Page 1

GB

Part number of this manual 90925520

Order number output

Document in original language | Version

Geniox Core

Air handling unit as Knock Down Ready version

Instruction about separation and reassembly

Unit sizes 16, 18, and 20 with rotary heat exchanger

Page 2

Instructions for unloading at the site as well as installation and connection |

I.1.10 Separate the air handling unit with rotary heat exchanger into doors, panels, profiles

and components to get the parts easily into the building for reassembly of the air

handling unit — sizes 16, 18 and 20

The unit is built without the use of rivets and without mastic between casing parts for easy and quick removal of panels

from profiles and internal walls.

Remove doors, panels and profiles to offer good access for the demounting and removal of components.

Internal parts to be removed are walls with fans, walls with filters, cables, control components, cabinet with controller

and rotary heat exchanger.

Reassemble the parts of the casing and reinstall the components in the opposite sequence of the separation.

Note:

During reassembly of the unit, application of the delivered mastic and placing of the delivered self-adhesive

flexible lists according to the below guidelines is important in order to achieve the air-tightness that

corresponds to Eurovent certified values.

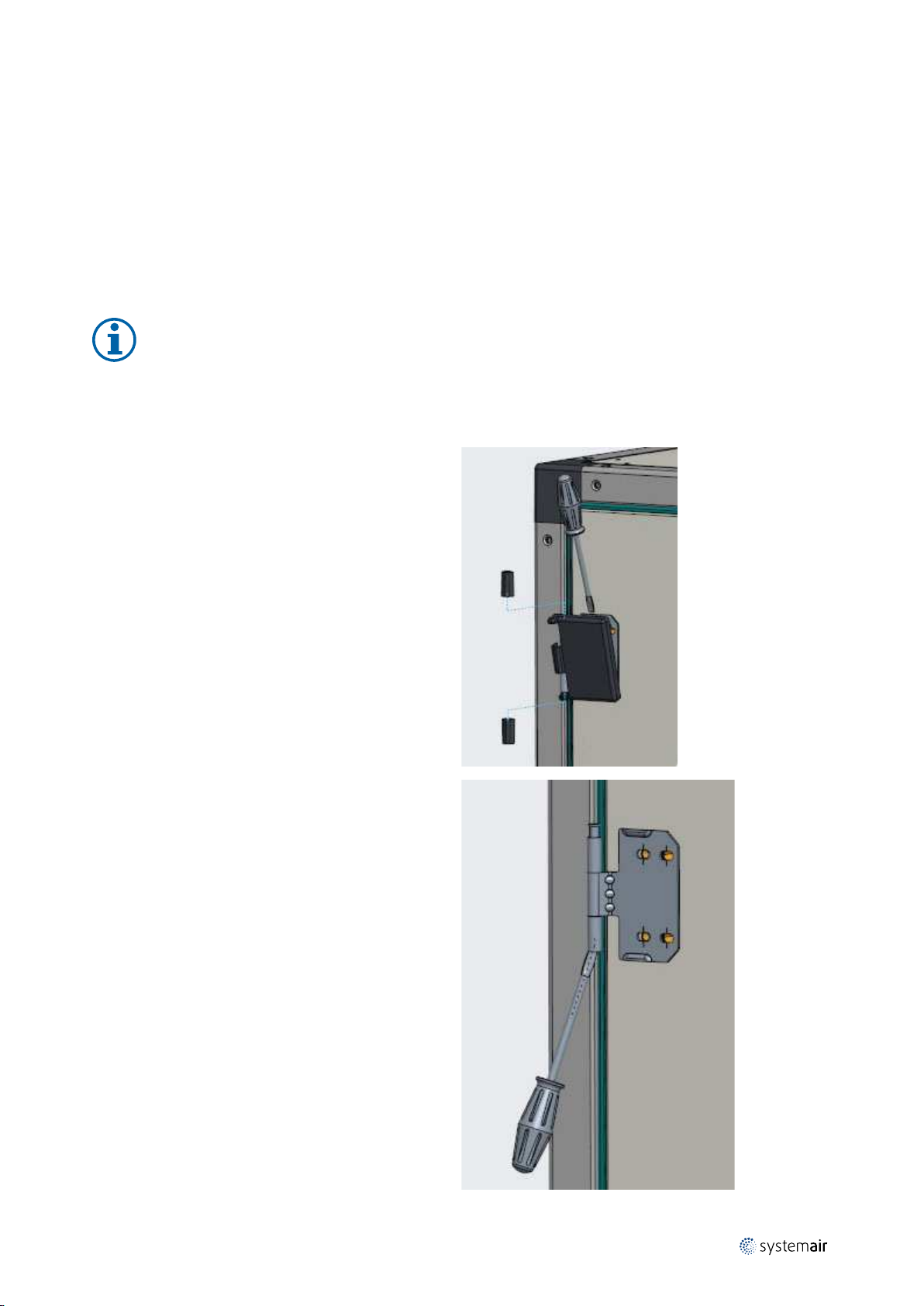

I.1.10.1 Removal of doors

Remove the 3 caps for free access to removal of the steel

shaft.

29

Remove the steel shaft in each hinge.

output |

Page 3

| Instructions for unloading at the site as well as installation and connection

30

Removal of door.

I.1.10.2 Remove panels, profiles and components

The first step is the removal of front panels.

The next step is the removal of duct connections.

output |

Page 4

Instructions for unloading at the site as well as installation and connection |

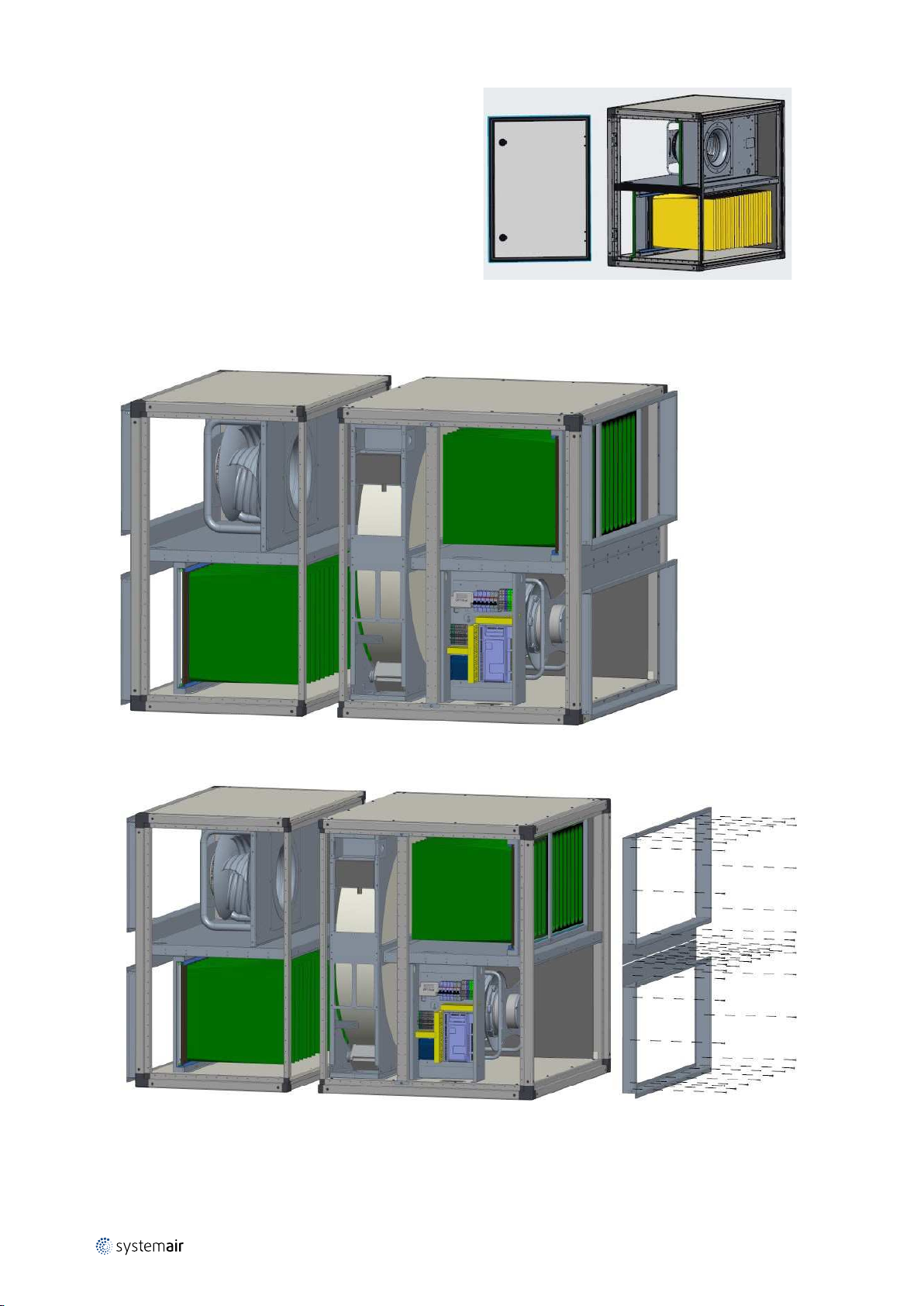

Remove the screws that hold internal walls with fans, walls with filters, as well as the rotary heat exchanger and the

cabinet.

31

Remove the walls with fans, walls with filters, as well as the rotary heat exchanger and the cabinet, cables, and control

components (cables are mounted in consoles with strips — please only cut the strips and leave the consoles without

damage. During reassembly, new strips can be inserted in the consoles for strips. New strips are included in the

delivery).

output |

Page 5

| Instructions for unloading at the site as well as installation and connection

32

Remove the back panels.

Remove the screws from the horizontal partition panels.

Note:

Several screws are found on the underside.

output |

Page 6

Instructions for unloading at the site as well as installation and connection |

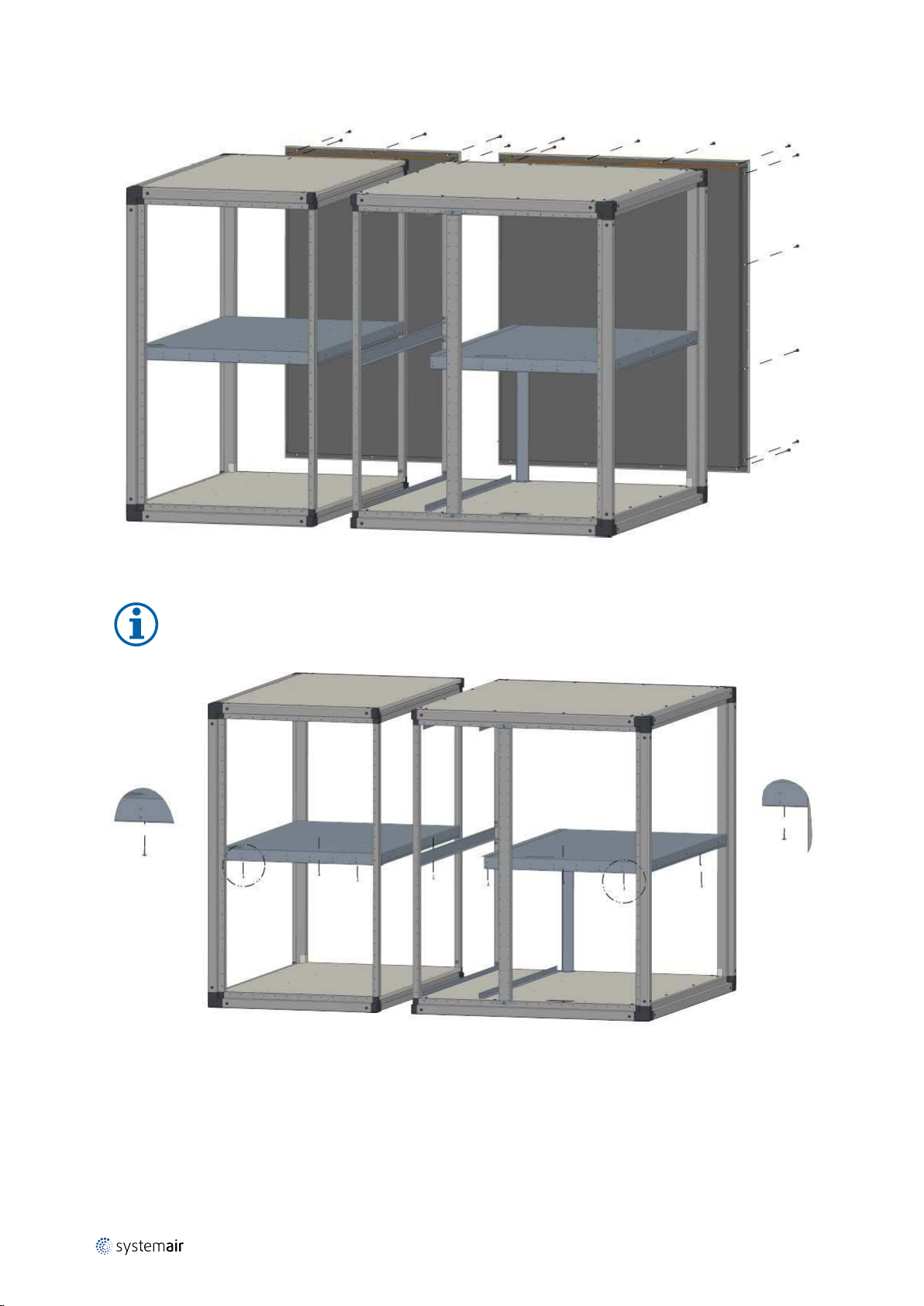

Remove the partition panels.

Remove the screws from the profiles that hold the partition panels.

33

Remove the profiles that hold the partition panels.

output |

Page 7

| Instructions for unloading at the site as well as installation and connection

34

Remove the screws that fastened the vertical profiles to the plastic corners.

Remove the upper panels, as well as the profiles.

Separation is completed and all parts can be carried into the building.

I.1.10.3 Reassembly of the unit with fans, filters, dampers, rotary heat exchanger as well as

cabinet, cables, and control components

Reassemble the parts of the casing and reinstall the components in the opposite sequence of separation described

above.

output |

Page 8

Instructions for unloading at the site as well as installation and connection |

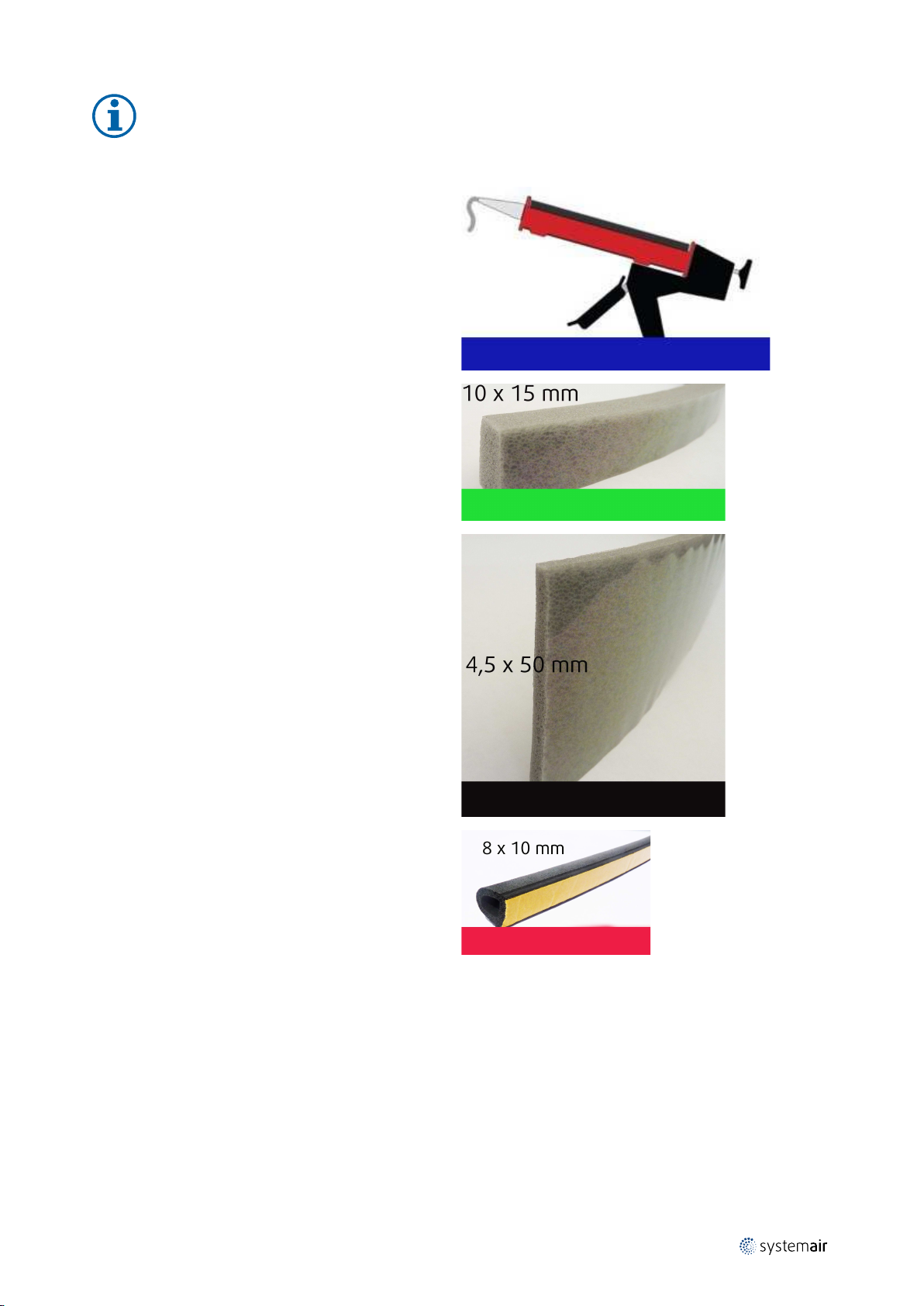

Note:

Application of the delivered mastic and placing of 3 different types of self-adhesive flexible sealing lists are

important in order to achieve the air-tightness that corresponds to Eurovent certified values for this air

handling unit.

This mastic must be applied to all connections between

vertical profiles and plastic corners and between the walls

with filters and the casing, between the walls with fans

and the casing, and around dampers. All places are

marked with blue colour on the unit. The number of

metres that must be applied appears from the table

below.

This is to some extent illustrated with blue colour in the

drawing below.

Place this self-adhesive sealing list on vertical edges that

are marked with green colour on the unit. This is illustrated with green colour in the drawing below.

35

Place this self-adhesive sealing list on horizontal edges

that are marked with black colour on the unit. This is illustrated with black colour in the drawing below.

Place this self-adhesive sealing list on the profiles of one

of the sections to achieve fully air-tight connection between two sections. The profiles of the section are

marked with red colour. This is illustrated with red colour

in the drawing below.

output |

Page 9

| Instructions for unloading at the site as well as installation and connection

36

Illustration of where to apply mastic and where to place the above mentioned sealing lists in the air handling unit

The number of metres to which mastic must be applied.

Size of unit Unit with rotary heat exchanger

16 18 m

18 20 m

20 22 m

output |

Page 10

Page 11

Page 12

Systemair

Unit 28, Gravelly Industrial Park

Birmingham, B24 8HZ

Systemair

Systemair A/S

Unit 02 Furry Park Ved Milepælen 7

Santry Dublin 9 DK-8361 Hasselager

Tel.: +44 (0)121 322 0200

info@systemair.co.uk

Tel.: +353 1 86 24 544 Tel.: +45 8738 7500

sales@systemair.ie mail@systemair.dk

www.systemair.co.uk www.systemair.co.uk www.systemair.dk

Geniox Core · User Manual · 90925520 · en_GB · · · output

Loading...

Loading...