Page 1

Air-water Heat Pump

Installation and maintenance manual

12.0 â 17.9kW

12-6 / 18-9

Aqu@ Scop HT V2

Page 2

Page 3

INSTALLATION INSTRUCTION

NOTICE D’INSTALLATION

INSTALLATIONSHANDBUCH

ISTRUZIONI INSTALLAZIONE

INSTRUCCIONES DE INSTALACIÓN

English

Français

Español

Deutsch

Italiano

Page 4

English

2

Aqu@Scop HT V2

CONTENTS

1. GENERAL RECOMMENDATIONS ........................................................................................................................................................ 3

1.1. SAFETY DIRECTIONS .......................................................................................................................................................................................................................3

1.2. WARNING .........................................................................................................................................................................................................................................3

1.3. EQUIPEMENT SAFETY DATA ...........................................................................................................................................................................................................4

2. INSPECTION AND STORAGE .............................................................................................................................................................. 5

3. WARRANTY ...................................................................................................................................................................................... 5

4. CONTENTS OF PACKAGE ................................................................................................................................................................... 5

5. PRODUCT PRESENTATION ................................................................................................................................................................. 5

6. ACCESSORIES .................................................................................................................................................................................... 6

7. DIMENSIONS .................................................................................................................................................................................... 6

8. HANDLING ........................................................................................................................................................................................ 6

8.1. NET WEIGHT .....................................................................................................................................................................................................................................7

9. TECHNICAL SPECIFICATIONS ............................................................................................................................................................. 7

9.1. PHYSICAL CHARACTERISTICS ........................................................................................................................................................................................................7

9.2. ELECTRICAL CHARACTERISTICS .....................................................................................................................................................................................................7

9.3. OPTIONS COMPATIBILITY ...............................................................................................................................................................................................................7

9.4. OPERATING LIMITS ..........................................................................................................................................................................................................................8

9.5. THERMODYNAMIC DOMESTIC HOT WATER PRODUCTION ........................................................................................................................................................9

10. REFRIGERATION AND HYDRAULIC DIAGRAM ............................................................................................................................... 10

11. INSTALLATION .............................................................................................................................................................................. 10

11.1. SITING THE INSTALLATION.........................................................................................................................................................................................................10

11.2. CLEARANCE .................................................................................................................................................................................................................................11

11.3. ATTACHEMENT TO THE GROUND ..............................................................................................................................................................................................11

12. HYDRAULIC LINKS ........................................................................................................................................................................ 12

12.1. GENERAL RECOMMENDATIONS................................................................................................................................................................................................12

12.2. STANDARD CIRCUITS ..................................................................................................................................................................................................................13

12.3. WATER QUALITY ..........................................................................................................................................................................................................................19

12.4. CONNECTION TO THE CENTRAL HEATING LOOP ....................................................................................................................................................................20

12.5. HEAT INSULATION .......................................................................................................................................................................................................................20

12.6. FILLING THE SYSTEM WITH WATER ..........................................................................................................................................................................................21

12.7. ELECTRONIC FLOW METER ........................................................................................................................................................................................................21

12.8. WATER FLOW REGULATION .......................................................................................................................................................................................................21

13. WIRING DIAGRAM AND LEGEND ..................................................................................................................................................22

13.1. WIRING DIAGRAM ......................................................................................................................................................................................................................22

13.2. LEGEND ........................................................................................................................................................................................................................................22

14. ELECTRICAL CONNECTIONS ........................................................................................................................................................... 25

14.1. PHASE SEQUENCE AND CUT-OUT CONTROLLER ....................................................................................................................................................................25

14.2. PROGRESSIVE START-UP ............................................................................................................................................................................................................26

14.3. CONNECTIONS .............................................................................................................................................................................................................................27

15. DOMESTIC HOT WATER ................................................................................................................................................................. 29

15.1. CONNECTION TO THE CENTRAL HEATING LOOP ....................................................................................................................................................................29

15.2. DOMESTIC HOT WATER PRODUCTION MODES .......................................................................................................................................................................30

15.3. DOMESTIC HOT WATER HEATING FUNCTION ACTIVATION ....................................................................................................................................................30

16. IN-LINE ELECTRIC HEATER ............................................................................................................................................................31

16.1. ELECTRICAL CONNECTIONS .......................................................................................................................................................................................................31

16.2. OPERATING MODE ......................................................................................................................................................................................................................31

16.3. ELECTRIC HEATER FUNCTION ACTIVATION ..............................................................................................................................................................................31

17. BOILER RELIEF .............................................................................................................................................................................. 32

17.1. ELECTRICAL CONNECTIONS .......................................................................................................................................................................................................32

17.2. OPERATING MODES ....................................................................................................................................................................................................................32

17.3. BOILER RELIEF FUNCTION ACTIVATION ...................................................................................................................................................................................32

18. DUAL ZONE ...................................................................................................................................................................................33

18.1. ELECTRICAL CONNECTIONS .......................................................................................................................................................................................................33

18.2. ACTIVATING THE DUAL ZONE FUNCTION ................................................................................................................................................................................33

18.3. AMBIENCE TERMINAL ................................................................................................................................................................................................................33

19. COMMISSIONING .......................................................................................................................................................................... 34

19.1. PRE-START CHECK LIST ..............................................................................................................................................................................................................34

20. STARTING THE APPLIANCE ........................................................................................................................................................... 35

20.1. USER INTERFACE .........................................................................................................................................................................................................................35

20.2. SIMPLIFIED START-UP PROCEDURE ..........................................................................................................................................................................................37

20.3. OPERATING CHECK LIST .............................................................................................................................................................................................................42

21. FINAL TASKS ................................................................................................................................................................................43

22. IN CASE OF WARRANTY - MATERIAL RETURN PROCEDURE .........................................................................................................43

23. ORDERING SERVICE AND SPARE PARTS ORDER ........................................................................................................................... 43

24. MAINTENANCE ............................................................................................................................................................................. 44

24.1. SERVICING CHECKLIST ................................................................................................................................................................................................................44

25. ALARM LIST AVAILABLE ON THE AQU@ SCOP HT DISPLAY ...........................................................................................................46

26. FAULTY DIAGNOSIS GUIDE ............................................................................................................................................................53

Page 5

English

3

Aqu@Scop HT V2

POWER SUPPLY MUST BE

SWITCHED OFF

BEFORE STARTING WORK IN THE

ELECTRIC CONTROL BOX

1. GENERAL RECOMMENDATIONS

Please read the following safety precautions very carefully before installing the unit.

1.1. SAFETY DIRECTIONS

Follow the safety rules in forces when you are working on your appliance.

The installation, commissioning and maintenance of these units should be performed by qualied personnel

having a good knowledge of standards and local regulations, as well as experience of this type of equipment.

This appliance has not been designed for use by persons (including children) with reduced physical, sensorial

or mental faculties or by persons without any experience or knowledge of heating systems, unless they act

under the safety and supervision of a responsible person or have received prior training concerning the use

of the appliance.

Children should be supervised to ensure that they do not play with the appliance.

The unit should be handled using lifting and handling equipment appropriate to the unit's size and weight.

Any wiring produced on site must comply with the corresponding national electrical regulations.

Make sure that the power supply and its frequency are adapted to the required electric current of operation,

taking into account specic conditions of the location and the current required for any other appliance

connected to the same circuit.

The unit must be EARTHED to avoid any risks caused by insulation defects.

It is forbidden to start any work on the electrical components if water or high humidity is present on the

installation site.

1.2. WARNING

Cutoff power supply before starting to work on the appliance.

When making the hydraulic connections, ensure that no impurities are introduced into the pipe work.

The manufacturer declines any responsibility and the warrantly becomes void if these instructions are

not respected.

If you meet a problem, please call the Technical Department of your area.

If possible, assemble the compulsory or optional accessories before placing the appliance on its nal location.

(see instructions provided with each accessory).

In order to become fully familiar with the appliance, we suggest to read also our Technical Instructions.

The information contained in these Instructions are subject to modication without advance notice.

Page 6

English

4

Aqu@Scop HT V2

1.3. EQUIPEMENT SAFETY DATA

Safety Data R407C

Toxicity Low

In contact with skin

Liquid splashes or sprays may cause freeze burns. Unlikely to be hazardous by skin absorption.

However, R407C may be slightly irritant and, if liquid, it has a strong degreasing effect. Flush contaminated skin

areas with running water. If it comes into contact with fabrics, the liquid refrigerant will cause them to freeze

and adhere to the skin. Carefully remove the contaminated clothing since it might adhere to the skin and cause

freeze burns. Contact a doctor if the affected skin areas are reddened or irritated.

In contact with eyes

Vapours have no effect. Liquid splashes or sprays may cause freeze burns. In these cases rinse your eyes with

running water or with a solution for eye lavages for at least 10 minutes. Immediately contact a doctor.

Ingestion

Very unlikely to occur. If this should be the case, it may cause freeze burns. Never induce vomiting.

Keep the patient awake. Make him rinse his mouth with running water and make him drink about 1/4 of a litre.

Immediately contact a doctor.

Inhalation

R407C: High concentration levels of its vapours in the air can produce an anaesthetic effect, including the loss of

consciousness. Particularly severe exposures may cause heart arrhythmia and sometimes prove to be also fatal.

At high concentrations there is a danger of asphyxia due to a reduced oxygen content in the atmosphere.

In these cases take the patient to the open air, in a cool place and keep him at rest. Administer oxygen, if

required. Apply artificial respiration if breathing has ceased or if it has become irregular. In case of heart failure

immediately apply cardiac massage. Immediately contact a doctor.

Further Medical Advice

A symptomatic and supportive therapy is generally suitable. A heart sensitisation has been observed in some

cases, as a result of exposures to particularly high concentrations. In the presence of catecholamines (such

as for example adrenaline) in the blood flow, it has increased the irregularity of the cardiac rhythm and then

caused the heart failure.

Long-term exposure

R407C: A lifetime study which has been conducted on the effects inhalation may have on rats at 50,000 ppm

has shown the onset of benign tumours of the testicle. These remarks suggest that there is no danger for

human beings if they are exposed to concentrations below the occupational limits or equal to them.

Occupational exposure

limits

R407C: Recommended limits: 1,000 ppm v/v

8 hours TWA.

Stability R407C: Not specified.

Conditions to avoid Use in the presence of exposed flames, red heat surfaces and high humidity levels.

Hazardous reactions

Possibility of violent reactions with sodium, potassium, barium and other alkaline substances.

Incompatible materials: magnesium and all the alloys containing over 2% of magnesium.

Hazardous

decomposition

products

R407 C: Halogen acids deriving from thermal decomposition and hydrolysis.

General precautions

Avoid the inhalation of high concentrations of vapours. The concentration in the atmosphere shall be kept at the

minimum value and anyway below the occupational limits. Since vapours are heavier than air and they tend to

stagnate and to build up in closed areas, any opening for ventilation shall be made at the lowest level.

Breathing protection

In case of doubt about the actual concentration, wear breathing apparatus. It should be self-contained and

approved by the bodies for safety protection.

Storage Preservation

Refrigerant containers shall be stored in a cool place, away from fire risk, direct sunlight and all heat sources,

such as radiators. The maximum temperature shall never exceed 45°C in the storage place.

Protection clothes Wear boots, safety gloves and glasses or masks for facial protection.

Behaviour in case of

leaks or escapes

Never forget to wear protection clothes and breathing apparatus. Isolate the source of the leakage, provided

that this operation may be performed in safety conditions. Any small quantity of refrigerant which may have

escaped in its liquid state may evaporate provided that the room is well ventilated.In case of a large leakage,

ventilate the room immediately. Stop the leakage with sand, earth or any suitable absorbing material. Prevent

the liquid refrigerant from flowing into drains, sewers, foundations or absorbing wells since its vapours may

create an asphyxiating atmosphere.

Disposal

The best procedure involves recovery and recycle. If this is not possible, the refrigerant shall be given to a

plant which is well equipped to destroy and neutralise any acid and toxic by-product which may derive from its

disposal.

Combustibility features R407C: Non flammable in the atmosphere.

Containers

If they are exposed to the fire, they shall be constantly cooled down by water sprays.

Containers may explode if they are overheated.

Behaviour in case of

fire

In case of fire wear protection clothes and self-contained breathing apparatus.

Page 7

English

5

Aqu@Scop HT V2

2. INSPECTION AND STORAGE

THE WARRANTY SHALL BE NULL AND VOID IN THE EVENT

OF NON-COMPLIANCE WITH ANY OF THE ABOVE CONDITIONS.

This range of air/water Aqu@ Scop HT (High Temperature) appliances offers the special feature of producing

hot water at 65° C at outdoor temperatures between 0° C and -20° C, while guaranteeing a high COP.

Between 0°C and +42°C, the temperature of the hot water produced varies between 65°C and 55°C for the

Heating mode and is maintained at 60°C for the Domestic Hot Water (DHW) mode.

Consequently, this Aqu@ Scop HT system is ideally suited to replace a traditional hot water boiler in producing

DHW without alterations to the rest of the system.

This technology uses two-stage compressors connected to a patented refrigeration circuit.

This technology ensures remarkably accurate "capacity supplied/heating needs" matching due to its ability

to run each compressor independently. Depending on the demand for heating capacity and the operating

temperature of heat emitters (i.e. radiators, etc.) the Aqu@ Scop HT regulator selects either the small or

large compressor to operate on its own or in a two-stage mode.

3. WARRANTY

4. CONTENTS OF PACKAGE

5. PRODUCT PRESENTATION

At the time of receiving the equipment carefully cross check all the elements against the shipping documents

in order to ensure that all the crates and boxes have been received. Inspect all the units for any visible or

hidden damage.

In the event of shipping damage, write precise details of the damage on the shipper’s delivery note and

send immediately a registered letter to the shipper within 48 hours, clearly stating the damage caused.

Forward a copy of this letter to the manufacturer or his representative.

Never store or transport the unit upside down. It must be stored indoors, completely protected from

rain, snow etc. The unit must not be damaged by changes in the weather (high and low temperatures).

Excessively high temperatures (above 60 °C) can harm certain plastic materials and cause permanent

damage. Moreover, the performance of certain electrical or electronic components can be impaired.

The units are delivered fully assembled and tested.

Any modication to the units without the manufacturer’s prior approval, shall automatically render the

warranty null and void.

The following conditions must be respected in order to maintain the validity of the warranty:

² Commissioning shall be performed by specialised technicians from technical services approved by

the manufacturer.

² Maintenance shall be performed by technicians trained for this purpose.

² Only Original Equipment spare parts shall be used.

² All the operations listed in the present manual shall be performed within the required time limits.

1 HEAT Pump Aqu@ Scop HT

1 Documentation pouch

1 Water lter kit

1 stop cock

4 Anti-vibration pads

Page 8

English

6

Aqu@Scop HT V2

6. ACCESSORIES

7. DIMENSIONS

SEE APPENDIX

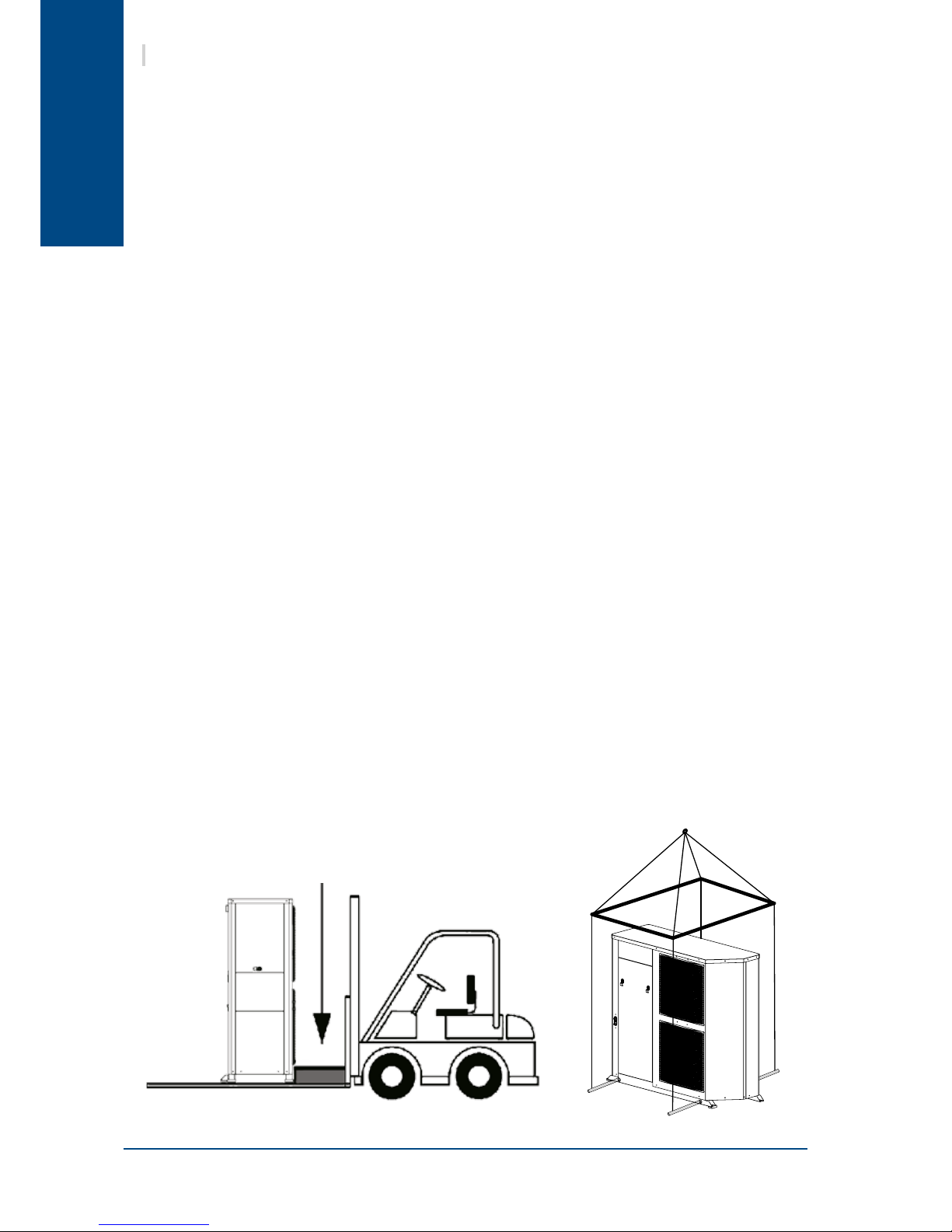

8. HANDLING

Take care to avoid any rough handling or impacts when unloading and moving the appliance. Only push or

pull the appliance by its base. Place a safety wedge between the unit base and the fork lift truck to avoid

damaging the unit’s structure and casing.

The handles present on the appliance's panels are intended for the removal/retting of the latter and must

not be used for handling the complete appliance (too heavy to be supported by the panels).

Transit holes

Ø30mm

Wedge required along the

entire length of the unit.

² Set of stop cocks with pressure tap

² Set of 2 exible pipes (length 1m)

² Hydraulic connection kit

² Sludge pot (decanting lter)

² Domestic hot water tank (300l)

² Domestic hot water plate exchanger kits for:

Wall-mounted electric tank (DHW outow via the bottom)

Floor-mounted electric tank (DHW outow via the top)

² Directional valve to be linked to the:

Domestic Hot Water function.

Boiler substitution function

Swimming pool function (with temperature probe kit)

² 140 litre buffer tank

² Anti-vibration pads (Anti-vibration mountings)

² 6kW in-line electric heater

² Dual zone Under-oor / Radiator heating kit (modulating valve + electric control box + temperature

probe)

² Dual zone management kit for existing valve (electric control box + temperature probe)

² Wired programmable ambience terminal

² Wireless programmable ambience terminal

}

Accessory recommended for an

optimal functioning

Page 9

English

7

Aqu@Scop HT V2

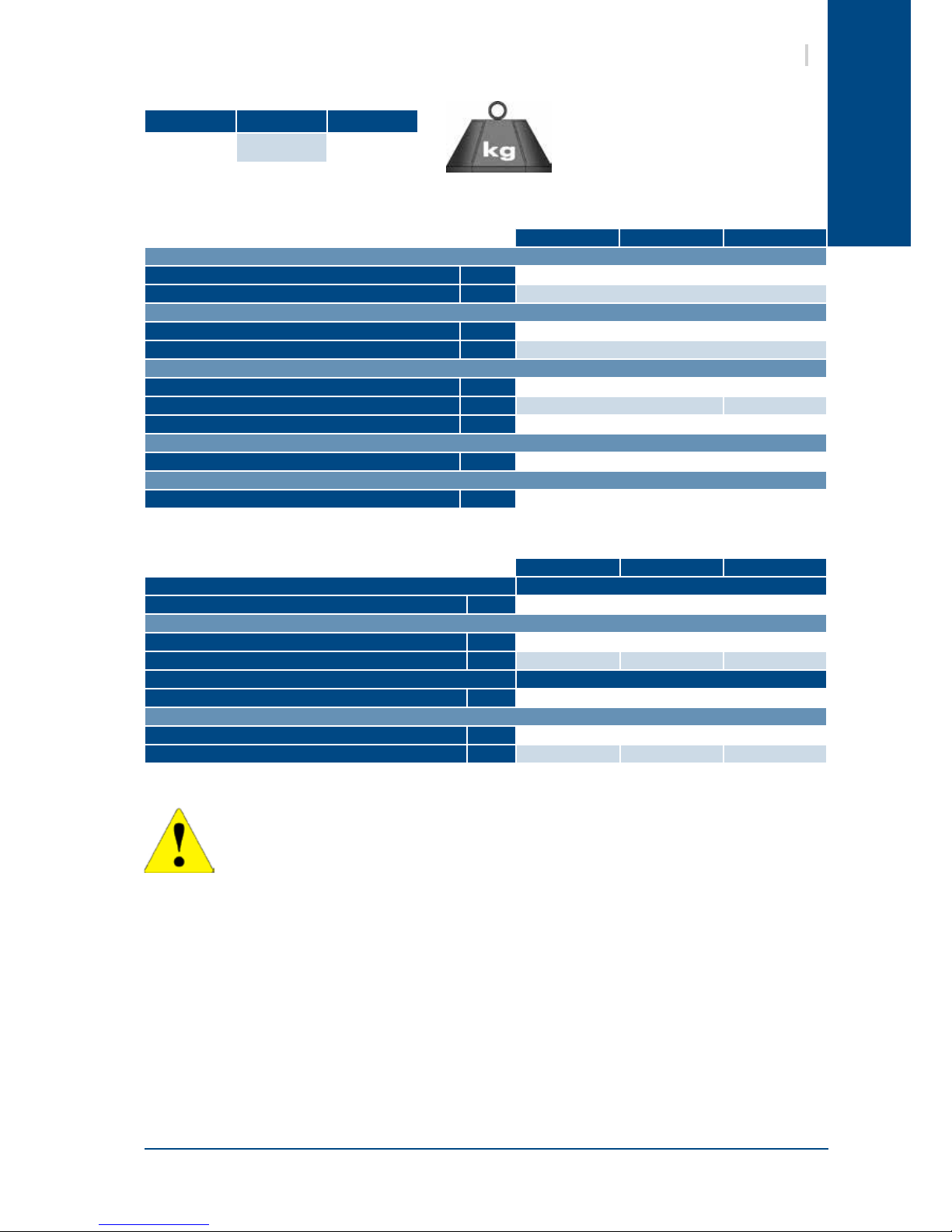

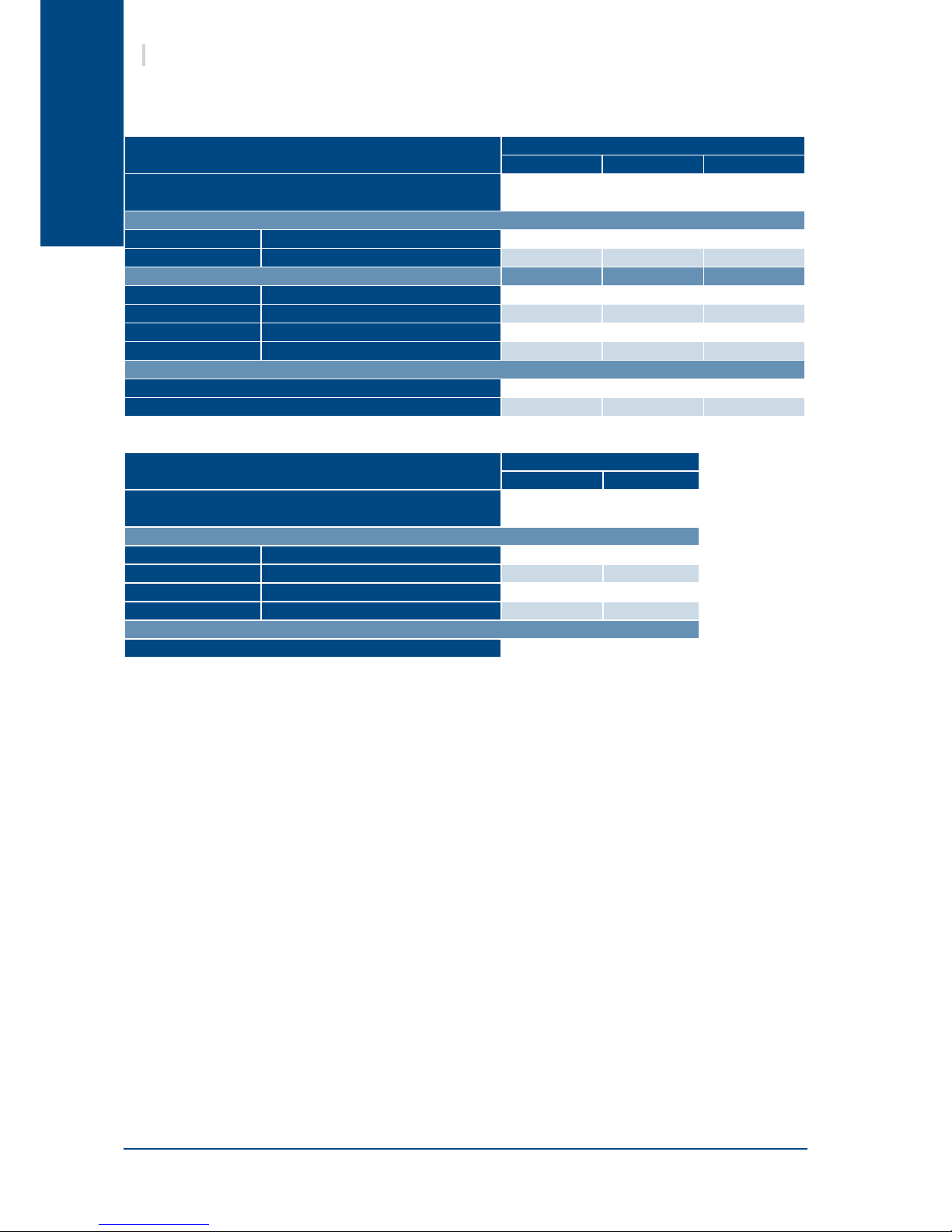

8.1. NET WEIGHT

9. TECHNICAL SPECIFICATIONS

9.1. PHYSICAL CHARACTERISTICS

This equipment contains uorinated gas with greenhouse gas effects covered by the Kyoto agreement.

12-6 14-7 18-9

REFRIGERANT

Type

R407C

Factory charge g

SEE NAME PLATE

HYDRAULIC LINKS

Inlet water gas

1" Female / Rotating nut

Outlet water gas

1" Female / Rotating nut

WATER FLOW

Nominal l/h

1030 / 1230 1480

Minimum l/h

880 / 1050 1260

Maximum l/h

1170 / 1390 1670

FANS

Fans (x2)

206W - 700tr/mn - 6000m3/h

ACOUSTIC PRESSURE

Acoustic pressure – outdoor unit dB(A)

65 65 65

12-6 14-7 18-9

184 209 213

9.2. ELECTRICAL CHARACTERISTICS

12-6 14-7 18-9

SUPPLY VOLTAGE 400V / 3 Ph / 50Hz

Start-up current draw with limiter A

< 60

Maximum current

Only Aqu@ Scop HT A

12.2 13.2 15.2

Aqu@ Scop HT + accessories A

15.5 16.5 18.5

SUPPLY VOLTAGE 230V / 1 Ph / 50Hz

Start-up current draw with limiter A

< 45

Maximum current

Only Aqu@ Scop HT A

25.7 27.2 /

Aqu@ Scop HT + accessories A

29 30.5 /

9.3. OPTIONS COMPATIBILITY

² Domestic hot water plate exchanger kits (SE4287)

² Dual zone kit (SE4288)

² Boilier relief (SE4289 or SE4290)

² Electric heater kit (SE4291 or SE4292)

² Domestic hot water tank (SE4290 or SE4291 or SE4293)

² Dual zone kit + boilier relief (SE4289)

² Dual zone kit + electric heater kit (SE4292)

² Dual zone kit + Domestic hot water tank (SE4293)

² Domestic hot water tank + boilier relief (SE4290)

² Domestic hot water tank + electric heater kit (SE4291)

The card µPC allows to install one or two options at most. The various possible congurations

are the following ones:

Page 10

English

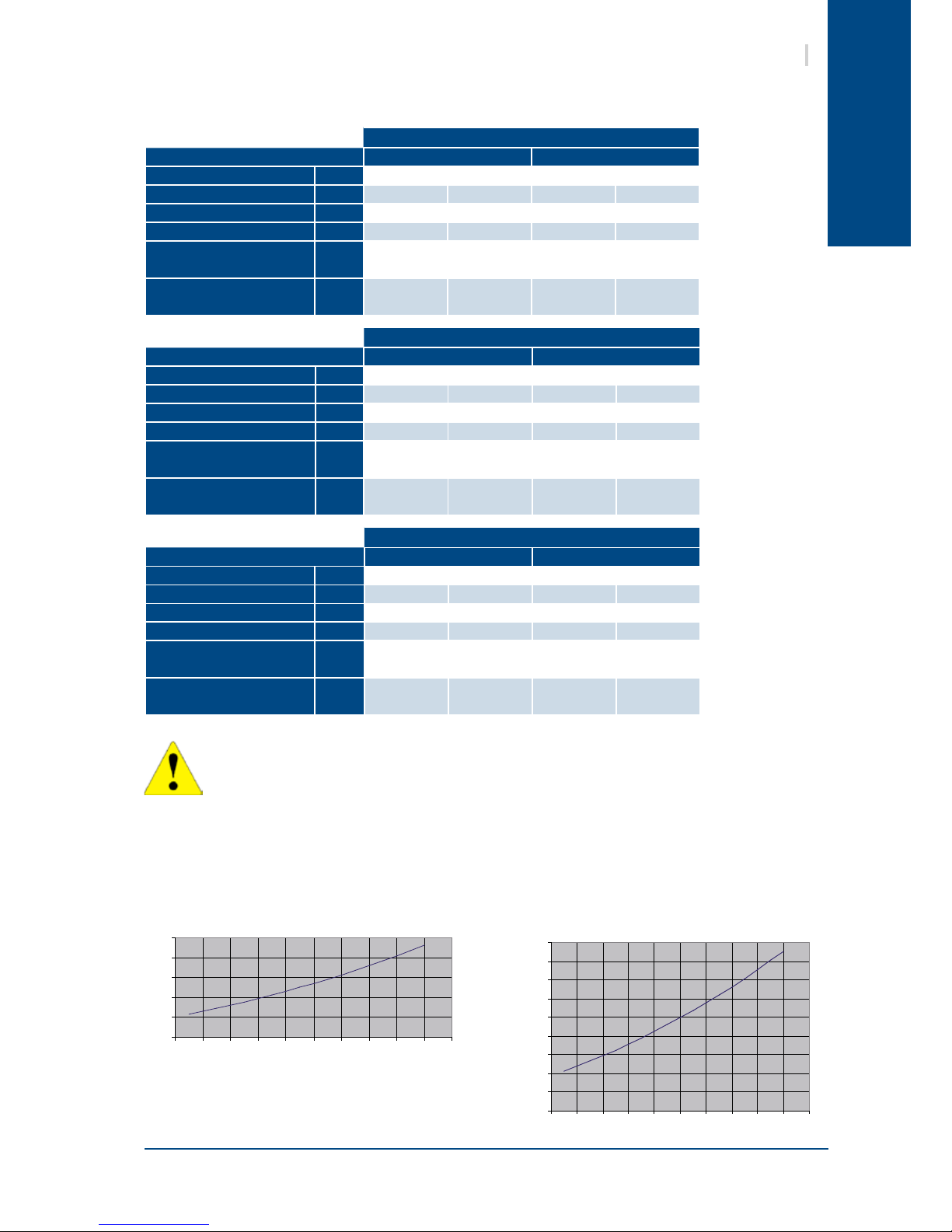

SINGLE /TWO STAGE OPERATING LIMITATIONS

10

15

20

25

30

35

40

45

50

55

60

65

70

-15 -10 -5 0 5 10 15 20-20-25 25

Outdoor temperature (°C)

Leaving water temperature setpoint (°C)

Two stage – min. entering water T.

Two stage – max. leaving water T.

Single stage – max. leaving water T.

TWO

STAGE

SINGLE

STAGE

8

Aqu@Scop HT V2

Aqu@ Scop HT appliances are equipped with a 2-stage output system with a ratio of 1:2.

When heating needs are low and when the required outlet water temperature is below 55° C, only the

rst stage is used at reduced capacity until the temperature balance point is reached. In other cases, the

Aqu@ Scop HT operates at full capacity to supply heating needs until the chosen balance point is reached.

The outlet water temperature is automatically adjusted to the water rule (heating curve) up to a maximum

temperature of 65° C.

9.4. OPERATING LIMITS

Page 11

English

0

0.5

1

1.5

2

2.5

800 900 1000 1100 12 00 1300 1400 1500 1600 1700 1800

kPa

Pressure loss

Water flow (l/h)

P

ressure loss

Water flow (l/h)

kPa

0

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800

9

Aqu@Scop HT V2

9.5. THERMODYNAMIC DOMESTIC HOT WATER PRODUCTION

Tank capacity: 300l

9.5.1. PERFORMANCE

9.5.2. PRESSURE LOSS

DHW TANK

300l

3-WAY-VALVE

HEATING/DHW

The tank is equipped with a 2.5kW back-up heating element for single or three phase connection. The

performances obtained and stated in the above table are without back-up heating. For higher domestic

hot water temperatures or for Legionnaires disease protection treatment, the use of the back-up electric

heating resistances is required.

The above performance gures are stated for a system with the Domestic Hot Water tank

accessory.

12-6

Conguration C2 Compressor C1+C2 Compressor

Outdoor temp. °C

40 7 0 -10

PAC max. outlet temp. °C

60 60 65 65

Average capacity kW

9 5.5 10.6 9.3

DHW temperature °C

56 58 58 58

Time [min]

Initial temperature: 15°C

min

97 163 85 98

Time [min]

Initial temperature: 35°C

min

49 87 45 53

14-7

Conguration C2 Compressor C1+C2 Compressor

Outdoor temp. °C

40 7 0 -10

PAC max. outlet temp. °C

60 60 65 65

Average capacity kW

11 7.1 13.6 12

DHW temperature °C

54 57 56 57

Time [min]

Initial temperature: 15°C

min

72 124 63 73

Time [min]

Initial temperature: 35°C

min

35 65 32 38

18-9

Conguration C2 Compressor C1+C2 Compressor

Outdoor temp. °C

40 7 0 -10

PAC max. outlet temp. °C

60 60 65 65

Average capacity kW

13.3 8.3 16 14.1

DHW temperature °C

53 56 55 56

Time [min]

Initial temperature: 15°C

min

60 103 52 61

Time [min]

Initial temperature: 35°C

min

28 53 26 31

Page 12

English

10

Aqu@Scop HT V2

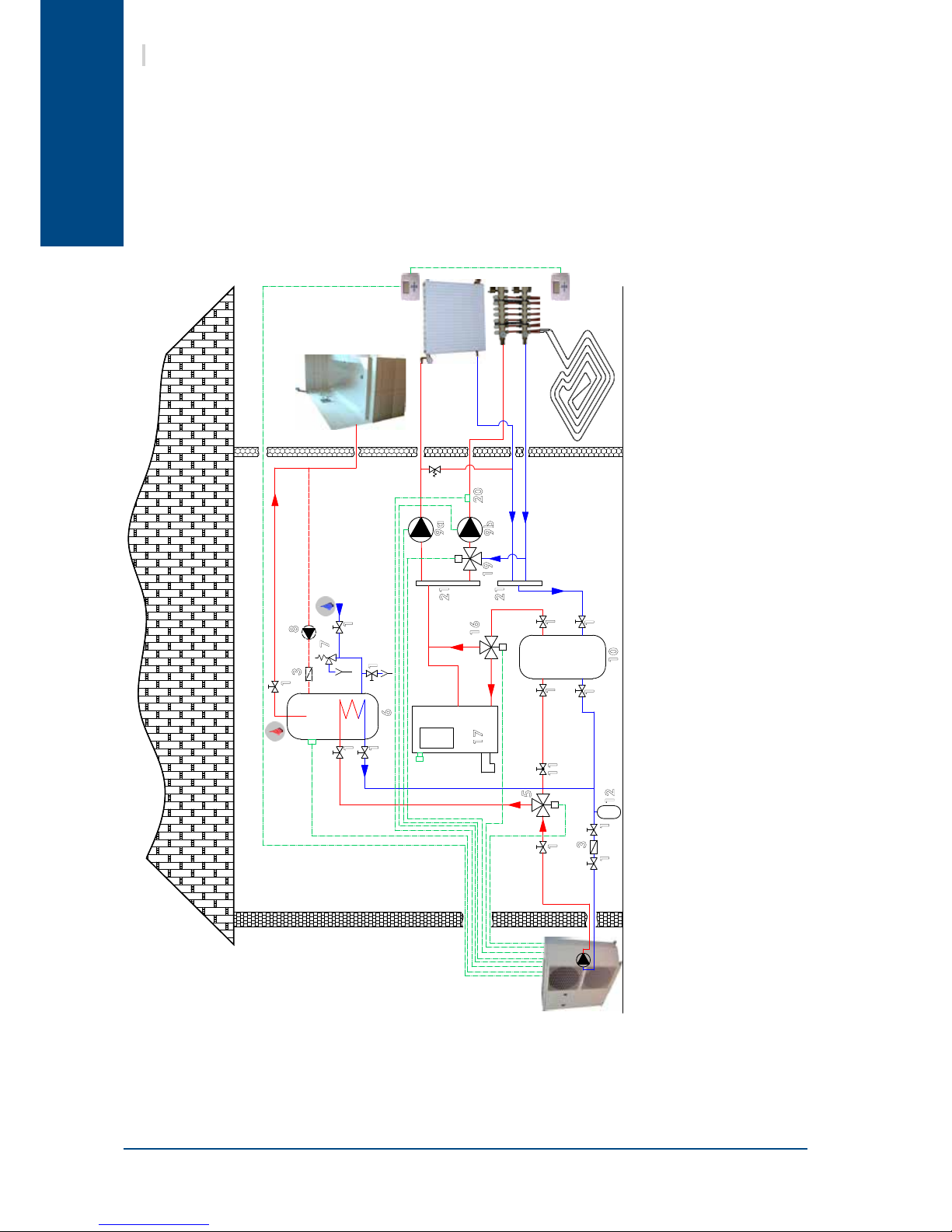

10. REFRIGERATION AND HYDRAULIC DIAGRAM

SEE APPENDIX

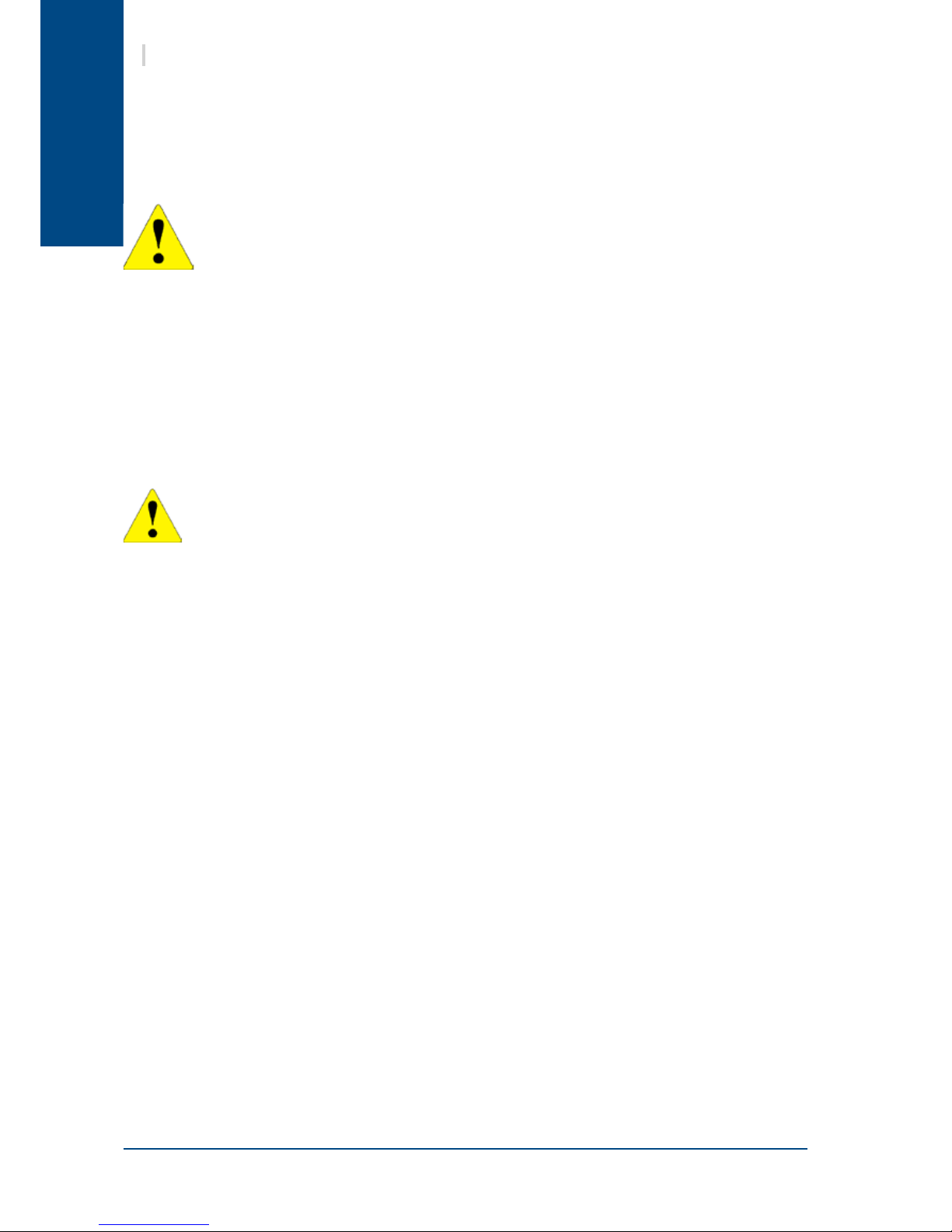

11. INSTALLATION

The unit is not designed to withstand weights or stresses from adjacent equipment, pipe work

or constructions. Any foreign weight or stress on the unit structure could lead to a malfunction

or a collapse with dangerous consequences for personnel and property. In such an event, the

warranty shall be null and void.

Unit operation depends on air temperature. Any recycling of air extracted by the fan lowers the

air intake temperature across the exchanger ns and alters the standard operating conditions.

The outdoor unit must be installed outdoors with sufcient surrounding clearance to enable unobstructed

air circulation through the appliance and access for maintenance work.

In the case of the unit being sited in areas exposed to high winds, you must avoid the wind hitting the

fan blowing surface areas directly to avoid any risk of recycling cooled air. Exchanger fan operation can be

disrupted by strong winds, which can cause de-icing problems and fan malfunctions.

The arrows show the direction of air circulation through the appliance. (Refer to the § ATTACHEMENT TO THE

GROUND, page 11).

Depending on temperature and outdoor air humidity conditions, water vapour contained in the air can

condense on the nned heat exchanger and even form ice under low outdoor temperature conditions (around

< 5°C). This condensate water and defrosted water runs off via outlets provided under the exchanger. To

aid water run-off and avoid frozen water remaining in the appliance in winter, we recommend that it is

mounted at a height of around 10cm off the ground by installing the ant-vibration mounting kit. In this way,

condensate and defrosted water can run off freely and be absorbed into the ground or channelled to a basin

built under the appliance in order to protect the environment.

In areas where outdoor temperatures fall below 1°C, the system can be equipped with a condensate antifreeze protection system (e.g. a heated pipe sheath, Not supplied).

In order to contain noise levels, we equip our appliances with quiet fans and encase the technical compartment

in sound-proofed panels. However, noise levels can be reduced even further by following a few installation

precautions:

² Do not install the appliance near a bedroom window. Avoid locating the appliance in a corner

(increased reverberated noise).

² Install the rubber pads supplied or anti-vibration pads (available as an option) under the appliance.

² Do not join the concrete slab supporting the appliance to the structure of the dwelling (structure-

borne noise transmission).

11.1. SITING THE INSTALLATION

11.1.1. PREVAILING WIND

11.1.2. CONDENSATE WATER MANAGEMENT

11.1.3. HOW TO REDUCE NOISE POLLUTION

Page 13

English

517

1711244

57414

1244.5

A

B

D

E

C

F

1%

11

Aqu@Scop HT V2

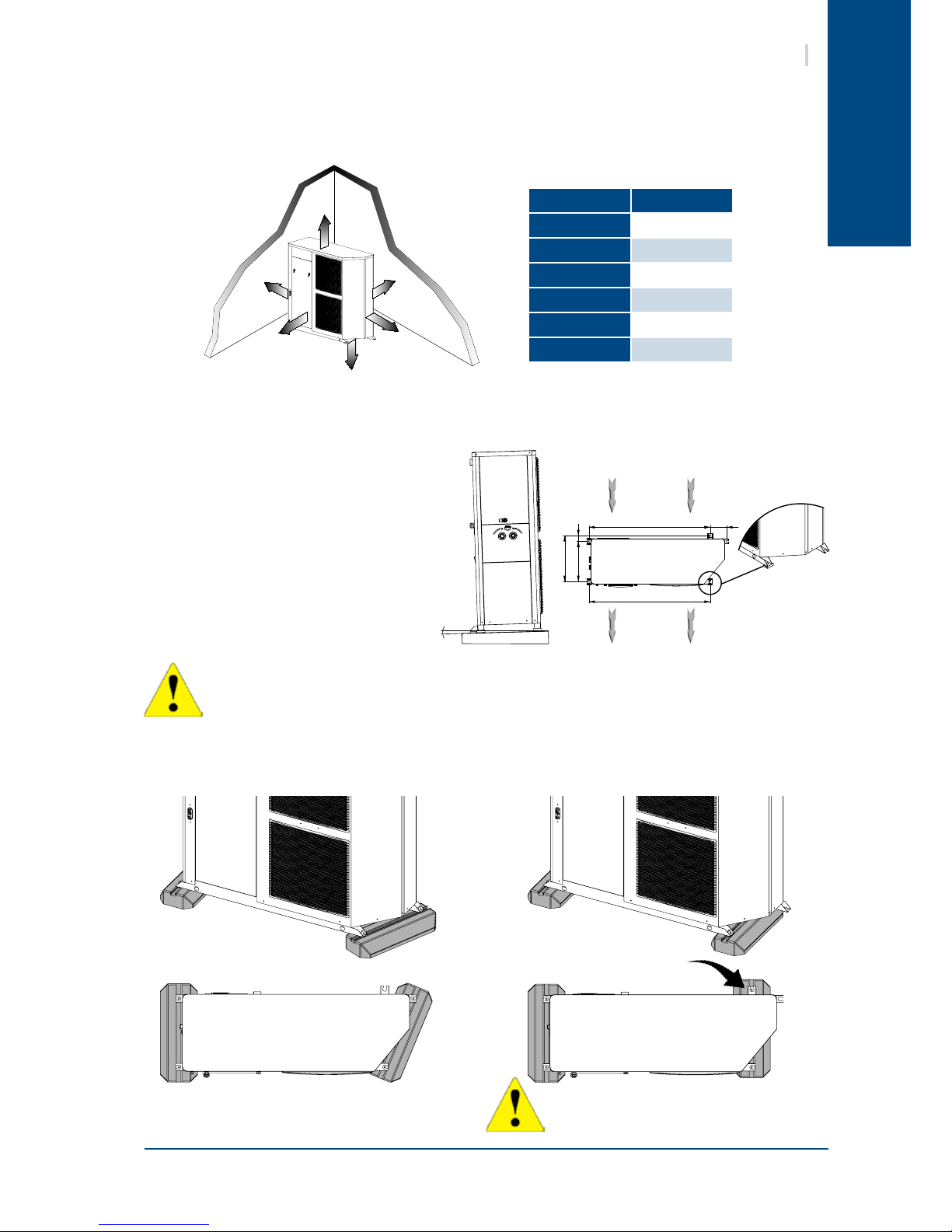

11.2. CLEARANCE

When choosing the location for the appliance, take care to leave sufcient free clearance on all sides to

ensure easy access for maintenance work. The minimum free clearance dimensions indicated must be

observed to ensure both proper system operation and allow access for maintenance and cleaning.

11.3. ATTACHEMENT TO THE GROUND

Unit mounting measurements are shown

on the drawing opposite. A slope of

1 cm/m should be created to assist

rainwater drainage.

Vibration dampers must be tted during

installation to overcome any risks of

vibration being transmitted due to direct

contact with a rigid support surface.

AIR FLOW

THE UNIT MUST NEVER BE

INSTALLED ON A WALL BRACKET.

The appliance must be sited on a level and solid oor and preferably on a masonry surface.

11.3.1. MOUNTING WITH ANTI-VIBRATION SUPPORTS

ANGLED FEET PARALLEL FEET

The rear mounting foot has not

been designed to support the

weight of the unit on its own.

THE REAR FOOT MUST BE USED IN

ACCORDANCE WITH THE ASSEMBLY

ILLUSTRATED BELOW.

REF. DIMENSION

A

800mm

B

500mm

C

500mm

D

400mm

E

800mm

F

100mm

Page 14

English

12

Aqu@Scop HT V2

12. HYDRAULIC LINKS

When choosing and installing water pipes, you must consult and observe all current local standards,

regulations and instructions.

12.1. GENERAL RECOMMENDATIONS

You must design the pipe network with the minimum number of bends and keep the number of changes in

height to the strict minimum. This will reduce installation costs and ensure optimum system performance.

The pipe network must include:

² A vibration elimination system (e.g.: link hoses available as an accessory) on all pipes connected to

the appliance in order to reduce vibrations and noise transmitted to the building fabric.

² Stop cocks to isolate the hydraulic circuit during maintenance.

² Manual or automatic bleed valves at the highest point on the water circuit.

² A suitable system for maintaining water pressure in the circuit (expansion tank).

² The installation of thermometers and pressure gauges on the heat exchanger inlet and outlet to

facilitate day-to-day controls and system maintenance.

12.1.1. ANTI-CLOGGING PROTECTION

When installing Aqu@ Scop HT appliances in existing water circuits,

a sludge trap and a removable mesh lter should be installed

upstream of the appliance.

To avoid any risk of foreign bodies entering the appliance and

to guarantee operating performance, WE STRONGLY RECOMMEND

THAT YOU INSTALL THE WATER FILTER ACCESSORY on the

Aqu@ Scop HT inlet pipe.

To ensure that the system operates correctly you must use suitably sized and properly routed pipes for the

hydraulic links between the Heat pump and the mains network.

The volume of water contained in the installation must be sufcient to avoid any possibility of the compressor

"short cycling", and to guarantee adequate compressor running times in order to provide optimum service

life and to ensure that de-icing cycles are performed properly.To ensure the Aqu@ Scop HT functions

efciently, available installation water volume must be:

12.1.2. MINIMUM HEATED WATER VOLUME REQUIREMENTS – BUFFER TANK.

200l < available water volume < 250l

When water circulation through heat emitters can be interrupted (thermostatic radiator valves closed) or the

heating supply halted, you must ensure that:

² The heat pump maintains its nominal water ow,

² The heat pump operates in a loop with a minimum available volume of 200 litres.

The use of a 3-speed circulation pump enables water ow through the appliance to be adapted to pressure

losses in the system. (Pump supplied set on Max position).

Page 15

English

1

3

2

1 1

1

1

1

1

3

1

5

6

7

8

1

1

12

15

1

14

13

13

Aqu@Scop HT V2

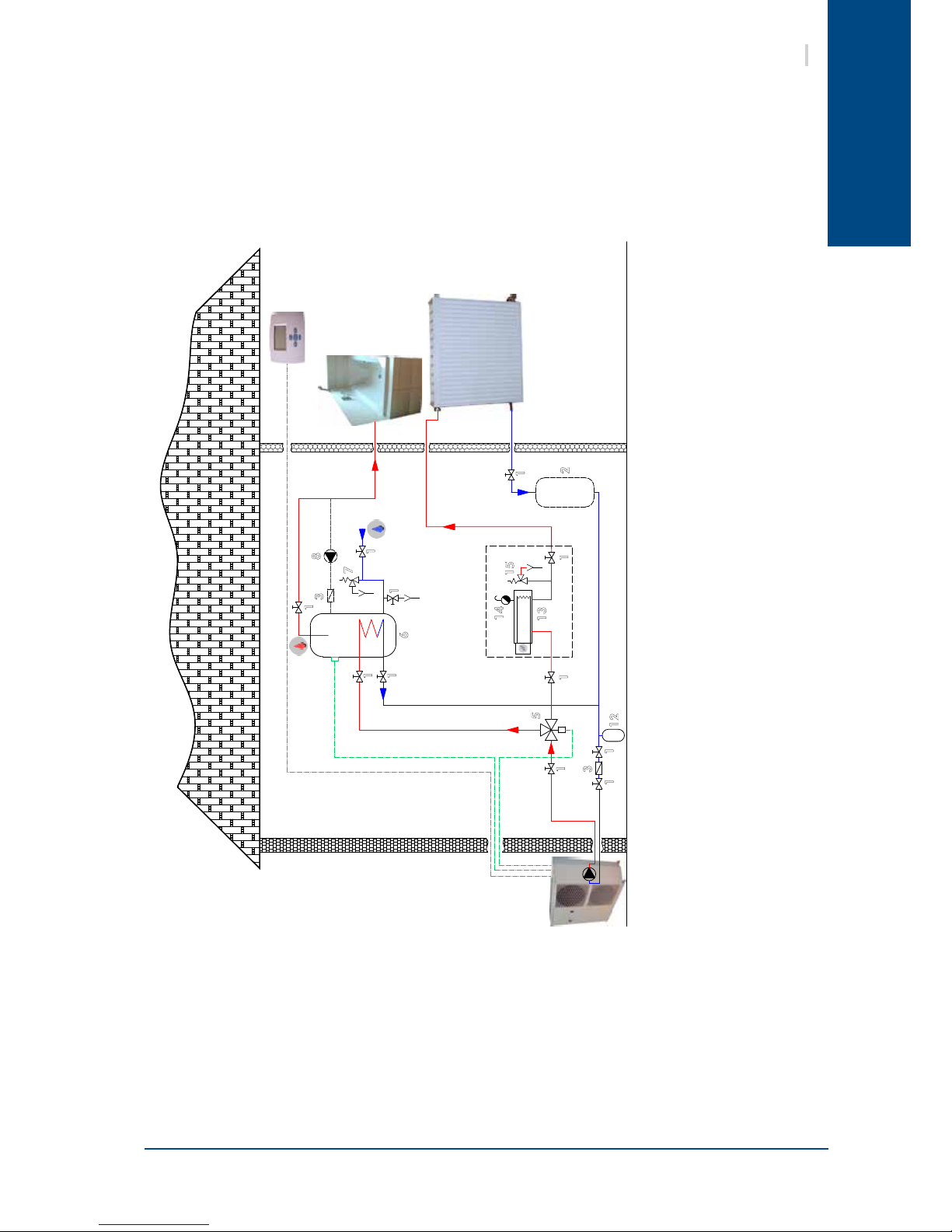

Layout 1: Application without room by room regulation

This layout is recommended when the Aqu@ Scop HT water ow is continuous and close to the nominal

value (no thermostatic valves).

The buffer tank (2) provides extra circulating water volume to maintain the minimum volume.

12.2. STANDARD CIRCUITS

12.2.1. AQU@ SCOP HT ONLY

1. Stop cocks

2. Buffer tank (optional)

3. Filter or sludge trap

4. Relief valve

5. 3-way valve – Domestic Hot Water

6. Domestic Hot Water tank

7. Safety devices

8. Recycling circulation pump

(optional)

12. Expansion tank

13. In-line heater

14. Bleed

15. Safety valve

Page 16

English

1

3

2

4

1 1

1

1

1

1

3

1

5

6

7

8

9

1

1

11

12

15

1

14

13

14

Aqu@Scop HT V2

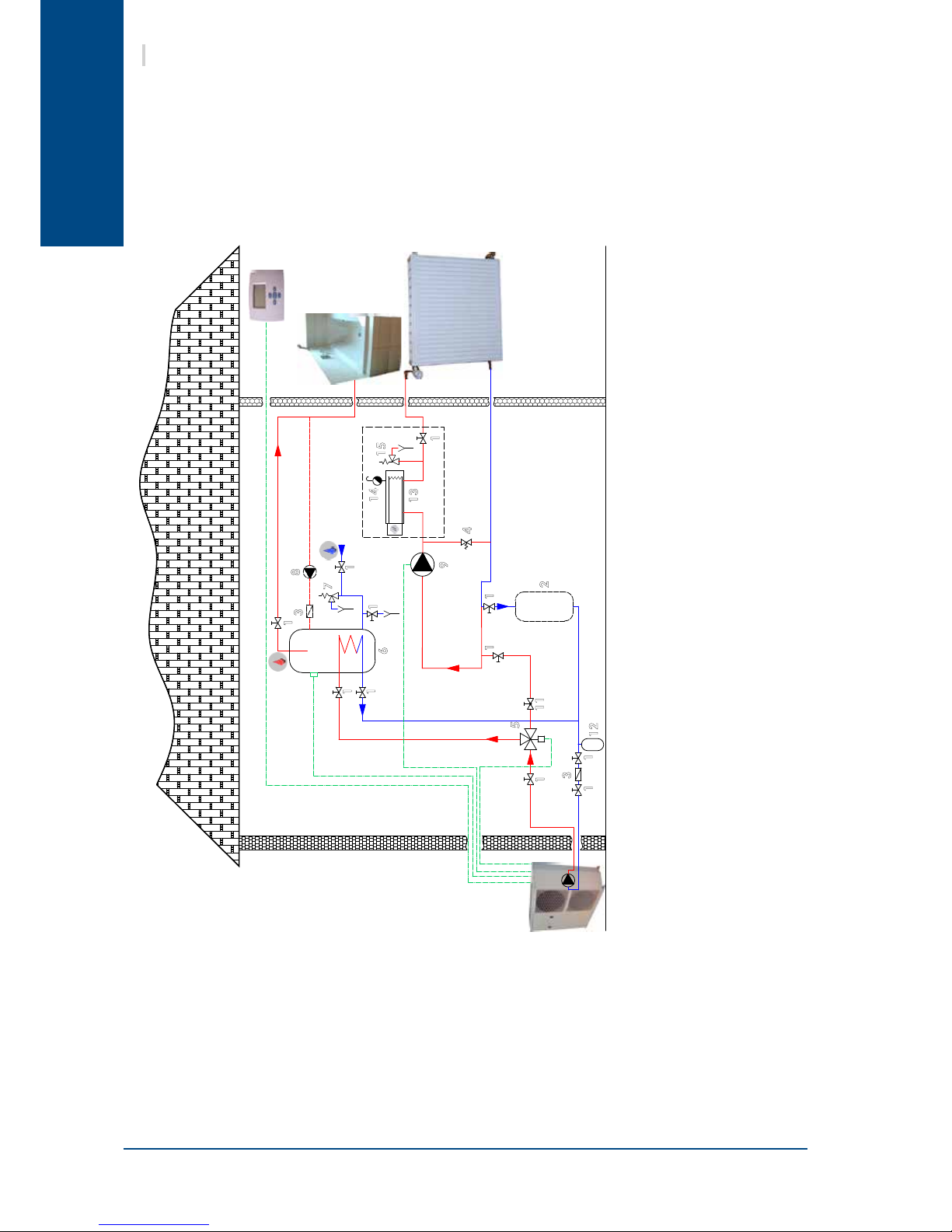

Layout 2: Application with room by room regulation

This layout is recommended for heating installations with wide operating water ow variations (radiator

thermostatic valves present in the system). We strongly recommend including the buffer tank (2) as it

guarantees that the heating loop capacity is higher than the minimum volume when the maximum number

of thermostatic valves are closed.

The ow regulating valve (11) is used to balance the ow in heating mode and domestic hot water production

mode to always ensure optimum Aqu@ Scop HT operation.

1. Stop cocks

2. Buffer tank (optional)

3. Filter or sludge trap

4. Relief valve

5. 3-way valve – Domestic Hot Water

6. Domestic Hot Water tank

7. Safety devices

8. Recycling circulation pump

(optional)

9. Circulation pump

11. Flow regulating valve

12. Expansion tank

13. In-line heater

14. Bleed

15. Safety valve

Page 17

English

1

3

10

4

1 1

1

1

1

3

1

5

6

7

8

9

1

1

1

1

1

11

12

15

1

14

13

15

Aqu@Scop HT V2

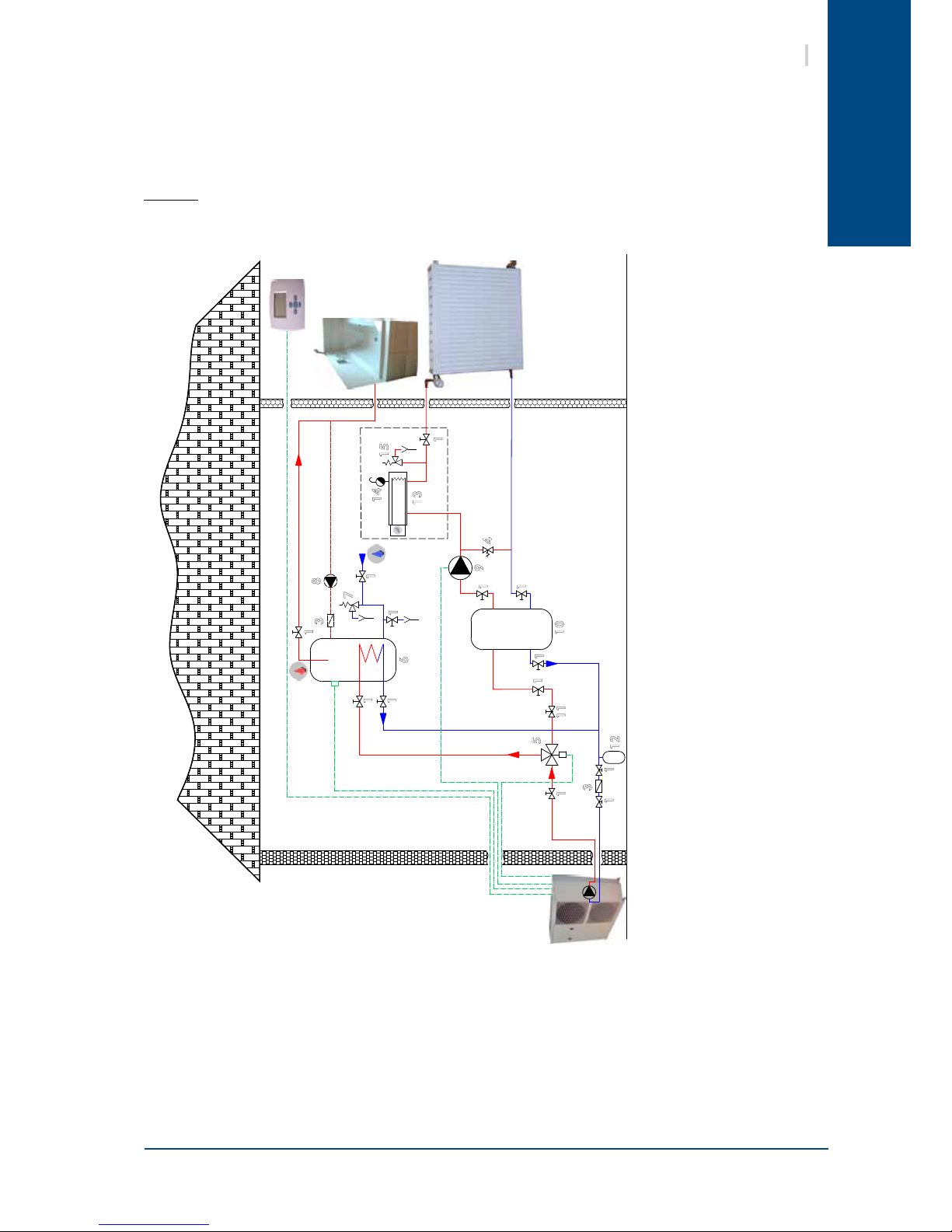

Layout 3: Application with room by room regulation

This layout is also recommended for heating installations with wide operating water ow variations (radiator

thermostatic valves present in the system). Minimum system volume is guaranteed by a mixing tank (10).

Take care when calculating the volume of water in the installation and only take account of 50% of the

mixing tank's volume.

Example: For a useful volume of 100 litres the actual mixing tank volume will be 200 litres.

The ow regulating valve (11) is used to balance the ow in heating mode and domestic hot water production

mode to always ensure optimum Aqu@ Scop HT operation.

1. Stop cocks

3. Filter or sludge trap

4. Relief valve

5. 3-way valve – Domestic Hot Water

6. Domestic Hot Water tank

7. Safety devices

8. Recycling circulation pump

(optional)

9. Circulation pump

10. Mixing tank

11. Flow regulating valve

12. Expansion tank

13. In-line heater

14. Bleed

15. Safety valve

Page 18

English

1

3

10

4

1 1

1

3

1

5

6

7

8

9

1

1

1

1

1

11

12

15

1

14

13

1

1

11

18

16

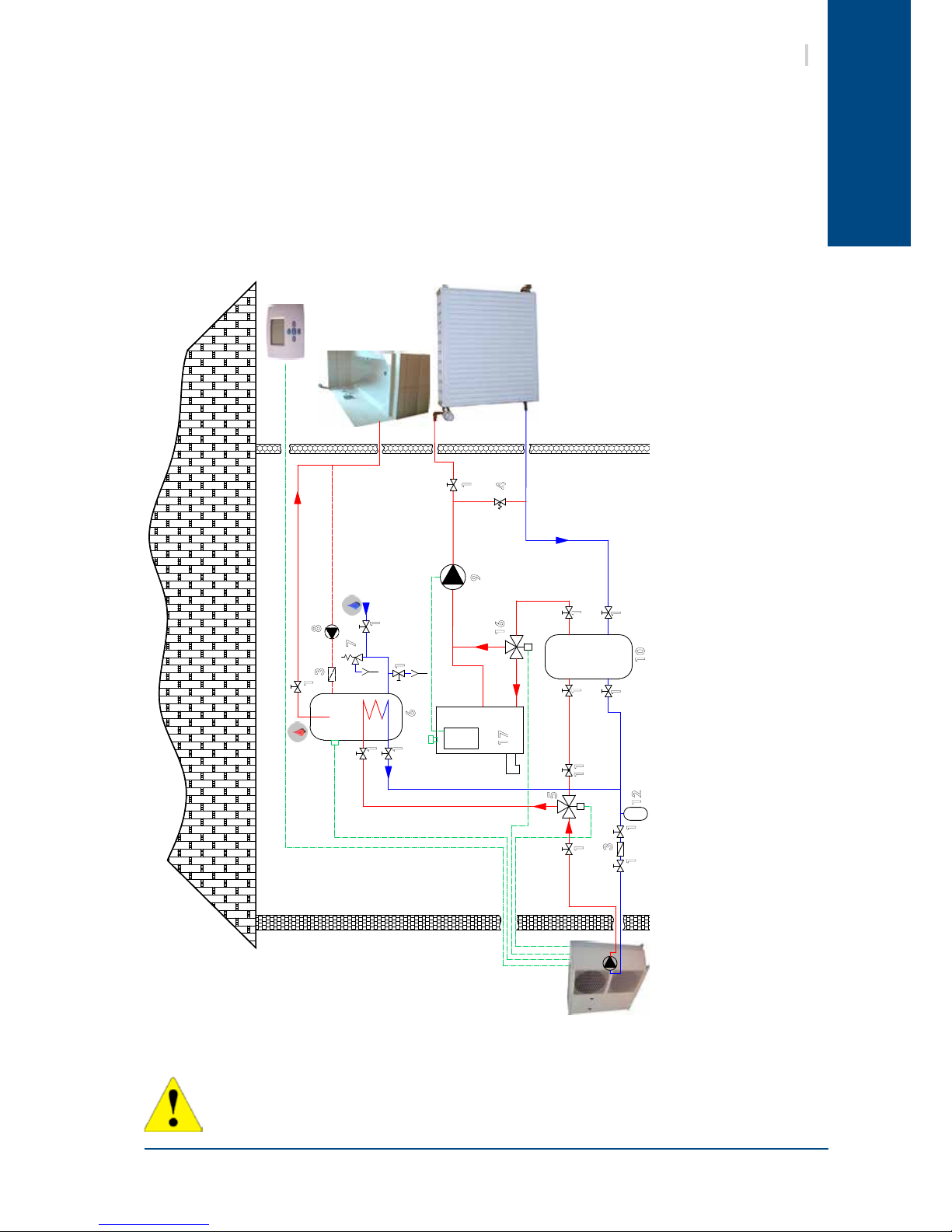

Aqu@Scop HT V2

1. Stop cocks

3. Filter or sludge trap

4. Relief valve

5. 3-way valve – Domestic Hot Water

6. Domestic Hot Water tank

7. Safety devices

8. Recycling circulation pump

(optional)

9. Circulation pump

10. Mixing tank

11. Flow regulating valve

12. Expansion tank

13. In-line heater

14. Bleed

15. Safety valve

18. Non-return valve

Layout 4: Domestic Hot Water (DHW) production by way of the plate exchanger kit for tment on the

existing DHW tank

Example for a wall-mounted tank (DHW outow via the bottom)

A different kit is required for a oor-mounted tank (DHW outow via the top). Please refer to the corresponding

documentation.

Page 19

English

1

3

4

1 1

1

1

1

3

1

6

7

8

9

1

11

12

1

16

17

5

10

1

1

1

1

17

Aqu@Scop HT V2

12.2.2. AQU@ SCOP HT AS A BOILER SUBSTITUTE

We recommend the tting of a zone valve to avoid heat losses via the boiler when the Aqu@ Scop HT is

working on its own.

All system devices should be of a suitable size to limit pressure losses.

Water ow within the heating circuit is normally driven by the circulation pump already present in the

installation (recommended solution) or by the Aqu@ Scop HT's circulation pump. In this case, you must

ensure that the circulation pump generates sufcient water pressure.

There is no need to replace the existing buffer tank on the circuit to take account of the small volume of

water added by the presence of the Aqu@ Scop HT.

IMPORTANT: the hydraulic kit available as an option enables you to prepare the circuit for connection to the

Aqu@ Scop HT in accordance with our recommendations. The hydraulic kit is available with or without zone

valves.

DO NOT FIT A BOILER SUBSTITUTE VALVE

1. Stop cocks

3. Filter or sludge trap

4. Relief valve

5. 3-way valve – Domestic Hot Water

6. Domestic Hot Water tank

7. Safety devices

8. Recycling circulation pump

(optional)

9. Circulation pump

10. Mixing tank

11. Flow regulating valve

12. Expansion tank

16. 3-way boiler substitute valve

17. Boiler

² WALL-MOUNTED GAS-FIRED BOILER with domestic hot water production and a single

circulation pump used for both heating and domestic hot water.

² BOILER with a circulation pump.

Page 20

English

1

3

1 1

1

1

1

3

1

6

7

8

1

11

12

16

17

5

10

1

1

1

1

9a

9b

19

20

21

21

18

Aqu@Scop HT V2

1. Stop cocks

3. Filter or sludge trap

4. Relief valve

5. 3-way valve – Domestic Hot Water

6. Domestic Hot Water tank

7. Safety devices

8. Recycling circulation pump (optional)

9. Circulation pump (a: radiator / b:

under-oor heating)

10. Mixing tank

11. Flow regulating valve

12. Expansion tank

16. 3-way boiler substitute valve

17. Boiler

19. Low temperature zone

(under-oor heating) 3-way

modulating valve)

20. Under-oor heating outlet

temperature probe (DZWT)

21. Collector

12.2.3. AQU@ SCOP HT – DUAL ZONE INSTALLATION (UNDER-FLOOR HEATING + RADIATORS)

The Aqu@ Scop HT manages a radiator zone (high temperature, zone 2) and an under-oor heating zone

(low temperature, zone 1) by way of an under-oor temperature outlet probe, a modulating 3-way valve

(230V 3 phase motor) and a water circulation pump for each zone.

Each zone can be controlled by a dedicated ambience terminal, which then enables the Aqu@ Scop HT to

manage 2 independent water laws. When the radiators zone is not in operation, the Aqu@ Scop HT switches

over automatically to the under-oor heating water law, and thereby optimises the seasonal COP for the

entire installation.

Page 21

English

19

Aqu@Scop HT V2

The Aqu@ Scop HTmust not run on a network with open loops, likely to cause incidents related to

oxygenation, or with non treated table water.

If the water circuit is to be drained for a time exceeding one month, the circuit must be fully

charged with nitrogen to prevent any risk of corrosion by differential venting.

The manufacturer is not liable for recommendations in terms of water treatment (call a specialized

company).

However, this matter has a critical nature, and particular care must be given to ensure that the type

of treatment applied is effective.

The liability of the manufacturer or its representative will not be sought when non treated water

or non compliant quality water is used.

12.3. WATER QUALITY

The water must be analyzed; the hydraulic network system installed must include all elements necessary

for water treatment: lters, additives, intermediate exchangers, drain valves, vents, check valves, etc.,

according to the results of the analysis.

Using improperly treated or non treated water in the Aqu@ Scop HT may cause scaling, erosion, corrosion

or algae or sludge deposits in the exchangers. Refer to a specialist skilled in water treatment to determine

any treatment to apply. The manufacturer will not be held liable for damages caused when non treated or

improperly treated water, demineralized water, salty water or sea water are used.

Apply the following guidelines :

² No NH4+ ammonium ions in the water, highly detrimental to copper. <10mg/l

² Cl- chloride ions are detrimental to copper with a risk of puncture by picking corrosion. <10mg/l.

² SO42- sulphate ions may cause perforating corrosion. < 30mg/l.

² No uoride ions (<0.1 mg/l)

² No Fe2+ and Fe3+ ions, particularly in case of dissolved oxygen. Fe< 5mg/l with dissolved oxygen

< 5mg/l. The presence of these ions with dissolved oxygen indicates corrosion of steel parts, likely

to generate corrosion of copper parts under Fe deposits, particularly in the case of multitubular

exchangers.

² Dissolved silica: silica is an acid element of water and may also cause corrosion. Content < 1mg/l.

² Water hardness: TH > 2.8K. Values between 10 and 25 may be recommended. This facilitates scaling

deposits likely to limit copper corrosion. Excess TH values may lead to clogging the pipes.

² TAC<100

² Dissolved oxygen: Prevent any sudden change in the water's oxygenation conditions. Also, avoid

deoxygenating water by sparging inert gas as well as overoxygenating it by pure oxygen sparging.

Disturbing oxygenation conditions destabilizes copper hydroxides and particle salting-out.

² Electrical Resistivity - Conductivity: The higher the resistivity, the slower the corrosion. Values above

3000 ohm/cm are preferred. A neutral environment favours maximum resistivity. For electrical

conductivity, values around 200-600 S/cm can be recommended.

² pH: neutral pH at 20°C (7 < pH < 8)

Page 22

English

20

Aqu@Scop HT V2

You must check water tightness and the cleanliness of the installation before connecting the Aqu@ Scop HT .

For the Aqu@ Scop HT 's WATER INLET and OUTLET connections, you must install manual stop cocks with

the same diameter as the main pipe work. This will enable maintenance work to be carried out on the

Aqu@ Scop HT without having to bleed the entire system.

A link valve with pressure tap kit is available.

The Aqu@ Scop HT must be protected by a water lter. When connecting this device to the Aqu@ Scop HT ,

take care to keep the water lter sieve pointing downwards. A sludge trap should be tted in the event of

high sludge build-ups.

WARNING!

Take care not to damage the hydraulic pipe links by applying too much tightening pressure. Use a second

wrench to compensate for the tightening torque.

You should always use a counter-wrench for

tightening valves.

To guarantee proper energy efciency and compliance with current standards, water pipes passing through

uninhabited zones should be properly lagged to retain heat.

To achieve correct insulation with conductivity of 0.04 W/mK, lag the pipes with insulating material with a

radial thickness between 25mm and 30 mm.

THE MANUFACTURER'S WARRANTY IS VOID IF THE FILTER SUPPLIED WITH THE AQU@ SCOP HT IS

NOT INSTALLED TO PROTECT THE APPLIANCE

AN EXPANSION TANK ADAPTED TO THE VOLUME OF WATER IN THE INSTALLATION MUST BE

INSTALLED.

It is important to ensure that the mains water supply pressure is sufficient to fill the installation.

12.4. CONNECTION TO THE CENTRAL HEATING LOOP

12.5. HEAT INSULATION

Page 23

English

21

Aqu@Scop HT V2

12.6. FILLING THE SYSTEM WITH WATER

Once the installation is complete and after having clean and rinsed out the circuit network, you must ll

the water circuit in accordance with current professional standards until you obtain the service pressure

which will be:

0.5 bar < P. service < 2.5 bars.

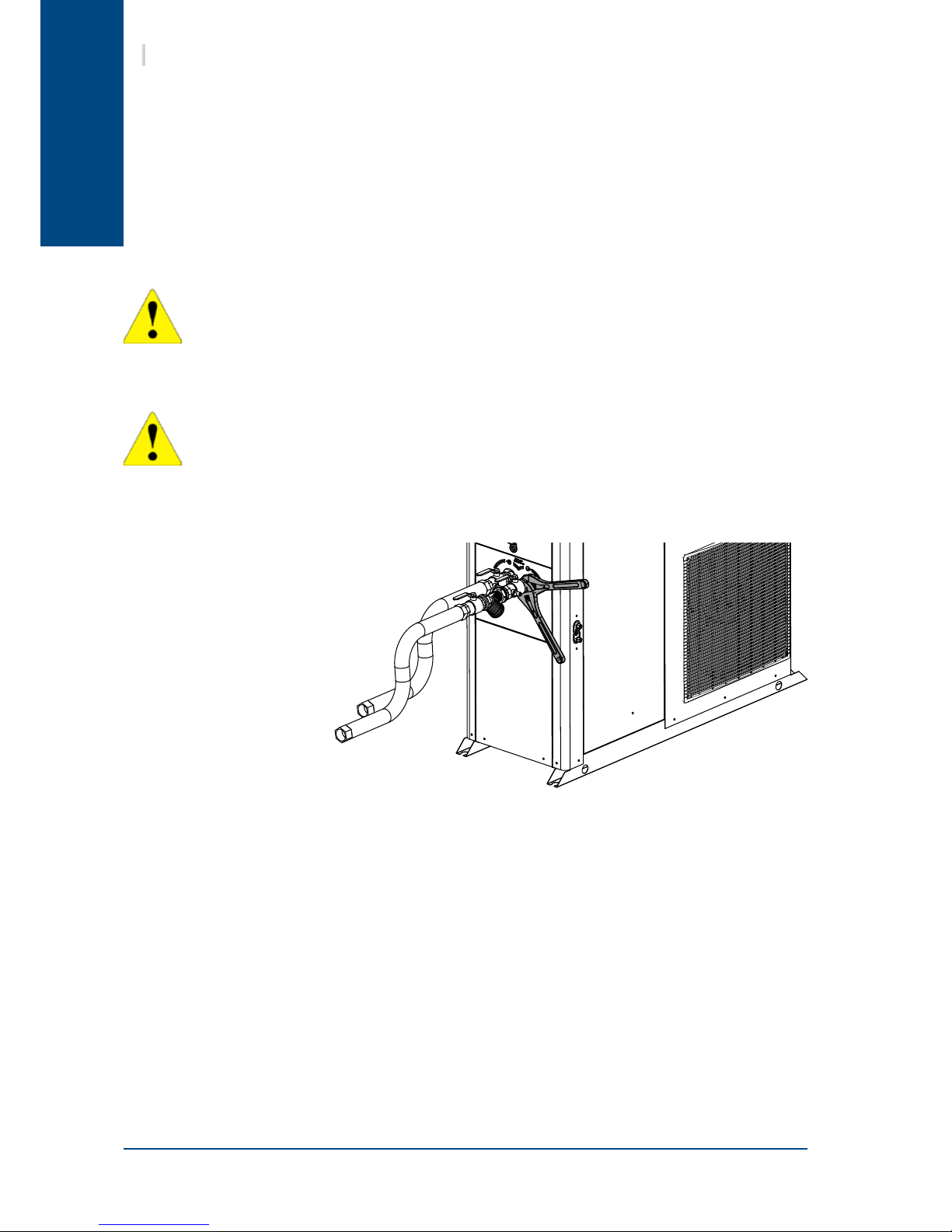

The Aqu@ Scop HT is equipped with an electronic water pressure sensor. This can be viewed on the main P1

screen on the display, as well as on the Maintenance screens.

The water supply should come either from the mains network or from the

Heat Pump or from any other point on the installation.

Check that the automatic bleed valve operates correctly.

You must completely bleed the circuit of all air to ensure efcient operation.

Close the inlet water valve once the hydraulic circuit is lled correctly.

The condenser water circuit is equipped with a vortex effect electronic ow

meter. This device provides real-time readings of the installation's water ow

and reassurance that this ow is adequate before starting the unit.

The appliance is also equipped with a group of safety devices including a

valve set at 3 bars, and a manual relief valve.

Water ow can be viewed on screen P2 as well as on the Maintenance screens.

Use the water circulation pump speed selector to adjust the ow in the installation at the recommended

nominal value (Refer to the § PHYSICAL CHARACTERISTICS, page 7). Pressure drop of the installation

must be situated in the circulator operating range.

12.7. ELECTRONIC FLOW METER

12.8. WATER FLOW REGULATION

Page 24

English

22

Aqu@Scop HT V2

13. WIRING DIAGRAM AND LEGEND

N 802

13.1. WIRING DIAGRAM

SEE APPENDIX

13.2. LEGEND

13.2.1. POWER SUPPLY

13.2.2. WIRING DIAGRAM KEY DESCRIPTIONS

FT1/2 : M1/2 compressors thermo-magnetic relay (three phase models)

FF1/2 : M1/2 compressors protection fuse carrier (single phase models)

KM1/2 : M1/2 compressors power contactor or relay

M1/2 : Compressors

CM1/2 : M1/2 compressors capacitors (single phase models)

AS1/2 : "Soft START" starter

R1/2 : Sump resistance

OF1/2 : Air exchanger fan motor

KOF1 : OF1 fan motor relay

FOF1/2 : OF1/2 motors internal safety

COF1/2 : OF1/2 motors capacitors

CF : OF1/2 fan motor variator

RAG : anti-freeze resistance

TAG : anti-freeze thermostat

FFC : Control circuit protection fuse carrier

Terminal connections:

230V +/-10% 50Hz

² L : phase

² N : neutral

² : ground

3N~400V +/-10% 50Hz

² L1 (L1) : phase

² L2 (L2) : phase

² L3 (L3) : phase

² N (N) : neutral

² : ground

This supply comes from a CIRCUIT BREAKER or a FUSE HOLDER equipped with aM type fuses supplied by the

installer. Fuse sizes are indicated on the chart on the following page.

The appliance's electrical installation and wiring must comply with the country's current standards.

SE 4213 Aqu@ Scop HT 12-6 Power 1-Phase 230V +/-10% 50Hz

SE 4214 Aqu@ Scop HT 12-6 Control 1-Phase 230V +/-10% 50Hz

SE 4215 Aqu@ Scop HT 14-7 Power 1-Phase 230V +/-10% 50Hz

SE 4216 Aqu@ Scop HT 14-7 Control 1-Phase 230V +/-10% 50Hz

SE 4217 Aqu@ Scop HT 12-6/14-7 Power 3-Phases 3N~400V +/-10% 50Hz

SE 4218 Aqu@ Scop HT 12-6/14-7 Control 3-Phases 3N~400V +/-10% 50Hz

SE 4219 Aqu@ Scop HT 18-9 Power 3-Phases 3N~400V +/-10% 50Hz

SE 4220 Aqu@ Scop HT 18-9 Control 3-Phases 3N~400V +/-10% 50Hz

Page 25

English

23

Aqu@Scop HT V2

KA1 : Phase sequence and cut-out control module (three phase models)

µPC : Controller

FT1/2 : Thermo-magnetic relays ancillary contacts for M1/2 compressors

HP : Automatic reset high pressure switch

EEV : Electronic pressure relief valve

IHP : Intermediate high pressure switch

DHP : De-icing high pressure switch

RV : 4-way cycle changeover valves

ISV : Injection valve

DRV : De-icing valve

ESV : Oil equalization valve

EP : Pressure transducer (evaporation pressure)

OCT : De-icing temperature probe (evaporator inlet)

OAT : Outdoor temperature probe

CDT : High discharge temperature

CST : Evaporation temperature probe

FFT : T1 transformer protection fuse (24V secondary circuit)

T1 : Ambience terminal 230/24V power supply transformer

WFL : Flow meter (water flow measurement)

WPR : Water pressure sensor

WP : Water pump

KWP : WP water pump relay

EWT : Inlet water temperature probe

LWT : Outlet water temperature probe

13.2.2.1. OPTIONS

DZ WP/2 : Dual zone water pumps

DZ MV : Dual zone mixer valve

AEH1 : Backup electric heating (Stage 1)

AEH2 : Backup electric heating (Stage 2)

BOILER : Hot water boiler (ON dry switch)

DHW WP : Domestic Hot Water circulation pump (kit with plate exchanger)

DHW V : Domestic Hot Water 3-way valve

DHW EH : Domestic Hot Water tank electric heating resistance

BR V : Substitute Boiler 3-way valve

DZWT : Dual zone water temperature probe (Under-floor heating outlet)

DHWT : Domestic hot water temperature probe

SPWT : Swimming pool water temperature probe

ON/OFF : Remote ON/OFF switch (Summer/Winter parameter settings)

LS : Off-peak hours electricity contact (DHW)

EMH : Backup heating switch (electric heater and boiler substitution)

Page 26

English

24

Aqu@Scop HT V2

13.2.3. CONTACTOR FUSE RATINGS, NOMINAL CURRENTS SETTINGS (CLASS AC3/AC1)

Supply voltages

3N~400V +/-10% 50Hz

12-6 14-7 18-9

Only Aqu@ Scop HT

General protection fuse rating (not supplied) aM type (1)

16A 16A 20A

Fuse ratings

FFC aM type

6A 6A 6A

FFT T type

1.6A 1.6A 1.6A

Thermo-magnetic cut-out switch

FT1 Plage

9 - 14A 9 - 14A 9 - 14A

Réglage

10A 11A 13A

FT2 Plage

4 - 6.3A 4 - 6.3A 4 - 6.3A

Réglage

4.2A 5.1A 5.6A

Contactors

KM1

12A 12A /

KM2

9A 9A 9A

(1) These values are provided for information purposes only and must be checked and adjusted in relation to

currently applicable standards. They vary depending on the type of installation and the choice of conductors.

Supply voltages

230V +/-10% 50Hz

12-6 14-7

Only Aqu@ Scop HT

General protection fuse rating (not supplied) aM type (1)

32A 32A

Fuse ratings

FF1 aM type

25A 25A

FF2 aM type

12A 16A

FFC aM type

6A 6A

FFT T type

1.6A 1.6A

Contactors

KM2

12A /

Page 27

English

25

Aqu@Scop HT V2

14. ELECTRICAL CONNECTIONS

WARNING

Before carrying out any work on the equipment,

make sure that the electrical power supply is

disconnected and that there is no possibility

of the unit being started inadvertently.

Non-compliance with the above instructions

can lead to injury or death by electrocution.

The electrical installation must be performed by a fully qualied electrician, and in accordance with local

electrical standards and the wiring diagram corresponding to the unit model.

Any modication performed without our prior authorisation may result in the unit’s warranty being declared

null and void.

The power supply cable section must be sufcient to provide the appropriate voltage to the unit’s power

supply terminals, both at start-up and under full load operating conditions.

The use of under-sized power supply cables can lead to major losses of around 100W to 200W.

The power supply cable shall be selected in accordance with the following criteria:

1. Power supply cable length.

2. Maximum unit starting current draw – the cables shall supply the appropriate voltage to the unit

terminals for starting.

3. Power supply cables’ installation mode.

4. Cables’ capacity to transport the total system current draw.

Short circuit protection shall be provided. This protection shall comprise fuses or circuit breakers with high

breaking capacity, mounted on the distribution board.

If the planned installation includes an ambience terminal, the latter must be connected with shielded cable

which must not run through the same conduits as the power supply cables, as the possible voltage generated

could cause a unit operating fault.

VERY IMPORTANT:

3N~400V-50HZ

The outdoor unit is equipped as standard with a phase sequence and cut-out controller located in the

electrical box.

THE LED’s INDICATE THE FOLLOWING CONDITIONS:

Green LED = 1

Yellow LED =1

Power ON

The compressor rotation

direction is correct.

Green LED = 1

Yellow LED =0

Phase inversion or phase

absent (L1)

The compressor and the fans

do not start.

Green LED = 0

Yellow LED =0

Phase absent (L2 or L3)

The compressor and the fans

do not start.

14.1. PHASE SEQUENCE AND CUT-OUT CONTROLLER

Page 28

English

26

Aqu@Scop HT V2

14.2. PROGRESSIVE START-UP

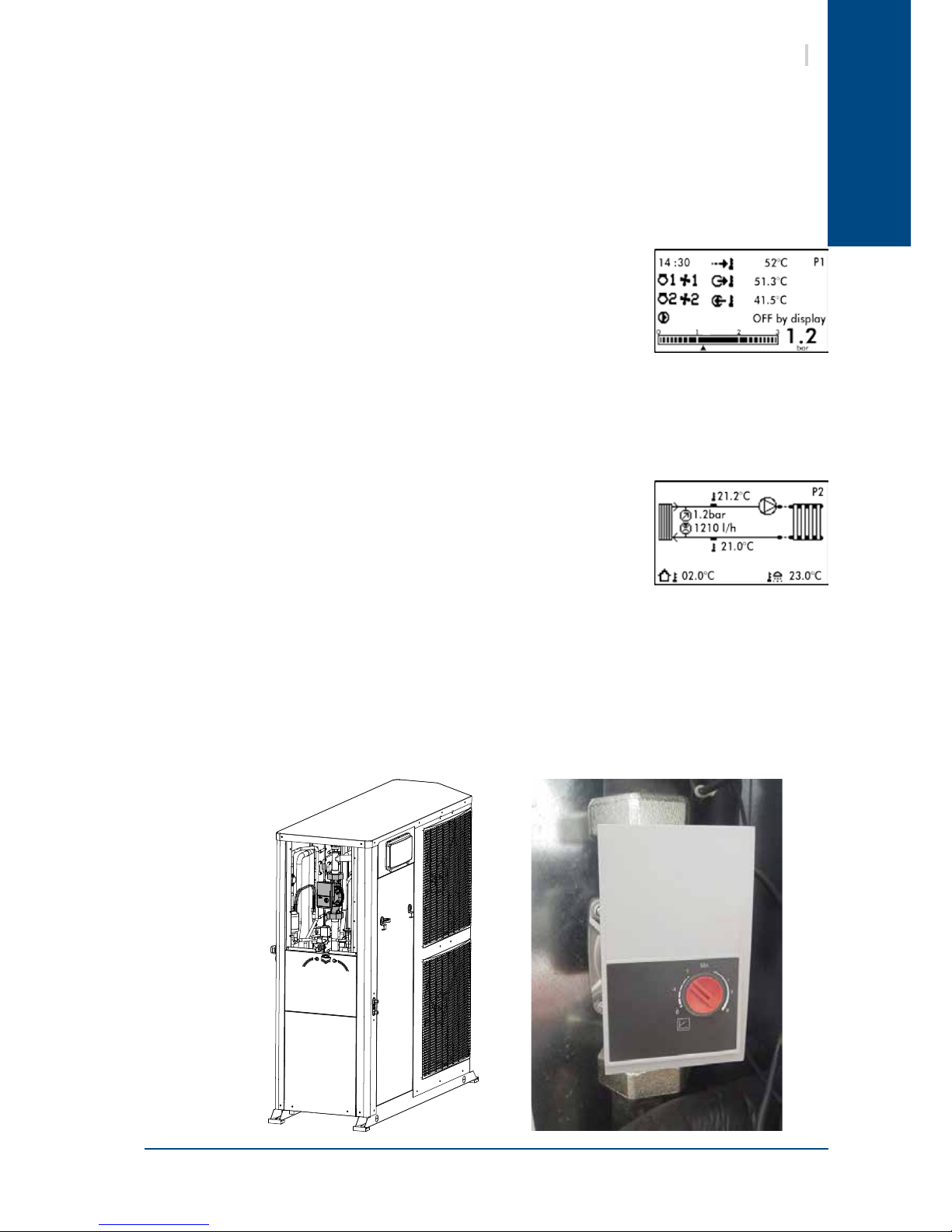

The Aqu@ Scop HT 18-9 is equipped with a progressive starter

(soft start) for the C1 compressor. The starter is situated in the

electrical box of the outdoor unit and marked "AS1".

It is important to check the following settings:

² Start slope 1s

² Stop slope 0s

² Minimum starting voltage 60%

Start slope

Stop slope

Minimum

starting

voltage

3N~400V-50HZ

IMPORTANT :

The compressors are equipped with a soft starter. The starter is situated in the electrical box of the outdoor

unit and marked "AS1/2".

230V +/-10% 50Hz

THE LED’s INDICATE THE FOLLOWING CONDITIONS:

Green

diode

Red diode Meaning Recommended action Comments

On Off No fault

Off Off

No supply voltage present

at starter terminals.

Check the power supply to the PAC.

Check the condition of the 230V

protection fuse. Replace the fuse if it

has melted.

Flashing Off

Insufficient supply voltage

(compressor stopped).

Measure the compressor starter

supply voltage at rest. Cut the power

supply to the PAC and check whether

or not the fault reappears. Refer to

the following cause in the event of

repeated failure.

Defective starter power

supply component.

Cut the power supply to the PAC. If the

fault persists, replace the starter.

On

Flashing

twice

Insufficient compressor

starting voltage (<190V).

Check the mains supply voltage at

rest. Contact the electricity supplier if

< 207V.

The alarm resets itself automatically

after 5 min. If the fault re-occurs

during the next start-up procedure,

the compressor seizes and the power

supply has to be disconnected to reset

it.

With the compressor running, check

the mains supply voltage and the

starter output voltage. In the event of

major voltage drop, check the diameter

of the PAC power supply cable. As

a last resort, contact the electricity

supplier.

On

Flashing 3

times

Excessive compressor

starting current.

Force the compressor to start several

times and check whether it is a oneoff or recurring fault.

The alarm resets itself automatically

after 5 min. If the fault re-occurs

during the next start-up procedure,

the compressor seizes and the power

supply has to be disconnected to reset

it.

If the fault persists, when the

compressor is running, check for

normal current draw. In the event of

excessively-high current draw, replace

the compressor.

Starter fault. Replace the starter.

On

Flashing 4

times

Starter internal condenser Replace the starter.

On

Flashing 5

times

Incomplete or defective

compressor starting

sequence

Force the compressor to start several

times and check whether it is a oneoff or recurring fault.

The alarm resets itself automatically

after 5 min. If the fault re-occurs

during the next start-up procedure,

the compressor seizes and the power

supply has to be disconnected to reset

it.

In the event of a persistent fault, check

the compressor power supply cable.

Page 29

English

NN L LNN

L1

L1 L2 L3

27

Aqu@Scop HT V2

14.3. CONNECTIONS

A circuit breaker or fuse holder ( not supplied ) must be installed on the main power supply of the unit in

accordance with the circuit diagram; for the ratings, refer to the electrical specications.

Remove the inspection cover to gain access to the electrical connection box.

Pass the power supply cable through the cable passage provided on the appliance.

Install end ttings suitable for the cable section to ensure a good contact. Make the connections as shown.

14.3.1. MAINS POWER SUPPLY

INSPECTION

COVER

MAINS POWER SUPPLY

ELECTRICAL CABLE

PASSAGE

MAINS POWER

SUPPLY 400V

MAINS POWER SUPPLY

230V

MAINS POWER

SUPPLY

3N~400V-50HZ 230V +/-10% 50Hz

Page 30

English

A

B

24V AC

24V AC

GND

{

{

A

B

24V AC/1

24V AC/2

GND

{

{

28

Aqu@Scop HT V2

14.3.2. AMBIENCE TERMINAL

AMBIENCE TERMINAL

CONNECTION

COMMUNICATION

POWER SUPPLY

2 separate cables for

power supply (24V) and

communication (A-B-GND).

Power supply 24V:

Single pair cable: 1 mm²

Communication:

Shielded twisted single pair

cable with screen 0.33 mm²

to 0.5mm² (AWG 20/22)

COMMUNICATION

POWER SUPPLY

Page 31

English

µPC

µPC

µPC

29

Aqu@Scop HT V2

15. DOMESTIC HOT WATER

Fit the valve in accordance with the ow direction marks etched on the valve.

THE CONNECTIONS MUST CORRESPOND EXACTLY WITH THE FLOW DIRECTIONS INDICATED ON THE LAYOUT

DIAGRAM FOR THE TYPE OF INSTALLATION.

15.1. CONNECTION TO THE CENTRAL HEATING LOOP

An On-Off 3-way valve directs hot water produced by the Aqu@ Scop HT to either the heating circuit or

the domestic hot water tank. Hydraulic connections must be made in accordance with the circuit layout

diagrams provided.

Warning: You must ensure that the 3-way valve orices (marked A, B and AB) are connected correctly to the

circuit in order for the valve to operate in accordance with the electrical diagram provided.

Position the ow changeover

control in the Y1 position.

A

B

AB

Motor disengagement

DOMESTIC HOT

WATER TANK

Aqu@ Scop HT

HEATING

CIRCUIT

DHW VALVE DHW TANK DHW SENSOR

15.1.1. 3-WAY HEATING / DOMESTIC HOT WATER VALVE

15.1.1.1. ELECTRICAL CONNECTIONS

Page 32

English

PROG

Main screens P1 P4

Screen Reference

INSTALLATION MENU

ENTER

Power on screen

ESC

INSTALLATION MENU

MAIN MENU

MP

ON/OFF-SUM/WIN

O0

HEAT CURVE

L1 L4

DOMESTIC HOT WATER

ES0 ES10

ROOM TERMINAL

TH0 TH3

ALARM LOG

H1 H2

OPERATING TIME

TM1 TM2

Screen Reference

Password

NEW PASSWORD

MANUAL OUPUTS

MANUAL DEICING

COMPRESSOR MNGT

MAINTENANCE

INSTALLATION CONFIG

DUAL ZONE

BOILER RELIEF

ELECTRIC HEATER

IE1 IE7

DOMESTIC HOT WATER

WATER SETPOINT

WATER PUMP

MI

ENTER ENTER

ENTER

BOILER RELIEF

R0 R1

30

Aqu@Scop HT V2

The Aqu@ Scop HT controller manages domestic hot water production in accordance with the following

operating modes:

² PERMANENT COMFORT MODE

Domestic hot water production has priority over heating except when the ambiance temperature /

set temperature difference is greater than 2° C (Maximum one hour).

Example: Set temperature = 20°C, Ambience < 18°C

² ECONOMY MODE

Domestic hot water is produced during off-peak hours (dry contact) or in accordance with times

programmed in the controller.

Option: Possibility to restart domestic hot water production outside off-peak hours if the water

temperature has reached a programmable minimum temperature.

² IMMEDIATE DOMESTIC HOT WATER PRODUCTION

The Aqu@ Scop HT 's regulator enables domestic hot water production to be forced as required. At

the end of the cycle, the system returns to its usual operating mode.

15.2. DOMESTIC HOT WATER PRODUCTION MODES

15.3. DOMESTIC HOT WATER HEATING FUNCTION ACTIVATION

The Legionnaires' Disease protection treatment managed by the Aqu@ Scop HT 's controller is fully

programmable (frequency, temperature threshold, treatment length).

The PERMANENT COMFORT and ECONOMY modes place priority on thermodynamic heating. In the event of

excessive demand for Domestic Hot Water Temperature that does not permit the compressor(s) to operate,

the backup electric heating function is activated. In order to achieve energy savings, it is important to use

the lowest possible set temperature points.

We recommend:

Eco set temperature < Comfort set temperature < 53°C

Page 33

English

PROG

Main screens P1 P4

Screen Reference

INSTALLATION MENU

ENTER

Power on screen

ESC

INSTALLATION MENU

MAIN MENU

MP

ON/OFF-SUM/WIN

O0

HEAT CURVE

L1 L4

DOMESTIC HOT WATER

ES0 ES10

ROOM TERMINAL

TH0 TH3

ALARM LOG

H1 H2

OPERATING TIME

TM1 TM2

Screen Reference

Password

NEW PASSWORD

MANUAL OUPUTS

MANUAL DEICING

COMPRESSOR MNGT

MAINTENANCE

INSTALLATION CONFIG

DUAL ZONE

BOILER RELIEF

ELECTRIC HEATER

EH0 EH7

DOMESTIC HOT WATER

WATER SETPOINT

WATER PUMP

MI

ENTER ENTER

ENTER

BOILER RELIEF

R0 R1

31

Aqu@Scop HT V2

16. IN-LINE ELECTRIC HEATER

16.1. ELECTRICAL CONNECTIONS

16.2. OPERATING MODE

SEE APPENDIX

Operating parameters for these modes can be set via the display on the Aqu@ Scop HT .

16.2.1. BOOST MODE

The backup electric heating offers additional capacity when the demand for heating is higher than the

capacity of the Aqu@ Scop HT. The aim is to maintain occupant comfort, while favouring thermodynamic

operation for optimised performance.

The resistances are only activated below a certain outdoor temperature (values can be set for Stage 1, AEH1

and Stage 1+2, AEH1+AEH2) and only if the Aqu@ Scop HT regulation system detects a lack of capacity in

compressor only mode (check on water temperature and ambient temperature).

Activation of the EMH Back-up switch on the heater switches the Aqu@ Scop HT into Back-up mode.

16.2.2. BACK-UP MODE

As opposed to Booster mode, this mode operates only when the user activates the EMH Back-up switch

(this supposes an alarm on the Aqu@ Scop HT ). Outdoor temperature conditions are overridden and priority

is no longer given to the thermodynamic mode but to the heating resistances that are nevertheless still

controlled by the Aqu@ Scop HT .

16.3. ELECTRIC HEATER FUNCTION ACTIVATION

Page 34

English

PROG

Main screens P1 P4

Screen Reference

INSTALLATION MENU

ENTER

Power on screen

ESC

INSTALLATION MENU

MAIN MENU

MP

ON/OFF-SUM/WIN

O0

HEAT CURVE

L1 L4

DOMESTIC HOT WATER

ES0 ES10

ROOM TERMINAL

TH0 TH3

ALARM LOG

H1 H2

OPERATING TIME

TM1 TM2

Screen Reference

Password

NEW PASSWORD

MANUAL OUPUTS

MANUAL DEICING

COMPRESSOR MNGT

MAINTENANCE

INSTALLATION CONFIG

DUAL ZONE

BOILER RELIEF

IR0 IR4

ELECTRIC HEATER

DOMESTIC HOT WATER

WATER SETPOINT

WATER PUMP

MI

ENTER ENTER

ENTER

BOILER RELIEF

R0 R1

32

Aqu@Scop HT V2

17. BOILER RELIEF

17.1. ELECTRICAL CONNECTIONS

The boiler relief function uses the digital outputs of the in-line electric heater function to control the hot

water boiler ON/OFF switch (Boiler dry contact switch) as well as a 3-way valve output (230V BRV). A

switch should be wired to the ICS input to ensure operation in Back-up mode.

We strongly recommend the installation of the ambience terminal for effective operation

of the Boiler Relief function. In the absence of an ambience terminal the Aqu@ Scop HT will

be unable to optimise hot water boiler operation and this will lead to unnecessary energy

consumption.

17.2. OPERATING MODES

Operating parameters for these modes can be set via the display on the Aqu@ Scop HT.

17.2.1. BOOST MODE

Hot water boiler operation is only authorised below a certain set outdoor temperature value and the appliance

can also be placed in forced shutdown mode below a different outdoor temperature value. Just as the

electric heater, the Aqu@ Scop HT continuously checks the water temperature and the ambient temperature

to optimise compressor operation and to only start the hot water boiler when absolutely necessary.

The Aqu@ Scop HT can also be set to manage a heat curve on the hot water boiler higher than the

temperature set for the appliance (65° C maximum).

17.2.2. BACK-UP MODE

Activation of the EMH switch (to be wired by the installer) or the Back-up parameter, via the "Boiler Relief"

tab on the main menu of the Aqu@ Scop HT display, switches the system into Back-up mode and both

outdoor temperature and ambient temperature conditions are overridden.

17.3. BOILER RELIEF FUNCTION ACTIVATION

Page 35

English

PROG

Main screens P1 P4

Screen Reference

INSTALLATION MENU

ENTER

Power on screen

ESC

INSTALLATION MENU

MAIN MENU

MP

ON/OFF-SUM/WIN

O0

HEAT CURVE

L1 L4

DOMESTIC HOT WATER

ES0 ES10

ROOM TERMINAL

TH0 TH3

ALARM LOG

H1 H2

OPERATING TIME

TM1 TM2

Screen Reference

Password

NEW PASSWORD

MANUAL OUPUTS

MANUAL DEICING

COMPRESSOR MNGT

MAINTENANCE

INSTALLATION CONFIG

DUAL ZONE

DZ1 DZ8

BOILER RELIEF

ELECTRIC HEATER

DOMESTIC HOT WATER

WATER SETPOINT

WATER PUMP

MI

ENTER ENTER

ENTER

BOILER RELIEF

R0 R1

You MUST install one room terminal per zone.

33

Aqu@Scop HT V2

18. DUAL ZONE

18.1. ELECTRICAL CONNECTIONS

SEE APPENDIX

18.2. ACTIVATING THE DUAL ZONE FUNCTION

18.3. AMBIENCE TERMINAL

CHANGING THE AMBIENCE TERMINAL ADDRESS FOR ZONE 2.

See the communicating ambiance terminal's installation manual (IOM WATTS 01-N-2ALL).

The double zone function requires the use of one ambiance terminal per zone. You must specify one address

per ambiance terminal.

² Zone 1 : Address 1

² Zone 2 : Address 2

You must specify the type of emitter for each zone. Zone 1 corresponds to the

low temperature zone. Setting the Aqu@Scop HT controls the water output

temperature using the DZMV modulating valve and the DZWT temperature

sensor.

Page 36

English

34

Aqu@Scop HT V2

19. COMMISSIONING

19.1. PRE-START CHECK LIST

1. Electrical installation has been carried out according to unit wiring diagram and the Supply Authority

Regulations.

2. Size fuses or circuit breaker has been installed at the main power supply.

3. Supply voltages as specied on unit wiring diagram.

4. Check the tightness of wire to component connections.

5. the cables and wires are clear of or protected from pipework and sharp edges.

6. Check the electrical grounding of the appliance.

1. Check that the external water circuit components (pumps, user equipment, lters, expansion tank

and reservoir if supplied) have been correctly installed in accordance with the manufacturer’s

recommendations and that the water inlet and outlet connections are correct.

2. Check the presence, direction and position of the water lter upstream of the appliance. Rinse the

lter after the rst 2 hours of operation.