Page 1

English

GB

GB

GB

Français EspañolDeutsch Italiano

Roof-mouted air conditioning unit

Unite d'air conditionne de toiture

Dachklimagerät

Unità d’aria condizionata da tetto

Unidad da aire acondicionado de tejado

Installation and maintenance manual

Manuel d’installation et de maintenance

Installations- und Wartungshandbuch

Manuale di installazione e di manutenzione

Manual de instalación y de mantenimiento

IOM PRODUIT-N-6

Part number / Code / Teil Nummer / Codice / Código : 3990513

Supersedes / Annule et remplace / Annulliert und ersetzt /

Annulla e sostituisce / Anula y sustituye : IOM PRODUIT-N-5

13.0

Ü

31.0 kW

12.1

Ü

30.5 kW

HAN

13 ÷ 31

2640

Ü

5530 m3/h

Page 2

Page 3

English

Français

Español

Deutsch

Italiano

INSTALLATION INSTRUCTION

NOTICE D’INSTALLATION

INSTALLATIONSHANDBUCH

ISTRUZIONI INSTALLAZIONE

INSTRUCCIONES DE INSTALACIÓN

Page 4

English

2

HAN

CONTENTS

1. GENERAL RECOMMENDATIONS ........................................................................................................................................................ 3

1.1. SAFETY DIRECTIONS .......................................................................................................................................................................................................................3

1.2. WARNING .........................................................................................................................................................................................................................................3

1.3. EQUIPMENT SAFETY DATA .............................................................................................................................................................................................................4

2. INSPECTION AND STORAGE .............................................................................................................................................................. 5

3. WARRANTY ...................................................................................................................................................................................... 5

4. CONTENTS OF PACKAGE ................................................................................................................................................................... 5

5. PRESENTATION ................................................................................................................................................................................. 5

6. DIMENSIONS .................................................................................................................................................................................... 6

7. HANDLING ........................................................................................................................................................................................ 6

7.1. NET WEIGHT .....................................................................................................................................................................................................................................6

8. TECHNICAL SPECIFICATIONS ............................................................................................................................................................. 7

8.1. REFIGERATION SPECIFICATIONS .................................................................................................................................................................................................... 7

8.2. ELECTRICAL SPECIFICATIONS .........................................................................................................................................................................................................7

8.3. AERAULIC SPECIFICATIONS ............................................................................................................................................................................................................7

8.4. OPERATING LIMITS ..........................................................................................................................................................................................................................8

9. INSTALLATION .................................................................................................................................................................................. 9

9.1. PLACE OF INSTALLATION AND REQUIREMENTS .........................................................................................................................................................................9

9.2. CLEARANCE ...................................................................................................................................................................................................................................... 9

9.3. ATTACHMENT TO THE GROUND ...................................................................................................................................................................................................9

9.4. CONDENSATE DRAIN PAIN ...........................................................................................................................................................................................................10

9.5. AERAULIC CONNECTIONS .............................................................................................................................................................................................................10

9.5.1. AIR INTAKE AND BLOWING DUCT OUTLET DIMENSIONS ...................................................................................................................................................................................10

9.5.2. AIR FLOW / PRESSION ADJUSTMENT ....................................................................................................................................................................................................................11

10. ELECTRIC HEAT ............................................................................................................................................................................. 11

11. WIRING DIAGRAM AND LEGEND ..................................................................................................................................................12

11.1. WIRING DIAGRAM ......................................................................................................................................................................................................................12

11.2. LEGEND ........................................................................................................................................................................................................................................12

11.2.1. POWER SUPPLY ..................................................................................................................................................................................................................................................... 12

11.2.2. WIRING DIAGRAM KEY DESCRIPTIONS ..............................................................................................................................................................................................................12

11.2.2.1. COOLING / SAFETY ..............................................................................................................................................................................................................................12

11.2.2.2. VENTILATION ........................................................................................................................................................................................................................................12

11.2.2.3. CONTROL AND REGULATION .............................................................................................................................................................................................................. 13

11.2.2.4. ELECTRIC HEATING KIT ........................................................................................................................................................................................................................13

11.2.3. RANGE AND SETTINGS OF THEMAL PROTECTION / NOMINAL INTENSITY OF THE CONTACTORS (CLASSE AC3).................................................................................13

11.2.4. COMPRESSOR CRANKCASE HEATER .................................................................................................................................................................................................................. 13

11.2.5. PRESSOSTATS SETTING ....................................................................................................................................................................................................................................... 13

11.2.6. COLOUR CODE .......................................................................................................................................................................................................................................................13

12. ELECTRICAL CONNECTIONS ........................................................................................................................................................... 14

12.1. CONNECTION OF RCW2 AND REMOTE ROOM TEMPERATURE ............................................................................................................................................15

13. COMMISSIONING .......................................................................................................................................................................... 16

13.1. PRE-START CHECK LIST ..............................................................................................................................................................................................................16

13.1.1. ELECTRICAL CHECK ............................................................................................................................................................................................................................................... 16

13.1.2. VISUAL CHECK ....................................................................................................................................................................................................................................................... 16

13.1.3. DUCTING ................................................................................................................................................................................................................................................................. 16

13.2. OPERATING CHECK LIST .............................................................................................................................................................................................................17

13.2.1. GENERAL ................................................................................................................................................................................................................................................................ 17

13.2.2. PHASE ROTATION PROTECTION .........................................................................................................................................................................................................................17

13.2.3. ELECTRICAL ............................................................................................................................................................................................................................................................ 17

13.2.3.1. OPERATING VOLTAGE: ......................................................................................................................................................................................................................... 17

13.2.3.2. CONTROL ............................................................................................................................................................................................................................................... 17

13.2.4. AIR BALANCING .................................................................................................................................................................................................................................................... 17

13.2.4.1. CASE N°1: ............................................................................................................................................................................................................................................. 17

13.2.4.2. CASE N°2: ............................................................................................................................................................................................................................................. 17

13.2.5. COMPRESSOR AND REFRIGERATION SYSTEM .................................................................................................................................................................................................. 17

14. FINAL TASKS ................................................................................................................................................................................18

15. IN CASE OF WARRANTY - MATERIAL RETURN PROCEDURE .........................................................................................................18

16. ORDERING SERVICE AND SPARE PARTS ORDER ...........................................................................................................................18

17. MAINTENANCE ............................................................................................................................................................................. 18

17.1. REGULAR MAINTENANCE ..........................................................................................................................................................................................................18

17.2. GENERAL INSPECTION ...............................................................................................................................................................................................................19

17.3. OPENING OF ACCESS PANELS ...................................................................................................................................................................................................19

17.4. BLOWER DRIVE SYSTEM ............................................................................................................................................................................................................19

17.5. COILS .............................................................................................................................................................................................................................................19

17.6. ELECTRICAL SECTION..................................................................................................................................................................................................................19

18. TROUBLE SHOOTING ..................................................................................................................................................................... 20

Page 5

English

3

HAN

POWER SUPPLY MUST BE

SWITCHED OFF

BEFORE STARTING TO

WORK IN THE ELECTRIC

CONTROL BOX

1. GENERAL RECOMMENDATIONS

Please read the following safety precautions very carefully before installing the unit.

1.1. SAFETY DIRECTIONS

Follow the safety rules in forces when you are working on your appliance.

The installation, commissioning and maintenance of these units should be performed by qualied personnel

having a good knowledge of standards and local regulations, as well as experience of this type of equipment.

Given the requirements of pressurising the system and the high current draws involved, this roof-

mounted air conditioning should only be installed by qualied personnel.

The unit should be handled using lifting and handling equipment appropriate to the unit's size and weight.

Given the high refrigerant temperatures present at certain points in the cooling circuit, access to the area

protected by the panels is strictly reserved for qualied personnel only.

Any wiring produced on site must comply with the corresponding national electrical regulations.

Make sure that the power supply and its frequency are adapted to the required electric current of operation,

taking into account specic conditions of the location and the current required for any other appliance

connected to the same circuit.

The unit must be EARTHED to avoid any risks caused by insulation defects.

It is forbidden to start any work on the electrical components if water or high humidity is present on the

installation site.

1.2. WARNING

Cutoff power supply before starting to work on the appliance.

The manufacturer declines any responsibility and the warrantly becomes void if these instructions are

not respected.

If you meet a problem, please call the Technical Department of your area.

If possible, assemble the compulsory or optional accessories before placing the appliance on its nal location.

(see instructions provided with each accessory).

In order to become fully familiar with the appliance, we suggest to read also our Technical Instructions.

-The informations contained in these Instructions are subject to modication without advance notice.

Page 6

English

4

HAN

1.3. EQUIPMENT SAFETY DATA

Safety Data R410A

Toxicity Low

In contact with skin

Skin contact with the rapidly evaporating liquid may cause tissue chilblains. In case of skin contact with

the liquid, warm the frozen tissue with water and call a doctor. Remove contaminated clothing and

footwear. Wash the clothing prior to re-use.

In contact with eyes

Vapours have no effect. Liquid splashes or sprays may cause freeze burns. In these cases rinse your eyes

with running water or with a solution for eye lavages for at least 10 minutes. Immediately apply to a

doctor.

Ingestion

In this case, burns may result. Do not attempt to make the patient vomit. If the patient is conscious, rinse

the mouth with water. Call a doctor immediately.

Inhalation

In case of inhalation, move the patient to an area with fresh air and provide oxygen if necessary. Perform

artificial respiration if the patient has stopped breathing or lacks air. In case of cardiac arrest, perform

external cardiac massage. Call a doctor immediately.

Further Medical Advice

Exposure to high concentrations can be dangerous for individuals with cardiac problems, as the presence

of catecholamines such as adrenalin in the bloodstream may lead to increased arrhythmia and possible

cardiac arrest.

Occupational exposure limits R410A: Recommended limits: 1,000 ppm v/v 8 hours TWA.

Stability Stable product

Conditions to avoid

Increased pressure due to high temperatures may cause the container to explode. Keep out of the sun

and do not expose to a temperature >50°C.

Hazardous reactions Possibility of dangerous reactions in case of fire due to the presence of F and/or CI radicals

General precautions

Avoid the inhalation of high concentrations of vapours. The concentration in the atmosphere shall be kept

at the minimum value and anyway below the occupational limits. Since vapours are heavier than air and

they tend to stagnate and to build up in closed areas, any opening for ventilation shall be made at the

lowest level.

Breathing protection

In case of doubt about the actual concentration, wear breathing apparatus. It should be self-contained

and approved by the bodies for safety protection.

Storage Preservation

Refrigerant containers shall be stored in a cool place, away from fire risk, direct sunlight and all heat

sources, such as radiators. The maximum temperature shall never exceed 50°C in the storage place.

Protection clothes Wear boots, safety gloves and glasses or masks for facial protection.

Behaviour in case of leaks or

escapes

Never forget to wear protection clothes and brething apparatus. Isolate the source of the leakage,

provided that this operation may be performed in safety conditions. Any small quantity of refrigerant

which may have escaped in its liquid state may evaporate provided that the room is well ventilated.

In case of a large leakage, ventilate the room immediately. Stop the leakage with sand, earth or any

suitable absorbing material. Prevent the liquid refrigerant from flowing into drains, sewers, foundations

or absorbing wells since its vapours may create an asphyxiating atmosphere.

Disposal

The best procedure involves recovery and recycle. If this is not possible, the refrigerant shall be given to

a plant which is well equipped to destroy and neutralise any acid and toxic by-product which may derive

from its disposal.

Combustibility features R410A: Non-inflammable at ambient temperatures and atmospheric pressures.

Containers

If they are exposed to the fire, they shall be constantly cooled down by water sprays.

Containers may explode if they are overheated.

Behaviour

in case of fire In case of fire wear protection clothes and self-contained breathing apparatus.

Page 7

English

5

HAN

2. INSPECTION AND STORAGE

At the time of receiving the equipment carefully cross check all the elements against the shipping documents

in order to ensure that all the crates and boxes have been received. Conrmation of the type of unit ordered

can be obtained by reading the maker’s plate.

Inspect the units for any visible or hidden damage.

In the event of shipping damage, write precise details of the damage on the shipper’s delivery note and

send immediately a registered letter to the shipper within 48 hours, clearly stating the damage caused.

Forward a copy of this letter to the manufacturer or their representative.

Never store or transport the unit upside down. Protect unit at the job side from domages made by others.

When unit is stored on the ground, avoid mud store unit leveled.

3. WARRANTY

The appliances are delivered fully assembled, factory tested and ready to operate.

Any modication to the units without the manufacturer’s prior approval, shall automatically render the

warranty null and void.

The following conditions must be respected in order to maintain the validity of the warranty:

² Commissioning shall be performed by specialised technicians from technical services approved by

the manufacturer.

² Maintenance shall be performed by technicians trained for this purpose.

² Only Original Equipment spare parts shall be used.

² All the operations listed in the present manual shall be performed within the prescribed schedule.

THE WARRANTY SHALL BE NULL AND VOID IN THE EVENT

OF NON-COMPLIANCE WITH ANY OF THE ABOVE CONDITIONS.

4. CONTENTS OF PACKAGE

1 HAN

1 Installation and maintenance manual

1 Control manual

5. PRESENTATION

The machine has been designed for an outdoor application, ensuring perfectly weatherproof circulation of

the air in the air treating compartments.

The HAN features a compact design and has an optimal foot print/weight ratio. All units are charged and

tested at the factory and are supplied ready to start for quick and easy installation.

Page 8

English

A

178

600

78

6

HAN

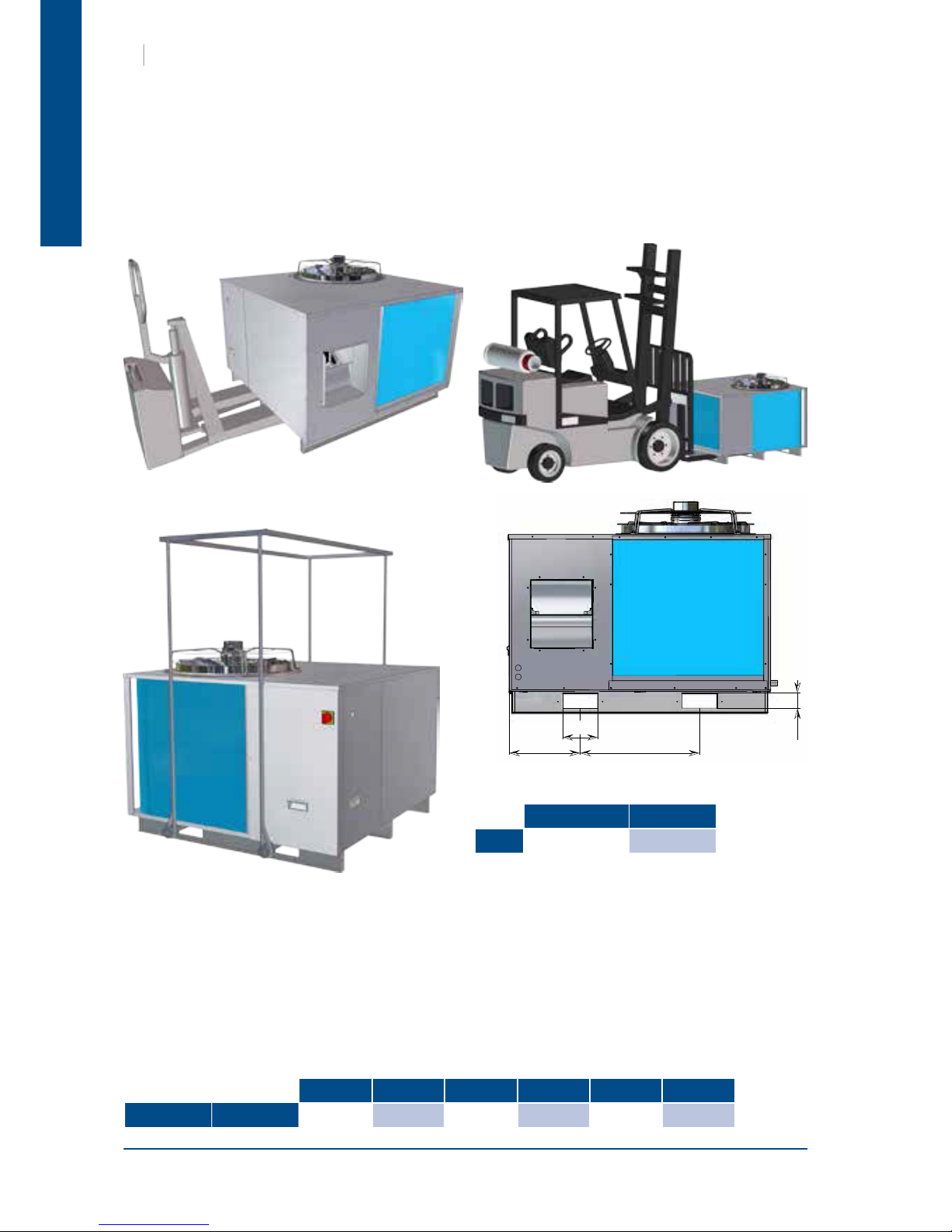

6. DIMENSIONS

7. HANDLING

SEE APPENDIX

7.1. NET WEIGHT

The unit can also be lifted by using slings.

A spreader must be used to avoid damaging the casing of the machine.

13-15-17-19 25-31

A

360 425

13 15 17 19 25 31

Weight Kg

219 223 223 243 320 343

Page 9

English

7

HAN

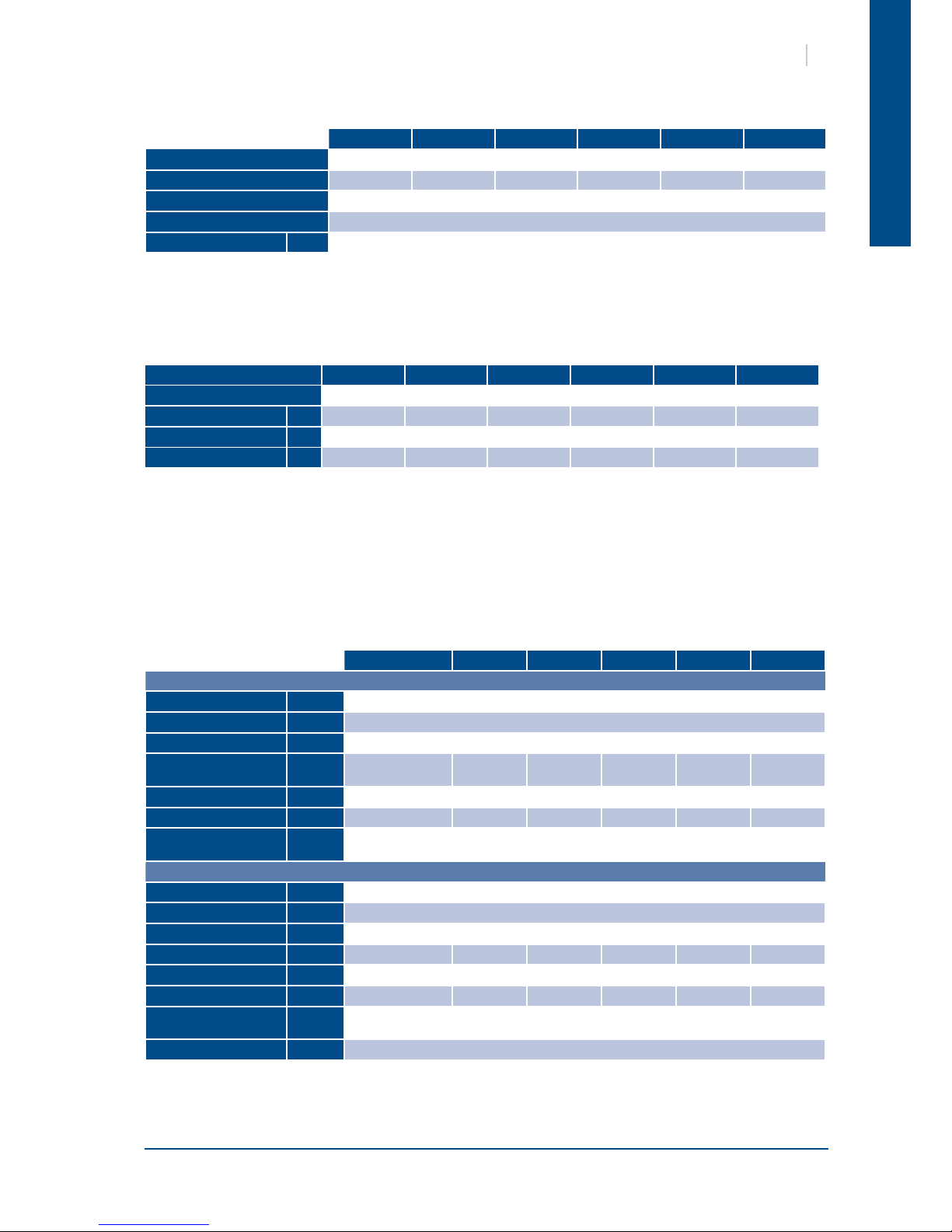

8. TECHNICAL SPECIFICATIONS

IMPORTANT

A main fuse must mandatorily be provided on the power supply.

² Fuses not supplied

² Cables not supplied

Units are supplied pre-charged with refrigerant uid.

This equipment contains uorinated gas with greenhouse gas effects covered by the Kyoto agreement.

(1) At nominal air ow and at maximum fan speed without air lter

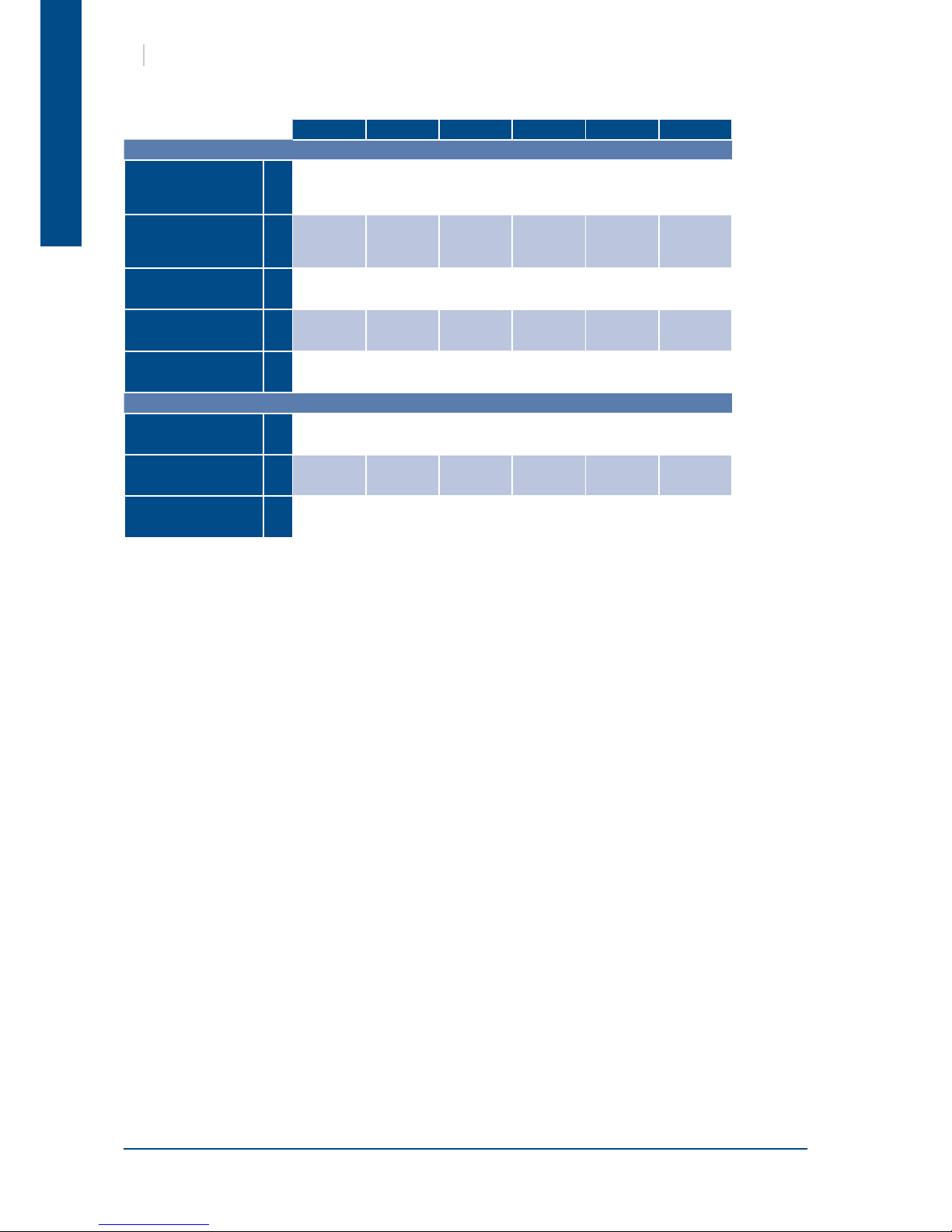

13 15 17 19 25 31

Compressor type

Scroll Scroll Scroll Scroll Scroll Scroll

Compressor quantity

1 1 1 1 1 1

Number of circuit

1 1 1 1 1 1

Refrigerant

R410A

Charge of circuit kg

SEE NAME PLATE

13 15 17 19 25 31

Indoor fan

Number of fan

1 1 1 1 1 1

Type

Centrifugal

Drive type

Direct Belt / variable pitch pulley

Motor nominal power

input

kW

0.60 0.75 0.75 1.10 1.10 1.50

Power supply V/Ph/Hz

230V/1~/50Hz 400V / 3~N /50Hz

Nominal airow m3/h

2640 2940 3190 3860 4780 5530

Available static

pressure

(1)

Pa

100 170 160 210 240 250

Outdoor fan

Number of fan

1 1 1 1 1 1

Type

Propeller

Number of blades

3 3 3 3 5 5

Fan diameter mm

610 610 610 610 710 710

Drive type

Direct

Nominal airow m3/h

9000 9000 9000 9000 12000 12000

Motor nominal power

input

kW

0.49 0.49 0.49 0.49 0.90 0.90

Power supply V/Ph/Hz

230V/1~/50Hz

13 15 17 19 25 31

Power supply

400V / 3~N /50Hz

Maximum current A

16 17 20 21 29 30

Starting current A

70 69 79 107 119 126

Fuse rating FFG aM A

16 20 20 25 32 32

8.1. REFIGERATION SPECIFICATIONS

8.2. ELECTRICAL SPECIFICATIONS

8.3. AERAULIC SPECIFICATIONS

Page 10

English

8

HAN

8.4. OPERATING LIMITS

13 15 17 19 25 31

Cooling mode

Outside temperature

min. for standard

version

°C

15 15 15 15 15 15

Outside temperature

min. with all seasons

kit

°C

-10 -10 -10 -10 -10 -10

Inside temperature

min. DB/WB

°C

21 / 15 21 / 15 21 / 15 21 / 15 21 / 15 21 / 15

Outside temperature

max..

°C

50 50 50 50 50 50

Inside temperature

max. DB/WB

°C

32 / 23 32 / 23 32 / 23 32 / 23 32 / 23 32 / 23

Heating mode

Outside temperature

min.

°C

-10 -10 -10 -10 -10 -10

Outside temperature

max. DB

°C

24 24 24 24 16 24

Inside temperature

max. DB

°C

27 27 27 27 27 27

The All Seasons kits modulates the outdoor fan speed to enable the machine to operate in Cooling mode at

outdoor ambient temperatures as low as -10°C.

DB: Dry Bulb temperature

WB: Wet bulb temperature

Page 11

English

9

HAN

The unit is not designed to withstand weights or stresses from adjacent equipment, pipe work

or constructions. Any foreign weight or stress on the unit structure could lead to a malfunction

or a collapse with dangerous consequences for personnel and property. In such an event, the

warranty shall be null and avoid.

9. INSTALLATION

² The building structure must be capable to carrying the weight of the unit during operation.

² The place of installation must not be subject to ooding.

² The HAN should be installed on a at, clean surface without any obstacles. The surface area must be

sufcient to spread the weight of the unit over the building structure.

² Ensure that the recommended free clearances around the unit are maintained to avoid any risk of

malfunctions.

² Ensure that there are no obstructions around the condenser or the air outlet to avoid any risk of

recycling old air.

² In addition to the service clearances stated on the dimensions sheet, it is imperative to provide a

safe and appropriate access to the unit for repairs and servicing.

² The installer is responsible for providing the weaterproof seal between the building and the HAN. The

installer must be fully versed in the practice of roof mounted equipments and must comply with the

recommendations and rules detailed in the Technical Directives.

² In order to avoid risk of condensation and energy losses, all outdoor ducting and piping must be

insulated.

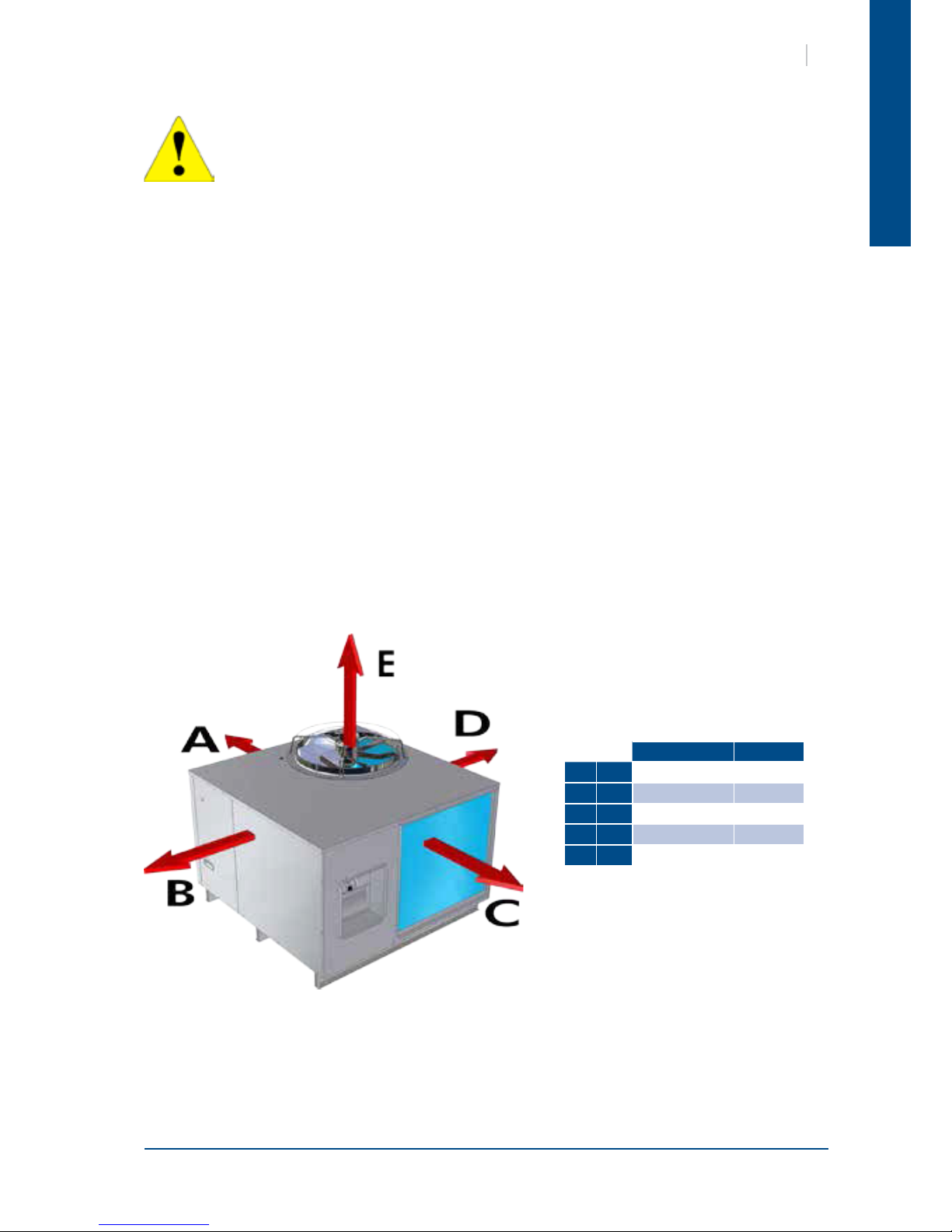

9.1. PLACE OF INSTALLATION AND REQUIREMENTS

SEE APPENDIX

13-15-17-19 25-31

A mm

800 800

B mm

800 800

C mm

800 800

D mm

850 1000

E mm

3000 3000

9.2. CLEARANCE

9.3. ATTACHMENT TO THE GROUND

Page 12

English

75 mm (Mini)

2% Mini

Ø1" (25.4 mm)

75 mm

A

30

A

B

C

D

G

H

F

D

10

HAN

Syphon to be supplied

by the installer

The installer must imperatively initiate thte syphon action.

9.5.1. AIR INTAKE AND BLOWING DUCT OUTLET DIMENSIONS

13-15-17-19 25-31

A

156 156

A B C D E F G H

13

290 295 110 272 35 765 155 712

15-17-19

320 345 110 316 35 765 155 712

25

320 345 137 316 35 860 155 1030

31

320 345 85 405 35 860 155 1030

CAUTION

For Heat pump models, where the outdoor temperature is likely to fall below +1°C, provide a system

to prevent the syphon from freezing (e.g. heating cord).

9.4. CONDENSATE DRAIN PAIN

9.5. AERAULIC CONNECTIONS

Page 13

English

10 mm maxi.

5 kg

90

11

HAN

If the unit is to be equipped with an electric heating kit, the latter must be installed on the blown air duct

inside the building.

Safety devices (automatic and manual reset thermostats) protect the appliance against any possible risks of

overheating due to insufcient ow around the shielded elements.

The electric heating kit power supply must be separated from the HAN unit's power supply. Only the electric

heating control functions are managed by the HAN unit (refer to appended wiring diagrams).

9.5.2. AIR FLOW / PRESSION ADJUSTMENT

SEE TO APPENDED AERAULIC CHARACTERISTICS

The HAN models 13 are equipped with direct drive centrifugal compressors.

From HAN model 15 upwards, air ow / static pressure is adjusted via a variable pulley. When adjusting this

pulley it is important to ensure that the drive belt is positioned correctly. The latter must not move out of its

groove or be located at the bottom of the groove. The pulley/drive belt assembly must be perfectly aligned

and the belt must be properly tightened in accordance with specications.

For a quick check, make sure that the small

rope touch each end of the pulleys as

shown on drawing above.

Belt alignment Belt tensioning

The HAN roof-mounted units are designed for ducted applications. In the event of an

application without a duct network on the blowing side ("free" blowing) it is necessary to

create an articial pressure loss on the blowing side to avoid damage to the fan motor due to

an abnormally high current draw. This pressure loss can be created for example by adding a

perforated plate that will also have the effect of improving blown air distribution.

To achieve optimal performance, this plate should be of an adequate size and suitably positioned to ensure

that the airow is close to the unit's nominal airow.

Perforated plate

(air distributor)

10. ELECTRIC HEAT

Page 14

English

12

HAN

SE 3676 HAN 13 400V/3N~/50Hz +/- 10%

SE 3678 HAN 15/17/19 400V/3N~/50Hz +/- 10%

SE 3679 HAN 25/31 400V/3N~/50Hz +/- 10%

FFG : Protective fuses (not supplied)

Q1 : Mains supply circuit switch

K1 : M1 compressor power circuit contactor

KA1 : Three-phase network control relay (phase sequence and cut-out)

HP1 : Automatic reset high-pressure pressostats

LP1 : Automatic reset low-pressure pressostats

M1 : Compressor

R1 : M1 compressor crankcase heater

RV1 : Cycle inversion valve (option)

MO1 : Outdoor fan motor

CO1 : Outdoor fan motor condenser

FO1 : MO1 motor internal protection

MI3 : Indoor fan motor

K3 : MI3 contactor.

FT3: MI3 thermal relay.

11.1. WIRING DIAGRAM

11.2. LEGEND

11.2.1. POWER SUPPLY

This supply is protected upstream by an FFG general supply fuse holder, to be provided by the installer, in

accordance with "ELECTRICAL SPECIFICATIONS".

The electrical installation and the wiring of this unit shall comply with local electrical installation standards.

² Three phase 400 V~ + Neutral + Ground:

On terminals PE, N, L1, L2, L3 on the Q1 mains supply circuit switch.

On the ground screw for the earth cable.

11.2.2. WIRING DIAGRAM KEY DESCRIPTIONS

11.2.2.1. COOLING / SAFETY

11.2.2.2. VENTILATION

N771

SEE APPENDIX

11. WIRING DIAGRAM AND LEGEND

Page 15

English

13

HAN

11.2.2.3. CONTROL AND REGULATION

RT : Ambient temperature probe (option)

ICT : Indoor exchanger temperature probe

OCT : Outdoor exchanger temperature probe

SM1 : Remote ON/OFF switch (not supplied) (remove the "SHM" shunt on the circuit board)

K5/6 : Heating elements power contactors

FM5/6 : Heating manual reset safety thermostat

FA5/6 : Heating automatic reset safety thermostat

11.2.2.4. ELECTRIC HEATING KIT

13 15 17 19 25 31

Thermal relay

FT3

Range

/ 1.8-2.6A 1.8-2.6A 1.8-2.6A 2.6-3.7A 2.6-3.7A

Adjustment

/ 1.9A 1.9A 2.5A 2.6A 3.4A

Contactor AC3

K1

12A 18A 18A 18A 25A 25A

K3

/ 9A 9A 9A 9A 9A

13 15 17 19 25 31

Power w

70 70 70 70 90 90

11.2.3. RANGE AND SETTINGS OF THEMAL PROTECTION / NOMINAL INTENSITY OF THE CONTACTORS

(CLASSE AC3)

11.2.4. COMPRESSOR CRANKCASE HEATER

11.2.5. PRESSOSTATS SETTING

LP1 : Factory low pressure adjustment 2bars (29PSI)

HP1 : Factory high pressure adjustment 42bars (609.16PSI)a

11.2.6. COLOUR CODE

BK : Black OG : Orange GNYE : Green/Yellow

BN : Brown WH : White RD : Red

BU : Blue GY : Grey VT : Violet

YE : Yellow

Page 16

English

14

HAN

12. ELECTRICAL CONNECTIONS

WARNING

BEFORE CARRYING OUT ANY WORK ON THE EQUIPMENT,

MAKE SURE THAT THE ELECTRICAL POWER SUPPLY IS

DISCONNECTED AND THAT THERE IS NO POSSIBILITY OF THE

UNIT BEING STARTED INADVERTENTLY.

NON-COMPLIANCE WITH THE ABOVE INSTRUCTIONS CAN

LEAD TO INJURY OR DEATH BY ELECTROCUTION.

The electrical installation must be performed by a fully qualied electrician, and in accordance with local

electrical standards and the wiring diagram corresponding to the unit model.

Any modication performed without our prior authorisation may result in the unit’s warranty being declared

null and void.

The power supply cable section must be sufcient to provide the appropriate amperage to the unit’s main

power terminals, at start-up and under full load operating conditions.

The power supply cable shall be selected in accordance with the following criteria:

1. Power supply cable length.

2. Maximum unit starting current draw – the cables shall supply the appropriate amperage to the unit

terminals for starting.

3. Power supply cables’ installation mode. (do not leave cable weight hang on connecting lugs)

4. Cables’ capacity to transport the total system current draw.

Short circuit protection shall be provided by others. This protection shall comprise fuses or circuit breakers

with high breaking capacity, mounted on the distribution board. The distribution board must support the

intensity of the whole of the machines installed.

VERY IMPORTANT:

3N~400V-50Hz +

The outdoor unit is equipped as standard with a phase sequence and cut-out controller located in the

electrical box.

THIS PRODUCT IS EQUIPPED WITH A PHASE SEQUENCE CONTROLLER. THE LED’s INDICATE THE FOLLOWING

CONDITIONS:

Green LED = 1

Yellow LED =1

Low voltage supply

The compressor rotation

direction is correct

Green LED = 1

Yellow LED =0

Phase inversion or phase

absent (L1)

The compressor and the fans

do not start.

Green LED = 0

Yellow LED =0

Phase absent (L2 or L3)

the compressor and the fans

do not start.

Page 17

English

RS485

GND

12v

12V

GND

1

2

RT

GND

15

HAN

Use a pozidrive M3.5 screwdriver, Form Z, to make the connections.

These units are equipped with a local switch used as general terminal board.

The proximity switch can be mounted at two different locations:

The switch can be padlocked.

A circuit breaker or fuse holder ( not supplied ) must be installed on the main

power supply of the unit in accordance with the circuit diagram; for the raitings,

refer to the electrical specications.

3N~400V

12.1. CONNECTION OF RCW2 AND REMOTE ROOM TEMPERATURE

100 m MAXI

1 mm² MAXI

Shielded cable

IF the RT sensor is not used, the RCW2 must be congured in Zone 1 with the local temperature function

activated.

Remote room

temperature sensor

delivred with the

machine (optional

installation)

1000 m MAXI

Shielded 2 twisted pairs cable

with setting with terminal GND.

0,12 à 0,3 mm²

Page 18

English

16

HAN

13. COMMISSIONING

13.1. PRE-START CHECK LIST

13.1.1. ELECTRICAL CHECK

1. Electrical installation has been carried out according to unit wiring diagram and the Supply Authority

Regulations.

2. size fuses or circuit breaker has been installed at the main switchboard.

3. Supply voltages as specied on unit wiring diagram.

4. All cables are properly identied and tight connected at the unit.

5. That the wiring is not in contact with surfaces subject to high temperatures or sharp angles, or is

protected against such risks.

13.1.2. VISUAL CHECK

1. Clearances around unit including outdoor air entry and discharge openings and service accesses.

2. Unit mounted as specied.

3. For loose or missing bolts or screws.

4. For refrigerant leaks in connections and components.

5. All panels are in place and secured.

6. The unit is clean and free of any extraneous installation materials.

13.1.3. DUCTING

1. Connections exible type, secure and detachable for service access.

2. Fan drive from HAN model 15 upwards

Correct variable diameter pulley adjustment guaranteeing the intended air quantity and static

pressure (see § "AIR FLOW / PRESSURE ADJUSTMENT").

3. Check that the fan shaft and motor pulleys are mounted correctly and turn true.

4. Ensure that both pulley grooves are correctly aligned. Improper alignment of the pulleys and belt

may cause vibration in the blower drive and result in premature wear and noise.

Page 19

English

17

HAN

13.2.4. AIR BALANCING

A variable pulley is tted to the motor shaft in order to adjust the blower performance to the pressure drop

at the duct work. The pulley must be adjusted when the measured external static pressure and air volume

(motor current draw) differ from the nominal values at the unit. As a default setting, the variable diameter

pulley is open by 2 turns.

13.2.4.1. CASE N°1:

The measured air ow is higher than the nominal air ow. You must reduce the fan rotation speed by

opening the variable diameter pulley. It is imperative to adjust the pulley, otherwise the motor’s internal

protection will trigger because of overheating taking the entire unit out of operation.

13.2.4.2. CASE N°2:

The measured air ow is lower than the nominal air ow. You must increase the fan rotation speed by

closing the variable diameter pulley.

13.2. OPERATING CHECK LIST

13.2.1. GENERAL

Cheek for any unusual noises or vibration in the running components, particularly at the main blower.

13.2.2. PHASE ROTATION PROTECTION

If the phase at the power supply are not correct, the phase rotation protection device will prevent the

machine from starting.

13.2.3. ELECTRICAL

13.2.3.1. OPERATING VOLTAGE:

Recheck voltage at unit supply terminals.

13.2.3.2. CONTROL

1. Operate system and thermostat switches.

2. Check unit is wired for correct control of blower, cooling and heating modes.

3. Verify all sensor signal, using the controller display.

This section applies to all HAN from model 15.

13.2.5. COMPRESSOR AND REFRIGERATION SYSTEM

1. If outdoor air temperature is below 0°C make sure that the compressor crankcase heater has been on

for at least one hour before starting compressor.

2. Running check: Start the compressor. Check for any unusual noise or vibration.

3. Operating Pressures: Operate the unit for at last 20 minutes and ensure that the refrigerant pressures

are stabilised, and cheek that they are within the normal operating ranges.

4. Operating Temperature: Check discharge, suction and liquid temperatures.

5. Compressor output temperature in cooling mode should not normally exceed 105° C.

6. Compressor intake air superheating must be between 5° K and 12° K.

Page 20

English

18

HAN

The user is responsible for ensuring that it is in a proper working condition and that technical

installation as well as the regular maintenance operations are performed by properly trained

technicians and in accordance with the instructions contained in this manual.

17. MAINTENANCE

17.1. REGULAR MAINTENANCE

These units have been designed to require only minimal servicing, thanks to the use of a maximum number

of lubricated-for-life components. Nevertheless, certain regular servicing operations are necessary to

guarantee optimal system operation.

Servicing must be performed by experienced and qualied personnel only.

WARNING : Isolate unit from main power supply before working on unit.

14. FINAL TASKS

Operate the air conditioner in the presence of the user and explain all functions.

As required, demonstrate lter removal, cleaning and replacement.

15. IN CASE OF WARRANTY - MATERIAL RETURN PROCEDURE

Material must not be returned without permission of our After Sales Department.

To return the material, contact your nearest sales ofce and ask for a "return form". The return form shall

be sent with the returned material and shall contain all necessary information concerning the problem

encountered.

The return of the part is not an order for replacement. Therefore, a purchase order must be entered through

your nearest distributor or regional sales ofce. The order should include part name, part number, model

number and serial number of the unit involved.

Following our personal inspection of the returned part, and if it is determined that the failure is due to faulty

material or workmanship, and in warranty, credit will be issued on customer's purchase order. All parts shall

be returned to our factory, transportation charges prepaid.

16. ORDERING SERVICE AND SPARE PARTS ORDER

The part number, the order conrmation and the unit serial number indicated on the name plate must be

provided whenever service works or spare parts are ordered.

For any spare part order, indicate the date of unit installation and date of failure. Use the part number

provided by our service spare parts, if it not available, provide full description of the part required.

IT IS RECOMMENDED THAT THE DISCONNECT SWITCH BE PADLOCKED

CAUTION

BEFORE CARRYING OUT ANY OPERATION ON THE EQUIPMENT, CHECK THAT THE

ELECTRICAL POWER SUPPLY IS SWITCHED OFF AND THAT IT CANNOT BE SWITCHED

ON INADVERTENTLY.

Page 21

English

19

HAN

17.2. GENERAL INSPECTION

Carry out a visual inspection of the complete installation in service.

Check the general cleanness of the installation, and check if the condensate evacuations is not blocked,

specialy on the indoor coil, before the cooling season.

Check the condition of the condesate tray by pulling it out of the casing.

17.3. OPENING OF ACCESS PANELS

All access panels are removable by unscrewing the self tapping retaining screws.

17.4. BLOWER DRIVE SYSTEM

blower shaft and motor bearings are of permanently lubricated, sealed type and require no regular

maintenance other than a check on their general condition. The blower belt tension should be checked

regularly and belt surfaces inspected for cracks or excessive wear.

17.5. COILS

The refrigeration system is hermetically sealed and should require no regular maintenance. However, it is

recommended to leak test the refrigerant system and check the general operating conditions and control

devices on a regular basis. The operating pressures should be checked particularly as they are an excellent

guide for maintenance. This equipment must be subjected to regular tightness checks conducted by qualied

personnel. Please refer to national requirements to determine the frequency of these checks. After any

intervention requiring the opening of the refrigerant circuit, the system must be completely vacuum drained

by using the pressure tap installed for this purpose (Refer to the appended refrigerant circuit diagram).

Clean the heat exchanger using a special product for aluminium-copper heat exchangers, and rinse with

water. Do not use hot water or steam, as this could cause the pressure of the refrigerant to rise.

Check that the surface of the aluminium ns of the heat exchanger is not damaged by impacts or scratches,

and clean with an appropriate tool if necessary.

If necessary, the air lter located on the air intake must be cleaned

or replaced at regular intervals to ensure that unit operate properly.

A clogged lter causes a reduction in the airow across the heat

exchanger and this reduces the performance output.

The filters are located

on slide rails upstream

of the evaporator.

A system of sliding rails

enables you to remove

the lters without

having to remove the aeraulic duct.

17.6. ELECTRICAL SECTION

The contact surfaces of relays and contactors should be inspected regularly by an electrician and replaced

as judged necessary.

On these occasions the control box should be blown out with compressed air to remove any gathwing of

dust.

Check that the main power supply cable is not damaged or altered in such a way as to affect the insulation.

Check the earth grounding connection.

Page 22

English

20

HAN

18. TROUBLE SHOOTING

Problem Probable cause Solution

Unit operates

continuously but

without performing

Insufficient refrigerant charge. Top up the refrigerant fluid charge.

Reduced output

Check the 4 way valve on the compressor and replace the

valve if necessary.

Frozen suction line

The overheating setting on the thermostatic

expansion valve is too low.

Increase the setting.

Insufficient refrigerant charge Add refrigerant charge.

Evaporator freezing

Filters clogged Replace filters

Insufficient charge Add refrigerant charge.

Excessive noise

Vibrating pipe work

Attach the pipe work correctly.

Check the pipe work attachments.

Whistling noise from the thermostatic expansion

valve

Add refrigerant charge.

Noisy compressor Check the pressure difference of the 4-ways valves.

No pressure increase / mechanical damage to the

compressor

Contact an approved Service Centre.

Low oil level in the

compressor

Presence of one or several oil or gas leaks in the

circuit

Locate and repair the leaks and add oil

Mechanical compressor damage. Contact an approved Service Centre.

Crankcase oil heater resistance fault.

Check the electrical circuit and the condition of the

resistance. Replace defective parts if necessary.

compressor do not

operate.

No power at compressor

Check the electrical circuit and seek out any grounding

and/or short- -circuits. Check the fuses.

High pressure pressostat activated. Check for dirty condenser coil or defective fan

Control circuit fuse blown.

Check the control circuit and look for any grounding and/or

short-circuits. Replace the fuses.

Connection problem

Check the tightness of all the electrical connection

terminals.

Electrical circuits thermal protection cuts in. Check the operation of the control and safety devices.

Incorrect wiring. Check the wiring of the control and safety devices.

Mains voltage too low.

Check the power line.If the problem is due to the network,

inform the Electricity Company.

Compressor motor short–circuited. Check the continuity of the motor winding.

Compressor seized Replace the compressor.

Low pressure

pressostat being

activated.

Presence of a leak. Identify and repair the leak.

Insufficient refrigerant fluid charge. Add refrigerant charge.

Low air volume on evaporator check the blower and duct

High pressure

pressostat being

activated.

Incorrect operation of the high pressure

pressostat.

Check the operation of the pressostat. Replace it if

required.

Outlet valve partially closed. Open the valve. Replace it if required.

Non-condensable particles in the circuit. Bleed the circuit

Condenser fan not operating.

Check the wiring and the motors. Repair and replace if

required.

Liquid line too hot

Insufficient refrigerant charge.

Locate and eliminate the causes of charge losses and top

up the refrigerant fluid charge.

Fans do not operate.

Electrical circuit problems. Check the connections.

Internal circuit thermal cut-out activated. Contact an approved Service Centre.

Fan surging

Duct network pressure too low.

Generate an additional pressure loss (refer to aeraulic

curves)

Reduced output in

both Heating and

Cooling mode

Compressor operating fault Contact an approved Service Centre.

Outdoor coil dirty Clean the coil.

Insufficient refrigerant charge. Add refrigerant charge.

Lack of air flow

Clean the battery

Replace the filter

Check the air flow / pressure settings

Page 23

APPENDIX

ANNEXE

ANLAGE

ALLEGATO

ANEXO

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 24

ANEXO

ALLEGATO

ANLAGE

ANNEXE

APPENDIX

DIMENSIONS ................................................................................III

HAN 13 / 15 / 17 / 19 .................................................................................... III

HAN 25 / 31 ...................................................................................................... IV

SCHEMA DU CIRCUIT FRIGORIFIQUE ..............................................V

SCHEMAS ELECTRIQUES .............................................................. VI

HAN 13 ..............................................................................................................VII

HAN 15 / 17 / 19 ...........................................................................................VIII

HAN 25 / 31 ...................................................................................................... IX

CARACTERITIQUES AERAULIQUES .................................................X

ABMESSUNGEN ............................................................................III

HAN 13 / 15 / 17 / 19 .................................................................................... III

HAN 25 / 31 ...................................................................................................... IV

KÄLTEKREISLAUFDIAGRAMM .......................................................V

STROMLAUFPLANS ..................................................................... VI

HAN 13 ..............................................................................................................VII

HAN 15 / 17 / 19 ...........................................................................................VIII

HAN 25 / 31 ...................................................................................................... IX

REGELUNG DES LÜFTERSYSTEMS ..................................................X

DIMENSIONI .................................................................................III

HAN 13 / 15 / 17 / 19 .................................................................................... III

HAN 25 / 31 ...................................................................................................... IV

SCHEMA DEL CIRCUITO REFRIGERANTE .........................................V

SCHEMA ELETRICO ...................................................................... VI

HAN 13 ..............................................................................................................VII

HAN 15 / 17 / 19 ...........................................................................................VIII

HAN 25 / 31 ...................................................................................................... IX

REGOLAZIONE DEL SISTEMA

DI TRATTAMENTO DELL'ARIA ........................................................X

DIMENSIONES ..............................................................................III

HAN 13 / 15 / 17 / 19 .................................................................................... III

HAN 25 / 31 ...................................................................................................... IV

ESQUEMA DEL CIRCUITO FRIGORIFÍCO...........................................V

ESQUEMA ELECTRICO .................................................................. VI

HAN 13 ..............................................................................................................VII

HAN 15 / 17 / 19 ...........................................................................................VIII

HAN 25 / 31 ...................................................................................................... IX

AJUSTE DEL ISTEMA AEROLICO ......................................................X

DIMENSIONS ................................................................................III

HAN 13 / 15 / 17 / 19 .................................................................................... III

HAN 25 / 31 ...................................................................................................... IV

REFRIGERANT CIRCUIT DIAGRAM .................................................V

WIRING DIAGRAM ...................................................................... VI

HAN 13 ..............................................................................................................VII

HAN 15 / 17 / 19 ...........................................................................................VIII

HAN 25 / 31 ...................................................................................................... IX

AERAULIC ADJUSTMENT ................................................................X

II

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 25

HAN 13 / 15 / 17 / 19

1340

571

88

577

1063 1320

1147

88

152

30

6 x Ø12

DIMENSIONS

DIMENSIONS

ABMESSUNGEN

DIMENSIONI

DIMENSIONES

III

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 26

HAN 25 / 31

1420

600

102

594

1320

1267

1445

88

157

28

6 x Ø12

IV

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 27

REFRIGERANT CIRCUIT DIAGRAM

SCHEMA DU CIRCUIT FRIGORIFIQUE

KÄLTEKREISLAUFDIAGRAMM

SCHEMA DEL CIRCUITO REFRIGERANTE

ESQUEMA DEL CIRCUITO FRIGORIFÍCO

C : Compressor

CD : Condenser

EV : Evaporator

FC : Centrifugal fan

FH : Propellor fan

HP : Condensing pressure switch

BP : Evaporator pressure switch

P : Pressure Tap

TEV : Thermodynamic Expansion Valve

V : 4 way valve

C : Compresseur

CD : Condenseur

EV : Evaporateur

FC : Ventilateur centrifuge

FH : Ventilateur hélicoïde

HP : Pressostat HP

BP : Pressostat BP

P : Prise de pression

TEV : Détendeur thermostatique

V : Vanne d'inversion

C : Kompressor

CD : Verüssiger

EV : Verdampfer

FC : Zentrifugalventilator

FH : Axialventilator

HP : Druckschalter Hochdruck

BP : Druckschalter Niederdruck

P : Druckanschlussstelle

TEV : Thermostatisches Druckminderventil

V : Umkehrventil

C : Compressore

CD : Condensator

EV : Evaporatore

FC : Centrifugo ventilatore

FH : Elicoidale ventilatore

HP : Pressostato HP

BP : Pressostato BP

P : Presa di pressione

TEV : Regolatore di pressione termostatico

V : Valvola di inversione

C : Compresor

CD : Condensador

EV : Evaporador

FC : Centrifugo ventilator

FH : Helicoidal ventilator

HP : Presostato AP

BP : Presostato BP

P : Toma de presión

TEV : Reductor de presión termostático

V : Válvula de inversión

V

TEV

FH FC EVCD

P

C

P

HP

BP

P

V

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 28

WIRING DIAGRAM

SCHEMAS ELECTRIQUES

STROMLAUFPLANS

SCHEMA ELETRICO

ESQUEMA ELECTRICO

TAKE CARE!

These wiring diagrams are correct at the time of publication. Manufacturing changes can lead to

modications. Always refer to the diagram supplied with the product.

ATTENTION

Ces schémas sont corrects au moment de la publication. Les variantes en fabrication peuvent entraîner

des modications. Reportez-vous toujours au schéma livré avec le produit.

ACHTUNG!

Diese Stromlaufplans sind zum Zeitpunkt der Veröffentlichung gültig. In Herstellung bendliche Varianten

können Änderungen mit sich bringen. In jedem Fall den mit dem Produkt gelieferten Stromlaufplan

hinzuziehen.

ATTENZIONE !

Questi schemi sono corretti al momento della pubblicazione. Le varianti apportate nel corso della

fabbricazione possono comportare modiche. Far sempre riferimento allo schema fornito con il prodotto.

ATENCIÓN !

Esto esquemas son correctos en el momento de la publicación. Pero las variantes en la fabricación pueden

ser motivo de modicaciones. Remítase siempre al esquema entregado con el producto.

PUESTA FUERA DE TNESIÓN OBLIGATORIA ANTES DE CUALQUIER

INTERVENCIÓN EN LAS CAJAS ELÉCTRICAS!

PRIMA DI OGNI INTERVENTO SULLE CASSETTE ELETTRICHE ESCLUDERE

TASSATIVAMENTE L’ALIMENTAZIONE !

VOR JEDEM EINGRIFF AN DEN ANSCHLUßKÄSTEN UNBEDINGT DAS GERÄT

ABSCHALTEN!

MISE HORS TENSION OBLIGATOIRE AVANT TOUTE INTERVENTION DANS LES

BOITIERS ELECTRIQUES.

POWER SUPPLY MUST BE SWITCHED OFF BEFORE STARTING TO WORK IN

THE ELECTRIC CONTROL BOXES!

VI

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 29

HAN 13

T1PRI

T1SEC

>

>

<

>

VII

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 30

HAN 15 / 17 / 19

T1PRI

T1SEC

>

>

> >

<

>

VIII

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 31

HAN 25 / 31

T1PRI

T1SEC

>

>

>>

<

>

IX

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 32

AERAULIC ADJUSTMENT

CARACTERITIQUES AERAULIQUES

REGELUNG DES LÜFTERSYSTEMS

REGOLAZIONE DEL SISTEMA DI TRATTAMENTO DELL'ARIA

AJUSTE DEL ISTEMA AEROLICO

HAN 13

WITHOUT AIR FILTER

SANS FILTRE À AIR

OHNE LUFTFILTER

SENZA FILTRO AD ARIA

SIN FILTRO A AIRE

WITH AIR FILTER

AVEC FILTRE À AIR

MIT LUFTFILTER

CON FILTRO AD ARIA

CON FILTRO A AIRE

0

20

40

60

80

100

120

140

160

180

2100 2200 2300 2400 2500 2600 2700 2800 2900

Pa

GV

PV

m3/h

2640

0

20

40

60

80

100

120

140

160

180

200

2100 2200 2300 2400 2500 2600 2700 2800 2900

Pa

GV

PV

m3/h

2640

X

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 33

HAN 15

WITHOUT AIR FILTER

SANS FILTRE À AIR

OHNE LUFTFILTER

SENZA FILTRO AD ARIA

SIN FILTRO A AIRE

WITH AIR FILTER

AVEC FILTRE À AIR

MIT LUFTFILTER

CON FILTRO AD ARIA

CON FILTRO A AIRE

0

20

40

60

80

100

120

140

2350 2450 2550 2650 2750 2850 2950 3050 3150

Pa

m

3

/h

2940

Closed pulley

Open pulley of 3 turns

0

20

40

60

80

100

120

140

160

180

200

2350 2450 2550 2650 2750 2850 2950 3050 3150

Pa

m

3

/h

2940

Closed pulley

Open pulley of 3 turns

XI

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 34

HAN 17

WITHOUT AIR FILTER

SANS FILTRE À AIR

OHNE LUFTFILTER

SENZA FILTRO AD ARIA

SIN FILTRO A AIRE

WITH AIR FILTER

AVEC FILTRE À AIR

MIT LUFTFILTER

CON FILTRO AD ARIA

CON FILTRO A AIRE

0

20

40

60

80

100

120

140

2550 2650 2750 2850 2950 3050 3150 3250 3350 3450

Pa

m

3

/h

3190

Closed pulley

Open pulley of 3 turns

0

20

40

60

80

100

120

140

160

180

200

2550 2650 2750 2850 2950 3050 3150 3250 3350 3450

Pa

m

3

/h

3190

Closed pulley

Open pulley of 3 turns

XII

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 35

HAN 19

WITHOUT AIR FILTER

SANS FILTRE À AIR

OHNE LUFTFILTER

SENZA FILTRO AD ARIA

SIN FILTRO A AIRE

WITH AIR FILTER

AVEC FILTRE À AIR

MIT LUFTFILTER

CON FILTRO AD ARIA

CON FILTRO A AIRE

0

50

100

150

200

250

3100 3200 3300 3400 3500 3600 3700 3800 3900 4000 4100 4200

Pa

m

3

/h

3860

Closed pulley

Open pulley of 3 turns

0

50

100

150

200

250

3100 3200 3300 3400 3500 3600 3700 3800 3900 4000 4100 4200

Pa

m

3

/h

3860

Closed pulley

Open pulley of 3 turns

XIII

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 36

HAN 25

WITHOUT AIR FILTER

SANS FILTRE À AIR

OHNE LUFTFILTER

SENZA FILTRO AD ARIA

SIN FILTRO A AIRE

WITH AIR FILTER

AVEC FILTRE À AIR

MIT LUFTFILTER

CON FILTRO AD ARIA

CON FILTRO A AIRE

0

50

100

150

200

250

300

385039504050415042504350445045504650475048504950 505051505250

Pa

m

3

/h

4780

Closed pulley

Open pulley of 3 turns

0

50

100

150

200

250

300

385039504050415042504350445045504650475048504950 505051505250

Pa

m

3

/h

4780

Closed pulley

Open pulley of 3 turns

XIV

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 37

HAN 31

WITHOUT AIR FILTER

SANS FILTRE À AIR

OHNE LUFTFILTER

SENZA FILTRO AD ARIA

SIN FILTRO A AIRE

WITH AIR FILTER

AVEC FILTRE À AIR

MIT LUFTFILTER

CON FILTRO AD ARIA

CON FILTRO A AIRE

0

50

100

150

200

250

300

4450 4600 4750 4900 5050 5200 5350 5500 5650 5800 5950 6100

Pa

m

3

/h

5530

Closed pulley

Open pulley of 3 turns

0

50

100

150

200

250

300

4450 4600 4750 4900 5050 5200 5350 5500 5650 5800 5950 6100

Pa

m

3

/h

5530

Closed pulley

Open pulley of 3 turns

XV

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 38

XVI

HAN

APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO

Page 39

And that the following paragraphs of the harmonised standards have been applied.

Et que les paragraphes suivants les normes harmonisées ont été appliqués.

Und dass die folgenden Paragraphen der vereinheitlichten Normen Angewandt wurden.

E che sono stati applicati i seguenti paragraphi delle norme armonnizzate.

Y que se han aplicado los siguientes apartados de las normas armonizadas.

HAN 13 - 15 - 17 - 19 - 25 -31

MACHINERY DIRECTIVE 98 / 37 / EEC

LOW VOLTAGE DIRECTIVE (DBT) 2006 / 95 / EEC

ELECTROMAGNETIC COMPATIBILITY DIRECTIVE 2004 / 108 / EEC

PRESSURISE EQUIPMENT DIRECTIVE (DESP) 97 / 23 / EEC

SUB-MODULE A CATEGORY I: HAN 13 - 15 - 17 - 19

SUB-MODULE A1 CATEGORY II: HAN 25 - 31

NOTIFIED BODY: TÜV RHEINLAND – 20 TER RUE DE BEZONS CS 60030 – 92415 COURBEVOIE CEDEX - FRANCE

THE PRODUCTS ARE PROVIDED WITH CE 0035 MARKING OF CONFORMITY

DIRECTIVE MACHINES 98 / 37 / C.E.E.

DIRECTIVE BASSE TENSION (DBT) 2006 / 95 / C.E.E.

DIRECTIVE COMPATIBILITE ELECTROMAGNETIQUE 2004 / 108 / C.E.E

DIRECTIVE DES EQUIPEMENTS SOUS PRESSION (DESP) 97 / 23 C.E.E.

SOUS-MODULE A CATEGORIE I : HAN 13 - 15 - 17 - 19

SOUS-MODULE A1 CATEGORIE II : HAN 25 - 31

AVEC SURVEILLANCE PAR LE TUV RHEINLAND 20 TER RUE DE BEZONS CS 60030 – 92415 COURBEVOIE CEDEX - FRANCE

LES PRODUITS SONT FOURNIS AVEC LE MARQUAGE DE CONFORMITE CE 0035

RICHTLINIE MASCHINEN 98 / 37 / EG

RICHTLINIE NIERDERSPANNUNG (DBT) 2006 / 95 / EG

RICHTLINIE ELEKTROMAGNETISHE VERTRÄGLICHKEIT 2004 / 108 / EG

RICHTLINIE FÜR AUSRÜSTUNGEN UNTER DRUCK (DESP) 97 / 23 / EG

UNTER MODUL A, KATEGORIE I : HAN 13 - 15 - 17 - 19

UNTER MODUL A1, KATEGORIE II : HAN 25 - 31

MIT KONTROLLE DURCH DEN TUV RHEINLAND 20 TER RUE DE BEZONS CS 60030 – 92415 COURBEVOIE CEDEX - FRANCE

DIE PRODUKTE WERDEN MIT DER MARKIERUNG CONFORMITE CE 0035 GELIEFERT.

DIRETTIVA MACHINE 98 / 37 / CEE

DIRETTIVA BASSA TENSIONE (DBT) 2006 / 95 / CEE

DIRETTIVA COMPATIBILITA ELETTROMAGNATICA 2004 / 108 / CEE

DIRETTIVA DEGLI IMPIANTI SOTTO PRESSIONE (DESP) 97 / 23 / CEE

SOTTOMODULO A, CATEGORIA I : HAN 13 - 15 - 17 - 19

SOTTOMODULO A1, CATEGORIA II : HAN 25 - 31

CON SUPERVISION POR EL TUV RHEINLAND 20 TER RUE DE BEZONS CS 60030 – 92415 COURBEVOIE CEDEX - FRANCE

I PRODOTTI SONO FORNITI CON LA MARCATURA DI CONFORMITE CE 0035.

DIRECTIVA MAQUIAS 98 / 37 / CEE

DIRECTIVA BAJA TENSION (DBT) 2006 / 95 / CEE

DIRECTIVA COMPATIBILIDAD ELECTROMAGNETICA 2004 / 108 / CEE

DIRECTIVA DE LOS EQUIPOS A PRESION (DESP) 97 / 23 / CEE

BAJA MODULO A, CATEGORIA I : HAN 13 - 15 - 17 - 19

BAJA MODULO A1, CATEGORIA II : HAN 25 - 31

CON SORVEGLIANZA DAL TUV RHEINLAND 20 TER RUE DE BEZONS CS 60030 – 92415 COURBEVOIE CEDEX - FRANCE

LOS PRODUCTOS SE PROPORCIONAN CON EL MARCADO DE CONFOR CE 0035.

Déclaration CE de conformité

Nous déclarons sous notre responsabilité que les produits désignés dans la présente notice sont conformes aux dispositions des directives CEE énoncées ci- après

et aux législations nationales les transposant.

EC Compliance declaration

Under our own responsibility, we declare that the product designated in this manual comply with the provisions of the EEC directives listed hereafter and with

the national legislation into which these directives have been transposed.

EG-Konformitätserklärung

Wir erklarën in eigener Verantwortung, das die in der vorliegenden Beschreibung angegebenen Produkte den Bestimungen der nachstehend erwähnten EG-

Richtlinien und den nationalen Gesetzesvorschriffen entsprechen, in denen diese Richtinien umgesetz sind.

Dichiarazione CE di conformità

Dichiariamo, assurmendone la responsasabilità, che i prodotti descritti nel presente manuale sono conformi alle disposizioni delle direttive CEE di cui sott e alle

lagislazionni nazionali che li recepiscono

Declaramos, bajo nuestra responsabilidad, que los productos designados en este manual son conformes a las disposiciones de las directivas CEE enunuciadas a

continuacion, asi como a las legislaciones nacionales que las contemplan.

Declaración CE de conformidad

EN 60 204 EN 378 EN 61 000-6-1

EN 61 000-6-3 EN 60 335-1 EN 60 335-2-40

A Tillières sur Avre

27570 - FRANCE

Le: 02/02/2015

Angélique Revel

Quality

Systemair AC SAS

Page 40

As part of our ongoing product improvement programme, our products are

subject to change without prior notice. Non contractual photos.

Dans un souci d’amélioration constante, nos produits peuvent être modiés

sans préavis. Photos non contractuelles.

In dem Bemühen um ständige Verbesserung können unsere Erzeugnisse

ohne vorherige Ankündigung geändert werden. Fotos nicht vertraglich

bindend.

A causa della politica di continua miglioria posta in atto dal costruttore, questi

prodotti sono soggetti a modiche senza alcun obbligo di preavviso. Le foto

pubblicate non danno luogo ad alcun vincolo contrattuale.

Con objeto de mejorar constantemente, nuestros productos pueden ser

modicados sin previo aviso. Fotos no contractuales.

Systemair AC SAS

Route de Verneuil

27570 Tillières-sur-Avre

FRANCE

& : +33 (0)2 32 60 61 00

6 : +33 (0)2 32 32 55 13

Loading...

Loading...