SystemAir IV Smart AC, IV Smart EC, IV Smart CO Installation And Operating Instructions Manual

Page 1

Jet fan — IV Smart AC, IV Smart EC, IV Smart EC CO

GB Installation and Operating Instructions ...........2 DE Montage- und Betriebsanleitung ................26

Document translated from English | 315802 · 002

Page 2

GB

Installation and Operating Instructions

© Copyright Systemair AB

All rights reserved

E&OE

Systemair AB reserves the rights to alter their products without notice.

This also applies to products already ordered, as long as it does not affect the previously agreed specifications.

GB

| 002

Page 3

Contents

1 General information ........... ..... ..... ........... ..... ....5

1.1 Notice symbols . ........... ..... ..... ........... .....5

1.1.1 Instruction symbols. ..... ........... ....5

2 Safety notes ... ..... ...... ..... ..... ..... ..... . ..... ..... ..... 5

2.1 Personnel ..... ........... ..... ..... ........... ..... ...6

2.2 Personal protective equipment. ..... . ..... ..... .6

2.3 5 rules of electrical safety ... ...... ..... ..... ..... 6

3 Warranty... ..... ........... ..... ..... ..... ...... ..... ..... ..... 6

4 Delivery, transport, storage ... ..... ..... ..... ........... ..6

4.1 Safety information....... ..... ........... ..... ..... .6

4.2 Delivery .......... ..... ..... ........... ..... ..... ......7

4.3 Transport... ..... ........... ..... ..... ...... ..... ..... .7

4.3.1 Safety information. ..... ........... ..... 7

4.4 Storage... ........... ..... ........... ..... ..... ........7

5 Description IV Smart..... ..... ..... ..... ..... . ..... ..... ..... 8

5.1 IV Smart EC equipped with an EC

motor . ..... ........... ..... ..... ........... ..... ..... ..8

5.2 IV Smart AC — equipped with an AC

motor . ..... ........... ..... ..... ........... ..... ..... ..8

5.3 IV Smart EC—CO — equipped with a

carbon monoxide control unit........ ..... ..... ..8

5.3.1 Carbon monoxide control

unit . ..... ...... ..... ..... ..... ..... . ..... ...8

5.3.2 Information on the effects of

CO on humans .... ..... ..... ..... ...... ..8

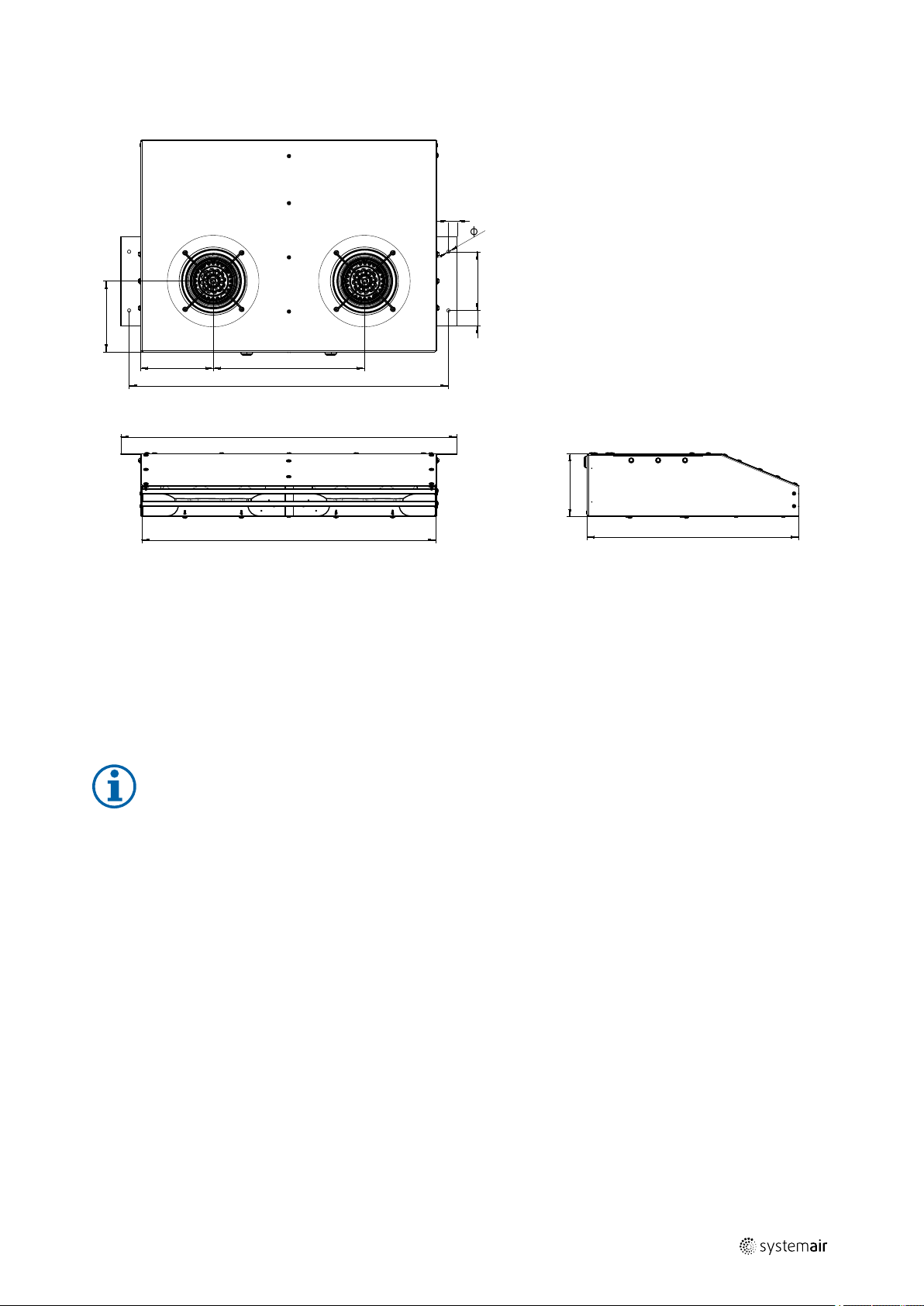

5.4 Dimensions... ..... ..... ........... ..... ..... .........9

5.5 Technical data of the fan... ..... ...... ..... ..... ..9

5.6 Technical data of the controller.......... ..... . 10

5.7 Motor data ... ..... ..... ..... ...... ..... ..... ..... .. 10

5.8 Intended use of all IV Smart

versions ...... ..... ..... ...... ..... ..... ..... ...... .. 10

5.9 Incorrect use . ..... ..... ..... ...... ..... ..... ..... .. 10

5.10 Terminal boxes ..... ..... ...... ..... ..... ..... ..... 10

6 Name plate and type key ... ...... ..... ..... ..... ...... .. 11

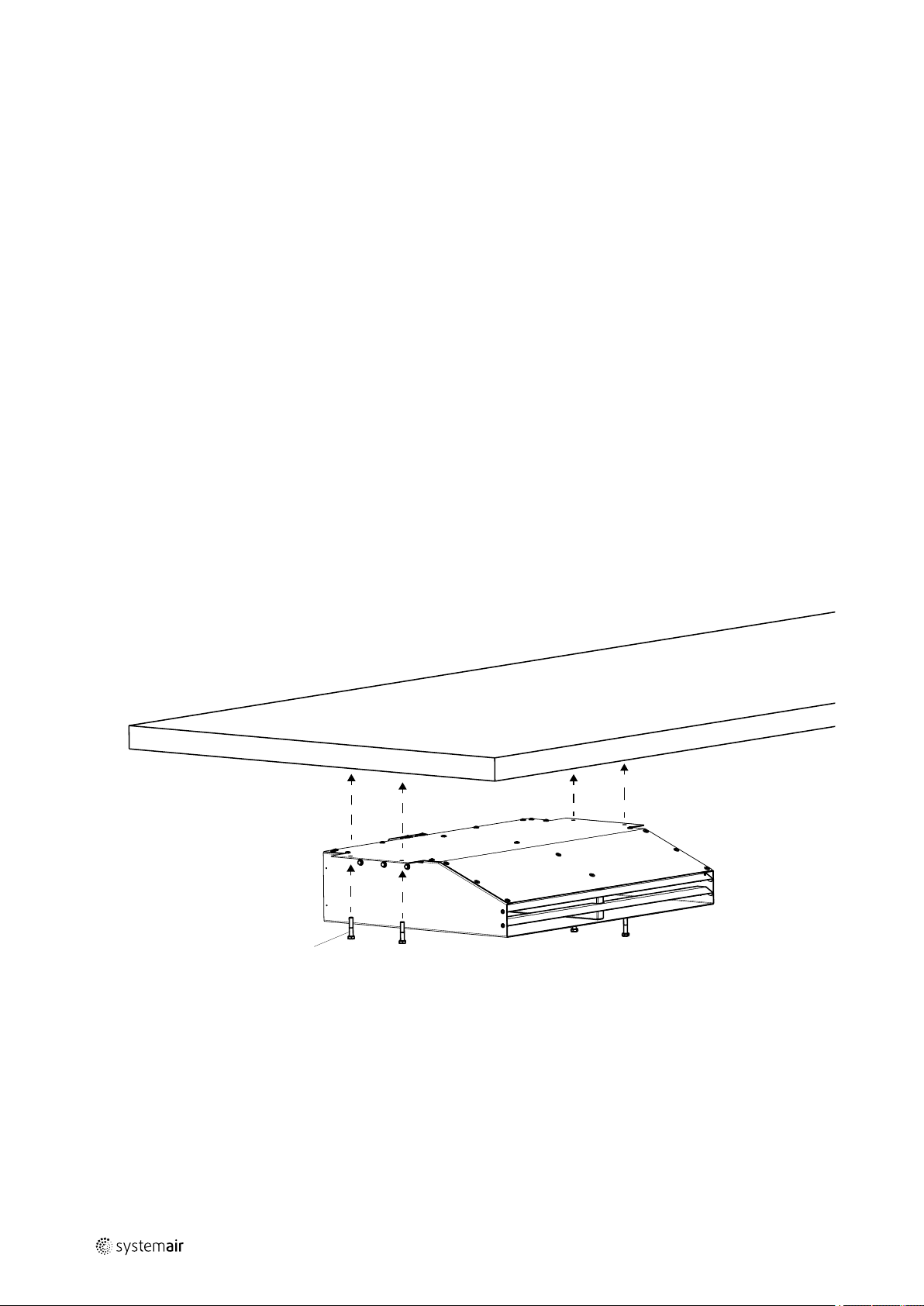

7 Installation.. ..... ..... . ..... ..... ..... ..... ...... ..... ..... .. 12

7.1 Preconditions ..... ..... . ..... ..... ..... ..... ...... . 12

7.2 Installation on the ceiling ... ...... ..... ..... .... 12

8 Electrical connection ... ........... ..... ..... ........... ... 13

8.1 Safety information /

Preconditions ..... ..... . ..... ..... ..... ..... ...... . 13

8.2 Preconditions ..... ..... . ..... ..... ..... ..... ...... . 13

8.3 Connection . ..... . ..... ..... ..... ..... ...... ..... ... 13

8.3.1 Wiring diagram IV Smart

AC .... ..... ........... ..... ..... ..........13

8.3.2 Wiring diagram IV Smart

EC.... ..... ..... ..... ...... ..... ..... ..... . 14

8.3.3 Wiring IV Smart EC-CO .......... ..... 15

8.4 Protective grounding wire . ........... ..... ..... 16

8.5 Residual current circuit breaker...... ..... ..... 16

8.6 Protecting the motor... ..... ..... ........... ..... 16

9 Commissioning .... ...... ..... ..... ..... ...... ..... ..... .... 16

9.1 Safety information.. ..... ..... ........... ..... ....16

9.2 Preconditions ..... ..... . ..... ..... ..... ..... ...... . 16

9.3 Commissioning Report.. ..... ........... ..... ....17

9.4 Tests before activation .... ..... ..... ..... . ..... . 17

9.5 Tests (AC motor)..... ..... ..... ..... ........... ... 17

9.6 Tests (EC motor) ... ........... ..... ..... ..... .....17

9.7 Tests when activated EC CO

version ... ..... ..... ...... ..... ..... ..... ...... ..... . 17

9.7.1 Function test ..... ..... ..... ..... ...... . 17

9.7.2 Warm-up time . ........... ..... ..... ... 18

9.7.3 Visual and audible

display... ...... ..... ..... ........... ..... 18

10 Operation ... ..... ..... ........... ..... ..... ...... ..... ..... .. 18

10.1 Safety information.. ..... ..... ........... ..... ....18

10.2 Preconditions ..... ..... . ..... ..... ..... ..... ...... . 18

11 Troubleshooting/maintenance/repair/CO

alarm..... ..... ..... ..... ........... ..... ..... ........... ..... . 19

11.1 Safety information.. ..... ..... ........... ..... ....19

11.2 Troubleshooting Fan ..... ..... ...... ..... ..... ... 19

11.3 Alarm and fault handling Carbon

monoxide control unit ... ..... ..... ........... ... 19

11.3.1 Thresholds for fault

displays... ........... ..... ..... ..... .....20

11.3.2 Potential-free alarm

contact .. ...... ..... ..... ........... ..... 20

11.3.3 Behaviour in the event of a CO

alarm and fault handling . ..... ...... 20

11.4 Maintenance.... ........... ..... ..... ..... ...... ... 20

11.5 Spare parts ... ..... ..... . ..... ..... ..... ..... . ..... . 21

12 Cleaning... ..... ........... ..... ..... ..... . ..... ..... ..... .... 21

| 002

Page 4

Contents GB

12.1 Safety information....... ..... ........... ..... ....21

12.2 Procedure..... ..... ..... ........... ..... ..... ....... 21

13 Deinstallation/dismantling. ..... ........... ..... ..... .... 22

14 Disposal .... ...... ..... ..... ..... ...... ..... ..... ........... .. 22

15 EU Declaration of conformity. ........... ..... ..... ...... 23

16 Commissioning Report.. ..... ...... ..... ..... ..... ...... .. 24

| 002

Page 5

GB

1 General information

1.1 Notice symbols

Danger

Direct hazard

Failure to comply with this warning will lead directly to death or to serious injury.

Warning

Potential hazard

Failure to comply with this warning may lead to death or serious injury.

Caution

Hazard with a low risk

Failure to comply with this warning may lead to moderate injuries.

Important

Hazard with risk of damage to objects

Failure to comply with this warning will lead to damage to objects.

General information |

5

Note:

Useful information and instructions

1.1.1 Instruction symbols

Instruction

♦ Carry out this action

♦ (if applicable, further actions)

Instruction with xed sequence

1. Carry out this action

2. Carry out this action

3. (if applicable, further actions)

2 Safety notes

Planners, plant builders and operators are responsible for the proper assembly and intended use.

♦ Read the operating instructions completely and carefully.

♦ Keep the operating instructions and other valid documents, such as the circuit diagram or motor instructions, with

the fan. They must always be available at the place of use.

♦ Observe and respect local conditions, regulations and laws.

♦ Only use the fan in a awless condition.

♦ Provide generally prescribed electrical and mechanical protective devices.

♦ During installation, electrical connection, commissioning, troubleshooting, and maintenance, secure the location and

premises against unauthorised access.

♦ Do not circumvent any safety components or put them out of action.

♦ Keep all the warning signs on the fan complete and in a legible condition.

♦ The device is not to be used by persons (including children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given supervision or instruction.

♦ Do not allow children to play with the device.

| 002

Page 6

Warranty GB

|

6

2.1 Personnel

The fan may only be used by qualified, instructed and trained personnel. The persons must know the relevant safety directives in order to recognise and to avoid risks. The individual activities and qualifications can be found in Table 1 Qual-

ifications, page 6.

Table 1 Qualifications

Activities

Storage, operation,

transport, cleaning,

disposal

Electrical connection,

commissioning, electrical

disconnection

Installation, disassembly

Maintenance

Repair

Electrical expert or

matching qualification

X

X X

Smoke extraction fans and EX fans only by agreement with Systemair.

Fitter or matching

qualification

Note:

The operator is responsible for ensuring that personnel are instructed and have understood the contents of

the operating instructions. If something is unclear, please contact Systemair or its representative.

2.2 Personal protective equipment

Wear protective equipment during all work in the vicinity of the fan.

• protective working clothes

• protective working shoes

• protective working gloves

• helmet

Trained personnel (see

following note)

X

X

• goggles

• hearing protection

2.3 5 rules of electrical safety

• Disconnect (disconnection of the electrical system from live components at all terminals)

• Prevent reactivation

• Test absence of voltage

• Ground and short-circuit

• Cover or restrict adjacent live parts

3 Warranty

The warranty for our products is determined by the contractual stipulations, our offers and our Terms and Conditions.

Warranty claims presuppose that the product is properly connected, operated according to data sheets and serviced as

needed. A correct commissioning report must also be presented upon request. Please find the commissioning report attached to this document.

4 Delivery, transport, storage

4.1 Safety information

Warning: Risk from rotating fan blades

♦ Prevent access by unauthorised persons by safety personnel or access protection.

Warning: Suspended loads

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 6.

♦ Do not walk under suspended loads.

| 002

Page 7

GB

♦ Make sure that there is nobody under a suspended load.

Delivery, transport, storage |

4.2 Delivery

Each fan leaves our plant in an electrically and mechanically proper condition. We recommend transporting the fan to

the installation site in the original packaging.

Checking delivery

♦ Check the packaging and the fan for transport damage. Any findings should be noted on the cargo manifest.

♦ Check completeness of the delivery.

Unpacking

Warning

When opening the transport packaging, there is a risk of damage from sharp edges, nails, staples,

splinters etc.

♦ Unpack the fan carefully.

♦ Check the fan for obvious transport damage.

♦ Only remove the packaging shortly before assembly.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective

equipment, page 6.

7

4.3 Transport

4.3.1 Safety information

Warning: Electrical or mechanical hazards due to fire, moisture, short circuit or malfunction.

♦ Never transport the fan by the connecting wire, terminal box, rotor, protection grille, inlet cone or silencer.

♦ In open transport, please make sure that no water can penetrate into the motor or other sensitive parts.

♦ We recommend transporting the fan to the installation site in the original packaging.

Caution: If transported without care during loading and unloading, the fan may be damaged.

♦ Load and unload the fan carefully.

♦ Use hoisting equipment that is suitable for the weight to be hoisted.

♦ Observe the transportation arrows on the packaging.

♦ Use the fan packaging exclusively as transport protection and not as a lifting aid.

4.4 Storage

♦ Store the fan in the original packaging in a dry, dust-free location protected against weather.

♦ Avoid the effects of extreme heat or cold.

Important

Hazard due to loss of function of the motor bearing

♦ Avoid storing for too long (recommendation: max. 1 year).

♦ Turn the rotor manually every three months, wear safety gloves when doing this.

♦ Check that the motor bearing functions properly before installation.

| 002

Page 8

Description IV Smart GB

|

8

5 Description IV Smart

5.1 IV Smart EC equipped with an EC motor

The fans are driven by two EC motors. These motors are delivered with a pre-wired potentiometer (0–10 V) that allows

you to easily find the required working point of the fan. All motors are suitable for 50/60 Hz. The input voltage for single-phase units can vary between 200 and 277 V.

5.2 IV Smart AC — equipped with an AC motor

The fans are driven by two AC motors. All motors are suitable for 50/60 Hz.

5.3 IV Smart EC—CO — equipped with a carbon monoxide control unit

The fans are driven by two EC motors (see 5.1 IV Smart EC equipped with an EC motor, page 8). The fan and the control

unit are pre—wired and ready for use.

5.3.1 Carbon monoxide control unit

The CO control unit controls two EC fans with a 0–10 V control signal originating from a CO sensor. Both fans are controlled with the same 0–10 V signal and monitored for fan failure. The CO alarm is triggered based on the threshold and

time specifications of DIN EN 50291-1.

5.3.2 Information on the effects of CO on humans

Warning

This CO control unit is designed to protect people from the acute effects of carbon monoxide. It cannot

prevent the chronic effects of carbon monoxide exposure. The CO control unit can not fully protect people at

special risk, such as those with particular medical conditions. In cases of doubt, consult a doctor.

The table below sets out the symptoms, the corresponding CO concentrations and lengths of time that a person needs

to be exposed to this concentration until symptoms occur.

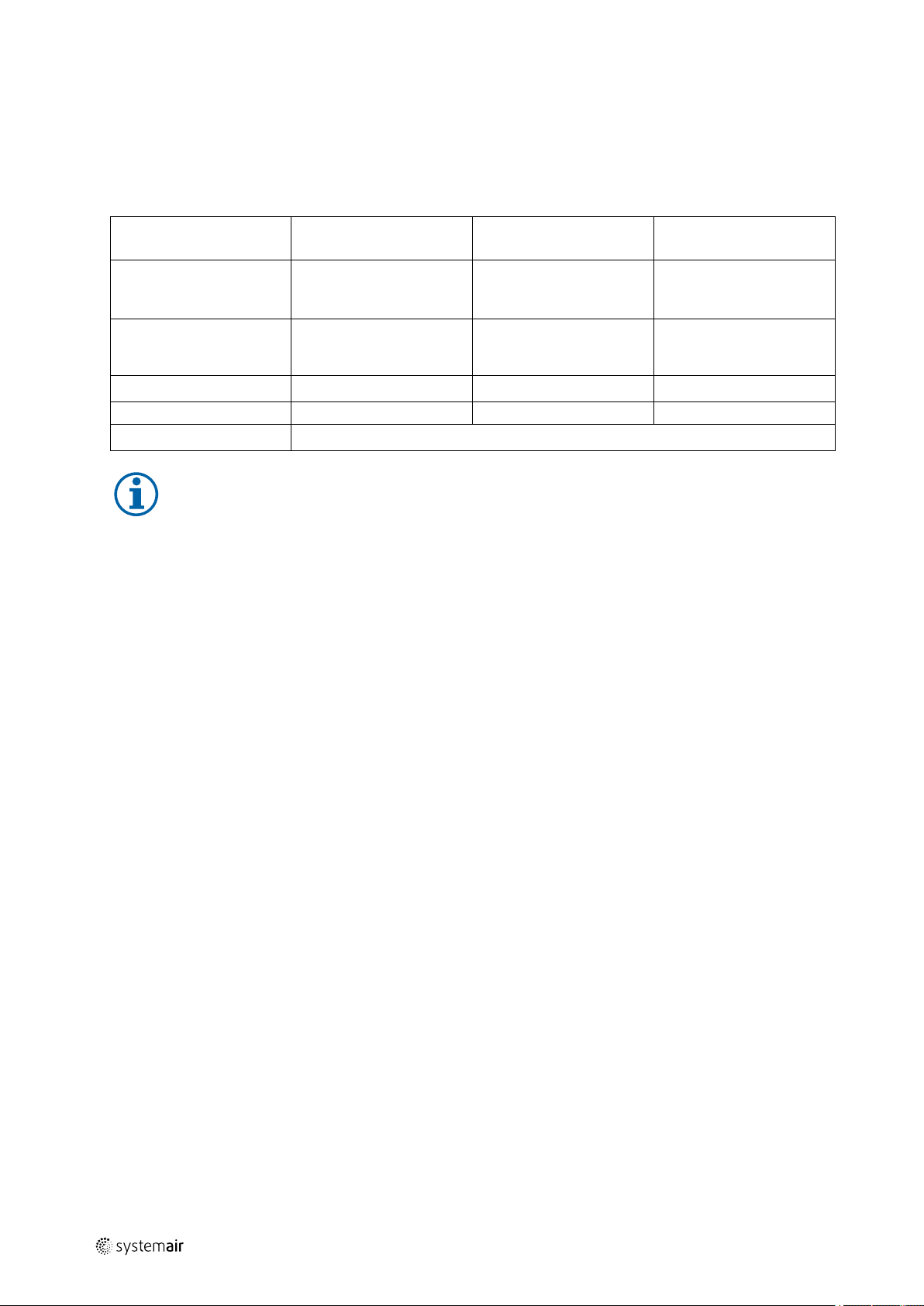

Table 2 Influence of carbon monoxide on the human body

CO concentration

30 ppm

100 ppm

200 ppm

300 ppm

400 ppm

800 ppm

1600 ppm

3200 ppm

8000 ppm

Symptoms

Maximum workplace concentration for 8 hours of

work, no symptoms

Even after a prolonged period, no symptoms

Headache 2…3 h

Mild headache, dizziness, weakness, nausea 2…3 h

Frontal headache

Life-threatening

Headache, dizziness, nausea, convulsions Within 45 min

Headache, dizziness and nausea

Loss of consciousness

Possible death

Headache, dizziness and nausea

Death

Death A few minutes

Time until occurrence of symptoms

-

-

1…2 h

3 h

Within 20 min

Within 2 h

Within 1 h

Within 5…10 min

Within 25…30 min

| 002

Page 9

GB Description IV Smart

169

760

36 140

150

800

700

8

503

173 360

20

5.4 Dimensions

|

9

Fig. 1 Dimensions IV Smart

5.5 Technical data of the fan

• IV Smart AC: Temperature range [°C] of transported air = -25 to 55

• IV Smart EC: Temperature range [°C] of transported air = -25 to 55

• IV Smart EC CO: Temperature range [°C] of transported air = -20 to 40

• Voltage/current/enclosure class/weight/impeller diameter = see name plate

• Sound pressure [dB(A)] = see data sheet

Note:

Further technical data can be found on the data sheet of your fan.

| 002

Page 10

Description IV Smart GB

|

10

5.6 Technical data of the controller

Voltage = 100…240 VAC

Frequency = 50…60 Hz

Table 3 CO control unit components

Component

Fan

CO sensor

External alarm device (optional)

Function

Two fans with a 0-10 V control input and hall output, for ventilation of the

room being monitored.

CO sensor with 4…20 mA measuring signal output that reflects a 0…300

ppm CO concentration.

Connection of an alarm siren or alarm light

5.7 Motor data

The motor data can be found on the name plate of the motor, or in the technical documents of the motor

manufacturer.

5.8 Intended use of all IV Smart versions

• The fans are intended for installation in underground and above-ground parking structures, to facilitate ventilation

and cold smoke extraction.

• For optimum operation, the jet fan must be suspended horizontally from the ceiling in such a position that intake and

outlet are unobstructed.

• The maximum admissible operating data on the name plate apply to an air density of 1.2 kg/3³ (sea level) and a

maximum air humidity of 80%.

• The fan is suitable for conveying clean air, with a density of 1.3 kg/m3 and a max. air humidity of 95%.

5.9 Incorrect use

Incorrect use refers mainly to using the fan in another way to that described. The following uses are incorrect and

hazardous:

• Conveying of explosive and combustible media

• Conveying of aggressive media

• Installation outside

• Operation in an explosive atmosphere

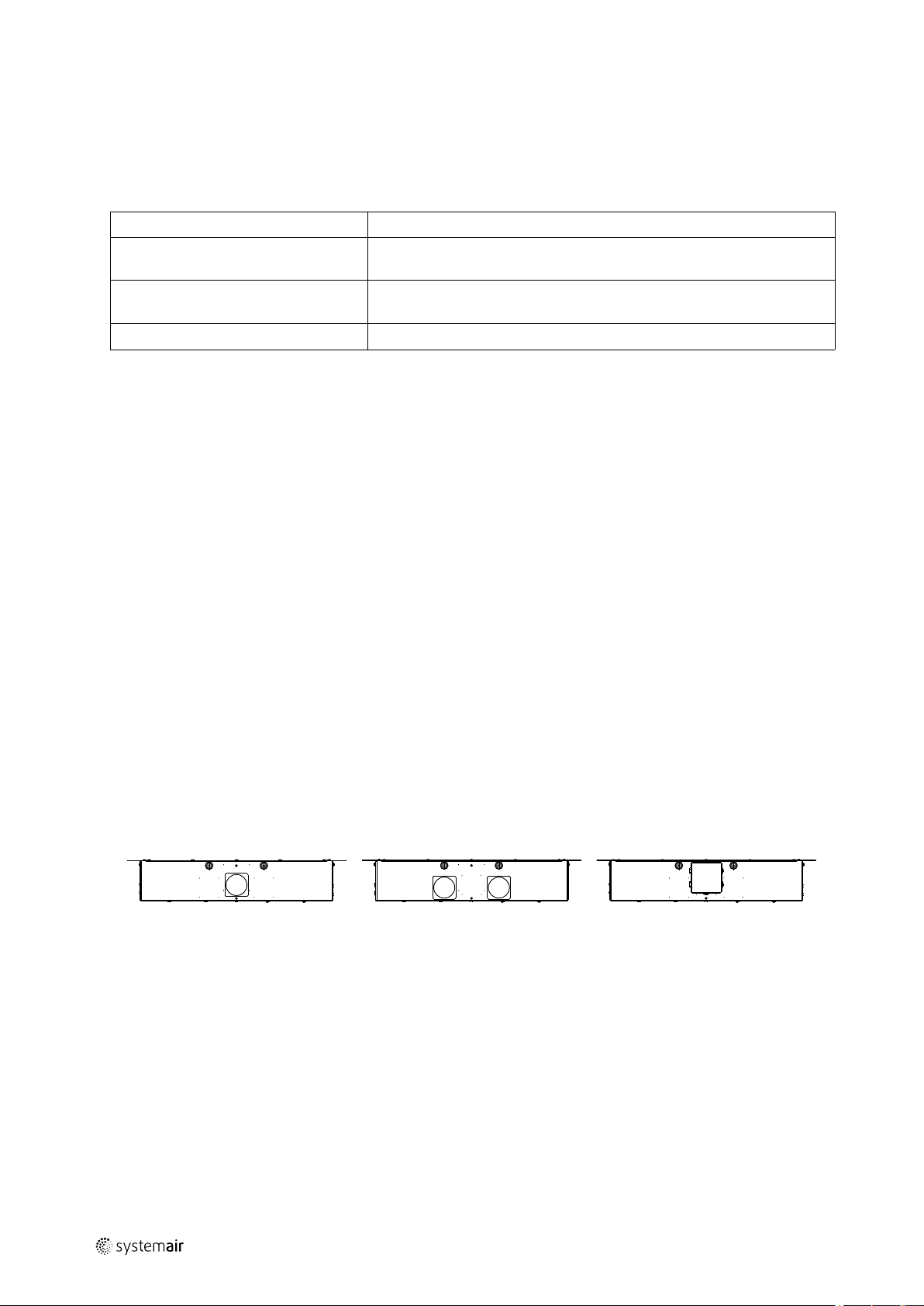

5.10 Terminal boxes

IV Smart AC IV Smart EC IV Smart CO

| 002

Page 11

GB

Serial.no: 84543/1002773290-001/20170131

IV Smart EC

230 V~

50 Hz

IP54

䰊

2510 min ¹

17kg

0,35 kW

Made in GER MANY

INS.CL.B

2,6 A

www.systemair.com

1

2

3

4

5

6

7

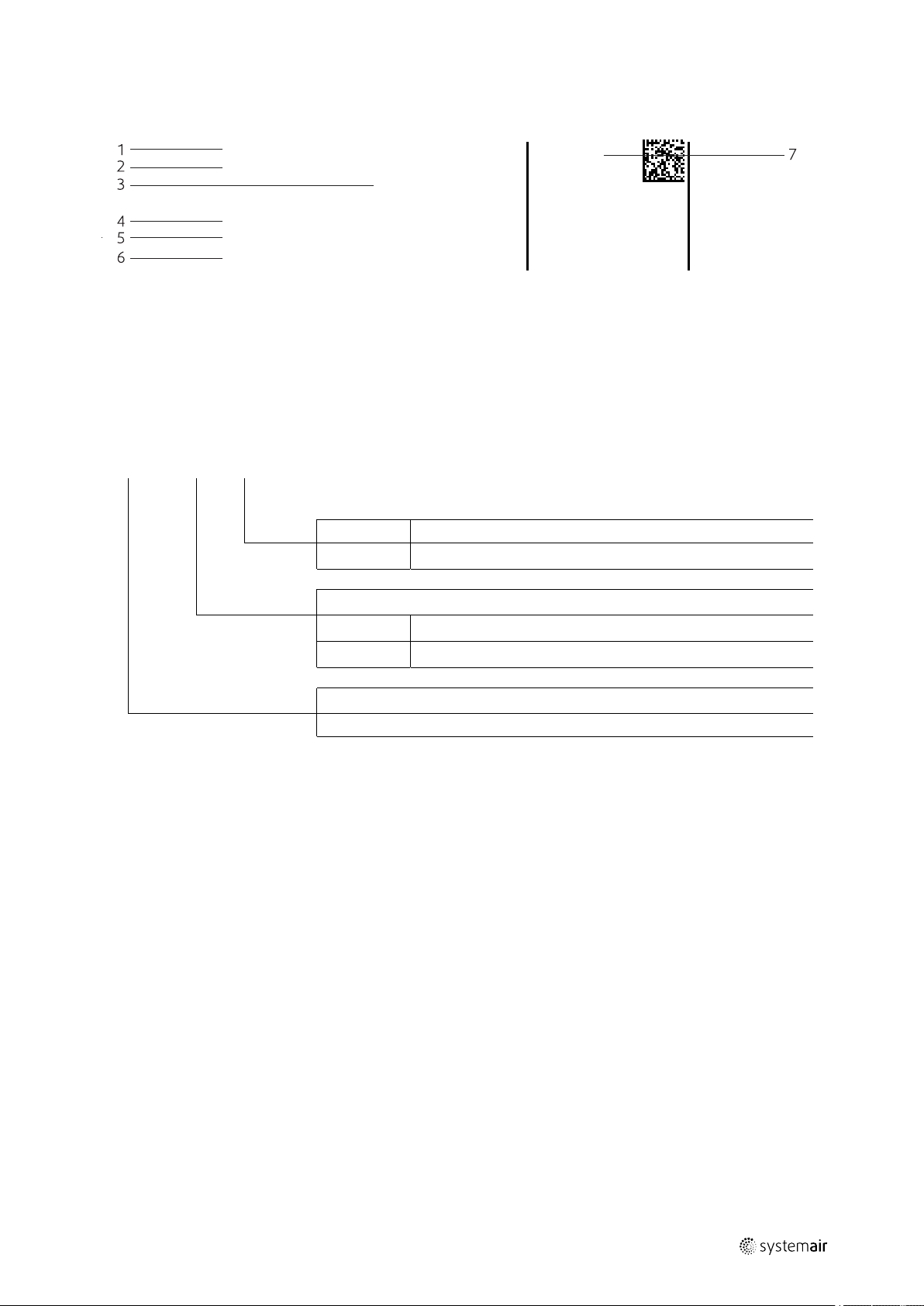

6 Name plate and type key

Name plate and type key |

11

1

Type designation

2

Voltage/current/frequency

3 Input power 7

4

Enclosure class/fan impeller speed/

weight

Table 4 Type key

IV Smart EC

-

-

CO

EC

AC

Induction fan Smart

5

Insulation class

6

Article number/production number/manufacturing date

Certifications

No controller

Equipped with a carbon monoxide control unit

Motor type

Electronically commutated/1 phased

2 poled/voltage controllable/1 phased

Fan type

| 002

Page 12

| Installation

4x

12

7 Installation

Warning: Danger from falling fan or fan parts.

♦ Check the surface before installation for load bearing capacity.

♦ Consider all static and dynamic loads when selecting hoisting equipment and fastening components.

General safety information

♦ Installation may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page 6.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 6.

♦ Abide by the system-related conditions and requirements of the system manufacturer or plant constructor.

♦ Do not dismantle or circumvent safety elements, or put them out of function.

♦ Provide contact and intake protection and ensure safety distances according to DIN EN ISO13857 and DIN 24167-1.

♦ Prevent the possibility of foreign bodies being drawn in.

7.1 Preconditions

♦ Ensure that the fan and all its components are undamaged.

♦ Ensure that the information on the name plates (fan and motor) matches up with the operating conditions.

♦ Ensure that there is enough space to install the fan.

♦ Protect against dust and moisture when installing.

♦ Fit the fans in such a way that there is sufficient access for troubleshooting, maintenance and repair.

GB

7.2 Installation on the ceiling

Installation IV Smart

| 002

Page 13

GB

Electrical connection |

8 Electrical connection

8.1 Safety information / Preconditions

Warning: Danger from electrical voltage!

♦ Observe the 5 rules of electrical safety, see 2.3 5 rules of electrical safety, page 6.

♦ Prevent the ingress of water into the connection box.

♦ Electrical connection may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page

6.

♦ Observe and respect local conditions, regulations and laws.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 6.

8.2 Preconditions

♦ Abide by the system-related conditions and requirements of the system manufacturer or plant constructor.

♦ Safety elements may not be dismantled, circumvented or deactivated.

♦ Install a circuit breaker in the permanent electrical installation, with a contact opening of at least 3 mm at each pole.

8.3 Connection

13

♦ Check if the data on the nameplate matches the connection data.

♦ Complete the electrical connection according to the circuit diagram.

♦ Lay the connection cables in the terminal box in such a way that allows the cover of the terminal box to be closed

without resistance.

♦ Use all of the locking screws.

♦ Insert the screws by hand to avoid damaging the thread.

♦ Tighten all glands well in order to guarantee protection class IP.

♦ Screw the lid of the terminal box/inspection switch evenly tight.

♦ Connect the cable end in a dry environment.

8.3.1 Wiring diagram IV Smart AC

Color

Black

Blue

Green/Yellow

L

N

PE

Function/pin assignment

Power supply 230 V AC, 50...60 Hz

Neutral conductor

Protective conductor

| 002

Page 14

| Electrical connection

14

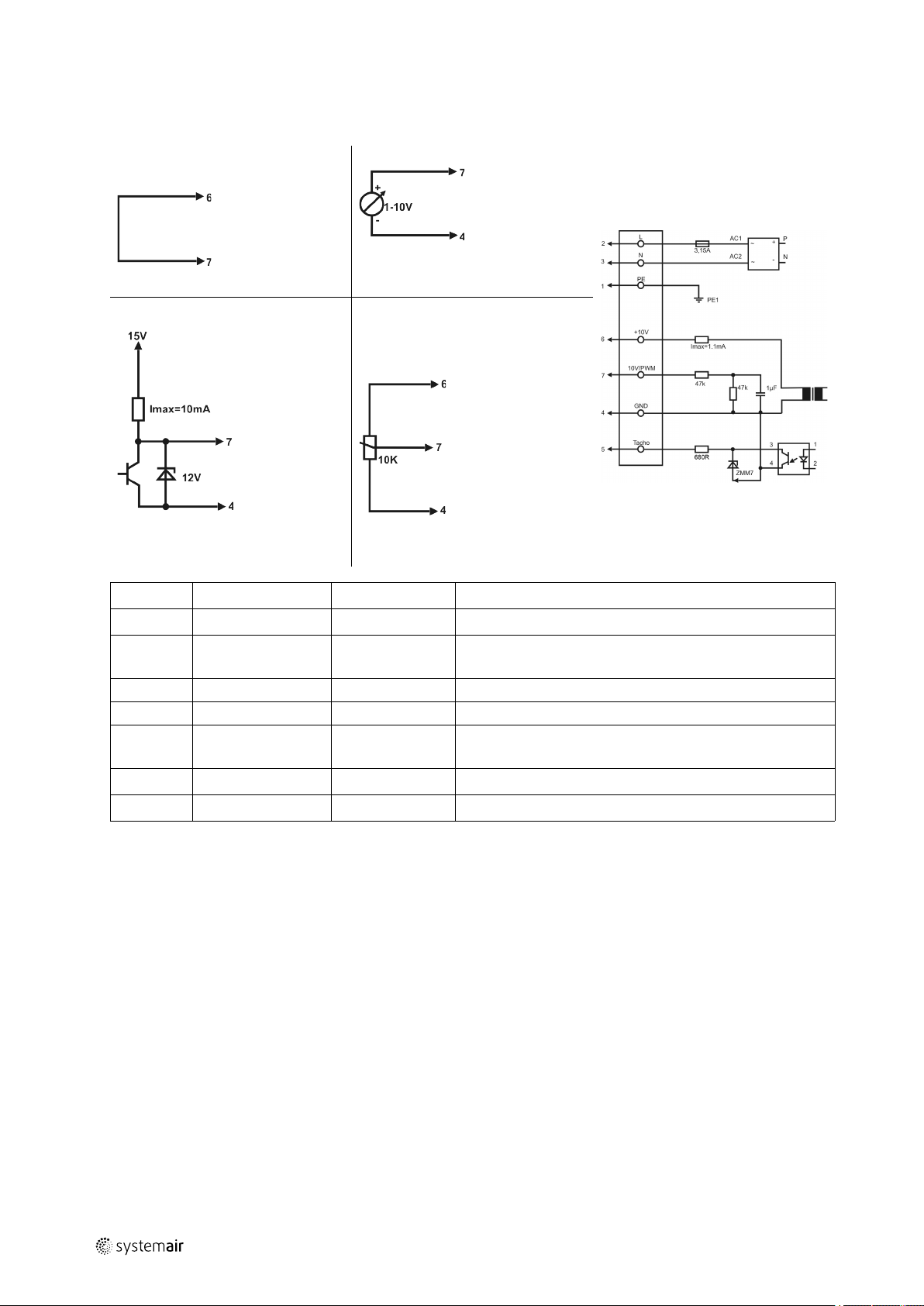

8.3.2 Wiring diagram IV Smart EC

Client side

Max. speed

Adjustable speed through PWM

1...10 KHz

GB

Adjustable speed

10V –> n = max

1V –> n = min

<1V –> 0

Adjustable speed through

potentiometer

100 % PWM –> n = max

10 % PWM –> n = min

< 10 % –> 0

Wire no. Connection

1 PE

2 L

3 N

4 GND

5

6

7 0...10 V PWM

speedometer white Speed output: Open Collector, 1 impulse per revolution,

10 V/max. 1,1 mA red Voltage output 10 V/1.1 mA

Color

green/yellow Protective conductor

brown Power supply 230 V AC, 50...60 Hz, see name plate for

blue Neutral conductor

blue GND-connection of the controller interface

yellow Controller input 0...10 V or PWM

Function/assignment

voltage range

electrically isolated, Isink_max = 10 mA

| 002

Page 15

GB

Electrical connection |

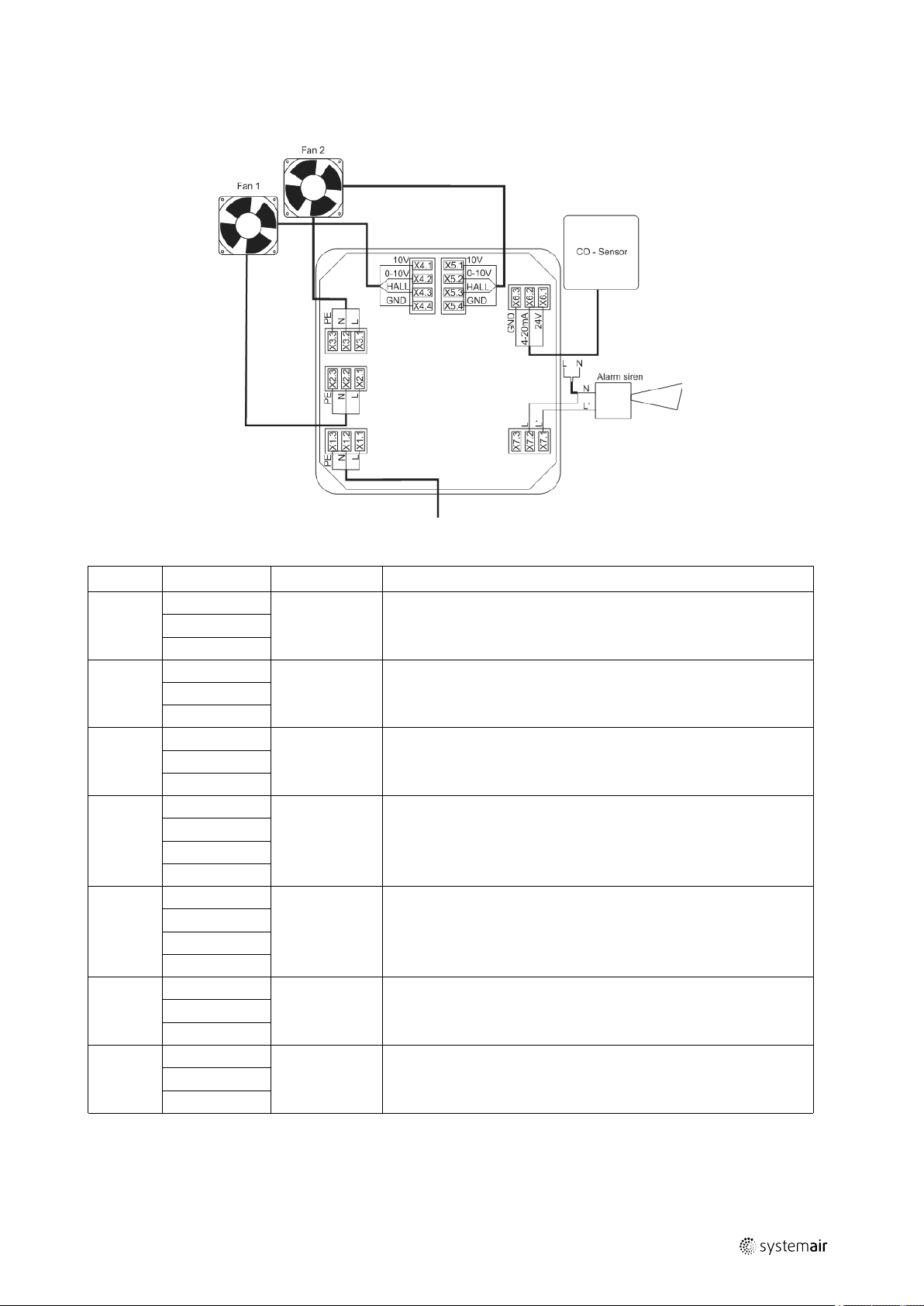

8.3.3 Wiring IV Smart EC-CO

The wiring diagram of the IV Smart EC-CO fan is not included in this document, but within this delivery.

15

Table 5 Electrical connections

Name Occupancy

1. L

X1

X2

X3

X4

X5

X6

X7

2. N

3. PE

1. L

2. N

3. PE

1. L

2. N

3. PE

1. 10 V

2. 0-10 V

3. HALL

4. GND

1. 10 V

2. 0-10 V

3. HALL

4. GND

1. 24 V

2. 4-20 mA

3. EARTH

1. NC

2. COM

3. NO

Designation Description

X1 SUPPLY

X2 FAN1

X3 FAN2

X4 FAN1

X5 FAN2

X6 SENSOR

X7 ALARM

Supply connection to the control unit

Supply connection to fan 1. Voltage corresponds to the control unit's

supply voltage

Supply connection to fan 2. Voltage corresponds to the control unit's

supply voltage

Control connection to fan 1. Speed specification and speed

feedback. If the fan has a 10 V output, it can be connected to

terminal X4.1.

Control connection to fan 2. Speed specification and speed

feedback. If the fan has a 10 V output, it can be connected to

terminal X5.1.

Connection for CO sensor supply connection and measuring signal

connection

Potential-free alarm contact connection option for controlling an

alarm siren or other auxiliary device.

8.3.3.1 Fan speed specification

The minimum fan speed can be set via a potentiometer in the range from 20 % to 40 %. The potentiometer is only accessible once the housing cover has been removed. The fan speed increases proportionately to the CO concentration

until the maximum speed at 50 ppm. If a fault is detected, the fans operate at maximum speed in order to remove any

| 002

Page 16

Commissioning GB

|

16

raised CO concentrations in the air. The following table provides information about the control unit's speed specifications to the fans.

Table 6 Fan speed specification

CO concentration

CO < 15 ppm Switch-off hysteresis 10

ppm

CO = 15 ppm

15 ppm < CO ≤ 50 ppm Min.…10 V

50 ppm < CO 10 V

Fault

Speed specification values

0 V

2 V…4 V (min.)

10 V

Comment

Fan standstill

Speed depending on set value

Linear rise in the characteristic curve

analogue to the CO concentration

starting with the minimum through to

the maximum fan speed

Maximum fan speed

Maximum fan speed

8.4 Protective grounding wire

The protective grounding must have a cross-section equal to or greater than that of the phase conductor.

8.5 Residual current circuit breaker

All-current-sensitive residual current circuit breakers are required for use in alternating-current systems with 50/60 Hz,

in combination with electronic devices such as EC motors, frequency converters or uninterruptible power supplies

(UPS).

8.6 Protecting the motor

Note:

In fans equipped with an EC motor, there is no additional motor protection needed. The motor protection is

integrated in the electronics of the motor.

Important

Damage to motor due to overcurrent, overload or short circiut.

♦ Use (all-pole) circuit breaker (characteristic C or K) or motor protection switches.

♦ Always connect thermo-contacts or cold conductors to a motor protection switch.

9 Commissioning

9.1 Safety information

♦ Commissioning may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page 6.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 6.

9.2 Preconditions

♦ Installation and electrical connection have been correctly performed.

♦ Residual material from installation and foreign objects have been removed from the fan and ducts.

♦ Inlet and outlet are free.

♦ Safety devices have been fitted.

♦ Ground cable is connected.

♦ Cable glands are tight.

♦ Nominal current (from the name plate) is not exceeded.

♦ Data on the name plate corresponds with the connection data.

| 002

Page 17

GB Commissioning

|

9.3 Commissioning Report

Important

• It is recommended to fill out the commissioning report 16 Commissioning Report, page 24.

• Please keep the completed commissioning report in a safe place. In the case of a warranty claim, this

report can be requested by Systemair GmbH. This document can also be downloaded from our online

catalogue.

9.4 Tests before activation

♦ Check that safety elements and protection grilles are securely fastened.

9.5 Tests (AC motor)

1. Before switching the fan on, check for externally visible damage and ensure that the protective equipment functions

properly.

2. Switch the fan on.

3. Checks:

♦ Direction of rotation/conveyance. The direction of rotation always applies looking at the rotor

• The direction of rotation is best observed just before the fan stops.

♦ Smooth running (any vibrations and noise)

♦ Current consumption

♦ Compare the current consumption with the nominal consumption on the name plate.

♦ Tightness of all connections

4. Switch the fan off.

17

9.6 Tests (EC motor)

1. Before switching the fan on, check for externally visible damage and ensure that the protective equipment functions

properly.

When the mains are switched on, the motor starts an initialization (a few seconds). After the initialization the control

input is active.

2. Switch the fan on via the control input.

3. Checks:

♦ Direction of rotation/conveyance. The direction of rotation always applies looking at the rotor

• The direction of rotation is best observed just before the fan stops.

♦ Smooth running (any vibrations and noise)

♦ Current consumption

♦ Compare the current consumption with the nominal consumption on the name plate.

♦ Tightness of all connections

4. Switch the fan off via the control input.

9.7 Tests when activated EC CO version

9.7.1 Function test

A function test is carried out once the voltage supply is connected, with the displays, the potential-free contact and the

fans being switched on briefly. The control unit has been installed correctly if the power display lights up permanently,

the CO alarm and fault display goes out after 2 seconds and the audible display does the same after 1 second. The potential-free contact must tighten after 1 second and therefore establish a connection between X7.2 and X7.3. In addition, no faults must be displayed after around 15 seconds. In the Chapter 9.7.3 Visual and audible display, page 18 the

meaning of the different signal types are explained.

| 002

Page 18

Operation GB

|

18

9.7.2 Warm-up time

Once the operating voltage has been connected, the control unit is in a warm-up state for around 6.5 minutes. During

this time, no CO measurements are carried out and no CO alarms are triggered. To ensure basic ventilation and to remove any raised CO concentrations in the air, the fans are controlled at a minimum speed. The warm-up time is needed

to give the CO sensor enough time for the CO measuring transducer's warm-up phase. Once the warm-up time has

elapsed, the control unit switches to its normal operating state (ready) and CO analysis takes place.

9.7.3 Visual and audible display

The table below distinguishes between the displays based on the control unit's four operating modes.

Table 7 Visible and audible display

Operating mode Audible signal

generator

Warm-up time No No On No

Ready

CO alarm

Fault 2 fast sounds / min

No No On No

On

CO alarm

Red LED

Rapid flashing 2 Hz

No On

Operation

Green LED

On No

Fault

Yellow LED

Rapid flashing 2 Hz

Table 8 Carbon monoxide alarm thresholds

CO concentration for activation of

the CO alarm

30 ppm

50 ppm

100 ppm

300 ppm

Control unit trigger times CO concentration for resetting of the

active CO alarm

No alarm No alarm

After around 75 min

After around 25 min

After around 1 min

< 40 ppm

< 40 ppm

< 40 ppm

10 Operation

10.1 Safety information

Warning: Hazard from electrical voltage or moving components.

♦ The device may only be operated by adequately qualified persons, details see Table 1 Qualifications, page 6.

♦ The device may only be operated by people who are instructed in and have understood the function and risks, and

can act accordingly.

♦ Abide by the system-related conditions and requirements of the system manufacturer or plant constructor.

10.2 Preconditions

♦ Ensure access only to persons who can safely handle the device.

♦ Only use the fan in accordance with the operating instructions and the operating instructions for the motor.

♦ Do not dismantle or circumvent safety elements, or put them out of function.

| 002

Page 19

GB

Troubleshooting/maintenance/repair/CO alarm |

11 Troubleshooting/maintenance/repair/CO alarm

11.1 Safety information

♦ Troubleshooting/maintenance/repair may only be carried out by adequately qualified persons, details see Table 1

Qualifications, page 6.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 6.

♦ Observe the 5 rules of electrical safety, see 2.3 5 rules of electrical safety, page 6.

♦ Abide by the system-related conditions and requirements of the system manufacturer or plant constructor.

♦ The rotor must be at a standstill.

11.2 Troubleshooting Fan

Table 9 Troubleshooting

Problem Possible causes Remedy

Fan does not run

smoothly

Rotor imbalance Rebalancing by a specialist company

Soiling on the rotor Clean carefully, rebalance

Material decomposition on the

rotor due to aggressive material

conveyed

Rotor rotates in wrong direction

Contact Systemair

Contact Systemair

19

Air output of fan too

low

Fan does not reach

nominal speed

Motor does not

rotate

Electronics/motor

overheated

Deformation of rotor due to

excessive temperature

Vibrations, oscillations Check the installation of the fan

Rotor rotates in wrong direction

Flow regulators not or only

partly open

Improperly aligned drive motor

Control units (if used) such as

frequency converter or

transformer are set incorrectly.

Mechanical blockage Remove the blockage

Faulty supply voltage Check the supply voltage, re-establish the voltage supply

Faulty connection Disconnect from the power supply, correct the

Temperature monitor has

responded

Insufficient cooling Improve cooling.

Overloaded motor Check if the correct fan is used for your application.

Ambient temperature too high Check if the correct fan is used for your application.

Ensure that the temperature does not exceed the certified

value/Install new rotor

Contact Systemair

Check opening position on site

Contact Systemair

Correct the settings of the control units.

connection, see circuit diagram.

Allow the motor to cool down, find and resolve the cause

of the fault.

Note:

For all other damage/defects, please contact Systemair. Defective fans must be completely replaced.

11.3 Alarm and fault handling Carbon monoxide control unit

The control unit continuously monitors the sensor's function, as well as the function of the fans. The following subpoints describe the the meaning of the fault and CO-Alarm display and the way in which they should be responded to.

| 002

Page 20

| Troubleshooting/maintenance/repair/CO alarm

20

11.3.1 Thresholds for fault displays

The control unit distinguishes between two fault types, which are specified in more detail in the table below.

Table 10 Fault display thresholds

GB

Fault type Setting threshold Reset threshold

Fan failure RPM < 130 rpm /

min

I

Sensor fault

< 3.0 mA I

4-20mA

RPM ≥ 180 rpm / min Fan fault or fault with the fan supply cables

≥ 3.5 mA

4-20mA

Comment

–> Signalled after 10 seconds

Short circuit or break in the sensor cable

–> Signalled after 3 seconds

11.3.2 Potential-free alarm contact

The illustration below explains the alarm contact's switching states.

Control terminals e.g. to connect an alarm signal

CO alarm — fault or voltage free Operating ok

11.3.3 Behaviour in the event of a CO alarm and fault handling

The control unit distinguishes between two fault types, which are specified in more detail in the table below.

Table 11 Behaviour in the event of a CO alarm and faults

No.

1

2

Problem Possible cause

CO alarm

Fault

Critical CO concentration

reached

- Fan failure

- Sensor fault

Remedy / suggested solution

1. If the fan and control unit is installed in a garage

and your vehicle engine is idling, switch the engine

off.

2. Leave the room immediately and seek fresh air.

Check that everyone is present. Do not go back

into the room before it has been ventilated and the

CO alarm has stopped.

3. If the alarm triggers again after 24 hours, repeat

steps 1-2 and call the emergency gas services

(please check you have their number now) and if

necessary notify the relevant gas fitter.

Contact Systemair

11.4 Maintenance

To ensure a reliable operation of the fan, we recommend periodic maintenance intervals. These maintenance intervals

must be specified by the operator. The frequency of maintenance activities or additional activities must be decided according to the use of the fans. It is important for traceability to create a maintenance plan, in which the work performed

is written down.

The maintenance intervals should be shorter if the following conditions (among others) apply:

• Fan used as kitchen exhaust application

• Ambient temperature > 40°C or < -10°C, or temperature variations > 20k

| 002

Page 21

GB

The following check list provides points of reference for the tasks to be carried out.

Table 12 Activities

Cleaning |

21

Activity

Check the fan and components for visible damage, corrosion and

contamination

Inspect the the rotor for damage and imbalance

Check that the condensate drain functions correctly

Clean the fan/ventilation system (see Chapter Cleaning)

Inspect screwed connections and tighten them if necessary

Ensure that the intake of the fan is free from dirt

Check that fan and components are being used as intended

Check the current consumption

Check that the vibration dampers function correclty (if used)

Check that the electrical and mechanical protective devices function

correctly

Check if the name plate of the fan is legible

Check that connection terminals and cables glands are tightly screwed and

have no visible damage/defects

Check flexible connections for leaks

Note:

If you have questions, please contact Systemair. Defective fans must be completely replaced.

As required Periodic intervals

X

X

X

X

X

X

X

X

X

X

X

X

X

11.5 Spare parts

♦ Use original spare parts from Systemair only.

♦ When ordering spare parts, please specify the serial number of the fan. This can be found on the name plate.

12 Cleaning

12.1 Safety information

♦ Cleaning may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page 6.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 6.

♦ Observe the 5 rules of electrical safety, see 2.3 5 rules of electrical safety, page 6.

♦ Ensure that the power supply has been switched off (all-pole circuit breaker).

♦ Ensure that the rotor is at a standstill.

12.2 Procedure

Important

Keeping the fan clean extends its service life.

♦ Install a filter monitor.

♦ Do not use steel brushes or sharp-edged objects.

♦ Do not use a high-pressure cleaner (steam jet cleaner) under any circumstances.

♦ Do not bend the fan blades when cleaning.

♦ When cleaning the rotor, pay attention to balance weights that have been positioned

♦ Keep the airways of the fan clear and clean them if necessary with a brush.

| 002

Page 22

| Deinstallation/dismantling

22

13 Deinstallation/dismantling

Deinstall and dismantle the fan in reverse order of installation and electrical connection.

14 Disposal

♦ Ensure material is recycled. Observe national regulations.

♦ The device and the transport packaging are predominantly made from recyclable raw materials.

♦ Disassemble the fan into its components.

♦ Separate the parts according to:

• reusable material

• material groups to be disposed of (metal, plastics, electrical parts, etc.)

GB

| 002

Page 23

GB

15 EU Declaration of conformity

The manufacturer: Systemair GmbH

Seehöfer Straße 45

DE-97944 Boxberg

Germany

+49 (7930) 9272 - 553

Product designation: Jet fans

EU Declaration of conformity |

23

Type designation:

Since of manufacture:

The manufacturer declares that the above mentioned products in their design and construction and the version

marketed by us complies with the Harmonization legislation listed below:

EU directives: 2006/42/EC Machinery directive

Regulations: 327/2011 Only for fans above 125W, CE marked fans

The following standards have been considered:

Harmonized standards:

AJR; AJ8; AJR (B); AJ8 (B); AJ (F); AJR-TR; IV; IV smart; prioJet

2016

2014/30/EU Directive electromagnetic compatibility

(EMC)

2011/65/EU RoHS directive

2009/125/EC ErP guidelines

used as components are CE marked by other

manufacturer.

DIN EN ISO 12100:2013

DIN EN 60204-1:2010

DIN EN 61000-6-1:2007

DIN EN 61000-6-2:2011

DIN EN 12101-3:2015*

Safety of machinery - General principles for

design Riskassessment and risk reduction

Safety of machinery - Electrical equipment of

machines - Part1: General requirements

Electromagnetic compatibility (EMC) - Part 61: Generic standards - Immunity for

residential, commercial and light-industrial

environments

Electromagnetic compatibility (EMC) - Part 62: Generic standards - Immunity for industrial

environments

Smoke an heat control systems, Part 3:

Specification for powered smoke and heat

exhaust ventilators

Boxberg, 20.04.2016

| 002

ppa. Harald Rudelgass, technical director

Page 24

Commissioning Report GB

|

24

16 Commissioning Report

Fan

Description:

Article no.: Manufacturing order no.:

Installer

Company: Contact person:

Company address:

Tel. no.: Email:

Operator (Place of installation)

Company: Contact person:

Company address:

Tel. no.: Email:

Type of connection

Directly to mains

0-10 V signal (EC motor)

via contactor control

Transformer

Frequency converter

Sinus filter

Shielded cables

Motor protection

Motor protection switch or motor protection relay

PTC resistor

Resistance value [Ω]:

Thermal contact

Electrical motor protection

Others:

Functional check

Impeller easily rotatable (by hand)

Rotation direction acc. to directional arrow

Yes No

□ □

□ □

□ □

□ □

□ □

□ □

□ □

Yes No

□ □

□ □

□ □

□ □

Yes No

□ □

□ □

Nominal data - Fan (name plate on fan housing)

Voltage [V]: Current [A]:

Frequency [Hz]: Power [kW]:

Fan impeller speed [rpm]:

| 002

Page 25

GB Commissioning Report

Measured data at commissioning

Voltage [V]: Temp. of transported air [°C]:

|

25

Current L1 [A]*:

Fan impeller speed [rpm]:

Current L2 [A]: Air volume [m3/s]:

Current L3 [A]:

*For single-phase fans, fill in line “Current L1 [A]” *Δ- Pressure between suction-side and discharge of the fan

Differential pressure [Pa]*:

If an air flow measurement is not possible, this value can be calculated using the following formula:

=

Air volume [m³/s]:

Duct cross-section [m²]

X

Flow speed [m/s]

Grille measurement acc. to VDI 2044

Yes No

Commissioning of the fan successful?

□ □

Date, installer's signature

Date, operator's signature

Please keep the completed commissioning report in a safe place. In the case of a warranty claim, this report can

be requested by Systemair GmbH. This document can also be downloaded from our online catalogue.

For technical questions, please contact the technical support division of Systemair GmbH (tel. +49 7930/9272 730).

| 002

Page 26

DE

Montage- und Betriebsanleitung

© Copyright Systemair AB

Alle Rechte vorbehalten

E&OE

Systemair AB behält sich das Recht vor, seine Produkte ohne Vorankündigung zu ändern.

Dies gilt auch für bereits bestellte Produkte, sofern die vorher vereinbarten Spezifikationen nicht beeinflusst werden.

DE

| 002

Page 27

Inhaltsverzeichnis

1 Allgemeine Hinweise ...... ..... ..... ........... ..... ..... 29

1.1 Hinweissymbole .... ..... ..... ...... ..... ..... .... 29

1.1.1 Anleitungssymbole... ..... ........... 29

2 Sicherheitshinweise.... ..... ..... ...... ..... ..... ..... .... 29

2.1 Personal. ..... ...... ..... ..... ..... ........... ..... .. 30

2.2 Persönliche Schutzausrüstung .......... ..... .. 30

2.3 Die 5 Sicherheitsregeln bei Arbeiten in

und an elektrischen Anlagen.. ..... ..... ....... 30

3 Gewährleistung ... ...... ..... ..... ..... ...... ..... ..... .... 30

4 Lieferung, Transport, Lagerung......... ..... ..... ...... 30

4.1 Sicherheitshinweise.... ..... ..... ..... . ..... ..... 30

4.2 Lieferung.......... ..... ..... ........... ..... ..... ... 31

4.3 Transport... ..... ........... ..... ..... ...... ..... ....31

4.3.1 Sicherheitshinweise... ..... . ..... ....31

4.4 Lagerung. . ..... ..... ..... ........... ..... ..... ...... 31

5 Beschreibung IV Smart ..... ..... ..... ........... ..... .... 32

5.1 IV Smart EC ausgestattet mit EC-

Motor ...... ..... ..... ........... ..... ..... ........... 32

5.2 IV Smart AC ausgestattet mit AC-

Motor ...... ..... ..... ........... ..... ..... ........... 32

5.3 IV Smart EC—CO — ausgestattet mit

Kohlenmonoxid-Steuerung... ..... ..... ..... ... 32

5.3.1 Kohlenmonoxid-

Steuerung... ...... ..... ..... ..... ...... . 32

5.3.2 Hinweise zu CO-

Auswirkungen auf

Menschen ......... ..... ..... ........... 32

5.4 Abmessungen ..... ........... ..... ..... ........... 33

5.5 Technische Daten der

Ventilatoren.... ..... ..... ...... ..... ..... ..... ..... 33

5.6 Technische Ventilatordaten .... ...... ..... ..... 34

5.7 Daten des Motors.. ..... ..... ...... ..... ..... ..... 34

5.8 Bestimmungsgemäße Verwendung

aller IV Smart-Versionen ..... ..... ........... ... 34

5.9 Bestimmungswidrige

Verwendung .... ..... ..... ........... ..... ..... .... 34

5.10 Klemmkästen ... ..... ..... . ..... ..... ..... ..... .... 34

6 Typenschild und Typenschlüssel . ..... ...... ..... ..... . 35

7 Installation.. ..... ..... . ..... ..... ..... ..... ...... ..... ..... .. 36

7.1 Voraussetzungen . ..... ........... ..... ..... ...... 36

7.2 Montage an der Decke ..... ..... ........... ..... 36

8 Elektrischer Anschluss . ..... ..... ..... . ..... ..... ..... .... 37

8.1 Sicherheitshinweise/

Voraussetzungen . ..... ........... ..... ..... ...... 37

8.2 Voraussetzungen . ..... ........... ..... ..... ...... 37

8.3 Anschluss . ..... ..... ..... ........... ..... ..... ...... 37

8.3.1 Anschlussplan IV Smart

AC .... ..... ........... ..... ..... ..........37

8.3.2 Anschlussplan IV Smart

EC.... ..... ..... ..... ...... ..... ..... ..... . 38

8.3.3 Anschlussplan IV Smart EC-

CO ... ..... ..... . ..... ..... ..... ..... . ..... 39

8.4 Schutzerdungsleiter . ..... ...... ..... ..... ..... ... 40

8.5 FI-Schutzschalter..... ..... ..... ...... ..... ..... ... 40

8.6 Motorschutz..... ..... ..... ..... ...... ..... ..... .... 40

9 Inbetriebnahme ..... ..... ........... ..... ..... ........... .. 40

9.1 Sicherheitshinweise.... ..... ..... ...... ..... ..... 40

9.2 Voraussetzungen . ..... ........... ..... ..... ...... 40

9.3 Inbetriebnahmeprotokoll.... ........... ..... .... 41

9.4 Tests vor der Aktivierung ... ..... ..... ..........41

9.5 Tests (AC-Motor) ...... ..... ..... ..... ...... ..... . 41

9.6 Testen Sie den Motor (EC-Motor)... ..... ..... 41

9.7 Tests bei Aktivierung EC-CO-

Version .... ..... ..... ...... ..... ..... ........... ..... 41

9.7.1 Funktionsprüfung . ..... ..... . ..... ....41

9.7.2 Aufwärmzeit . ..... ..... ..... ..... . ..... 42

9.7.3 Optische und akustische

Anzeige ......... ..... ..... ........... ... 42

10 Betrieb.... ..... ..... ..... ..... . ..... ..... ..... ...... ..... ..... 42

10.1 Sicherheitshinweise.... ..... ..... ...... ..... ..... 42

10.2 Voraussetzungen . ..... ........... ..... ..... ...... 42

11 Fehlersuche/Wartung/Reparatur/CO-

Alarm ..... ..... ...... ..... ..... ..... ...... ..... ..... ..... .....43

11.1 Sicherheitshinweise.... ..... ..... ...... ..... ..... 43

11.2 Fehlersuche Ventilator.. ..... . ..... ..... ..... .... 43

11.3 Alarm- und Fehlerbehandlung

Kohlenmonoxid-Steuerung... ..... ..... ..... ... 44

11.3.1 Schwellenwerte der

Fehleranzeigen ..... ..... ........... ... 44

11.3.2 Potentialfreier

Alarmkontakt ...... ..... ..... ..... .....44

| 002

Page 28

Inhaltsverzeichnis

12 Reinigung ..... ...... ..... ..... ..... ..... . ..... ..... ..... ..... 45

13 Demontage/Ausbau ........... ..... ..... ........... ..... . 46

14 Entsorgung ..... ..... ..... ........... ..... ..... ........... ... 46

15 EG-Konformitätserklärung.......... ..... ..... ........... 47

16 Inbetriebnahmeprotokoll.... ...... ..... ..... ........... .. 48

11.3.3 Verhalten bei CO-Alarm und

Fehlerbehandlung .... ..... ..... ..... . 44

11.4 Wartung....... ..... ..... ........... ..... ..... ....... 45

11.5 Ersatzteile ..... ..... ..... ........... ..... ..... ...... 45

12.1 Sicherheitshinweise.... ..... ..... ..... . ..... ..... 45

12.2 Vorgehensweise . ..... . ..... ..... ..... ..... . ..... . 46

DE

| 002

Page 29

DE

1 Allgemeine Hinweise

1.1 Hinweissymbole

Gefahr

Unmittelbare Gefährdung

Die Nichtbeachtung des Warnhinweises führt unmittelbar zum Tod oder zu schweren Verletzungen.

Warnung

Potenzielle Gefahr

Die Nichtbeachtung des Warnhinweises kann zum Tod oder zu schweren Verletzungen führen.

Vorsicht

Gefährdung mit geringem Risiko

Die Nichtbeachtung des Warnhinweises kann zu mittelschweren Verletzungen führen.

Wichtig

Gefahr mit Risiko für Sachbeschädigungen

Die Nichtbeachtung des Warnhinweises kann zu Sachbeschädigungen führen.

Allgemeine Hinweise |

29

Hinweis!

Nützliche Informationen und Anleitungen

1.1.1 Anleitungssymbole

Anleitung Anleitung mit fester Schrittfolge

♦ Führen Sie diese Handlung aus

♦ (ggf. weitere Handlungen)

1. Führen Sie diese Handlung aus

2. Führen Sie diese Handlung aus

3. (ggf. weitere Handlungen)

2 Sicherheitshinweise

Planer, Anlagenbauer und Betreiber sind für die ordnungsgemäße Montage und den bestimmungsgemäßen Betrieb

verantwortlich.

♦ Lesen Sie die Betriebsanleitungen vollständig und sorgfältig.

♦ Betriebsanleitungen und mitgeltende Unterlagen, wie elektrische Anschlussbilder oder Betriebsanleitungen des Mo-

tors, sind bei dem Ventilator aufbewahren. Sie müssen ständig am Einsatzort zur Verfügung stehen.

♦ Örtliche und nationale Gesetze und Regelungen sind zu beachten und einzuhalten.

♦ Der Ventilator darf nur in einwandfreiem Zustand verwendet werden.

♦ Es müssen die allgemein vorgeschriebenen elektrischen und mechanischen Schutzvorrichtungen bereitgestellt

werden.

♦ Sichern Sie während der Montage, elektrischem Anschluss, Inbetriebnahme, Fehlersuche, Fehlerbehebung und War-

tung die Montagestelle und die Räumlichkeiten für vor Zutritt von Unbefugten.

♦ Sicherheitseinrichtungen dürfen weder demontiert, noch umgangen oder außer Funktion gesetzt werden.

♦ Sorgen Sie dafür, dass alle Warnschilder auf dem Ventilator vollständig und lesbar sind.

♦ Dieses Gerät ist nicht für den Gebrauch durch Personen (einschließlich Kinder) mit eingeschränkten körperlichen oder

geistigen Fähigkeiten oder ohne Erfahrung und Vorkenntnisse bestimmt, es sei denn, diese Personen wurden von einer für ihre Sicherheit verantwortlichen Person in den Gebrauch des Geräts unterwiesen.

♦ Kinder dürfen nicht mit dem Gerät spielen.

| 002

Page 30

| Gewährleistung

30

2.1 Personal

Der Ventilator darf nur von qualifiziertem, eingewiesenen und geschultem Personal betrieben werden. Diese Personen

müssen die einschlägigen Sicherheitsvorschriften kennen, um mögliche Gefahren zu erkennen und zu vermeiden. Die

einzelnen Handlungen und Qualifikationen sind unter Tabelle 1 Qualifikation, Seite 30 nachzusehen.

Tabelle 1 Qualifikation

DE

Handlungen Elektrofachkraft oder

Personen mit

entsprechender

Qualifikation

Lagerung, Betrieb,

Transport, Reinigung,

Entsorgung

Elektrischer Anschluss,

Inbetriebnahme,

elektrische Trennung

Installation, Demontage

Wartung X X

Reparieren

Entrauchungsventilatoren und EX-Ventilatoren nur in Absprache mit Systemair.

X

Montagefachkraft oder

Personen mit

entsprechender

Qualifikation

X

Hinweis!

Der Betreiber hat sicherzustellen, dass das Personal in die Bedienung unterwiesen wurde und die

Betriebsanleitung verstanden hat. Bei Unklarheiten wenden Sie sich bitte an Systemair oder an unsere

Vertreter.

2.2 Persönliche Schutzausrüstung

Bei jeglichen Arbeiten im Umfeld des Ventilators ist die Schutzausrüstung zu tragen.

Geschultes Personal (s.

folgende Hinweise)

X

• Schutzkleidung

• Sicherheitsschuhe

• Schutzhandschuhe

• Schutzhelm

• Schutzbrille

• Gehörschutz

2.3 Die 5 Sicherheitsregeln bei Arbeiten in und an elektrischen Anlagen

• Freischalten (allpoliges Trennen einer elektrischen Anlage von spannungsführenden Teilen)

• Gegen Wiedereinschalten sichern

• Spannungsfreiheit feststellen

• Erden und Kurzschließen

• Benachbarte, unter Spannung stehende Teile abdecken oder abschranken

3 Gewährleistung

Die Gewährleistung für unsere Produkte richtet sich nach den Vertragsbestimmungen, unseren Angeboten sowie unseren allgemeinen Geschäftsbedingungen. Für die Geltendmachung von Gewährleistungsansprüchen müssen die Produkte ordnungsgemäß angeschlossen sowie gemäß den Datenblättern betrieben, genutzt und gewartet werden.

Zudem muss auf Nachfrage das korrekt ausgefüllte Inbetriebnahmeprotokoll vorgelegt werden. Das Inbetriebnahmeprotokoll befindet sich im Lieferumfang des Produkts.

4 Lieferung, Transport, Lagerung

4.1 Sicherheitshinweise

Warnhinweis: Gefahr durch rotierende Ventilatorblätter

♦ Verhindern Sie den Zutritt unbefugter Personen durch Sicherheitspersonal oder einen Zugangsschutz.

| 002

Page 31

DE

Warnhinweis: Schwebenden Lasten

♦ Bei jeglichen Arbeiten im Umfeld des Ventilators ist die Schutzausrüstung zu tragen, s. 2.2 Persönliche Schutzausrü-

stung, Seite 30.

♦ Niemals unter schwebende Last treten.

♦ Es ist sicherzustellen, dass sich niemand unter einer schwebende Last befindet.

Lieferung, Transport, Lagerung |

4.2 Lieferung

Jeder Ventilator verlässt unser Werk in elektrisch und mechanisch einwandfreiem Zustand. Es wird empfohlen, den Ventilator bis zur Montagestelle original verpackt zu transportieren.

Lieferung prüfen

♦ Überprüfen Sie die Verpackung auf Transportschäden. Jeder Schaden ist im Ladungsverzeichnis zu vermerken.

♦ Kontrollieren Sie, ob die Lieferung vollständig ist.

Auspacken

Warnung

Beim Entfernen der Transportverpackung besteht die Gefahr der Beschädigung durch scharfe Kanten,

Nägel, Klammern, Splitter usw.

♦ Entpacken Sie den Ventilator vorsichtig.

♦ Überprüfen Sie den Ventilator auf offensichtliche Transportschäden.

♦ Entfernen Sie die Verpackung erst kurz vor der Montage.

♦ Bei jeglichen Arbeiten im Umfeld des Ventilators ist die Schutzausrüstung zu tragen, s. 2.2 Persönliche

Schutzausrüstung, Seite 30.

31

4.3 Transport

4.3.1 Sicherheitshinweise

Warnhinweis: Elektrische oder mechanische Gefährdung durch Feuer, Feuchtigkeit, Kurzschluss oder Fehlfunktion.

♦ Der Ventilator darf niemals am Anschlusskabel, Anschlusskasten, Laufrad, Schutzgitter, Einströmstutzen oder Schall-

dämpfer getragen werden.

♦ Stellen Sie bei einem offenen Transport sicher, dass kein Wasser in den Motor oder andere empfindliche Komponen-

ten eindringen kann.

♦ Es wird empfohlen, den Ventilator bis zur Montagestelle original verpackt zu transportieren.

Vorsicht: Unvorsichtiges Auf- oder Abladen kann zu Beschädigungen des Ventilators führen.

♦ Führen Sie das Auf- oder Abladen sorgfältig durch.

♦ Verwenden Sie eine auf die Last ausgelegte Hebeausrüstung.

♦ Beachten Sie die Transportpfeile auf der Verpackung.

♦ Die Verpackung dient ausschließlich als Transportschutz und darf nicht zum Anheben verwendet werden.

4.4 Lagerung

♦ Lagern Sie den Ventilator in der Originalverpackung an einem trockenen, staubfreien Ort, der vor Witterungseinflüs-

sen geschützt ist.

♦ Vermeiden Sie extreme Hitze- oder Kälteeinwirkung.

| 002

Wichtig

Gefährdung durch Funktionsverlust des Motorlagers

♦ Zu lange Lagerzeiträume vermeiden (Empfehlung: max. 1 Jahr).

♦ Drehen Sie den Rotor alle drei Monate per Hand - Schutzhandschuhe tragen.

♦ Überprüfen Sie vor der Installation, ob das Motorlager korrekt funktioniert.

Page 32

| Beschreibung IV Smart

32

5 Beschreibung IV Smart

5.1 IV Smart EC ausgestattet mit EC-Motor

Die Ventilatoren werden über zwei EC-Motoren angetrieben. Die Ventilatoren sind mit einem Potentiometer (0-10V)

ausgestattet, über das der Betriebspunkt direkt eingestellt werden kann. Alle Motoren sind für 50/60 Hz geeignet. Die

Eingangsspannung für einphasige Geräte kann zwischen 200 und 277 V variieren.

5.2 IV Smart AC ausgestattet mit AC-Motor

Die Ventilatoren werden über zwei AC-Motoren angetrieben. Alle Motoren sind für 50/60 Hz geeignet..

5.3 IV Smart EC—CO — ausgestattet mit Kohlenmonoxid-Steuerung

Die Ventilatoren werden über zwei EC-Motoren angetrieben (s. 5.1 IV Smart EC ausgestattet mit EC-Motor, Seite 32).

Ventilator und Steuerung sind vorinstalliert und betriebsbereit.

5.3.1 Kohlenmonoxid-Steuerung

Die CO-Steuerung steuert zwei EC-Ventilatoren mit einem 0-10 V Steuereingang anhand eines Messsignals das von einem CO-Sensor stammt. Beide Ventilatoren werden über das gleiche 0–10 V Signal geregelt und auf Ventilatorfehler

überwacht. Der CO-Alarm wird entsprechend der Verzögerungszeit und den Zeitvorgaben der DIN EN 50291-1

ausgelöst.

DE

5.3.2 Hinweise zu CO-Auswirkungen auf Menschen

Warnung

Diese CO-Steuerung ist für den Schutz von Menschen vor akuten Auswirkungen durch CO ausgelegt. Es

schützt nicht vor langfristigen Folgen durch CO-Belastung. Die CO-Steuerung kann Personen mit speziellen

Risiken, wie besondere medizinische Eigenschaften, nicht vollständig schützen. Im Zweifelsfall sollten Sie

einen Arzt befragen.

Die folgende Tabelle stellt die Symptome den entsprechenden CO-Konzentrationen und Zeiten die ein Mensch dieser

Konzentration ausgesetzt sein muss bis die Symptome auftreten gegenüber.

Tabelle 2 Wirkungen von CO auf den menschlichen Körper

CO-Konzentration

30 ppm

100 ppm

200 ppm

300 ppm

400 ppm

800 ppm

1600 ppm

3200 ppm

8000 ppm

Symptome

maximale Arbeitsplatzkonzentration bei 8 Stunden

Arbeitszeit, keine Symptome

auch nach längerer Zeit, keine Symptome

Kopfschmerzen 2…3 h

leichte Kopfschmerzen, Schwindel, Schwäche,

Übelkeit

stirnseitige Kopfschmerzen

lebensbedrohlich

Kopfschmerzen, Schwindel, Übelkeit, Krämpfe

Kopfschmerzen, Schwindel und Übelkeit

Bewusstlosigkeit

möglicher Tod

Kopfschmerzen, Schwindel und Übelkeit

Tod

Tod

Zeit bis zum Auftreten von

Symptomen

-

-

2…3 h

1…2 h

3 h

innerhalb 45 Min.

innerhalb 20 Min.

innerhalb 2 h

innerhalb 1 h

innerhalb 5…10 Min.

innerhalb 25…30 Min.

ein paar Minuten

| 002

Page 33

DE

169

760

36 140

150

800

700

8

503

173 360

20

5.4 Abmessungen

Beschreibung IV Smart |

33

Bild 1 Abmessungen IV Smart

5.5 Technische Daten der Ventilatoren

• IV Smart AC: Temperaturbereich [°C] geförderte Luft = -25 bis 55

• IV Smart EC: Temperaturbereich [°C] geförderte Luft = -25 bis 55

• IV Smart EC CO: Temperaturbereich [°C] geförderte Luft = -20 bis 40

• Spannung/Strom/Schutzklasse/Gewicht/Rotordurchmesser = siehe Typenschild

• Schalldruckpegel [dB(A)] = s. Datenblatt

Hinweis!

Weitere technische Daten sind dem Datenblatt des jeweiligen Ventilators zu entnehmen.

| 002

Page 34

| Beschreibung IV Smart

34

5.6 Technische Ventilatordaten

Spannung = 100…240 VAC

Frequenz = 50…60 Hz

Tabelle 3 Bestandteile der CO-Steuerung

Bestandteil Funktion

Fan

CO-Sensor

Externes Alarmgerät (optional)

Zwei Ventilatoren mit 0-10 V Kontrolleingang und Hall-Ausgang, zur

Lüftung des zu überwachenden Raumes.

CO-Sensor mit 4…20 mA Messsignalausgang für CO-Konzentrationen von

0…300 ppm.

Anschluss Alarmsirene oder Alarmanzeigelampe

5.7 Daten des Motors

Die Motordaten befinden sich auf dem Typenschild des Motors oder in der technischen Dokumentation des

Motorenherstellers.

5.8 Bestimmungsgemäße Verwendung aller IV Smart-Versionen

• Die Ventilatoren sind für unter- und oberirdische Parkhäuser konzipiert, um die Belüftung und Absaugung von kaltem

Rauch zu vereinfachen.

• Für einen optimalen Betrieb muss der Jet-Ventilator horizontal von der Decke hängen und so positioniert sein, dass

Ein- und Auslass ungehindert erfolgen.

• Die maximal zulässigen Betriebsdaten auf dem Typenschild gelten für eine Luftdichte = 1,2 kg/m³ (Meereshöhe)

und eine maximale Luftfeuchtigkeit von 80%.

• Der Ventilator ist geeignet für die Beförderung von sauberer Luft mit einer Dichte von 1,3 kg/m³ und einer max. Luftfeuchte von 95%.

DE

5.9 Bestimmungswidrige Verwendung

Eine unsachgemäße Verwendung liegt hauptsächlich dann vor, wenn der Ventilator anders als beschrieben genutzt

wird. Folgende Anwendungen sind bestimmungswidrig und gefährlich:

• Fördern von explosiven und brennbaren Medien

• Fördern von aggressiven Medien

• Installation im Außenbereich

• Betrieb in explosionsfähiger Umgebung

5.10 Klemmkästen

IV Smart AC IV Smart EC IV Smart CO

| 002

Page 35

DE

Serial.no: 84543/1002773290-001/20170131

IV Smart EC

230 V~

50 Hz

IP54

䰊

2510 min ¹

17kg

0,35 kW

Made in GER MANY

INS.CL.B

2,6 A

www.systemair.com

1

2

3

4

5

6

7

6 Typenschild und Typenschlüssel

Typenschild und Typenschlüssel |

35

1

Typbezeichnung

2

Spannung/Stromstärke/Frequenz

3 Eingangsspannung 7

4

Schutzklasse/Drehzahl/Gewicht

Tabelle 4 Typenschlüssel

IV Smart EC

-

- keine Steuerung

CO

EC

AC

Induktionsventilator Smart

5

Isolationsklasse

6

Artikelnummer/Produktionsnummer/Fertigungsdatum

Zertifizierungen

ausgestattet mit Kohlenmonoxid-Steuerung

Motortyp

elektronisch kommutiert/1-phasig

2-polig/spannungsregelbar/1-phasig

Ventilatortyp

| 002

Page 36

| Installation

4x

36

7 Installation

Warnhinweis: Stoßgefahr durch herabfallenden Ventilator oder Ventilatorteile.

♦ Überprüfen Sie vor der Installation die Oberfläche auf Tragfähigkeit.

♦ Berücksichtigen Sie bei der Auswahl der Hebeausrüstung und der Befestigungsteile alle statischen und dynamischen

Lasten.

Allgemeine Sicherheitshinweise

♦ Die Installation darf nur von entsprechend qualifizierten Personen ausgeführt werden, Einzelheiten, s. Tabelle 1 Qua-

lifikation, Seite 30.

♦ Bei jeglichen Arbeiten im Umfeld des Ventilators ist die Schutzausrüstung zu tragen, s. 2.2 Persönliche Schutzausrü-

stung, Seite 30.

♦ Berücksichtigen Sie die anlagenrelevanten Bedingungen und Anforderungen des Anlagenherstellers oder

Anlagenbauers.

♦ Sicherheitseinrichtungen dürfen weder demontiert, noch umgangen oder außer Funktion gesetzt werden.

♦ Sehen Sie Berührungs-, Ansaugschutz und Sicherheitsabstände gemäß DIN EN ISO13857 und DIN 24167-1 vor.

♦ Verhindern Sie ein Einsaugen von Fremdpartikeln.

7.1 Voraussetzungen

♦ Stellen Sie sicher, dass der Ventilator und alle seine Komponenten unbeschädigt sind.

♦ Stellen Sie sicher, dass die Angaben auf dem Typenschild (Ventilator und Motor) mit den Betriebsbedingungen

übereinstimmen.

♦ Stellen Sie sicher, dass ausreichend Platz für die Montage des Ventilators vorhanden ist.

♦ Bei der Montage ist das Gerät vor Staub und Feuchtigkeit zu schützen.

♦ Montieren Sie die Ventilatoren so, dass ausreichend Zugang für Fehlersuche, Wartungs- und Reparaturarbeiten vor-

handen ist.

DE

7.2 Montage an der Decke

Installation IV Smart

| 002

Page 37

DE

Elektrischer Anschluss |

8 Elektrischer Anschluss

8.1 Sicherheitshinweise/Voraussetzungen

Warnhinweis: Gefährdung durch elektrische Spannung!

♦ Die 5 Sicherheitsregeln sind einzuhalten, s. 2.3 Die 5 Sicherheitsregeln bei Arbeiten in und an elektrischen Anlagen,

Seite 30.

♦ Verhindern Sie das Eindringen von Wasser in den Anschlusskasten.

♦ Der elektrische Anschluss darf nur von entsprechend qualifizierten Personen ausgeführt werden, Einzelheiten s. Ta-

belle 1 Qualifikation, Seite 30.

♦ Örtliche und nationale Gesetze und Regelungen sind zu beachten und einzuhalten.

♦ Bei jeglichen Arbeiten im Umfeld des Ventilators ist die Schutzausrüstung zu tragen, s. 2.2 Persönliche Schutzausrü-

stung, Seite 30.

8.2 Voraussetzungen

♦ Berücksichtigen Sie die anlagenrelevanten Bedingungen und Anforderungen des Anlagenherstellers oder

Anlagenbauers.

♦ Sicherheitseinrichtungen dürfen weder demontiert, noch umgangen oder außer Funktion gesetzt werden.

♦ Installieren Sie bei der Elektroinstallation dauerhaft einen Sicherungsautomaten (allpolige Kontaktöffnung mind. 3

mm).

37

8.3 Anschluss

♦ Prüfen Sie, ob die Daten auf dem Typenschild mit den Anschlussdaten übereinstimmen.

♦ Führen Sie den elektrischen Anschluss gemäß Schaltplan aus.

♦ Verlegen Sie die Anschlusskabel so in den Anschlusskasten, dass dessen Abdeckung ohne Widerstand geschlossen

werden kann.

♦ Verwenden Sie alle Sicherungsschrauben.

♦ Setzen Sie die Schrauben per Hand ein, damit das Gewinde nicht beschädigt wird.

♦ Ziehen Sie alle Schrauben fest an, um die IP-Schutzart zu gewährleisten.

♦ Schrauben Sie den Deckel des Anschlusskastens/Revisionsschalters gleichmäßig fest.

♦ Schließen Sie das Kabelende in einer trockenen Umgebung an.

8.3.1 Anschlussplan IV Smart AC

Farbe Funktion/Belegung

Schwarz

Blau

grün/gelb

L Spannungsversorgung 230 V AC, 50...60

Hz

K

Neutralleiter

PE

Schutzleiter

| 002

Page 38

| Elektrischer Anschluss

38

8.3.2 Anschlussplan IV Smart EC

Kundenseite

max. Drehzahl

einstellbare Drehzahl über PWM

1...10 KHz

DE

einstellbare Drehzahl

10 V –> n = max.

1 V –> n = min.

<1 V –> 0

einstellbare Drehzahl über

Potentiometer

100 % PWM –> n = max

10 % PWM –> n = min

< 10 % –> 0

Leitung

Nr.

1 PE

2 L

3 N

4 GND

5

6

7 0...10 V PWM

Anschluss Farbe Funktion/Belegung

Drehzahlmesser weiß Drehzahlausgang: Open Collector, 1 Impuls pro Umdrehung,

10 V/max. 1,1 mA

grün/gelb Schutzleiter

braun

blau Neutralleiter

blau GND-Anschluss der Reglerschnittstelle

rot

gelb Reglereingang 0...10 V oder PWM

Spannungsversorgung 230 V AC, 50...60 Hz,

Spannungsbereich s. Typenschild

elektrisch isoliert, Isink_max. = 10 mA

Ausgangsspannung 10 V/1,1 mA

| 002

Page 39

DE

Elektrischer Anschluss |

8.3.3 Anschlussplan IV Smart EC-CO

Der Anschlussplan für IV Smart EC-CO ist nicht in diesem Dokument, jedoch in dieser Lieferung enthalten.

39

Tabelle 5 Elektrische Anschlüsse

Name

X1

X2

X3

X4

X5

X6

X7

Belegung Bezeichnung Beschreibung

1. L

2. N

3. PE

1. L

2. N

3. PE

1. L

2. N

3. PE

1. 10 V

2. 0-10 V

3. HALL

4. GND

1. 10 V

2. 0-10 V

3. HALL

4. GND

1. 24 V

2. 4-20 mA

3. Erde

1. NC

2. COM

3. NO

X1

Spannungsversorgung

X2 Ventilator 1

X3 Ventilator 2

X4 Ventilator 1

X5 Ventilator 2

X6 Sensor

X7 ALARM

Spannungsversorgung der Steuerung

Anschlüsse Spannungsversorgung für Ventilator 1 Spannung

entspricht der Anschlussspannung der Steuerung

Anschlüsse Spannungsversorgung für Ventilator 2 Spannung

entspricht der Anschlussspannung der Steuerung

Regelanschlüsse für Ventilator 1 Drehzahlvorgabe und

Drehzahlrückmeldung Falls der Ventilator über ein 10 V Ausgang

verfügt, kann er an X4.1 angeschlossen werden.

Regelanschlüsse für Ventilator 2 Drehzahlvorgabe und

Drehzahlrückmeldung Falls der Ventilator über ein 10 V Ausgang

verfügt, kann er an X5.1 angeschlossen werden.

Anschluss für CO-Sensor und Messsignal

Potentialfreier Alarmkontakt für den optionalen Anschluss einer

Alarmsirene oder anderer Zusatzgeräte.

8.3.3.1 Ventilatordrehzahlvorgabe

Die Mindestdrehzahl der Ventilatoren kann über einen Potentiometer zwischen 20 % und 40 % eingestellt werden. Der

Potentiometer kann nur erreicht werden, wenn die Gehäuseabdeckung abgenommen wird. Die Ventilatordrehzahl wird

proportional zu der CO-Konzentration bis zur Maximaldrehzahl von 50 ppm erhöht. Wenn ein Fehler erkannt wird, läuft

| 002

Page 40

| Inbetriebnahme

40

der Ventilator mit Maximaldrehzahl, um die angestiegene CO-Konzentration in der Luft zu beseitigen. Die folgende Tabelle enthält Angaben zu den Drehzahlvorgaben der Ventilatoren.

Tabelle 6 Ventilatordrehzahlvorgabe

DE

CO-Konzentration

CO < 15 ppm Ausschalthysterese 10 ppm

CO = 15 ppm

15 ppm < CO ≤ 50 ppm Min.…10 V

50 ppm < CO 10 V

Fehler

Ventilatordrehzahlvorgabe Anmerkung

0 V

2 V…4 V (min.)

10 V

Stillstand Ventilator

Drehzahl abhängig vom eingestellten

Wert

Linearer Anstieg der Kennlinie analog

zur CO-Konzentration, beginnend von

Mindest- bis Maximaldrehzahl der

Ventilatoren

Maximale Ventilatordrehzahl

Maximale Ventilatordrehzahl

8.4 Schutzerdungsleiter

Der Querschnitt des Schutzerdungsleiters muss gleich oder größer als der Phasenquerschnitt betragen.

8.5 FI-Schutzschalter

Für den Einsatz in Wechselstromsystemen mit 50/60 Hz sind in Verbindung mit elektronischen Geräten wie EC-Motoren, Frequenzumrichtern oder unterbrechungsfreien Stromversorgungen (USV) allstromsensitive Fehlerstromschutzschalter erforderlich.

8.6 Motorschutz

Hinweis!

Ventilatoren mit EC-Motor erfordern keinen zusätzlichen Motorschutz. Der Motorschutz ist in die

Motorelektronik integriert.

Wichtig

Motorschäden durch Überspannung, Überlast oder Kurzschluss.

♦ Es sind allpolige Leitungsschutzschalter (Auslösecharakteristik C oder K) oder Motorschutzschalter zu

verwenden.

♦ Thermokontakte oder der Kaltleiter sind immer an einen Motorschutz anzuschließen.

9 Inbetriebnahme

9.1 Sicherheitshinweise

♦ Die Inbetriebnahme darf nur von entsprechend qualifizierten Personen ausgeführt werden, Einzelheiten, s. Tabelle 1

Qualifikation, Seite 30.

♦ Bei jeglichen Arbeiten im Umfeld des Ventilators ist die Schutzausrüstung zu tragen, s. 2.2 Persönliche Schutzausrü-

stung, Seite 30.

9.2 Voraussetzungen

♦ Montage und elektrischer Anschluss sind fachgerecht abgeschlossen.

♦ Restmaterial von der Installation und Fremdkörper wurden aus dem Ventilator und den Kanälen entfernt.

♦ Ein- und Auslass sind frei.

♦ Die Sicherheitsvorrichtungen wurden angebracht.

♦ Das Erdungskabel ist angeschlossen.

♦ Die Kabelverschraubungen wurden fest angezogen.

♦ Der Nennstrom (siehe Typenschild) wird nicht überschritten.

| 002

Page 41

DE

♦ Die Daten auf dem Typenschild entsprechen den Anschlussdaten.

Inbetriebnahme |

9.3 Inbetriebnahmeprotokoll

Wichtig

• Es wird empfohlen, das Inbetriebnahmeprotokoll auszufüllen 16 Inbetriebnahmeprotokoll, Seite 48.

• Das vollständige Inbetriebnahmeprotokoll ist an einem sicheren Ort aufzubewahren. Im

Gewährleistungsfall kann das Inbetriebnahmeprotokoll von Systemair GmbH angefordert werden. Dieses

Dokument kann auch in unserem Online-Katalog heruntergeladen werden.

9.4 Tests vor der Aktivierung

♦ Prüfen Sie, ob die Sicherheitsvorrichtungen oder Schutzgitter sicher befestigt sind.

9.5 Tests (AC-Motor)

1. Überprüfen Sie den Ventilator vor Einschalten auf sichtbare Schäden und stellen Sie die ordnungsgemäße Funktion

der Schutzeinrichtungen sicher.

2. Schalten Sie den Ventilator ein.

3. Zu prüfen:

♦ Drehrichtung/Förderrichtung Es gilt immer die Drehrichtung mit Blick auf das Laufrad.

• Die Drehrichtung kann am besten festgestellt werden, bevor der Ventilator anhält.

♦ Laufruhe (eventuelle Schwingungen und Geräusche)

♦ Stromverbrauch

♦ Vergleichen Sie die Stromaufnahme mit den Nenndaten auf dem Typenschild.

♦ Dichtigkeit aller Anschlüsse

4. Schalten Sie den Ventilator aus.

41

9.6 Testen Sie den Motor (EC-Motor)

1. Überprüfen Sie den Ventilator vor Einschalten auf sichtbare Schäden und stellen Sie die ordnungsgemäße Funktion

der Schutzeinrichtungen sicher.

Bei eingeschalteter Netzspannung startet der Motor eine Initialisierung (einige Sekunden). Nach der Initialisierung ist

der Steuereingang aktiv.

2. Ausschalten des Ventilators über den Steuereingang.

3. Zu prüfen:

♦ Drehrichtung/Förderrichtung Es gilt immer die Drehrichtung mit Blick auf das Laufrad.

• Die Drehrichtung kann am besten festgestellt werden, bevor der Ventilator anhält.

♦ Laufruhe (eventuelle Schwingungen und Geräusche)

♦ Stromverbrauch

♦ Vergleichen Sie die Stromaufnahme mit den Nenndaten auf dem Typenschild.

♦ Dichtigkeit aller Anschlüsse

4. Ausschalten des Ventilators über den Steuereingang.

9.7 Tests bei Aktivierung EC-CO-Version

9.7.1 Funktionsprüfung

Nach Aufschalten der Versorgungsspannung wird eine Funktionsprüfung durchgeführt. Dabei werden die Anzeigen, potentialfreie Kontakte und die Ventilatoren durch kurzes Anschalten geprüft. Die Steuerung wurde korrekt installiert

wenn die Power-Anzeige dauerhaft leuchtet und die CO-Alarm- und Störungs-Anzeige nach 2 Sekunden, sowie die

akustische Anzeige nach 1 Sekunde ausgehen. Der potentialfreie Kontakt muss nach 1 Sekunde anziehen und somit

eine Verbindung zwischen X7.2 und X7.3 herstellen. Außerdem dürfen nach ungefähr 15 Sekunden keine Fehler angezeigt werden. Im Kaptiel 9.7.3 Optische und akustische Anzeige, Seite 42 werden die Bedeutung der unterschiedlichen

Signalisierungsarten genauer beschrieben.

| 002

Page 42

| Betrieb

42

9.7.2 Aufwärmzeit

Nachdem die Versorgungsspannung anliegt, befindet sich die Steuerung für 6,5 Minuten in einer Aufwärmzeit. In dieser