SystemAir AXC Series, AXR Series, AJR Series, AXCBF Series, AJ8 Series Installation And Operating Instructions Manual

...Page 1

Axial Fans/Jet fans

Installation and Operating Instructions

Document in original language | · 003

GB

Page 2

© Copyright Systemair AB

All rights reserved

E&OE

Systemair AB reserves the rights to alter their products without notice.

This also applies to products already ordered, as long as it does not affect the previously agreed specifications.

| 003

Page 3

Contents

1 General information ......... .... ......... .... .... ......... ..1

1.1 Notice symbols . .... ............. .... ............. ...1

1.1.1 Instruction symbols...... .... ...........1

2 Important safety information ..... .... .... ..... .... .... ...1

2.1 Personnel .... ............. .... .... ..... .... .... .......2

2.2 Personal protective equipment.. .... .... ........2

2.3 5 rules of electrical safety ......... .... .... .......2

3 Warranty....... .... .... ............. .... .... ......... .... .... ..2

4 Delivery, transport, storage ........ .... .... ......... .... ..2

4.1 Safety information.......... .... ......... .... .... ...2

4.2 Delivery .... .... ......... .... .... ............. .... .....3

4.3 Transport... .... ............. .... .... ......... .... .... .3

4.3.1 Safety information...... .... .... ........3

4.4 Storage... .... .... ......... .... .... ......... .... .... ...3

4.4.1 Safety information...... .... .... ........3

4.4.2 Preconditions ......... .... ............. ..3

4.4.3 Long storage time ... .... ............. ..3

5 Description ... .... .... ..... .... .... ......... .... .... ...........4

5.1 General........... .... ............. .... .... ......... ...4

5.1.1 Sensors (optional) . .... .... ......... .... 4

5.1.2 Standstill heating

(optional) ..... .... .... ..... .... .... .......4

5.1.3 Technical data of the fan.... .... .... ..4

5.1.4 Motor data .. .... ............. .... .... ....4

5.1.5 Temperature types .... .... .... ..... ....5

5.2 Description axial fans (AXR, AXC) ............. ..5

5.2.1 Construction.... .... ......... .... .... .....5

5.2.2 Types ..... .... .... ......... .... .... ........6

5.2.3 Dimensions....... .... .... ............. ...7

5.2.4 Accessories........ .... .... ......... .... ..8

5.3 Description Jet fans .... .... ......... .... .... ........9

5.3.1 Description AJR/AJ8 . ......... .... .... ..9

5.3.2 Description IV fan .... .... .... ......... 10

5.4 Description AXCBF ... ......... .... .... ......... ...11

5.4.1 Construction.... .... ......... .... .... ... 11

5.4.2 Dimensions....... .... .... ............. . 12

5.5 Intended use .... .... .... ......... .... .... .......... 12

5.5.1 Intended use axial fans........ .... .. 12

5.5.2 Intended use jet fans.... .... .... ..... 12

5.6 Incorrect use . .... .... ......... .... .... ............. 12

6 Name plate and type key .... .... ......... .... .... ....... 13

7 Installation.. .... .... ......... .... .... ............. .... ....... 14

7.1 Safety information...... .... .... ......... .... .... . 14

7.2 Preconditions ............. .... ......... .... .... ....14

7.3 Tightening torques of screw-type

connections according to DIN 13....... .... ... 15

7.4 Mounting feet . .... .... ..... .... .... ............. .. 15

7.5 Avoid resonance frequencies . .... .... ......... 15

7.5.1 Vibration dampers .... .... ......... ...15

7.6 Lifting and positioning ......... .... .... ......... . 15

7.6.1 Anchor the fan..... .... ............. ...16

7.7 Installation axial fans/AXCBF.. .... ............. 16

7.7.1 Installation of the ventilation

system ......... .... ......... .... .... ....16

7.7.2 Distance from the wall/

ceiling......... .... .... ......... .... .... .. 17

7.7.3 Installation of flexible

connections ......... .... ............. .. 17

7.7.4 Installation silencer ... .... ......... ...18

7.7.5 Special points of

installation.. .... ..... .... .... .... ....... 19

7.7.6 Air gap........ .... ............. .... .... .. 19

7.8 Installation jet fans AJR, AJ8 and

IV ..... .... .... ......... .... .... ......... .... .... ...... 20

7.8.1 Air gap........ .... ............. .... .... .. 20

7.8.2 Deflector ......... .... .... ......... .... .. 20

8 Electrical connection ........ .... ............. .... .... ..... 21

8.1 Safety information...... .... .... ......... .... .... . 21

8.2 Preconditions ............. .... ......... .... .... ....21

8.3 Protecting the motor... .... ............. .... .... . 21

8.4 Connection . ......... .... .... ............. .... ...... 22

8.4.1 Connection diagrams..... .... .... ....23

8.5 Frequency converter (if used) . ............. ...23

8.6 Protective grounding wire ... .... ......... .... .. 24

8.7 Residual current circuit breaker. ............. .. 24

9 Commissioning .... .... ............. .... .... ......... .... ... 24

9.1 Safety information...... .... .... ......... .... .... . 24

9.2 Preconditions ............. .... ......... .... .... ....24

9.3 Tests before activation .... .... .... ..... .... .... . 24

9.4 Tests when activated ........ .... .... ......... ...24

9.5 Commissioning of speed-controlled

fans .... .... ............. ............. .... .... ........25

| 003

Page 4

Contents

9.6 Adjusting the blade angle.. .... ............. .... 25

10 Operation . ............. .... .... ......... .... .... ......... .... 25

10.1 Safety information.......... .... ......... .... .... . 25

10.2 Preconditions ............. .... ............. .... .... 25

10.3 Speed-controlled fan operation .... ..... .... .. 25

11 Troubleshooting/maintenance/repair ........ .... .... 25

11.1 Safety information.......... .... ......... .... .... . 25

11.2 Troubleshooting.. .... .... ..... .... .... ......... ...26

11.3 Maintenance... ..... .... .... ............. .... ...... 26

11.3.1 Variable-speed fans ......... .... .... . 27

11.3.2 Maintenance intervals . ..... .... .... . 27

11.3.3 Monthly maintenance .... ......... .. 27

11.3.4 Half-yearly maintenance.. .... .... .. 27

11.3.5 Annual maintenance .... ............. 27

11.3.6 Overhaul/further

maintenance.... .... ............. .... .. 28

11.3.7 After 20,000 hours of

operation or 5 years of normal

operation .... .... ............. .... .... .. 28

11.3.8 After 30,000 to 40,000 hours

of operation ... ..... .... .... ......... ...28

11.4 Work before switching on again ..... ......... 28

11.5 Spare parts ... ......... .... .... ............. .... ....28

12 Cleaning....... .... .... ............. .... .... ..... .... .... ..... 28

12.1 Safety information.......... .... ......... .... .... . 28

12.2 Preconditions ............. .... ............. .... .... 28

12.3 Procedure.... ............. .... .... ..... .... .... ..... 29

13 Deinstallation/dismantling. .... ......... .... .... ......... 29

14 Disposal .... .... .... ......... .... .... ......... .... ............29

15 EU Declaration of conformity — Axial

fans .... ............. .... ............. .... .... ......... .... .... 30

16 Commissioning Report.. .... ............. .... .... ......... 31

| 003

Page 5

1 General information

1.1 Notice symbols

Danger

Direct hazard

Failure to comply with this warning will lead directly to death or to serious injury.

Warning

Potential hazard

Failure to comply with this warning may lead to death or serious injury.

Caution

Hazard with a low risk

Failure to comply with this warning may lead to moderate injuries.

Important

Hazard with risk of damage to objects

Failure to comply with this warning will lead to damage to objects.

General information |

1

Note:

Useful information and instructions

1.1.1 Instruction symbols

Instruction

♦ Carry out this action

♦ (if applicable, further actions)

Instruction with xed sequence

1. Carry out this action

2. Carry out this action

3. (if applicable, further actions)

2 Important safety information

Planners, plant builders and operators are responsible for the proper assembly and intended use.

♦ Read the operating instructions completely and carefully.

♦ Keep the operating instructions and other valid documents, such as the circuit diagram or motor instructions, with

the fan. They must always be available at the place of use.

♦ Observe and respect local conditions, regulations and laws.

♦ Only use the fan in a awless condition.

♦ Provide generally prescribed electrical and mechanical protective devices.

♦ During installation, electrical connection, commissioning, troubleshooting, and maintenance, secure the location and

premises against unauthorised access.

♦ Do not circumvent any safety components or put them out of action.

♦ Keep all the warning signs on the fan complete and in a legible condition.

♦ The device is not to be used by persons (including children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given supervision or instruction.

♦ Do not allow children to play with the device.

| 003

Page 6

Warranty

|

2

2.1 Personnel

The fan may only be used by qualified, instructed and trained personnel. The persons must know the relevant safety directives in order to recognise and to avoid risks. The individual activities and qualifications can be found in Table 1 Qual-

ifications, page 2.

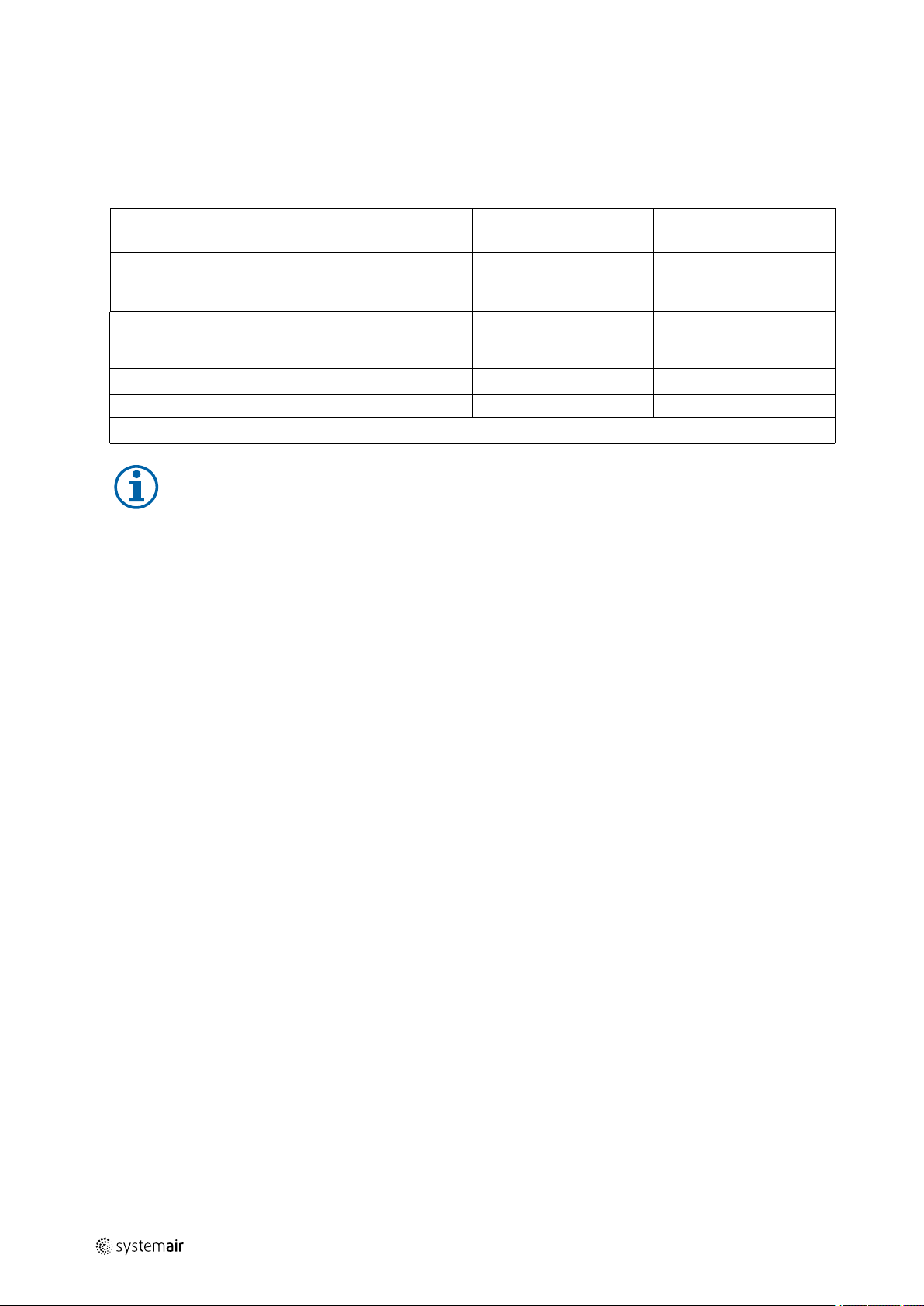

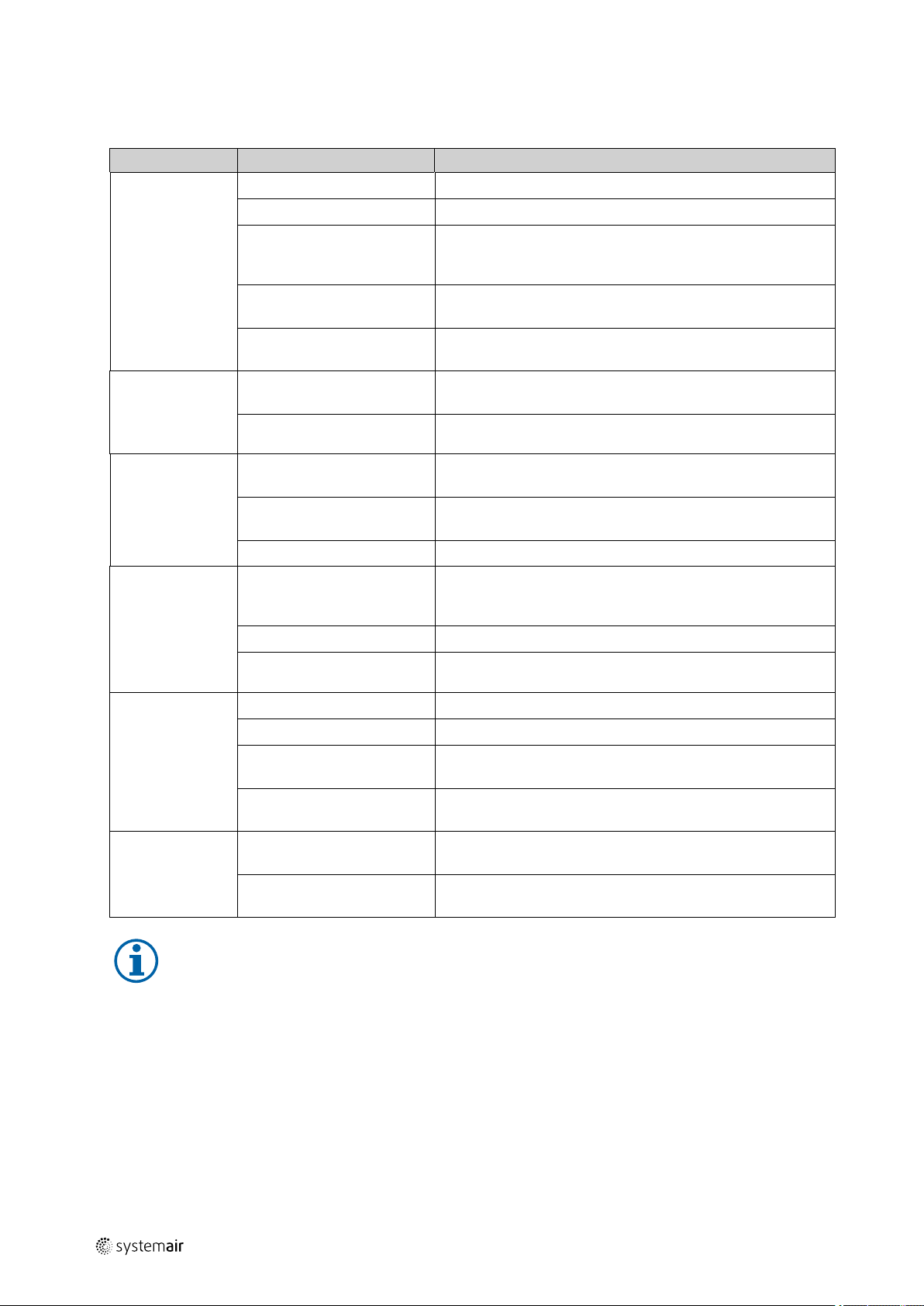

Table 1 Qualifications

Activities

Storage, operation,

transport, cleaning,

disposal

Electrical connection,

commissioning, electrical

disconnection

Installation, disassembly

Maintenance X X

Repair

Electrical expert or

matching qualification

X

Smoke extraction fans and EX fans only by agreement with Systemair.

Fitter or matching

qualification

Note:

The operator is responsible for ensuring that personnel are instructed and have understood the contents of

the operating instructions. If something is unclear, please contact Systemair or its representative.

2.2 Personal protective equipment

Wear protective equipment during all work in the vicinity of the fan.

• protective working clothes

• protective working shoes

• protective working gloves

• helmet

• goggles

• hearing protection

Trained personnel (see

following note)

X

X

2.3 5 rules of electrical safety

• Disconnect (disconnection of the electrical system from live components at all terminals)

• Prevent reactivation

• Test absence of voltage

• Ground and short-circuit

• Cover or restrict adjacent live parts

3 Warranty

The warranty for our products is determined by the contractual stipulations, our offers and our Terms and Conditions.

Warranty claims presuppose that the product is properly connected, operated according to data sheets and serviced as

needed. A correct commissioning report must also be presented upon request. Please find the commissioning report attached to this document.

4 Delivery, transport, storage

4.1 Safety information

Warning: Risk from rotating fan blades

♦ Prevent access by unauthorised persons by safety personnel or access protection.

Warning: Suspended loads

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 2.

♦ Do not walk under suspended loads.

| 003

Page 7

Delivery, transport, storage |

♦ Make sure that there is nobody under a suspended load.

4.2 Delivery

Each fan leaves our plant in an electrically and mechanically proper condition. We recommend transporting the fan to

the installation site in the original packaging.

Checking delivery

♦ Check completeness of the delivery.

♦ Check the packaging for transport damage.

Unpacking

Warning

When opening the transport packaging, there is a risk of damage from sharp edges, nails, staples,

splinters etc.

♦ Unpack the fan carefully.

♦ Check the fan for obvious transport damage.

♦ Only remove the packaging shortly before assembly.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective

equipment, page 2.

3

4.3 Transport

4.3.1 Safety information

Warning: Electrical or mechanical hazards due to fire, moisture, short circuit or malfunction.

♦ Never transport the fan by the connecting wire, terminal box, rotor, protective grille, inlet cone or silencer.

♦ In open transport, please make sure that no water can penetrate into the motor or other sensitive parts.

♦ We recommend transporting the fan to the installation site in the original packaging.

Caution: If transported without care during loading and unloading, the fan may be damaged.

♦ Load and unload the fan carefully.

♦ Use hoisting equipment that is suitable for the weight to be hoisted.

♦ Observe the transportation arrows on the packaging.

♦ Use the fan packaging exclusively as transport protection and not as a lifting aid.

4.4 Storage

4.4.1 Safety information

Warning: Risk of injury and damage to the fan.

♦ Do not stack the fans on top of one another.

♦ Do not use transport packaging as hoisting aids.

♦ Use hoisting equipment that is suitable for the weight to be hoisted.

4.4.2 Preconditions

♦ Store the devices in a clean, dry and vibration-free environment.

♦ Storage temperature should be between –20°C and 60°C.

4.4.3 Long storage time

Storage more than 3 months

♦ Turn the rotor at least 10 revolutions once a month.

♦ Please ensure that the rotor is at a different position afterwards.

| 003

Page 8

Description

|

4

Storage more than 12 months

♦ We recommend an inspection by the after-sales service of Systemair before commissioning.

Test the motor windings:

♦ Measure the insulation resistance of each motor winding against grounding at 500 V DC. The insulation resistance

must be > 10 mΩ.

Measures for an insulation resistance < 10 mΩ:

1. If the motor has drain plugs, remove them to allow any moisture to drain and replace them when the motor windings

are suitably dry.

2. Dry the motor in a warm dry airflow (typically 40 degrees Celsius).

3. Measure the insulation resistance of each motor winding against grouding at 500 V DC.

4. Repeat the aforementioned steps until the measurement outcome > 10 mΩ.

Test the motor:

♦ Connect an ammeter to each phase of the motor.

♦ Switch the fan on and check the current consumption.

♦ Compare the current consumption with the nominal consumption on the name plate.

5 Description

5.1 General

• The fan conveys air in an axial direction from the intake side via the electric motor to the outlet side. (except AXCBF).

• The electrical connection is made through a terminal box installed on the outside of the housing (except AXCBF).

5.1.1 Sensors (optional)

Sensors can be connected to the fan to monitor the roller bearings and for vibration monitoring.

5.1.2 Standstill heating (optional)

The standstill heating starts when the motor switches off and vice versa.

5.1.3 Technical data of the fan

The technical data of the fan can be seen on the name plate or the data sheet.

5.1.4 Motor data

The motor data can be found on the name plate of the motor or in the technical documents of the motor manufacturer.

| 003

Page 9

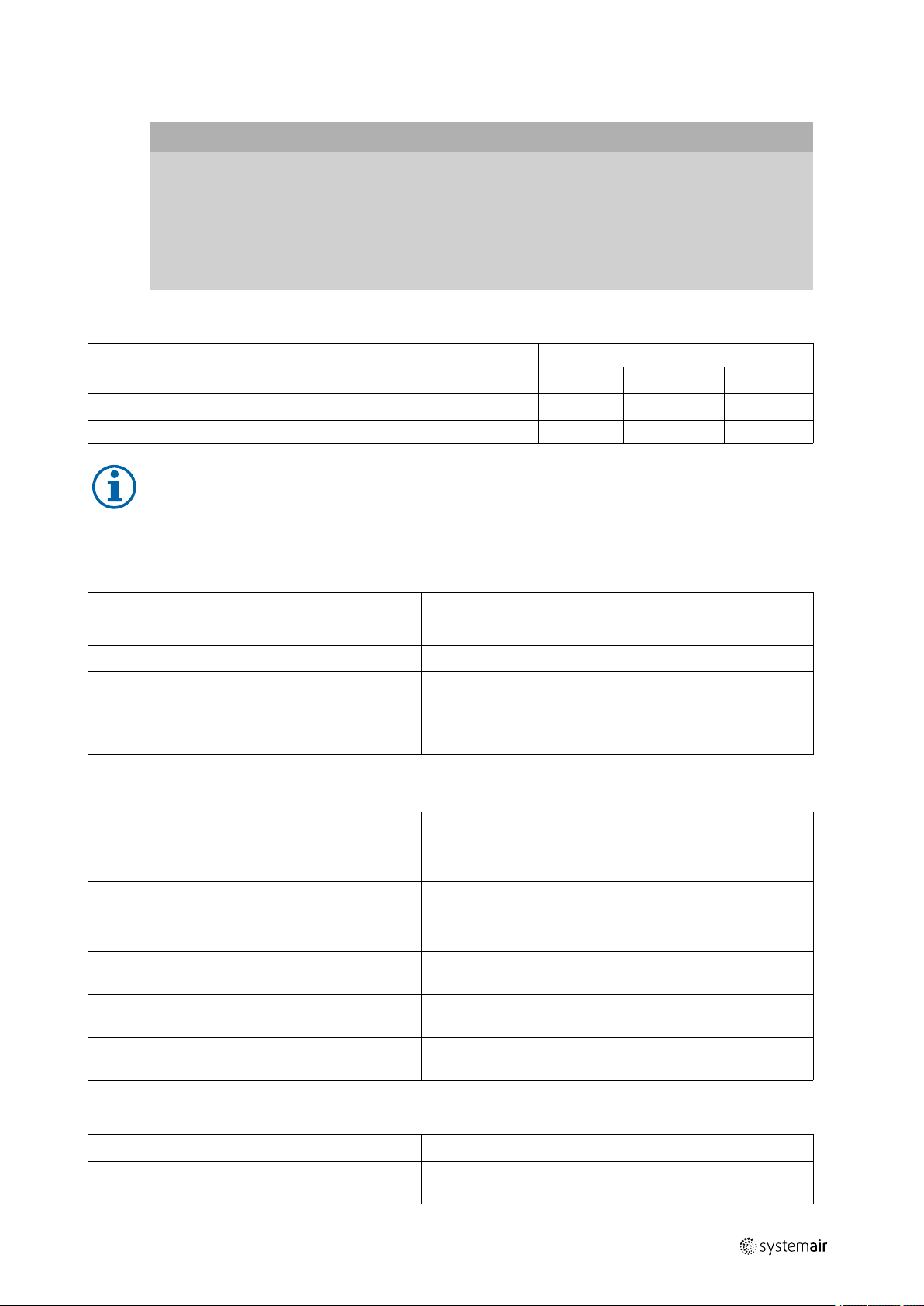

5.1.5 Temperature types

Table 2 Types of fans

Description

|

5

Type

AXC/AXR

AXC (K)/AXR (K)

AXC (B)/AXR (B)

AXC (F)/AXR (F)

AJR/AJ8

AJR (K)/AJ8 (K)

AJR (B)/AJ8 (B)

AJR (F)/AJ8 (F)

IV 50, 85, 100

IV (B)

IV(F)

AXCBF- Thermo fans are equipped with an encapsulated motor, permanent operation temperature up to 200°C.

F250, F300, F400 according to DIN EN 12101–3

Diameter [mm]

315 — 1600

315 — 1600

315 — 1600

315 — 1600

315 — 400

315 — 400

315 — 400

315 — 400

50, 85, 100

50, 85, 100

Long-term

operation –20°

C...55°C

X

X X

X X

X X

X

X X

X X

X X

X

X X

X X

(K) 250°C/120

min.

(B) 300°C/120

min.

(F) 400°C/120

5.2 Description axial fans (AXR, AXC)

min.

• In B3 conventional motors, the motor bracket is made from galvanized steel sheet. B30 “pad mounted” motors are

fitted in the housing via threaded rods or a welded motor support.

• The motor with impeller is mounted to a sturdy supporting structure made of galvanized steel sheet.

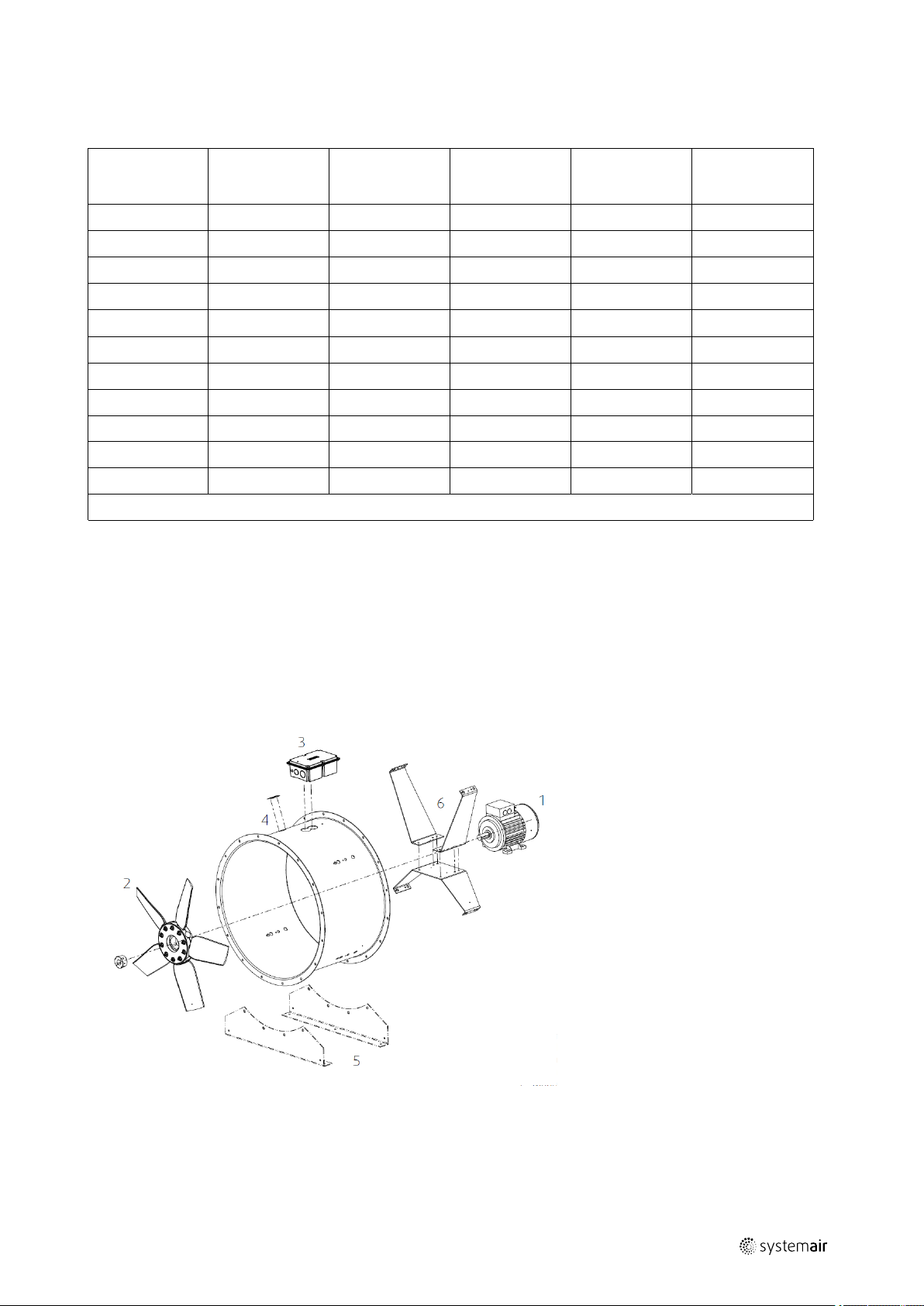

5.2.1 Construction

1 Motor

2

Impeller

3

Terminal box

4

Housing

5

Mounting feet

6

Motor brackets

| 003

Page 10

Description

|

6

5.2.2 Types

Table 3 Constructive features

Type

AXC

AXC-G

AXR

Constructive features

As a default, the fans are provided in protection class IP55, ISO F.

Fans constructed as garage version. Arrangement of two fans in series, switched behind one another.

The conveying direction can be reversed by switching the direction of rotation.

AXC(K),

AXR(K)

AXC(B),

AXR(B)

AXC(F),

AXR(F)

Table 4 Possible Combinations

AXC...-B

AXC...-G

AXC...-G-B

AXC...(B)-B

AXC...(B)-G Smoke extraction axial fan, 2 fans connected in series (2–stage)

AXC...(B)-G-B Smoke extraction axial fan, 2 fans connected in series (2–stage) inside a sound-isolated box

AXC...(F)-B

AXC...(F)-G Smoke extraction axial fan, 2 fans connected in series (2–stage)

AXC...(F)-G-B Smoke extraction axial fan, 2 fans connected in series (2–stage) inside a sound-isolated box

As a default, the fans are provided in protection class IP54/55, ISO H. The connection wire from the motor

to the terminal box is protected via an additional flexible metal hose. The standard motors (400 V type

B3) are without motor protection.

As a default, the fans are provided in protection class IP54/55, ISO H. The connection wire from the motor

to the terminal box is protected via an additional flexible metal hose. The standard motors (400 V type

B3) are without motor protection.

As a default, the fans are provided in protection class IP54/55, ISO H. The connection wire from the motor

to the terminal box is protected via an additional flexible metal hose. The standard motors (400 V type

B30) are without motor protection.

Axial fan, inside a sound-insulated box

Axial fan, 2 fans connected in series (2-stage)

Axial fan, 2 fans connected in series (2-stage) inside a sound-isolated box

Smoke extraction axial fan in sound-isolated box

Smoke extraction axial fan in sound-isolated box

| 003

Page 11

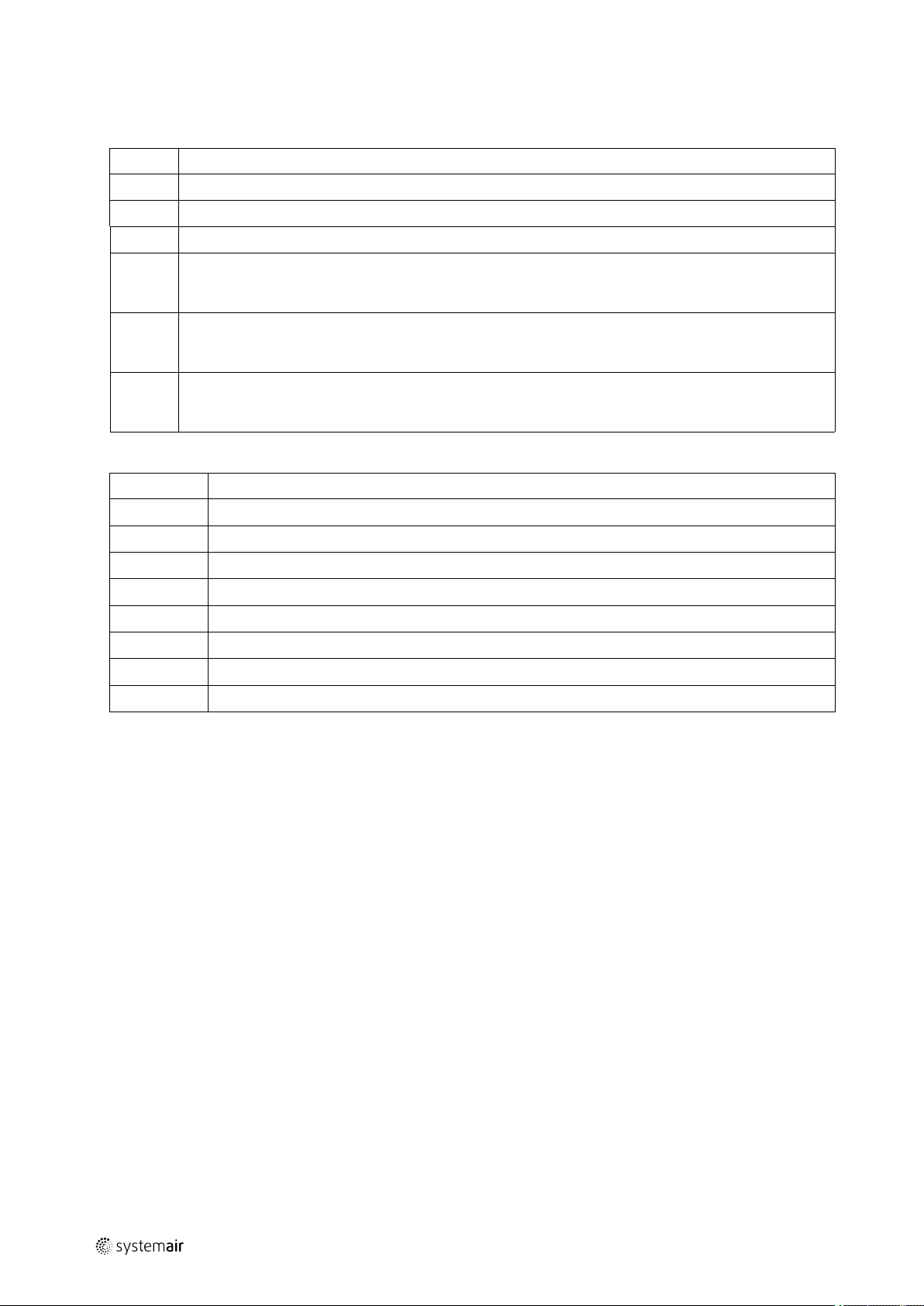

5.2.3 Dimensions

L

W

1/2 W

Ø B x T

ØDa

ØDi

ØTk

S

Description

|

7

Size

(AXC/

AXR)

315

355

400

450

500

560

560

630

630

710

710

710

800

800

900

900

1000

1000

1120

1120

1250

1250

1400

1400

1600

1600

Motor size B3/IEC Motor size B30/

IEC

71/80/90 80/90

71/80/90 80/90

71/80/90/100 80/90/100

71/80/90/100/

112

71/80/90/100/

112/132

80/90/100/112 80/90/100/112

132/160 132/160/180

80/90/100/112 80/90/100/112

132/160 132/160/180

80/90/100/112 80/90/100/112

132/160M 132/160

160L/180 160/180/200

90/100/112 90/100/112

132/160 132/160

100/112/132 100/112/132

160/180/20 160/180/200

100/112/132 100/112/132

160/180/200 160/180/200

132/160 132/160/180

180/200/220/250 200/225/250

132/160/180/200 132/160/180/200

225/250/280M 225/250/280

160/180/200/225 160/180/200/225

250/280/315 250/280

160/180/200/225 160/180/200/225

250/280/315 250/280

80/90/100/112

80/90/100/112/

132

Ø Di

[mm]

315 395 355 375 2.5 45° 10 8

355 435 395 375 2.5 45° 10 8

400 480 450 450 2.5 45° 12 8

450 530 500 500 2.5 45° 12 8

500 590 560 540 3.0 30° 12 12

560 650 620 500 3.0 30° 12 12

560 650 620 750 3.0 30° 12 12

630 720 690 500 3.0 30° 12 12

630 720 690 750 3.0 30° 12 12

710 800 770 500 3.0 22.5° 12 16

710 800 770 700 3.0 22.5 12 16

710 800 770 800 4.0 22.5 12 16

800 800 860 500 3.0 22.5 12 16

800 890 860 700 3.0 22.5 12 16

900 1005 970 640 4.0 22.5 15 16

900 1005 970 850 4.0 22.5 15 16

1000 1105 1070 640 4.0 22.5 15 16

1000 1105 1070 850 4.0 22.5 15 16

1120 1260 1190 700 4.0 18.0° 15 20

1120 1260 1190 1000 5.0 18.0° 15 20

1250 1390 1320 850 5.0 18.0° 15 20

1250 1390 1320 1050 6.0 18.0° 15 20

1400 1540 1470 950 5.0 18.0° 15 20

1400 1540 1470 1360 6.0 18.0° 15 20

1600 1740 1680 950 5.0 15.0° 19 24

1600 1740 1680 1360 6.0 15.0° 19 24

Ø Da

[mm]

Ø Tk

[mm]

L

[mm]

s

[mm]

w

[mm]

Ø B

[mm]

T

| 003

Page 12

Description

1

2

3

4

5

6 7

8

9

10

11

12

13

8

14

15

1

2

3

4

5

11

6

13

14

|

8

5.2.4 Accessories

Horizontal installation

Vertical Installation

1 SG

2 ESD-F

3 RSA

4

EV, EVH (F400)

5 MPR

6

7

REV (60°C)

REV (fire rated)

8 MP

9 MFA

10 SD

11 FSD

12 ZSD

Protection guard

Inlet cone

Silencer

Flexible connection

Mounting ring from size 315 to 1000

Isolator switch

Isolator switch

Mounting bracket from size 1120

Mounting foot

Rubber anti-vibration mounts

Spring anti-vibration mounts

Suspension spring anti-vibration

mounts

13 LRK

14 GFL

15 ABS

Air operated damper

Counter flange

Outlet cowl

Note:

Some accessories are also available for jet fans and AXCBF, please

check our online catalogue or contact Systemair.

| 003

Page 13

Description

|

5.3 Description Jet fans

5.3.1 Description AJR/AJ8

• In B3 conventional motors, the motor bracket is made from galvanized steel sheet. B30 “pad mounted” motors are

fitted in the housing via threaded rods or a welded motor support.

• The fan conveys air in an axial direction from the intake side via the electric motor to the outlet side.

• The silencers are equipped with protection grille made of galvanized steel.

• The acoustic insulation is non-flammable in accordance with DIN 4102 as described in directive 97/69 EC.

Table 5 Constructive features

AJR, AJ8

As a default, the fans are provided in protection class IP55, ISO F.

9

AJR(K),

AJ8(K)

AJR(B),

AJ8(B)

AJR(F),

AJ8(F)

As a default, the fans are provided in protection class IP54/55, ISO H. The wiring from the motor to the

terminal box is protected via an additional flexible metal hose. The standard motors (400 V type B3) are

without motor protection.

As a default, the fans are provided in protection class IP54/55, ISO H. The wiring from the motor to the

terminal box is protected via an additional flexible metal hose. The standard motors (400 V type B3) are

without motor protection.

As a default, the fans are provided in protection class IP54/55, ISO H. The wiring from the motor to the

terminal box is protected via an additional flexible metal hose. The standard motors (400 V type B30)

are without motor protection.

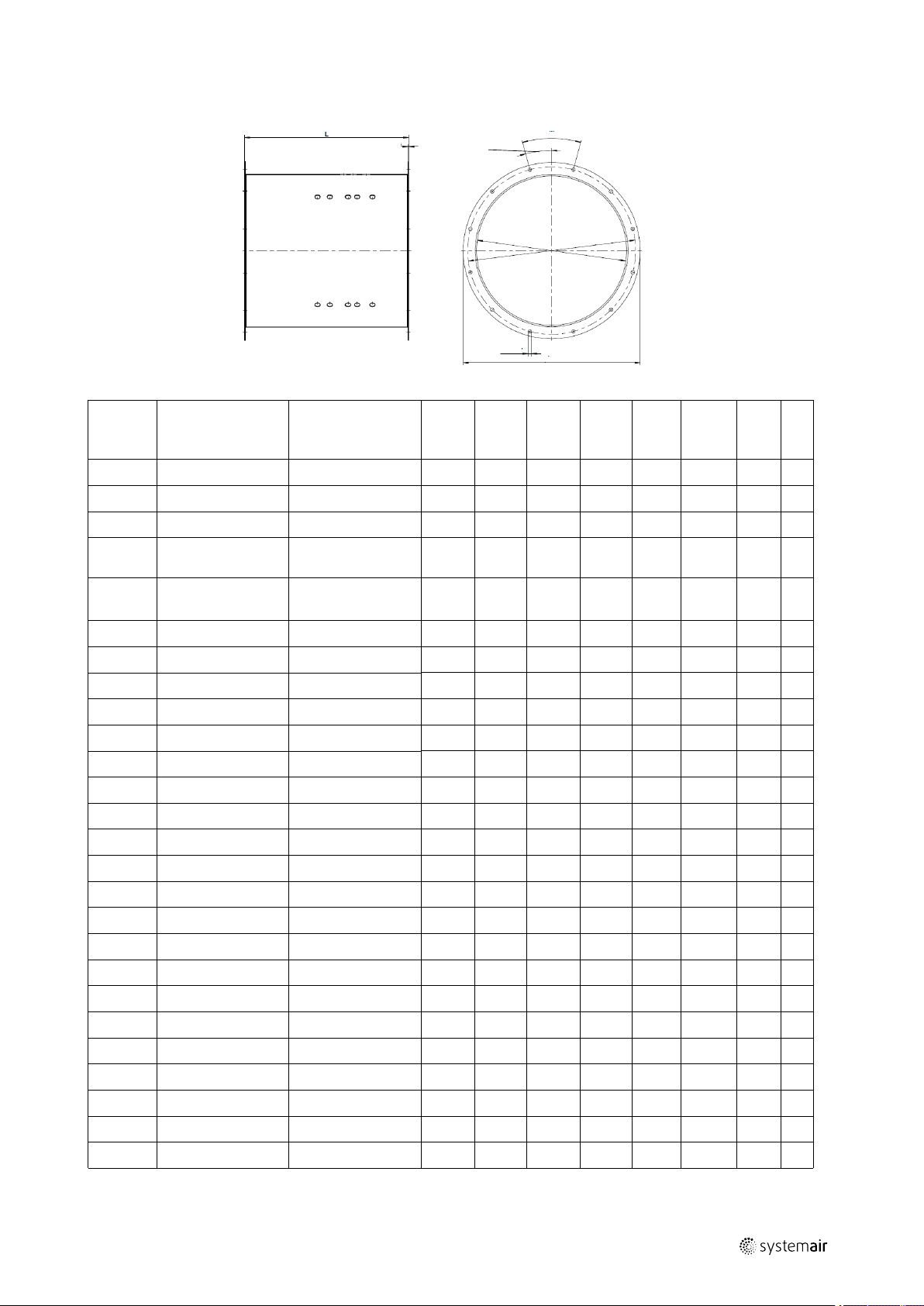

5.3.1.1 Construction

AJ8

AJR

| 003

1 — Motor

2 — Impeller

3 — Terminal box

4 — Housing

5 — Protective guard

6 — Silencer

Page 14

Description

|

10

5.3.1.2 Dimensions AJ8, AJR

AJ8

AJR

Size

AJ8 315 (B), (F)

AJ8 355 (B), (F)

AJ8 400 (B), (F)

ARJ 315 (B), (F)

ARJ 355 (B), (F)

ARJ 400 (B), (F)

H [mm] B [mm] E [mm] F [mm] L [mm]

365 550 635 678 1535

395 550 635 678 1695

445 600 684 727 1875

365 223 265 433 1535

465 243 305 473 1695

505 266 350 516 1875

5.3.2 Description IV fan

The induction fan is equipped with a radial fan with revision switch (optional).

5.3.2.1 Construction

1

Integrated deflector

2

Safety guard

3

Terminal box

4

Impeller

5 Motor 7 Fastener

6

Motor bracket

| 003

Page 15

5.3.2.2 Dimensions

Description

|

11

Size

50 790 834 870 1248 285 370 185 210 13.5

85 1140 1184 1220 1900 340 420 210 230 13.5

A [mm] B [mm] C [mm] D [mm] E [mm] F [mm] H [mm] I [mm] 6xØK

[mm]

5.4 Description AXCBF

Directly powered axial fan with motor outside the air flow. The fan can be run in permanent operation up to a conveying

media temperature of 200°C. Maximum ambient temperature 55°C. Housing flanges on both sides with bores according to eurovent 1/2 standard. B3 conventional motors with add-on terminal box.

5.4.1 Construction

1 — Motor

2 — Impeller

3 — Housing

4 — Mounting feet

5 — Motor bracket

| 003

Page 16

Description

F

A

B

C

D

H

I

I/2

E

B

A

C

I/2

I

H

|

12

5.4.2 Dimensions

Size 250 — 500 Size 630 — 800

Size

A [mm] ØB [mm] ØC [mm] ØD [mm] ØF [mm] ØH [mm]

I

250 535 448 328 250 280 10 4x90°

315 535 452 385 320 355 10 8x45°

400 625 585 480 401 450 10 8x45°

500 660 695 590 504 560 12 12x30°

630 790 728 634

800 880 890 797

-

-

690 12 12x30°

860 12 16x22.5°

5.5 Intended use

• The maximum admissible operating data on the name plate apply to an air density of 1.2 kg/3³ (sea level) and a

maximum air humidity of 80%.

• The temperature of the air transported through the fan must not exceed 55°C/131°F nor be lower than -20°C/-4°F.

• For the temperature resistance of the smoke extraction fans (K), (B), (F), which can also be used to extract CO, please

refer to the name plate (e.g. 300°C/120 min).

• The standard motors are suitable for operation with frequency converters.

5.5.1 Intended use axial fans

• The axial fans of the series AXC/AXR/AXCBF in the versions G (K), (B), (F) are intended for installation in ventilation

systems.

• The axial fans of the series AXC/AXR/AXCBF are ready-to-use products and are used as components for ventilation

devices, machines and systems. These fans can be used to extract, draw in or convey air.

• The fans can be installed both in duct systems and also with free suction via an inlet cone and a suction-side contact

protection grille. Free discharge via a contact protection grille is also possible.

5.5.2 Intended use jet fans

• The model AJ8, AJR and IV jet fans are intended for installation in underground and above-ground parking structures,

to facilitate ventilation and smoke extraction (K), (B), (F).

• For optimum operation, the jet fan must be suspended horizontally from the ceiling in such a position that intake and

outlet are unobstructed.

5.6 Incorrect use

Use the fans only for the requirements described in “intended use” and within the limits for use stated on the name

plate.

• The fan is not suitable for intake of aggressive media or media with a dust content so high that dust deposits on the

impeller or fan housing can affect the operation of the fan.

• The fan must not be installed in hazardous areas (areas with a potentially explosive atmosphere).

• The motors cannot be voltage controlled.

| 003

Page 17

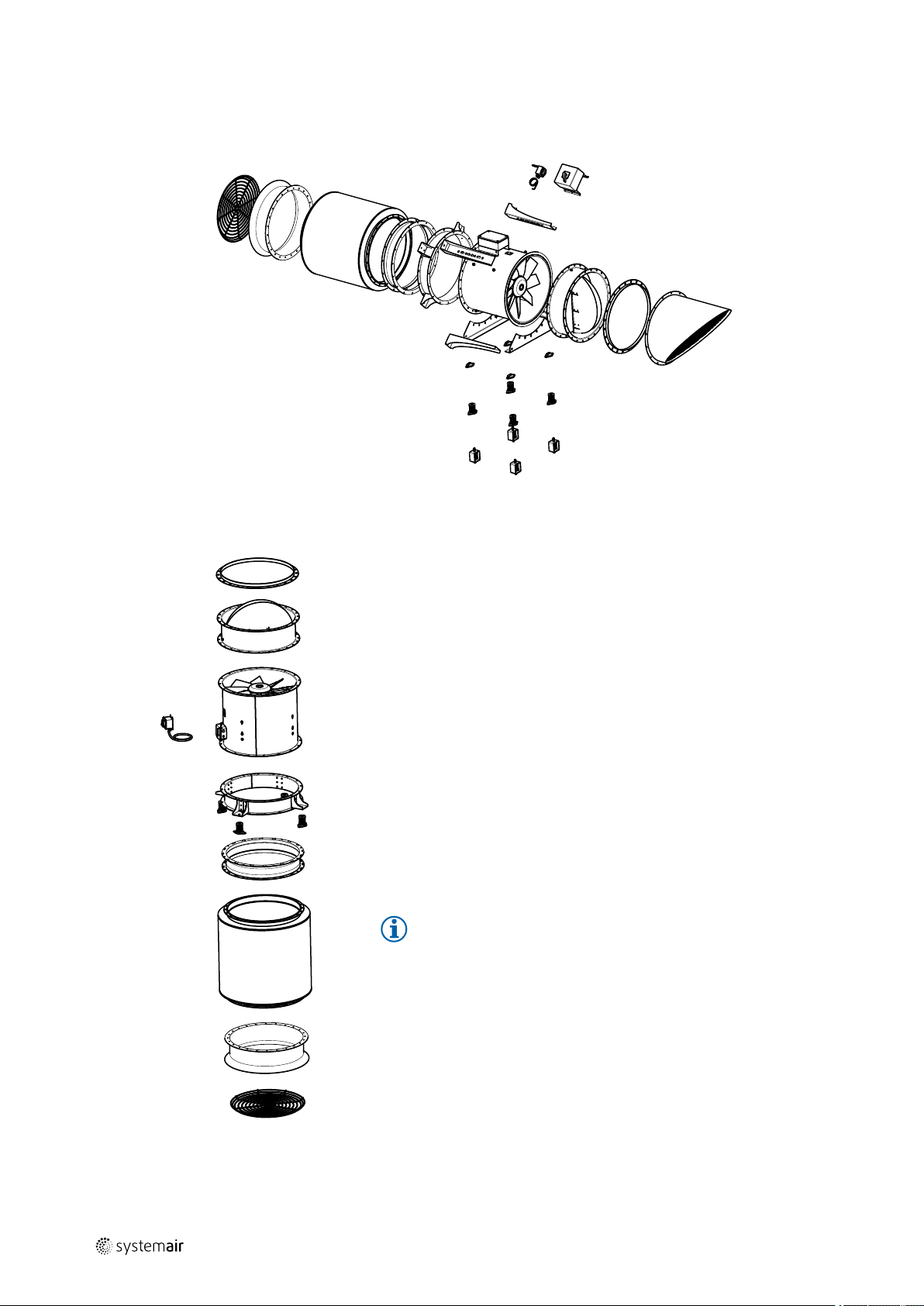

6 Name plate and type key

Type: AXC 400-7/10°-2 (F)

Manufacturing order no.: 1002888063

Manufacturing date: 03/2017

Made in: Germany

Voltage: 230 / 400 V Y

Frequency: 50 Hz

Nominal power at shaft (P2): 0,75 kW

Current: 2,95 / 1,69 A

Insulation class: H

Enclosure class, motor: IP55

Fan impeller speed: 2850 1/min

Weight: 36 kg

Max. temperature of transported air: 55 °C - 400 °C/2h

Number of certificate: 0036-CPR-RG04-11

EN 12101-3 (2015)

Powered Smoke and Heat Control ventilator

Systemair GmbH - Seehöferstraße 45 - 97944 Boxberg - Germany

Values for the fan unit at optimal energy efficiency point,

determined without speed control:

η: 48,2 % Pitch angle: 14°

V: 11.105 m³/h psf: 574 Pa

P1: 3,67 kW RPM: 2940

Measurement cat. / Efficiency cat.: A / Static

Efficiency grade: (N38) N= 51,0

This Powered Smoke and Heat Control ventilator shall be installed as per the manufacturer's instruction.

Installation and Operating Instructions are within the delivery.

20

1

2

3

4

5

6

Name plate and type key |

1

General data

2

Technical data

Temp./Time information/

3

only listed on smoke

extraction fans

4

ErP data

Certifications and QR—

5

Codes

6

Manufacturer Address

13

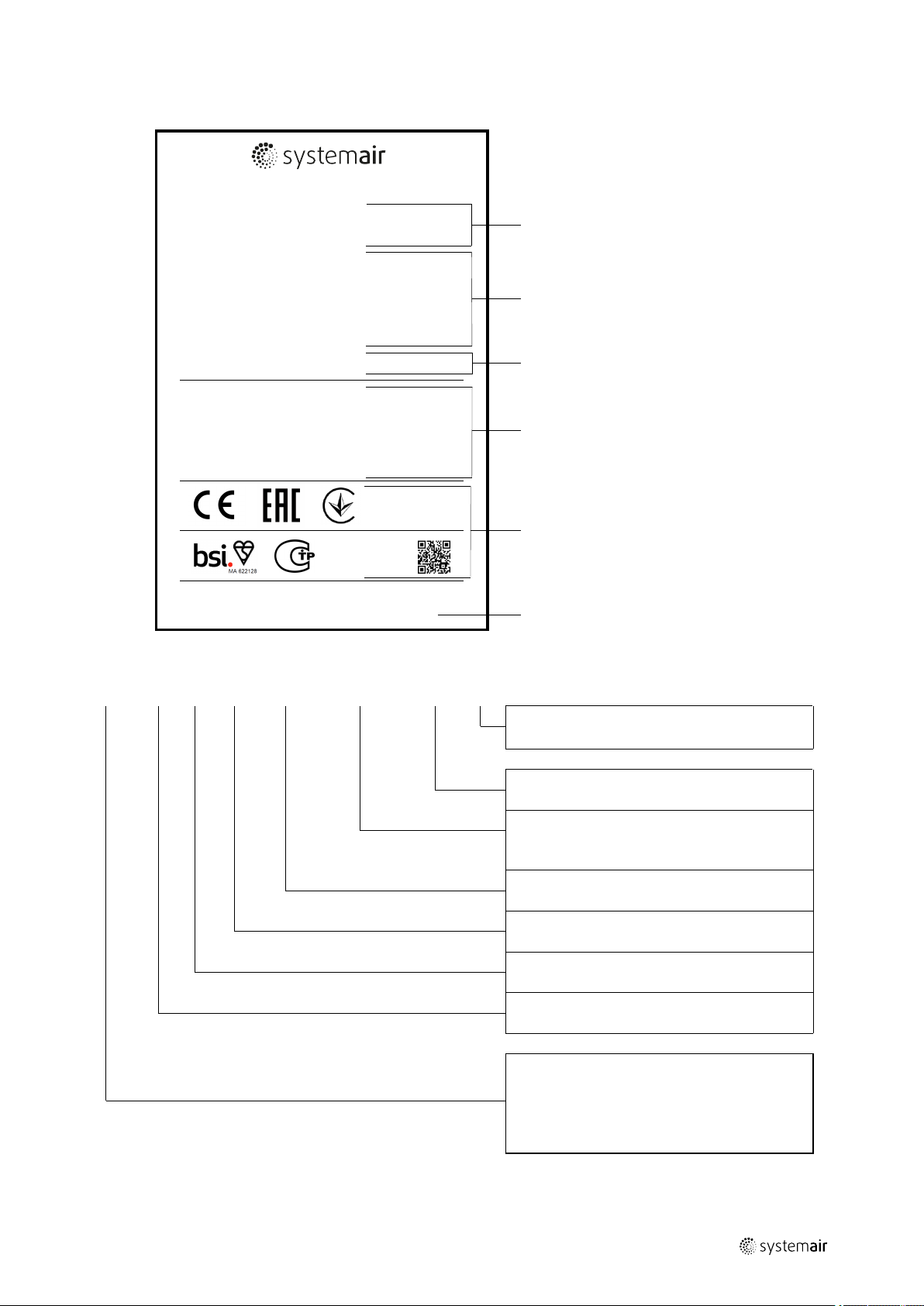

Table 6 Type key

AXC 400 -7

/10°* -2*

(-)(K), (B), (F)

-* —**

TR — Reversible

No sign — Uni-directional

-G – 2 fans in series

-B — Axial fan with insulated box

Temperature- Time information (smoke

extraction fan), see 5.1.5 Temperature types,

page 5

Number of poles

Blade angle

Number of blades

Nominal diameter of the fan

AXC

AXR

AJR

AJ8

Axial fan

Axial fan — reversible

Circular jet fan

Octagonal jet fan

*only AXC and AJ // **only AJR and AJ8

| 003

Page 18

| Installation

14

Table 7 AXCBF Type key

AXCBF 500– D2 20° IE2

Axial fan bifurcated Nominal diameter of

the fan

Table 8 IV Type key

IV 50– 4

Induction fan Thrust 50N Number of poles

3-phase motor 2–

pole

Blade angle International

efficiency

-

Temperature- Time

information (smoke

extraction fan), see 5.1.5

Temperature types, page 5

7 Installation

7.1 Safety information

Danger: Risk that the fan does not work in case of fire.

♦ Spring vibration mounts made from unsuitable materials do not fulfil their function! For smoke extraction fans (K),

(B) and (F) only use spring vibration mounts made of steel!

♦ Use installation material with fire resistance classes that meet temperature requirements.

Warning: Danger from falling fan or fan parts.

♦ Check the surface before installation for load bearing capacity.

♦ Consider all static and dynamic loads when selecting hoisting equipment and fastening components.

♦ Tighten all screw-type connections according to the data, see Table 9 Tightening torques according to DIN 13, page

15.

General safety information

♦ Installation may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page 2.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 2.

♦ Abide by the system-related conditions and requirements of the system manufacturer or plant constructor.

♦ Safety elements may not be dismantled, circumvented or deactivated.

♦ Move the impeller of the fan by hand before you install it in order to check whether that moves freely.

♦ Provide the fan at least with an IP 20 protective grille, if the fan is not installed in a duct system.

♦ Prevent the possibility of foreign bodies being drawn in.

♦ To reduce transmission of vibration to the duct system, we recommend flexible connections from our accessory

range, see 5.2.4 Accessories, page 8.

♦ Bear in mind that parts of the impeller may protrude out of the fan housing.

7.2 Preconditions

• Ensure that the fan and all its components are undamaged.

• Ensure that the information on the name plates (fan and motor) matches up with the operating conditions.

• Ensure that there is enough space to install the fan.

• Protect against dust and moisture when installing.

• Fit the fans in such a way that there is sufficient access for troubleshooting, maintenance and repair.

| 003

Page 19

7.3 Tightening torques of screw-type connections according to DIN 13

Table 9 Tightening torques according to DIN 13

Installation |

15

Screw size

Thread

M6 10 9 10 15 18 8

M7 11+12 14 17 25 28 14

M8 13+14 22 26 35 42 21

M10 15+17 42 50 71 85 40

M12 19+21 74 87 123 147 70

M14 22+23 117 138 194 235 110

M16 24+26 178 210 299 358 159

M18 27 245 289 412 490 231

M20 30 348 412 579 696 330

M22 32 471 559 785 941 447

M24 36 598 711 1000 1196 569

M27 41 888 1049 1481 1775 839

M30 46 1206 1422 2010 2403 1138

M33 50 1628 1932 2716 3266 1546

M36 55 2099 2481 3491 4197 1985

M39 60 2716 3226 4531 5443 2581

M42 65 3364 3991 5609 6727 3193

Key width

SW

6.9 M [Nm] 8.8 M [Nm] 10.9 M [Nm] 12.9 M [Nm] Aluminium

hubs [Nm]

7.4 Mounting feet

Depending on the kind of fan and the construction size, mounting feet are either included in the delivery or available as

accessories. If you are not sure, check the online catalogue or contact Systemair.

7.5 Avoid resonance frequencies

Important

Risk of damage to the fan due to resonance frequencies

♦ The minimum fan speed should be double the resonance frequency of the anti-vibration system

(vibration dampers).

♦ To avoid resonance frequencies, see 8.5 Frequency converter (if used), page 23.

7.5.1 Vibration dampers

Important

Risk of damage to the fan due to incorrect vibration dampers

♦ Use the vibration dampers suitable for the respective weight.

♦ Use the vibration dampers with fire resistance classes that match the respective application.

7.6 Lifting and positioning

The weight of the fan units varies depending on the motor size and accessories. As a result, the fan unit can also be

very bulky and heavy. You can find precise information on the name plate or the data sheet.

| 003

Caution

Risk of parts falling down

♦ When fitting the fan, pay attention to its weight and the weight of the components.

Page 20

| Installation

3

min. 2,5xD

3

1

2

min. 2,5xD

16

Lifting

♦ Lift the fan unit slowly and carefully.

♦ Use hoisting gear permitted for the weight of the fan.

♦ Attach the hoisting equipment to flanges and foot bores or at the marked places.

♦ Use transport equipment (e.g. lifting eyes) if available.

♦ Please observe the marking “oben/top” on the fan.

Positioning

♦ Observe the arrows on the name plate or the housing of the fan. They show the direction of rotation and air flow.

♦ Position the fan unit so that it is standing in the planned direction of flow.

♦ Provide enough free space for inspection and maintenance work on the fan unit.

7.6.1 Anchor the fan

Anchor

♦ Use suitable fittings.

♦ Screw the fittings with the correct tightening torques, see Table 9 Tightening torques according to DIN 13, page 15

♦ If you are not sure, contact Systemair.

7.7 Installation axial fans/AXCBF

Installation is possible in any mounting position. From size 1250 and above, please contact Systemair if the mounting

position should be different to horizontal or vertical.

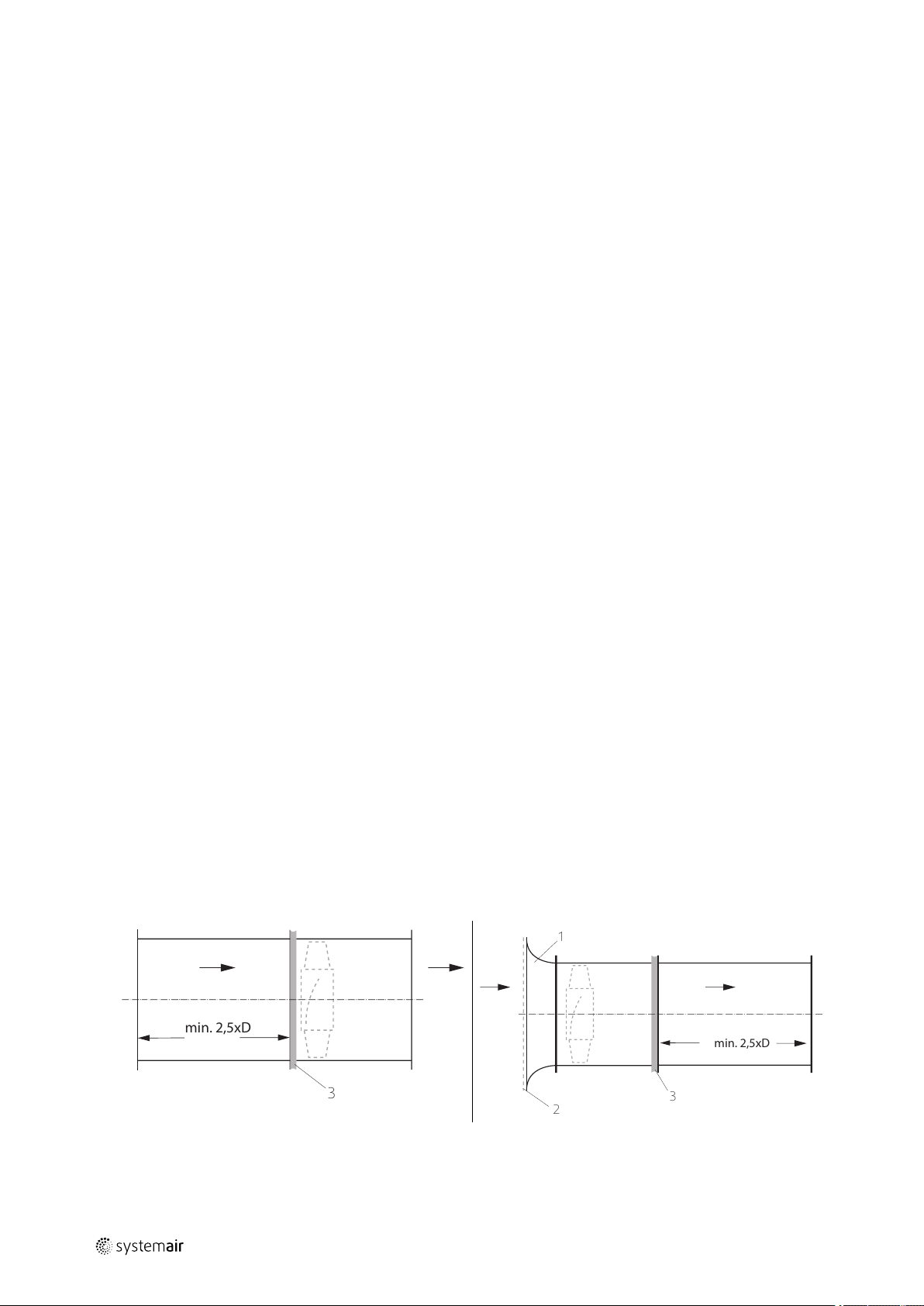

7.7.1 Installation of the ventilation system

7.7.1.1 Preconditions

♦ The air flow of the fan must be able to open the air operated damper (LRK).

7.7.1.2 Installation duct

♦ Do not place a duct bend directly before or after the fan!

• This can cause damage to the bearings or other parts of the fan.

• The duty point may not be reachable.

• The fan may make noise.

♦ Ensure a direct, smooth and constant air flow to the device. Ensure a free exhaust, see the following pictures.

♦ Install an inlet cone or a channel section with a length of at least 2.5 x D

♦ To reduce transmission of vibration to the duct system, we recommend flexible connections from our accessory

range, see 5.2.4 Accessories, page 8.

D = nominal diameter

1

Inlet cone

2

Protective guard

3

Flexible connection

| 003

Page 21

Installation |

min. 1xD

1xD

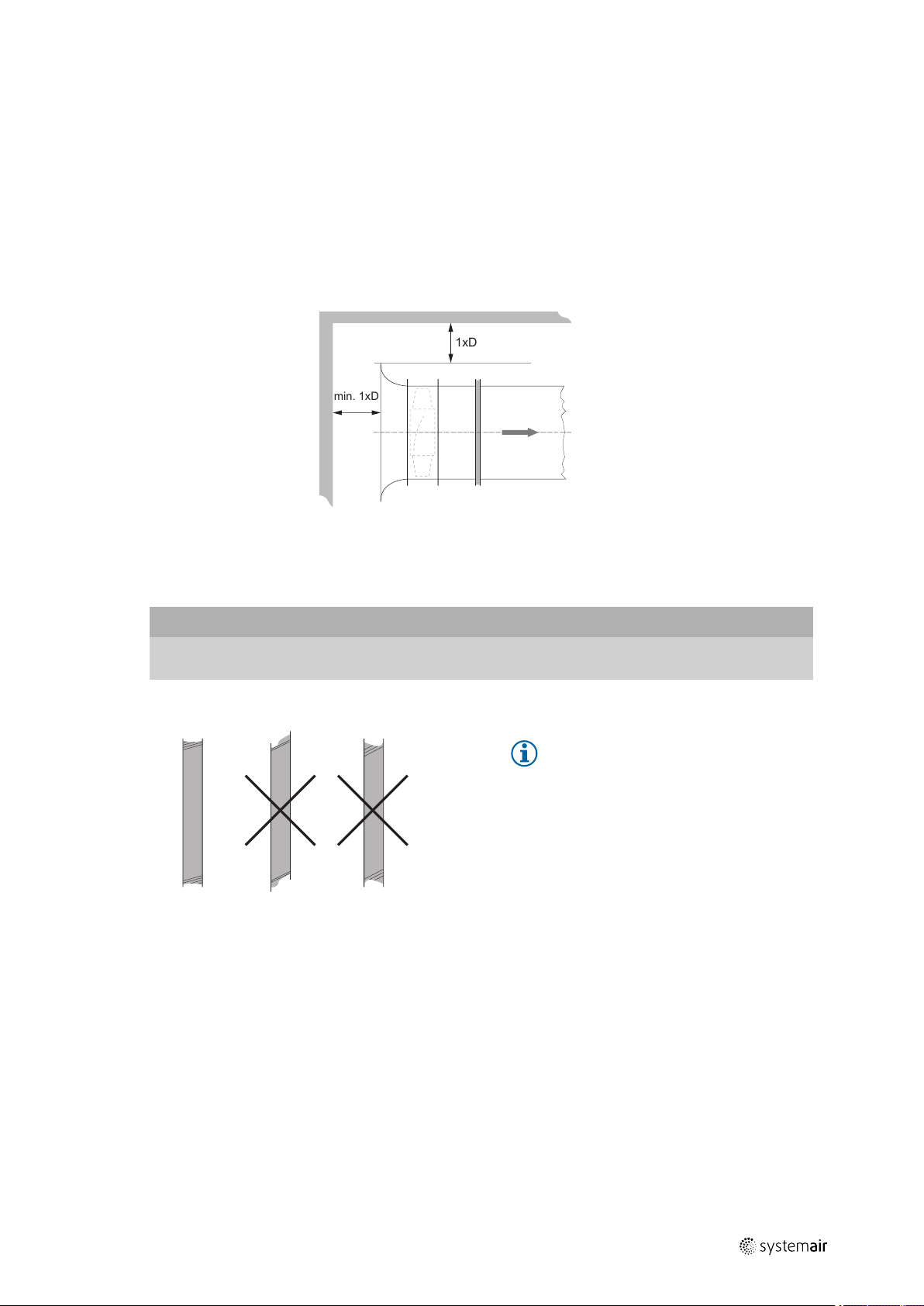

7.7.2 Distance from the wall/ceiling

♦ Ensure enough distance between the ceiling and the wall.

• The duty point may not be reachable.

• The fan may make noise.

If the minimal distances are not possible for construction reasons, install a deflector in front of the fan in a way that en-

sures a direct, smooth and constant flow of air. On the pressure side, provide a duct with a length of at least 2.5xD in order to reach the duty point. Contact with rotating parts must be ruled out at all times – either by ducts of a

corresponding length or by protective grids.

D = Nominal diameter

17

distance wall/ceiling

7.7.3 Installation of flexible connections

Important

Increasing noise emission

♦ Do not install the flexible connections at an angle.

Note:

When fitting the flexible connections,

make sure that they are fitted according

to the installation length (Table 10

Flexible connections — Installation length,

page 18), without compression or tensile

strain. They must not be used to

compensate any lack of precision in the

assembly.

| 003

Page 22

| Installation

LB

18

Table 10 Flexible connections — Installation length

Size

315

355

400

450

500

560

630

710

800

900

1000

1120

1250

1400

1600

EV (-25...70°C) EVH (400°C/2h)

LB full length

[mm]

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

157 (+/-5)

LE Installation

length [mm]

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 15

LB — 15

LB — 15

LB — 15

LB Overall

length [mm]

147 (+/-5)

147 (+/-5)

147 (+/-5)

147 (+/-5)

147 (+/-5)

147 (+/-5)

147 (+/-5)

147 (+/-5)

147 (+/-5)

147 (+/-5)

147 (+/-5)

147 (+/-5)

147 (+/-5)

200 (+/-5)

200 (+/-5)

LE Installation

length [mm]

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 10

LB — 15

LB — 15

LB — 15

LB — 15

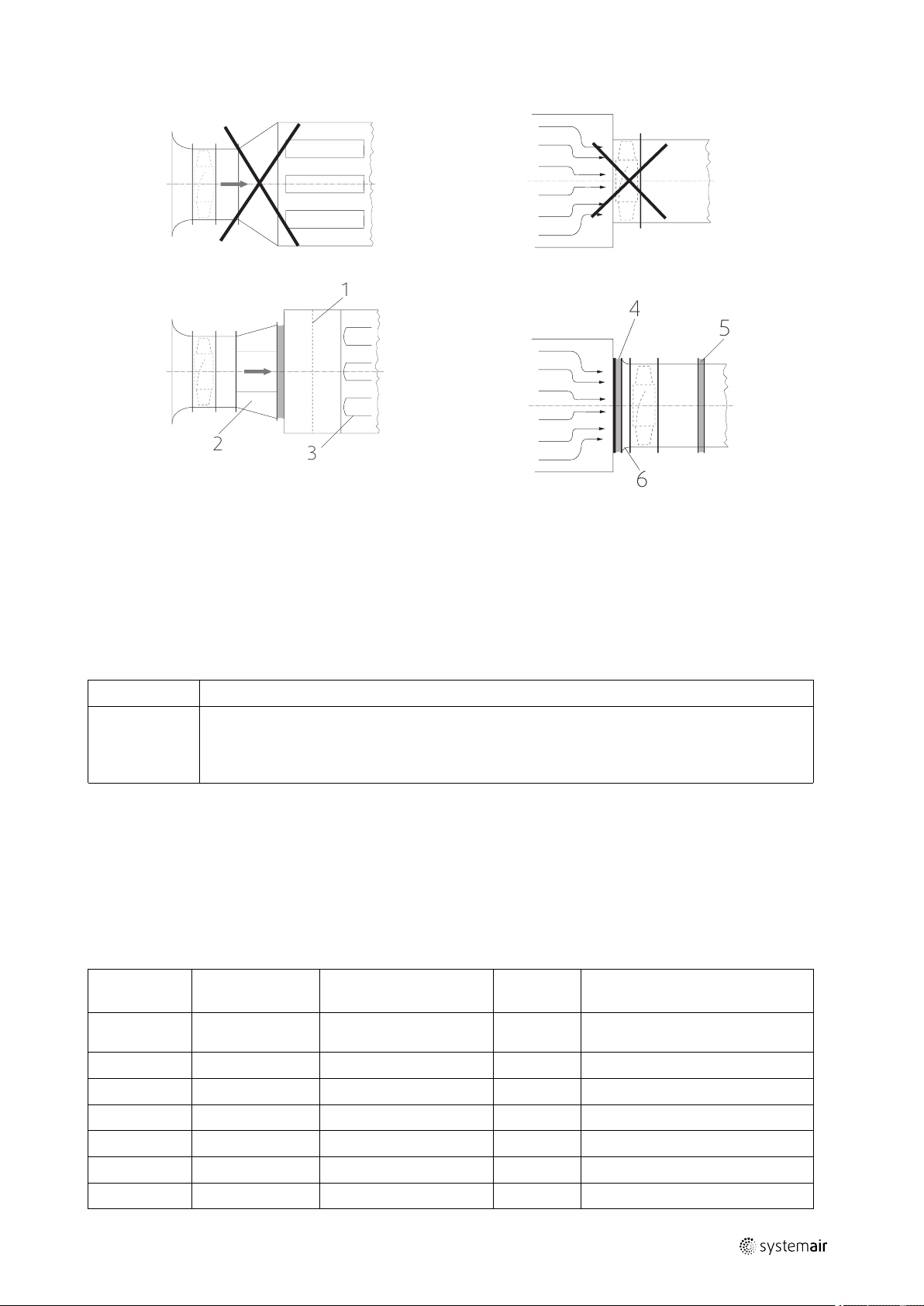

7.7.4 Installation silencer

♦ Ensure correct installation of the silencer.

• This can cause damage to the bearings or other parts of the fan.

• The duty point may not be reachable.

• The fan may make noise.

♦ Ensure a direct, smooth and constant air flow to the device. Ensure a free exhaust, see the following pictures.

♦ To reduce transmission of vibration to the duct system, we recommend flexible connections from our accessory

range, see 5.2.4 Accessories, page 8.

| 003

Page 23

Installation |

3

1

2

6

4

5

19

1

Plenum box with perforated sheet (flow straightener)

2

Deflector with inner core

3

Baffles

4

Flexible connection

5

Flexible connection

6

Inlet cone

7.7.5 Special points of installation

Type

AXC (B), (K), (F)

AXR (B), (K), (F)

Special points for assembly

Smoke exhaust fans are suitable for installation inside or outside a smoke reservoir, as well as

outdoors. If positioned outside the smoke reservoir, but still inside the building, the fan must be

provided with heat insulation by the customer. The heat insulation must be provided with fire

proof material L120 according to DIN 4102-4.

7.7.6 Air gap

Ensure that the air gap between the housing and the impeller is complied with.

♦ Check if the air gap complies with the table.

♦ Do not install the fan if the gap in the table below is not complied with.

♦ Contact Systemair.

Table 11 Air gap AXC/AXR

AXC/AXR

(K) + (B)

Nominal

width

315

355

400

450

500

560

Housing tolerance

+/– 1mm

+/– 1mm

+/– 1mm

+/– 1mm

+/– 1mm

+/– 1mm

AXC/AXR (Standard

temperature)

Rotor Ø Rotor Ø Rotor Ø

312 mm 310 mm 306 mm

352 mm 350 mm 346 mm

397 mm 395 mm 391 mm

445 mm 443 mm 440 mm

495 mm 493 mm 489 mm

555 mm 551 mm 547 mm

AXC/AXR (F)

| 003

Page 24

| Installation

20

Air gap AXC/AXR cont'd

630

710

800

900

1000

1120

1250

1400

1600

+/– 1mm

+/– 1mm

+/– 1mm

+/– 1mm

+/– 2mm

+/– 2mm

+/– 2mm

+/– 2mm

+/– 3mm

625 mm 621 mm 615 mm

705 mm 701 mm 695 mm

795 mm 789 mm 783 mm

895 mm 889 mm 881 mm

992 mm 988 mm 978 mm

1112 mm 1105 mm 1095 mm

1242 mm 1234 mm 1223 mm

1386 mm 1383 mm 1370 mm

1583 mm 1581 mm 1567 mm

7.8 Installation jet fans AJR, AJ8 and IV

Always install in a horizontal position.

7.8.1 Air gap

Ensure that the air gap between the housing and the impeller is complied with.

♦ Check if the air gap complies with the table.

♦ Do not install the fan if the gap in the table below is not complied with.

♦ Contact Systemair.

Table 12 Air gap

Nominal

width

315

355

400

Housing tolerance

+/– 1 mm

+/– 1 mm

+/– 1 mm

AJR/AJ8 (Standard temperature) AJR/AJ8

(K) + (B)

Rotor Ø Rotor Ø Rotor Ø

312 mm 310 mm 306 mm

352 mm 350 mm 346 mm

397 mm 395 mm 391 mm

AJR/AJ8 (F)

7.8.2 Deflector

For optimal guidance of the air current, a deflector made of galvanized steel sheet can be mounted on the pressureside silencer (accessory).

The deflector as accessory for AJR/AJ8 is delivered in a separate package.

♦ Before installing the jet fan, fasten the deflector on the silencer of the pressure side (see arrow).

♦ Position the deflector fins so that after fastening the jet fan to the ceiling, the air flow is directed downwards at a

10° angle. It may be possible to readjust the fans afterwards depending on the structures located in the immediate

vicinity, such as girders.

| 003

Page 25

Electrical connection |

A

B

C

D

A — Position the fins to the specified angle and secure

them with 4.2 x 13 self-drilling screws..

B — Use M4 x 12 self- locking screws to fasten the

deflector to the fan.

C— Fasten the deflector with an M6 x 40 screw, an M6

nut and a Ø6 serrated washer.

D— Position the fins to specified angle and secure them

with 4.2 x 13 self-drilling screws.

21

8 Electrical connection

8.1 Safety information

Warning: Danger from electrical voltage.

♦ Observe the 5 rules of electrical safety, see 2.3 5 rules of electrical safety, page 2.

♦ Prevent the ingress of water into the connection box.

♦ Electrical connection may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page

2.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 2.

8.2 Preconditions

♦ Observe and respect local conditions, regulations and laws.

♦ Abide by the system-related conditions and requirements of the system manufacturer or plant constructor.

♦ Safety elements may not be dismantled, circumvented or deactivated.

♦ Install a circuit breaker in the permanent electrical installation, with a contact opening of at least 3 mm at each pole.

8.3 Protecting the motor

Important

| 003

Damage as a result of motor overheating.

The motor can overheat and be destroyed if the thermo-contacts or cold conductor have not been

functionally connected.

♦ Always connect thermo-contacts or cold conductors to a motor protection device.

Page 26

| Electrical connection

22

Table 13 Motor protection

Type

AXC,-B,-D,-G,-P By customer PTC

AXC (B),(F),(K)

AXR (B),(F),(K)

AXR By customer PTC

AXCBF By customer PTC

AJ8 (B), (K), (F)

AJR (B), (K), (F)

AJ8

AJR

Motor protection

By customer- must be

bypassed in case of fire

By customer- must be

bypassed in case of fire

By customer PTC

Thermal protection,

standard

without (PTC optional)

without (PTC optional)

Speed regulation

Possible via frequency converter

Possible via frequency converter—

must be bypassed in case of fire

Possible via frequency converter

Possible via frequency converter

Possible via frequency converter—

must be bypassed in case of fire

Possible via frequency converter

8.4 Connection

♦ Check that the data on the name plate matches the connection data.

♦ Complete the electrical connection according to the circuit diagram.

♦ Lay the connection cables in the terminal box in such a way that allows the cover of the terminal box to be closed

without resistance.

♦ Use all of the locking screws.

♦ Insert the screws by hand to avoid damaging the thread.

♦ Tighten all glands well in order to guarantee protection class IP.

♦ Screw the lid of the terminal box/REV switch evenly tight.

♦ Connect the cable end in a dry environment!

Type

AXC,-B,-D,-G

AXR

AXC (B), (K), (F)

AXR (B), (K), (F)

AXCBF

AJ8 (B), (K), (F)

AJR (B), (K), (F)

AJ8

AJR

Electrical Connection

Connection via terminal box. The terminal box is fitted on the outside of the housing.

Connection via terminal box. The terminal box is fitted on the outside of the housing.

Connection via terminal box. The terminal box is fitted on the outside of the housing.

Connection via terminal box. The terminal box is attached to the motor.

Connection via terminal box. The terminal box is fitted on the outside of the housing.

Connection via terminal box. The terminal box is fitted on the outside of the housing.

| 003

Page 27

8.4.1 Connection diagrams

3–phase motor with

optional thermal

contacts or cold

conductor.

Electrical connection |

23

Dahlander motor

with optional

thermal contacts or

cold conductor.

Motor, 2 windings

with optional

thermal contacts or

cold conductor.

8.5 Frequency converter (if used)

Risk from resonant frequencies when using frequency converter.

♦ Only operate the fan outside these speed ranges.

♦ Pass through these speed ranges so quickly that any vibration cannot exceed the admissible resonant frequency

values.

♦ For variable-speed fans, use a permanent vibration monitoring for long-term safe operation.

♦ Observe the operating instructions of the frequency converter.

| 003

Page 28

Commissioning

|

24

Commissioning of the frequency converter

♦ Install the fan and frequency converter as near as possible to one another.

♦ Use shielded cables.

♦ All components (fan, frequency converter and motor) must be grounded.

♦ We recommend using all-pole sinus filters.

Operation of the frequency converter

♦ Avoid running the fan via the frequency converter below 10 Hz.

♦ If controlling the fans via a frequency converter, provide thermal protection in the form of a PTC resistor or thermal

contacts (TC) in the motor.

♦ Starting time: min. 60 sec.

8.6 Protective grounding wire

• The terminal box is provided with a labeled grounding connection.

• The protective grounding must have a cross-section equal to or greater than that of the phase conductor.

8.7 Residual current circuit breaker

♦ Observe and respect local conditions, regulations and laws.

♦ If controlling the fans via a frequency converter, provide thermal protection in the form of a PTC resistor or thermal

contacts (TC) in the motor.

9 Commissioning

9.1 Safety information

♦ Commissioning may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page 2.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 2

9.2 Preconditions

♦ Installation and electrical connection have been correctly performed.

♦ Residual material from installation and foreign objects have been removed from the fan and ducts.

♦ Inlet and outlet are free.

♦ Safety devices have been fitted.

♦ Ground cable is connected.

♦ Cable glands are tight.

♦ Nominal current (from the name plate) is not exceeded.

♦ Data on the name plate corresponds with the connection data.

9.3 Tests before activation

♦ Check that safety elements and protective grilles are securely fastened.

9.4 Tests when activated

1. Before switching the fan on, check for externally visible damage and ensure that the protective equipment functions

properly.

2. Switch the fan on.

3. Checks:

♦ Direction of rotation/conveyance. The direction of rotation always applies looking at the rotor

♦ Smooth running (any vibrations and noise)

♦ Current consumption

♦ Tightness of all connections

| 003

Page 29

Operation

4. Switch the fan off.

9.5 Commissioning of speed-controlled fans

Check the fan for vibrations at all normal operation speeds during commissioning. Determine and evaluate vibrations

on the housing and bearing areas in accordance with DIN ISO 14694 depending on motor power and positioning.

Measurable vibration velocities depend e.g. on following factors:

• positioning

• bottom section/foundation state

• flow conditions

The working point of the fan, as well as used external devices and accessories, also influence the running

characteristics.

9.6 Adjusting the blade angle

If the working point of the fan has to be changed and it is necessary to adjust the blade angle, please contact

Systemair!

10 Operation

10.1 Safety information

|

25

Warning: Hazard from electrical voltage or moving components.

♦ Operation may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page 2.

♦ The device may only be operated by people who are instructed in and have understood the function and risks, and

can act accordingly.

♦ Abide by the system-related conditions and requirements of the system manufacturer or plant constructor.

10.2 Preconditions

♦ Ensure access only to persons who can safely handle the device.

♦ Only use the fan in accordance with the operating instructions and the operating instructions for the motor.

♦ Safety elements may not be dismantled, circumvented or deactivated.

10.3 Speed-controlled fan operation

Please observe 8.5 Frequency converter (if used), page 23.

11 Troubleshooting/maintenance/repair

11.1 Safety information

♦ Troubleshooting/maintenance/repair may only be carried out by adequately qualified persons, details see Table 1

Qualifications, page 2.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 2

♦ Observe the 5 rules of electrical safety, see 2.3 5 rules of electrical safety, page 2.

♦ Observe and respect local conditions, regulations and laws.

♦ Abide by the system-related conditions and requirements of the system manufacturer or plant constructor.

♦ The rotor has to be at a standstill.

| 003

Page 30

| Troubleshooting/maintenance/repair

26

11.2 Troubleshooting

Table 14 Troubleshooting

Problem Possible causes

Fan does not run

smoothly

Air output of fan

too low

Thermal contacts/

resistors have

triggered

Fan does not

reach nominal

speed

Motor does not

rotate

Rotor imbalance Rebalancing by a specialist company

Soiling on the rotor Clean carefully, rebalance

Material decomposition on

the rotor due to aggressive

material conveyed

Rotor rotates in wrong

direction

Deformation of rotor due to

excessive temperature

Rotor rotates in wrong

direction

Intake or pressure paths are

blocked

Motor overheated

Rotor rotates in wrong

direction

Motor blocked

Electrical devices

(transformer, frequency

converter, etc.) set incorrectly

Defective motor winding

Improperly aligned drive

motor

Mechanical blockage Remove the blockage

Incorrect supply voltage Check the supply voltage, re-establish the voltage supply

Incorrect connection

Corrective actions

Contact Systemair

Change direction of rotation (swap two phases in case of a 3–

phase motor)

Ensure that the temperature does not exceed the certified

value/Install new rotor

Change direction of rotation (swap two phases in case of a 3–

phase motor)

Remove the blockage

Check the cooling impeller (if used), measure the motor

winding (if possible) / contact Systemair

Change direction of rotation (swap two phases in case of a 3–

phase motor)

Contact Systemair

Check and possibly reset setting of the devices

Contact Systemair

Contact Systemair

Disconnect from the power supply, correct the connection, see

circuit diagram

Temperature monitor has

responded

Electronics/motor

overheated

Insufficient cooling Check, if the correct fan is used for your application/improve

Ambient temperature too

high

Note:

For all other damage/defects, please contact Systemair. Defective fans must be completely replaced.

11.3 Maintenance

Draw up maintenance plan

♦ Draw up a regular maintenance plan.

♦ Document the work performed.

Allow the motor to cool down, find and resolve the cause of

the fault

cooling

Check, if the correct fan is used for your application

| 003

Page 31

Troubleshooting/maintenance/repair |

11.3.1 Variable-speed fans

Important

The fan may be destroyed due to unpermitted frequencies.

♦ Pay particular attention to damage from vibrations.

♦ After commissioning, start with shorter maintenance intervals.

♦ If no damage occurs, adjust the maintenance intervals up to the those stated in the operating

instructions.

♦ Responsibility for gradual adaptation is with the system operator.

11.3.2 Maintenance intervals

Conditions Maintenance intervals

monthly biannually annually

Fan unit in rare use (less than once a month) or in emergency operation

Fan unit in use under normal conditions

X X X

-

X X

Note:

The following sections contain suggestions from Systemair on the maintenance intervals.

♦ Shorten the intervals if the fan unit is used in a particularly dirty environment.

27

11.3.3 Monthly maintenance

Check (if present)

Operational readiness of the fan unit Allow the fan to run for 2 hours

Operational readiness of the emergency system Allow the "emergency" system to run for 15 minutes

Function of the “emergency” control Test whether the “emergency” control effectively bridges all

Function of the standstill heating Switch the motor off. The standstill heating must switch on

Measures

the other controls and switches

automatically and remain switched on

11.3.4 Half-yearly maintenance

Check (if present)

Condition of the ventilation system Remove all deposits, dirt and objects, which can influence

Cooling ribs of the motor Remove all contaminations between the ribs of the motor

Fastening components (screws, nuts, cable glands,

etc.)

Blades Remove all dirt and dust deposits. Make sure that the blades

Condition of the safety devices and protective

devices

Measures

proper condition

Check the fastening components (screws, nuts, cable glands,

etc.) and tighten them if necessary.

are tight. Replace any rotors which may be damaged

Clean the safety devices and protective devices

Replace them if there are indications of damage/rust

Condition of the standstill heating Remove the motor from the electric mains

Check whether the standstill heating is activated

11.3.5 Annual maintenance

Check (if present)

Air gap between the blades and the housing of the

fan

| 003

Measures

Make sure that the air gap between the blade and the

housing is correct. See chapter Air gap.

Page 32

| Cleaning

28

Pitch angle setting and the safety of the blades Make sure that the blades are tight. If any changes are

necessary, contact Systemair

Tightening torques of the fan fittings on the base/

foundation

Fittings of the motor, fan and ancillary equipment Make sure that all fittings are present, correct, and as tight as

Condition of the anti-vibration system Check for unusual movement and screw the connection tight

Motor voltage and motor current Make sure that the measured data matches with the data on

Optional lubrication device: regreasing See manual of the motor

Make sure that the tightening torques are as tight as possible

If in doubt about the suitable tightening torques, contact

Systemair

possible

If in doubt about the suitable tightening torques, contact

Systemair.

if necessary

the name plate

Line connections of the fan accessories

Check all line connections (including grounding) for safety

and condition

11.3.6 Overhaul/further maintenance

Pay attention to the safety references and preconditions as in normal maintenance. For the following activities and

functions, contact Systemair:

• complete overhaul of motors

• replacement of bearings

• re-winding of motors

• monitoring of condition

• vibration analysis

11.3.7 After 20,000 hours of operation or 5 years of normal operation

♦ Replace the shaft sealing rings and shaft bearings.

11.3.8 After 30,000 to 40,000 hours of operation

♦ The bearings must be replaced at the end of the grease service life (about 30,000 to 40,000 h in standard

applications).

11.4 Work before switching on again

♦ Attach all the safety and protective devices tightly and securely.

♦ Remove all the devices with which you have blocked the rotor.

♦ Remove all assembly residues and foreign bodies from the area around the fan unit.

11.5 Spare parts

♦ Use original spare parts from Systemair only!

♦ When ordering spare parts, please specify the serial number of the fan. This can be found on the name plate.

12 Cleaning

12.1 Safety information

♦ Cleaning may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page 2.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 2.

♦ Observe the 5 rules of electrical safety, see 2.3 5 rules of electrical safety, page 2!

12.2 Preconditions

♦ The power supply has been switched off (all-pole circuit breaker).

| 003

Page 33

Deinstallation/dismantling |

♦ The rotor is at a standstill.

12.3 Procedure

Note:

Keeping the fan clean extends its service life.

♦ Install a filter monitor.

♦ Do not use steel brushes or sharp-edged objects.

♦ Do not use a high-pressure cleaner (steam jet cleaner) under any circumstances.

♦ Do not bend the fan blades when cleaning.

♦ When cleaning the rotor, pay attention to balance weights that have been positioned.

♦ Keep the airways of the fan clear and clean them if necessary with a brush.

13 Deinstallation/dismantling

Deinstall and dismantle the fan in reverse order of installation (7 Installation, page 14) and electrical connection (8 Electrical connection, page 21).

14 Disposal

29

♦ Ensure material is recycled. Observe national regulations.

♦ The device and the transport packaging are predominantly made from recyclable raw materials.

♦ Disassemble the fan into its components.

♦ Separate the parts according to:

• reusable material

• material groups to be disposed of (metal, plastics, electrical parts, etc.)

| 003

Page 34

| EU Declaration of conformity — Axial fans

30

15 EU Declaration of conformity — Axial fans

The manufacturer: Systemair GmbH

Seehöfer Straße 45

97944 Boxberg

Germany

Product designation: Axial Fans

Type designation:

Since of manufacture:

The manufacturer declares that the above mentioned products in their design and construction and the version

marketed by us complies with the Harmonization legislation listed below:

EU directives: 2006/42/EC Machinery directive

Regulations: 327/2011 only for fans above 125W, CE marked

The following standards have been considered:

Harmonized standards:

AXC; AXC (K); AXC (B); AXC (F); AXC-G; AXC (B)-G; AXC-P; AXC (B)-P; AXS;

AXC-E; AXC-EK; AXC(B)- EK; AXR; AXR (K); AXR (B); AXR (F); AXCBF; AXS; AJ;

AJ (K); AJ (B); AJ (F); AJ-TR; AR; AW

2016

2014/30/EU Directive electromagnetic compatibility

(EMC)

2011/65/EU RoHS directive

2009/125/EC ErP guidelines

fans used as components are CE

marked by other manufacturer.

DIN EN ISO 12100:2013

DIN EN 60204-1:2010

DIN EN 61000-6-1:2007

DIN EN 61000-6-2:2011

DIN EN 12101-3:2015*

Safety of machinery - General

principles for design Riskassessment

and risk reduction

Safety of machinery - Electrical

equipment of machines - Part1: General

requirements

Electromagnetic compatibility (EMC) Part 6-1: Generic standards - Immunity

for residential, commercial and lightindustrial environments

Electromagnetic compatibility (EMC) Part 6-2: Generic standards - Immunity

for industrial environments

Smoke an heat control systems, Part 3:

Specification for powered smoke and

heat exhaust ventilators

*only smoke extract fans

Boxberg, 20.04.2016

ppa. Harald Rudelgass, technical director

| 003

Page 35

16 Commissioning Report

Fan

Description:

Article no.: Manufacturing order no.:

Installer

Company: Contact person:

Company address:

Tel. no.: Email:

Operator (Place of installation)

Company: Contact person:

Company address:

Tel. no.: Email:

Commissioning Report

|

31

Type of connection

Directly to mains

0-10 V signal (EC motor)

via contactor control

Transformer

Frequency converter

Sinus filter

Shielded cables

Motor protection

Motor protection switch or motor protection relay

PTC resistor

Resistance value [Ω]:

Thermal contact

Electrical motor protection

Others:

Functional check

Impeller easily rotatable (by hand)

Rotation direction acc. to directional arrow

Yes No

□ □

□ □

□ □

□ □

□ □

□ □

□ □

Yes No

□ □

□ □

□ □

□ □

Yes No

□ □

□ □

Nominal data - Fan (name plate on fan housing)

Voltage [V]: Current [A]:

Frequency [Hz]: Power [kW]:

Fan impeller speed [rpm]:

| 003

Page 36

Commissioning Report

|

32

Measured data at commissioning

Voltage [V]: Temp. of transported air [°C]:

Current L1 [A]*:

Fan impeller speed [rpm]:

Current L2 [A]: Air volume [m3/s]:

Current L3 [A]:

*For single-phase fans, fill in line “Current L1 [A]” *Δ- Pressure between suction-side and discharge of the fan

Differential pressure [Pa]*:

If an air flow measurement is not possible, this value can be calculated using the following formula:

=

Air volume [m³/s]:

Duct cross-section [m²]

X

Flow speed [m/s]

Grille measurement acc. to VDI 2044

Yes No

Commissioning of the fan successful?

□ □

Date, installer's signature

Date, operator's signature

Please keep the completed commissioning report in a safe place. In the case of a warranty claim, this report can

be requested by Systemair GmbH. This document can also be downloaded from our online catalogue.

For technical questions, please contact the technical support division of Systemair GmbH (tel. +49 7930/9272 730).

| 003

Page 37

| 003

Page 38

Systemair GmbH

Seehöfer Str. 45

97944 Boxberg

Germany

Tel.: +49 (0)7930/9272-0

Fax: +49 (0)7930/9273-92

info@systemair.de

www.systemair.de

Axial Fans/Jet fans · Installation and Operating Instructions · · en_GB · 2017-09-26 · 003

Loading...

Loading...