Sys Tec Electronic GW-003 System Manual

system house for distributed automation

CAN-Ethernet Gateway

GW-003

Systems Manual

Edition April 2007

CAN – Ethernet Gateway

© SYS TEC electronic GmbH 2007 L-1032e_9

In this manual are descriptions for copyrighted products, which are not explicitly

indicated as such. The absence of the trademark (™) and copyright (©) symbols

does not infer that a product is not protected. Additionally, registered patents and

trademarks are similarly not expressly indicated in this manual

The information in this document has been carefully checked and is believed to be

entirely reliable. However, SYS TEC electronic GmbH assumes no responsibility

for any inaccuracies. SYS TEC electronic GmbH neither gives any guarantee nor

accepts any liability whatsoever for consequential damages resulting from the use

of this manual or its associated product. SYS TEC electronic GmbH reserves the

right to alter the information contained herein without prior notification and

accepts no responsibility for any damages, which might result.

Additionally, SYS TEC electronic GmbH offers no guarantee nor accepts any

liability for damages arising from the improper usage or improper installation of

the hardware or software. SYS TEC electronic GmbH further reserves the right to

alter the layout and/or design of the hardware without prior notification and

accepts no liability for doing so.

© Copyright 2006 SYS TEC electronic GmbH, D-07973 Greiz/Thuringia. Rights

- including those of translation, reprint, broadcast, photomechanical or similar

reproduction and storage or processing in computer systems, in whole or in part are reserved. No reproduction may occur without the express written consent from

SYS TEC electronic GmbH.

EUROPE NORTH AMERICA

Address: SYS TEC electronic GmbH

August-Bebel-Str. 29

D-07973 Greiz

GERMANY

PHYTEC America LLC

203 Parfitt Way SW, Suite G100

Bainbridge Island, WA 98110

USA

Ordering

Information:

+49 (0) 36 61 / 62 79-0

info@systec-electronic.com

1 (800) 278-9913

info@phytec.com

Technical

Support:

+49 (0) 36 61 / 62 79-0

support@systec-electronic.com

1 (800) 278-9913

support@phytec.com

Fax: +49 (0) 36 61 / 62 79-99 1 (206) 780-9135

Web Site: http://www.systec-electronic.com http://www.phytec.com

9th Edition April 2007

Contents

© SYS TEC electronic GmbH 2007 L-1032e_9

Table of Contents

1 Introduction......................1

1.1 Fundamentals ...............................................................................1

1.2 Application Fields........................................................................2

1.2.1 Connecting Two CAN Networks over Ethernet.............2

1.2.2 Remote Diagnostics and Configuration of CAN

Networks .........................................................................

4

1.3 Delivery Contents.........................................................................5

2 Technical Data..................7

3 Getting Started.................9

3.1 Power Supply ...............................................................................9

3.2 Network Connection ....................................................................9

3.2.1 Connecting to a CAN Bus...............................................9

3.2.2 Ethernet Connection......................................................10

3.2.3 RS-232 Interface ...........................................................11

3.3 Device Status Display ................................................................12

3.4 Switches......................................................................................13

3.5 Initial Setup and Operation ........................................................14

3.5.1 Standard Configuration.................................................14

3.5.2 Initial Configuration using the RS-232 Interface..........15

3.5.3 Configuration and Operation using Telnet ...................22

4 Device Functions ............23

4.1 Overview....................................................................................23

4.2 Interfaces....................................................................................24

4.2.1 Fundamentals ................................................................24

4.2.2 UDP/TCP Server Interface............................................26

4.2.3 UDP/TCP Client Interface ............................................28

4.2.4 CAN Interface...............................................................31

4.2.5 LED Interface Status Display .......................................33

4.3 Filtering......................................................................................34

4.3.1 Concept of Message Filtering .......................................34

4.3.2 Input Filter.....................................................................34

4.3.3 Output Filter..................................................................34

4.3.4 Filter Description (Syntax)............................................35

4.4 File System.................................................................................38

4.4.1 Structure........................................................................38

4.4.2 Data Storage in EEPROM.............................................39

4.5 Command Set Description .........................................................40

4.5.1 cd...................................................................................40

4.5.2 ls....................................................................................40

4.5.3 mkif ...............................................................................41

CAN – Ethernet Gateway

© SYS TEC electronic GmbH 2007 L-1032e_9

4.5.4 mem............................................................................... 42

4.5.5 rm.................................................................................. 43

4.5.6 write ..............................................................................43

4.5.7 cat.................................................................................. 44

4.5.8 sync ............................................................................... 44

4.5.9 version...........................................................................45

4.5.10 exit................................................................................. 45

4.5.11 reset...............................................................................45

4.5.12 ipcfg ..............................................................................46

4.5.13 siocfg............................................................................. 47

5 Gateway Configuration. 49

5.1 Fundamentals............................................................................. 49

5.2 Example for a Customer-Specific Configuration Script............50

5.3 Creating a Configuration Script................................................. 51

5.4 Resetting the Device to its Standard Configuration................... 52

5.5 Assigning Passwords .................................................................52

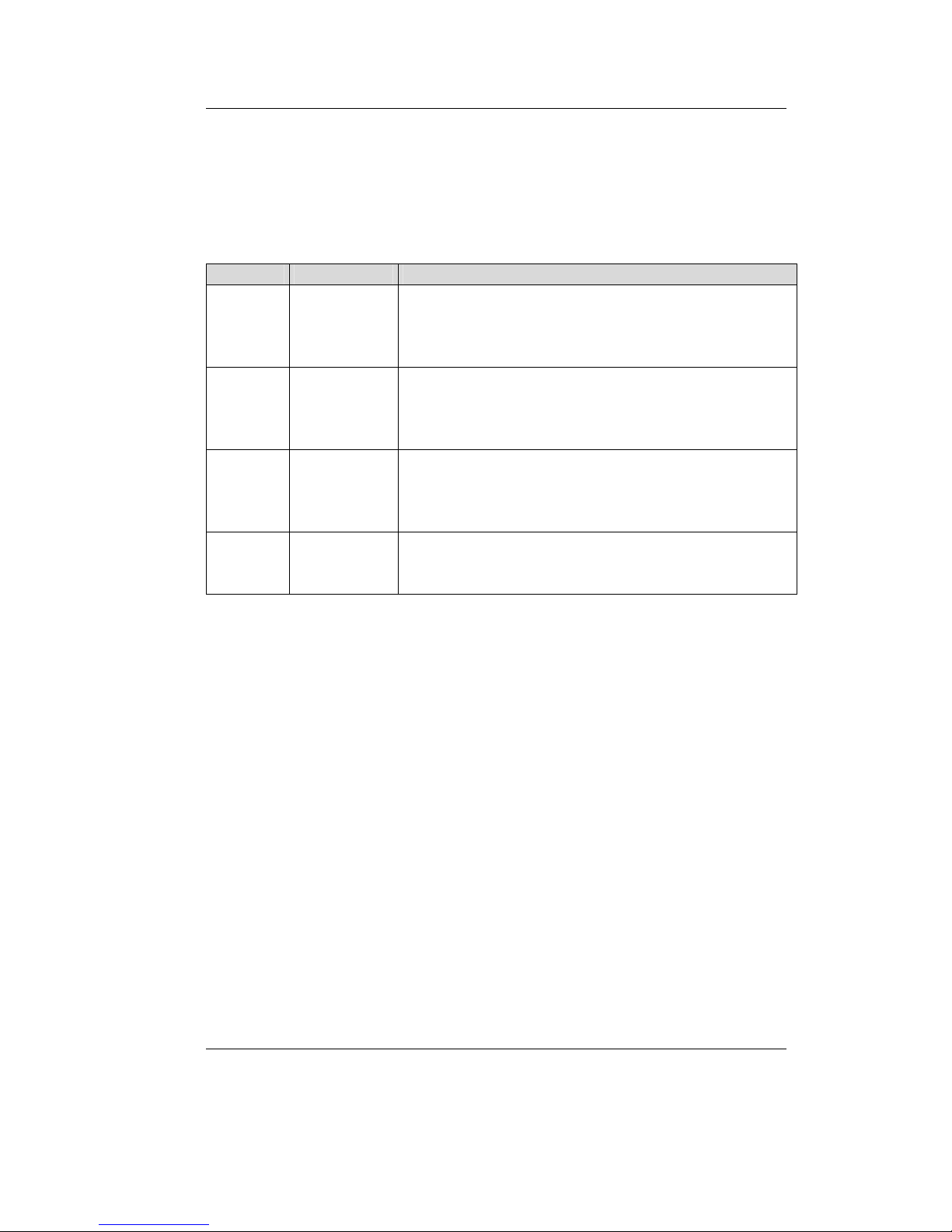

6 Error Handling ..............53

6.1 CAN-Ethernet Gateway Error Signals....................................... 53

6.2 Error Indication under Windows ...............................................56

6.3 Error Messages over CAN......................................................... 56

7 Software Support........... 59

7.1 Interfacing the CAN-Ethernet Gateway to a PC........................ 59

7.2 Driver Installation under Windows............................................ 59

7.3 Dynamic Linked Library EthCan.Dll........................................61

7.3.1 The Concept of the EthCan.Dll .................................... 61

7.3.2 EthCan.Dll Function Interface...................................... 62

7.3.2.1 EthCanGetVersion......................................... 63

7.3.2.2 EthCanInitHardware...................................... 64

7.3.2.3 EthCanDeinitHardware .................................69

7.3.2.4 EthCanReadCanMsg .....................................73

7.3.2.5 EthCanWriteCanMsg .................................... 76

7.3.2.6 EthCanGetStatus............................................ 78

7.3.2.7 EthCanGetConnectionState........................... 80

7.3.2.8 EthCanResetCan............................................ 82

7.3.3 Error Code Description................................................. 84

7.3.4 CAN Error Code Description .......................................88

7.3.5 Using the DLL Functions .............................................90

7.3.5.1 Demo project .................................................90

7.3.5.2 Starting the Demo Program........................... 91

8 Updating the device Firmware........................................................93

8.1 Preparations................................................................................ 93

8.2 Firmware download ................................................................... 94

Contents

© SYS TEC electronic GmbH 2007 L-1032e_9

Index.........................................97

CAN – Ethernet Gateway

© SYS TEC electronic GmbH 2007 L-1032e_9

Index of Figures

Figure 1: Application Example #1: Transparent Connection of two CAN

Networks using Intranet/Ethernet..............................................

3

Figure 2: Application Example #2: Remote Diagnostics of CAN

Networks on a Service Computer over the Internet ..................

5

Figure 3: View of the CAN-Ethernet Gateway......................................... 8

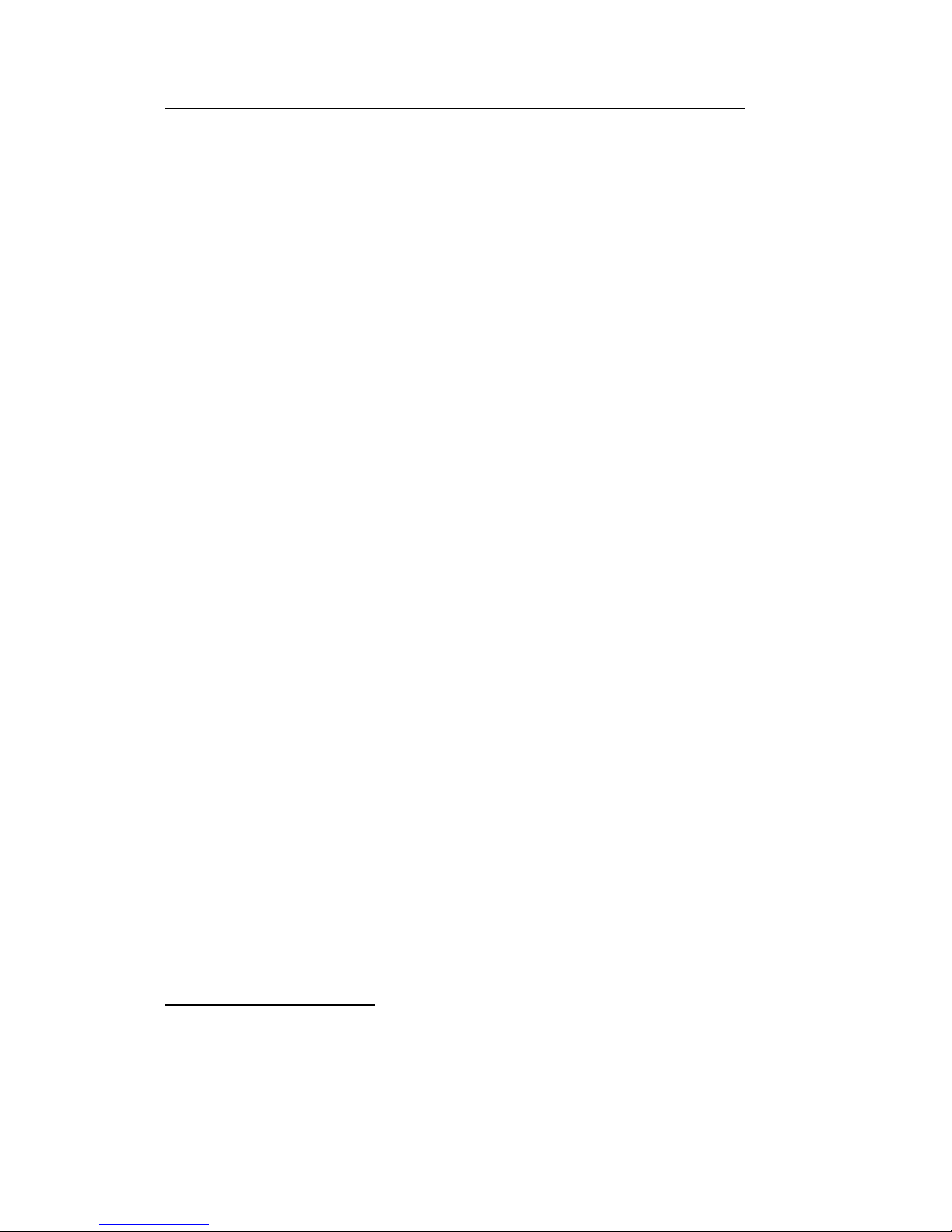

Figure 4: HyperTerminal Configuration (1)............................................ 15

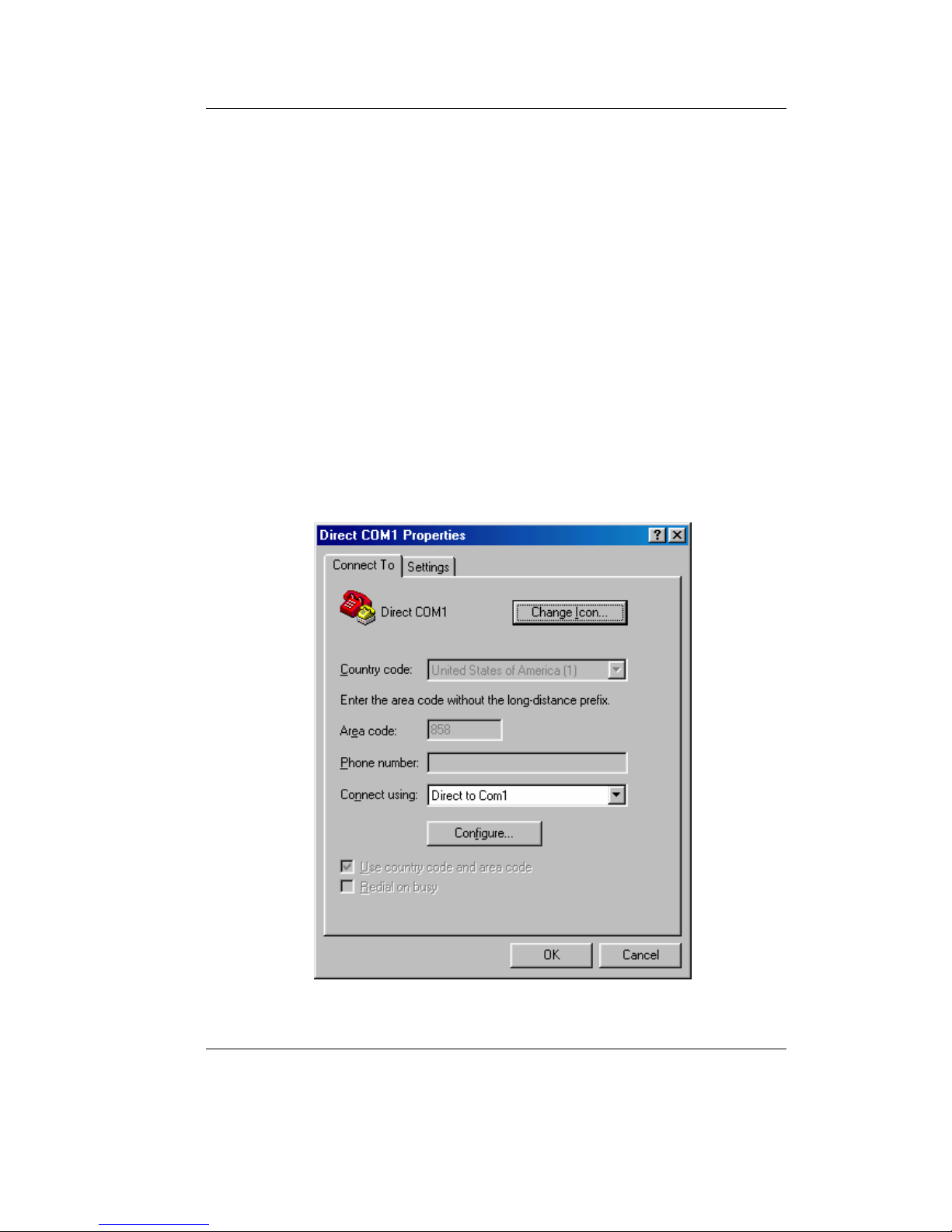

Figure 5: HyperTerminal Configuration (2)............................................ 16

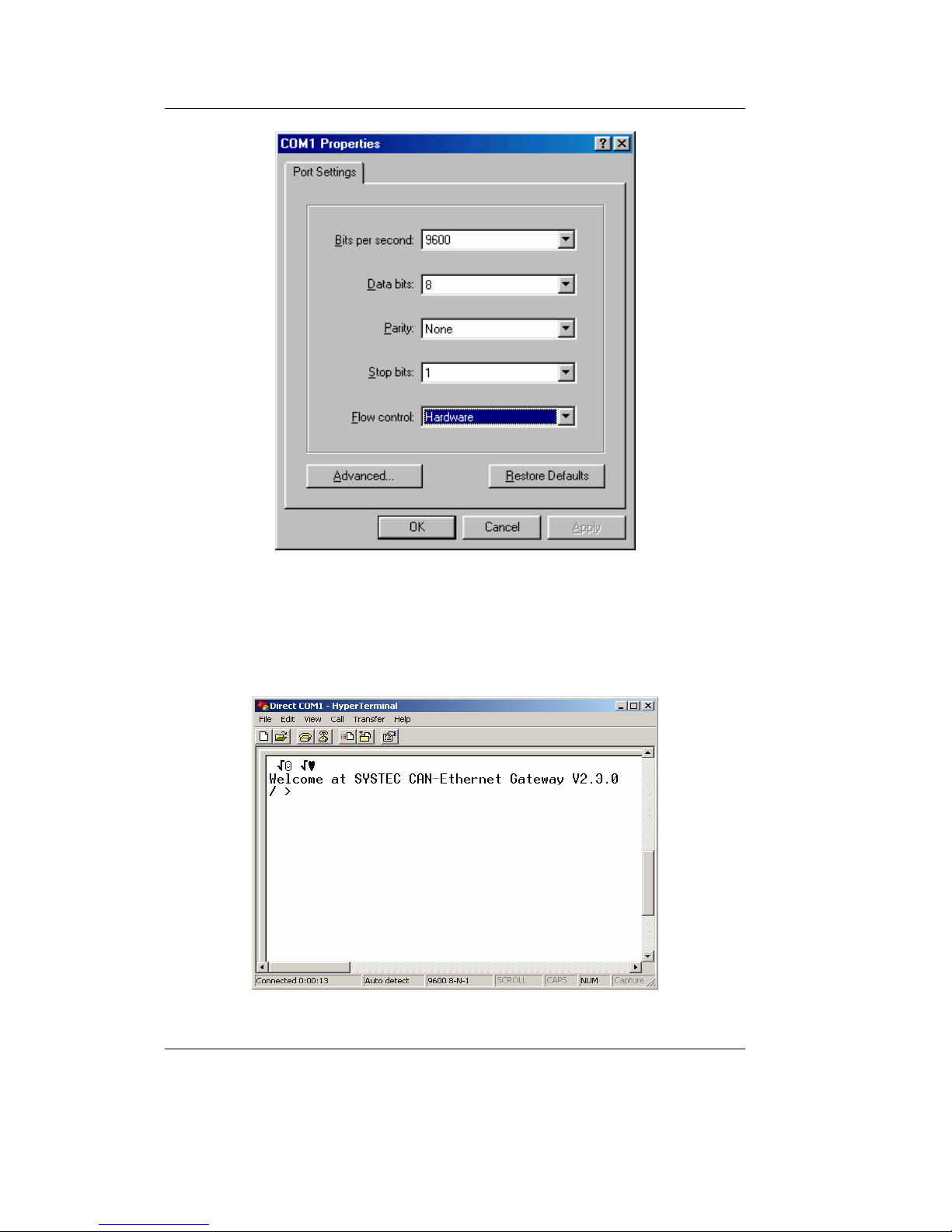

Figure 6: CAN-Ethernet Gateway Start Message................................... 16

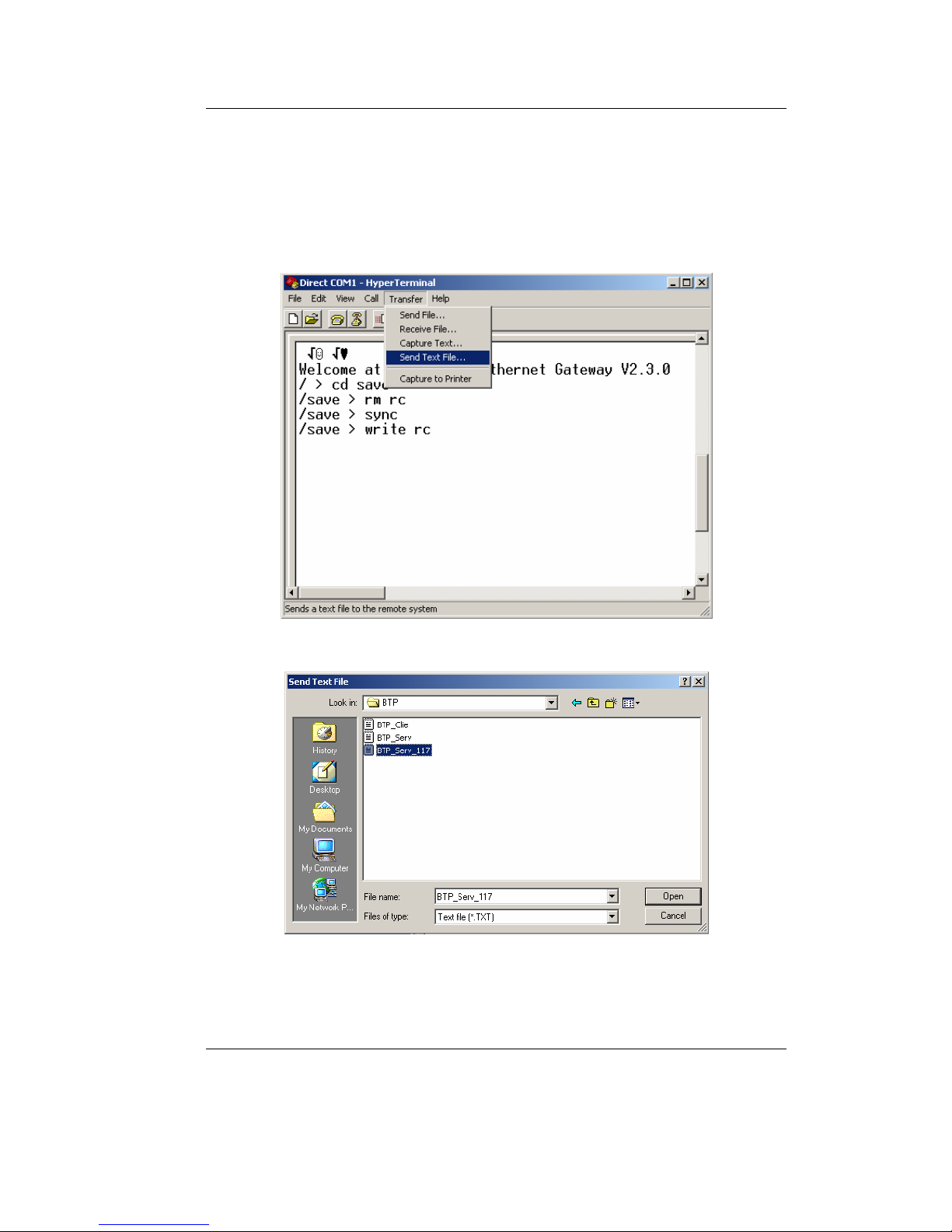

Figure 7: Sending a Configuration File via HyperTerminal................... 19

Figure 8: Selecting a Configuration File................................................. 19

Figure 9: Successful Transmission of a Configuration File, Terminate

with Crtl+D..............................................................................

20

Figure 10: Finishing the Configuration..................................................... 20

Figure 11: Verifying the Selected Configuration...................................... 21

Figure 12: CAN-Ethernet Gateway Functional Overview........................ 23

Figure 13: File System Structure............................................................... 38

Figure 14: Hardware Parameter Structure Overview................................ 65

Figure 15: CAN-Ethernet-Gateway Transfer Protocols............................ 65

Figure 16: CAN-Ethernet Gateway Connection Status ............................ 67

Figure 17: CAN Message Structure .......................................................... 73

Figure 18: The CAN timestamp structure................................................. 74

Figure 19: CAN-Status Structure.............................................................. 78

Figure 20: MemTool software................................................................... 94

Figure 21: Memory sectors of the CAN-Ethernet Gateway...................... 95

Figure 22: Memory areas and sector assignment...................................... 95

Index of Tables

© SYS TEC electronic GmbH 2007 L-1032e_9

Index of Tables

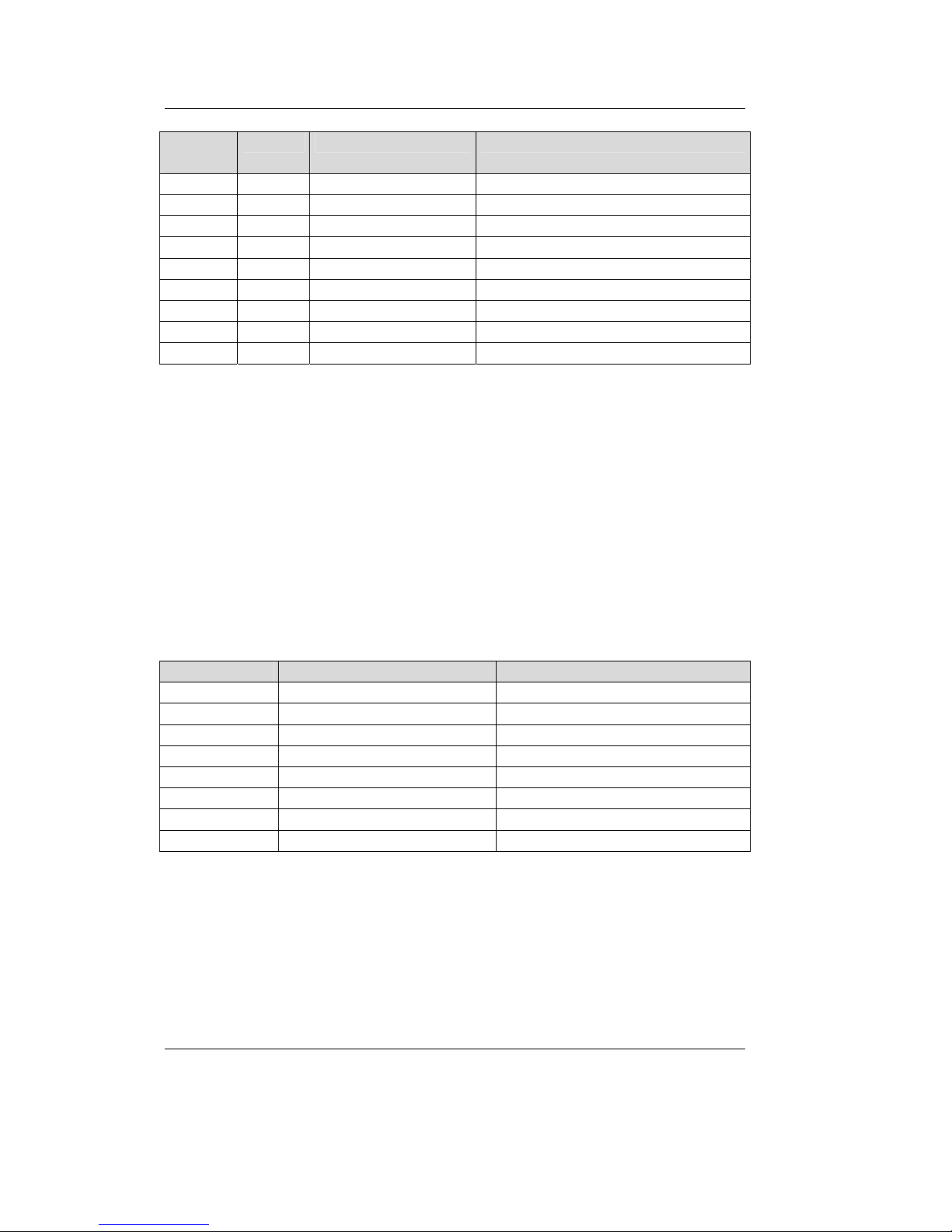

Table 1: CAN Connector Pin Assignment.............................................10

Table 2: Ethernet Connector Pin Assignment........................................ 10

Table 3: RS-232 Interface Connector Pin Assignment..........................11

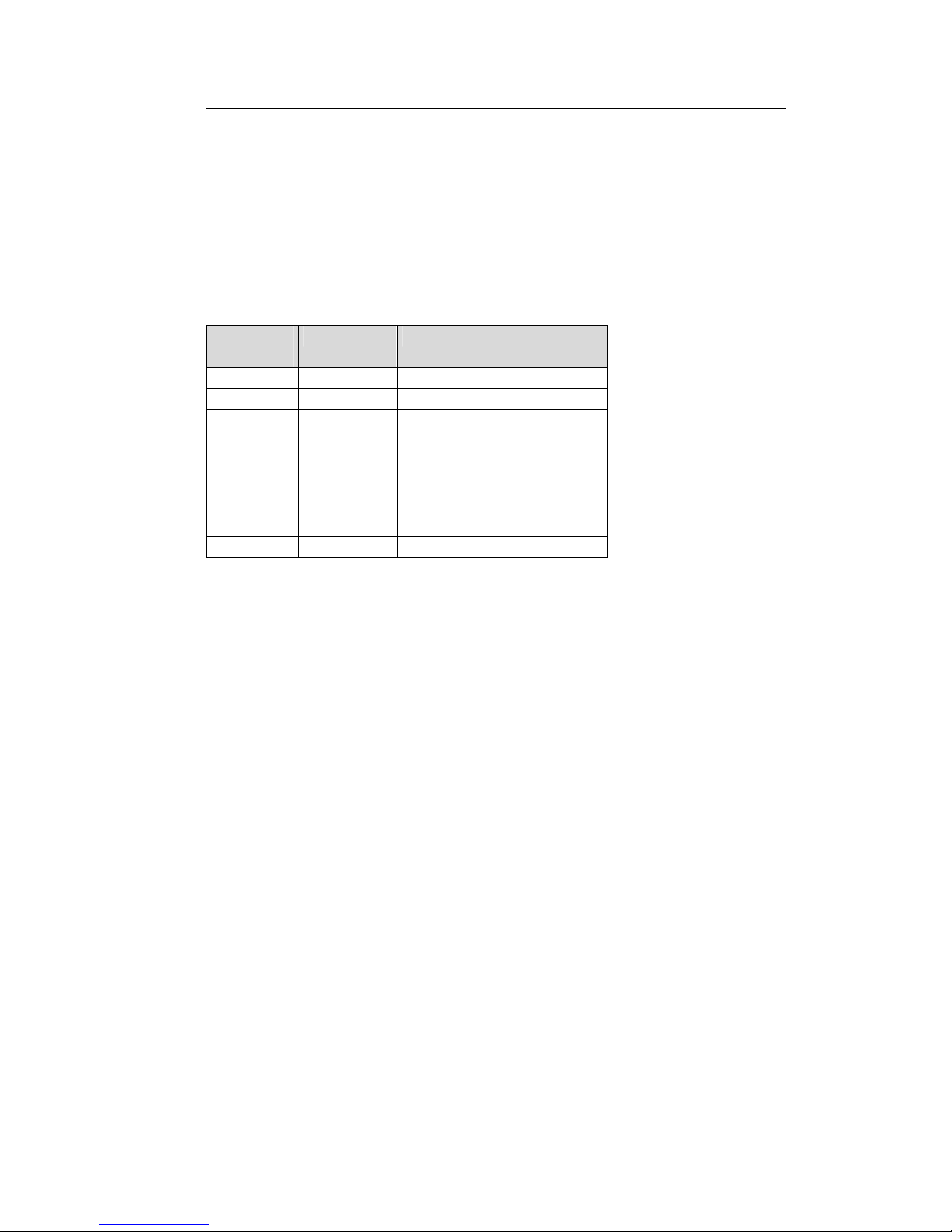

Table 4: Meaning of the Device Status LEDs........................................12

Table 5: Meaning of the Switches..........................................................13

Table 6: Interface Overview...................................................................24

Table 7: Error Display Overview...........................................................55

Table 8: Structure of a CAN Emergency Message ................................56

Table 9: File Structure of the CAN-Ethernet Gateway Utility Disk......60

Table 10: Available Functions within the Software States......................62

Table 11: EthCan.Dll Interface Function Error Codes.............................84

Table 12: CAN Error Codes.....................................................................88

CAN – Ethernet Gateway

© SYS TEC electronic GmbH 2007 L-1032e_9

Introduction

© SYS TEC electronic GmbH 2007 L-1032e_9 1

1 Introduction

1.1 Fundamentals

Internet communication via TCP/IP is finding ever-increasing

implementation in industrial applications. The CAN-Ethernet Gateway

from SYS TEC electronic GmbH is a solution that enables CAN

networks to be coupled together over the Internet/Ethernet, whereby

remote monitoring and control is possible. The CAN-Ethernet

Gateway controls networked communication and makes a transparent

CAN-based application interface available to the user.

The device supports a transparent, protocol-independent transfer of the

CAN messages, thus allowing its implementation into a wide range of

possible applications. Furthermore, the CAN-Ethernet Gateway can be

used with various higher layer CAN protocols (e.g. CANopen, SDS,

J1939, DeviceNet or other proprietary protocols).

The CAN-Ethernet Gateway can be used in CAN networks with a

transfer rate of up to 1 MBit/s corresponding to CAN Specification

2.0A (11-bit CAN identifier) and 2.0B (29-bit CAN identifier). For

each CAN message a time stamp can be created by the CAN-Ethernet

Gateway that is transferred along with the data.

The CAN-Ethernet Gateway can be configured via an asynchronous

serial interface (UART with RS-232 using hardware flow control) or

via a Telnet connection. The user can therefore adapt the functions of

the CAN-Ethernet Gateway to the specific application environment.

CAN – Ethernet Gateway

2 © SYS TEC electronic GmbH 2007 L-1032e_9

For communication between the CAN-Ethernet Gateways a BTP/IPbased network protocol (BTP = Block Transfer Protocol) is used. This

enables the CAN messages to be routed over the Ethernet with

minimal delay time. The TCP/IP protocol time for establishing and

ending a network connection is thereby eliminated.

As an option, the CAN messages can also be transferred using a

TCP/IP network protocol.

The Gateway firmware is designed for high data throughput. The

optimized buffer management requires minimal resources for copying

and temporarily storing data. Transmission rate spikes that may occur

in the CAN network will be easily handled. If a large amount of data

is transmitted, multiple CAN messages are combined in one UDP or

TCP package and transmitted as a single block.

The CAN-Ethernet Gateway identifies errors and sends CAN

messages (error messages) that contain the reason for the error. The

error message's CAN identifier is configurable (refer to section

6.3).

1.2 Application Fields

1.2.1 Connecting Two CAN Networks over Ethernet

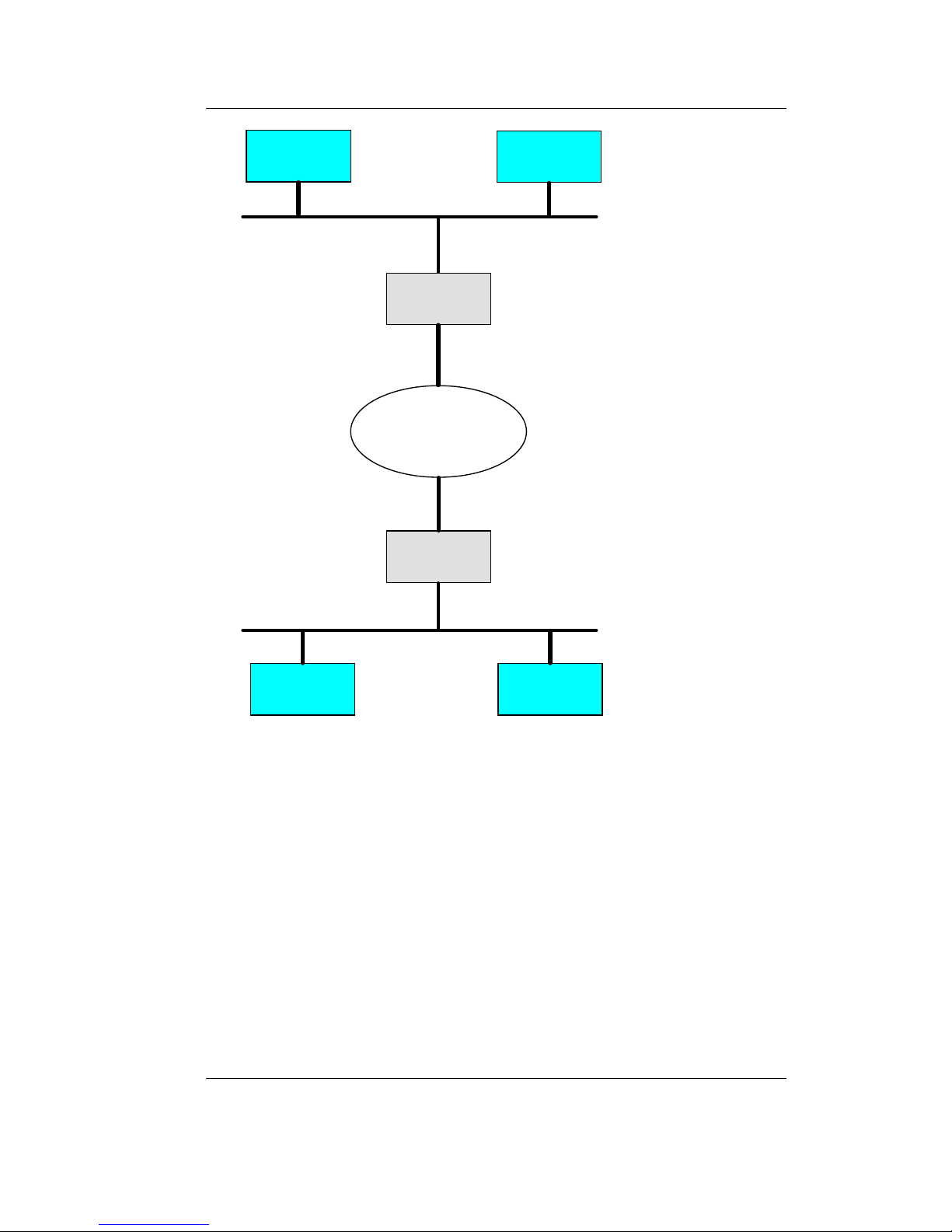

A typical application is the connection of two CAN networks via

Ethernet over a great distance. A CAN-Ethernet Gateway is present in

each CAN network. CAN messages are transferred transparently

between the CAN-Ethernet Gateways.

The firmware of the CAN-Ethernet Gateway allows for filtration of

the CAN messages to be sent on, thus only the relevant data gets

transmitted over the Ethernet.

The principle possibilities for building a network structure using

CAN-Ethernet Gateways are represented in

Figure 1.

Introduction

© SYS TEC electronic GmbH 2007 L-1032e_9 3

Figure 1: Application Example #1: Transparent Connection of two CAN

Networks using Intranet/Ethernet

Intranet

CAN-Ethernet

Gateway

CAN-Ethernet

Gateway

CAN - Bus 1

CAN - Bus 2

Ethernet

Ethernet

CAN-Devic e C CAN-Devic e D

CAN-Devic e A

CAN-Devic e B

CAN – Ethernet Gateway

4 © SYS TEC electronic GmbH 2007 L-1032e_9

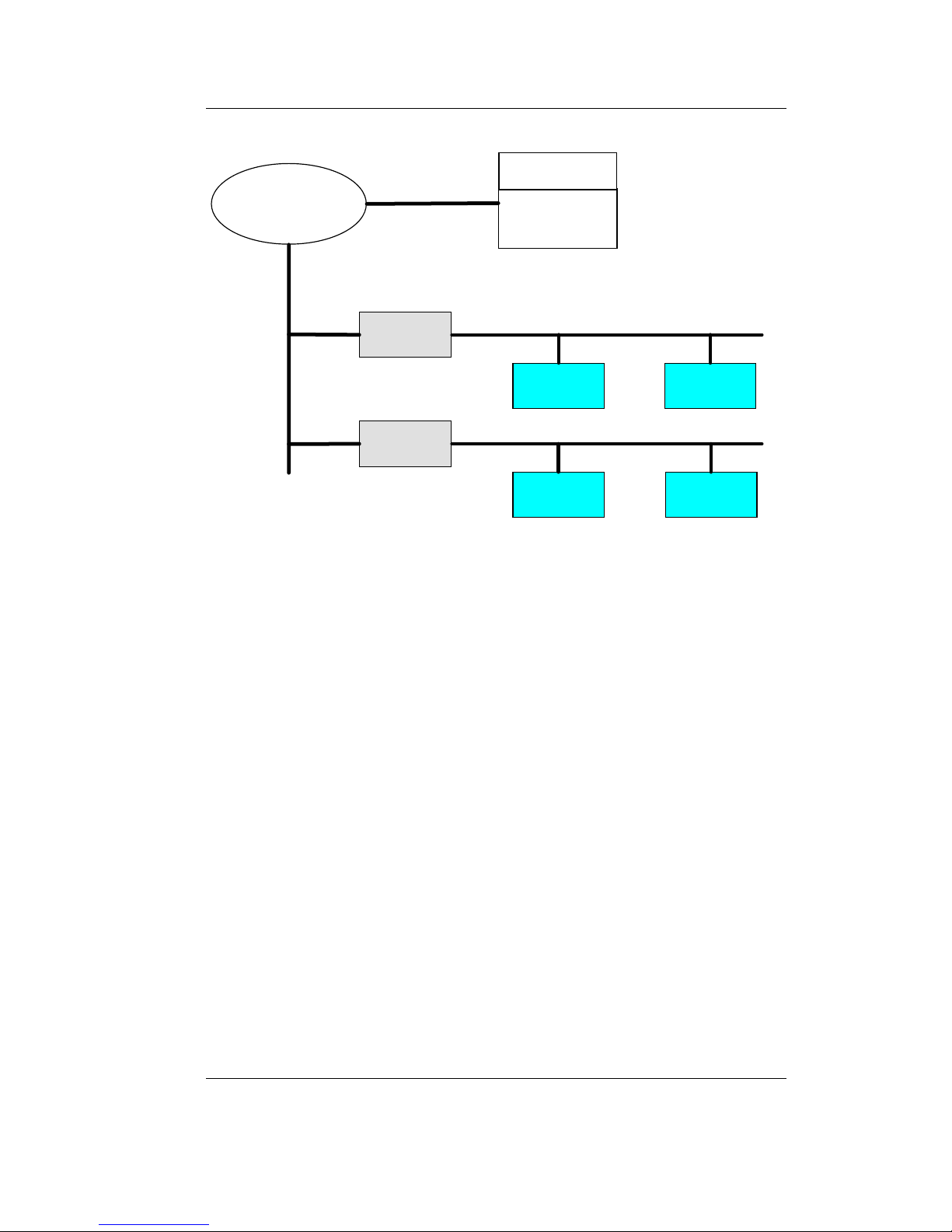

1.2.2 Remote Diagnostics and Configuration of CAN Networks

Another possible application is the connection of a CAN network with

a computer. The user only requires a network connection over the

Ethernet in order to establish a connection with the remote CAN

network. No CAN hardware is required on the host computer.

A virtual CAN-Ethernet Gateway in the form of PC software (DLL) is

available for MS Windows systems. The interface of the virtual CANEthernet Gateway corresponds to a CAN driver.

Thus it is possible to use standard CAN programs, which use a CAN

driver (e.g. CANopen configuration tools like CANsetter

TM

and

ProCANopen

TM

or CAN analyzer tools like PCAN-ExplorerTM or

PCANview

TM

).

The virtual CAN-Ethernet Gateway for PC extends the CAN network

over the Ethernet/Intranet/Internet into the office and offers new

possibilities for configuration and diagnosis of CAN networks in the

field level. The computer in the communication management level

requires an Ethernet connection to the field level, however it offers the

convenience of familiar CAN and CANopen tools.

The functions and parameters of the Gateway itself can be accessed

and modified remotely using the Telnet protocol.

Introduction

© SYS TEC electronic GmbH 2007 L-1032e_9 5

Figure 2: Application Example #2: Remote Diagnostics of CAN Networks on a

Service Computer over the Internet

1.3 Delivery Contents

The following parts are included in the CAN-Ethernet Gateway’s

delivery contents:

• GW-003 CAN-Ethernet Gateway (1* CAN) in housing for DIN

rail assembly, including a 2-pin and a 5-pin removable screw

clamp connector

• L-1032 User's Manual (this manual is on CD-ROM)

• CD-ROM with installation program for PCANview (SO-1010),

documentation, example configuration files (SO-1027)

• WK041 null-modem cable for configuration of the CAN-

Ethernet Gateway via RS-232

in preparation:

• GW-003-2 CAN-Ethernet Gateway (2* CAN) in housing for DIN

rail assembly, including a 2-pin and a 5-pin removable screw

clamp connector

Intranet

or Internet

virtual Gateway

CAN to Eth e rnet

Service PC

CAN-Ethernet

Gateway

CAN-Ethernet

Gateway

Ethernet

Ethernet

CAN - Bus 1

CAN - Bus 2

CAN-Device C CAN-Device D

CAN-Device A CAN-Device B

CAN – Ethernet Gateway

6 © SYS TEC electronic GmbH 2007 L-1032e_9

Technical Data

© SYS TEC electronic GmbH 2007 L-1032e_9 7

2 Technical Data

The CAN-Ethernet Gateway has the following technical features and

functions:

• Monitors and controls remote CAN networks over the Internet

• Couples two CAN networks

• Gateway configurable via Telnet (remote maintenance) or RS-232

• based on internal file system for configuration data

• capability of executing scripts (e.g. upon start up of the Gateway)

• flexible configuration through implementation of multiple

interfaces (refer to section

4.2)

• multiple filter mechanisms for CAN messages with the possibility

of prioritization

• Generation of a time stamp for CAN messages

• connection to Windows application programs for CAN and

CANopen

• 7 LEDs for visualization of the Gateway's state

• generation of CAN error messages

• high data throughput

• 10Base-T interface (10 Mbit/s) with RJ45 socket, galvanic isolated

• CAN interface according to CiA

1

DS102, up to 1 Mbit/s, high-

speed CAN according to ISO11898-1/2, galvanic isolated

• CAN bus connection, D-Sub-9 plug and 5-pin removable screw

clamp connector according to CiA DS102 or DeviceNet standard

• Supports CAN specification 2.0A (11-bit CAN identifier) and 2.0B

(29-bit CAN identifier)

• RS-232 interface via D-Sub-9, hardware flow control

• Supply voltage 24 VDC +20% -60%, reversed polarity protection

• Current draw approximately 90 mA

• Power connector, 2-position removable screw clamp connector

• Dimensions without connectors, 70 x 100 x 61 (L x B x H) mm³,

suitable for DIN/EN rail assembly

• Protection level: IP20

1

CiA, CAN in Automation, international users and manufacturers group

CAN – Ethernet Gateway

8 © SYS TEC electronic GmbH 2007 L-1032e_9

• Operational temperature range 0°C to +70°C

Figure 3: View of the CAN-Ethernet Gateway

Getting Started

© SYS TEC electronic GmbH 2007 L-1032e_9 9

3 Getting Started

3.1 Power Supply

A direct current voltage of 24 V –60% to +20% is required to operate

the device. The current draw of the device amounts to approximately

90 mA. The supply voltage is connected over a 2-pin, removable

screw clamp connector. Labels for the "+" and "–" polarity are printed

on the device's connector. Correct connection of the supply voltage is

indicated with the green "power" LED.

3.2 Network Connection

3.2.1 Connecting to a CAN Bus

A D-Sub-9 plug is provided for connection of the device to a CAN

network. Alternatively a connection via the 5-pin removable screw

clamp connector is also possible (suitable connector Weidmueller

‘Omnimate Range – raster 3,5mm’). This connector is wired parallel

to the D-Sub-9 plug. Its configuration corresponds to the DeviceNet

and CANopen standard.

The supply voltage for the CAN bus (pin 9 at D-Sub-9 or pin 5 at 5pin socket connector) is not connected in the Gateway. The CAN

shield potential is only connected between the two CAN connectors.

The CAN bus is galvanic isolated (optically isolated) from the

Gateway's internal circuitry.

CAN – Ethernet Gateway

10 © SYS TEC electronic GmbH 2007 L-1032e_9

D-Sub-9

Plug

5-pol. Signal Name Description

1 n.c. not connected

2 2 CL (CAN_L) CAN_L bus line

3 1 V- (CAN_GND) CAN Ground

4 n.c. not connected

5 3 SH (CAN_SHLD) CAN Shield

6 GND CAN Ground (optional)

7 4 CH (CAN_H) CAN_H bus line

8 n.c.

9 5 V+ (CAN_V+) not connected

Table 1: CAN Connector Pin Assignment

3.2.2 Ethernet Connection

The Ethernet (10Base-T) signals are routed to an RJ45 socket for easy

connection using a standard CAT 3 or CAT 5 network cable. For

direct connection (without a hub or switch) of a CAN-Ethernet

Gateway and a PC, a crosslink cable is required.

The Ethernet connection is galvanic isolated from the CAN-Ethernet

Gateway

Pin Name Description

1 TX+ Transmit Data +

2 TX- Transmit Data 3 RX+ Receive Data +

4 n.c. not connected

5 n.c. not connected

6 RX- Receive Data +

7 n.c. not connected

8 n.c. not connected

Table 2: Ethernet Connector Pin Assignment

Getting Started

© SYS TEC electronic GmbH 2007 L-1032e_9 11

3.2.3 RS-232 Interface

The CAN-Ethernet Gateway provides an RS-232 interface with

hardware flow control. This interface is connected to a D-Sub-9 plug.

This interface allows for configuration of the CAN-Ethernet Gateway.

This connector is specifically intended for initial configuration (refer

to section

3.5). The RS-232 interface is not galvanically separated.

DB-9 Plug,

Pin#

Name Signal Description

1 CD Carrier Detect

2 RXD Receive Data

3 TXD Transmit Data

4 DTR Data Terminal Ready

5 GND System Ground

6 DSR Data Set Ready

7 RTS Request to Send

8 CTS Clear to Send

9 RIN Ring Indicator

Table 3: RS-232 Interface Connector Pin Assignment

The CAN-Ethernet Gateway is connected to the PC via a null modem

cable.

CAN – Ethernet Gateway

12 © SYS TEC electronic GmbH 2007 L-1032e_9

3.3 Device Status Display

There are a total of 7 LEDs (refer to Table 4) for displaying the

operational state of the device. The displays are arranged according to

their meaning to the networks (refer to

Figure 3). One red and one

green LED show the state of the CAN or Ethernet network. Detailed

description of the "error" LEDs can be found in section

6.1.

LED Name Description

power Supply Voltage OK [green]

connect A connection to the other Gateway is established over

UDP or TCP [green]

error (Ethernet) Error during data transfer on the Ethernet connection

(refer to section 6.1) [red]

link Connection to Ethernet established, cabling OK [green]

active Data transfer over Ethernet [yellow]

traffic Indicates data traffic on the CAN bus [green]

error (CAN) Error during data transfer on the CAN connection (refer

to section 6.1) [red]

Table 4: Meaning of the Device Status LEDs

Getting Started

© SYS TEC electronic GmbH 2007 L-1032e_9 13

3.4 Switches

Four DIP-switches are available on the CAN-Ethernet Gateway for

configuration purposes of the device. Their function is described in the

following table:

Switch # Name Description

1 TERM Defines whether the CAN terminating resistor of

120 Ohm is active or not

ON Æ terminating resistor active/enabled

OFFÆ terminating resistor not active/disabled

2 DEFT Defines the start initialization of the CAN-Ethernet

Gateway (refer to section 3.5)

ON Æ factory default configuration will be loaded

OFFÆ user configuration will be loaded

3 BOOT Activate the “Bootstrap-Mode” of the CAN-Ethernet

Gateway (refer to section 8)

ON Æ “Bootstrap-Mode” will be entered

OFFÆ Firmware of the CAN-Ethernet Gateway starts

4 RES Reset the CAN-Ethernet Gateway (refer to section 8)

ON Æ Reset active/enabled

OFFÆ Reset not active/disabled

Table 5: Meaning of the Switches

CAN – Ethernet Gateway

14 © SYS TEC electronic GmbH 2007 L-1032e_9

3.5 Initial Setup and Operation

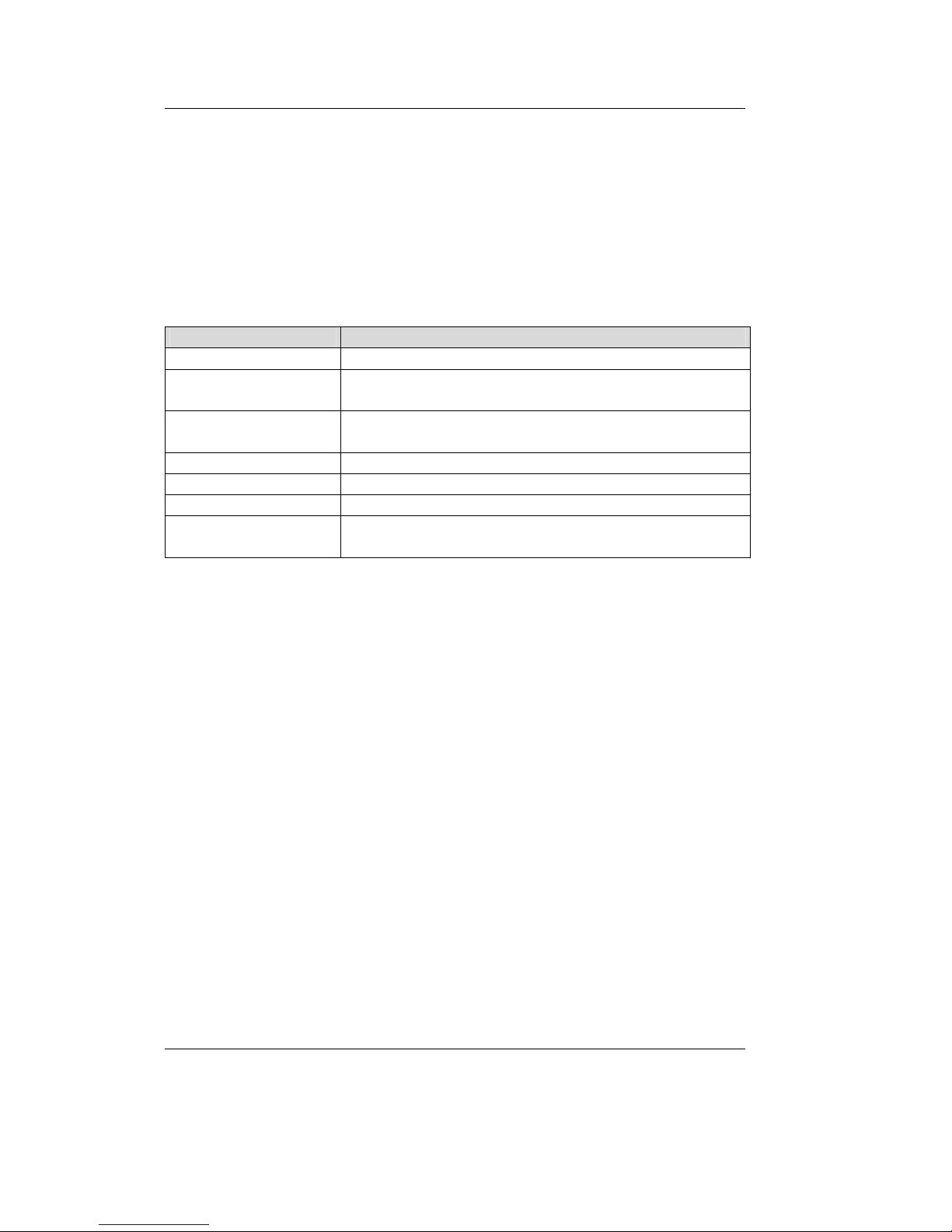

3.5.1 Standard Configuration

The CAN-Ethernet Gateway has the following standard (factory

default) configuration (Setting the Configuration Script, refer to

section

5.1):

Ethernet/Internet settings

IP address of the CAN-Ethernet Gateway: 192.168.10.111

Subnet- Mask: 255.255.255.0

Standard Gateway: 192.168.10.1

one UDP

2

server

one TCP server

CAN settings

CAN bit rate: 1 Mbit/s

CAN identifier for error messages: 0xFE

RS-232 interface

Baud rate: 9600 baud

Data bits: 8

Parity: none

Stop bits: 1

Protocol/flow control: hardware

2

BTP: Block Transfer Protocol for transmitting CAN messages via UDP/IP

Getting Started

© SYS TEC electronic GmbH 2007 L-1032e_9 15

3.5.2 Initial Configuration using the RS-232 Interface

The CAN-Ethernet Gateway must be configured to meet the specific

application requirements before CAN messages can be transmitted.

The following steps are required:

• Connect the included null modem cable to the RS-232 interface of

the CAN-Ethernet Gateway and a free serial interface on the PC

(e.g. COM1).

• Start a terminal program on the PC, the program "HyperTerminal"

will be used for the following examples, this program is part of the

MS-Windows operating system (if you use a different terminal

program, appropriate configuration must be made).

• Set the baud rate and the protocol for the serial interface (e.g.

COM1) in HyperTerminal (refer to

Figure 4 and Figure 5).

Figure 4: HyperTerminal Configuration (1)

CAN – Ethernet Gateway

16 © SYS TEC electronic GmbH 2007 L-1032e_9

Figure 5: HyperTerminal Configuration (2)

• Be sure that you have correctly connected the supply voltage

(polarity) and then turn on the power.

Figure 6: CAN-Ethernet Gateway Start Message

Getting Started

© SYS TEC electronic GmbH 2007 L-1032e_9 17

Proper startup of the device is indicated by a (refer to Figure 6)

Welcome at SYSTEC CAN-Ethernet Gateway V2.3.0

/ >

message.

The device then waits for the input of commands. The startup message

portion "V2.3.0" represents the current version number and may vary.

Since the CAN-Ethernet Gateway is based on an internal file system,

there are commands for navigation. These commands are (refer to

section

4.5):

ls to show the contents of the current directory,

cd to switch the current directory

write to create a new file

rm to delete a directory/file

sync in order to store a file in non-volatile memory (EEPROM)

Predefined files are included for initial configuration. These are

located on the CD under

\Products\GW-003\SO-1027\RC-Files\UDP (for the UDP transfer) or

\Products\GW-003\SO-1027\RC-Files\TCP (for the TCP transfer).

Each folder contains a file for a server configuration

UDP_Server_1CAN.txt or TCP_Server_1CAN.txt and a file for a

client configuration UDP_Client_1CAN.txt or TCP_Client._1CANtxt.

• Copy these files into a folder of your choice on your PC (e.g.

C:\SYSTEC\GW-003\RC-Files). Before you transfer one of these

files to the CAN-Ethernet Gateway you must modify the file. Open

the file Udp_Server_1CAN.txt with an editor.

• Modify the local IP address, the subnet mask and the standard

Gateway address to the values that correspond to your application

requirements (refer to section

4.5.12).

for example:

CAN – Ethernet Gateway

18 © SYS TEC electronic GmbH 2007 L-1032e_9

ipcfg 192.168.10.117 255.255.255.0 192.168.10.1

• Set the CAN bitrate and the CAN identifier for error messages,

(refer to section

4.2.4)

for example: to 125 kBit/s and CAN identifier 0x81

/if/can0 baud:4 canid:81 on

• Save the configuration file under a different name,

for example

UdpServer_1CAN_117.txt

The generated configuration file is written to the CAN-Ethernet

Gateway as follows:

1. Change to the directory /save

/ >cd /save↵

/save >

2. Erase the existing configuration file rc

/save >rm rc↵

/save >sync↵

Getting Started

© SYS TEC electronic GmbH 2007 L-1032e_9 19

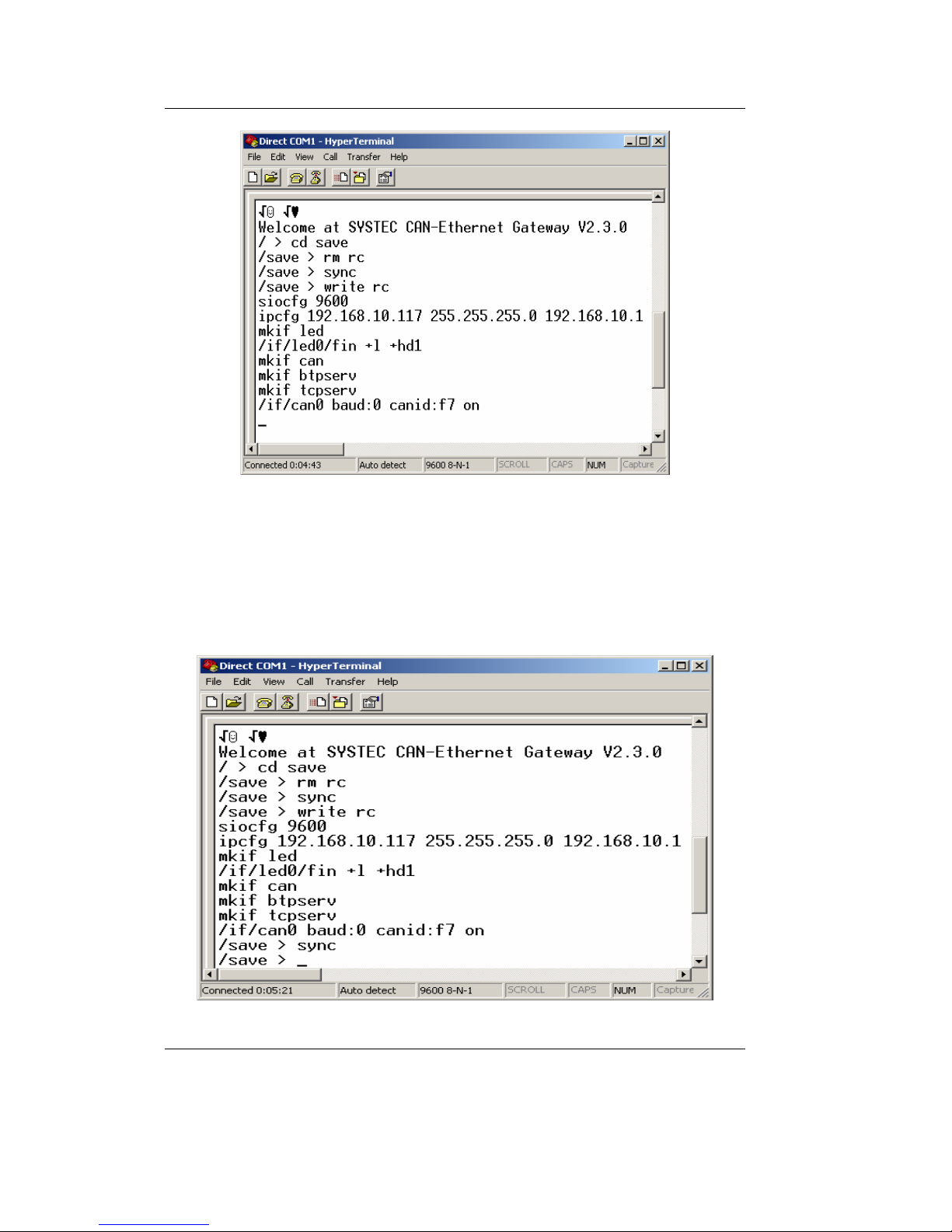

3. Write a new configuration file rc

/save >write rc↵

After you’ve input the command you can send a file to the CANEthernet Gateway using the HyperTerminal tool. The following

images show how to do this:

Figure 7: Sending a Configuration File via HyperTerminal

Figure 8: Selecting a Configuration File

CAN – Ethernet Gateway

20 © SYS TEC electronic GmbH 2007 L-1032e_9

Figure 9: Successful Transmission of a Configuration File, Terminate with

Crtl+D

4. To end the transfer push Ctrl+D. The Gateway will show the

execution with the prompt

/save >

5. Save the file rc with the command sync in EEPROM.

Figure 10: Finishing the Configuration

Getting Started

© SYS TEC electronic GmbH 2007 L-1032e_9 21

6. Set the switch 2 "DEFT" to OFF and restart the CAN-Ethernet

Gateway. Upon restart of the CAN-Ethernet Gateway with poweron or via the command

reset, the saved configuration file will be

executed and the CAN-Ethernet Gateway will be configured.

/save >reset↵

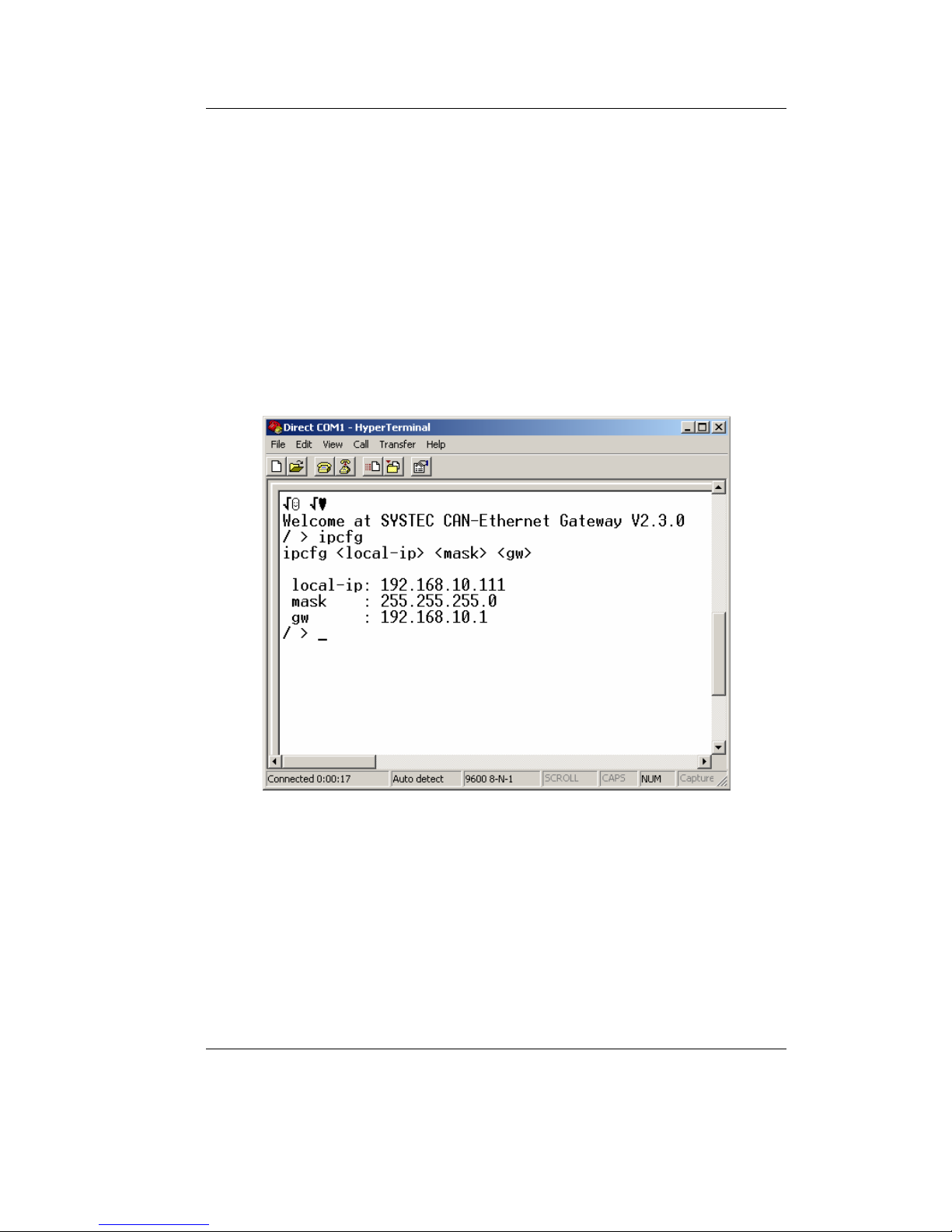

7. Verify the new configuration by inputting the command

ipcfg (see

Figure 11). The parameter IP address, subnet mask and standard

gateway stored in the configuration file all correspond to their

settings. Now the Gateway is configured and can be accessed over

the Ethernet (e.g. Telnet).

Figure 11: Verifying the Selected Configuration

This concludes the initial start up of the device.

The CAN-Ethernet Gateway functions with different interfaces (refer

to section

4.2), which enable the data exchange over the Ethernet and

CAN. Interfaces are created with the command

mkif and deleted with

the command

rm. All created interfaces appear in the folder /if. An

interface can be addressed and configured via a direct call to the

directory (refer to section

4.2.4).

CAN – Ethernet Gateway

22 © SYS TEC electronic GmbH 2007 L-1032e_9

3.5.3 Configuration and Operation using Telnet

Configuration of the CAN-Ethernet Gateway during operation is also

possible via Telnet (TCP port 23). The function parameters are the

same as those of the RS-232 interface. Use of Telnet also enables

configuration of remote CAN-Ethernet Gateways. A condition for this,

however, is the initial configuration of the IP address with the

command

ipcfg (refer to section 4.5.12). Without this initial

configuration of the IP address the CAN-Ethernet Gateway can only

be addressed via its standard configuration (refer to section

3.5.1).

A Telnet client is already included in the Windows package. This

Telnet client can be called via

telnet <Address>. Under Linux the

programs

telnet or netcat can be used.

Loading...

Loading...