Page 1

F-R60

Fire Damper

Page 2

2/49 | F-R60

Table of Contents

Overview .........................................................3

Technical Parameters ..................................................5

Diagrams .........................................................9

Dimensions ........................................................11

Ordering Codes ......................................................13

Installation ........................................................14

Electrical parameters ...................................................31

Operation manual ....................................................43

Page 3

3/49 | F-R60

Fire Damper F-R60

Description

Fire dampers represent passive fire protection and are designed to utilize compartmentalization to prevent the spread

of toxic gases, smoke and fire. The opening and closure of the damper blade can be activated remotely for actuator

versions. In case of fire when the air in the duct exceeds 72 °C or 74 °C, the thermal fuse melts in both actuator and

manual versions. The melting of the thermal fuse activates the closure of the damper blade automatically. The damper

blade is then mechanically locked in the closed position.

Highlights

• Short body

• Fire resistivity EI60S

• Interchangeable mechanism and actuator

• Manual mechanism with end position switches

• Casing leakage according to EN 1751, class C

• Blade leakage according to EN 1751, class 3

Fire Resistivity

F-R60 fire dampers are CE certified following the Construction Products Regulation according to EN 15650:2010.

Dampers are tested according to EN 1366-2:2015 and classified according to EN 13501-3 + A1:2009. The fire damper

together with its installation form an inseparable part of the fire resistivity rating. F-R60 fire dampers are designed for

the installations listed and described in their Handbook.

• Damper with standard supporting construction in accordance with EN 1366-2:2015: EI60 (ve - ho i↔o)S

Accessory

Detailed information about accessories is available at design.systemair.com

• FCR: Flexible Duct Connection

Page 4

4/49 | F-R60

Design

Material Composition

The F-R60 damper has a galvanized sheet metal casing, blades from non-asbestos calcium silicate board with

polyurethane foam seals for cold smoke and an intumescent seal that expands in case of fire. Ethylene-propylene

rubber as duct seal. The product contains no hazardous substances, except for the solder in the thermal fuse, which

contains a milligram of lead. All materials are processed in accordance with local regulations.

Activation Types

Manually Operated Fire Dampers

By default, manually operated fire dampers are supplied with manual control, optionally with micro switches. In case of

fire, the fire damper is closed automatically The actuating mechanism is activated when the temperature of the air in

the duct reaches 74 °C and the damper closes within 10 seconds after fuse melts.

• H0

Fire damper with an activation mechanism with a cover, manual crank and with a spring return release mechanism

activated by a fusible thermal link set to 74 °C.

• H2

Fire damper with an H0 activation mechanism + open and closed indication with AC 230 V or AC/DC 24 V contact

switches.

Actuator Operated Fire Dampers

By default, actuator operated fire dampers are supplied with an actuator with micro switches, optionally with a

communication and power supply unit. A fire damper can be equipped with a spring return actuator which can be

closed by a command from the building management system, or after the breaching of the thermoelectric fuse.

Actuator operated fire dampers are equipped as standard with a thermoelectric fuse, that activates the closing of the

damper after the reaching or exceeding the ambient temperature of 72 °C. The actuator power circuit is interrupted

and its spring closes the damper blade within 20 seconds.

• B230T or G230T

Fire damper with an activation mechanism with a Belimo or Gruner spring return actuator (AC 230 V) with 72 °C

electro-thermal fuse and auxiliary switches.

• B24T or G24T

Fire damper with an activation mechanism with a Belimo or Gruner spring return actuator (AC/DC 24 V) with 72 °C

electro-thermal fuse and auxiliary switches.

• BST0 or GST0

Fire damper with an activation mechanism with a Belimo or Gruner spring return actuator (AC/DC 24 V) with an 72 °C

electro-thermal fuse and auxiliary switches, with a Belimo communication and power supply unit BKN230-24 or Gruner

communication and power supply unit FSC-UFC24-2 (FSC-UFC24-2 bus protocols RS-485: BACnet MS/TP and Modbus

RTU). Other communication and power supply units on demand.

• B24T-W or G24T-W

Fire damper with an activation mechanism with a Belimo or Gruner spring return actuator (AC/DC 24 V) with an 72 °C

electro-thermal fuse and auxiliary switches, with provided cable connectors for the supply and communication unit

(communication unit not part of the mechanism).

• B24T-SR or G24T-SR

Fire damper with an activation mechanism with a Belimo or Gruner spring return actuator (AC/DC 24 V) with 72°C

electro-thermal fuse and auxiliary switches for Modulated dampers (possibility to open the blade at the desired angle).

Page 5

5/49 | F-R60

Technical Parameters

Durability Test

50 cycles with no change to the required properties

10000 cycles, actuator controlled (0 … 90 degrees rotation) – with no change to the required properties

10000 cycles, actuator controlled for modular possibility (45 ... 60 degrees rotation) - with no change of the required

properties

Testing Pressure

Under-pressure up to 300 Pa

Safe Position

Closed. (in case of fire the damper closes via a spring in the actuator or a spring in the manual mechanism)

Airflow Direction

Both directions

Allowed Air Velocity

Damper can still operate at max. 12 m/s. Air without any mechanical or chemical contamination

Side with Fire Protection

Depending on installation classification: From both sides (i <-> o)

Repeated Opening

Suitable for daily check procedure in a suitable environment

Closing/Opening Time

Manually operated < 10 s, actuator operated < 20 s

Indicator Closed/Open

Manually operated - Activation type H0 visually (arrow on the mechanism) and H2 with microswitches

Actuator operated - built-in microswitches

Activation Temperature for the fire damper closing

Manually operated: 74 °C by means of a spring after the melting of the thermal fuse

Actuator operated: 72 °C by means of a spring after current interruption in the electro-thermal fuse

Temperature of transported air

Minimum: 0 °C, for all types of mechanism

Maximum: 60 °C for 74 °C and 72 °C thermofuse (all mechanism types)

Environment suitability

Protected against weather disruptions, with temperature above 0 °C (3K5 according to EN 60721-3-3)

Page 6

6/49 | F-R60

Inspection possibility

Inspection of blade and gaskets can be done through electro thermal fuse opening with an endoscopic camera.

Manually operated additionally by removal of the mechanism through opening for its thermal fuse. In order to access

the damper's internal parts a flexible connection or duct with access doors must be connected to the damper.

Maintenance

Not required. Dry cleaning if legaly required in the country in which the dampers are installed.

Revisions

Determined by law in the country in which the fire dampers are installed. Recommended at least every 12 months.

Allowed pressure

1200 Pa

Declared blade tightness (EN 1751)

Class 3 as standard up to 500 Pa

Declared housing tightness (EN 1751)

Class C as standard up to 500 Pa

Conformity with EC directives

2006/42/EC Machinery Directive

2014/35/EU Low Voltage Directive

2014/30/EU Electromagnetic Compatibility Directive

Driving actuator types

Belimo BFL, BFN; Gruner 340-…-05, 360-…-12

Transport and Storage

Dry indoor conditions with a temperature range of -20 °C to +50 °C

Page 7

7/49 | F-R60

P1 P9

P10P7

P8

P4P6

P5P2

P3

Product Parts

Note:

Depicting all mechanism types. Damper is delivered only with one of them.

Legend:

P1 Damper casing

P2 Damper blade

P3 Manual mechanism

P4 Actuator

P5 Communication unit (only for BST0 and GST0 activation types)

P6 Holder for communication unit (only for B24T-W and G24T-W activation types)

P7 Thermal fuse

P8 Bendable hangers

P9 Duct connection sealings

P10 Product label

Page 8

8/49 | F-R60

Assessed Performance

21 CE 1396

Systemair Production a.s.

90043 Kalinkovo 371, Slovakia

21

1396-CPR-0196

EN 15650:2010

Circular fire dampers

F-R60

Nominal activation conditions/sensitivity

• Sensing element load bearing capacity - Pass

• Sensing element response temperature - Pass

Closure during test at correct time and in allowable time

• Closure time and in allowable time - Pass

Operational reliability

• Manual mechanism = 50 cycles - Pass

• Actuator mechanism = 10 200 cycles: 0° to 90° - Pass 10 000 cycles: 45° to 60° - Pass

Fire resistance:

Resistivity depending on installation method and situation

• Integrity E

• EI60(ve-ho-i↔o)S

• Insulation I

• Smoke leakage S

• Mechanical stability (under E)

• Maintenance of the cross section (under E)

Durability of response delay

• Sensing element response temperature and load bearing capacity - Pass

Durability of operational reliability

• Opening and closing cycle - Pass

Page 9

9/49 | F-R60

Diagrams

The pressure drop and A-weighted total discharged sound power level depend on the nominal diameter of the damper

and air flow volume at different duct pressures.

F-R60-...-H0

Pressure drop & sound power level (A-weighted)

Pa

50

50 100 150 l/s

Size: 100

60 dB(A)

55 dB(A)

50 dB(A)

45 dB(A)

40 dB(A)

35 dB(A)

30 dB(A)

25 dB(A)

100 200 300 400 500 600 700 m³/h

30 dB(A)

25 dB(A)

25 dB(A)

35 dB(A)

30 dB(A)

50 dB(A)

45 dB(A)

40 dB(A)

40 dB(A)

35 dB(A)

55 dB(A)

45 dB(A)

50 dB(A)

F-R60-...-H0

Pressure drop & sound power level (A-weighted)

100 200 300 l/s

Pa

20

10

50 dB(A)

Size: 160

45 dB(A)

45 dB(A)

40 dB(A)

40 dB(A)

40 dB(A)

35 dB(A)

35 dB(A)

30 dB(A)

30 dB(A)

25 dB(A)

25 dB(A)

5

25 dB(A)

400 600 800 1000 1200 1400m³/h

35 dB(A)

30 dB(A)

50 dB(A)

45 dB(A)

Size: 180

50 dB(A)

Size: 125

Size: 140

Size: 200

F-R60-...-B230T

Pressure drop & sound power level (A-weighted)

Pa

50

50 100 150 l/s

Size: 100

60 dB(A)

55 dB(A)

50 dB(A)

40 dB(A)

40 dB(A)

35 dB(A)

30 dB(A)

50 dB(A)

45 dB(A)

45 dB(A)

35 dB(A)

45 dB(A)

40 dB(A)

35 dB(A)

30 dB(A)

25 dB(A)

100 200 300 400 500 600 700 m³/h

30 dB(A)

25 dB(A)

25 dB(A)

60 dB(A)

55 dB(A)

50 dB(A)

F-R60-...-B230T

Pressure drop & sound power level (A-weighted)

100 200 300 l/s

Pa

50

40 dB(A)

35 dB(A)

30 dB(A)

30 dB(A)

25 dB(A)

25 dB(A)

5

25 dB(A)

400 600 800 1000 1200 1400m³/h

45 dB(A)

40 dB(A)

40 dB(A)

35 dB(A)

30 dB(A)

Size: 160

50 dB(A)

50 dB(A)

35 dB(A)

Size: 180

55 dB(A)

50 dB(A)

45 dB(A)

45 dB(A)

Size: 125

55 dB(A)

Size: 140

Size: 200

Page 10

10/49 | F-R60

F-R60-...-H0

Pressure drop & sound power level (A-weighted)

Pa

5

30 dB(A)

25 dB(A)

1000 2000 3000 4000 5000 m³/h

500 1000 1500 l/s

Size: 315 Size: 400

55 dB(A)

Size: 250

55 dB(A)

50 dB(A)

45 dB(A)

40 dB(A)

35 dB(A)

35 dB(A)

30 dB(A)

25 dB(A)

25 dB(A)

50 dB(A)

45 dB(A)

40 dB(A)

30 dB(A)

55 dB(A)

50 dB(A)

45 dB(A)

40 dB(A)

35 dB(A)

60 dB(A)

Legend:

ps (Pa) - Pressure drop

qv (m3^/h), (l/s) - Air flow volume

±Δ (%) - Deviation from measured value

Lwa (dB(A)) - A-weighted total sound power level

v (m/s) - Face air velocity

F-R60-...-B230T

Pressure drop & sound power level (A-weighted)

Pa

5

25 dB(A)

1000 2000 3000 4000 5000 m³/h

500 1000 1500 l/s

Size: 315

55 dB(A)

Size: 250

55 dB(A)

40 dB(A)

35 dB(A)

30 dB(A)

30 dB(A)

25 dB(A)

50 dB(A)

45 dB(A)

35 dB(A)

25 dB(A)

45 dB(A)

40 dB(A)

35 dB(A)

30 dB(A)

50 dB(A)

50 dB(A)

45 dB(A)

40 dB(A)

Size: 400

55 dB(A)

Page 11

11/49 | F-R60

A

V

(m2)

DN (mm)

100 125 140 150 160 180 200 225 250 280 315 355 400

0,065 0,069 0,072 0,074 0,076 0,081 0,087 0,094 0,103 0,115 0,130 0,150 0,176

145

45 45

R1

DN-2

220

(310)

≤80 (H0; H2 )

≤90 (B230T; B... )

≤100 (G230T; G... )

(mm)

50

R1

(mm)

DN (mm)

100 125 140 150 160 180 200 225 250 280 315 355 400

-45,0 -32,5 -25,0 -20,0 -15,0 -5,0 5,0 17,5 30,0 45,0 62,5 82,5 105,0

Dimensions & Weights

Free Area

Dimensions

Note:

H0, H2 - Manual activation types

B... - Belimo activation types

G... - Gruner activation types

Overhangs

Page 12

12/49 | F-R60

m

(kg)

DN (mm)

100 125 140 150 160 180 200 225 250 280 315 355 400

H0, H2 2,0 2,2 2,5 2,5 2,5 2,8 3,0 3,4 3,8 4,3 5,1 6,2 7,8

B230T 3,5 3,7 4,0 4,0 4,0 4,3 4,5 4,9 5,3 5,8 6,6 7,7 9,3

G230T 3,6 3,8 4,1 4,1 4,1 4,4 4,6 5,0 5,4 5,9 6,7 7,8 9,4

BST0 4,3 4,5 4,8 4,8 4,8 5,1 5,3 5,7 6,1 6,6 7,4 8,5 10,1

GST0 4,8 5,0 5,3 5,3 5,3 5,6 5,8 6,2 6,6 7,1 7,9 9,0 10,6

B24T,

B24T-W,

B24T-SR

3,5 3,7 4,0 4,0 4,0 4,3 4,5 4,9 5,3 5,8 6,6 7,7 9,3

G24T,

G24T-W,

G24T-SR

3,6 3,8 4,1 4,1 4,1 4,4 4,6 5,0 5,4 5,9 6,7 7,8 9,4

Weights

Page 13

13/49 | F-R60

Ordering Code

DN

Dimension, øDN:

100, 125, 140, 150, 160, 180, 200, 225, 250, 280, 315, 355, 400 mm

A - Type of Activation

H0 (Manual crank, no switches)

H2 (Manual crank, 2 switches 230V AC or 24V AC/DC)

B230T (230V AC Belimo Actuator)

G230T (230V AC Gruner Actuator)

B24T (24V AC/DC Belimo Actuator)

G24T (24V AC/DC Gruner Actuator)

BST0 (230V AC Supply comm.unit & 24V AC/DC Belimo Actuator)

GST0 (24V AC/DC Supply comm.unit & 24V AC/DC Gruner Actuator)

B24T-W (24V AC/DC Belimo Actuator & Wire connector for comm.unit)

G24T-W (24V AC/DC Gruner Actuator & Wire connector for comm.unit)

B24T-SR (24V AC/DC Belimo Actuator, modulated 0 V ... 10 V)

G24T-SR (24V AC/DC Gruner Actuator, modulated 0 V ... 10 V)

Example of the F-R60 Fire Damper Ordering Code

F-R60-400-B24T-SR

Fire damper with nominal diameter 400 mm, with in-wall EI60S installation. Activated by thermal fuse and a 24 V

Modulated Belimo actuator (0 V ... 10 V) that can be used for airflow balancing.

Page 14

14/49 | F-R60

1 Wet

F-R60

DN100 ... DN400

EI 60 (ve - i ↔ o) S

a) b)

360°

≥ 100 mm ≥ 100 mm

EI 90 (ho - i ↔ o) S

c)

≥ 125 mm

(≥ 620 kg/m3)

3 Soft

F-R60

DN100 ... DN400

EI 60 (ve - i ↔ o) S

a) b)

360°

≥ 100 mm ≥ 100 mm

EI 60 (ho - i ↔ o) S

c)

≥ 125 mm (≥ 620 kg/m3)

≥ 110 mm (≥ 2200 kg/m3)

3H Hilti

F-R60

DN100 ... DN400

EI 60 (ve - i ↔ o) S

a) b)

360°

≥ 100 mm ≥ 100 mm

EI 60 (ho - i ↔ o) S

c)

≥ 125 mm

(≥ 620 kg/m3)

Installation Methods

Notes:

a) - Flexible (plasterboard) wall

b) - Concrete/masonry/cellular concrete (rigid) wall

c) - Concrete/cellular concrete (rigid) floor/ceiling

ve - Vertical wall placement

ho - Horizontal floor/ceiling placement

Page 15

15/49 | F-R60

Installation Rules

• The duct connected to the fire damper must be supported or hung in such a way that the damper does not carry its

weight. The damper must not support any part of the surrounding construction or wall which could cause damage

and consequent damper failure.

• Easy access to mechanism and internal parts during inspection must be considered during damper placement.

• According to the EN 1366-2 standard, the distance between the smoke control damper bodies must be at least 200

mm.

• The distance between the adjacent wall/ceiling and the damper must be at least 75 mm.

• When the damper is installed into a fire partition structure, it must be placed so that the damper blades in its closed

position are located inside this structure.

• The gap in the installation opening between the damper and the wall/ceiling can be increased by up to 50% of the

gap area or decreased to the smallest amount possible that still provides sufficient space for the installation of the

seal.

• The damper must be earthed after being installed into the duct.

• Installation in a thinner wall is permitted under the following conditions:

a) That, the alternative thinner wall should be classified in accordance with EN 13501-2:2007 + A1: 2009 for the fire

resistance required for product applications.

b) That the same length (thickness) of penetration seal (filling) as approved is achieved. This can be done by adding

wall thickness around the damper to at least 200 mm from the opening.

c) That this added thickness will have the same wall construction or additional layer/layers of fire protective board

are fixed to a flexible wall. For a protruding/shaft wall, the additional layers must be fixed to the steel supporting

construction of the wall.

• Lists of all permitted installation methods are provided in Handbook.

Installation, Maintenance & Operation

Some damper parts may have sharp edges – therefore, to protect yourself from harm, please use gloves during damper

installation and manipulation. In order to prevent electric shock, fire or any other damage which could result from

incorrect damper usage and operation, it is important to:

1. Ensure that installation is performed by a trained person.

2. Follow the written and depicted instructions provided within the Handbook closely.

3. Perform damper inspection in accordance with the Handbook.

4. Check the damper’s functionality as per the chapter “Functionality Check” before you install the damper. This

procedure prevents the installation of a damper that has been damaged during transportation or handling.

Information about installation, maintenance and operation is available in the “Handbook_F-R60” document or more

can be found at design.systemair.com.

Page 16

16/49 | F-R60

1 Wet

F-R60

DN100 ... DN400

EI 60 (ve - i ↔ o) S

a) b)

360°

≥ 100 mm ≥ 100 mm

EI 90 (ho - i ↔ o) S

c)

≥ 125 mm

(≥ 620 kg/m3)

Installation 1 - Wet

Using Plaster/Mortar/Concrete Filling

1. The supporting construction's opening must be prepared as depicted in the Opening and Wall Preparation section.

Opening surfaces must be even and cleaned off. The flexible wall opening must be reinforced as per the standards

for plasterboard walls.

2. The opening dimension D1 is driven by the nominal dimensions of the damper with added clearance.

3. Insert the closed damper into the middle of the opening so that the damper blade is in the wall. Use the bendable

hanger (2) to secure the damper against the wall using a suitable screw (F1).

4. Avoid any damage or bend to the damper housing from the weight of the filling.

5. Fill in the area between the wall and the damper with plaster, mortar or concrete filling (F2)

Note: Prevent the fouling of the damper’s functional parts, which could limit its correct functioning. The best way is to

cover the functional parts during installation. The seepage of the filling material can be prevented by using plaster

boards. However, these are not required for wet installation.

6. If necessary, uncover and clean the damper after installation.

7. Check the damper’s functionality

Installation Distances

According to the standard EN 1366-2, the minimum distance from the wall or ceiling to the damper body is 75 mm. For

multiple crossings through a fire resistant wall the minimum distance between two damper bodies is 200 mm. This

applies for distances between the damper and other nearby objects crossing the fire resistive wall.

Notes:

a) - Flexible (plasterboard) wall

b) - Concrete/masonry/cellular concrete (rigid) wall

c) - Concrete/cellular concrete (rigid) floor/ceiling

ve - Vertical wall placement

ho - Horizontal floor/ceiling placement

Page 17

17/49 | F-R60

4

1

3

2

Y

F2

120 mm

Y

1

2

1

F2

F1

≥100

(mm)

≥50

≥12,5

D1 = DN+100

DN

(50)

220

120

Y

2

2

1

F2

F1

≥100

(mm)

D1 = DN+100

DN

(50)

220

120

Page 18

18/49 | F-R60

2

F2

1

3

Y

120 mm

Y

1

≥125

(mm)

D1 = DN+100

DN

220

120

(50)

F1 2 F2 1

Y

2

≥125

(mm)

D1 = DN+100

DN

220

120

(50)

F1 2 F2 1

Page 19

19/49 | F-R60

D1

≥

100 mm

≥100 mm

≤

625 mm

A

B C

4b

4d

4c

4d

4c

4a

C

B

A

øD

1

4a

4a: ≥12,5 mm; 4c: ≥50 mm; 4d: ≥50 mm, ≥50 kg/m

3

≥

100 mm

øD

1

3

øD

1

≥125 mm

3

≥75

≥75

≥200

≥200

(mm)

Opening and Wall and/or Ceiling Preparations

Damper Minimum Distances

Page 20

20/49 | F-R60

Legend for installation 1 - Wet

F1 - Screw ≥ 5,5 DIN7981 or suitable wall plug and screw size 6.

F2 - Plaster/mortar/concrete filling

1 - Fire damper (F-R60)

2 - Bendable hanger (part of the damper)

3 - Concrete/masonry/cellular concrete wall or ceiling

4 - Flexible (plasterboard) wall

4a - 2 layers of plasterboard fireproof plate type F, EN 520

4b - Vertical CW – profiles

4c - Horizontal CW – profiles

4d - Mineral wool; for thickness/cubic density see picture.

Page 21

21/49 | F-R60

3 Soft

F-R60

DN100 ... DN400

EI 60 (ve - i ↔ o) S

a) b)

360°

≥ 100 mm ≥ 100 mm

EI 60 (ho - i ↔ o) S

c)

≥ 125 mm (≥ 620 kg/m3)

≥ 110 mm (≥ 2200 kg/m3)

Installation 3 - Soft

Installation in a Soft Crossing with Fire Resistive Coating

With this installation we recommend using a flexible connection (see accessory FCR) due to thermal expansion of

connected ducts during a fire. Install the compensator so that the flexible part has a minimum distance of 50 mm from

the edge of a damper‘s blade in open position.

1. The supporting construction's opening must be prepared as depicted in the Opening and Wall Preparation section.

Opening surfaces must be even and cleaned off. The flexible wall opening must be reinforced as per the standards

for plasterboard walls.

2. The opening dimension D1 is driven by the nominal dimensions of the damper with added clearance.

3. Prepare mineral wool installation segments with the thickness of the opening height (F3).

4. Apply a suitable fire resistive coating (F4) onto the damper at the place of its future placement; assemble and glue

the filling of the future installation with the same fire resistive coating.

5. Insert the closed damper into the middle of the opening so that the damper blade is in the wall. Use the bendable

hanger (2) to secure the damper against the wall using a suitable screw (F1).

6. Avoid any damage or bend to the damper housing from the pressure of filling insertion.

7. Apply fire resistive coating (F6), at least 2 mm thick and 100 mm wide, onto the exposed filling and wall edges

evenly from both sides of the wall. Do not apply this layer in the place where the mechanism, inspection openings

or manufacturer's label are located.

8. If necessary, uncover and clean the damper after installation.

9. Check the damper’s functionality.

Installation Distances

According to the EN 1366-2 standard, the minimum distance from the wall or ceiling to the damper body is 75 mm. For

multiple crossings through a fire resistive wall the minimum distance between two damper bodies needs to be 200

mm. This applies for distances between the damper and other nearby objects crossing the fire-resistive wall.

Notes:

a) - Flexible (plasterboard) wall

b) - Concrete/masonry/cellular concrete (rigid) wall

c) - Concrete/cellular concrete (rigid) floor/ceiling

ve - Vertical wall placement

ho - Horizontal floor/ceiling placement

Page 22

22/49 | F-R60

120 mm

120 mm

4

1

3

2

Y

F4

F3

4

1

3

2

Y

F4

F3

Y

1

1

F3

≥100

(mm)

≥50

≥12,5

D1 = DN+100

DN

(50)

220

120

Y

2

2

1

F3

F1

≥100

(mm)

DN

(50)

220

120

≥100

D1 = DN+100

≥100

F4

2

F1

F4

Page 23

23/49 | F-R60

2

F3

1

3

Y

F4

120 mm 120 mm

2

F3

1

3

Y

F4

Y

1

≥125

(mm)

D1 = DN+100

DN

220

120

(50)

F1 2 F3 1

Y

2

≥125

(mm)

D1 = DN+100

DN

220

120

(50)

F1 2 F3 1

≥100

≥100

F4

F4

Page 24

24/49 | F-R60

D1

≥

100 mm

≥100 mm

≤

625 mm

A

B C

4b

4d

4c

4d

4c

4a

C

B

A

≥

100 mm

≤

625 mm

4b

4d

4c

C

B

A

D1

D

1

øD

1

4a4a

4a: ≥12,5 mm; 4c: ≥50 mm; 4d: ≥50 mm, ≥50 kg/m

3

≥

100 mm

øD

1

3

øD

1

≥125 mm

3

D1

D

1

≥

100 mm

3

≥125 mm

3

D

1

D

1

≥75

≥75

≥200

≥200

(mm)

Opening and Wall and/or Ceiling Preparations

Damper Minimum Distances

Page 25

25/49 | F-R60

Legend for installation 3 - Soft

F1 - Screw ≥ 5,5 DIN7981 or suitable wall plug and screw size 6.

F3 - Mineral wool segment (minimum 150 kg/m3).

F4 - Layer of fire resistive coating (Promastop-CC/Promat) at least 2 mm thick for exposed surfaces.

1 - Fire damper (F-R60)

2 - Bendable hanger (part of the damper)

3 - Concrete/masonry/cellular concrete wall or ceiling

4 - Flexible (plasterboard) wall

4a - 2 layers of plasterboard fireproof plate type F, EN 520

4b - Vertical CW – profiles

4c - Horizontal CW – profiles

4d - Mineral wool; for thickness/cubic density see picture.

Page 26

26/49 | F-R60

3H Hilti

F-R60

DN100 ... DN400

EI 60 (ve - i ↔ o) S

a) b)

360°

≥ 100 mm ≥ 100 mm

EI 60 (ho - i ↔ o) S

c)

≥ 125 mm

(≥ 620 kg/m3)

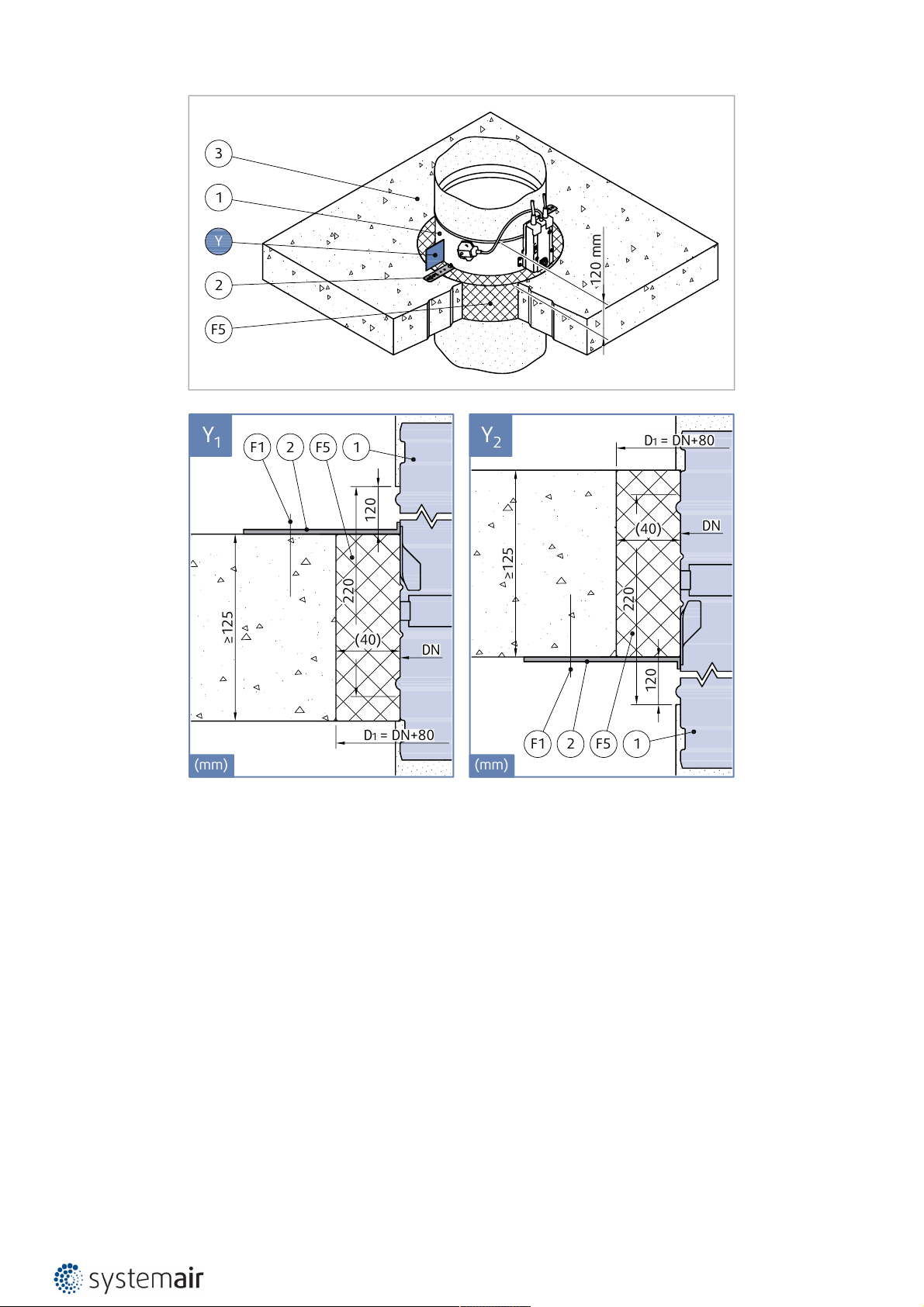

Installation 3H - Hilti

Filling Made Only from Hilti Foam

With this installation we recommend using a flexible connection (see accessory FCR) due to thermal expansion of

connected ducts during a fire. Install the compensator so that the flexible part has a minimum distance of 50 mm from

the edge of a damper‘s blade in open position.

Tip:

Excess material can be reused as the filling for this installation. It can be inserted into the cavity before you add new

foam from the gun.

1. The supporting construction's opening must be prepared as depicted in the Opening and Wall Preparation section.

Opening surfaces must be even and cleaned off. The flexible wall opening must be reinforced as per the standards

for plasterboard walls.

2. The opening dimension D1 is driven by the nominal dimensions of the damper with added clearance.

3. Insert the closed damper into the middle of the opening so that the damper blade is in the wall. Use the bendable

hanger (2) to secure the damper against the wall using a suitable screw (F1).

Wear protective gloves when handling the foam.

4. Insert the barrel of the foam gun into the middle of the cavity between the damper and the opening and fill it

completely with foam (F5) pushed out foam can be quickly hand pushed back into the cavity.

5. After the filling (F5) solidifies, though it will always remain partly flexible, you can cut the excess foam that stands

out from the wall.

6. If necessary, uncover and clean the damper after installation.

7. Check the damper’s functionality.

Installation Distances

According to the EN 1366-2 standard, the minimum distance from the wall or ceiling to the damper body is 75 mm. For

multiple crossings through a fire-resistive wall the minimum distance between two damper bodies is 200 mm. This

applies to distances between the damper and other nearby objects crossing the fire-resistive wall.

Notes:

a) - Flexible (plasterboard) wall

b) - Concrete/masonry/cellular concrete (rigid) wall

c) - Concrete/cellular concrete (rigid) floor/ceiling

ve - Vertical wall placement

ho - Horizontal floor/ceiling placement

Page 27

27/49 | F-R60

4

1

3

2

Y

F5

120 mm

Y

1

2

1

F5

F1

≥100

(mm)

≥50

≥12,5

D1 = DN+80

DN

(40)

220

120

Y

2

2

1

F5

F1

≥100

(mm)

D1 = DN+80

DN

(40)

220

120

Page 28

28/49 | F-R60

2

F5

1

3

Y

120 mm

Y

1

≥125

(mm)

D1 = DN+80

DN

220

120

(40)

F1 2 F5 1

Y

2

≥125

(mm)

D1 = DN+80

DN

220

120

(40)

F1 2 F5 1

Page 29

29/49 | F-R60

D1

≥

100 mm

≥100 mm

≤

625 mm

A

B C

4b

4d

4c

4d

4c

4a

C

B

A

øD

1

4a

4a: ≥12,5 mm; 4c: ≥50 mm; 4d: ≥50 mm, ≥50 kg/m

3

≥

100 mm

øD

1

3

øD

1

≥125 mm

3

≥75

≥75

≥200

≥200

(mm)

Opening and Wall and/or Ceiling Preparations

Damper Minimum Distances

Page 30

30/49 | F-R60

Legend for installation 3H - Hilti

F1 Screw ≥ 5,5 e.g. DIN7981 or suitable wall plug and screw size 6.

F5 Foam CFS-F FX/HILTI.

1 - Fire damper (F-R60)

2 - Bendable hanger (part of the damper)

3 - Concrete/masonry/cellular concrete wall or ceiling

4 - Flexible (plasterboard) wall

4a - 2 layers of plasterboard fireproof plate type F, EN 520

4b - Vertical CW – profiles

4c - Horizontal CW – profiles

4d - Mineral wool; for thickness/cubic density see picture

Page 31

31/49 | F-R60

A

DN (mm)

100 125 140 150 160 180 200 225 250 280 315 355 400

Belimo BFL… / Gruner 340TA-…-05

AT A T

(Nm)

NV

(V)

F

(Hz)

CO CR

WS

(VA)

WN

(W)

H0, H2 - -

DC 12/24

AC 150/250

50/60

- - - 3A

B230T BFL230-T 4 AC 230 3,5 1,1 6,5 Imax 4 A @ 5 ms

G230T 340TA-230-…-05-… 5 AC 230 5,5 2 9,5 -

BST0 BFL24-T-ST & BKN230-24 4 AC 230 10 3,5 11 Imax 4 A @ 5 ms

GST0

340TA-24-…-05-.../ST01

& FSC-UFC24-2

5 AC/DC 24 8,5 4 11 -

B24T,

B24T-W

BFL24-T, BFL24-T-ST 4 AC/DC 24 2,5 0,8 4 Imax 8,3 A @ 5 ms

G24T,

G24T-W

340TA-24-…-05-...

340TA-24-…-05-.../ST01

5 AC/DC 24 6,5 2 9 -

B24T-SR BFL24-SR-T 4 AC/DC 24 3 1 6,5 Imax 8,3 A @ 5 ms

G24T-SR 340CTA-24-…-05-… 5 AC/DC 24 6,5 2 7,5

DC (0)2 V ...10 V /

Ri > (100 kΩ)

50 kΩ (0)4 ... 20 mA

Electrical Connections

IMPORTANT

• Danger of electric shock!

• Switch off the power supply before working on any electrical equipment.

• Only qualified electricians are permitted to work on the electrical system.

Electrical Parameters per Activation and Actuator Type

Actuator Size Map of F-R60

Notes

AT - Activation type

A - Belimo Actuator type

T - Torque

NV - Nominal Voltage

F - Frequency

CO - Consumption in Operation

CR - Consumption in Rest

WS - Wire sizing consumption

WS - Wire sizing consumption Note

Page 32

32/49 | F-R60

Type of Activation H0

This type of activation mechanism does not have any electrical equipment.

Type of Activation H2

IMPORTANT: Risk of electric shock!

Microswitch:

Power Supply: 125/250V AC or 12/24V DCElectric Parameters: 3A

Notes:

• Switch off the power supply before working on any electrical equipment.

• Only qualified electricians are permitted to work on the electrical system.

• Power consumption must be observed!

Legend

NO Blue cable colour

C Black cable colour

NC Grey cable colour

Page 33

33/49 | F-R60

Type of Activation B230T

IMPORTANT: Risk of electric shock!

Switch off the power supply before working on any electrical equipment.

Only qualified electricians are permitted to work on the electrical system.

Actuator power supply: 230V AC, 50/60 Hz

Notes:

• A device that disconnects the pole conductors (minimum contact gap 3 mm) is required for isolation from the power

supply.

• Parallel connection of several actuators possible.

• Power consumption must be observed!

Legend

1 - Blue cable colour

2 - Brown cable colour

S1 - Violet cable colour

S2 - Red cable colour

S3 - White cable colour

S4 - Orange cable colour

S5 - Pink cable colour

S6 - Grey cable colour

Tf - Thermal fuse

Page 34

34/49 | F-R60

Type of Activation G230T

IMPORTANT: Risk of electric shock!

Switch off the power supply before working on any electrical equipment.

Only qualified electricians are permitted to work on the electrical system.

Actuator power supply: 230V AC, 50/60 Hz

Notes:

• A device that disconnects the pole conductors (minimum contact gap 3 mm) is required for isolation from the power

supply.

• Parallel connection of several actuators possible.

• Power consumption must be observed!

Legend

1 - Blue cable colour

2 - Brown cable colour

S1 - Violet cable colour

S2 - Red cable colour

S3 - White cable colour

S4 - Orange cable colour

S5 - Pink cable colour

S6 - Grey cable colour

Tf - Thermal fuse

Page 35

35/49 | F-R60

Type of Activation B24T

IMPORTANT: Risk of electric shock!

Switch off the power supply before working on any electrical equipment.

Only qualified electricians are permitted to work on the electrical system.

Actuator power supply: AC (50/60 Hz)/DC 24 V

Legend

1 - Blue cable colour (black for BF24-T)

2 - Red cable colour (white for BF24-T)

S1 - Violet cable colour (white for BF24-T)

S2 - Red cable colour (white for BF24-T)

S3 - White cable colour (white for BF24-T)

S4 - Orange cable colour (white for BF24-T)

S5 - Pink cable colour (white for BF24-T)

S6 - Grey cable colour (white for BF24-T)

Tf - Thermal fuse

Page 36

36/49 | F-R60

Type of Activation G24T

IMPORTANT: Risk of electric shock!

Switch off the power supply before working on any electrical equipment.

Only qualified electricians are permitted to work on the electrical system.

Actuator power supply: AC (50/60 Hz)/DC 24 V

Notes:

• Supply via safety isolation transformer.

• Parallel connection of several actuators possible.

• Power consumption must be observed!

Legend

1 - Black cable colour

2 - Red cable colour

S1 - Violet cable colour

S2 - Red cable colour

S3 - White cable colour

S4 - Orange cable colour

S5 - Pink cable colour

S6 - Grey cable colour

Tf - Thermal fuse

Page 37

37/49 | F-R60

Type of Activation BST0

• The actuator and the control module are factory wired.

• Connect the supply voltage to the connecting cable (approx. 1 m, with ferrules).

• Switch off the power supply before working on any electrical equipment.

• Only qualified electricians are permitted to work on the electrical system.

• This type of activation comes with a Belimo communication and power supply unit BKN230-24 (other communication

units on demand).

• Actuator power supply: AC (50/60 Hz)/DC 24 V

Two LEDs in the device indicate the function status

LED / Status / Function

Yellow / Flashing / Damper moves OPEN

Yellow / On / Damper OPEN

Green / Flashing / Damper moves CLOSED

Green / On / Damper CLOSED

Yellow and Green / Flashing at double frequency / Fault

Yellow and Green / Off / Power failure

Notes:

• Caution! Main power supply voltage!

• Parallel connection of several actuators possible.

• Power consumption and switching thresholds must be observed!

• Combination of power supply voltage and safety extra-low voltage not permitted at both auxiliary switches.

Legend

1)

- Jumper factory-fitted. Can be removed if necessary to be replaced by a thermoalectric trip (the safety function will

be triggered if terminals 1 and 2 are not linked).

2) - Jumper only used for commissioning purposes and without BKS24-..!

3) - 2-wire conductor to BKS24-...

Page 38

38/49 | F-R60

Type of Activation GST0

• The actuator and the control module are factory wired.

• Individual control of 2 fire dampers

• Bus protocols (RS-485): BACnet MS/TP and Modbus RTU

• Automatic baud rate detection with BACnet

• Bus monitoring function

Notes:

• Caution! Main power supply voltage!

• Power consumption and switching thresholds must be observed!

• Combination of power supply voltage and safety extra-low voltage not permitted at both auxiliary switches.

IMPORTANT:

If only one actuator is connected to the FSC-UFC24-2, the LED's of the side where no actuator is connected will

indicate an alarm. A jumper has to be installed between S4 and S6 in the terminal where there is no actuator

connected, to indicate an “opened” position in the LED. If the second connection is not activated via bus, there will be

no alarm signal in the bus system.

Legend

A1, A2 Analogue Application; Digital input for manual override is default: "Normally Open" or selected via bus as:

"Normally Open" (= standard open) or "Normally Closed" (= standard closed)

B Position of line termination 120 ohm if FSC-UFC24-2 is last Modbus or BACnet device in line

C RS-485 Coms; Modbus RTU or BACnet MS/TP dip switch selectable

D1, D2 Damper 1, Damper 2; Fire or smoke extraction application

P Main power 24 V AC/DC; Daisy chain from and to other FSC-UFC24-2

So Contact open

Sc Contact closed

Page 39

39/49 | F-R60

Type of Activation B24T-W

IMPORTANT: Risk of electric shock!

Switch off the power supply before working on any electrical equipment.

Only qualified electricians are permitted to work on the electrical system.

This type of activation comes with provided cable connectors for the supply and communication unit (communication

unit not part of the mechanism).

Actuator power supply: AC (50/60 Hz)/DC 24 V

Notes:

• Supply via safety isolation transformer.

• Parallel connection of several actuators possible.

• Power consumption must be observed!

Legend

1 Blue cable colour (black for BF24-T) in connector 1

2 Brown cable colour (white for BF24-T) in connector 1

S1 Violet cable colour (white for BF24-T) in connector 2

S2 Red cable colour (white for BF24-T) in connector 2

S3 White cable colour (white for BF24-T) in connector 2

S4 Orange cable colour (white for BF24-T) in connector 2

S5 Pink cable colour (white for BF24-T) in connector 2

S6 Grey cable colour (white for BF24-T) in connector 2

Tf Thermal fuse

Page 40

40/49 | F-R60

Type of Activation G24T-W

IMPORTANT: Risk of electric shock!

Switch off the power supply before working on any electrical equipment.

Only qualified electricians are permitted to work on the electrical system.

This type of activation comes with provided cable connectors for the communication and power supply unit

(communication unit not part of the mechanism).

Notes:

• Supply via safety isolation transformer.

• Parallel connection of several actuators possible.

• Power consumption must be observed!

Legend

1 Black cable colour (black for BF24-T) in connector 1

2 Red cable colour (white for BF24-T) in connector 1

S1 Violet cable colour (white for BF24-T) in connector 2

S2 Red cable colour (white for BF24-T) in connector 2

S3 White cable colour (white for BF24-T) in connector 2

S4 Orange cable colour (white for BF24-T) in connector 2

S5 Pink cable colour (white for BF24-T) in connector 2

S6 Grey cable colour (white for BF24-T) in connector 2

Tf Thermal fuse

Page 41

41/49 | F-R60

Type of Activation B24T-SR

IMPORTANT: Risk of electric shock!

Switch off the power supply before working on any electrical equipment.

Only qualified electricians are permitted to work on the electrical system.

Actuator power supply: AC (50/60 Hz)/DC 24 V

Notes:

• Supply via safety isolation transformer.

• Power consumption must be observed!

Legend

1 Blue cable colour

2 Brown cable colour

3 White cable colour

5 Orange cable colour

S1 Violet cable colour

S2 Red cable colour

S3 White cable colour

S4 Orange cable colour

S5 Pink cable colour

S6 Grey cable colour

Tf Thermal fuse

Page 42

42/49 | F-R60

Type of Activation G24T-SR

IMPORTANT: Risk of electric shock!

Switch off the power supply before working on any electrical equipment.

Only qualified electricians are permitted to work on the electrical system.

Actuator power supply: AC (50/60 Hz)/DC 24 V

Notes:

• Supply via safety isolation transformer.

• Power consumption must be observed!

Legend

1 Blue cable colour

2 Brown cable colour

3 Black cable colour

4 Grey cable colour

S1 Violet cable colour

S2 Red cable colour

S3 White cable colour

S4 Orange cable colour

S5 Pink cable colour

S6 Grey cable colour

Tf Thermal fuse

Page 43

43/49 | F-R60

A

B

1

B

2

✓

C

1

C

2

C

3

✓

Handling & Manipulation

Handling and manipulation must be done with care. For safety reasons, manipulate the damper in its closed position

and whilst wearing gloves.

Fusible Thermal Link Replacement on Manual Activation Mechanism

• Press the test button

• Check the damper is in closed position

• Remove two front mechanism screws

• Remove the mechanism from the damper body

• Remove the remaining parts of the thermal link you wish to replace

• Press the spring with the nut against the mechanism

• Place the new thermal link on plastic hook and the spring hook simultaneously

• Check that the blade remained in closed position and that the axle indication is aligned

• Place the mechanism onto the dampers axis and base plate

• Fix the two top screws slightly (avoid damage to threads and bends to mechanism cover)

• Perform dampers functionality check

Page 44

44/49 | F-R60

A

2

A

1

B

3

B

2

B

4

B

1

✓

Actuator Replacement and Thermal Fuse Replacement

Disconnect main power supply

• Remove two screws from the thermal fuse and remove the fuse from the damper body

• Check if the blade is in the closed position if not drive actuator manually to closed position

• Mark the upwards facing (visible) actuator side "L" or "R"

• Remove two front actuator screws

• Remove the actuator from the mechanism base plate

• Mark the shafts groove position

Check the thermal fuse for damage and test if needed un-click and replace the fuses bottom replaceable part

• insert the fuse's bottom part into the cavity on dampers body

• Fix the two fuse screws

• Check that the blade remained in closed position and that the axle indication is aligned

• Place the actuator with the same side pointing upwards (as previously marked side "L" or "R") onto the dampers axis

and base plate

• Fix the two top screws slightly (avoid damage to threads)

• Perform dampers functionality check

Page 45

45/49 | F-R60

A

1

B

1

B

2

B

3

C

1

C

2

✓

A

2

B

5

B

4

B

3

A

1

B

1

B

2

A

2

✓

i

55

A

3

A

4

Page 46

46/49 | F-R60

10

P14

O

C

P12

P13

P11

H0, H2

Operation Manual

Warning: Damper blades are spring loaded in the open position and are closing rapidly. To avoid injury, make sure to

keep the blade movement area clear while manipulating the fire damper.

After installation, it is necessary to adjust the damper into its operating position - Open the fire damper:

Manually Operated Activation Mechanism

Turn the red crank into the "OPEN" position. The damper blade must remain in the open position.

Spring Return Actuator Operated Activation Mechanism

Connect the electric driving mechanism to the relevant electric power supply (see Electrical Connection section). The

electromotor is activated and adjusts the damper into its open position.

Functionality Check

Manually Operated Activation Mechanism

• While performing the check, focus on the thermal fuse link’s integrity and the correct position of the damper blades

after their retention in the OPEN and CLOSED positions.

• Open the damper - turn the red crank (P11) by hand or by using a hexagonal bent wrench No. 10 (P14). Turn the red

crank so that the indicator arrow (P13) is pointing to the OPEN position (O), the red crank needs to remain in the

"OPEN" position, and the microswitch for the open position indication must be pushed (if installed).

• Close the damper – release the mechanism by pressing the release button (P12), the red crank will adjust its indicator

arrow (P13) to point to the CLOSED position (C) and remain locked in this position, then the microswitch for the

closed position indication must be pushed (if installed).

• Open the damper - turn the red crank (P11) using a hexagonal bent wrench No. 10. (P14) Turn the red crank so that

the indicator arrow is pointing to the OPEN position (O), the red crank needs to remain in the "OPEN" position, and the

microswitch for the open position indication must be pushed (if installed).

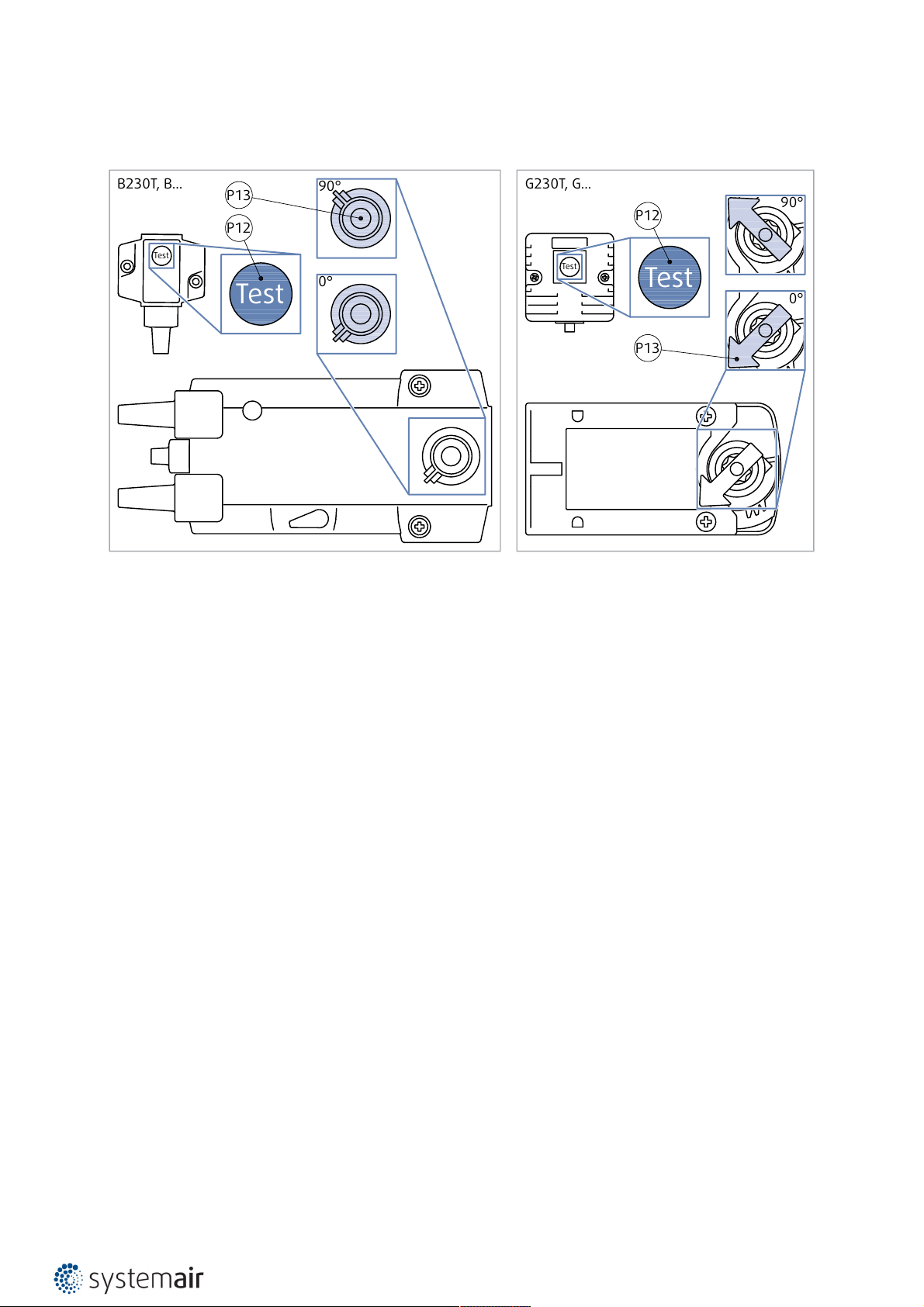

Spring Return Actuator Operated Activation Mechanism

• While performing the check, focus on the thermal fuse link’s integrity and the correct position of the damper blades

after their retention in the OPEN and CLOSED positions.

• The fire damper must open automatically after the actuator receives power – the arrow (P13) on the actuator axis in

open position must point to 90°.

• Press and hold the control switch (P12) on the Thermo electric fuse until the fire damper is fully closed – the arrow

(P13) on the actuator axis in closed position must point to 0° - the safety position.

Page 47

47/49 | F-R60

Test

Test

G230T, G...

Test

B230T, B...

90°

0°

Test

90°

0°

P13

P12

P13

P12

• Release the control switch (P12) on the Thermo electric fuse. The fire damper must become fully open – the arrow

(P13) on the actuator axis in open position must point to 90° - the operating position.

Damper Inspection

The activation mechanism keeps the dampers on stand-by throughout their entire life cycle in accordance with this

manual issued by the manufacturer. It is not permitted to alter the dampers in any way nor perform any changes to

their structure without the manufacturer’s consent.

The operator needs to performs regular checks of the dampers as per established regulations and standards at least

once every 12 months. The check needs to be performed by an employee who has been specifically trained for this

purpose. The fire damper's current condition determined during the inspection needs to be entered into the "Operating

Journal" along with the date of the inspection, and the legible name, surname and signature of the employee who

performed the inspection. The Operating Journal includes a copy of the employee’s authorization.

If any discrepancies are discovered, these need to be entered into the Operating Journal along with a proposal for their

removal. The Operating Journal can be found in product's "Documents" section at design.systemair.com. Immediately

after the installation and activation of the damper, it needs to be checked under the identical conditions as apply to the

above mentioned 12-month inspections.

The visual check ensures that visible damage to the inspected damper parts are seen. Externally, the damper housing

and the activation mechanism are checked. Due to the need to perform a visual check of the damper’s internal parts,

open the inspection lid connected to the damper or remove the flexible connection connected to the damper. Visual

checks can be performed with an endoscopic camera through the hole where the thermal fuse is installed.

The damper’s internal casing, thermal fuse, seals, foaming substance, the damper blade's condition and the accuracy of

its closure during its leaning against the backstop in the closed position must all be checked. There must not be any

strange objects or a layer of impurities from the air distribution systems inside the damper.

NEVER INSPECT THE DAMPERS WHEN THERE IS AIR FLOWING IN THE DUCT SYSTEM!

Recommended Inspection Steps According to EN 15 650:

1. Damper identification

2. Date of inspection

3. Inspection of the activation mechanism's electrical connection (where applicable)

4. Inspection of the damper for cleanliness and possible need for cleaning (where needed)

5. Inspection of blade and sealing condition, possible correction and logging (where needed)

Page 48

48/49 | F-R60

6. Inspection of the proper fire damper closure

7. Inspection of the damper's functionality – opening and closing using the control system, physical examination of

the damper’s behavior, possible correction and logging (where needed)

8. Inspection of the end switches’ functionality in the open and closed position, possible correction and logging

(where needed)

9. Inspection of whether the damper is fulfilling its role as part of the regulation system (where needed)

10. Inspection of whether the damper remains in its standard operating position.

11. The damper is usually part of a system. In such case, the whole system needs to be checked as described in its

operation requirements published by the builder of the system.

Supplement

Any deviations from the technical specifications contained in SystemairDESIGN and the terms should be discussed with

the manufacturer. We reserve the right to make any changes to the product without prior notice, provided that these

changes do not affect the quality of the product and the required parameters.

Page 49

Systemair DESIGN • 2021-03-17 • HandBook_F_R60_en-GB • AFD5D334-DD53-44A3-B3AF-F2074D65249A

Loading...

Loading...