Systema INFRA...ROSSO SCR 1 25M, INFRA...ROSSO SCR 1 45M, INFRA...ROSSO SCR 1 45A, INFRA...ROSSO SCR 1 25A Instruction Manual

Page 1

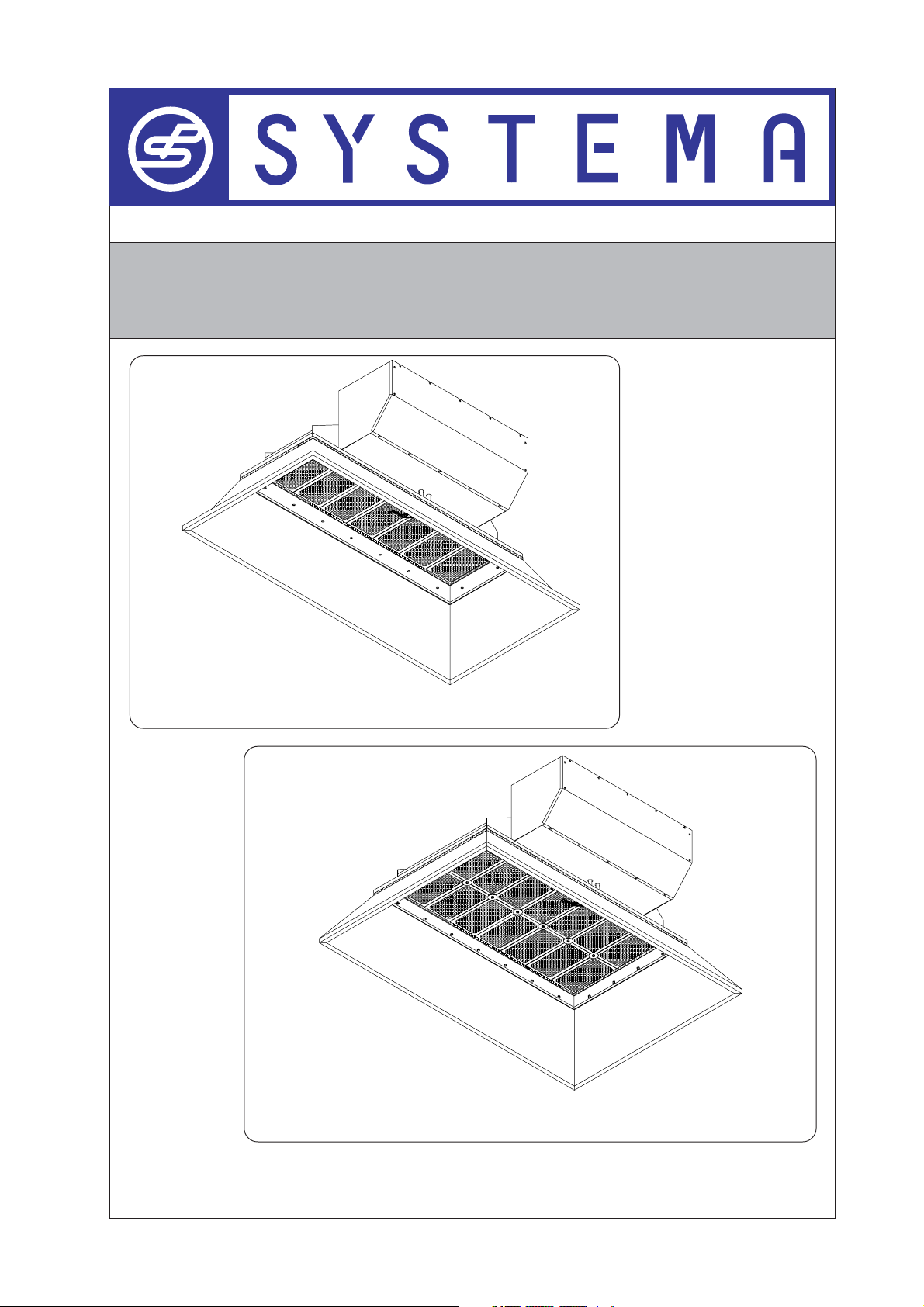

INFRA-RED VARIABLE POWER CERAMIC HEATERS

"INFRA…ROSSO SCR 1"

"INFRA…ROSSO SCR 1" 25m - 25a

REV. 03GB0602

"INFRA…ROSSO SCR 1" 45m - 45a

INSTRUCTIONS MANUAL

"INSTALLATION - USE - MAINTENANCE"

Page 2

SYSTEMA

!

IMPORTANT

Read carefully this manual before proceeding to the start up of the installation. In order to

improve the product, SYSTEMA reserves the right to modify the content without prior notice.

SYSTEMA S.p.A.

Via San Martino 17/23

S. GIUSTINA IN COLLE (PD)

loc. Fratte Fontane Bianche

PADOVA - ITALY

Tel. 0039 0499355663

Fax 0039 0499355699

E-mail: systema@systema.it

http://www.systema.it

Rev. 03GB0602

This product is manufactured and certified by

SYSTEMA S.p.A.

SYSTEMA POLSKA Sp. zo.o.

Ul. Szadkowska, 72

98-220 Zdunska Wola

Poland

Tel. +48 43 8247287

Fax +48 43 8233064

http://www.systemapolska.pl

E-mail: systema@systemapolska.pl

2

Page 3

SYSTEMA

Summary

1 GENERAL RULES ................................................................................................... 4

2 EQUIPMENTS DESCRIPTION .............................................................................. 5

2.1 General description ............................................................................................................. 5

2.2 Functionning description .....................................................................................................6

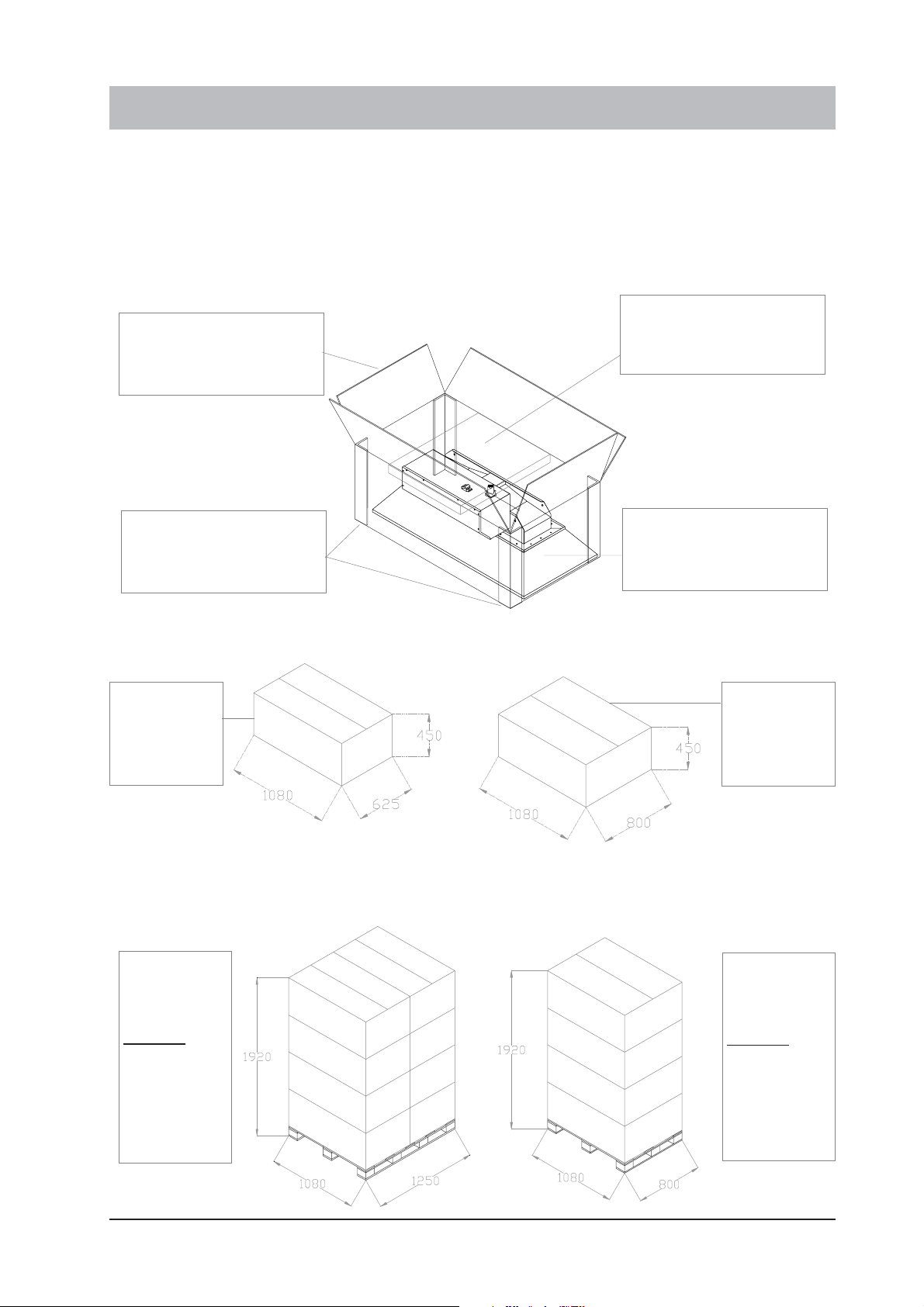

3 PACKING - TYPOLOGY AND DIMENSIONS .........................................................7

3.1 Ceramic heater packing ...................................................................................................... 7

3.2 External dimension of equipment packing ........................................................................ 7

3.3 Packing dimensions on pallet ............................................................................................. 7

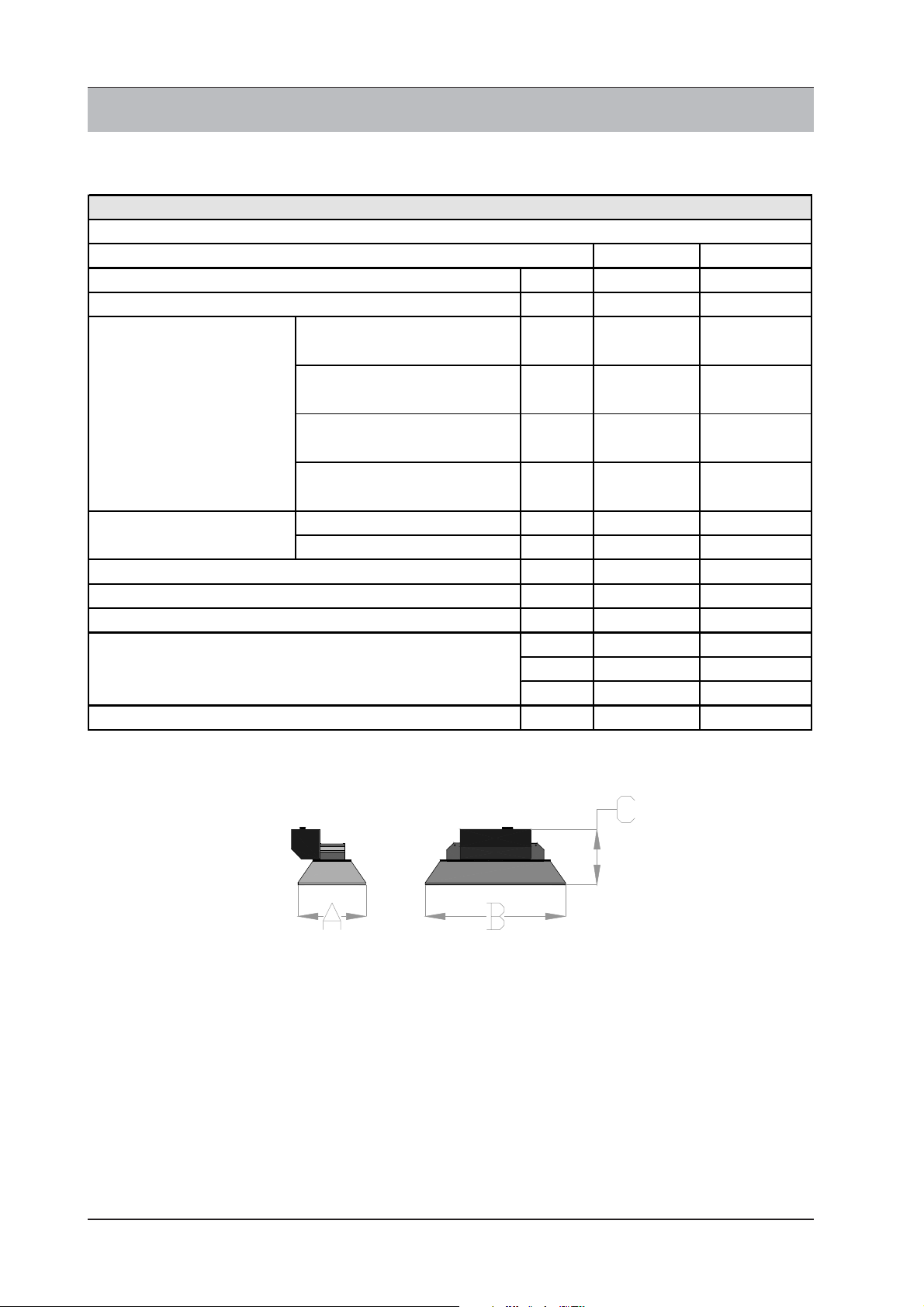

4 TECHNICAL DATA ................................................................................................ 8

4.1 General technical data ........................................................................................................ 8

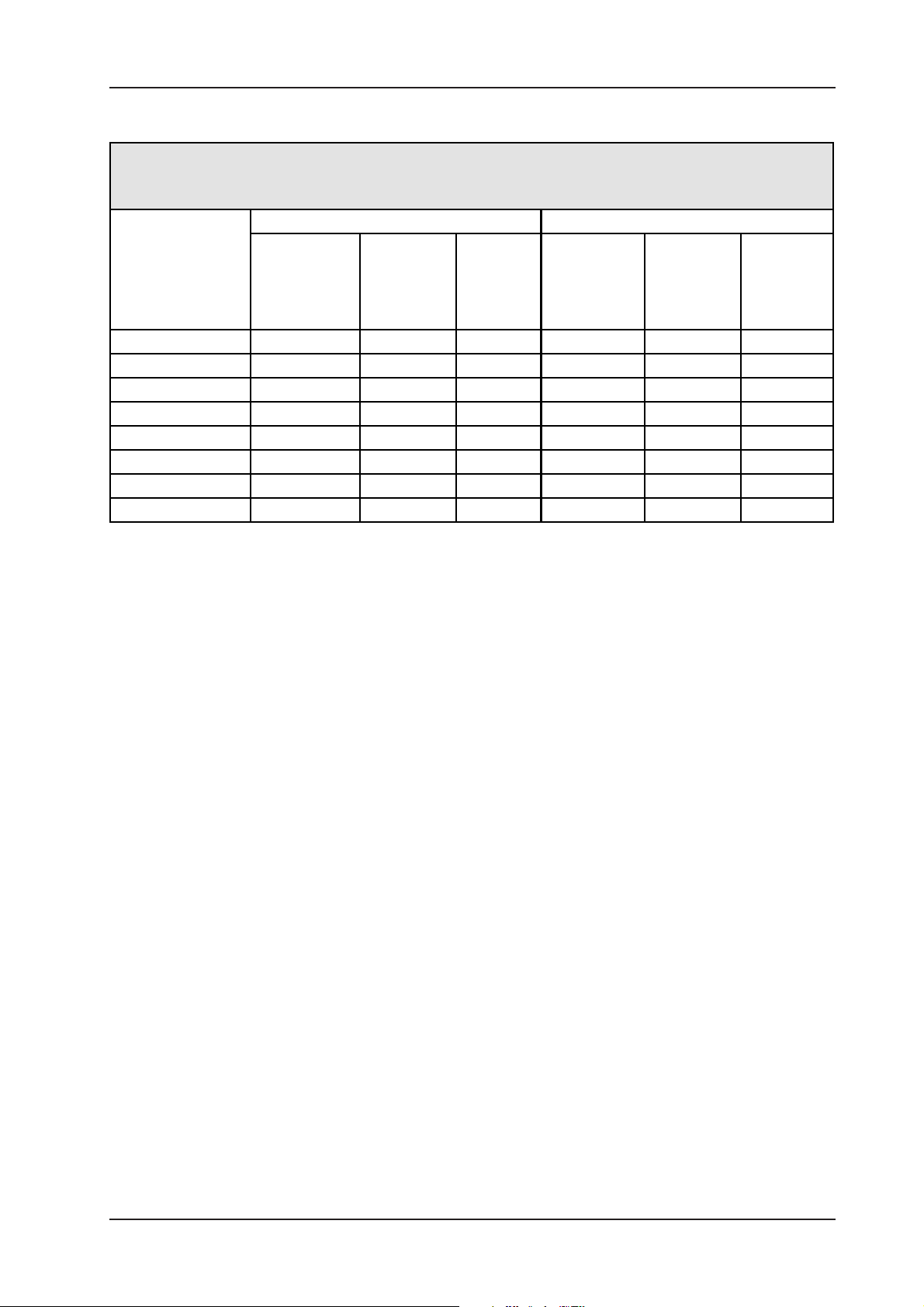

4.2 Thermal power table ........................................................................................................... 9

5 EQUIPMENT BASIC PARTS ............................................................................... 10

5.1 Fan characteristics ventilateur .......................................................................................... 10

5.2 Gas solenoid valve ............................................................................................................. 10

5.3 Flame control electronic device ....................................................................................... 10

5.4 Air - Gas mixer ................................................................................................................... 10

5.5 Ceramic plate .................................................................................................................................. 10

6 ELECTRICAL CONNECTIONS ............................................................................. 11

6.1 Wiring diagram SCR 25 m - SCR 45 m .............................................................................. 11

6.2 Fan digital PWM regulator ................................................................................................ 12

6.3 Wiring diagram of SCR 25 a - SCR 45 a ........................................................................... 13

6.4 Serial INFRANET network wiring diagram ....................................................................... 14

6.5 Master INET control board ................................................................................................. 14

7.1 EXPLODED DRAWING SCR 25m - SCR 45m equipments ................................................. 15

7.2 EXPLODED DRAWING SCR 25a - SCR 45a equipments .................................................. 15

7.3 Exploded Drawing SCR 25 m - SCR 25 a equipments ..................................................... 17

7.4 Exploded drawing SCR 45 m - SCR 45 a equipment ....................................................................... 18

8 "INFRA…ROSSO SCR" HEATERS INSTALLATION ......................................... 19

8.1 Security distance from inflammable materials ............................................................... 19

8.2 Ceiling installation ............................................................................................................. 20

8.3 Installation on a wall ......................................................................................................... 21

9 START UP AND OPERATING ............................................................................. 22

10 CHANGE OF FUEL SUPPLY .............................................................................. 23

10.1 Operating anomalies .........................................................................................................24

11 GUARANTY .......................................................................................................... 25

11.1 Object and validity of guaranty ......................................................................................... 25

11.2 Exclusions from guaranty .................................................................................................. 25

3

Rev. 03GB0602

Page 4

SYSTEMA

1 GENERAL RULES

This manual is an integral and essential part of this device and it must be carefully stored in its vicinity

for purposes of rapid consultation.

Read carefully the instructions and warnings provided herein because they provide important information

regarding safety, installation, use and maintenance.

In case of loss of the present manual, contact immediately the manufacturer.

ATTENTION!!

Being established that:

The "INFRA…ROSSO" ceramic heaters are heating according to the principle of visible radiation with

open air combustion.

The "INFRA…ROSSO" ceramic heaters have no chimney for the evacuation of exhausts outside, therefore

the combustion products remain in the premises mixed with the air. They will have to be ejected outside

by an adequate ventilation.

The ceramic plate of "INFRA…ROSSO" ceramic heater can reach temperatures of about 1.200 °C.

The "INFRA…ROSSO" ceramic heater need to be operated gas and electric energy.

The present manual does not indicate with absolute precision the type of places where these

equipments can be installed

For each installation, qualified personnel must evaluate the environment risk.

To make the installation easier , we strongly suggest to use the following basic suggestions:

The "INFRA…ROSSO" ceramic heater have to be installed in premises where there is absolutely no

risk of fire. The installation is forbidden in premises where gas or inflammable products are present or

where there is the risk that corrosive or inflammable gas could be generated.

The installation, control and maintenance of "INFRA…ROSSO" ceramic heaters have to be done in the

respect of laws, rules and good technique principles in force in the Country where the equipments are

installed.

The "INFRA…ROSSO" ceramic heaters have to be installed, verified and submitted to maintenance by

qualified personnel.

The "INFRA…ROSSO" ceramic heaters can be installed on a wall or on the ceiling, without any limit of

inclination, but with full respect of safety distances between the emitting source and the structure of the

building or the material present in the premises.

The premises where the "INFRA…ROSSO" ceramic heaters are installed will have to be

permanently ventilated in order to eject outside the combustion products. The minimum

ventilation admitted for the premises must respect the laws and the rules of the Country

where the installation is made.

The absence of ventilation in the premises is determining accumulation of CO2 and subsequently

carbon monoxide, which is a sign of bad functioning of "INFRA…ROSSO" ceramic heaters and

is very dangerous for the health of people and animals: in certain cases exhaust could be

cause of death for people and animals.

ATTENTION!

In the case the ceramic heaters are not compatible with the use, by the safety standpoint, we

invite you to consider our products INFRA B (airtight gas radiant tubes) and OHA (airtight gas

radiant strips).

Rev. 03GB0602

4

Page 5

SYSTEMA

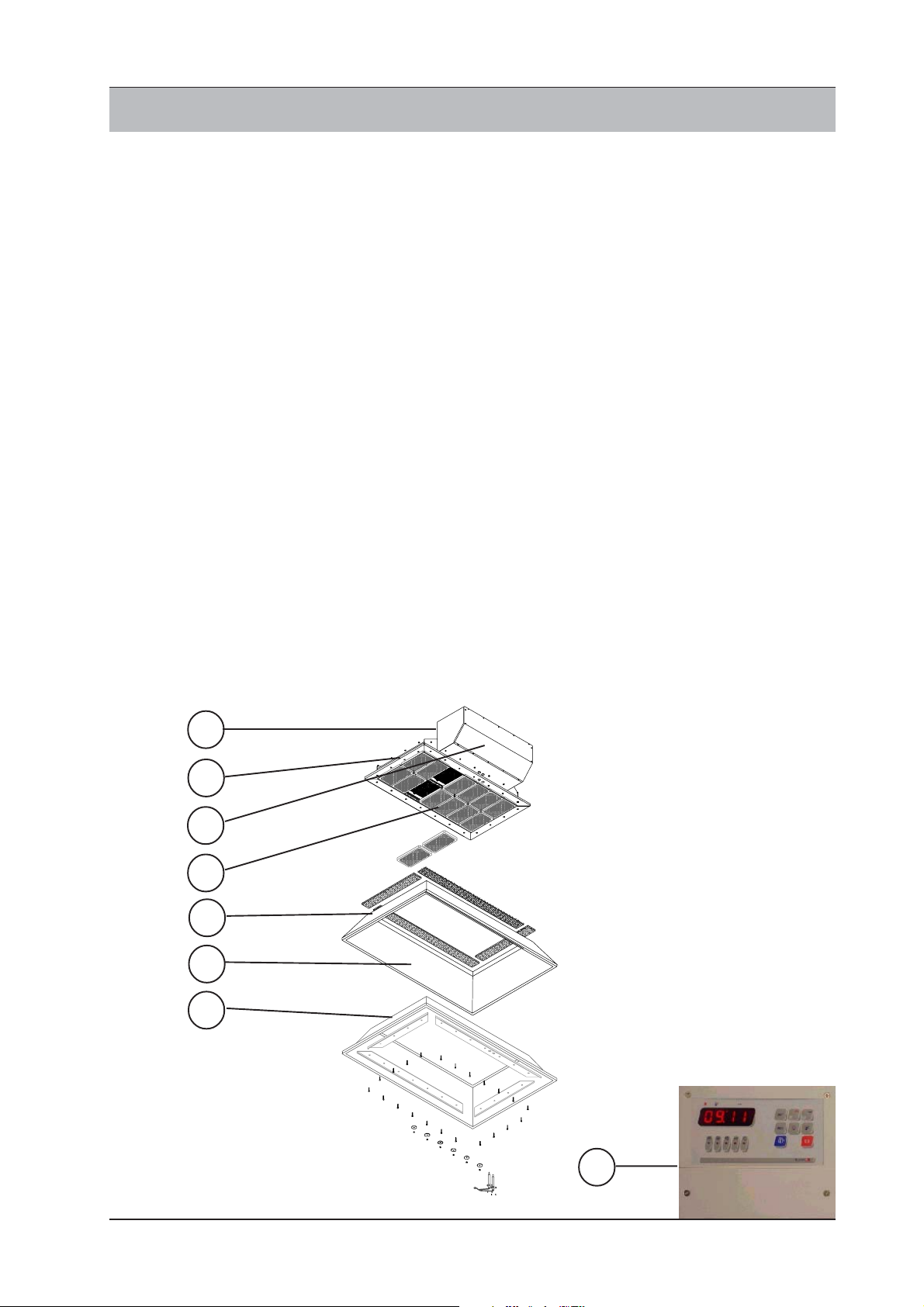

2 EQUIPMENTS DESCRIPTION

2.1 General description

The "INFRA…ROSSO" ceramic heaters have to be considered as new generation products because

they are based on new innovating concepts : a pre-mix burner, the very high thermal performance, the

modularity of thermal power, the radiating performance, the highest flexibility of installation and use.

The "INFRA…ROSSO" ceramic heaters consist in

a) A steel chamber where takes place the mixing of air and gas.

b) A waterproof box containing the equipment, with the possibility of installation of air filters or

connection with a duct taking the air form outside. NEW !

c) Pre-mixed system of combustion, with a variable speed fan and modulating gas valve, working in

depression conditions. NEW !

d) Emitting source (burner) : a ceramic plate.

e) A standard stainless steel parabola reflector or (in option) a sandwich consisting inside in a

parabola reflector in aluminized and calorized steel with quartz finishing (e1) with high reflection and

infrared emission characteristics NEW !, a thermal isolating sheet (e2) NEW ! and an external parabola

in galvanized steel, for protection and isolation (e).

f) In the models …m (manual) the thermal power can be regulated manually with digital variation of

power within the modulation range of the model.

The thermal power modification can be by cable remote control, manual on the electric board or by

infrared remote control. NEW !

g) The centralized control of the heaters for the models …a (automatic) consist in the INET serial

network, with a regulation which is independent by the thermal power of each thermal zone, with the

integral proportional method (thermal power variation based on the established comfort temperature and

on the detected ambient temperature). NEW !

b

a

c

d

e

e2

e1

g

5

Rev. 03GB0602

Page 6

SYSTEMA

2.2 Functionning description

The "INFRA…ROSSO" ceramic heaters models are the following:

a) Mod. SCR 25 m with pre-mix combustion and manual variation of thermal power.

b) Mod. SCR 45 m with pre-mix combustion and manual variation of thermal power.

c) Mod. SCR 25 a with pre-mix combustion and automatic variation of thermal power by a InfraNet

control network and a Inet electric board (see specifications in the following paragraphs).

d) Mod. SCR 45 a with pre-mix combustion and automatic variation of thermal power by a InfraNet

control network and a Inet electric board (see specifications in the following paragraphs).

The functioning procedure of the over described models can be resumed in the following points :

A) The models …m (manual), with the digital PWM variator situated inside the equipment are regulated

at the factory during the final control before delivery to the thermal power requested (see table at

paragraph 2.3).

The demanded power will remain fix. If necessary it will be possible to modify the power according the

climate conditions of the moment, by the ground control board, using a linear potentiometer or by a

remote infrared control (optional).

The models …m (manual) with the remote control, will be programmed with the power requested by the

final user (see table at paragraph 2.3) and they will be controlled by a ON/OFF ambient thermostat.

Sequence of functioning of models …m (manual):

After the reception of the electric input, the lighting and start up procedure begins, with the following

steps :

1) The 577 DBC device starts the fan for the mixing chamber washing, for a minimum of 10 seconds.

The fan will start at the maximum speed, for a determined time, then it twill go down to the

programmed speed with the digital PWM variator.

2) When the washing stage is completed, the lighting discharge takes place for a minimum of ten

seconds (Ts 10) ; in the same time the gas valve 848 Sigma will be put in the open position by

electronic card.

3) The 848 Sigma gas valve will supply the gas at a pressure equal to the depression generated by

the fan (for instance fan depression 5 mbar > pressure delivered by the valve 5 mbar > pressure

read downstream the valve = 0).

4) The mixture generated inside the mixing chamber will be lighted on the ceramic plate. After a time

interval Ts the ignition discharge will stop and the electrode will switch automatically to the function

of flame detection.

If lighting will not take place or the flame will not be detected, the 577 DBC device, after a time interval

of 20 seconds, will make a second lighting attempt.

The equipment reset is of electric type with extinction and new lighting of electric supply.

5) The power at start up will be equal to the maximum power of the heater for the time interval

programmed in the PWM variator. After this lighting step, the thermal power of the heater will be

the one which will have been established (for instance : for SCR 25 m - programmed power PWM

20% - Start at 70% of PWM corresponding to 24 kW/h - After the start up time, the thermal flow

of the heater will be the one which will have been fixed PWM 20% = 12 kW/h).

B) The models…a (automatic) will be different from the manual models only by the standpoint of

control of the emitted power which in the manual models can be selected manually while in the

automatic models the thermal power is modulated by the master INET electric board (which is

outside the heater) as a function of the temperature detected in the ambient air, compared with

the established temperatures of manual models (SET POINT).

The master INET electric board, will change with the proportional integrated the fan speed and, as a

consequence, the gas flow and the emitted power.

The lighting sequence for the automatic models will be the one shown at the previous points 1-2-3-4.

Rev. 03GB0602

6

Page 7

SYSTEMA

3 PACKING - TYPOLOGY AND DIMENSIONS

The "INFRA…ROSSO SRC1" ceramic heaters are delivered completely assembled, ready to be installed in

their definitive position. They are packed for transportation inside reinforced cardboard boxes.

This cardboard box contains the ceramic heater and this manual.

The supports (if requested), the electric control board or thermostat and accessories, are delivered in separate

packages

3.1 Ceramic heater packing

Upper protection

Equipment packing

cardboard box

polystyrene

Rainforce corner

cardboard

3.2 External dimension of equipment packing

Equipment

packing for

SCR 25 a/m

23 Kg

3.3 Packing dimensions on pallet

Packing on

pallet 8 units

SCR 25

184 Kg

Ceramic heater

"INFRA…ROSSO SCR1"

Equipment

packing for

SCR 45 a/m

32 Kg

Packing on

pallet 4 units

SCR 45

128 Kg

7

Rev. 03GB0602

Page 8

SYSTEMA

4 TECHNICAL DATA

4.1 General technical data

"INFRA…ROSSO” SRC CERAMIC HEATER

TECHNICAL CHARACTERISTICS

MODELES

THERMAL FLOW (maximum nominal)

THERMAL FLOW (minimum nominal)

Maximum

Natural gas G2O

CONSUMPTION

Nominal at 15°C and

1013,25 mbar

NOZZLE DIAMETER

ELECTRICAL SUPPLY

MAX ELECTRICAL POWER absorbed

GAS CONNEXION (M)

DIME NSIONS

WEIGHT (standard version)

Minimum

Natural gas G2O

Maximum

L.P.G. Propane G31

Minimum

L.P.G. Propane G31

Natural gas G20 mm 3,7 5,5

L.P.G. Propane G31 mm 3 4,1

SCR 25a/m SCR 45 a/m

kW (HI) 24 48

kW (HI) 12 24

3

Nm

/h

3

Nm

/h

kg/h 1,86 3,72

kg/h 0,93 1,86

V/Hz 230/50 230/50

W60 60

" 3/4" 3/4"

mm A) 514 A) 514

mm B) 1055 B) 1055

mm C) 418 C) 418

kg 27 36

2,54 5.08

1,27 2.54

Rev. 03GB0602

8

Page 9

SYSTEMA

4.2 Thermal power table

CERAMIC HEATER “INFRA…ROSSO” SCR 25 a/m - SCR 45 a /m

NOMINAL THERMAL FLOW AND GAS CONSUMPTION AT REGULATION LEVEL

SRC 25a/m SRC 45a /m

REGULATION

LEVEL PWM

THERMAL

FLOW

kW

NAT.GAS

G20

3

Nm

/h

L.P.G.

G31

kg/h

THERMAL

FLOW

kW

NAT.GAS

G20

3

Nm

/h

0,25 12 1,27 0,93 24 2,54 1,86

0,3 15 1,58 1,16 32 3,38 2,48

0,35 18 1,9 1,39 36 3,81 2,79

0,4 20 2,11 1,54 40 4,23 3,1

0,45 22 2,32 1,69 42 4,44 3,25

0,5 24 2,54 1,86 44 4,66 3,41

0,55 ----------- ----------- ----------- 46 4,87 3,56

0,6 ----------- ----------- ----------- 48 5,08 3,72

L.P.G.

G31

kg/h

9

Rev. 03GB0602

Page 10

SYSTEMA

5 EQUIPMENT BASIC PARTS

5.1 Fan characteristics ventilateur

Manufacturer .................................................................................................... L.N.

type ................................................................................................................. EVB 30-230

electrical supply ............................................................................................... 230 V ~ 50 Hz

electrical power ................................................................................................ 50 W

protection degree ............................................................................................. IP 40

maximum rotation speed (r.p.m.) ...................................................................... 4200

5.2 Gas solenoid valve

Manufacturer .................................................................................................... SIT CONTROLS

type ................................................................................................................. 848 SIGMA

functioning........................................................................................................ pneumatic modulating

electrical supply ............................................................................................... 230 V ~ 50 Hz

electrical power ................................................................................................ 6 W

protection degree ............................................................................................. IP 40

stopping delay .................................................................................................. <1 sec.

temperature of use ........................................................................................... 0 ÷ 60 °C

inlet maximum pressure ................................................................................... 60 mbar

outlet pressure ................................................................................................. variable

5.3 Flame control electronic device

Manufacturer .................................................................................................... SIT CONTROLS

type ................................................................................................................. 577 DBC

electric supply .................................................................................................. 230 V ~ 50/60 Hz

protection degree ............................................................................................. IP 40

pre-washing time (TW) ..................................................................................... 10 sec.

security time (TS)............................................................................................. max. 10 sec.

security time at extinction ................................................................................ <1 sec.

ignition attempts .............................................................................................. 2

time interval between ignition attempts ............................................................. 10 sec.

resetting type ................................................................................................... electrical

electrodes ........................................................................................................ 1

5.4 Air - Gas mixer

Manufacturer .................................................................................................... SIT CONTROLS

type ................................................................................................................. 391 AGM

5.5 Ceramic plate

Manufacturer .................................................................................................... BRAY

type ................................................................................................................. Ceramic plaque

dimensions ...................................................................................................... 179x104x13 mm

Maximum operating temperature ...................................................................... 1200 °C

Rev. 03GB0602

10

Page 11

SYSTEMA

6 ELECTRICAL CONNECTIONS

6.1 Wiring diagram SCR 25 m - SCR 45 m

The following wiring diagram for "INFRA…ROSSO" SCR 25 m and 45 m ceramic heater concern only the

internal connections of the equipment.

The external connections of the equipment are under the responsibility of the installation technicians and they

must respect the laws and the rules of the Country where the installation has been made.

SPARK

1 Fan E VB 30 230-S 29 3 poles plu g for fan connection

11 Plug elec tri c s uppl y 230 V. 3 Burner

12 Male fastom for ground connection 31 Ignition and flam e dete ct ion el ec trode

13 PV N conn ect ion 32 Ground ele ct rode

2 Flame co ntrol device 577 DBC 33 Silicon. cable for equipmen t c onnec ti on

21 MOLEX 12 poles connector 34 ground connect ion wire

22 Male fastom 3*0,7 ignit ion c able 4 PW M fan digital reg ulat or

23 Male fastom groun d connect ion valve body 41 Remote potent iom ete r 10 K (optional)

24 Cable 3*0,5 m m² main electric al s upply 42 3 poles plugs potentiometer connec tion

25 Cable 3*0,5 m m² fan electric al s uppl y 5 Control board (optional)

26 Cable 2*0,5 mm² remote stop warning 51 Electri cal supply 230 V. 50 Hz phase/ground/neutral

27 5 poles plug for elec tri cal connect ion 52 Prot ectio n fuse Max 3 A

F1 Fuse 3,15 A. 53 Infrared sens itive ambient thermos t at

Free 5 poles plug for elect ric al c onnect ion 54 Green warning light burner O N - Connection L2

Connec tions : 55 Red warning light burner STOP - Connex ion L 1

L1 - phas e cha rge 230 V . s top warning 7 Ground equipo tent ial poi nt

28

L2 - phas e cha rge 230 V . opera ting warning

PE - ground c onnecti on

N - neutral line 230 V. 50 Hz

L3 - phas e line 230 V. 50 Hz

11

Rev. 03GB0602

Page 12

SYSTEMA

6.2 Fan digital PWM regulator

The fan speed is fixed by the digital regulator situated inside the equipment box.

For each model the manufacturer is programming the minimum and maximum value of PWM which will determine

the minimum and maximum thermal power of the ceramic heater (for instance : PWM minimum 25% = 12 kW

- PWM maximum 60% = 24 kW) with no possibility of modification by the final user. In this interval, it's possible

to choose the requested thermal power, fixing a value, acting on the digital regulator situated inside the equipment

box.

For operational needs, it's possible to modify the thermal power from a place accessible by the operator by a

10 K potentiometer (optional) connected to the contact 1 and 2 of digital regulator, at a maximum distance of

15 m.

To fix the thermal power, the digital PWM regulator must be used. In order to modify the thermal power press

SET, find the percent desired value using the arrows up and down and confirm pressing SET.

Attention!

The percent maximum value which is fixed corresponds to the maximum thermal power of the heater and the

percent minimum value of PWM corresponds to the minimum thermal power of the heater.

THE FIXED PWM VALUES ARE UNCHANGEABLE AND THEY CAN BE MODIFIED ONLY AND EXCLUSIVELY

BY THE MANUFACTURER

DIGITAL PWM PROGRAMMING

1) Press at the same time the switch UP and DOWN (switches avec the arrows) for a few seconds.

2) Select with the switches the parameters to be modified

3) Press SET, modify the parameters, press SET to go out

4) When programming is finished, wait 30 seconds to memorize the new program

Operation paramete rs of digital control PWM SCP 960/A

cod. parameter interv al unit def

Ope ration parameters

Presence potentiometer 10 k for remote variation PWM 0…1 –

Р

Regulation parameters

Minimum level PWM 0… rH %

rL

Maximum level PWM 0…99 %

rH

Output parameters

Boos t period (starting time at maximum PW M)

Lb

Othe r parameters

Keyboard Block 0=NO, 1=YES 0…1

HL

Pass word activation 0=NO, 1=YES 0…1

HP

Thermal power change example:

1) Take out the cover of the equipment box

2) Act on the digital PWM control like indicated in the example

0…99 с

65/45

0

25

60

0

0

VALUE ACTUALLY

SET UP

NEW VALUE SET UP SEE

TABLE AT PAGE 9 FOR THE

CORRESPONDENCE OF

THERMAL POWERS

Rev. 03GB0602

3) PRESS THE SWITCH SET

4) PRESS THE ARROWS TO SELECT

THE NEW VALUE

5) PRESS THE SWITCH SET TO

MEMORIZE THE NEW VALUE

12

Page 13

SYSTEMA

6.3 Wiring diagram of SCR 25 a - SCR 45 a

The following wiring diagram for the "INFRA…ROSSO" ceramic heaters SCR 25a and 45 a concerns exclusively

the internal connections of the equipment.

The external connections of the equipment up to the Master INFRANET board will be illustrated in the following

paragraphs.

The power supply connections will be at the charge of the technicians charged of installation and they must

respect the laws and rules in force in the Country were the installation is made.

SPARK

1 Fan EVB 30 230-S 6 INFRANET network module interface

11 Plug electrical supply 230 V.

12 Male fastom for ground connection 1- Connection stop warning light

13 PV N connection 2- Connection operating warning light

2 Flame c ontrol device 577 DBC 3-Neutral 230 V. 50 Hz power supply

21 MOLEX 12 poles c onnector 4 -Phase 230 V. 50 Hz power supply

22 Male fastom 3*0,7 ignition cable Serial INET network connection terminals

23 Male fastom ground connection valve body 13-Connection +A

24 Cable 3*0,5 mm² main electrical supply 14-Connection -B

25 Cable 3*0,5 mm² fan electrical supply 15-Connection of protection to ground

26 Cable 2*0,5 mm² rem ote stop warning 63 11 - 12 Thermos tat connection

27 3 poles plug for electrical supply 64 Code Switch devic e

28 Free 3 poles electrical supply PW M fan connection terminals

29 3 poles fan connection 21-PW M signal

3 Burner 22-Ps + s upply

31 Ignition and flame detector electrode 23-Ps - supply

32 Ground electrode 66 S erial INET line sect. 2x 0,5 mm ² and screen ground

33 Silicon cable for equipm ent connection 67 3 poles INET plugs > L1=+A N=-B PE=S

34 Ground connection cable 7 Ground equipotential point

5 Electrical supply 230 V . 50 Hz phas e/ground/neutral

Electrical supply 230 V. 50 Hz and warning lights

terminals and warning

61

62

65

13

Rev. 03GB0602

Page 14

SYSTEMA

6.4 Serial INFRANET network wiring diagram

The INFRANET network allows to control from just one Master INET control board from a minimum of one SCR

25a/45a ceramic heater to a maximum of 16 SCR 25a/45a ceramic heaters divided in 4 independent zones.

The following wiring diagram for "INFRA…ROSSO SCR 25a et 45a ceramic heaters shows the connections to

the INFRANET network.

The detailed instructions for the connections are available in the Master INET instruction manual.

General switch

1

Master INET c ontrol board

2

Hemispherical infrared sensitive probe

3

Thermal zone (4 for 4 ceramic heaters)

4

Ceramic heaters

5

General electrical s upply 230 V.

6

phase/ground/neutral

Serial INFRANET cable (2 poles cable

7

with protection connected to ground)

Hemispherical probes cables

8

6.5 Master INET control board

The INET control board can control at maximum 16 ceramic heaters "SCR…a".

The main characteristics are :

- PVC box

- Not authorized tampering with access to password for programming

- Membrane keyboard for all programming

- Sequential display of all detected temperatures

- 4 independent working zones in standard operating conditions at comfort temperature and antifreeze program

- Possibility to install 4 heaters for each zone

- Independent operation for each zone and each heater (on/off)

- Daily or weekly temperature programmer for each zone

- External probe (optional) for functioning with optimization (pre-lighting of heaters as a function of

the external temperature)

- Connection and control by PC (optional)

For further information on operating conditions of Master INET control board, consult the technical

manual for INET control board installation.

Rev. 03GB0602

14

Page 15

SYSTEMA

7.1 EXPLODED DRAWING SCR 25m - SCR 45m equipments

1

2

3

22

16

10

4

5

7

6

9

11

8

12

13

14

15

29

25

26

27

28

30

32

33

17

18

23

21

19

20

24

7.2 EXPLODED DRAWING SCR 25a - SCR 45a equipments

41

36

27

37

42

43

28

33

30

32

24

35

3829 30

4031

39

15

34

Rev. 03GB0602

Page 16

SYSTEMA

a

Pos. Code # Description 1 Gas solenoid valve fastening bracket

1 1 Main equipment body 2 M 5X35 mm. zinc plated sc rew

2 2 M 5x15 mm. bolt 14 5x10 mm zinc plated washer.

3 1 Thermal isolation of equipment box 24 1 SIT 577DBC flame control device

4 1 Equipment box 25 1 M4 x 40 mm. fas t ening s c rew

5 1 Electrical equipment bracket 26 1

7 4 Thermal isolation of fan 27 1 Fan connect ion electric plug

8 1 Evb 30 centrifuge fan 28 1

9 1 Digital variator PWM 29 1

11

12 1 Air/gas mixer 32

13

14

15 1 Injector nozzle bracket 35 1

16

17 1 Aluminium gasket 40 1 4 x 8 mm. self tapping screw

18 2 Female ¾ collar 41 1 Equipment box

19 1 Sit 848 Sigma solenoid valve 42 1 Equipment box cover

20 1 ¾ female/female connector 43 14 4,2 x 8 mm. self tapping

21 1 Male ¾ threaded connector

22

4M 5 nut 30 1

4 5x14 mm. zinc plated washer 31 1 Electrodes fastening

1 Air flow regulator for SCR 25 m/a 1

1 Air flow regulator for SCR 45 m/a 2 5 x 10 mm. zinc plated washer

3 M 4 x 10 mm. zinc plated screw 1 5 mm. zinc plated washer

3 4 x 8 z inc plated washer 2 M 5 nut

3 mm² LPG nozz le for SCR 25 m/a

1

3,7 mm² natural gas

1 G20 nozzle for SCR 25 m/a 37 1

1 4,1 mm² LPG nozzle for SCR 45 m/

5,5 mm² natural gas G20 nozz le for

1

SCR 45 m /a

Sit 848 Sigma solenoid valve

1

bracket

1 M5 pressure nut

23

5x10 mm. s elf tapping screw to fix

the box cover

Plug for electrical connection to

external supply line

Lighting and flame detection

connection cable

Ignition and flame detection

electrode ground c onnection cable

Green/yellow cable for solenoid

valve ground connection

M 5x35 mm. zinc plated screw for

equipotential ground connection

33

5 poles connection cable of external

card to the equipment

36 1 3 poles cable for fan connection

Box of electronic device for

automatic SCR models

38 1 Ignition/flame control electrode

39 1 Ground electrode

Rev. 03GB0602

16

Page 17

7.3 Exploded Drawing SCR 25 m - SCR 25 a equipments

1

2

3

4

5

SYSTEMA

10

6

7

8

9

Position Code Qty Description

1 18 M 5 s tainless steel nut

2 1 Equipment body

3 1 Thermal isolation

4 7 Ceramic plate

5 4 Ceramic fiber thermal isolation

61

7 4 Fas tening bars

818

9 2 Electrodes

Stainless steel parabola

reflector

M 5 x 25 mm. stainless steel

bolts

10 4 3,5 x 5 mm. self tapping screw

17

Rev. 03GB0602

Page 18

SYSTEMA

7.4 Exploded drawing SCR 45 m - SCR 45 a equipment

1

2

3

4

5

6

7

8

9

10

11

12

13

Position Code Qty Description

122

21

34

414

56

66

74

8

91

10 4

11 22

12 1

13 4

M 5 stainless steel nut

Equipment body

Thermal isolation

Ceramic pl ate

5 x16 stainless st eel washer

M 5 stainless steel nuts

Ceramic fiber thermal isolation

Stainless steel parabola reflector (standard)

1

Calorized steel parabola reflector (optional)

1

Galvanized steel parabola reflector (optional)

Fastening bars

M 5 x 25 mm. stainless steel bolts

Electrodes set - 2 pieces

3,5 x 5 mm. self tapping screw

Rev. 03GB0602

18

Page 19

SYSTEMA

8 "INFRA…ROSSO SCR" HEATERS INSTALLATION

The "INFRA…ROSSO SCR" ceramic heaters can be installed only in premises which are compatible with this

type of equipment. Before deciding the installation a project has to be done by a qualified technician, who has

to evaluate the environmental risk.

THE INSTALLATION OF "INFRA…ROSSO SCR" CERAMIC HEATERS MUST RESPECT THE LAWS AND

THE RULES IN FORCE IN THE COUNTRY WHERE THE INSTALLATION IS MADE.

THE PRODUCT IN OBJET HAVE BEEN CERTIFIED BY THE FONCTIONNING SAFETY STANDPOINT.

THE MANUFACTURER WILL HAVE NO RESPONSIBILITY FOR INADEQUATE OR RISKY INSTALLATIONS

The electrical connections and the gas connections have to be realized by qualified technicians, in

the full respect of lows and rules in force in the Country were the installation is made.

8.1 Security distance from inflammable materials

MINIMUM DISTANCES BETWEEN THE HEATER AND THE INFLAMMABLE MATERIALS

(wood, cardboard, plastic products, pallets etc.)

ACCORDING TO :

- DIN 3372 Section 6 paragraph 3.12

- DVGW, G63/11, section 12/3.1.2

- Minimum distance suggested "A" > 4 m.

- Minimum distance suggested "B" > 0,5 m.

- Minimum distance suggested "C" > 1,5 m.

In any case, the distance must be such that the maximum surface temperature of any material is below 85°C

Supporting and fastening devices must reach temperatures below 50°C.

19

Rev. 03GB0602

Page 20

SYSTEMA

8.2 Ceiling installation

THE "INFRA…ROSSO SCR1" CERAMIC HEATERS ARE PERFECTLY FONCTIONNING IN ANY POSITION

AND WITH ANY INCLINATION.

The "INFRA…ROSSO SCR1" ceramic heaters, installed at the ceiling have to be fixed in an adequate manner,

in order to avoid hunting or risk of crash.

The distance from the ceiling or from the supporting structure will have to be in conformity with the indications

of paragraph 8.1.

The installation of the ceramic heaters must be perfectly horizontal, unless there are practical reasons to take

into account.

The minimum installation height suggested is 4 m. from floor.

The maximum installation height suggested is 15÷18 m. for models SCR 25 m/a and 20÷25 m. for models SCR

45 m/a

Pos. Description Indicati ons for install ation

“INFRA…ROSSO” ceramic

1

heaterSCR 25/45 m/a

“INFRA…ROSSO” ceramic heater

2

SCR 25/ 45 m/ a

Supporting s t ructure

3

Elec t rical connect ions

4

Gas connection

5

Flexibl e connection

6

Inclinati on angl e The minimum incli nat ion angle i s 0° both sides.

7

Convecti ve flow of exhaust

8

Lateral vi ew of inst allat ion

Front vi ew of install at ion

Use rigid material t o avoid oscil lati on movement s (for

instance Ø 8 mm. steel bars)

The elect ri cal connection has to be done in conformit y

with laws an rul es of t he Country were the inst al lation is

made.

The cables have to be install ed far from the flow of

combust i on product s , if possi ble inside t he equipment.

For the manual models :

Power supply line c oming from INET cont rol board 230 V

(alternate c urrent ) 50 Hz wit h ground connection cable.

Eventual 2 poles cable for remote st op warning l ight.

For the automatic models :

Power supply line c oming from INET cont rol board 230 V

(alternate c urrent ) 50 Hz wit h ground connection cable.

Serial cable 2 poles with mini mum sec tion 0, 5 sq. mm,

with protec t ion connect ed to ground.

The gas connec t ion has to be done in conformity wit h

laws and rules of the Country were the inst all at ion is

made.

The pipes have to be inst alled far from the flow of

combust i on product s , if possi ble inside t he equipment.

In order t o allow a good functioni ng of t he SIGMA

solenoid val ve and for t he general s afet y of ins t allat ion,

the gas supply pres sure has to be lower than :

50 mbar for LPG, propane and butane

20 mbar for natural gas

The final connection t o t he gas suppl y line has t o be

done with a metall ic flex ible pi pe.

Verify that t he fl ow does not meet s upporting structures,

electrical l ines , gas pipes.

Rev. 03GB0602

20

Page 21

8.3 Installation on a wall

12

SYSTEMA

10

9

5

13

11

Pos. Description Indications for installation

14

“INFRA… ROS SO” ceramic heater

1

SCR 25/45 m/a

“INFRA… ROS SO” ceramic heater

2

SCR 25/45 m/a

Supporting struc ture

3

Allaciamento elettrico

4

Gas connec tion

5

Flexible connection

6

Inclination angle The minimum inclination angle is 0° both sides.

7

Convective flow of exhaust

8

Lateral view of installation

Front view of installation

Use rigid material to avoid osc illation movem ent s

(for instance Ø 8 mm. steel bars)

The electric al c onnection has t o be done in conformity

with laws an rules of the Country were the installation is

made.

The cables have to be installed far from the flow of

combustion products, if pos sible inside the equipment.

For the manual models :

Power supply line coming from INET cont rol board 230 V

(alternate c urrent ) 50 Hz with ground c onnect ion c able.

Eventual 2 poles cable for remote s top warning light .

For the automatic models :

Power supply line coming from INET cont rol board 230 V

(alternate c urrent ) 50 Hz with ground c onnect ion c able.

Serial cable 2 poles with minimum section 0,5 sq.mm,

with protection connected to ground.

The gas connec tion has t o be done in conformit y with

laws and rules of the Country were the installation is

made.

The pipes have to be installed far from the flow of

combustion products, if pos sible inside the equipment.

In order to allow a good func tioning of the SIGMA

solenoid valve and for the general safety of ins tallat ion,

the gas supply pres sure has to be lower than :

50 mbar for LPG, propane and butane

20 mbar for nat ural gas

The final connection to the gas supply line has to be

done with a metallic flexible pipe.

Verify that the flow does not meet supporting s tructures,

electric al lines , gas pipes.

21

Rev. 03GB0602

Page 22

SYSTEMA

9 START UP AND OPERATING

Before starting up the equipment, verify

1) The correct installation of the equipment :

2) The respect of safety conditions.

3) Verify the gas pipeline and if necessary purge the gas pipes.

4) VERIFY THE PRESSURE AND THE TYPE OF GAS SUPPLY.

5) Verify the electrical installation and THE RESPECT OF POLARITIES PHASE/NEUTRAL/GROUND

After these controls it will be possible to start the ignition procedure using the control boards of the equipment.

THE CERAMIC HEATER "INFRA…ROSSO SCR" IS TOTALLY REGULATED BY THE MANUFACTURER

DURING THE FINAL CONTROL AT THE FACTORY AND READY FOR USE.

DO NOT MODIFY AIR ANG GAS REGULATIONS INSIDE THE EQUIPMENT

Electrical

Signal

1

8

4

10

Ignition

effected

Burner

in

FUNCTION

IGNITION

PREWASHING

Tw 10 sec.

Ts 10 sec.

Ignition

failure

PREWASHING

Tw 10 sec.

IGNITION

Ts 10 sec.

Waiting time

10 sec.

First ignition cycle Second ignition cycle

Pos. Description Indications for start up a nd operating control

1 848 Sigma solenoid valve

2 E lec tri cal c onnec tor Direct c onnec ti on 577 DBC device

3Gas inlet

4 Gas ou tlet

56Gas INLET pres sure co ntrol point

2

3

9

7

56

Gas OUTLET pressure control

point

7 Con nection of depres si on s ignal Not in us e :

Regula tion of the max imum gas

8

flow

10 Connec ti on of pres s ure signal Not in use :

Ac cess to meas ure t he gas su pply pres sur e

The gas suppl y p ressure

- 50 mb ar for L. P. G., propa ne and bu tane

- 20 mb ar for nat ural gas

The gas suppl y p ressure

- 15 mb ar for L. P. G., propa ne and bu tane

- 15 mb ar for nat ural gas

Ac cess to meas ure t he gas pres sure at the bu rner.

During the pre washing pro ced ure the meas ure gi ve a

depres sion whi ch i s proport ional to t he fan s peed (for

ins t. : m ax imu m power heater - 12 m bar)

During funct ioni ng the mea sure gives the gas pres sur e

outlet.

THE MEASURED VALUE MUST BE ZERO. (The Sigma

sol enoi d valve com pens ate the meas ured depress ion

with the same gas pressure)

Sc rew for regu lation of m aximum gas flow.

THE RE GU LA TOR IS EXCLUDE D, THE SCRE W IS

COM PL ETE LY OPEN : DO NOT MODIFY

The sc rew c los ing i s determ ini ng a redu ct ion o f gas fl ow

and a c ons equent dec rease of burne r thermal p ower.

Use only on manufacturer request

it must be completely open

it must be completely open

Ignition

effected

Ignition

failure

has to be l ower than :

has to be h igher than :

Burner

in

FUNCTION

Equipment

on

STOP

2

7

Rev. 03GB0602

Pos. Description I ndicati ons for start up and ope rating control

1 EVB 30 Fan

2 Ai r/g as M ixer 391 A GM

Air flow regulator3

4 Gas inlet co nnec ti on

5 Primary air inlet Proportional to fan speed

6 Secondary air inlet

4 5

3

6

1

7 M ixer tightening s crew THIS SCREW MUST BE COMPLETELY TIGHTEN

- In SCR 25 models the secondary air is not regulated

(regulator closed)

- In SCR 45 a/ m mo dels the s ec ondary air i s regu lat ed :

the regu lat or has som e openi ngs .

DO NOT MODIFY THE POSITION.

the m anufacturer during th e final cont rol.

It will be possible to regulate the air flow by turning

clockwise the regulator, or vice vers a, only on demand of

the m anufac tur er and in ex cepti onal c ase s (re duct ion of

thermal flow in case of change of gas type - decrease of

temperature of ceramic plates)

Series of holes for secondary air only on regulator for

SCR 45 m

T he r egulat ion is ma de by

22

Page 23

SYSTEMA

10 CHANGE OF FUEL SUPPLY

The change of fuel type must be done by qualified personnel in the respect of security rules in force.

The manufacturer refuse any responsibility in case of damages due to a wrong transformation or an

inadequate and/or incorrect use of the equipment.

Gas type change

1) Close gas supply and cut off electrical supply

2) Disconnect the electronic device (1)

3) Disconnect the flexible gas connection

4) Disconnect the part (3) from its support (2)

5) Separate the part (3) from the solenoid valve (4)

6) Take out the Sigma solenoid valve and the nozzle (6) of air/gas mixer

7) Unscrew the injector (6) from the collar (8) and keep the aluminium gasket

8) Replace the nozzle (7) situated inside the injector (6)

9) Reassemble the equipment in the contrary order of disassembling

ATTENTION !! NO REGULATION HAS TO BE DONE AFTER THE MODIFICATION

10) Connect the gas and the electrical supply

11) Verify that there is no gas leakage

12) Start up the equipment following the procedures of paragraph 9

7

8

5

2

3

4

6

1

Rev. 03GB0602

23

Page 24

SYSTEMA

For the automatic models, reduce Maximum

10.1 Operating anomalies

Anomaly Reason Intervention

No gas supply Open the gas valve

No ignition discharge

No flame

The fan does not turn

The gas is not arriving to the nozzle

The PWM is faulty Replace the regulator

The burners st arts but after

a few seconds it stops

The flame disappears Ceramic plates broken

The flame disappears and

appears when functioning at

maximum power (ceramic

plates have a very bright

yellow colour)

The ground connection is insufficient Establish again the ground connection

The control device is faulty Replace

Presence of air in the gas pipes Purge the gas pipes

Gas supply

PWM electronic variator

Excess of thermal power

Verify t he electrode position

Verify the connection of the electrode

cables

Replace the 577 DBC electronic device

Verify the electrical connections = remake

the faulty connections

Verify electrical tension at the fan card =

establish the right connection

If the tension is right = replace the

electronic device of the fan

Replace the 577 DBC electronic device

Verify the opening of the valve = Replace If

necessary the coil of Sigma valve

Verify the gas supply = bring the gas to the

nozzle

Verify the type of gas is corresponding to

the one is foreseen for the equipment

Replace the ceramic plates broken

Assure a good connection

Replace the variator

Replace the electronic card of the fan

Verify t he type of gas in use

Control the secondary air (increase the flow)

Reduce the maximum thermal power

For the manual models act on PWM digital

regulator and reduce % PWM

The flame disappears and

appears when functioning at

the minimum power

Impossible t o modify the

thermal power (version …m)

Rev. 03GB0602

Thermal power too low

Electronic problem

Verify t he type of gas in use

Verify t he secondary air (decrease the flow)

Increase the minimum thermal power

For the manual models act on PWM digital

regulator and increase % PWM

For the automatic models increase the

minimum PWM in Master INET board

Replace PWM digital variator

Replace the fan electronic card

If in use, verify 10K potentiometer

and the connect ion line

24

Page 25

SYSTEMA

11 GUARANTY

11.1 Object and validity of guaranty

1) The Guaranty covers the defects of material or manufacturing for the parts supplied by SYSTEMA.

In case of defective material or manufacturing faults, SYSTEMA will take the charge of free repairing

or replacement ex works of faulty parts BEING FORMALLY EXCLUDED ANY OTHER FORM OF

GUARANTY OR PAIEMENT OF DAMAGES, ACCORDING TO THE LAW OR THE USAGE.

- Parts to be replaced will be rapidly sent back to SYSTEMA, at its factory of Zdunska Wola Poland, at the charge of the Customer.

- In case of Guaranty intervention, the Customer will support the charge of the fix call right and

travelling expenses from the nearest Assistance Centre.

2) The Guaranty begins at the moment at the first start up of the equipment, at the condition that this

takes place within the six (6) months from the Customer purchase. In any case the guaranty ends

18 (eighteen) months after the SYSTEMA invoice date.

3) The possible replacement of defective parts (or of the entire equipment) will not postpone the

initial Guaranty validity. The Guaranty on replaced parts will end at the end of the initial guaranty

on the full equipment.

4) The validity of Guaranty is 12 (twelve) months on all the parts of the equipment.

11.2 Exclusions from guaranty

1) The Guaranty is not valid in the following cases :

a) Faults not referred to material or manufacture, without limitation :

- damages during transportation ;

- non conformity of installation to the laws or to the local rules in force in the Country where the

installation is made ;

- non respect of the installation instructions described in the technical notes and the technical

documentation delivered with the equipment and/or the rules of good technique ;

- damages caused by accidents, fire, disasters of any type or negligence not concerning SYSTEMA.

b) Not authorized interventions or faults due to intervention of personnel not authorized.

c) Faults due to anomalies of the electricity or fuel supply circuits.

d) Faults due to : bad maintenance, negligence or non adequate use of the equipment, electrical

supply tension fluctuation, humidity or dust in the premises, incorrect dimensioning or defective

installation.

e) Corrosion or braking due to : stray currents, condensation, overheating, wrong regulation of gas

pressure or use of a fuel of a gas which characteristics are different from those indicated on the

equipment plate.

f) Use of spare parts not original or not authorized by SYSTEMA

g) Wear and normal consumption

h) Products stored or stocked in non adequate conditions

25

Rev. 03GB0602

Page 26

SYSTEMA

Rev. 03GB0602

26

Page 27

SYSTEMA

27

Rev. 03GB0602

Page 28

Loading...

Loading...