Page 1

INSTRUCTION MANUAL

“INSTALLATION, USE AND MAINTENANCE”

GREAT BRITAIN

AIRTIGHT GAS CONVECTORS

Pilot flame thermocouple series, natural balanced mod.K21, K28, K40, K55

Ventilated pilot flame thermocouple series, natural balanced mod.K28V, K40V, K55V

Electronic series, natural balanced mod.K21E, K28E,

K40E, K55E

Ventilated electronic series, natural balanced mod.K28VE, K40VE, K55VE

Ventilated/forced circulation series mod.K21FE, K28FE, K40FE,

K55FE

Page 2

2

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

IMPORTANT: Read this manual carefully before starting up the system. In order to improve the product,

Systema reserves the right to modify the content without prior notice.

Via San Martino 17/23

S. GIUSTINA IN COLLE (PD)

loc. Fratte Fontane Bianche

PADOVA - ITALY

Tel 0039 0499355663

(8 linee r.a.)

Fax 0039 0499355699

E-mail: systema@systema.it

technical informations

http://www.systema.it

commercial informations

Page 3

3

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

1 GENERAL RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 GENERAL TECHNICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . .5

2.1 Device classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Packing list and check on incoming material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.3 Description and operational characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4 Principal elements of the control and safety systems . . . . . . . . . . . . . . . . . . . . . . .6

2.5 Pilot flame series technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.6 Electronic series technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.7 Overall dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.8 Exploded view of convector with parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.9 Device wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3 INSTRUCTIONS FOR INSTALLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.1 Technical Reference Standards and Legislation . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.2 Places of installation and safety distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.3 Device installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.4 Gas line connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.5 Transformations for various types of gas supplies for pilot flame-type devices (Mod.

K21, K28, K40, K55, K28V, K40V, K55V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.7 Transformations for various types of gas supplies for electronic devices (Mod. K21E,

K28E, K40E, K55E, K28VE, K40VE, K55VE, K21FE, K28FE, K40FE, K55FE) . . . . .27

3.8 Electrical connections from the control panels to the devices . . . . . . . . . . . . . . . .28

3.9 Starting and operation of pilot flame devices (Mod. K21, K28, K40, K55, K28V, K40V,

K55V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.10 Starting and operation of electronic devices (Mod. K21E, K28E, K40E, K55E, K28VE,

K40VE, K55VE, K21FE, K28FE, K40FE, K55FE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.11 Utilization of the daily programmer (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.12 Utilization of the weekly programmer (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.13 Malfunctions and solutions for pilot flame devices (Mod. K21, K28, K40, K55, K28V,

K40V, K55V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.14 Malfunctions and solutions for electronic devices (Mod. K21E, K28E, K40E, K55E,

K28VE, K40VE, K55VE, K21FE, K28FE, K40FE, K55FE) . . . . . . . . . . . . . . . . . . . . . .31

4 INSTRUCTIONS FOR THE USER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.1 General rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.2 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.2.1 Object and duration of the guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.2.2 Exclusions from the guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.2.3 Competence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.2.4 Operativity and effectiveness of the guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Page 4

4

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

4.2.5 Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.2.6 Legal disputes - Territorial competence and rights of the parties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5 PUTTING THE DEVICE OUT OF USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6 SCRAPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7 CE CONFORMITY CERTIFICATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Page 5

5

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

1 GENERAL RULES

This Manual is an integral and essential part of this device and must be carefully stored in its vicinity for purposes of rapid consultation.

Read the instructions and warnings provided herein

carefully because they provide important information

regarding safety, installation, use and maintenance.

Installation must be performed exclusively by qualified

professional personnel in complete respect of the safety

regulations in force. The Manufacturer declines all liability for damages caused by the erroneous installation or

incorrect and/or inappropriate use of the device.

Keep all potentially dangerous packaging elements

(nylon, polystyrene foam, wood, staples, etc.) far from

the reach of children.

The device must be started for the first time by qualified

personnel only.

Immediately switch off the device whenever it stops

and/or malfunctions. All repairs must be performed by

qualified personnel using original spare parts only.

Failure to observe the above can compromise operational safety.

Scrupulously respect the indications provided by the

Manufacture to guarantee satisfactory operation.

Never leave clothes, paper or other objects that might

obstruct the passage of hot air from the slots on top of

the radiator.

Delicate surfaces such as curtains, furniture, and wooden or plastic chairs must be kept at a minimum distance of 30 cm from the device.

Provide extra protection against the risk of burning by

contact of children, the elderly or disabled with the hot

surfaces of the shell wherever necessary. Such additional protection must not obstruct the passage of hot air

and the irradiation of heat from the front panel.

2 GENERAL TECHNICAL CHARACTERISTICS

2.1 Device classification

Device type: Type C11 (natural draught) and C13 (forced draught) depending on the flue gas suction and

expulsion system used.

Device output class: 1

2.2 Packing list and check on

incoming material

a) The device is delivered complete with all its parts in

a box that also contains a set of wall attachment

screws.

b) The air/flue gas terminals and the grille are packed

separately.

Page 6

6

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

CONVECTOR FLUE GAS-AIR KIT

Draw 1 Package contents

2.3 Description and operational

characteristics

The airtight gas convector radiator is composed of a

combustion chamber for the combustion of a gaseous

component (methane or LPG) in airtight cast iron divided into two half-shells that can be opened for cleaning

and the inspection of the burner. The working temperature of the external surface of the combustion chamber

as fanned by the natural convection movement of the

surrounding air or the forced circulation of the fans is

usually reached in a few minutes.

The device functions automatically, and is equipped with

the appropriate systems for safety, control, mixing, combustion, starting, the suction of combustion air and flue

gas expulsion.

The combustion air suction and flue gas expulsion

systems must be mandatorily connected directly to the

building’s exterior (C-type devices) and therefore there

is no contact between the combustion chamber and the

building’s interior. This guarantees the maximum safety

and permits the installation of the device indoors in complete respect of the standards in force.

2.4 Principal elements of the control and safety systems

a) Electric control unit for the Electronic series

models: this can be of two types depending on the

convector model involved (forced or naturally

balanced circulation). After receiving the electric

signal from the room thermostat, the control unit

runs a normal check on the pressure-switch when

forced convectors are being controlled (if this check

is not positive, the control unit does not grant triggering). The control unit then gives the signal for

the performance of the pre-starting lubrication of

the combustion chamber (>4 lubrications) and then

the signal for spark ignition and starting by opening

the gas solenoid valve. If no flame is detected (by

the ionization probe) within the established safety

time, the device goes into lock-out. In order to reset

after lock-out, switch off the bipolar switch with the

orange l.e.d. and then switch it back on again.

Page 7

7

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

CONTROL UNIT TECHNICAL CHARACTERISTICS

Power supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220/240 V 50/60Hz

Work temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-20 ÷ 60°C

Pre-starting lubrication time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 s

Starting safety time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .max. 5 s

Switch-off safety time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .< 1 s

b) Pilot gas valve: there is only one type of pilot gas

valve for all pilot flame convector models - a multifunctional valve with single control and combined

manual all-or-nothing thermostat control equipped

with thermoelectric flame detection device with

reset inhibition, maximum flowrate pre-selection

device or pressure regulator, minimum flowrate preselection screw, all-or-nothing modulation thermostat, pilot flame output with gas flowrate pre-selection screw, inlet filter and pilot filter, inlet and outlet

pressure taps - lateral gas outlets or gas outlets

from below with RP 3/8 ISO 7 threads. To start,

press the dial and switch on the pilot flame by keeping the dial pressed down for a few seconds. Then

release the dial and check to make sure that the

pilot flame remains on. If the pilot flame has gone

out in the meantime, the reset inhibition device will

prevent the re-starting of the convector until the

established pilot flame detection device safety time

has elapsed.

PILOT GAS VALVE TECHNICAL DATA

Gas connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RP 3/8 ISO 7

Max. inlet pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 mbar

Pressure setting range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 ÷ 18 mbar

Room temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0° ÷ 80°C

Pressure regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CLASS C

Pilot flame detection device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sit series 200 or 290 thermocouple

Starting time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .< 10 s

Switch off time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .< 60 s

c) Gas solenoid valve: for all electronic series and for-

ced ventilation convectors, multifunctional and multigas with a double safety solenoid valve (connected in series) in Class A and a built-in rectifier bridge. The aluminum body holds the inlet gas connec-

tions - threaded G 3/8" outlet with respective pressure taps. Equipped with pressure regulator to be

adjusted only by qualified technicians, the only

maintenance operation possible on the valve.

GAS VALVE TECHNICAL DATA

Power supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220/240 VAC 50/60 Hz

Electrical protection rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IP40

Closing time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .01 s

Work temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-20 ÷ +60°C

Max. inlet pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 mbar

Work pressure range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 ÷ 100 mb

Gas flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,5 m3/h (Natural gas DP = 2,5 mb)

d) Air suction unit: this serves to suck the air from the

outside and inject it into the combustion chamber

with the consequent expulsion of the flue gases

outwards through the appropriate flue gas duct.

SUCTION UNIT MOTOR RATING PLATE DATA

Electrical power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230 VAC 50 Hz

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CLASS H

Motor pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .da 30 mm

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 WATT

Page 8

8

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

2.5 Pilot flame series technical

characteristics

THERMOSTAT CHARACTERISTICS

Electrical power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .240 V 20 A

Work range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6° ÷ 30°C

Max. bulb temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42°C

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .copper

Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .copper

f) Daily or weekly programmer (only on request): this

serves to program the device’s daily and weekly

operation cycles and is positioned on the control

e) Adjustment thermostat: this is a sensor-type ther-

mostat that permits the temperature to be adjusted

as required by the user for a comfortable room tem-

perature, and also permits the control of the starting

and switching off of the device from the control unit.

panel for access by the user for adjustment purposes.

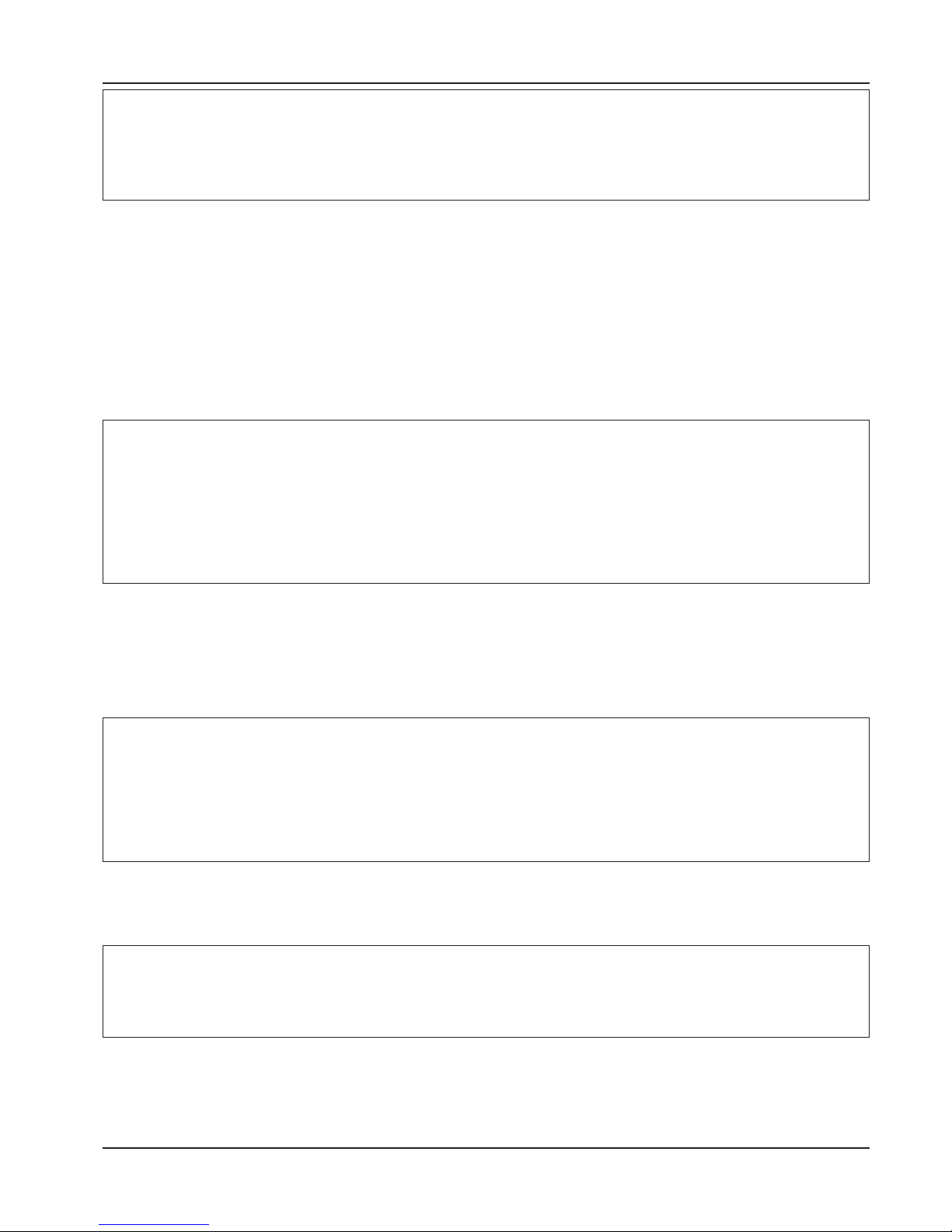

TECHNICAL SPECIFICATIONS OF AIRTIGHT GAS CONVECTORS

PILOT FLAME THERMOCOUPLE SERIES MODELS

NON-VENTILATED

VENTILATED

K21 K28 K40 K55 K28V K40V K55V

RATED HEAT FLOW

kW 2 2,5 4 4,6 2,5 4 4,6

kcal/h 1720 2150 3440 3960 2150 3440 3960

WORKING HEAT OUTPUT

kW 1,8 2,2 3,5 4,1 2,2 3,6 4,1

kcal/h 1550 1900 3010 3530 1900 3100 3530

COMBUSTION EFFICIENCY

% 90,0 87,0 87,3 87,5 87,5 88,0 88,0

CATEGORY EFFICIENCY

1 1 1 1 1 1 1

INJECTOR PRESSURE

(power supply=20mbar)

Methane G20

mbar 13,2 12,0 12,5 14,0 12,0 12,5 14,0

INJECTOR PRESSURE

(power supply=25mbar)

Gas L - G25

mbar

-

INJECTOR PRESSURE

(power supply=29mbar)

GPL Butane - G30

mbar 28.9 28.8 28.9 29.0 28.8 28.9 29.0

INJECTOR PRESSURE

(power supply=37mbar)

GPL Propane - G31

mbar 36.6 36.8 36.7 36.5 36.6 36.7 36.5

BURNER INJECTOR DIAMETER

Methane G20

mm 1,25 1,45 1,90 1,90 1,45 1,90 1,90

Gas L - G25

mm 1.25 1.45 1.90 1.90 1.45 1.90 1.90

GPL Butane - G30

mm 0.75 0.85 1.05 1.10 0.85 1.05 1.10

GPL Propane - G31

mm 0,75 0,85 1,05 1,10 0,85 1,05 1,10

MAX FUEL

CONSUMPTION

(0°C - 1013 mbar)

Methane G20

m

3

0,21 0,26 0,42 0,49 0,26 0,42 0,49

Gas L - G25

m

3

0.25 0.31 0.49 0.57 0.31 0.49 0.57

GPL Butane - G30

kg/h 0.158 0.197 0.315 0.363 0.197 0.315 0.363

GPL Propane - G31

kg/h 0,155 0,194 0,311 0,357 0,194 0,311 0,357

ELECTRICAL POWER SUPPLY

V -- -- -- -- 230 230 230

Hz -- -- -- -- 50 50 50

ELECTRICAL POWER (absorbed)

W -- -- -- -- 25 30 30

TREATED AMBIENT AIR FLOW

m3/h -- -- -- -- 150 240 270

HEATED AMBIENT VOLUME

m

3

36 44 70 82 48 78 88

FAN SPEED NUMBER

-- -- -- -- 2 2 2

OVERALL DIMENSIONS

Width

mm 420 420 560 560 420 560 560

Height

mm 615 615 615 615 615 615 615

Depth

mm 225 225 225 225 225 225 225

WEIGHT

kg 31 31 45 45 32 46 46

GAS FITTING DIAMETER

inc. (”) 1/2"- M 1/2"- M 1/2"- M 1/2"- M 1/2"- M 1/2"- M 1/2"- M

AIR-FUME COAXIAL

PIPE DIAMETERS

Air

mm 120 120 160 160 120 160 160

Fumes

mm 90 90 90 90 90 90 90

AIR-FUME MAX LENGHT

coaxial pipes

mm 500 500 500 500 500 500 500

TYPE OF EQUIPMENT

C11

Page 9

9

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

2.6 Electronic series technical

characteristics

(*) N.B. One meter of length must be removed for every elbow used in forced ventilation electronic models (FE).

Categories

AT . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3B/P

DE . . . . . . . . . . . . . . . . . . . . . . . . . .II

2ELL3B/P

FI . . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3B/P

GR . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3P

IT . . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3+

NO . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3B/P

BE . . . . . . . . . . . . . . . . . . . . . . . . . . .I

2E+

/ I

3+

DK . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3B/P

FR . . . . . . . . . . . . . . . . . . . . . . . . . .II

2E+3+

IE . . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3P

LU . . . . . . . . . . . . . . . . . . . . . . . . . .II

2E3P

PT . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3P

CH . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3B/P

ES . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3P

GB . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3P

NL . . . . . . . . . . . . . . . . . . . . . . . . . .II

2L3B/P

SE . . . . . . . . . . . . . . . . . . . . . . . . . .II

2H3B/P

IS . . . . . . . . . . . . . . . . . . . . . . . . . . .I

3B/P

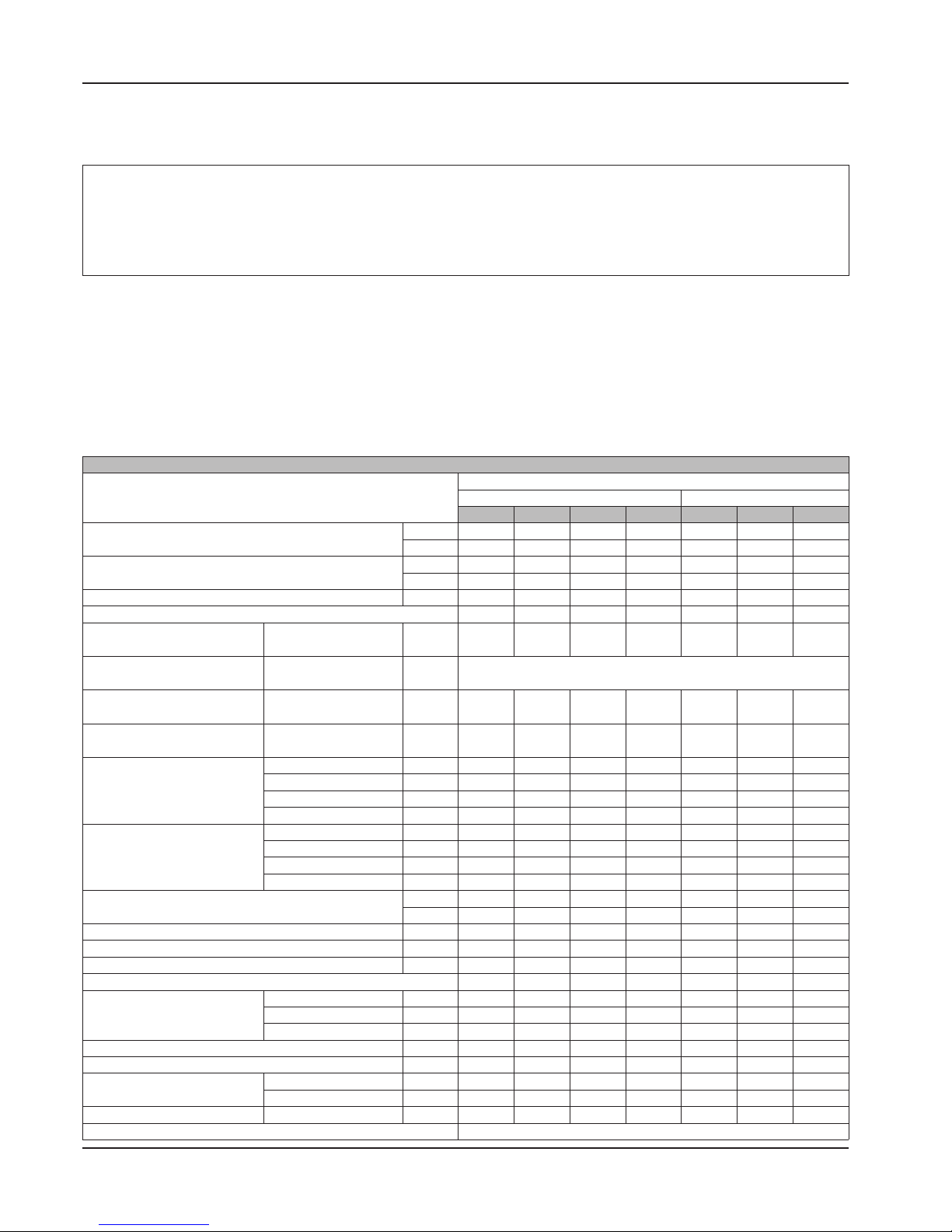

TECHNICAL SPECIFICATIONS OF AIRTIGHT GAS CONVECTORS

ELECTRONONIC SERIES MODELS

NON-VENTILATED VENTILATED NON-VENTILATED

K21E K28E K40E K55E K28VE K40VE K55VE K21FE K28FE K40FE K55FE

RATED HEAT FLOW

kW

2 2,5 4 4,6 2,5 4 4,6 2,4 3 4,3 5,3

kcal/h

1720 2150 3440 3960 2150 3440 3960 2070 2580 3700 4560

WORKING HEAT OUTPUT

kW

1,8 2,3 3,6 4,1 2,3 3,6 4,1 2,2 2,7 3,8 4,6

kcal/h

1550 1980 3100 3530 1980 3100 3530 1900 2330 3270 3960

COMBUSTION EFFICIENCY

%

89,8 90,0 88,0 88,0 90,0 88,0 88,0 88,5 88,0 88,3 85,0

CATEGORY EFFICIENCY

1 1 1 1 1 1 1 1 1 1 1

INJECTOR PRESSURE

(power supply=20mbar)

Methane G20

mbar

14,0 12,0 11,0 13,5 12,0 11,0 13,5 12,0 13,0 12,0 12,0

INJECTOR PRESSURE

(power supply=25mbar)

Gas L - G25

mbar

13,5 12,5 11,0 10,0 12,5 11,0 10,0 12,0 13,0 12,0 12,0

INJECTOR PRESSURE

(power supply=29mbar)

GPL Butane - G30

mbar

28,5 28,5 28,0 29,0 28,5 28,0 29,0 28,5 28,5 28,4 28,6

INJECTOR PRESSURE

(power supply=37mbar)

GPL Propane - G31

mbar

36,5 37,0 35,5 37,0 37,0 35,5 37,0 36,5 36,5 36,4 36,4

BURNER INJECTOR DIAMETER

Methane G20

mm

0,75 0,85 1 1,1 0,85 1 1,1 0,82 0,9 1,05 1,15

Gas L - G25

mm

1,5 1,6 2,1 2,3 1,6 2,1 2,3 1,5 1,7 2,1 2,4

GPL Butane - G30

mm

0,75 0,85 1 1,1 0,85 1 1,1 0,82 0,9 1,05 1,15

GPL Propane - G31

mm

1,25 1,45 1,9 1,9 1,45 1,9 1,9 1,4 1,6 1,9 2,1

MAX FUEL

CONSUMPTION

(0°C - 1013 mbar)

Methane G20

m

3

0,21 0,26 0,42 0,49 0,26 0,42 0,49 0,25 0,32 0,46 0,56

Gas L - G25

m

3

0,25 0,31 0,49 0,57 0,31 0,49 0,57 0,30 0,37 0,53 0,65

GPL Butane - G30

kg/h

0,158 0,197 0,315 0,363 0,197 0,315 0,363 0,189 0,237 0,339 0,418

GPL Propane - G31

kg/h

0,155 0,194 0,311 0,357 0,194 0,311 0,357 0,186 0,233 0,334 0,412

ELECTRICAL POWER SUPPLY

V

230 230 230 230 230 230 230 230 230 230 230

Hz

50 50 50 50 50 50 50 50 50 50 50

ELECTRICAL POWER (absorbed)

W

20 20 20 20 45 65 65 65 65 85 85

TREATED AMBIENT AIR FLOW

m3/h

-- -- -- -- 150 240 270 150 180 260 310

HEATED AMBIENT VOLUME

m

3

36 46 72 82 50 78 88 48 58 84 102

FAN SPEED NUMBER

-- -- -- -- 2 2 2 2 2 2 2

OVERALL DIMENSIONS

Width

mm

420 420 560 560 420 560 560 560 560 730 730

Height

mm

615 615 615 615 615 615 615 615 615 615 615

Depth

mm

225 225 225 225 225 225 225 225 225 225 225

WEIGHT

kg

32 32 46 46 32 46 46 32 33 52 52

GAS FITTING DIAMETER

inc. (”)

3/8"- F 3/8"- F 3/8"- F 3/8"- F 3/8"- F 3/8"- F 3/8"- F 3/8"- F 3/8"- F 3/8"- F 3/8"- F

AIR-FUME COAXIAL PIPE

DIAMETERS

Air

mm

120 120 160 160 120 160 160 60 60 60 60

Fumes

mm

90 90 90 90 90 90 90 38 38 38 38

AIR-FUME MAX LENGHT coaxial pipes

mm

500 500 500 500 500 500 500 5000 5000 5000 3000

TYPE OF EQUIPMENT C11 C13

Page 10

10

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

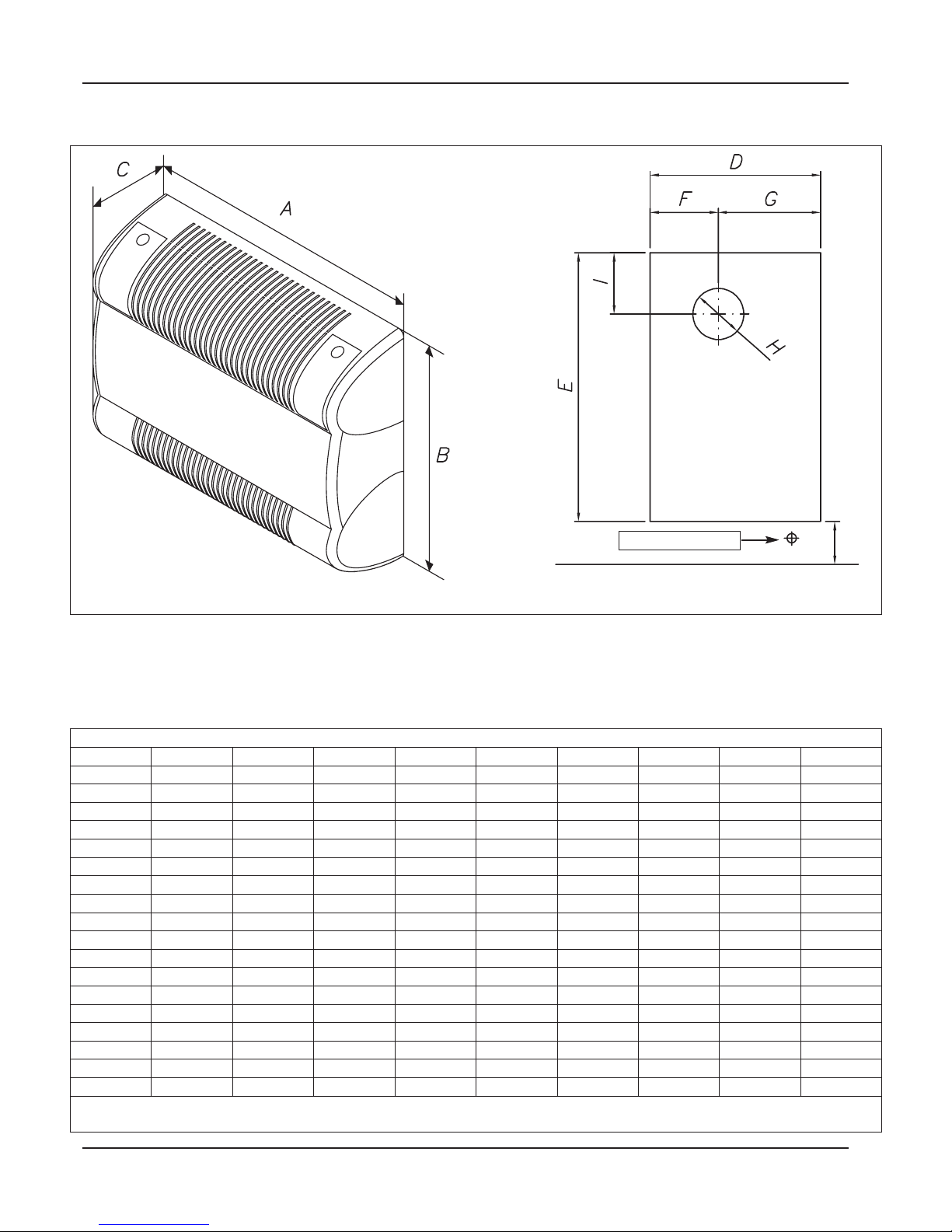

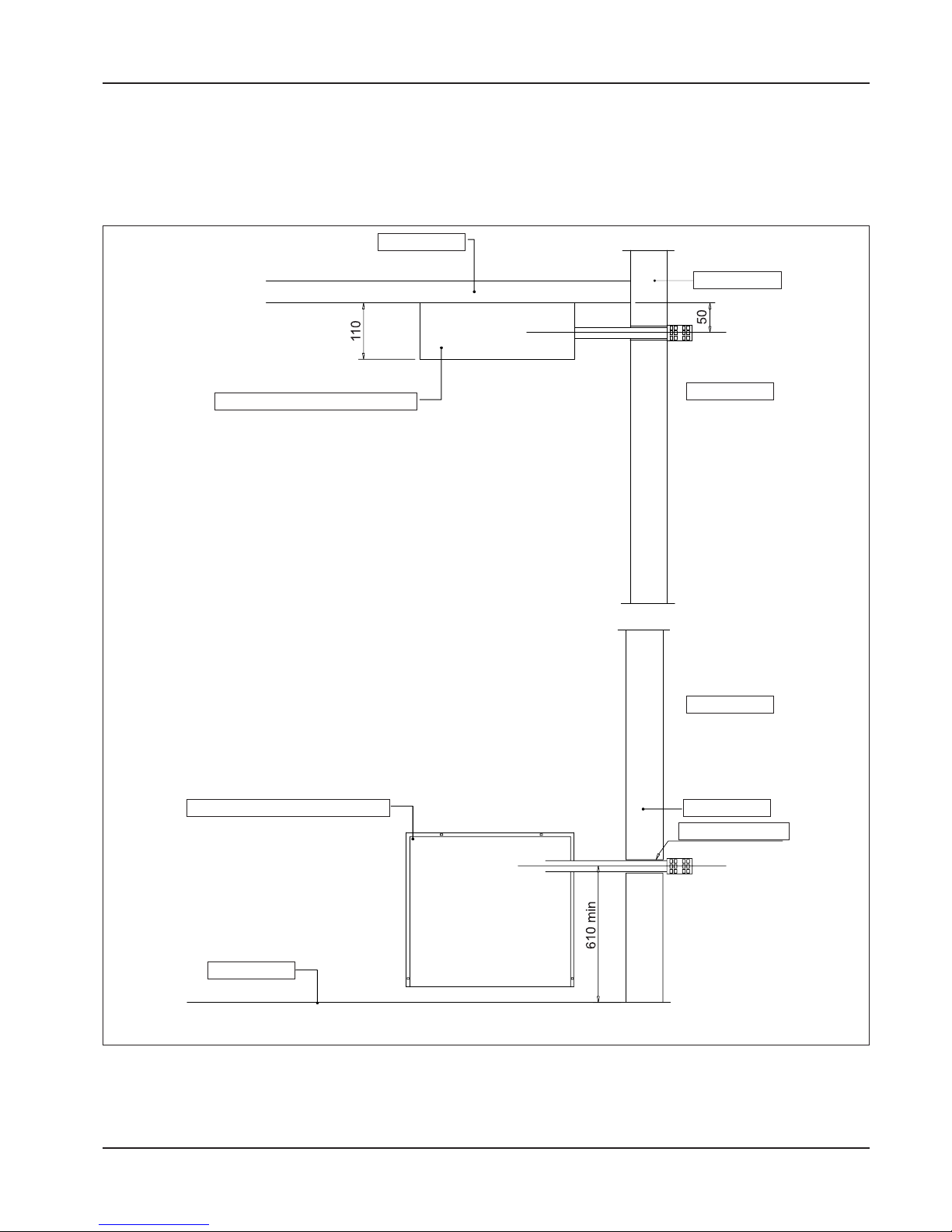

Draw2

2.7 Overall dimensions

GAS CONNECTION

10 cm

min.

ATTENTION: the KING gas convector must be installed at 10 cm minimum distance from the ground; it

is necessary to forsee the space for the gas interception. The hole for the gas pipe has to be provided

under the appliance, between the appliance and the ground, according to the gas inlet of the appliance

itself.

CONVECTOR OVERALL DIMENSIONS AND ASSEMBLY FRAME

MODELS A B C D E F G H I

K21

440 624 225 385 611 173 212 125 116

K28

440 624 225 385 611 173 212 125 116

K40

600 624 225 549 611 264 285 160 124

K55

600 624 225 549 611 264 285 160 124

K28V

440 624 225 385 611 173 212 125 117

K40V

600 624 225 549 611 264 285 160 124

K55V

600 624 225 549 611 264 285 160 124

K21E

440 624 225 385 611 173 212 125 117

K28E

440 624 225 385 611 173 212 125 117

K40E

600 624 225 549 611 264 285 160 124

K55E

600 624 225 549 611 264 285 160 124

K28VE

440 624 225 385 611 173 212 125 117

K40VE

600 624 225 549 611 264 285 160 124

K55VE

600 624 225 549 611 264 285 160 124

K21FE

585 616 225 535 612 305 230 60 108

K28FE

585 616 225 535 612 305 230 60 108

K40FE

745 616 225 689 612 399 290 60 108

K55FE

745 616 225 689 612 399 290 60 108

The data provided above are purely indicative. The Manufacturer reserves the right to perform modifications without notice.

Page 11

11

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

2.8 Exploded view of convector

with parts list

Draw 3 Exploded view of Model K21, K28, K40, K55 generator

PILOT FLAME TYPE THERMOCOUPLE SERIES CONVECTOR (Ref. Draw 3)

POS. Q. ITEM

K21 K28 K40 K55

CODE CODE CODE CODE

1 1 PAIR OF COAXIAL TUBES 02ACKT0808 02ACKT0808 02ACKT0810 02ACKT0810

2 1 AIR BOX 02CNSA0378 02CNSA0378 02CNSA0379 02CNSA0379

3 1 EUROSIT PILOT FLAME VALVE 02CNVE0679 02CNVE0679 02CNVE0679 02CNVE0679

4 1 REAR CAST IRON CASTING 02CNFU0201 02CNFU0201 02CNFU0203 02CNFU0203

5 1 BURNER 02CNBR0050 02CNBR0050 02CNBR0052 02CNBR0051

6 1 FRONT CAST IRON CASTING 02CNFU0200 02CNFU0200 02CNFU0202 02CNFU0202

7 1 SHELL 02MACO0028 02MACO0028 02MACO0029 02MACO0029

Page 12

12

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Draw 4 Exploded view of Model K28V, K40V, K55V generator

VENTILATED PILOT FLAME THERMOCOUPLE SERIES CONVECTORS (Ref. Draw 4)

POS. Q. ITEM

K28V K40V K55V

CODE CODE CODE

1 1 PAIR OF COAXIAL TUBES 02ACKT0808 02ACKT0810 02ACKT0810

2 1 FAN TRIGGERING THERMOSTAT 02CETR0470 02CETR0470 02CETR0470

3 1 AIR BOX 02CNSA0378 02CNSA0379 02CNSA0379

4 1 EUROSIT PILOT FLAME VALVE 02CNVE0679 02CNVE0679 02CNVE0679

5 1 MOLVENO I-II SWITCH 02CEDE0234 02CEDE0234 02CEDE0234

6 1 TANGENTIAL FAN 02CEVT0622 02CEVT0623 02CEVT0623

7 1 REAR CAST IRON CASTING 02CNFU0201 02CNFU0203 02CNFU0203

8 1 BURNER 02CNBR0050 02CNBR0052 02CNBR0051

9 1 FRONT CAST IRON CASTING 02CNFU0200 02CNFU0202 02CNFU0202

10 1 SHELL 02MACO0028 02MACO0029 02MACO0029

Page 13

13

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Draw 5 Exploded view of Model K21E, K28E, K40E, K55E generator

ELECTRONIC SERIES CONVECTORS (Ref. Draw 5)

POS. Q. ITEM

K21E K28E K40E K55E

CODICE CODICE CODICE CODICE

1 1 PAIR OF COAXIAL TUBES 02ACKT0808 02ACKT0808 02ACKT0810 02ACKT0810

2 1 LIMIT THERMOSTAT 02CETR0471 02CETR0471 02CETR0471 02CETR0471

3 1 AIR BOX 02CNSA0378 02CNSA0378 02CNSA0379 02CNSA0379

4 1

BRAHMA CM11F DEVICE 02CEAP2701 02CEAP2701 02CEAP2701 02CEAP2701

IMIT AC02 DEVICE 02CEAP1028 02CEAP1028 02CEAP1028 02CEAP1028

5 1 ELECTRIC CONTROL PANEL KING E 02CEQU0345 02CEQU0345 02CEQU0345 02CEQU0345

6 1

WHITE ROGERS ELECTRONIC VALVE 02CEEC0164 02CEEC0164 02CEEC0164 02CEEC0164

SIT 850 MICRO ELECTRONIC VALVE 02CEEL0166 02CEEL0166 02CEEL0166 02CEEL0166

7 1 REAR CAST IRON CASTING 02CNFU0201 02CNFU0201 02CNFU0203 02CNFU0203

8 1 BURNER 02CNBR0058 02CNBR0050 02CNBR0051 02CNBR0051

9 1 FRONT CAST IRON CASTING 02CNFU0200 02CNFU0200 02CNFU0202 02CNFU0202

10 1 SHELL 02MACO0028 02MACO0028 02MACO0029 02MACO0029

Page 14

14

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Draw 6 Exploded view of Model 28VE, K40VE, K55VE generator

VENTILATED ELECTRONIC SERIES CONVECTORS (Ref. Draw 6)

POS. Q. ITEM

K28VE K40VE K55VE

CODE CODE CODE

1 1 PAIR OF COAXIAL TUBES 02ACKT0808 02ACKT0810 02ACKT0810

2 1 LIMIT THERMOSTAT 02CETR0471 02CETR0471 02CETR0471

3 1 FAN TRIGGERING THERMOSTAT 02CETR0470 02CETR0470 02CETR0470

4 1 AIR BOX 02CNSA0378 02CNSA0379 02CNSA0379

5 1

BRAHMA CM11F DEVICE 02CEAP2701 02CEAP2701 02CEAP2701

IMIT AC02 DEVICE 02CEAP1028 02CEAP1028 02CEAP1028

6 1 ELECTRIC CONTROL PANEL KING VE 02CEQU0344 02CEQU0344 02CEQU0344

7 1 TANGENTIAL FAN 02CEVT0622 02CEVT0623 02CEVT0623

8 1

WHITE ROGERS ELECTRONIC VALVE 02CEEC0164 02CEEC0164 02CEEC0164

SIT 850 MICRO ELECTRONIC VALVE 02CEEL0166 02CEEL0166 02CEEL0166

9 1 REAR CAST IRON CASTING 02CNFU0201 02CNFU0203 02CNFU0203

10 1 BURNER 02CNBR0050 02CNBR0058 02CNBR0058

11 1 FRONT CAST IRON CASTING 02CNFU0200 02CNFU0202 02CNFU0202

12 1 SHELL 02MACO0028 02MACO0029 02MACO0029

Page 15

15

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

31

2

4567

8

9

10

11 12 13 14

Draw 7 Exploded view of Model K21FE, K28FE, K40FE, K50FE generator

VENTILATED/FORCED CIRCULATION SERIES CONVECTORS (Ref. Draw 7)

POS. Q. ITEM

K21FE K28FE K40FE K55FE

CODE CODE CODE CODE

1 1

PAIR OF COAXIAL TUBES

02ACKT0800 02ACKT0800 02ACKT0800 02ACKT0800

2 1

STAINLESS STEEL ANTI-WIND GRILLE FOR

RECESSED WALL MOUNTING

02ACKT0801 02ACKT0801 02ACKT0801 02ACKT0801

3 1

LIMIT THERMOSTAT

02CETR0471 02CETR0471 02CETR0471 02CETR0471

4 1

FAN TRIGGERING THERMOSTAT

02CETR0470 02CETR0470 02CETR0470 02CETR0470

5 1

AIR BOX

02CNSA0376 02CNSA0376 02CNSA0377 02CNSA0377

6 1

IMIT AC02 DEVICE

02CEAP1028 02CEAP1028 02CEAP1028 02CEAP1028

7 1

ELECTRIC CONTROL PANEL KING FE

02CEQU0343 02CEQU0343 02CEQU0343 02CEQU0343

8 1

EV 100 CENTRIFUGAL FAN

02CEAS3002 02CEAS3002 02CEAS3002 02CEAS3002

9 1

TANGENTIAL FAN

02CEVT0622 02CEVT0622 02CEVT0623 02CEVT0623

10 1

WHITE ROGERS ELECTRONIC VALVE

02CEEC0164 02CEEC0164 02CEEC0164 02CEEC0164

SIT 850 MICRO ELECTRONIC VALVE 02CEEL0166 02CEEL0166 02CEEL0166 02CEEL0166

11 1

REAR CAST IRON CASTING

02CNFU0201 02CNFU0201 02CNFU0203 02CNFU0203

12 1

BURNER

02CNBR0050 02CNBR0050 02CNBR0058 02CNBR0058

13 1

FRONT CAST IRON CASTING

02CNFU0200 02CNFU0200 02CNFU0202 02CNFU0202

14 1

SHELL

02MACO0031 02MACO0031 02MACO4055 02MACO4055

Page 16

16

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

2.9 Schema elettrico apparecchi

Series V wiring diagram

Series E wiring diagram

Draw 8

Draw 9

KEY

L Phase wire

N Neutral wire

W

Ground

DB Bipolar switch

TR Regulation thermostat

SB Lock-out light

SF Operation light

EV1 EV2 Electronic valve

ER Detection electrode

E ACC. Starting electrode

CEN

Imit AC02 or Brahma CM11F

electronic valve

TL Work thermostat

KEY

L Phase wire

N Neutral wire

W

Ground

TCV Fan triggering thermostat

DV Speed change gear

VT Tangential fan

Page 17

17

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Series E with timer wiring diagram

Series VE wiring diagram

Draw 10

Draw 11

KEY

L Phase wire

N Neutral wire

W

Ground

DB Bipolar switch

TR Regulation thermostat

SB Lock-out light

SF Operation light

EV1 EV2 Electronic valve

ER Detection electrode

E ACC. Starting electrode

CEN

Imit AC02 or Brahma CM11F

electronic valve

TL Work thermostat

KEY

L Phase wire

N Neutral wire

W

Ground

DB Bipolar switch

TR Regulation thermostat

TCV Fan triggering thermostat

VT Fan

DV Fan switch

SB Lock-out light

SF Operation light

EV1 EV2 Electronic valve

ER Detection electrode

E ACC. Starting electrode

CEN

Imit AC02 or Brahma CM11F

electronic valve

TL Work thermostat

Page 18

18

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Series VE with timer wiring diagram

Series FE wiring diagram

Draw 12

Draw 13

KEY

L Phase wire

N Neutral wire

W

Ground

DB Bipolar switch

TR Regulation thermostat

TCV Fan triggering thermostat

VT Fan

DV Fan switch

SB Lock-out light

SF Operation light

EV1 EV2 Electronic valve

ER Detection electrode

E ACC. Starting electrode

CEN

Imit AC02 or Brahma CM11F

electronic valve

TL Work thermostat

KEY

L Phase wire

N Neutral wire

W

Ground

DB Bipolar switch

TR Regulation thermostat

TCV Fan triggering thermostat

VT Fan

DV Fan switch

SB Lock-out light

SF Operation light

EV1 EV2 Electronic valve

ER Detection electrode

E ACC. Starting electrode

CF Fan

CEN Imit AC02 electronic valve

TL Work thermostat

Page 19

19

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Series FE with timer wiring diagram

Draw 14

KEY

L Phase wire

N Neutral wire

W

Ground

DB Bipolar switch

TR Regulation thermostat

TCV Fan triggering thermostat

VT Fan

DV Fan switch

SB Lock-out light

SF Operation light

EV1 EV2 Electronic valve

ER Detection electrode

E ACC. Starting electrode

CF Fan

CEN Imit AC02 electronic valve

TL Work thermostat

Page 20

20

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Draw 15

3 INSTRUCTIONS FOR INSTALLERS

3.1 Places of installation and

safety distances

We recommend observing the following rules in order to

obtain the maximum convector output efficiency:

- Position the device while bearing in mind the priority

areas to be heated, the absorption walls (windows,

doors, French windows etc.), and the existence of

shelves and other obstacles that might compromise

the circulation of the hot air released by the radiator

above and the effect of the heat radiated from the

front panel.

- If more than one device must be installed in the

same room, we recommend staggered and opposing positioning in order to provide the entire area

with uniform coverage.

- The devices must never be installed in recessed

niches or positions that do not ensure sufficient

aeration for good operation.

- Install the devices along perimetral walls whenever

possible.

- Observe the following rules to simplify interven-

tions on the radiator or the removal of the shell:

a) the distance of the device from the floor must

never be less than 10 cm.;

b) any shelves installed above the radiator must be

positioned at least 10 cm higher;

c) a minimum distance of 10 cm from the wall must

be respected whenever devices are installed in

recessed niches;

- avoid positioning furnishings above the shell.

Installation must be performed only by qualified professionals in complete respect of the safety regulations in

force. The Manufacturer declines all liability for erroneous installation or the inappropriate or incorrect use of

the device.

Page 21

21

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

8

8613

2

T

Y

6

8

G

3.2 Installation of the natural

balanced appliance.

For the assembling of the appliance, please follow the

instruction given in the following pages:

1) Place the template on the wall and fix it with adhesi-

ve tape at a distance of minimum 10 cm from the

floor perfectly in square (see draw 16). Draw the hole

for the exhaust and, if possible, make it with a 2%

inclination outwards the wall (see draw 17).

2) Place the template in square again and be careful

when centring it with the hole for the exhaust, then

make 4 holes of 8 mm in diameter and insert the supplied inserts (see draw 16).

Draw 17

Draw 16

INTERNAL

GROUND

EXTERNAL

Draw 18

Draw 19

Cutting Pipes exhaust kit natural balanced models

3) When the hole is done, measure the thickness of

the wall (M).

- Cut the suction pipe (8) on the side without rim (see

draw 17) 10mm longer than the thickness of the

wall (M).

- Cut the exhaust pipe (6) 65mm longer than the

thickness of the wall (M) measuring it from the air

intake grid (G) to the end (T) of the pipe, which has

to be inserted in the convector (see draw 18).

Assembling exhaust kit natural balanced models

4) Remove the shell (1) after having unloosing the

fixing screws (2) (see draw 19)

5) Superimpose the gasket on the pipe.

- Fix the suction pipe on the side of the rim (8) with

the 4 self-threading screws supplied (see draw 22).

6) Place the convector with the supplied screws,

wedge the fumes pipe grille (6) in the internal collar

of the air box (3) and fix it on the external wall with

the two supplied inserts.

Page 22

22

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

8

8

6

6

8

6

6

Y

A

4

8

6

1

2

8

Draw 22

Draw 21

3.2.1 Installation of the forced appliance with model grille

For the assembling of the appliance, please follow the

instruction given in the following pages:

1) Place the template on the wall and fix it with adhesi-

ve tape at a distance of minimum 10 cm from the

floor perfectly in square (see draw 20). Draw the hole

for the exhaust and, if possible, make it with a 2%

inclination outwards the wall (see draw 21).

2) Place the template in square again and be careful

when centring it with the hole for the exhaust, then

make 4 holes of 8 mm in diameter and insert the supplied inserts (see draw 20).

Draw 20

GROUND

Draw 23

Cutting pipes exhaust kit forced with production

model grille

3) When the hole is done, measure the thickness of

the wall (M).

- Cut the suction pipe (8) 70mm longer than the

thickness of the wall (M) and on the opposite side

of the final part (see draw 21)

- Cut the exhaust pipe (6) 90mm longer than the

thickness of the wall (M) (see draw 21).

Assembling exhaust kit forced with production

model grille

4) Remove the shell (1) after having unloosing the

fixing screws (2) (see draw 23)

5) Thread up the fumes pipe (6) in the internal collar

of the air box (see draw 22)

6) Thread up the gasket (Y) on the suction pipe (8)

(see draw 22)

- Fix the pipe (8) on the small collar (A) of the air box

using the screws supplied (see draw 22)

7) Place the convector (4) (draw 23) on the wall next

to the hole done before, and then fix it with the

screws supplied.

Page 23

23

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

8

6

8

6

6

Y

A

48361

2

8

Draw 26

Draw 25

3.2.2 Installation of the forced with grille appliance squared up

For the assembling of the appliance, please follow the

instruction given in the following pages:

1) Place the template on the wall and fix it with adhe-

sive tape at a distance of minimum 10 cm from the

floor perfectly in square (see draw 24). Draw the

hole for the exhaust and, if possible, make it with a

2% inclination outwards the wall (see draw 25).

2) Place the template in square again and be careful

when centring it with the hole for the exhaust, then

make 4 holes of 8 mm in diameter and insert the

inserts given (see draw 24).

Draw 24

GROUND

Draw 27

Cutting pipes exhaust kit forced with grille squared

up

3) When the hole is done, measure the thickness of

the wall (M).

- Cut the suction pipe (8) 65mm shorter than the

thickness of the wall (M) (see draw 25).

- Cut the exhaust pipe (6) 25mm shorter than the

thickness of the wall (M) (see draw 25).

Assembling exhaust kit forced with grille squared

up

4) 4) Remove the shell (1) after having unloosing the

fixing screws (2) (see draw 27)

5) Thread up the fumes pipe (6) in the internal collar

of the air box (see draw 27)

6) Thread up the gasket (Y) on the suction pipe (8)

(see draw 26)

- Fix the pipe (8) on the small collar (A) of the air box

with the supplied screws (see draw 26)

7) Place the convector (4) (draw 27) on the wall next

to the hole done before, then fix it with the supplied

screws.

8) Couple the template very closed to the wall (3)

(draw 27) from the outside and fix it with the inserts

supplied.

Page 24

24

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Side on which the

air box has to be

connected

Lift the pre-cut tongue to

prepare the support for

the housing.

1) side exhaust back connector

2) exhaust pipe hole

3) hole for cage nuts or screw anchor

4) gas convector

5) air box

6) sealing

7) female 60 Ø collar for exhaust fixing

8) pre-cut tongue to support the housing

9) sealing

Installation of King with side wall exhaust pipe

1) Drill (Ø60) the wall following the instructions at A

and B measures (see drawing 29)

2) Fix on the wall the back connector for the side wall

exhaust pipe (1) with the exhaust pipe hole (2) on

the right or on the left keeping the centre of the hole

Ø 60

3) Put the 4 cage nuts inside the fitting holes (3)

4) Fix on the gas convector (4) the air box (5) using

the 4 screw included in the equipment

5) Fix the box (5) to the female Ø60 collar (7) using

the 4 screws included in the equipment - don't forget to put the sealing (9) before the screw

6) Lift the 4 pre-cut tongues (8) placed on the back

connector (1)

Draw 28

Page 25

25

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

7) Fix the gas convector (4) to the back connector

using the screws included in the equipment - they

have to be screwed on the cage nuts (3)

8) Cut the coaxial tube at the right measure and fit it

on the air box (5) and on the Ø60 collar (7)

Draw 29

WALL

SIDE FUME KIT

SIDE FUME KIT

WALL

VIEW B

VIEW A

GROUND

WALL

HOLE Ø 60mm

Page 26

26

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

3.3 Gas line connection

The gas line connection must be made with respect to

the regulations in force.

a) The device cannot withstand pressures of higher

than 40 mbar (0,04 bar) without risking the breakage of the gas valve membrane.

b) Always use ball valves and flexible joints for gas

when connecting the devices.

c) Gas supply line pressure adjustment: all the devices

are tested and calibrated at the Manufacturer’s factory for their respective operating pressures (see the

data provided in the table).

To check the outlet pressure (Natural gas) use the check

point 4 (Draw 30) and 1 (Draw 30a) placed above the

valve outlet after removing the locking screw. In case the

pressure value should not corrispond to the valued indicated check (burner working) the inlet pressure trough

the check point (5 Draw 30) the inlet pressure must be

like indicated in the tables to the page 8, 9.

For gas LPG (butane-propane), the valve flow adjuster

must be totally excluded. On the heaters supplied with

EUROSIT valve turn anti-clock-wise 1/2 spin the pressure adjuster 9 (Draw 30). On the heaters supplied with

WHITE ROGER or SIT 850 MICRO turn completely the

pressure adjuster 3 as Draw 30a. To check the inlet pressure use the check point placed (5 Draw 30 and 2 Draw

30a) above the valve inlet gas connector. Whenever the

inlet pressure values should not correspond to the value

indicated on the regulation data table, adjust the pressure (burner working) manually trough the pressure adjuster placed on the top of the valve.

After these pressure adjustment operations have been

completed, remember to close the pressure taps located

on the gas safety valve using the respective screws.

VALVE FOR PILOT FLAME DEVICES (K21, K28, K40,

K55, K28V, K40V, K55V)

LEGEND

1) Control dial

2) Pilot frame adjustment screw

3) Minimum flow adjustment screw

4) Outlet pressure tap (at nozzle)

5) Inlet pressure tap (from mains)

6) Pilot flame supply line pipe

7) Thermocouple

8) Magnet unit

9) Pressure regulator - stabilizer

10) Gas inlet connector thread

11) Main burner supply line pipe

12) Piezoelectric button

13) Sealing connector

14) Nozzle-holder sleeve

15) Nozzler

“EUROSIT” TYPE

Draw 30

Page 27

27

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

2

1

3

SOLENOID VALVE FOR ELECTRONIC DEVICES

(K21E, K28E, K40E, K55E, K28VE, K40VE, K55VE,

K21FE, K28FE, K40FE, K55FE)

LEGEND

1) Outlet pressure tap (at nozzle)

2) Inlet pressure tap (from mains)

3) Pressure regulator - stabilizer

4) Main burner supply line pipe

5) Sealing connector

6) Nozzle-holder sleeve

7) Nozzle

8) Brass closing plug

“WHITE ROGER” TYPE

“SIT 850 MICRO” TYPE

3.4 Transformations for various

types of gas supplies for pilot

flame-type devices (Mod. K21,

K28, K40, K55, K28V, K40V,

K55V)

Transformation must be performed only by qualified professionals in complete respect of the safety regulations

in force. The Manufacturer declines all liability for erroneous installation or the inappropriate or incorrect transformation or use of the device.

Transformation from Methane gas to LPG. gas

1) Close the gas supply line and disconnect the elec-

trical power supply.

2) Remove the cast-iron front panel by unscrewing the

four M8 screws at the corners.

3) Remove the gas supply line pipe from the main bur-

ner (11) using the sealing connector (13) (See Draw

30).

4) Remove the nozzle-holder (14) and the nozzle (15),

and replace the nozzle with the one contained in the

transformation kit after first checking to make sure

that the diameter corresponds to the diameter listed

on the rating plate.

5) Disable the valve's pressure regulator by screwing

the screw (9) clockwise (+) all the way down.

6) Remove the gas pipe (6) from the pilot, remove the

pilot nozzle and replace it with the one contained in

the transformation kit.

7) Re-close the cast-iron front panel, making sure that

the fiberglass sealing liner remains in place.

8) Check for leakage of gas along the threaded joints.

9) Start the device, and make sure that the supply

pressure to the burner is like indicated in the tables

to the page 8, 9 (*) using the pressure tap (5).

10) Indicate on the rating plate the type of gas transformation performed on the device.

(*) For LPG gas (Butane-Propane), a “I” stage pressu-

re reducer must be installed near the tank in order to

reduce the pressure to 1.5 bar; a “II” stage pressure

reducer must be installed on the main external

supply line in order to reduce the pressure like indicated in the tables to the page 8, 9.

Transformation from LPG gas to Methane gas

1) Close the gas supply line and disconnect the electrical power supply.

2) Remove the cast-iron front panel by unscrewing the

four M8 screws at the corners.

3) Remove the gas supply line pipe from the main burner (11) using the sealing connector (13) (See Draw

30).

4) Remove the nozzle-holder (14) and the nozzle (15),

and replace the nozzle with the one contained in the

transformation kit after first checking to make sure

that the diameter corresponds to the diameter listed

on the rating plate.

Draw 30a

Page 28

28

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

5) Remove the gas pipe (6) from the pilot, remove the

pilot nozzle and replace it with the one contained in

the transformation kit.

6) Re-close the cast-iron front panel, making sure that

the fiberglass sealing liner remains in place.

7) Check for leakage of gas along the threaded joints.

8) With a 20 mbar supply pressure, use the adjustment

screw (9) to bring burner pressure (4) to its nominal

rating plate value. Screwing in the clockwise direction increases the pressure, while unscrewing counter-clockwise decreases the pressure.

9) Indicate on the rating plate the type of gas transformation performed on the device.

EURO SIT SOLENOID VALVE REGULATION

Take out the plastic cover of the valve.

Regulation of gas flow of pilot burner

Turn the knob in Pilot position (). To increase the flow

turn the PILOT regulation screw counter-clockwise and

vice-versa.

Regulation of gas pressure (output) at the main burner

The gas regulator is adjusted to the right position by the

manufacturer. Modifications of such adjustment have to

be done by qualified personnel, respecting the following

instructions.

Turn the knob to the position 7, corresponding to the

maximum (the bulb of the thermostat has to be at the

minimum declared temperature)

Using a screwdriver take out the plastic cover of the

valve.

To increase the output pressure turn the screw "9" counter-clockwise and vice-versa.

After this adjustment the regulator has to be in compliance with the UNI EN 126 standard for pressure regulators.

At the end of regulations, put again the plastic cover

onto the valve.

Disabling the pressure regulator

Using a screwdriver take out the plastic cover of the

valve.

Turn completely clockwise the screw "9" : the internal

bush will be released from the screw, disabling the pressure regulator (gas of III family).

At the end of regulations, put again the plastic cover

onto the valve.

3.5 Transformations for various

types of gas supplies for electronic devices (Mod. K21E,

K28E, K40E, K55E, K28VE,

K40VE, K55VE, K21FE,

K28FE, K40FE, K55FE)

ransformation must be performed only by qualified professionals in complete respect of the safety regulations

in force. The Manufacturer declines all liability for erroneous transformation or the inappropriate or incorrect

use of the device.

Transformation from Methane gas to LPG gas

1) Close the gas supply line and disconnect the elec-

trical power supply.

2) Remove the cast-iron front panel by unscrewing the

four M8 screws at the corners.

3) Remove the gas supply line pipe from the main bur-

ner (4) using the sealing connector (5) (See Draw

30a).

4) Remove the nozzle-holder (6) and the nozzle (7),

and replace the nozzle with the one contained in

the transformation kit after first checking to make

sure that the diameter corresponds to the diameter

listed on the rating plate.

5) Disable the valve's pressure regulator by removing

the brass plug (8) and then screwing the screw (3)

clockwise (+) all the way down.

6) Re-close the cast-iron front panel, making sure that

the fiberglass sealing liner remains in place.

7) Check for leakage of gas along the threaded joints.

8) Fire the device, and make sure that the supply

pressure to the burner is like indicated in the tables

to the page 8, 9 (*) using the pressure tap (5).

9) Indicate on the rating plate the type of gas transfor-

mation performed on the device.

(*) For LPG gas (Butane-Propane), a “I” stage pressu-

re reducer must be installed near the tank in order

to reduce the pressure to 1.5 bar; a “II” stage pressure reducer must be installed on the main external

supply line in order to reduce the pressure like indicated in the tables to the page 8, 9.

Transformation from LPG gas to Methane gas

1) Close the gas supply line and disconnect the elec-

trical power supply.

2) Remove the cast-iron front panel by unscrewing the

four M8 screws at the corners.

3) Remove the gas supply line pipe from the main bur-

ner (4) using the sealing connector (5) (see Draw

30a).

4) Remove the nozzle-holder (6) and the nozzle (7),

and replace the nozzle with the one contained in the

transformation kit after first checking to make sure

that the diameter corresponds to the diameter listed

on the rating plate.

Page 29

29

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

5) Re-close the cast-iron front panel, making sure that

the fiberglass sealing liner remains in place.

6) Check for leakage of gas along the threaded joints.

7) With a 20 mbar supply pressure read on the pressure tap (2), use the adjustment screw (3) to bring

the pressure of the burner (1) to its nominal rating

plate value. Screwing in the clockwise direction

3.6 Adaptation of the electronic

devises for France and

Belgium (Mod. K21E, K28E,

K40E, K55E, K28VE, K40VE,

K55VE, K21FE, K28FE, K40FE,

K55FE)

The transformation must be performed exclusively by

qualified professional personnel in complete respect of

the safety rules in force; the manufacturer declines liability for damages caused by the erroneous transformation

or incorrect and/or inappropriate use of the device.

For France and Belgium, in case of methane gas feeding, the valve must be installed us the one represented

on the draw.

For the transformation from LPG into METHANE gas,

the burner nozzle must be substituted (A see draw 31)

and remove the diaphragm (B see draw 31).

3.7 Electrical connections from

the control panels to the devices

Check to make sure that a good ground connection has

been made and respect the correct connections of the

phase and neutral wires. otherwise the flame detection

and control systems will not work.

increases the pressure, while unscrewing counterclockwise decreases the pressure.

8) Indicate on the rating plate the type of gas transformation performed on the device.

Draw 31

Page 30

30

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

3.9 Starting and operation of pilot

flame devices (Mod. K21, K28,

K40, K55, K28V, K40V, K55V)

1) Set the dial (1) in the position () on the index (See

Draw 30).

2) Press the dial (1) and keep it pressed down for

approx. 10 seconds.

3) Press the piezoelectric button (12) to light the bur-

ner’s pilot flame.

4) After lighting the burner’s pilot flame, keep the dial

(1) pressed down for approx. 10 seconds, and then

release.

5) Turn the dial (1) counter-clockwise to fire the main

burner and set it on the index at values from 1 to 7

which correspond to 13 ° - 38 °C respectively.

6) In order to switch the main burner off, rotate the dial

(1) to the (î) position () on the index. In order to

switch the burner’s pilot flame off (and consequently

the unit itself), turn the dial (1) to the (l) position ()

on the index.

Wait 60 seconds before trying to start the device again.

3.11 Utilization of the daily programmer (optional)

1) Set the right time using the white reference triangle

positioned above the programmer disk’s

starting/switch-off switch by rotating clockwise.

2) Pull the sectors on the programmer disk correspon-

ding to the period of operation desired outward (for

example, from 10.00 AM to 17.00 PM). These sectors are used to set the period of operation.

3) Numerous intervals of operation throughout the day

can be programmed by selecting the sectors as

required.

4) When setting starting at 10.00 AM and switch-off at

17.00 PM, the device will always start and stop at

the same time, day after day, for the period of time

set.

3.10 Starting and operation of

electronic devices (Mod.

K21E, K28E, K40E, K55E,

K28VE, K40VE, K55VE,

K21FE, K28FE, K40FE,

K55FE)

1) Press the bipolar switch “ON - OFF” to connect vol-

tage to the circuit.

2) Position the 0-40 °C thermostat on the desired tem-

perature value. After these operations have been

performed, the “green operation” light will automatically light up. Once the temperature set on the thermostat has been reached, the “green operation”

light that indicates flame presence will switch off.

3) Press the bipolar switch to turn the device off.

ATTENTION! When using the daily programmer, the program set will be run when the

switch is set in the central position. When

set in the “I” position, the device will operate

continuously and the timer will be disabled.

When set in the “O” position, the device will

switch off and the timer will be disabled.

Draw 32

Page 31

31

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

3.12 Utilization of the weekly programmer (optional)

1) Push the programmer disk sectors corresponding to

the period of operation desired towards the center

(for example, from 08.00 AM Monday morning until

20.00 PM Tuesday). The red sector that appears at

the edge of the disk indicates the period of device

starting.

2) Set the right time by rotating the white reference

triangle at the center of the programmer disk clockwise.

3) When setting starting at 08.00 AM Monday and

switch-off at 20.00 PM Tuesday, the device will

always start and stop at the same time and day,

week after week.

3.13 Malfunctions and solutions for pilot flame devices (Mod. K21, K28, K40,

K55, K28V, K40V, K55V)

Draw 33

DEFECTS CAUSES SOLUTIONS

1. The burner pilot flame fails to

light.

a) There is no gas or the pressure is

too high.

a) Check the supply pressure on the

valve (5 Draw 30).

b) There is no electrical spark dis-

charge on the burner.

b) Check the spark plug, cable and

piezoelectric element.

c) The pilot flame nozzle is clogged

or inadequate to the type of gas

being used (Methane or LPG).

c) Replace using original spare parts.

2. The burner pilot flame lights but

goes off when the dial is released.

a) The dial (1 Draw 30) has been

released before ten seconds have

passed.

a) Keep the dial pressed down for

more than ten seconds.

b) The thermocouple has oxidized. b) Replace using original spare parts.

c) The solenoid valve coil is malfunc-

tioning.

c) Replace using original spare parts.

3. The main burner flame goes off.

a) The gas pressure reaching the

nozzle is too high.

a) Adjust the pressure to the rating

plate values using the pressure

tap (4 Draw 30).

b) The wrong type of nozzle has

been used.

b) Replace using the right type of

nozzle for the type of gas being

used.

c) The flue gas expulsion pipe has

not been perfectly connected between the cast-iron casting and the

external anti-wind grille.

c) Check the connection seal.

d) The anti-wind grille has been clog-

ged.

d) Clean the grille.

Page 32

32

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

3.14 Malfunctions and solutions for electronic devices (Mod. K21E, K28E,

K40E, K55E, K28VE, K40VE, K55VE, K21FE, K28FE, K40FE, K55FE)

DEFECTS CAUSES SOLUTIONS

1. The “red” lock-out light switches on.

a) There is no gas or the pressure is

too high.

a) Check the supply pressure on the

valve (5 Draw 30a).

b) There is no electrical spark dis-

charge on the burner.

b) Check the condition of the starting

electrodes, the respective spark

detection system, and the position

of the starting electrodes.

c) The electric polarity of the neutral

phase has been inverted.

c) Invert the polarity of the neutral

phase.

d) The device has not been correctly

grounded.

d) Ground the device correctly.

e) There is a malfunction in the elec-

tronic unit (in most cases this is

due to electrical discharges produced by lightning. We recommend

disconnecting the electrical power

supply during periods when the

device will not be used.

e) Replace using original spare parts.

f) Air is present in the pipes and cau-

ses the device to lock-out after 10

seconds of discharge on the burner.

f) Switch the bipolar switch equipped

with the “orange l.e.d.” off and on

to reset.

g) The centrifugal fan positioned in

the combustion air suction circuit

is malfunctioning (no starting

occurs).

g) Replace using original spare parts.

h) failure of one or both coils of gas

solenoid valve.

h) Replace with an original spare part

i) failure of the redresser bridge of

gas solenoid valve

i) replace with an original spare part

2. The tangential fan for the supply

of surrounding air fails to start

working.

a) The fan is jammed.

a) Check and remove all foreign

objects.

b) The fan motor is malfunctioning. b) Replace the entire fan-motor unit.

c) The fan triggering thermostat is

malfunctioning (this can be checked by making an electric bridge

on the thermostat itself).

c) Replace the fan triggering thermo-

stat (38 - 40 °C) using original

spare parts.

3. Main burner with the flame

which is detaching

a) Gas pressure at the nozzle too

high

a) Regulate the pressure at the nomi-

nal value using the 4 intake (Draw

30)

b) Wrong nozzle.

b) Replace the nozzle with the one

corresponding to the gas actually

used

c) Exhaust pipe not correctly connec-

ted between the cast iron body

and the external terminal

c) Verify the seal of the connection

d) Obstructed terminal d) Clean the terminal

Page 33

33

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

4 INSTRUCTIONS FOR THE USER

4.1 General rules

This Manual is an integral and essential part of this device and must be carefully stored in its vicinity for purposes of rapid consultation.

Read the instructions and warnings provided herein

carefully because they provide important information

regarding safety, installation, use and maintenance.

The device must be started for the first time by qualified

personnel only.

Immediately switch off the device whenever it stops

and/or malfunctions. All repairs must be performed by

qualified personnel using original spare parts only.

Failure to observe the above can compromise operational safety.

Scrupulously respect the indications provided by the

Manufacturer and have the device serviced by qualified

personnel (at least once a year) to guarantee satisfactory operation.

Delicate surfaces such as curtains, furniture, and wooden or plastic chairs must be kept at a minimum distance of 30 cm from the device.

Provide extra protection against the risk of burning by

the contact of children, the elderly or disabled with the

hot surfaces of the shell wherever necessary. Such additional protection must not obstruct the passage of hot air

and the irradiation of heat from the front panel.

4.2 Warranty

4.2.1 Object and duration of the guarantee

1) The Guarantee is limited to defects in the material or

manufacturing of the components supplied by

SYSTEMA. In the case of material or manufacturing

defects, SYSTEMA shall repair or replace the faulty

parts free of charge ex works; ANY OTHER FORM

OF GUARANTEE OR COMPENSATION, BOTH

LEGAL AND CONVENTIONAL, IS EXPRESSLY

EXCLUDED. The replaced parts shall be promptly

returned to SYSTEMA, carriage paid to the works at

S. Giustina in Colle (PD) at the user’s expense. If

work is carried out under guarantee, the user shall

be charged a flat rate, as well as a distance refund

if the place of intervention is more than ten kilometres from the S.C. (Service Centre).

2) The validity of the Guarantee runs from

“Commissioning”, on condition that this takes place

within 6 (six) months of the date of purchase of the

appliance by the user. In any case the Guarantee

expires 18 (eighteen) months from the date of the

SYSTEMA invoice.

3) Any replacement of faulty parts (or of the whole

appliance) shall not prolong the original expiry term

of the Guarantee. The Guarantee on the replaced

parts shall cease with the expiry date of the

Guarantee on the Appliance.

4) The “duration of the guarantee” shall be 1 (one) year

on each component of the appliance.

4.2.2 Exclusions from the guarantee

1) The Guarantee is not operative in the following cases:

a) Faults that cannot be attributed to defects in the

material or manufacture, without limitation:

- breakages that occurred during transport;

- non conformity of the plant with the laws and the

local regulations in force;

- failure to respect the installation specifications given

in the technical notes accompanying the appliance

and/or of good technical practice;

- damage caused by accidents, fire, general accidents or negligence that cannot be attributed to

SYSTEMA.

b) Tampering or faults due to interventions of non

authorised personnel.

c) Defects caused by malfunctions depending on the

electric power supply mains or on fuel.

d) Faults due to: bad maintenance, neglect or improper

use, variations in voltage in the power supply, humidity and dust in the premises, errors in dimensions

and/or faulty performance of installation.

e) Corrosion or breakages caused by: stray current,

condensation, overheating caused by incorrect

regulation of the gas pressure in the supply or in the

burner, or the use of gas fuel with different heating

characteristics from those on the data plate.

f) Use of non original spare parts or parts not authori-

sed by SYSTEMA.

g) Normal wear and tear.

h) Products that have been incorrectly kept or stored.

2) The Guarantee is not operative in the following cases:

a) Payment of the appliance has not been carried out

within the terms contemplated in the contract.

b) If “Commissioning” has not been performed by the

S.C. and/or a copy of the respective Guarantee

Certificate, duly compiled in all parts and signed,

Page 34

34

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

5 PUTTING THE DEVICE OUT OF USE

6 SCRAPPING

has not been received.

c) The user has not reported with fault within 10 days

of discovering it.

4.2.3 Competence

1) Operations under Guarantee must be requested,

on pain of expiry, to the S.C. that carried out

“Commissioning”. In this case the user must show

the S.C. the Guarantee Certificate.

2) The S.C. will take action during normal working

hours, depending on its own organisation necessities.

4.2.4 Operativity and effectiveness of

the guarantee

1) In order to make the Guarantee operative and

effective, the user must:

a) Ask the installer for the name of the S.C. for

“Commissioning”.

b) Show the Guarantee Certificate to the personnel in

charge, completing it in all parts and asking the

S.C. to apply the stamp and sign it in the spaces

provided.

4.2.5 Responsibility

The customer relieves the supplier of all responsibility

for accidents for damage that may occur to the machines or the plants during operation. The supplier is

responsible to the buyer only he guarantee obligations

specified above.

4.2.6 Legal disputes - Territorial competence and rights of the parties

It is established that the competent court is the Court of

Padua (Italy), even in the case of action for connection

or call under guarantee. The loss of a suit does not exonerate the buyer from the obligations to make payment,

which must be fulfilled according to contract, until the

final decision is made by the Legal Authority.

Whenever the device will not be used for a long period

of time, we recommend performing the following operations:

Set the main power switch in the “O” position and disconnect the device from the electrical power mains.

Close the gas supply line valve and disconnect the device from the gas supply mains.

ATTENTION! Please make sure that all operations of deconnecting are performed by

authorized personnel.

Whenever this device will no longer be used, we recommend making it inoperative by disconnecting it from the

electrical power and gas mains removing the control

panel.

We also recommend making harmless all parts that may

constitute sources of risk.

Remove the entire electrical system by observing the

laws in force regulating the elimination of such materials.

ATTENTION! Please make sure that all operations of deconnecting are performed by

authorized personnel.

Scrap the rest of the device as scrap metal and take it to

an authorized collection center for such materials.

Page 35

35

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

7 CE CERTIFICATE

Page 36

36

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Page 37

37

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Page 38

38

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Page 39

39

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

Page 40

Loading...

Loading...