SystemAir Rotovex 2400 EL, Rotovex 2400HW, Rotovex 3800 HW, Rotovex 4800 HW, Rotovex 3800 EL Operating And Maintenance Instruction Manual

...Page 1

Air Handling Unit

ROTOVEX

Operating and Maintenance

GB

SE

Instruction

Drift- och skötselanvisning

Page 2

GB

Contents

Page

3 Declaration of Conformity

4 Electrical connection

5 Check after connection

6 Automatic system/control

7 External connections

8 Description of functions/electrical heating

9 Description of functions/water heating

10 Starting up ROTOVEX

11 Inspection and care of fans

12 Inspection and care of electrical heater

13 Inspection and care of water heater

14 Inspection and care of filter and rotor

15 Measurements and specifications

16 Alarms, damper

17 Configuration of Corrigo

NB. Systemair AB reserve the rights at any time, without prior notice, make changes

and improvements to the contents of this manual.

2

Page 3

GB

Manufacturer

Our products are manufactured in compliance with

applicable international standards and regulations.

The manufacturer hereby confirms that the following

products:

Air handling units

Rotovex 2400HW Rotovex 2400 EL, Rotovex

3800 HW, 3800 EL, Rotovex 4800 HW, Rotovex

4800 EL.

Comply with the following EC-directives:

Systemair AB

Industrivägen 3

SE-739 30

Skinnskatteberg

SWEDEN

Office: +46 222 440 00

Fax: +46 222 440 99

EC Declaration of Conformity

as defined by the EC Machinery Directive

98/37/EEC, Annex II A. Fans for ventilation in air

handling systems with air from non-explosion

hazardous premises. This machinery must not be

put into operation until prior to reading mounting

instructions and safety information.

The following harmonized standards are in use:

EN 60 034-1 Rotating electric machinery; ratings

and performances.

EN 60 204-1

Safety of machinery; electrical equipment of

machines; general requirements.

EN 292-1

Safety of machinery; basic concepts, general

principles for design.

EN 294

Safety of machinery; safety distances to prevent

danger zones reached by the upper limbs.

Remark: EN 294 only complies when fitted contact

safety device is part of the extent of delivery.

EC Declaration of Conformity

as defined by the EC Low Voltage Directive

73/23/EEC and 93/68/EEC

The following harmonized standards are in use:

EN 60 335-1

Electric domestic products and similar – safetygeneral requirements.

EN 60 335-2-40

Safety of household and similar electrical

appliances - Part 2-40: Particular requirements for

electrical heat pumps, air-conditioners and

dehumidifiers.

EN 50 106 Electric domestic products and similarSafety-Instructions for control of manufacture.

Remark: EN 50 106 complies for internally wired

products only.

EC Declaration of Conformity

as defined by EC’s EMC-directive 89/336/EEC,

92/31/EEC and 93/68/EEC

The following harmonized standards are in use:

EN 61000-6-4: Electromagnetic compatibility (EMC)

- Part 6-4: Generic standards - Emission standard

for industrial environments

EN 61000-6-2 Electromagnetic compatibility (EMC)

– Part 6-2: General requirements – Immunity for

appliances in industrial environments.

The complete technical documentation is available.

Skinnskatteberg, 06 Feb 2003

Mats Sándor

Technical Manager

3

Page 4

GB

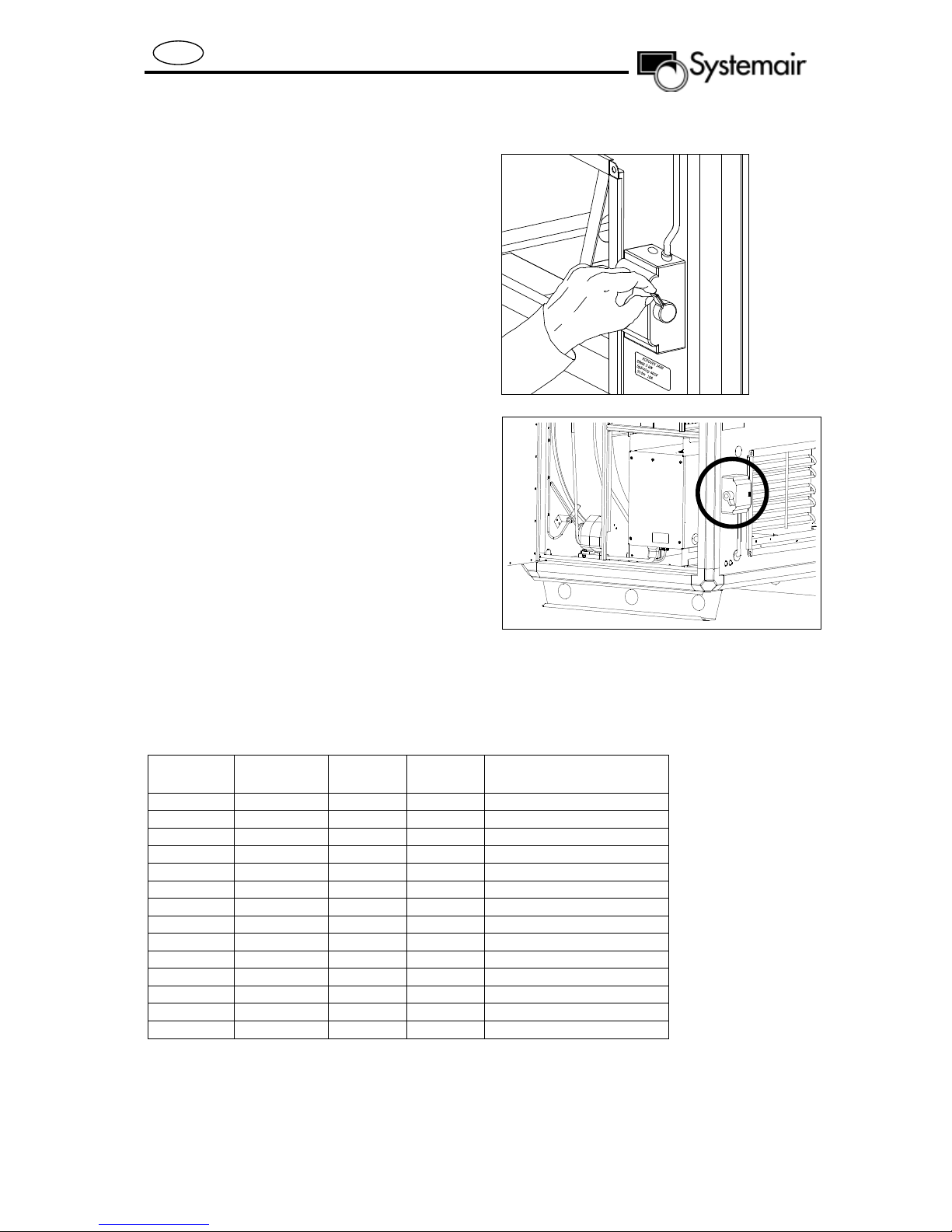

Electrical connection

The unit must not be put into

operation until all the electrical and

mechanical safety precautions have

been taken.

The ROTOVEX unit should be permanently connected to the mains electric

supply through the lockable safety

switch on the gable, as shown in the

figure.

The unit’s nominal electrical values

and manufacturing number are shown

on the plate just under the safety

switch.

If the unit is equipped with a heater

that has separate power supply

(see table below). The unit shall bee

provided with a working switch,

see figure.

Switch for disconnection from the

supply, shall have at least 3 mm

contact separation in all poles.

Electrical data for the unit:

Rotovex Mains Unit (A)

2400HW 230V1~ 5,5 *10,0 2400EL 400V3N~ 10,0 3,0 2400EL 400V3N~ 5,5 **12,0 **17,5

2400EL 230V3~ 5,5 **12,0 **30

3800HW 400V3N~ 6,0 *15,0 3800EL 400V3N~ 12,5 4,5 3800EL 400V3N~ 6,0 **15,0 **22

3800EL 230V3~ 6,0 **15,0 **38

4800HW 400V3N~ 8,5 *20,0 4800EL 400V3N~ 17,0 6,0 4800EL 400V3N~ 8,5 **12,0 **17,5

4800EL 400V3N~ 8,5 **24,0 **35

4800EL 230V3~ 8,5 **12,0 **30

4800EL 230V3~ 8,5 **24,0 **60

*For incoming/outgoing hot water 55/40°C

**Electric heater (above 6 KW) has separate incoming power supply. For 230V3~ you need a

transformer (230V3~ to 400V3~) for the unit supply.

Heater

[kW]

Heater with separate

power supply [A]

4

Page 5

GB

To check after connection

• Fans

Make sure the fan wheels

rotates in correct direction.

• Damper

Make sure the damper motors opens

and shuts correctly.

• Stop/control valve for hot water

Make sure the valve opens and shuts

correctly.

• Pressure/Temperatures

Make sure the pre-set values for

airflow and temperature is correct.

• Closing pressure difference for the

filter

Make sure the pressure sensors at the

filter are set to the correct closing

pressure = alarm mode.

Recommended closing pressure

approx. 240 Pa.

5

Page 6

GB

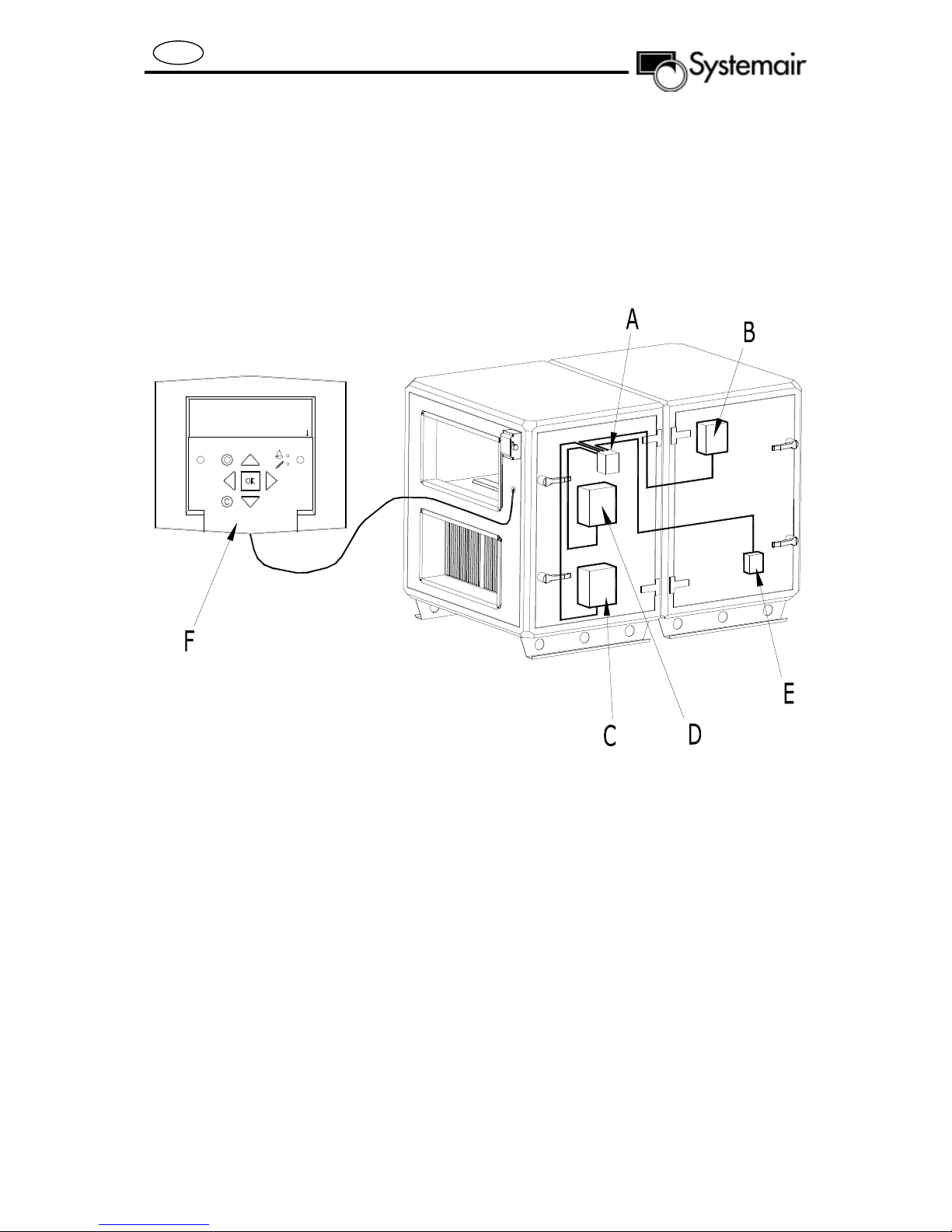

Automatic system/control

All ROTOVEX functions are controlled

from the Corrigo panel. For further

information refer to the supplied

Corrigo user manual.

Regulator vent. sys

05:05:30 15:45

System: Normal run

Sp: 18.0 Act: 17.8

A - Control box: Corrigo E28

B - Control box: rotor

C - Control box: supply air fan

D - Control box: exhaust air fan

E - Control box: electric heating

F – Control panel. Connects to a fast coupling inside

the connection box on the gable of the unit.

6

Page 7

GB

33/35

36/38

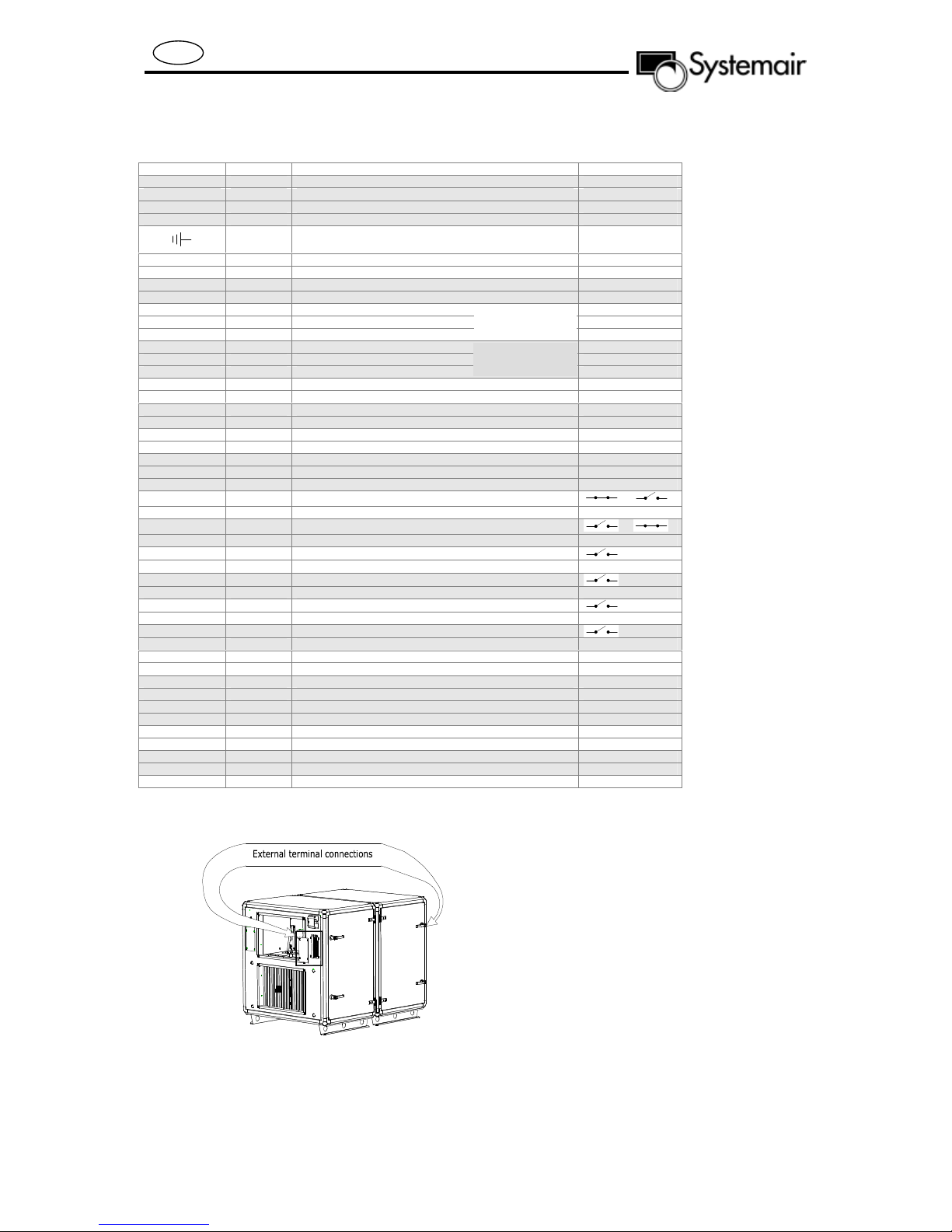

External connections

Terminal block Description Remark

13 G Valve actuator, supply voltage, Heating/cooling 24V AC

14 G0 Valve actuator, supply voltage, Heating/cooling Neutral

43 AO1 Control signal water heating 0-10V DC

57 AO3 Control signal water cooling 0-10V DC

PE Water pump, supply voltage. HW Heating Ground

45 N W ater pump, supply voltage. HW Heating Neutral

46 L1 Water pump, supply voltage. HW Heating 230V AC

39 DO6 Water pump, control voltage (contactor). Cooling 24V AC, 0,5A

G DO ref Water pump, control voltage (contactor). Cooling

33 DO2 Damper, exhaust air 24V AC, 0,5A

34 G0 Damper, exhaust air Neutral

35 G Damper, exhaust air 24V AC

36 DO1 Damper, fresh air 24V AC, 0,5A

37 G0 Damper, fresh air Neutral

38 G Damper, fresh air 24V AC

56 AI3 Extract air temperature sensor PT 1000

Agnd AI ref Extract air temperature sensor

27 UAI1 Fresh air temperature sensor PT 1000

Agnd UI ref Fresh air temperature sensor

31 AI4 Supply air temperature sensor PT 1000

32 AI ref Supply air temperature sensor

55 DO4 DX cooling, step1 24V AC, 0,5A

54 DO5 DX cooling, step2 24V AC, 0,5A

53 DO ref DX cooling, step1 and 2

*64 DI3 Run-indication/alarm circulation pump Cooling

*Ref DI DI ref Run-indication/alarm circulation pump Cooling

*47 DI5 Fire alarm

*Ref DI DI ref Fire alarm

*48 DI6 External stop

*Ref DI DI ref External stop

*49 DI7 Extended operation, Normal

*50 DI ref Extended operation, Normal

*59 DI8 External alarm

*Ref DI DI ref External alarm

40 DO7 Sum alarm, A- and B-alarm

G DO ref Sum alarm, A- and B-alarm

51 Net + LON

52 Net - LON

60 G Pressure transmitter, supply voltage 24V AC

61 AI1 Pressure transmitter, control signal. Supply air 0-10V DC

62 AI ref Pressure transmitter

63 AI2 Pressure transmitter, control signal. Extract air 0-10V DC

28 UAI2 Free to use

Agnd UI ref Free to use

58 UAI3 Free to use

Agnd UI ref Free to use

*Ref DI DI ref Is used together with UDI

* These inputs may only be wired to voltage free contacts.

By spring-loaded

damper, co nnect

By spring-loaded

damper, connect

or

or

All external connections are done in the connection boxes found on each end plate of

the unit. There is a sign on the inside illustrating the various functions and how they

are to be connected.

7

Page 8

GB

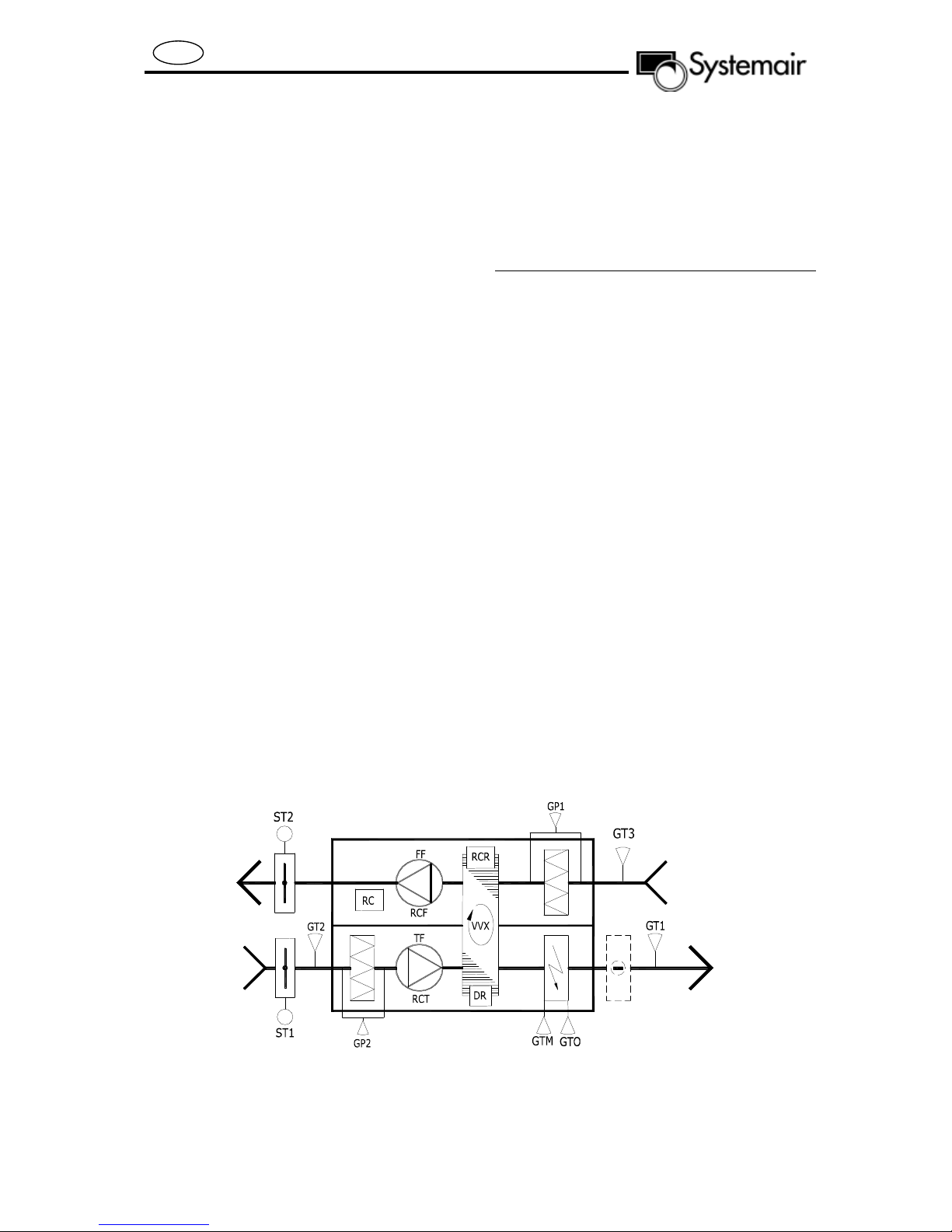

Description of functions

Electrical heating, extract air temperature

control with cascade function.

Function

Start and stop times are set in the

Control panel. To maintain constant

room temperature the RC receives a

signal from GT3 and regulates the VVX

and the electrical heater in sequence.

The GT1 sensor is used to limit the

max and min supply air temperature.

Maximum temperature in the electrical

re-heater is controlled by GTM. GTO

disconnects the heater, gives an alarm

signal and stops the appliance in case

of overheating.

ST1 closes the fresh air damper when

the appliance is stopped. In case of an

unintended stop on the rotor, the RCR

gives an alarm, which is displayed on

the Control panel as an alarm.

Also displayed in the Control panel are

date and time, operating status,

desired and actual room temperature.

GP1 and GP2 give alarm signals when

the actual value exceeds the pre-set

desired value for pressure drop over

the filter.

Designation Name

FF Exhaust air fan

TF Supply air fan

GT1 Sensor, supply air

GT2 Sensor, fresh air

GT3 Sensor, extract air

GTM Sensor, max temperature

in the electrical re-heater.

GTO Sensor overheating in

heater

GP1 Pressure guard, extract

air filter

GP2 Pressure guard, supply

air filter

RC Regulator Corrigo E28

RCF Control box: exhaust air

RCT Control box: supply air

RCR Control box for rotor

DR Motor, rotor

VVX Heat exchanger rotor

ST1 Damper, fresh air

ST2 Damper, exhaust air

8

Page 9

GB

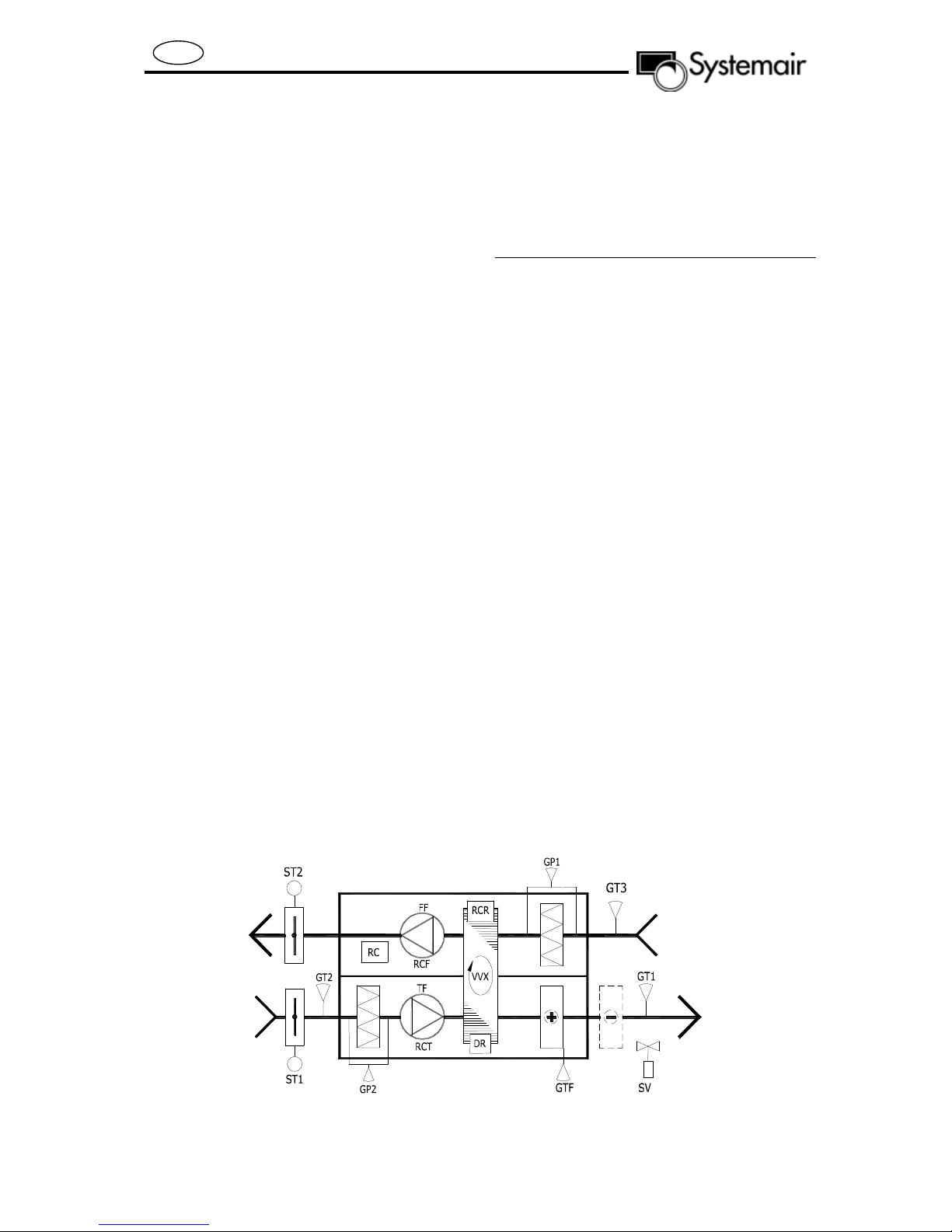

Description of functions

Water heating, extract air temperature

control with cascade function.

Function

Start and stop times are set in the

Control panel. To maintain constant

room temperature the RC receives a

signal from GT3 and regulates the VVX

and SV in sequence. The GT1 sensor

is used to limit the max and min supply

air temperature.

If there is a risk of frost in the water

heater SV opens completely.

If the temperature drops further, an

alarm is set off and the appliance

stops. GTF maintains constant water

temperature even when the fans have

stopped.

ST1 closes the fresh air damper when

the appliance stops. In case of an

unintended stop on the rotor, the RCR

gives an alarm, which is displayed on

the Control panel as an alarm.

Also displayed in the Control panel are

date and time, operating status,

desired and actual room temperature.

GP1 and GP2 give alarm signals when

the actual value exceeds the pre-set

desired value for pressure drop over

the filter.

Designation Name

FF Exhaust air fan

TF Supply air fan

GT1 Sensor, supply air

GT2 Sensor, fresh air

GT3 Sensor, extract air

GTF Sensor for frost protection

GP1 Pressure guard, extract

air filter

GP2 Pressure guard, supply

air filter

RCF Control box: exhaust air

RCT Control box: supply air

RC Regulator Corrigo E28

RCR Control box for rotor

DR Motor, rotor

VVX Heat exchanger rotor

SV Valve regulator, water

valve

ST1 Damper, fresh air

ST2 Damper, exhaust air

9

Page 10

GB

Starting up ROTOVEX

Instructions

In order to start up and run all the

functions the sensors and other

external attachments must be fitted.

Start the Rotovex by using the control

panel. Follow the instructions in the

Corrigo E – User Manual. Start with

chapter 6. Display, LEDs and buttons.

Set the menu language

Press the OK button while switching on

the mains supply.

Press the OK button. Choose language

with the UP / DOWN buttons. Confirm

the choice with the OK button.

Configuration/Settings

Refer to the Corrigo E – User Manual.

The unit is pre-set to constant airflow

and Extract air temperature control

with cascade function. Week schedule

is pre-set to Normal fan speed

between 07:00–16:00 Monday to

Sunday and stopped the rest of the

time.

For more detailed information see the

Commissioning record in the Operating

and Maintenance Instruction.

Important!

Do not forget to set the current time

and date.

10

Page 11

GB

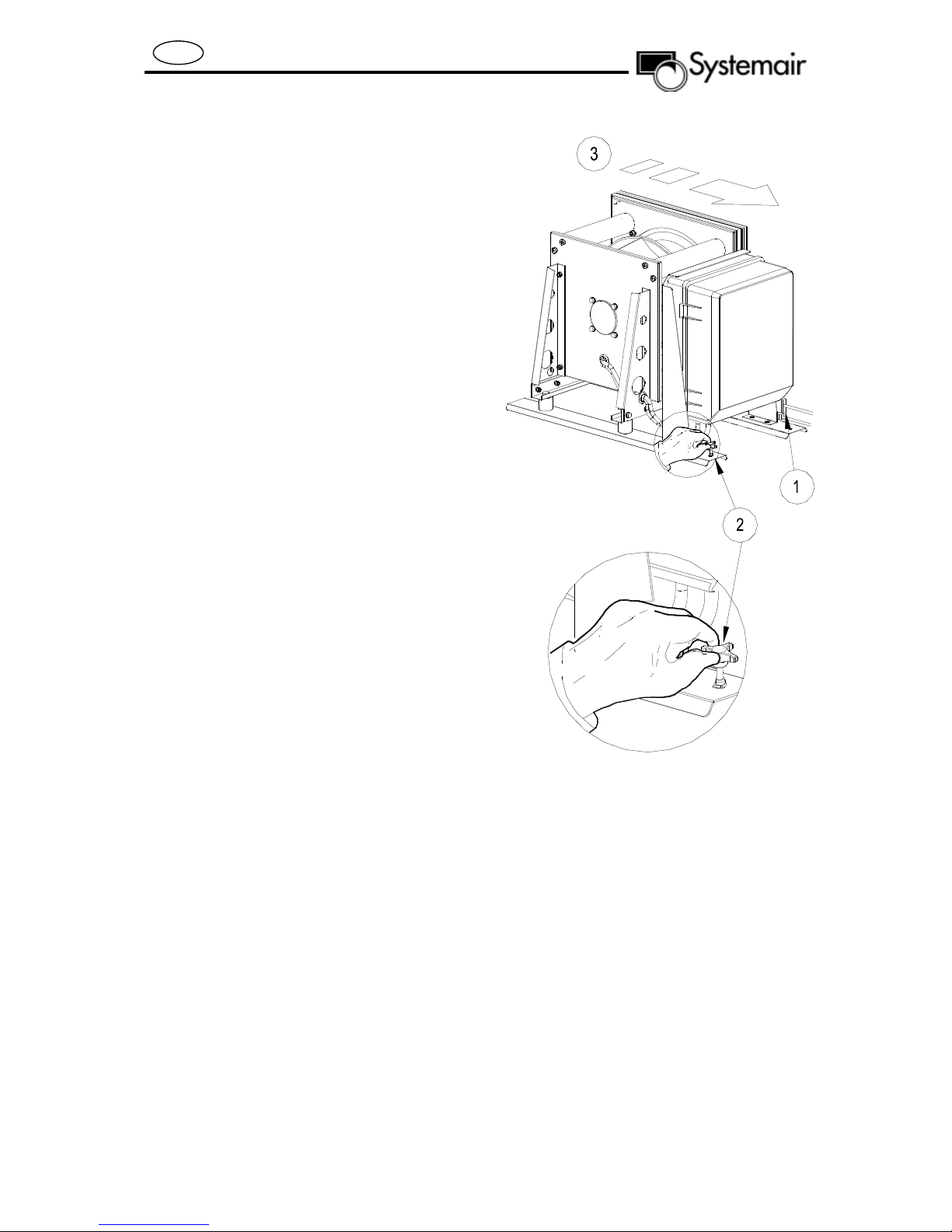

Inspection and care of the fans

For inspection and care of the fans

open the front covers of the unit.

Important!

Disconnect the power supply before

opening the covers.

Fans

When cleaning or carrying out other

maintenance work where the fans

need to be removed, proceed as

follows:

1. Loosen all cable connectors and

pressure hoses

2. Loosen the lock nut at the foot

3. Pull out the fan cartridge

Proceed in the reverse order when

replacing the fan.

Push the fan cartridge in and make

sure that the lock nut is in place (fig 2).

Important!

DO NOT use water when cleaning the

inside of the unit.

11

Page 12

GB

Inspection and care of the

electrical heater

The heater is positioned in the same

section of the appliance as the rotor. It

is easy to remove for servicing or

cleaning. The connecting cables are

provided with quick connectors for

easy disconnection.

Regulating the heater

The power requirement for the heater

is adjusted according to the extract air

temperature, as set on the control

panel. The temperature is indicated

using a sensor in the extract air.

A Pulser regulates the power

requirements for the heaters.

ROTOVEX 2400 3000W 12000W

ROTOVEX 3800 4500W 15000W

ROTOVEX 4800 6000W 12000W

24000W

If the manual overheating protection for

the heater trips, it can be reset as

follows after the appliance has cooled

down:

1. Loosen the cable connectors

2. Pull out the heater until the

reset button is visible

3. Press the reset button

4. Push in the heater

5. Reconnect the cables

Position of the heater

12

Page 13

GB

Inspection and care of the water

heater

The heater is positioned in the same

section of the appliance as the rotor. It

is easy to access for installation of hot

water pipes.

When starting, the battery should be

bled using the air nipple on the collector to prevent air bubbles disturbing the

water flow. See figure below (A).

Regulating the heater

The power requirements for the heater

are adjusted according to the extract

air temperature, as set on the control

panel. The temperature is indicated

using a sensor in the extract air.

Position of the heater

Service and maintenance

The heater does not normally require

any service or maintenance. Check the

supply air side a couple of times a year

and clean if necessary.

Brush or vacuum the radiator. Take

great care when in contact with the

surface of the radiator, which must not

be deformed.

Heater power

ROTOVEX 2400 10000W

ROTOVEX 3800 15000W

ROTOVEX 4800 20000W

A – Venting device

B – Frost protection sensor

13

Page 14

GB

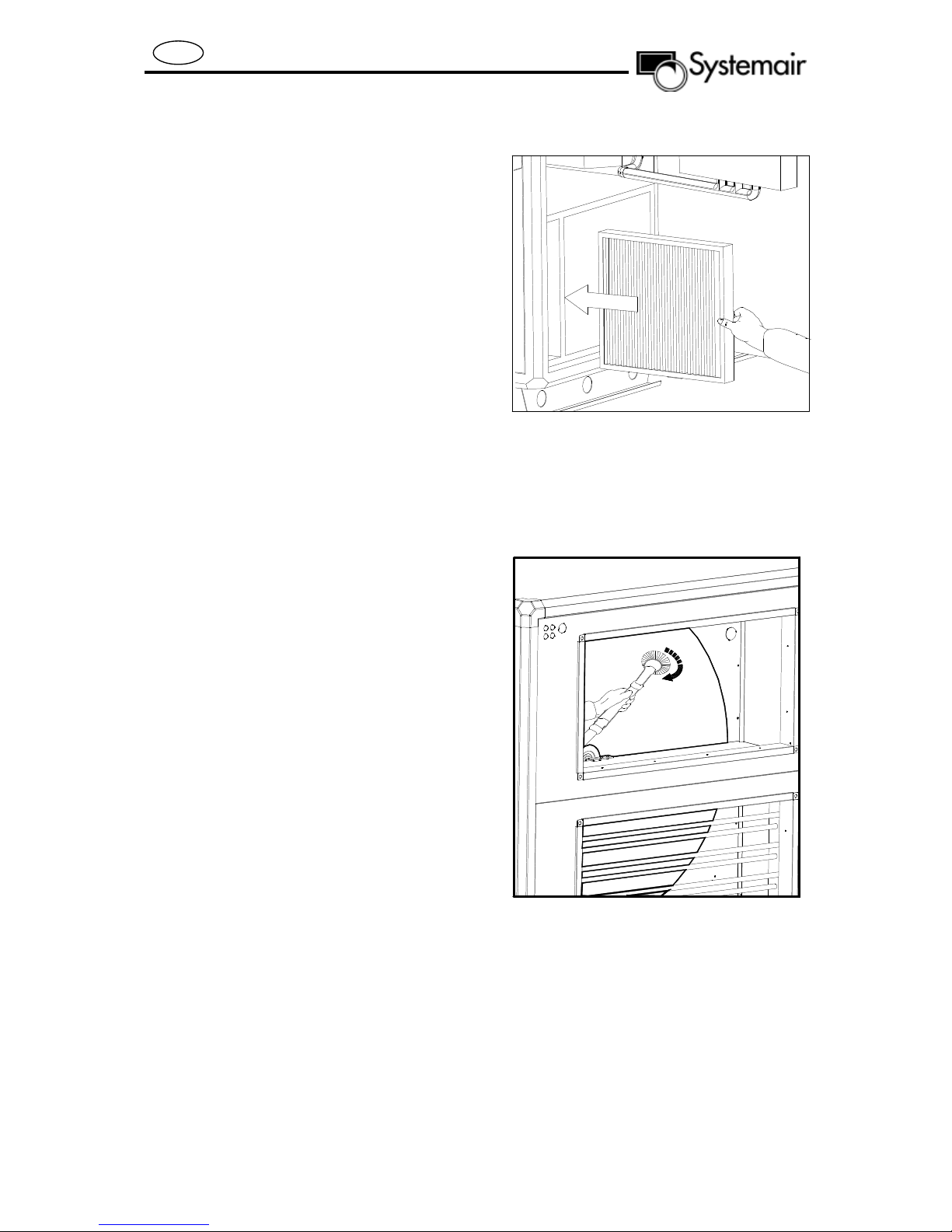

Inspection and care of filter

ROTOVEX is supplied with a class F7

supply air filter and class F5 exhaust

air filter. The filter is divided into 2

cassettes for ease of handling. The

filters are stretched with extensiblerails against sealing strips to minimise

leakage.

The filters are disposable and should

be replaced when the pressure drop

exceeds the given limit.

The filter can be ordered from

ROTOVEX suppliers or from

Systemair.

Inspection and care of rotating

heat exchanger

ROTOVEX is fitted with a rotating heat

exchanger. The rotor is made of

aluminium.

Service and maintenance

Clean the surface of the exchanger

using a vacuum cleaner with a brush

fitting. Take great care not to damage

the surface. Inspect and clean the heat

exchanger surface when changing the

filter, at least twice a year.

Clean using the exhaust air filter

space, turning the rotor by hand to

access the whole surface. If

necessary, compressed air may be

used to remove dirt.

If the transmission belt is worn or slack

it should be replaced. Contact

Systemair Service for help.

14

Page 15

GB

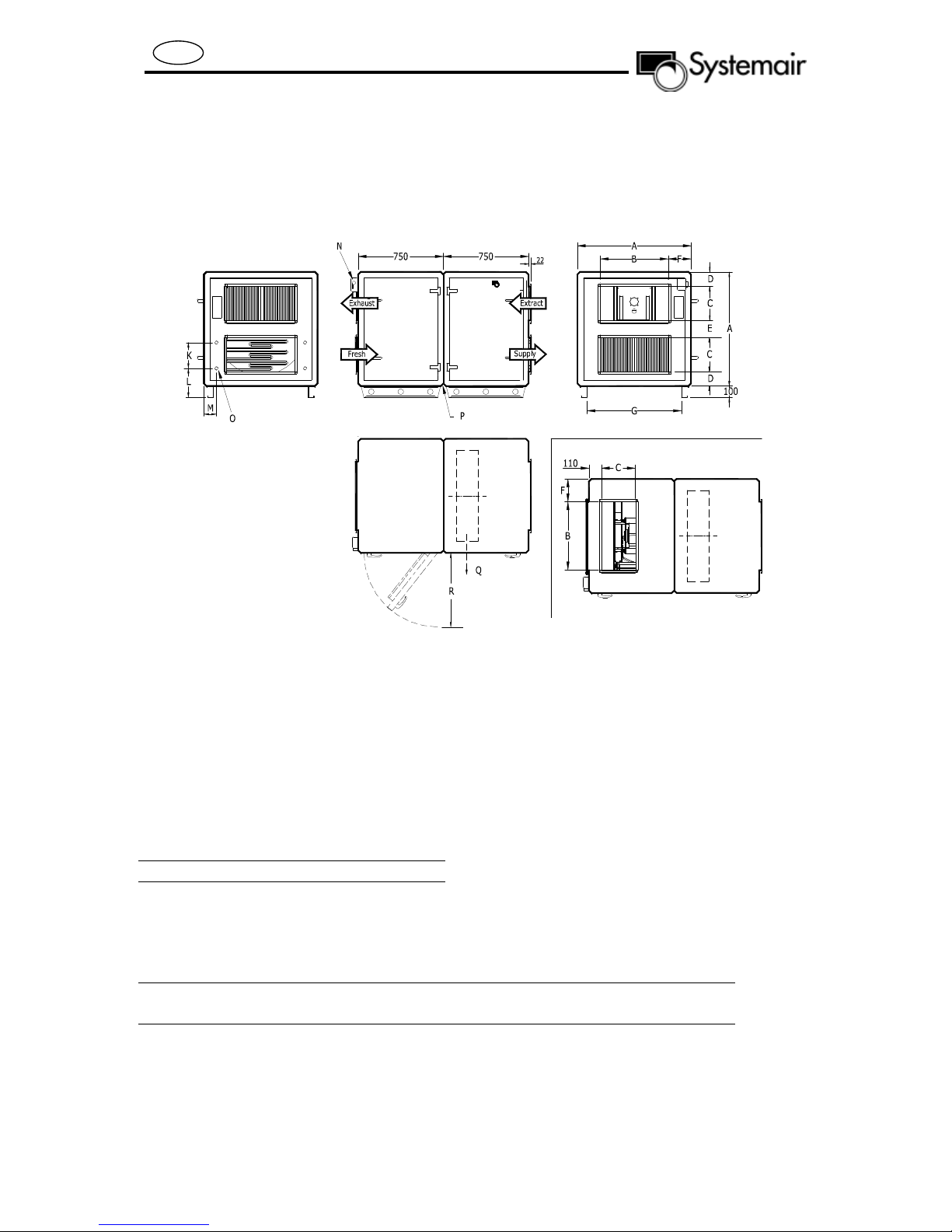

Measurements and specifications

Illustrations below are of a right-mounted version. The left-mounted version has the

inspection hatch on the opposite side. Duct connectors are rectangular, with

connection frame for joining guides.

For connection directed upward on exhaust air, see view below.

Systemair

Exhaust air connection upwards (Option)

N - Electrical connection through safety switch

O - Pipe connection for water heating, internal dimension 15 R (1/2”)

P - Appliance separates here

Q - Minimum space to enable rotor replacement = A-150

R - Minimum space for door 670 mm

Dimensions, heater connection

K L M

ROTOVEX 2400 337 210 145

ROTOVEX 3800 434 190 145

ROTOVEX 4800 487 190 145

Table of measurements

A

B

C

D

E

F

G

Weights

[kg]

ROTOVEX 2400 1000 600 300 125 150 200 795 300

ROTOVEX 3800 1120 600 400 108 104 260 915 340

ROTOVEX 4800 1230 800 400 135 165 215 1025 375

15

Page 16

GB

Damper (accessories)

Table of measurements

A

B

ROTOVEX 2400 600 300

ROTOVEX 3800 600 400

ROTOVEX 4800 800 400

Alarms

Alarm button (pos.1) opens the alarm

queue.

Press this button and active and nonacknowledged alarms will be displayed

in the menu window. The LED for

alarms (pos.2 ) is blinking if there are

non-acknowledged alarms and steady

if the alarms are still active but have

been acknowledged.

If there are multiple alarms use UP /

DOWN buttons to move between them.

An alarm can be acknowledged or

blocked by using OK and UP / DOWN

buttons. To abort and go back to start

menu select Cancel and press LEFT

button. For alarm settings see the

Commissioning protocol.

Extra stop function

For some alarm types such as electric

heating high temperature limit and

water heating frost protection it would

Damper option:

1. Two position actuator

2. Spring return actuator

The damper is intended for closing

the fresh air/exhaust air connections.

Standard air tightness class

be dangerous to not stop the unit on

alarm. Therefore, for such alarm types,

the program will always reset the stop

function to Active even if the operator

should choose Inactive.

It is unfortunately not possible to

remove the display text concerning the

stop function for these alarm types.

This since the available program space

demands that all alarms are treated in

the same way in the display.

16

Page 17

GB

Commissioning record

Company

Responsible

Customer Date Installation

Object / Unit Item no. Installation address

Model / size Series no.

Present time and date set. Week schedule set.

External connections such as sensors, dampers, external alarms etc. done.

Function

Temperature (°C).

Control function Temp.

Set point

Outdoor compensating

(supply air controlling)

Outdoor / supply temp.

Min. supply set point

Max. supply set point

Switching point, between

supply and cascade

regulating

Air flow

Fan regulation

Point 1,2 and 3

Point 4,5 and 6

Point 7 and 8

Preset value Set value

Supply Exhaust Room

18,0 °C

-30,0 / 22,0 -20,0 / 21,0 -11,0 / 20,5

-4,0 / 20,0 5,0 / 19,5 12,5 / 19,0

21,0 / 18,5 30,0 / 18,0

12,0 °C

30,0 °C

13,0 °C

Airflow (m3/h)

Pressure (Pa)

CO2 (ppm)

Supply Exhaust Room

°C

/

/

/

°C

°C

°C

Airflow (m3/h)

Pressure (Pa)

CO2 (ppm)

/

/

/

/

/

Set point Normal

Set point Reduced

Outdoor compensation

Supply fan

Supply fan

Lower point -20.°C 0 .m3/h, Pa

Upper point 10.°C 0 .m3/h, Pa

Only reduced fan speed

when outdoor is below.

Rotovex 2400 * 2300 m3/h or 250Pa ** 2300 m3/h or 250Pa *** 1500 m3/h or 100Pa **** 1500 m3/h or 100Pa

Rotovex 3800 * 3500 m3/h or 250Pa ** 3500 m3/h or 250Pa *** 2000 m3/h or 100Pa **** 2000 m3/h or 100Pa

Rotovex 4800 * 4500 m3/h or 250Pa ** 4500 m3/h or 250Pa *** 2500 m3/h or 100Pa **** 2500 m3/h or 100Pa

-20 °C °C

17

* .

Extract fan

***.

Extract fan

** .

Supply fan

Supply fan

****.

Extract fan

Extract fan

Lower point °C m3/h, Pa

Upper point °C m3/h, Pa

Page 18

GB

Function Preset value Set value

Cooling

Control function cooling

On/off function

Number of binary steps 1 2 3 1 2 3

Lowering of min. control

temp. supply air, DX cooling

Humidity

Control function

humidification.

Sensors

(0-10V DC for 0-100% RH)

Set point

Max. limit (duct sensor) 80. % RH % RH

Week scheduler settings

Preset week schedule is:

Period 1. 07:00-16:00 Monday-Sunday, normal fan-speed.

Period 2. 00:00-00:00 Monday-Sunday. 00:00-00:00 inactivates the period.

Weekday Period Normal Reduced

Not active 0-10V On/off

Mon. 1

2

Thu. 1

2

Wed. 1

2

Thurs. 1

2

Fri. 1

2

Sat. 1

2

Sun. 1

2

Holidays (month.day) Holidays (month.day) Holidays (month.day) Holidays (month.day)

1step 2step 3step binary step

5,0 . °C °C

Disable

Humidification

De-humidification

Humidification / De-humidification

Room sensor

Room and Duct sensor (max limiting)

50. % RH % RH

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

Not active 0-10V On/off

1step 2step 3step binary step

Disable

Humidification

De-humidification

Humidification / De-humidification

Room sensor

Room and Duct sensor (max limiting)

1. . - . 7. . - . 13. . - . 19. . - .

2. . - . 8. . - . 14. . - . 20. . - .

3. . - . 9. . - . 15. . - . 21. . - .

4. . - . 10. . - . 16. . - . 22. . - .

5. . - . 11. . - . 17. . - . 23. . - .

6. . - . 12. . - . 18. . - . 24. . - .

18

Page 19

GB

Function Preset value Set value

Frost Protection

Mode (EL unit Off): On On Off

Frost limit temperature:

Set point when stopped:

(return water)

P-band when running:

Pressure Input

Supply/Exhaust Air Fan

Supply Air Fan Pressure at 0V

Supply Air Fan Pressure at 10V

Exhaust Air Fan Pressure at 0V

Exhaust Air Fan Pressure at 10V

Night cooling

Mode: Off On Off

Run when day outdoor temp is

higher than:

Stop when night outdoor temp is

higher than:

Stop when night outdoor temp is

lower than:

Stop when room temp is lower

than:

See Alarm settings/

Low frost guard temp

10. °C °C

5.

0. (Pa)

CAV 1600 Pa VAV 500 Pa

0. (Pa)

CAV 1600 Pa VAV 500 Pa

22. °C °C

15. °C °C

5. °C °C

18. °C °C

See Alarm settings/

Low frost guard temp

(Pa)

(Pa)

(Pa)

(Pa)

Cool Recycling

Mode: Off On Off

Start Limit: 2. °C °C

Control On Demand

Min time for control on demand: 60. min min

Support control: Off On Off

Run Exhaust Air Fan when support

control active

CO2 control Off

CO2 control Type Damper

On On Off

On when active time channel

On when in-active time channel

On

Fan

Off

On when active time channel

On when in-active time channel

On

Damper

Fan

19

Page 20

GB

Function Preset value Set value

Fire Function

Fire damper function: Off

Extraction when fire alarm: Off On Off

Fire input: Normally opened

Fire damper exercise: No exercise

Fire damper run time: 90. s s

Fire damper interval: 1. days days

Fire damper exercise hour 0. h h

Mixing damper Min Limitation

Mode: Off On Off

Limit: 5. %

External Set point Knob

External set point knob: Off

Damper normally closed

Damper normally opened

Normally closed

Exercise with

ventilation running

Exercise with

ventilation stopped

Off

Damper normally closed

Damper normally opened

Normally opened

Normally closed

No exercise

Exercise with

ventilation running

Exercise with

ventilation stopped

%

On Off

Min set point of knob: 12. °C

Max set point of knob: 30. °C

Heat Pump (HW unit)

Pump stop mode (EL unit Off): On

Pump stop delay: 5. min

Stop pump at temp: 10. °C

Pump stop hysteretic: 1. °C

Pump exercise hour: 15.

Cool Pump

Pump stop delay 5. min

General

Heat Pump Indication

Cool Pump Indication

Outdoor Temperature Related

Settings

Full heat when outdoor temp is

below

Motor Protection

Run Indication

Motor Protection

Run Indication

3. °C °C

°C

°C

On Off

min

°C

°C

min

Motor Protection

Run Indication

Motor Protection

Run Indication

20

Page 21

GB

Function Preset value Set value

Miscellaneous

Extended operation

Min. set point reduction, Supply

air. At DX-Cooling:

60. min

5. °C

min

°C

Alarm configuration.

Alarm settings

1. Supply Air Fan is out of operation 26. Sensor error

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

2. Exhaust Air Fan is out of operation 28. Rotation guard exchanger

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

3. P1-Heater is out of operation 29. Fire damper is out of operation

(Applies to HW units) Class B Class B

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

4. P1-Cooler is out of operation 30. Supply Air Fan Pressure control error

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

6. Filter guard 31. Exhaust Air Fan Pressure control error

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

8. External frost guard 32. Supply Air Fan external operation

Stop ventilation unit if alarm active Yes Stop ventilation unit if alarm active No

10. Fire alarm 33. Exhaust Air Fan external operation

Stop ventilation unit if alarm active Yes Stop ventilation unit if alarm active No

11. External switch 34. Ventilation stopped

Stop ventilation unit if alarm active Yes Stop ventilation unit if alarm active No

12. External alarm 35. Manual supply air control

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

13. Supply Air control error 36. Manual Supply Air Fan mode

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

Max diff between set point and supply 5 °C

14. High supply air temp 37. Manual Supply Air Fan freq control

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

High supply air temp 35 °C

15. Low supply air temp 38. Manual Exhaust Air Fan mode

Stop ventilation unit if alarm active Yes Stop ventilation unit if alarm active No

Low supply temp 10 °C

Preset

value

Class B Class B

Delay 300 s

Class B Class B

Delay 300 s

Delay 5 s

Class B Class B

Delay 5 s

Class B Class B

Delay 300 s

Class Off Class Off

Delay 0 s

Class A Class Off

Delay 0 s

Class C Class C

Delay 0 s

Class B Class C

Delay 0 s

Class B Class C

Delay 4 min

Class B Class C

Delay 300 s

Class A Class C

Delay 300 s

Set

value

Alarm settings

Max diff between set point and actual pressure

Max diff between set point and actual pressure

Preset

value

Delay 5 s

Delay 60 s

Delay 90 s

Delay 4 min

50 Pa

Delay 4 min

50 Pa

Delay 120 s

Delay 120 s

Delay 0 s

Delay 0 s

Delay 0 s

Delay 0 s

Delay 0 s

Set

value

21

Page 22

GB

Alarm settings

18. High room temp 39. Manual Exhaust Air Fan freq control

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

High room temp 30 °C

19. Low room temp 40. Manual heater control

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

Low room temp 10 °C

20. High exhaust air temp 41. Manual cooler control

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

High exhaust temp 30 °C

21. Low exhaust air temp 42. Manual exchanger control

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

Low exhaust temp 10 °C

22. Electric heating is overheated 43. Manual P1-Heater

(Set to Off on HW units) Class A (Applies to HW units) Class C

Stop ventilation unit if alarm active Yes Stop ventilation unit if alarm active No

23. Frost risk 44. Manual P1-Cooler

(Set to Off on EL units) Class B Class C

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

24. Low frost guard temp 46. Manual fire damper

(Applies to HW units) Class A Class B

Stop ventilation unit if alarm active Yes Stop ventilation unit if alarm active No

Frost limit 7 °C

25. Low efficiency 47. Internal battery error

Stop ventilation unit if alarm active No Stop ventilation unit if alarm active No

Low efficiency 50 %

Preset

value

Class B Class C

Delay 30 min

Class B Class C

Delay 30 min

Class B Class C

Delay 30 min

Class B Class C

Delay 30 min

Delay 0 s

Delay 60 s

Delay 0 s

Class Off Class A

Delay 30 min

Set

value

Alarm settings

Preset

value

Delay 0 s

Delay 0 s

Delay 0 s

Delay 0 s

Delay 0 s

Delay 0 s

Delay 0 s

Delay 0 s

Set

value

In/Output Configurations.

Possible choices of

Analogue input signal

Outdoor temperature sensor UAI 1

Supply air temperature sensor AI 4

Exhaust air temperature sensor AI 3

Extract temperature sensor

Room temperature sensor 1

Room temperature sensor 2

CO2 / VOC sensor 0…10V DC

Extra sensor / Set point potentiometer

Pressure transmitter, supply air 0…10V DC AI 1

Pressure transmitter, exhaust air 0…10V DC AI 2

De-icing sensor, heat exchanger

Frost protection sensor, Hot water heater.

Room Humidity sensor

Duct Humidity sensor

Preset

Configuration

UAI 4

(HW units)

22

Set

Configuration

Page 23

GB

Possible choices of

Analogue output signal

Y1 Actuator Heating AO 1

Y2 Actuator Exchanger AO 2

Y3 Actuator Cooling AO 3

Frequency converter, supply air fan AO 4

Frequency converter, exhaust air fan AO 5

Actuator Humidity control

Split of any one of temp outputs Y1,Y2 or Y3

Possible choices of

Digital input signal

Filter guard, supply air and exhaust air DI 1

Run-indication/alarm circulation pump, heating

Run-indication/alarm circulation pump, cooling DI 3

Run-indication/alarm circulation pump, exchanger

Fire alarm DI 5

Fire damper end-switch monitoring

Extended Operation, Normal DI 7

Extended Operation, Reduced

External stop DI 6

External alarm DI 8

Flow-switch

Rotation sentinel, exchanger DI 4

Run-indication/alarm supply air fan

Run-indication/alarm exhaust air fan

De-icing, exchanger

Frost protection thermostat

Overheated electric heater

Preset

Configuration

Preset

Configuration

DI 2

(HW units)

UDI 4

(EL units)

Set

Configuration

Set

Configuration

Possible choices of

Digital output signal

Start/stop supply air fan (SAF) 1/1-speed DO 1

Start/stop exhaust air fan (EAF) 1/1-speed DO 2

Start/stop supply air fan (SAF) 1/2-speed

Start/stop exhaust air fan (EAF) 1/2-speed

Start/stop circulation pump, heating

Fire dampers

Sum alarm A- and B-alarm DO 7

Sum alarm A-alarm

Sum alarm B-alarm

Start/stop circulation pump,cooling DO 6

Start/stop circulation pump, liquid exchanger

Activation-signal SAF frequency converter

Activation-signal EAF frequency converter

Activation heating

Activation cooling

Activation heat exchanger

Preset

Configuration

DO 3

(HW units)

DO 3

(EL units)

Set

Configuration

23

Page 24

GB

Possible choices of

Digital output signal

Extract air close-off damper

Fresh air close-off damper

Re-circulation damper

Heating 3-pos. actuator, increase

Heating 3-pos. actuator, decrease

Exchanger 3-pos. actuator, increase

Exchanger 3-pos. actuator, decrease

Cooling 3-pos. actuator, increase

Cooling 3-pos. actuator, decrease

Step controller heating, step 1

Step controller heating, step 2

Step controller heating, step 3

Step controller heating, step 4

Step controller cooling, step 1 DO 4

Step controller cooling, step 2 DO 5

Step controller cooling, step 3

Extra Timer channel 1

Extra Timer channel 2

Extra Timer channel 3

Extra Timer channel 4

Extra Timer channel 5

Notes

Preset

Configuration

Set

Configuration

24

Page 25

SE

Innehållsförteckning

Sida

26 Tillverkardeklaration

27 Elektrisk anslutning

28 Kontrollera efter anslutning

29 Automatik/styrning

30 Externa förbindningar

31 Funktionsbeskrivning/elvärme

32 Funktionsbeskrivning/vattenvärme

33 Start och inställning av ROTOVEX

34 Inspektion och tillsyn av fläktar

35 Inspektion och tillsyn av el värmare

36 Inspektion och tillsyn av vattenvärmare

37 Inspektion och tillsyn av filter och rotor

38 Mått och viktuppgifter

39 Larmfunktioner, spjäll

41 Konfigurering Corrigo

Not. Systemair AB förbehåller sig rätten att utan föregående information göra ändringar och

förbättringar till innehållet i denna manual.

25

Page 26

SE

Tillverkare

Våra produkter är tillverkade i enlighet med gällande

EU-direktiv.

Tillverkaren försäkrar härmed att följande produkter:

Luftbehandlingsaggregat

Rotovex 2400HW Rotovex 2400 EL, Rotovex

3800 HW, 3800 EL, Rotovex 4800 HW, Rotovex

4800 EL.

överensstämmer med kraven i nedanstående EUdirektiv.

Systemair AB

Industrivägen 3

739 30 Skinnskatteberg

Tel: 0222-440 00

Fax: 0222-440 99

EU-försäkran om överensstämmelse

enligt EUs maskindirektiv 98/37/EEC, bilaga IIA.

Aggregat för ventilation i luftbehandlingssystem

grupp A med luft från icke explosionsfarligt utrymme

(ELSÄK-FS 1999:5 830.1, 830.3).

Fläktar får ej tas i bruk innan installationsanvisning

och säkerhetsanvisning har beaktats.

Harmoniserade standarder:

EN 60 034-1

Roterande elektriska maskiner; märkdata och

driftsegenskaper

EN 60 204-1

Maskinsäkerhet; elutrustning för maskiner: allmänna

fordringar.

EN 292-1

Maskinsäkerhet; grundläggande begrepp; allmänna

konstruktionsprinciper.

EN 294

Maskinsäkerhet; skyddsavstånd för att hindra att

man når riskområden med händer och armar.

Anmärkning: Överensstämmelsen med EN 294

avser endast monterade skyddsutrustningar

EU-försäkran om överensstämmelse

enligt EUs lågspänningsdirektiv 73/23/EEC och

93/68/EEC

Harmoniserade standarder:

EN 60 335-1

Elektriska hushållsapparater och liknande

bruksföremål- Säkerherhet-Allmänna fordringar.

EN 60 335-2-40 Elektriska hushållsapparater och

liknande bruksföremål - Säkerhet - Del 2: Särskilda

fordringar på elektriska värmepumpar,

Internationella standarder

EN 50 106

Elektriska hushållsapparater och liknande

bruksföremål-Säkerhet-Anvisningar för

tillverkningskontroll.

Anmärkning: Överensstämmelse med EN 50 106

gäller kopplade produkter.

EU-försäkran om överensstämmelse

enligt EUs EMC-direktiv 89/336/EEC, 92/31/EEC

och 93/68/EEC

Harmoniserade standarder:

EN 61000-6-4 Elektromagnetisk kompatibilitet

(EMC) - Del 6-4: Generella fordringar - Emission

från utrustning i industrimiljö.

EN 61000-6-2 Elektromagnetisk kompatibilitet

(EMC)- Del 6-2: Generella fordringar-Immunitet hos

utrustning i industrimiljö.

Komplett teknisk dokumentation finns tillgänglig.

Skinnskatteberg, 06 Feb 2003

Mats Sándor

Teknisk chef

26

Page 27

SE

Elektrisk anslutning

Aggregatet får ej tas i drift innan

samtliga el-tekniska och mekaniska

säkerhetsanordningar anbringats.

Elektrisk anslutning av ROTOVEX sker

genom fast nätanslutning av den låsbara säkerhetsbrytaren på aggregatgaveln, se bilden.

Elektrisk märkdata och tillverkningsnummer för aggregatet, se märkskylten

som sitter under säkerhetsbrytaren.

Om aggregatet är utrustad med värmare som kräver extern kraftmatning (se

tabell nedan). Skall den förses med en

arbetsbrytare för att servicearbeten

skall kunna utföras, se bild.

En allpolig brytare med 3 mm brytavstånd måste användas vid fast

installation.

Elektriska data för aggregatet:

Rotovex Nät Aggregat (A) Värmare [kW]

2400HW 230V1~ 5,5 *10,0 2400EL 400V3N~ 10,0 3,0 2400EL 400V3N~ 5,5 **12,0 **17,5

2400EL 230V3~ 5,5 **12,0 **30

3800HW 400V3N~ 6,0 *15,0 3800EL 400V3N~ 12,5 4,5 3800EL 400V3N~ 6,0 **15,0 **22

3800EL 230V3~ 6,0 **15,0 **38

4800HW 400V3N~ 8,5 *20,0 4800EL 400V3N~ 17,0 6,0 4800EL 400V3N~ 8,5 **12,0 **17,5

4800EL 400V3N~ 8,5 **24,0 **35

4800EL 230V3~ 8,5 **12,0 **30

4800EL 230V3~ 8,5 **24,0 **60

*Vid värmevatten in/ut 55/40°C

**El värmare (över 6 KW) har separat matning. För 230V3~ behövs en transformator

(230V3~ till 400V3~) för matning till aggregatet.

Värmare med separat

kraftmatning [A]

27

Page 28

SE

Kontrollera efter anslutning

• Rotationsriktning fläkthjul

Kontrollera fläkthjulens

rotationsriktning.

• Spjäll

Kontrollera att spjällen stänger och

öppnar korrekt.

• Ställdon/styrventil värmevatten

Kontrollera att ventilen stänger och

öppnar korrekt.

• Tryck/Temperaturer

Kontrollera att inställda värden på luftflöden och temperaturer är korrekta.

• Filter sluttryckfall

Kontrollera att tryckgivarna vid filtren är

inställda på rätt sluttryck = larmläge.

Rekommenderat sluttryck ca: 240 Pa.

28

Page 29

SE

Automatik/styrning

All manövrering av ROTOVEX

funktioner sker från Kontroll panelen.

För information om handhavandet, se

Corrigo användarmanual.

Regulator vent. sys

05:05:30 15:45

System: Normal run

Sp: 18.0 Act: 17.8

A - Reglercentral: Corrigo E28

B - Reglercentral: rotor

C - Reglercentral: tilluftsfläkt

D - Reglercentral: frånluftsfläkt

E - Reglercentral: el-värme

F – Kontroll Panel. Ansluts inuti

kopplings boxen (snabbkontakt) på

aggregatets gavel.

29

Page 30

SE

Externa förbindningar

Kopplingsplint Beskrivning Anmärkning

13 G Ventilställdon, matarspänning. Värme/kyla 24V AC

14 G0 Ventilställdon, matarspänning. Värme/kyla Nolla

43 AO1 Styrsignal hetvatten batteri 0-10V DC

57 AO3 Styrsignal kallvatten batteri 0-10V DC

PE Vatten pump, matarspänning. Hetvatten batteri Jord

45 N Vatten pump, matarspänning. Hetvatten batteri Nolla

46 L1 Vatten pump, matarspänning. Hetvatten batteri 230V AC

39 DO6 Vatten pump, styrspänning (kontaktor). Kallvatten batteri 24V AC, 0,5A

G DO ref Vatten pump, styrspänning (kontaktor). Kallvatten batteri

33 DO2 Avluft spjäll 24V AC, 0,5A

34 G0 Avluft spjäll Nolla

35 G Avluft spjäll 24V AC

36 DO1 Uteluft spjäll 24V AC, 0,5A

37 G0 Uteluft spjäll Nolla

38 G Uteluft spjäll 24V AC

56 AI3 Givare, Frånluft temperatur PT 1000

Agnd AI ref Givare, Frånluft temperatur

27 UAI1 Givare, Uteluft temperatur

Agnd UI ref Givare, Uteluft temperatur

31 AI4 Givare, Tilluft temperatur PT 1000

32 AI ref Givare, Tilluft temperatur

55 DO4 DX kyla, steg1 24V AC, 0,5A

54 DO5 DX kyla, steg2 24V AC, 0,5A

53 DO ref DX kyla, steg1 och 2

*64 DI3 Driftindikering/larm cirkulationspump, Kyla

*Ref DI DI ref Driftindikering/larm cirkulationspump, Kyla

*47 DI5 Brandlarm

*Ref DI DI ref Brandlarm

*48 DI6 Extern brytare

*Ref DI DI ref Extern brytare

*49 DI7 Förlängd drift, Normal hastighet

*50 DI ref Förlängd drift, Normal hastighet

*59 DI8 Externt larm

*Ref DI DI ref Externt larm

40 DO7 Summalarm, A- och B-larm

G DO ref Summalarm, A- och B-larm

51 Net + LON

52 Net - LON

60 G Tryckgivare, matarspänning 24V AC

61 AI1 Tryckgivare, styrsignal. Tilluft 0-10V DC

62 AI ref Tryckgivare

63 AI2 Tryckgivare, styrsignal. Frånluft 0-10V DC

28 UAI2 Ledig

Agnd UI ref Ledig

58 UAI3 Ledig

Agnd UI ref Ledig

*Ref DI DI ref Används som referens tillsammans med UDI

* Dessa ingångar får endast anslutas till spänningsfria kontakter.

Med fjäderretur

spjäll, anslu t 33/35

Med fjäderretur

spjäll, anslut 36/38

PT 1000

eller

eller

All extern inkoppling sker till kopplingsboxarna, placerade på aggregatets båda

kortsidor, där också inkopplingsinstruktion med funktionsbeskrivning finns att tillgå.

30

Page 31

SE

Funktionsbeskrivning

Elvärme, kaskadkopplad frånlufts

temperatur reglering.

Funktion

Start/stopp sker via inprogrammerad

tid i Kontroll panelen. Konstanthållning

av rums-temperaturen sker genom att

RC via signal från GT3, styr VVX och

el-värmaren i sekvens. GT1 givaren

används för max och min begränsning

av tillufttemperaturen. Max

begränsning av temperaturen i elvärmaren styrs av GTM. GTO bryter

strömmen till värmaren vid

överhettning, ger larm och stoppar

aggregatet.

ST1 stänger uteluftsspjället vid stoppat

aggregat. Vid ofrivilligt stopp av rotorn

larmar RCR. Larmet avläses på

Kontroll panelen.

På Kontroll panelen visas även Datum

och tid, driftläge, önskad och verklig

rums temperatur.

GP1 och GP2 larmar när ärvärdet

överstiger inställt börvärde på tryckfallen över filtren.

Beteckning Benämning

FF Frånluftsfläkt

TF Tilluftsfläkt

GT1 Givare tilluft

GT2 Givare uteluft

GT3 Givare frånluft

GTM Givare max temperatur el-

värmare

GTO Givare övertemperatur

skydd el-värmare

GP1 Tryckvakt frånluftsfilter

GP2 Tryckvakt tilluftsfilter

RC Reglercentral Corrigo E28

RCF Reglercentral frånluftsfläkt

RCT Reglercentral tilluftsfläkt

RCR Reglercentral rotordrivning

DR Drivmotor, rotor

VVX Värmeväxlare (rotor)

ST1 Spjällställdon uteluft

ST2 Spjällställdon avluft

31

Page 32

SE

Funktionsbeskrivning

Vattenvärme, kaskadkopplad frånlufts

temperatur reglering.

Funktion

Start/stopp sker via inprogrammerad

tid i Kontroll panelen. Konstanthållning

av Rums-temperaturen sker genom att

RC via signal från GT3, styr VVX och

SV steglöst, i sekvens. GT1 givaren

används för max och min begränsning

av tillufttemperaturen.

Vid frysrisk i vattenvärmaren öppnar

SV helt. Om temperaturen sjunker

ytterligare ges larm och aggregatet

stoppas. GTF konstanthåller vattentemperaturen även när fläktarna har

stannat.

ST1 stänger uteluftsspjället vid stoppat

aggregat. Vid ofrivilligt stopp av rotorn

larmar RCR. Larmet avläses på

Kontroll panelen.

På Kontroll panelen visas även Datum

och tid, driftläge, önskad och verklig

rums temperatur.

GP1 och GP2 larmar när ärvärdet

överstiger inställt börvärde på tryckfallen över filtren.

Beteckning Benämning

FF Frånluftsfläkt

TF Tilluftsfläkt

GT1 Givare tilluft

GT2 Givare uteluft

GT3 Givare frånluft

GTF Givare frysskydd

GP1 Tryckvakt frånluftsfilter

GP2 Tryckvakt tilluftsfilter

RCF Reglercentral frånluftsfläkt

RCT Reglercentral tilluftsfläkt

RC Reglercentral Corrigo E28

RCR Reglercentral rotordrivning

DR Drivmotor, rotor

VVX Värmeväxlare (rotor)

SV Ställdon vattenventil

ST1 Spjäll ställdon uteluft

ST2 Spjäll ställdon avluft

32

Page 33

SE

Start och inställning av ROTOVEX

Instruktioner

För att kunna starta och köra alla

funktioner ska aggregatets givare och

övrig extern utrustning vara monterad.

Starta upp aggregatet via Kontroll

panelen. Följ anvisningarna i Corrigo E

– Manualen. Starta med kapitel 6.

Display, lysdioder och knappar.

Ställa in meny språk

Håll in OK knappen samtidigt som

matningsspänningen slås på.

Tryck på OK knappen. Välj önskat

språk med UPP / NER knapparna och

bekräfta valet med OK knappen.

Konfigurering/inställningar

Se Corrigo E – Manualen och

Igångkörnings protokoll i Drift och

skötsel anvisningen.

Aggregatet är från fabrik förinställt för

konstantflödes reglering och Frånluft

temperatur reglering med kaskad

funktion.

Veckoschemat är förinställt till Normal

fläkthastighet mellan 07:00-16:00

måndag till söndag och stoppat resten

av tiden.

Viktigt!

Glöm inte att ställa tiduret med aktuell

dag och klockslag.

33

Page 34

SE

Inspektion och tillsyn av fläktar

För inspektion och tillsyn av komponenter i aggregatet öppnas frontluckorna.

Viktigt!

Aggregatet ska vara strömlöst innan

luckorna öppnas.

Fläktarna

Vid rengöring eller annat servicearbete

där fläkten behöver tas ut ska följande

moment utföras:

1. Lossa alla kabelkontakter och

tryckslangar till fläkten

2. Lossa låsratten vid foten

3. Drag ut fläktpaketet

Vid återmontering omvända ordningen.

Skjut in fläktpaketet och se till att sätta

dit låsratten ordentligt på plats (fig. 2).

Viktigt!

Vid rengöring invändigt i aggregatet får

vatten INTE användas.

34

Page 35

SE

Inspektion och tillsyn av

elvärmare

Värmaren är placerad i samma aggregatdel som rotorn. Den är lätt demonterbar för service eller rengöring.

Anslutna kablage är försedda med

kontaktdon för snabb hantering.

Reglering värmare

Värmarens effektbehov anpassas efter

den frånluftstemperatur som ställs in

på kontroll panelen. Temperaturen

indikeras via givaren i frånluften.

Värmarens effektbehov styrs av en

Pulser.

Värmarnas effekt

ROTOVEX 2400 3000W 12000W

ROTOVEX 3800 4500W 15000W

ROTOVEX 4800 6000W 12000W

24000W

Om värmarens manuella överhettningsskydd löst ut, återställs detta

enligt följande, när elementen kallnat:

1. Lossa kablagekontakterna

2. Drag ut värmaren tills

återställningsknappen blir synlig

3. Tryck in återställningen

4. Skjut in värmaren

5. Återmontera kablagekontakterna

Placering av värmare

35

Page 36

SE

Inspektion och tillsyn av

vattenvärmare

Värmaren är placerad i samma aggregatdel som rotorn. Den är lätt åtkomlig

för installation av anslutande värmevattenrör.

Vid start ska batteriet luftas vid luftnippeln på ena samlingsröret för att

förhindra att luftblåsor stör vattenflödet,

se bild nedan (A).

Reglering värmare

Värmarens effektbehov anpassas efter

den frånluftstemperatur som ställs in

på kontroll panelen. Temperaturen

indikeras via givaren i frånluften.

Placering av värmare

Service och underhåll

Värmaren behöver som regel ingen

service eller underhåll. Inspektera

tilluftssidan ett par gånger om året och

rengör vid behov.

Borsta eller dammsug lamellytan.

Iakttag stor försiktighet vid beröring av

ytan, lamellerna får inte deformeras.

Värmarnas effekt

ROTOVEX 2400 10000W

ROTOVEX 3800 15000W

ROTOVEX 4800 20000W

A – Luftningsnippel

B – Frysskyddsgivare

36

Page 37

SE

Inspektion och tillsyn filter

ROTOVEX är från leverans utrustad

med tilluftsfilter klass F7 och frånluftsfilter i klass F5. Filtren är delade i två

kassetter för enkel hantering. Tätning

av filtren med utdragbar plåtskena och

tätningslister för att minimera läckage.

Filtren är avsedda för engångsbruk och

ska bytas när tryckfallet överstiger

angivet tryckgränsvärde.

Filtren beställes hos ROTOVEXåterförsäljaren eller Systemair.

Inspektion och tillsyn roterande

värmeväxlare

ROTOVEX är utrustad med roterande

värmeväxlare. Rotorn är tillverkad av

aluminium.

Service och underhåll

Växlarens yta rengöres genom dammsugning av ytan med borstmunstycke.

Stor försiktighet iakttas vid beröring av

rotorytan för att undvika skador.

Inspektion och rengöring utföres i samband med filterbyte, intervall minst två

gånger/år.

Rengöringen utföres från frånluftsfiltrets utrymme och rotorn snurras för

hand för att komma åt hela ytan. Vid

stark försmutsning kan tryckluft användas för renblåsning.

Om drivremmen är sliten eller slak,

måste den bytas ut. Kontakta

Systemair Service för åtgärd.

37

Page 38

SE

Mått- och viktuppgifter

Ritad som högerutförande. Vänsterutförande har inspektionssida på motsatta sidan.

Kanalanslutningarna är rektangulära med anslutningsram för gejdskarv.

För anslutning uppåt på avluften, se vy nedan.

Systemair

Anslutning avluft uppåt (tillval)

N - El-anslutning via säkerhetsbrytare

O - Anslutning av rör vid vattenvärmeutförande, inv. ansl. 15 R (1/2”)

P - Aggregatet delbart här

Q - Min utrymme vid ev. rotorbyte = A-150

R - Min utrymme för dörr, 670 mm

Mått värmaranslutning

K L M

ROTOVEX 2400 337 210 145

ROTOVEX 3800 434 190 145

ROTOVEX 4800 487 190 145

Mått tabell

A

B

C

D

E

F

G

Vikter

[kg]

ROTOVEX 2400 1000 600 300 125 150 200 795 300

ROTOVEX 3800 1120 600 400 108 104 260 915 340

ROTOVEX 4800 1230 800 400 135 165 215 1025 375

38

Page 39

SE

Spjäll (tillbehör)

Mått tabell

A

ROTOVEX 2400 600 300

ROTOVEX 3800 600 400

ROTOVEX 4800 800 400

Larm

Larm knappen (pos.1 i fig.2) öppnar

larm kön. Vid tryck på denna knapp

visas aktiva och okvitterade larm i

menyrutan. Larm lysdioden (pos.2 i

fig.2) blinkar om det ligger okvitterade

larm och lyser med fast sken om det

finns larm som är kvitterade men

fortsatt aktiva. Finns det flera larm

används UPP / NER knapparna för att

bläddra mellan dem. Ett larm kan

kvitteras eller blockeras genom att

använda OK och UPP / NER

knapparna. För att avbryta och gå

tillbaka till start menyn väljs Avbryt,

tryck därefter på VÄNSTER knapp.

För larm inställningar se Igångkörnings

protokoll.

B

Alternativa spjällmotorer:

1. Tvåläges

2. Fjäder återgång

Spjällen är avsedda för avstängning av

uteluft-/avluftanslutningarna. De är

som standard utförda i täthetsklass 2.

Extra stoppfunktion

För vissa larm såsom överhettning och

frysskyddslarm vore det direkt farligt att

låta regleringen löpa vidare efter larm

varför programmet, för dessa larm,

alltid kommer att återställa

39

Page 40

stoppfunktionen till Aktiv även om

operatören skulle välja Inaktiv.

Tyvärr går det inte att för dessa larm få

bort texten rörande stoppfunktionen

från displayen. Detta eftersom det

tillgängliga programutrymmet kräver att

alla larm hanteras på samma sätt i

displayen.

40

Page 41

SE

Igångkörningsprotokoll

Företag

Handläggare

Kund Datum Anl.

Objekt / Aggregat Individnr. Anl.adress

Typ / storlek Serienr.

Aktuell tid & datum inställd. Veckoschema inställt.

Externa anslutningar så som givare, spjäll, externa alarm etc. klart.

Funktion Fabriksinställt värde Inställt värde

Temperatur (°C).

Reglerfunktion Temp.

Börvärde

Ute kompensering

(Tillufts reglering)

Utomhus / tillufts temp.

Brytpunkt 7 och 8

Min. börvärde tilluft

Max. börvärde tilluft

Utetemp. för att växla mellan

tillufts och kaskad reglering

Luftflöde

Fläktreglering Luftflöde (m3/h)

Börvärde Normal hast.

Börvärde Reducerad

hast.

Ute temp. kompenserings kurva.

(flöde, tryck komp.)

Endast reducerad hastighet

när utetemp. är under.

Brytpunkt 1,2 och 3

Brytpunkt 4,5 och 6

Rotovex 2400 * 2300 m3/h el.250Pa ** 2300 m3/h el.250Pa *** 1500 m3/h el.100Pa **** 1500 m3/h el.100Pa

Rotovex 3800 * 3500 m3/h el.250Pa ** 3500 m3/h el.250Pa *** 2000 m3/h el.100Pa **** 2000 m3/h el.100Pa

Rotovex 4800 * 4500 m3/h el.250Pa ** 4500 m3/h el.250Pa *** 2500 m3/h el.100Pa **** 2500 m3/h el.100Pa

Tilluft Frånluft Rum

18,0 °C

-30,0 / 22,0 -20,0 / 21,0 -11,0 / 20,5

-4,0 / 20,0 5,0 / 19,5 12,5 / 19,0

21,0 / 18,5 30,0 / 18,0

12,0 °C

30,0 °C

13,0 °C

Tryck (Pa)

CO2 (ppm)

Tillufts fläkt

Tillufts fläkt

Nedre punkt -20.°C 0 .m3/h, Pa

Övre punkt 10.°C 0 .m3/h, Pa

-20 °C °C

* .

***.

Tilluft Frånluft Rum

°C

/

/

/

°C

°C

°C

Luftflöde (m3/h)

Tryck (Pa)

CO2 (ppm)

Frånlufts fläkt

Frånlufts fläkt

** .

Tillufts fläkt

****.

Tillufts fläkt

Nedre punkt °C m3/h, Pa

Övre punkt °C m3/h, Pa

/

/

/

Frånlufts fläkt

Frånlufts fläkt

/

/

41

Page 42

SE

Funktion Fabriksinställt värde Inställt värde

Kyla

Reglerfunktion kyla

On/off. funktion

Antal element, Dx kyla

Sänkning min. börvärde

tilluft vid DX kyla

Fukt

Reglerfunktion

luftbefuktning/avfuktning

Givare

(0-10V DC för 0-100% RH)

Börvärde

Max. begränsning

(kanalgivare)

Inställning veckoschema

Fabriksinställda tider är:

Period 1. 07:00-16:00 Måndag-Söndag, normal fläkthastighet.

Period 2. 00:00-00:00 Måndag-Söndag, 00:00-00:00 inaktiverar perioden.

Veckodag Period Normal fläkthast. Reducerad fläkthast.

Måndag 1

2

Tisdag 1

2

Onsdag 1

2

Torsdag 1

2

Fredag 1

2

Lördag 1

2

Söndag 1

2

Helgdag (månad.dag) Helgdag (månad.dag) Helgdag (månad.dag) Helgdag (månad.dag)

1. . - . 7. . - . 13. . - . 19. . - .

Ej aktiv 0-10V On/off

1steg 2steg 3steg binära steg

1 2 3 1 2 3

5,0 . °C °C

Ej aktiv

Fuktning

Avfuktning

Fuktning / Avfuktning

Rumsgivare

Rum och Kanalgivare (max begränsn.)

50. % RH % RH

80. % RH % RH

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

: - : : - :

Ej aktiv 0-10V On/off

1steg 2steg 3steg binära steg

Ej aktiv

Fuktning

Avfuktning

Fuktning / Avfuktning

Rumsgivare

Rum och Kanalgivare (max begränsn.)

2. . - . 8. . - . 14. . - . 20. . - .

3. . - . 9. . - . 15. . - . 21. . - .

4. . - . 10. . - . 16. . - . 22. . - .

5. . - . 11. . - . 17. . - . 23. . - .

6. . - . 12. . - . 18. . - . 24. . - .

42

Page 43

SE

Funktion Fabriksinställt värde Inställt värde

Frysskydd (HW aggregat)

Läge (EL aggr Av): På På Av

Låg frysvakts temperatur:

Börvärde ej drift (returvatten)

P-band drift

Tryckingång

Till/ Frånlufts fläkt

Tillufts fläktens tryck vid 0V

Tillufts fläktens tryck vid 10V

Frånufts fläktens tryck vid 0V

Frånufts fläktens tryck vid 10V

Nattkyla

Se larminställningar/

Låg frysvaktstemp

10. °C °C

5.

0. (Pa)

CAV 1600 Pa VAV 500 Pa

0. (Pa)

CAV 1600 Pa VAV 500 Pa

Se larminställningar/

Låg frysvaktstemp

(Pa)

(Pa)

(Pa)

(Pa)

Läge: Av På Av

Aktivera när dagute temperaturen

är högre än:

Stoppa när nattute temperaturen

är högre än:

Stoppa när nattute temperaturen

är lägre än:

Stoppa när rums temperaturen är

lägre än:

Kylåtervinning

Läge: Av På Av

Kylgräns: 2. °C °C

Behovsstyrd drift

Min tid för behovsstyrd drift: 60. min min

Stöddrift: Av På Av

Kör frånluftsfläkt vid stöddrift På På Av

CO2 reglering Av

Typ av CO2 reglering Spjäll

22. °C °C

15. °C °C

5. °C °C

18. °C °C

På när aktiv tidkanal

På när inaktiv tidkanal

På

Fläkt

Av

På när aktiv tidkanal

På när inaktiv tidkanal

På

Spjäll

Fläkt

43

Page 44

SE

Funktion Fabriksinställt värde Inställt värde

Brandfunktion

Brandspjälls funktion: Av

Avluftning vid brand: Av På Av

Brandingång: Normalt öppen

Brandspjälls motionering: Ingen motionering

Gångtid brandspjälls motionering: 90. s s

Intervall brandspjälls motionering: 1. dagar dagar

Timme för brandspj. motionering: 0. h h

Minbegränsning blandn. spjäll

Läge: Av

Minbegränsning: 5. %

Börvärdesomställare

Extern börvärde omställare: Av

Spjället normalt stängt

Spjället normalt öppet

Normalt stängd

Motionering med körande

ventilering

Motionering med stoppad

ventilering

Av

Spjället normalt stängt

Spjället normalt öppet

Normalt öppen

Normalt stängd

Ingen motionering

Motionering med körande

ventilering

Motionering med stoppad

ventilering

På Av

%

På Av

Min börvärde omställare: 12. °C

Max börvärde omställare: 30. °C

P1-Värme (HW pump)

Pumpstopp: (EL aggr Av) På

Stoppfördröjning: 5. min

Stoppa pumpen vid utetemp.: 10. °C

Hysteres: 1. °C

Timme för motionering: 15.

P1-Kyla (kylvatten pump)

Stoppfördröjning 5. min min

Generellt

P1-Värme (HW pump)

P1-Kyla (kylvatten pump)

Utetemp. relaterade

inställningar

Värmestart när utetemp

är under:

Motorskydd

Driftsindikering

Motorskydd

Driftsindikering

3. °C

°C

°C

På Av

min

°C

°C

Motorskydd

Driftsindikering

Motorskydd

Driftsindikering

°C

44

Page 45

SE

Funktion

Fabriksinställt värde Inställt värde

Övrigt

Förlängd drift:

Sänkning min. börvärde tilluft vid

DX kyla:

60. min

5. °C

min

°C

Larm konfigurering.

Larm inställningar

1. Driftsfel tillufts fläkt 26. Givarfel

Fördröjning 300 s

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

2. Driftsfel frånlufts fläkt 28. Rotationsvakt VVX

Fördröjning 300 s

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

3. Driftsfel P1-Värme (HW pump) 29. Driftsfel brandspjäll

(inaktiv för EL aggregat) Klass B Klass B

Fördröjning 5 s

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

4. Driftsfel P1-Kyla (kylvatten pump) 30. Reglerfel tryck tilluftsfläkt

Fördröjning 5 s

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

6. Filtervakt 31. Reglerfel tryck frånluftsfläkt

Fördröjning 300 s

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

8. Extern frysvakt 32. Extern drift tilluftsfläkt

Fördröjning 0 s

Stoppa vent-aggregatet om larmat Ja Stoppa vent-aggregatet om larmat Nej

10. Brandlarm 33. Extern drift frånluftsfläkt

Fördröjning 0 s

Stoppa vent-aggregatet om larmat Ja Stoppa vent-aggregatet om larmat Nej

11. Extern brytare 34. Driftläge avstängd

Fördröjning 0 s

Stoppa vent-aggregatet om larmat Ja Stoppa vent-aggregatet om larmat Nej

12. Externt larm 35. Tillufts regulator i manuellt läge

Fördröjning 0 s

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

13. Reglerfel tilluftstemp 36. Tilluftsfläkt i manuellt läge

Fördröjning 4 min

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

Max skillnad mellan börv och tilluftstemp 5 °C

14. Hög tilluftstemp 37. Tryckregulator för tilluftfl i man läge

Fördröjning 300 s

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

Hög tilluftstemp 35 °C

15. Låg tilluftstemp 38. Frånluftsfläkt i manuellt läge

Fördröjning 300 s

Stoppa vent-aggregatet om larmat Ja Stoppa vent-aggregatet om larmat Nej

Låg tilluftstemp 10 °C

Förinst

värde

Klass B Klass B

Klass B Klass B

Klass B Klass B

Klass B Klass B

Klass Inaktiv Klass Inaktiv

Klass A Klass Inaktiv

Klass C Klass C

Klass B Klass C

Klass B Klass C

Klass B Klass C

Klass A Klass C

Inst.

värde

Larm inställningar

Max skillnad mellan börv och tilluftstryck

Max skillnad mellan börv och frånluftstryck

Förinst

värde

Fördröjning 5 s

Fördröjning 60 s

Fördröjning 90 s

Fördröjning 4 min

50 Pa

Fördröjning 4 min

50 Pa

Fördröjning 120 s

Fördröjning 120 s

Fördröjning 0 s

Fördröjning 0 s

Fördröjning 0 s

Fördröjning 0 s

Fördröjning 0 s

Inst.

värde

45

Page 46

SE

Larm inställningar

18. Hög rumstemp

Fördröjning 30 min

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

Hög rumstemp 30 °C

19. Låg rumstemp 40. Värmebatteri i manuellt läge

Fördröjning 30 min

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

Låg rumstemp 10 °C

20. Hög frånluftstemp 41. Kylbatteri i manuellt läge

Fördröjning 30 min

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

Hög frånluftstemp 30 °C

21. Låg frånluftstemp 42. VVX i manuellt läge

Fördröjning 30 min

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

Låg frånluftstemp 10 °C

22. Överhettning elvärme 43. P1-Värme i manuellt läge (HW pump)

(inaktiv för HW aggregat) Klass A (inaktiv för EL aggregat) Klass C

Fördröjning 0 s

Stoppa vent-aggregatet om larmat Jaj Stoppa vent-aggregatet om larmat Nej

23. Frysrisk 44. P1-Kyla i manuellt läge (kylv. pump)

(inaktiv för EL aggregat) Klass B Klass C

Fördröjning 60 s

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

24. Låg frysvaktstemp 46. Brandspjäll i manuellt läge

(inaktiv för EL aggregat) Klass A Klass B

Fördröjning 0 s

Stoppa vent-aggregatet om larmat Ja Stoppa vent-aggregatet om larmat Nej

Frysgräns 7 °C

25. Låg verkningsgrad 47. Fel på internt batteri

Fördröjning 30 min

Stoppa vent-aggregatet om larmat Nej Stoppa vent-aggregatet om larmat Nej

Låg verkningsgrad 50 %

Förinst

värde

Klass B Klass C

Klass B Klass C

Klass B Klass C

Klass B Klass C

Klass Inaktiv Klass A

Inst.

värde

Larm inställningar

39. Tryckregulator för frånluftfl i man läge

Fördröjning 0 s

Fördröjning 0 s

Fördröjning 0 s

Fördröjning 0 s

Fördröjning 0 s

Fördröjning 0 s

Fördröjning 0 s

Fördröjning 0 s

Förinst

värde

Inst.

värde

Ingångs- och utgångs-konfigurationer.

Möjliga val för

Analoga ingångs signaler

Utomhus temperatur givare UAI 1

Tillufts temperatur givare AI 4

Frånlufts temperatur givare AI 3

Avlufts temperatur givare

Rums temperatur givare 1

Rums temperatur givare 2

CO2-givare 0…10V DC

Extra givare / Börvärde potentiometer

Tryckgivare tilluft 0…10V DC AI 1

Tryckgivare frånluft 0…10V DC AI 2

Avfrostnings temperatur givare, VVX

Frysvakts temperatur givare, Hetvatten batteri

Rums fuktighets givare

Kanal fuktighets givare

Förinställd

konfiguration

UAI 4

(HW aggr)

Inställd

Konfiguration

46

Page 47

SE

Möjliga val för

Analoga utgångs signaler

Y1 Ställdon värme AO 1

Y2 Ställdon VVX AO 2

Y3 Ställdon kyla AO 3

Frekvensriktare, Tilluftsfläkt AO 4

Frekvensriktare, Frånluftsfläkt AO 5

Ställdon Avfuktning/ Befuktning

Split av någon av Y1,Y2 eller Y3

Möjliga val för

Digitala ingångs signaler

Filtervakt, Till och Frånluft DI 1

Driftindikering/larm cirkulationspump, värme

Driftindikering/larm cirkulationspump, kyla DI 3

Driftindikering/larm cirkulationspump, VVX

Brandlarm DI 5

Ändläges Indikering brandspjäll

Förlängd drift, Normal hastighet DI 7

Förlängd drift, Reducerad hastighet

Extern brytare DI 6

Externt larm DI 8

Flödesvakt

Rotationsvakt VVX DI 4

Driftindikering/larm tilluftsfläkt

Driftindikering/larm frånluftsfläkt

Avfrostningstermostat VVX

Frysvaktstermostat vattenvärme

Överhettning elvärme

Möjliga val för

Digitala utgångs signaler

Start frekvensriktare, tillufts fläkt DO 1

Start frekvensriktare, frånlufts fläkt DO 2

Start tilluftsfläkt, Normal hastighet

Start frånluftsfläkt, Normal hastighet

Start tilluftsfläkt, Reducerad hastighet

Start frånluftsfläkt, Reducerad hastighet

Start cirkulationspump värme

Brandspjäll

Summalarm DO 7

Summalarm A

Summalarm B

Start cirkulationspump kyla DO 6

Start cirkulationspump VVX

Aktivera Värme

Aktivera kyla

Aktivera VVX

Avstängningsspjäll Avluft

Avstängningsspjäll Friskluft

Förinställd

konfiguration

Förinställd

konfiguration

DI 2

(HW aggr)

UDI 4

(EL aggr)

Förinställd

konfiguration

DO 3

(HW aggr)

DO 3

(EL aggr)

Inställd

Konfiguration

Inställd

Konfiguration

Inställd

Konfiguration

47

Page 48

SE

Möjliga val för

Digitala utgångs signaler

Återluftsspjäll

Värmeventil öka

Värmeventil minska

VVX-ventil öka

VVX-ventil minska

Kylventil öka

Kylventil minska

Stegkopplare Elvärme, steg 1

Stegkopplare Elvärme, steg 2

Stegkopplare Elvärme, steg 3

Stegkopplare Elvärme, steg 4

Stegkopplare kyla, steg 1 DO 4

Stegkopplare kyla, steg 2 DO 5

Stegkopplare kyla, steg 3

Extra tidkanal 1

Extra tidkanal 2

Extra tidkanal 3

Extra tidkanal 4

Extra tidkanal 5

Anteckningar

Förinställd

konfiguration

Inställd

Konfiguration

48

Page 49

Systemair AB

Industrivägen 3

SE-739 30 Skinnskatteberg

Phone +46 222 440 00

Fax +46 222 440 99

www.systemair.com

204263 (2007-06-01)

49

Loading...

Loading...