Page 1

Fire Safety Products

PKIR3G-Ex, PKIS3G-Ex, PKIS-EI90S-Ex & PKIS-EI120S-Ex

Atex Fire Dampers

Data Sheet

Page 2

2 / 12 | Fire Dampers

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fire Resistivity . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ordering Codes . . . . . . . . . . . . . . . . . . . . . . . . 7

Technical Parameters . . . . . . . . . . . . . . . . . . . . . 8

Installation, Maintenance & Operation . . . . . . . . . . . . 9

Transport & Storage . . . . . . . . . . . . . . . . . . . . . . 9

Supplement . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Related Products. . . . . . . . . . . . . . . . . . . . . . . . 10

Good to know

Current information on all products is

available at design.systemair.com

Page 3

FTZÚ 14 ATEX 0127X

FTZÚ 14 ATEX 0127X

1396 - CPR - 0077

FTZÚ 13 ATEX 0046X

1396 - CPR - 0076

Description

Fire Dampers | 3 / 12

1396 - CPD - 0062

Fire damper is the closure for the HVaC ductworks so that the damper blade on the mechanical, thermal, or electrical

impulse close the duct and restrict the spread of re, heat and smoke. Explosion-proof version is modied by 2014/34/

EU directives, which set out the technical requirements for equipment and protective systems intended for use in

potentially explosive atmospheres - re dampers are in the design of group II category 2 G against the ignition of gas

explosion group IIB, temperature class T5 and Equipment Protection Level Gb according EN ISO 80079-36.2016.

Manually Operated Fire Dampers

In case of re, the re damper is automatically set to the closed position. Depending on the version, the damper closes

either after the thermal fuse melts or by means of activation in electromagnet in impulse connection, or disconnecting

the electromagnet in interrupted connection (see wiring diagrams in the Installation, operation and inspection manual of

the re dampers UserManual_PKIR_PKIS). After the closing of the damper blade, it is mechanically locked in the closed

position and can only be opened manually. The actuating mechanism is activated when the temperature of the air in the

duct reaches 74°C and the damper closes within 10 seconds after the fuse melts.

Actuator Operated Fire Dampers

The re damper can be equipped with a actuator which closes the damper after the command from the building

management system, or after the breach of the thermoelectric fuse. The actuator controlled re dampers are standardly

equiped with a thermoelectric fuse that activates the closing of the damper after reaching or exceeding of an ambient

temperature of 72°C, the actuator circuit is interrupted and the spring closes the damper blade within 20 seconds.

Pictures of the re dampers components and dimensions are available in the “DataSheet_PKIR_PKIS”

document on Systemair DESIGN.

Page 4

4 / 12 | Fire Dampers

List of Accessories

Detailed information about accessories for PKI-Ex is available within the “DataSheet_PKIR_PKIS” technical

documentation on

• PRR-PKI and PRS-PKI: Coverplates

• MPA-PKI: METO-PG20 Adapter

• MPC-PKI: METO-PG Clutch

• CVR-PKI, CVRF-PKI and CVS-PKI: Thermal Dilatation Compensator

• SSAR-PKI and SSAS-PKI: Adapter with Smoke Sensor

• RFA-PKI: Flanges for the Circular Fire Dampers

• IPOR-PKI, IPOS-PKI: Parts of the Installation on/out of a Wall

• IKOWS-PKI: Installation Kit for the Installation out of a Wall by Means of Promatect Boards

Systemair DESIGN.

Design

Fire dampers have casings made from galvanized sheet metal, the blades from non-asbestos insulants have a cold

rubber seal and an intumescent one for a re situation.

Material Composition

The product contains galvanized sheet metal, calciumsilicate board, reproof carbon berglass, polyurethane foam

and ethylene - propylene rubber. These are processed in accordance with local regulations. The product contains no

hazardous substances, with the exception of the solder in the thermofuse, which contains a milligram of lead.

Connection of the Electrical Parts

Connection of all electrical parts according to the types of activation mechanisms is described in the Installation,

operation and inspection manual of the re dampers “UserManual_PKIR_PKIS” on

Systemair DESIGN.

Tightness of the Blade and the Casing of the Fire Damper

All rectangular re dampers have tightness of the blade and casing class 2C according to EN 1751.

On demand rectangular re dampers can be supplied with tightness class 3C. All circular dampers have standard

tightness class 3C.

Inspection Openings

Each Systemair re damper has a minimum one inspection opening:

Dimension Range (mm) Inspection Opening Implemented with Second Standard Inspection Opening Additional Inspection Opening

DN ≤ ø150 Removable Activating Mechanism - -

ø160 ≤ DN ≤ ø630 Removable Activating Mechanism Inspection lid On demand

ø630 < DN ≤ ø1000 Inspection Lid - On demand

W and H < 180 Removable Activating Mechanism - -

W ≥ 180 Removable Activating Mechanism Inspection lid On demand

W > 800 Removable Activating Mechanism 2 inspection lids * -

NOTE: * PKIS3GA 1 inspection lid

Page 5

Fire Dampers | 5 / 12

Fire Dampers Fitted with Explosion-proof Electrical Equipment

Each explosion-proof electrical equipment installed in or on the re damper must conform to its explosion proof given

explosive atmospheres according to EN 60079-10.

Activation Types

ZV; Basic model with manual crank and an actuating mechanism with spring return release driven by a fusible thermal

link set to 74°C (on demand 100°C)

DV1; ZV + closed position indication with a 230V/24V contact switch

DV 1-2; ZV + open and closed indication with 230V/24V contact switches

Actuator-operated Fire Dampers

DV 7-9-T; Fire dampers with actuator (with universal supply unit 24...240 VAC/DC) with a spring, with a thermal actuator

and auxiliary switches signaling position.

Each re damper for an explosive environment has to be operated by an actuator, which is in accordance with EN

60079-10 and has the same or higher explosion proof class as the re damper. For example Schischek ExMax-15BF.

Fig. 1: Actuator Schischek ExMax-15BF Fig. 2: Release device ExPro-TT-72

Page 6

6 / 12 | Fire Dampers

Fire Resistivity

Permitted installation methods for the re dampers can be found in the “UserManual_PKIR_PKIS” document

on

Systemair DESIGN.

Circular Fire Dampers PKIR3G-Ex

Circular re dampers are certied according to EN 15650, tested according to EN 1366-2, classied

according to EN13501 and explosion-proof certied according to Directive 2014/34/EU and EN ISO 80079-36.2016,

part 1 - reached class is:

Rectangular Fire Dampers PKIS3G-Ex, PKIS-EI90S-Ex and PKIS-EI120S-Ex

Rectangular re dampers are certied according to EN 15650, tested according to EN 1366-2, classied

according to EN13501-3 and explosion-proof certied according to Directive 2014/34/EU and EN ISO 80079-36.2016

- reached class is:

Dimensions

Tables of dimensions, weights, free areas and blade overhang are available in the “DataSheet_PKIR_PKIS” document

on

Systemair DESIGN.

Page 7

Ordering Codes

Circular ø100 - 1000 PKIR3G-Ex

Rectangular 100 × 100 - 1200 × 800 PKIS3G-Ex

Rectangular 800 < W ≤ 1200 and 100 ≤ H ≤ 300 PKIS3GA-Ex

Rectangular W > 1200 and/or H > 800 PKIS-EI90S-Ex

Type Rectangular W > 1200 and/or H > 800 PKIS-EI120S-Ex

Circular

Dimensions Rectangular

Type of Activation DV7-9-T

NOTE: Fire resistivity depends on the installation method.

Fire Dampers | 7 / 12

- -

ZV

DV1

DV1-2

Examples of the Ordering Codes:

Circular re dampers 3G, example:

PKIR3G-Ex-1000-DV1-2

Circular re damper, re resistivity depends on the installation method in the “UserManual_PKIR_PKIS“ document,

nominal diameter 1000 mm, manual activation mechanism, 230 V switches indicating the damper’s closed and open

position, explosion proof class

Rectangular re dampers 3G – dimensions 100 ≤ W ≤ 1200 mm and 100 ≤ H ≤ 800 mm, example:

PKIS3G-Ex-1200×800-ZV

Rectangular re damper, re resistivity depending on the installation method in the “UserManual_PKIR_PKIS“

document, nominal dimensions width × height = 1200 × 800 mm, manual activation mechanism,

explosion proof class

Rectangular re dampers – dimensions W > 1200 mm and/or H > 800 mm, example:

PKIS-EI120S-Ex-1600×1000-DV7-9-T

Rectangular re damper with re resistance EI120S, nominal dimensions width × height = 1600 × 1000 mm,

with actuator 24 V and 230 V (both are usable) and thermoelectric fuse, explosion proof class

Page 8

8 / 12 | Fire Dampers

Technical Parameters

Pressure loss and noise of re dampers for explosive atmospheres are the same as for conventional re dampers.

Diagrams are available in the “DataSheet_PKIR_PKIS” document on

Systemair DESIGN.

Durability Test

Testing Under Pressure 300/500 Pa, depending on the method of installation

Safe Position Closed

Possible Installation

Airow Direction Optional

Allowed Air Velocity Max. 12 m/s

Side Protected from the Fire Optional

Closing Temperature/Maximum

Temperature of Transfered Air

Closing Time Manually < 10 s, actuator driven < 20 s

Ambient Temperature 0°C to 60°C

Repeated Opening It is possible to open the device in cold conditions

Indicator Closed/Open

Environment Suitability Only indoor environment (3K5 according to EN 60721-3-3)

Inspection Possibility After removing the activation mechanism, or by opening the inspection lid

50 cycles/manual actuating mechanism – with no change of the required properties

10000 + 100 + 100 cycles actuator controlled – with no change of the required properties

Vertical/horizontal, rigid/exible wall, wet/dry

(see „UserManual_PKIR_PKIS“ on

Manual mechanism:

74°C standard/60°C

100°C on demand/85°C

Actuator mechanism:

72°C standard/60°C

Manual 230 V microswitch versions DV1, DV1-2

Actuator controlled - built-in microswitches - version DV7

Systemair DESIGN for more details)

Maintenance

Explosion Proof Class

Allowed Pressure 1200 Pa

Blade Tightness (STN EN 1751) Rectangular: class 2/class 3 on request; Circular: class 3 standardly

Tightness of the Housing (STN EN 1751) Class C standardly

Conformity with EC directives

Not required. Only revisions determined by law (in the country in which the re dampers are installed - usually

every 12 months) and the periodic dry cleaning of the entire ventilation / climatisation system are necessary.

2006/42/ES Machinery Directive

2014/35/EU Low Voltage Directive

2014/30/EU Electromagnetic Compatibility Directive

Page 9

Fire Dampers | 9 / 12

Installation, Maintenance & Operation

Fire dampers must be installed, operated and inspected according to the Installation, operation and inspection manual

of the re dampers “UserManual_PKIR_PKIS” on

IMPORTANT: The device must be installed in such a way, that forming of creeping discharges is prevented

(static surface charging).

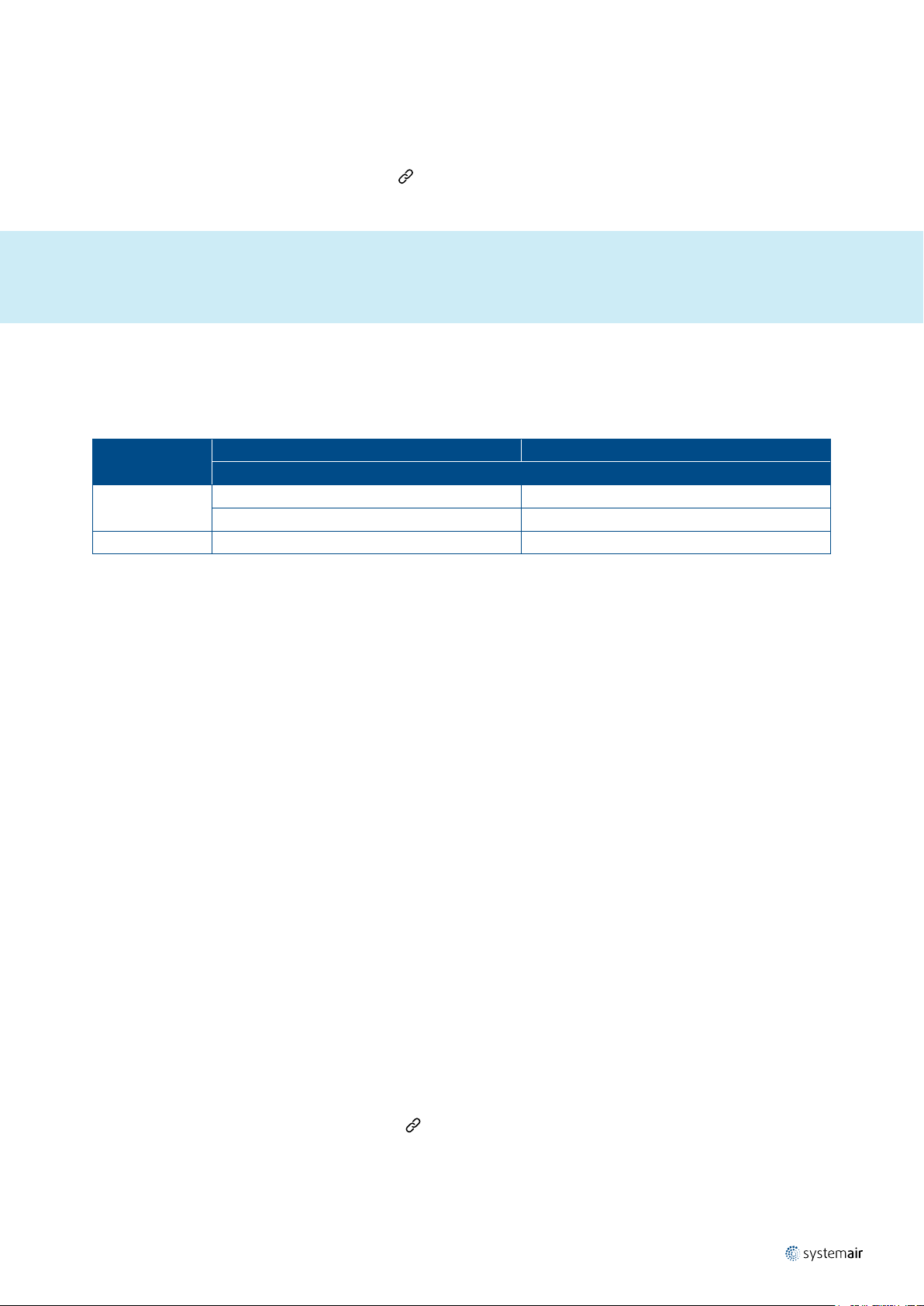

The re dampers can be installed in places with temperatures according to following table.

Tab. 1: Temperatures of the re dampers closing and allowed temperatures

Systemair DESIGN.

Type of Activation

Mechanism

ZV, DV1, DV1-2

DV7-9-T 72 Standard 0 up to 60

Active re sealing must not be exposed to direct contact with water. The maximum air velocity is 12 m/s

with clean air without mechanical or chemical contamination, with uniform ow without condensation and icing

or ice. Maximum permissible pressure difference before and after the blade is 1200 Pa.

Higher temperatures must be consulted with the manufacturer and indicated in the order.

Temperature of the Fire Damper Closing Permissible Temperature in the Duct and Its Surroundings

(°C)

74 Standard 0 up to 60

100 on demand 0 up to 85

Transport & Storage

Fire dampers must be transported in covered means of transport on pallets or in boxes. While handling during transport,

the dampers must be protected from damage and weather. Blades of the dampers must be in a “closed” position. It is

recommended to store the products in a closed, dry place where the temperature is up to +50°C. The temperature during

storage, transportation and operation must not exceed 60°C in any circumstances!

Supplement

Any deviations from the technical specications contained herein and the terms should be discussed

with the manufacturer. We reserve the right to make any changes to the product without prior notice,

provided that these changes do not affect the quality of the product and the required parameters.

Current information on all products is available on

Systemair DESIGN.

Page 10

10 / 12 | Fire Dampers

Related Products

PKI-C

Cartridge Fire Dampers

Product information is available within the “DataSheet_PKI-C” technical documentation on Systemair DESIGN.

1396 - CPD - 0050

PKIS, PKIR3G, PKIS3G and PKIS3GA

Fire Dampers

Product information is available within the “DataSheet_PKIR_PKIS” technical documentation on Systemair DESIGN.

1396 - CPR - 0076

1396 - CPD - 0062

1396 - CPR - 0077

Page 11

Fire Dampers | 11 / 12

Page 12

www.systemair.com

Systemair Production a.s. · March 2020 · DataSheet_PKI-EX_ EN_202003

Loading...

Loading...