SystemAir KD-EC 315E, KD-EC 355E, KD-EC 400E, KD-EC 400D, KD-EC 450D Operation And Maintenance Instructions

...Page 1

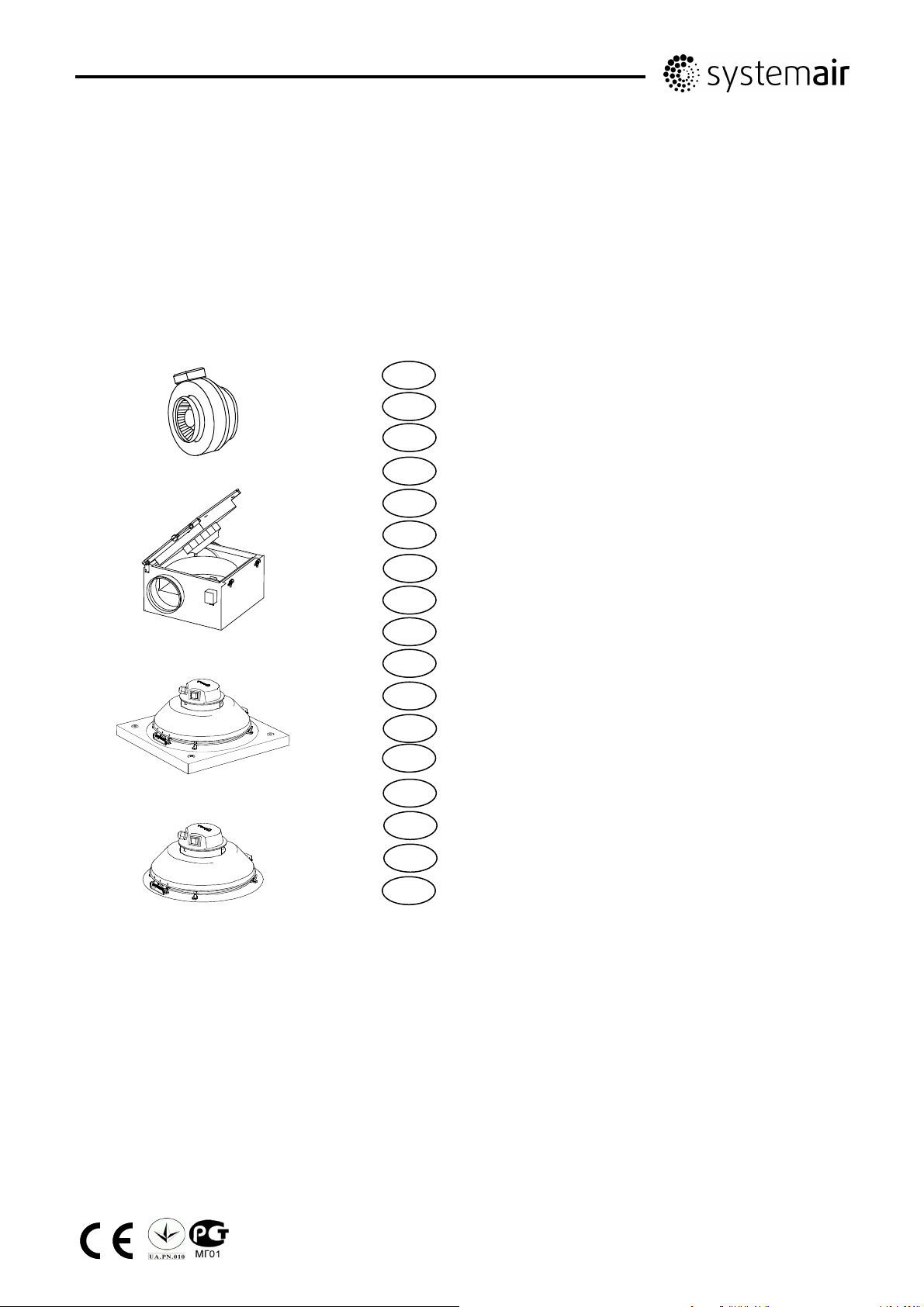

K EC, KVKE EC, TFSR EC, TFSK EC, KVO EC, KD EC

Operation and maintenance instructions……..…….……………..16

GB

SE

DE

DK

ES

EE

FI

IT

LT

LV

NL

NO

PL

RU

SK

SI

FR

Drift och underhållsinstruktion……………..………………….…..18

Betriebsanleitung..……………..………..………………………….20

Drifts- og vedligeholdelsesvejledning …..…...…………………...23

Instrucciones de uso y mantenimiento.........................................25

Käitamis- ja hooldusjuhised..........................................................27

Käyttö- ja huolto-ohjeet….............................................................29

Istruzioni di funzionamento e manutenzione................................31

Naudojimo ir techninės priežiūros instrukcijos..............................34

Lietošanas un montāžas instrukcija..............................................36

Gebruiks- en onderhoudsinstructies …….………...……………...38

Drifts- og vedlikeholdsanvisning...................................................40

Instrukcja obsługi i konserwacji....................................................42

Руководство по эксплуатации и техническому обслуживани

Pokyny týkajúce sa prevádzky a údržby ………………..….……..47

Navodila za uporabo in vzdreževanje ……. ..…………………….49

Instructions d’utilisation et d’entretien.........................................51

.44

A002

Page 2

r

r

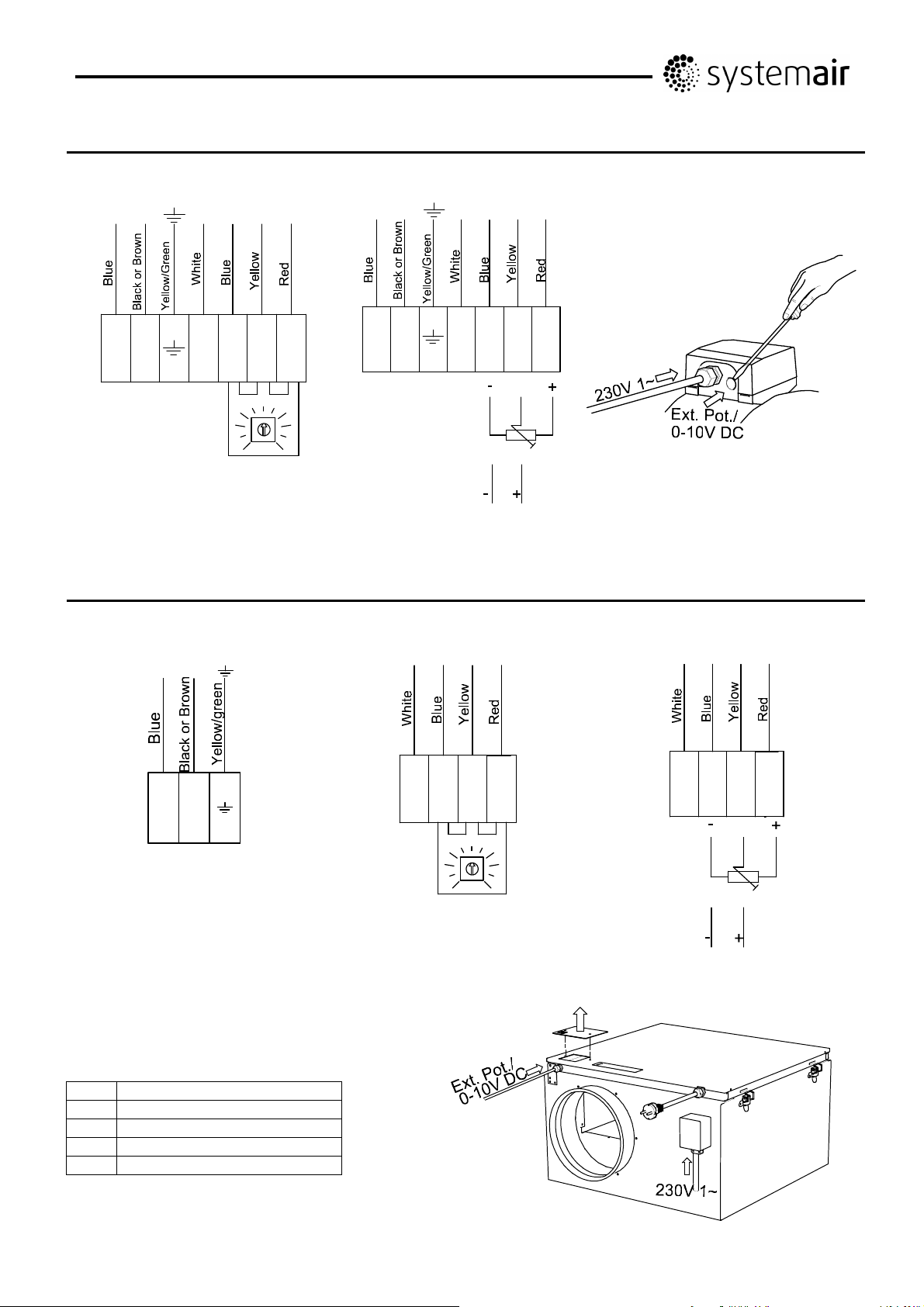

K EC:

230V 1~

L

N

NL 1 2 3 4

Internal potentiometer

KVKE EC:

230V 1~

-

1=Min

0

230V 1~

L

N

K EC

NL 12 34

+

5

10

External potentiometer

Optional

Internal potentiomete

010

10K

0-10V DC

External potentiomete

LN

NL

No. Description

1 Tach output, Isink max 10mA

2 GND

3 Control input 0-10 VDC/PWM

4 Output 10 VDC max 1.1 mA

321 4

010

10K

0-10V DC

-

1=Min

0

321 4

5

10

+

KVKE EC

2

206268 Systemair AB

Page 3

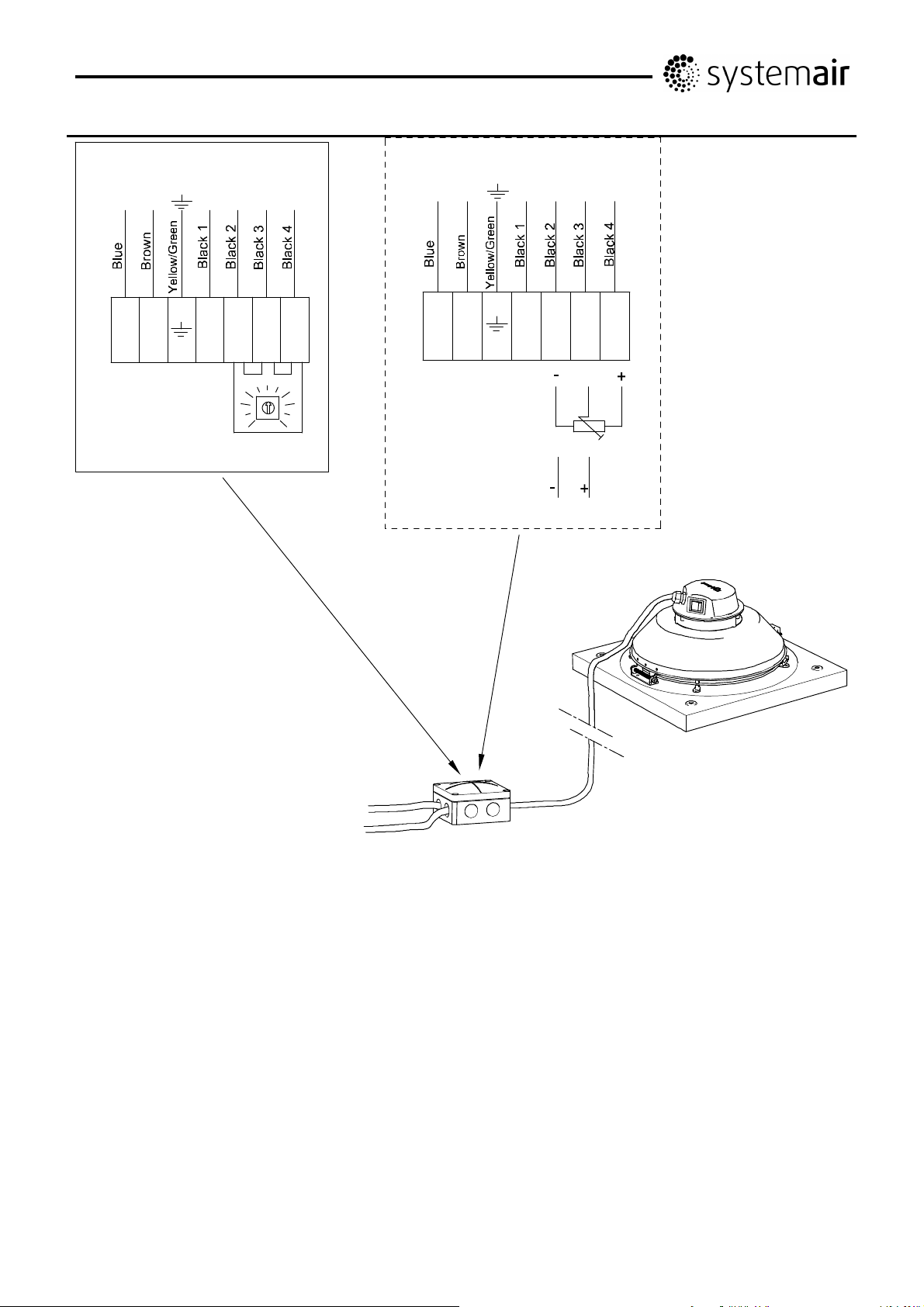

TFSR/TFSK EC:

230V 1~

L

N

NL 1 2 3 4

Internal potentiometer

-

1=Min

0

230V 1~

L

N

NL 12 3 4

+

5

10

External potentiometer

Optional

010

10K

0-10V DC

230 V 1~

Ext. Pot/0-10V DC

3

206268 Systemair AB

Page 4

KVO EC:

4

206268 Systemair AB

Page 5

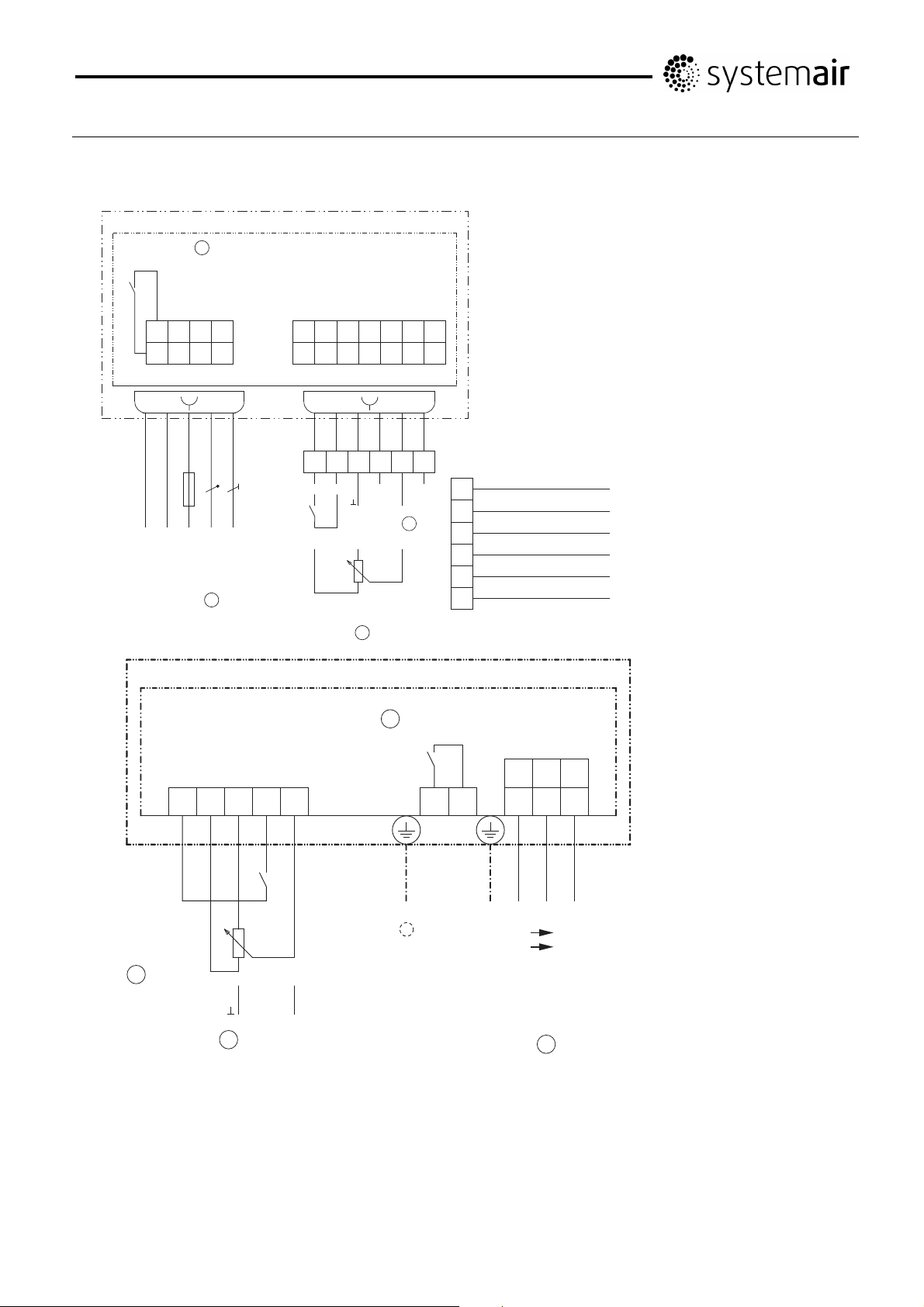

KD EC:

For KD-EC 315E, 355E, 400E

Motor size “B ” (type: _ _ _ _ _-_ I _.B _._ _ _ _)

ECblue Basic

K1

11 - L1 N

14 - - PE

WH

11 14

(_ _ _ _ _-_I_.B_._ _ _ _)

5

Kontaktbelastung

Contact rating

max. AC 250 V 2 A

WH

BU

BN

NL1PE

Netz

Line

1 ~ 200...277 V

50/60 Hz

1

11

A2 GND 10V - - - -

E1 D1 A1 - - - -

GNYE

BU

Eingang

0...10 V

GY

Input

YE

WH

+

4

GN

RD

10V D1GNDA2E1A1

10 kΩ

Internal speed setting

10 V DC Out (I

10V

D1 Digital In 1

D1

GND

GND

A2 Operation Out OC

A2

E1 Analog In 1

E1

A1 Status Out OC

A1

Line voltage 1 ~ 200...277 V, 50/60 Hz

External speed setting

Input 0...10 V

Contact rating max. AC 250 V 2 A

Relay output (K1)

An external fault indicator is available over the potentialfree contact of the built-in relays

(max. contact rating Technical data and connection

diagram).

For operation the relay is energized, connections “11”

and “14” are bridged. For fault the relay is de-energized

(Diagnostics/faults).

When switching off via enable (D1 = Digital In 1), the

relay remains energized.

= 10 mA)

max

RD

GN

BU

GY

YE

WH

For KD-EC 400D, 450D, 500D

ECblue Basic

24V 10V GND D1 E1 11 14

Internal speed setting

3

= 70 mA)

max

DC Out

(I

(_ _ _ _ _-_I_.D_._ _ _ _), (_ _ _ _ _-_I_.G_._ _ _ _)

= 10 mA)

max

(I

DC Out

Digital In 1

10 kΩ

Input

4

0...10 V

Analog In 1

+

3

Kontaktbelastung

2

max. AC 250 V 2 A

PE

Contact rating

L1

L2 L3

L1

K1

Netzspannung Leistungsschild

Line voltage Rating-plate

3 ~ Typ nur in Sonderausführung

für IT-System geeignet

3 ~ type only in special version

suitable for IT-System

1

N

L3/NL2L1PE

Line voltage rating plate (3 ~ type only in special version suitable for IT-System)

Contact rating max. AC 250 V 2 A

External speed setting

Input 0...10 V

5

206268 Systemair AB

Page 6

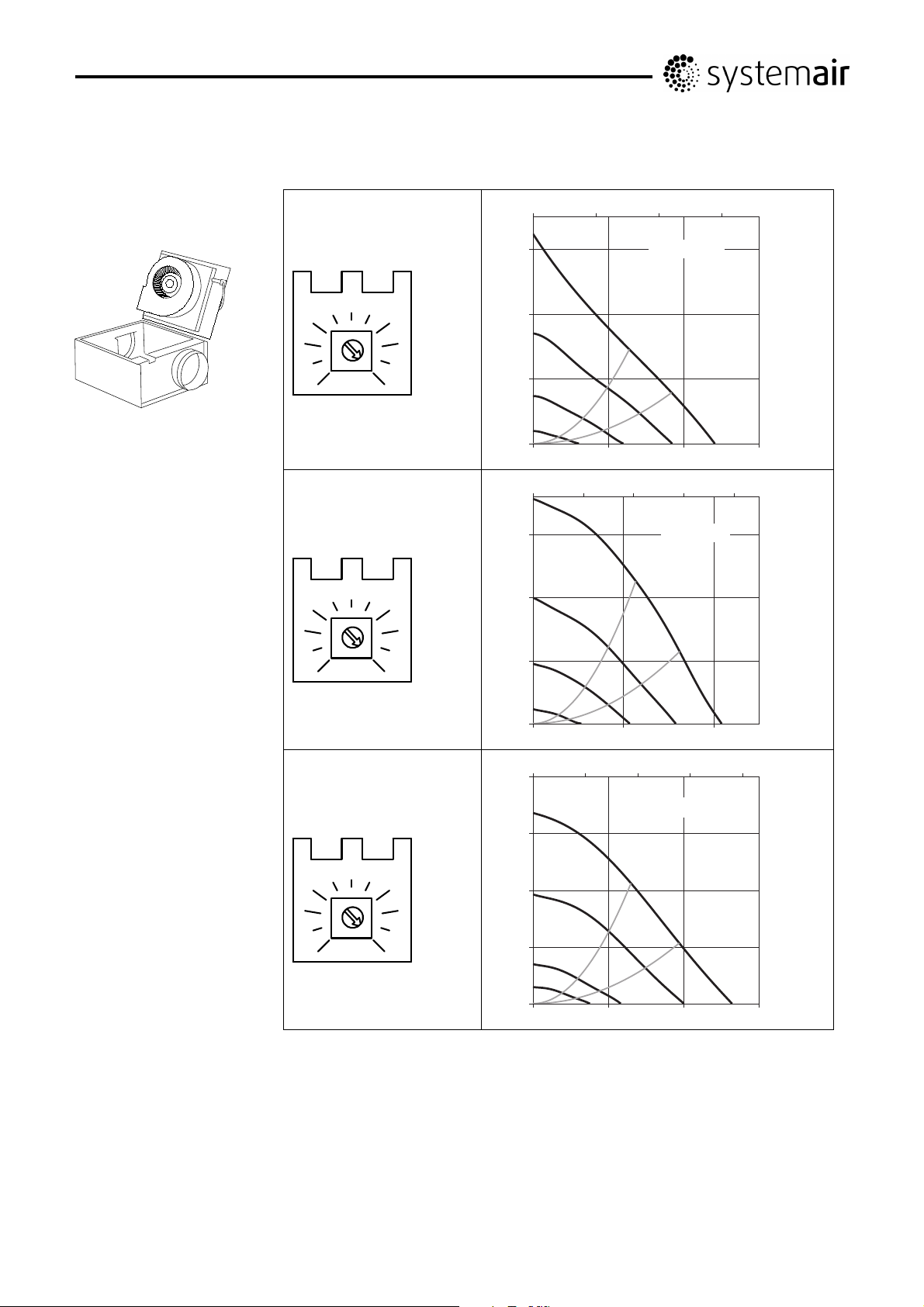

K EC:

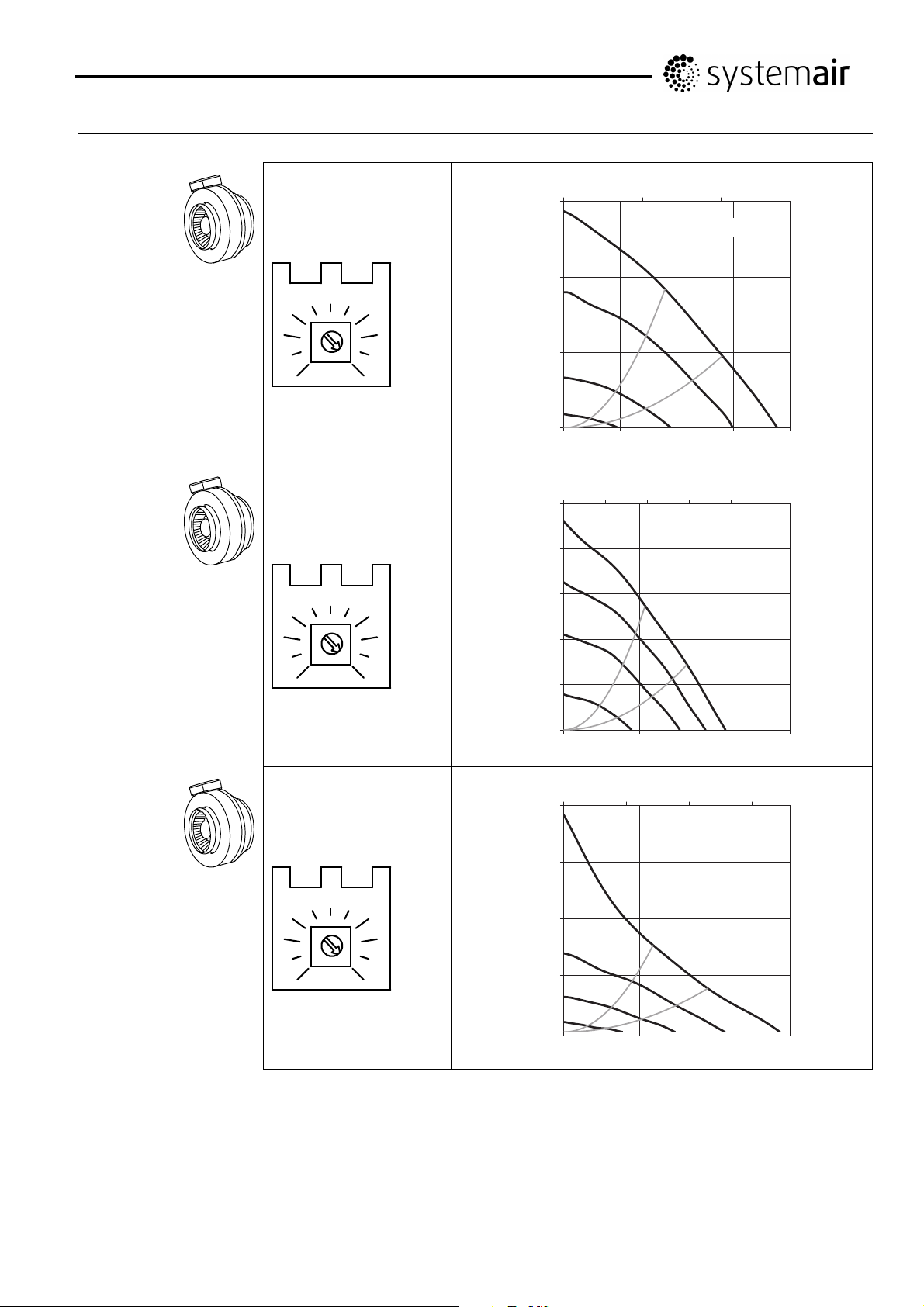

K EC 160

1=Min

5

0

K EC 200

1=Min

5

10

(10,0V)

0 200 400

600

400

[Pa]

200

0

0 0.04 0.08 0.12 0.16

0 200 400 600 800 1000

500

400

300

[Pa]

200

3V

[m³/h]

K EC 160

4V

[m³/s]

[m³/h]

K EC 200

7,5V

8213/8214

10V

7735/7736

0

K EC 250

1=Min

0

Fig 1

10

(10,0V)

100

0

0 0.1 0.2 0.3

0 300 600 900

1000

750

4V 6,5V

[m³/s]

[m³/h]

10V

8V

K EC 250

7791/7792

5

500

[Pa]

10

(10,0V)

250

0

0 0.1 0.2 0.3

2V 3,5V 5V 10V

[m³/s]

6

206268 Systemair AB

Page 7

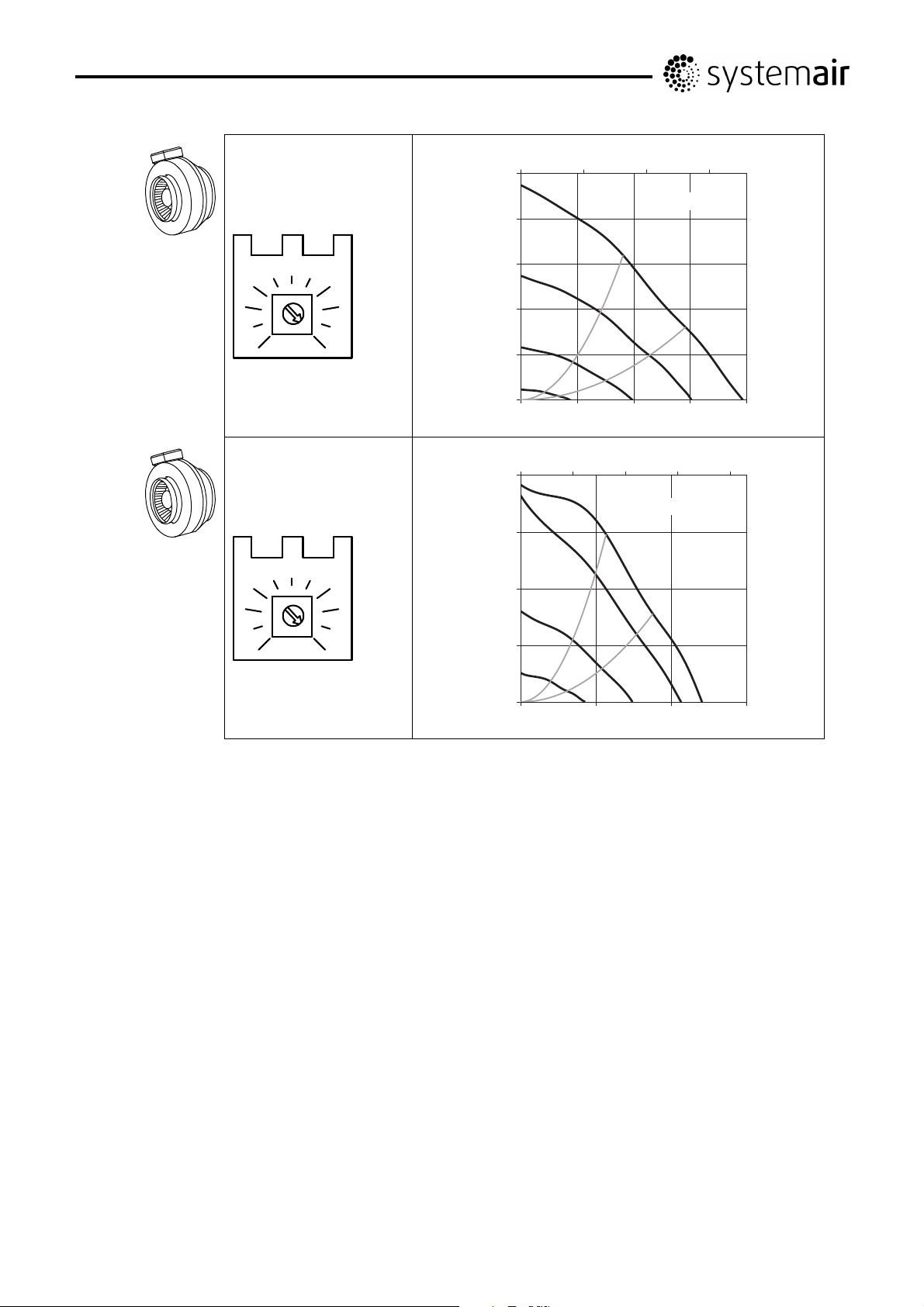

K EC 315 M

1=Min

5

0

K EC 315 L

1=Min

5

10

(10,0V)

0 400 800 1200

500

400

300

[Pa]

200

100

0

0 0.1 0.2 0.3 0.4

0 500 1000 1500 2000

800

600

400

[Pa]

2,5V 5V 7,3V 10V

[m³/h]

K EC 315 M

[m³/s]

[m³/h]

K EC 315 L

7765/7766

7760/7761

0

10

200

(10,0V)

[m³/s]

5V

7,2V

10V

Fig 2

0

0 0.2 0.4 0.6

3V

7

206268 Systemair AB

Page 8

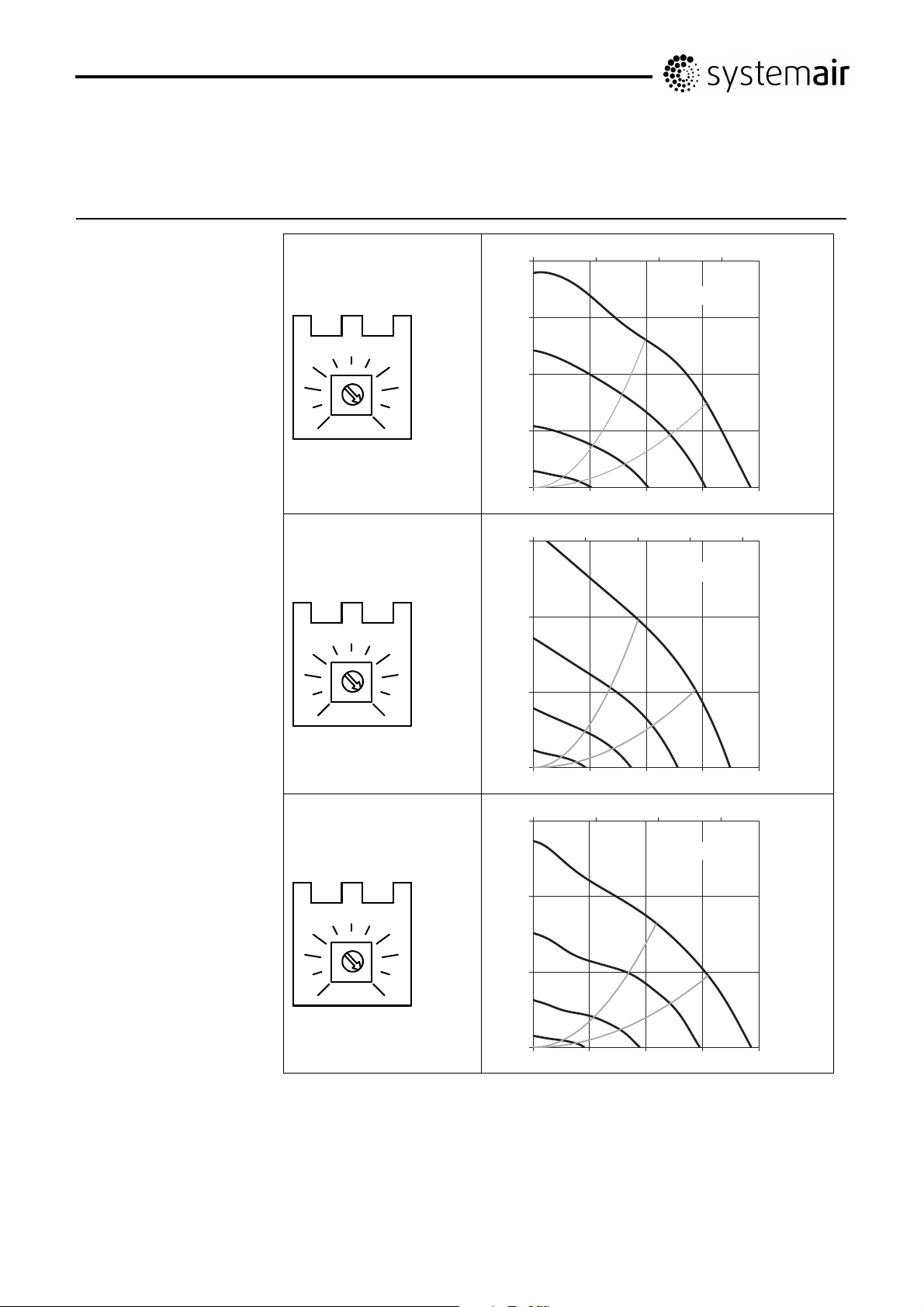

KVKE EC

KVKE EC 125

1=Min

5

0

10

(10,0V)

KVKE EC 160

1=Min

5

0 100 200 300 400

800

600

400

[Pa]

200

0

0 0.03 0.06 0.09 0.12

0 200 400

600

400

[Pa]

2V

[m³/h]

4,8V

[m³/s]

[m³/h]

KVKE EC 125

7V

KVKE EC 160

8166/8167

10V

7721/7722

0

KVKE EC 200

1=Min

5

0

Fig 3

10

10

(10,0V)

(10,0V)

200

0

0 0.04 0.08 0.12 0.16

0 300 600 900

1000

750

500

[Pa]

250

0

0 0.1 0.2 0.3

4V

6V

[m³/s]

[m³/h]

KVKE EC 200

5V

[m³/s]

7V

10V

8V

7755/7756

10V

8

206268 Systemair AB

Page 9

KVKE EC 250

1=Min

5

0

10

KVKE EC 315

1=Min

5

(10,0V)

0 300 600 900 1200

1000

750

500

[Pa]

250

0

0 0.1 0.2 0.3 0.4

0 500 1000 1500 2000

1000

750

500

[Pa]

2,5V 4,2V

[m³/h]

KVKE EC 250

6V

[m³/s]

[m³/h]

KVKE EC 315

7788/7789

10V

8159/8228

0

10

250

(10,0V)

[m³/s]

6,5V

10V

0

Fig 4

2,5V 4,5V

0 0.2 0.4 0.6

9

206268 Systemair AB

Page 10

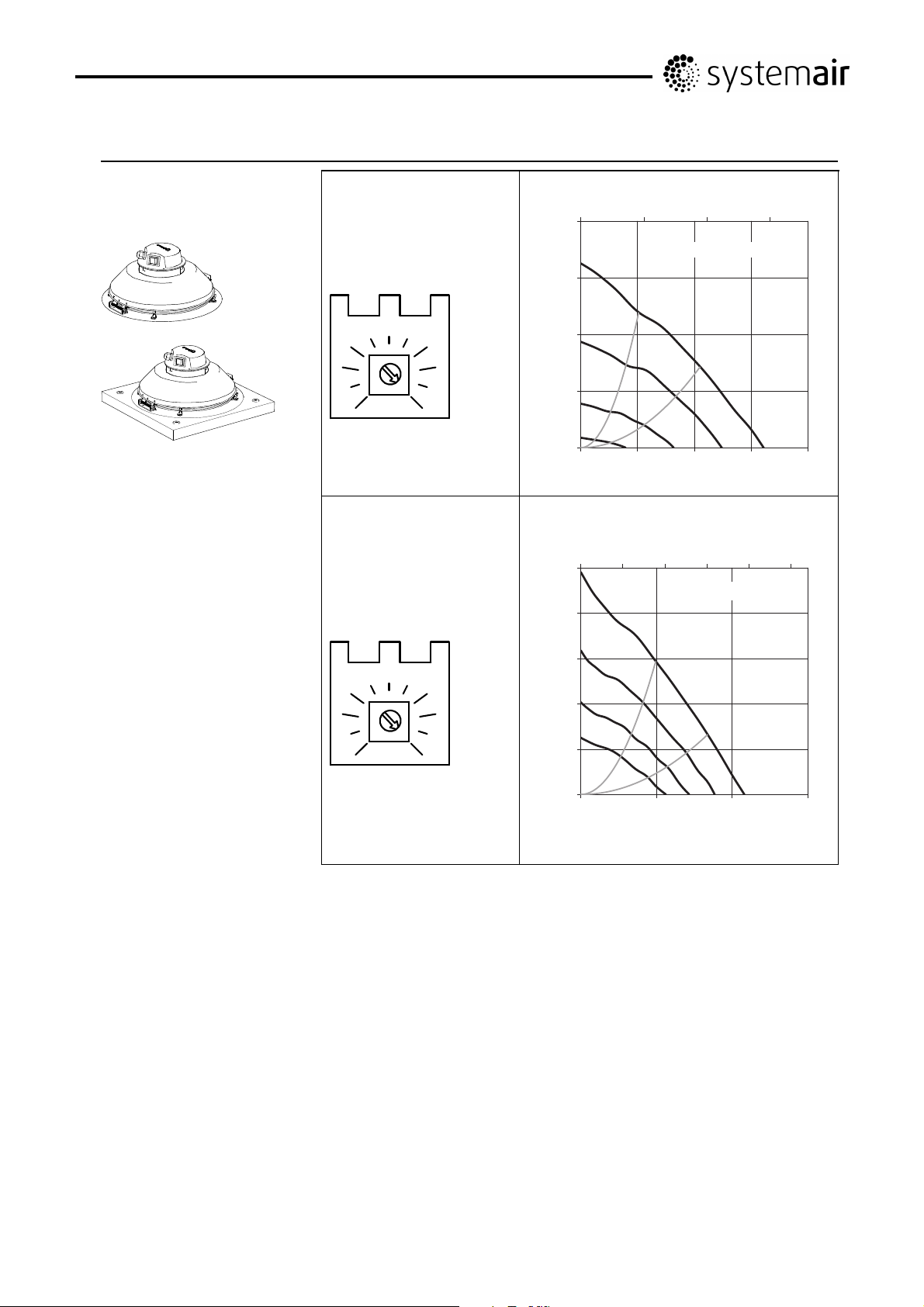

TFSR EC/TFSK EC

[m³/h]

TFSR EC/TFSK EC 160

TFSR EC/

TFSK EC 160

1=Min

5

0

10

0 200 400 600

800

600

400

[Pa]

200

(10,0V)

4,9V

[m³/s]

[m³/h]

TFSR EC/TFSK EC 200

TFSR EC/

0

0 0.05 0.1 0.15 0.2

0 200 400 600 800 1000

500

400

2,4V

TFSK EC 200

1=Min

5

300

[Pa]

200

8471/8472

7,2V 10V

8376/8529

0

10

100

(10,0V)

0

0 0.1 0.2 0.3

Fig 5

5V

[m³/s]

7V

6V

10V

10

206268 Systemair AB

Page 11

KVO EC

KVO EC 100

1=Min

5

0

10

(10,0V)

KVO EC 125

1=Min

5

2,1V

[m³/h]

KVO EC 100

4,8V

[m³/s]

[m³/h]

KVO EC 125

0 100 200 300

400

300

200

[Pa]

100

0

0 0.03 0.06 0.09

0 200 400

500

400

300

[Pa]

200

7,3V

11327/11328

10

11340/11341

0

KVO EC 160

1=Min

0

10

(10,0V)

5

10

100

4,5V

0

0 0.04 0.08 0.12 0.16

0 200 400

600

400

[Pa]

200

2,3V

7,3V

[m³/s]

[m³/h]

KVO EC 160

8,2V

10V

11317/11318

(10,0V)

2,5V

0

0 0.04 0.08 0.12 0.16

Fig 6

4V

[m³/s]

6,5V

10V

11

206268 Systemair AB

Page 12

[m³/h]

KVO EC 200

11323/11324

KVO EC 200

1=Min

5

0

10

0 300 600 900

600

400

[Pa]

200

KVO EC 250

1=Min

5

(10,0V)

1,9V

0

0 0.1 0.2 0.3

0 400 800 1200 1600

750

500

[Pa]

3,4V

5V

[m³/s]

[m³/h]

KVO EC 250

10

11338/11339

0

10

250

(10,0V)

0

0 0.2 0.4

KVO EC 315

1=Min

5

0

10

0 500 1000 1500 2000

1000

750

500

[Pa]

250

2,4V 4,3V

6,2V

[m³/s]

[m³/h]

KVO EC 315

10V

11349/11351

(10,0V)

4,3V

0

0 0.2 0.4 0.6

Fig 7

3V

[m³/s]

6,9V

10V

12

206268 Systemair AB

Page 13

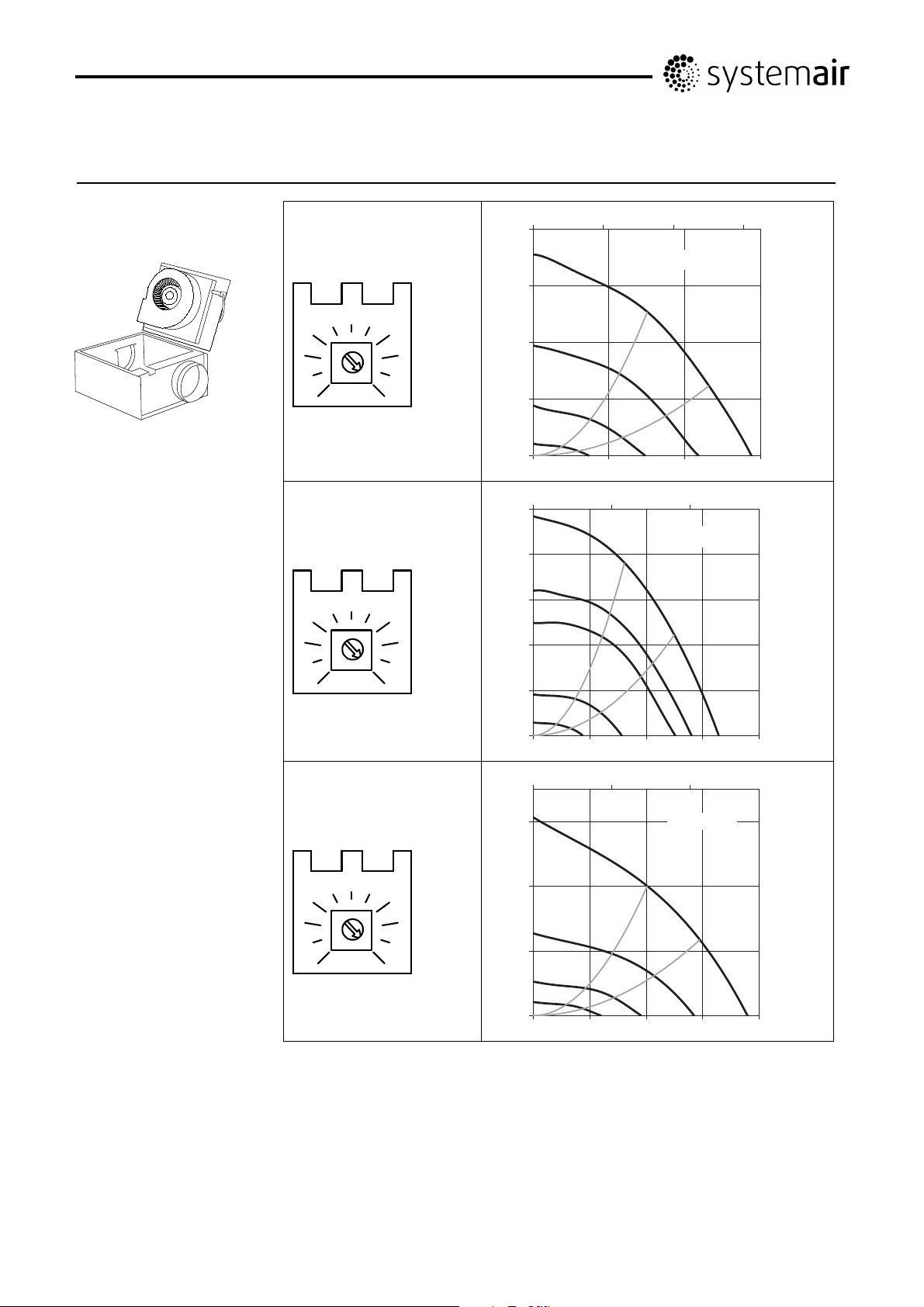

0

KD EC

KD EC 315E

1=Min

5

0

10

KD EC 355E

1=Min

5

(10,0V)

0 1000 2000 3000

400

300

200

[Pa]

100

0

0 0.25 0.5 0.75 1

0 1000 2000 3000 4000

300

200

[Pa]

[m³/h]

KD EC 315E

3V 5,5V

[m³/s]

[m³/h]

KD EC 355E

11087/11346

10

8V

11354/11355

100

0

10

(10,0V)

0

0 0.3 0.6 0.9 1.2

0 2000 4000 6000

600

3V

KD EC 400E

400

1=Min

5

[Pa]

200

0

10

5,2V

[m³/s]

[m³/h]

7,2V

KD EC 400E

10V

11360/11388

(10,0V)

0

0 0.5 1 1.5 2

Fig 8

2,8V

5V 7,5V

[m³/s]

1

13

206268 Systemair AB

Page 14

0 3000 6000

1000

KD EC 400D

1=Min

5

0

10

[Pa]

750

500

250

[m³/h]

KD EC 400D

11352/11353

(10,0V)

3V

0

0 1 2 3

KD EC 450D

1=Min

5

0 2500 5000 7500 10000

800

600

400

[Pa]

5,2V 7,2

[m³/s]

[m³/h]

10V

KD EC 450D

11344/11345

0

10

200

(10,0V)

0

0 1 2 3

KD EC 500D

1=Min

5

0

10

0 2500 5000 7500 10000

800

600

400

[Pa]

200

2,9V 5,3V

[m³/s]

[m³/h]

KD EC 500D

7,V5

10V

11358/11359

(10,0V)

[m³/s]

6V

8V 10V

0

0 1 2 3

Fig 9

3,5V

14

206268 Systemair AB

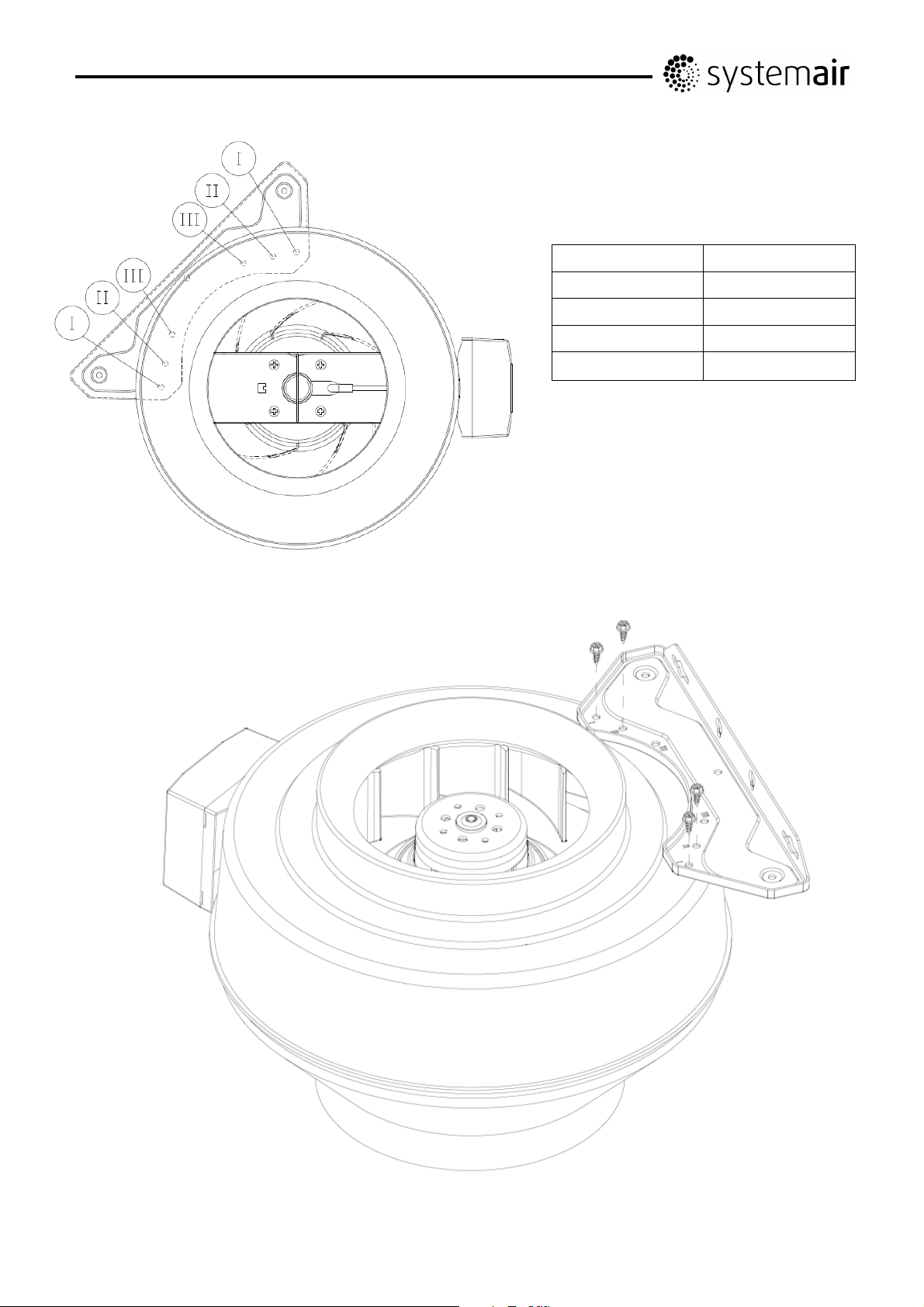

Page 15

Type Screw

K EC 160 II

K EC 200 I + II

K EC 250 I + II

K EC 315 M/L I + II

15

206268 Systemair AB

Page 16

GB

Declaration of Conformity

Manufacturer

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg SWEDEN

Office: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

hereby confirms that the following products:

Duct fans with circular connection: K EC 160-315L, KVO EC 100-315, KD EC 315-500

Insulated duct fans with circular connection: KVKE EC 125-315

Roof fans with circular or square connection: TFSR EC/TFSK EC 160-200

(The declaration applies only to product in the condition it was delivered in and installed in the facility in

accordance with the included installation instructions. The insurance does not cover components that are added

or actions carried out subsequently on the product)

Comply with all applicable requirements in the following directives

Machinery Directive 2006/42/EC

Low Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC

The following harmonized standards are applied in applicable parts:

EN ISO 12100-1 Safety of machinery – Basic concepts, general principles for design – Part 1: Basic

terminology, methodology

EN ISO 12100-2 Safety of machinery – Basic concepts, general principles for design – Part 2: Technical

principles

EN 14121-1:2007 Safety of machinery – Risk assessment – Part 1: Principles

EN 13857 Safety of machinery – Safety distances to prevent hazard zones being reached by upper or

lower limbs

EN 60 335-1 Household and similar electrical appliances – Safety Part 1: General requirements

EN 60 335-2-80 Household and similar electrical appliances – Safety – Part 2-80: Particular requirements

for fans

EN 50 366-1 Household and similar electrical appliances – Electromagnetic fields – Methods for

evaluations and measurement

EN 50 106:2007 Safety of household and similar appliances – Particular rules for routine tests referring to

appliances under the scope of EN 60 335-1 and EN 60967

EN 60 034-5 Rotating electrical machines – Part 5: Degrees of protection provided by the integral design

of rotating electrical machines (IP code)

EN 60 204-1 Safety of machinery – Electrical equipment of machines – Part 1: General requirements

EN 60730-1 Automatic electrical controls for household and similar use - Part 1: General requirements

EN 61000-6-2 Electromagnetic compatibility (EMC) – Part 6-2: Generic standards – Immunity for industrial

environments

EN 61000-6-3 Electromagnetic compatibility (EMC) – Part 6-3: Generic standards – Emission

standards for residential, commercial and light-industrial environments

Skinnskattberg 15-05-2012

Mats Sándor

Technical Director

Doument in original language

16

Page 17

GB

Safety Information

This machinery must not be put into operation prior to

reading mounting instructions and safety information.

All fans are intended for transportation of air in air handling

systems. If installed in non-heated rooms, fan casing must

be insulated in order to avoid condensation. They are

designed to be used once built into machines or ducted to

be used into machines or duct systems or after contact

protection grid has been installed. (EN ISO 13857). Fans

with duct connections must be connected to ducts on both

sides (inlet/outlet). Should there be a risk of water entering

the motor, via the ducts, external protection is required. No

moving parts shall be accessible after installation. The fans

are not to be used in hazardous environments or connected

to flue ducts. The fans must not be installed outdoors

(except TFSR/TFSK EC, K EC ). Safety accessories (i.e.

safety grille) may not be dismounted, short cut or

disconnected. CAUTION Before servicing or maintenance,

switch off power, (all-pole circuit breaker), and make sure

the impeller has come a standstill. CAUTION the fans can

have sharp edges and corners which may cause injuries.

CAUTION be careful when opening the fans service-hatches

(swing-out), the fan and motor assembled on the hatch is

relatively heavy (applies to KVKE, KVO).

The fan motor has built in protection for locked rotor, which

implies that the motor tries to restart with a preprogrammed

interval whenever it senses that the rotor is standing still.

When the blockage is removed the fan will start up by itself

without any further measures. At high motor temperatures

the current will be cut from the motor. It can then only be

restarted by manually disconnecting the mains supply to the

fan for couple of minutes.

Transportation and Storage

All fans are packaged at the factory to withstand normal

transport handling. When handling the goods use suitable

lifting equipment in order to avoid damage to fans and

personnel. Do not lift the fans by the connecting cable,

connection box, impeller or inlet cone. Avoid blows and

shock loads. Store the fans in a dry place protected from

weather and dirt until final installation. Permissible storage

temperatures -40…+80°C

Installation

Refer to Safety information above. Installation, electrical

connection and commissioning are only to be carried out by

authorised personnel and in accordance with requirements

and demands. Electrical connection according to the wiring

diagram in the terminal box, markings on terminal blocks or

on cable. CAUTION do not use metal compression gland

fittings with plastic terminal boxes. Use a dummy plug seal

for the compression gland fitting as well. The K-EC fan must

be installed with the connection box at the top of the unit ±

90 degrees. If permanent installation is carried out using

cables with diameter 12-14 mm, the electrical gland must be

replaced (applies to type K-EC). Assemble the fan in the

direction of airflow (see arrow on unit). The fan must be

installed so that vibration is not transmitted via ducted

systems or building structure. (Suitable accessories such as

fast clamps and diffusers are available). Make sure the

assembly of the fan is firm and stable. The fan can be

mounted in any direction unless stated otherwise. The fans

must be assembled so that service and maintenance can be

performed easily and safely. Disturbing noise can be

avoided by installing silencers (available accessory).

The fans are meant for continuous use within the

temperature range stated.

For fans which reset by cutting the current, must be taken

into consideration when connecting surrounding equipment

with automatic on/off function.

EC motors have a leakage current to earth corresponding to

<=3,5 mA. This needs to be considered whenever the fan is

connected together with an earth fault breaker.

Integral potentiometer

The integral potentiometer is factory preset (Fig. 1-9). This

value can be changed manually to obtain a different motor

rpm/fan performance. Fan preformance charts for this

purpose are shown in the table by voltage steps on page 513 (Fig. 1-9) to the right of the pot. symbols. An external

potentiometer can be connected if necessary. If so the

internal potentiometer needs to be disconnected from the

connection terminals.

Tach output

Terminal No. 1 in the wiring diagrams (white signal cable)

enables connection of an rpm counter (one pulse per

revolution), controller, alarm or a speed display. The Tacho

a signal with max 10mA.

Operation

Before initial operation, check the following:

- Electrical connection has been properly completed.

- Protective conductor has been connected.

- Safety devices in place (protection grid)

- Leftover installation materials and foreign materials have

been removed from the casing.

When putting into operation, check the following:

- Connection data corresponds to the specifications on the

nameplate: Maximum voltage +6%, -10%, according to IEC

38. Rated current must not be exceeded with more than 5%

at rated voltage.

- Smoothness of motor operation, (no abnormal noises).

-Fans must only be operated by a person which has suitable

knowledge or education within this field or carried out with

the supervision of a suitably qualified person.

Maintenance, Service and Repair

Prior to maintenance, service or repair make sure that:

- Power supply is interrupted (all-pole circuit breaker).

- Fan impeller has come to a complete standstill

- Observe personnel safety regulations!

The fan should be cleaned when necessary, at least 1/year

to avoid imbalance and unnecessary damage to the

bearings. A filter will further improve the time interval

between cleaning of the fan. (It is sometimes recommended

to install a filter guard). The fan bearings are maintenance

free and should only be replaced if damaged. Do not use a

high-pressure cleaner (steam jet) when cleaning the fan.

Make sure the fan impeller's balance weights are not moved

or the fan impeller distorted. Listen for abnormal operating

noise.

The following applies in case the fan has stopped:

- Try to restart the fan by cutting the power a couple of

minutes.

- Ensure that the impeller is not locked. Possible obstruction

to be removed after the current has been switched off.

Check that the fan starts after reconnecting the current.

Should the fan not start please contact your place of

purchase.

Doument in original language

17

Page 18

SE

Försäkran om överensstämmelse

Tillverkare

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg SVERIGE

Kontor: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

intygar härmed att följande produkter:

Kanalfläktar med cirkulär anslutning: K EC 160-315L, KVO EC 100-315, KD EC 315-500

Isolerade kanalfläktar med cirkulär anslutning: KVKE EC 125-315

Takfläktar med cirkulär eller rektangulär anslutning: TFSR EC/TFSK EC 160-200

( Intyget gäller endast för produkten i det skick i vilket den levererats och installerats vid anläggningen i enlighet

med medföljande installationsanvisningar. Intyget omfattar inte komponenter som senare lagts till eller åtgärder

som senare vidtagits på produkten.)

uppfyller alla tillämpliga krav i nedanstående direktiv.

Maskindirektivet 2006/42/EG

Lågspänningsdirektivet 2006/95/EG

EMC-direktivet 2004/108/EG

Tillämpliga delar av nedanstående harmoniserade standarder tillämpas.

EN ISO 12100-1 Maskinsäkerhet – Grundläggande begrepp, allmänna konstruktionsprinciper – Del 1:

Grundläggande terminologi, metodik

EN ISO 12100-2 Maskinsäkerhet – Grundläggande begrepp, allmänna konstruktionsprinciper – Del 2:

Tekniska principer

EN 14121-1:2007 Maskinsäkerhet – Riskbedömning – Del 1: Principer

EN 13857 Maskinsäkerhet – Skyddsavstånd för att hindra att armar och ben når in i riskområden

EN 60335-1 Elektriska hushållsapparater och liknande bruksföremål – Säkerhet – Del 1: Allmänna

fordringar

EN 60335-2-80 Elektriska hushållsapparater och liknande bruksföremål – Säkerhet – Del 2-80: Särskilda

fordringar på fläktar

EN 50366-1 Hushållsapparater och liknande bruksföremål – Mätning och bestämning av

elektromagnetiska fält

EN 50106:2007 Elektriska hushållsapparater och liknande bruksföremål – Säkerhet – Anvisningar för

tillverkningskontroll av apparater som omfattas av EN 60335-1 och EN 60967

EN 60034-5 Roterande elektriska maskiner – Del 5: Kapslingsklasser för elektriska maskiner (IP beteckning)

EN 60204-1 Maskinsäkerhet – Maskiners elutrustning – Del 1: Allmänna fordringar

EN 60730-1 Automatiska elektriska styr- och reglerdon för hushållsbruk – Del 1: Allmänna fordringar

EN 61000-6-2 Elektromagnetisk kompatibilitet (EMC) – Del 6-2: Generella fordringar – Immunitet hos

utrustning i industrimiljö

EN 61000-6-3 Elektromagnetisk kompatibilitet (EMC) – Del 6-3: Generella fordringar – Emission från

utrustning i bostäder, kontor, butiker och liknande miljöer

Skinnskatteberg 2012-05-15

Mats Sándor

Teknisk Direktör

Dokument översatt från engelska

18

Page 19

SE

Säkerhet

Fläktar får ej tas i bruk innan installationsanvisning och

säkerhetsanvisning har beaktats.

Fläktar för ventilation i luftbehandlingssystem med luft från

icke explosionsfarligt utrymme. Vid montering i ouppvärmda

utrymmen skall fläkten isoleras så att kondensutfällning

undviks. Fläktar är produkter som är avsedda att tas i bruk

endast efter inbyggnad, kanalanslutning eller att produkten

försetts med beröringsskydd. (EN ISO 13857). På fläktar

som har kanalanslutningar ska kanaler monteras på sug/tryck-sida, när risk finns för att vatten via kanaler kan

tränga in i motorn så måste någon form av externt skydd

monteras på kanaler. Efter Installation/kanalanslutning ska

beröring av rörliga delar ej vara möjlig. Fläktarna får ej

användas i explosiv miljö eller anslutas till rökgaskanal.

Fläktarna får ej monteras utomhus (gäller ej TFSR/TFSK

EC, K EC). Säkerhetsdetaljer (t.ex. beröringsskydd) får ej

demonteras. OBS! Innan service och underhåll påbörjas

måste fläktarna göras spänningslösa, allpolig brytning, och

fläkthjulet ha stannat. OBS! Fläktarna kan ha vassa kanter

och hörn, vilket kan orsaka skärskador. OBS! Iaktag

försiktighet vid öppnande av fläktarnas serviceluckor, då

fläkt med motor monterad på serviceluckan kan vara relativt

tung.

Fläktmotorn har ett inbyggt skydd för låst rotor, vilket

innebär att motorn, när den känner att rotorn står still

försöker starta igen med ett förprogrammerat intervall. När

blockeringen har avlägsnats startar motorn av sig själv utan

vidare åtgärd. Vid höga temperaturer i motorn kommer

strömmen till motorn att brytas. Fläkten kan då endast

återstartas efter att den gjorts spänningslös under några

minuter.

Transport och lagring

Samtliga fläktar som levereras från Systemair är

emballerade för att klara normal godshantering. Vid

godshantering använd lämplig lyftanordning för att undvika

skador på fläktar och personer. OBS! Lyft ej fläktarna i

motorkabel, kopplingsdosa, fläkthjul eller insugningskona.

Undvik slag och stötar. Fläktarna ska lagras torrt och

väderskyddat och skyddas från smuts och damm före slutlig

installation. Tillåtna lagringstemperaturer: -40…+80°C

Installation

Se även avsnitt säkerhet. Installation, elektrisk anslutning

samt idrifttagande ska göras av behörig installatör och

utföras i enlighet med för installationen gällande föreskrifter

och krav. Elektrisk anslutning ska göras enligt kopplingsscheman i kopplingsdosa, märkning på kopplingsplint eller

på kabel. OBS! Använd ej förskruvningar av metall om

kopplingsdosan är av plast. Täta ev. tomma

förskruvningshål med blindplugg. Anslutningsdosa ska på

K-EC fläktar monteras i en position rakt upp ± 90 grader.

Om fast installation sker med kabel som har diam. 1214mm så måste införings-bussningen bytas, gäller typ KEC. Montera fläkten i rätt luftriktning (se luftriktningspil).

Fläkten ska monteras så att vibrationer ej kan överföras till

kanalsystem och byggnadsstomme. (För ändamålet finns

fästklammer som tillbehör). Fläktar kan monteras i valfritt

inbyggnadsläge om annat ej anges. Fläkten ska monteras

på ett stadigt och stabilt sätt. Fläkten ska monteras så att

service och underhåll kan utföras på ett enkelt och säkert

sätt. Ljudproblem kan förebyggas genom installation av

ljuddämpare (finns som tillbehör). Fläktar är avsedda för

kontinuerlig drift inom angivna temperaturområden.

För kopplingschema gäller följande färger på signalkablar:

White = Vit, Red = Röd, Yellow = Gul, Blue = Blå.

För matningskablar gäller:

Black = Svart, Blue = Blå, Yellow/green = Gul/grön.

För fläktar som återställs genom att göra fläkten

spänningslös så måste detta beaktas vid inkoppling av

kringutrustning som bryter och kopplar in strömmen

automatiskt.

EC motorer har en läckström till jord på <=3,5 mA. Detta

ska beaktas vid installation tillsammans med jordfelsbrytare.

Inbyggd potentiometer

Den inbyggda potentiometern är förinställd från fabrik

(Fig. 1-9). Detta värde går att ändra manuellt för att få

annat rpm/luftflöde. Se fläktdiagram för detta ändamål i

tabellen på sid. 5-13 (Fig. 1-9) med inkluderade

spänningssteg till höger om potentiometersymbolerna. En

extern potentiometer kan anslutas till plint vid behov. Den

interna potentiometern skall då kopplas bort från plint.

Tacometerutgång (Tach output)

Plint nr. 1 i ovan anslutningssheman (vit signal kabel),

möjliggör inkoppling av varvräknare (en puls per rotation),

extern styrning, larm, eller varvtalsdisplay. Tacometern

sänker en signal med max 10mA.

Drift

Före idrifttagande kontrollera följande:

-Elektrisk anslutning är slutförd.

-Skyddsjorden ansluten.

-Säkerhetsutrustning monterad (beröringsskydd).

-Inga främmande föremål finns i fläkten.

Vid idrifttagande kontrollera följande:

Att uppmätta data ej överstiger på fläktens typskylt angivna

märkdata: Maximalt tillåten spänning +6%, -10 %, enligt IEC

38. Märkströmmen får ej överskridas med mer än 5 % vid

märkspänning.

-Att inga missljud hörs från fläkten.

-Fläktar i drift får endast handhas av person som har

kunskap eller utbildning för detta, eller att handhavande

sker under överinseende av sådan person.

Underhåll, service och reparation

Innan service, underhåll eller reparation påbörjas måste:

-Fläkten göras spänningslös (allpolig brytning).

-Fläkthjulet stannat.

-Gällande säkerhetsföreskrifter beaktats.

Fläkten ska rengöras vid behov, dock minst 1 gång/år för att

undvika obalans med onödiga lagerskador som följd. Med

ett filter monterat före fläkten kan rengöringsintervallet

förlängas. (Användande av andningsskydd vid byte av filter

rekommenderas). Fläktens lager är underhållsfria och ska

endast bytas vid behov. Vid rengöring av fläkten får

högtryckstvätt ej användas. Rengöring måste ske försiktigt

så att fläkthjulets balansvikter ej rubbas eller fläkthjulet

deformeras. Kontrollera att inga missljud hörs från fläkten.

Om fläkten har stannat gäller följande:

- Prova att återstarta genom att göra fläkten spänningslös

under några minuter.

- Kontrollera att fläkthjulet inte är blockerat. Ev. blockering

avlägsnas efter att strömmen brutits. Kontrollera att fläkten

startar när strömmen kopplas åter. Om fläkten efter kontroll

och/eller återställning inte startar, kontakta ert inköpsställe.

Dokument översatt från engelska

19

Page 20

DE

Konformitätserklärung

Hersteller

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg SCHWEDEN

Büro: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

bestätigt hiermit, dass die folgenden Produkte:

Rohrventilatoren mit Rundverbindung: K EC 160-315L, KVO EC 100-315, KD EC 315-500

Schallgedämmte Rohrventilatoren mit Rundverbindung: KVKE EC 125-315

Dachventilatoren mit Rund- oder rechteckiger Verbindung: TFSR EC/TFSK EC 160-200

(Die Erklärung gilt nur für diese Produkte, wenn sie in die Einrichtung geliefert und dort gemäß den

dazugehörigen Installationsanweisungen installiert wurden. Die Versicherung deckt keine Komponenten ab, die

hinzugefügt wurden, oder Handlungen, die nachfolgend am Produkt vorgenommen wurden.)

Mit allen geltenden Anforderungen der folgenden Richtlinien im Einklang stehen

Maschinenrichtlinie 2006/42/EG

Niederspannungsrichtlinie 2006/95/EG

EMV-Richtlinie 2004/108/EG

Die folgenden harmonisierten Normen gelten für die entsprechenden Teile:

EN ISO 12100-1 Sicherheit von Maschinen - Grundbegriffe, allgemeine Gestaltungsleitsätze - Teil 1

Grundsätzliche Terminologie, Methodologie

EN ISO 12100-2 Sicherheit von Maschinen - Grundbegriffe, allgemeine Gestaltungsleitsätze - Teil 2

Technische Leitsätze

EN 14121-1:2007 Sicherheit von Maschinen - Risikobeurteilung - Teil 1 Leitsätze

EN 13857 Sicherheit von Maschinen - Sicherheitsabstände gegen das Erreichen von

Gefährdungsbereichen mit den oberen oder unteren Gliedmaßen

EN 60.335-1 Elektrische Geräte für den Hausgebrauch und ähnliche Zwecke - Sicherheit Teil 1:

Allgemeine Anforderungen

EN 60.335-2-80 Elektrische Geräte für den Hausgebrauch und ähnliche Zwecke - Sicherheit - Teil 2-80:

Besondere Anforderungen für Ventilatoren

EN 50.366-1 Elektrische Geräte für den Hausgebrauch und ähnliche Zwecke - Elektromagnetische Felder

- Methoden für Auswertungen und zur Messung

EN 50 106:2007 Sicherheit elektrischer Geräte für den Hausgebrauch und ähnliche Zwecke - Besondere

Regeln für Stückprüfungen von Geräten im Anwendungsbereich der EN 60 335-1 und EN 60967

EN 60.034-5 Drehende elektrische Maschinen - Teil 5: Schutzarten aufgrund der Gesamtkonstruktion von

drehenden elektrischen Maschinen (IP Code)

EN 60.204-1 Sicherheit von Maschinen - Elektrische Ausrüstung von Maschinen - Teil 1: Allgemeine

Anforderungen

EN 60730-1 Automatische elektrische Regel- und Steuergeräte für den Hausgebrauch und ähnliche

Anwendungen - Teil 1: Allgemeine Anforderungen

EN 61000-6-2 Elektromagnetische Verträglichkeit (EMV) - Teil 6-2: Fachgrundnorm - Störfestigkeit für

Industriebereiche

EN 61000-6-3 Elektromagnetische Verträglichkeit (EMV) - Teil 6-3: Fachgrundnorm - Störaussendung

Fachgrundnorm für Wohnbereich, Geschäfts- und Gewerbebereich sowie Kleinbetriebe

Skinnskattberg 15.05.2012

Mats Sándor

Technischer Direktor

Aus dem Englischen übersetztes Dokument

20

Page 21

DE

Sicherheitshinweise

Diese Maschinen dürfen nur in Betrieb genommen werden,

wenn zuvor die Montage-, Betriebsanleitung und die

Sicherheitsvorschriften gelesen wurden. Alle Ventilatoren

sind zur Förderung von Luft in Lüftungssystemen geeignet.

Um Kondensation zu vermeiden sollten Ventilatoren die in

unbeheizten Räumen installiert sind, zusätzlich isoliert

werden. Der Betrieb der Ventilatoren ist erst nach erfolgtem

Einbau in Maschinen oder Kanalsysteme oder nach dem

Einbau eines Berührungsschutzgitters vorgesehen (EN ISO

13857). Ventilatoren mit Kanalanschluss müssen an beiden

Seiten (Zu-/Abluft) an die Kanäle angeschlossen werden. Um

das Eindringen von Wasser aus den Kanälen in den Motor zu

verhindern, ist eine außenliegende Schutzvorrichtung

notwendig. Nach dem Einbau sollten keine beweglichen Teile

mehr zugänglich sein. Die Ventilatoren dürfen nicht in

gefährlichen Bereichen betrieben und nicht an Flüssigkeit

leitende Kanäle angeschlossen werden. Die Ventilatoren

dürfen nicht im Freien angebracht werden (auser TFSR/TFSK

EC, K EC). Sicherheitszubehör (z.B. Schutzgitter) dürfen

nicht entfernt werden. ACHTUNG! Vor Wartungsarbeiten

muss die Stromzufuhr abgestellt werden (allpolige

Stromunterbrechung; Absicherung gegen unbeabsichtigtes

Wiedereinschalten). Das Laufrad muss beim Öffnen absolut

stillstehen, ansonsten besteht Verletzungsgefahr. ACHTUNG!

Die Ventilatoren können scharfe Kanten oder Ecken haben,

es besteht Verletzungsgefahr. ACHTUNG ! Die

Wartungstüren (bei aufklappbaren Ventilatoren) nur vorsichtig

öffnen, da das Motorlüfterrad, welches auf der Tür montiert

ist, sehr schwer sein kann. Der Ventilatormotor ist mit ein

Schutz für blockierten Rotor augerüstet. Der Motor versucht

mit einen vorprogrammierten Intervall den Rotor wieder

anzulaufen. Das widerholt sich biss die Blockierung entfernt

ist, danach startet der Motor von allein wider auf. Bei hohen

Temperaturen wird die Stromversorgung des motors

unterbrochen. Der Ventilator kann dan nur wieder gestartet

werden nachdem er ein paar Minuten spannungslos gemacht

wird.

Transport und Lagerung

Alle Ventilatoren sind werksseitig so verpackt, dass sie gegen

normale Transportbelastungen geschützt sind. Verwenden

Sie geeignetes Hebematerial beim Transport der Geräte, um

Schäden an Personen oder Material zu vermeiden.

Transportieren Sie die Geräte nicht am Anschlusskabel, am

Klemmkasten, am Laufrad oder an der Einströmdüse.

Vermeiden Sie Belastungen durch Schläge und Stöße.

Lagern Sie die Ventilatoren bis zur endgültigen Installation an

einem trockenen, wetter- und staubgeschützten Ort.

Zugelassene Lagerungstemperaturen: -40...+80°C.

Montage

Die oben genannten Sicherheitshinweise sind einzuhalten.

Die Montage und der elektrische Anschluß darf nur durch

autorisiertes Fachpersonal und in Übereinstimmung mit den

gültigen Vorschriften durchgeführt werden. Die

Elektroanschlüsse im Klemmenkasten sind gemäß dem

Schaltbild im Klemmenkasten, den Markierungen auf den

Kabeln oder den Klemmen vorzunehmen. ACHTUNG! Bitte

verwenden Sie bei Klemmkästen aus Kunststoff keine

Kabelverschraubungen aus Metall. Verwenden Sie auch für

die Kabeldurchführungen geeignete Gummitüllen. K-EC

Ventilatoren müssen mit dem Klemmkasten oben am Gerät ±

90 º angebracht werden. Werden für einen dauerhaften

Betrieb Kabel mit einem Durchmesser von 12 - 14 mm

verwendet, muss die Kabeldurchführung ausgetauscht

werden (dies gilt für Typ K-EC). Montieren Sie den Ventilator

in der richtigen Luftströmungsrichtung (siehe Pfeil auf dem

Gerät). Der Ventilator muss so eingebaut werden, dass keine

Vibrationen auf das Kanalsystem oder den Gehäuserahmen

übertragen werden können. (Passendes Zubehör wie z.B.

Verbindungsmanschetten ist verfügbar). Stellen Sie sicher,

dass der Ventilator fest und stabil eingebaut ist. Falls nichts

anderes angegeben ist, kann der Ventilator in jeder

Einbaulage montiert werden. Die Ventilatoren müssen so

eingebaut sein, dass eine Reparatur und Wartung problemlos

und sicher möglich ist. Störende Geräusche können durch

den Einbau von Schalldämpfern vermieden werden (als

Zubehör erhältlich).

Die angegebene Temperatur ist die Temperatur, bei der der

Ventilator dauerhaft betrieben werden kann. Ventilatoren die

durch Strohmunterbruch rückgestellt werden müssen in

Betracht gezogen werden, wenn Zubehör mit automatischer

AN/AUS Funktion angeschlossen wird.

EC Motoren haben en Leckstrom zu Erde entsprechend

<=3,5 mA. Dies soll bei Installation zusammen mit

Erdschlussrelais beachtet werden.

Internes Potentiometer

Der eingebauter Potentiometer ist Werksseitig eingestellt.

(Fig. 1-7). Der Wert kann manuell geändert werden um eine

Änderung der Drehzahl/Ventilatorleistung zu erreichen. In der

Tabelle auf Seite 5-13 (Fig. 1-7) sind Ventilatorkennlinien für

diesen Zweck mit eingezeichneten Spannungsstufen rechts

von den Potentiometersymbolen dargestellt.

Ein externes Potentiometer kann bei Bedarf angeschlossen

werden. Hierzu wird das interne Potentiometer von den

Klemmen abgeklemmt.

Tacho Ausgang (Tach Output)

Anschluß Nr. 1 im Schaltbild (weißes Signalkabel) erlaubt

einen Anschluß des Drehzahlimpuls (1 Impuls/Umdrehung)

an eine Drehzahlüberwachnung, Alarm oder

Drehzahlanzeige. Der Tacho senkt ein Signal mit max 10mA.

Betrieb

Überprüfen Sie folgendes vor der ersten Inbetriebnahme:

- wurde der elektrische Anschluss korrekt vorgenommen

- wurde der Schutzleiter angeschlossen

- befinden sich die Schutzeinrichtungen an entsprechender

Stelle

- wurde von der Installation übriggebliebenes Material oder

sonstige Fremdkörper vom Gehäuse entfernt

Bei Inbetriebnahme überprüfen Sie bitte:

Stimmen die Anschlussdaten mit den Angaben auf dem

Typenschild überein? Spannungstoleranzen sind gemäß IEC

38 mit maximal +6% oder -10% zulässig. Der Nennstrom

darf die Nennspannung nur um maximal 5 % übersteigen.

- Läuft der Motor ruhig? (keine ungewöhnlichen Geräusche)

- Die Inbetriebnahme der Ventilatoren darf nur von

ausgebildetem Fachpersonal erfolgen oder muss von diesem

beaufsichtigt werden.

Aus dem Englischen übersetztes Dokument

21

Page 22

DE

Wartung, Überprüfung und Reparatur

Vor Wartung, Überprüfung oder Reparatur ist sicherzustellen:

- Die Stromzufuhr ist unterbrochen (allpolig).

- das Laufrad ist komplett zum Stillstand gekommen

- die Sicherheitsvorschriften wurden eingehalten!

Um eine Unwucht der Lager zu vermeiden, sollte der

Ventilator wenn notwendig mindestens einmal jährlich

gereinigt werden. Ein Filter verlängert die

Reinigungsintervalle (Gegebenenfalls wird die Installation

einer Filterüberwachung empfohlen). Die Ventilatorlager sind

wartungsfrei und sollten nur im Schadensfall ausgetauscht

werden. Verwenden Sie keine Hochdruckreiniger

(Dampfstrahler) zum Reinigen des Ventilators. Versichern Sie

sich, dass die Wuchtgewichte des Ventilatorlaufrades sich

nicht verschoben haben, und dass das Laufrad nicht

verbogen ist. Achten Sie auf ungewöhnliche

Betriebsgeräusche.

Falls der Ventilator nicht läuft gilt folgendes:

- Versuch den Ventilator indem man die Stromzufuhr einige

Minuten unterbricht wider anzulaufen.

- Überprüfen Sie, ob das Laufrad blockiert ist. Ev. Blockierung

wird nachdem die Stromzurfuhr unterbrochen ist entfernt.

Kontrollieren Sie dass der Ventilator wieder anläuft

nachdem der Strohm wieder eingeschaltet ist. Nehmen Sie

Kontakt mit Ihrem Lieferanten auf, falls der Motor nach

Überprüfung und/oder Rückstellung nicht wieder anläuft.

Aus dem Englischen übersetztes Dokument

22

Page 23

DK

Overensstemmelseserklæring

Producent

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg Sverige

Kontor: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

Erklærer hermed, at følgende produkter:

Kanalventilatorer til cirkulær tilslutning: K EC 160–315L, KVO EC 100-315, KD EC 315-500

Isolerede kanalventilatorer til cirkulær tilslutning: KVKE EC 125-315

Tagventilatorer med cirkulær eller rektangulær tilslutning: TFSR EC/TFSK EC 160-200

(Erklæringen gælder kun for produktet i den stand, det blev leveret og installeret i anlægget iht. den

medfølgende installationsvejledning. Forsikringen dækker ikke eftermonterede dele eller efterfølgende indgreb i

produktet)

Alle gældende krav i følgende direktiver skal overholdes

Maskindirektivet 2006/42/EC

Lavspændingsdirektivet 2006/95/EC

EMC-direktivet 2004/108/EC

Følgende harmoniserede standarder anvendes i relevant omfang:

EN ISO 12100-1 Maskinsikkerhed – Grundlæggende begreber og generelle principper for udformning – Del 1:

Grundlæggende terminologi, metoder

EN ISO 12100-2 Maskinsikkerhed – Grundlæggende begreber og generelle principper for udformning – Del 2:

Tekniske principper

EN 14121-1:2007 Maskinsikkerhed – risikovurdering – Del 1: Principper

EN 13857 Maskinsikkerhed – Sikkerhedsafstande der forebygger, at fareområder er tilgængelige for

brugerens arme eller ben

EN 60 335-1 Husholdningsapprater og lignende elektriske apparater – Sikkerhed – Del 1: Generelle krav

EN 60 335-2-80 Husholdningsapprater og lignende elektriske apparater – Sikkerhed – Del 2-80: Særlige krav

for ventilatorer

EN 50.366-1 Husholdningsapparater og lignende elektriske apparater – Elektromagnetiske felter –

Metoder til evaluering og måling

EN 50.106:2007 Sikkerhed for husholdningsapparater og lignende – Særlige regler for rutinetest vedrørende

apparater, der er omfattet af EN 60 335-1 og EN 60967

EN 60.034-5 Roterende elektriske maskiner – Del 5: Beskyttelsesgrader ved det komplette design af

roterende elektriske maskiner (IP-kode)

EN 60.204-1 Maskinsikkerhed – Elektrisk udstyr på maskiner – Del 1: Generelle krav

EN 60730-1 Automatiske elektriske styringer til husholdningsbrug og lignende brug – Del 1: Generelle

krav

EN 61000-6-2 Elektromagnetisk kompatibilitet (EMC) – Del 6-2: Generiske standarder – Immunitetsstandard

for industrielle miljøer

EN 61000-6-3 Elektromagnetisk kompatibilitet (EMC) – Del 6-3: Generiske standarder –

Emissionsstandarder for bolig-, erhvervs- og lette industrimiljøer

Skinnskattberg 15-05-2012

Mats Sándor

Teknisk direktør

Dokument oversat fra engelsk

23

Page 24

DK

Sikkerhed

Monteringsanvisningerne og sikkerhedsforskrifterne skal læses, før

maskinen tages i drift.

Alle ventilatorerne er beregnet til transport af luft i

ventilationssystemer. Hvis ventilatorerne er installeret i uopvarmede

rum, skal de isoleres for at undgå kondensvand og fugt. De er

beregnet til at blive taget i brug, efter at de er indbygget i maskiner

eller kanaler, eller efter at de er forsynet med et beskyttelsesnet

(EN ISO 13857). Ventilatorer med flanger til kanaler skal have

monteret kanaler på både tilluft- og fraluftside. Når der er risiko for,

at der kan komme vand ind i motoren gennem kanalerne, skal der

monteres ventilationshætte eller ydervægsrist. Installationen skal

udføres, så berøring med bevægelige dele er umulig. Ventilatorerne

må ikke anvendes i eksplosive miljøer eller tilsluttes røggaskanaler.

Ventilatorerne må ikke installeres udendørs (undtagen TFSR/TFSK

EC, K EC). Sikkerhedsdetaljer, f.eks. motorbeskyttelse, må ikke

undlades, og beskyttelsesnet må ikke afmonteres. FORSIGTIG!

Inden service og vedligeholdelse påbegyndes, skal spændingen

være afbrudt og ventilatorhjulet stoppet. FORSIGTIG!

Ventilatorerne kan have skarpe kanter og hjørner, som kan

forårsage personskader. FORSIGTIG! Udvis forsigtighed ved

åbning af servicedøren på modeller, hvor ventilator og motor er

monteret i døren, fordi døren kan være relativ tung (gælder KVKE,

KVO).

Ventilatormotoren er forsynet med beskyttelse for blokeret

ventilatorhjul, så motoren vil forsøge at genstarte med et

foruddefineret interval, når den registrerer, at ventilatorhjulet er

standset. Når blokeringen er afhjulpet, starter ventilatoren

automatisk uden yderligere indgreb. Ved høje motortemperaturer

afbrydes strømmen til motoren. Den kan da kun genstartes ved

manuelt at afbryde strømforsyningen til ventilatoren et par minutter.

Transport og opbevaring

Samtlige ventilatorer er emballeret til at kunne klare almindelig

godshåndtering. Anvend en egnet løfteanordning ved håndteringen.

Løft ikke ventilatorerne i motorkabel, koblingsdåse, ventilatorhjul

eller indløbskonus. Undgå slag og stød. Ventilatorerne skal

opbevares tørt og vejrbeskyttet, samt beskyttet mod smuds og fugt

før endelig installation. Tilladt opbevaringstemperatur -40…+80 °C

Installation

Se afsnittet om sikkerhed ovenfor. Installation, elektrisk tilslutning

samt drifts-start skal udføres af en autoriseret installatør og skal

udføres i overensstemmelse med de for installationen gældende

regler og krav. Elektrisk tilslutning skal udføres ifølge eldiagrammet

i koblingsdåsen, mærkningen på klemrækken eller på kablet.

FORSIGTIG! Benyt ikke forskruninger af metal, hvis koblingsdåsen

er af plast. Luk eventuelt tomme forskruningshuller med blindplugs.

K-EC-ventilatoren skal monteres med klemmekassen oven på

ventilatorhuset i en vinkel på ± 90 grader. Hvis kablet fra den faste

installation har en diameter på 12-14 mm, skal forskruningen i

klemmekassen udskiftes (gælder for K-EC). Monter ventilatoren i

den korrekte luftretning (se luftretningspil). Ventilatoren skal

monteres sikkert og stabilt og på en sådan måde, at vibrationer ikke

overføres til kanalsystemet eller bygningskonstruktionen. For

vibrationsdæmpningen til kanaler findes montagebøjler og

flexforbindelser som tilbehør. Kontroller, at ventilatoren er monteret

sikkert og stabilt. Nogle ventilatortyper kan monteres valgfrit med

luftretning op, ned, vandret eller enhver anden retning. Ventilatoren

skal monteres, så service og vedligeholdelse kan udføres enkelt og

sikkert. Støjproblemer kan undgås ved brug af lyddæmpere, der fås

som tilbehør.

Ventilatorerne er beregnet for kontinuerlig drift inden for det angivne

temperaturområde.

Ventilatorer, som genstartes ved at afbryde spændingen, fordrer

øget opmærksomhed med, om ventilatoren stopper, fordi et

automatisk ur-anlæg i bygningen stopper ventilatoren automatisk,

eller om motoren bliver stoppet af termosikringen. Når

termosikringen er blevet aktiveret, er der en fejl, som skal

identificeres og rettes.

EC-motorer har lækstrøm til stel svarende til <=3,5 mA. Dette skal

der tages højde for, når ventilatoren forbindes med en

jordfejlsafbryder.

Integreret potentiometer

Det integrerede potentiometer er indstillet fra fabrikken (Fig. 1-9).

Denne værdi kan ændres manuelt for at opnå et andet

motoromdrejningstal eller en anden ventilatorydelse.

Ventilatorydelsesdiagrammer til dette formål inklusive

spændingstrin fremgår af tabellen på side 5-13 (Fig. 1-9) til højre

for potentiometersymbolerne. Et eksternt potentiometer kan

tilsluttes om nødvendigt. I givet fald skal det interne potentiometer

afbrydes fra tilslutningsklemmerne.

Udgang til omdrejningstæller

Klemme nr. 1 i eldiagrammerne (hvidt signalkabel) gør det muligt at

tilslutte en omdrejningstæller (én impuls pr. omdrejning), en

controller, en alarm eller et omdrejningstællerdisplay.

Omdrejningstælleren sender et signal med maks. 10 mA.

Drift

Kontroller følgende før driftsstart:

- Elektrisk tilslutning er udført forskriftsmæssigt.

- Jordforbindelse er monteret.

- Eventuelt beskyttelsesnet er monteret.

- Ingen uvedkommende ting befinder sig i ventilatoren.

Kontroller følgende ved ibrugtagning:

- At den målte optagne effekt ikke overstiger den effekt, der er

angivet på ventilatorens typeskilt: Tilladt maks. +6%, -10% ifølge

IEC 38. Mærkestrømmen må ikke overskrides med mere end 5%

ved en optimeret drift.

- At der ikke er mislyde fra motor eller hjul.

- Ventilatorerne må kun betjenes af personer, som har indgående

kendskab til eller uddannelse inden for dette fagområde. Hvis det

ikke er tilfældet, skal betjening udføres på grundlag af vejledning fra

en person med kendskab eller uddannelse inden for dette

fagområde.

Vedligeholdelse, service og reparation

Inden service, vedligeholdelse eller reparation påbegyndes skal:

- Spændingen være afbrudt på alle poler.

- Ventilatorhjulet være standset.

- Gældende sikkerhedskrav være opfyldt.

- Ventilatoren skal rengøres efter behov, dog mindst en gang om

året, for at undgå ubalance med unødvendige lejeskader som følge.

Et filter forlænger rengøringsintervallet. Nogle gange kan det

anbefales at installere en filtervagt. Ventilatorens lejer er

vedligeholdelsesfri og skal kun skiftes efter behov. Ved rengøring af

ventilatoren må højtryksspuling ikke anvendes. Rengøring skal ske

så forsigtigt at ventilatorhjulets balancevægte ikke forskubbes eller

hjulet får deformiteter. Kontroller, at der ikke kommer mislyde fra

ventilatoren.

Følgende gælder, i tilfælde af at ventilatoren er stoppet:

- Forsøg at genstarte ventilatoren ved at afbryde strømmen et par

minutter.

- Kontroller, at ventilatorhjulet ikke er blokeret. En eventuel

blokering er blevet afhjulpet, efter at strømmen er blevet afbrudt.

Kontroller, at ventilatoren starter, når strømmen er blevet slået til

igen. Hvis ventilatoren stadig ikke starter, skal du henvende dig

der, hvor du har købt den.

Dokument oversat fra engelsk

24

Page 25

ES

Declaración de Conformidad

Fabricante

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg SUECIA

Oficina: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

por el presente confirma que los siguientes productos:

Ventiladores de conducto con conexión circular: K EC 160-315L, KVO EC 100-315, KD EC 315-500

Ventiladores de conducto aislado con conexión circular: KVKE EC 125-315

Ventiladores de tejado con conexión circular o cuadrada: TFSR EC/TFSK EC 160-200

(La declaración únicamente será de aplicación a los productos entregados en la misma condición en la que se

entregaron e instalaron siguiendo las instrucciones de instalación incluidas. El seguro no cubre los componentes

añadidos o las acciones realizadas posteriormente sobre el producto).

Cumple con todos los requisitos aplicables según las siguientes directivas

Directiva de máquinas 2006/42/EC

Directiva de baja tensión 2006/95/EC

Directiva de compatibilidad electromagnética CEM 2004/108/EC

Las siguientes normas armonizadas son de aplicación a las partes correspondientes:

EN ISO 12100-1 Seguridad de las máquinas: Conceptos básicos, principios generales de diseño. Parte 1:

Terminología básica, metodología

EN ISO 12100-2 Seguridad de las máquinas: Conceptos básicos, principios generales de diseño. Parte 2:

Principios técnicos

EN 14121-1:2007 Seguridad de las máquinas: Evaluación de riesgos. Parte 1: Principios

EN 13857 Seguridad de las máquinas: Distancias de seguridad para prevenir el contacto de los

miembros superiores o inferiores con zonas peligrosas

EN 60 335-1 Electrodomésticos o dispositivos eléctricos similares: Seguridad. Parte 1: Requisitos

generales

EN 60 335-2-80 Electrodomésticos o dispositivos eléctricos similares: Seguridad. Parte 2-80: Requisitos

específicos para ventiladores

EN 50.366-1 Electrodomésticos o dispositivos eléctricos similares: Campos electromagnéticos. Métodos

para las evaluaciones y mediciones

EN 50 106:2007 Seguridad de electrodomésticos y dispositivos similares: Normas específicas para las

pruebas rutinarias referentes a los dispositivos bajo el marco de las normas EN 60 335-1 y

EN 60967

EN 60.034-5 Máquinas eléctricas rotativas. Parte 5: Grados de protección proporcionados por el diseño

integral de las máquinas eléctricas rotativas (Código IP)

EN 60.204-1 Seguridad de las máquinas: Equipamiento eléctrico de las máquinas. Parte 1: Requisitos

generales

EN 60730-1 Controles eléctricos automáticos para electrodomésticos o usos similares: Seguridad. Parte

1: Requisitos generales

EN 61000-6-2 Compatibilidad electromagnética (CEM). Parte 6-2: Normas genéticas. Inmunidad para

ambientes industriales.

EN 61000-6-3 Compatibilidad electromagnética (CEM). Parte 6-3: Normas genéricas. Normas de emisión

para ambientes residenciales, comerciales y de industria ligera

Skinnskattberg 15-05-2012

Mats Sándor

Documento traducido del inglés

25

Page 26

ES

Director técnico

Información de seguridad

Antes de poner en marcha la máquina, lea las instrucciones de

montaje y la información de seguridad.

Todos los ventiladores están diseñados para impulsar aire por las

unidades de tratamiento de aire. Si se instalan en estancias sin

calefacción, la carcasa debe cubrirse con aislamiento para evitar

que se forme condensación. Los ventiladores solamente deben

utilizarse una vez instalados en las máquinas o sistemas de

conductos o después de cubrirlos con rejillas de protección para

evitar el contacto (EN ISO 13857). Los ventiladores con conexiones

a conducto deben conectarse en ambos lados (entrada y salida).

Cuando existe el riesgo de que entre agua en el motor a través de

los conductos, es necesaria una protección exterior. Terminada la

instalación no habrá piezas móviles accesibles. Los ventiladores no

se deben utilizar en entornos peligrosos ni conectarse a

chimeneas. Tampoco se deben instalar en exteriores (salvo los

modelos TFSR/TFSK EC, K EC). Los accesorios de seguridad

(como las rejillas de seguridad) no se deben desmontar,

cortocircuitar ni desconectar. ¡ATENCIÓN! Antes de realizar tareas

de revisión o mantenimiento, desconecte la alimentación

(interruptor multipolar) y asegúrese de que el rodete esté

completamente parado. ¡ATENCIÓN! Los ventiladores pueden

tener bordes afilados que pueden provocar heridas. ¡ATENCIÓN!

Tenga cuidado al abrir las tapas de acceso para efectuar el

mantenimiento, ya que los ventiladores con el motor instalado en la

tapa son relativamente pesados (modelo KVKE, KVO).

El motor del ventilador tiene una protección de rodete bloqueado

integrada, lo que significa que el motor intenta arrancar en un plazo

de tiempo predefinido siempre que detecta que el rodete está

parado. Cuando se elimina el bloqueo, el ventilador arranca por sí

solo sin necesidad de otras medidas. Si la temperatura del motor

sube excesivamente, se interrumpe el suministro de corriente al

motor. La única forma de ponerlo otra vez en marcha es cortando

manualmente la alimentación al ventilador durante un par de

minutos.

Transporte y almacenamiento

Todos los ventiladores se empaquetan en la fábrica para que

soporten la manipulación normal durante el transporte. Al manipular

el material, utilice equipos de elevación adecuados con el fin de

evitar que los ventiladores o el personal sufran daños. No levante

los ventiladores sujetándolos por el cable de conexión, la caja de

conexión, el rodete o el cono de aspiración. Evite que la carga sufra

golpes y sacudidas. Almacene los ventiladores en lugar seco y

protegido de las inclemencias y de la suciedad hasta su instalación

final. El rango admisible de temperaturas de almacenamiento es de

-40 a +80°C.

Instalación

Consulte la información de seguridad anterior. La instalación,

conexión eléctrica y puesta en marcha sólo pueden ser llevadas a

cabo por personal autorizado y de acuerdo con los requisitos

correspondientes. La conexión eléctrica debe realizarse según el

esquema de la caja de bornas y el marcado de las regletas de

bornas o los cables. ¡ATENCIÓN! No utilice casquillos metálicos de

compresión con cajas de bornas de plástico. Utilice un tapón

aislante para el casquillo de compresión también. El ventilador KEC debe instalarse con la caja de conexiones en la parte superior

del equipo ± 90 grados. Si la instalación final se hace con cables de

12-14 mm de diámetro, habrá que cambiar la junta de entrada (sólo

modelo K-EC). Monte el ventilador en la dirección del flujo de aire

(compruebe la

instalarse de modo que las vibraciones no se transmitan a los

conductos o a la estructura del edificio (hay accesorios adecuados

para evitarlo, como abrazaderas (bridas) y difusores). Asegúrese

de que la fijación del ventilador sea firme y estable. El ventilador se

puede montar en cualquier posición, salvo que se indique otra

cosa. Los ventiladores se deben montar de tal modo que las

revisiones y el mantenimiento se puedan realizar de forma sencilla

y segura. Se pueden evitar ruidos molestos instalando un

silenciador (accesorio).

Los ventiladores están diseñados para uso continuo dentro del

rango de temperaturas indicado.

flecha que lleva el equipo). El ventilador debe

Algunos ventiladores se reinician apagando la alimentación, hecho

que es preciso tener en cuenta si se conectan equipos

complementarios con función de apagado/encendido automática.

Los motores EC tienen una corriente de fuga a tierra equivalente a

<=3,5 mA. Este dato debe tenerse en cuenta siempre que el

ventilador se conecte con un interruptor de falta a tierra.

Potenciómetro integrado

El potenciómetro integrado está ajustado de fábrica (fig. 1-7). El

valor se puede cambiar manualmente para obtener una relación

régimen del motor/rendimiento del ventilador diferente. Para facilitar

el ajuste, la tabla de la página 5-13 (fig. 1-7) muestra gráficas del

rendimiento del ventilador acompañadas de las etapas de tensión,

a la derecha de los símbolos de potenciómetro. El procedimiento

requiere desconectar el potenciómetro interno de las bornas de

conexión.

Salida para tacómetro

La borna 1 de los esquemas del cableado (cable de señal blanco)

permite conectar un tacómetro (un pulso por revolución),

controlador, alarma o visualizador de velocidades. El tacómetro

envía una señal de 10 mA como máximo.

Funcionamiento

Antes de la primera puesta en marcha, compruebe que:

- La conexión eléctrica esté adecuadamente terminada.

- El conductor de protección esté conectado.

- Los dispositivos de seguridad estén instalados (rejilla protectora).

- No queden materiales sobrantes de la instalación ni objetos

extraños dentro de la carcasa.

Al realizar la puesta en marcha, compruebe que:

- Los datos se conexión se correspondan con las especificaciones

de la placa de características: tensión máxima +6%, -10%, según

IEC 38. La intensidad nominal no debe sobrepasar en más del 5%

la tensión nominal.

- El motor funcione con suavidad (sin ruidos anormales).

- El manejo de los ventiladores esté a cargo de una persona con

los conocimientos o la formación debidos en la materia o de otra

bajo su supervisión directa.

Mantenimiento, revisiones y reparaciones

Antes de iniciar tareas de mantenimiento, revisión o reparación,

asegúrese de que:

- La alimentación esté desconectada (interruptor multipolar).

- Las palas del ventilador se hayan parado totalmente.

- Se respetan todas las normas de seguridad personal.

El ventilador debe limpiarse siempre que sea necesario y al menos

una vez al año para evitar desequilibrios y daños innecesarios en

los rodamientos. La instalación de un filtro prolonga los intervalos

de tiempo entre limpiezas del

instalar una rejilla con filtro). Los rodamientos del ventilador son sin

mantenimiento y solamente es preciso cambiarlos si se estropean.

No utilice un equipo de lavado a presión (chorro de vapor) para

limpiar el ventilador. Asegúrese de que los pesos de equilibrado de

las palas del ventilador no se desplacen ni las palas se deformen.

Preste atención por si se oyen ruidos anormales durante el

funcionamiento.

Si el ventilador se ha parado:

- Intente ponerlo de nuevo en marcha cortando la alimentación un

par de minutos.

- Compruebe que el rodete no esté bloqueado. Si hay alguna

obstrucción, corte la alimentación antes de quitarla. Compruebe

que el ventilador se ponga en marcha después de volver a

conectar la alimentación. Si sigue sin arrancar, póngase en

contacto con el establecimiento de compra.

ventilador (a veces es recomendable

Documento traducido del inglés

26

Page 27

EE

Vastavusdeklaratsioon

Tootja

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg ROOTSI

Kontor: +46 222 440 00 Faks: +46 222 440 99

www.systemair.com

Käesolevaga kinnitab tootja, et alljärgnevad tooted:

Ümartorude ühendusega kanaliventilaatorid: K EC 160-315L, KVO EC 100-315, KD EC 315-500

Ümartorude ühendusega isoleeritud kanaliventilaatorid: KVKE EC 125-315

Ümartorude või ruudukujulise ühendusega katuseventilaatorid: TFSR EC/TFSK EC 160-200

(Deklaratsioon kehtib ainult tootele seisukorras, milles see tarniti ja juhul, kui see paigaldati vastavalt komplektis

olnud paigaldusjuhendile. See ei laiene lisatud komponentidele või tegevustele, mis tootega hiljem tehakse)

Vastab järgmiste direktiivide kõigile kohalduvatele nõuetele

Masinadirektiiv 2006/42/EÜ

Madalpingedirektiiv 2006/95/EÜ

Elektromagnetilise ühilduvuse direktiiv 2004/108/EÜ

Kohalduvate osade puhul on järgitud järgmisi ühtlustatud standardeid:

EN ISO 12100-1 Masinaohutus – Põhimõisted, konstrueerimise üldpõhimõtted – Osa 1: Põhiterminoloogia,

metoodika

EN ISO 12100-2 Masinate ohutus – Põhimõisted, konstrueerimise üldpõhimõtted – Osa 2: Tehnilised

põhimõtted

EN 14121-1:2007 Masinate ohutus – Riskide hindamine – Osa 1: Põhimõtted

EN 13857 Masinaohutus – Ohutusvahemikud, mis väldivad käte ja jalgade sattumist ohtlikku alasse

EN 60 335-1 Majapidamis- ja muude taoliste elektriseadmete ohutus – Osa 1: Üldnõuded

EN 60 335-2-80 Majapidamis- ja muud taolised elektriseadmed – Ohutus – Osa 2-80: Erinõuded

ventilaatoritele

EN 50 366-1 Elektri rakendused majapidamises ja muudel taolistel juhtudel – Elektromagnetilised väljad –

Hindamis- ja mõõtmismeetodid

EN 50 106:2007 Elektriliste majapidamismasinate ja muude taoliste elektriseadmete ohutus – EN 60335-1 ja

EN 60967 käsitlusalasse kuuluvate seadmete kontrollkatsetuste erireeglid

EN 60 034-5 Pöörlevad elektrimasinad – Osa 5: Pöörlevate elektrimasinate konstruktsiooniga tagatud

kaitseastmed (IP-kood)

EN 60 204-1 Masinate ohutus – Masinate elektriseadmestik – Osa 1: Üldnõuded

EN 60730-1 Elektrilised automaatjuhtimisseadmed majapidamis- ja muuks taoliseks kasutuseks – Osa 1:

Üldnõuded

EN 61000-6-2 Elektromagnetiline ühilduvus – Osa 6-2: Erialased põhistandardid – Häiringukindlus

tööstuskeskkondades

EN 61000-6-3 Elektromagnetiline ühilduvus – Osa 6-3: Erialased põhistandardid – Olme-, kaubandus- ja

väiketööstuskeskkondade emissioonistandard

Skinnskattberg 15-05-2012

Mats Sándor

Tehnikadirektor

Dokument tõlgitud inglise keelest

27

Page 28

EE

Ohutusalane informatsioon

Enne seadme kasutuselevõttu lugege tingimata

paigaldusjuhendit ja ohutusnõudeid.

Kõik ventilaatorid on ette nähtud õhu transportimiseks

ventilatsioonisüsteemides. Kütteta ruumidesse paigaldamisel

tuleb ventilaatori korpus isoleerida, et vältida kondensatsiooni

teket. Ventilaatorid on ette nähtud kasutamiseks pärast nende

paigaldamist seadmetesse või kanalisüsteemidesse või pärast

kaitsevõre paigaldamist. (EN ISO 13857). Kanaliühendustega

ventilaatorid tuleb kanalitega ühendada mõlemalt küljelt

(sissevõtt/väljavool). Kui esineb oht, et vesi võib kanalite kaudu

mootorisse siseneda, tuleb kasutada välist kaitset. Pärast

paigaldamist ei tohi liikuvad osad jääda juurdepääsetavaks.

Ventilaatoreid ei tohi kasutada ohtlikes keskkonnatingimustes

ning neid ei tohi ühendada suitsukanalite ega gaasikäikudega.

Ventilaatoreid ei tohi paigaldada väliskeskkonda (v.a

TFSR/TFSK EC, K EC). Ohutusseadiseid (nt kaitsevõre) ei tohi

demonteerida, lühistada ega lahti ühendada. HOIATUS! Enne

hooldust või remonti lülitage seade vooluvõrgust välja (kõigi

pooluste kaitselüliti) ja kontrollige, et tiivik oleks täielikult

seiskunud. HOIATUS! Ventilaatoril on teravad servad ja nurgad,

mis võivad põhjustada kehavigastusi. HOIATUS! Olge

ettevaatlik, kui avate ventilaatorite hooldusluuke (väljapoole

kallutatavad), luugile monteeritud ventilaator ja mootor on

suhteliselt rasked (kehtib tüübi KVKE, KVO kohta).

Ventilaatori mootoril on sisseehitatud kaitse lukustatud rootori

jaoks, mis tähendab, et mootor üritab rootori seiskumise korral

eelprogrammeeritud intervalliga taaskäivituda. Blokeeringu

eemaldamisel käivitub ventilaator ise ilma täiendavate abinõude

kasutamise vajaduseta. Mootori kõrge temperatuuri korral

katkestatakse vooluühendus mootoriga. Seejärel saab mootori

taaskäivitada ainult ventilaatori käsitsi vooluvõrgust mõneks

minutiks lahti ühendamisel.

Transportimine ja ladustamine

Kõik ventilaatorid on tehases pakitud vastavalt normaalsetele

transportimistingimustele. Kasutage seadmete käsitsemisel

sobivat tõstevarustust, et vältida ventilaatorite kahjustamist ja

isikute vigastamist. Ärge kasutage ventilaatorite tõstmiseks

ühenduskaablit, ühenduskarpi, tiivikut ega sisselaske koonust.

Vältige lööke ja löökkoormusi. Ladustage ventilaatoreid kuni

lõpliku paigaldamiseni kuivas kohas, kaitstes neid

ilmastikumõjude ja mustuse eest. Lubatud

ladustamistemperatuur -40…+80°C.

Paigaldus

Lugege eespool antud ohutusalast informatsiooni. Paigaldamist,

elektrisüsteemiga ühendamist ja esmakäivitust peab teostama

ainult selleks volitatud vastava kvalifikatsiooniga personal

kooskõlas kehtivate normide ja nõuetega. Elektriühendused tuleb

teostada vastavalt klemmikarbis asuvale elektriskeemile ja

klemmiliistul või kaablil olevatele märgistele. HOIATUS! Ärge

kasutage metallist surveliitmikke ja tihendeid plastikust

klemmikarpide puhul. Kasutage surveliitmike asemel lihtsaid

korktihendeid. K-EC tüüpi ventilaator tuleb paigaldada koos

ühenduskarbiga seadme peal ± 90 kraadi. Kui statsionaarse

paigalduse teostamisel kasutatakse kaableid läbimõõduga 12–14

mm, tuleb sisenemisläbiviik välja vahetada (kehtib tüübi K-EC

kohta). Monteerige ventilaator õhuvoolu suunas (vaadake

seadmel olevat noolt). Ventilaator tuleb paigaldada nii, et

vibratsioon ei kanduks üle kanalisüsteemidele ega hoone

karkassile. (Saadaval on sobivad kiirühendusklambrid ja

difuusorid.) Kontrollige, et ventilaator oleks tugevasti kinnitatud ja

stabiilselt paigaldatud. Ventilaatori võib monteerida igas suunas,

kui ei ole ette nähtud teisiti. Ventilaatorid tuleb paigaldada nii, et

hooldust ja remonti oleks lihtne ja ohutu teostada. Häiriva müra

vältimiseks võib paigaldada spetsiaalse summuti (tarvik on

saadaval).

Ventilaatorid on ette nähtud pidevaks töötamiseks

kindlaksmääratud temperatuurivahemikus.

Ventilaatorite puhul, mille lähtestamine toimub vooluühenduse

katkestamise kaudu, tuleb seda arvestada, kui ühendate

ümbritsevaid seadmeid, mis on varustatud automaatse sisse/väljalülitamise funktsiooniga.

EC mootorite lekkevool maasse on <=3,5 mA. Seda tuleb

arvestada ventilaatori ühendamisel koos maaühendusvoolu

katkestiga.

Sisseehitatud potentsiomeeter

Sisseehitatud potentsiomeeter on tehases eelseadistatud

(Joonis 1-7). Määratud väärtust saab käsitsi reguleerida mootori

pöörete ja ventilaatori jõudluse muutmiseks. Ventilaatori

jõudlusdiagrammid koos pinge astmetega on toodud tabelis lk 513 (Joonis 1-7) potentsiomeetri sümbolitest paremal. Vajadusel

võib ühendada välise potentsiomeetri. Sel juhul tuleb sisemine

potentsiomeeter ühendusklemmidelt lahti ühendada.

Tahhomeetri võimsus

Klemm nr 1 elektriskeemidel (valge signaalkaabel) võimaldab

ühendada pöörete lugeja (üks impulss pöörde kohta), kontrolleri,

häire- või kiirusekraani. Tahhomeetri signaal max 10 mA.

Käitamine

Enne esimest käivitamist kontrollige järgmist:

- elektriühendused on teostatud nõuetekohaselt;

- kaitsejuht on ühendatud;

- kaitseseadised on õigesti paigaldatud (kaitsevõre);

- korpusest on eemaldatud paigaldamisel üle jäänud materjalid ja

muud kõrvalised esemed.

Käivitamisel kontrollige järgmist:

- elektriühenduste andmed vastavad seadme andmesildil

olevatele tehnilistele andmetele: maksimaalne pinge +6%, -10%

vastavalt IEC 38 nõuetele. Nimivoolu ei tohi ületada rohkem kui

5% nimivoolupingel;

- mootori töötamise sujuvus (puudub ebatavaline müra);

- ventilaatoritega võib töötada ainult vastavate teadmistega isik

ning ventilaatorite käitamine peab toimuma nimetatud isiku

järelevalve all.

Hooldus, teenindus ja remont

Enne hooldust, teenindust või remonti kontrollige järgmist:

- voolutoide on katkestatud (kõigi pooluste kaitselüliti);

- ventilaatori tiivik on täielikult seiskunud;

- järgige ohutuseeskirju.

Ventilaatorit peab vajadusel puhastama, vähemalt üks kord

aastas, et vältida tasakaalutust ja laagrite asjatut kahjustamist.

Filter pikendab ventilaatori puhastamiskordade vahelisi

ajavahemikke. (Mõnikord on soovitatav filtri kaitse paigaldamine).

Ventilaatori laagrid ei vaja hooldust ning kahjustuste esinemisel

tuleb need välja vahetada. Ärge kasutage ventilaatori

puhastamiseks kõrgsurvepuhastajat (aurujuga). Kontrollige, et

ventilaatori tiivik oleks tasakaalus ja et see ei oleks kõverdunud.

Kuulake, kas ei esine ebatavalist müra.

Ventilaatori seiskumisel toimige järgmiselt:

- proovige ventilaatorit taaskäivitada, katkestades mõneks

minutiks vooluühenduse;

- veenduge, et tiivik ei oleks blokeeritud. Võimalik takistus

kõrvaldatakse pärast vooluühenduse katkestamist. Veenduge,

et ventilaator käivituks pärast vooluühenduse taastamist. Kui

ventilaator ei käivitu, võtke ühendust oma seadme

müügikohaga.

Dokument tõlgitud inglise keelest

28

Page 29

FI

Vaatimustenmukaisuusvakuutus

Valmistaja

Systemair AB

Industrivägen 3

SE-73930 Skinnskatteberg RUOTSI

Puh. +46 222 440 00 Faksi: +46 222 440 99

www.systemair.com

vakuuttaa, että seuraavat tuotteet:

Kanavapuhaltimet pyöreällä liitännällä: K EC 160-315L, KVO EC 100-315, KD EC 315-500

Eristetyt kanavapuhaltimet pyöreällä liitännällä: KVKE EC 125-315

Huippuimurit pyöreällä tai nelikulmaisella liitännällä: TFSR EC/TFSK EC 160-200

(Tämä vakuutus koskee tuotetta siinä kunnossa, missä se on toimitettu ja asennettu laitteistoon

asennusohjeiden mukaisesti. Tämä vakuutus ei koske jälkikäteen asennettuja osia tai tuotteelle tehtyjä

toimenpiteitä)

täyttävät seuraavien EY-direktiivien kaikki sovellettavat vaatimukset

Konedirektiivi 2006/42/EY

Matalajännitedirektiivi 2006/95/EY.

EMC-direktiivi 2004/108/EY

Seuraavia yhdenmukaistettuja standardeja on käytetty:

EN ISO 12100-1 Koneturvallisuus. Perusteet ja yleiset suunnitteluperiaatteet. Osa 1: Peruskäsitteet ja

menetelmät

EN ISO 12100-2 Koneturvallisuus. Perusteet ja yleiset suunnitteluperiaatteet. Osa 2: Tekniset periaatteet

EN 14121-1:2007 Koneturvallisuus. Riskiarviointi. Osa 1: Periaatteet

EN 13857 Koneturvallisuus. Turvaetäisyydet yläraajojen ja alaraajojen ulottumisen estämiseksi

vaaravyöhykkeille

EN 60 335-1 Kotitaloussähkölaitteiden ja vastaavien turvallisuus. Osa 1: Yleiset vaatimukset

EN 60 335-2-80 Kotitaloussähkölaitteiden ja vastaavien turvallisuus. Osa 2-80: Erityisvaatimukset tuulettimille

EN 50 366-1 Kotitaloussähkölaitteiden ja vastaavien turvallisuus. Sähkömagneettiset kentät – Arviointi- ja

mittausmenetelmät.

EN 50 106:2007 Kotitaloussähkölaitteiden ja vastaavien turvallisuus - Erityisvaatimukset standardien EN

60 335-1 ja EN 60967 soveltamisalaan kuuluvien laitteiden kappaletesteille

EN 60 034-5 Pyörivät sähkökoneet - Osa 5: Pyörivien sähkökoneiden kotelointiluokat (IP-koodi) Luokittelu

EN 60 204-1 Koneturvallisuus - Koneiden sähkölaitteet. Osa 1: Yleiset vaatimukset

EN 60730-1 Kotitalouteen ja vastaavaan käyttöön tarkoitetut automaattiset sähköiset ohjauslaitteet. Osa

1: Yleiset vaatimukset

EN 61000-6-2 Sähkömagneettinen yhteensopivuus (EMC). Osa 6-2: Yleiset standardit – Häiriönsieto

teollisuusympäristöissä

EN 61000-6-3 Sähkömagneettinen yhteensopivuus (EMC). Osa 6-3: Yleiset standardit – Häiriönpäästöt

kotitalous-, toimisto- ja kevyen teollisuuden ympäristöissä

Skinnskattberg 15-05-2015

Mats Sándor

Tekninen johtaja

Englannin kielestä käännetty asiakirja

29

Page 30

FI

Turvallisuustiedot

Lue asennus- ja turvaohjeet huolella ennen puhaltimen

käyttöönottoa.

Kaikki puhaltimet on tarkoitettu ilman siirtämiseen

ilmankäsittelyjärjestelmissä. Jos puhallin asennetaan

lämmittämättömään tilaan, kotelo on eristettävä veden tiivistymisen

välttämiseksi. Puhaltimet on tarkoitettu käytettäväksi koneeseen tai