Page 1

Air Cooled Water Chillers and Heat Pumps

Refroidisseurs de liquide à condensation par air et pompes à chaleur air-eau

Luftgekühlte Flüssigkeitskühler und Wärmepumpen

Refrigeratori d’Acqua e Pompe di Calore Raffreddati ad Aria

Enfriadores de Agua y Bomba de Calor Condensadas con Aire

Installation and maintenance manual

Manuel d'installation et de maintenance

Installations- und Wartungshandbuch

Manuale di installazione e di manutenzione

Manual de instalación y de mantenimiento

Part number / Code / Code / Codice / Código: 342605/A

Supersedes / Annule et remplace / Annulliert und ersetzt / Annulla e sostituisce /

Anula y sustituye: 035B09058-000

Notified Body / Organisme Notifié / Benannte Zertifizierungsstelle / Organismo

Notificato / Organismo Notificado N°. 1115

”

English Deutsch EspañolItalianoFrançais

380

634 kW

418

702 kW

AQWL/AQWH

AQWC/AQWR

ISO 9001:2008 certified management system

Page 2

Page 3

1

English

Table of Contents

1 - FOREWORD

1.1 Introduction..........................................................................2

1.2 Warranty..............................................................................2

1.3 Emergency stop/Normal stop ...............................................2

1.4 An introduction to this manual ..............................................2

2 - SAFETY

2.1 Foreword..............................................................................3

2.2 Definitions............................................................................ 4

2.3 Access to the unit ...............................................................4

2.4 General precautions..............................................................4

2.5 Precautions against residual risks.........................................4

2.6 Precautions during maintenance operations ..........................5

2.7 Safety labels ................................................................. 6 & 7

2.8 Safety regulations........................................................8 to 10

3 - TRANSPORT, LIFTING AND POSITIONING

3.1 Inspection ..........................................................................11

3.2 Lifting ................................................................................11

3.3 Anchoring ..........................................................................12

3.4 Storage ..............................................................................12

4 - INSTALLATION

4.1 Positioning of the unit......................................................... 13

4.2 Spring isolator installation.......................................... 13 & 14

4.3 External hydraulic circuit............................................ 14 & 15

4.4 Hydraulic connections .......................................................15

4.5 Draining the defrosting waste water (AQWH only) .............. 15

4.6 Power supply .....................................................................16

4.7 Electrical connections................................................ 16 & 17

4.8 Connecting plate-type evaporator

temperature sensors ................................................. 18 & 19

4.9 Total heat recovery features................................................19

5 - START-UP

5.1 Preliminary check...............................................................20

5.2 Start-up .............................................................................20

5.3 Checking the operation.......................................................20

5.4 Delivery to the customer..................................................... 20

6 - CONTROL

6.1 The “Chiller Control” system...............................................21

6.2 Display...............................................................................22

6.3 Keyboard ...........................................................................22

6.4 Protection and Safety Equipment ........................................25

6.5 HPF version configuration................................................... 26

7 - PRODUCT DESCRIPTION

7.1 Introduction........................................................................27

7.2 General specifications ........................................................27

7.3 Compressors .....................................................................27

7.4 Refrigeration circuits ..........................................................27

7.5 Water heat exchanger.........................................................27

7.6 Air heat exchanger..............................................................27

7.7 Fans...................................................................................27

7.8 Electrical power supply and control system .......................28

7.9 Accessories ......................................................................28

8 - TECHNICAL DATA

8.1 Pressure drops...................................................................33

8.2 Technical data ........................................................... 34 to 43

8.3 Unit electrical data..................................................... 44 & 45

8.4 Hydraulic Features..................................................... 46 & 47

8.5 Position of shock adsorbers

and weight distribution on supports ....................................48

8.6 Dimensional Drawings............................................... 49 to 51

8.7 Service spaces................................................................... 52

9 - MAINTENANCE

9.1 General requirements ........................................................53

9.2 Planned maintenance .........................................................53

9.3 Refrigerant charge.............................................................. 54

9.4 Compressor .......................................................................54

9.5 Condenser ........................................................................ 54

9.6 Fans...................................................................................54

9.7 Dehydrating filter ................................................................54

9.8 Sight glass.........................................................................55

9.9 Electronic expansion valve.................................................. 55

9.10 Evaporator .........................................................................55

10 - TROUBLESHOOTING .......................................... 56

11 - SPARE PARTS

11.1 Spare par t list.....................................................................57

11.2 Oil for compressors............................................................57

11.3 Wiring diagrams ................................................................. 57

12 - DISMANTLING, DEMOLITION AND SCRAPPING

12.1 Generalities ........................................................................58

Page 4

2

1 - Introdução

1 - Foreword

1.1 Introduction

Units, manufactured to state-of-the-art design and implementation

standards, ensure top performance, reliability and fitness to any type

of air-conditioning systems.

These units are designed for cooling water or glycoled water (and for

water heating in heat pump models) and are unfit for any purposes

other than those specified in this manual.

This manual includes all the informatio n required for a proper

installation of the u nits, as well as the relevant operati ng and

maintenance instructions.

It is therefore recommended to read this manual carefully before

installation or any operation on the machine. The chiller installation

and maintenance must be carried out by skilled personnel only

(where possible, by one of Authorised Service Centers).

The manufacturer may not be held liable for any damage to people or

property caused by improper installation, start-up and/or improper

use of the unit and/or failure to implement the procedures and

instructions included in this manual.

1.2 Warranty

These units are delivered complete, tested and ready for being

operated. Any form of warranty will become null and void in the event

that the appliance is modified without manufacturer’s preliminary

written authorisation.

This warranty shall apply providing that the installation instructions

have been complied with (either issued by manufacturer, or deriving

from the current practice), and the Form 1 (“Start-up”) has been

filled-in and mailed to manufacturer (attn. After-Sales Service).

In order for this warranty to be valid, the following conditions shall be

met :

QThe machine must be operated only by skilled personnel from

Authorised After-Sales Service.

QMaintenance must be performed only by skilled personnel - from

one of Authorised After-Sales Centers.

QUse only original spare parts.

QCarry out all the planned maintenance provided for by this manual

in a timely and proper way.

Failure to comply with any of these conditions will automatically void

the warranty.

1.3 Emergency stop / Normal stop

The emergency stop of the unit can be enabled using the master

switch on the control panel (move down the lever).

For a normal stop, press the relevant push-buttons.

To restart the appliance, follow the procedure detailed in this manual.

1.4 An introduction to the manual

For safety reasons, it is imperative to follow the instructions given in

this manual. In case of any damage caused by non-compliance with

these instructions, the warranty will immediately become null and

void.

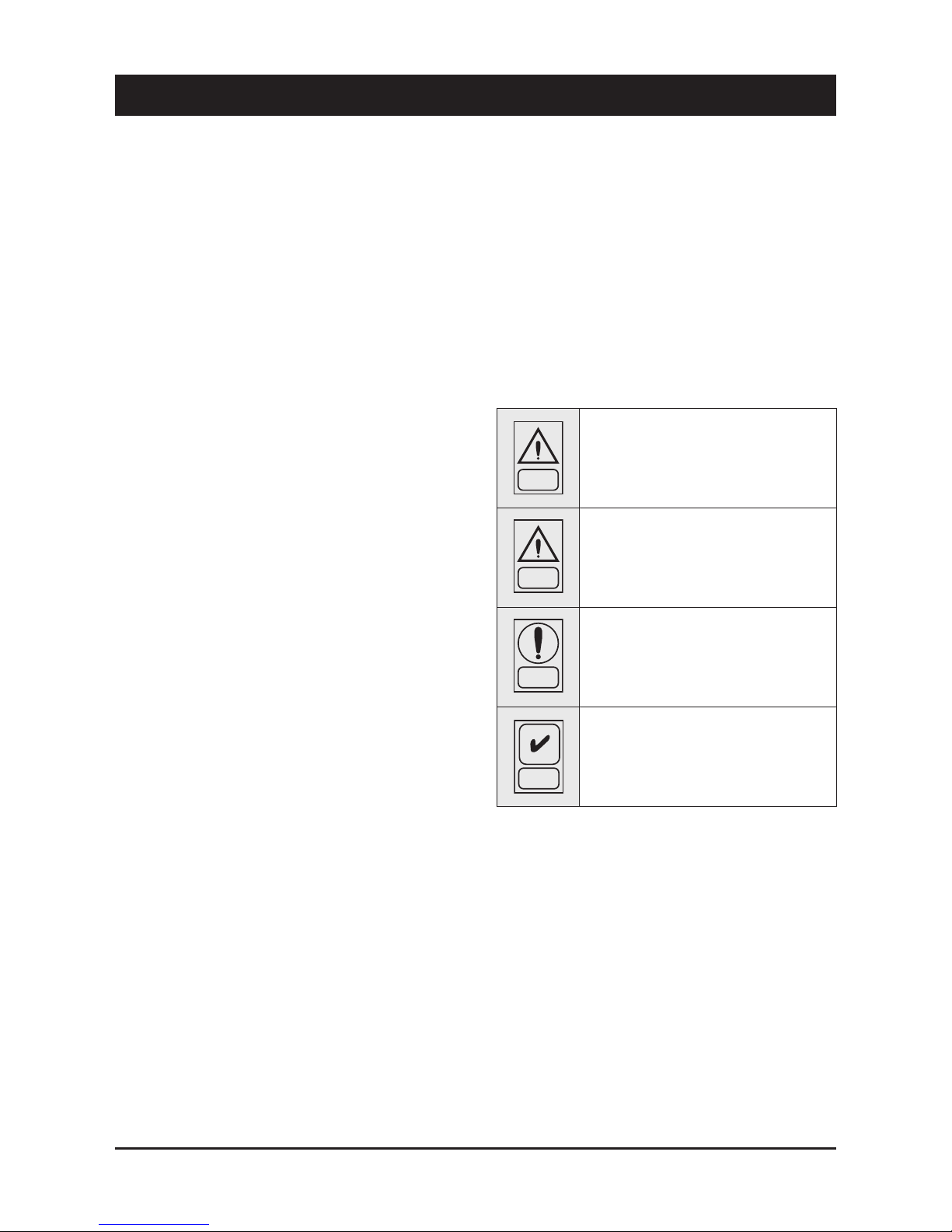

Conventions used throughout the manual:

DANGER

The Danger sign recalls your attention to a

certain procedure or practice which, if not

followed, may result in serious damage to

people and property.

The Warning sign precedes those procedures

that, if not followed, may result in serious

damage to the appliance.

The Notes contain important observations.

The Useful Tips provide valuable information

that optimises the efficiency of the appliance.

This manual and its contents, as well as the documentation which

accompanies the unit, are and remain the property of manufacturer,

whic h re serves any and all righ ts t hereon. This ma nu al may

not be copied, in whole or in part, without manufacturer’s written

authorization.

WARNING

NOTE

USEFUL TIPS

Page 5

3

English

2 - Safety

2.1 Foreword

These units must be installed in conformity with the

provisions of Machinery Directive 2006/42/EC, Low Voltage

Directive 2006/95/EC, Pressure Vessels Directive 97/23/

EC, Electromagnetic Interference Directive 2004/108/EC,

as well as with other regulations applicable in the country

of installation. If these provisions are not complied with, the

unit must not be operated.

DANGER

The unit must be grounded, and no

installation and/or maintenance operations

may be carried out before deenergising the

electrical panel of the unit.

Failure to respect the safety measures mentioned above may result

in electrocution hazard and fire in the presence of any short-circuits.

DANGER

Inside the heat exchangers, the compressors

and the refrigeration lines, this unit contains

liqu id and ga seous re frigera n t under

pressure. The release of this refrigerant may

be dangerous and cause injuries.

DANGER

The units are not designed to be operated with

natural refrigerants, such as hydrocarbons.

Manufacturer may not be held liable for any

problems deriving from the replacement

of original refrigerant or the introduction of

hydrocarbons.

Units are designed and manufactured according to the requirements

of European Standard PED 97/23/EC (pressure vessels).

QThe used refrigerants are included in group II (non-hazardous

fluids).

QThe maximum working pressure values are mentioned on the

unit’s data plate.

QSuitable safety devices (pressure switches and safety valves)

have been provided, to prevent any anomalous overpressure

inside the plant.

QThe vents of the safety valves are positioned and oriented in such

a way as to reduce the risk of contact with the operator, in the

event that the valve is operated. Anyway, the installer will convey

the discharge of the valves far from the unit.

QDedicated guards (removable panels with tools) and danger signs

indicate the presence of hot pipes or components (high surface

temperature).

DANGER

The guards of the fans (only for units provided

with air heat exchangers) must be always

mounted and must never be removed before

de-energising the appliance.

DANGER

It is the User’s responsibility to ensure that

the unit is fit for the conditions of intended use

and that both installation and maintenance are

carried out by experienced personnel, capable

of resp ecti ng all th e recomme ndat ions

provided by this manual.

It is important that the unit is adequately

supported, as detailed in this manual. Noncompliance with these recommendations may

create hazardous situations for the personnel.

DANGER

The unit must rest on a base which meets the

characteristics specified in this manual; a

base with inadequate characteristics is likely

to become a source of serious injury to the

personnel.

WARNING

Th e unit ha s not bee n design to withst and

loads and/or stress that may be transmitted by

adjacent units, piping and/or structures.

Each external load or stress transmitted to the

unit ma y break or cause breakdowns in t he

unit’s structure, as well as serious dangers to

people. In these cases, any form of warranty will

automatically become null and void.

WARNING

The packaging material must not be disposed of

in the surrounding environment or burnt.

Page 6

4

2.2 Definitions

OWNER: means the legal representative of the company, body or

individual who owns the plant where unit has been installed; he/she

has the responsibility of making sure that all the safety regulations

specified in this manual are complied with, along with the national

laws in force.

INSTALLER: means the legal representative of the company who

has been given by the owner the job of positioning and performing

the hydraulic, electric and other connections of unit to the plant: he/

she is responsible for handling and properly installing the appliance,

as specified in this manual and according to the national regulations

in force.

OPERATOR: means a person authorised by the owner to do on unit

all the regulation and control operations expressly described in this

manual, that must be strictly complied with, without exceeding the

scope of the tasks entrusted to him.

ENGINEER: means a person authorised directly by manufacturer or,

in all EC countries, excluding Italy, under his full responsibility, by

the distributor of product, to perform any routine and extraordinary

maintenance operations, as well as any regulation, control, servicing

operations and the replacement of pieces, as may be necessary

during the life of the unit.

2.3 Access to the unit

The unit must be placed in an area which can be accessed also

by OPERATORS and ENGINEERS; ot herwise the unit must be

surrounded by a fence at not less than 2 meters from the external

surface of the machine.

OPERATORS and ENGINEERS must enter the fenced area only

after wearing suitable clothing (safety shoes, gloves, helmet etc.).

The INSTALLER personnel or any other visitor must always be

accompanied by an OPERATOR.

For no reason shall any unauthorised personnel be left alone in

contact with the unit.

2.4 General precautions

The OPERATOR must simply use the controls of the unit; he must not

open any panel, other than the one providing access to the control

module.

The INSTALLER must simply work on the connections between plant

and machine; he must not open any panels of the machine and he

must not enable any control.

When you approach or work on the unit, follow the precautions listed

below:

Qdo not wear loose clothing or jewellery or any other accessory tat

may be caught in moving parts

Qwear suitable personal protective equipment (gloves, goggles

etc.) when you have to work in the presence of free flames

(welding operations) or with compressed air

Qif the unit is placed in a closed room, wear ear protection devices

Qcut off connecting pipes, drain them in order to balance the

pressure to the atmospheric value before disconnecting them,

disassemble connections, filters, joints or other line items

Qdo not use your hands to check for any pressure drops

Quse tools in a good state of repair; be sure to have understood the

instructions before using them

Qbe sure to have removed all tools, electrical cables and any other

objects before closing and starting the unit again

2.5 Precautions against residual risks

Prevention of residual risks caused by the control

system

Qbe sure to have perfectly understood the operating instructions

before carrying out any operation on the control panel

Qwhen you have to work on the control panel, keep always the

operating instructions within reach

Qstart the unit only after you have checked its perfect connection to

the plant

Qpromptly inform the ENGINEER about any alarm involving the unit

Qdo not reset manual restoration alarms unless you have identified

and removed their cause

Prevention of residual mechanical risks

Qinstall the unit according to the instructions provided in this

manual

Qcarry out all the periodical maintenance operations prescribed by

this manual

Qwear a protective helmet before accessing the interior of the unit

Qbefore opening any panelling of the machine, make sure that it is

secured to it by hinges

Qdo not touch air condensation coils without wearing protective

gloves

Qdo not remove the guards from moving elements while the unit is

running

Qcheck the correct position of the moving elements’ guards before

restarting the unit

Prevention of residual electrical risks

Qconnect the unit to the mains according to the instructions

provided in this manual

Qperiodically carry out all the maintenance operations specified by

this manual

Qdisconnect the unit from the mains by the external disconnecting

switch before opening the electrical board

Qcheck the proper grounding of the unit before start-up

Qcheck all the electrical connections, the connecting cables, and in

particular the insulation; replace worn or damaged cables

2 - Safety (continued)

Page 7

5

English

Qperiodically check the board’s internal wiring

Qdo n ot use cables h aving an in ad equate se ct ion or flyi ng

connections, even for limited periods of time or in an emergency

Prevention of other residual risks

Qmake sure that the connections to the unit c on form to the

instructions provided in this manual and on the unit’s panelling

Qif you have to disassemble a piece, make sure that it has been

properly mounted again before restarting the unit

Qdo not touch the delivery pipes from the compressor, the

compresso r and any othe r piping or component ins ide the

machine before wearing protective gloves

Qkeep a fire extinguisher fir for electrical appliances near the

machine

Qon the units installed indoor, connect the safety valve of the

refrigeration circuit to a piping network that can channel any

overflowing refrigerant outside

Qremove and leak of fluid inside and outside the unit

Qcollect the waste liquids and dry any oil spillage

Qperiodically clean the compressor compartment, to remove any

fouling

Qdo not store flammable liquids near the unit

Qdo not disperse the refrigerant and the lubricating oil into the

environment

Qweld only empty pipes; do not approach flames or other sources

of heat to refrigerant pipes

Qdo not bend/hit pipes containing fluids under pressure

2.6 Precautions during maintenance operations

Maintenance operations can be carried out by authorised technicians

only.

Before performing any maintenance operations:

Qdisc o n nect the uni t f rom th e m a ins w ith the e x ternal

disconnecting switch

2 - Safety (continued)

Qplace a warning sign “do not turn on - maintenance in progress”

on the external disconnecting switch

Qmake sure that on-off remote controls are inhibited

Qwear suitable personal protective equipment (helmet, safety

gloves, goggles and shoes etc.)

To carry out an y measur em en ts or checks which require the

activation of the machine:

Qwork with the electrical board open only for the necessary time

Qclose the electrical board as soon as the measurement or check

has been completed

Qfor outdoor units, do not carry out any operations in the presence

of dangerous climatic conditions (rain, snow, mist etc.)

The following precautions must be always adopted:

Qdo n ot scatter th e fluids of t he refriger at ion circu it in the

surrounding environment

Qwhen replacing an eprom or electronic cards, use always suitable

devices (extractor, antistatic bracelet, etc.)

Qto replace a compressor, the evaporator, the condensing coils or

any other weighty element, make sure that the lifting equipment is

consistent with the weight to be lifted

Qin air units with independent compressor compartment, do not

access the fan compartment unless you have disconnected the

machine by the disconnecting switch on the board and you have

placed a warning sign “do not turn on - maintenance in progress”

Qcontact manufacturer for any modifications to the refrigeration,

hydraulic or wiring diagram of the unit, as well as to its control

logics

Qcontact manufacturer if it is necessary to perform very difficult

disassembly and assembly operations

Quse only orig i nal s p are p arts purc h ased dire c tly f rom

manufacturer or the official retailers of the companies on the

recommended spare parts list

Qcontact manufacturer if it is necessary to handle the unit one year

after its positioning on site or if you wish to dismantle it.

Page 8

6

2 - Safety (continued)

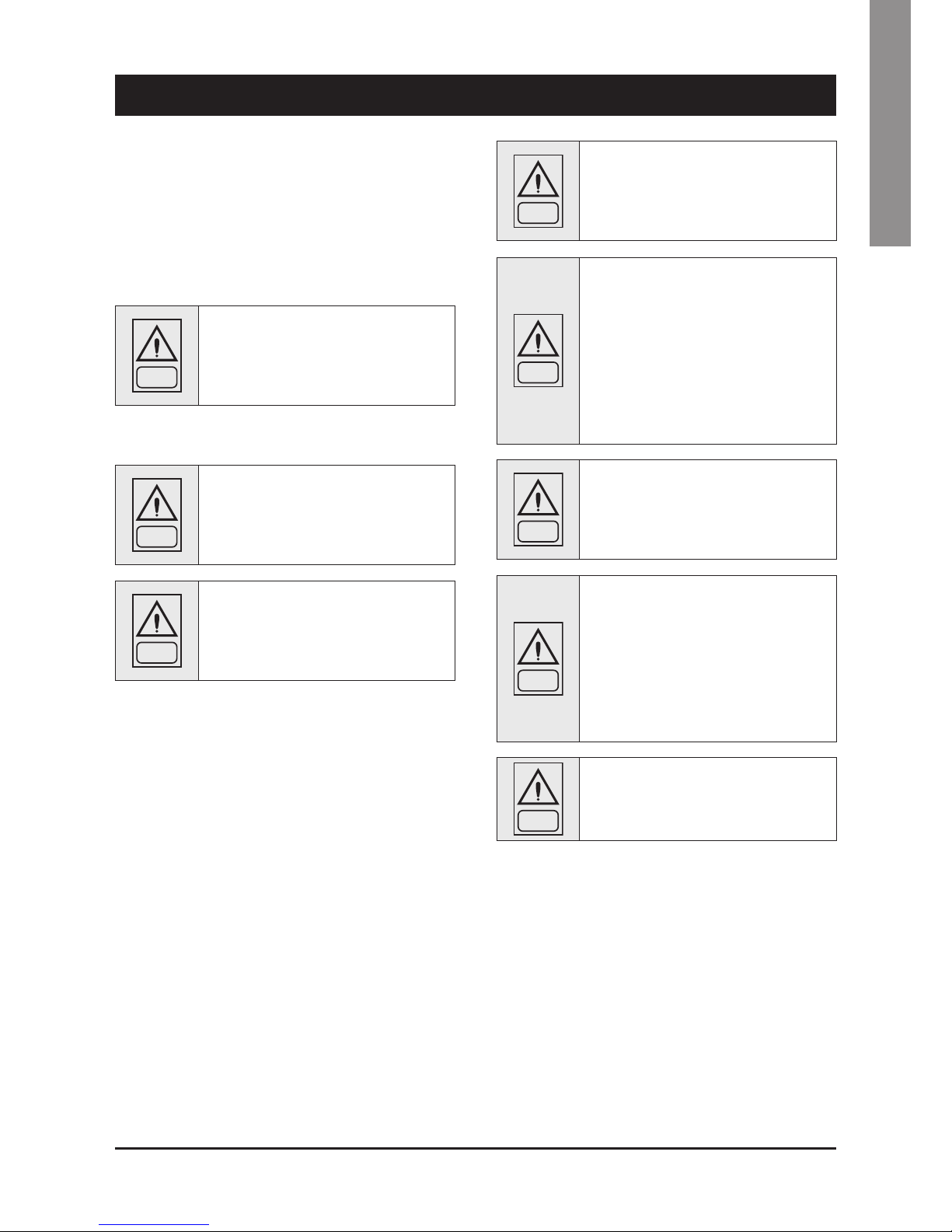

2.7 Safety labels

Identification of the refrigerant - External door

USARE SOLO

R 410A

E

RECUPERARE FLUIDO - NON DISPERDERE NELL’AMBIENTE - REGOLAMENTO CEE N° 3093/94

RECOVER - DO NOT VENT - EEC REGULATION N° 3093/94

SPECIAL ESTER OIL

USE ONLY

Electrical warning - Adjacent to the master switch

ATTENZIONE !

Prima di

aprire togliere

tensione

CAUTION !

Disconnect

electrical

supply before

opening

ACHTUNG !

Vor offne n des

gehauses

hauptschalter

ausschalten

ATENCION !

Cor tar la

corrente antes

de abrir

el aparato

ATTENTION !

Enlever

l’alimentation

electrique

avant d’ouvrir

Read the instruction on the electrical board

On the compressor box

WARNING

Circuit drain - Outside, on the right-hand front column

ATTENTION! Don’t leave the unit with water inside hydraulic circuit during

winter or when it is in stand by.

ATTENZIONE! Non lasciare l’unità con acqua nel circuito idraulico durante

l’inverno o quando non è funzionante.

ATTENTION! Ne laissez pas l’unitè avec de l’eau dans le circuit hydraulique

pendant l’hiver ou quand elle ne travaille pas.

WARNUNG! Lassen Sie nicht das Wasser in die Schaltung während des

Winters oder wenn es nicht funktionient.

¡ATENCÍON! No deje el agua en el circuito hidráulico durante el invierno o

cuando no esta trabajando.

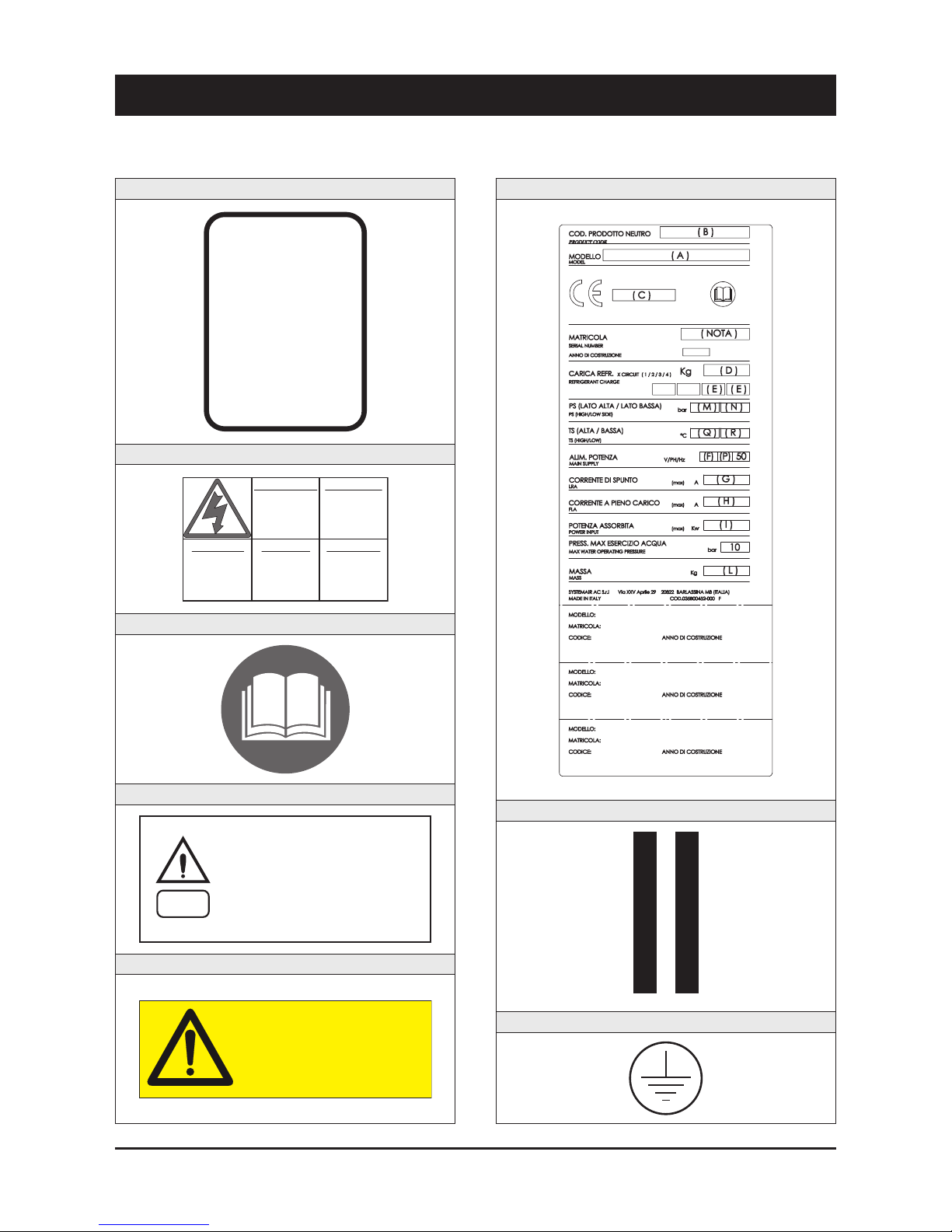

Identification of the unit - Outside, on the right-hand front column

Gravity centre - Base

TENERE SU QUESTA LINEA

GANCIO DI SOLLEVAMENTO

KEEP LIFT HOOK

ON THIS LINE

Grounding connection on the electrical board, adjacent to the connection

DO NOT OPEN THE PANEL

WHILE UNIT IS RUNNING

Page 9

7

English

2 - Safety (continued)

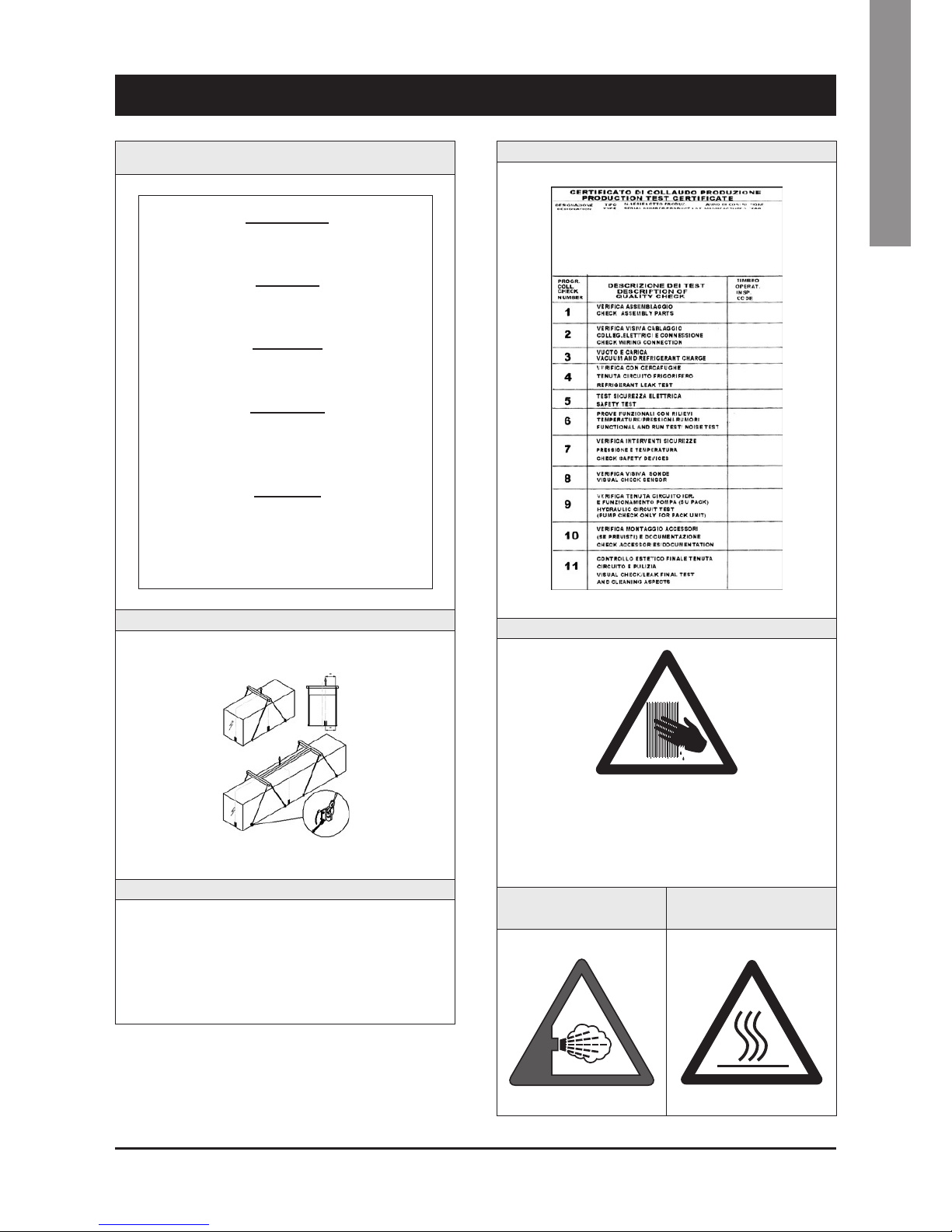

Final Test Certificate - Inside the external door

On the coil

ATTENZIONE! BORDI TAGLIENTI

VORSICHT! SCHARFE RÄNDER

CAUTION! SHARP EDGES

ATTENTION! BORDS COUPANTS

ATENCION! PERFIL AFILADO

Warning - Safety valve vents

Warning - High temperature

zone adjacent to hot pipes or

components

Start-up warning - Outside the door

of the electrical board

ATTENZIONE

INSERIRE LE RESISTENZE DI RISCALDAMENTO OLIO ALMENO 12

ORE PRIMA DI OGNI AVVIAMENTO (SE PREVISTE)

PRIMA DELLA MESSA IN TENSIONE ASSICURARSI CHE LE VITI DEI

CIRCUITI ELETTRICI SIANO SERRATE COMPLETAMENTE

WARNING

ENERGIZE THE CRANCKCASE HEATER FOR AT LEAST 12 HOURS

BEFORE EACH STARTING (IF FITTED)

BEFORE TIGHTENING-UP, TO TIGHTEN ALL TERMINAL SCREWS

ESPECIALLY THOSE IN MAIN CIRCUIT

WARNUNG

OLSUMPFHEIZUNG (FALLS VORHANDEN) 12 STUNDEN VOR DEM

START EINSCHALTEN

VOR INBETRIEBNAHME ALLE SCHRAUBENVERBINDUNGEN

NACHZIEHEN, BESONDERS DIE ELEKTRISCHEN ANSCHLUSSE

ATTENTION

ALIMENTER ELECTRIQUEMENT LA RESISTANCE DE CARTER AU

MOINS 12 HEURES AVANT CHAQUE DEMARRAGE (SI MONTE SUR

LE PRODUIT)

AVANT DE DEMARRER LA MACHINE, VERIFIER LE SERRAGE DE

TOUTES LES BORNES A VIS, SPECIALEMENT DANS LE BOITIER

ELECTRIQUE

ATENTION

ATENCIÓN ALIMENTAR ELÉCTRICAMENTE LA RESISTENCIA DE

CARTER AL MENOS 12 HORAS ANTES DE CADA PUESTA EN

MARCHA (SI ESTA EQUIPADA EN LA UNIDAD)

ANTES DE LA PUESTA EN MARCHA, COMPROBAR QUE LOS

BORNES ESTAN BIEN APRETADOS, ESPECIALMENTE EN EL

CUADRO ELÉCTRICO

035B00057-000 MADE IN ITALY

Instruction for the lifting

Fitting identification - Adjacent to fittings

EIN - INLET

ENTRÉE - ENTRATA

AUS - OUTLET

SORTIE - USCITA

Page 10

8

2 - Safety (continued)

REFRIGERANT DATA SAFETY DATA: R410A

Toxicity Low

Contact with skin

If sprayed, the refrigerant is likely to cause frost burns. If absorbed by the skin, the danger is very limited;

it may cause a slight irritation, and the liquid is degreasing. Unfreeze the affected skin with water.

Remove the contaminated clothes with great care - in the presence of frost burns, the clothes may stick

to the skin. Wash with plenty of warm water the affected skin.

In the presence of symptoms such as irritation or blisters, obtain medical attention.

Contact with eyes

Vapours do not cause harmful effects. The spraying of refrigerant may cause frost burns.

Wash immediately with a proper solution or with tap water for at least 10 minutes, and then obtain

medical attention.

Ingestion

Very unlikely - should something happen, it will cause frost burns.

Do not induce vomiting. Only if the patient is conscious, wash out mouth with water and give some

250 ml of water to drink. Then, obtain medical attention.

Inhalation

R410A: remarkable concentrations in the air may have an anaesthetic effect, up to fainting.

The exposure to considerable amounts may cause irregular heartbeat, up to the sudden death of the

patient. Very high concentrations may result in the risk of asphyxia, due to the reduction in the oxygen

percentage in the atmosphere. Remove the patient to fresh air and keep warm and at rest.

If necessary, give oxygen. In case of breathing difficulties or arrest, proceed with artificial respiration.

In case of cardiac arrest, proceed with cardiac massage. Then, obtain medical attention.

Recommendations

Semiotics or support therapy is recommended. Cardiac sensitisation has been observed that, in

the presence of circulating catecholamines such as adrenalin, may cause cardiac arrhythmia and

accordingly, in case of exposure to high concentrations, cardiac arrest.

Prolonged exposure

R410A: a study on the effects of exposure to 50,000 ppm during the whole life of rats has identified the

development of benign testicle tumour.

This situation should therefore be negligible for personnel exposed to concentrations equal to or lower

than professional levels.

Professional levels R410A: Recommended threshold: 1000 ppm v/v - 8 hours TWA.

Stability R410A: Not specified

Conditions to avoid Do not use in the presence of flames, burning surfaces and excess humidity.

Hazardous reactions

May react with sodium, potassium, barium and other alkaline metals.

Incompatible substances: magnesium and alloys with magnesium concentrations > 2%.

Hazardous decomposition

products

R410A: Halogen acids produced by thermal decomposition and hydrolysis.

2.8 Safety regulations

Page 11

9

English

2 - Safety (continued)

REFRIGERANT DATA SAFETY DATA: R410A

General precautions

Do not inhale concentrated vapours. Their concentration in the atmosphere should not exceed the

minimum preset values and should be maintained below the professional threshold. Being more weighty

than the air, the vapour concentrates on the bottom, in narrow areas. Therefore, the exhaust system must

work at low level.

Respiratory system protection

If you are in doubt about the concentration in the atmosphere, it is recommended to wear a respirator

approved by an accident-prevention

Authority, of the independent or oxygen type.

Storage

Cylinders must be stored in a dry and fresh place, free from any fire hazard, far from direct sunlight or

other sources of heat, radiators etc.

Keep a temperature below 50 °C.

Protective clothing Wear overalls, protective gloves and goggles or a mask.

Accidental release measures

It is important to wear protective clothing and a respirator.

Stop the source of the leak, if you can do this without danger. Negligible leaks can be left evaporating

under the sun, providing that the room is well ventilated.

Considerable leaks: ventilate the room. Reduce the leak with sand, earth or other absorbing substances.

Make sure that the liquid does is not channelled into gutters, sewers or pits where the vapours are likely

to create a stuffy atmosphere.

Disposal

The best method is recovery and recycling. If this method is not practicable, dispose according to an

approved procedure, that shall ensure the absorption and neutralization of acids and toxic agents.

Fire fighting information R410A: Not flammable in the atmosphere.

Cylinders The cylinders, if exposed to fire, shall be cooled by water jets; otherwise, if heated, they may explode.

Protective fire fighting equipment In case of fire, wear an independent respirator and protective clothing.

2.8 Safety regulations (continued)

Page 12

10

2 - Safety (continued)

LUBRICANT OIL DATA SAFETY DATA: POLYESTER OIL (POE)

Classification Not harmful.

Contact with skin

May cause slight irritation. Does not require first aid measures. It is recommended to follow usual

personal hygiene measures, including washing the exposed skin with soap and water several times a day.

It is also recommended to wash your overalls at least once a week.

Contact with eyes Wash thoroughly with a suitable solution or tap water.

Ingestion Seek medical advice immediately.

Inhalation Seek medical advice immediately.

Conditions to avoid

Strong oxidising substances, caustic or acid solutions, excess heat.

May corrode some types of paint or rubber.

Protection of the

respiratory system

Use in well ventilated rooms.

Protective clothing

Always wear protective goggles or a mask. Wearing protective gloves is not mandatory, but is

recommended in case of prolonged exposure to refrigerant oil.

Accidental release measures

It is important to wear protective clothing and, especially, goggles.

Stop the source of the leak. Reduce the leak with absorbing substances (sand, sawdust or any other

absorbing material available on the market).

Disposal

The refrigerant oil and its waste will be disposed of in an approved incinerator, in conformity with the

provisions and the local regulations applicable to oil waste.

Fire fighting information

In the presence of hot liquid or flames, use dry powder, carbon dioxide or foam. If the leak is not burning,

use a water jet to remove any vapours and to protect the personnel responsible for stopping the leak.

Cylinders The cylinders exposed to a fire will be cooled with water jets in case of fire.

Fire fighting protective equipment In case of fire, wear an independent respirator.

2.8 Safety regulations (continued)

Page 13

11

English

3 - Transport, Lifting and Positioning

Refrigerators are supplied assembled (apar t from standard

antivibrating rubber supports, that will be installed on site). The

equipment are full of refrigerant and oil, in the quantity required for a

proper operation.

3.1 Inspection

When the unit is delivered, it is recommended to check it carefully

and to identify any damage occurred during transportation. The

goods are shipped ex-factory, at the buyer’s risk. Check that the

delivery includes all the components listed in the order.

In case of damage, note it down on the carrier’s delivery note and

issue a claim according to the instructions provided in the delivery

note.

In the presence of any serious damage, that does not affect the

surface only, it is recommended to inform manufacturer immediately.

Please note that manufacturer may not be held liable for any damage

to the equipment during transportation, even though the carrier has

been appointed by the factory.

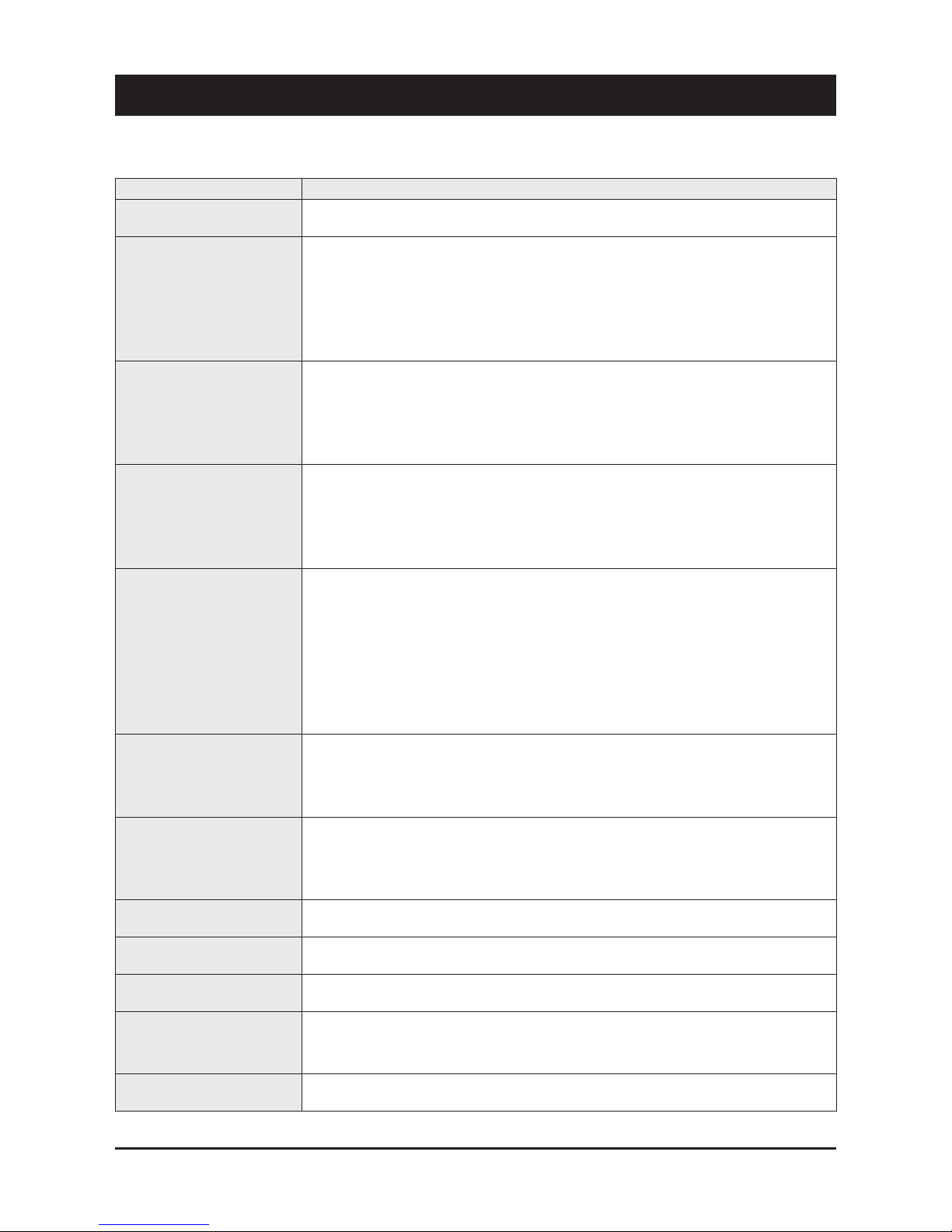

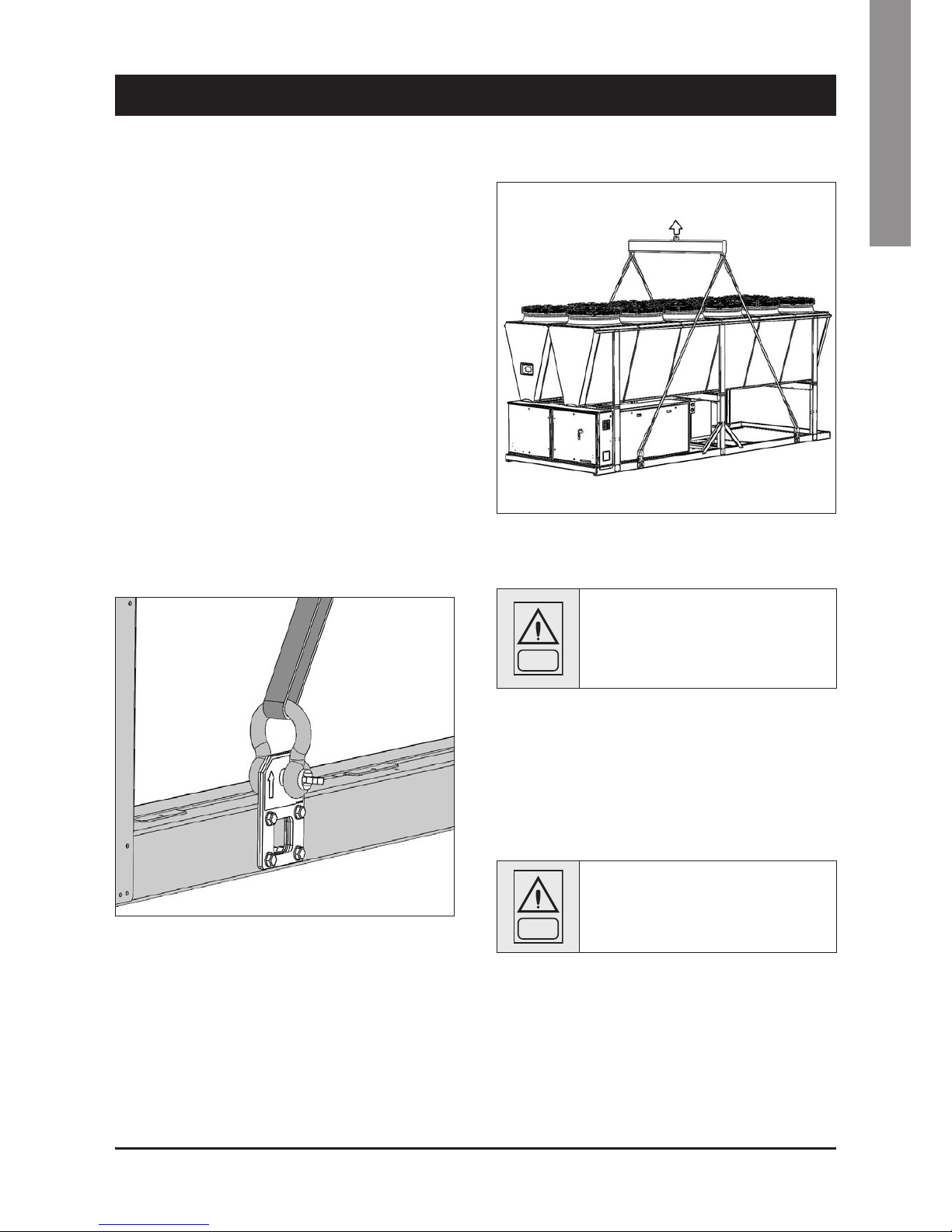

3.2 Lifting

The unit must be lifted by using the hooks inserted into the relevant

eyebolts (see the figure).

It is recommended to use a spacer to prevent cables from

damaging the unit (see the figure).

Before positioning the unit, make sure that the place of installation is

appropriate and sturdy enough to hold the weight and to withstand

the stress caused by the operation of the whole assembly.

WARNING

Do not displace the unit on rollers, and do not

lift it with a lift truck.

Unit must be lifted carefully.

To lift unit slowly and regularly.

To lift and displace the unit:

Q

Insert and secure eyebolts into the holes marked on the frame.

Q

Insert spacer between cables.

Q

Hook near the barycentre of the unit.

Q

The cables must be long enough to form, if tensioned, an angle

of at least 45° with respect to the horizontal plane.

WARNING

For lifting operations, use only tools and

material fit for this purpose, in accordance with

accident-prevention regulations.

Page 14

12

3 - Transport, Lifting and Positioning (continued)

WARNING

During the lifting and handling of the unit, be

careful not to damage the finned pack of the

coils positioned on the sides of the unit.

The sides of the unit must be protected by

cardboard or plywood sheets.

WARNING

It is recommended not to remove the protective

plastic envelope, that should prevent scraps

from penetrating into the appliance and any

damage to the surfaces, until the unit is ready

for operation.

WARNING

The lifting eyebolts protrude from the base

of the unit; it is therefore recommended to

remove them once the unit has been lifted and

positioned, if in your opinion they are likely to

become a source of hazard and injury.

The eyebolts must be mounted on the unit whenever it shall be

displaced and then lifted again.

3.3 Anchoring

It is not essential to secure the unit to the foundations, unless in

areas where there is a serious risk of earthquake, or if the appliance

is installed on the top of a steel frame.

3.4 Storage

When the unit is to be stored before installation, adopt a few

precautions to prevent any damage or risk of corrosion or wear:

Qplug or seal every single opening, such as water fittings

Qdo not store the appliance in a room where the temperature

exceeds 50 °C for the units using R410A and, if possible, do not

expose to direct sunlight

Qminimum storage temperature is -25 °C

Qit is recommended to store the unit in a roof where traffic is

minimized, to prevent the risk of accidental damage

Qthe unit must not be washed with a steam jet

Qtake away and leave to the site manager all the keys providing

access to the control board

Finally, it is recommended to carry out visual inspections at regular

intervals.

Page 15

13

English

4 - Installation

4.1 Positioning of the unit

DANGER

Before installing the unit, make sure that the

structure of the building and/or the supporting

surface can withstand the weight of the

appliance. The weights of the units are listed in

Chapter 8 of this manual.

These units have been designed for outdoor installation on a solid

surface. Standard accessories include antivibrating rubber supports,

that must be positioned under the base.

When the unit is to be installed on the ground, it is necessary to

provide a concrete base, to ensure a uniform distribution of the

weights.

As a general rule, no special sub-bases are required. However, if the

unit is to be installed on the top of inhabited rooms, it is advisable

to rest it on spring shock absorbers (optional), that will minimise the

transmission of any vibration to the structures.

To choose the place of installation of the unit, bear in mind that :

Qthe longitudinal axis of the unit must be parallel to the direction of

prevailing winds, so as to ensure a uniform distribution of the air

on finned exchangers

Qthe unit must not be installed near boilers’ vent pipes

Qthe unit must not be installed leeward with respect to sources of

air contaminated by greases, such as, for example, the outlets

to kitchen exhaust hoods into the atmosphere. Otherwise,

the grease is likely to deposit on the fins of the refrigerant /air

exchangers, and would fix every type of atmospheric impurity,

resulting in the quick clogging of the exchangers

Qthe unit must not be installed in areas subject to considerable

snow falling

Qthe unit must not be installed in areas subject to flooding, under

gutters etc.

Qthe unit must not be installed in air shafts, narrow courts or other

small places, where the noise may be reflected by the walls or

the air ejected by fans may short-circuit itself on refrigerant/air

heat exchangers or condenser

Qthe place of installation must be have all the necessary spaces

for air circulation and maintenance operations (see Chapter 8).

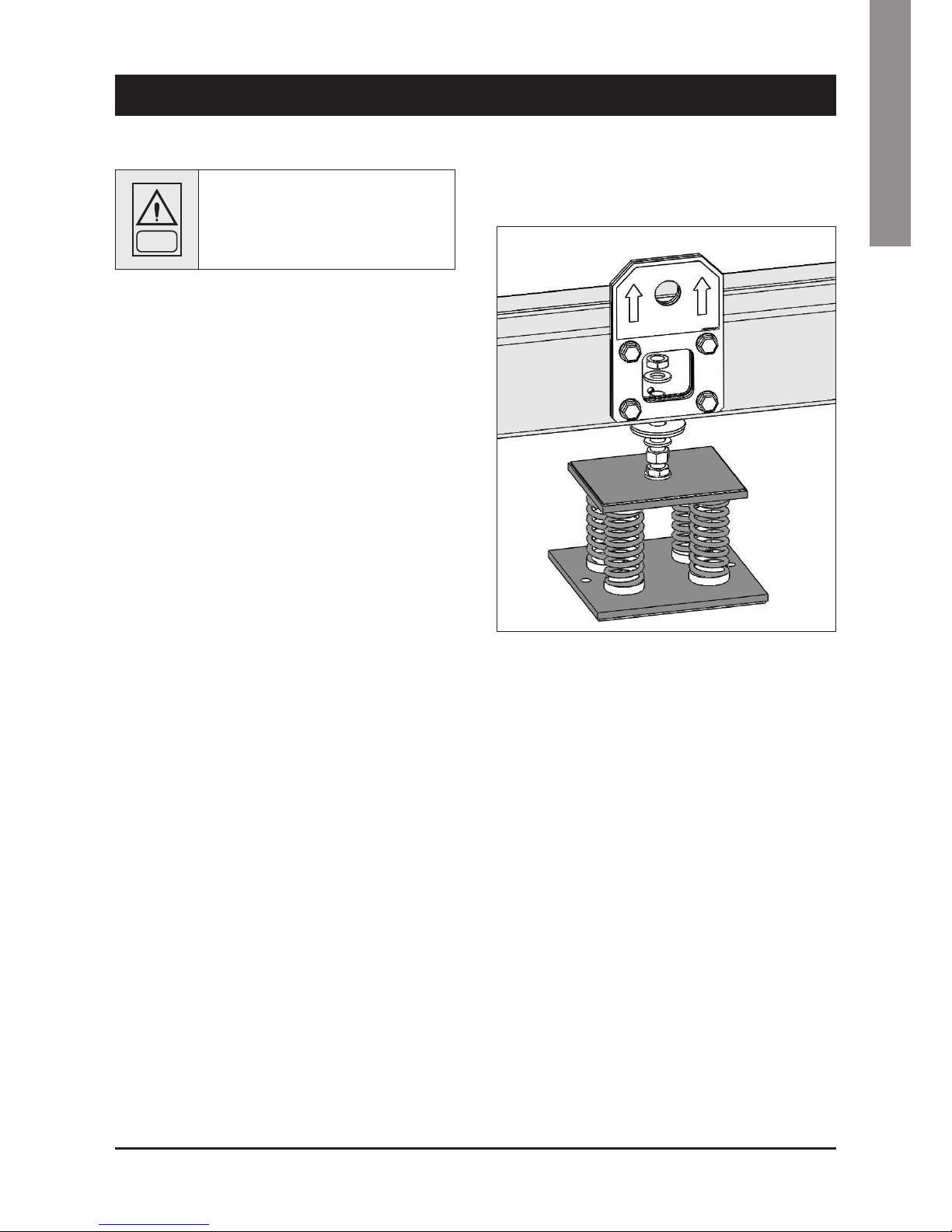

4.2 Spring Isolator Installation

Q

Prepare the base, that must be flat and plane.

Q

Lift the appliance and insert shock absorbers as follows:

Page 16

14

4 - Installation (continued)

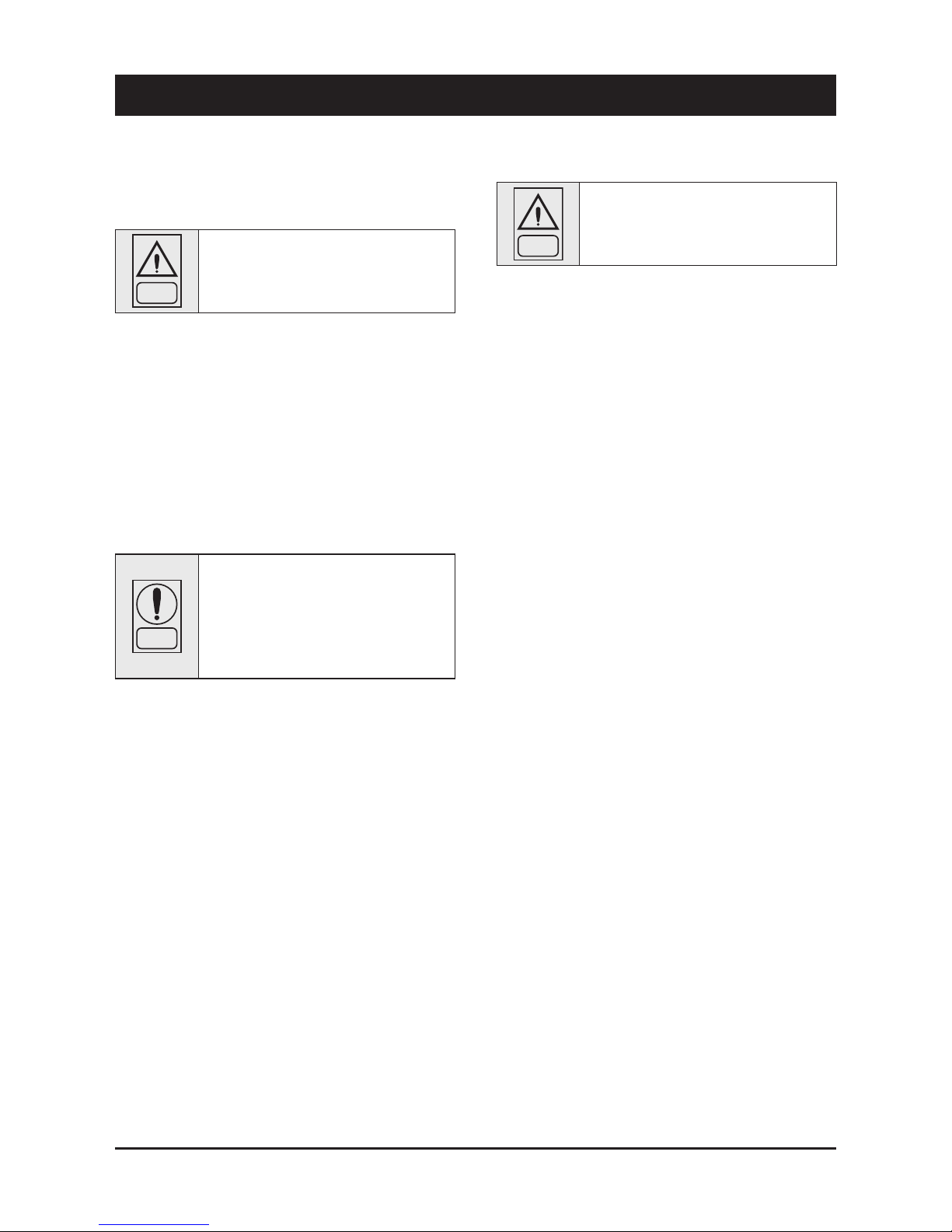

4.3 External Water Circuit

The flow switch and the filter water, although not included in the

supply, must always be fitted such as plant components. Their

installation is mandatory for warranty.

WARNING

The external hydraulic circuit must ensure the

water flow to the evaporator under any working

or adjustment conditions.

The circuit shall be composed by the following elements:

Q

A circulation pump which can ensure the necessary capacity

and discharge head.

Q

The capacity of the primary hydraulic circuit should not be less

than 2.4 litres/KW of cooling capacity, in order to prevent the

repeated start-up of the compressor and any damage to it. If

the water capacity in the primary piping of the circuit and in the

evaporator is lower than this value, an insulated storage tank

shall be installed.

Q

A membrane expansion vessel provided with safety valve with

vent, that must be visible.

NOTE

The capacity of the expansion vessel must allow

for an expansion of at least 2% of the volume of

the fluid in the circuit (evaporator, piping, user

circuit and standby tank, if any). The expansion

vessel needs not be isolated, because no water

can circulate inside it.

A flo w switch, to dis able the appliance when t he water is not

circulating.

WARNING

The flow switch must be connected (terminals

1-2) as s ho wn in the w ir ing diagram of the

“User’s Terminal Box” (Paragraph 4.7).

To install the flow switch, follow the manufacturer’s instructions.

As a general rule, the flow switch shall be mounted on a horizontal

pipe, at a distance from the curves equal to 10 times the diameter

of the pipe and far from valves or other components that are likely

to hinder the water flow upstream of or downstream from the flow

switch.

Q

The bleed valves must be mounted on the highest point of the

piping.

Q

The stop valves must be mounted on the piping of the water entering/leaving the condenser.

Q

The discharge points (provided with plugs, cocks etc.) must be

arranged in the lowest point of the piping.

Page 17

15

English

4 - Installation (continued)

Then:

Q

Provide the evaporator with a by-pass circuit equipped with a

valve to wash the plant.

Q

Insulate the piping, to prevent the risk of heat loss.

Q

Position a filter on the suction side of the evaporator of the heat

recovery condenser.

WARNING

Before filling the circuit, it is important to check

that it is free from any foreign matter, sand,

gravels, rust, welding deposits, waste and other

materials that may damage the evaporator.

When cleaning the lines, it is recommended to create a circuit bypass. It is important to mount a filtering medium (30 mesh) upstream

of the chiller.

NOTE

If necessary, the water required to fill the circuit

must be treated to obtain the requested PH.

If necessary, the water required to fill the circuit must be treated to

obtain the requested PH.

4.4 Hydraulic connection

The water inlet/outlet fittings shall conform to the instructions

provided by the plates affixed near the connection points.

4.5 Draining the defrosting waste water (for

heat pump unit only)

When heat pump units work in heating mode, during defrosting

cycles, they may discharge water from the base. This is why the

units should be installed at least 200 mm above the floor level, so

as to allow the free drainage of waste water, without the risk of

producing ice banks.

The heat pump units must be in stalled in positions whe re th e

defrosting water cannot create any damage.

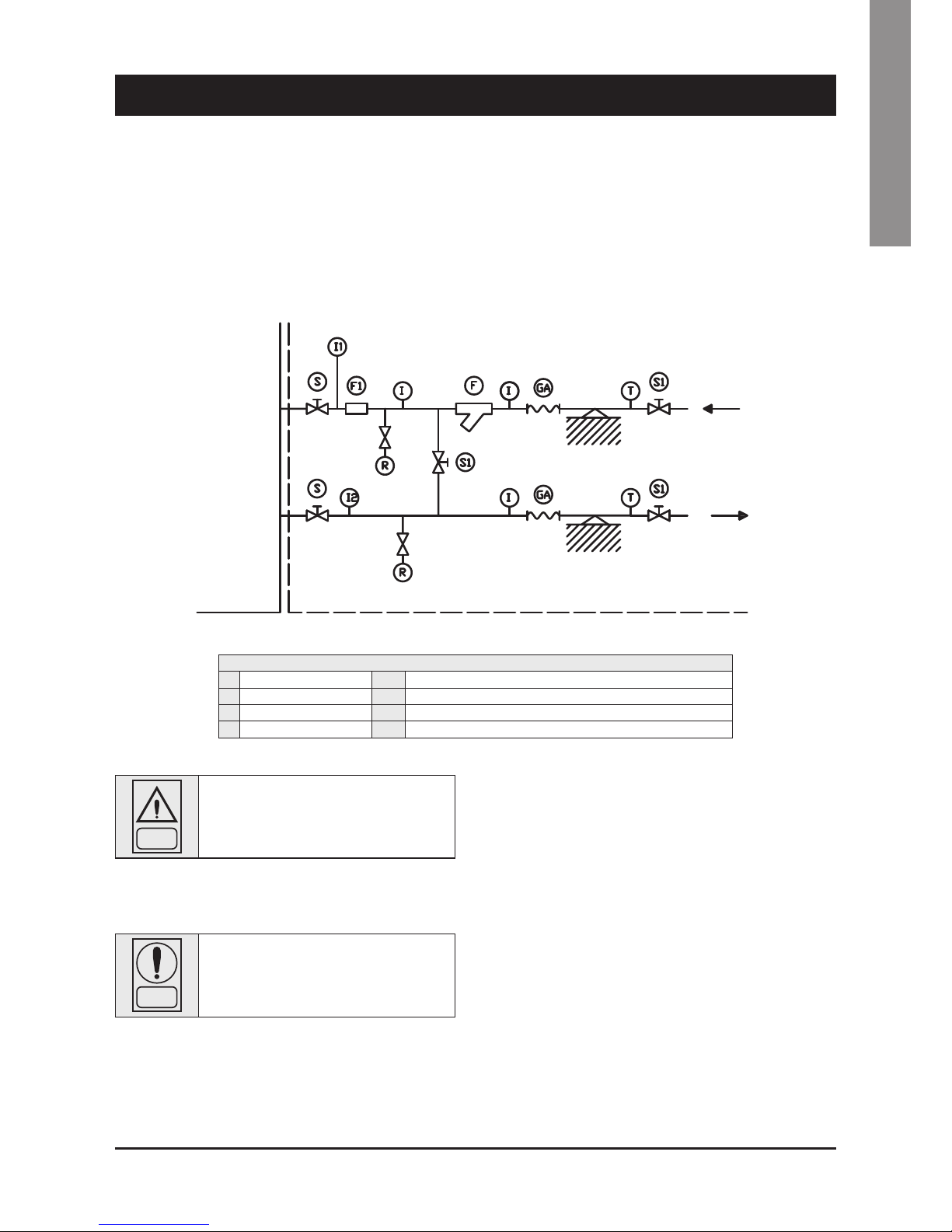

Installation Flow Switch

External Hydraulic Circuit

Connection Diagram

Unit

COMPONENTS

I Pressure gauge connection R Drain cock

S Gate valve T Thermometer

F1 Flow Switch F Filter

GA Flexible hoses I1/I2 Pressure gauge connection to measure pressure drop or head pressure

Page 18

16

4 - Installation (continued)

4.6 Power supply

DANGER

Before carrying out any operations on the

electrical system, make sure that the unit is

deenergised.

DANGER

It is important that the appliance is grounded.

DANGER

The company in charge of the installation shall

conform to the standards applicable to outdoor

electrical connections.

The manufacturer may not be held liable for any damage and/or

injury caused by failure to comply with these precautions.

The unit conforms to EN 60204-1.

The following connections shall be provided:

QA 3-phase and grounding connection for the power supply

circuit.

QThe electrical distribution system shall meet the power absorbed

by the appliance.

QThe disconnecting and magnetothermal switches must be sized to

control the starting current of the unit.

QThe power supply lines and the insulation devices must be

designed in such a way that every line independent.

QIt is recommended to install differential switches, to prevent any

damage caused by phase drops.

QThe fans and compressors are supplied through contactors

controlled from the control panel.

QEach motor is provided with an internal safety thermal device

and external fuses.

QThe power supply cables must be inserted into dedicated

openings on the front of the unit, and the will enter the electrical

board through holes drilled on the bottom of the board.

4.7 Electrical connections

The unit must be installed on site according to the Machinery

Directive (2006/42/EC), the Low Voltage Directive (2006/95/EC),

the Electromagnetic Interference Directive (2004/108/EC) and

the usual procedures and standards applicable in the place of

installation.

The unit must not be operated if its installation has not been

carried out according to the instructions provided in this manual.

The power supply lines must consist of insulated copper

conductors, dimensioned for the maximum absorbed current.

Connection to terminals must be performed according to the diagram

of connections (User’s Terminal Box) provided in this manual and

according to the wiring diagram which accompanies the unit.

WARNING

Before connecting the power supply lines, check

that the available voltage value does not exceed

the range specified in the Electric Data (Chapter

8).

For 3-phase systems, check also that the unbalance between the

phases does not exceed 2%. To perform this check, measure the

differences between the voltage of each phase couple and their mean

value during operation.

The maximum % value of these differences (unbalance) must not

exceed 2% of the mean voltage.

If the unbalance is unacceptable, contact the Energy Distributor to

solve this problem.

WARNING

Supplying the unit through a line whose

unbalance exceeds the permissible value will

automatically void the warranty.

Page 19

17

English

4 - Installation (continued)

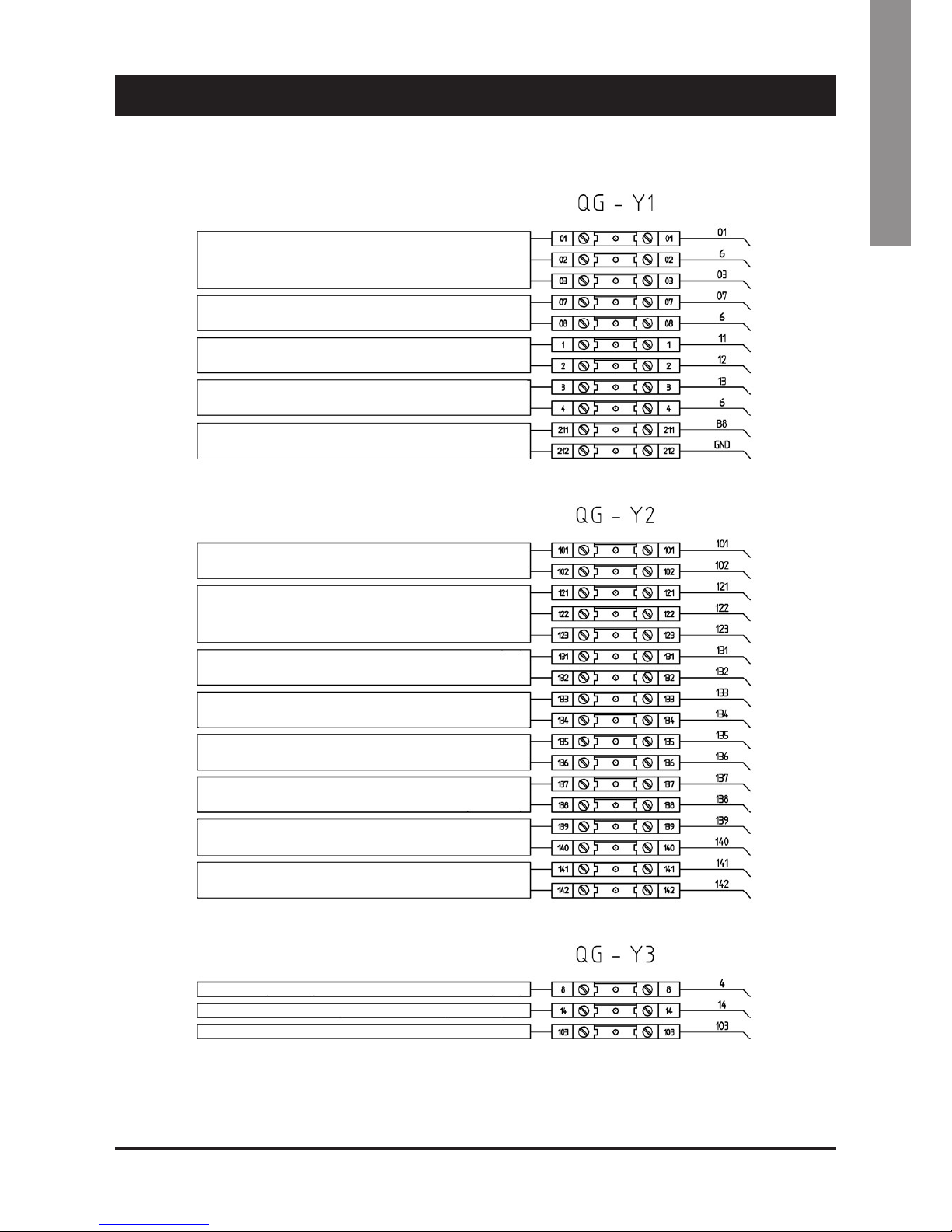

REMOTE START/STOP SWITCH

(SRS)

(SDN)

(B8)

(NO)

(NO)

(NO)

(NO)

(NO)

(NO)

(NO)

(NO)

(NC)

(GND)

(COMMON)

(COMMON)

(COMMON)

(COMMON)

(COMMON)

(COMMON)

(COMMON)

(COMMON)

(SRHP)

(COMMON)

REMOTE SUMMER/WINTER SWITCH (ONLY HEAT PUMP)

DOUBLE SET-POINT (DAY/NIGHT)

EXTERNAL INTERLOCK (OPTIONAL) CIRC PUMP ETC

LAN WATER TEMPERATURE PROBE

REMOTE INDICATION VOLTAGE ON

REMOTE INDICATION COMPRESSOR 1 ON

REMOTE INDICATION COMPRESSOR 2 ON

REMOTE INDICATION COMPRESSOR 3 ON

REMOTE INDICATION COMPRESSOR 4 ON

REMOTE INDICATION COMPRESSOR 5 ON

REMOTE INDICATION COMPRESSOR 6 ON

GENERAL ALARM SYSTEM 1-2

FLOW SWITCH (SF)

COMMON (COM)

ANTIFREEZE RELAY CONTROL (NO)

PUMP RELAY CONTROL (NO)

AQWL/AQWH - Electrical connections

Page 20

18

4 - Installation (continued)

4.8 Connecting plate-type evaporator

temperature sensors

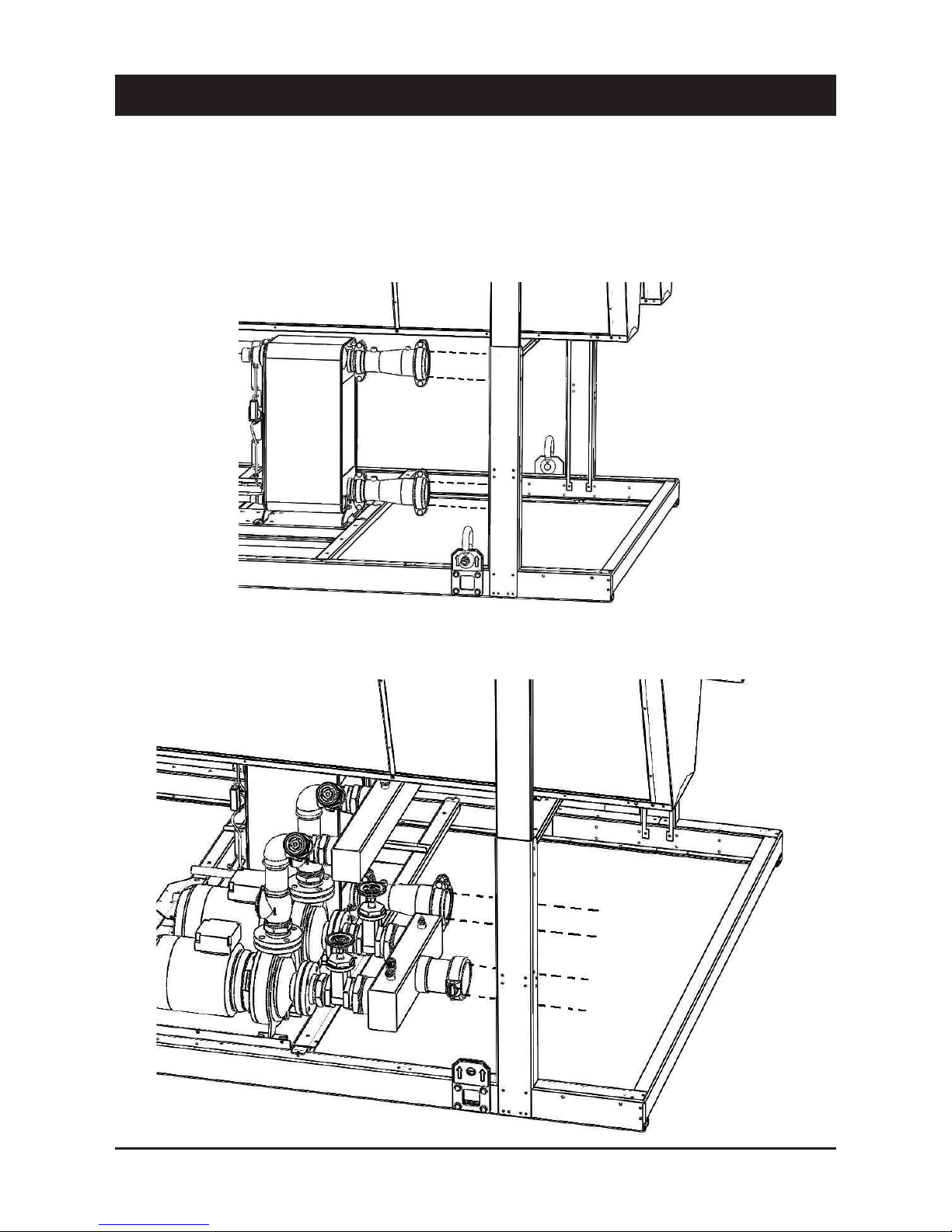

AQWL, AQWH and AQWR units are provided with fittings for hydraulic

connections between heat exchangers and plant.

Water connection units with pump(s)

Each fittings is complete with sensor well to fasten temperature

sensor (BT-IN and BT-OUT). Fittings are supplied separate and must

be mounted during the installation of the unit.

Page 21

19

English

4 - Installation (continued)

4.9 Total heat recovery features

Temperature sensors

Temperature sensors for recovery system water control, BTRin e

BTRout, are supplied by factory with the unit, already wired, and

must be fitted on the water connections at the heat reclaim condenser inlet and outlet (see wiring diagram).

Three-way valve

The three-way valve must be installed on-site. It permits bypassing

the heat reclaim condenser for correct operation at low return water

temperature. Water and electrical connections, as well as thermal

insulation must be made at the time of installation on-site.

The best position is close to heat reclaim condenser (to achieve a

small water circuit).

NOTE: The space required by this valve does not permit installation

on the factory.

Water connection units with pump and buffer tank

Forced shuttering

When recovery system is on, a commutation from air condensing

and water condensing takes place.

At the same time compressor-tandem is automatically shuttered to

allow the control of condensation in the transient phase. The same

process takes place when the system commutates from water condensing to air condensing.

Page 22

20

5 - Start-Up

WARNING

The unit must be started for the first time by

personnel suitably trained by one Authorised

Service Centre. Failure to meet this requirement

will immediately void the warranty.

NOTE

The operations carried out by authorised

personnel are limited to the star t-up of the unit,

and do not include any other operation on the

plant, such as, for example, electrical and

hydraulic connections etc.

All the other operations before start-up, including

oil pre-heating for at least 12 hours, must be

performed by the Installer.

5.1 Preliminary check

The checks listed below shall be performed before starting the unit

and before the arrival of the personnel authorised.

QCheck the section of power supply and grounding cables; make

sure that terminals are tightened and check the correct operation

of contactors, with the main switch open.

QCheck that any voltage and phase variation in the power supply

does not exceed the prefixed thresholds.

QConnect the contacts of the flow switch and the thermal relay of

the pump and of the other devices (if any), to terminals 1-2 and

3-4, respectively.

QCheck that the components of the external water circuit (pump,

user equipment, filters, power supply tank and reservoir, if any)

have been installed properly, and according to the manufacturer’s

instructions.

QCheck the filling of the hydraulic circuits, and make sure that

the fluid circulation is correct, without any trace of leaks and air

bubbles. If you use ethylene glycol as antifreeze, check that its

percentage is correct.

QCheck that the direction of rotation of the pumps is correct, and

that fluids have been circulating for at least 12 hours for both

pumps. Then, clean the filters on the suction side of the pumps.

QAdjust the liquid distribution network in such a way that the flow

rate is within the specified range.

QCheck that the water quality is up to the specifications.

QCheck that oil heaters, if any, have been turned on at least 12

hours before.

5.2 Start-up

Start-up sequence:

QTurn on the Main switch (at least 12 hours before).

QCheck that the oil in the compressor has reached the requested

temperature (the minimum temperature outside the pan must be

approx. 40°C) and that the auxiliary control circuit is energised.

QCheck the operation of all the external equipment, and make sure

that the control devices of the plant are properly calibrated.

QStart the pump and check that the water flow is correct.

QSet the desired fluid temperature on the control board.

QStart the appliance (see Chapter 6).

QCheck the correct direction of rotation of compressors. Scroll

compressors cannot compress the refrigerant when they rotate

in the opposite direction. To make sure that they are rotating in

the correct direction, simply check that, just after the start-up

of the compressor, the pressure drops on the LP side and rises

on the HP side. Furthermore, if a scroll compressor rotate in

the opposite direction, there is a considerable rise in the sound

level of the unit, as well as in a dramatic reduction of current

absorption compared to normal values. In case of wrong

rotation, the scroll compressor can be definitely damaged. Phase

monitor is assembled in the unit as a standard to prevent wrong

compressors rotation.

QAfter about 15 minutes of operation check that there are no

bubbles, through the sight glass on the liquid line.

WARNING

The presence of bubbles may indicate that a

part of the refrigerant charge has been released

in one or more points. It is important to remove

these leaks before proceeding.

QRepeat the start-up procedure after removing the leaks.

QCheck the oil level in the compressor’s sight glass.

5.3 Checking the operation

Check the following:

QThe temperature of the water entering the evaporator.

QThe temperature of the water leaving the evaporator.

QThe level of the water flow rate in the evaporator, if possible.

QThe current absorption upon the start of the compressor and in

case of stabilised operation.

QThe fan’s current absorption.

Check that the condensing and evaporation temperatures, during

operation at high and low pressure detected by the pressure gauges

of the refrigerant, are within the following range:

(On the units not provided with HP/LP pressure gauges for the

refrigerant, connect a pressure gauge to the Shrader valves on the

refrigeration circuit).

HP side

Approx. 15 to 21 °C above the temperature of

the air entering the condenser, for R410A units.

LP side

Approx. 2 to 4 °C below the temperature of the

leaving chilled water, for R410A units.

5.4 Delivery to the customer

QTrain the user according to the instructions provided in Section 6.

Page 23

21

English

6 - Control

General information

Introduction

This document contains the information and the operating

instructions for the units.

This information is for the after-sales service and the production

operators, for the end-of-line testing.

Main characteristics

– Microprocessor control

– User-friendly keyboard

– Proportional and integral control of the return

water temperature (RWT)

– Hysteresis control of the leaving water

temperature (LWT)

– Access code to enter the Manufacturer’s Level

– Access code to enter the Assistance Level

– Alarm and LED

– Backlighted LCD

– Closed-loop condensing pressure control

– Pump-Down logic (start-stop)

– Rotation of the compressor operation

– Oil return function

– Night mode (or Low Noise) control

– Counting of the pump/compressors’ hours of

operation

– Display and control of superheating by EEV

– Display of discharge and suction pressure values

– History of stored alarms (option)

– Programming of different setpoints with 4 ranges

of time/setpoint.

The following accessories can be also connected:

– Real Time Clock Memory Card: alarm history and programming of

different setpoints with ranges of time

– serial communication RS485 card; to connect the “Chiller

Control” to a BMS network

– remote display terminal

– wire remote control.

6.1 The "CHILLER CONTROL" system

Units are provided with a microprocessor card which is fully

programmed in factory for the control of a chiller with 2 circuits,

2/3 compressors per circuit, a high-pressure transducer and an

electronic expansion valve per circuit.

Keyboard & Display Terminal

General information

The figure shows the terminal with the front door open.

It is provided with a LCD 4 lines x 20 columns, keyboard and

microprocessor-controlled LED’s, so as to allow the programming of

the control parameters (setpoint, differential bands, alarm thresholds)

and themain operations to be carried out by the user.

Terminal & Key Board description

The terminal makes it possible to carry out the following operations:

– the initial configuration of the machine

– the change of all the main operating parameters

– the display of the detected alarms

– the display of all the measured quantities

The terminal and the card are connected by a 6-way phone cable.

The connection of the terminal to the basic card is not essential for

the normal operation of the controller.

Page 24

22

6.2 Display

The display is an LCD 4 lines x 20 columns. The quantities and the

information about the operation of the unit are alternated in the form

of subsequent screens, named.

x

Home

Line 0

Line 1

Line 2

Line 3

6.3 Keyboard

Arrows key - Up/Down/Enter

If the cursor is in the top left-hand corner (Home), press the UP/

DOWN keys to access the subsequent masks associated to the

selected branch. If a mask includes some value setting fields and

you press the ENTER key, the cursor will reach these fields.

Once you have reached the quantity setting field, you can modify any

value (within the expected limits) by pressing the UP/DOWN keys.

After you have selected the desired value, press the ENTER key again

to store it.

6 - Control (continued)

Access to the “display mask” of the machine status.

Esc key: allows you to move from one mask to another.

Alarm key: used to display the alarms, to reset them in

manual. Press it one to display the mask of the activated

alarm, press it again to reset the alarm signal.

+

Prg+Esc keys: pressing these keys at the same time,

allows you to turn the unit On/Off.

Up-down keys: allows you to set the control parameters’

values and to move from one mask to another (not

backlighted).

Enter key: used to move the cursor inside the masks and

to save the values of the set parameters.

+

Alarm+Enter keys: press these keys at the same time

to enter the “storical alarm” after 1’ come back at status

machine menu.

User

Manufactured

Maintenance

In/Out

Setpoint

Release

On/Off

Daily time zone

Page 25

23

English

6 - Control (continued)

Alarms

Alarm Description

Comp SYS 1

Status

Comp SYS 2

Status

Fan SYS 1

Status

Fan SYS 2

Status

Pump

Status

Reset

Auto/Man

AL01 Power supply wrong OFF OFF OFF OFF OFF MAN

AL02 Antifreeze alarm OFF OFF OFF OFF OFF MAN

AL03 Interlock OFF OFF OFF OFF OFF MAN

AL04 Lack of flow OFF OFF OFF OFF OFF MAN

AL05 SYS #1 Low suction pressure OFF ON OFF ON ON MAN

AL06 SYS #2 Low suction pressure ON OFF ON OFF ON MAN

AL07 SYS #1 High pressure supply OFF ON OFF ON ON MAN

AL08 SYS #2 High pressure supply ON OFF ON OFF ON MAN

AL91 SYS #2 Thermal compressor 1 OFF COMP1 ON ON ON ON MAN

AL92 SYS #2 Thermal compressor 2 OFF COMP2 ON ON ON ON MAN

AL93 SYS #2 Thermal compressor 3 OFF COMP3 ON ON ON ON MAN

AL101 SYS #1 Thermal compressor 1 ON OFF COMP1 ON ON ON MAN

AL102 SYS #1 Thermal compressor 2 ON OFF COMP2 ON ON ON MAN

AL103 SYS #1 Thermal compressor 3 ON OFF COMP3 ON ON ON MAN

AL11 Recovery antifreeze alarm Recovery disabled

AL141 SYS #1 Thermal cond.fans1 OFF ON OFF ON ON MAN

AL142 SYS #1 Thermal cond.fans2 OFF ON OFF ON ON MAN

AL151 SYS #2 Thermal cond.fans1 ON OFF OFF ON ON MAN

AL152 SYS #2 Thermal cond.fans2 ON OFF OFF ON ON MAN

AL16 SYS #1 Compressor diff.press.alarm OFF ON OFF ON ON MAN

AL17 SYS #2 Compressor diff.press.alarm ON OFF ON OFF ON MAN

AL21 Remote setpoint out of range OFF OFF OFF OFF OFF MAN

AL22 Press.suction SYS1 Sensoralarm OFF ON OFF ON ON MAN

AL23 Press.discharge SYS1 Sensoralarm OFF ON OFF ON ON MAN

AL24 Temp.Return Water Damaged Sensor OFF OFF OFF OFF OFF MAN

AL25 Temp Leaving Water Damaged Sensor OFF OFF OFF OFF OFF MAN

AL26 Press Suction SYS2 Sensoralarm ON OFF ON OFF ON MAN

AL27 Press.Discharge SYS2 Sensoralarm ON OFF ON OFF ON MAN

AL28 Temperatur Chill.net Sensoralarm OFF OFF OFF OFF OFF MAN

AL29 Temperatur Coil SYS1 Sensoralarm OFF ON OFF ON ON MAN

AL30 Temperatur Coil SYS2 Sensoralarm ON OFF ON OFF ON MAN

AL301 Outdoor Air Temper. Sensoralarm OFF OFF OFF OFF OFF MAN

AL302 Temp.Discharge SYS1 Sensoralarm OFF ON OFF ON ON MAN

AL303 Temp.Discharge SYS2 Sensoralarm ON OFF ON OFF ON MAN

AL304 Temp.Return Recovery Sensoralarm OFF OFF OFF OFF OFF MAN

AL305 Temp Leaving Recovery Sensoralarm OFF OFF OFF OFF OFF MAN

AL311 SYS #1 compressor 1 maintenance ON ON ON ON ON MAN

AL312 SYS #1 compressor 2 maintenance ON ON ON ON ON MAN

AL313 SYS #1 compressor 3 maintenance ON ON ON ON ON MAN

AL321 SYS #2 compressor 1 maintenance ON ON ON ON ON MAN

AL322 SYS #2 compressor 2 maintenance ON ON ON ON ON MAN

AL323 SYS #2 compressor 3 maintenance ON ON ON ON ON MAN

AL33 Evaporator Pump Maintenance ON ON ON ON ON MAN

AL37 pCO Eeprom broken OFF OFF OFF OFF OFF MAN

AL44 pCOe disconnected ON ON ON ON ON MAN

AL45 Analog input probe channel 1 broken OFF OFF OFF OFF OFF MAN

AL46 Analog input probe channel 2 broken OFF OFF OFF OFF OFF MAN

AL47 Analog input probe channel 3 broken OFF OFF OFF OFF OFF MAN

AL48 Analog input probe channel 4 broken OFF OFF OFF OFF

OFF MAN

AL50 EVD Eeprom error OFF OFF OFF OFF OFF MAN

AL51 EEV Motor error (check wirings) SYS1 OFF ON OFF ON ON MAN

AL52 MOP timeout (check timeout) SYS1 OFF ON OFF ON ON MAN

AL53 LOP timeout (check timeout) SYS1 OFF ON OFF ON ON MAN

AL54 Low SuperHeat (check timeout) OFF ON OFF ON ON MAN

Page 26

24

Setpoint

Pressing the Set key allows you to enter the Set point level accessible to the user. The parameters that can be set are listed below, along with the

limit values and the default values (standard shop settings):

Each alarm is memorized in alarm history. If it is of manual reset type, its code is indicated in previous table. On the other hand, if it is of automatic

reset type, it is recorded with a special code as shown in table below:

User parameters Control mode Min value Max value Default

Cooling Setpoint

RWT Return Control 8 20 10

LWT Leaving Control 6 20 8

Cooling Setpoint - glycol water

RWT Return Control -15 20 10

LWT Leaving Control -15 20 8

Proportional band RWT Return Control 1 10 5

Neutral band LWT Leaving Control 1 6 2

Heating Setpoint

RWT Return Control 20 45 40

LWT Leaving Control 20 50 40

Languages —— ITA ENG FRE GER SPA ITA

System On/Off

System 1 # —— OFF ON OFF

System 2 # —— OFF ON OFF

Unit management Cooling Heating

6 - Control (continued)

Alarm Description

Comp SYS 1

Status

Comp SYS 2

Status

Fan SYS 1

Status

Fan SYS 2

Status

Pump

Status

Reset

Auto/Man

AL55 Low suction alarm SYS 1 OFF ON OFF ON ON MAN

AL58 S1 sensor fault OFF ON OFF ON ON MAN

AL59 S2 sensor fault OFF ON OFF ON ON MAN

AL61 EVD Lan disconnected OFF OFF OFF OFF OFF MAN

AL62 Regulation alarm SYS 1 OFF ON OFF ON ON MAN

AL63 Autotune alarm SYS 1 OFF ON OFF ON ON MAN

AL64 EEV Motor error (check wirings) ON OFF ON OFF ON MAN

AL65 MOP timeout (check timeout) ON OFF ON OFF ON MAN

AL66 LOP timeout (check timeout) ON OFF ON OFF ON MAN

AL67 Low SuperHeat (check timeout) ON OFF ON OFF ON MAN

AL68 Low suction alarm SYS 2 ON OFF ON OFF ON MAN

AL69 Battery alarm OFF OFF OFF OFF OFF MAN

AL71 S3 sensor fault ON OFF ON OFF ON MAN

AL72 S4 sensor fault ON OFF ON OFF ON MAN

AL74 Regulation alarm SYS 2 ON OFF ON OFF ON MAN

AL75 Autotune alarm SYS 2 ON OFF ON OFF ON MAN

Alarm description Manual reset code Auto reset code

Lack of flow AL04 AL904

SYS#1 low suction pressure AL05 AL905

SYS#2 low suction pressure AL06 AL906

SYS#1 high pressure supply AL07 AL907

SYS#2 high pressure supply AL08 AL908

SYS#2 thermal compressor 1 AL91 AL901

SYS#2 thermal compressor 2 AL92 AL902

SYS#2 thermal compressor 3 AL93 AL903

SYS#1 thermal compressor 1 AL101 AL991

SYS#1 thermal compressor 2 AL102 AL992

SYS#1 thermal compressor 3 AL103 AL993

Page 27

25

English

Compressor protection

Compressors are equipped with a heating element to prevent

oil dilution, which may result in remarkable risks of failure of

compressors.

The windings of the compressors’ motors are provided with a

thermal protection.

For AQW models an accessory kit for thermal protection is available,

for any overcurrent of scroll compressors, which shall be shopmounted.

Electrical flow switch

To ensure the correct operation of the unit, a electrical flow switch

must be installed, to prevent the unit working in case of insufficient

circulation of the chilled fluid.

WARNING

The electrical flow switch must be carefully

installed, according to the instructions given by

the Manufacturer.

The electrical flow switch must be installed on the pressing side

of the circulation pump for the fluid, just upstream of the heat

exchanger’s inlet. The electrical flow switch must be installed in a

horizontal straight length of piping, in a position reasonably far (both

upstream and downstream) from localized pressure drops (curves,

valves etc.).

Continuous Regulation of the Fan Speed

The fans’ speed regulator, if installed, allows the unit to work at an

ambient temperature down to -18 °C.

Differential pressure switch

This pressure switch halts the operation of the unit in the event that

it does not detect a sufficient pressure drop through the exchanger.

6.4 Protection and Safety Equipment

Defrosting System (only for AQWH models)

The AQWH units are provided with an automatic defrosting system,

which prevents the formation of excessive ice banks on coolant/air

exchangers during heat pump operation.

This system, which is part of the electronic control system, is of the

time/suction pressure type, and when the suction pressure detected

by a sensor drops below a fixed limit, once the preset time is over,

switches from heating to cooling the operation of the unit, with the

fans stopped.

During the defrosting cycle the compressor works normally, but the

coil’s fans remain off. The defrosting cycle stops after the coil has

been defrosted, and at this point the unit can work in heating mode

again.

NOTE

For safety purposes, fans are started also during

defrosting, if the discharge pressure reaches

considerable values.

Frost Protection for the Chilled Fluid

These units are provided with frost protection for the chilled fluid. This

protection consists of an electrical resistor positioned in contact with

the coolant/circulating fluid exchanger, which is activated (although

the unit is off) when the temperature of the fluid drops below 5 °C the standard value for a non-glycol unit.

If the leaving water temperature drops below 4 °C (standard value for

a non-glycol unit) the machine’s antifreeze alarm is activated. If the

circulating fluid is water, before the beginning of the cold season it is

advisable to drain the circuit to prevent water frosting.

If the circuit cannot be drained, it is essential to avoid de-energizing

the unit, so as to permit the activation, when necessary, of the frost

protection.

6 - Control (continued)

Page 28

26

6 - Control (continued)

6.5 HPF version configuration

Units equipped with special brushless fans (HPF) can be set-up on the field to give the unit a specific static pressure.

By entering parameter in service level - Max Speed (Vdc) - it is possible to modify high static pressure.

The table below shows the correspondance between chiller model, fan RPM, high static pressure.

Sizes Fan Static Pressure (Pa) Fan rpm

Parameter in Service Level

Max Speed (Vdc)

1404

40 900 8.3

60 930 8.5

80 970 8.8

100 1000 9.1

120 1030 9.3

1604

40 900 8.2

60 930 8.5

80 970 8.8

100 1000 9.1

120 1030 9.3

1806

40 900 8.3

60 930 8.5

80 970 8.8

100 1000 9.1

120 1030 9.3

2106

40 900 8.3

60 940 8.6

80 970 8.8

100 1000 9.1

120 1040 9.4

2406

40 1010 9.1

60 1040 9.4

80 1080 9.7

100 1100 9.8

120 1130 10.0

Note: Values in bold are standard factory settings.

Page 29

27

English

7 - Product Description

7.1 Introduction

AQW units are water chillers /air-water heat pumps provided with

hermetic scroll compressors with two refrigeration circuits.

These units are fit for cooling and heating intermediate fluids (glycoled

water), for air-conditioning applications in industrial processes.

These units can be installed outdoor on the roof of a building or at

ground level.

This series includes the following versions:

7.2 General specifications

AQW units are supplied complete and provided with all connecting

pipes for the refrigerant and internal wiring.

The refrigeration circuit of each unit undergoes a pressure test, is

drained, vacuumised, dehydrated and filled with refrigerant, and

includes the necessary oil. Once assembled, each unit is subjected

to a complete final testing and the correct operation of all refrigeration

circuits is checked.

The base and the frame of each unit are made of very thick

galvanised sheet, and are secured by screw and stainless bolts. All

panels are secured by screw and tropicalised steel bolts, they can be

disassembled for easy access to internal components.

All galvanised steel parts are painted with white polyester resin

(RAL 9001), to ensure the resistance of the unit to corrosion and

weather agents over time.

7.3 Compressors

These units are provided with hermetic scroll compressors, with

built-in motor protection.

Compressors are mounted on shock absorbers to reduce vibrations.

Motors are of direct start-up type, cooled by the sucked refrigerant

gas.

Thermistors protect the windings from any over temperatures and the

electronic control checks that the delivery temperature is within the

permissible range.

The capacity control, as well as the control of the delivered cooling

capacity, are always ensured by the electronic control.

7.4 Refrigeration circuits

Each unit has two complete refrigeration circuits, including: a service

valve to fill the unit with refrigerant, shut-off valves, thermostatic

expansion valve, dehydrating filter, sight glass with humidity indicator,

a differential pressure switch for the water.

The outdoor AQWC units, deriving from the AQWL versions, are

marked by the absence of the evaporator, and are equipped with

shutoff cocks on the suction line and on the liquid line, so as to allow

the connection of remote evaporators.

Furthermore, each circuit is equipped with safety devices in

accordance with PED 97/23/EC: HP and LP pressure switches,

safety valves providing protection in case of fire or malfunction of

compressors.

7.5 Water heat exchanger

The evaporators are of stainless steel plate type.

Their thermal insulation is ensured by a thick flexible closed-cell

heat-insulating jacket. Furthermore, the frost protection is ensured

by electric heaters.

These exchangers can work at pressures up to 10 bar on the

hydraulic side and 45 bar on the refrigerant side.

The hydraulic connections to the evaporator are of 3” Victaulic type.

7.6 Air heat exchanger

Coils are made of copper pipes in staggered rows, mechanically

expanded inside an aluminium finned pack.

7.7 Fans

Fans are of directly coupling propeller type, provided with aluminium

blade with wing profile.

Each fan is provided with galvanised steel accidentprevention guard.

Finally, motors are completely closed, protection class IP54,

protection thermostat immersed in windings.

VERSION (STD/HSE) (1) DESCRIPTION

Base Low Noise version (BLN) (2)

Air condensing chillers/heat pumps, using R410A refrigerant.

Low Noise version (LN)

Extra Low Noise version (ELN)

High Temperature version (HT)

OPTIONS DESCRIPTION

AQWL/D

The heat recovery is carried out by a desuperheater mounted on the compressor’s discharge line.

AQWH/D

AQWR

Total heat recovery is carried out by a heat exchanger mounted on the compressor’s discharge line in parallel with

the condensing circuit. Heat recovery function is activated by mean of a 4-ways valve.

(1) High efficiency units (HSE) with brushless fans (2) A high pressure fan (HPF) version is available

For each AQW version, the corresponding condensing unit version (AQWC) is available.

Available options:

Page 30

28

7 - Product Description (continued)

7.8 Electric power supply and control system

The control compartment contains and electronic card with keyboard

and a display for working parameters, alarms, if any, and operating

blocks.

It is complete with remote control switches and protection fuses for

the motors of compressors, fans and pumps.

7.9 Accessories

List of available accessories, provided separately, to be mounted on

site by the installer:

Water flow switch

Prevents the operation of the unit when the chilled fluid is insufficient.

It is advisable to install a flow switch, to ensure the correct operation

of the unit.

Water filter

Filter to be mounted on the suction side of the water heat exchanger.

Antivibrating supports (AVM)

Isolating spring supports, equipped with bolts for fastening to

the base. They are supplied separated from the unit and must be

mounted on site by the customer, at his own expense.

Fan speed regulator

The speed regulator of the fans is mounted as a standard accessory

for the Extra Low Noise units, and is an optional accessory for the

Standard and Low Noise units. The fan speed is controlled in order to

work at a low room temperature, and allows the unit to work down to

a room temperature of -18 °C.

The control can be of the pressostatic step type, with temperature

correction, or of continuous type (under pressure), with electronic

regulator. The regulator is of electronic type only for the Extra Low

Noise versions.

Wire-type remote control kit

The kit includes a remote control for wall mounting, complete with

3m-long connecting cable, and installation manual and a transformer.

For longer distances (i.e. up to 50m) you can use a multipolar cable

of minimum section (0.25mm). Conductors should be connected

directly and according to the diagram with accompanies the

installation instructions.

Remote wall terminal