Page 1

205913 (A003)

TLP

Operation and maintenance instructions……….3

Drift och underhållsinstruktion……………….………5

Käyttö- ja huolto-ohjeet…………………….………..…..7

Instructions d’utilisation et d’entretien....................9

Instrukcja obsługi i konserwacji...............................11

Руководство по эксплуатации и

техническому обслуживанию……….......………..13

GB

SE

FI

FR

PL

RU

Page 2

2

TLP 125/1,2 TLP 160/2,1

TLP 200/3,0 TLP 200/5,0 TLP 200/5,4 TLP 315/6,0

TLP 315/9,0

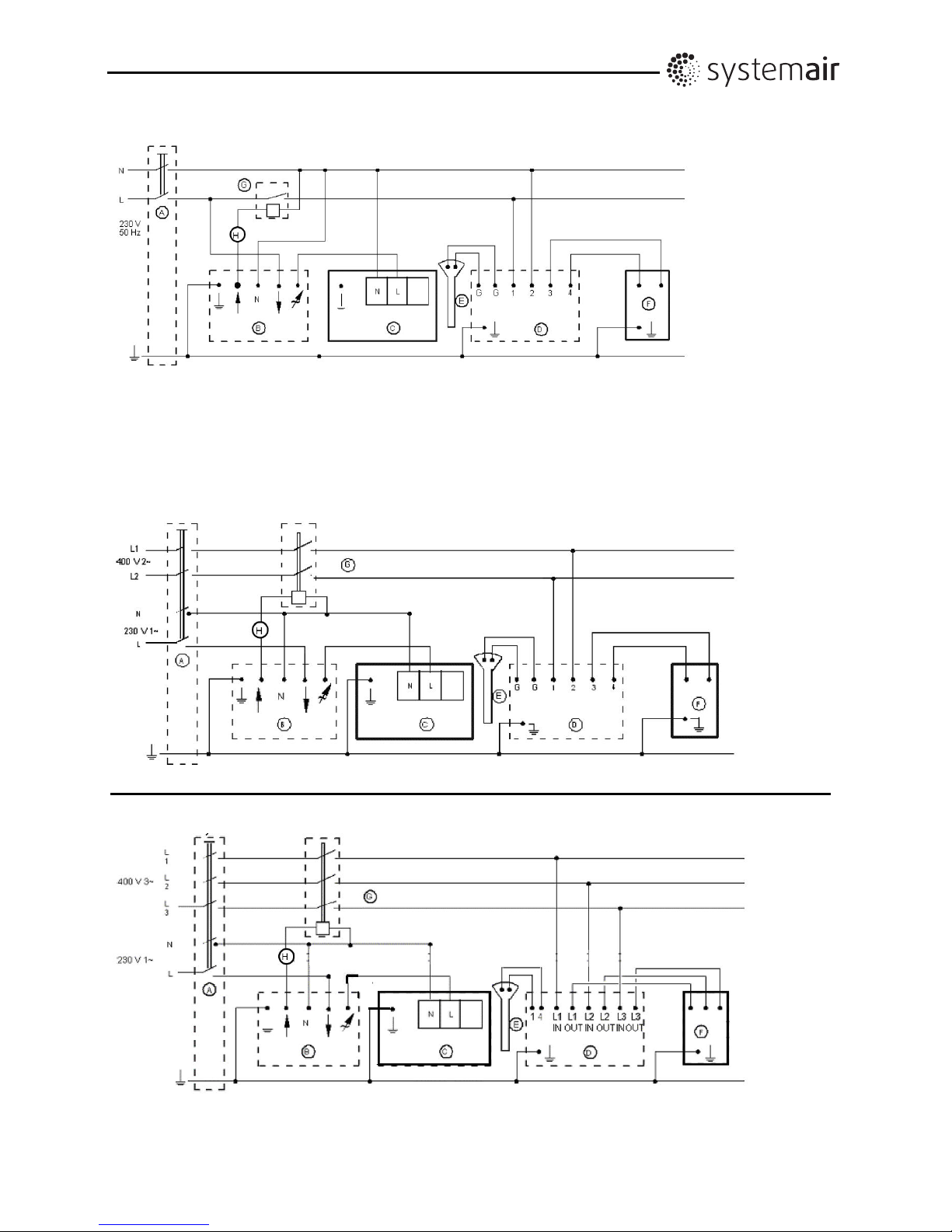

A Main switch

B Thyristor (Fan control)

C Fan

D Heat regulator (Pulser or TTC 2000)

E Temperature sensor

F Heater battery

G Relay

H Air flow guard (pressure sensor)

A Main switch

B Thyristor (Fan control)

C Fan

D Heat regulator (Pulser 230/400)

E Temperature sensor

F Heater battery

G Relay

H Air flow guard (pressure sensor)

Page 3

Original

3

GB IE

Declaration of Conformity

Manufacturer

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg SWEDEN

Office: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

hereby confirms that the following products:

Air handling unit: TLP125-315

(The declaration applies only to product in the condition it was delivered in and installed in the facility in

accordance with the included installation instructions. The insurance does not cover components that are added

or actions carried out subsequently on the product)

Comply with all applicable requirements in the following directives

Machinery Directive 2006/42/EC

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

The following harmonized standards are applied in applicable parts:

EN ISO 12100:2010 Safety of machinery - General principles for design – Risk assessment and risk reduction.

EN 13857 Safety of machinery – Safety distances to prevent hazard zones being reached by upper

or lower limbs.

EN 60204-1 Safety of machinery – Electrical equipment of machines – Part 1: General requirements

EN 60 335-1 Household and similar electrical appliances – Safety Part 1: General requirements.

EN 60 335-2-80 Household and similar electrical appliances – Safety – Part 2-80: Particular requirements

for fans.

EN 50 106:2007 Safety of household and similar appliances – Particular rules for routine tests referring to

appliances under the scope of EN 60 335-1 and EN 60967.

EN 60529 Degrees of protection provided by enclosures (IP Code).

EN 62233 Measurement methods for electromagnetic fields of household appliances and similar

apparatus with regard to human exposure.

EN 61000-6-2 Electromagnetic compatibility (EMC) – Part 6-2: Generic standards – Immunity for

industrial environments.

EN 61000-6-3 Electromagnetic compatibility (EMC) – Part 6-3: Generic standards – Emission standards

for residential, commercial and light-industrial environments.

Skinnskattberg 26-01-2017

Mats Sándor

Technical Director

Page 4

Original

4

GB IE

Safety Information

This machinery must not be put into operation until prior

to reading mounting instructions and safety information.

All units are intended for transportation of air in air

handling systems. They are meant to be used after

building them into machines or duct systems or after

contact protection grid have been installed. (EN ISO

13857). The unit must be connected to ducts on both

sides (inlet/outlet). When there is a risk of water

entering the motor, via the ducts, external protection is

required. No moving parts shall be accessible after

installation. The units are not to be used in hazardous

environments or connected to flues. The TLP units must

not be installed outdoors. Safety accessories (i.e. motor

protection, safety grille) may not be dismounted, short

cut or disconnected. CAUTION Before servicing or

maintenance, switch off power, (all-pole circuit breaker),

and make sure the impeller has come to a standstill.

CAUTION The equipment can have sharp edges and

corners which may cause injuries.CAUTION, be careful

when opening the units service-hatches in case the unit

is mounted with the inspection hatch downward.

Transportation and Storage

The TLP units are packaged at the factory to withstand

normal transport handling. When handling the goods use

suitable lifting equipment in order to avoid damage to

equipment and personnel. Do not lift the unit by the

connecting cable, connection box, impeller or inlet cone.

Avoid blows and shock loads. Store the unit in a dry

place protected from weather and dirt until final

installation

.

Installation

Refer to Safety information above. Installation, electrical

connection and commissioning are only to be carried out

by authorised personnel and in accordance with

requirements and demands. Electrical connections are

made according to the wiring diagram, markings on

terminal blocks or on cable. All 3 phase units are

delivered from factory in 400V 3~ connection. CAUTION

do not use metal compression gland fittings with plastic

terminal boxes. Use a dummy plug seal for the

compression gland fitting as well. If the wiring to the K

fan in the unit is carried out using cables with diameter

12-14 mm, the entrance bushing must be replaced

(applies to type K). Assemble the TLP unit in the

direction of the airflow (see arrow on unit). The unit must

be installed so that vibrations are not transmitted to duct

systems or the frame of the building. (Suitable

accessories like fast clamps and diffusers are available).

Make sure the assembly of the fan is firmly fixed and

stable. The smaller sized of TLP 125 to 200, can be

mounted upside down in false ceilings. In this case the

heater must be rotated so that the connection box with

the overheating protection switches face upward or to

the side. NB TLP 315 cannot be placed upside down.

The TLP units must be mounted so that service and

maintenance can be performed easily and safely.

Disturbing noise can be avoided by installing silencer

(available accessory).

For frequency regulation an all pole sinus filter must be

mounted between motor and frequency controller

(version all poles: phase to phase, phase to earth). The

TLP unit is meant for continuous use within the

temperature range stated.

The fans inside the TLP unit are equipped with manual

thermal contacts (reset by cutting the current, motor

protection SP1), must be taken into consideration when

connecting surrounding equipment with automatic on/off

function.

Operation

Before initial operation, check the following:

- Electrical connection has been properly completed.

- Protective conductor has been connected.

- Safety devices in place (protection grid)

- Leftover installation materials and foreign materials

have been removed from the casing.

When putting into operation, check thefollowing:

- Connection data corresponds to the specifications on

the nameplate: Maximum voltage +6%, -10%, according

to IEC 38. Rated current must not be exceeded with

more than 5% at rated voltage. CAUTION when speed

regulating by reducing the voltage the motor current may

exceed the rated current at a lower voltage. In this case

the motor windings are protected by the thermal contact.

- Smoothness of motor operation, (no abnormal noises).

-Fans must only be operated by a person that has

sustainable knowledge or education within this field or

handling must be carried out with the supervision of such

person.

Maintenance, Service and Repair

Before maintenance, service or repair, make sure that:

- Power supply is interrupted (all-pole circuit breaker).

- Fan impeller has come to a complete standstill

- Observe personnel safety regulations!

The fan in the unit should be cleaned when necessary,

at least 1/year to avoid imbalance and unnecessary

damage to the bearings. Periodical changing of the filter

inside the unit will prolong the time interval between

each cleaning of the fan. The fan bearings are

maintenance free and should only be replaced if

damaged. Do not use a high-pressure cleaner (steam

jet) when cleaning the unit. Listen for abnormal operating

noise.

Resetting of the thermal trips

Manual thermal trips (SP1) are reset by disconnecting

the mains for approx. 10-20min.

Make sure the unit has not been blocked or that the

motor protection has tripped. Contact the supplier if the

motor does not start after controlling and/or resetting the

motor protection.

Page 5

5

SE

Försäkran om överensstämmelse

Tillverkare

Systemair Sverige AB

Industrivägen 3

739 30 Skinnskatteberg

Tel: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

Försäkrar härmed att produkter:

Luftbehandlingsaggregat: TLP125-315

(Försäkran gäller endast för produkt i leveransutförande och installerad i anläggning i enligt medlevererad

montageanvisning. Försäkring omfattar inte komponenter som läggs till eller åtgärder som därefter genomförs på

produkt)

Överensstämmer med alla tillämpliga bestämmelser i följande direktiv:

Maskindirektivet 2006/42/EG

Lågspänningsdirektivet 2014/35/EU

EMC direktivet 2014/30/EU

Följande harmoniserade standarder är tillämpade i tillämpliga delar:

EN ISO 12100-2010 Maskinsäkerhet – Generella konstruktionsprinciper – riskbedömning och riskminskning.

EN 14121-1:2007 Maskinsäkerhet – Riskbedömning – Del 1: Principer.

EN 13857 Maskinsäkerhet – Skyddsavstånd för att hindra fara riskområden med övre eller nedre

extremiteterna.

EN 60204-1 Maskinsäkerhet – Maskiners elutrustning – Del 1: Allmänna fordringar

EN 60 335-1 Elektriska hushållsapparater och liknande bruksföremål – Säkerhet Del 1: Allmänna krav.

EN 60 335-2-80 Elektriska hushållsapparater och liknande bruksföremål – Säkerhet - Del 2-80: Särskilda

fordringar på fläktar.

EN 50 106:2007 Elektriska hushållsapparater och liknande bruksföremål – Särskilda regler för

rutinundersökningar med hänvisning till apparater som omfattas av EN 60 335-1 och EN

60967.

EN 60529 Kapslingsklasser för elektrisk materiel (IP-beteckning).

EN 62233 Hushållsapparater och liknande bruksföremål – Mätning av elektromagnetiska fält med

avseende på exponering

EN 61000-6-2 Elektromagnetisk kompatibilitet (EMC) – Del 6-2: Generella fordringar – Immunitet hos

utrustning i industrimiljö.

EN 61000-6-3 Elektromagnetisk kompatibilitet (EMC) – Del 6-3: Generella fordringar – Emission normer

för bostäder, kommersiella och liknande miljöer.

Skinnskattberg 26-01-2017

Mats Sándor

Teknisk Direktör

Page 6

6

SE

Säkerhet

Aggregatet får ej tas i bruk innan installationsanvisning

och säkerhetsanvisning har beaktats.

Luftbehandlingsaggregat för ventilation i

luftbehandlingssystem med luft från icke

explosionsfarligt utrymme. TLP luftbehandlingsaggregat

är produkter som är avsedda att tas i bruk endast efter

inbyggnad, kanalanslutning eller att produkten försetts

med beröringsskydd. (EN ISO 13857). Kanaler ska

monteras på aggregatets sug-/tryck-sida, när risk finns

för att vatten via kanaler kan tränga in i fläktmotorn så

måste någon form av externt skydd monteras på

kanaler. Efter Installation/kanalanslutning ska beröring

av rörliga delar ej vara möjlig. TLP får ej användas i

explosiv miljö eller anslutas till rökgaskanal. Enheten får

ej monteras utomhus. Säkerhetsdetaljer (t ex

beröringsskydd) får ej demonteras, förbikopplas eller

bortkopplas. OBS! Innan service och underhåll påbörjas

måste enheten göras spänningslös, allpolig brytning, och

fläkthjulet ha stannat. OBS! Enheten kan ha vassa

kanter och hörn, vilket kan orsaka skärskador. OBS!

Iakttag försiktighet vid öppnande av serviceluckan om

aggregatet monterats med serviceluckan nedåt.

Transport och lagring

TLP aggregaten som levereras från Systemair är emballerade för att klara normal godshantering. Vid godshantering använd lämplig lyftanordning för att undvika

skador på utrustning och personer. OBS! Lyft ej enheten

i motorkabel, kopplingsdosa, fläkthjul eller

insugningskona. Undvik slag och stötar. Aggregatet ska

lagras torrt och väderskyddat och skyddas från smuts

och damm före slutlig installation.

Installation

Se även avsnitt säkerhet. Installation, elektrisk

anslutning samt idrifttagande ska göras av behörig

installatör och utföras i enlighet med för installationen

gällande föreskrifter och krav. Elektrisk anslutning ska

göras enligt kopplings-schema, märkning på

kopplingsplint eller på kabel. Alla 3-fas aggregat är

kopplade 400V 3~ från fabrik. OBS! Använd ej

förskruvningar av metall om kopplingsdosan är av plast.

Täta ev. tomma förskruvningshål med blindplugg. Om

fast installation sker med kabel som har diam. 12-14mm

så måste införings-bussningen bytas, gäller enheter

innehållande fläkt typ K. Montera TLP enheten i rätt

luftriktning (se luftriktningspil). Aggregatet ska monteras

så att vibrationer ej kan överföras till kanalsystem och

byggnadsstomme. (För ändamålet finns fästklammer

som tillbehör. De mindre storlekarna av TLP kan också

placeras upp och ned i undertak. Det kräver dock att

värmaren vrids i lådan så att överhettningsskyddets

placering alltid är uppåt eller åt sidan för rätt funktion.

OBS! TLP 315 får inte placeras upp och ned. Aggregatet

ska monteras på ett stadigt och stabilt sätt. Montera

enheten så att service och underhåll kan utföras på ett

enkelt och säkert sätt. Ljudproblem kan förebyggas

genom installation av ljuddämpare (finns som tillbehör).

För frekvensreglering gäller att ett allpoligt sinusfilter

måste monteras mellan motor och frekvensstyrning

(version allpolig: fas till fas, fas till jord). TLP aggregaten

är avsedda för kontinuerlig drift inom angivna

temperaturområden.

För kopplingschema gäller:

A Main swith = Allpolig brytare

B Thyristor (Fan control) = Tyristor (Fläktreglering)

C Fan = Fläkt

D Heat regulator = Värmestyrning

E Temperature sensor = Temperatursensor

F Heater battery = Värmare,

G Relay = Relä

H Air flow guard (pressure control) = Flödesvakt

(tryckvakt)

Fläkten i TLP aggregatet är försedd med manuell

termokontakt (återställs genom att fläkten görs strömlös,

motorskydd typ SP1). Detta måste beaktas vid

inkoppling av kringutrustning som bryter och kopplar in

strömmen automatiskt.

Drift

Före idrifttagande kontrollera följande:

-Elektrisk anslutning är slutförd.

-Skyddsjorden ansluten.

-Säkerhetsutrustning monterad (beröringsskydd).

-Inga främmande föremål finns i enheten.

Vid idrifttagande kontrollera följande:

Att uppmätta data ej överstiger på aggregatets typskylt

angivna märkdata: Maximalt tillåten spänning +6%, 10%, enligt IEC 38. Märkströmmen får ej överskridas

med mer än 5% vid märkspänning. OBS! Vid

varvtalsreglering genom spänningssänkning kan

strömmen i motorn vid en lägre spänning överstiga den

angivna märkströmmen. I dessa fall skyddas

motorlindingen av termokontakten!

-Att rotationsriktning på fläkthjulet överensstämmer med

rotationsriktningspilen (3-fas).

-Att inga missljud hörs från enheten.

- Fläktar i drift får endast handhas av person som har

kunskap eller utbildning för detta, eller att handhavande

sker under överinseende av sådan person.

Underhåll, service och reparation

Innan service, underhåll eller reparation påbörjas måste:

-Fläkten göras spänningslös (allpolig brytning).

-Fläkthjulet stannat.

-Gällande säkerhetsföreskrifter beaktats.

Fläkten i aggregatet ska rengöras vid behov, dock minst

1 gång/år för att undvika obalans med onödiga

lagerskador som följd. Byte av filtret i aggregatet med

jämna mellanrum gör att rengöringsintervallet kan

förlängas. ( Det kan i vissa fall vara befogat att använda

andningsskydd vid byte av filter). Fläktens lager är

underhållsfria och ska endast bytas vid behov. Vid

rengöring av fläkten får högtryckstvätt ej användas.

Rengöring måste ske försiktigt så att fläkthjulets

balansvikter ej rubbas eller fläkthjulet deformeras.

Kontrollera att inga missljud hörs.

Om termokontakten har löst ut gäller följande:

- Manuell termokontakt (typ SP1) återställs genom att

bryta strömmen under ca: 10-20 min.

Kontrollera att fläkthjulet inte är blockerat eller att

motorskyddet har löst ut. Om fläkten efter kontroll

och/eller återställning av motorskyddet ej startar

kontakta er installatör/inköpsställe.

Page 7

7

FI

Vaatimustenmukaisuusvakuutus

Valmistaja

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg RUOTSI

Toimisto: +46 222 440 00 Faksi: +46 222 440 99

www.systemair.com

vakuuttaa täten, että seuraavat tuotteet:

Ilmanvaihtokoneet: TLP125-315

(Vakuutus on voimassa vain tuotteelle, joka on samassa kunnossa kuin toimitettaessa ja asennettu mukana

toimitettujen asennusohjeiden mukaisesti. Vakuutus ei kata myöhemmin tuotteeseen asennettuja komponentteja

tai tuotteelle tehtyjä toimenpiteitä)

noudattavat seuraavien direktiivien vaatimuksia soveltuvin osin

Konedirektiivi 2006/42/EY

Pienjännitedirektiivi 2014/35/EU

EMC-direktiivi 2014/30/EU

Seuraavia yhdenmukaistettuja standardeja on käytetty soveltuvin osin:

EN ISO 12100-2010 Koneiden turvallisuus – Yleiset suunnitteluperiaatteet – Riskiarviointi ja riskien

vähentäminen.

EN 13857 Koneturvallisuus. Turvaetäisyydet yläraajojen ja alaraajojen ulottumisen estämiseksi

vaaravyöhykkeille.

EN 60204-1 Koneturvallisuus. Koneiden sähkölaitteet. Osa 1: Yleiset vaatimukset.

EN 60 335-1 Kotitaloussähkölaitteiden ja vastaavien turvallisuus. Osa 1: Yleiset vaatimukset

EN 60 335-2-80 Kotitaloussähkölaitteiden ja vastaavien turvallisuus. Osa 2-80: Puhaltimia koskevat

erityisvaatimukset.

EN 50 106:2007 Kotitaloussähkölaitteiden ja vastaavien turvallisuus. Standardien EN 60 335-1 ja EN

60967 piiriin kuuluville laitteille suoritettavien rutiinitestien erityisohjeet.

EN 60529 Sähkölaitteiden kotelointiluokat (IP-koodi).

EN 62233 Kotitaloussähkölaitteiden ja vastaavien sähkömagneettisten kenttien aiheuttaman

altistumisen mittausmenetelmät.

EN 61000-6-2 Sähkömagneettinen yhteensopivuus (EMC). Osa 6-2: Yleiset standardit. Häiriönsieto

teollisuusympäristöissä.

EN 61000-6-3 Sähkömagneettinen yhteensopivuus (EMC). Osa 6-3: Yleiset standardit. Häiriönpäästöt

kotitalous-, toimisto- ja kevyen teollisuuden ympäristöissä.

Skinnskattberg 26-01-2017

Mats Sándor

Tekninen johtaja

Page 8

8

FI

Turvallisuustiedot

Lue asennus- ja turvaohjeet huolella ennen koneen

käyttöönottoa.

Kaikki yksiköt on tarkoitettu ilman siirtämiseen

ilmankäsittelyjärjestelmissä. Ne on tarkoitettu

käytettäväksi koneeseen tai kanavistoon

sisäänrakennettuna tai suojaverkolla varustettuna. (EN

ISO 13857). Yksikkö tulee liittää kanavaan molemmilta

puolilta (tulo/lähtö). Jos moottoriin voi päästä vettä

kanaviston kautta, tarvitaan ulkopuolinen suojaus.

Liikkuviin osiin koskettaminen ei saa olla mahdollista

asennuksen jälkeen. Yksiköitä ei saa käyttää

räjähdysvaarallisissa ympäristöissä eikä liittää

savuhormeihin. TLP-yksiköitä ei saa asentaa ulkotiloihin.

Suojavarusteita (esim. moottorinsuojaus, suojaritilä) ei

saa irrottaa, ohittaa tai kytkeä irti. HUOM. Katkaise

virransyöttö turvakytkimellä ennen huolto- tai

kunnossapitotöiden aloitusta ja varmista, että siipipyörä

on pysähtynyt. HUOM. Laitteissa voi olla teräviä reunoja

ja kulmia, jotka voivat aiheuttaa tapaturmia. HUOM. Ole

varovainen yksikön huoltoluukkuja avatessasi, jos

yksikkö on asennettu tarkastusluukku alaspäin.

Kuljetus ja varastointi

TLP-yksiköt on pakattu tehtaalla kestämään normaalia

kuljetuskäsittelyä. Käytä sopivia nostolaitteita pakkausten

käsittelyyn välttääksesi henkilö- ja omaisuusvahingot. Älä

nosta yksikköä kytkentäkaapeleista, kytkentärasiasta,

siipipyörästä tai imukartiosta. Varo altistamasta iskuille ja

voimakkaille tärähdyksille. Säilytä yksikkö asennukseen

saakka kuivassa paikassa säältä ja lialta suojattuna.

Asennus

Lue turvaohjeet. Asennuksen, sähkökytkennän ja

käyttöönoton saa tehdä vain valtuutettu asentaja

annettujen ohjeiden ja vaatimusten mukaisesti.

Sähkökytkennät tehdään kytkentäkaavion sekä

kytkentärimoissa ja kaapeleissa olevien merkintöjen

mukaisesti. Kaikki 3-vaiheiset yksiköt toimitetaan

tehtaalta 400 V 3-vaiheliitännällä. HUOM Älä käytä

metallisia kaapeliläpivientejä muovisissa

kytkentärasioissa. Tulppaa mahdolliset ylimääräiset

kaapeliläpiviennit suojatulpilla. Jos yksikön K-puhaltimen

johdotus tehdään ø 12-14 mm kaapeleilla,

kaapeliläpivienti tulee vaihtaa (koskee tyyppiä K).

Asenna TLP-yksikkö ilmavirtaan nähden oikein päin

(katso yksikön nuoli). Yksikkö on asennettava niin, ettei

värinöitä siirry kanavistoon tai rakenteisiin.

(Lisävarusteena on saatavana mm. kanava- tai joustavia

liittimiä). Varmista, että puhallin on kunnolla ja tukevasti

kiinnitetty. TLP:n pienemmät koot 125 – 200 voidaan

asentaa ylösalaisin alakattoihin. Tässä tapauksessa

lämmitin pitää kääntää niin, että liitäntäkotelo

ylikuumenemissuojakytkimineen tulee ylöspäin tai sivulle.

Mallia NB TLP 315 ei voi asentaa ylösalaisin. TLPyksiköt on asennettava niin, että huolto- ja

kunnossapitotyöt voidaan suorittaa helposti ja

turvallisesti. Häiritsevä melu voidaan estää asentamalla

äänenvaimennin (saatavana lisävarusteena).

Taajuudensäätöä varten moottorin ja taajuudensäätimen

välille on asennettava kaikkinapainen siniaaltosuodatin

(kaikkinapainen versio: vaiheesta vaiheeseen ja

vaiheesta maadoitukseen). TLP-yksikkö on tarkoitettu

jatkuvaan käyttöön ilmoitetulla lämpötila-alueella.

Alla oleva viittaa kytkentäkaavioon:

A Main swith = Pääkytkin

B Thyristor (Fan control) = Tyristori (puhaltimen ohjaus)

C Fan = Puhallin

D Heat regulator = Lämpötilasäädin

E Temperature sensor = Lämpötila-anturi

F Heater battery = Lämmityspatteri

G Relay = Rele

H Air flow guard (pressure control) = Virtausvahti

(paine-erokytkin)

TLP-yksikön sisällä olevat puhaltimet on varustettu

manuaalisilla lämpökatkaisimilla (palautetaan

katkaisemalla virta, moottorinsuoja SP1) tämä tulee ottaa

huomioon, kun kytketään oheislaitteita automaattiseen

on/off –toimintaan.

Käyttö

Tarkista seuraavat ennen käyttöönottoa:

- Sähkökytkennät on tehty oikein.

- Suojamaadoitus on kytketty.

- Suojavarusteet ovat paikoillaan (suojaverkko)

- Ylimääräiset asennustarvikkeet ja vieraat esineet on

poistettu kotelosta.

Tarkista seuraavat käyttöönoton aikana:

- Mitatut arvot vastaavat tyyppikilven erittelyjä: suurin

sallittu jännite +6 %, -10 %, standardin IEC 38 mukaan.

Nimellisvirta ei saa ylittyä yli 5 %:lla nimellisjännitteellä.

HUOM. Kun nopeuttaa säädetään pienentämällä

jännitettä, moottorin virta saattaa ylittää nimellisvirran

pienemmällä jännitteellä. Tässä tapauksessa

lämpökatkaisin suojaa moottorin käämityksiä.

- Moottorin toiminnan tasaisuus (ei vieraita ääniä).

- Puhaltimia saavat käyttää ainoastaan henkilöt, joilla on

tarpeeksi tietoa tai koulutusta tällä alalla, tai käytön tulee

tapahtua tällaisen henkilön valvonnassa.

Kunnossapito, huolto ja korjaus

Varmista ennen kunnossapito-, huolto- ja korjaustöiden

aloittamista, että:

- Jännitteensyöttö on katkaistu (turvakytkimellä).

- Siipipyörä on pysähtynyt

- Noudata turvaohjeita!

Yksikön puhallin tulee puhdistaa tarvittaessa, kuitenkin

vähintään kerran vuodessa epätasapainon ja laakerien

turhan kulumisen välttämiseksi. Suodattimen vaihto

määräajoin pidentää puhaltimen puhdistusvälejä.

Puhaltimen laakerit ovat huoltovapaita ja ne tulee vaihtaa

vain, jos ne vaurioituvat. Älä käytä paine- tai

höyrypesuria yksikön puhdistukseen. Tarkasta, ettei

puhaltimesta kuulu epänormaalia melua.

Lämpökatkaisimien palautus

Manuaaliset lämpökatkaisimet (SP1) palautetaan

katkaisemalla jännitteensyöttö n. 10-20 minuutiksi.

Varmista, että yksikkö ei ole tukkeutunut ja että

moottorinsuoja ei ole lauennut. Ota yhteyttä toimittajaan,

ellei moottori käynnisty tarkastuksen ja/tai

moottorinsuojan palautuksen jälkeen.

Page 9

9

FR

Déclaration de conformité

Le fabricant :

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg SUÈDE

Téléphone: +46 222 440 00 Fax: +46 222 440 99

www.systemair.com

certifie par les présentes que le produit suivant:

Centrale de traitement d’air: TLP125-315

(La déclaration s’applique exclusivement au produit dans l’état où il a été livré et installé sur site conformément

aux instructions jointes. L’assurance ne couvre pas les composants ajoutés ou les interventions effectuées

ultérieurement sur le produit.)

Est conforme à l’ensemble des exigences des directives suivantes

Directive machines 2006/42/EC

Directive basse tension 2014/35/EU

Directive CEM 2014/30/EU

Les normes harmonisées suivantes sont d’application pour les parties concernées:

EN ISO 12100-2010 Sécurité de la machine – Principes généraux de conception – Appréciation du risque et

reduction du risqué.

EN 13857 Sécurité des machines – distances de sécurité pour les membres supérieurs ou inférie.

EN 60204-1 Sécurité des machines – Équipement électrique des machines – Partie 1 : règles

generals.

EN 60 335-1 Appareils électrodomestiques et analogues – Sécurité. Partie 1: Généralités.

EN 60 335-2-80 Appareils électrodomestiques et analogues – Sécurité – Partie 2-80: règles particulières

pour les ventilateurs.

EN 50 106:2007 Sécurité des appareils électrodomestiques et analogues – Règles particulières pour les

essais de série concernant les appareils dans le domaine d’application des normes EN

60 335-1 et EN 60967.

EN 60529 Degrés de protection procurés par les enveloppes (code IP).

EN 62233 Méthodes de mesure des champs électromagnétiques des appareils électroménagers et

similaires en relation avec l’exposition humaine.

EN 61000-6-2 Compatibilité électromagnétique (CEM) – Partie 6-2: exigences générales – Immunité des

appareils en environnements industriels.

EN 61000-6-3 Compatibilité électromagnétique (CEM), Partie EN 6-3: Normes génériques – Émissions

standards pour les environnements résidentiels, commerciaux et l'industrie légère.

Skinnskattberg 26-01-2017

Mats Sándor

Directeur technique

Page 10

10

FR

Sécurité

Lire impérativement les instructions de montage et les

consignes de sécurité avant la mise en service de cet

équipement.

Les centrales sont destinées à transporter l’air dans les

systèmes de ventilation et à être intégrées dans des

machines ou réseaux de gaines, ou utilisées de manière

autonome pour autant qu’elles soient munies d’une grille de

protection (EN ISO 13857). La centrale doit être raccordée à

des gaines des deux côtés (entrée et sortie). En cas de

risque d’infiltration d’eau dans le moteur via les gaines,

prévoir une protection externe. Aucun élément mobile ne

doit être accessible une fois l'installation terminée. Ne pas

utiliser les centrales dans des environnements explosibles

et ne pas les raccorder à un conduit de cheminée. Ne pas

installer les centrales TLP à l’extérieur. Ne pas démonter,

court-circuiter ni déconnecter les dispositifs de sécurité (par

ex. protection moteur, grille de sécurité). ATTENTION.

Avant toute intervention sur les ventilateurs, couper

l'alimentation électrique principale et attendre l'arrêt complet

des pièces en mouvement. ATTENTION. Les angles et

bords des équipements peuvent être source de blessures.

ATTENTION. Ouvrir prudemment la porte d’inspection de la

centrale lorsqu’elle s’ouvre vers le bas.

Transport et stockage

Les centrales TLP sont emballées en usine pour supporter

des conditions de stockage, de manutention et de transport

normales. Utiliser des équipements de manutention adaptés

pour garantir la sécurité du personnel et des produits. Ne

pas soulever les équipements par leur câble d’alimentation

électrique, boîtier de connexion, hélice ou cône d’entrée.

Éviter tout choc. Avant installation, stocker les centrales à

l’intérieur, à l'abri de l'humidité et de la poussière.

Installation

Voir les consignes de sécurité ci-dessus. L'installation, le

branchement électrique et la mise en service doivent être

effectués selon les règles de l’art par un professionnel

qualifié. Le raccordement électrique doit être effectué

conformément au schéma de câblage et en respectant le

marquage des câbles ou borniers. Les centrales triphasées

sont livrées en standard en version 400 V 3~. ATTENTION

– Ne pas utiliser de presse-étoupe métallique avec les

boîtes de raccordement en plastique. Utiliser également une

fiche isolante pour le presse-étoupe. Lorsque le ventilateur

K de la centrale est connecté par des câbles de Ø12 à

14 mm, remplacer la bague d’entrée (concerne le type K).

Assembler la centrale TLP dans le sens du débit d'air

(flèche sur l’appareil). Installer la centrale de façon à éviter

la transmission de vibrations dans le réseau de gaines ou à

la structure du bâtiment (par ex. en installant des

manchettes ou des plots antivibratiles). Vérifier que le

ventilateur est stable et bien fixé. Les petits modèles – TLP

125 à 200 – se montent également en faux plafond, trappe

vers le bas. Dans ce cas, tourner la batterie chauffante pour

que le boîtier de raccordement contenant les dispositifs antisurchauffe soit orienté vers le bas ou le côté. Remarque : la

centrale TLP 315 ne peut pas être installée trappe vers le

bas. Les centrales TLP doivent être montées de manière à

faciliter toute intervention ultérieure de maintenance. Des

silencieux spéciaux proposés en option permettent d’éviter

les bruits gênants.

Dans le cas de variation de fréquence, un filtre multipolaire

à sinusoïde doit être installé entre le variateur et le

ventilateur (version tous pôles : phase à phase, phase à

terre). Les centrales TLP sont conçues pour une utilisation

permanente dans la limite des températures de

fonctionnement recommandées.

Légendes du schéma de câblage :

A Main switch = Coupure de proximité principal

B Thyristor (Fan control) = Variateur ventilateur

C Fan = Ventilateur

D Heat regulator = Régulateur batterie (triac)

E Temperature sensor = Sonde de température

F Heater battery = Batterie électrique

G Relay = Relais

H Air flow guard (pressure control) = Pressostat (contrôle de

présence de débit d’air)

Les ventilateurs équipés d’une protection thermique à

réarmement manuel (par coupure d’alimentation, protection

moteur SP1) doivent être pris en considération lors du

raccordement d’équipements à fonction marche / arrêt

automatique.

Fonctionnement

Avant la première mise en route, vérifier les points suivants :

- Le raccordement électrique doit être effectué selon les

règles de l'art.

- Les conducteurs électriques doivent être bien isolés.

- Les protections mécaniques doivent être en place (grille de

protection).

- Les résidus des matériels d'installation et objets étrangers

doivent être enlevés.

Lors de la mise en route, vérifier les points suivants :

- Les caractéristiques électriques doivent correspondre à

celles figurant sur la plaque signalétique : écart de tension

entre +6% et -10% suivant la norme IEC38. Courant

nominal ne dépassant pas de 5% la valeur nominale à la

tension nominale. ATTENTION. En cas de régulation de la

vitesse par réduction de la tension, l’alimentation du moteur

peut dépasser l’intensité nominale à une tension inférieure.

Dans ce cas, les bobinages du moteur sont protégées par le

thermocontact.

- Vérifier que le moteur fonctionne avec régularité (sans de

bruits anormaux).

-L’utilisation et la manipulation des ventilateurs seront

exclusivement effectuées par du personnel compétent ou

sous sa surveillance.

Maintenance, entretien et réparation

Avant toute intervention de réparation ou de maintenance,

vérifier les points suivants :

- Mettre l’équipement hors tension (coupure multipolaire).

- Attendre l’arrêt complet de l'hélice.

- Respecter les consignes de sécurité.

Le ventilateur de la centrale sera nettoyé aussi souvent que

nécessaire et au minimum une fois par an pour éviter un

déséquilibrage et l’usure précoce des roulements. Pour

espacer les entretiens du ventilateur, remplacer

régulièrement le filtre à l’intérieur de la centrale. Les

roulements ne nécessitent ni entretien ni graissage et ne

doivent être remplacés que s’ils sont endommagés. Ne pas

utiliser de système à haute pression ou à vapeur pour

nettoyer le ventilateur. Vérifier qu’aucun bruit anormal n’est

détecté. Réarmement de la protection thermique

Pour réarmer manuellement l’équipement après le

déclenchement de la protection thermique (SP1), le mettre

hors tension pendant environ 10 à 20 minutes.

Vérifier que l’hélice n’est pas bloquée et que le

thermocontact du moteur ne s’est pas déclenché. Si le

moteur persiste à ne pas démarrer après les vérifications cidessus ou le réarmement du thermocontact, contactez votre

distributeur.

Page 11

11

PL

Deklaracja zgodności

Producent

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg SZWECJA

Biuro: +46 222 440 00 Faks: +46 222 440 99

www.systemair.com

niniejszym potwierdza, że następujące produkty:

Centrala wentylacyjna: TLP125-315

(Deklaracja dotyczy wyłącznie produktów w niezmienionym stanie od czasu dostawy, zainstalowanych w

obiekcie zgodnie z dołączoną instrukcją montażu. Ubezpieczenie nie obejmuje dodanych elementów ani

późniejszych modyfikacji produktów).

Spełniają wszystkie obowiązujące postanowienia następujących dyrektyw

Dyrektywa maszynowa 2006/42/WE

Dyrektywa niskiego napięcia 2014/35/EU

Dyrektywa kompatybilności elektromagnetycznej 2014/30/EU

W odpowiednich częściach zastosowano następujące normy zharmonizowane:

EN ISO 12100-2010 Bezpieczeństwo maszyn – Ogólne zasady projektowania – Ocena ryzyka i zmniejszanie

ryzyka.

EN 13857 Bezpieczeństwo maszyn – Odległości bezpieczeństwa uniemożliwiające sięganie

kończynami górnymi i dolnymi do stref niebezpiecznych.

EN 60204-1 Bezpieczeństwo maszyn – Wyposażenie elektryczne maszyn – Część 1: Wymagania

ogólne.

EN 60335-1 Bezpieczeństwo elektryczne urządzeń domowych i podobnych – Część 1: Wymagania

ogólne.

EN 60335-2-80 Bezpieczeństwo elektryczne urządzeń domowych i podobnych – Część 2-80: Wymagania

szczegółowe dla wentylatorów.

EN 50106:2007 Bezpieczeństwo elektrycznych przyrządów do użytku domowego i podobnego –

Postanowienia szczegółowe dotyczące badań wyrobu przyrządów wchodzących w zakres

EN 60 335-1 i EN 60967.

EN 50529 Stopnie ochrony zapewnianej przez obudowy (kod IP).

En 62233 Metody pomiaru pól elektromagnetycznych elektrycznego sprzętu do użytku domowego i

podobnego z uwzględnieniem naraż

ania człowieka.

EN 61000-6-2 Kompatybilność elektromagnetyczna (EMC) – Część 6-2: Normy ogólne – Odporność

w środowiskach przemysłowych.

EN 61000-6-3 Kompatybilność elektromagnetyczna (EMC) – Część 6-3: Normy ogólne – Wymagania

dotyczące emisyjności w środowisku mieszkalnym, handlowym i lekko

uprzemysłowionym.

Skinnskattberg 26-01-2017

Mats Sándor

Dyrektor Techniczny

Page 12

12

PL

Informacje dotyczące bezpieczeństwa

Przed uruchomieniem tego urządzenia należy bezwzględnie

przeczytać instrukcję montażu i ostrzeżenia dotyczące

bezpieczeństwa.

Wszystkie urządzenia są przeznaczone do przetłaczania

powietrza w systemach wentylacji bytowej. Wentylatory można

eksploatować po wbudowaniu w instalacje albo w urządzenia,

których część mają stanowić albo po zainstalowaniu osłon

ochronnych na wlotach/ częściach wirujących. (EN ISO 13857).

Urządzenia muszą być obustronnie podłączone do instalacji

kanałowej (wlot/wylot). Jeśli istnieje ryzyko przedostawania się

kanałami wody do wnętrza wentylatora, należy zainstalować

odpowiednie zabezpieczenie. Po zainstalowaniu wentylatora

żadne jego wirujące części nie mogą być dostępne z zewnątrz.

Urządzenia nie mogą być eksploatowane w środowiskach

niebezpiecznych ani używane do wyci

ągu z kominów, okapów

kuchennych itd. Centrale TLP nie mogą być montowane na

zewnątrz. Elementy zabezpieczające (np. zabezpieczenie

silnika, kratki ochronne) nie mogą być demontowane, zwierane

ani odłączane. UWAGA: Przed przystąpieniem do obsługi lub

serwisowania należy odłączyć zasilanie (rozłącznik izolacyjny

na wszystkich przewodach roboczych) i upewnić się, że wirnik

zatrzymał się. UWAGA: Wentylator i jego wirnik mogą mieć

ostre krawędzie i naroża, które mogą być przyczyną skaleczeń.

UWAGA: W urządzeniach, gdzie silnik osadzony jest na

uchylnej klapie, należy zachować ostrożność podczas

otwierania klapy – silnik jest relatywnie ciężki i może

spowodować obrażenia albo uszkodzenia przy nieostrożnym

otwarciu.

Transport i przechowywanie

Wszystkie centrale TLP posiadają fabryczne opakowanie

przystosowane do standardowych warunków transportu. Do

transportu i podnoszenia należy używać narzędzi oraz

urządzeń o odpowiedniej nośności, aby uniknąć uszkodzeń

transportowych lub obrażeń u ludzi. Nie wolno podnosić

urządzeń za kable elektryczne, puszkę przyłączeniową, wirnik

wentylatora lub stożek wlotowy. Podczas transportu unikać

wstrząsów, nie rzucać. Przed montażem urządzenie należy

przechowywać w suchym pomieszczeniu i chronić przed

kurzem i warunkami atmosferycznymi.

Montaż

Patrz powyższe informacje dotyczące bezpieczeństwa. Montaż,

podłączenie elektryczne i odbiór mogą być wykonywane tylko

przez wykwalifikowany personel zgodnie z odpowiednimi

przepisami. Podłączenia elektryczne należy wykonać zgodnie

ze schematem umieszczonym na listwie zaciskowej albo na

przewodach. Wszystkie urządzenia trójfazowe są dostosowane

do zasilania napięciem 3 x 400 V. UWAGA: Nie używać

metalowych dławików na puszkach przyłączeniowych z plastiku.

Dławik należy również zabezpieczyć zaślepką. Jeśli

okablowanie wentylatora K w urządzeniu zostało wykonane

przy użyciu przewodów o średnicy 12-14 mm, należy wymienić

przepust (dotyczy typu K). Centrale TLP należy montować

zgodnie kierunkiem przepływu powietrza (patrz strzałki na

obudowie). Urządzenie musi być zamontowane w taki sposób,

aby drgania nie przenosiły się na kanały wentylacyjne oraz na

konstrukcję budynku. (Dostępne są odpowiednie akcesoria,

takie jak zaciski i anemostaty). Upewnić

się, że wentylator jest

zamontowany w sposób stabilny i pewny. Mniejsze centrale

wentylacyjne typu TLP125 do TLP200 mogą być instalowane w

sufitach podwieszanych pokrywą serwisową do dołu. W tym

przypadku nagrzewnicę należy tak obrócić, aby puszka

przyłączeniowa, zawierająca przełączniki zabezpieczenia przed

przegrzaniem, była skierowana do góry lub poziomo na bok.

UWAGA: Centrale TLP 315 nie mogą być montowane otworem

rewizyjnym do dołu! Centrale TLP należy montować w sposób

umożliwiający łatwe i bezpieczne serwisowanie i obsługę.

Dokuczliwy hałas można zmniejszyć, instalując tłumik (dostępny

jako wyposażenie dodatkowe).

Stosowanie przemienników częstotliwości (tzw. falowników)

dopuszczalne jest pod warunkiem zastosowania skutecznego

filtra wygładzającego napięcie wyjściowe falownika (należy

stosować filtr typu „SINUS”, kondensatorowe filtry „EMC” nie

spełniają wymagań). Centrale TLP są przeznaczone do pracy

ciągłej w podanym zakresie temperatur.

Legenda do schematu połączeń:

A Main switch = Wyłącznik główny

B Thyristor (Fan control) = Tyrystor (regulacja wentylatora)

C Fan = Wentylator

D Heat regulator = Regulator temperatury

E Temperature sensor = Czujnik temperatury

F Heater battery = Nagrzewnica elektryczna

G Relay = Przekaźnik

H Air flow guard (pressure control) = Czujnik przepływu

powietrza (regulacja ciśnienia)

Wentylatory z wbudowany autonomicznym zabezpieczeniem

termicznym z resetem manualnym (SP1) po przegrzaniu się

zostają wyłączone przez wbudowane zabezpieczenie

termiczne. Reset zabezpieczenia możliwy jest po odłączeniu

zasilania oraz po ostygnięciu silnika.

Użytkowanie

Przed pierwszym uruchomieniem sprawdzić:

- Poprawność podłączenia elektrycznego.

- Podłączenie przewodu ochronnego PE.

- Czy zainstalowano osłony (kratki) zabezpieczające

- Czy z wnętrza obudowy lub kanałów usunięto niepotrzebne

pozostałości po procesie montażowym.

Podczas pierwszego uruchomienia sprawdzić:

- Zgodność danych przyłącza z danymi na tabliczce

znamionowej: napięcie maksymalne +6%, -10%, według IEC

38. Prąd znamionowy nie może przekraczać wartości I

n

o więcej

niż 5% przy napięciu znamionowym. UWAGA: Przy regulacji

napięciowej, prąd przy obniżonym napięciu zasilania może być

większy niż I

n

. W takim przypadku uzwojenie silnika jest

chronione przez styk termiczny.

- Sprawdzić, czy wirnik obraca się bez zacięć oraz bez

nadmiernych oporów (czy pracy wentylatora nie towarzyszy

nienaturalny hałas).

- Uruchomienie wentylatora musi przeprowadzać osoba

dysponująca odpowiednią wiedzą fachową.

Obsługa, serwisowanie i naprawy

Przed przystąpieniem do obsługi, serwisowania lub naprawy

należy upewnić się, że:

- zasilanie jest odłączone od wentylatora (rozłącznik serwisowy)

- wirnik wentylatora zatrzymał się

- spełnione są wymagania dotyczące bezpieczeństwa!

Wentylator w urządzeniu należy czyścić w razie potrzeby, co

najmniej raz w roku, aby uniknąć niewyważenia od

nawarstwionych zanieczyszczeń i niepotrzebnego uszkodzenia

łożysk. Regularna wymiana filtra w urządzeniu wydłuży okres

między kolejnym czyszczeniem wentylatora. Łożyska

wentylatorów są bezobsługowe i powinny być wymieniane na

ścisłe odpowiedniki w razie uszkodzeń. Nie wolno używać

wysokociśnieniowych urządzeń (dyszy parowej) do czyszczenia

lub mycia wnętrza wentylatora albo jego wirnika. Nasłuchiwać

nietypowych odgłosów pracy.

Reset zabezpieczenia termicznego

Autonomiczne zabezpieczenie termiczne typ „SP-1” – manualny

reset – wymaga odłączenia zasilania na 10-20 minut (do

ostygnięcia silnika wentylatora).

Należy upewnić się, że urządzenie nie jest zablokowane i że nie

zadziałało zabezpieczenie silnika. Jeśli silnik nie uruchamia się

po sprawdzeniu i/lub zresetowaniu zabezpieczenia, należy

skontaktować się z dostawcą.

Page 13

13

RU

Декларация о соответствии

Изготовитель

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg ШВЕЦИЯ

Тел.: +46 222 440 00 Факс: +46 222 440 99

www.systemair.com

Воздухообрабатывающий агрегат TLP 125-315

Действие настоящей декларации распространяется только на продукцию, находящуюся в состоянии, в

котором она была доставлена и смонтирована на объекте в соответствии с руководством по монтажу,

входящим в комплект поставки. Гарантия не распространяется на компоненты, установленные отдельно,

и действия, выполненные впоследствии.

Изготовитель подтверждает, что данное оборудование соответствует требованиям указанных

ниже нормативных директив.

Директива по машинам и механизмам 2006/42/ EC

Директива по низковольтным устройствам 2014/35/EU

Директива по электромагнитной совместимости 2014/30/EU

Учтены требования указанных ниже гармонизированных стандартов.

EN ISO 12100-2010 Безопасность оборудования. Общие принципы конструирования. Оценка и снижение

риска.

EN 13857 Безопасность оборудования. Безопасные расстояния для предотвращения контакта

верхних или нижних конечностей с опасными зонами.

EN 60204-1 Безопасность оборудования. Электрооборудование промышленных машин. Часть 1. Общие

требования.

EN 60 335-1 Бытовые и аналогичные электрические приборы. Безопасность. Часть 1. Общие

требования.

EN 60 335-2-80 Бытовые и аналогичные электрические приборы. Безопасность. Часть 2-80. Особые

требования к вентиляторам.

EN 50 106:2007 Безопасность бытовых и аналогичных электрических приборов. Особые правила

проведения контрольных испытаний, имеющих отношение к приборам, согласно

стандартам EN 60 335-1 и EN 60967.

EN 60529 Степени защиты, обеспечиваемые кожухами (коды IP).

EN 62233 Методы измерения электромагнитных полей, создаваемых бытовыми и

аналогичными электрическими приборами, касательно их воздействия на человека.

EN 61000-6-2 Электромагнитная совместимость. Часть 6-2. Общие требования.

Невосприимчивость к промышленной окружающей

среде.

EN 61000-6-3 Электромагнитная совместимость (ЭМС). Часть 6-3. Общие стандарты. Излучение.

Общие стандарты для бытового, офисного, торгового и аналогичного оборудования.

Скиннскаттеберг, 26-01-2017

.

Матс Сандор (Mats Sándor),

технический директор

Page 14

14

RU

Техника безопасности

Настоящее оборудование может эксплуатироваться только

после изучения инструкций по монтажу и правил техники

безопасности.

Все узлы предназначены для транспортировки воздуха в

воздухообрабатывающих системах. Эксплуатация

оборудования разрешается только после установки

оборудования в машины, подсоединения к воздуховодам или

после установки защитных решеток, предотвращающих контакт

(EN ISO 13857). Агрегат должен быть подключен к

воздуховодам с обеих

сторон (вход и выход). В случае риска

попадания воды в электродвигатель через воздуховоды

требуется установить внешние защитные приспособления.

После завершения монтажа доступ к движущимся частям

должен быть закрыт. Агрегат не предназначен для

эксплуатации в опасных средах и подключения к

дымоотводным каналам. Запрещается устанавливать агрегат

TLP вне помещения. Защитные средства, такие как

устройство

защиты электродвигателя, защитная решетка и т. д., не должны

быть отключены, разобраны или неисправны.

ВНИМАНИЕ! Перед обслуживанием или ремонтом отключите

питание и убедитесь в том, что рабочее колесо остановилось.

ВНИМАНИЕ! Кромки и углы лопастей вентиляторов могут быть

острыми, что может привести к порезам.

ВНИМАНИЕ! Будьте осторожны, открывая крышки люков для

обслуживания, если из-за особенностей установки агрегата

смотровой люк направлен вниз.

Транспортировка и хранение

Агрегат TLP упаковывается на заводе в соответствии с

общепринятыми стандартами транспортировки. При работе с

изделиями используйте подъемные устройства, чтобы

предотвратить повреждение оборудования и травмирование

персонала. Не поднимайте агрегат за соединительный кабель,

клеммную коробку, рабочее колесо или входной конус. Не

допускайте ударов или ударных нагрузок. До окончательного

монтажа в систему агрегат должен храниться

в сухом

помещении, защищенном от атмосферных воздействий и грязи.

Монтаж

Соблюдайте изложенные выше правила безопасности. Монтаж,

электрическое подключение и пусконаладочные работы

должны выполняться только уполномоченным персоналом в

соответствии с инструкцией по монтажу. Электрическое

подключение должно выполняться в соответствии со схемой,

изображенной на клеммной коробке, маркировкой на клеммах

или на кабеле. Все трехфазные агрегаты поставляются с

завода-изготовителя с подключением на 400 В

~3.

ВНИМАНИЕ! Не используйте металлические сальники для

пластмассовых клеммных коробок. Также используйте на

сальниках пробки-заглушки. Если при установке вентилятора

используются кабели диаметром 12—14 мм, замените

кабельный ввод (применимо к вентиляторам типа K). Агрегат

TLP должен быть установлен в направлении потока воздуха

(см. стрелку направления на агрегате) и таким образом, чтобы

вибрация не

передавалась системе воздуховодов или

фундаменту здания (с этой целью поставляются

быстросъемные хомуты и диффузоры). Убедитесь в том, что

смонтированный вентилятор хорошо зафиксирован. Малые

типоразмеры агрегатов, от TLP 125 до TLP 200, можно

устанавливать в перевернутом положении в фальшпотолках. В

этом случае проверните электронагреватель таким образом,

чтобы клеммная коробка с реле защиты от перегрева была

направлена

вверх или в сторону. Монтаж агрегата модели

NB TLP 315 в перевернутом положении не допускается.

Выполняйте монтаж агрегата TLP таким образом, чтобы

обеспечить максимальную простоту и безопасность

технического обслуживания и ремонта. Раздражающий шум

может быть легко устранен с помощью шумоглушителя

(дополнительная принадлежность).

При частотном регулировании скорости вентиляторов между

электродвигателем и преобразователем частоты установите

многополюсный синус-фильтр (модель для всех полюсов:

фаза-фаза, фаза-земля). Агрегат TLP предназначен для

непрерывной работы в пределах заданного диапазона

температур.

Ниже представлены условные обозначения принципиальной

схемы.

A Main swith = A Сетевой выключатель

B Thyristor (Fan control) = B Тиристор (управление

вентилятором)

C Fan = C Вентилятор

D Heat regulator = D Терморегулятор

E Temperature sensor = E Датчик температуры

F Heater battery = F Батарея нагревателя

G Relay = G Реле

H Air flow guard (pressure control) = H Датчик расхода воздуха

(регулятор давления)

Вентиляторы, установленные

в агрегате TLP, оснащены

термоконтактами с ручным перезапуском (SP1 для, защита

электродвигателя SP1, перезапуск посредством

обесточивания). Учитывайте это при подключении к агрегату

оборудования с функцией автоматического включения и

выключения.

Эксплуатация

Перед первым пуском убедитесь в том, что:

— электрическое подключение выполнено правильно;

—провод заземления подключен;

— предохранительные устройства (защитная решетка)

установлены;

—монтажные материалы и посторонние предметы убраны из

корпуса агрегата.

Перед началом работы убедитесь в том, что:

— электрические параметры соответствуют спецификации на

заводской табличке (максимальное напряжение +6 %, -10 % в

соответствии с IEC 38; номинальный

ток не должен быть выше

более чем на 5 % при номинальном напряжении).

ВНИМАНИЕ! При скорости вращения путем уменьшения

напряжения, значение тока в двигателе при более низком

напряжении может превысить номинальное (паспортное)

значение тока.« Для таких случев обмотки двигателя

вентилятора защищаются термоконтактом;

— двигатель работает плавно (без нехарактерного шума);

— эксплуатация вентиляторов должна

проводиться только

лицом, обладающим достаточным уровнем знаний или

образования в этой отрасти, либо под руководством такого

лица.

Техническое обслуживание и ремонт

Перед началом технического обслуживания или ремонта

убедитесь в том, что:

— подача электропитания прекращена (всеполюсный автомат

защиты выключен);

— рабочее колесо вентилятора полностью остановилось;

— соблюдены правила техники безопасности персонала.

По мере необходимости производите очистку вентилятора, по

меньшей мере, раз в год, для предотвращения дисбаланса и

преждевременного выхода из строя подшипников.

Периодическая

замена фильтра, установленного внутри

агрегата, увеличит интервал между очистками вентилятора.

Подшипники вентилятора не обслуживаются и подлежат

замене в случае их повреждения. При очистке вентилятора не

используйте устройства, работающие под высоким давлением

(паровая форсунка). Обращайте внимание на появление

нехарактерных шумов в процессе работы агрегата.

Перезапуск при срабатывании термоконтактов

Термоконтакты с ручным

перезапуском (SP1) перезапускаются

отключением от сети приблизительно на 10—20 минут.

Убедитесь в том, что вентилятор не заблокирован и защита

двигателя не сработала. Если электродвигатель не запускается

после проверки и (или) перезапуска защиты двигателя,

свяжитесь с поставщиком.

Page 15

15

Page 16

16

Systemair Sverige AB

Industrivägen 3

SE-739 30 Skinnskatteberg

Phone: +46 222 440 00

Fax: +46 222 440 99

www.systemair.com

205913 (26-01-2017)

Loading...

Loading...