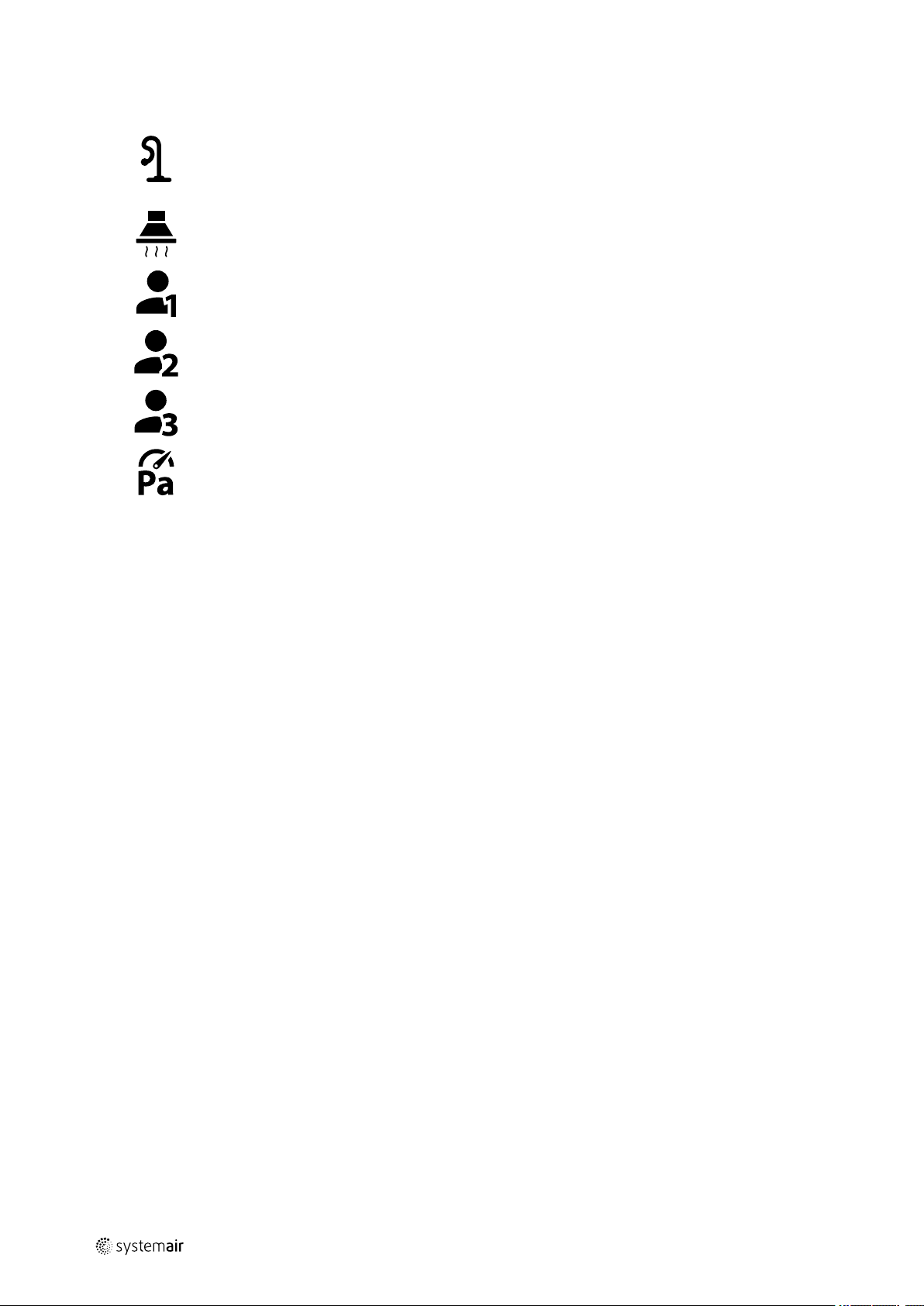

6.5.1.3 Digital input functions

Digital input functions always active while digital input is activated.

211471 | A003, 29

Page 10

10

| Configuration

GB

Icon Text

Central

Vacuum

Cleaner

Cooker Hood

Configurable

Digital Input

1

Configurable

Digital Input

2

Configurable

Digital Input

3

Pressure

Guard

Function sets speed of supply air fan to High level and extract air fan to Low

level to increase air pressure within the apartment for better dust collection

through central vacuum cleaner.

Function can be activated via digital input — Central Vacuum Cleaner

Function.

Sets speed of both supply and extract air fans to Maximum level to increase

airflow in the cooker hood.

Function can be activated via digital input — Cooker Hood Function.

Configurable digital input for custom user function. Airflow levels for both fans

are freely configurable.

High–priority function.

Configurable digital input for custom user function. Airflow levels for both fans

are freely configurable.

Mid–priority function.

Configurable digital input for custom user function. Airflow levels for both fans

are freely configurable.

Low–priority function.

Configurable digital input for pressure switch connection. Airflow levels for both

fans are freely configurable.

6.5.1.3.1Configurable digital inputs

Description

A custom airflow settings for supply and extract fans can be set and assigned to a digital input. Each fan can have a different airflow setting.

Configurable digital input can be activated via signal triggered by push button, presence detector or any other external

device with digital output, such as Building Management Systems (BMS)

Configurable digital inputs are grouped in levels of priority, Configurable Digital Input 1 being the highest,

meaning it can’t be overwritten by other user functions.

6.5.1.4 Digital input and Mode hierarchy

User modes and functions have a different hierarchy. User functions activated via HMI or mobile APP, such as AWAY,

CROWDED, FIREPLACE, HOLIDAY and REFRESH, are interrupted by manual selection of AUTO and MANUAL fan modes.

A FIREPLACE function has the highest priority between user functions. Other functions activated via HMI/APP can interrupt each other.

If FIREPLACE function is hard-wired on the connection board and configured as digital input (DI) then it has a higher

priority than AUTO and MANUAL mode. Digital input for a FIREPLACE function has also a higher priority than other

hard-wired digital inputs (DI) for: AWAY, CENTRAL VACUUM CLEANER, COOKER HOOD, CROWDED, HOLIDAY or REFRESH.

211471 | A003, 29

Page 11

GB

Configuration |

11

Fig. 2 Hierarchy of user modes and digital inputs

Modes are listed from the highest to lowest priority; A — user modes that can be activated from the control panel; B —

user modes and functions activated via digital input

6.5.2 Temperature settings

Temperature can be set at SET TEMPERATURE menu accessible from the home screen by touching

TEMPERATURE icon with thermometer. Default temperature value is 18°C (range 12–30°C).

Use up and down arrows or a slider to change the value.

Then touch the OK button to confirm changes.

Temperature set point is for room air temperature, supply air temperature or for extract air temperature depending on

which control mode is active. Default setting is Supply air temperature control.

Control mode of the temperature can be changed in Service menu.

6.5.2.1 ECO mode

ECO mode is a power saving function that can be activated in SET TEMPERATURE menu.

ECO mode function is available only when an internal heater is installed and configured.

While ECO mode is active, a temperature setpoint at which heater is activated is lowered to avoid activation of the heater during cold nighttime.

211471 | A003, 29

Page 12

| Configuration

12

If the temperature is very low and the heater is activated during the nighttime (even with lowered temperature setpoint), then during the upcoming daytime indoor temperature will be increased using the heat exchanger so that accumulated heat could be used during the next cold nighttime, the lowered setpoint for the heater remains.

GB

ECO mode will have impact for the following user

functions/modes if selected:

• AUTO mode

• MANUAL mode

• AWAY mode

• HOLIDAY mode

• CENTRAL VACUUM CLEANER function

• COOKER HOOD function

• FIREPLACE mode

ECO mode is always activated by the following modes:

• AWAY mode

• HOLIDAY mode

ECO mode is always deactivated by the following user

functions/modes:

• CROWDED mode

• REFRESH mode

• FREE COOLING function

6.5.3 Airflow settings

Airflow settings are available only in MANUAL mode. Click on fan icon on the main screen to enter SET

AIRFLOW menu.

Use up and down arrows or a slider to change the airflow value.

The airflow may be adjusted in these steps: Off/Low/Normal/High. These settings control output signals to the supply and extract fans.

Important

It is not recommended to set fan to Off in standard households. If manual fan stop is activated, the unit

should be provided with dampers in exhaust and fresh air ducts to avoid cold draught and risk of

condensation when the unit has been stopped.

The fan can be set to Off by activating Manual Fan Stop function in Service menu.

6.5.4 Indoor Air Quality

The unit automatically controls indoor humidity and/or CO2levels by adjusting airflow setting. Airflow is

increased if air quality is decreasing.

Demand Control function is responsible for IAQ (Indoor Air Quality) regulation. Relative humidity (RH) and/or CO

sors are responsible for IAQ monitoring.

Indoor air quality (IAQ) indicator is available if AUTO mode and Demand Control function is activated.

IAQ levels:

• ECONOMIC: Actual IAQ value is below low IAQ set point.

• GOOD: Actual IAQ value is between low and high IAQ limits.

• IMPROVING: Actual IAQ value is above high IAQ set point.

Different airflow settings can be set for IMPROVING and GOOD IAQ levels in Service menu.

2

sen-

Setpoint for relative humidity and CO

level can be set in Service menu.

2

6.5.5 Status line

Status line located at the bottom area of home screen displays information about:

211471 | A003, 29

Page 13

GB

Configuration |

13

List of active alarms. See

chapter 11.1 for more

information.

Touching any of these lines will move you to the next page with more detailed list and information about each alarm or

active user function.

List of active user functions.

See chapter 6.6 for more

information.

6.6 Description of User function icons

Icon Text

Heating

Heat recovery

Cooling

Cooling

recovery

Connected heater or pre-heater is active and air heating is in process.

Heat recovery from apartment is active.

Connected cooler is active and air cooling is in process.

Automatic cooling recovery is active when extract air temperature from

apartment is lower than outdoor air temperature and there is a cooling demand

(temperature setpoint is lower than outdoor air temperature).

No cooling recovery with heating demand. If the outdoor air temperature is

higher than then thee indoor air temperature and there is a heating demand,

function Free heating is activated instead.

Description

Free cooling

Moisture

transfer

Defrosting

Secondary air

Vacuum

cleaner

Cooker Hood

User lock

Function decreases indoor air temperature by using only cool outdoor air during

nighttime to save energy consumption.

Function controls the rotation speed of the heat exchanger to prevent moisture

transfer to supply air due to high relative humidity in the extract air.

Function is only available for units with Rotating type heat exchanger.

Function prevents formation of the ice on the heat exchanger during cold

outdoor temperatures.

Warm air from the living space is used to defrost the heat exchanger using a

damper inside the outdoor air duct. The unit switches from outdoor air to

secondary air while the extract air fan stops and warm secondary air increases

the temperature inside the heat exchanger.

Function sets speed of supply air fan to High level and extract air fan to Low

level to increase air pressure within the apartment for better dust collection

through central vacuum cleaner.

Function can be activated via digital input — Central Vacuum Cleaner

Function.

Always active while digital input is activated.

Sets speed of both supply and extract air fans to Maximum level to increase

airflow in the cooker hood.

Function can be activated via digital input — Cooker Hood Function.

Function indicates that the system is locked with a password and cannot be

edited or settings changed in any way. System must be unlocked first to make

changes.

211471 | A003, 29

Configurable

Digital Input

1

Configurable

Digital Input

2

Configurable digital input for custom user function. Airflow levels for both fans

are freely configurable.

High–priority function.

Configurable digital input for custom user function. Airflow levels for both fans

are freely configurable.

Mid–priority function.

Page 14

14

| Configuration

GB

Configurable

Digital Input

3

Pressure

Guard

Configurable digital input for custom user function. Airflow levels for both fans

are freely configurable.

Low–priority function.

Configurable digital input for pressure guard connection. Airflow levels for both

fans are freely configurable.

6.7 Week Schedule

The unit can be configured to operate at set airflow levels up to two time periods (00:00–23:59) on user

selected days.

Week Schedule is active only during AUTO mode.

6.7.1 Schedule airflow settings

Touch settings icon to go to SCHEDULE AIRFLOW SETTINGS menu. In this menu set airflow level for

scheduled and unscheduled periods. Available levels: Off, Low, Normal, High or Demand.

Set temperature setpoint offset for both periods (-10°C – 0°C).

Demand level is available only if Demand Control or External fan function is active.

6.7.2 Edit schedule

Touch icon at the bottom left corner of the screen to add a new schedule or press EDIT button to modify

already added schedule.

To configure the schedule:

1. Set the time. Touch the START TIME or END TIME values to change time. Use arrow buttons

or decrease value. Confirm with OK button.

and to increase

Note:

Scheduled time can start but never end at midnight (00:00). The latest END TIME period is 23:59.

Scheduled time cannot go to the next day.

12 or 24 hour time format can be changed in System Preferences menu.

If necessary, activate second scheduled period and set up time.

2. Once time is set, click on the day(s) when schedule should be active. It is possible to set a separate schedule for each

day.

Already scheduled days are not available for selection for new schedules.

3. Confirm schedule with OK button.

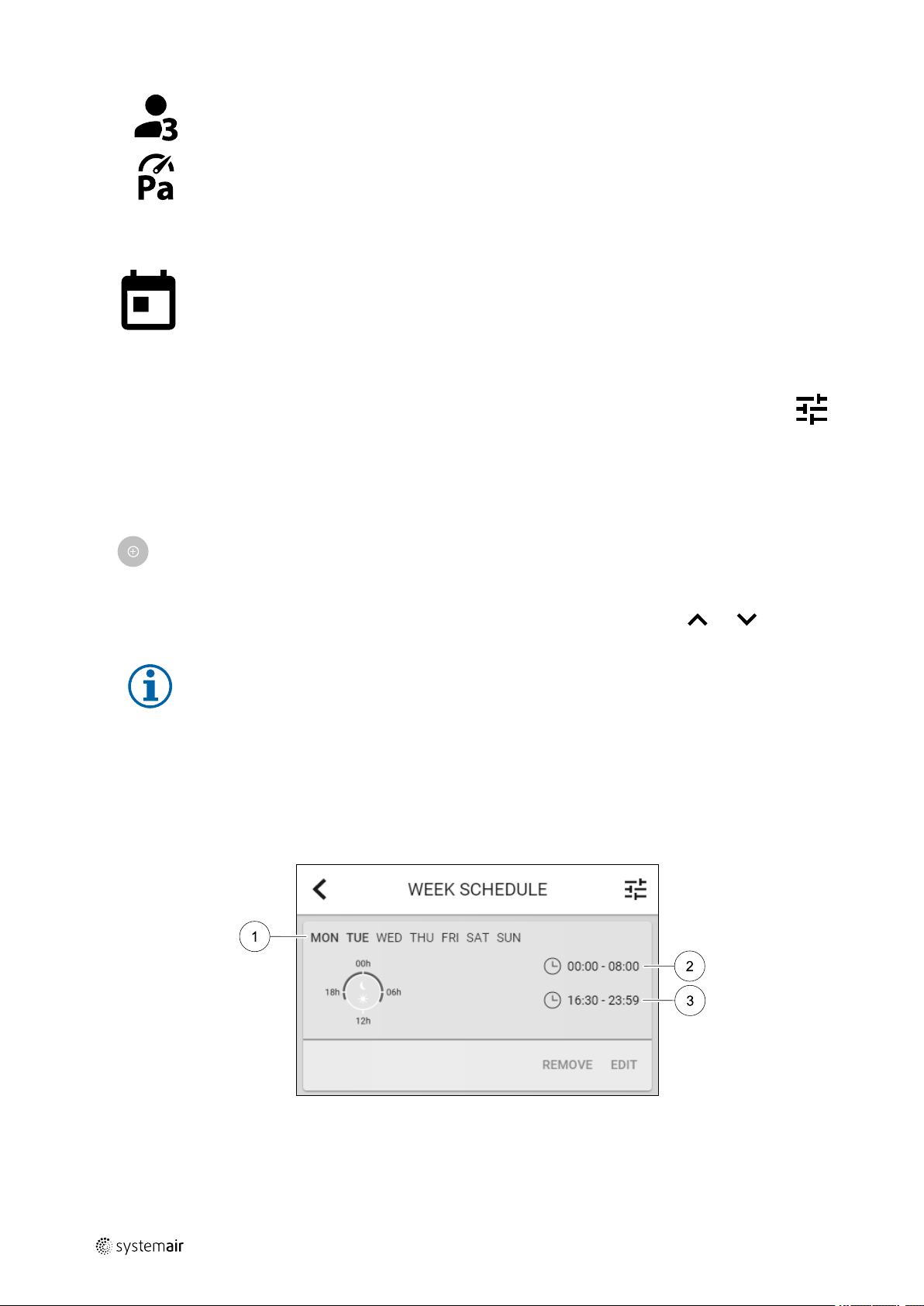

Fig. 3 Week schedule example

Scheduled days are highlighted (pos. 1). First time period (pos. 2) and the second time period (pos. 3) are shown on the

right side of each schedule.

211471 | A003, 29

Page 15

GB

7 Cooker hood maintenance

7.1 Cleaning cooker hood

Warning

There is fire hazard if the cooker hood is not cleaned within given intervals.

• The filter is to be cleaned every second month during

normal use. Clean more often during intense use.

• Clean the inside of the cooker hood at least twice a

year.

Remove the filter as shown in the image:

The metal grease filter can be cleaned in a dishwasher or

by hand using a mild detergent or liquid soap. When replacing, ensure that it is dry.

The other parts of the cooker hood are wiped with a

damp cloth and mild liquid household cleaner. Never use

abrasive cleaning materials.

Cooker hood maintenance |

Fig. 2 Remove cooker hood filter

15

8 Maintenance of the unit

Maintenance of the SAVE VTR 150/K should normally be performed 3 - 4 times a year.

8.1 Warnings

Danger

• Make sure that the mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• All electrical connections and maintenance work must be carried out by an authorized installer and in

accordance with local rules and regulations.

Warning

• This product must only be operated by a person who has suitable knowledge or training within this field

or carried out with the supervision of a suitably qualified person.

• Beware of sharp edges during mounting and maintenance. Use protective gloves.

Warning

• All though the mains supply to the unit has been disconnected there is still risk for injury due to rotating

parts that have not come to a complete standstill.

Important

• The installation of the unit and complete ventilation system must be performed by an authorized installer

• The system should operate continuously, and only be stopped for maintenance/service.

• Do not connect tumble dryers to the ventilation system.

• Duct connections/duct ends must be covered during storage and installation.

• Make sure that filters are mounted before starting the unit.

211471 | A003, 29

and in accordance with local rules and regulations.

Page 16

| Maintenance of the unit

16

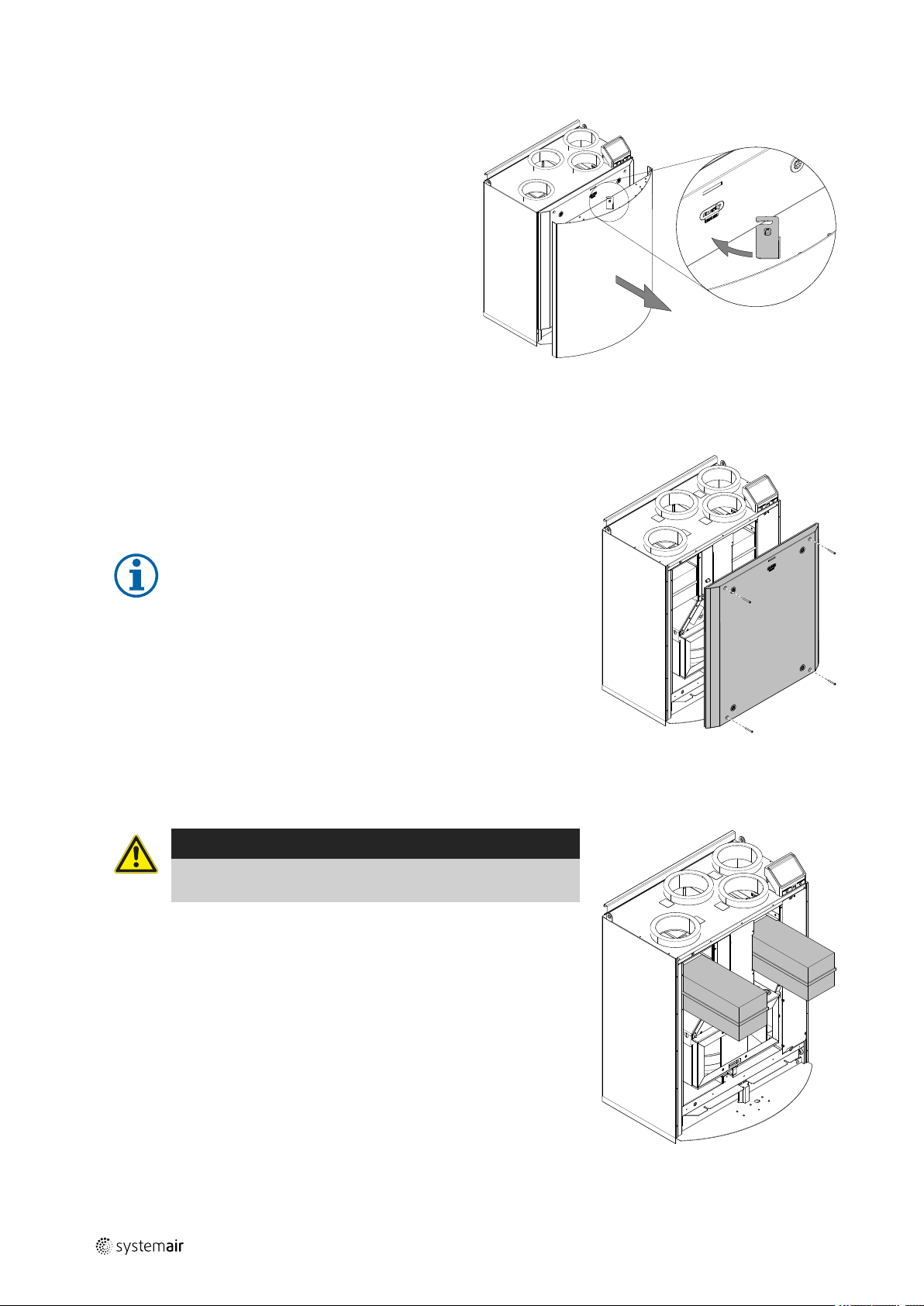

8.2 Remove/mount the outer front

The outer front is mounted with four pins and is removed

by pushing the locking hock to the left and pulling the

front towards you.

Re-mount the outer front in reverse order.

8.3 Remove/mount the inner front

The inner front is mounted with four screws. Loosen the screws and pull the

inner front towards you.

GB

Fig. 3 Remove/mount the outer front

Mount the inner front and tighten the mounting screws properly to prevent

air leakage.

Note:

When mounting the inner front, note the two guide screws at the

bottom of the inner front. These screws shall be fitted into the

two slots in the inner hatch support bracket.

8.4 Changing filters

Danger

Make sure that the Mains supply to the unit is disconnected

before performing any maintenance or electrical work!

The filters are to be changed every 3–15 months, default value is 12 months.

When the filters have been changed the filter timer will reset automatically

after alarm is acknowledged.

Fig. 4 Remove/mount the inner front

The factory installed filters are of filter quality M5/ePM10 50% for the supply

air and M5/ePM10 50% for the extract air filter. The filters need to be replaced when polluted. New sets of filters can be acquired from your installer

or wholesaler.

Filter quality M5/ePM10 50% can be installed for supply air filtering.

The filter type is labelled on the top of the filter.

Fig. 5 Heat exchanger filters

211471 | A003, 29

Page 17

GB

Maintenance of the unit |

8.4.1 Resetting the filter time

Once filter is changed, it is necessary to reset filter time. Go to Filter menu (see 6.4 Menu overview, page 8, pos. E)

or if filter alarm is present, click on alarm status line (see 6.5 Home screen, page 8, pos. 5) and select filter alarm. Select

CHANGE FILTER, in the pop up menu define a new filter period and press OK to confirm selection.

Filter time is now reset.

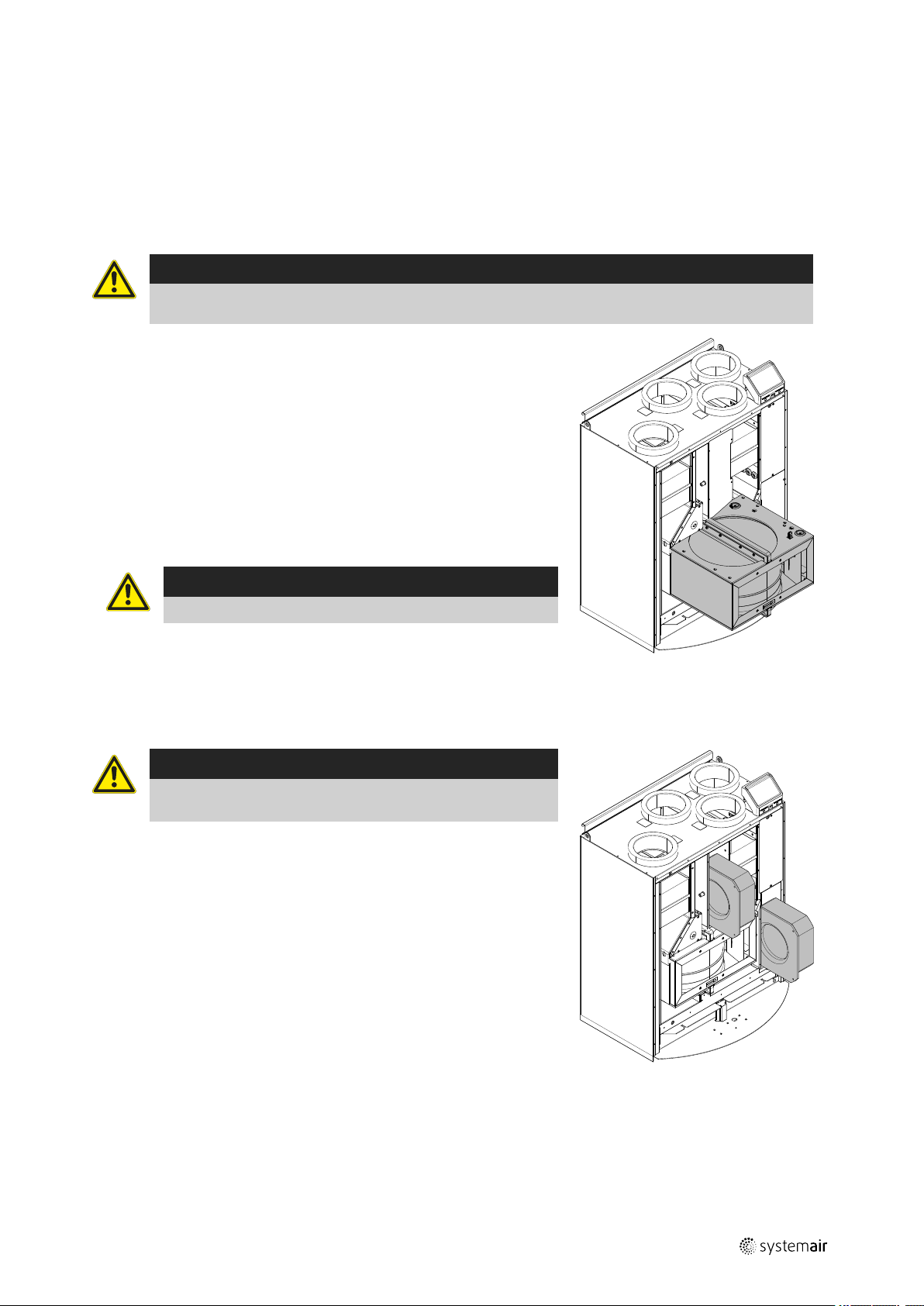

8.5 Checking and cleaning the heat exchanger

Danger

• Make sure that the Mains supply to the unit is disconnected before performing any maintenance or

electrical work!

Even if the required maintenance is carried out, dust will build up in the exchanger block. It is therefore of vital importance for the upkeep of a high efficiency that the exchanger block is removed from the unit and cleaned

periodically as illustrated below. Clean the heat exchanger at least every 3

years or when required.

1. Disconnect the rotor power supply and the rotor sensor. The cables are

found beside the rotor at the back.

2. Pull out the rotor towards you. Some force may be needed.

3. Clean the rotor.

Wash in hot soapy water. Do not use detergent containing ammonia. Rinse

using, for instance, a shower handle.

17

Warning

Ensure the rotor motor is not exposed to moisture

4. Remount the rotor. Don’t forget to reconnect the rotor power and sensor

cables.

8.6 Cleaning the fans

Danger

• Make sure that the Mains supply to the unit is disconnected

before performing any maintenance or electrical work!

The motor bearings are life time lubricated and maintenance free.

Even if the required maintenance, such as changing of filters is carried out,

dust and grease may slowly build up inside the fans. This will reduce the

efficiency.

The fans may be cleaned as illustrated in below procedure.

1. Disconnect the fan power cables. The cables are found beside the fan at

the back.

2. Pull out the fans towards you. Some force may be needed.

3. Clean the fans with a cloth or a soft brush. Do not use water. White spirit

can be used to remove obstinate deposits.

Allow the fans to dry properly before remounting.

4. Remount the fans. Don’t forget to reconnect the fan power cables.

Fig. 6 Heat exchanger

Fig. 7 Extract and supply air fans

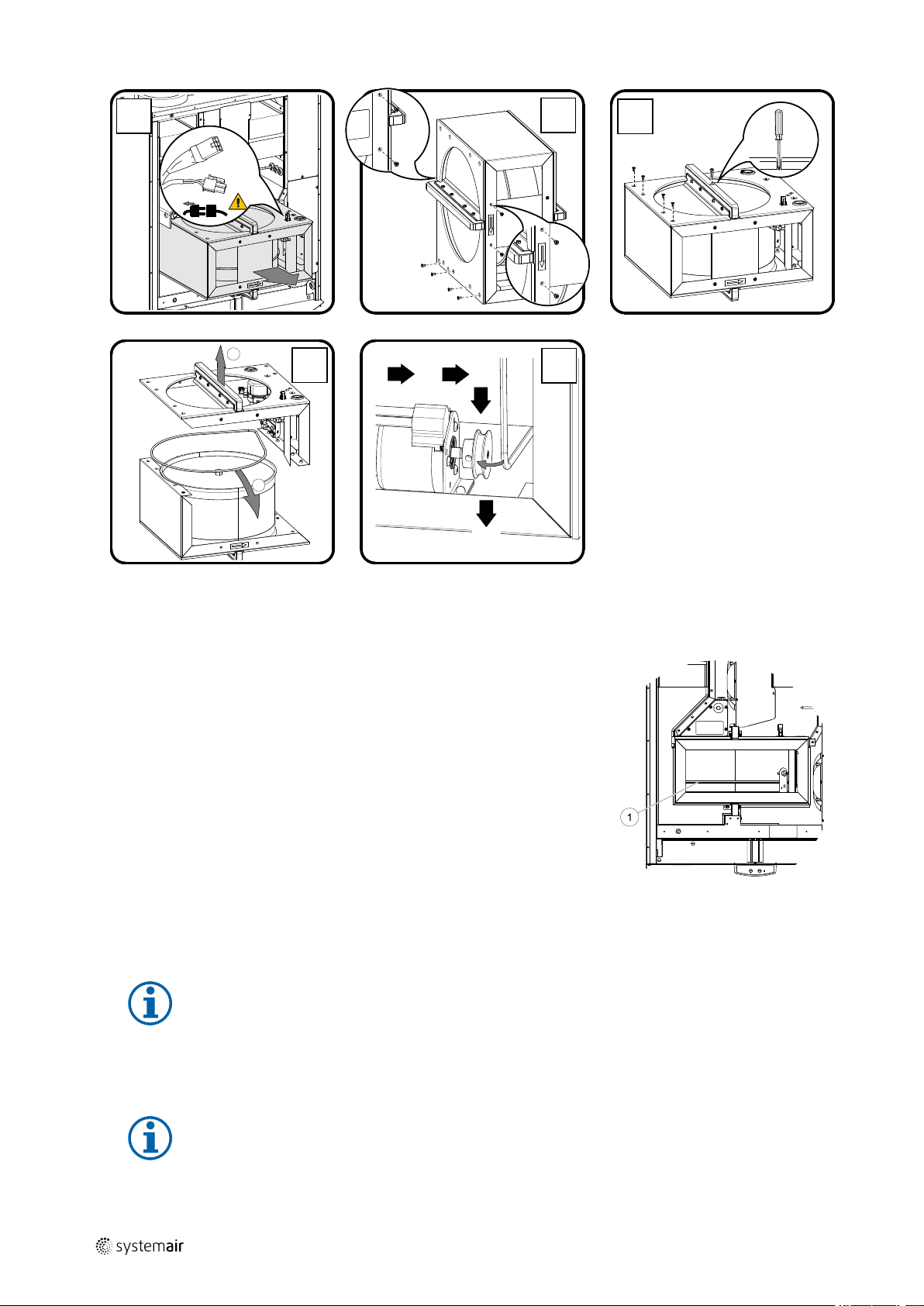

8.7 Replacing rotor drive belt

If the alarm Rotor guard is raised, see chapter 11.1, the rotor drive belt may be damaged or broken.

A spare drive belt is already placed on the heat exchanger rotor and delivered with the unit.

211471 | A003, 29

Page 18

| Maintenance of the unit

18

GB

A

11

22

11

D

22

D

C

B

B

C

E

A

In case both welded belts break it is possible to use joint nipple as a temporarily quick repair solution until the welded

belt can be replaced with a new one. Depending of how the unit is installed, it may be not necessary to remove the

heat exchanger package in order to temporary repair a broken drive belt if the belt pulley can be accessed.

Temporary belt repair solution

1. Stop the unit by disconnecting the mains.

2. Open and remove the side cover.

3. Remove the broken drive belt.

4. Use tape to attach the drive belt to the rotating heat exchanger, and rotate

the exchanger by hand to get hold of the drive belt.

5. Remove the tape and put the ”empty” end on to the nipple. Press the ends

firmly towards each other and tighten the nipple.

Fig. 8 Rotor drive belt

6. Pull the drive belt on to the belt pulley and rotate the exchanger by hand. Check that the belt pulley rotates.

Note:

If the drive belt slips, the drive belt may be too long and needs to be shortened. Cut the drive belt 5 mm

and go to step 5.

7. Replace and lock the side cover and connect the unit to mains.

8. Check that the alarm has ceased on the Control Display.

Note:

If the alarm remains, check the rotor sensor.

211471 | A003, 29

Page 19

GB Duct system maintenance

|

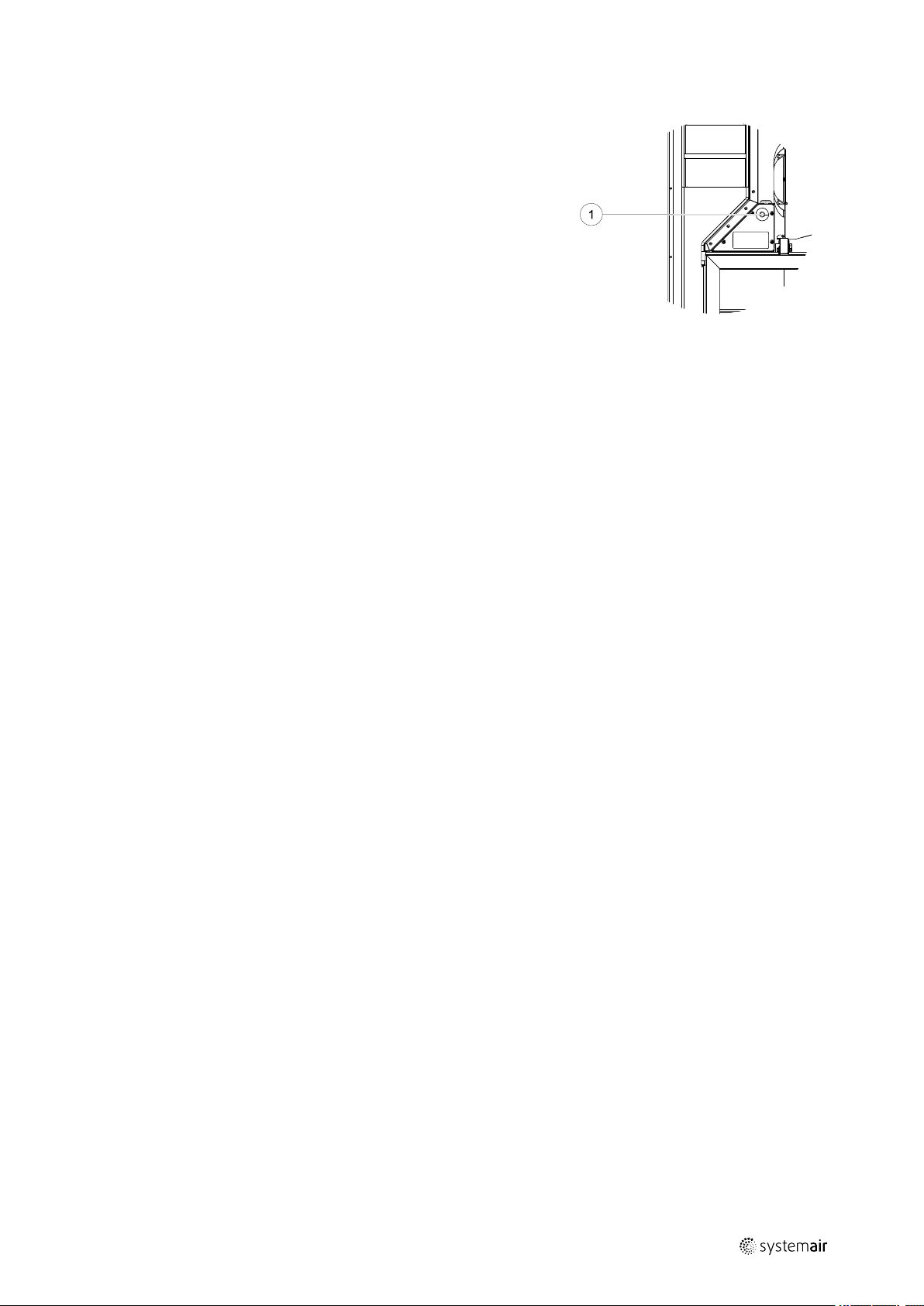

8.8 Overheat protection reset button

If the supply air temperature is low, it can indicate that the over heat protection is triggered. The overheat protection can be reset by pressing the reset

button.

9 Duct system maintenance

9.1 Cleaning extract louvres and supply air diffusers

The system supplies fresh air to your home and extracts the used indoor air via the duct system and diffusers/louvres.

Diffusers and louvres are mounted in ceilings/walls in bedrooms, living room, wet rooms, WC etc. Remove diffusers

and louvres and wash in hot soapy water as required (diffusers/louvres must not be exchanged). Cleaning of diffusers/

louvres can be done as necessary.

19

9.2 Checking the outdoor air intake

Leaves and pollution could plug up the air intake grille and reduce the capacity. Check the air intake grille, and clean as

necessary. It is recommended to do this at least twice a year.

9.3 Checking the roof cowl (if fitted)

The roof cowl (if fitted) connected to the exhaust air duct needs to be checked at least twice a year and cleaned if

necessary.

9.4 Checking and cleaning the duct system

Dust and grease deposits may build up in the duct system, even if required maintenance such as changing of filters is

being carried out. This will reduce the efficiency of the installation.

The duct runs should therefore be cleaned/changed when necessary. Steel ducts can be cleaned by pulling a brush

soaked in hot soapy water through the duct via diffuser/louvre openings or special inspection hatches in the duct system (if fitted).

It is recommended to do this every 5 years and is normally carried out by authorized companies specialized in this area.

10 Troubleshooting

If problems should occur, please check the items below before calling your service representative.

211471 | A003, 29

Page 20

| Troubleshooting

20

GB

Malfunction

Fans do not start

Reduced airflow

Action

1. Check the HMI for alarms.

2. Check that all fuses and fast couplings are connected (main power supply and fast

couplings for supply and extract air fans).

3. Check that the week schedule is ON and running in AUTO mode. The week schedule

might be in OFF mode with the air flow set to OFF (chapter 6.7).

1. Check the HMI for alarms. Some alarms can reduce the airflow to LOW if active.

2. The unit could be in defrost mode. This reduces the fan speed and in some cases shuts

down the supply air fan completely during the defrosting cycle. The fans go back to

normal after finished defrosting. There should be a defrosting function icon visible in the

APP or HMI home screen if defrosting is active.

3. If the outdoor air temperature is below 0°C (Outdoor air temperature sensor (OAT)

measures < 0°C) outdoor airflow compensation function can be active (if enabled). Fan

speed (Supply or Supply/Extract air fans) is linearly reduced for decreasing outdoor air

temperature.

4. Check if temporary user mode that reduces airflow is not activated, for example AWAY,

HOLIDAY, etc. Also check digital inputs CENTRAL VACUUM CLEANER and COOKER HOOD.

5. Check setting of airflow in the HMI.

6. Check week schedule settings (chapter 6.7).

7. Check filters. Is change of filters required?

8. Check diffusers/louvres. Is cleaning of diffusers/louvres required?

9. Check fans and heat exchange block. Is cleaning required?

10.Check if the buildings air intake and roof unit (exhaust) have been clogged.

11.Check visible duct runs for damage and/or build up of dust/pollution.

12.Check diffuser/louvre openings.

The unit cannot be

controlled (control

functions are stuck)

Low supply air

temperature

Noise/vibrations

1. Reset control functions by pulling out the plug for 10 seconds.

2. Check the modular contact connection between the HMI and the main printed circuit

board.

1. Check the display for alarms.

2. Check the active user functions in HMI screen if Defrosting function is running.

3. Check set supply air temperature in the HMI.

4. Check if ECO mode is activated in HMI (it is a power saving function and prevents the

heater from activating).

5. Check if user modes HOLIDAY, AWAY or CROWDED are activated in the HMI or via a

hardwired switch.

6. Check the analogue inputs in the service menu to verify that the temperature sensors

are functioning correctly.

7. In case of installed electrical/other re-heater battery: Check if the overheat protection

thermostat is still active. If necessary, reset by pressing the red button on the front plate

of the electrical re-heater.

8. Check if the extract filter must be changed.

9. Check if the unit has a re-heater battery connected. At very cold outdoor conditions an

electrical or water heating battery might be necessary. A re-heater battery can be

acquired as an accessory.

1. Clean fan impellers.

2. Check that the screws holding the fans are tightened.

3. Check that the anti vibration lists are fitted to the mounting bracket and to the back of

the unit.

4. Check that the rotor belt is not slipping if the unit has rotating heat exchanger.

211471 | A003, 29

Page 21

GB

Alarms |

11 Alarms

Press HELP button on the active alarm to access FAQ and troubleshooting (if available). Press ACKNOWLEDGE on the individual alarm to clear it. Depending on alarm type and the cause, it might be necessary to do a troubleshooting first to

acknowledge active alarm.

It may be not possible to clear the status of alarm if the cause of alarm is still present, as that would immediately trigger

alarm to return.

11.1 Alarm list

Alarm name Explanation Do the following

Frost protection

Frost protection temperature

sensor

Defrosting error

Supply air fan rpm

Extract air fan rpm

Supply air fan control error

Extract air fan control error

Fire alarm

Frost protection of return water in

heating coil.

• Alarm stops the unit and opens

the water valve completely.

Indicates malfunction of water

heater temperature sensor.

• Alarm stops the unit.

Indicates failure of pre-heater to

preheat the incoming outdoor air (in

case Extra controller is configured as

Preheater).

• Alarm stops the unit.

Rotation speed of the supply air fan

is lower than minimum required. Fan

malfunction.

• Alarm stops the unit.

Rotation speed of the extract air fan

is lower than minimum required. Fan

malfunction.

• Alarm stops the unit.

Flow or pressure alarm for supply air.

The pressure is bellow pressure limit.

• Alarm stops the unit.

Flow or pressure alarm for extract

air. The pressure is bellow pressure

limit.

• Alarm stops the unit.

Fire alarm is active.

• Alarm stops the unit.

The alarm will reset once the water

temperature reaches 13°C.

Check the water fluid temperature in

heating coil.

Check the circulation pump of water

heater. Contact your installation

company or place of purchase.

Check that frost protection

temperature sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check the pre-heater reset button.

Check the pre-heater cabling.

Contact your installation company or

place of purchase.

Defrosting error may be caused by

extremely low outdoor air

temperatures or pre-heater failure.

Check quick connectors of the fan.

Contact your installation company or

place of purchase.

Check quick connectors of the fan.

Contact your installation company or

place of purchase.

Check that air tube for pressure

sensor is connected properly and

cable is not damaged.

Contact your installation company or

place of purchase.

Check that air tube for pressure

sensor is connected properly and

cable is not damaged.

Contact your installation company or

place of purchase.

Once the external Fire alarm is

disabled – alarm has to be

acknowledged and unit restarted.

21

211471 | A003, 29

Page 22

| Alarms

22

Alarm name Explanation Do the following

Emergency thermostat

Bypass damper

Rotor guard

Secondary air damper

Outdoor air temperature

sensor

Overheat temperature sensor

Supply air temperature

sensor

Room air temperature sensor

Indicates triggered overheat

protection (in case of installed

electric re-heater battery).

Indicates malfunction in bypass

damper.

Indicates a rotor malfunction.

No rotation guard signal for 180

seconds.

Secondary air defrosting failed.

Outdoor air temperature sensor

measures < 10°C in 2 sec after

defrosting

OR

Outdoor air temperature sensor

measures < 5°C in 5 min after

defrosting

Indicates outdoor air temperature

sensor malfunction.

Indicates overheat temperature

sensor malfunction.

Indicates supply air temperature

sensor malfunction.

Indicates room air temperature

sensor malfunction.

A triggered manual or automatic

overheat protection (EMT) gives an

alarm in the control panel.

In case a manual overheat protection

is triggered, reset it by pushing the

reset button.

If the automatic overheat protection

is triggered, it will reset

automatically once the temperature

has dropped.

If the problem continues contact

your installation company or place of

purchase.

Disconnect the main power supply

for 10 seconds to reset control

function.

Power up the unit, an automatic

bypass damper test will be

performed.

If the alarm occurs again after

approximately 2 minutes – contact

your installation company or place of

purchase.

If the rotating heat exchanger has

stopped. Check the rotor belt.

If the heat exchanger is still rotating,

check that the quick connector for

the sensor is connected and that

there is an air gap of 5-10 mm

between the sensor and the magnet.

Adjust the gap if necessary.

If the alarm persists, the rotor sensor

may be faulty. Contact your

installation company or place of

purchase.

Check if secondary air damper is in

correct position.

Check that damper is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

GB

211471 | A003, 29

Page 23

GB

Alarm name Explanation Do the following

Extract air temperature

sensor

Extra controller temperature

sensor

Efficiency temperature

sensor

PDM RH

PDM RH Extract air

temperature

Filter warning

Filter

Extra controller alarm

External stop

Manual fan stop active

Overheat temperature

Low supply air temperature

Indicates extract air temperature

sensor malfunction.

Indicates extra controller

temperature sensor malfunction.

Indicates efficiency temperature

sensor malfunction.

Indicates internal relative humidity

sensor malfunction.

Active: measured humidity = 0%

Returned: measured humidity > 5%

Indicates internal extract air

temperature sensor malfunction.

Active: measured temperature = 0°C

Returned: measured temperature >

5°C

Notification about filter change. Filter have to be replaced in one

Time for filter change. Change the filter.

Error from external device. Check if external device is connected

Unit is stopped by external signal. Operation is stopped by digital signal

Operation stopped, fans are in

manual mode and selected as OFF.

Temperature after reheater is too

high.

Active: (Overheat temperature

sensor measures > 55°C)

Returned: (Overheat temperature

sensor measures < 50°C)

Supply air temperature is too low.

Active: (Outdoor air temperature

sensor measures < 0°C) AND (Supply

air temperature sensor measures <

5°C)

Returned: (Supply air temperature

sensor measures > 10°C)

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

Check that sensor is connected

properly and cable is not damaged.

Contact your installation company or

place of purchase.

month time. Please acquire new

filters.

Change filter according to the

instructions in the User Manual.

Details about filter retailers can be

found in Help menu.

properly and cable is not damaged.

Reset overheat protection on

electrical pre-heater. Contact your

installation company or place of

purchase.

from external remote device or

signal from building management

system.

Select another speed of fans (LOW /

NORMAL / HIGH) or AUTO mode in

HMI home screen.

Alarm is possible if supply airflow is

too low when the reheater is

switched on.

Check the supply airflow.

Check that intake grille is not

blocked.

Check that shut off damper for

outdoor air is open in operation.

Contact your installation company or

place of purchase.

Check the heat exchanger and reheater or refer to Point 2 in

“Troubleshooting” menu.

Alarms |

23

211471 | A003, 29

Page 24

| Alarms

24

Alarm name Explanation Do the following

CO₂

External CO

sensor malfunction. Check that sensor is connected

2

properly and cable is not damaged.

In case sensor wireless – check

RS485 gateway status and sensor

status in HMI.

Contact your installation company or

place of purchase.

RH

External relative humidity sensor

malfunction.

Check that sensor is connected

properly and cable is not damaged.

In case sensor wireless – check

RS485 gateway status and sensor

status in HMI.

Contact your installation company or

place of purchase.

Output in manual mode

One or more of analogue outputs are

in manual mode.

Check Service menu for Output

settings, and check all configured

outputs to be in Auto mode. If any

outputs in Manual - change back to

Auto mode.

Alarm Fire Alarm can be only activated with a digital signal from a smoke/fire detection system or similar. Digital input has to be configured as Fire Alarm for this alarm to work.

GB

Digital output configured as Sum Alarm sends a generic signal every time the alarm is triggered, except for alarms Ex-

ternal stop, Output in manual mode and Manual Fan Stop. This signal does not specify the alarm type.

211471 | A003, 29

Page 25

2114711 | A003, 29

Page 26

SV

Användarhandbok

© Upphovsrätt Systemair AB

Alla rättigheter förbehållna

Med förbehåll för eventuella fel och förbiseenden

Systemair AB förbehåller sig rätten för ändringar av produkterna utan föregående meddelande.

Detta gäller även redan beställda produkter, så länge det inte påverkar tidigare överenskomna specifikationer.

SE

2114711 | A003, 29

Page 27

Innehåll

1 Avfallshantering och återvinning .... ........ . ........ . 29

2 Varning........ ........ . ........ . ........ . ........ ........ . ... 29

3 Märkskylt ...... ........ ......... . ........ ......... ........ . .. 30

4 Inledning . ......... . ........ ......... ........ . ........ . .......30

5 Köksfläkt . ......... ........ . ........ ......... . ........ ........ 30

6 Konfiguration ..... . ........ ......... . ........ ........ . ...... 31

6.1 Allmänt...... ........ . ........ ......... . ........ ..... 31

6.2 Startguide..... ......... ......... ......... ........ . .. 31

6.3 Vanliga symboler .... ........ . ........ ......... ... 31

6.4 Menyöversikt ........ ......... ......... ........ . ... 32

6.5 Hemskärmen... . ......... ........ . ........ ......... 32

6.5.1 Användarlägen ... ......... ........ . ... 32

6.5.2 Inställning av

temperatur ....... ......... ......... .... 35

6.5.3 Luftflödesinställningar ........ . ...... 36

6.5.4 Inomhusluftens kvalitet ..... . .......36

6.5.5 Statusraden...... ......... ........ ...... 36

6.6 Beskrivning av användarfunktionernas

ikoner... ......... . ........ ......... ........ . ........ . 37

6.7 Veckoschema ....... . ........ . ........ . ........ .. 38

6.7.1 Schema för

luftflödesinställningar.. . ........ . .... 38

6.7.2 Redigera schema . ......... ........ . .. 38

7 Köksfläktsunderhåll ....... ......... ......... ........ ...... 39

7.1 Rengöring av köksfläkt ..... . ........ ........ . ... 39

8 Underhåll av aggregatet . ........ . ........ ......... ...... 39

8.1 Varning....... . ........ . ........ . ........ ........ . ... 39

8.2 Demontering/montering av utvändig

front....... ........ . ......... ........ . ........ ........40

8.3 Demontering/montering av invändig

front....... ........ . ......... ........ . ........ ........40

8.4 Filterbyte..... . ........ ......... ........ . ........ . ... 40

8.4.1 Återställning av

filtertiden . ......... ........ . ........ . ... 41

8.5 Kontroll och rengöring av

värmeväxlaren . ........ . ........ . ........ ......... 41

8.6 Rengöring av fläktar .... ......... ......... .......41

8.7 Byte av rotordrivrem........ . ........ . ........ . .. 41

8.8 Återställningsknapp för

överhettningsskydd....... . ........ . ........ ..... 43

9 Underhåll av kanalsystemet.. . ........ . ........ ......... 43

9.1 Rengöring av frånluftsgaller och

tilluftsdiffusorer ....... . ........ ......... ......... . 43

9.2 Kontroll av uteluftsintag.. ......... ......... ..... 43

9.3 Kontroll av takhuv (om sådan

finns)...... ........ . ........ . ........ . ........ ........43

9.4 Kontroll och rengöring av

kanalsystemet.... ......... ........ ......... . ...... 43

10 Felsökning .. . ........ ........ . ........ . ........ . ........ ..... 43

11 Larm ...... . ........ ......... ......... ........ . ........ . .......45

11.1 Larmlista ..... ........ . ........ . ........ . ........ .... 45

2114711 | A003, 29

Page 28

Page 29

SV

1 Avfallshantering och återvinning

Denna produkt är i överensstämmelse med direktivet om elektriskt och elektroniskt avfall. Vid

kassering av aggregatet ska lokala regler och föreskrifter följas.

Produktens förpackningsmaterial är återvinningsbart och kan återanvändas. Släng inte med

hushållsavfall.

2 Varning

Fara

• Säkerställ att spänningsmatningen är bruten före underhållsarbete och elarbete.

• Arbete med elektriska anslutningar och underhåll får endast utföras av behörig personal och i enlighet

med gällande krav och föreskrifter.

Varning

Avfallshantering och återvinning |

29

• Denna produkt får endast användas av en person som har lämplig kunskap eller utbildning inom detta

område eller står under överinseende av en person med lämpliga kvalifikationer.

• Se upp för vassa kanter vid installation och underhåll. Använd skyddshandskar.

Varning

• Det dröjer något innan alla rörliga delar stannat helt efter att aggregatet kopplats bort från elnätet – risk

för personskada.

Viktigt

• Aggregatet och hela ventilationssystemet ska installeras av behörig personal och i enlighet med gällande

krav och föreskrifter.

• Systemet bör ständigt vara i gång och får bara stoppas vid underhåll/service.

• Anslut inte torktumlare till ventilationssystemet.

• Kanalanslutningar/kanaländar ska vara täckta vid förvaring och installation.

• Kontrollera att alla filter är monterade innan du startar aggregatet.

2114711 | A003, 29

Page 30

| Märkskylt

30

3 Märkskylt

Ha aggregatets huvuddata och tillverkningsnummer till hands när du kontaktar servicetekniker. Uppgifterna finns på

märkskylten på aggregatets sida, nära de externa anslutningarna.

Fig. 1 Märkskylt

SV

Position

1

2

3

4 Serienummer

5

6

7

Beskrivning

Produktkod (produktspecifikation)

Artikelnummer för produkten

Produktionsordernummer

Tillverkningsdatum (ÅÅ.MM.DD)

QR kod för tillverkningsorder (MO) nummer och version av programvara

QR kod för reservdelslista och dokumentation

4 Inledning

SAVE VTR 150/K är ett ventilationsaggregat med värmeåtervinningsfunktion med högeffektiv inbyggd roterande värmeväxlare och köksfläkt. SAVE VTR 150/K är lämplig för mindre lägenheter och småhus. Aggregatet förser bostadsutrymmen med filtrerad uteluft och evakuerar frånluft från kök och från badrum och andra våtrum.

Aggregatet finns i vänsterutförande (L) och högerutförande (R). Båda utförandena finns med monterat eftervärmningsbatteri på 500 W eller 1000 W . De olika modellerna känns igen på placeringen av de interna komponenterna. Den här

instruktionsboken innehåller grundläggande information om användning och underhåll av ett aggregat i vänsterutförande (L) och det system det är anslutet till.

Obs!

I handboken beskrivs vänsterutförandet (L). Högerutförandet (R) är invändigt en spegelvändning av

vänsterutförandet.

5 Köksfläkt

Fara

• Flambera INTE under köksfläkten när den används.

• Tillräckligt luftflöde måste säkerställas till rummet medan köksfläkten används.

Tryck på knapp A för att tända lamporna.

Tryck på knapp B en gång för att öppna ventilationsspjället under matlagning. Indikatorn (C) lyser med fast sken.

Tryck på knapp B igen för att forcera ventilationen. Indikatorn blinkar.

2114711 | A003, 29

Page 31

SV

A B C

Tryck på knapp B en tredje gång för att stänga ventilationsspjället. Ventilationsfläkten återgår till nominell hastighet och indikatorn slocknar.

Om spjället inte har stängts manuellt stängs det automatiskt efter 60

minuter.

Ingen frånluft strömmar genom köksfläkten när den är avstängd. Frånluft från

köket kräver en separat luftventil.

Tips! Låt spjället vara öppet en stund före och efter matlagning för att hindra

os från att sprida sig i rummet.

Fig. 9 Köksfläktens frontplåt

Konfiguration |

6 Konfiguration

6.1 Allmänt

SAVE VTR 150/K har en modern LCD-pekskärmsmanöverpanel, vanligtvis benämnd HMI - (Human Machine Interface).

Displayen ger information om aggregatets aktuella status och gör att du kan styra alla systemfunktioner.

Inställningar görs genom att röra vid ikonerna eller alternativen. Pekskärmen är känslig och det är inte nödvändigt att

trycka för hårt.

31

6.2 Startguide

Under den första påslagningen av aggregatet blir du ombedd att ange:

• Menyspråk

• Tid och datum

• importera konfigurationsfil (om internetåtkomstmodulen (IAM) och konfigurationsfil finns tillgängliga)

• Luftflödesregleringstyp (manuell/Varvtal) och luftflödesnivåvärdena.

• Typ av värmare (Ingen//ElektriskVattenKombi-batteri)

Det går inte att hoppa över startguiden (”Startup Wizard”).

6.3 Vanliga symboler

Följande symboler är vanliga och förekommer i de flesta menysidor:

Knappen tillbaka för att gå tillbaka till

en föregående meny, finns i det övre

vänstra hörnet

Uppåtpilen för att öka ett värde AVBRYT Knapp för att avbryta ändringar

Nedåtpilen för att minska ett värde

Vissa meny har flera än en sida. Tryck på sidans indikator i det övre högre hörnet för att gå till nästa sida. Ex (1/2) Den

första siffran anger det aktuella sidonumret och den andra siffran anger den totala summan av alla sidor.

STÄLL

IN/OK

På- och avreglaget finns för att

aktivera eller avaktivera en funktion.

Vit bubbla - funktion är inaktiv, gröna

bubbla - funktion är aktiv.

Knappar för att bekräfta ändringar

Många alternativ visas upp i en form av popup-fönster. Välj bland alternativen som visas i listan i popup-fönstret och

tryck på OK för att bekräfta valet.

2114711 | A003, 29

Page 32

| Konfiguration

32

6.4 Menyöversikt

A.Gå tillbaka till hemskärmen

B. Grundläggande skrivskyddad information om

aggregatet

C. Aktiva larm och larmhistorik

D.Konfigurera och kontrollera veckoschema

E. Kontrollera och ändra återstående tid till filterbyte

F. Allmänna systeminställningar

G.Konfiguration av alla systemparametrar

H.Hjälp- och felsökningsmeny

SV

6.5 Hemskärmen

Tryck på hemknappen (position A) i rullgardinsmenylista (position 1) tar dig alltid tillbaka till hemskärmen

efter driftsättning.

1. Rullgardinsmenylista

2. Aktivt användarläge

3. Luftflödesinställningar

4. Inställning av temperatur

5. Lista över aktiva larm

6. Ikonlista över aktiva användares funktioner

6.5.1 Användarlägen

Den första ikonen längst upp på hemskärmen visar för närvarande aktiva användarlägen. För att ändra användarläge

tryck på det aktiva användarlägets ikon (position 2) och välj ett nytt användarläge från listan. Aggregatet har 2 fasta

och 5 tillfälliga användarlägen som kan väljas. Bara ett läge åt gången kan vara aktivt.

2114711 | A003, 29

Page 33

SV

Inställningar i alla lägen kan ändras i Service- menyn.

Konfiguration |

6.5.1.1 Permanenta lägen

Permanenta lägen är alltid aktiva om de inte avbryts av tillfälliga lägen, aktiverade användarfunktioner eller larm:

33

Ikon

Text

AUTO

MANUELL

Beskrivning

Automatisk luftflödesreglering. AUTO -läge kan väljas när Behovsstyrning,

Veckoschema och/eller externa fläktstyrningsfunktioner är konfigurerade,

annars kommer AUTO symbolen inte synas i aktiva användarlägens meny. AUTO

-läget aktiverar Behovsstyrning, Veckoschema och/eller externa

fläktstyrningsfunktioner. Behov finns att välja som luftflöde i

veckoprogrammet.

Manuellt val av luftflödesnivåer. Aggregatet kan ställas in till en av fyra

tillgängliga luftflödeshastigheter: Av/Låg/Normal/Hög.

Obs!

Fläkten kan ställas in till AV genom att aktivera Manuellt Fläktstopp

funktionen i servicemenyn .

6.5.1.2 Tillfälliga lägen

Tillfälliga lägen är endast aktiva under en bestämd tidsperiod om de inte avbryts av aktiva användarlägen, aktiverade

funktioner eller larm:

Ikon

Text

SEMESTER

Beskrivning

Ställer in hastigheten för både till- och frånluftsfläktar till Låg nivå när

användaren är bortrest under en längre period.

ECO-läget är aktivt.

Inställ tid i dagar.

Ställer in hastigheten för både till- och frånluftsfläktar till maximalt höga nivåer

och temperaturvärdesförskjutning till -3 K när lägenhet är mer välbesökt än

PARTY

BORTA

VÄDRING

ELDSTAD

Inställningar i alla lägen kan ändras i Service- menyn.

Tillfälliga lägen och funktioner är endast aktiva under en bestämd tidsperiod efter vilken de avslutas och aggregatet

återgår till ett tidigare AUTOMATISKT eller MANUELLT läge beroende på vilket som var aktiverat före tillfälligt läge eller

användarfunktion var aktiverad.

Temporära lägen kan även aktiveras via digital ingångssignal som aktiveras av t.ex. en tryckknapp eller närvarogivare.

vanligt.

Standard temperaturbörvärdesförskjutning är -3 K.

Inställning av tid i timmar.

Ställer in hastigheten för både till- och frånluftsfläktar till Låg när användaren är

bortrest under en kort tid.

ECO-läget är aktivt.

Inställning av tid i timmar.

Ställer in hastigheten för både till- och frånluftsfläktar till maximala hög nivå för

att ersätta inomhusluft med frisk luft på kort tid.

Inställning av tid i minuter.

Ställer in hastigheten av tilluftsfläkt till hög nivå och frånluftsfläkten till låg nivå

för att öka lufttrycket i lägenheten för bättre rökevakuering genom skorstenen.

Inställning av tid i minuter.

6.5.1.3 Digital ingångsfunktioner

Digitala ingångsfunktionerna är alltid aktiva medan den digitala ingången är aktiverad.

2114711 | A003, 29

Page 34

34

| Konfiguration

SV

Ikon

Text

Centraldamm-

sugare

Spiskåpa

Konfigurerbar

digital

ingång 1

Konfigurerbar

digital

ingång 2

Konfigurerbar

digital

ingång 3

Tryckvakt

Funktionen ställer in hastigheten av tilluftsfläkt på hög nivå och frånluftsfläkten

till låg nivå för att öka lufttrycket inom lägenheten för bättre uppsamling av

damm genom den centrala dammsugare.

Funktionen kan aktiveras via en digital ingång Centraldammsugarfunktionen.

Ställer in hastigheten för både till- och frånluftsfläktar till Maximum nivå för att

öka luftflödet i spiskåpan.

Funktionen kan aktiveras via digital ingång – Spiskåpsfunktion.

Konfigurerbar digital ingång för egeninställd funktionalitet. Luftflödesnivåerna för

båda fläktarna kan konfigureras fritt.

Högt prioriterad funktion.

Konfigurerbar digital ingång för egeninställd funktionalitet. Luftflödesnivåerna för

båda fläktarna kan konfigureras fritt.

Normalt prioriterad funktion.

Konfigurerbar digital ingång för egeninställd funktionalitet. Luftflödesnivåerna för

båda fläktarna kan konfigureras fritt.

Lågt prioriterad funktion.

Konfigurerbar digital ingång för tryckgivaranslutning. Luftflödesnivåerna för båda

fläktarna kan konfigureras fritt.

6.5.1.3.1Konfigurerbara digitala ingångar

Beskrivning

En egeninställd luftflödesinställning för tillufts- och frånluftsfläktar kan ställas in och tilldelas en digital ingång. Varje

fläkt kan ha olika luftflödesinställningar.

Konfigurerbara digitala ingångar kan aktiveras via signal som aktiveras av en tryckknapp, närvarogivare eller någon annan extern enhet med digital utgång, så som ett BMS-system.

Konfigurerbara digitala ingångar grupperas efter prioritetsnivå, där Konfigurerbar digital ingång 1 är den högsta, vilket innebär att den inte kan skrivas över av andra användarfunktioner.

6.5.1.4 Digital ingång och hierarkiläge

Användarlägen och funktioner har en annan hierarki. Användarnas funktioner som aktiveras via HMI eller mobilapp är

sådana som BORTA, PARTY, ELDSTAD, SEMESTER och VÄDRA avbryts av manuellt val av AUTOMATISKA och MANUEL-

LA fläktlägen.

EnELDSTADSFUNKTION har högsta prioritet mellan användarfunktioner. Andra funktioner aktiveras via HMI/APP kan

störa varandra.

Om eldstadsfunktionen är fastkopplad på anslutningskortet och konfigureras som digital ingång (DI) har det därefter högre prioritet än AUTOMATISKT och manuellt läge. Den digitala ingången för en Eldstadsfunktion har också en högre prioritet än andra hårt dragna digitala ingångar (DI) för: BORTA, CENTRALDAMMSUGARE, SPISKÅPA,

PARTY, SEMESTER eller VÄDRA.

2114711 | A003, 29

Page 35

SV

Konfiguration |

35

Fig. 2 Hierarki för användarlägen och digitala ingångar

Lägen listas från högsta till lägsta prioritet; A – användarlägen som kan aktiveras från manöverpanelen; B – användarlägen och funktioner aktiverade via digital ingång

6.5.2 Inställning av temperatur

Temperaturen kan ställas in på VÄLJ TEMPERATUR-meny tillgänglig från hemskärmen genom att trycka

Temperatursymbolen med en termometer. Standard temperaturvärde är 18°C (12- 30°C).

Använd upp- och nedpilarna eller ett skjutreglage för att ändra värdet.

Tryck sedan på OK för att bekräfta ändringarna.

Temperaturbörvärdet är för rumsluftstemperatur, tilluftstemperatur eller för frånluftstemperatur beroende på vilket

kontrolläge som är aktivt. Standardinställning är tilluftstemperatur.

Kontrolläge av temperaturen kan ändras i Servicemenyn.

6.5.2.1 ECO-läge

ECOLÄGE är en energisparfunktion som kan aktiveras i VÄLJ TEMPERATUR-menyn.

ECO-läge funktion är möjlig bara när en intern värmare är installerad och konfigurerad.

Medan ECO-läget är aktivt, sänks ett temperaturbörvärde vid vilket värmaren är aktiverad för att undvika aktivering

av värmaren under den kalla natten.

2114711 | A003, 29

Page 36

| Konfiguration

36

Om temperaturen är mycket låg och värmaren aktiveras under natten (även med sänkt temperaturbörvärde), kommer

inomhustemperaturen sedan att ökas under kommande dagtid med värmeväxlaren så att lagrad värme kan användas

under nästa kalla natt, där det sänkta börvärdet för värmaren kvarstår.

SV

ECO- läget kommer att påverka de följande

funktionerna/lägena om valda:

• AUTOLÄGE

• MANUELLT LÄGE

• BORTALÄGE

• SEMESTERLÄGE

• CENTRALDAMMSUGARE

• SPISKÅPA

• ELDSTADSLÄGE

ECO-LÄGET är alltid aktiverad av följande lägen:

• BORTALÄGE

• SEMESTERLÄGE

ECO-läge avaktiveras alltid med följande funktioner/

lägen:

• PARTYLÄGE

• VÄDRINGSLÄGE

• FRIKYLNINGSFUNKTIONEN

6.5.3 Luftflödesinställningar

Luftflödesinställningarna är endast tillgängliga i manuellt läge. Klicka på fläktikonen på huvudskärmen för

att gå in på meny för att Välja LUFTFLÖDE.

Använd upp- och nedpilarna eller ett skjutreglage för att ändra luftflödets värde.

Luftflödet kan ställas in i följande steg: Av/Låg/Normal/Hög. Inställningen styr utsignalerna till tillufts- och

frånluftsfläktarna.

Viktigt

Vi rekommenderar inte att ställa in fläkten på AV i vanliga bostäder. Om manuellt fläktstopp aktiveras bör

aggregatet förses med spjäll i avlufts- och uteluftskanalerna för att undvika kallras och risk för kondens när

aggregatet har stoppats.

Fläkten kan sättas till Från genom att aktiveraManuell Fläktstoppfunktion i servicemenyn .

6.5.4 Inomhusluftens kvalitet

Enheten styr automatiskt luftfuktigheten inomhus och/eller CO2nivåerna genom att justera luftflödet.

Luftflöde ökar om luftkvalitet minskar.

Behovsstyrningsfunktionen ansvarar för IAQ (Inomhusluftens kvalitet) reglering. Relativ fuktighet (RH) och/eller

CO

-sensorerna är ansvariga för IAQ-övervakning.

2

Luftkvalitetens (IAQ) inomhusindikator finns om AUTOLÄGE och behovsstyrning är aktiverat.

IAQ-nivåer:

• EKONOMI: Faktiska IAQ-värdet är lägre än låg IAQ-börvärdet.

• BRA: Faktiska IAQ-värdet ligger mellan de låga och höga IAQ-gränserna.

• FÖRBÄTTRAS: Faktiska IAQ-värdet är högre än ett högt IAQ-börvärde.

Olika Luftflödesinställningar kan ställas in för att FÖRBÄTTRAS och BRA IAQ-nivåer i servicemenyn.

Börvärde för relativ luftfuktighet och CO

Nivån kan ställas in i servicemenyn .

2

6.5.5 Statusraden.

Statusraden i området längst ned på hemskärmen visar information om:

2114711 | A003, 29

Page 37

SV

Konfiguration |

37

Lista över aktiva larm. Se

kapitel 11.1för mer

information

Rör vid någon av dessa linjer för att gå till nästa sida med en mer detaljerad lista och information om varje larm och aktiv användarfunktion.

Lista över aktiva funktioner.

Se kapitel 6.6 för mer

information.

6.6 Beskrivning av användarfunktionernas ikoner

Ikon

Text

Värme Ansluten värmare eller förvärmare är aktiv och luftuppvärmning pågår.

Värmeåtervin-

ning

Kylning

Kylåtervin-

ning

Värmeåtervinning från lägenhet är aktiv.

Ansluten kylare är aktiv och luftkylning pågår.

Automatisk kylåtervinning är aktiv när frånluftstemperaturen från lägenhet är

lägre än uteluftstemperaturen och det finns ett kylbehov (temp. börvärde är

lägre än uteluftstemperaturen).

Ingen kylåtervinning vid uppvärmningsbehov. Om utomhustemperaturen är

högre än inomhusluftens temperatur och det finns ett uppvärmningsbehov,

aktiveras funktionen Fri uppvärmning i stället.

Beskrivning

Frikyla

Fuktöverför-

ing

Avfrostning

Sekundär luft

Dammsugare

Spiskåpa

Användarlås

Konfigurerbar

digital

ingång 1

Konfigurerbar

digital

ingång 2

Funktionen minskar inomhusluftens temperatur genom att endast använda sval

uteluft på natten för att spara energi.

Funktionen styr rotationshastigheten hos värmeväxlaren för att förhindra

fuktöverföring till tilluften på grund av för hög relativ fuktighet i frånluften.

Funktionen är endast tillgänglig för enheter med roterande värmeväxlare.

Funktionen förhindrar bildande av is på värmeväxlaren vid låga utetemperaturer.

Varm luft från vardagsrum används för att avfrosta värmeväxlaren med ett spjäll

inuti uteluftskanalen. Enheten växlar från uteluft till sekundärluft medan

frånluftsfläkten stannar och varm sekundärluft höjer temperaturen inuti

värmeväxlaren.

Funktionen ställer in hastigheten av tilluftsfläkt på hög nivå och frånluftsfläkten

till låg nivå för att öka lufttrycket inom lägenheten för bättre uppsamling av

damm genom centraldammsugare.

Funktionen kan aktiveras via en digital ingång Centraldammsugarfunktionen.

Alltid aktiv medan digital ingång är aktiverad.

Ställer in hastigheten för både till- och frånluftsfläktar till Maximum nivå för att

öka luftflödet i spiskåpan.

Funktionen kan aktiveras via digital ingång – Spiskåpsfunktion.

Funktion indikerar att systemet är låst med ett lösenord och inställningar kan inte

redigeras eller ändras på något sätt. Systemet måste först låsas upp för att göra

ändringar.

Konfigurerbar digital ingång för egeninställd funktionalitet. Luftflödesnivåerna för

båda fläktarna kan konfigureras fritt.

Högt prioriterad funktion.

Konfigurerbar digital ingång för egeninställd funktionalitet. Luftflödesnivåerna för

båda fläktarna kan konfigureras fritt.

Normalt prioriterad funktion.

2114711 | A003, 29

Page 38

38

| Konfiguration

SV

Konfigurerbar

digital

ingång 3

Tryckvakt

Konfigurerbar digital ingång för egeninställd funktionalitet. Luftflödesnivåerna för

båda fläktarna kan konfigureras fritt.

Lågt prioriterad funktion.

Konfigurerbar digital ingång för tryckvaktsanslutning. Luftflödesnivåerna för båda

fläktarna kan konfigureras fritt.

6.7 Veckoschema

Enheten kan konfigureras till att fungera vid inställda luftflödesnivåer i upp till två tidsperioder (00:0023:59) på användarens inställda dagar.

Veckoschema är endast aktivt under AUTOLÄGE .

6.7.1 Schema för luftflödesinställningar

Tryck på ikonen för inställningar för att gå till SCEMEMA FÖR LUFTFLÖDESINSTÄLLNINGAR-menyn . I den

här menyn väljer man luftflödesnivåerna för planerade och oplanerade perioder. Tillgängliga nivåer:

Avstängd, Låg, Normal, Hög och behov.

Ställ in temperaturbörvärdesförskjutningen för båda perioderna (-10°C - 0°C).

Behovs-nivån är endast tillgängligt om Behovsstyrning eller extern fläktfunktion är aktivt.

6.7.2 Redigera schema

Tryck på ikon längst ner till vänster på skärmen för att lägga till ett nytt schema eller tryck på knappen

REDIGERA för att ändra redan tillagt schema.

För att konfigurera ett schema:

1. Ställ in tiden. Tryck på START- och SLUTTID-värdena för att ändra tiderna. Använd pilknapparna

öka eller minska värdet. Bekräfta med OK- knappen.

och För att

Obs!

Schemalagda tiden kan börja men aldrig ta slut vid midnatt (00:00). Den senaste SLUTTIDS-perioden är

23:59. Schemalagd tidpunkt kan inte gå över till nästa dag.

12 eller 24 timmar tidformat kan ändras i inställningar meny.

Om nödvändigt, aktivera en annan schemalagd period och bestäm tid.

2. När tiden är inställd, klicka på den dag(ar) när schemat ska vara aktivt. Det är möjligt att ställa in ett separat schema

för varje dag.

Redan schemalagda dagar finns inte tillgängliga att väljas för nya scheman.

3. Bekräfta planering med OK- knappen.

Fig. 3 Veckoprogramsexempel

Schemalagda dagar är markerade (position. 1). Första tidsperioden (position. 2) och den andra tidsperioden (position.

3) Visas till höger om varje schema.

2114711 | A003, 29

Page 39

SV

7 Köksfläktsunderhåll

7.1 Rengöring av köksfläkt

Varning

Om köksfläkten inte rengörs inom angivna intervall finns det risk för brand.

• Vid normal användning ska filtret rengöras varannan

månad. Rengör oftare vid intensiv användning.

• Insidan av köksfläkten ska rengöras minst en gång om

året.

Ta bort filtret enligt illustrationen:

Metallfettfiltret kan diskas i diskmaskin eller rengöras för

hand med milt rengöringsmedel eller flytande tvål. Filtret

måste vara helt torrt när det sätts dit.

Övriga delar i köksfläkten torkas av med fuktig trasa och

milt flytande hushållsrengöringsmedel. Använd aldrig

rengöringsmedel med slipmedel.

Köksfläktsunderhåll |

Fig. 10 Borttagning av köksfläkt

39

8 Underhåll av aggregatet

Underhåll på SAVE VTR 150/K bör normalt utföras 3–4 gånger per år.

8.1 Varning

Fara

• Säkerställ att spänningsmatningen är bruten före underhållsarbete och elarbete.

• Arbete med elektriska anslutningar och underhåll får endast utföras av behörig personal och i enlighet

med gällande krav och föreskrifter.

Varning

• Denna produkt får endast användas av en person som har lämplig kunskap eller utbildning inom detta

område eller står under överinseende av en person med lämpliga kvalifikationer.

• Se upp för vassa kanter vid installation och underhåll. Använd skyddshandskar.

Varning

• Det dröjer något innan alla rörliga delar stannat helt efter att aggregatet kopplats bort från elnätet – risk

för personskada.

Viktigt

• Aggregatet och hela ventilationssystemet ska installeras av behörig personal och i enlighet med gällande

krav och föreskrifter.

• Systemet bör ständigt vara i gång och får bara stoppas vid underhåll/service.

• Anslut inte torktumlare till ventilationssystemet.

• Kanalanslutningar/kanaländar ska vara täckta vid förvaring och installation.

• Kontrollera att alla filter är monterade innan du startar aggregatet.

2114711 | A003, 29

Page 40

| Underhåll av aggregatet

40

8.2 Demontering/montering av utvändig front

Den utvändiga fronten är fäst med fyra stift. Demontera

genom att föra spärren åt vänster och dra fronten mot

dig.

Montera den utvändiga fronten genom att följa stegen i