Page 1

Geniox

Air handling unit

User Manual

Document in original language |

GB

Part number of this manual 90925500

Order number output

Page 2

output |

Page 3

Detailed table of contents on the following pages

General description

A Manufacturer

B Name of machines

C Declaration of Conformity - example

D General descriptions, dangers and warnings

E Drawings, diagrams, guides and instructions for the use, maintenance and repair

F Employees in charge of operation/control/maintenance

G Intended use and range of applications

H Unintended use and misuse – inappropriate applications for the machine

Installation

I Instructions for unloading on the site as well as installation and connection

J Installation and assembly instructions for reduction of noise and vibration emissions

Start-up, adjustments and operation

K Start-up, adjustments, use, commissioning and unit in hipernation

L Information about the residual risks

M Instructions on the protective measures during repair and maintenance

N The essential characteristics of tools which may be fitted to the machinery

Machine stability

O The conditions of stability during use, transportation, assembly, dismantling when out of service

P Instructions for machinery where these are regularly to be transported

Breakdown

Q The operating method to be followed in the event of breakdown. Safe restart.

Maintenance

R Adjustment and maintenance operations

S Instructions to enable adjustment and maintenance safely

T The specifications of the spare parts to be used, when these affect the health and safety of operators

Noise

U Information on airborne noise emissions exceeding 70 dB(A)

Annexes

1 Declaration of conformity with production number (in separate cover)

2 Technical data – unique data for every unit (in separate cover)

3 Spare part list (in separate cover)

4 Assembly of base frame – height 118 mm for unit sizes 10 – 18

5 Assembly of base frame – height 118 mm for unit sizes 20 – 31

6 Assembly of base frame – height 218 mm for unit sizes 10 – 18

7 Assembly of base frame – height 218 mm for unit sizes 20 – 31

8 Installation of steel roof in the sizes 10 – 31

9 Speed control for rotor and assembly of divided rotor

10 Reversible heat pump unit (in separate cover, if heat pump was delivered)

11 Menu for internal controller in the heat pump unit (in separate cover, if heat pump was delivered)

12 Connection of fan motor and set-up manual for frequency converter

13 Commissioning protocol – proposal (in separate cover)

14 Report with data from final functional test on the Systemair factory (in separate cover, if control system was

delivered)

15 Short description of main components in the control system

16 Wiring diagram (in separate cover, if control system was delivered)

17 Operator’s guide (how to use the Systemair control panel) (in separate cover, if control system was delivered)

output |

Page 4

Contents

A Manufacturer.......... . . . .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . ............. . . . . ............ . . . ............ . . . 1

B Name of machines . ............. . . . ............ . . . .. ............ . . . . .. ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. ...1

C Declaration of Conformity - example. . . . ............. . . . .. ............ . . . ............ . . . . .. ............. . . .. ............ . . . .. ............. 2

D General descriptions, dangers and warnings ... . . . . ............. . . . ............ . . . ............. . . . .. .. ............ . . . ............ . . . .. .. 3

D.1 Overview via pictograms on the inspection side of the unit ........ . . .. ............ . . . .. ............. . . . .. ............ . . . .3

D.1.1 Where are pictograms placed on the units.... . . . ............. . . . .. ............ . . . ............ . . . . .. ............ . . . 3

D.1.2 Weight of each section and production number – example for the Geniox unit ........... . . .. ............4

D.1.3 CE label — example for the Geniox unit . . ............. . . . ............ . . . .. ............ . . . . .. ............ . . . ........4

D.1.4 Pictograms for all available functions in the units .. . .. ............ . . . .. ............ . . . .. .. ............. . . .. .....5

D.1.5 Pictograms about warnings and dangers on the units . . . ............ . . . ............ . . . . .. ............. . . .. .....6

D.2 Data about the unit according to cards and labels in and on the unit ......... . . . .. .. .. ............ . . . ............ . . . .. .. 6

D.2.1 Machine card with unique data on every unit. . . . .. .. .. ............ . . . ............ . . . .. .. .. ............ . . . ........6

D.2.2 Label with data about the cabinet — example.... . . . ............ . . . ............. . . . . ............ . . . ............ . . . 7

D.2.3 Flowchart – example of the label placed on or with the cabinet . .. ............. . . .. ............ . . . .. .........7

D.2.4 Symbols in the flowchart and explanation about the symbols ........... . . . ............ . . . ............ . . . . .. .8

D.2.5 Example of label placed on or with the cabinet – Terminal plan for external components . . . . .. .......9

D.3 Hand terminal ..... . . . .. .. ............ . . . .. ............ . . . ............. . . . . ............ . . . ............ . . . .. .. .. ............ . . . ........9

D.4 Dimensions of the units . . . . ............. . . .. .. .. ............ . . . .. ............ . . . ............. . . . . ............ . . . ............ . . . .. .. 9

D.5 Ordinary automatically operation – only manual operation by new parameters..... . . . ............. . . . .. .......... 10

D.6 Warnings about dangers .. . . .. ............. . . . . ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. .......... 10

E Drawings, diagrams, guides and instructions for the use, maintenance and repair.... . . .. ............ . . . . .. ............ . . . .. 10

F Employees in charge of operation/control/maintenance .. .. ............. . . .. ............ . . . .. .. .. ............ . . . ............ . . . .. 10

G Intended use and range of applications........ . . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . ............. 10

H Unintended use and misuse – inappropriate applications for the machine ........... . . . ............. . . . .. ............ . . . ...... 11

H.1 Air handling unit in operation ....... . . . ............ . . . . ............. . . . ............ . . . ............ . . . . .. ............ . . . .. ....... 11

I Instructions for unloading on the site as well as installation and connection .......... . . . ............ . . . . .. ............. . . .. ... 11

I.1 Unloading on the site..... . . . .. .. ............. . . . ............ . . . ............ . . . . .. ............ . . . .. ............ . . . .. .. ............ . 11

I.1.1 Unloading by fork-lift truck . . ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . ............. . . . . ... 11

I.1.2 Unloading by crane . .. .. ............. . . .. ............ . . . .. .. ............. . . .. ............ . . . .. ............. . . . .. ....... 12

I.1.3 Transport of unit without base frame on the site. ........... . . . .. ............. . . . .. ............ . . . ............ . 12

I.1.4 Lifting a unit with straps......... . . . ............ . . . .. .. ............ . . . .. ............ . . . .. .. ............. . . .. .......... 12

I.1.5 Lifting a unit with preinstalled brackets on the base frame for lifting........... . . . .. .. ............. . . .. ... 12

I.1.6 Lifting a unit without base frame and legs but with preinstalled brackets for lifting. .. . . . ............. 12

I.1.7 Roof unit with PVC roof. .. ............ . . . . .. ............ . . . .. ............ . . . .. .. ............ . . . .. ............ . . . ...... 14

I.1.8 Roof unit with steel roof . . . . ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. .. ............. . . . ... 15

I.1.9 Pre-assembly storage. ........... . . . ............ . . . . .. ............ . . . ............ . . . .. .. .. ............ . . . ............ . 15

I.1.10 Tilt less than 30˚ during transportation of the section with heat pump .... . . . ............ . . . . .. .......... 15

I.1.11 Transport of rotary heat exchanger — always in vertical position ........ . . . ............ . . . . ............. . . 15

I.2 Installation - mechanical ... . . . ............ . . . .. ............ . . . . ............. . . .. ............ . . . .. ............. . . . .. ............ . . 15

I.2.1 Free area in front of and above the unit ........ . . . ............ . . . .. ............. . . . .. ............ . . . ............ . 15

I.2.2 Supporting surface...... . . . ............ . . . ............. . . . .. .. ............ . . . ............ . . . .. .. ............. . . . ....... 16

I.2.3 Adjustable feet under legs or base frame and transport of sections.... . . . ............. . . . .. ............ . . 16

I.2.4 Base frame assembly . ............. . . . .. ............ . . . ............ . . . . .. ............. . . .. ............ . . . .. .. ......... 16

I.2.5 Base frames for outdoor units . . .. ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. .......... 16

I.2.6 Outdoor units — support under the base frame of the unit ........... . . .. ............ . . . ............. . . . . ... 16

I.2.7 Installation on the site of unit sections at the base frame when sections are delivered on

pallets. . . . ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . .. .. ............. . . .. ............ . . . .. ....... 17

I.2.8 Joining the AHU sections . . . . ............ . . . ............. . . . . ............ . . . ............ . . . .. .. ............. . . . ....... 20

I.2.9 Fitting the ductwork .......... . . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . ............. 22

I.2.10 Risk of stack effect by vertical ducts and wind pressure on louvers ....... . . .. ............. . . . .. .......... 23

I.2.11 Remove transport brackets – when spring mounts are installed..... . . .. ............ . . . . .. ............ . . . .. 23

I.2.12 Refitting of guards ....... . . . .. ............ . . . .. ............. . . . ............ . . . .. ............ . . . . .. ............ . . . ...... 24

I.2.13 Lock the doors by using the key........... . . . ............. . . . . ............ . . . ............ . . . .. .. .. ............ . . . .. 25

I.3 Installation - electrical ............ . . .. ............ . . . . .. ............ . . . .. ............ . . . .. .. ............ . . . .. ............ . . . .. .. .. 25

I.3.1 Description...... . . . ............. . . . .. .. ............ . . . ............ . . . .. .. ............. . . . ............ . . . ............ . . . . . 25

I.3.2 Wiring diagrams . . ............. . . . .. .. ............ . . . ............ . . . .. ............. . . . .. ............ . . . ............ . . . . . 25

I.3.3 Installation of mains power supply ...... . . . ............ . . . . .. ............ . . . ............ . . . .. ............. . . . .. ... 25

I.3.4 Electrical connection of components and functions. . . ............ . . . ............. . . . .. ............ . . . .. ....... 26

output |

Page 5

Contents

I.3.5 Lock the doors by using the key...... . . . . ............ . . . .. ............ . . . .. ............. . . . ............ . . . .. ....... 27

I.4 Installation – Pipes for water – hot and chilled, valves and drains . . ............. . . .. ............ . . . . .. ............ . . . .. 27

I.4.1 Description...... . . . ............. . . . .. .. ............ . . . ............ . . . .. .. ............. . . . ............ . . . ............ . . . . . 27

I.4.2 Pipe connections .. .. ............ . . . . .. ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . .. .. ......... 27

I.4.3 Possibility of extracting components from the unit ......... . . . . ............. . . . ............ . . . .. ............ . . 27

I.4.4 Pipe connections to batteries ............ . . . . ............ . . . ............ . . . .. .. ............. . . . ............ . . . ...... 27

I.4.5 Draining condensate water ......... . . . ............ . . . .. ............. . . . ............. . . .. ............ . . . . .. .......... 29

I.4.6 Draining condensate water from heat exchanger... . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. . 29

I.4.7 Draining condensate water from cooling battery — .......... . . . ............ . . . ............. . . . . ............ . . 30

J Installation and assembly instructions for reduction of noise and vibration emissions . . . . ............ . . . . .. ............ . . . .. 31

K Start-up, adjustments, use, commissioning and unit in hipernation . . . .. ............ . . . ............ . . . .. .. .. ............ . . . ...... 31

K.1 Print-outs on paper ........... . . . .. ............ . . . .. ............. . . . ............ . . . .. ............ . . . . .. ............ . . . ............ . 31

K.2 Electronic media.. . . .. ............. . . . .. ............ . . . ............. . . . .. .. ............ . . . ............ . . . .. .. .. ............ . . . ...... 31

K.3 Documentation is available for download . . ............ . . . ............ . . . . .. ............ . . . .. ............ . . . .. .. ............ . 32

K.4 Start-up by installer .. . . ............ . . . .. .. ............ . . . .. ............ . . . ............. . . . . ............ . . . ............ . . . .. .. .. ... 32

K.4.1 Checklist, relevant values .. . ............ . . . .. .. ............. . . .. ............ . . . .. ............. . . . ............. . . .. ... 32

K.5 Adjustments and use..... . . . ............. . . .. ............ . . . . .. ............ . . . ............. . . .. .. .. ............ . . . .. ............ . . 33

K.6 Description of functions ..... . . . .. ............ . . . .. .. ............. . . .. ............ . . . ............. . . . . ............ . . . ............ . 33

K.6.1 Remote control .. ............ . . . .. .. ............. . . .. ............ . . . ............. . . . . ............ . . . ............. . . .. .. . 33

K.6.2 Extended operation and external start/stop (for example by presence detectors) . .. ............ . . . .. 33

K.6.3 Valve and valve motor for heating coil....... . . . .. ............ . . . . .. ............ . . . ............ . . . .. .. .. .......... 33

K.6.4 Valve and valve motor for cooling coil .......... . . . ............. . . . .. ............. . . .. ............ . . . .. .. .. ....... 33

K.6.5 DX cooling........... . . . . .. ............. . . .. ............ . . . .. .. ............. . . .. ............ . . . .. ............. . . . .. ....... 33

K.6.6 Circulation pump, heating ... . . .. ............ . . . . .. ............ . . . ............. . . .. .. .. ............ . . . .. ............ . . 33

K.6.7 Fire alarm function . . ............. . . . . ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. .......... 34

K.6.8 E tool - configuration tool ........ . . . ............ . . . .. .. ............. . . . ............ . . . ............ . . . . .. ............ . 34

K.6.9 Electrical heater battery . . ............ . . . . .. ............ . . . .. ............ . . . .. .. ............ . . . .. ............ . . . .. .. .. 34

K.6.10 Speed control of fans .......... . . . .. ............ . . . . .. ............ . . . ............ . . . .. .. .. ............ . . . ............ . 34

K.6.11 Cabinet .. . . .. .. ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. ............. . . . .. ............ . . . ...... 35

K.6.12 Temperature sensors . ............ . . . .. .. ............. . . .. ............ . . . ............. . . . . ............ . . . ............ . 35

K.6.13 Damper motors.. . . .. ............. . . . . ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. .......... 35

K.6.14 Filter guards . . . ............ . . . .. ............. . . . .. ............ . . . ............ . . . . ............. . . . ............ . . . .. ....... 35

K.6.15 Room temperature sensors......... . . . .. ............. . . . ............ . . . ............. . . . .. ............. . . .. .......... 35

K.6.16 Frost protection... . . . ............ . . . .. ............. . . . .. ............ . . . ............ . . . . .. ............ . . . .. ............ . . 35

K.6.17 Systemair Control Panel - SCP..... . . .. ............ . . . .. .. ............. . . .. ............ . . . ............. . . . . .......... 36

K.6.18 Cooling recovery ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. .. ............ 36

K.6.19 Free cooling ....... . . . ............ . . . .. ............. . . . .. ............ . . . ............ . . . . .. ............ . . . .. ............ . . 36

K.6.20 Alarm signal . . .. .. ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. ............. . . . .. ............ . . . .. 36

K.6.21 Heat recovery...... . . . . .. ............. . . .. ............ . . . .. ............. . . . ............. . . .. ............ . . . . .. .......... 36

K.6.22 Frost protection – plate heat exchanger ... . . .. .. ............. . . . ............ . . . .. ............ . . . . .. ............ . . 36

K.7 Commissioning ....... . . . ............. . . . .. ............ . . . ............ . . . . .. ............ . . . .. ............ . . . .. .. ............. . . .. ... 36

K.8 Unit in hipernation ........ . . . ............. . . . .. .. ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. .......... 36

L Information about the residual risks........... . . . ............ . . . .. ............. . . . .. ............ . . . ............ . . . . .. ............. . . .. ... 36

L.1 Unit casing ........... . . . .. .. .. ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. ............. . . . ............ . . . .. 36

L.1.1 Design of the machine to make transport safe .......... . . . ............. . . . ............. . . . ............. . . .. ... 36

L.1.2 Common for all unit sections ............ . . . .. ............ . . . ............ . . . . ............. . . . ............ . . . .. ....... 37

L.1.3 Common for all unit sections by insufficient lighting .... . . . .. ............ . . . .. ............ . . . .. .. ............ . 37

L.1.4 Dampers......... . . . ............. . . .. ............. . . . .. ............ . . . ............. . . . .. .. ............ . . . ............ . . . .. 37

L.1.5 Attenuators. . . ............ . . . .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . .. .. ............. . . . 37

L.1.6 Filters ....... . . . . ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . .. .. .. ............ . . . ............ . . . .. 38

L.1.7 Plug fans . . . . .. ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. . 38

L.1.8 Batteries for heating . . . ............. . . .. .. .. ............ . . . .. ............ . . . .. .. ............ . . . .. ............ . . . .. .. .. 39

L.1.9 Heat pump units. . . . . ............ . . . .. ............ . . . .. .. ............ . . . .. ............ . . . .. .. ............. . . .. .......... 39

M Instructions on the protective measures during repair and maintenance .......... . . . .. .. .. ............ . . . ............. . . .. .. . 40

N The essential characteristics of tools which may be fitted to the machinery..... . . . ............ . . . . .. ............ . . . .. ....... 40

O The conditions of stability during use, transportation, assembly, dismantling when out of service ...... . . . . .. .......... 40

O.1 Installed reliable to avoid units to be tilted or moved by storm. . . . ............. . . . .. ............ . . . ............. . . . .. .. 40

O.2 Transport of section with heat pump unit.... . . . ............. . . .. ............ . . . . .. ............ . . . ............. . . .. .. ........ 40

O.3 Disposal of the heat pump system - type Geniox - HP ............ . . . ............ . . . ............. . . . . ............ . . . ...... 41

O.4 General disassembly – sharp edges. . . . ............ . . . .. ............. . . . .. ............ . . . ............ . . . . .. ............. . . .. ... 41

P Instructions for machinery where these are regularly to be transported ...... . . . ............. . . . .. ............ . . . ............ . 41

Q The operating method to be followed in the event of breakdown. Safe restart. . . . ............ . . . ............. . . .. .. ........ 41

R Adjustment and maintenance operations .. . . . . ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . .. .. .. ............ . . 41

R.1 Shutdown of the unit to a safe state ........ . . .. ............. . . . .. ............ . . . ............. . . . .. ............. . . .. .......... 41

R.2 Unlock and lock the doors by using the key .......... . . .. ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. .......... 42

R.3 Recommended maintenance intervals.......... . . . . ............ . . . .. ............ . . . .. .. ............ . . . .. ............ . . . .. .. .. 42

output |

Page 6

Contents

R.4 Filters – always replace filters with new filters with the same characteristics to maintain SFP

value ... . . . .. ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. .. ............ . . . .. ............ . . . .. .. ............ . 43

R.4.1 Bag filters – the number of filters and sizes of frames .. . ............ . . . .. .. .. ............ . . . ............ . . . .. 43

R.4.2 Panel filters – the number of filters and the sizes of the frames ......... . . . ............ . . . .. .. ............ . 44

R.4.3 Bag filters . . ............ . . . ............. . . . . ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. .. ...... 44

R.4.4 Panel filters ........... . . . . ............. . . .. ............ . . . ............. . . . . ............ . . . ............ . . . .. .. .. .......... 47

R.5 Changing the Internal Battery in the controller .......... . . . ............. . . . .. ............ . . . ............ . . . . .. ............ . 47

R.6 Other functions to maintain .. . .. ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. ............. . . . .......... 48

R.6.1 The unit..... . . . . ............ . . . .. ............ . . . .. ............. . . . ............ . . . .. ............ . . . . .. ............ . . . ...... 48

R.6.2 Dampers............ . . . ............ . . . . .. ............ . . . .. ............ . . . .. ............. . . . ............ . . . .. ............ . . 48

R.6.3 Rotary heat exchanger . . . . .. ............ . . . . .. ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. . 50

R.6.4 Cross flow and counter flow exchanger . . .. ............. . . .. ............ . . . .. .. .. ............ . . . ............ . . . .. 51

R.6.5 Run-around heat exchanger.... . . . ............ . . . ............ . . . . .. ............ . . . .. ............ . . . .. .. ............ . 52

R.6.6 Heating coil ..... . . . ............. . . . . ............ . . . ............. . . .. ............. . . . .. ............ . . . ............. . . . .. .. 53

R.6.7 Plug fans .... . . . ............ . . . .. ............. . . . .. ............ . . . ............ . . . . ............. . . . ............ . . . .. ....... 54

R.6.8 Silencer.. . . . ............. . . . .. ............ . . . ............. . . . ............. . . . ............. . . .. ............ . . . . .. .......... 55

R.6.9 Outdoor air section .... . . . . ............ . . . ............. . . .. .. .. ............ . . . .. ............ . . . .. ............. . . . ...... 56

R.6.10 Heat pump unit .......... . . . ............ . . . ............. . . . . ............ . . . ............. . . .. .. .. ............ . . . .. ....... 56

S Instructions to enable adjustment and maintenance safely . . ............. . . .. .. .. ............ . . . .. ............ . . . .. ............. . . 57

S.1 Protective measures and additional protective measures. . .. ............ . . . ............. . . .. .. ............. . . . .......... 57

S.1.1 Necessary protection measures prior to start-up ......... . . .. ............ . . . .. ............. . . . .. ............ . . 57

S.1.2 Safe adjustment and maintenance ......... . . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. .......... 58

S.1.3 Personal protective equipment for maintenance staff – health and safety. . . . ............. . . .. .......... 58

T The specifications of the spare parts to be used, when these affect the health and safety of operators .. . . . .......... 58

T.1 Spare parts - Mechanical .......... . . . ............ . . . ............. . . . .. .. ............ . . . ............ . . . .. .. .. ............ . . . ...... 58

T.2 Spare parts - Electrical .. ............ . . . .. ............ . . . . ............. . . . ............ . . . ............ . . . . .. ............ . . . .. ....... 58

U Information on airborne noise emissions exceeding 70 dB(A) ........... . . .. .. .. ............ . . . .. ............ . . . .. ............. . . 58

Annex 1 Declaration of conformity with production number (in separate cover) .. . . . ............ . . . .. .. ............. . . . ......1-1

Annex 2 Technical data – unique data for every unit (in separate cover) .. . . . ............. . . . .. .. ............ . . . ............ . . . .2-1

Annex 3 Spare part list (in separate cover)... . . . ............ . . . .. .. ............. . . .. ............ . . . ............. . . . . ............ . . . .....3-1

Annex 4 Assembly of base frame – height 118 mm for unit sizes 10 – 18.......... . . .. ............ . . . . .. ............ . . . .. ......4-1

4.1 Base frame length 482 – 2564 [mm] Unit size 10 – 18 .......... . . .. .. .. ............ . . . .. ............ . . . .. .. ............4-2

4.2 Base frame length 2582 – 4964 [mm] Unit size 10 – 18 .. . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ..4-3

4.3 Base frame length 4982 – 6164 [mm] Unit size 10 – 18 .. . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ..4-4

Annex 5 Assembly of base frame – height 118 mm for unit sizes 20 – 31.......... . . .. ............ . . . . .. ............ . . . .. ......5-1

5.1 Base frame length 482– 2564 [mm] Unit size 20 – 31 .. . . . ............ . . . . .. ............. . . .. ............ . . . .. .. .. ......5-1

5.2 Base frame length 2582 – 4964 [mm] Unit size 20 – 31 .. . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ..5-2

5.3 Base frame length 4982 – 6164 [mm] Unit size 20 – 31 .. . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ..5-3

Annex 6 Assembly of base frame – height 218 mm for unit sizes 10 – 18 ..... . . . . ............ . . . ............ . . . .. .. ...........6-1

6.1 Base frame length 482– 2564 [mm] Unit size 10 – 18 .. . . . ............ . . . . .. ............. . . .. ............ . . . .. .. .. ......6-1

6.2 Base frame length 2582 – 4964 [mm] Unit size 10 – 18 .. . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ..6-2

6.3 Base frame length 4982 – 6164 [mm] Unit size 10 – 18 .. . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ..6-4

Annex 7 Assembly of base frame – height 218 mm for unit sizes 20 – 31.......... . . .. ............ . . . . .. ............ . . . .. ......7-1

7.1 Base frame length 482– 2564 [mm] Unit size 20-31 . . . . . ............ . . . ............ . . . .. .. .. ............ . . . ............7-1

7.2 Base frame length 2582 – 4964 [mm] Unit size 20 – 31 .. . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ..7-2

7.3 Base frame length 4982 – 6164 [mm] Unit size 20 – 31 .. . .. .. .. ............ . . . .. ............ . . . .. .. ............. . . .. ..7-3

Annex 8 Installation of steel roof in the sizes 10 – 31.. . . . ............. . . .. ............ . . . . .. ............ . . . ............. . . .. .........8-1

8.1 Overview. . . .. ............. . . .. ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. .. ...........8-1

8.1.1 Mount rails. Units of size 10, 11, 12, and 14... . . . .. .. ............. . . .. ............ . . . .. ............. . . . .. ......8-1

8.1.2 Mount rails. Units of size 16 and units larger than size 16....... . . . .. .. ............ . . . .. ............ . . . .. ...8-1

8.1.3 Roof overhang along the long sides of the unit . ............ . . . .. .. ............. . . . ............ . . . ............8-2

8.1.4 Calculation of the overhang at the ends of the unit. Mount overhang profile – G1. . .. ............ . . . . 8-2

8.1.5 Foam bands between rails and roof plates – mount roof plates.... . . . ............ . . . .. ............. . . . .. ..8-3

8.1.6 Foam bands between roof plates .. .. ............ . . . ............ . . . . ............. . . . ............ . . . .. ............ .8-3

8.1.7 Mount roof plates – some of them are overlapping by 2 ribs..... . . . . ............ . . . ............ . . . .. .. .. ..8-3

8.1.8 Mount overhang profile – G5 on the other end of the unit. . . .. ............ . . . .. .. ............. . . .. .........8-3

8.1.9 Mount side profiles and corners along the edges of the roof to protect persons... . . . ............ . . . .8-3

8.1.10 Apply sealing on plate joints to ensure water resistance. ...... . . .. ............ . . . .. .. .. ............ . . . .....8-3

Annex 9 Speed control for rotor and assembly of divided rotor ............ . . .. ............ . . . .. .. .. ............ . . . ............ . . . .9-1

9.1 Speed control .. ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. ............. . . . .........9-1

9.1.1 Selection of correct signal via the 8DIP switch levers ............ . . . ............ . . . . .. ............ . . . .. ......9-1

9.1.2 Indication of operation mode via red and green LED as well as test of motor. . . . .. .. .. ............ . . . .9-2

9.1.3 Copy of the label with information about connection of cables.......... . . . ............ . . . ............ . . . . 9-3

9.2 Assemble the Systemair casing for Geniox 22, Geniox 24 and Geniox 27 ...... . . . .. ............ . . . ............ . . . . 9-3

9.3 Assemble divided rotor for Geniox 29 and Geniox 31... . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. .. .....9-4

output |

Page 7

Contents

9.4 Installation of motor that turns rotor and sensor for rotation....... . . . .. .. ............ . . . ............ . . . .. .. .. .........9-4

Annex 10 Reversible heat pump unit (in separate cover, if heat pump was delivered) .. . . . .. ............ . . . ............ . . 10-1

10.1 Geniox-HP section (reversible heat pump unit) ... . . . . .. ............ . . . ............. . . .. .. .. ............ . . . .. ........... 10-1

Annex 11 Menu for internal controller in the heat pump unit (in separate cover, if heat pump was

delivered) .. . . ............ . . . . .. ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. 11-1

Annex 12 Connection of fan motor and set-up manual for frequency converter... . . . ............ . . . .. .. .. ............ . . . ... 12-1

12.1 Connection of fan motor .... . . . .. ............ . . . . .. ............ . . . ............ . . . .. .. ............. . . . ............ . . . .......... 12-1

12.2 Set-up for Danfoss FC101 for Geniox-units with AC motors . . .. ............ . . . ............. . . . .. ............ . . . .. .... 12-1

12.3 AC-fan operation without thermistor for Danfoss FC101. . ............ . . . .. ............ . . . . .. ............ . . . .......... 12-2

12.4 Set-up Danfoss FC101 for Geniox-units with PM motors......... . . . ............ . . . ............. . . . . ............ . . . ... 12-2

12.5 Installation ECblue ...... . . . .. ............. . . .. ............ . . . .. ............. . . . ............. . . .. ............ . . . . .. ............ . . 12-4

12.5.1 Connection. . . . ............ . . . . .. ............ . . . ............ . . . .. .. .. ............ . . . ............ . . . .. .. .. ............ . . 12-4

12.5.2 Diagnostic/faults . . . .. .. ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. .. .. ............ . . . .. .... 12-6

Annex 13 Commissioning protocol – proposal (in separate cover).. . . .. ............ . . . . .. ............ . . . ............. . . .. .. .. ... 13-1

Annex 14 Report with data from final functional test on the Systemair factory (in separate cover, if control

system was delivered) .. ............ . . . ............. . . .. .. ............. . . . ............ . . . ............. . . . .. .. ............ . . . ............ . . 14-1

Annex 15 Short description of main components in the control system . . . .. ............ . . . ............ . . . . .. ............. . . .. 15-1

15.1 Geniox units delivered in several sections ......... . . . ............. . . . .. ............ . . . ............ . . . . .. ............. . . .. 15-1

15.1.1 External components.... . . . .. ............ . . . .. .. ............. . . .. ............ . . . .. .. .. ............ . . . ............ . . 15-1

15.2 Geniox unit delivered assembled on base frame .. .. ............ . . . ............ . . . .. .. .. ............ . . . ............. . . .. 15-1

15.2.1 External components.... . . . .. ............ . . . .. .. ............. . . .. ............ . . . .. .. .. ............ . . . ............ . . 15-1

Annex 16 Wiring diagram (in separate cover, if control system was delivered) . .. ............ . . . ............ . . . .. .. .. ....... 16-1

Annex 17 Operator’s guide (how to use the Systemair control panel) (in separate cover, if control system was

delivered). . . . ............. . . . .. ............ . . . ............ . . . . .. ............ . . . .. ............ . . . .. .. ............. . . .. ............ . . . .. ........ 17-1

output |

Page 8

Page 9

Manufacturer |

A Manufacturer

This User Manual covers all air handling units with control system delivered by Systemair A/S.

Manufacturer and supplier data:

Systemair A/S

Ved Milepælen 7

DK-8361 Hasselager

Responsible for documentation: Ulf Bang

B Name of machines

This manual is about Systemair air handling units called Geniox 10, Geniox 11, Geniox 12, Geniox 14, Geniox 16, Geniox

18, Geniox 20, Geniox 22, Geniox 24, Geniox 27, Geniox 29 and Geniox 31.

1

output |

Page 10

| Declaration of Conformity - example

2

C Declaration of Conformity - example

The manufacturer:

Systemair A/S

Ved Milepælen 7

DK - 8361 Hasselager

Hereby declares that, air handling units of the flowing types:

DANVENT DV10, DANVENT DV15, DANVENT DV20, DANVENT DV25, DANVENT DV30, DANVENT DV40,

DANVENT DV50, DANVENT DV60, DANVENT DV80, DANVENT DV100, DANVENT DV120, DANVENT

DV150, DANVENT DV190 and DANVENT DV240.

TIMEec 10, TIMEec 15, TIMEec 20, TIMEec 25, TIMEec 30, TIMEec 40

Geniox: 10DR, 11DR, 12DR, 14DR, 16DR, 18DR, 20DR, 22DR, 24DR, 10SR, 11SR, 12SR, 14SR, 16SR,

18SR, 20SR, 22SR, 24SR, 27SR, 29SR, 31SR, 10DRR, 11DRR, 12DRR, 14DRR, 16DRR, 18DRR, 20DRR,

22DRR, 24DRR, 27SRR, 29SRR, 31SRR, 10MRR, 11MRR, 12MRR, 14MRR, 16MRR, 18MRR, 20MRR,

22MRR, 24MRR, 27MRR, 29MRR, 31MRR, 10.05/10.05TR, 11.055/11.055TR, 12.06/12.06TR, 14.07/

14.07TR, 16.08/16.08TR, 18.09/18.09TR, 20. 10/20.10TR, 22.11/22.11TR, 24.12/24.12TR, 27.13/

27.13TR, 29.14/29.14TR, 31.15/31.15TR, 10.05IR, 11.055IR, 12. 06IR, 14.07IR, 16.08IR, 18.09IR,

20.10IR, 22.11IR, 24.12IR, 27.13IR, 29.14IR, 31.15IR, 10DL, 11DL, 12DL, 14DL, 16DL, 18DL, 20DL, 22DL,

24DL, 10SL, 11SL, 12SL, 14SL, 16SL, 18SL, 20SL, 22SL, 24SL, 27SL, 29SL, 31SL, 10DLL, 11DLL, 12DLL,

14DLL, 16DLL, 18DLL, 20DLL, 22DLL, 24DLL, 27SLL, 29SLL, 31SLL, 10MLL, 11MLL, 12MLL, 14MLL,

16MLL, 18MLL, 20MLL, 22MLL, 24MLL, 27MLL, 29MLL, 31MLL, 10.05/10.05TL, 11.055/11.055TL,

12.06/12.06TL, 14.07/14. 07TL, 16.08/16.08TL, 18.09/18.09TL, 20.10/20.10TL, 22.11/22.11TL,

24.12/24.12TL, 27.13/27.13TL, 29.14/29.14TL, 31. 15/31.15TL, 10.05IL, 11.055IL, 12.06IL, 14.07IL,

16.08IL, 18.09IL, 20.10IL, 22.11IL, 24.12IL, 27.13IL, 29.14IL, 31.15IL

Serial No: ”YYMM-000XXXXXXX-XX”

are manufactured and delivered in accordance with following directives:

Machinery directive 2006/42/EC

Ecodesign — Commission regulation 1253/2014

EMC – directive 2014/30/EC

Low voltage directive 2014/35/EC

Pressure equipment directive 2014/68/EC

European Standard EN378–1 & 2 — 2016

Equipment type: Heat Pump Unit — Geniox and DVU Series

Consisting of: Compressor, evaporator and condenser

Verification and Assessment by:

Notified Body Bureau VERITAS CE0041 for PED

Bureau VERITAS UK, “Parklands”, Wilmslow Road

Didsbury, Manchester M20 2RE

The declaration is only valid, if the installation of the air handling unit is carried out according to the instructions delivered with the unit. The installer will be responsible for the CE marking and documentation, if any construction or functional changes are applied to the air handling unit.

Hasselager 15.08.2017

Module: A2

Certificate no:

CE-0041-PED-A2-SYA-001-17-DNK

output |

Page 11

General descriptions, dangers and warnings |

D General descriptions, dangers and warnings

Geniox air handling units are order specific machines available in thousands of different configurations. Only a few examples of machine configurations are described below. The air handling units are intended for the transport and treatment of air between -40 °C and + 40 °C.

The units are exclusively for comfort ventilation.

Maintenance of the units must be carried out by skilled technicians.

On the drawing below, a right hand unit is shown because the inspection doors are mounted on the right hand side of

the unit when looked in direction of SUPPLY airflow. The unit below is with rotary heat exchanger.

3

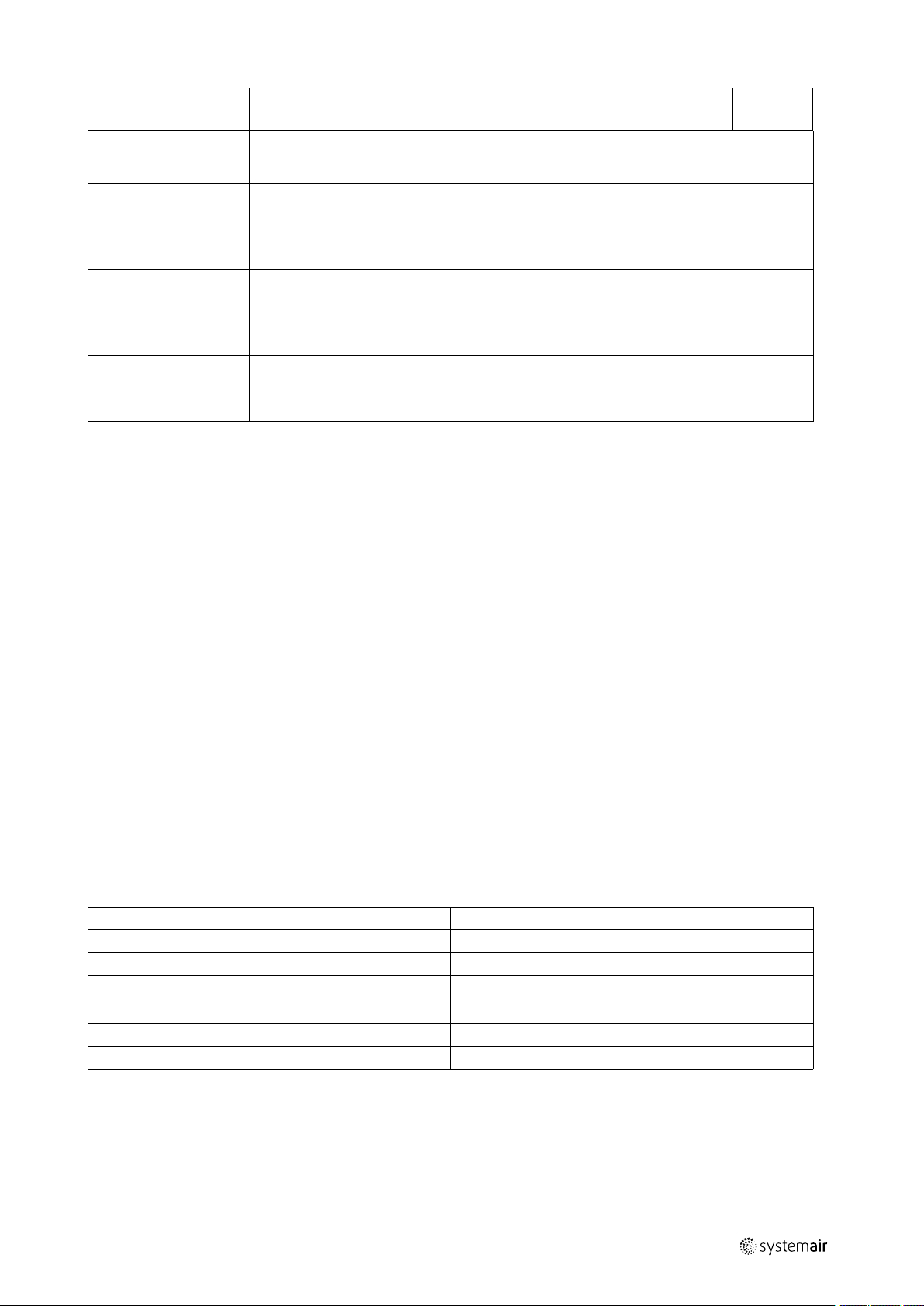

Position

A

B

C

D

Description

Connection, supply air (to the rooms)

Connection, exhaust air

Connection, outdoor air in

Connection, extract air (from the rooms)

D.1 Overview via pictograms on the inspection side of the unit

Symbol

D.1.1 Where are pictograms placed on the units

Example (Pictograms and labels with descriptions of functions for fast identification)

Position Description

1

2

output |

At each section a label with production number of this air handling unit as well as weight of

each section

Machine card

Symbol

Page 12

| General descriptions, dangers and warnings

4

Position Description

3

4

5

6

7

8

9

10 Damper – extract air

Damper - supply air

Filter - supply air

Fan- supply air

Heating battery - supply air

Fan - extract air

Heat exchanger

Filter – extract air

Symbol

11

Integrated control system in a cabinet behind this inspections door.

D.1.2 Weight of each section and production number – example for the Geniox unit

Weight of the section. Production number of the unit.

Number of the section in the unit.

Product name in this example Geniox 27SL, where 27 indicates the size of the unit. The unique production number for the complete unit in this example is 1712–

0004601640–10 where 17 indicates production year

2017 and 12 indicates month.

D.1.3 CE label — example for the Geniox unit

CE marking is printed on the machine card.

output |

Page 13

General descriptions, dangers and warnings |

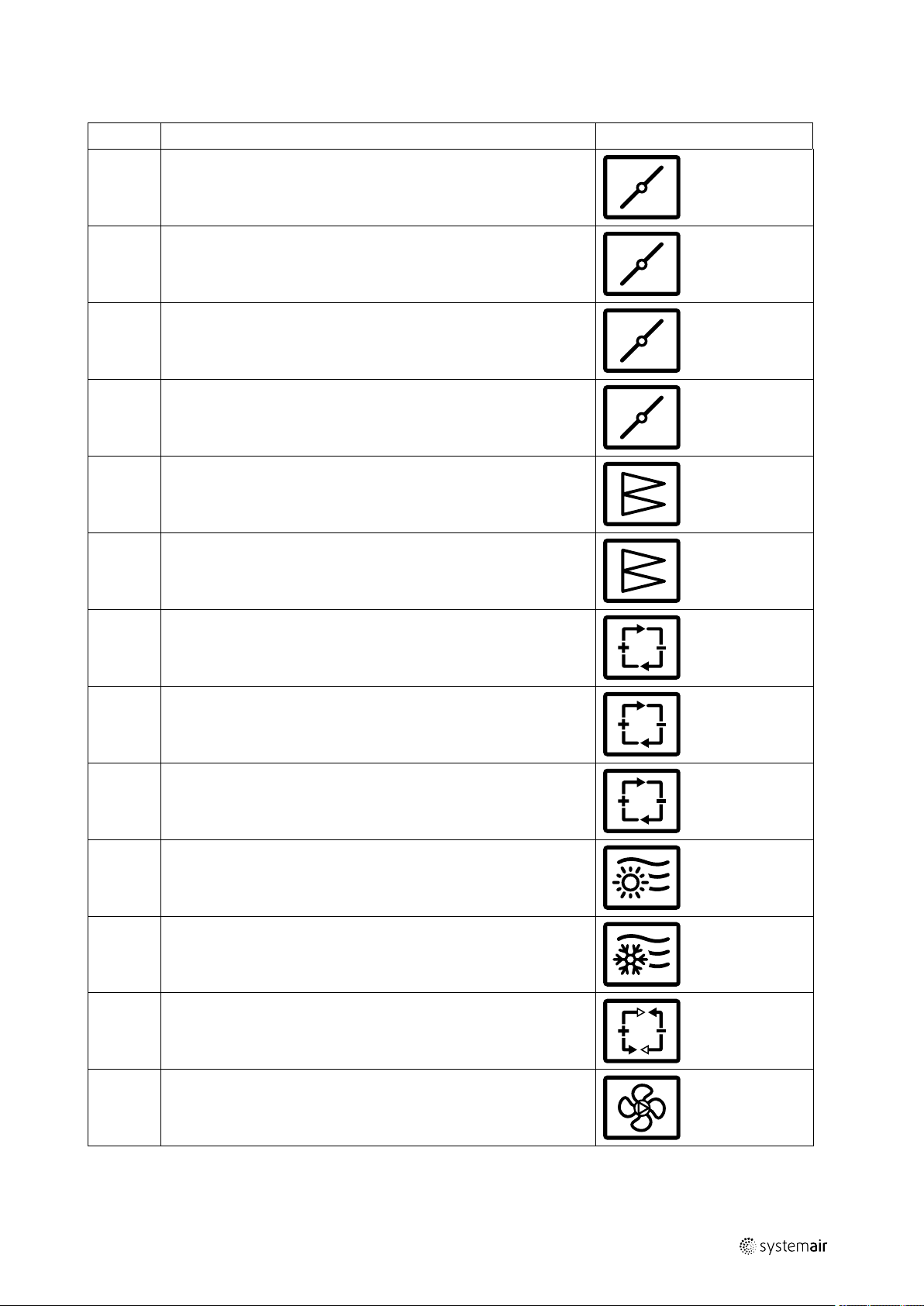

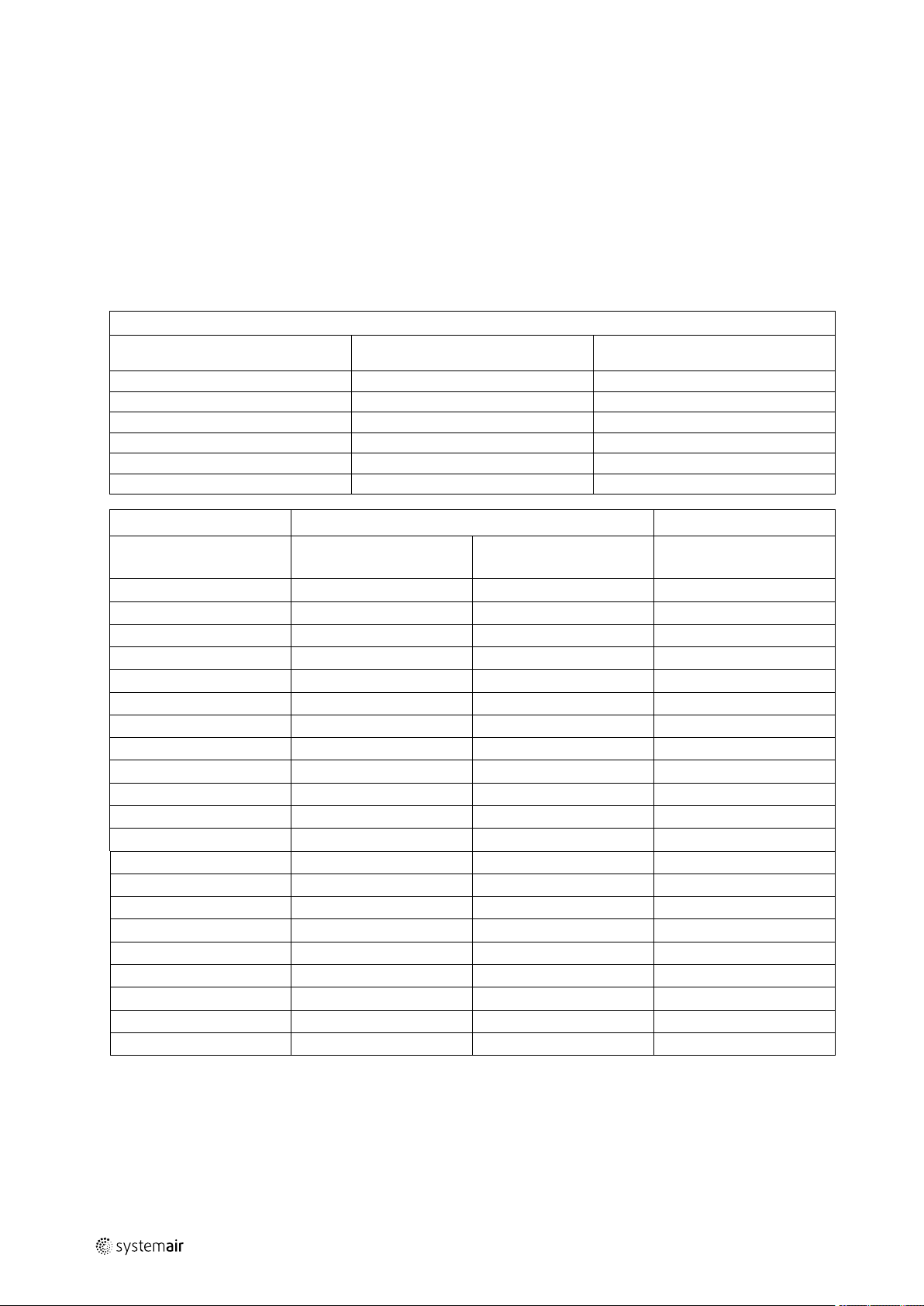

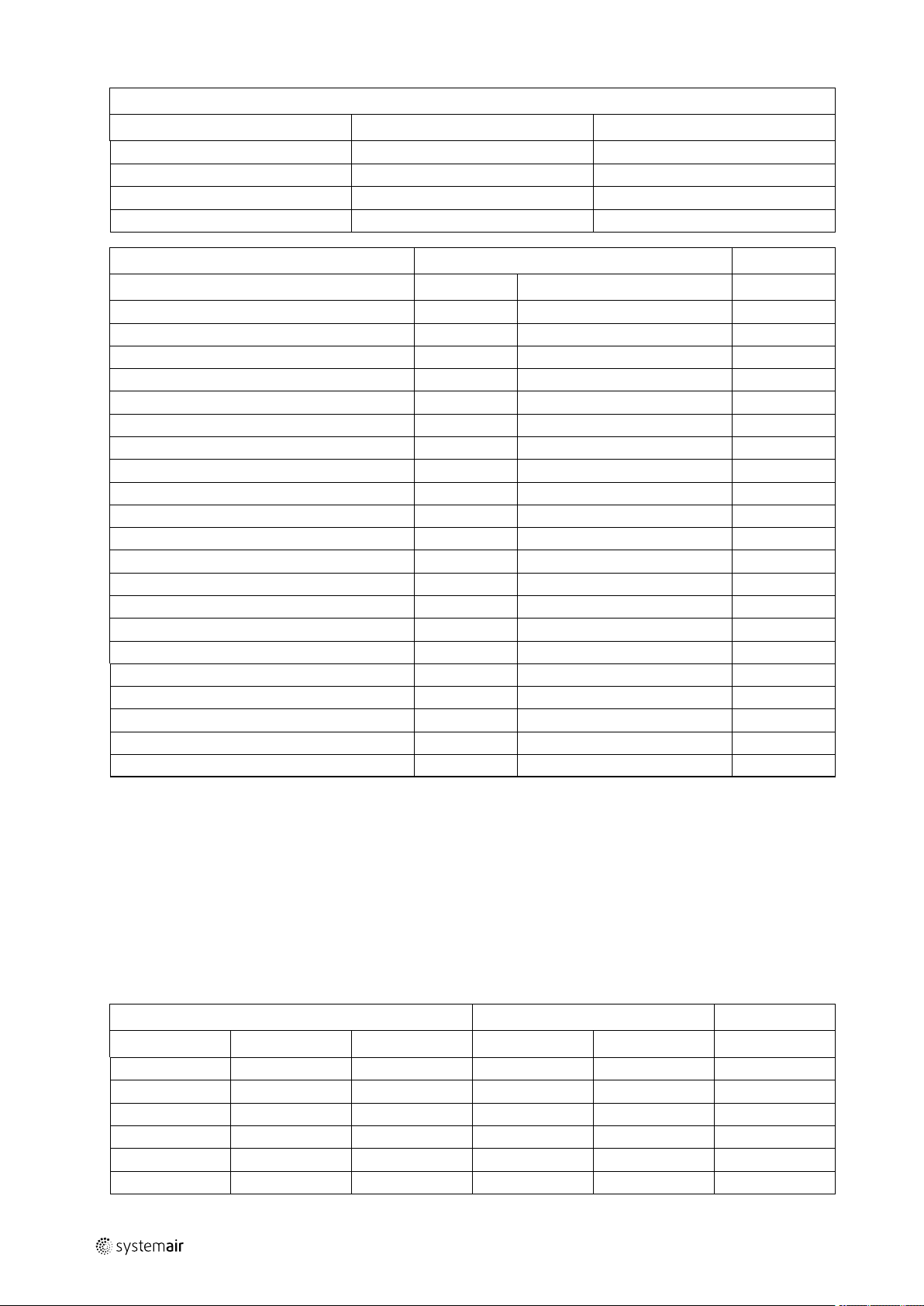

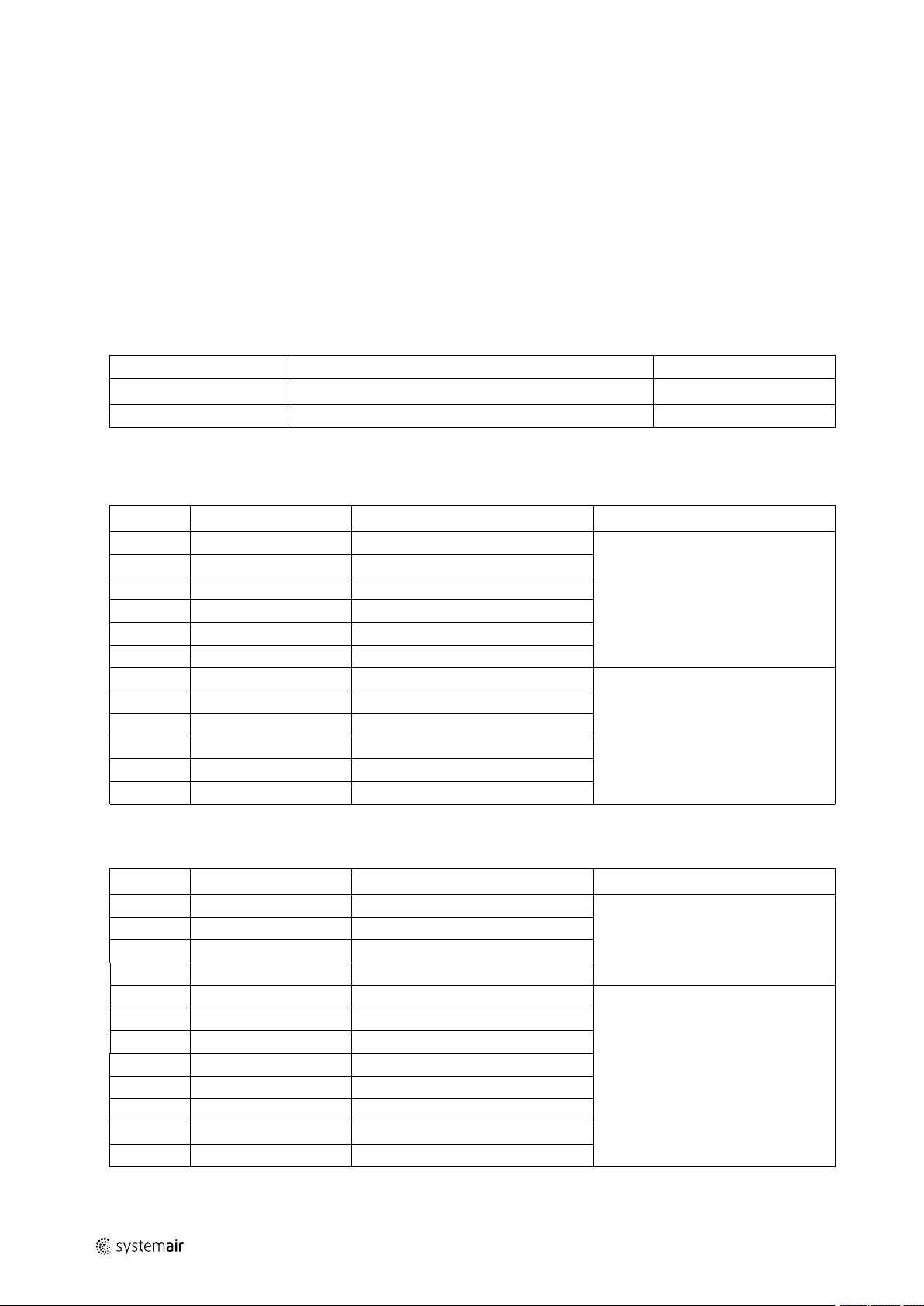

D.1.4 Pictograms for all available functions in the units

5

Id

GenioxA Damper

GenioxB Damper

GenioxM

GenioxP

GenioxG

GenioxF

Description

Damper for mixing

Damper for mixing

Panel filter

Bag filter

Symbol

GenioxC

GenioxQ

GenioxR

GenioxH

GenioxK

GenioxU Heat pump unit

Rotary heat exchanger

Plate heat exchanger (cross flow and counter flow)

Run around heat exchanger

Heating battery

Cooling battery

GenioxE

output |

Plug fan

Page 14

| General descriptions, dangers and warnings

6

Id

GenioxD

GenioxX

Description

Silencer

Humidifier

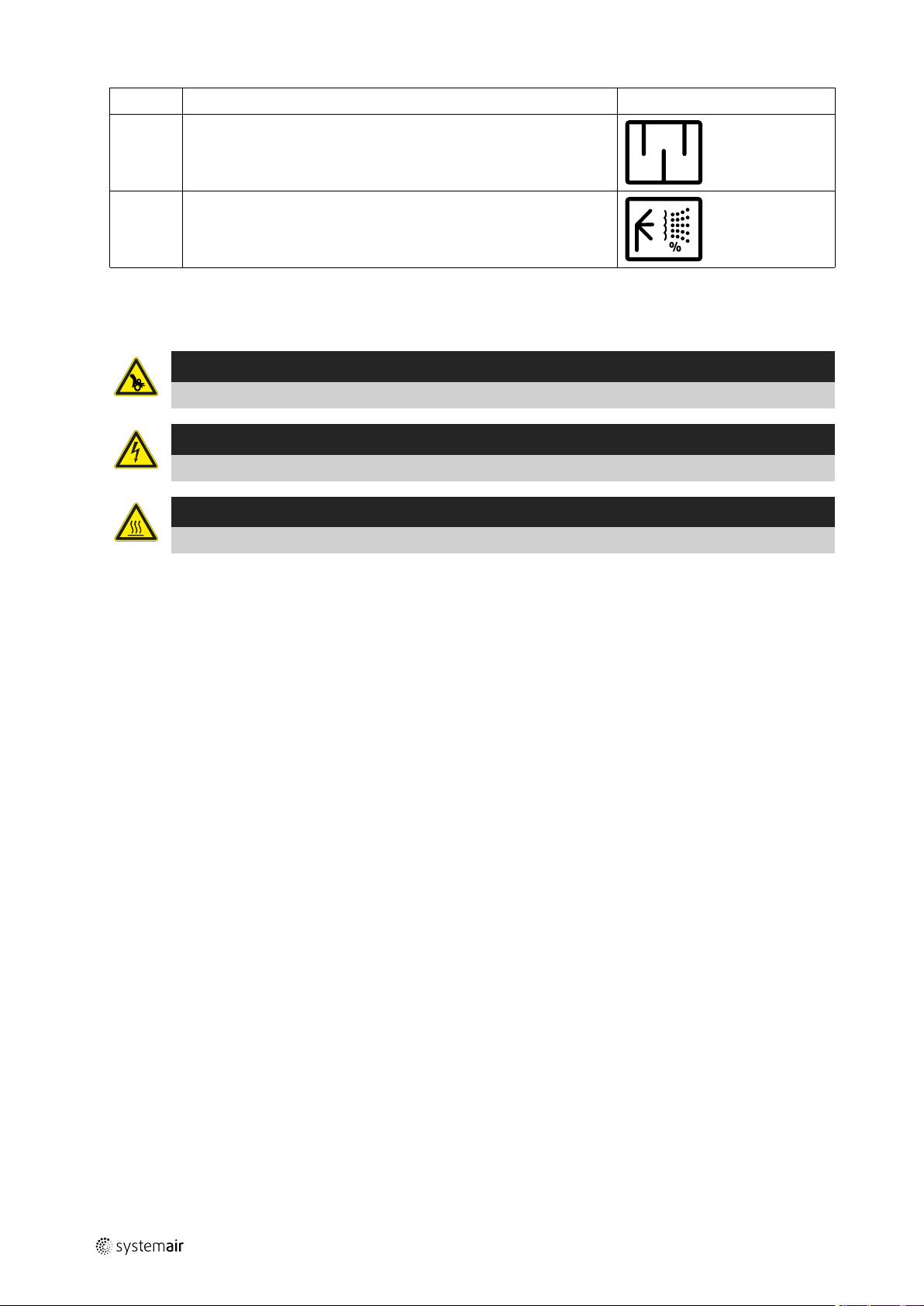

D.1.5 Pictograms about warnings and dangers on the units

Pictograms according to EN1886 about

Warning

Warning about danger by rotating parts

Warning

Warning about danger by electricity

Warning

Warning about danger by heat

Symbol

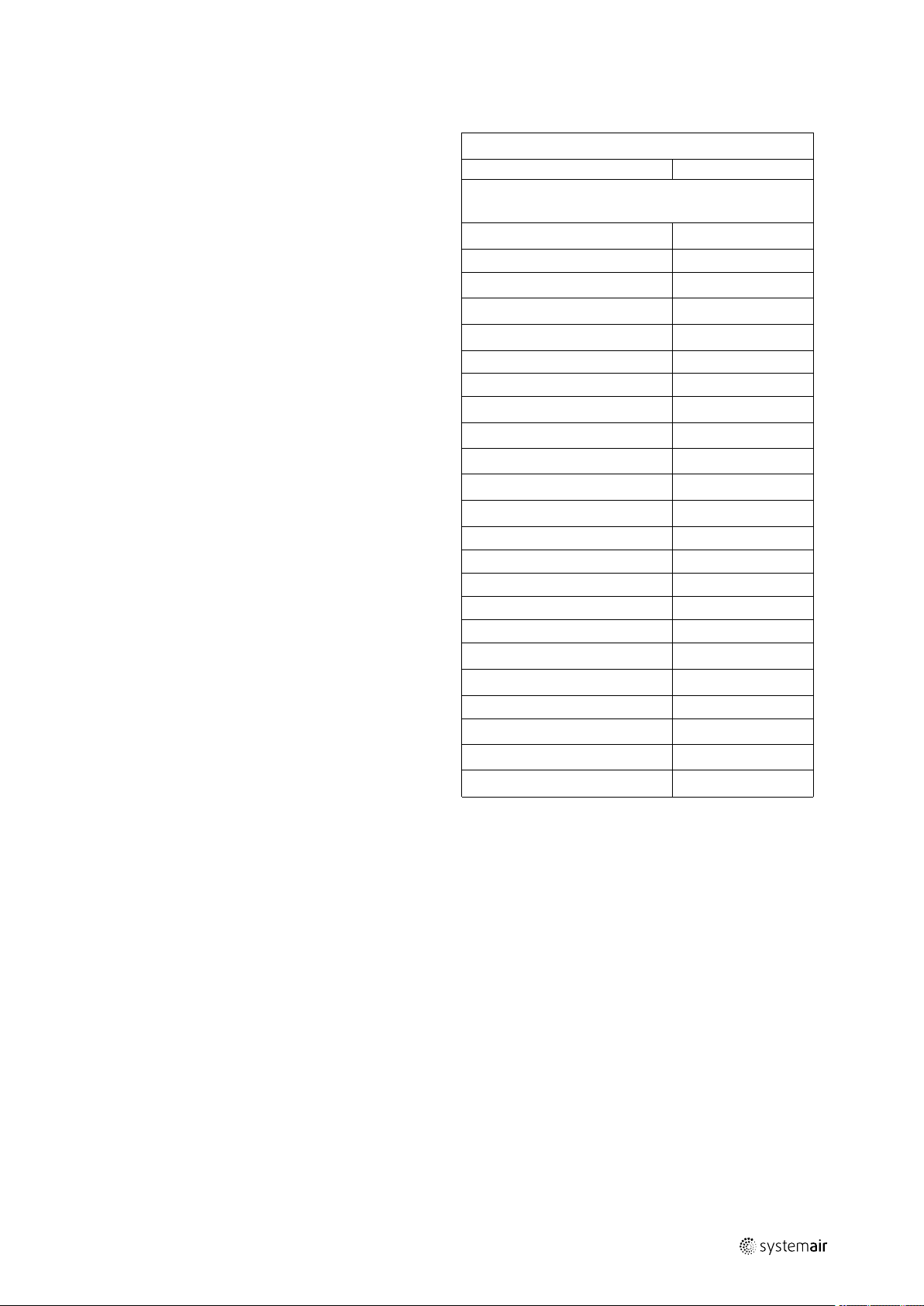

D.2 Data about the unit according to cards and labels in and on the unit

D.2.1 Machine card with unique data on every unit

output |

Page 15

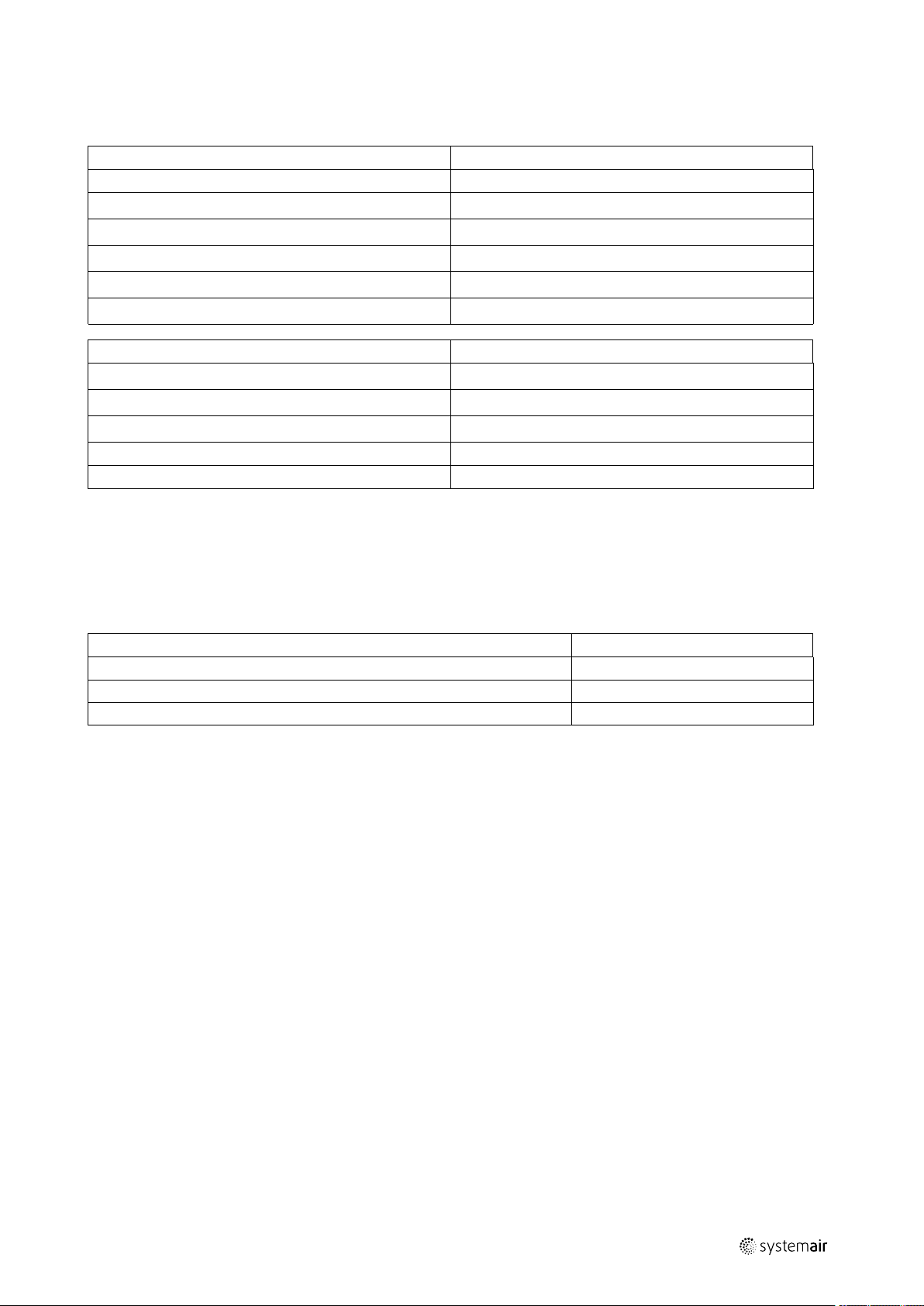

D.2.2 Label with data about the cabinet — example.

An example of the label that is always placed on or with

the cabinet

Systemair A/S

Systemair declares hereby that the cabinet is in

conformity with:

SBB Low voltage panels:

Electrical material on machines:

EMC-directive environment: 89/336/EOF

Diagram version Geniox ver. X:XX

Systemair order number

Unit size 10

Cabinet data:

System ground

Current type AC

Frequence 50 HZ

Rated voltage

Control voltage

PSCC max

PSCC min 650 A

Max fuse

Min fuse

Cable colors:

Protection circuit

230 VAC phase Black

0 VAC neutral Blue

24 VDC Grey

0 VDC Grey

Analog/digital

General descriptions, dangers and warnings |

N60439-1

EN60204-1

72800-1

TN-S

3*400 V+N+PE VAC

24 VDC

6 kA

25

10

Green/yellow

Grey

7

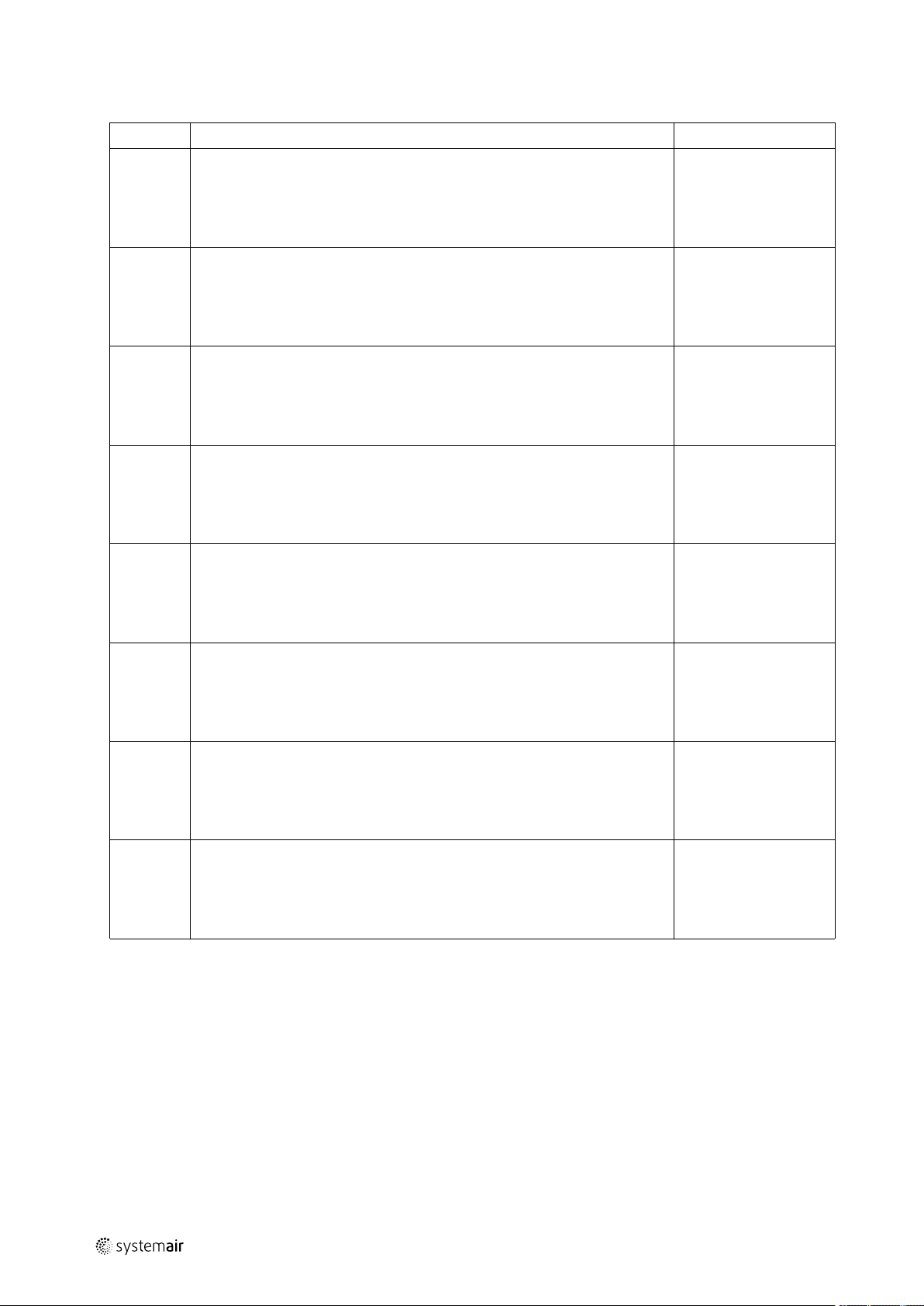

D.2.3 Flowchart – example of the label placed on or with the cabinet

output |

Page 16

| General descriptions, dangers and warnings

8

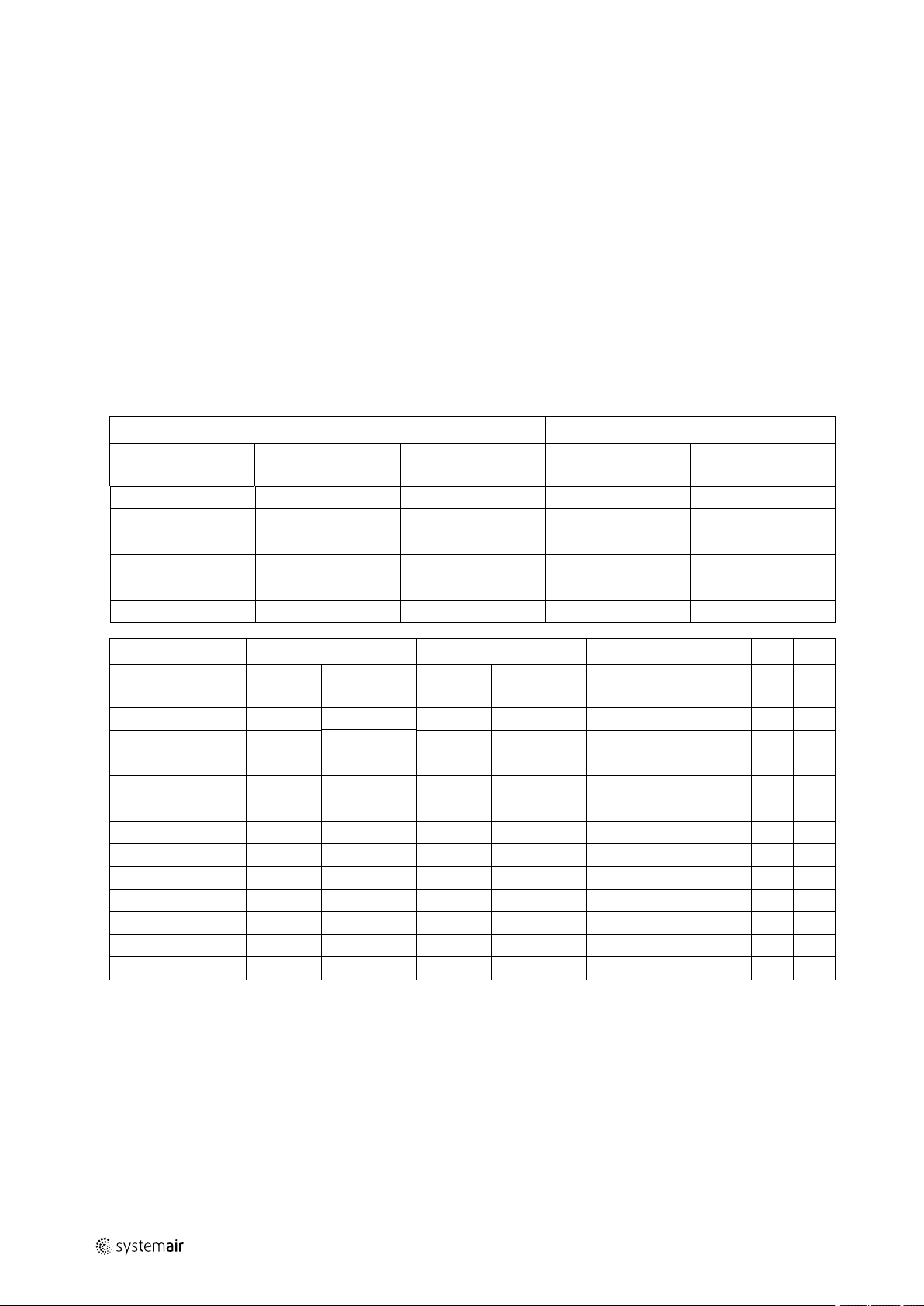

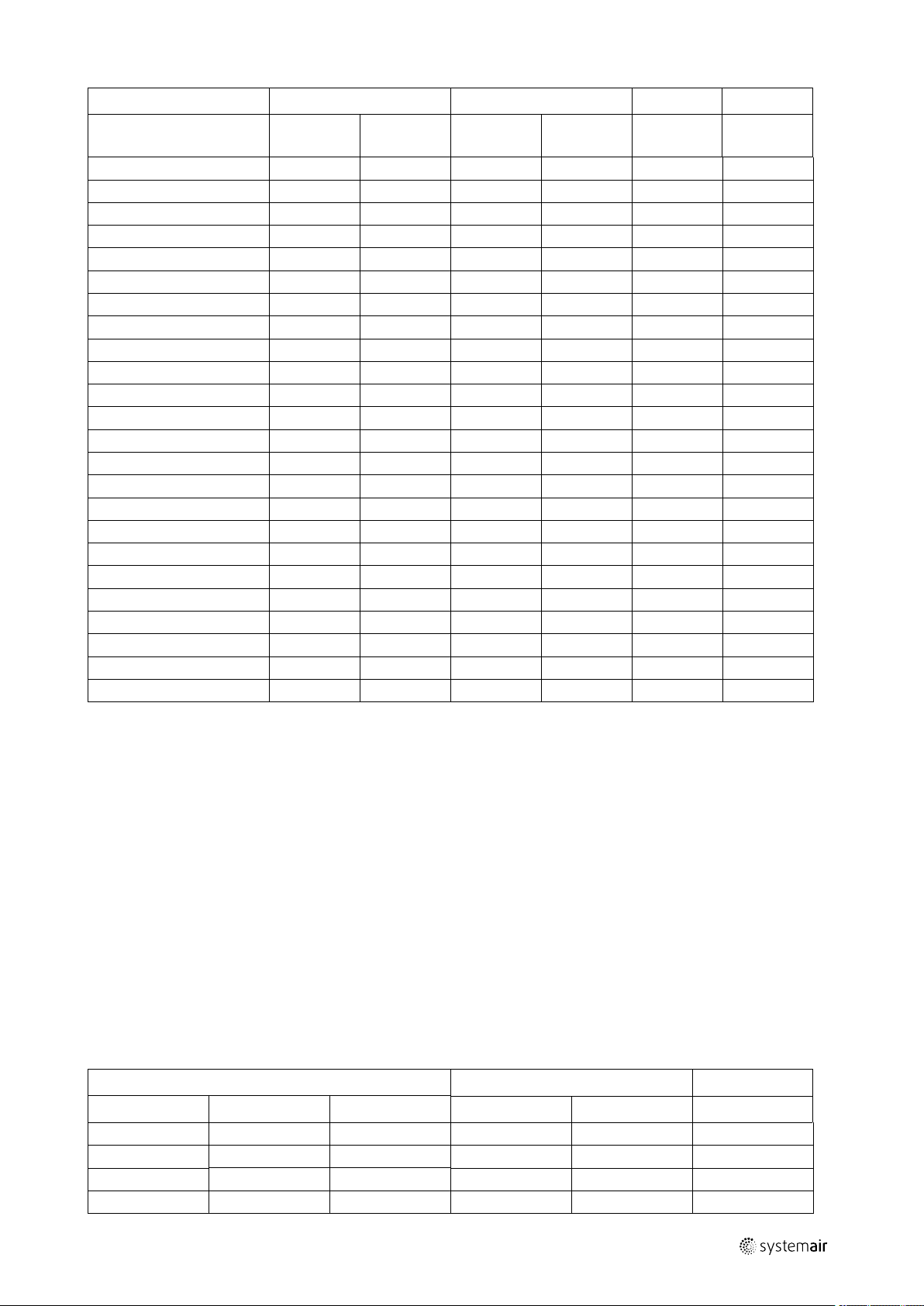

D.2.4 Symbols in the flowchart and explanation about the symbols

Id

T Temperature sensor - PT1000

M

M Damper motor – 0-10V

P

P Pressure transmitter – 0-10V

Description

Damper motor — on/off

Filter guard - digital

Symbol

RH

CO2

M

Sensor for relative humidity – 0-10V

Sensor for CO2 – 0-10V

Controller and drive motor for rotary heat exchanger – 0-10V

output |

Page 17

General descriptions, dangers and warnings |

D.2.5 Example of label placed on or with the cabinet – Terminal plan for external

components

9

D.3 Hand terminal

The hand terminal is delivered in a cardboard box containing the other external components. This cardboard box is usually, but not always, placed in the section with the supply air fan. The Operator’s Guide for the hand terminal is the Annex 17 attached to this – User Manual.

Important

All LEDs on the hand terminal must be off before startup of the unit.

1. ALARM: Press for alarm list

2. Alarm LED – red light for alarm

3. LED indicating change of parameters

4. OK/ENTER

5. Press for clear

6. Press for move of curser in menu

D.4 Dimensions of the units

See Annex 2 with information about the exact dimensions.

output |

Page 18

| Drawings, diagrams, guides and instructions for the use, maintenance and repair

10

D.5 Ordinary automatically operation – only manual operation by new parameters

The unit is operating fully automatically and manual operation includes only selection of new parameters via the buttons on the hand terminal. The hand terminal is connected by a cable to the controller in the cabinet. 10 meters of cable

is delivered with the unit and the customer has the possibility to replace this cable with an identical type of cable that is

up to 100 meters long. The alternative is that the controller is connected to a BMS system with the ability to select new

parameters via PC, tablet or SmartPhone.

D.6 Warnings about dangers

Pictograms according to EN1886 about

Warning

Warning about danger by rotating parts

Warning

Warning about danger by electricity

Warning

Warning about danger by heat

Warning

Disregards of instructions shown on warning signs are connected by risk for injury or damage on material.

E Drawings, diagrams, guides and instructions for the use, maintenance and

repair

All Geniox units with integrated control system are manufactured in compliance with the EC Declaration of Conformity

and they are CE marked as machines. Unique Declaration with production number of the machine is an integral part of

the machine – enclosed as Annex 1to this manual. If the buyer carries out changes or adds components in or on the machine, the buyer must issue a new EC Declaration of Conformity and a new CE marking of the machine.

To promote correct use of the machines, the below-mentioned instructions are an integral part of the machine:

• Unique drawings, data and description of functions for the delivered unit – Annex 2

• Wiring diagrams – Annex 16

• Operator’s Guide – Annex 17

• Instructions for use of the machine – chapter K in this manual

• Instructions about adjustment and maintenance – chapter R in this manual

• Safety during adjustment and maintenance – chapter S

F Employees in charge of operation/control/maintenance

The units are constructed and built with a fully integrated control system. After start-up and hand-over from installer to

operators, the unit operates fully automatically.

Indications of operating status as well as indication of faults are visible in the display and on the LEDs at the hand terminal. The operators can enter new parameters in the controller via the buttons on the hand terminal. Alternatively, the

controller can be connected to a BMS system so that new parameters can be selected via PC, tablet or Smartphone.

The operators do not need to open inspections doors for the operation.

Skilled technicians must carry care out maintenance as well as repairs.

G Intended use and range of applications

The air handling units are intended for the transport and treatment of air between -40 °C and + 40 °C The units are exclusively for comfort ventilation. The units are not for environments that exceed the corrosion class C4 according to EN

ISO 12944-2.

Intended applications for the units are:

output |

Page 19

Unintended use and misuse – inappropriate applications for the machine |

• Offices

• teaching rooms

• hotels

• shops

• homes and similar comfort zones

H Unintended use and misuse – inappropriate applications for the machine

Units for outdoor installation must be specified and ordered for outdoor installation. The units must not be used in environments that exceed corrosion class C4 according to EN ISO 12944-2, and for transport of solid particles.

Examples of not intended use:

• Kitchen extraction

• swimming pools

• off-shore

• Ex-areas

• drying of washed clothes.

• Do not use the unit with partly finished duct systems.

• Do not use the unit for ventilation of the building site until the unit is properly provided with guards.

11

H.1 Air handling unit in operation

The pressure difference between interior and exterior of the unit must not exceed 2000 Pa for the Geniox 10 and up to

Geniox 31 (including Geniox 31), and 1500 Pa for Geniox 36 and Geniox 44.

Before start-up of the unit all ducts, safety guards and all protective devices must be mounted to prevent any access to

rotating fan impellers. All inspection doors must be closed and locked when the unit is in operation.

Do not use the unit without filters.

I Instructions for unloading on the site as well as installation and connection

I.1 Unloading on the site

The air handling unit – AHU - is delivered as one section or in several sections, which are to be assembled on site. The

AHU is delivered on transport pallets, legs or on a base frame. Loading and unloading as well as transport on the site is

possible by fork-lift truck or by crane using suitable lifting straps.

I.1.1 Unloading by fork-lift truck

The forks of the truck must be sufficiently long to avoid any damage to the AHU underside.

output |

Page 20

| Instructions for unloading on the site as well as installation and connection

12

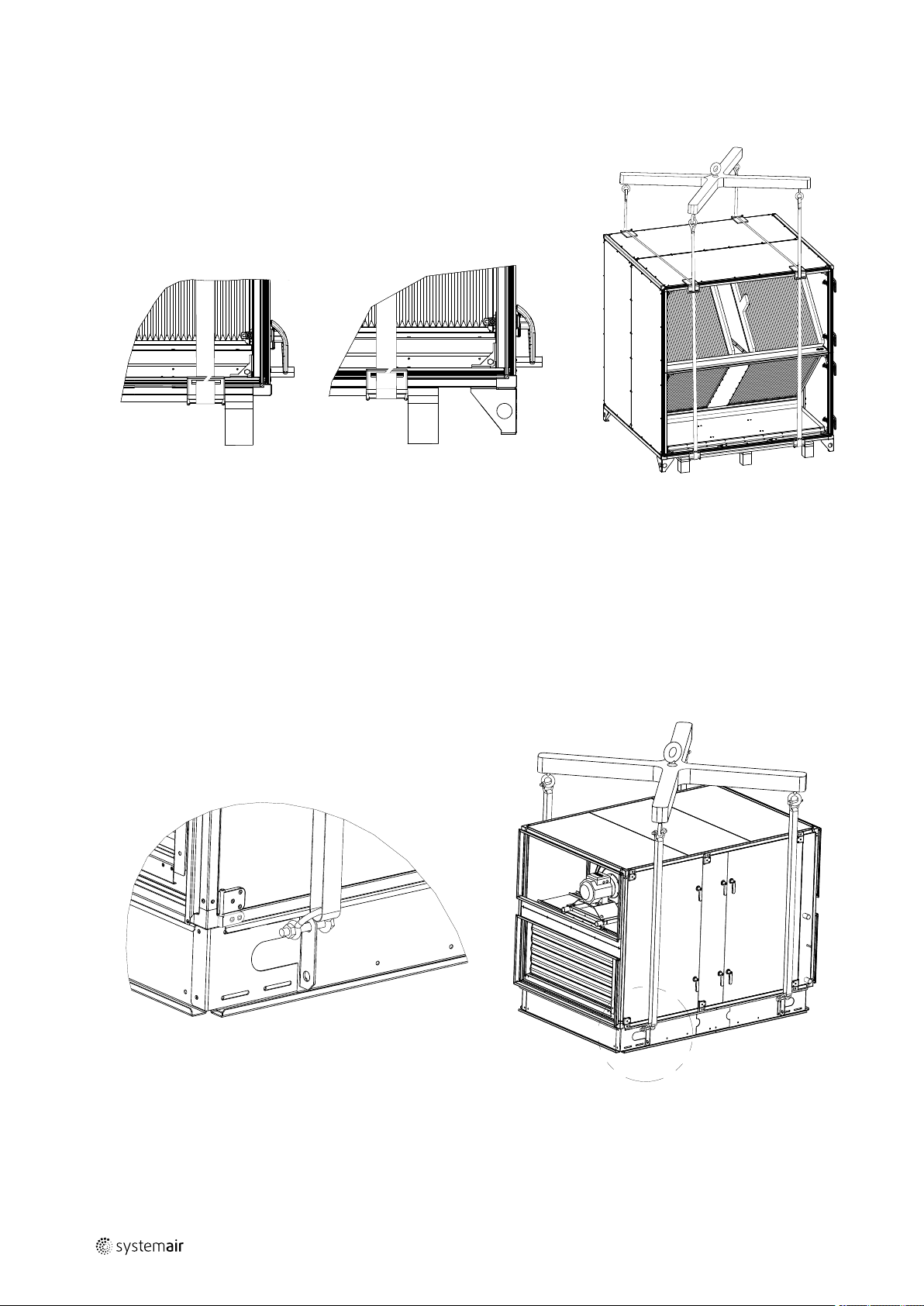

I.1.2 Unloading by crane

AHU delivered on transport pallet must be lifted by straps as shown in the illustration.

I.1.3 Transport of unit without base frame on the site

Units without base frame are always delivered in sections with each section on a pallet. Sections can be transported on

the site by hand manual forklifts.

I.1.4 Lifting a unit with straps

Use an appropriate lifting beam with a sufficient span to avoid that the straps touch and damage the drip nose profiles

and the inspection side with handles, pipes and accessories – for example manometers, cabinets, tabs for measuring

the pressure.

I.1.5 Lifting a unit with preinstalled brackets on the base frame for lifting.

Lifting beam and straps are not included in the delivery.

I.1.6 Lifting a unit without base frame and legs but with preinstalled brackets for lifting.

Attach straps carefully to the 4 brackets at the bottom of sections on Geiniox units sizes 20 — 31, because those brackets are mounted to the profiles that are bearing the heavy components in the section

output |

Page 21

Instructions for unloading on the site as well as installation and connection |

This type of bracket at the bottom of Geniox units in the

sizes 20 to 31 is reinforced for lifting the unit. Mount a

shackel in each of the 4 brackets that should be suitable

for lifting the weight of the section. The weight of the

section is printed on the label placed on the inspection

side of the unit.

13

Caution

Do not lift the section in the 4 brackets at the top of the section, because those brackets are not mounted

on profiles that are bearing. The connection between these profiles at the top of the section is not designed

to lift the bottom of the section with the heavy components. There is a potential risk that the bottom with

the heavy components may fall down with serious risk of injury and damage to property.

Bracket at the bottom for lifting and assembling Geniox

units in the sizes 20 — 31

output |

Page 22

| Instructions for unloading on the site as well as installation and connection

14

Look at the backside of the bracket for lifting and assembling Geniox units in the sizes 20 — 31. Check that each

of the 4 brackets is mounted on the horizontal profiles by

screws with M6 mm thread and on the vertical profiles by

6 mm tap tights. Only brackets that are mounted in this

way are suitable for lifting.

This bracket at the bottom of Geniox units in the sizes 16

and 18 is not reinforced for lifting the unit. Furthermore,

this bracket is not firmly fastened for lifting the section.

This bracket is only for the assembly of sections.

I.1.7 Roof unit with PVC roof

Avoid damaging the drip nose profiles along the PVC roof. Keep the protection profiles of Styrofoam on the unit until

the installation has been completed. If the unit is lifted by straps, the straps must be kept away from the drip nose profiles by bars to avoid damage to roofing profiles.

output |

Page 23

Instructions for unloading on the site as well as installation and connection |

I.1.8 Roof unit with steel roof

Caution

For units with steel plate roof, the steel plates are delivered uninstalled on a separate pallet. Do not step or

walk on the plates.

15

I.1.9 Pre-assembly storage

The AHU must be protected from the weather and accidental impact. Plastic packaging must be removed and the unit

covered with tarpaulin or similar materials. In order to minimize condensation, sufficient air circulation must be ensured

between the covering and the unit.

I.1.10 Tilt less than 30˚ during transportation of the section with heat pump

During transportation, the unit section must always be in the upright position or tilted less than 30˚. If it is necessary to

tilt the unit more than 30˚, the suction pipe of the compressor must point upwards to prevent the escape of oil from the

compressor sump.

I.1.11 Transport of rotary heat exchanger — always in vertical position

During transportation, the unit section must always be in the upright vertical position and never in a horizontal or tilted

position. The rotary heat exchanger is not constructed for transportation in a horizontal or tilted position.

I.2 Installation - mechanical

I.2.1 Free area in front of and above the unit

Important

When positioning the unit on the site, it must be ensured that an area with the same width as the unit is

kept free for service and inspection and also for replacement of fans and exchanger, if needed. The width of

the free area must be at least 900 mm.

output |

Important

For safe access to the cabinet with electrical components, if the cabinet is placed on top of the unit, the free

area from the upper edge of the cabinet to the ceiling must be at least 700 mm.

Page 24

| Instructions for unloading on the site as well as installation and connection

16

I.2.2 Supporting surface

Caution

Duct work must be sound insulated and must not be mounted directly on beams, trusses or other critical

building parts.

Caution

The surface beneath the unit must be level, horizontal and vibration-free. The surface must be able to

withstand the load of the AHU. Weights of the sections are written in Annex 2.

I.2.3 Adjustable feet under legs or base frame and transport of sections

Adjustable feet are provided in a carton box placed inside the unit. Adjustable feet are delivered for indoor units and

not for outdoor units.

Sections can be transported on the site by hand manual forklifts or similar. The frame profiles in the edges of the sections have carrying capacity for lifting by the hand manual forklifts.

I.2.4 Base frame assembly

Base frame is delivered unassembled for the indoor units that are delivered in sections on pallets. Assembly of the base

frame is illustrated on 4 pages in a manual in a plastic bag which is attached to one of the large base frame parts.

The 4 pages with the illustration regarding the assembly of the base frame are also available in this user manual in Annex 4, 5, 6 or7.

There are two types of base frames:

1. 118 mm high base frames

2. 218 mm high base frames

There are 4 different manuals and each of them illustrates the assembly of the 4 different types of base frames:

1. Manual about the 118 mm high base frames for AHUs in the sizes from Geniox 10 to Geniox 18. The name of this

manual is – Base frame 118 sizes10 - 18

2. Manual about the 118 mm high base frames for AHUs in the sizes from Geniox 20 to Geniox 31. The name of the

manual is – Base frame 118 sizes20 - 31

3. Manual about the 218 mm high base frames for AHUs in the sizes from Geniox 10 to Geniox 18. The name of the

manual is – Base frame 218 sizes10 - 18

4. Manual about the 218 mm high base frames for AHUs in the sizes from Geniox 20 to Geniox 31. The name of the

manual is – Base frame 218 sizes20 - 31

Mount adjustable feet with a distance of maximum 1500 mm between each foot under the base frame. The base frame

can now be levelled by the adjustable feet. The next step is to place and assemble AHU sections on the base frame.

I.2.5 Base frames for outdoor units

Outdoor units must be installed on 218 mm high base frames and are always fitted to the AHU sections. Hot-dip galvanized base frames are recommended for outdoor units. Systemair delivers these base frames without the above mentioned adjustable feet.

I.2.6 Outdoor units — support under the base frame of the unit

The installer must provide a frame that supports the base frame of the unit under the inspection side and under the

back side of the unit. The frame must support the base frames of the unit under the entire length of the unit.

output |

Page 25

Instructions for unloading on the site as well as installation and connection |

Caution

To avoid that the unit may tilt during storm the base frame of the unit must be properly fastened to the

frame provided by the installer

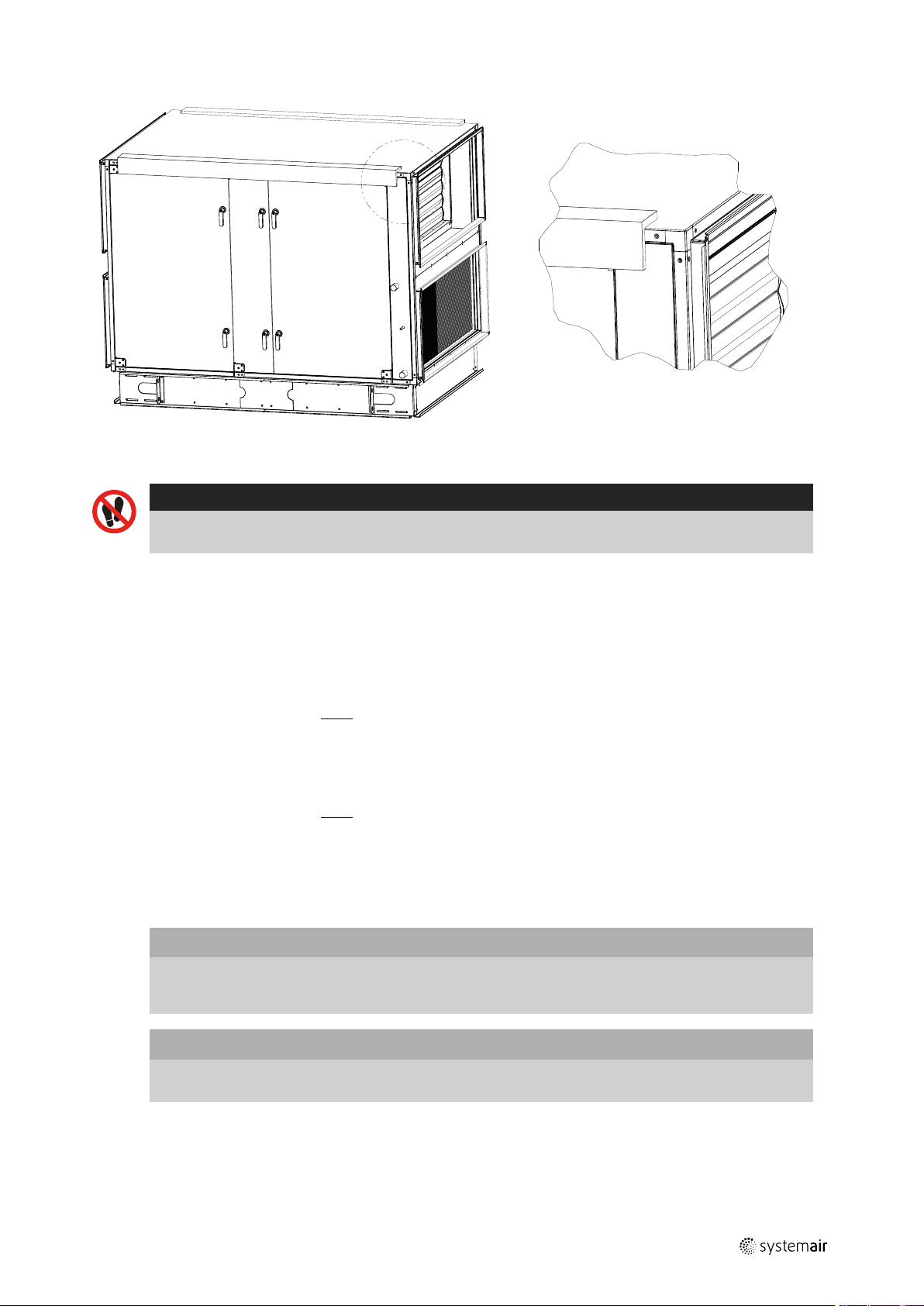

I.2.7 Installation on the site of unit sections at the base frame when sections are

delivered on pallets

17

Caution

It is strictly forbidden to lift a section under the top of the section. The plastic corners and brackets are not at

all reinforced for lifting the unit under the top. There is serious danger that the bottom with the heavy

components will fall down with the risk of serious injury and damage to property.

Lift up the section by hand manual forklifts to the level where the underside of the section is even with the overside of

the base frame.

Pull the section to the correct position on the base frame

by lifting straps – it is maybe necessary to support the

section by heavy duty furniture trolleys (see the photos

below)

Example of heavy duty furniture trolley turned with the

wheels upwards. Placed in this way on the forks of the

hand manual forklifts the heavy duty furniture trolleys are

suitable for safe and careful rolling of the unit sections

over the base frames.

output |

Page 26

| Instructions for unloading on the site as well as installation and connection

18

Example of very heavy duty furniture trolleys. Turned

with the wheels upwards and placed on the forks of hand

manual forklifts these heavy duty furniture trolleys are

very suitable for safe and careful rolling of the unit sections over to the base frames.

Pull sections together with a strap. We recommend the

shown type of strap because this type is not damaging

the frame profiles in the bottom of the units. An example

of strap is shown to the right. Note! Do not place the

strap on the vertical profiles because the plastic corners

and the profiles are not at all reinforced for the heavy

load and stress that is created by the tensioner when a

section is pulled along the base frame. To avoid any load

and stress on the plastic corners the strap must be carefully placed on the bottom profiles of the unit when sections are pulled together.

Note! Never — place the strap on the vertical profile too close to a corner, because the plastics corners and the profiles are not at all reinforced for the heavy load and stress created by the tensioner when a section is pulled along

the base frame or on the floor.

output |

Page 27

Instructions for unloading on the site as well as installation and connection |

Place the strap on the bottom profiles of the unit to avoid any load and stress on the vertical profiles when sections are

pulled together along the base frame. The sections must be pulled fully and tight together with the strap is placed on

the bottom profiles. Do not pull and slide a section unless the strap is placed on the bottom profile.

19

When the sections are pulled fully together it may be helpful to place the strap halfway up on the unit to press the sections fully together so that the rubber seals are closing 100% tight. Only gentle tension is allowed because the vertical

profiles are not reinforced for brutal stress in this direction and they may be bent.

output |

Page 28

| Instructions for unloading on the site as well as installation and connection

20

Sections are mounted to base frames with self-drilling screws. In the base frame you will find a sufficient number of 5

mm holes that are prepared for the self drilling screws. In this picture you are standing and you are watching the assembled base frame on the floor or roof.

Use self-drilling screws — 4,8 X 18 mm — to be screwed upward through the holes into the bottom profile of the air

handling unit Note! A screw must be placed in every hole to achieve the necessary strength. In this picture you are lying on the floor or roof looking upward under the base frame. The screws will not be visible, when you are standing beside the unit looking at the unit

I.2.8 Joining the AHU sections

The sections must be placed on the base frame and if the unit is delivered with 150 mm legs, the sections must be positioned directly in line with each other.

Ensure that the internal factory-fitted rubber sealing is undamaged

output |

Page 29

Instructions for unloading on the site as well as installation and connection |

The sections are then to be positioned directly opposite

each other. If the sections are built with legs, the adjustable feet can be used to get the sections in line and at the

same height.

Press the sections hard together so that the rubber profiles are so flat that the iron frames of the two sections

are joined. Strap with tensioner is suitable for pressing

the sections hard together.. Note! Do not place the strap

on the vertical profiles because the plastics corners and

the profiles are not at all reinforced for the heavy load

and stress created by the tensioner. To avoid any load

and stress on the plastic corners and the profiles the

strap must be carefully placed on the bottom profiles of

the unit.

21

The sections must then be locked permanently together

with 8 mm bolts and nuts. Bolts and nuts are not delivered from Systemair

output |

Page 30

| Instructions for unloading on the site as well as installation and connection

22

Assembly is done sucesfully

Bracket inside the unit for assembly of Geniox unit sections in the sizes 16 and 18

Bracket inside the unit for assembly of Geniox unit sections in the sizes 20 to 31

I.2.9 Fitting the ductwork

Flexible duct connections between AHU and ductwork must always be installed. Be sure that flexible duct connections

are almost fully stretched. (Flexible connections are ordered as accessories and they are placed inside the unit). At the

fan outlet on a centrifugal fan, the duct size should be as close to the outlet size as possible. Avoid blockage and turbulence at the fan outlet.

output |

Page 31

Instructions for unloading on the site as well as installation and connection |

I.2.10 Risk of stack effect by vertical ducts and wind pressure on louvers

Important

The Systemair air handling units can be ordered and delivered without dampers, and the installer/user must

check that duct systems with the described risk of stack effect (chimney effect) will be provided with

dampers and spring return motors.

On special occasions stack effect – also called chimney effect – in the ducts create airflows that drives the impellers by

turned off motors.

A rotating impeller is a potential hazard during cleaning and maintenance of the unit. Eliminate this airflow by dampers

with spring return motors for automatic closing of the dampers - even by power failure.

I.2.11 Remove transport brackets – when spring mounts are installed

I.2.11.1 Impeller diameters 220 – 560 mm

If the fans are installed on spring mounts the transport brackets must be removed after the installation of the air handling unit. Two transport brackets are fitted to the coil springs during transport and installation. Both transport brackets

must all be removed to give the full anti-vibration function to the coil springs. The transport brackets are made more

visible with yellow labels. After removal of the transport brackets they must be disposed of safely.

23

I.2.11.2 Impeller diameters 630 – 1.000 mm

If the fans are installed on spring mounts the transport brackets must be removed after the installation of the air handling unit. Four transport brackets are fitted to the coil springs during transport and installation. The four transport

brackets must all be removed to give the full anti-vibration function to the coil springs. The transport brackets are made

more visible with yellow labels, as shown in the picture below. After removal of the transport brackets they must be

disposed of safely.

output |

Page 32

| Instructions for unloading on the site as well as installation and connection

24

After disposal of the transport brackets the yellow label on the outside of the fan inspection door has no function and

should be removed.

I.2.12 Refitting of guards

The guard is a safety guard installed inside the door. Tools are necessary for the removal of the guard. If the guard has

been demounted during the installation on the site, the guard must be refitted before startup of the unit.

Use an Allan key — size 6 or size 8 — for refitting the

safety guard. Replace the vibration damping rubber list if

it is damaged.

output |

Page 33

Instructions for unloading on the site as well as installation and connection |

I.2.13 Lock the doors by using the key

Use the key to lock the doors. The doors are not locked

automatically by turning the handle to the vertical

position.

25

I.3 Installation - electrical

I.3.1 Description

The position of components is shown and described in Annex 2.

Connections to terminals are shown in the wiring diagram.

When control of constant pressure in the ducts (also called demand controlled capacity) is required, the pressure transmitters must measure in the duct system at places where all pressure changes can be registered accurately for reliable

pressure control. This placement is left to the customer’s free choice.

It is important to achieve a constant pressure – also for the most faraway diffusers.

I.3.2 Wiring diagrams

The wiring diagrams are printed in separate manuals delivered with the units.

The wiring diagrams are not unique for the order specific units, but it is standard wiring diagrams with data about all

configurations of the units. Hereby the wiring diagrams will inform about components that are not ordered and delivered. See the order confirmation and Annex 2 with exact information about the accessory components that are ordered

and delivered.

The wiring diagram includes:

• General description, Circuit diagrams, Cabinet layout, Terminal matrix and Cable plan.

• The wiring diagrams are on the DVD delivered with every unit.

I.3.2.1 Geniox units – labels on or with the cabinet

• Label with data about the cabinet – including data about fuses – see chapter D.2.2

• Flowchart – see chapter D.2.3– unique for the order specific unit – printed with the unique production number of the

unit

• Label with terminal plan for external components – see chapter D.2.5– standard, and not unique for the order specific

unit

I.3.3 Installation of mains power supply

An AC/DC residual current device must be installed in the power supply. The power supply for the units is 3*400 V + N

+ PE - 50 Hz. Protection of the units in accordance with the local statutory requirements for the additional protection of

systems with frequency converters and EC fans. The operator is responsible for the installation of the necessary protection equipment (supply disconnecting device is not delivered by Systemair.

output |

Page 34

| Instructions for unloading on the site as well as installation and connection

26

I.3.3.1 Necessary mains power supply for Geniox units with cabinet/control system

Necessary mains power supply is printed on the unique machine card placed on the front of every unit (see example of

a machine card in chapter D.2.1).

I.3.3.2 Necessary overvoltage protection device, that leads lightning overvoltage to an

earth lead on a safe way.

The Installer and user must be aware of the fact that lightning strikes make a risk that requires installation of overvoltage protection devices to lead the lightning overvoltage to an earth lead in a safe way. Installer and user must take care

of this according to local statutory requirements.

I.3.4 Electrical connection of components and functions

External components and functions are delivered according to the order confirmation. Cable numbers appear from the

label inside or on the cabinet, and cable numbers appear from the wiring diagrams.

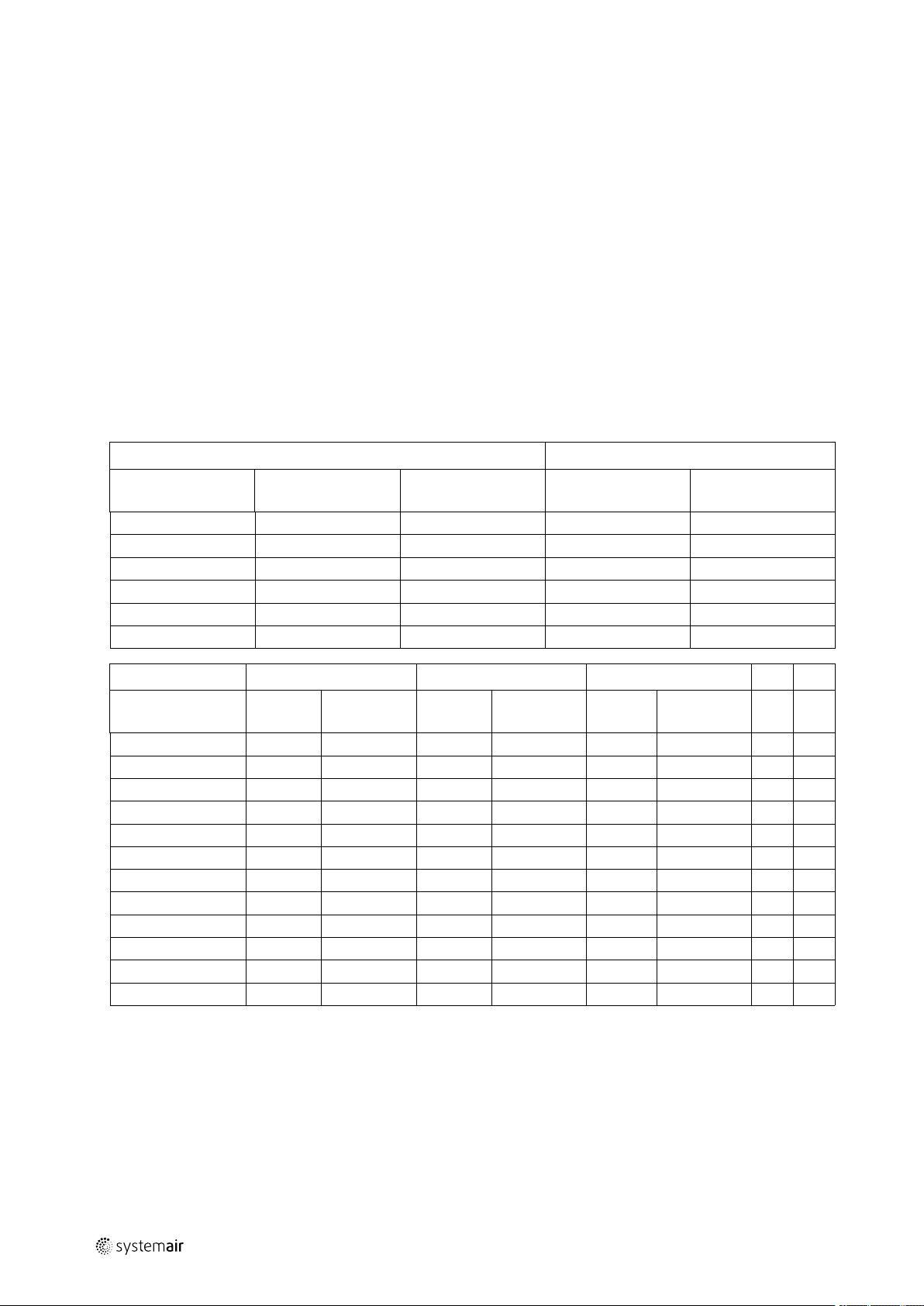

I.3.4.1 Connection of the Systemair Control Panel to the Corrigo E28 controller

The SCP panel is provided with 10 metres of cable. Demount the cable at the back of the Systemair Control Panel - pull

the cable through the cable entry in the cabinet - and remount the cable in the panel, or add more cable – up to 100 m

of cable between the Systemair Control Panel and the controller is possible. Place the Systemair Control Panel on the

outer side of the unit or on a wall.

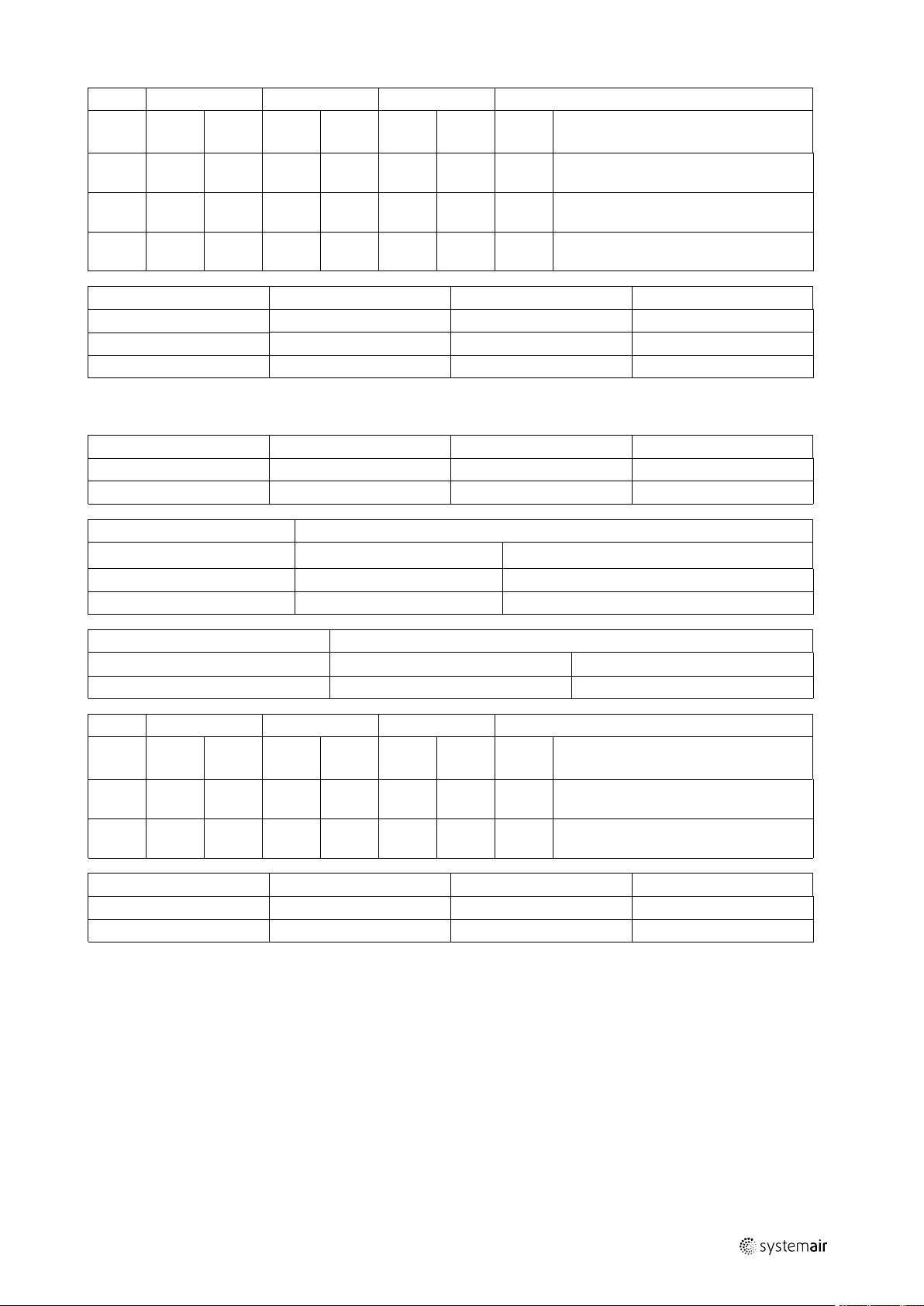

Position Description

1

2

3

4

5

6

7

8

9

10

11

12

13

Alarm button: Press for alarm list.

Alarm indicator: Flashing for unacknowledged alarm.

Write enable LED: Slow flashing indicates parameters can be changed.

OK button: Press to activate a selected menu/setting, if possible.

Button for clear: Abort a parameter setting or – if possible - restore the original value.

Right/left – and up/down buttons: Used for navigation up and down and to the right and left in the menu

tree. Up/down buttons are also used for increasing or decreasing values of parameters.

Holes for mounting

Terminal block

No cable on terminal 5 for software version 3.4 (illustrated with number 9 on the above drawing)

Brown cable on terminal 4 for software version 3.4 (illustrated with number 10 on the above drawing)

Yellow cable on terminal 3 for software version 3.4 (illustrated with number 11 on the above drawing)

White cable on terminal 2 for software version 3.4 (illustrated with number 12 on the above drawing)

Black cable on terminal 1 for software version 3.4 (illustrated with number 13 on the above drawing)

output |

Page 35

Instructions for unloading on the site as well as installation and connection |

I.3.5 Lock the doors by using the key

Use the key to lock the doors. The doors are not locked

automatically by turning the handle to the vertical

position.

27

I.4 Installation – Pipes for water – hot and chilled, valves and drains

I.4.1 Description

If ordered with the unit, the valves and valve motors are stored in a carton box placed inside the unit. Water trap(s) –

standard or optional - is (are) necessary to ensure escape of water from the tray under plate heat exchanger and (or)

cooling coil. Water trap(s) is (are) stored in a carton box placed inside the unit.

I.4.2 Pipe connections

Connection pipes on heating- and cooling coils are provided with external thread. Drainage outlets on drip trays are provided with straight pipe for quick connect fittings on the pipe with the water trap.

I.4.3 Possibility of extracting components from the unit

Pipes and cables must not obstruct the inspection doors and components which can be extracted from the unit. Potential components for extraction are filters, fans and rotary heat exchanger.

I.4.4 Pipe connections to batteries

I.4.4.1 Heating coils

Pipes for hot water must be protected by insulation against frost and loss of heat. Further protection against frost can

be obtained by installing electrical heating wires around the pipes and under the insulation combined with temperature

sensors and a control system. Pipes, insulation, electrical heating wires, control system for heating wires and circulation

pump are not delivered by Systemair.

I.4.4.2 Cooling coils

If ordered with the unit, the valves and valve motors are stored in a carton box placed inside the unit. Pipes for cooling

must be protected by insulation against condensation on the pipes and loss of cooling in the summer. Pipes and insulation are not delivered by Systemair.

I.4.4.3 Rigid pipe mounting brackets for valves, circulation pumps and pipe system

The coil and pipes from the coil are not constructed to withstand the weight and stress from valves, circulation pumps,

long pipes and insulation of pipes. The system must be supported carefully in rigid pipe mounting brackets to roof, floor

and walls.

I.4.4.3.1 Pipe connection to heating coils

The heating capacity of the coil with only 2 rows is independent of the connection of the hot water in equal flow or in

counter flow to the direction of the air, but connection of the hot water to the pipe marked for inlet and the return

output |

Page 36

| Instructions for unloading on the site as well as installation and connection

28

water to the pipe marked for outlet is very important to ensure that the sensor for transmission of the water temperature really will be placed in a return circuit of the coil (Screw-joint for the water temperature sensor is welded in the

main collection pipe for return water).

For the frost protection of heating coil, the water temperature in the coil is transmitted to the controller The controller

always generates a signal to the valve motor that keeps a sufficient flow of hot water to protect the coil against frost.

This frost protection is also activated when the running mode is “off”.

Coils with 3 rows or more must always be connected in counter flow to the airflow.

Note:

If glycol is added, the glycol must be without additives and auto glycol must not be used.Automatic bleeding

has to be installed at the highest point of the 2 pipes — supply or return pipe.

If the heating battery is built with 3 or more rows, the water flow must be in counter flow to the direction of the air.

To protect against frost a temperature sensor for the

transmission of an analog signal to the controller is placed

in a pipe on the collection pipe for return water. The sensor must be fitted water tight with a cap in the pipe before water under pressure is in the battery. The pipe for

the sensor is soldered on the collection pipe and it is important to hold contra on the pipe, when the cap is

tightened.

Battery seen from above. The sensor measures the

water temperature of the water inside one of the small

pipes for return water in the battery. The sensor reduces

the area in this pipe and hereby also the flow of warm

water in this pipe. The temperature in this pipe is reduced

more than the temperature in all other pipes by the airflow through the battery. Because the lowest temperature in the battery probably is measured here, this system

creates early and safe warning of frost.

It is important that the cap is tightened sufficient to keep

the sensor system fully water tight.

I.4.4.3.2 Pipe connection to cooling coils for chilled water

Coils with 3 rows or more must always be connected in counter flow to the airflow.

Caution

The glycol must be without additives and auto glycol must not be used.

Automatic bleeding has to be installed at the highest point of the 2 pipes — supply or return pipe

output |

Page 37

Instructions for unloading on the site as well as installation and connection |

I.4.4.3.3 Valve motor and valve for heating

The valve and valve motor are not installed. 2-way or 3-way valve is available.