Page 1

Air Distribution Products

OPTIMA-RES-A

Residential VAV System Box

Data Sheet

Variable Air Volume Controllers | 1 / 22

Page 2

Table of Contents

Description .......................................1

Design ..........................................1

Controls .........................................2

Factory Settings ................................2

Basic Functional Characteristics ...................2

Basic Parameters and Features ....................2

Master/Slave Conguration .......................2

Dimensions ......................................4

Ordering Code ....................................4

Accessories .......................................5

RC-C3DOC .....................................5

MZ3-Touch ....................................5

EC-Basic – CO2 + Temperature Room Controller ......6

CO2RT ........................................6

ZTH-EU .......................................6

Technical Parameters ..............................7

Solutions for Room Controls

with VAV Ventilation Systems ........................10

MZ3-Touch ...................................11

Ventilation Control Panel .........................11

EC-Basic – CO

RC-C3DOC .....................................15

+ Temperature Room Controller .......13

2

Installation, Maintenance & Operation .................22

Transport & Storage ................................22

Supplement ......................................22

Related Products ..................................23

Good to

know

Current information on all

products is available at

design.systemair.com

Page 3

Variable Air Volume Controllers | 1 / 24

Description

OPTIMA-RES-A is a compact system of supply

and extract VAV controllers intended for ventilation

control of residential premises. The basic functionality

is continuous supply and extract air ow volume control

in master/slave operation mode. Additionally, it can be

switched into override operation modes like open

or close damper, or minimum or maximum air ow

volume control.

Highlights

• Complete VAV supply and extract master/slave solution

• AC 230 V power supply

• Electrical safety elements and connection terminals

on board

• Noise attenuators included

• Fit for installation on surface or into gypsum walls

or ceilings

• VAV controllers can be easily detached and mounted

in other supply/extract conguration

Design

The system of OPTIMA-RES-A system is encased

in a galvanised steel box. The system consists of:

• One supply and one extract variable OPTIMA-R air ow

controller in a circular galvanised steel body

• Electric part with power supply and control circuitry

• Acoustic attenuation

The VAV controllers are mounted to the circular duct

connections by sleeves, so the VAV controllers are easily

removable. The system box is equipped with cable pass

diaphragms for cables related to power supply, setpoint

control signal, feed-back signal and override signal.

These cables shall be connected by a service person

on site. The corresponding terminals are available

according to the wiring diagram.

List of Accessories

Detailed information about accessories

for OPTIMA-RES-A is available

• RC-C3DOC: Room Controller

• MZ3-Touch: Ventilation Control Panel

• EC-Basic – CO2 + Temperature Room Controller

• CO2RT: CO

• ZTH-EU: Service Tool for VAV Controllers

Room Transmitter

2

on page 5.

Page 4

2 / 24 | Variable Air Volume Controllers

Controls

The residential VAV system is equipped with BLC4 type compact controllers in the master/slave connection.

The controllers use analog input for the setpoint signal and analog output for the feedback signal. The type of the

signals is DC 0 V ... 10 V. The VAV controllers are factory calibrated as standard to the air volume indicated in the table

below or, upon request, they can be adjusted to site required settings of the V

also be readjusted on site with the ZTH-EU

hand held service tool. If specic air volumes for V

required, they must be indicated in the ordering code or noted in the order for adequate calibration in the factory.

Factory Settings

min

/V

range. The air volumes can

max

and V

min

max

would be

Size V

(mm) (m

100 57 16 254 71 311 86

125 88 24 398 111 486 135

160 145 40 651 181 796 221

@ 2 m/s V

min

3

/h) (l /s) (m3/h) (l /s) (m3/h) (l /s)

@ 9 m/s V

max

@ 11 m/s

nom

Basic Functional Characteristics

Controller type: OPTIMA-RES-A-…BLC4

Basic Parameters and Features

Flow volume adjustment setpoint signal:

Analog input DC 0 V … 10 V. The Systemair MZ3-Touch room control device is primarily foreseen to be connected

to the analog input. It can operate in automatic mode, continuously controlling the air ow volume dependent from

temperature, VOC or CO

four discrete steps between the preset V

Other control devices with 0 V ... 10 V control output can also be used, e.g. Systemair RC-C3DOC.

Controller parameters setup tools: Belimo ZTH-EU

concentration. If switched to manual mode, the air ow setpoint can be adjusted manually in

2

min

and V

of OPTIMA-RES-A.

max

Feedback signal (actual air ow volume): Analog output DC 0 V … 10 V

Power supply (each VAV controller, secured by transformer on board):

AC 24 V/50 Hz DC 24 V

4 VA 2 W

Power supply (whole system): AC 230 V/50 Hz

Protection class (closed system box): IP40

Master/Slave Conguration

The VAV system is congured as master/slave. The supply air VAV controller (the master) reads the ow volume

setpoint from an external source like e.g. a room controller or manual setpoint dial. The control range (V

the master VAV controller can be adjusted at the factory or on site with the ZTH-EU conguration tool. The feedback

signal from master VAV represents the actual measured air ow volume. This signal is connected to the extract air

VAV controller (the slave) as the setpoint for the air ow volume. So the air ow volumes of supply and extract air are

always equal with high reliability.

min

, V

max

) of

Page 5

Variable Air Volume Controllers | 3 / 24

Master (Supply Air) VAV Controller Setup

V

adjustable between 0 and V

min

V

adjustable between V

max

min

nom

and V

. Lowest possible adjustment is 20% of V

nom

nom

.

Slave (Extract Air) VAV Controller Setup

V

adjusted to 0, shall not be changed.

min

V

adjusted equal V

max

, shall not be changed.

nom

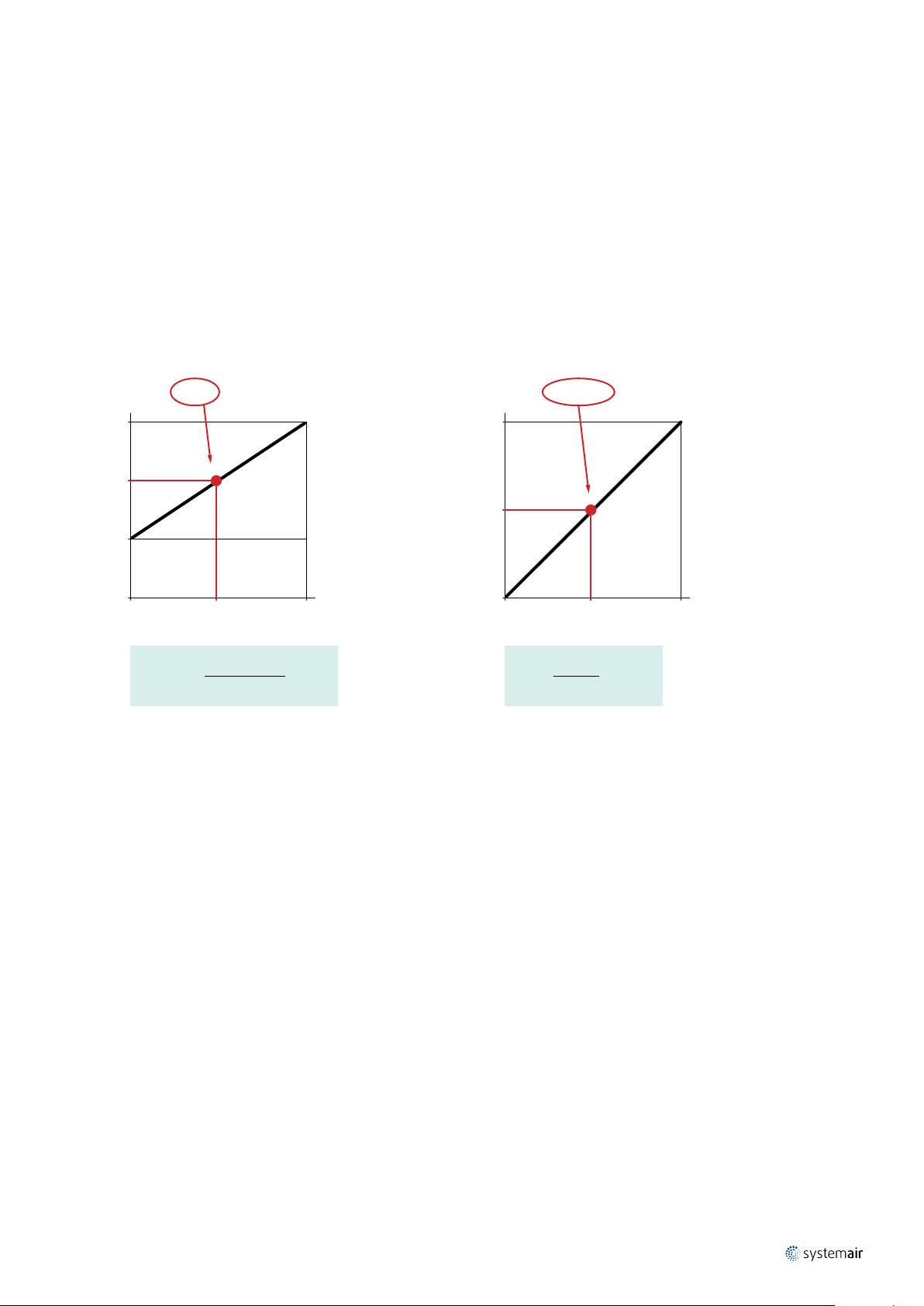

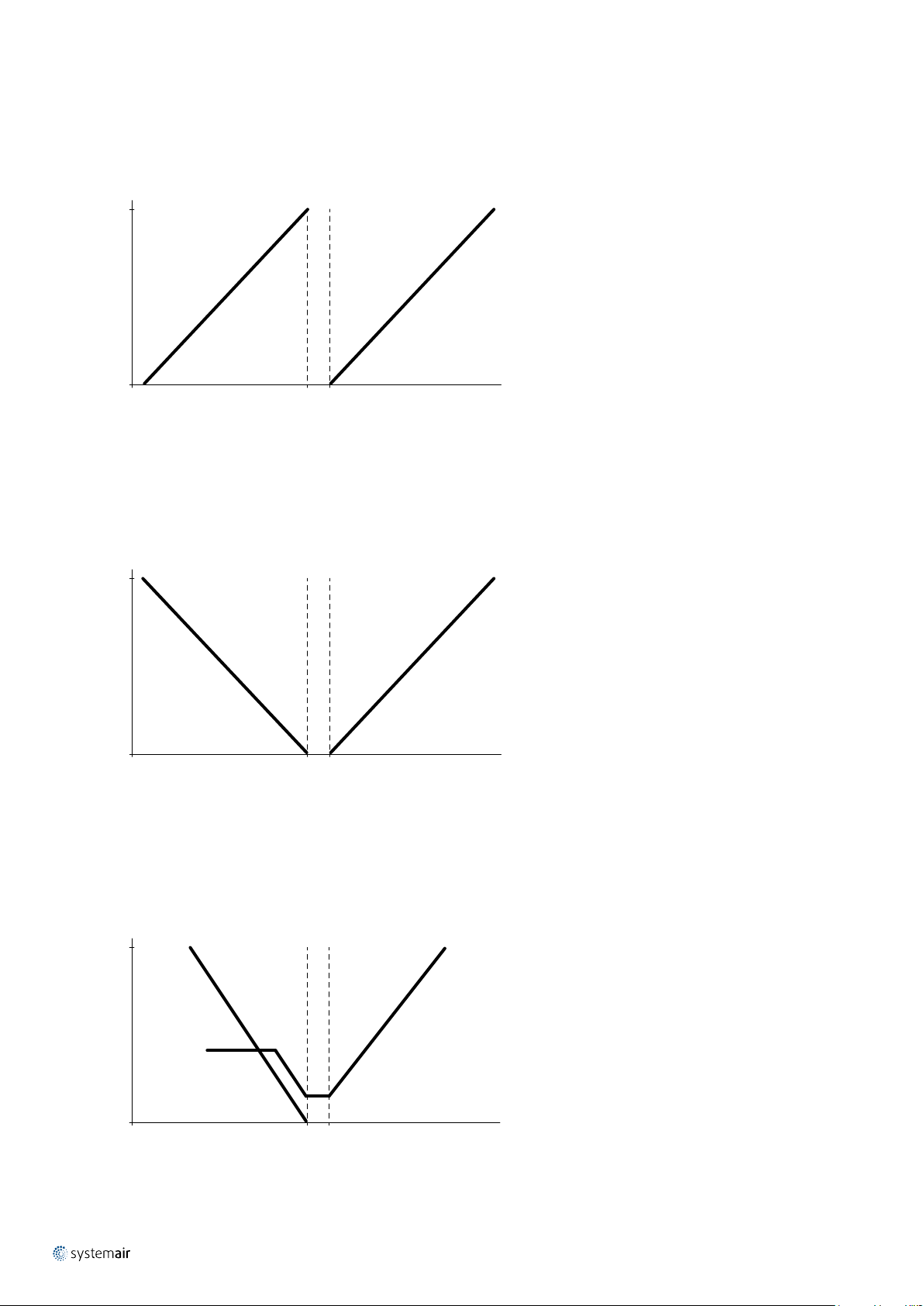

Setpoint/Feedback Signal and Air Flow Volume Calculation for VAV Controller

Setpoint, UC : 0 V ... 10 V

V

max

/h)

3

q (m

V

min

0 10

UC (V) =

: Air ow volume setpoint signal value (range DC 0 V … 10 V)

U

c

UC (V)

V

q - V

- V

max

min

· 10

min

q: Air ow volume

Feedback, U: 0 V ... 10 V

10

U (V)

0 V

q (m3/h)

U (V)

q =

10

· V

nom

nom

: Minimum adjusted air ow volume (lower limit of control range)

V

min

: Maximum adjusted air ow volume (upper limit of control range)

V

max

U: Measured air ow volume feedback signal value (range DC 0 … 10 V)

: Nominal air ow volume calibrated in factory – not adjustable.

V

nom

Page 6

4 / 24 | Variable Air Volume Controllers

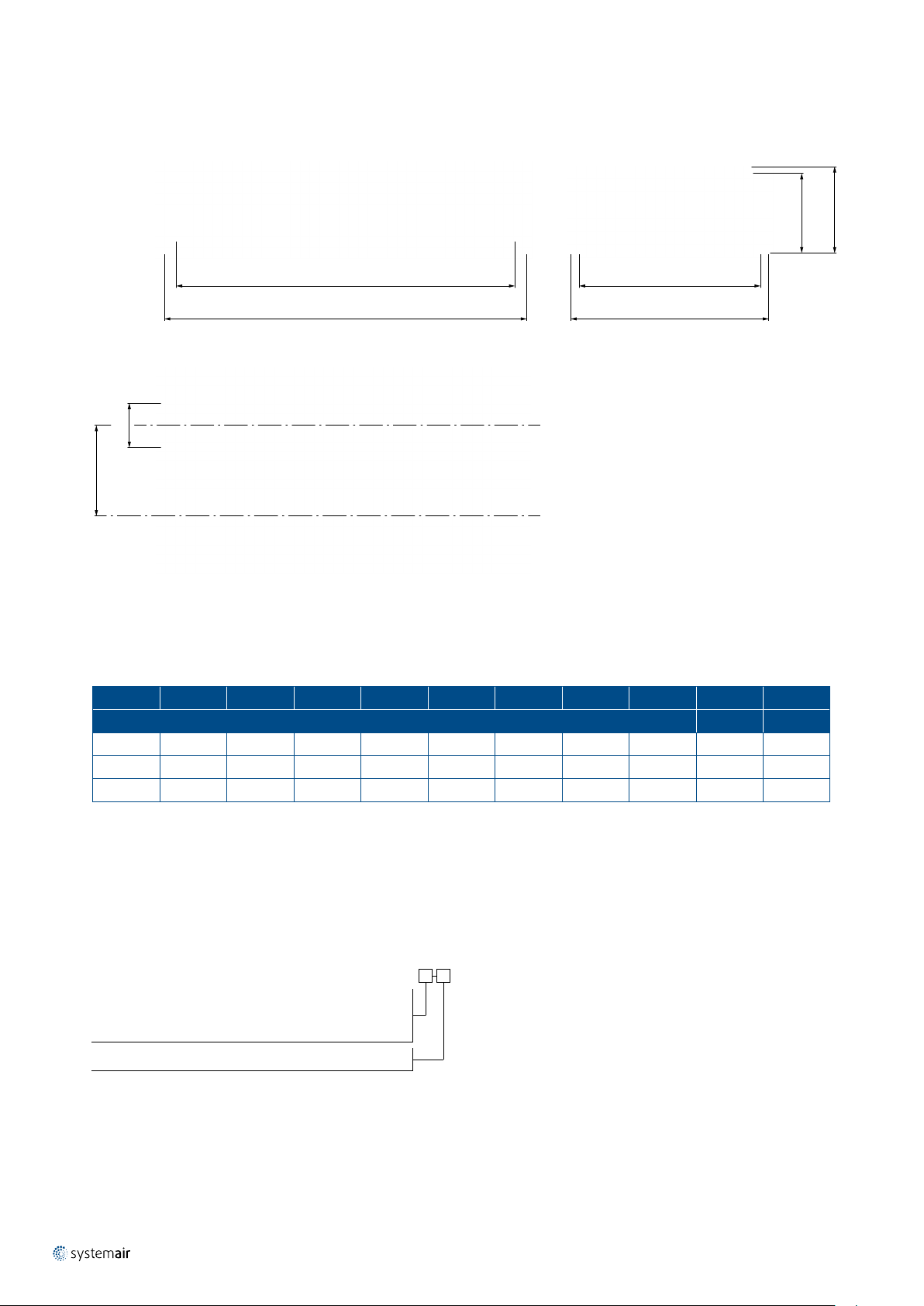

Dimensions

1

H

H

W

W

1

L

L

1

øD

K

Fig. 1: Dimensions of the OPTIMA-RES-A

Tab. 1: Dimensions of the OPTIMA-RES-A

DN øD K W W

(mm) (kg) (l)

100 98 250 495 555 200 225 1080 1170 25 147

125 123 280 550 610 235 260 1180 1270 29 202

160 157,5 320 640 700 282 306 1190 1280 35 275

1

H H

1

L L

1

m v

Ordering Code

OPTIMA-RES-A-

100

Nominal size

Control range setup

ø (mm)

V

... V

min

max

(m3/h)

Example of the Ordering Code

OPTIMA-RES-A-125-130-310

Residential VAV control system of size 125, control range 130 m³/h (V

125

160

) up to 310 m³/h (V

min

max

)

Page 7

Accessories

RC-C3DOC

Room Controller

Art. No.: 27142

Variable Air Volume Controllers | 5 / 24

Complete pre-programmed room controller intended to control heating, cooling, CO

in a zone control system.

and other physical parameters

2

MZ3-Touch

Ventilation Control Panel

Art. No.: 92690

• Positioner and controller for comfort ventilation with a touch panel.

• Design according to Feller EDIZIOdue®.

• Manual operation with 4 steps.

• AUTO operation: The controller activates the ventilation based on controls curve.

• Automatic reset of the party air level.

• One DC 0 V … 10 V controls output to control the ventilation system. One DC 0 V … 10 V input to

measure CO

or other sensors.

2

Page 8

6 / 24 | Variable Air Volume Controllers

EC-Basic – CO2 + Temperature Room Controller

Art.No. 24808

• For simultaneous control of the room temperature and the CO

of the value with the higher control difference.

• Pre-adjustable heating or cooling control loop.

• One DC 0 V ... 10 V VAV control output.

concentration (on-board sensors) based on priority

2

CO2RT

Room Transmitter

CO

2

Art. No.: 13704, 14357

Room sensor for measuring carbon dioxide concentration in indoor environments.

ZTH-EU

Service Tool for VAV Controllers

Art. No.: 27655

Conguration and setup tool for VAV controllers.

Page 9

Technical Parameters

Discharged Sound Power Level

Legend

Variable Air Volume Controllers | 7 / 24

p

s

q

V

L

WA

L

W

Pa Pressure drop

m3/h

l/s

Air ow volume

dB(A) A-weighted total discharged sound power level

dB Non-weighted total discharged sound power level

OPTIMA-RES-A-100

Air Flow p

3

/h Pa dB dB(A) 63 Hz 125 Hz 250 Hz 500 Hz 1 kHz 2 kHz 4 kHz 8 kHz

m

s

L

WA

L

W

Non-Weighted Sound Power Level

100 28 42 34 41 20 19 20 9 -8 2

250 32 42 33 41 26 27 28 18 5 15

500 37 43 33 41 30 33 35 26 15 25

750 41 45 33 41 33 36 38 30 21 30

@ 2 m/s *

min

57

V

1000 43 46 33 41 35 39 41 33 25 34

100 28 34 15 32 19 23 25 18 <5 10

250 37 40 18 36 28 33 36 27 13 21

500 45 47 20 39 34 40 43 34 21 30

750 49 51 21 41 38 44 48 38 26 35

155

1000 52 54 22 42 41 48 51 41 29 39

100 31 34 12 30 19 26 29 23 9 19

250 42 44 18 38 30 37 40 32 18 28

500 50 52 23 44 38 46 48 39 25 35

750 55 56 26 48 43 51 53 43 29 39

@ 9 m/s *

max

254

V

1000 58 60 28 50 47 54 56 46 32 42

NOTE:

* Standard factory air volume setting, if not indicated differently upon order.

can be adjusted from 0 m3/h to V

The V

min

can be adjusted from 20% to 100% of the V

The V

max

value from from the table above.

max

value from the table above.

max

Page 10

8 / 24 | Variable Air Volume Controllers

OPTIMA-RES-A-125

Air Flow p

3

/h Pa dB dB(A) 63 Hz 125 Hz 250 Hz 500 Hz 1 kHz 2 kHz 4 kHz 8 kHz

m

s

L

WA

100 27 42 34 41 20 21 19 9 -7 2

250 32 43 36 42 26 29 27 19 5 15

500 37 45 38 43 31 35 33 26 14 25

750 41 47 39 43 34 38 37 31 20 31

@ 2 m/s *

min

88

V

1000 43 48 40 44 36 41 39 34 24 35

100 26 36 18 35 20 22 23 14 <5 <5

250 36 41 20 38 29 33 34 25 11 19

500 44 47 22 40 36 41 42 34 20 29

750 49 51 22 42 40 46 47 39 26 35

243

1000 53 54 23 43 43 49 50 43 29 39

100 30 38 20 37 23 25 28 18 5 13

250 41 46 24 43 33 37 39 29 16 24

500 49 53 27 48 41 47 47 38 24 32

750 55 57 29 50 46 52 52 43 28 37

@ 9 m/s *

max

398

V

1000 58 60 30 52 49 56 56 46 32 41

L

W

Non-Weighted Sound Power Level

OPTIMA-RES-A-160

Air Flow p

3

/h Pa dB dB(A) 63 Hz 125 Hz 250 Hz 500 Hz 1 kHz 2 kHz 4 kHz 8 kHz

m

s

L

WA

L

W

Non-Weighted Sound Power Level

100 31 47 40 46 24 25 22 11 -5 4

250 37 49 39 48 31 33 32 23 8 18

500 43 51 39 50 37 39 40 33 18 29

750 47 53 39 51 40 43 44 38 24 35

@ 2 m/s *

min

145

V

1000 50 55 38 52 42 46 48 42 28 39

100 30 38 25 36 22 25 27 18 <5 10

250 40 44 26 42 31 36 37 29 15 23

500 47 51 27 46 39 43 45 38 23 32

750 52 54 27 49 43 48 50 42 28 38

398

1000 55 57 28 51 46 51 53 46 32 42

100 35 40 26 38 24 29 33 24 11 19

250 44 49 29 47 35 39 42 33 20 29

500 51 56 33 53 43 47 49 41 27 36

750 55 60 35 57 47 52 53 45 31 40

@ 9 m/s *

max

651

V

1000 58 63 36 60 51 55 56 48 34 44

Page 11

Variable Air Volume Controllers | 9 / 24

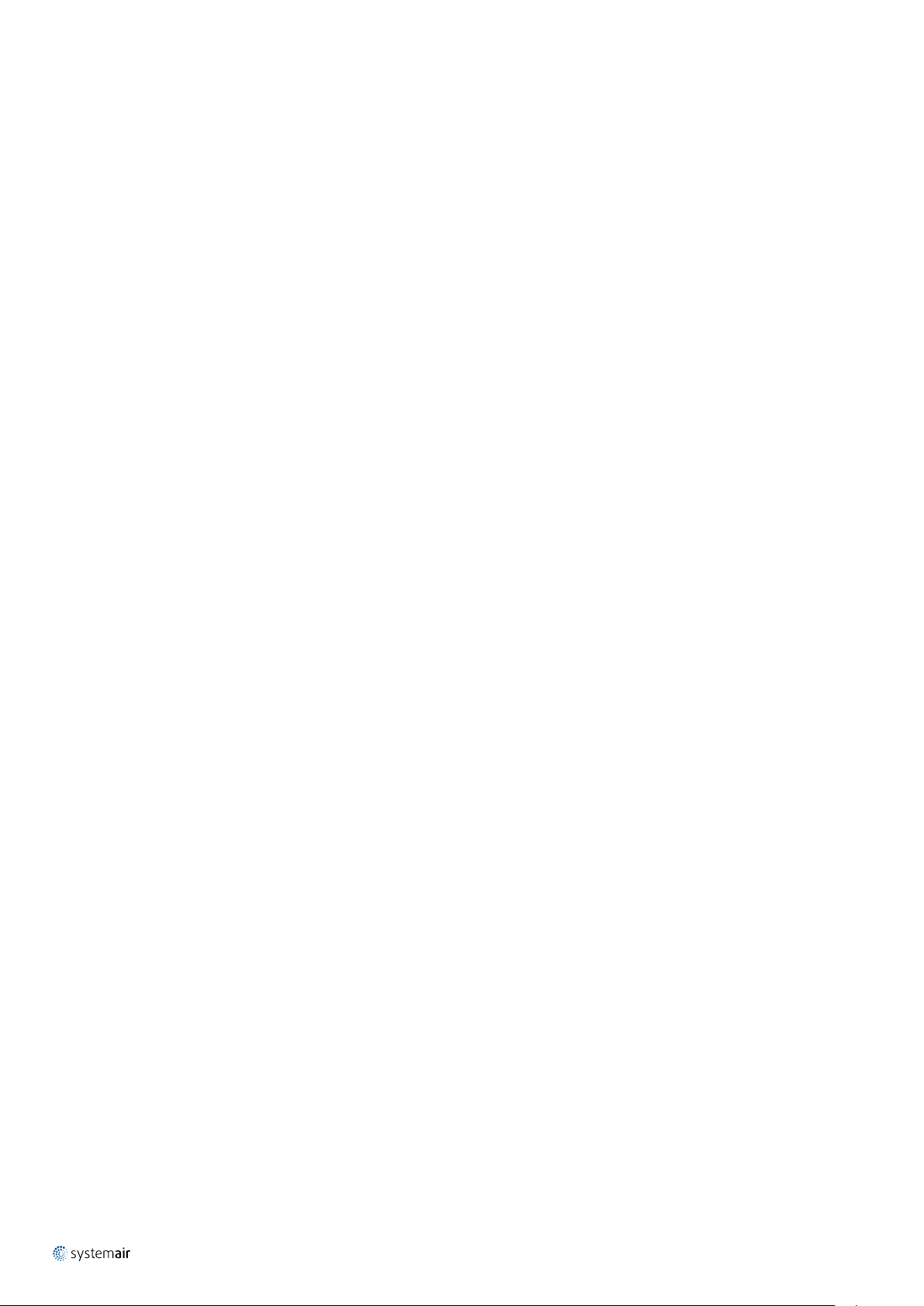

0...10V

0V AO

24V AI 24V

0V AO

-CO2/VOC

-MZ3

0...10V

-RC-a

Flow control

FC

5

G

G

G0

0V

200 V

2x2x0,8

J-Y(St)Y

-WS-RC-a

extract

5

3

Feedback / MP-BUS

supply

Feedback / MP-BUS

4XEH:1

3

4

w

U5

2002-474

2002-479/011-000

2002-479/011-000

2002-479/011-000

XEH:1 2 3

3

2 4 XRC:1 2 3

XSU:1

2

˜

1 2 4

1

-

500 V

5x0,75

YSLCY

WS-VAV-EHa

5

w

3

U5

2

˜

1

-

500 V

5x0,75

YSLCY

/3

WS-SUa

24V AC

VAV-EHa

M M

24V AC

VAV-SUa

-T1

2 4

+VAV-VERa

1 3

230V/24V, 30VA

F1

T1A

230V

2002-433

L1

NX:PE

500 V

3x1,5

CYKY-J

-WL-VAVa

LN

PE

Via Topology

-RC_VAVa

Page 12

10 / 24 | Variable Air Volume Controllers

Solutions for Room Controls with VAV Ventilation Systems

The variable air ow controlled ventilation as a part of demand oriented control of room climate can be integrated

in different ways according to various user requirements. The basic part of the climate control is the various room

controllers. Each of them ts a different control solution at a corresponding cost level.

Room Control Solutions, Quick Overview

Room Controller

Parameters, Functions

Number of control loops 3 1 2

Value assigment to control loop Freely adjustable Fixed Fixed

Control loop sequence Freely adjustable - Fixed (simultaneous)

Analog outputs (control setpoints) Heating valve, Cooling valve, VAV VAV VAV

Internal sensors (analog values) 1 × Temperature -

External sensor analog inputs 1 × Pt1000, 1 × DC 0 V ... 10 V 1 × DC 0 V ... 10 V -

Binary inputs 2 (congurable) - -

Controlled values for VAV

Measurement range of controlled

values

VAV control normal operation

0(2) V ... 10 V = V

VAV control manual override

modes available

Bus communication protocols/

Physical media

... V

min

max

RC-C3DOC MZ3-Touch

Temp. Heat/Temp. Cool, CO

Humidity, Others

Adjustable for CO

Yes Yes Yes

Open/Close/V

Modbus RTU, BACNet MSTP/RS485 - -

, Fixed for others

2

min /Vmax

, VOC,

2

(by BMS)

, VOC Temp. Cool, CO

CO

2

Fixed Fixed

, 40%, 60%, 100%

V

min

(120 min) of V

max

EC-Basic – CO2

+ Temperature Room Controller

1 × Temperature, 1 × CO

2

-

2

Page 13

Variable Air Volume Controllers | 11 / 24

MZ3-Touch

Ventilation Control Panel

For VAV air ow control based on a single physical value like CO2 or VOC concentration.

Functions

The room controller can set the air ow volume on the VAV controller by the 0 V ... 10 V signal. The leading value

for the control is the concentration of CO

transmitter shall be used with with a 0 V ... 10 V measurement signal. For CO

This signal shall be connected to the analog input of the room controller. No setpoint or control parameter

adjustments are possible. The operation modes can be adjusted on the room controller by touching the key

on the cover plate.

, eventually VOC in the air. For the measurement of this value, a separate

2

, it corresponds to 0 ppm ... 2000 ppm.

2

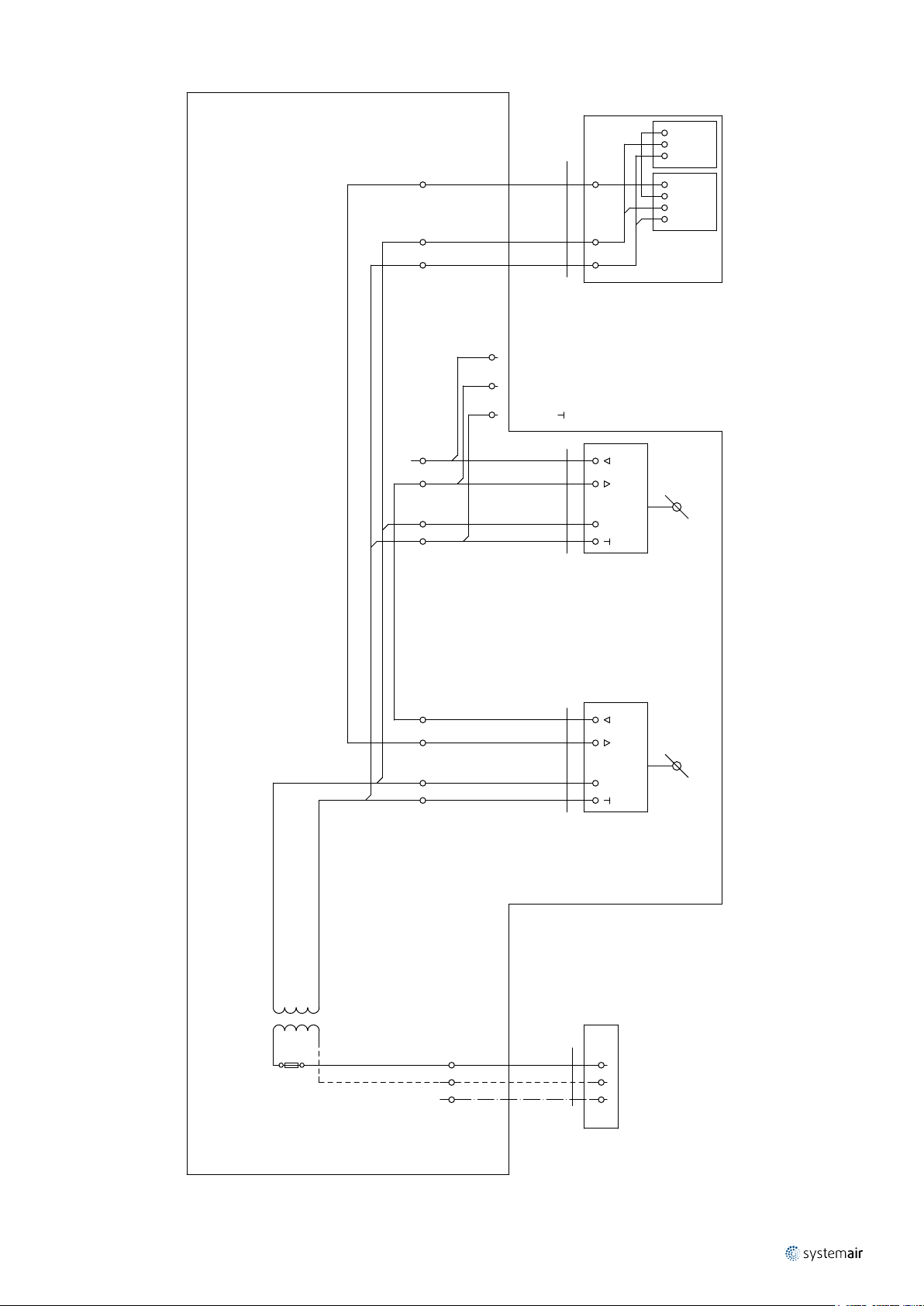

In automatic mode, the CO

2

the air ow setpoint for VAV.

V

max

max

80%

= 10 V ⇒ V

C

U

60%

40%

min

V

min

= 0 V ⇒ V

C

U

0 400

0 ppm ⇒ UC = 0 V 2000 ppm ⇒ U

800 1200 1600 2000

CO2 (ppm)

concentration inuences

= 10 V

C

In manual mode, the chosen ow volume level

inuences the air ow set-point for VAV. The “party”

position (V

) is temporary. After 120 minutes, the

max

system changes the position to “Maximum” (60%).

V

max

max

80%

= 10 V ⇒ V

C

U

60%

40%

min

V

min

= 0 V ⇒ V

C

U

0 Minimum

Normal Maximum Party

Page 14

12 / 24 | Variable Air Volume Controllers

Topology

OPTIMA...

VAV Controller

0 V ... 10 V

MZ3-Touch

Ventilation Control Panel

0 V ... 10 V

CO2RT

CO

Room Transmitter

2

Page 15

Variable Air Volume Controllers | 13 / 24

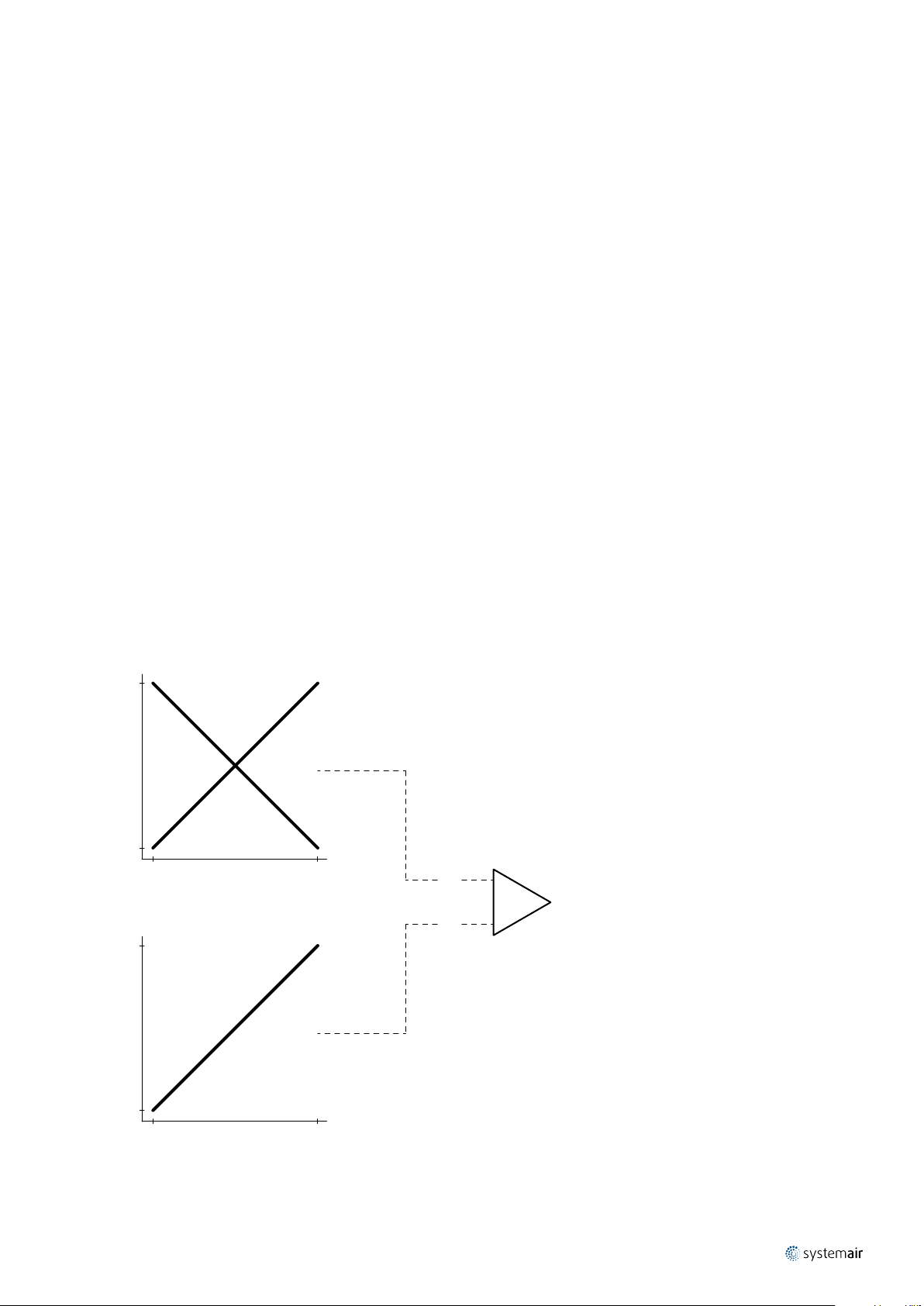

EC-Basic – CO2 + Temperature Room Controller

For VAV air ow control based on two physical values, temperature and CO2 concentration simultaneously.

Functions

The room controller can set the air ow volume on the VAV controller by the 0 V ... 10 V signal. The leading values for

the control are the temperature (cooling mode or heating mode) and the concentration of CO

are measured inside the room controller, no additional transmitters shall be connected. The temperature and the CO

level are measured and evaluated simultaneously. The one with the currently larger control difference is chosen as

the actual control value for the VAV setpoint. The CO

control has no set-point or range to adjust. The temperature

2

setpoint can be adjusted manually by a dial on the room controller. The cooling or the heating mode can be preadjusted by jumper switches.

in the air. Both values

2

2

RC temperature control

control

RC CO

100

100

2

Heating

demand value (%)

Min Max

Room temperature Tr (°C)

demand value (%)

Min Max

Room air CO2 value Q (ppm)

Cooling

Comparator,

max. value selection

Y1

Y = Max (Y1, Y2) VAV flow demand value

Y2

Page 16

14 / 24 | Variable Air Volume Controllers

Topology

0 V ... 10 V

OPTIMA...

VAV Controller

EC-Basic

CO

+ Temperature Room Controller

2

Page 17

Variable Air Volume Controllers | 15 / 24

RC-C3DOC

Room Controller

For VAV air ow control based on multiple physical values and control states in different congurable operation modes

and sequences.

Functions

The room controller has the following main control functions:

• Heating control, separate controls of the heating valve and VAV in heating mode

• Cooling control, separate controls of the cooling valve and VAV in cooling mode

• CO

(or VOC, or humidity or other values) control by VAV

2

• Dew point surveillance protection

• Frost protection

• Different operation modes switched according to room occupation state

• Energy conservation procedures in case of room control conditions disturbance (e.g. open window)

The following measurement and detection capabilities are included or can be connected to the RC:

• Room temperature measurement on board

• External temperature measurement connectable via analog input

• External CO

(or other value) measurement connectable via analog input

2

• External change-over switch connectable via digital input

• External dew point detection connectable via digital input

• External presence/occupation detection connectable via digital input

• External window opening detection connectable via digital input

Page 18

16 / 24 | Variable Air Volume Controllers

The following control loop sequences can be congured on the RC:

• Heating/Heating

100%

Output signal

0%

• Heating/Cooling

100%

Neutral zone

Heating 1 Heating 2

48% 52%

Heating demand

Neutral zone

100%

Output signal

0%

Heating Cooling

SP SP

Room temperature Tr (°C)

• Heating/Cooling with VAV-control

100%

Output signal

0%

Heating output Cooling output

Max air flow

on heating

demand

(settable)

Heating Cooling

Neutral zone

SP SP

Room temperature Tr (°C)

100%

Increasing air flow on heating demand

Basic air flow (settable)

100%

Page 19

• Cooling/Cooling

Variable Air Volume Controllers | 17 / 24

100%

Output signal

0%

Cooling 1 Cooling 2

• Heating/Cooling/VAV

100%

Neutral zone

48% 52%

Cooling demand

Neutral zone Neutral zone

Y1 Y2 Y3

100%

Output signal

20% by default min. flow

at cool output for VAV control

0%

100% ... 0% 0% ... 48%

Controller output

52% ... 100%

Page 20

18 / 24 | Variable Air Volume Controllers

• Heating/Cooling/VAV simultaneaously with CO2 control

Value with higher control difference becomes control value.

100%

Output signal

20% by default min. flow

at cool output for VAV control

0%

100%

Neutral zone Neutral zone

Y1 Y2 Y3

100% ... 0% 0% ... 48%

Controller output

(Y3 cooling demand, CO

Y3 cooling demand

CO2 reduction demand

Y3

52% ... 100%

Comparator, maximum

reduction demand)

2

Y3 output - VAV damper

20% by default min. flow

at cool output for VAV control

• Heating/VAV/Cooling

(reversed sequence)

reduction

demand

2

CO

0%

100%

Output signal

600 ppm by default

level to start

CO

2

open damper

CO2 level

Y1 Y3 Y2

800 ppm by default

level when damper

CO

2

fully open

Neutral zone Neutral zone

20% by default min. flow

at cool output for VAV control

0%

100% ... 0% 0% ... 48%

Controller output

52% ... 100%

Page 21

• Heating/Cooling with forced ventilation

Variable Air Volume Controllers | 19 / 24

100%

Y1

Neutral zone

Output signal

20% by default min. flow

at cool output for VAV control

0%

100% ... 0% 0% ... 48%

• Heating/Cooling or Heating/Heating via change-over

Summer mode activated by change-over input

Neutral zone

100%

Y1 Y2

Y3 = 100% at forced ventilation

Y2

Neutral zone

52% ... 100%

Controller output

Output signal

0%

22°C by default heating setpoint 24°C by default cooling setpoint

Room temperature Tr (°C)

Winter mode activated by change-over input

Neutral zone

100%

Output signal

0%

Y1

52% ... 100% 0% ... 48%

Room temperature Tr (°C)

Y2

22°C by default heating setpoint

Page 22

20 / 24 | Variable Air Volume Controllers

• Full range change-over determined heating/cooling control by VAV combined with CO2 control

100

Heating

demand value (%)

RC temperature control

Min Max

Room temperature Tr (°C)

100

control

2

Cooling

Comparator,

max. value selection

Y1

Y = Max (Y1, Y2) VAV flow demand value

Y2

RC CO

demand value (%)

Min Max

Room air CO2 value Q (ppm)

Page 23

Variable Air Volume Controllers | 21 / 24

Adjustment and indication of parameters

The operation parameters, procedures and limits can be adjusted with the help of pushbuttons and indicated

by the LCD display on the room controller.

Adjustment and indication are also possible via PC with corresponding hardware and software.

Communication

The room controller has an RS485 on-board communication serial port for which the Modbus RTU or BACNet MS/TP

bus communication protocols can be turned on.

Topology

BMS

OPTIMA...

VAV Controller

IR24-PC

Presence detector

0/1 potential-free 0/1 potential-free

0 V ... 10 V

0/1 potential-free

Modbus RTU

or BACNet MS/TP

Bus communication

Room Controller

RC-C3DOC

Heating valve

0 V ... 10 V

0 V ... 10 V

0 V ... 10 V/Pt1000

Cooling valve

CO2RT

CO

Room transmitter

2

y

Window contact

Humidistat/Thermostat/Timer switch, etc.

Page 24

22 / 24 | Variable Air Volume Controllers

Installation, Maintenance & Operation

Information about installation, maintenance and operation is available in the document “UserManual_OPTIMA-RES-A”.

OPTIMA-RES-A is mounted on the wall or ceiling and is connected to a spiro duct by a rubber gasket tight connection.

The system box can be xed to the wall or ceiling by screws through the holes in four mounting ears on the bottom

plate. The electrical connection terminals and VAV controllers can be found under the cover of the system box. The

cover can be removed by turning the two locks on the cover plate with a screw driver by 90°. To avoid falling out

after unlock the cover plate is tight to the system box by chains. The cover plate in the closed position is sunken into

the frame. This enables to attach a plaster board to the outer surface of the cover. So the inspection opening cover

can be from the same material and ush with the surrounding wall or ceiling where the system box is installed. The

plaster board for the cover must be foreseen with cut-outs to keep the cover locks accessible.

The power supply and signal cables can be pulled into the box through the diaphragm between the supply/extract

air connections. The cables must be xed inside the box on the xing ridge by cable straps. This avoids excessive

mechanical stress on the cables. The cables shall be connected to the spring terminals according to the wiring

diagram. To protect the circuitry from overload or short circuit fault, there is a fuse terminal on the power supply.

Dry indoor conditions with an operation temperature range of -20°C to +70°C.

Transport & Storage

Dry indoor conditions with a temperature range of -40°C to +50°C.

Supplement

Any deviations from the technical specications contained herein as well as the terms should be discussed

with the manufacturer. We reserve the right to make any changes to the product without prior notice,

provided that these changes do not affect the quality of the product and the required parameters.

Current information on all products is available at

design.systemair.com

Page 25

Related Products

OPTIMA-R

VAV Controller

Air ow volume control units for standard air ow velocity range.

Product information is available within the

and on

Systemair DESIGN.

“DataSheet_OPTIMA-R” technical documentation

Variable Air Volume Controllers | 23 / 24

OPTIMA-LV-R

Low Velocity VAV Controller

Air ow volume control units for low to medium air ow velocity range.

Product information is available within the

and on

Systemair DESIGN.

“DataSheet_OPTIMA-LV-R” technical documentation

Page 26

www.systemair.com

Systemair Production s.s. · October 2019 · DataSheet_OPTIMA-RES-A_EN_201910

Loading...

Loading...