SystemAir MAXK Series, MAXK-I3 DC Series, MAXK-I3 2000 DC, MAXK-I3 3000 DC, MAXK-I3 4000 DC Installation And Operating Instructions Manual

...Page 1

MAXK

Installation and Operating Instructions

Document in original language | ·

GB

Page 2

© Copyright Systemair AB

All rights reserved

E&OE

Systemair AB reserves the rights to alter their products without notice.

This also applies to products already ordered, as long as it does not affect the previously agreed specifications.

|

Page 3

Contents

1 Declaration of Incorporation........ ..... ......... ..... ....1

2 General information ..... ..... ..... ......... ..... ..... ..... ..2

2.1 Notice symbols . ..... ..... ......... ..... ..... ..... ...2

2.1.1 Instruction symbols.. ......... ..... .....2

2.2 Notes on the documentation ..... ..... ..... .....2

3 Warnings. ..... ..... .............. ..... ..... ......... ..... ..... .2

4 Product information ... ..... ..... ..... ..... ......... ..... ....3

4.1 General... .... ..... ..... ..... .............. ..... ..... ..3

4.2 Power range ........ ..... ..... ..... ......... ..... ....3

4.3 Dimensions... .... ..... ..... ..... ......... ..... ..... ..4

4.4 Technical data ......... ..... ..... ..... ......... ..... .4

4.5 Acoustics.... ..... ..... ..... .... ..... ..... ..... ........5

5 Transport and storage . ..... ..... ..... .... ..... ..... ..... ...5

5.1 General... .... ..... ..... ..... .............. ..... ..... ..5

5.2 Crane transport........ ..... ..... ..... ......... ..... .6

5.3 Forklift transport ... ..... ..... ..... ......... ..... ....6

5.4 Big units ..... .... ..... ..... ..... ..... ......... ..... ....6

5.5 Storage on the construction site . ......... ..... .6

6 Installation.. .............. ..... ..... ..... ......... ..... ..... ...7

6.1 Installation site ..... ..... ..... ..... ......... ..... ....7

6.1.1 Roof installations ... .... ..... ..... ..... .7

6.2 Operating doors ........ ..... ..... .............. ..... 7

6.3 Mounting of device units.... .... ..... ..... ..... ...7

6.4 Mounting steps... ..... ..... ......... ..... ..... ..... .8

6.5 Mounting indications for the kind of

delivery: „dismantled assembly

group“ ... ..... ..... ......... ..... ..... ..... .... ..... ...9

6.5.1 Unit profile... .... ..... ..... ..... ......... .9

6.6 Mounting indications for wet

parts .... ..... ..... .............. ..... ..... ..... .... .. 10

7 Internal components .... ..... ..... ......... ..... ..... ..... 10

7.1 V-cell-filter ..... ......... ..... ..... ..... ......... ... 10

7.2 Air heater, air cooler and glycol-

compound system ..... ..... .... ..... ..... ..... ... 11

7.3 Steel-galvanized registers ........ ..... ..... ....11

7.4 Electrical heater . ......... ..... ..... ......... ..... . 12

7.5 Counter flow plate heat

exchanger ..... ..... ..... ......... ..... ..... ..... ... 12

7.6 Jalousie damper ... ..... ..... ..... .............. ... 13

7.7 Doors and door locks..... .............. ..... ..... 13

7.7.1 Interception safety ..... ......... ..... 13

7.8 Silencer. ..... ......... ..... ..... ..... ......... ..... .. 13

7.9 Internal lightening ..... ..... ......... ..... ..... ... 13

7.9.1 Roof units ..... ......... ..... ..... ....... 14

8 Syphon ..... .... ..... ..... ..... ..... ......... ..... ..... ..... .. 14

8.1 Syphon for cooler ......... ..... ..... ..... .........15

8.1.1 General information ..... ..... ..... ... 15

9 Outdoor installation . ......... ..... ..... ......... ..... ..... 16

9.1 Roof frame made of galvanized

sheet. ......... ..... ..... ..... ..... ......... ..... ..... 17

10 Condensation and heat insulation . ..... ......... ..... . 18

11 Maintenance.... ..... ..... ......... ..... ..... ......... ..... . 18

11.1 Warnings. ..... .............. ..... ..... ..... ......... 18

11.2 General... .... ..... ..... ..... ..... ......... ..... ..... 19

11.3 Maintenance instructions ......... ..... ..... ....19

12 Disturbances and troubleshooting .... ..... ......... ... 21

|

Page 4

Page 5

1 Declaration of Incorporation

Declaration of Incorporation |

1

|

Page 6

| General information

2

2 General information

2.1 Notice symbols

Danger

Direct hazard

Failure to comply with this warning leads directly to death or to serious bodily harm.

Warning

Potential hazard

Failure to comply with this warning possibly leads to death or serious bodily harm and damage to objects.

Caution

Hazard with a low risk

Failure to comply with this warning may potentially lead to moderate injuries or/and damage to objects.

Important

Hazard with risk of damage to objects

Failure to comply with this warning will lead to damage to objects.

Note:

Useful information and instructions

2.1.1 Instruction symbols

Instruction

♦ Carry out this action

♦ (if applicable, further actions)

2.2 Notes on the documentation

Warning

Hazard as a result of improper handling of the fan

These operating instructions describe the safe use of the fan.

♦ Read the operating instructions completely and carefully!

♦ Keep the operating instructions and other valid documents, such as the circuit diagram or motor

instructions, with the fan. They must be permanently available at the place of use.

Instruction with xed sequence

1. Carry out this action

2. Carry out this action

3. (if applicable, further actions)

3 Warnings

The following admonitions will be presented in the different sections of the document.

Danger

• Make sure that the Mains supply to the unit is disconnected before performing any maintenance or

electrical work!

• All electrical connections must be carried out by an authorized installer and in accordance with local rules

and regulations.

|

Page 7

Product information |

Warning

• Keep the doors locked during operation to ensure required level of safety for the unit.

• The unit must be duct connected or in some other way provided with protection so that it is not possible

to come in contact with the fans through the duct connections

• Beware of hot surface an the heating battery during maintenance and service.

• The unit is heavy. Be careful during transport and mounting. Risk of injury through pinching. Use

protective clothing

• Beware of sharp edges during mounting and maintenance. Make sure that a proper lifting device is used.

Use protective clothing.

• The units electrical connection to the mains supply must be preceded by an all pole circuit breaker with a

minimum 3 mm gap.

Caution

• If the unit is installed in a cold place make sure that all joints are covered with insulation, and tape well

• Duct connections should be covered during storage and installation

• Do not connect tumble dryers to the ventilation system

• Take care not to damage the water battery when connecting water pipes to connectors. Use a spanner to

tighten the connection.

3

4 Product information

4.1 General

This installation manual concerns air handling unit type MAXK-I3 DC.

• Model: MAXK-I3 2000 DC, MAXK-I3 3000 DC, MAXK-I3 4000 DC, MAXK-I3 5000 DC, MAXK-I3 6000 DC, MAXK-I3

7000 DC

• Wall thickness: 50mm. T3/TB3 (DIN EN 1886) casing T2/TB2 or T1/TB1 on request

The MAXK-I3 DC series is a passive house certified air handling unit. The air handling units with heat recovery consists

of a counter flow plate heat exchanger with integrated bypass, supply and exhaust air fan with EC motor and an outdoor- and extract air filter. Six sizes in modular design with extendible accessories like damper, recirculating air damper,

heater modules, cooling modules and silencer. This manual consists of basic-information and recommendations concerning the design, installation, start-up and operation, to ensure a proper fail-free operation of the unit. The key to

proper and safe operating of the unit is to read this manual thoroughly, use the unit according to given guidelines and

follow all safety requirements.

4.2 Power range

|

Page 8

| Product information

4

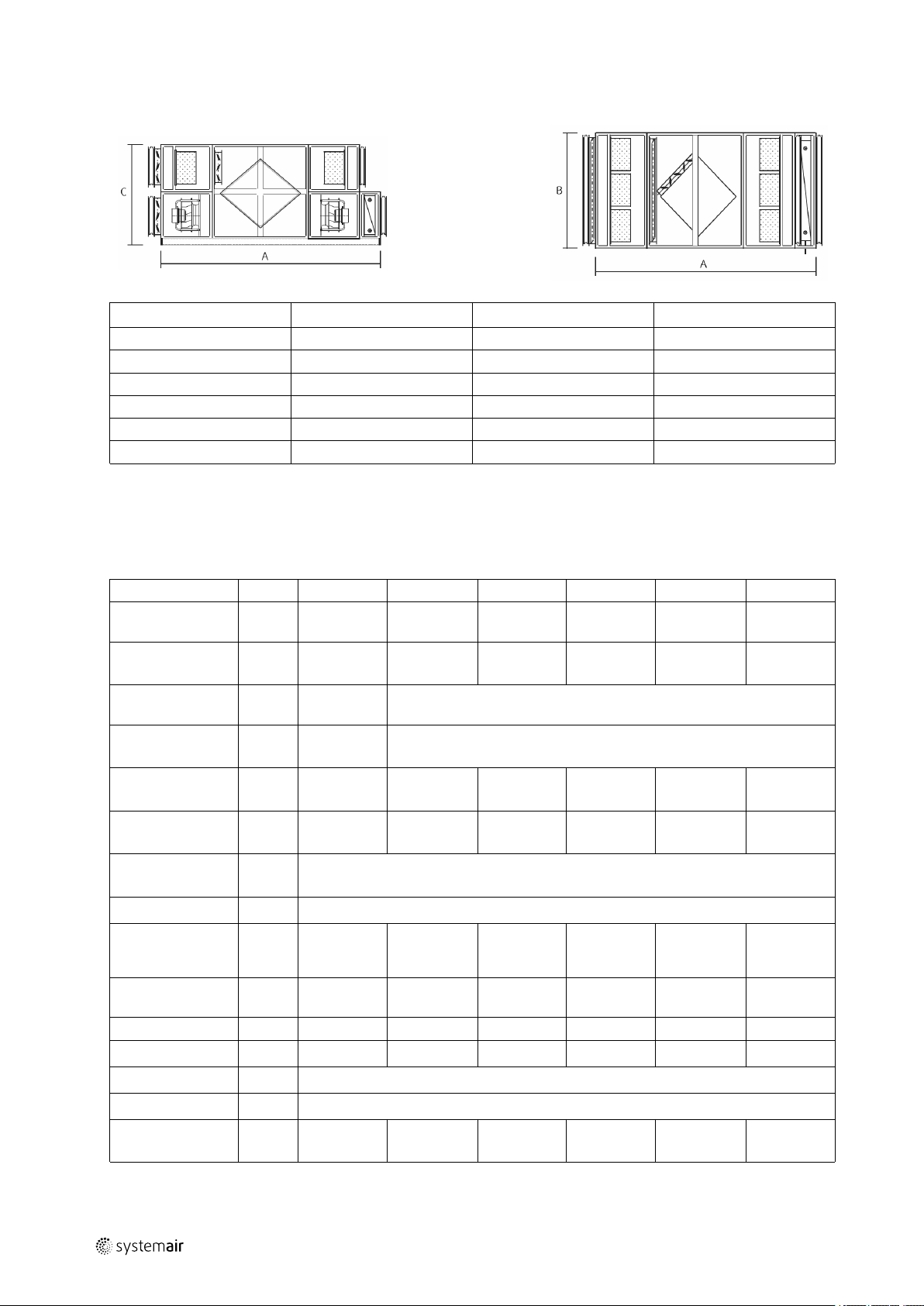

4.3 Dimensions

MAXK-I3 DC A B

2000 DC 3326 800 1664

3000 DC 3486 1120 1664

4000 DC 3586 1600 1664

5000 DC 3686 1900 1664

6000 DC 3686 2280 1664

7000 DC 2786 2600 1664

* incl. 100 mm base frame.

(dimensions in mm)

C*

4.4 Technical data

MAXK-I3 2000 DC 3000 DC 4000 DC 5000 DC 6000 DC 7000 DC

Non-residential

construction

At an external

pressure of*

Residential

construction

At an external

pressure of*

Effective heat

recovery rate

Electric power

consumption

Type of heat

exchanger

Fan motor

max. power

consumption of a

fan

Supply voltage of

the fans

Phases

Frequency Hz

Filter Outdoor air F7 / extract air M6

Integrated bypass Available

Duct connection

(W x H)

m³/h

Pa 217 242 270 290 299 328

m³/h

Pa 190

% 84 84 84 84 84 87

Wh/m³

W 423 1000 1400 1850 2730 2730

V 200... 277 380... 480 200... 277 380... 480 380... 480 380... 480

~

mm

600–1400 700–2200 800–3200 1100–4200 1300–5200 1400–6200

600–1600

0,39 0,45 0,45 0,45 0,45 0,43

1 3 1 3 3 3

50/60 50/60 50/60 50/60 50/60 50/60

658 x 638 976 x 638 1456 x 638 1756 x 638 2136 x 638 2456 x 638

Also suitable for application in residential construction

Also suitable for application in residential construction

Counter flow plate heat exchanger

Direct current (EC technology)

|

Page 9

Transport and storage |

5

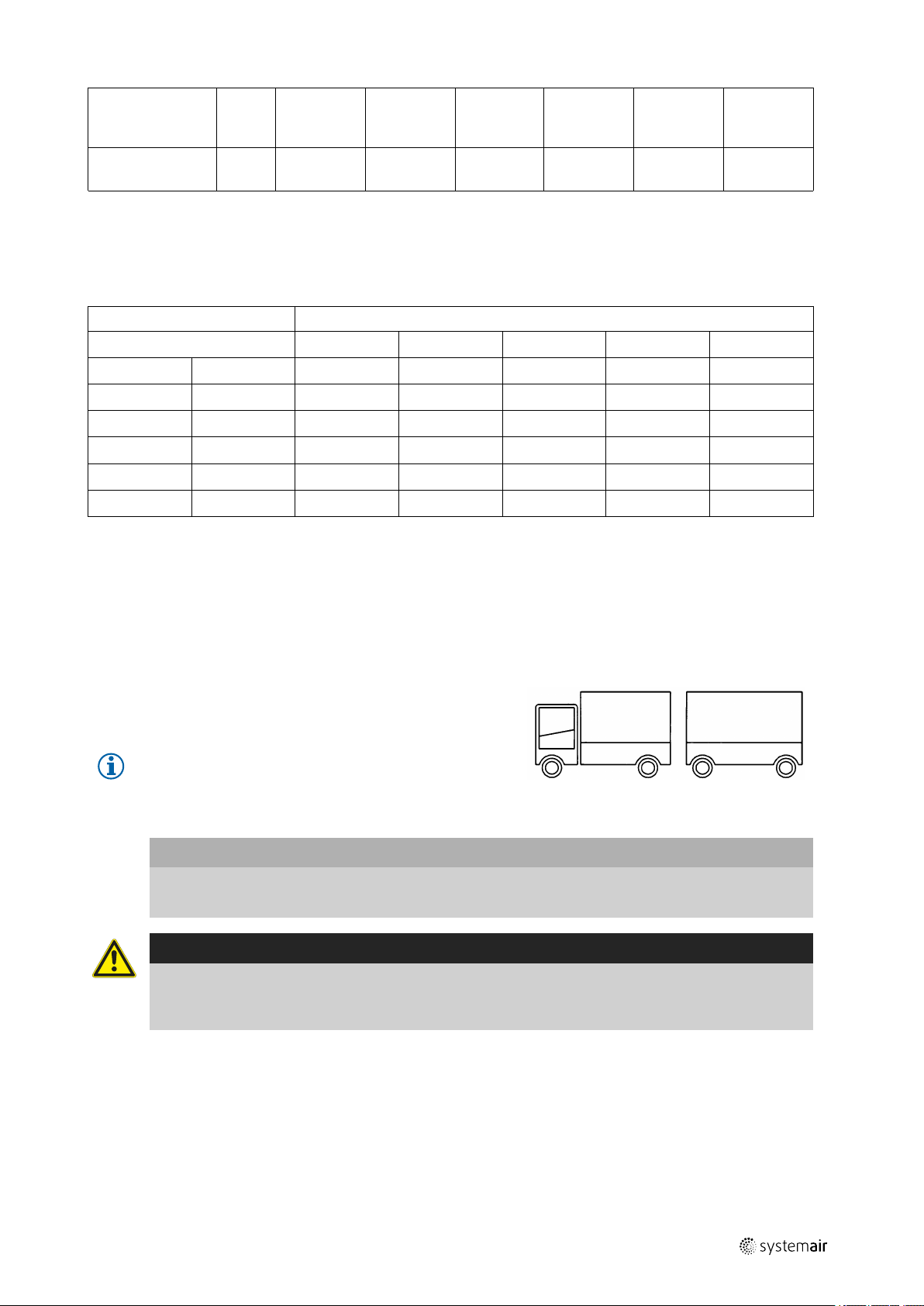

Total weight

without heating

battery

Total weight with

heating battery

* with built in filters (outdoor air F7 and extract air M6).

Additional installed units such as, for example, heating battery reduce the available external pressure

kg

kg

880 1000 1200 1390 1620 1840

956 1093 1330 1521 1792 2031

4.5 Acoustics

MAXK-I3 DC

2000 DC

3000 DC

4000 DC

5000 DC

6000 DC

7000 DC

* Operation at the upper limit.

dB(A)

dB(A)

dB(A)

dB(A)

dB(A)

dB(A)

Sound level*

Casing

63,7 79,2 60,3 58,6 78,4

64,8 75,2 68,6 68,6 75,2

65,8 80,4 73,3 73,3 80,4

66,7 82,3 76,3 76,3 82,3

67,9 80,7 74,3 74,3 80,7

63,6 78,3 63,6 61,8 79,6

Supply air

Extract air

Outdoor air Exhaust air

5 Transport and storage

5.1 General

MAXK-I3 DC air handling units are delivered in transport

units. The width of the lorry (inside width approx. 2,34 m

) resp. loading level (inside width approx. 2,55 m – width

for a jumbo approx. 2,9 up to 3,05 m ) determine the

quantity of the single parts.

Note:

The quantiy of the single parts is shown in the

detailed drawing.

Important

• The shaft of the ventilator must always be arranged horizontally during the transport

• Units for outdoor installation with weather roof: weights without snow load!

Warning

• The unit is heavy. Be careful during transport and installation. Risk of injury through pinching. Use

protective clothing.

• The unit must not be put into operation before the enclosed parts are removed and installed properly.

|

Page 10

| Transport and storage

6

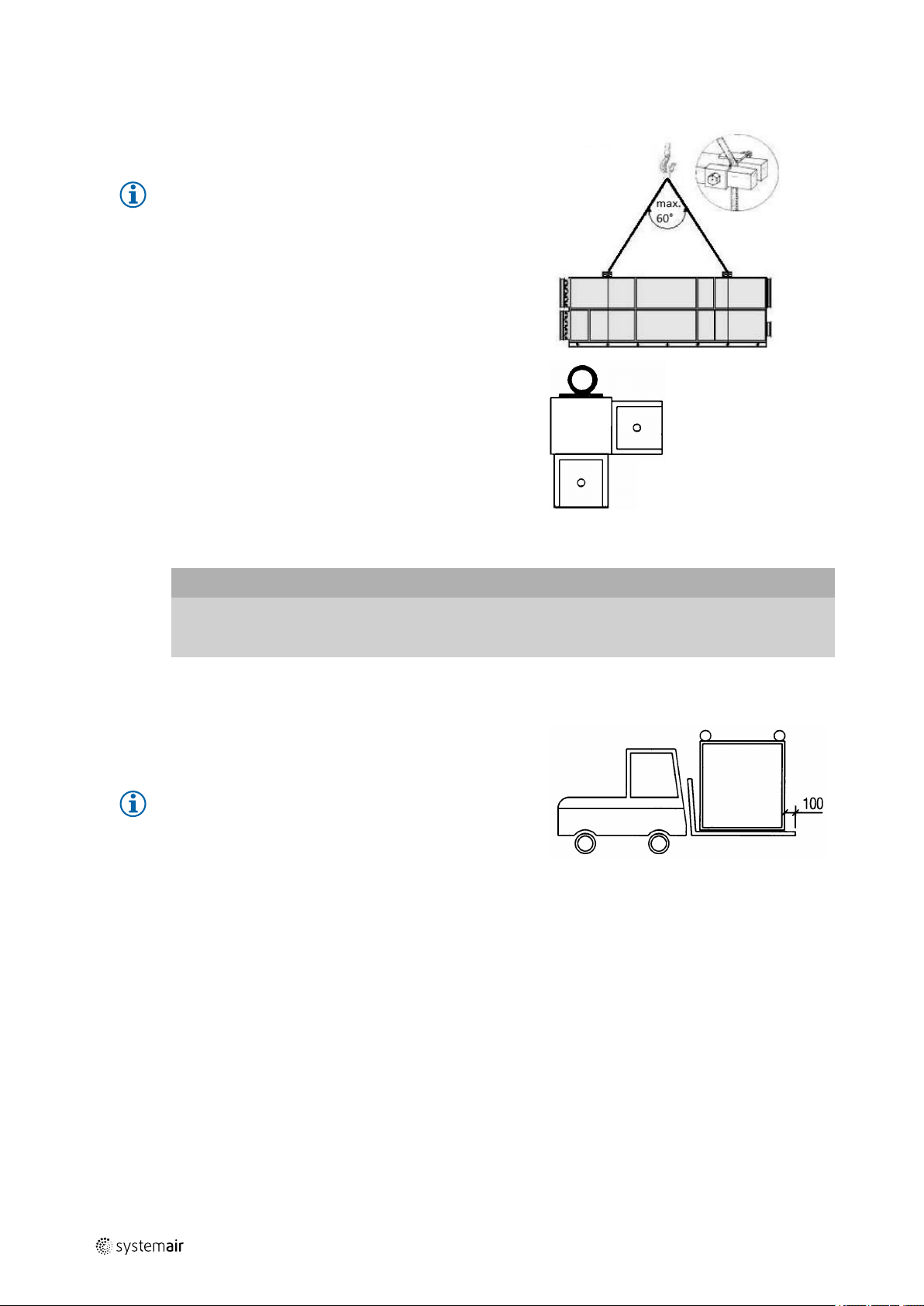

5.2 Crane transport

Small units are equipped with 2 eyebolts (diagonally

staggered), big parts with 4 eyebolts.

Note:

• load suspension device acc. to UVV188.4§4

• slope angle: 60°

• it must be guaranteed that the crane doesn’t

jerk

• „long“ ropes should be prepared to keep the

stipulated lifting angle

Grading of the eyebolts:

• M 16 up to 1300 kg wall thickness 50mm

• M 20 up to 2500 kg wall thickness 50mm

• over 2500 kg special measures

Important

After the mounting, the devices have to be protected against pollution, humidity at building site and

damages.

Outdoor units: Do not disassembly the lifting eyes after installation.

5.3 Forklift transport

Use only forks which extend to the whole width of the

single parts.

Note:

lenght of fork = width of equipment + approx.

100 mm

Too short forks cause damages at the range of the floor

covering.

5.4 Big units

Aluminium corner with internal

thread M16 up to M24.

Single parts with a total weight as from approx. 2000 kg resp. with heavy built-in parts as from approx. 800 kg have to

be transported to the place of destination with several lifting vans (3 – 4 lifting vans)

5.5 Storage on the construction site

If parts are packed in foil, it must be removed immediately after delivery. Foil supports water formation through

condensation and thus appearances of oxidation, especially on hot-dipped galvanized material.

Following measures are to be considered if parts cannot be brought immediately to the construction site:

♦ Remove foil

♦ Store units against atmospheric exposure at a protected temporary storage place.

♦ Close unit openings so that no dirt (dust, vermin, etc.) can penetrate.

|

Page 11

Installation |

6 Installation

6.1 Installation site

Floors, foundations, ceilings or steel construction must be checked as to the planeness. Unplaneness causes a more difficult mounting and the canting of the doors. The consequences among other things are doors which can heavily be

opened and which are untight.

Additional stripy foundations resp. cross slides are necessary as from a device width of 2,4 m (e.g.: ventilator parts consisting of 2 box parts because of maximal load width).

When choosing the location it should be kept in mind that the unit requires maintenance regularly and that the inspection doors should be easily accessible. Leave free space for opening the doors and for taking out the main components.

The outdoor air intake of the building should if possible be put in the northern or eastern side of the building and away

from other exhaust outlets like kitchen fan outcasts or laundry room outlets.

Warning

The devices have to be adjusted to vibration elements (Mafund, Asozell, Silomer a.s.o.) to avoid a

transmission of structure-borne noise and to guarantee the ventilation of the device base floor.

The unit must be duct connected or in some other way provided with protection so that it is not possible to

come in contact with the fans through the duct connections.

6.1.1 Roof installations

7

Roof units and roof platforms have to be fixed with screws to the delivered baseframe after the mounting to prevent a

slipping because of wind load. The drillings and screws have to be fixed on site.

Important

• wind load of the devices

• our weight indications of the devices do not include snow loads

6.2 Operating doors

The device is to be set up so that all operating doors can

be opened completely in order to carry out maintenance

work without hindrance (filter change, cleaning, etc.)

6.3 Mounting of device units

Important

♦ Tighten screws only after pushing the parts of the unit together!

♦ Appliances like bar clamps or winches are compulsory.

♦ Check elastic joints for cracks after assembly and in annual cycle, if necessary seal again.

|

Page 12

8

| Installation

Note:

The necessary screws and sealings for the mounting are attached loose to each delivery and deposited in

the ventilator part.

type term

A

B

B

C

C

Galvanized sheet, thickness: 2–3 mm

U-structural steel, rounded

U-structural steel, rounded U-100 und U-120

U-structural steel, DIN

U-structural steel, DIN U-100 DIN und U-

U-70 M8 x 20 mm

U-80 DIN M8 x 20 mm

120 DIN

screws

M8 x 20 mm

M8 x 25 mm

M8 x 25 mm

6.4 Mounting steps

With the following proceeding an expertly done installation is guaranteed. Thus the function of the devices is guaranteed and leakages at doors or device connections are prevented.

Step 1

Check the mounting surfaces as to their planeness.

Unplane mounting surfaces have to be mended with lined

stripes.

Step 2

Align the housing frame at the operating side first at the

bottom with a screw clamp.

Step 3

Insert bar into the crane eyes and align the housings

against each other. When required use a piece of wood as

a lever bar.

Step 4

Mount screws and nuts, but do not tighten them. Screwed

joints see

Step 5

Pull the housing frames together with the screw clamp in

the length direction of the unit. Check the device joints

and the planeness.

Step 6

Tighten the screws.

|

Page 13

Installation |

Important

Through jolting during the transportation bore chips can loosen from the bolting connections and fall on the

ground. Please vacuum these chippings immediately from the housing parts since rust spots can ensue.

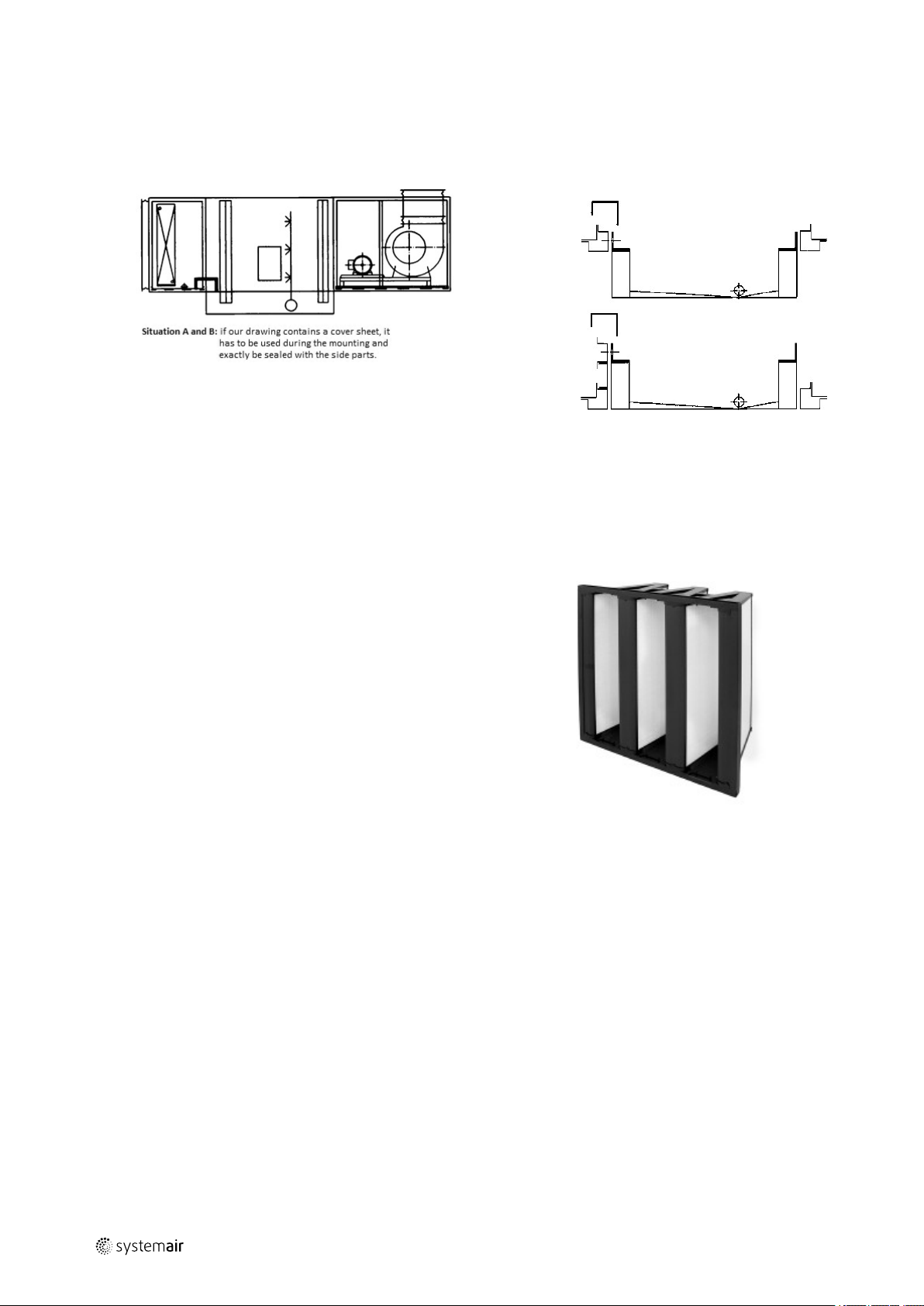

6.5 Mounting indications for the kind of delivery: „dismantled assembly group“

• Kind of delivery: delivery of devices partially screwed resp. completely

dismantled

♦ Before plugging on the

device profiles, the stops

of the plug-in corners

have to be sprayed off

with a permanently

elastical mass.

♦ Duo-Taptite screws 8 x 16

cross recess Z

9

6.5.1 Unit profile

• door and ceiling parts are regularly designed as complete units, if the opening to bring in the parts, permits this.

|

Page 14

| Internal components

10

6.6 Mounting indications for wet parts

Cooler parts have to be mounted and filled very

thoroughly

7 Internal components

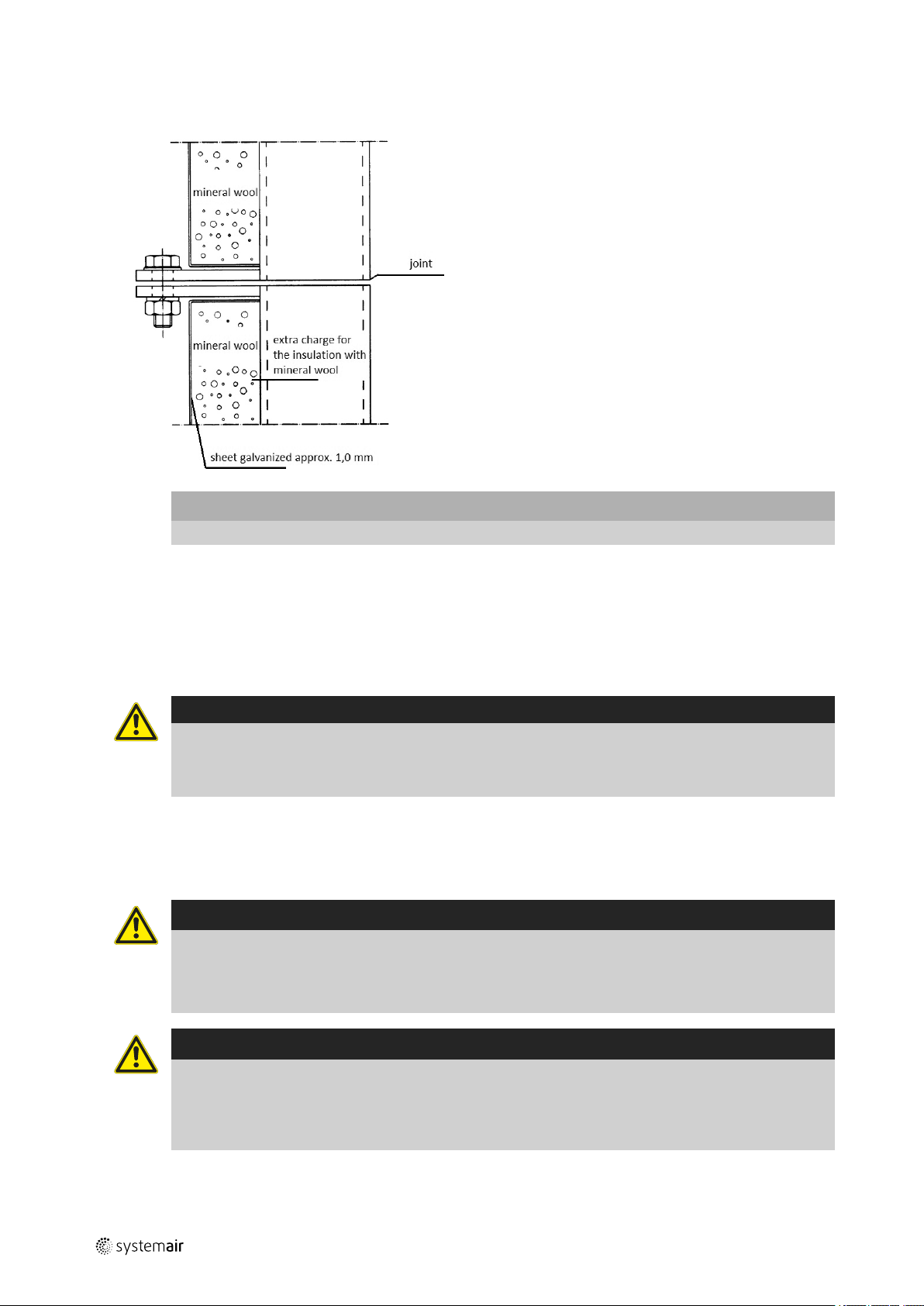

7.1 V-cell-filter

Due to its large filter surface has a high air throughput.

The pollution must be controlled with a differential

pressure device (U-tube, inclined tube). Filter cells have to

be renewed completely after the maximum difference

pressure has been reached. Check the standard frame as

to the correct fitting resp. check the sealing when

exchanging the filter. Torn filters and filters with low

qualitiy pollute built-in parts which are connected in

series. The bottom of the filter units must be cleaned

monthly (wipe – cleaning)

• Extract air filter = M6

• Supply air filter= F7

Detail A: tub protruding at the bottom

Detail B: tub flush at the bottom

|

Page 15

Internal components |

7.2 Air heater, air cooler and glycol-compound system

After the mounting of the heat exchanger units the ribbed surfaces must be covered to avoid mechanical damages.

The connection of the heat exchanger, air heaters as well as the coolers must be made de-energized. When

exchanging the filter, pollutions must be removed.

Heat exchangers: When connecting the supply and return lines the threaded cable glands must be protected against

twisting in counterpressing. Heat exchangers with copper collectors should be treated with caution. Register Cu-Alu

are suitabel for a max. temperature of 120°C and a pressure of 16 bar. Register steel galvanized are built differently.

Pressure minimum 6 bar, maximum 25 bar. In case of hot water resp. steam operation operate the ventilator with

slowing down time.

To avoid frost damages reliable sensors for the protection against frost must be installed. The ventilation must be

carried out thoroughly to avoid air in the register. When filling with water pay attention to leakages which could be

the result of transport or mounting damages (e.g. pay attention to the drilling into the waterways by mistake).

In connection with plastic separators a warming up via artificial heat must be avoided. (caution in case of heating

media with more than 90 ° C.)

In close range to the forerunning and reverse running connections, connections which can be locked up must be

provided and which at the same time can be used for measurements. Ventilation and drain valves in the pipes must

be put in on site.

If coolers are arranged in the fresh air and are operated with mixed temperature there is the danger that it freezes

up. The forerun gland is marked with a riveted plate. Check the supply and reverse running connections whether

they are correctly connected.

Mounting of the piping: General rule for Cu/Alu register. The water forerun has to be connected on that collector

which is situated very close to the air outlet. Attention: In case of mounting the connection must be made volt-free

and decoupled. The pipe connections at site must be dimensioned that way that no vibrations from the device to the

piping system or vice versa are transmitted. Also the connection to the heat transmitter itself must be made voltfree.

If the exchangers have indented supply and return stubs :

As from 3°C empty completely remaining water. Because of the danger to freeze up inform all responsible persons.

The ends of the collectors are not locked. If the pipes are not connected within 8 days we recommend to make them

blind, so that no unauthorized foreign parts can reach the collector.

11

Caution

• use only non-corrosive and suitable heating resp. cooling media

• the remaining water must be removed via compressed air to avoid frost damages

• water systems with glycol filling have to be adapted to the respective climatic zones

• after the pressure test with tap water there is the danger that it freezes up if no suitable mixture with

glycol is guaranteed

• protective means reduce the output transmission of the exchanger

• in case of cleaning the surface of the exchanger do not use high-pressure water or high-pressure steam

• the heat transmission segments can be deformed

• during the first operation hours punching oil remnants which cannot be avoided might exist

7.3 Steel-galvanized registers

• steam and water operation

Steam operation in connection with heat recovery should principally be avoided. In order to prevent stress cracks,

the transport fixing must be loosened after the mounting of the devices (Z-angle). The piping on site must be made

with compensators.

Important

• if plastic separators are closely arranged, the ventilators should be driven with slowing down time to

avoid radiant heat

• improper condensate conductors cause steam impacts and destroy the core pipes of the heat exchangers

|

Page 16

| Internal components

12

7.4 Electrical heater

The casing is made of Aluzinc-coated sheet steel, AZ 185,

that conforms to the requirements for corrosivity class C4.

The heater elements are made of stainless steel to EN

1.4301. The junction box includes the terminal blocks

necessary for the electrical connections. The electrical

heaters are produced to degree of protection IP43, but

are also available to IP55 of IP65 to special order. The

heaters are adapted for max 50°C outgoing temperature

and min. air velocity of 1.5 m/s.

All heaters have at least two overheating protections –

one with automatic reset and one with manual reset. All

duct heaters have the overheating protection reset button

on the heater cover.

A built-in regulator ensures simple installation, e.g. due to

fewer cable runs, which lowers the installation cost and

reduce the risk of incorrect wiring. The regulator is

electronic and controls the output across a triac by means

of time proportional control (intermittent ON/OFF

control). This provides very accurate temperature control.

Since control is electronic, it is entirely silent and sustains

a minimum of wear. On heaters with higher ratings, part

of the output are controlled by a step controller. However,

fine adjustment of the temperature is always carried out

by the electronic ON/OFF control.

Control by means of built-in regulator for 0…10V control

signal.

Follow the special instructions of the manufacturer!

Important

• Slowing down time, to avoid radiant heat.

7.5 Counter flow plate heat exchanger

MAXK I3 2000-7000 DC models are equipped with a

highly efficient, counterflow heat exchanger. The counter

flow heat exchanger is equipped with a 100% bypass.

This means that a damper is covering the counter flow

heat exchanger during deicing.In summer there is no

undesirable heat recovery. Plate material of noncorroding aluminum alloy. Required supply air

temperature is therefore normally maintained without

adding additional heat. The operation of the heat

exchanger is automatic and depends on the set

temperature. The heat exchanger is removable for

cleaning and maintenance. After a long time of use dust

may build up in the exchanger and block the airflow. It is

important to clean the exchanger regularly (once a year)

to maintain high efficiency. The heat exchanger can be

taken out of the unit for maintenance. Wash in hot soapy

water or use pressure air. Do not use detergent containing

ammonia.

|

Page 17

7.6 Jalousie damper

Jalousie flaps are equipped with polyamid-bearingsleeves. These need not be maintained (do not put oil or

grease on them). Please pay attention that the jalousie

flaps must be opened before switching on the ventilator

and that the ventilator must be switched off before the

closing of the jalousie flaps. If it is operated by hand the

housing part might be deformed. Impact loads f.ex. by

unsecured jalousie flaps lead to a destruction of housing

parts.

7.7 Doors and door locks

Doors and door locks must be checked whether they can

be locked and closed. Lubricate the movable parts.

Internal components |

13

7.7.1 Interception safety

Check the interception safety devices of the doors at

pressure side (release chains only after standstill of the

ventilators)

7.8 Silencer

To avoid fan noise being transferred via the duct system,

silencers should be installed both on supply and extract

air.

To avoid noise being transferred between rooms via the

duct system and also to reduce noise from the duct

system itself, installation of silencers before every inlet

diffuser is recommended.

The links of the sound absorbers have to be cleaned with

vacuum cleaners (depending on the pollution). Dirty

perforated sheets reduce the absorption qualities.

7.9 Internal lightening

Lights are wired on external terminal boxes. The wiring of

the terminal boxes between each other resp. from

component to component must be made on site.

Radiated heat in case of the medium steam resp. hot

water might lead to the damage of the lights and the

cables. Standstill damages in case of opening heating

valves

|

Page 18

| Syphon

14

7.9.1 Roof units

Lights are wired on internal terminal boxes. Internal

wiring of the terminal boxes between each other resp.

from component to component must be made on site.

8 Syphon

1a Rubber sleeve 40–30

1b Rubber sleeve 40–30

2 Jaining piece 40–40

3 Sleeve nut 1 1/2“

4 Sealing Ø 40

5 Arc Ø 40

6 Plunger tube Ø 40

7 Sleeve nut 1 1/2”

8 Bearing ring Ø 40

9 Sealing Ø 40

10 Terminal arc Ø 40

11 Sealing 1 1/2”

12 Check valve with drain

13 Sealing 1 1/2”

14 Screw cap 1 1/2”

15 Ball

16 Screw cap 1 1/2”

For each device drain a syphon must be provided. The installation can be

seen in picture 1. The length of the arc (5) and plunger tube (6) has to

be adapted to the existing negative pressure. In case of drains of ¾“ up

to 1 ½“ connecting elements and rubber sleeves are automatically

delivered (parts 1 to 5). The syphon may not be connected directly with

a drain conduction but it must be guaranteed that it can run out freely.

Before putting into operation the device or longer standstill periods the

syphon must be cleaned (cleaning 4 times a year). Also the drop

separators have to be cleaned half - yearly with a steam vacuum

cleaner. If there are several drains in one device then a separate syphon

has to be put on each sleeve. Do not connect on one common

conduction. If the syphons are regulary delivered a functional test must

be made in time to avoid water damages.

Note:

Other types of construction may only be used after consultation.

negative

pressure in

unit P (Pa)

2000

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

shortening

of the

plunger

tube no. 6

by mm

100

110

110

110

110

110

-

-

-

-

-

-

-

-

shortening

of the arc

no. 5 by

mm

-

10

20

30

40

0

10

20

30

40

50

60

70

|

Page 19

Ground clearance of the central units

The function and mounting of a syphon requires a

sufficient ground clearance of the respective device. The

minimum ground distance R to picture 2 is:

Important

In case of disregarding the base height the overflowing of the tub is preprogrammed

Syphon |

15

8.1 Syphon for cooler

Pressure operation:

Note:

For tubs which have to be connected within the overpressure range, hand – made syphons must be

installed. These must have a refilling piece. Drain problems can occur in connection with multi – speed

motors resp. with converter operation.

8.1.1 General information

• make a functional test with tap water in due time!

• use a separate syphon with free drain for each drain.

|

Correct installation

Page 20

| Outdoor installation

16

Negative pressure

9 Outdoor installation

Overpressure

Important

♦ If the weather protection roof cannot be bought immediately, the top of the unit must be covered

watertight.

♦ The outside joints of outdoor units have to be permanently elastic sealed. While assembly work the joints

must be proved. If necessary you have to reseal the joints. Please prove all joint gaps.

|

Page 21

kind of delivery. box sheets pre-punched drilling screws

4,8 x 19 loose

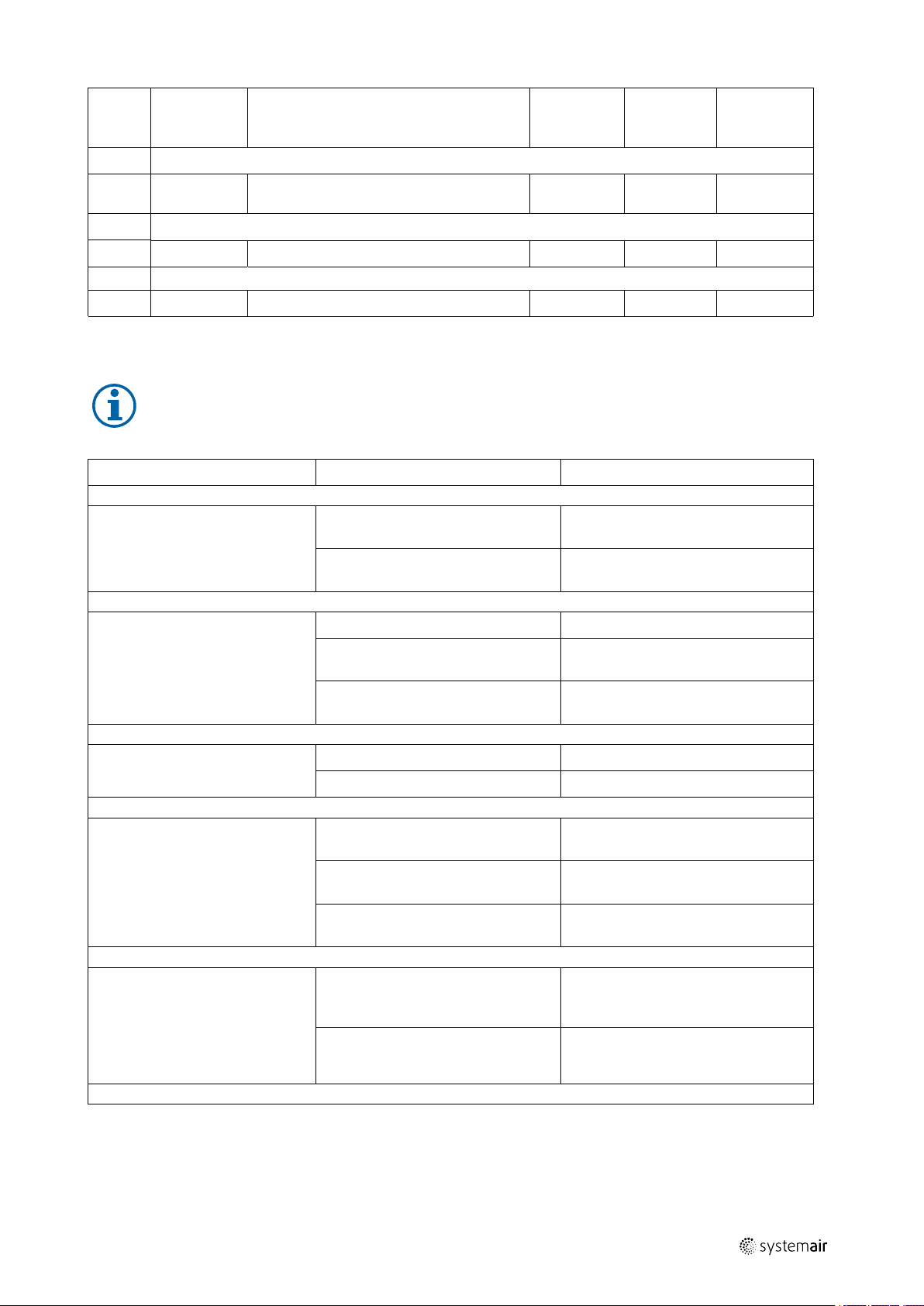

9.1 Roof frame made of galvanized sheet

Outdoor installation |

17

Cut: roof frame insulated (extra charge)

detail: drip ledge

Mounting of the drip ledge

♦ install, set up, bolt the device

♦ screw the drip ledge with a drilling screw

(4.8 x 19) at the device brace. Mount prefabricated corner parts and cut off the

intermediate parts.

♦ clean and degrease drip ledge and spray

with permanent elastic material very

thinly

|

Page 22

| Condensation and heat insulation

18

Top view

Important

It should be ensured that the base frame is insulated. Without insulation it can occur condensat.

10 Condensation and heat insulation

Outdoor air duct and exhaust ducts must always be well insulated against condensation. Correct insulation installation

on ducts connected to the unit is especially important. All ducts installed in cold rooms/areas must be well insulated.

Use insulating covering (minimum 100 mm mineral wool) with plastic diffusion barrier. In areas with extremely low outdoor temperatures during the winter, additional insulation must be installed. Total insulation thickness must be at least

150 mm.

Caution

• If the unit is installed in a cold place make sure that all joints are covered with insulation, and tape well

• Duct connections/duct ends should be covered during storage and installation

• Do not connect tumble dryers to the ventilation system

11 Maintenance

11.1 Warnings

Danger

• Make sure that the Mains supply to the unit is disconnected before performing any maintenance or

electrical work

• All electrical connections must be carried out by an authorized installer and in accordance with local rules

and regulations

Warning

• Although the Mains supply to the unit has been disconnected there is still risk for injury due to rotating

part that have not come to a complete standstill

• Beware of sharp edges during mounting and maintenance. Use protective clothing

• Beware of hot surface on the heating battery during maintenance and service

|

Page 23

Maintenance

|

11.2 General

The maintenance manual is only for Systemair air handling units of the MAXK-I3 series.

Keep attention to the listed warnings above during maintenance work. Follow the valid general safety requirements

and the valid operating rules. Use suitable and safe ads (ladder, working platform etc.)

Mainly the maintenance work consists of a visual inspection of the air handling unit, periodic filter change and cleaning

of the heat exchanger.

You have to read this instructions before starting maintenance work. Please keep attention to your health during maintenance work. We recommend the use of conventional protection means (breathing protection, disposable gloves etc.).

The specifications of the instructions must be observed. Maintenance shall be performed in accordance with the instructions solely by technical persons qualified for the purpose.

It is recommended to perform maintenance and cleaning by a specialist company periodically.

Please note: if damage is caused due to your failure to observe these instructions, the guarantee is invalidated.

11.3 Maintenance instructions

Performance

Component

1 Fan

1.1

1.2

1.3

1.4

1.5

1.6

2

2.1

2.2

2.3

2.4 Venting

3

3.1

3.2

3.3

3.4

4

4.1

4.2

4.3

4.4 Venting

Air heater (water)

Air heater (electro)

Water cooling battery

Activity

Examine for dirt, damage and corrosion

Function sustenance cleaning of the air

contact parts of the ventilator as well as the

water drain

Check impeller for damage and unbalancing

Check engin mounts for strange noises

Relubrication engin mounts

Check flexible connector for leaks

Check the proper function of the vibration

dampers

Examine for dirt, damage and corrosion

Clean the air heater on air side

Check the proper function of the flow and

return pipes

Check the electrical connection for

corrosion

Function sustenance cleaning (air side)

Check the proper function

Check the function of control- and safety

devices

Examine for dirt, damage and corrosion

Function sustenance cleaning (air side)

Check the proper function of the flow and

return pipes

Periodic If required Number per

year

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

2

1

1

1

1

1

1

4

1

1

2

1

1

2

2

2

19

|

Page 24

20

Maintenance

|

4.5

5 Drop separator

5.1

5.2

5.3

6

6.1

6.2

6.3

6.4

6.5

7

7.1

7.2

7.3

8

8.1

8.2

9 Damper

9.1

9.2

9.3

9.4

9.5

10

10.1

10.2

10.3

10.4

10.5

10.6

11

11.1

11.2

Counterflow heat exchanger

Filter

Weather protection guard

Compartments / unit housing

Air pipes

Check the function of the water drain and

odour seal

examine for dirt, incrustration, damage and

corrosion

Function sustenance cleaning

Check the function of the water drain and

odour seal

Examine for dirt, damage and corrosion

Function sustenance cleaning (air side)

Check the function of the water drain and

odour seal

Check the condensat drip tray for dirt,

corrosion and function

Check the function of the Siphon

Examine for impremissble contamination

and damage (leakage)

Examine differential pressure

Replace filter and document the filter

change

Examine for dirt, mounting, damage and

corrosion

Function sustenance cleaning

Examine for dirt, damage and corrosion

Function sustenance cleaning

Check mechanical function

Relubrication bearing and rod

Check the proper function of the actuator

Function sustenance cleaning

Check the function of the outlets

Clean the outlets

Check the operability and tightness of the

doors and closures

Check the insulation for damage

Clean the inside of the chamber

Check the tightness of the flexible

connectors

Examine accessible air pip sections for

damage, mounting and corrosion

Check the tightness of accessible flexible

connectors

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

1

1

1

2

1

1

4

4

1

1

1

1

1

1

1

1

1

1

|

Page 25

Disturbances and troubleshooting |

21

11.3

12

12.1

13

13.1

14

14.1

Air passages

Wall grid

Silencer

Examine interior air pipe surface for

contamination and corrosion on two or

more representative place

Examine installed perforated metal plate,

wire mesh of filter for contamination

Examine for dirt and mounting

Examine for dirt, damage and corrosion

12 Disturbances and troubleshooting

Note:

When error occur first read the table below and follow the instructions. If the error is still not fixed please

contact the customer service

Interruption

The air handling unit is not

working

Potential cause

no electricity supply Connect the air handling unit with the

The connection cables are damaged Disconnect the unit from the power

x

x

x

x

Repair

power supply

supply and contact the manufacturer

1

1

1

Fan running roughly/unsteady Imbalance of the impeller Rebalancing by spcialized company

Wrong direction of rotation of the

impeller

Deformation of the impeller Consultation with the manufacturer.

Air performance to low Pressure drop in the unit to high Check components for dirt

Cloged air passages

Motor does not turn Mechanical blocking Switch off power and remove the

Mains voltage faulty Control the Mains supply, restore

Supply faulty Switch off power, adjust supply, see

Supply air flow to low Filters are polluted Switch off the air handling unit.

Mechanical barriers on the outdoor

air inlet or on the supply air inlet

Consultation with the manufacturer

Install a new impeller.

mechanical blockage

power supply, apply control signal

circuit diagram

Disconnect the unit from the power

supply. Change the filter.

Control the outdoor air inlet and the

supply air inlet. If necessary remove

barriers

|

Page 26

| Disturbances and troubleshooting

22

Air handling unit does not heat or

heats insufficiently

Air handling unit does not cool or

cools insufficiently

Water drops out of the air

handling unit

Air in the water heating battery

To low temperature of the hot water

in the water heating battery

To low power of the heating battery Contact the manufacturer

Heat recovery defect Contact the manufacturer

Air in the water cooling battery

To high temperature of the cooling

coil

To less flow rate of the cooling

medium

To low power of the cooling coil Contact the manufacturer

Damaged or blocked condensation

pipe

Venting

Control the temperature of the heating

medium

Venting

Control the temperature of the cooling

medium

Control the valve. If necessary clean

the valve

Disconnect the unit from the power

outlet. Clean the condensation pipe

incl. syphon

|

Page 27

|

Page 28

Systemair GmbH

Seehöfer Str. 45

97944 Boxberg

Germany

Tel.: +49 (0)7930/9272-0

Fax: +49 (0)7930/9273-92

info@systemair.de

www.systemair.de

MAXK · Installation and Operating Instructions · · en_GB · 2017-06-13 ·

Loading...

Loading...