Page 1

Topvex FR03, FR06, FR08, FR11

Air Handling Unit

Installation instructions

Document in original language | 151625 · A002

GB

Page 2

© Copyright Systemair AB

All rights reserved

E&OE

Systemair AB reserves the rights to alter their products without notice.

This also applies to products already ordered, as long as it does not affect the previously agreed specifications.

151625 | A002

Page 3

1 EU Declaration of Conformity . .. ..... ..... .... .... .... . ...1

2 Warnings. ..... .... .... . .... .... .... . .... .... .... ..... .... .... . .2

3 Product information ... . .... .... .... . .... .... .... . .... .... ...2

3.1 General... .... .... . .... .... .... . ... . .... .... ..... .... ..2

3.2 Technical data .... . ... . .... .... ..... .... .... . .... .... 3

3.2.1 Dimensions... .... .... . .... .... .... . .... ..3

3.2.2 Weights . . .... .... ..... .... .... . ... . .... ...4

3.2.3 Space required. .... .... .... . .... .... .... .5

3.2.4 Electrical data . .... . .... .... ..... .... .... .5

3.3 Transport and storage . ..... .... .... ..... .... .... ..6

4 Installation.. .... ..... .... .... . .... .... .... . .... .... .... ..... ...7

4.1 Unpacking ... . .... .... ..... .... .... . ... . .... .... .... . .7

4.2 Where/how to install .... . ... . .... .... .... . .... .... 7

4.3 Installing the unit. .... .... .... . .... .... ..... .... .... .8

4.4 Supply air sensor... .... .... . .... .... .... . .... .... . 10

4.5 Mounting the sliding door kit. . .... .... .... ..... 10

4.6 Connections .... . ... . .... .... ..... .... .... . .... .... . 13

4.6.1 Ducting ... .... . .... .... .... . .... .... ..... 13

4.6.2 Condensation and heat

insulation .... ..... .... .... . ... . .... .... . 14

4.6.3 Silencers ... . .... .... ..... .... .... . ... . .. 14

4.6.4 Electric connections . . .... .... .... . ...14

4.6.5 Electrical connections,

components. . .... .... .... . .... .... .... . 15

4.6.6 External connections . .... .... .... . ... 16

4.6.7 BMS Connection.. .... .... . .... .... .... 17

4.7 Installing NaviPad control panel .... . .... .... .. 18

4.7.1 Dimensions... .... .... . .... .... .... . .... 18

4.7.2 Mounting control panel. .... . .... .... 19

4.8 Additional equipment . .... . .... .... .... . .... .... . 19

Contents

151625 | A002

Page 4

Page 5

1 EU Declaration of Conformity

Manufacturer

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg SWEDEN

Office: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

hereby confirms that the following products:

Air handling units

EU Declaration of Conformity |

1

Topvex FR03 EL Topvex FR03

Topvex FR06 EL Topvex FR06

Topvex FR08 EL Topvex FR08

Topvex FR11 EL Topvex FR11

(The declaration applies only to product in the condition it was delivered in and installed in the facility in accordance with the included

installation instructions. The insurance does not cover components that are added or actions carried out subsequently on the

product)

Topvex FR03 HWL/HWH

Topvex FR06 HWL/HWH

Topvex FR08 HWL/HWH

Topvex FR11 HWL/HWH

Comply with all applicable requirements in the following directives and regulations

Machinery Directive 2006/42/EC Ecodesign Directive 2009/125/EC

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

The following harmonized standards are applied in applicable parts:

EN ISO 12100:2010

EN 13857

Safety of machinery - General principles for design - Risk assessment and risk reduction

Safety of machinery – Safety distances to prevent hazard zones being reached by upper

327/2011 Requirements for fans

1253/2014 Requirements for ventilation units

or lower limbs

EN 60204-1

EN 60335-1

EN 60335-2-40

Safety of machinery – Electrical equipment of machines – Part 1: General requirements

Household and similar electrical appliances – Safety Part 1: General requirements

Safety of household and similar electrical appliances - Part 2-40: Particular requirements

for electrical heat pumps, air-conditioners and dehumidifiers

EN 50106:2007

Safety of household and similar appliances – Particular rules for routine tests referring to

appliances under the scope of EN 60 335-1 and EN 60967

EN 60529

EN 62233

Degrees of protection provided by enclosures (IP Code)

Measurement methods for electromagnetic fields of household appliances and similar

apparatus with regard to human exposure

EN 61000-6-2

Electromagnetic compatibility (EMC) – Part 6-2: Generic standards – Immunity for

industrial environments

EN 61000-6-3

Electromagnetic compatibility (EMC) – Part 6-3: Generic standards – Emission standards

for residential, commercial and light-industrial environments

The complete technical documentation is available.

Skinnskatteberg, 09-05-2018

Mats Sándor

Technical Director

151625 | A002

Page 6

Warnings

|

2

2 Warnings

The following admonitions will be presented in the different sections of the document:

Danger

• Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or

serious injury.

Warning

• Indicates a potentially hazardous situation that may result in minor or moderate injuries.

Caution

• Indicates a risk of damaging the product or prevent optimal operation.

Important

• This appliance can be used by children aged from 8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and understand the hazards involved.

• Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children

without supervision.

3 Product information

3.1 General

This installation manual concerns air handling unit type Topvex FR manufactured by Systemair Sverige AB. Topvex FR

include the following model options:

• Model: FR03, FR06, FR08, FR11

• Heating coil: EL (Electric), HWL (Water coil, low power), HWH (Water coil, high power) or None.

• Right or left models: R (Right) L (Left). The side where the supply air is located when viewed from the access side.

• Airflow control: CAV – Constant Air Volume, VAV (as accessory) – Variable Air Volume = Constant duct pressure

control

• M0: Aluminium fan impeller

More information regarding VAV control can be found in the VAV kit instruction.

This manual consists of basic information and recommendations concerning the design, installation, start-up and operation, to ensure a proper fail-free operation of the unit.

The key to proper and safe operation of the unit is to read this manual thoroughly, use the unit according to given

guidelines and follow all safety requirements.

151625 | A002

Page 7

3.2 Technical data

M

X

Y

X

G

G

H

H

I

I

L

L/2

L/2

A

B

C

D

J

N

B

N

K

R

C

S

U

øD

Q

P

A

E

E

W W

T

F

1

4

1/2"

M

X

Y

X

G

G

H

H

I

I

L

L/2

L/2

A

D

B

C

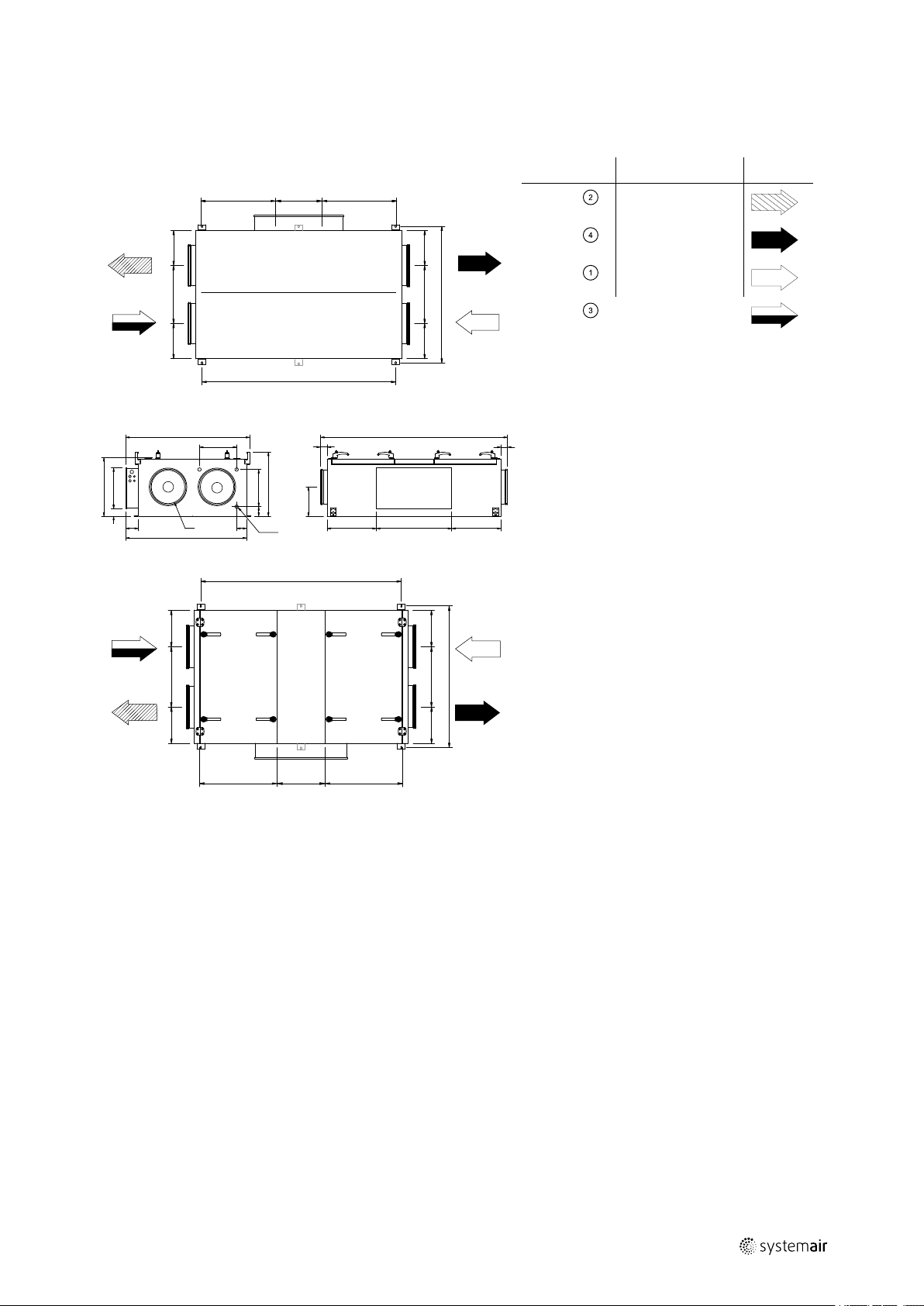

3.2.1 Dimensions

Product information |

3

Bottom side, left hand unit

Left hand unit

Position Description

A

B

C

D

Supply air

Exhaust air

Outdoor air

Extract air

Symbol

Operating side, left hand unit

151625 | A002

Page 8

| Product information

L

X

Y

X

G

H

M

G

H

I

L/2

L/2

A

D

B

C

J

N

B

N

K

R

C

S

U

øD

Q

P

A

E

E

W W

T

F

3

2

L

X

Y

X

G

H

I

M

G

H

I

L/2

L/2

A

D

B

C

4

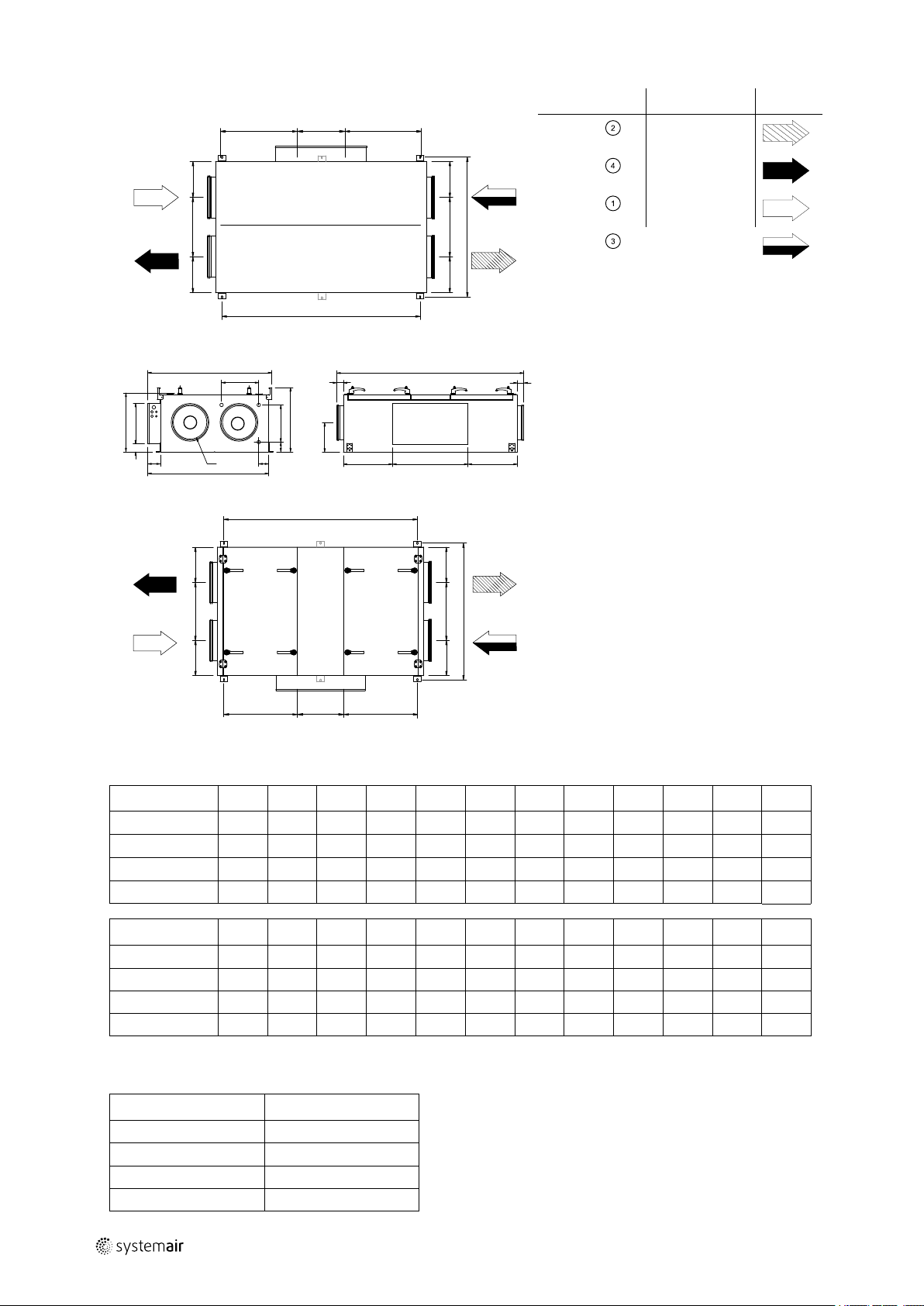

Bottom side, right hand unit

Right hand unit

Position

A

B

C

D

Description Symbol

Supply air

Exhaust air

Outdoor air

Extract air

Operating side, right hand unit

Table 1 Dimensions

Model

A B C D E F G H I

FR03 1720 1115 540

FR06 2160 1315 640

FR08 2230 1515 740

FR11 2440 1715 840

Model

FR03

L/2

M N P

-

1050 388 64 68 120 375 730 72 456 576 358

ø315

ø400

ø500

ø630

60 270 275 450 275 1145 590 1502

80 275 325 550 325 1345 705 1902

60 355 350 650 400 1545 790 2004

80 405 400 765 432 1745 904 2206

Q

R S T U W X Y

J

K L

FR06 951 1260 414 103 106 102 375 730 158 653 763 384

FR08 1002 1450 514 103 106 120 375 730 275 706 807 384

FR11 1103 1650 614 103 106 120 375 730 329 801 844 520

3.2.2 Weights

Model

FR03 196

FR06 275

FR08 345

FR11 433

Weight (kg)

151625 | A002

Page 9

Product information |

3.2.3 Space required

Fig. 1 Space required

In case the sliding door application is installed the required space corresponds to the height of the sliding door support

bars (50 mm).

5

Model

FR03 576

FR06 763

FR08 807

FR11 844

W (mm)

3.2.4 Electrical data

Table 2 Power Consumption

Fans (W tot.)

Model

FR03 EL 1352 1352 5 3x16 3x25

FR03 (None,

HWL/HWH)

FR03 EL M0 954 954 5 3x16 3x20

FR03 (None,

HWH) M0

FR06 EL 1882 1882 10 3x20 3x35

FR06 (None,

HWL/HWH)

FR08 EL 1944 1944 12 3x25 3x40

FR08 (None,

HWL/HWH)

FR11 EL 4478 4478 15 3x32 3x63

FR11 (None,

HWL/HWH)

FR11 EL M0 5666 6142 15 3x35 3x63

FR11 (None,

HWH) M0

230V 1~ and

400 V 3N~

1352

954

1882 1882

1944 1944

4478 4478

5666 6142

Fans (W tot.)

230V 3~

– –

– –

El Heating

battery (kW

tot.)

–

–

–

–

Fuse (mains) (A)

for 230V 1~ and

400 V 3N~

10 10

10 10

3x10 3x10

3x10 3x10

3x10 3x10

3x10 3x20

Fuse (mains) (A)

for 230V 1~ and

230V 3~

151625 | A002

Page 10

| Product information

6

3.3 Transport and storage

The Topvex FR03–11 should be stored and transported in such a way that it is protected against physical damage that

can harm panels, handles, display etc. It should be covered so that dust, rain and snow cannot enter and damage the

unit and its components. The appliance is delivered in one piece containing all necessary components, wrapped in plastic on a pallet for easy transportation.

When transporting the FR03 unit use a fork lift placed on the gable of the unit (figure 2). Topvex FR06, FR08, and FR11

have specially constructed pallets that allow lifting at the long side of the unit (figure 3). These models can alternatively

be lifted using 2 fork lifts from the gable sides.

Warning

The unit is heavy. Be careful during transport and mounting. Risk of injury through pinching. Use protective

clothing.

Fig. 2 Transporting the unit

Fig. 3 Transporting units FR06-11

151625 | A002

Page 11

Installation |

4 Installation

4.1 Unpacking

Topvex FR03–11 are delivered on a pallet (figure 2 and figure 3). Necessary components like handles and supply air

temperature sensor are placed inside the unit.

The inspection hatches are opened by the use of a 16 mm cap key (figure 4). To facilitate opening and closing of the inspection hatches apply the 8 handles that are placed inside the unit on delivery.

After completed installation the handles need to be removed to prevent unauthorized opening of the unit.

Verify that all ordered equipment are delivered before starting the installation. Any discrepancies from the ordered

equipment must be reported to the supplier of Systemair products.

7

Fig. 4 Opening inspection hatches with a cap key

4.2 Where/how to install

The unit is meant for indoor installation. The electronic components should not be exposed to lower temperature than

0 °C or higher than +50 °C. If the unit is installed in a cold place it is important that the unit is not shut-off by the main

switch. As long as the main voltage is on the electrical cabinet will be kept warm also in cold climates. Although the unit

is turned off by the control system the current is on.

When mounting; make sure to leave enough space to access the service doors (figure 3.2.3).

Note:

If there is not sufficient space to open the inspection doors it is possible to unscrew the hinges to remove

the doors completely for inspection and maintenance. Another option, when installing the unit suspended

with the inspection door facing downwards, is to acquire the sliding door accessory kit.

Avoid placing the unit against a wall, as low frequency noise can cause vibrations in the wall.

The outdoor air intake of the building should if possible be put in the northern or eastern side of the building and away

from other exhaust outlets like kitchen fan outcasts or laundry room outlets. The extract air should ideally be led out via

a roof cowl away from any outdoor air intakes, windows, balconies etc.

Warning

• The door handles are only intended to be used during the installation. Handles must be removed before

the unit is put into operation to ensure the required level of safety for the unit.

• The unit must be duct connected or in some other way provided with protection so that it is not possible

to come in contact with the fans through the duct connections

151625 | A002

Page 12

| Installation

8

4.3 Installing the unit

The unit can be installed in the following positions

Fig. 5 Possible installation positions

Position Description

A

B

C

D

Installation flat on the ground. Left and right connections are possible.

Ceiling installation. Left and right connections are possible.

Vertical wall installation with the supply air upward.

Horizontal wall installation Left and right connections are possible.

Note:

The unit may not be installed with the electrical connection box facing downward!

E

Arrow symbol description (table 3).

Installation according to A-D

Vertical wall installation with the supply air downward, not allowed.

Warning

Beware of sharp edges during mounting and maintenance. Make sure that a proper lifting device is used.

Use protective clothing.

1 Prepare the surface where the unit is to be mounted.

Make sure that the surface is flat, levelled and that it

supports the weight of the unit. Perform the installation in accordance with local rules and regulations.

2 Lift the unit in place.

3 Connect the unit electrically to the mains power sup-

ply through the all pole circuit breaker, safety switch

(accessory). The wiring is led through the gable to the

electrical connection box.

See enclosed wiring diagram, and chapter 4.6.6 for

more information.

151625 | A002

Page 13

Installation |

4 Install the unit by the use of the mounting brackets fit-

ted on the unit on delivery.

Note:

If the unit is installed in the ceiling or on

the wall assure that the unit is pressed

tightly to the mounting surface before

fastening the mounting brackets. Make

sure to use proper fastening device

(screw/bolts) considering the weight of

the unit and the type of surface it is fitted

to. The installation can only be performed

by an authorized installer.

Double mounting brackets (figure 6, pos 1) are used for Topvex FR03-FR06 to ensure a stable fit. Topvex FR08-FR11

have brackets as shown in pos. 2.

9

Fig. 6 Mounting brackets

151625 | A002

Page 14

| Installation

10

4.4 Supply air sensor

The supply air sensor is enclosed in the unit package on delivery. Mount the supply air sensor the supply air duct 3 m

after the air handling unit (figure 7). Connect the sensor to terminal 30–31 (chapter 4.6.6) in the electrical connection

box. Other temperature sensors are built in to the unit from factory.

Fig. 7 Installed supply air sensor

4.5 Mounting the sliding door kit

A sliding door kit for the inspection doors can be acquired as an accessory and can be mounted on units, which are installed with the inspection doors facing downward, e.g. in false ceiling installation. The kit is installed according to below

procedure.

1 Remove guide rails

Open one of the inspection hatches completely and

remove the guide rails (pos. 1) supporting the hatch

by unscrewing screws, pos. 2 and pos. 3.

2 Hinges

Close the hatch with all 4 handles and unscrew the 2

hinges.

3 Repeat procedure

Repeat the procedure from step 1 on the other hatch.

151625 | A002

Page 15

4 Mount the wheels

Mount the wheels in the prepared threaded inserts on

the side of the inspection hatch with the enclosed

screws and washers.

5 Sliding door support rails

Mount the sliding door rails on each side of the unit.

Fasten it to the casing with screws in the prepared

threaded inserts.

Installation |

11

6 Fasten with BSS screws

Fasten the rail to the side of the casing with the enclosed BSS screws.

151625 | A002

Page 16

| Installation

12

7 Open hatch

Open the hatch by unlocking the 2 inner handles (pos.

1) followed by the 2 outer handles (pos. 2). The hatch

can now be pushed toward the centre of the unit. Only one hatch at the time can be opened like this.

8 Apply seal

Apply the enclosed self adhesive seal strip to the inner frame of the unit casing.

9 Close hatch

Close the hatch with the 4 handles. Make sure the

hatch closes properly.

Repeat the procedure from step 7 on the other hatch.

10 Remove Handles

After the hatch is closed, the handles need to be removed before the unit is put in operation.

Warning

The door handles are only intended to be

used during the installation. Handles must

be removed before the unit is put into

operation to ensure the required level of

safety for the unit.

151625 | A002

Page 17

4.6 Connections

4.6.1 Ducting

Fig. 8 Air direction, left hand unit

Installation |

13

Fig. 9 Air direction, right hand unit

Table 3 Symbols and descriptions

Position Description

A

B

C

D Extract air

1

2

3

4 Fan extract air

5

6

7

Supply air

Exhaust air

Outdoor air

Filter supply air

Filter extract air

Fan supply air

Heat exchanger

Rotor control (location depending on size of unit)

Electrical connection box

Symbol

151625 | A002

Page 18

| Installation

14

4.6.2 Condensation and heat insulation

Outdoor air duct and exhaust ducts must always be well insulated against condensation. Correct insulation installation

on ducts connected to the unit is especially important. All ducts installed in cold rooms/areas must be well insulated.

Use insulating covering (minimum 100 mm mineral wool) with plastic diffusion barrier. In areas with extremely low outdoor temperatures during the winter, additional insulation must be installed. Total insulation thickness must be at least

150 mm.

Caution

• If the unit is installed in a cold place make sure that all joints are covered with insulation, and tape well

• Duct connections/duct ends should be covered during storage and installation

• Do not connect tumble dryers to the ventilation system

4.6.3 Silencers

To avoid fan noise being transferred via the duct system, silencers should be installed both on supply and extract air.

To avoid noise being transferred between rooms via the duct system and also to reduce noise from the duct system itself, installation of silencers before every inlet diffuser is recommended.

4.6.4 Electric connections

All electric connections are made in the electrical connection box which can be found on the long side of the unit (figure

10). The hatch is removed by unscrewing six screws as displayed in below figure (figure 10).

The unit must not be put into operation before all the electrical safety precautions have been read and understood. See

the enclosed wiring diagram for internal and external wiring.

All external connections to possible accessories are made to terminals inside the electrical connection box (chapter

4.6.6).

Fig. 10 Opening the electrical connection box

Danger

• Make sure that the mains power supply to the unit is disconnected before performing any maintenance

or electrical work!

• All electrical connections must be carried out by an authorized installer and in accordance with local rules

and regulations.

Warning

The units electrical connection to the mains power supply must be preceded by an all pole circuit breaker

with a minimum 3 mm gap.

151625 | A002

Page 19

4.6.5 Electrical connections, components

Topvex FR03–11 are equipped with a built in regulator and internal wiring (figure 11).

Fig. 11 Electric components

Pos 10 shows location of TTC in FR03 and FR06-FR11

Installation |

15

Position

1

2

3

4

5

6

7

8

9

10

11

Description

Control unit CU283W-4

Transformer 230/24V AC

Terminals for internal and external components

Terminals for internal wiring

Terminals for mains power supply to the unit

Contactor (K2) On/Off Pump control water (HW

units only, not present in EL-units)

Automatic fuse

Automatic fuse for heater

Contactor (K3) EL heater

TTC El heater control

Switch module

151625 | A002

Page 20

| Installation

16

4.6.6 External connections

Table 4 Connections to external functions

Terminal block

PE

N N

L1 L1

L2 L2

L3 L3

1 G

2 G0

10

1

12

WP L1

1

14

1

15

1

16

1

17

30

31 AI 1

40

2

41

2

42

44

3

4

P1:50/P2:60

P:151/P2:61

P1:52/P2:62

3

74

3

75

76

3

90

93 AO 3

94 AO 4

1

Maximum current load for all DO combined: 8A

2

Connection to external pressure sensor in case of pressure controlled unit (VAV)

3

These inputs may only be wired to voltage free contacts

DO ref DO reference

DO 2

DO 4

DO 5

DO 6

DO 7

AI Ref Supply air temperature sensor reference neutral

Agnd UI reference neutral

UAI 1/(UDI 1)

UAI 2/(UDI 2)

UAI 3/(UDI 3)

DI ref Extended running/Fire alarm reference

B

A

N

DI 4

DI 5

DI 6

Agnd AO Reference neutral

Description

Remark

Ground

Earthed neutral (mains power supply)

Used for phase 230V 1~ and

400V 3~

Phase (mains power supply)

Used for phase 230V 1~ if the

unit has this mains

400V 3~/230V 3~

Phase (mains power supply) 400V 3~/230V 3~

Phase (mains power supply) 400V 3~/230V 3~

Auxiliary supply (Pressure transmitter. Water

24V AC

valve actuators)

Reference (Water valve actuator mains)

24V AC

G (24V AC)

Outdoor/Exhaust air damper

24V AC

Max. 2,0 A continuous load

Circulation pump hot water system

Cooling pump

DX Cooling step 1

DX Cooling step 2

Alarm output for DO signals

230V AC

24V AC

24V AC

24V AC

24V AC

Temperature sensor, supply air

Pressure transmitter extract air

Pressure transmitter supply air

Frost protection sensor water heating

Use terminal 40 as reference

battery

+ 24V DC

Exo-line B Modbus, Exo-line connection

Exo-line A Modbus, Exo-line connection

Exo-line N Modbus, Exo-line connection

Extended running Normally open contact

Use terminal 4 as reference

Fire alarm Normally open contact

Use terminal 4 as reference

External stop Normally open contact

Use terminal 4 as reference

Control signal valve actuator, Water Heating

Control signal valve actuator, Cooling

0–10V DC

0–10V DC

151625 | A002

Page 21

4.6.7 BMS Connection

Communication possibilities for control unit.

• RS485(Modbus): 50-51-52 or 60-61-62

• RS485(BACnet): 50-51-52 or 60-61-62

• RS485(Exoline): 50-51-52-53 or 60-61-62-63

• TCP/IP Exoline

• TCP/IP Modbus

• TCP/IP WEB

• TCP/IP BACnet

RS 485 connection

Installation |

17

Fig. 12

TCP/IP connection

Connect the device to panel outlet or switch module, depending on type of air handling unit.

Fig. 13 Panel outlet view is an example,

Note:

24V HMI connection dedicated for the display. The connection is only for HMI and no other

connections is permitted.

151625 | A002

Page 22

| Installation

B

A

C

F

E

D

3 m

18

4.7 Installing NaviPad control panel

The protection class of the NaviPad control panel is IP 54 and 0-50° permitted ambient temperature. If NaviPad is

mounted outdoor the panel needs to be protected against direct UV radiation. Communication between the panel and

the controller in the cabinet is possible with up to 100 meters of cable.

4.7.1 Dimensions

NaviPad is the control panel for Systemair´s Air handling units. NaviPad has an easy to understand menu structure and

contains 13 languages.

A B C

153 221 40,3 59,4 77,5 3,2

c/cD

E F

151625 | A002

Page 23

Installation |

4.7.2 Mounting control panel

The NaviPad control panel with 3 m cable and holder are enclosed with the air handling unit. Self drilling screws are enclosed at delivery for mounting of the panel holder on the air handling. For mounting to a wall use suitable fastenings

screws depending on the surface. NaviPad is connected to the switch module in the air handling unit at delivery.

See enclosed Quick guide for operating of the control panel.

19

Fig. 14 Installation on unit or on wall

4.8 Additional equipment

For information concerning additional external equipment such as valve actuators, motorized dampers, roof units, wall

grilles etc. see technical catalogue and their enclosed instructions.

For electrical connections of external components see enclosed wiring chart.

151625 | A002

Page 24

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg, Sweden

Phone +46 222 440 00

Fax +46 222 440 99

www.systemair.com

Topvex FR03, FR06, FR08, FR11 · Installation instructions · 151625 · en_GB · 2018-10-11 · A002

Loading...

Loading...