Page 1

EOLO

GAS AIRTIGHT SUSPENDED

WARM AIR HEATERS

Series with axial fan models 20AE, 30AE, 50AE, 70AE, 90AE

Series with centrifugal fan models 20AC, 30AC, 50AC, 70AC, 90AC

INSTRUCTION MANUAL

INSTALLATION, USE AND MAINTENANCE

ENGLISH

Page 2

IMPORTANT

Read this manual carefully before starting up the system. In order to improve the product,

Systema reserves the right to modify the content without prior notice.

Via San Martino 17/23

S. GIUSTINA IN COLLE (PD)

loc. Fratte Fontane Bianche

PADOVA - ITALY

Tel 0039 0499355663

(8 linee r.a.)

Fax 0039 0499355699

Revion 10EE0112

E-mail: systema@systema.it

commercial informations

http://www.systema.it

technical informations

Page 3

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

Contents

1 GENERAL RULES .............................................................................. 5

2 PACKAGING ....................................................................................... 5

2.1 List of packing ...................................................................................................... 5

3 GENERAL TECHNICAL SPECIFICATIONS ....................................... 7

3.1 Description and operating specifications .......................................................... 7

3.2 Technical specifications....................................................................................... 8

3.2.1 Suction series with axial fans .............................................................................................8

3.2.2 Suction series with centrifugal fans ...................................................................................9

3.3 Main control and safety components on the appliance .................................. 10

3.4 Overall dimensions ............................................................................................. 12

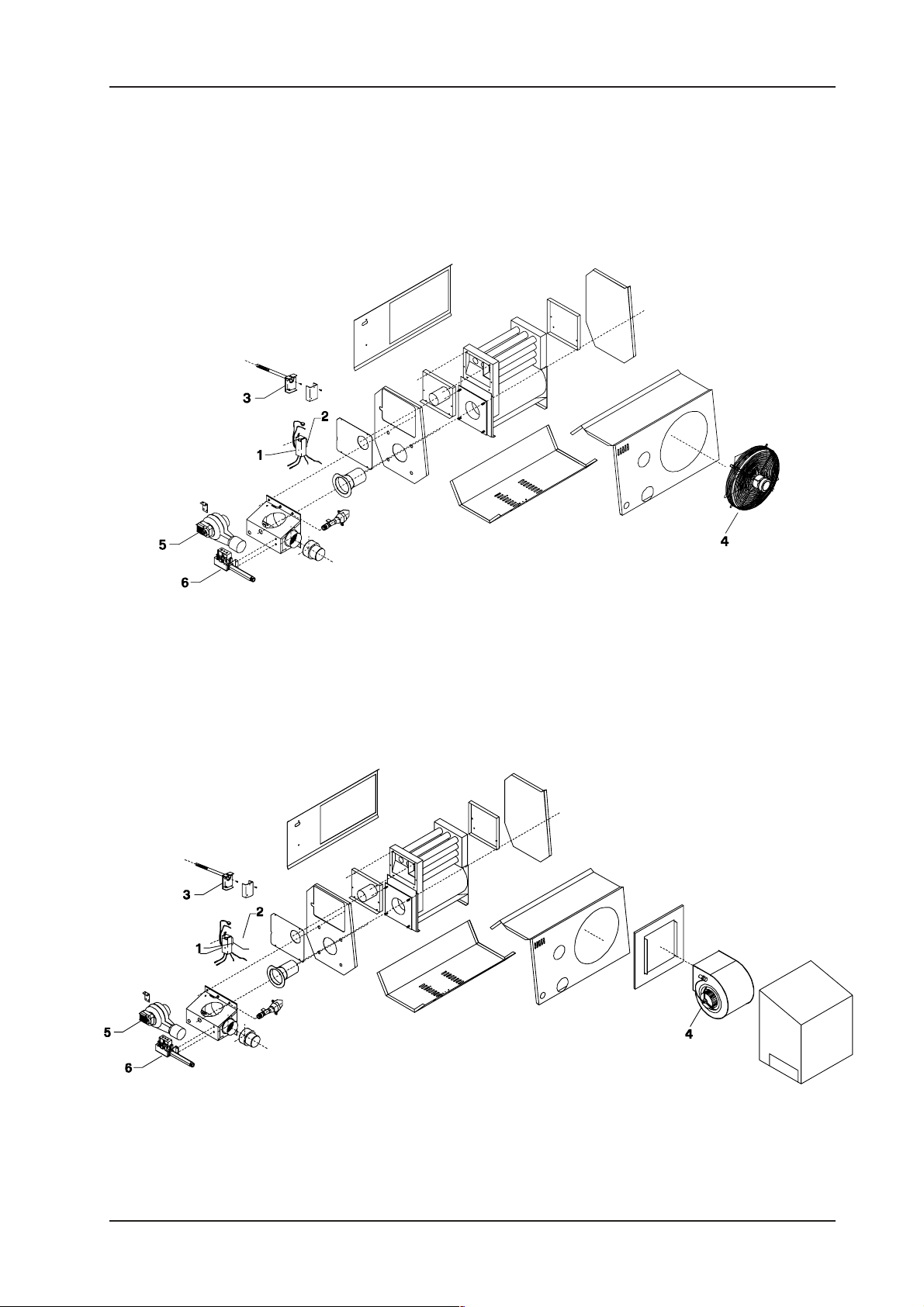

3.5 Exploded view of Eolo heaters ..........................................................................13

3.5.1 Exploded view of Eolo20AE .............................................................................................13

3.5.2 Exploded view of Eolo20AC............................................................................................. 13

3.5.3 Exploded view of Eolo30AE .............................................................................................14

3.5.4 Exploded view of Eolo30AC............................................................................................. 14

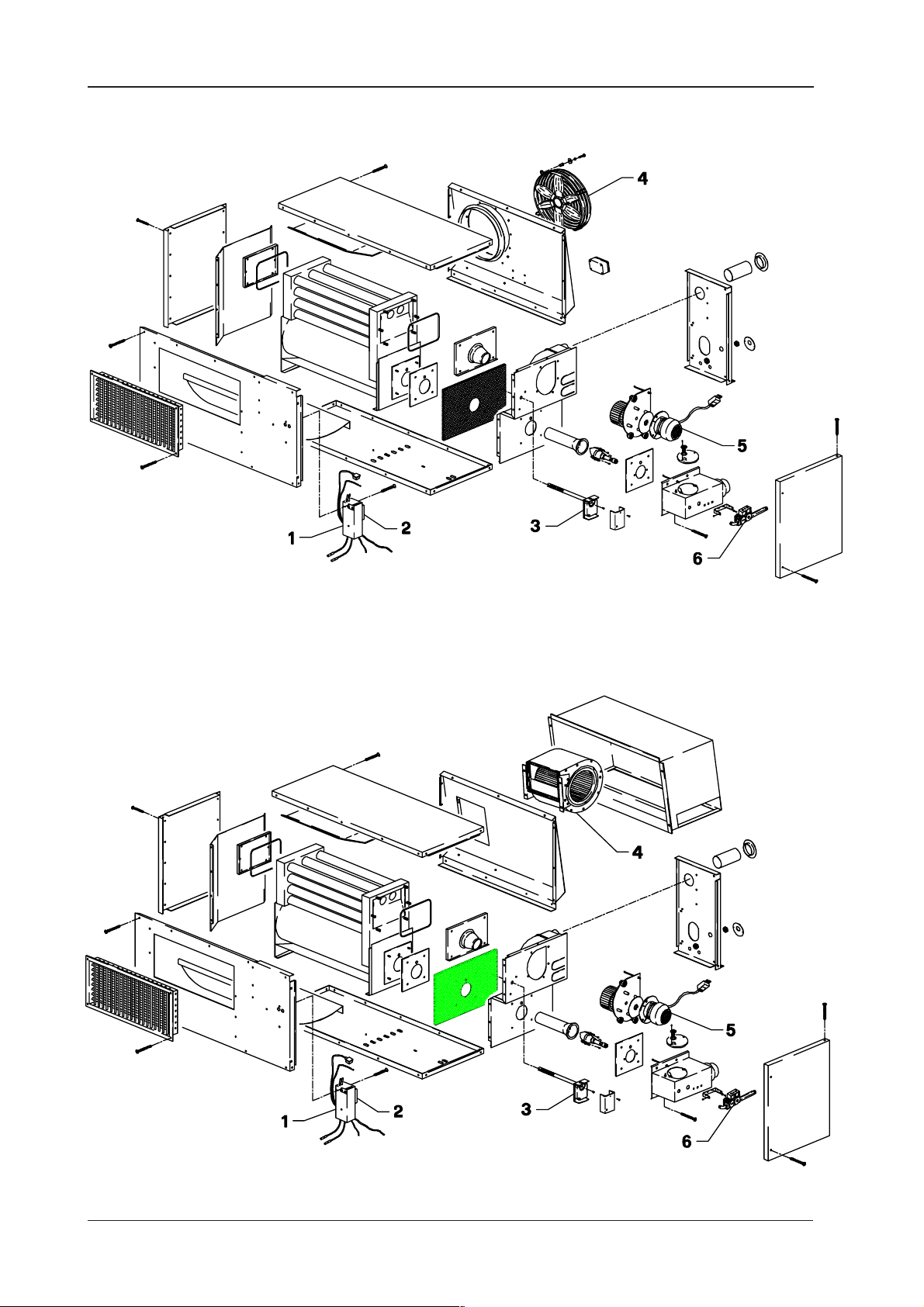

3.5.5 Exploded view of Eolo50AE-Eolo70AE ............................................................................ 15

3.5.6 Exploded view of Eolo50AC-Eolo70AC ...........................................................................15

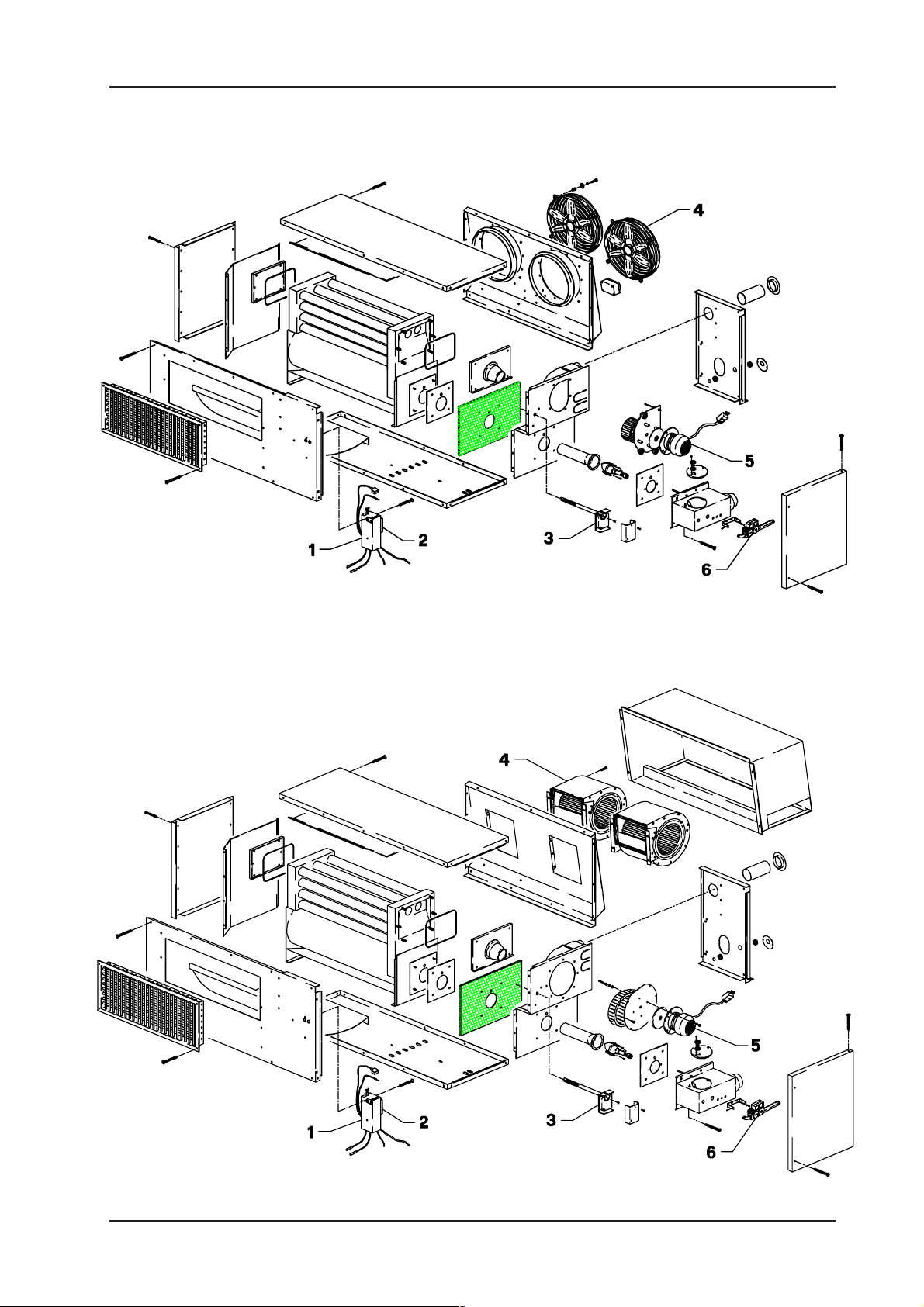

3.5.7 Exploded view of Eolo90AE .............................................................................................16

3.5.8 Exploded view of Eolo90AC............................................................................................. 16

3.5.9 Legend of components ....................................................................................................17

3.6 Position of the ignition and detection electrodes............................................ 18

3.7 Position of the nozzle ........................................................................................ 18

4 INSTALLATION ................................................................................. 19

4.1 Place of installation and safety distances ........................................................19

4.2 Installing the appliance ...................................................................................... 20

4.2.1 Fitting the brackets for Eolo 20 ........................................................................................ 20

4.2.2 Fitting the brackets for Eolo 30-50-70-90 ........................................................................ 21

4.3 Fitting the fire damper (optional) ....................................................................... 22

5 SETTING UP THE APPLIANCE ........................................................ 23

5.1 Examples of applications ................................................................................... 23

6 DISCHARGE AND SUCTION DUCTS .............................................. 24

6.1 Coaxial roof discharge for Eolo20 (type C32) ..................................................25

6.2 Coaxial wall discharge for Eolo20 (type C12) .................................................. 26

6.3 Separate wall discharge for Eolo20 (type C12) ................................................ 27

6.4 Coaxial roof discharge for Eolo30-50-70-90 (type C32) ................................... 28

6.5 Coaxial wall discharge for Eolo30-50-70-90 (type C12) ................................... 29

6.6 Separate wall discharge for Eolo30-50-70-90 (type C12) ................................. 30

6.7 Separate roof discharge for Eolo30-50-70-90 (type C32) ................................ 31

7 GAS PIPES........................................................................................ 32

7.1 Connecting the appliance .................................................................................. 32

8 ELECTRICAL SYSTEM..................................................................... 33

3

Rev. 10EE0112

Page 4

SYSTEMA S.p.A.

8.1 Connection diagram to CE type boards mod. 04CEQU1202 (without timer)

and mod. 04CEQU1203 (with timer) .................................................................. 33

8.2 Connection to the board code 04CEQU1204 .................................................... 34

8.3 Internal wiring diagram Eolo 20-30-50 ............................................................... 35

8.4 Internal wiring diagram Eolo 70-90 .................................................................... 36

Gas airtight suspended warm air heaters - EOLO

9 INSPECTION AND STARTING UP THE SYSTEM ......................... 37

9.1 Preliminary ignition procedures ........................................................................ 37

9.2 Ignition phases.................................................................................................... 37

9.3 Adjusting the pressure on the solenoid valve and pressure intake ............... 38

9.4 Bi-thermostat for adjusting fan start-up ............................................................ 39

9.3 Measuring the efficiency .................................................................................... 40

9.3.2 Measuring the temperature of combustion air .................................................................. 40

10 MAINTENANCE ................................................................................ 41

10.1 Gas conversion ................................................................................................... 41

10.1.1 Conversion from Natural Gas to LPG .............................................................................. 41

10.1.2 Conversion from LPG to Natural Gas .............................................................................. 42

10.2 Operating faults................................................................................................... 43

11 WARRANTY ...................................................................................... 44

11.1 Subject-matter and duration of the warranty .................................................... 44

11.2 Exclusions from the warranty ............................................................................ 44

11.3 Competence ........................................................................................................ 45

11.4 Operativeness and efficacy of the warranty ..................................................... 45

11.5 Responsibility ..................................................................................................... 45

11.6 Legal disputes Territorial competence and rights of the parties .................. 45

12 SETTING ASIDE............................................................................... 4 5

13 NOTES .............................................................................................. 46

Rev. 10EE0112

4

Page 5

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

1 GENERAL RULES

This instruction manual is an integral and essential part of the appliance and must be kept carefully

beside the appliance for further consultation.

Read the instructions and warnings contained in this manual carefully as they provide important

information on safety, installation, use and maintenance.

IMPORTANT !!

In the event of this manual being misplaced contact the manufacturer immediately.

Several appliances installed in the same room or in directly communicating rooms, are considered as

a single system, with a thermal capacity of the total of the thermal capacities of each single appliance.

Their use is not permitted to heat rooms destined for handicraft or industrial activities in which processes

and materials stored may cause the formation of gas, vapours or powders susceptible to induce fires

or explosions.

Installation must be performed by professionally qualified personnel responsible for compliance with

the current safety standards. The manufacturer declines all responsibility in the event of damages

caused by erroneous installation or improper and/or incorrect use of the appliance.

The packaging materials (nylon, foamed polystyrene, wood, staples, etc.) must not be left within the

reach of children as they are potential sources of danger.

Initial ignition of the appliance must be performed by qualified personnel.

In the case of the appliance shutting down or functioning incorrectly it must be switched off. Any

repairs or replacement of spare parts must be performed solely by qualified personnel using exclusively

original spare parts. Non-compliance with the aforesaid rules may endanger the safety of the appliance.

To guarantee correct operation of the appliance it is fundamental to carefully follow the instructions

provided by the manufacturer and to have the appliance serviced by qualified personnel at least once

a year.

N.B. To switch off the appliance always used the ambient thermostat and not the master switch on the

control board on the ground, as this could cause overheating in the combustion chamber with

consequent damage to the appliance.

The heater may be installed outdoors with temperatures down to -15°C. Below this temperature operation

of the appliance is no longer guaranteed.

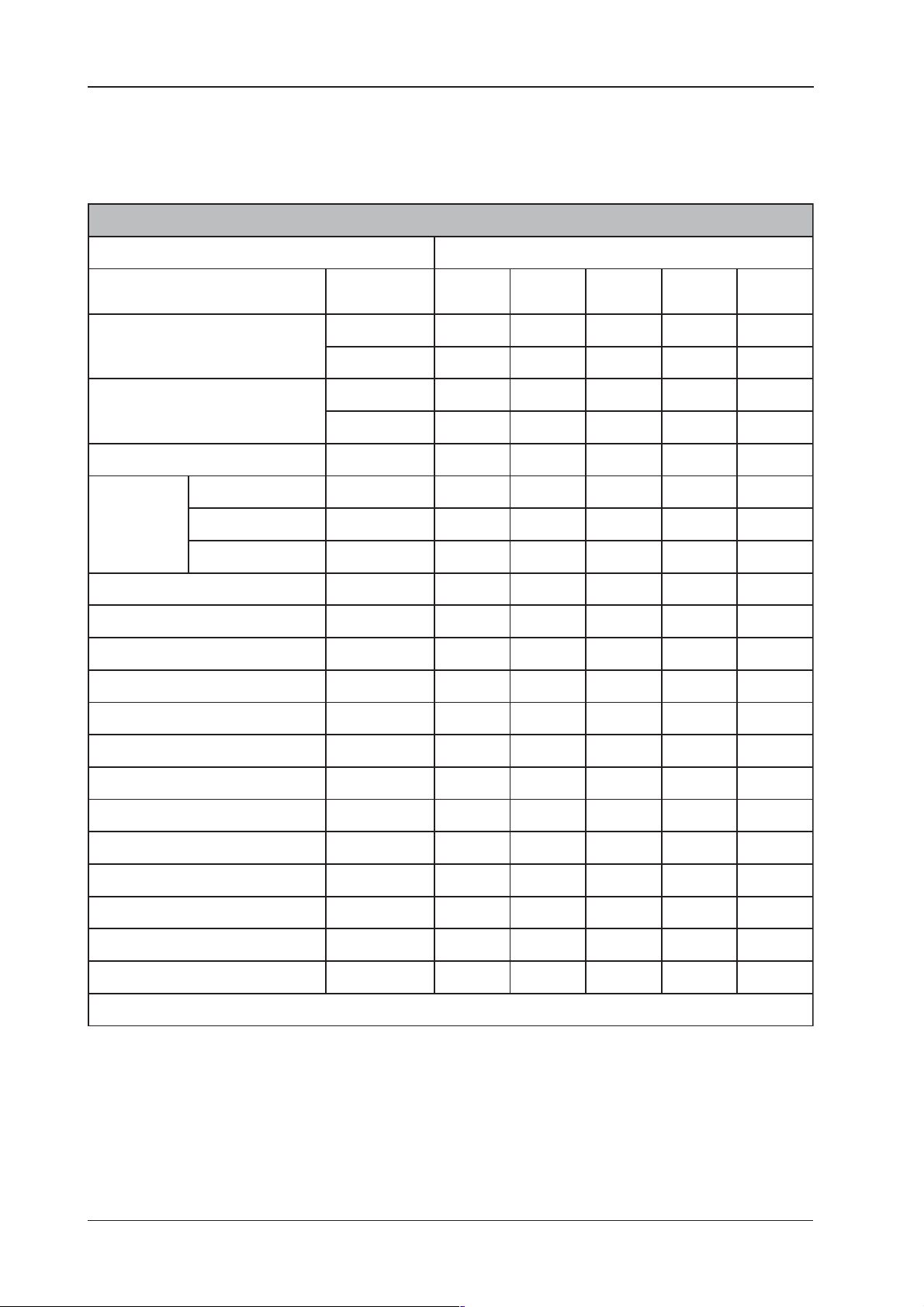

2 PACKAGING

2.1 List of packing

a) The appliance complete with all its parts is delivered packed and wrapped in a protective nylon film

inside which the following are also found: the wall-mounting brackets, the electric control board

with relevant thermostat with probe (if requested) and two air/fume terminations (if requested).

5

Rev. 10EE0112

Page 6

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

Fig.1 Appliance Packing

ledoM

EAseireS

]gk[

02OLOE5,7798

03OLOE5,411231

05OLOE5,051371

07OLOE8,761391

09OLOE8,891922

CAseireS

]gk[

Rev. 10EE0112

6

Page 7

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

3 GENERAL TECHNICAL SPECIFICATIONS

3.1 Description and operating specifications

EOLO suspended gas warm air heater is composed of a combustion chamber in stainless steel,

inside which a gaseous component (natural gas or LPG) is combusted. In just a few minutes the

external surfaces of the combustion chamber and fume tube nest, lapped by ambient air circulated by

the fans, reach their operating temperature.

The appliance operates automatically; the systems for electronic control, mixing, combustion, ignition,

suction of combustion air and discharge of fumes are housed in a compartment provided with an

inspection hatch that makes adjustment and maintenance operations easy to perform. A fan-limit

safety bi-thermostat controls start-up and shut-down of the fan unit, also shutting down the burner in

the case in which the supply air temperature exceeds the safety values permitted.

Suction of combustion air and discharge of fumes can be conveyed directly outside the building (type

C appliance); therefore, there is no communication between the combustion chamber and the indoor

environment (this guarantees maximum safety).

In the summer the fan unit can be operated alone to provide ambient comfort and provide a supply of

fresh air. To switch to this operation press the button on the aluminium front of the bi-thermostat.

7

Rev. 10EE0112

Page 8

SYSTEMA S.p.A.

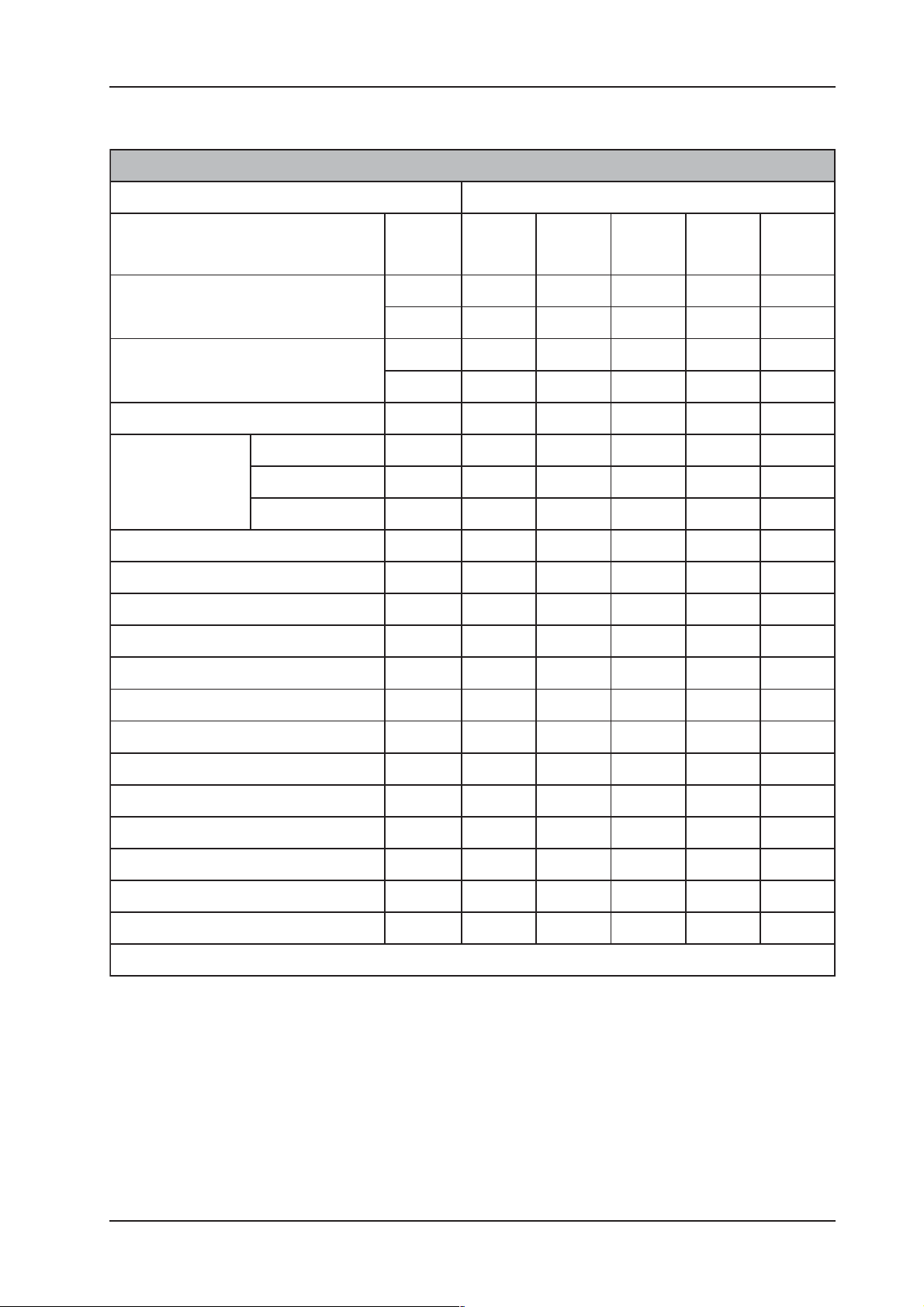

3.2 Technical specifications

3.2.1 Suction series with axial fans

Gas airtight suspended warm air heaters - EOLO

SNAFLACILEHHTIWSEIRESRIA-DEKCUS

SLEDOM

NOITPIRCSED

tupnilamrehtdetaR

tuptuolamrehtdetaR

ecnamofrepnoitsubmoC%8,0901,099,192,984,98

XAM

-ITPMUSOC

C°51(NO

52.3101

)rabm

retemaidrotcennocleuFsehcni"4/3"4/3"4/3"4/3"4/3

retemaidteltuoemuFmm08001001001001

retemaidekatnImm08001001001001

noitatnemilanoisneTzH/V05/03205/03205/03205/03205/032

02GsaglarutaNh/cmN33,206,317,514,759,9

03GnatuBPGLh/gk37,186,262,425,514,7

13GnaporPPGLh/gk17,246,202,444,503,7

deriuqerrewopcirttelelatoTW502042593075085

fotinU

tnemerusaem

(h/lacK iH )029.81042.92044.64002.06048.08

(Wk iH )2243450749

(h/lacK iH )971.71543.62876.24896.35172.27

(Wk iH )0213052648

EA02EA03EA05EA07EA09

yticapacriadetaerTh/cm059.1000.3005.4009.5009.6

worhtriAm0151026292

pmujlamrehTC°8282030343

rewoPW581561003574553

snoituloveR'n044.1004.1044.10931044.1

srotalitnevfo.oN°n 11223

)m5ta(leveldnuoS)A(bd0586948556

sdioPgk5,775,4115,0518,7618,891

naflacileh=E;nafria-dekcus=A

Rev. 10EE0112

8

Page 9

Gas airtight suspended warm air heaters - EOLO

3.2.2 Suction series with centrifugal fans

fotinU

NOITPIRCSED

yticapaclamrehT

Wk )iH( 2243450749

rewoplamrehtlufesU

Wk )iH( 0213052648

ycneiciffenoitsubmoC%8,0901,099,192,984,98

-erusaem

tnem

h/lacK )iH( 029.81042.92044.64002.06048.08

h/lacK )iH( 971.71543.62876.24896.35172.27

SYSTEMA S.p.A.

SNAFLAGUFIRTNECHTIWSEIRESNOITCUS

SLEDOM

CA02CA03CA05CA07CA09

NOITPMUSOCXAM

52.3101C°51(

)rabm

sgnilpuocleufforetemaiDsehcnI"4/3"4/3"4/3"4/3"4/3

retemaidegrahcsidemuFmm08001001001001

retemaidnoitcuSmm08001001001001

egatlovylppuSzH/V05/03205/03205/03205/03205/032

rewopdebrosbalatoTW0720560080380081

yticapacriadetaerTh/cm009.1051.3005.4007.5006.8

erusserplatoT

daehlamrehTC°9272031372

rewop)s(naFW052575007537075.1

snoituloveR'n009009009009009

snafforebmuN°n 11223

)m5ta(.ldnuoS)A(bd5426544506

02GsaglarutaNh/cmN33,206,317,514,759,9

03GenatuBGPLh/gk37,186,262,425,514,7

13GenaporPGPLh/gk17,246,202,444,503,7

Hmm

O

2

2101112101

thgieWgk98231371391922

naflagufirtnec=Crenrubrianoitcus=A

Category..........................II

2H3+

9

Rev. 10EE0112

Page 10

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

3.3 Main control and safety components on the appliance

a) Electronic control unit: one for all models. This controls opening of the gas solenoid valve and

ignition of the burner. After receiving the electrical signal from the ambient thermostat, it checks

that the pressure switch is operating normally (ignition is not enabled unless this check is passed).

It then enables prewash of the combustion chamber (4 exchanges) and then ignition by means of

a spark. If the flame is not detected (ionization probe) within the safety time the appliance shuts

down. To restart it wait a few seconds and press the specific reset button with LED on the control

board.

CONTROL UNIT TECHNICAL SPECIFICATIONS

Make ............................................................ BRAHMA ........................BRAHMA

Mod .............................................................. CM 31 F .......................... CM 32 F

Supply voltage .............................................. 220/240 V 50/60 Hz ....... 220/240 V 50/60 Hz

Utilization temperature .................................. de -20 °C à + 60°C ......... de -20 °C à + 60°C

Prewash time ............................................... 20 sec ............................. 20 sec

Safety time at start-up .................................. max 10 sec ..................... max 10 sec

Safety time at shut-down .............................. < 1sec............................. < 1 sec

b) Differential pressure switch: the aim of this is to interrupt operation of the appliance if the flow rate

of the fan-exhaust fan is insufficient caused either by a fault in the fan or by clogging in the combustion

circuit (combustion air duct, combustion chamber, heat exchanger, combustion products discharge),

both of which can be caused by bad combustion CO forming above the permitted limits. This is

located inside the compartment which houses all the control components, and detects, by means

of two silicone tubes, both the pressure in the combustion air suction duct and the pressure inside

the burner box in which the combustion torch is located. The difference between the two pressure

values with the exhaust fan operating is the control signal for safe and correct combustion.

PRESSURE SWITCH SPECIFICATIONS

Make ..................................................................................................... HUBA CONTROL

Code ...................................................................................................... 605.99501

Assembly position ................................................................................. vertical

Max. working pressure .......................................................................... 5000 Pa

Reset point (opening) ............................................................................ 110 Pa (+/- 16 Pa)

Pneumatic connection ...........................................................................Ø 6,2 mm

Utilization temperature ...........................................................................-30°C, +85°C

c) Gas valve: this is multifunction and multigas with double safety solenoid valve (connected in series)

in class B. Provided with a pressure regulator, slow ignition device and gas filter. Located on the

aluminium body are the threaded gas inlet-outlet connection ½ RP UNI-ISO 7, with relevant pressure

inlet and outlet. Gas valve adjustment and the only maintenance operation that can be performed

on the valve (replacement of the coils) must only be executed by qualified technicians.

GAS VALVE TECHNICAL SPECIFICATIONS

Make ..................................................................................................... SIT CONTROLS

Mod. ...................................................................................................... 830 TANDEM

Supply voltage .......................................................................................220/240 V 50/60 Hz

Degree of electrical protection ...............................................................IP 54

Closing time .......................................................................................... < 1s

Utilization temperature ...........................................................................0° ÷ +60 °C

-20° ÷ +60 °C (on request)

Range of output pressure ......................................................................3 ÷ 50 mbar

Rev. 10EE0112

10

Page 11

Gas airtight suspended warm air heaters - EOLO

d) Fan-limit safety bi-thermostat with automatic reset: this has a double aim:

-to control start-up of the fans after the air has reached 50°C and shut-down of these when the air

temperature has dropped below 30°C;

-to interrupt operation of the appliance if there is abnormal overheating of the air (>90°C); the appliance

can be reset manually using the reset button located on the board.

SAFETY BI-THERMOSTAT TECHNICAL SPECIFICATIONS

Limit control ...........................................................................................4 (4) A

Fan control ............................................................................................ 7 (7) A

Supply voltage ....................................................................................... 230-240 V

SYSTEMA S.p.A.

11

Rev. 10EE0112

Page 12

SYSTEMA S.p.A.

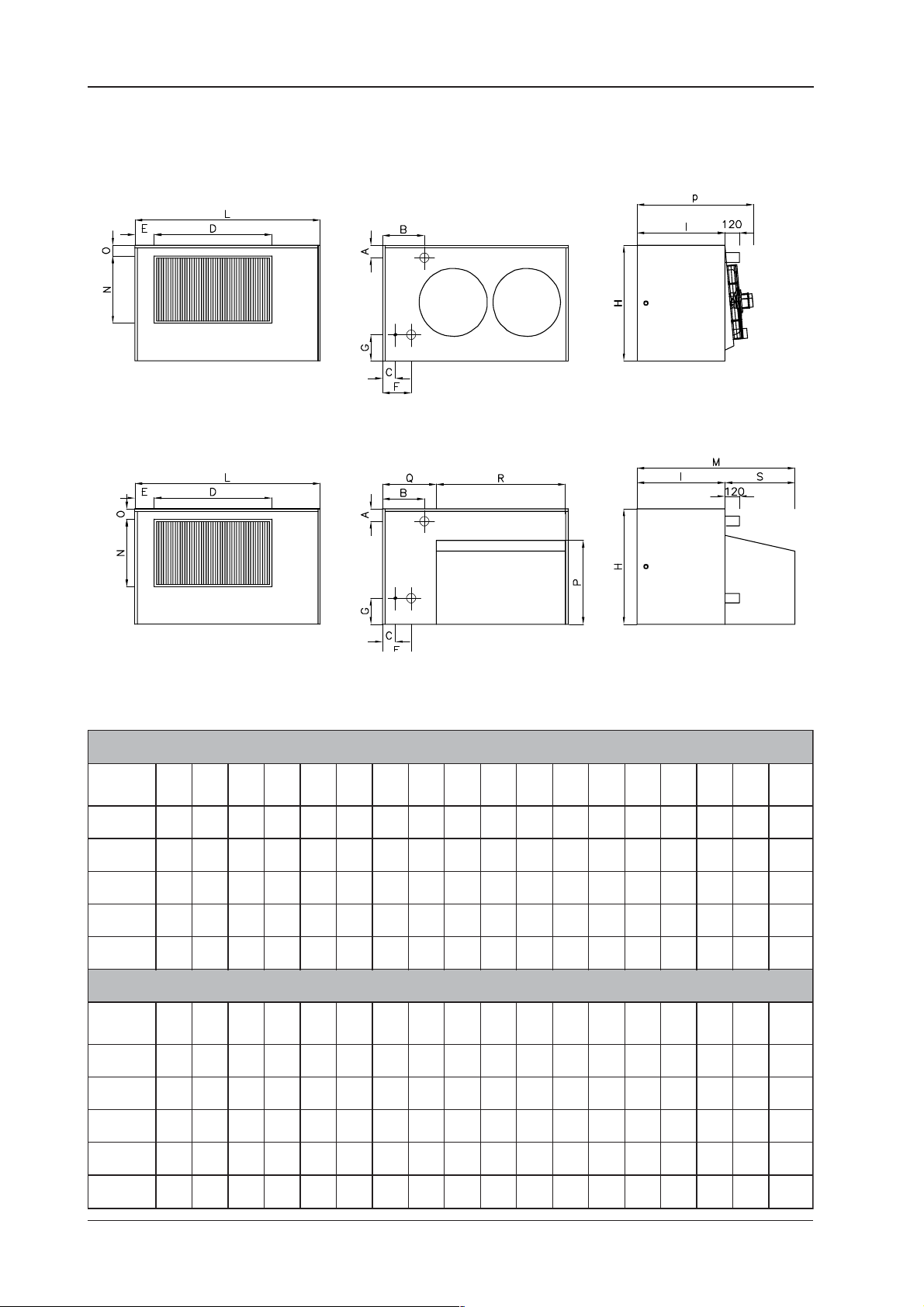

3.4 Overall dimensions

SERIES AE with axial fan

Front view Rear view Side view

SERIES AC with centrifugal fan

Gas airtight suspended warm air heaters - EOLO

Front view Rear view Side view

Fig.2 Overall dimensions

SEIRESLAIXASNOISNEMIDLLAREVO

A

B

C

D

E

F

G

H

I

L

M

N

O

P

Q

R

SLEDOM

EA0257158154005245020125660040780030310255,77

EA03502032350376213120020075840711083001056511

EA050015435010395715325120085550451083001527151

EA070015435010395715325120085550451083001527861

EA0903304300104210610425120085550381083001527991

SLEDOM

CA02571581540052450201256600407802800303106559307408398

CA03502032350376213120020075840711599083001046623068015231

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

SEIRESLAGUFIRTNECSNOISNEMIDLLAREVO

A

B

C

D

E

F

G

H

I

L

M

N

O

P

Q

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

]mm[

S

]mm[

]mm[

R

S

]mm[

]mm[

thgieW

]gk[

thgieW

]gk[

CA05001543501039571532512008555045156010830015574440011015371

CA07001543501039571532512008555045156010830015574440011015391

CA090330430010421061042512008555038156010830015570840041015922

Rev. 10EE0112

12

Page 13

Gas airtight suspended warm air heaters - EOLO

3.5 Exploded view of Eolo heaters

3.5.1 Exploded view of Eolo20AE

SYSTEMA S.p.A.

Fig. 3 Exploded view of EOLO20AE

3.5.2 Exploded view of Eolo20AC

Fig. 4 Exploded view of EOLO20AC

13

Rev. 10EE0112

Page 14

SYSTEMA S.p.A.

3.5.3 Exploded view of Eolo30AE

Gas airtight suspended warm air heaters - EOLO

Fig.5 Exploded view of EOLO30AE

3.5.4 Exploded view of Eolo30AC

Rev. 10EE0112

Fig.6 Exploded view of EOLO30AC

14

Page 15

Gas airtight suspended warm air heaters - EOLO

3.5.5 Exploded view of Eolo50AE-Eolo70AE

SYSTEMA S.p.A.

Fig. 7 Exploded view of Eolo50AE-Eolo70AE

3.5.6 Exploded view of Eolo50AC-Eolo70AC

Fig. 8 Exploded view of Eolo50AC-Eolo70AC

15

Rev. 10EE0112

Page 16

SYSTEMA S.p.A.

3.5.7 Exploded view of Eolo90AE

Gas airtight suspended warm air heaters - EOLO

Fig. 9 Exploded view of Eolo90AE

3.5.8 Exploded view of Eolo90AC

Rev. 10EE0112

Fig. 10 Exploded view of Eolo90AC

16

Page 17

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

3.5.9 Legend of components

.SOP EDOC NOITPIRCSED YT.Q .SOP EDOC NOITPIRCSED YT.Q

EA02OLOESTNENOPMOCFODNEGEL CA02OLOESTNENOPMOCFODNEGEL

1

2

3

4

5

6

0100PAEC10F13MCTINULORTNOC

8011RPEC40

1400IBEC40TATSOMREHT-IBYTEFASTIMIL-NAF

9080EVEC40

4003SAEC20

7350VEEC20MEDNAT038TISEVLAVDIONELOS

ABUHHCTIWSERUSSERPRIA

aP011-506.DOMSLORTNOC

004E6A

SEEMUFRUETARIPSARUETOM

C2/002VEINILATAN

11

12

13

MBE-LHEIZLADIOCILEHRUETALITNEV

14

15

16

EA03OLOESTNENOPMOCFODNEGEL CA03OLOESTNENOPMOCFODNEGEL

1

2

3

4

5

6

0100PAEC10F13MCTINULORTNOC

8011RPEC40

1400IBEC40TATSOMREHT-IBYTEFASTIMIL-NAF

9080EVEC40004E4AMBE-LHEIZNAFLAIXA

4003SAEC20

7350VEEC20MEDNAT038TISEVLAVDIONELOS

11

ABUHHCTIWSERUSSERPRIA

aP011-506.DOMSLORTNOC

12

13

14

INILATANROTOMNAFTSUAHXEEMUF

C2/002VE

15

16

EA05OLOESTNENOPMOCFODNEGEL CA05OLOESTNENOPMOCFODNEGEL

1

2

3

4

5

6

0100PAEC10F13MCTINULORTNOC

8011RPEC40

1400IBEC40TATSOMREHT-IBYTEFASTIMIL-NAF

9080EVEC40004E4AMBE-LHEIZNAFLAIXA

7820TMEC00

7350VEEC20MEDNAT038TISEVLAVDIONELOS

ABUHHCTIWSERUSSERPRIA

aP011-506.DOMSLORTNOC

.A.RW001

11

12

13

24

LEMISROTOMNAFTSUAHXEEMUF

15

16

EA07OLOESTNENOPMOCFODNEGEL CA07OLOESTNENOPMOCFODNEGEL

1

2

3

4

5

6

4670PAEC10F23MCTINULORTNOC

8011RPEC40

1400IBEC40TATSOMREHT-IBYTEFASTIMIL-NAF

0180EVEC40054E4AMBE-LHEIZNAFLAIXA

7280TMEC00

7350VEEC20MEDNAT038TISEPAPUOS

ABUHHCTIWSERUSSERPRIA

aP011-506.DOMSLORTNOC

.A.RW001

11

12

13

24

LEMISROTOMNAFTSUAHXEEMUF

15

26

EA09OLOESTNENOPMOCFODNEGEL CA09OLOESTNENOPMOCFODNEGEL

1

2

3

4

5

6

4670PAEC10F23MCTINULORTNOC

8011RPEC40

1400IBEC40TATSOMREHT-IBYTEFASTIMIL-NAF

9080EVEC40004E4AMBE-LHEIZNAFLAIXA

1062OMEC40

7350VEEC20MEDNAT038TISEVLAVDIONELOS

ABUHHCTIWSERUSSERPRIA

aP011-506.DOMSLORTNOC

.O.RW081

11

12

13

34

LEMISROTOMNAFTSUAHXEEMUF

15

26

0100PAEC10F13MCTINULORTNOC

8011RPEC40

1400IBEC40TATSOMREHT-IBYTEFASTIMIL-NAF

7790EVEC40

4003SAEC20

7350VEEC20MEDNAT038TISEVLAVDIONELOS

0100PAEC10F13MCTINULORTNOC

8011RPEC40

1400IBEC40TATSOMREHT-IBYTEFASTIMIL-NAF

7790EVEC40

4003SAEC20

7350VEEC20MEDNAT038TISEVLAVDIONELOS

0100PAEC10F13MCTINULORTNOC

8011RPEC40

1400IBEC40TATSOMREHT-IBYTEFASTIMIL-NAF

7790EVEC40

7820TMEC00

7350VEEC20MEDNAT038TISEVLAVDIONELOS

0100PAEC10F23MCTINULORTNOC

8011RPEC40

1400IBEC40TATSOMREHT-IBYTEFASTIMIL-NAF

7790EVEC40

7280TMEC00

7350VEEC20MEDNAT038TISEVLAVDIONELOS

0100PAEC10F23MCTINULORTNOC

8011RPEC40

1400IBEC40TATSOMREHT-IBYTEFASTIMIL-NAF

7790EVEC40

1062OMEC40

7350VEEC20MEDNAT038TISEVLAVDIONELOS

7/9ADEPYT513317.DOC

C2/002VE

8/01ADEPYT653317.DOC

C2/002VE

7/9ADEPYT713317.DOC

.A.RW001.TOM

8/01ADEPYT653317.DOC

.A.RW001

8/01ADEPYT653317.DOC

.O.RW081

1

ABUHHCTIWSERUSSERPRIA

aP011-506.DOMSLORTNOC

1

1

ITAROZRAMNAFLAGUFIRTNEC

1

INILATANROTOMNAFTSUAHXEEMUF

1

1

1

ABUHHCTIWSERUSSERPRIA

aP011-506.DOMSLORTNOC

1

1

ITAROZRAMNAFLAGUFIRTNEC

1

INILATANROTOMNAFTSUAHXEEMUF

1

1

1

ABUHHCTIWSERUSSERPRIA

aP011-506.DOMSLORTNOC

1

1

ITAROZRAMNAFLAGUFIRTNEC

2

LEMISROTOMNAFTSUAHXEEMUF

1

1

1

ABUHHCTIWSERUSSERPRIA

aP011-506.DOMSLORTNOC

1

1

ITAROZRAMNAFLAGUFIRTNEC

2

LEMISROTOMNAFTSUAHXEEMUF

1

2

1

ABUHHCTIWSERUSSERPRIA

aP011-506.DOMSLORTNOC

1

1

ITAROZRAMNAFLAGUFIRTNEC

3

LEMISROTOMNAFTSUAHXEEMUF

1

2

17

Rev. 10EE0112

Page 18

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

3.6 Position of the ignition and detection electrodes

Fig. 11 Position of electrodes

3.7 Position of the nozzle

Fig. 12a Position of nozzles

Rev. 10EE0112

Fig. 12b Position of nozzles - second flame level

(Eolo 70 AE/AC, Eolo 90 AE/AC)

18

Page 19

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

4 INSTALLATION

4.1 Place of installation and safety distances

To obtain the maximum yield from EOLO suspended warm air heaters the following rules should be followed:

- Establish the position, bearing in mind the type of work, priority zones to be heated and absorbing walls

(windows, doors, entrances etc.) see fig. (11a, 11b, 11c).

- Install the appliances respecting the correct

distances from the walls see. fig. ( 11d,11e)

- Install the EOLO suspended heaters as near

as possible to the zone to be heated complying with a distance from the floor and from

people to ensure the jet of warm air is not

aimed directly at them.

- When positioning the EOLO suspended

heaters take into account any obstacles, such

as shelves, walls, columns, etc..

- If several appliances are to be installed in the

same environment, it is advisable to position

these on opposite walls and between one

another to cover the area to be heated

uniformly.

- If there are any drafts of cold air from

entrances, doors, etc., it is advisable to install

the appliances so that the jet of hot air is aimed

towards the source of cold air.

- Appliances must never be installed in niches

or positions that do not guarantee sufficient

aeration for correct operation.

- Several appliances installed in the same room

or in directly communicating rooms, are

considered as a single system, with a thermal

capacity of the total of the thermal capacities

of each single appliance.

- In environments subjected to vacuum

pressures or in which processes develop a

noteworthy amount of non-combustible dust,

the appliances must be installed so that air

suction and discharge of fumes is performed

directly from the outside through the outside

wall (or aperture) of the room in which the

appliances are installed.

- Installation must be performed by

professionally qualified personnel responsible

for complying with the current safety

standards. The manufacturer declines all responsibility in the case of damages caused

by erroneous installation or improper and/or incorrect use of the appliance.

Fig.11a

Fig.11d

Fig.11b

Fig.11c

Fig.11e

N.B. Make sure that rooms are specifically ventilated for type B applications

19

Rev. 10EE0112

Page 20

SYSTEMA S.p.A.

4.2 Installing the appliance

4.2.1 Fitting the brackets for Eolo 20

Gas airtight suspended warm air heaters - EOLO

1= Bracket to be fixed to the wall

2= Bracket to be fixed under Eolo

3= Supporting bracket

Rev. 10EE0112

Fig. 13 Fixing brackets for Eolo20

20

Page 21

Gas airtight suspended warm air heaters - EOLO

4.2.2 Fitting the brackets for Eolo 30-50-70-90

SYSTEMA S.p.A.

Holes for fixing the plate

under Eolo

Slots for fixing the plate (1) to

the bracket (2)

1

2

Holes for Eolo series

AE

Holes for Eolo series AC

1) Fix the two plates (1) under

Eolo with the corresponding

holes.

2) Fix the two brackets (2) to the

wall complying with the

distance of the plates (1) fixed

under Eolo.

3) Fix Eolo using the two slots on

the plates to the wall-mounted

brackets (2); for Eolo AC the

fixing holes are those farthest

from the wall.

1

2

Fig.14 Fitting the brackets Eolo 30/50/70/90

21

Rev. 10EE0112

Page 22

SYSTEMA S.p.A.

4.3 Fitting the fire damper (optional)

Gas airtight suspended warm air heaters - EOLO

Rev. 10EE0112

Fig. 15 Fitting the fire damper

22

Page 23

Gas airtight suspended warm air heaters - EOLO

5 SETTING UP THE APPLIANCE

5.1 Examples of applications

IMPORTANT!!

The heater may be installed outdoors with temperatures down to -15°C. Below this

temperature operation of the appliance is no longer guaranteed.

SYSTEMA S.p.A.

Fig. 16 Examples of application

For the examples of applications shown above, the company Systema only provides the main components,

namely the heater with original air outlets and adjustable fins, fire damper, original filters, supporting brackets,

fume termination. All other components required to perform complete application, namely air pipe fittings,

intake and external air regulation shutters, covers, cooling batteries, etc., must be identified by the installing

company.

LEGEND

1= Pipe

2= Dielectric joint

3= Manual on-off valve in an easy to reach

position

4= Gas feed pipe

5= Supporting bracket

6= Vibration damping joint

7= Manual gas on-off valve

8= Combustion air inlet termination

9= Combustion products outlet termination

10= Heater

11= Two-way fire damper

12= Distribution outlet

13= Protective canopy

14= External perimeter wall

15= Centrifugal fan

16= Control board with ambient thermostat

23

Rev. 10EE0112

Page 24

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

6 DISCHARGE AND SUCTION DUCTS

The fume discharge ducts relevant to type C appliances with natural or forced draft, must comply with

the following conditions:

they must be metal, be constructed in materials resistant to normal mechanical stress,

heat and the action of combustion products and any condensation through time; the use of

corrugated ducting is not permitted.

It is possible to use both rigid pipe in stainless steel and in aluminium (the latter with a minimum

thickness of 1.5 mm).

As a connection it is possible to utilize double wall flexible stainless steel pipe with a smooth internal

surface (previously subjected to testing according to EN 166/21).

For combustion air ducts to the burner any kind of metal pipe can be used.

(1)

ventilated for type B applications

(1) Make sure that rooms are specifically

(1)

Fig. 17 Lengths of fume and combustion air ducts

For fume ducts over 5-6 m in length, bear in mind that condensation phenomena could occur

inside the ducts if these are not sufficiently insulated.

Rev. 10EE0112

24

Page 25

Gas airtight suspended warm air heaters - EOLO

6.1 Coaxial roof discharge for Eolo20 (type C32)

SYSTEMA S.p.A.

Fig. 18 Example of coaxial roof discharge for Eolo20

1= Female coupling Ø100 mm

2= Tandem connection

3= Rigid component Ø 80 mm M/M length 320

mm

4= Elbow bend 90° Ø 80 mm F/F

5= Rigid component Ø 80 mm M/F length 125 mm

6= Eolo20

7= Elbow bend 90° Ø 80 mm M/F

8= Gasket

9= Rigid component Ø 100 mm M/F length 1.000

mm

10= Rigid component Ø 60 mm M/F length 1.000

mm

11= Reduction

12= Ceiling termination

25

Rev. 10EE0112

Page 26

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

6.2 Coaxial wall discharge for Eolo20 (type C12)

Fig. 19 Example of coaxial wall discharge for Eolo20

1= Rigid component Ø 80 mm M/F length 250 mm

2= Gasket

3= Female coupling Ø 100 mm

4= Hole flange

5= Coaxial wall termination

6= Tandem connection

7= Elbow bend 90° Ø 80 mm M/F

8= Eolo20

Rev. 10EE0112

26

Page 27

Gas airtight suspended warm air heaters - EOLO

6.3 Separate wall discharge for Eolo20 (type C12)

SYSTEMA S.p.A.

Fig. 20 Example of coaxial wall discharge for Eolo20

1= Rigid component Ø 80 mm M/F length 1000 mm

2= Hole flange

3= Cover for fume discharge termination

4= Cover for air termination

5= Eolo20

27

Rev. 10EE0112

Page 28

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

6.4 Coaxial roof discharge for Eolo30-50-70-90 (type C32)

Fig. 21 Example of coaxial roof discharge for Eolo30/50/70/90

1= Coaxial roof termination Ø 150/100 mm

2= Top collar

3= Lead flashing

4= Hole flange

5= Tandem connection

6= Clamping band

Rev. 10EE0112

7= Elbow bend 90° Ø 100 mm M/F

8= Silencer

9= Eolo

10= Band for clamping flexible air pipe

11= Flexible pipe for combustion air

28

Page 29

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

6.5 Coaxial wall discharge for Eolo30-50-70-90 (type C12)

Fig. 22 Example of coaxial wall discharge for Eolo30/50/70/90

1= Silencer

2= Clamping band

3= Tandem connection

4= Coaxial wall termination Ø 150/100 mm

5= Hole flange

6= Band for clamping flexible air pipe

7= Flexible pipe for combustion air

8= Eolo

29

Rev. 10EE0112

Page 30

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

6.6 Separate wall discharge for Eolo30-50-70-90 (type C12)

Fig. 23 Example of separate wall discharge for Eolo30/50/70/90

1= Silencer

2= Clamping band

3= Wall fume termination Ø 100 mm

4= Wall air termination Ø 100 mm

5= Hole flange

6= Eolo

Rev. 10EE0112

30

Page 31

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

6.7 Separate roof discharge for Eolo30-50-70-90 (type C32)

D= minimun 50 cm

Fig. 24 Example of separate roof discharge for Eolo30/50/70/90

1= Roof fume termination Ø 100 mm

2= Top collar

3= Lead flashing

4= Hole flange

5= Clamping band

6= Silencer

7= Elbow bend 90° Ø 100 mm M/F

8= Eolo

9= Rigid component Ø 100 mm M/F length 500

mm

10= Roof air termination Ø 100 mm

31

Rev. 10EE0112

Page 32

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

7 GAS PIPES

7.1 Connecting the appliance

The gas supply pipe must be executed in compliance with the regulations in force in the country in

which the system is installed.

The sizes of the pipes and any pressure reducers must guarantee correct operation of appliances.

Materials used must conform to regulations in force in the country in which the system is installed.

a) The appliance must not be subjected to pressures exceeding 40 mbar (0.04 bar); otherwise the

membrane of the gas valve may break.

b) For natural gas: on the main line upstream, below the meter, always install a pressure stabiliser and

a gauge with a scale of 0÷60 mbar (0.06 bar) and adjust the pressure to 20 mbar (0.02 bar); higher

pressure can be the cause of bad combustion and difficulty in flame ignition.

c) For LPG (butane-propane) gas: a stage 1 pressure reducer must be installed near the tank in

order to reduce the pressure to 1.5 bar; on the main outside line beside the building always install

a stage 2 pressure reducer to reduce the pressure to the values indicated in the table on page 39.

Below the stage 2 reducer install a gauge with a scale of 0÷60 mbar (0.06 bar) and adjust the

pressure to the values indicated in the table on page 39; higher pressure can be the cause of poor

combustion and difficulty in flame ignition.

d) Upstream and downstream of the main gas supply line a gauge must be installed in a visible

position with a scale of 0÷60 mbar (0.06 bar) to check any differences upstream and downstream,

thus checking the flow rate of the entire mains.

e) Moreover, by closing the main gate valve and switching off all the appliances, the seal of the

system and gas valves can be checked by determining whether after a short period there is any

reduction in pressure on the gauges.

f) Always connect appliances using ball valve and anti-vibrating flexible joint for gas.

g) Adjusting the gas supply pressure: all appliances are inspected and regulated in the factory for the

pressures for which they are predisposed (see ratings plate on the burner or table on page 39).

IMPORTANT

For natural gas supply with pressures above 20 mbar (200 mm c.a.), always fit a pressure

stabiliser for each appliance and adjust the pressure to 20 mbar.

Rev. 10EE0112

32

Page 33

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

8 ELECTRICAL SYSTEM

8.1 Connection diagram to CE type boards mod. 04CEQU1202

(without timer) and mod. 04CEQU1203 (with timer)

All electrical connection must be performed in compliance with the regulations in force in the country in

which the system is installed.

Refer to the wiring diagram given in this manual to connect the control board to the appliance.

In particular:

a) Use an electrical cable with no. 8 wires, for phase, neutral, earth, appliance reset, operating

telltale, shut-down telltale and ambient thermostat.

b) Check that it is accurately earthed and comply with the phase and neutral connections; otherwise

the series CE control board will break.

c) Position the ambient thermostat at a height of 1.5 1.8 m from the ground.

Fig. 25 Connection to the series CE board

33

Rev. 10EE0112

Page 34

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

8.2 Connection to the board code 04CEQU1204

Fig. 26a Connection to the board code 04CEQU1204 (with 11 terminal)

Rev. 10EE0112

Fig. 26b Connection to the board code 04CEQU1204 (with 5 terminal)

34

Page 35

Gas airtight suspended warm air heaters - EOLO

8.3 Internal wiring diagram Eolo 20-30-50

SYSTEMA S.p.A.

on the ground

To the control board

Electrical supply

1/N/PE ~ 50Hz 230V

Fig. 27 Eolo internal connection diagram with

control unit CM 31F

35

Rev. 10EE0112

Page 36

SYSTEMA S.p.A.

8.4 Internal wiring diagram Eolo 70-90

Gas airtight suspended warm air heaters - EOLO

Fig. 28 Eolo internal connection diagram

with control unit CM 32F

1/N/PE ~ 50Hz 230V

To the control board

on the ground

Electrical supply

Rev. 10EE0112

36

Page 37

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

9 INSPECTION AND STARTING UP THE

SYSTEM

9.1 Preliminary ignition procedures

a) Check that the appliances have been set for the available type of gas (consult paragraph 10.1 on

gas conversion if required), check the mains pressure (see table below) and turn on the gas. Seal

the gas valve adjustment component after regulation.

b) Check that the electrical connection between the burner and switchboard is correct.

c) Position the ambient thermostat for the zone to the required temperature (consult the instructions

provided with the switchboard); the heaters start up.

9.2 Ignition phases

1) The gas pressure switch closes the contact of the phase line, supplying the CM 31F/32F instrument

with power; this then starts the feed procedure.

2) The fume exhaust fan then starts up, triggering the air pressure switch; at this point the instrument

checks the air pressure switch operation and if this is regular the prewash procedure in the combustion

chamber starts; this lasts for a minimum of 20 seconds. FOR FURTHER INFORMATION ON THE

INSTRUMENT REFER TO THE RELEVANT TECHNICAL NOTES.

3) After the prewash procedure, the instrument gives the ignition charge for 5 seconds and the green

telltale lights up simultaneously. If the flame does not ignite, the instrument shuts down and the red

telltale lights up. Press the reset button to restart it.

4) In models with two solenoid valves, the burner ignites at the first flame level and only after receiving

further consent by the CM 32F instrument does it operate at full power.

IMPORTANT:

If the connection S3 B4 are inverted (with electronic thermostat) = the thermostat does not switch on

and does not enable burner operation.

If T1 T2 are inverted = the shut-down telltale lights up with the burner operating.

If phase and neutral are inverted during supply = the burner ignites the flame and then shuts down (10

seconds).

If the burner is reset with the phase signal = the CM 31F/32F control unit is damaged or it will not reset.

If the thermostat is fitted to the main line = the combustion chamber is not cooled and damage is

caused to this and the fan units.

Permanent jumper on terminals S3 and B4 with the heaters switching on and off = same damage as

above.

Check electrical connections: the electrical connections listed below MUST be complied with.

37

Rev. 10EE0112

Page 38

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

9.3 Adjusting the pressure on the solenoid valve and pressure intake

1= Slow ignition regulation

2= Pressure intake downstream

3= Flow rate regulation

4= Pressure intake upstream

5= Second flame level

Fig. 29 Solenoid valve for Eolo mods. 20-30-50 Fig. 30 Solenoid valve for Eolo mods. 70-90

N.B. Seal the adjustment component of the gas solenoid valve after regulation.

LEDOM

02GHsaglarutaN

YLPPUSSNIAM

ERUSSERP

EHTTAERUSSERP

RENRUB

RETEMAIDELZZON

NOITPMUSNOClanimoN

52,3101dnaC°51ta

rabm

03GenatuBGPL

13GenaporPGPL

02GHsaglarutaN

03GenatuBGPL

13GenaporPGPL

02GHsaglarutaN

03GenatuBGPL

13GenaporPGPL

02GHsaglarutaN

03GenatuBGPL

13GenaporPGPL

rabm

rabm

rabm

rabm

rabm

rabm

mm

mm

mm

h/³mN

h/gK

h/gK

02OLOE

CA/EA

0202020202

9292929292

7373737373

0,111,70,81,77,7

9,728,82824,725,62

3,633,63538,435,33

0,45,50,77,55,6

3,20,36,39,24,3

3,20,36,39,24,3

33,206,317,514,759,9

37,186,262,425,514,7

17,146,202,444,503,7

03OLOE

CA/EA

05OLOE

CA/EA

07OLOE

CA/EA

09OLOE

CA/EA

Rev. 10EE0112

38

Page 39

Gas airtight suspended warm air heaters - EOLO

9.4 Bi-thermostat for adjusting fan start-up

Adjustment levers

SYSTEMA S.p.A.

Automatic/manual

operation button

Fig. 31 Fan-limit bi-thermostat

During normal operation the sensor of the bi-thermostat rotates and, once the temperature set on the

set point has been reached, closes the contact that supplies power to the fan.

The bi-thermostat has a bi-metal thermostat that operates the fan within 90 seconds of being enabled.

IMPORTANT !!

When setting temperatures and using the adjustment levers, hold the housing firmly so that

it does not rotate and supply power to the sensor.

Adjustment levers

FAN OFF .......................................................................... Fan shut-down temperature

FAN ON ............................................................................ Fan start-up temperature

LIMIT OFF ........................................................................ Eolo limit shut-down temperature

Automatic/manual operation button .................................. Button for manual operation of the fan

39

Rev. 10EE0112

Page 40

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

9.3 Measuring the efficiency

Taking a sample of combustions products:

Taking a sample of combustion products and measuring of the temperature of these must be performed

by means of the special through hole in the combustion product discharge duct.

After taking measurements, the operator must close the hole accurately to guarantee the seal of the

combustion product discharge duct during normal operation of the system.

The person in charge of operation and maintenance of the system must have the hole made by a

certified technician or service engineer, unless the heater has already been provided with a specific

hole, or one has remained following other measurements taken in compliance with the instructions

above, in conformance with the standard UNI 10389.

The hole must be located at a distance from the heater outlet equivalent to twice the internal diameter

of the combustion products discharge duct. If there is a bend in the duct inside this distance, the hole

must be located at a distance from the far end of the bend equivalent to one internal diameter of the

combustion products discharge duct.

If the concentration of CO detected in the condition of dry and air-less combustion products is

greater than 0.1% (1000 ppm) and the operator or service engineer cannot reduce it to below

this value, the combustion test must be considered as failed, notwithstanding the measured

value of combustion efficiency.

NOTE

If heat recovery systems are fitted

downstream of the heater, the

hole must be located on the

stretch of the combustion

products discharge duct below

the recover systems; this is the

case for a metal fume duct,

without insulation and located inside the room (see fig. 29a), that

provides the room with heat

either through convection and

irradiation.

B

COMBUSTION

ANALYSER

Fig. 32 Hole for taking samples for combustion analysis with

heat recovery systems (point B)

9.3.2 Measuring the temperature of combustion air

This must be performed in a suitable point of the combustion air supply duct.

After taking measurements, the operator must close the hole accurately to guarantee the seal of the

duct during normal operation of the system.

Rev. 10EE0112

40

Page 41

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

10 MAINTENANCE

10.1 Gas conversion

The conversion must be performed by professionally qualified personnel responsible for complying

with the current safety standards. The manufacturer declines all responsibility in the case of damages

caused by erroneous conversion or improper and/or incorrect use of the appliance.

10.1.1 Conversion from Natural Gas to LPG

1) Close the gas supply and disconnect the power supply.

2) Disconnect the combustion torch from the solenoid valve EV1 (30 mm spanner).

3) Unscrew the nozzle (it has a crosswise slot on the head) from inside the torch (see fig. 12 page 18)

taking care not to damage the electrodes (ignition and flame detection) located on the head of the

torch and relevant wires.

4) Replace with the nozzle in the conversion kit after checking that the diameter corresponds to the

one given on the ratings plate.

5) Connect and clamp the torch to the solenoid valve.

6) Adjust the burner pressure with the pressure regulator of the solenoid valve, turning the screw (3)

in fig. 30 on page 38: exclude the pressure regulator of the solenoid valve by clamping the screw

(3) in a clockwise direction (+).

7) Check that the supply pressure to the burner measured at point (2) figs. 29-30 page 38, corresponds

to the ratings plate value. (*)

8) Check the gas seal on the threaded joints.

9) Affix the label (Appliance regulated for ) indicating the new type of gas to the plate provided on

the appliance.

Seal the gas valve adjustment component after regulation.

(*) For LPG (Butane G30/Propane G31) gas, a stage I pressure reducer must be installed in the

vicinity of the tank to reduce the pressure to 1.5 bar; another stage II pressure reducer must be

installed on the main outside line beside the building to reduce the pressure to the values indicated

on page 38.

On models EOLO 70/EOLO 90

Models Eolo 70 and Eolo 90 are provided with a second solenoid valve (see fig. 30 page 38).

Change the nozzle on the second solenoid valve as follows:

1) Disconnect the tube (5) from the solenoid valve EV2 (30 mm spanner), (fig. 30 page 38).

2) Unscrew the nozzle (it has a crosswise slot on the head) from inside the extension connected to the

tube (5).

3) Replace with the nozzle in the conversion kit after checking that the diameter corresponds to the

one given on the ratings plate.

4) Connect and clamp the tube (5) to the solenoid valve EV2.

5) Adjust the burner pressure with the pressure regulator of the solenoid valve, turning the screw (3)

in fig. 30 on page 38: exclude the pressure regulator of the solenoid valve by clamping the screw

(3) in a clockwise direction (+).

6) Check that the supply pressure to the burner measured at point (2) figs. 29-30 page 38, corresponds

to the ratings plate value. (*)

7) Check the gas seal on the threaded joints.

41

Rev. 10EE0112

Page 42

SYSTEMA S.p.A.

8) Affix the label (Appliance regulated for ) indicating the new type of gas to the plate provided on the

appliance.

Seal the gas valve adjustment component after regulation.

(*) For LPG (Butane G30/Propane G31) gas, a stage I pressure reducer must be installed in the

vicinity of the tank to reduce the pressure to 1.5 bar; another stage II pressure reducer must be

installed on the main outside line beside the building to reduce the pressure to the values indicated

on page 39.

Gas airtight suspended warm air heaters - EOLO

10.1.2Conversion from LPG to Natural Gas

1) Close the gas supply tap and disconnect the power supply.

2) Disconnect the combustion torch from the solenoid valve EV1 (30 mm spanner).

3) Unscrew the nozzle (it has a crosswise slot on the head) from inside the torch (see fig. 12 page 18)

taking care not to damage the electrodes (ignition and flame detection) located on the head of the

torch and relevant wires.

4) Replace with the nozzle in the conversion kit after checking that the diameter corresponds to the

one given on the ratings plate.

5) Connect and clamp the torch to the solenoid valve.

6) Adjust the burner pressure with the pressure regulator of the solenoid valve, turning the screw (3)

in fig. 30 on page 38.

7) Start up the appliance and check that the supply pressure to the burner measured at point (2) figs.

29-30 page 38 corresponds to the ratings plate value.

8) Check the gas seal on the threaded joints.

9) Affix the label (Appliance regulated for ) indicating the new type of gas to the plate provided on

the appliance.

Seal the gas valve adjustment component after regulation.

On models EOLO 70/EOLO 90

Models Eolo 70 and Eolo 90 are provided with a second solenoid valve (see fig. 30 page 38).

Change the nozzle on the second solenoid valve as follows:

1) Disconnect the tube (5) from the solenoid valve EV2 (30 mm spanner), (fig. 30 page 38).

2) Unscrew the nozzle (it has a crosswise slot on the head) from inside the extension connected to the

tube (5).

3) Replace with the nozzle in the conversion kit after checking that the diameter corresponds to the

one given on the ratings plate.

4) Connect and clamp the tube (5) to the solenoid valve EV2.

5) Adjust the burner pressure with the pressure regulator of the solenoid valve, turning the screw (3)

in fig. 30 on page 38.

6) Start up the appliance and check that the supply pressure to the burner measured at point (2) figs.

29-30 page 38, corresponds to the ratings plate value.

7) Check the gas seal on the threaded joints.

8) Affix the label (Appliance regulated for ) indicating the new type of gas to the plate provided on

the appliance.

Seal the gas valve adjustment component after regulation.

Rev. 10EE0112

42

Page 43

Gas airtight suspended warm air heaters - EOLO

10.2 Operating faults

TLUAF ESUAC YDEMER

SYSTEMA S.p.A.

rewoplartuendnaesahp)a

.detrevniylppus

noitcennochtraetneiciffusnI)b.noitcennochtraeehtkcehC)b

gulproedortcelenoitceteD)c

yltcerrocnidenoitisop

nwodstuhsdnasetingirenrubehT

.sdnoceswefaretfa

eht,pustratsrotomnaftsuahxeehT

tubnoitingistpmettanehttinulortnoc

.etingitonseodhcrotnoitsubmoceht

.ytluaf

.hctiwserusserp

tluaftnemurtsnilortnoC)dlanigirohtiwtnemurtsniecalpeR)d

sepipsagniriA)e.riaehtdeelB)e

erusserpsagtcerrocnI)fseulavehthtiwerusserpehtkcehC)f

.renrubehtotsagon)a.enilylppusehtkcehc)a

sievlavdionelosehtfoliocehT)b

riaehtfotuo-tucybdereggirtton

sievlavdionelosehtfoliocehT)c

.)launam

.!!eraps

.noitarepo

.pu-tratsgnirud

.snoitcennocehttrevnI)a

morfmm11=noitisopedortcelE)c

sihtedisnimargaidees(etalpeht

.etalpsgnitarehtno sagehtlaeS

tnenopmoctnemtsujdaevlav

.noitalugerretfa

ehtfonoitcennocehtkcehC)b

hctiwserusserpriadnaebutenocilis

eht;revirdwercsagnisutseT)c

liocehtybdetcarttasirevirdwercs

erusserpsaglarutanevissecxE)d

.elzzonehtot

.ylppusrewopon)asehctiwsehtfonoitisopehtkcehc)a

.draob

.ytluafsirotomehT)bsitifi;trapanoitareponafkcehC)b

tratstonseodnaftsuahxeemufehT

.pu

.detrevni

sag

eht,pustratsrotomnaftsuahxeehT

eht,noitingistpmettanehttinulortnoc

hcrotehttubsnepoevlavdionelos

.etingitonseod

ehttubpustratsrotomnaftsuahxeehT

otlangisehtdnestonseodtinulortnoc

.evlavdionelosdnahcroteht

.ytluafsiroticapacehT)cehthtiwroticapacahtiwecalpeR)c

.puthguacsinafrotomehT)dnafehteerF)d

eraseriwhctiwserusserpehT)e

seviecerhcrotehttahtkcehc)a

siedortcelenoitingieht)b

.yltcerrocnidenoitisop

hgihootsierusserpsagehT)c.seulavetalpgnitarehtottiteS)c

ehtgnitsetlaitinignirud)a

erusserpehtdnuoftnemurtsni

.)deulg(desolcstcatnochctiws

.ytluafsitnemurtsnilortnocehT)bnahtiwtnemurtsniehtecalpeR)b

.eraps

.snoitacificepsemas

)63.53.ppmargaid

.wensisiht

.sgnittesnoitaluger

!!erapslanigiro

.eulavetalpsgnitarehtottiteS)d

hctiwsdnadraoblortnocehtno

lanigironahtiwecalpernekorb

ees(yltcerrocseriwehttcennoC)e

fi,metsysehtmorfriaynadeelb)a

etalpehtmorfmm5tinoitisoP)b

)launamsihtnimargaidees(

htiwhctiwserusserpehtecalper)a

emasehthtiw!!erapslanigirona

43

Rev. 10EE0112

Page 44

SYSTEMA S.p.A.

Gas airtight suspended warm air heaters - EOLO

11 WARRANTY

11.1 Subject-matter and duration of the warranty

1) The Warranty is limited to faults in the material or machining of components supplied by SYSTEMA.

In the event of a fault in the material or machining, SYSTEMA shall repair or replace faulty parts exworks free of charge. ALL OTHER FORMS OF WARRANTY OR COMPENSATION, LEGAL OR

CONVENTIONAL, ARE EXPRESSLY EXCLUDED. Replaced parts shall be returned immediately

to SYSTEMA, free at its works in S. Giustina in Colle (PD), by and to the expense of the user. In the

event of operations covered by warranty, the user shall be charged the fixed call-out fee and refund

for mileage in the event of the place of the operation being over 10 kilometres from the Service

Centre.

2) The Warranty becomes valid as from Initial ignition, provided that this is performed within 6 (six)

months of the date on which the appliance is purchased by the user. In any case, the Warranty shall

expire 18 (eighteen) months from the date on which the SYSTEMA invoice is issued.

3) Any replacement of faulty parts (or the entire Appliance) shall not extend the original expiry terms

of the Warranty. The Warranty on replaced parts shall expire on the same date as the expiry date

of the Appliance Warranty.

4) The duration of the warranty shall be 1 (one) year for each component of the appliance.

11.2 Exclusions from the warranty

1) The Warranty is not valid in the case of:

a) Defects that cannot be attributed to faulty materials or machining, without limits:

- breakages during transport;

- non-compliance of the system with local laws and regulations in force;

- failure to comply with the installation instructions set down in the technical notes supplied

with the Appliance and/or the rules of correct technique;

- damage caused by accidents in general, fires or negligence that cannot be attributed to

SYSTEMA.

b) Tampering or faults due to operations performed by unauthorized personnel.

c) Defects caused by faults concerning the electrical or gas supply mains.

d) Failures caused by: incorrect maintenance, negligence or improper use, variations in the

power supply voltage, dampness and dust in the rooms, incorrect dimensioning and/or faulty

execution of installation.

e) Corrosion or breakage caused by: stray currents, condensation, overheating caused by incorrect

regulation of the pressure of supply gas or to the burner, or the use of gas with different

heating specifications than the rating plate values.

f) Use of non-original spare parts or parts not authorised by SYSTEMA.

g) Normal wear and tear.

h) Products not correctly cared for or stored.

2) Moreover, the Warranty is not valid if:

a) payment for the Appliance was not effected within the terms established in the contract.

b) Initial ignition was not effected by the Service Centre and/or its copy of the Warranty duly

compiled and signed in all parts was not received.

c) The user did not report the fault within 10 days of discovering it.

Rev. 10EE0112

44

Page 45

Gas airtight suspended warm air heaters - EOLO

SYSTEMA S.p.A.

11.3 Competence

1) Requests for operations under Warranty must be submitted, subject to forfeiture, to the Service

Centre that performed initial ignition. The user must, in this case, present the Certificate of Warranty

to the Service Centre.

2) The Service Centre shall perform operations according to its organizational requirements, during

normal working hours.

11.4 Operativeness and efficacy of the warranty

1) In order for the warranty to become operative and efficacious the user must:

a) Request the name of the Service Centre for Initial ignition from its installer.

b) Present the Service Centre personnel with the Certificate of Warranty, compile all parts of this

and ask the Service Centre to stamp and sign it in the specific spaces.

11.5 Responsibility

The customer shall exonerate the supplier from all responsibility for accidents or damages to the

machines or systems during operation. The supplier shall be liable to the purchaser only within the

limits of the warranty obligation specified above.

11.6 Legal disputes Territorial competence and rights of the parties

The Court of Padua is established as the competent court, also in the event of actions connected to or

called for by warranty. Outstanding disputes do not exonerate the customer from the obligation to

make payments, which must be made according to the contract, until the final ruling by the Judicial

Authority.

12 SETTING ASIDE

If the appliance is to be set aside for a lengthy period of time, the following operations must be performed:

Turn the master switch to 0 and disconnect the appliance from the power supply.

Close the gas supply valve and disconnect the appliance from the gas mains.

In the case of change in ownership or a new tenant, give all documents regarding the heating system

to the new owner/tenant.

IMPORTANT !!

All disconnection operations must be performed by authorised technical personnel!

45

Rev. 10EE0112

Page 46

SYSTEMA S.p.A.

13 NOTES

Gas airtight suspended warm air heaters - EOLO

Rev. 10EE0112

46

Page 47

Page 48

Loading...

Loading...