Page 1

deltawaveC-F/P

Manual

1 systec Controls Mess- und Regeltechnik GmbH

Manual

deltawaveC-F/P

Ultrasonic flow and heat measurement

portable

Stationary

Ver. 1.43.xx

Page 2

deltawaveC-F/P

Manual

2 systec Controls Mess- und Regeltechnik GmbH

Table of content

Table of content ........................................................................................................ 2

1 Preamble ........................................................................................................... 5

2 About this manual .............................................................................................. 6

3 deltawaveC-F/P & components ......................................................................... 7

3.1 Approvals / EMC .................................................................................... 7

3.2 Scope of delivery deltawaveC-F / P basic package ............................... 8

3.3 Transducer............................................................................................. 9

3.4 Safety instructions ............................................................................... 10

3.5 Important instructions for the use of deltawaveC-P ............................. 10

4 Measuring principle.......................................................................................... 11

4.1 2-channel device applications .............................................................. 13

5 deltawaveC-F/P Interfaces .............................................................................. 14

5.1 Overview deltawaveC-P ...................................................................... 14

5.2 Overview deltawaveC-F ....................................................................... 15

5.3 Connection notes ................................................................................. 16

6 Operating ......................................................................................................... 17

6.1 Control Buttons .................................................................................... 17

6.2 How to navigate ................................................................ ................... 17

6.3 Select measurement channel .............................................................. 17

7 First Start ......................................................................................................... 18

7.1.1 Adjustment of the display language ................................................ 18

7.1.2 Navigation in main menu ................................................................ 19

7.1.3 Setting time and date ...................................................................... 20

8 Preparing for measurement deltawaveC-F/P ................................................... 21

8.1 Preparation of the measurement / installation location ........................ 21

8.1.1 Inlet and outlet distances ................................................................ 21

8.1.2 Basic principles for ultrasonic transducer assembly ........................ 23

8.1.3 Ultrasonic sensor Mounting on horizontal pipelines ........................ 23

8.1.4 Ultrasonic transducer on uneven surfaces ...................................... 24

8.2 Fundamentals of parameterization ...................................................... 25

8.3 Parameterization with the Quick Setup ................................................ 26

8.4 Sensor assembly / Sensor distance ..................................................... 33

8.4.1 Introduction to the installation of ultrasonic transducers ................. 33

8.4.2 Mounting ultrasonic transducer ....................................................... 34

8.4.3 Correct selection of transducer types .............................................. 35

8.4.4 Correct selection of mounting options ............................................. 35

8.4.5 Mounting of the Transducer in V-Mode or W-Mode ....................... 36

8.4.6 Mounting the ultrasonic transducers based on the Z method ......... 38

8.4.7 Mounting the ultrasonic transducers at two crossed measuring paths

40

8.5 Zero Setting ......................................................................................... 41

9 Heat measurement .......................................................................................... 42

Page 3

deltawaveC-F/P

Manual

3 systec Controls Mess- und Regeltechnik GmbH

9.1 Introduction .......................................................................................... 43

9.2 Installing the Pt100 .............................................................................. 44

9.3 Parameterization of the Pt100 for the heat quantity measurement ...... 45

10 Measuring windows deltawaveC-F/P ........................................................ 46

10.1 Headline .............................................................................................. 46

10.2 Measuring window "Flow 1" ................................................................. 47

10.3 Measuring window "Flow 2" ................................................................. 48

10.4 The measuring window "heat quantity" ................................................ 49

10.5 Password protection ............................................................................ 50

10.6 The measurement windows of the 2-channel deltawaveC-F ............... 51

11 The main menu (complete menu) ............................................................. 52

11.1 Loading, saving and managing parameter data ................................... 52

11.2 The pipe parameters ............................................................................ 54

11.3 The Fluid Setup ................................................................................... 55

11.4 The Transducer Setup ......................................................................... 56

11.5 Parameterization of the inputs and outputs ......................................... 57

11.5.1 Parameterization of the 4-20mA outputs ......................................... 57

11.5.2 Parameterization of the relay .......................................................... 59

11.5.3 Parameterization of the pulse output .............................................. 60

11.5.4 Impulse-Overflow-Error; IOE ........................................................... 61

11.6 Serial communication, Modbus & Logger ............................................ 61

11.6.1 Serial data transmission .................................................................. 61

11.6.2 Modbus ........................................................................................... 63

11.6.3 The Data Logger ............................................................................. 64

11.6.3.1 Activation of the data logger function:.................................... 64

11.6.3.2 Administration and structure of log data ................................ 65

11.6.3.3 Starting a time-controlled data record.................................... 65

11.6.3.4 Cancelling a time-controlled data record ............................... 67

11.6.3.5 Quick-Logger ......................................................................... 67

11.7 Systems Settings ................................................................................. 68

11.7.1 Editing the time and date ................................................................ 68

11.7.2 Changing the indicator light............................................................. 68

11.7.3 Changing the menu language ......................................................... 69

11.7.4 System test ..................................................................................... 69

11.7.5 System information ......................................................................... 70

11.7.6 System Reset .................................................................................. 70

11.8 Unit selection ....................................................................................... 71

11.9 Calibration ........................................................................................... 72

11.9.1 Flow-Offset ...................................................................................... 72

11.9.2 Matching the Pt100 ......................................................................... 72

11.9.3 Pt100 Offset .................................................................................... 72

11.9.4 Calibration of analogue outputs ...................................................... 73

11.9.5 Parameterization of a flow velocity characteristic ............................ 73

11.10 Miscellaneous Parameters .................................................................. 75

11.10.1 Damping & Burnout ......................................................................... 75

11.10.2 Cut off Flow ..................................................................................... 76

Page 4

deltawaveC-F/P

Manual

4 systec Controls Mess- und Regeltechnik GmbH

11.10.3 Zero ................................................................................................ 76

11.10.4 The totalizer (counters) ................................................................... 76

11.10.5 Sensor distance ................................ .............................................. 78

12 Additional information about the hardware ............................................... 79

12.1 Hardware and Software Reset ............................................................. 79

12.2 Data export and import ........................................................................ 80

12.3 Parameterization of the deltawaveC-F pulse output hardware ............ 81

12.3.1 Operating mode 1: High Side (PNP-Switch) ................................... 82

12.3.2 Operating mode 2: LOW Side (NPN-Switch) ................................. 83

12.3.3 Operation Mode Push-Pull .............................................................. 84

12.4 RS232 / RS485 Interfaces ................................................................... 85

13 Tips and Tricks ......................................................................................... 87

13.1 Measuring unknown fluids ................................................................... 88

14 Troubleshooting ........................................................................................ 90

14.1 The Oscilloscope Window ................................................................... 91

14.2 Signal analysis ..................................................................................... 92

14.2.1 Signal-to-noise ratio (SNR) ............................................................. 93

14.2.2 Signal sharpness ............................................................................ 95

14.2.3 Signal decoupling on small pipelines .............................................. 96

14.2.4 The Auto window function / AFC-Technology ................................. 97

14.3 The diagnose window of the deltawaveC-F/P ...................................... 99

14.4 Integrated sensor test function........................................................... 100

14.5 What to do if the pipe is not fully filled? .............................................. 101

14.6 Checklist ............................................................................................ 102

Appendix A – Material data ................................ ................................................... 105

Appendix B – Technical data ................................................................................ 108

Appendix C – Modbus register overview .............................................................. 110

Appendix D – Transducer type overview .............................................................. 112

Appendix E – Mounting equipment and accessories ............................................ 114

Page 5

deltawaveC-F/P

Manual

5 systec Controls Mess- und Regeltechnik GmbH

1 Preamble

Welcome to the team of deltawaveC-F/P users and many thanks for using

an ultrasonic clamp-on flowmeter from systec Controls GmbH Germany.

deltawaveC-F/P was developed based on the KISS principle – “keep it safe

and simple”.

That means maximum user friendliness paired with optimal and accurate

measurements.

Our aim is to fulfil these aspirations both now and in the future. Our

strength lies in continually improving and optimising our products and we

want you to be part of this.

deltawaveC-F/P is an important product for us and not just one product on

a long list of others.

Thanks to your competent and constructive suggestions you have helped

to co-create deltawaveC and contribute to its success.

Please don´t hesitate to share your expert knowledge about deltawaveCF/P with us.

We wish you all the best and great success with using deltawaveCF/P!

Page 6

deltawaveC-F/P

Manual

6 systec Controls Mess- und Regeltechnik GmbH

2 About this manual

You don't have much time for reading? Use the beacon!

Next to the chapters you will find red, orange or green dots. They will help

you to find a quick introduction to the deltawaveC-F/P

Newcomer?

You have never worked with an ultrasonic meter before?

Start at the first chapter. You will receive a step-by-step introduction to

ultrasonic measuring technology.

Advanced?

You have occasionally used ultrasonic measuring equipment?

Start with chapter 10.1.3 "Quick setup"

Start with the chapters that are marked with an orange spot. You may also

want to continue reading the chapters with the green spot.

Professional?

You already have professional knowledge of ultrasonic measuring

systems?

Start with the deltawaveC-F Getting Started (separate attachment)

You may also want to read the green dot chapters

The fields identified with an exclamation mark contain important

information that relates to the basic data and operation of the

device.

The fields identified with the “i“ contain supplementary and helpful

information.

The instruction manual describes the function of both deltawaveC-P and

deltawaveC-F in 1-channel and 2-channel version. In addition to the chapters

you will find the corresponding pictograms. This indicates which of the

devices the chapter applies to.

deltawaveC-P

portable deltawaveC (1 Channel)

deltawaveC-F

stationary deltawaveC

1CH = 1 Channel; 2CH = 2 Channel

Page 7

deltawaveC-F/P

Manual

7 systec Controls Mess- und Regeltechnik GmbH

3 deltawaveC-F/P & components

deltawaveC-F/P key points:

deltawaveC-F/P is a clamp-on ultrasonic flow meter for liquids in

completely filled pipelines.

deltawaveC-F/P works based on the transit time method.

deltawaveC-F/P provides heat measurement by default. Clamp-on Pt100

temperature sensors are available as an optional.

The power is supplied via integrated AC-power supply. For deltawaveC-F

DC-power supply is available.

The device supports measurements on pipelines with diameters in the

range DN10 to DN6000 (depending on the sensor used)

Temperature range (fluid): –40°C to +150°C (equates the temperature

range of the clamp-on ultrasound transducers)

deltawaveC-F/P is equipped with an electrically isolated relay output, as

well as 4 to 20 mA current and impulse outputs that can be operated in

active and passive mode.

The stationary deltawaveC-F can optionally be equipped with an RS232 or

RS485 interface card as well as with two additional analogue inputs.

3.1 Approvals / EMC

deltawaveC-F/P is compliant with the following European

Directives and Standards:

2014/35/EU Low voltage directive

2014/30/EU Electromagnetic compatibility

Inspection specifications:

EN 55011 (2011-04)

EN 61000-4-2 (2009-12)

EN 61000-4-3 (2011-04)

EN 61000-4-4 (2013-04)

EN 61000-4-5 (2015-03)

EN 61000-4-6 (2014-08)

EN 61000-4-8 (2010-11)

EN 61000-4-11 (2005-02)

Inspection requests:

EN 61000-6-1 (2016-05)

EN 61000-6-3 (2011-09)

Page 8

deltawaveC-F/P

Manual

8 systec Controls Mess- und Regeltechnik GmbH

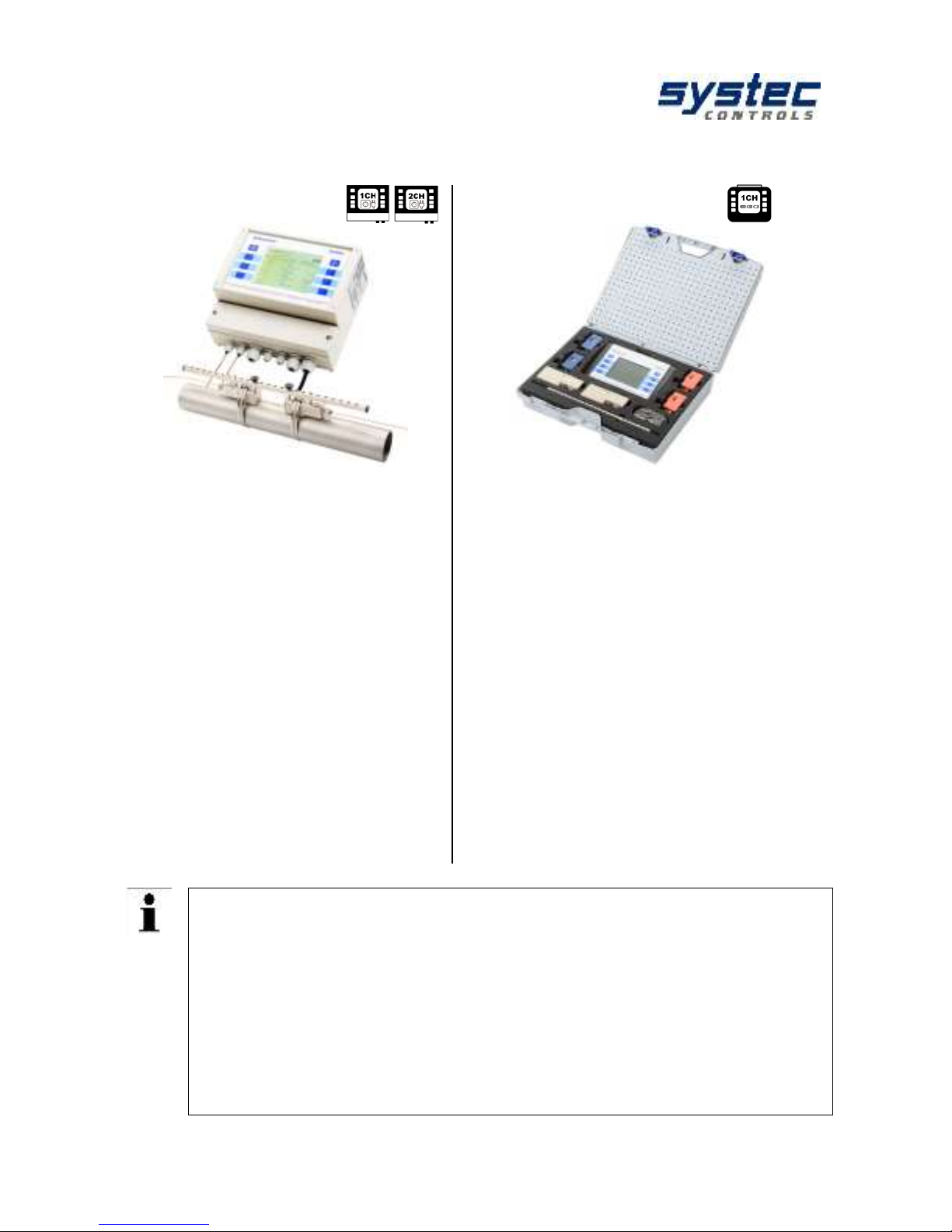

3.2 Scope of delivery deltawaveC-F / P basic package

deltawaveC-F

deltawaveC-P

deltawaveC-F & ultrasonic transducers

deltawaveC-P hard-shell case

deltawaveC-F flow transmitter

Ultrasonic transducers incl.

signal cables (cable length

according to order)

Spacer bar for transducers,

except for FW05

Mounting belt – stainless steel

Quick start Guide

CD with manual

Acoustic coupling pads

Hard-shell case

deltawaveC-P flow transmitter

Plug-in power adapter, including

an IEC appliance power cable

RG 58 connector cable for

transducer

Ultrasonic transducer (as

ordered by the customer)

Mounting material and spacer

bar for transducers

Cable for 4mA to 20mA analogue

output (Mini DIN, alligator clips)

Quick start Guide

CD with Manual

Ultrasonic coupling grease

Other ultrasonic transducers for smaller or larger pipe dimensions, as well

as clamp-on temperature sensors, are available on separate order.

Every deltawaveC-F can be retrofitted with a serial interface board

(optional). It can be connected either to an RS232 serial interface board or

to a RS485 interface.

You can reach your personal contact partner on the Internet at

www.systec-controls.de, or at the phone number +49 (0)89 80 90 60.

An overview of accessories and available transducer can be found in the

appendix.

Page 9

deltawaveC-F/P

Manual

9 systec Controls Mess- und Regeltechnik GmbH

3.3 Transducer

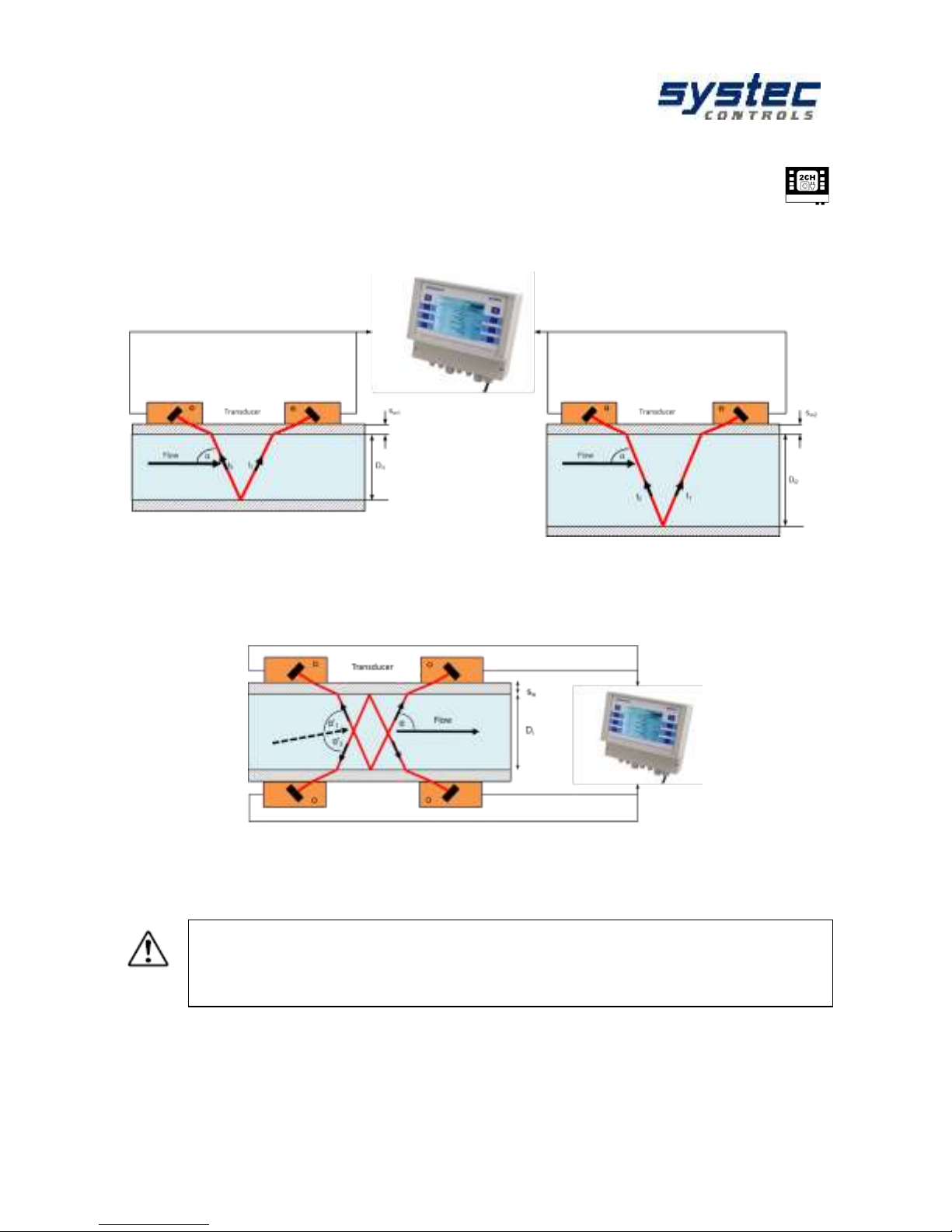

Figure 1: deltawaveC-F/P – measuring converter and mounted ultrasound transducer;

left: deltawaveC-F, right: deltawaveC-P

Your deltawaveC-F / P essentially consist of the ultrasonic transducers mounted on

your pipeline and the transmitter. The transmitter performs the signal processing

and provides the user with the measurement results. The ultrasonic transducers

transform the electrical energy into kinetic energy (acoustic wave). The ultrasonic

transducer can also receive acoustic waves and convert these into electrical

energy. An overview of the available converters can be found in the appendix.

The ultrasonic transducers will be mounted on the pipeline, they generate and

receive the ultrasonic signals, by means of which flow rate will calculated in the

transmitter.

As a result of the measuring principle, each transmitter is equipped with a

pair of ultrasonic transducers (A & B). Make sure ultrasonic transducers are

aligned with the direction of flow. Pay attention with the deltawaveC-F

(screw terminals), the loop has to be at the correct position and correct

polarity:

( + ) = red cable (core)

( – ) = black cable (shield)

UP-Transducer (upstream positioned transducer):

The ultrasound transducer, which the flow passes first, is connected at the UPcontacts.

DOWN-Transducer (downstream positioned transducer):

The ultrasound transducer, which the flow passes second, is connected at the

DOWN-contacts.

Page 10

deltawaveC-F/P

Manual

10 systec Controls Mess- und Regeltechnik GmbH

3.4 Safety instructions

The operating temperature of the transmitter from -20°C to 60°C must

not be exceeded!

The ultrasonic sensors are sensitive to strong mechanical impacts

(irreparable damage possible)!

The transmitter and ultrasound transducers are generally not approved

for operation in potentially explosive atmospheres (request documents

for ATEX equipment).

The ultrasonic sensors must not exceed the specified operating

temperatures.

3.5 Important instructions for the use of

deltawaveC-P

The plug-in power supply is only suitable for indoor use! In the case of mechanical

or electrical damage to the plug-in power supply unit or the 230V power supply

cable, these must be completely replaced!

DeltawaveC-P is equipped with a nickel metal hydride battery (NiMH, 2300mAh).

This battery power is sufficient for approximately 5 hours of network-independent

operation.

To increase the battery life time, we recommend the following:

Charge and discharge the battery 3 times completely as soon as you have received

your deltawaveC-P.

If the deltawaveC-P is not used for a long time, recharge the battery at

least once every 3 ... 6 months.

The deltawaveC-P is equipped with a deep discharge protection. A pop-up

message informs you before the device switches off automatically.

To avoid unnecessary stress to the battery avoid connecting the

deltawaveC-P to a power supply if it is already charged completely.

deltawaveC-P is equipped with a quick-charge function. The quick-charge

function is automatically activated for 20 minutes after deltawaveC-P is

connected to the power supply. This allows for quick instant operation of

the device.

General information about the charge states:

Charging

50-100%

25-49%

10-25%

<10%

Page 11

deltawaveC-F/P

Manual

11 systec Controls Mess- und Regeltechnik GmbH

The exclamation point in the battery indicator appears if the charge is too

low, or if deltawaveC-P is busy determining the current charge status.

Determining the charge level might take up to one minute.

If the exclamation mark persists, the battery actually has a capacity <10%.

If "Err" appears in front of the battery symbol and "x" in the battery symbol,

this means that the battery is defective or there is a fault in the charging

circuit. If you restart deltawaveC-P three times and the error message

persists, please contact systec Controls.

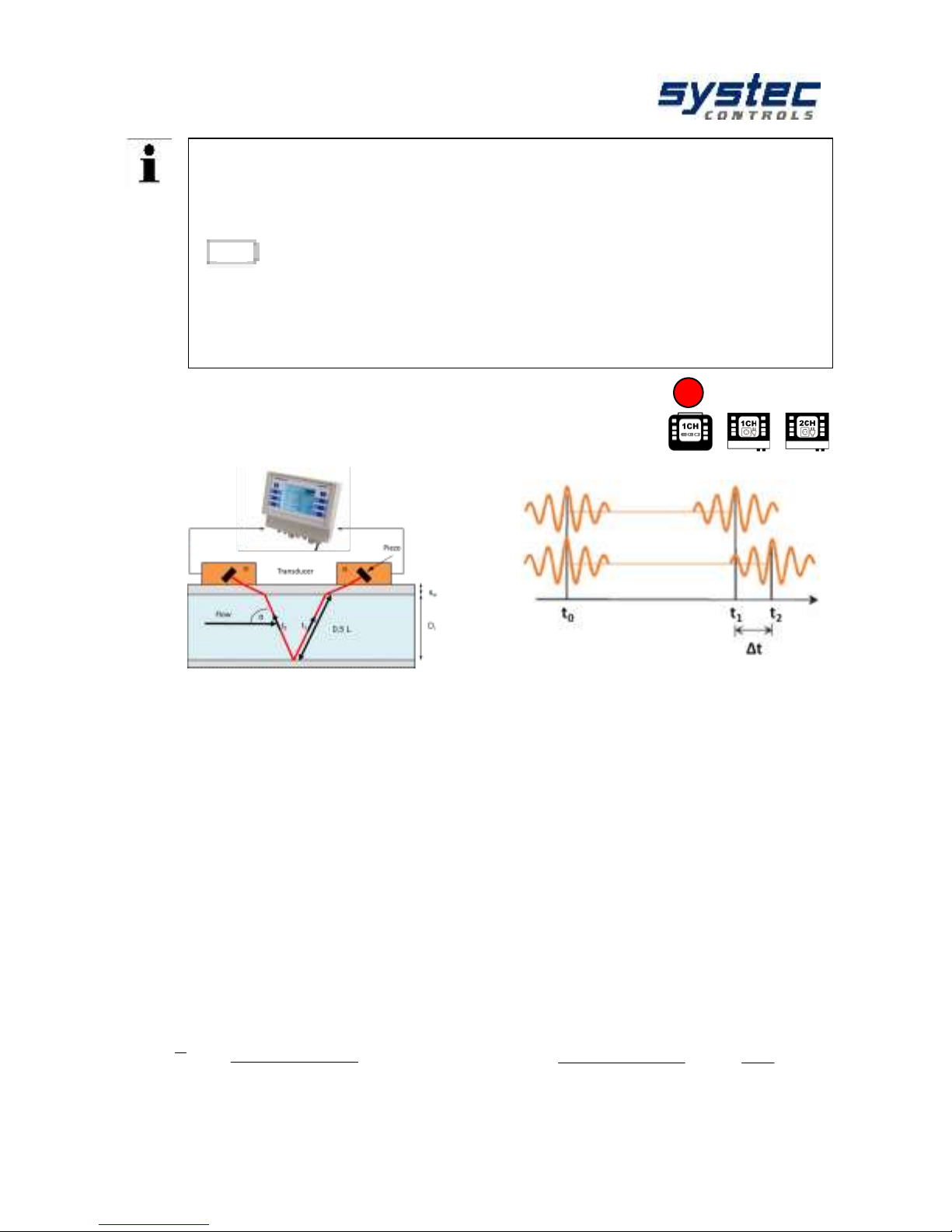

4 Measuring principle

Measuring principle: Ultrasonic transit time difference method (Clamp-On)

For this purpose two ultrasonic transducers are mounted on the pipeline from

outside and connected to the evaluation electronics.

The ultrasonic transducers work alternately as transmitters and receivers and send

ultrasonic signals at each other. These signals are accelerated or decelerated by

the medium flow. The resulting difference in the two signal propagation times is

proportional to the flow rate and is used together with the pipeline geometry for the

precise calculation of the flow rate.

Signal evaluation by means of cross-correlation:

The signal processing operates on the basis of a cross-correlation-based method,

which enables signal detection even at a low signal-to-noise ratio. On the basis of

the high-quality signal evaluation, measurements with gas input or solid load of the

medium are also possible within certain limits.

Calculation of the flow velocity [m/s]:

Calculation of the volume flow:

x

4cos2

)(

2

Re

12

D

k

tt

t

LQ

Re

12

cos2

)(

k

tt

t

Lv

Page 12

deltawaveC-F/P

Manual

12 systec Controls Mess- und Regeltechnik GmbH

Integrated Reynolds-compensation (kRe):

The transit time difference method provides to determine the mean flow velocity

along the measuring path. The mean flow velocity over the tube cross-section can

be determined by means of a compensation factor which is dependent on the

Reynolds number.

The Reynolds number is determined iteratively from the current flow rate, the pipe

diameter and the kinematic viscosity of the fluid. For fluids of the device-internal

material database the data is provided.

The configuration of a user-defined medium is possible. For this purpose, the sound

velocity (can be practically determined by iterative approximation, see 13.2) and the

kinematic viscosity of the medium must be parameterized. The input of density and

heat capacity is additionally required for determining the heat quantity.

Re… Reynolds number,

v… flow velocity,

D… diameter,

ρ… density,

µ… dynamic viscosity,

υ… kinematic viscosity,

Integrated temperature compensation / Automatic Fluid Control (AFC):

Changes to the sound velocity of the liquid (temperature-dependent or when the

medium changes) cause changes of signal path angles and path length. These

deviations from the ideal path and the resulting measurement uncertainties are

compensated automatically by a correction factor (qp factor) determined by

deltawaveC-F / P without mechanical displacement of the transducers.

Standard:

The basis for the calculation is the VDI/VDE directive 2642: "ULTRASONIC FOWRATE MEASUREMENT OF FLUIDS IN PIPES UNDER CAPACITY FLOW

CONDITIONS" (12/1996)

DvDv

Re

Page 13

deltawaveC-F/P

Manual

13 systec Controls Mess- und Regeltechnik GmbH

4.1 2-channel device applications

The deltawaveC-F 2-channel transmitter enables the realization of exceptional

measurement requirements for special applications. These are briefly described

below.

Two measuring paths can be operated separately at two different measuring points.

In addition to the separate results of measuring points (CH1 or CH2), the sum, the

difference as well as the mean value of both measuring paths are provided

additionally (CH1 + CH2, CH1 - CH2, (CH1 + CH2) / 2).

The mean value calculation is intended in particular for the use of both measuring

paths at one measuring point. This utilization makes it possible to increase the

accuracy and to reduce the effects of cross currents.

The heat quantity determination is limited to the use of two measuring

paths at one measuring point (only one pair of Pt100 can be connected).

The calculation is performed only for (CH1 + CH2) / 2.

A separate calculation only for CH1 and/or CH2 is not provided.

Page 14

deltawaveC-F/P

Manual

14 systec Controls Mess- und Regeltechnik GmbH

5 deltawaveC-F/P Interfaces

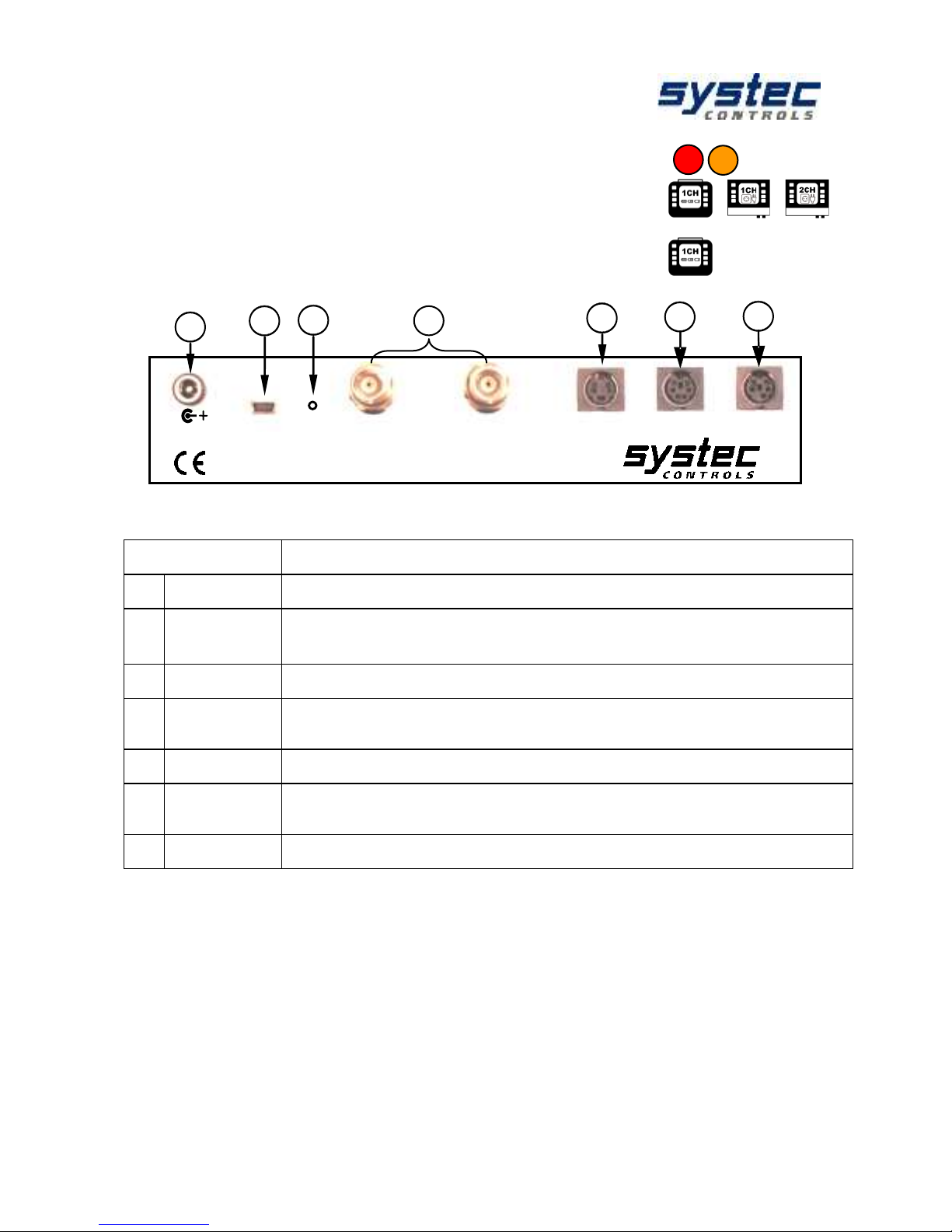

5.1 Overview deltawaveC-P

Term

Description

1

UP/ DWN

BNC-Inputs for ultrasonic transducer

2

Relays/

Impulse

Mini-DIN-4 connectors output: Relay connection (passive, potential-free);

Digital output (open collector: 20, 40, 60 ms square pulses)

3

T1/T2

Mini-DIN-6 connectors: 1 pair 3-conductor Pt100 (heat measurement):

4

Analog Out

2 Analogue outputs: 4…20mA signal, 24VDC, active (optional passive)

from CTRL 2.1 according to Namur NE43 (3.8-20.5 mA)

5

RESET

Hardware-Reset (Restart of the system)

6

USB

USB Interface (Mini-USB Type B), access to the integrated SD memory card

Windows XP or later versions detect the SD Card as mass storage medium

7

Power

Plug-in power: 19 V/DC, 3,42 A

Power

18,5 VDC

USB

Down

Up

T1/T2

Relays/Impulse

Analog Out

deltawaveC

Reset

1

4 3 5

6

7

2

Page 15

deltawaveC-F/P

Manual

15 systec Controls Mess- und Regeltechnik GmbH

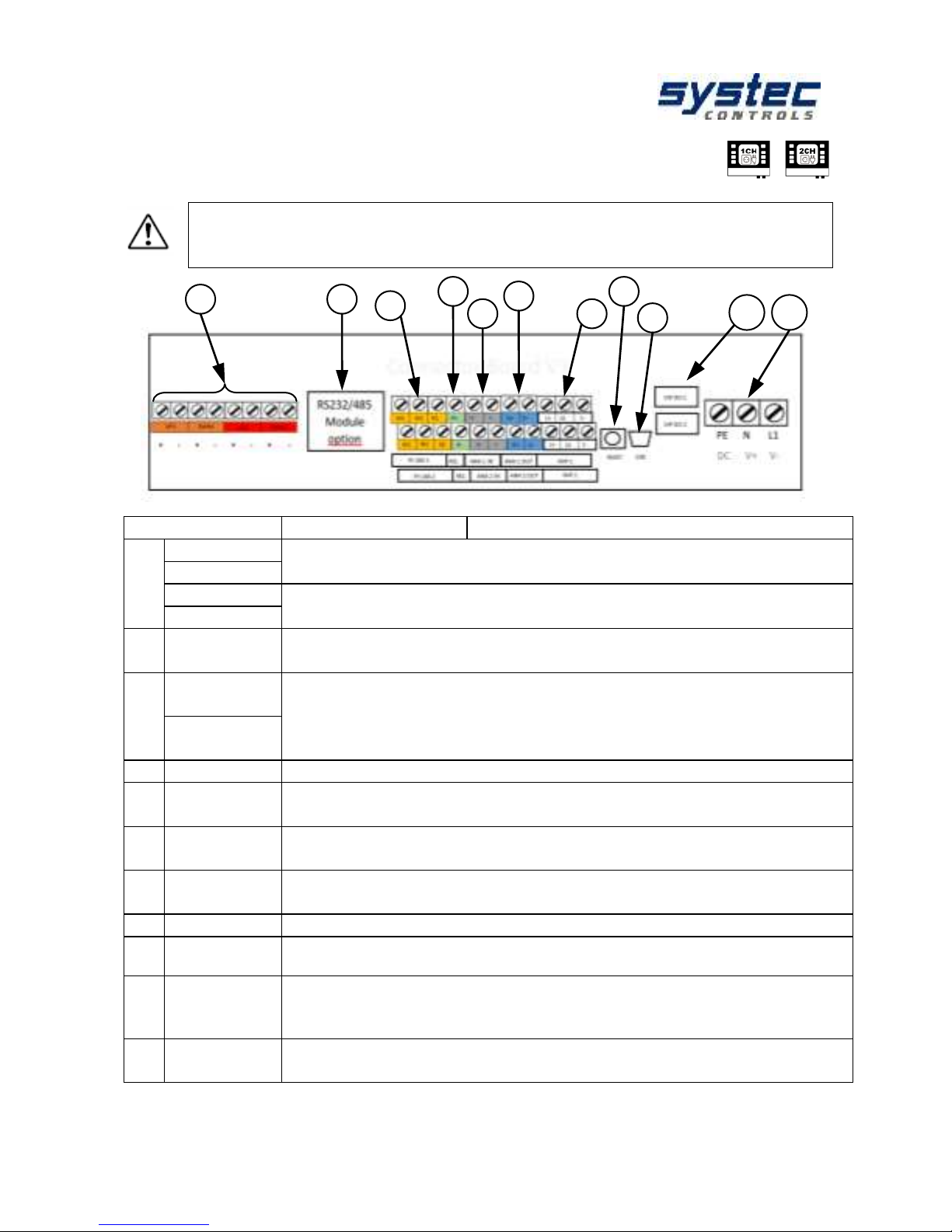

5.2 Overview deltawaveC-F

The overview of the connection area and the terminal diagram corresponds

to the connector board V3.0 (double-pole terminals with additional

analogue inputs). Documentation for older versions can be requested.

Term

Connection

Description

1

UP1

input for ultrasonic transducer measurement path 1

( + ) = red cable (core); ( – ) = black cable (shield)

DWN1

UP2

input for ultrasonic transducer measurement path 2

Only 2-channel transmitter

DWN2

2

RS232 /

RS485

optional + retrofitted (Digital Interface board X1 & X2)

Data transmission via serial communication or Modbus

3

PT100 – 1

(T

input

)

1 pair 3-conductor Pt100 (heat measurement)

W terminals: Sense lines (cables of the same polarity / colour)

R-Terminal: GND cable (different colour cable).

For 3-wire Pt100, bridging the sense connections.

PT100 – 2

T

output

4

REL

Relay connection, passive, potential-free

5

ANA 1 OUT

ANA 2 OUT

Retrofitting requires CTRL-Board V2.2

Analogue inputs: 4 ... 20mA Unit signal, 24VDC, active (optional passive)

6

ANA 1 OUT

ANA 2 OUT

Analogue inputs: 4 ... 20mA Unit signal, 24VDC, active (optional passive)

from CTRL 2.1 according to Namur NE43 (3.8-20.5 mA)

7

IMP 1

IMP 2

Digital output (open collector: 20, 40, 60 ms square pulses)

IMP2 Only 2-channel transmitter usable

8

RESET

Hardware-Reset (Restart of the system)

9

USB

USB Interface (Mini-USB Type B), access to the integrated SD memory card

Windows XP or later versions detect the SD Card as mass storage medium

10

DIP 1 DO

DIP 2 DO

DIP Switch for configuring IMP1 and IMP2

NPN, PNP, push-pull, active / passive

IMP2 Only 2-channel transmitter usable

11

PE N L1

V+ V-

Two power supply options available:

alternating current 90 ... 240 V / AC, direct current 18 ... 36 V / DC

1 2 3 4 5 6 7 8 9

10

11

Page 16

deltawaveC-F/P

Manual

16 systec Controls Mess- und Regeltechnik GmbH

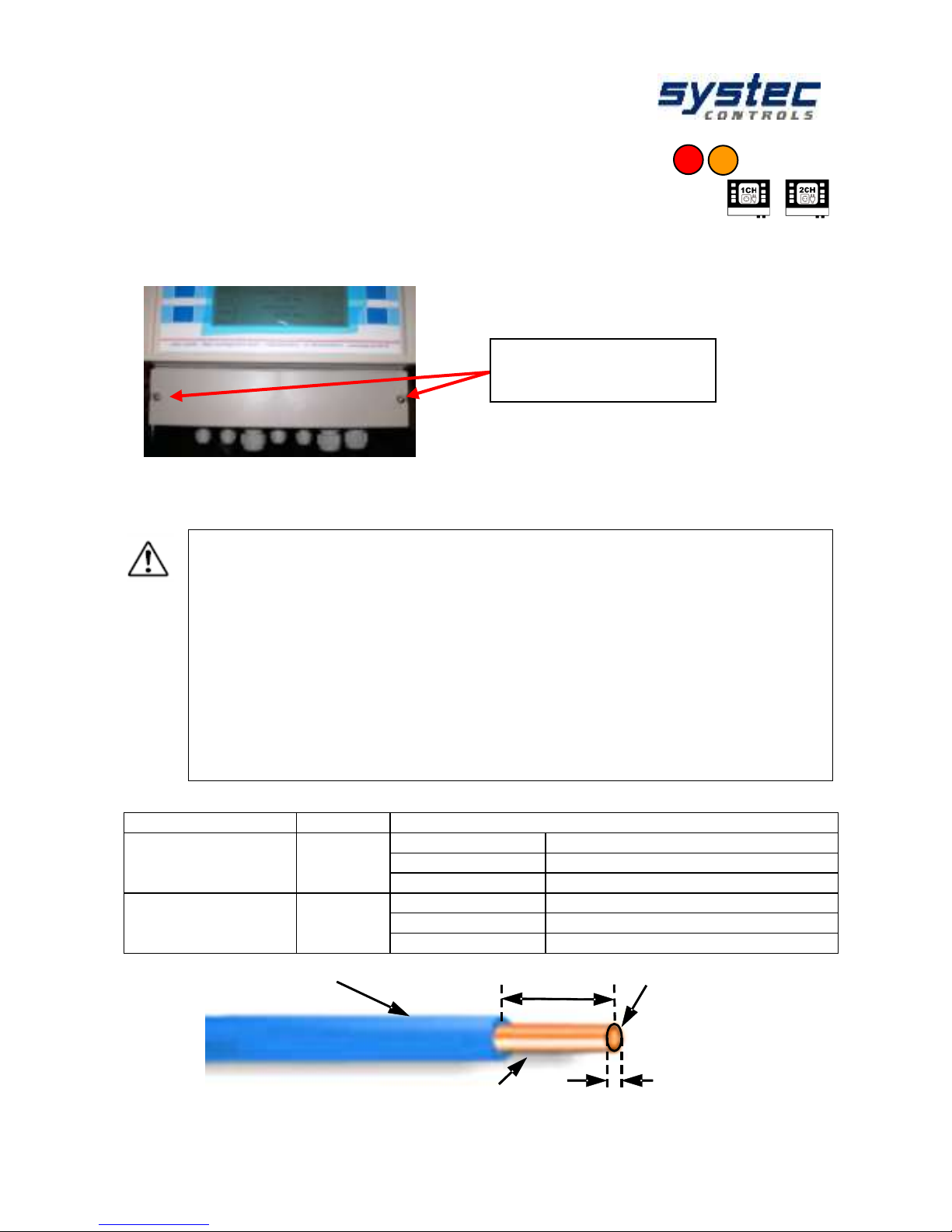

5.3 Connection notes

To access the deltawaveC-F cable space, please detach the cable both screws and

remove the cover plate:

Figure 2: Remove cover from cable compartment

Please always make sure to put the correct voltage to your deltawaveC-F.

Improper supply voltage might seriously damage the flow transmitter.

You can check the type of power supply at the name plate, printed on

right side of enclosure of flow transmitter.

All in- and outputs (except relay) have defined potential on the

internal devices ground. For potential free operation of the in- and

outputs additional hardware is needed (with galvanic isolation). With

the normal in- and output it is not possible!

The analogue in- and outputs are active ex works 24V/DC (could

be set in passive mode by systec controls)

The maximum permitted load of the relay is 45V, 0,25A

Table 1: Recommendations for cable contacts

Terminal designation

description

recommendation

X2

In-/

Output

Cross-section:

0,5 - 4,0 mm²

Diameter:

0,8 - 2,3 mm

Contact length:

8,0 mm

X5

Powersupply

Cross-section:

0,13 - 1,3 mm²

Diameter:

0,4 - 1,3 mm

Contact length:

6,0 mm

Figure 3: Cable assembly

Fastening screws on

cover (cross-slot).

insolation

stripped cable

length

cross section

diameter

Page 17

deltawaveC-F/P

Manual

17 systec Controls Mess- und Regeltechnik GmbH

6 Operating

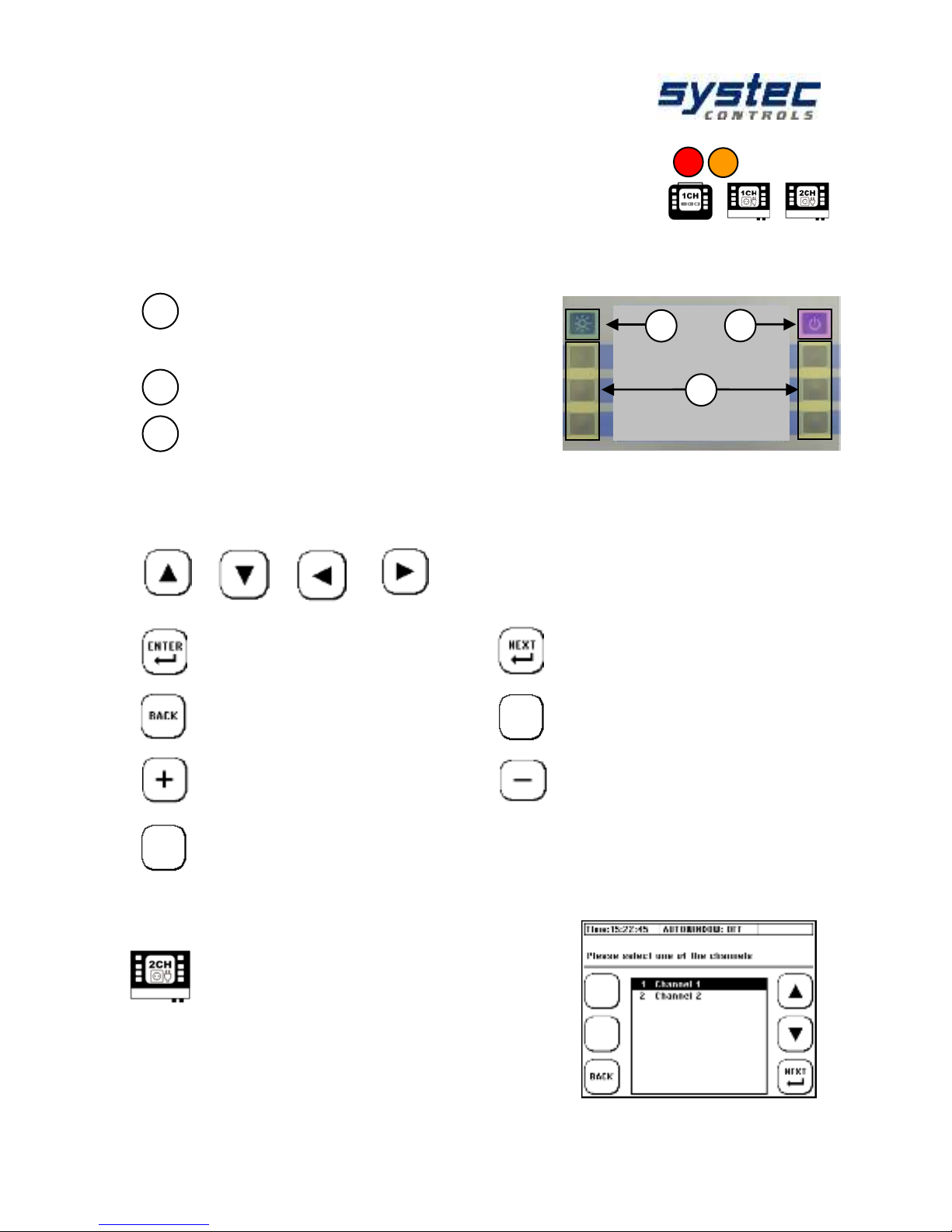

6.1 Control Buttons

Switches the device On and Off. To shut down

the device, press the button for duration of

approx. 3 seconds and then release it. No

function on deltawaveC-F

Switches the backlight On and Off

Multifunctional buttons: Activate the function

displayed beneath the button.

6.2 How to navigate

Use the corresponding multifunctional buttons:

Arrow buttons for navigation

Confirms your entry

Confirms your entries and

opens the next window

Returns you to the previous

window

Triggers the XYZ function

(variable, depending on the

application)

Increases the value

Reduces the value

No function

6.3 Select measurement channel

The operation of the 2-channel transmitter differs

from conventional operation only (in a large part)

through an additional selection of the relevant

channel / measuring path.

3

2

1

1

2

3

XYZ

Page 18

deltawaveC-F/P

Manual

18 systec Controls Mess- und Regeltechnik GmbH

7 First Start

7.1 Basic settings, main menu, navigation

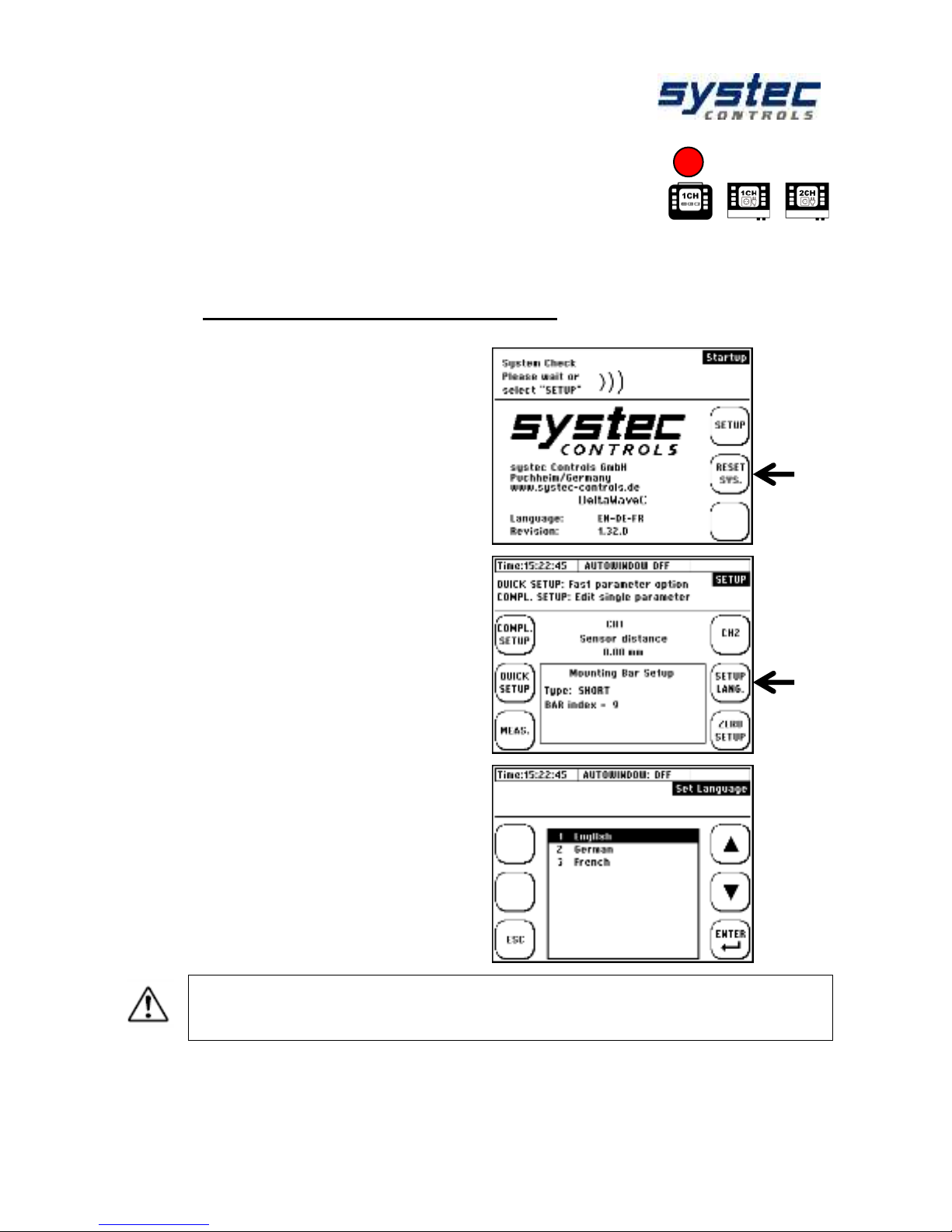

7.1.1 Adjustment of the display language

1. Plug in the device.

During the starting sequence please

press the multifunctional key next to the

section “SETUP”.

2. Press the button “SETUP

LANGUAGE“.

3. In the window choose the required

display language using the arrow keys.

Confirm your input by pressing “ENTER“.

Leave the menu with “SETUP”.

By setting the language you adjust the language used in the menus. The

language in the boxes next to the multifunctional keys remains most widely

unchanged.

Page 19

deltawaveC-F/P

Manual

19 systec Controls Mess- und Regeltechnik GmbH

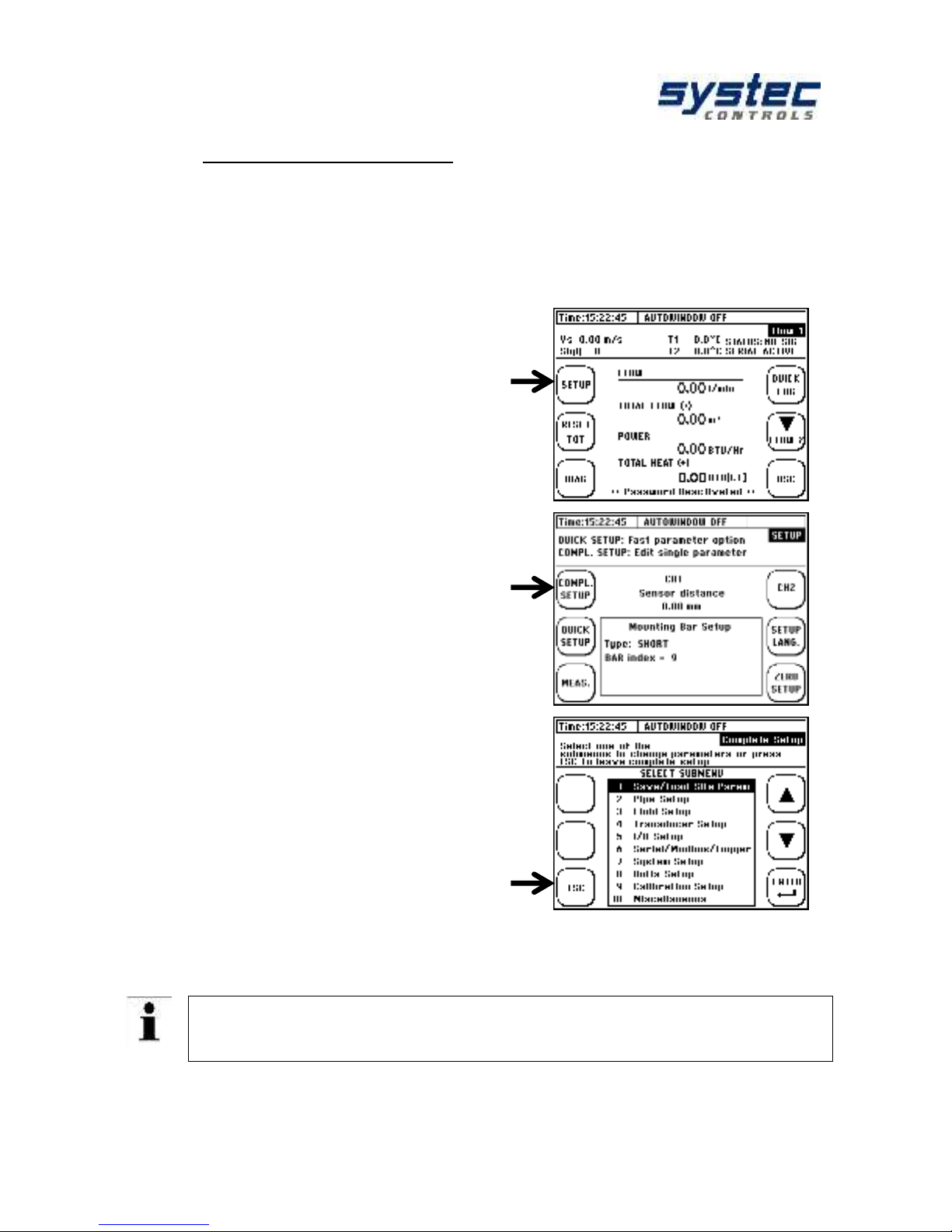

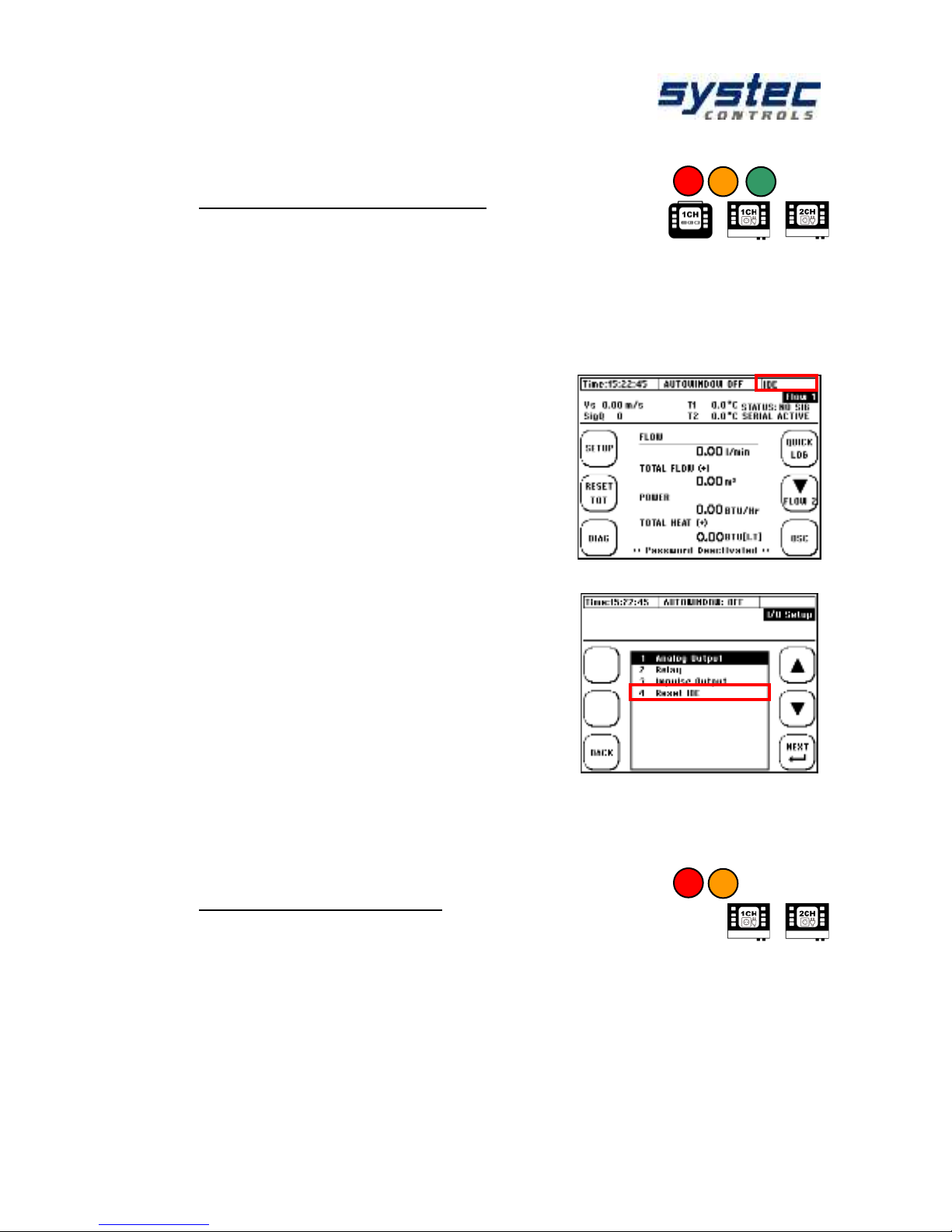

7.1.2 Navigation in main menu

After switching deltawaveC-F/P on and passing through the start screen,

the measuring window “Flow 1” will appear automatically after few seconds.

The measuring window “Flow 1” shows an overview of all necessary

information for the measurement of flow and heat quantity.

1. Select “Setup“.

If the required window does not appear

after pressing “Setup“, please check if the

password function is deactivated.

2. If you can see this window, please

choose “COMPL” Setup“.

3. You are in the main menu now. From

this menu all necessary functions of

the device can be selected.

4. To return to the measuring window

please proceed as follows:

Choose “ESC” -> in the following window

please select “MEAS”.

Now you have become acquainted with the basic operation of your deltawaveC-FP.

There is a trick to reach the main menu even faster after switching the

device on: select “SETUP” during the start sequence right after switching

your deltawaveC-F on. In the following window choose “COMPL” SETUP”.

Page 20

deltawaveC-F/P

Manual

20 systec Controls Mess- und Regeltechnik GmbH

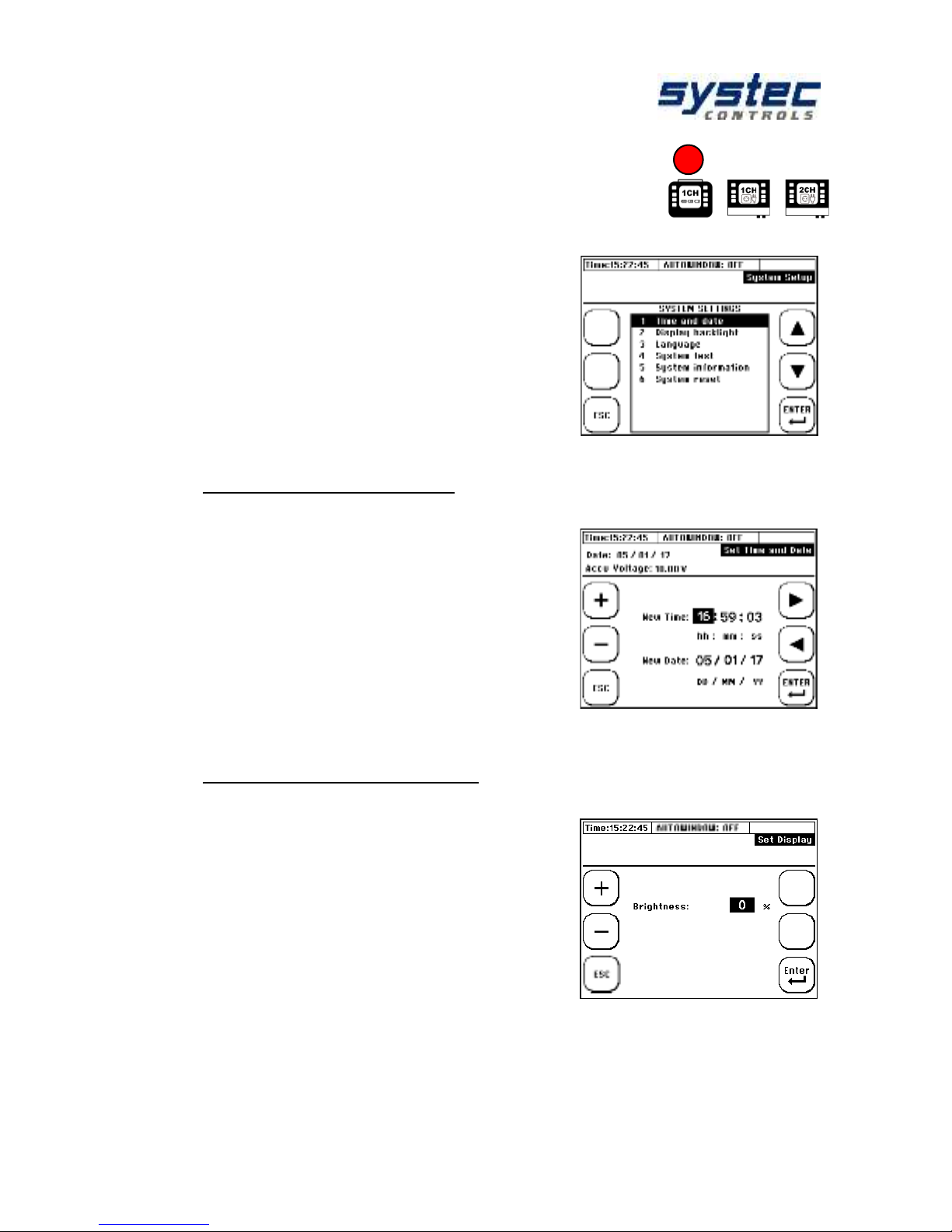

7.1.3 Setting time and date

Having chosen the language for the menu you are in the main menu of the device.

1. Select the menu item (7) System

Settings using the arrow key.

2. In the following window choose menu

item (1) Time and Date.

3. By using the arrow keys the position can

be changed, by using +/- the value can be

adjusted. Please enter the time in the

following format:

Hour(hh) : minute(mm) : second(ss)

Afterwards, please enter the date in the

following format:

Day (dd) : Month (mm) : Year (yy)

4. Subsequently, press “ENTER“ to

confirm your input and return to the system

settings.

Page 21

deltawaveC-F/P

Manual

21 systec Controls Mess- und Regeltechnik GmbH

8 Preparing for measurement deltawaveC-F/P

Set-up your flow measurement in 5 steps

1. Choose suitable mounting position for your transducers

2. Parameterize your flow transmitter

3. Mount ultrasonic transducers onto your pipe

4. Set zero point (if possible)

5. Start your flow measurement

8.1 Preparation of the measurement /

installation location

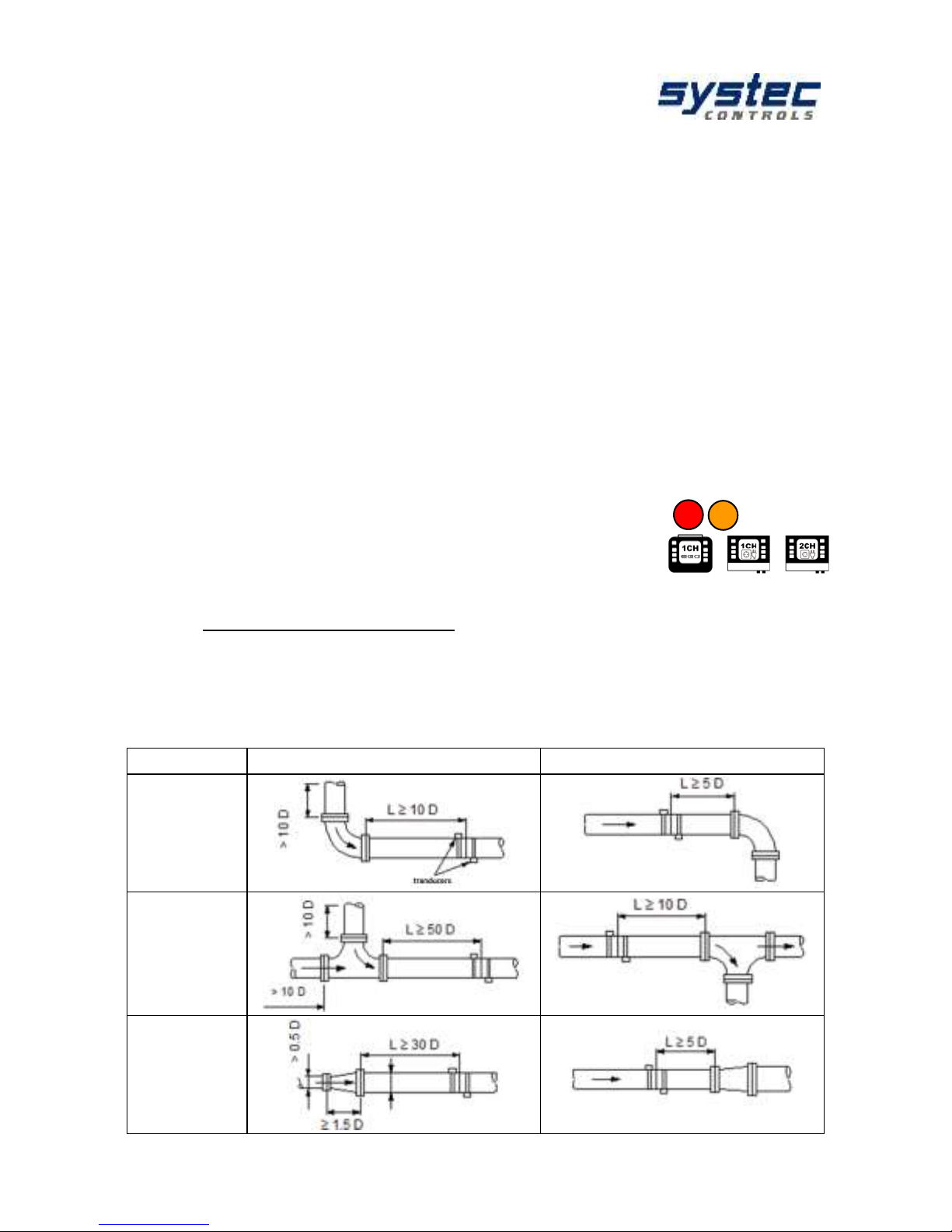

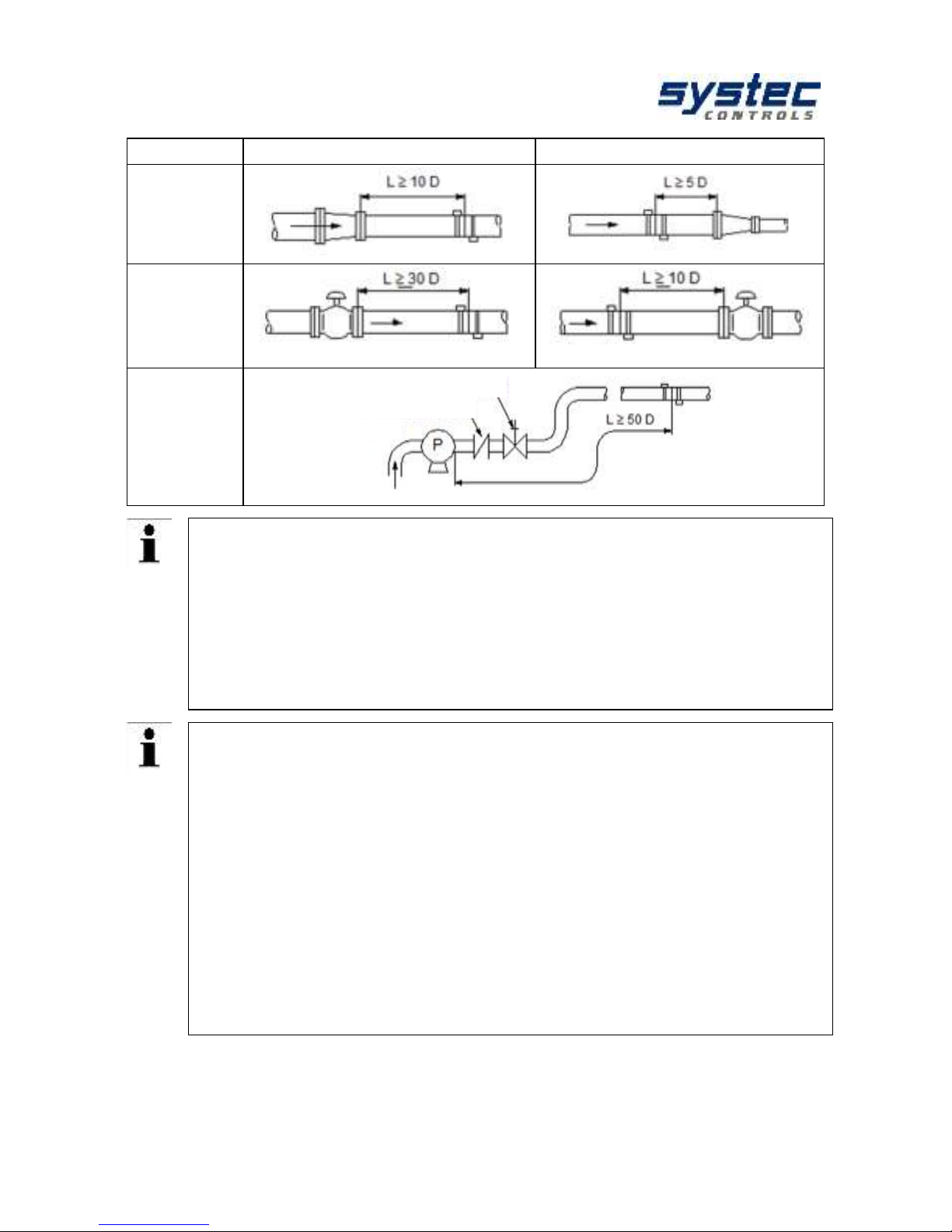

8.1.1 Inlet and outlet distances

The selection of the mounting location has a considerable influence on the quality of

the measurement. Especially the inlet and outlet distance. Please consider the

recommendations in the table below.

The letter "D" stands for the pipe diameter.

Classification

Upstream side

Downstream side

90° bend

Tee

Diffuser

Page 22

deltawaveC-F/P

Manual

22 systec Controls Mess- und Regeltechnik GmbH

Classification

Upstream side

Downstream side

Reducer

Control valves

Pump

The distance “L” is defined as the distance from a fitting (e.g. a 90° bend) to the

middle of the position of the ultrasonic transducers.

Example: 90° bend (at upstream side) at the inlet, 90° bend (at downstream side) in

the outlet.

Diameter of the pipe: 110 mm

Recommendation according to the chart.

Running-in distance: 10D inlet = 10 x 110 mm = 1100 mm

Running-out distance: 5D outlet = 5 x 110 mm = 550 mm

What happens if the recommended inlet and outlet sections cannot be

complied with?

With simple pipe bends or T-pieces a reduction of inlet or outlet distances leads to a

greater uncertainty of measurement. The closer to the fitting the transducers are

mounted, the greater the measurement error will be.

With higher velocities of flow a shortened inlet section can also lead to lasting

disturbance of the flow profile which can induce a measurement failure. If there is a

temporary measurement failure and there is no possibility to change the mounting

position of the ultrasonic transducers, then the recommendation is to use the next

higher ultrasonic transducer type even with small pipe sizes:

F10 Transducer from DN32…DN200

F05 Transducer from DN200

Pumps or flaps/valves produce permanent disturbances of the flow profile, which are

not improved by switching to a different transducer type. In this case, the

recommended inlet/outlet distances should be adhered to consistently.

pump

back- pressure Vale

stop valve

Page 23

deltawaveC-F/P

Manual

23 systec Controls Mess- und Regeltechnik GmbH

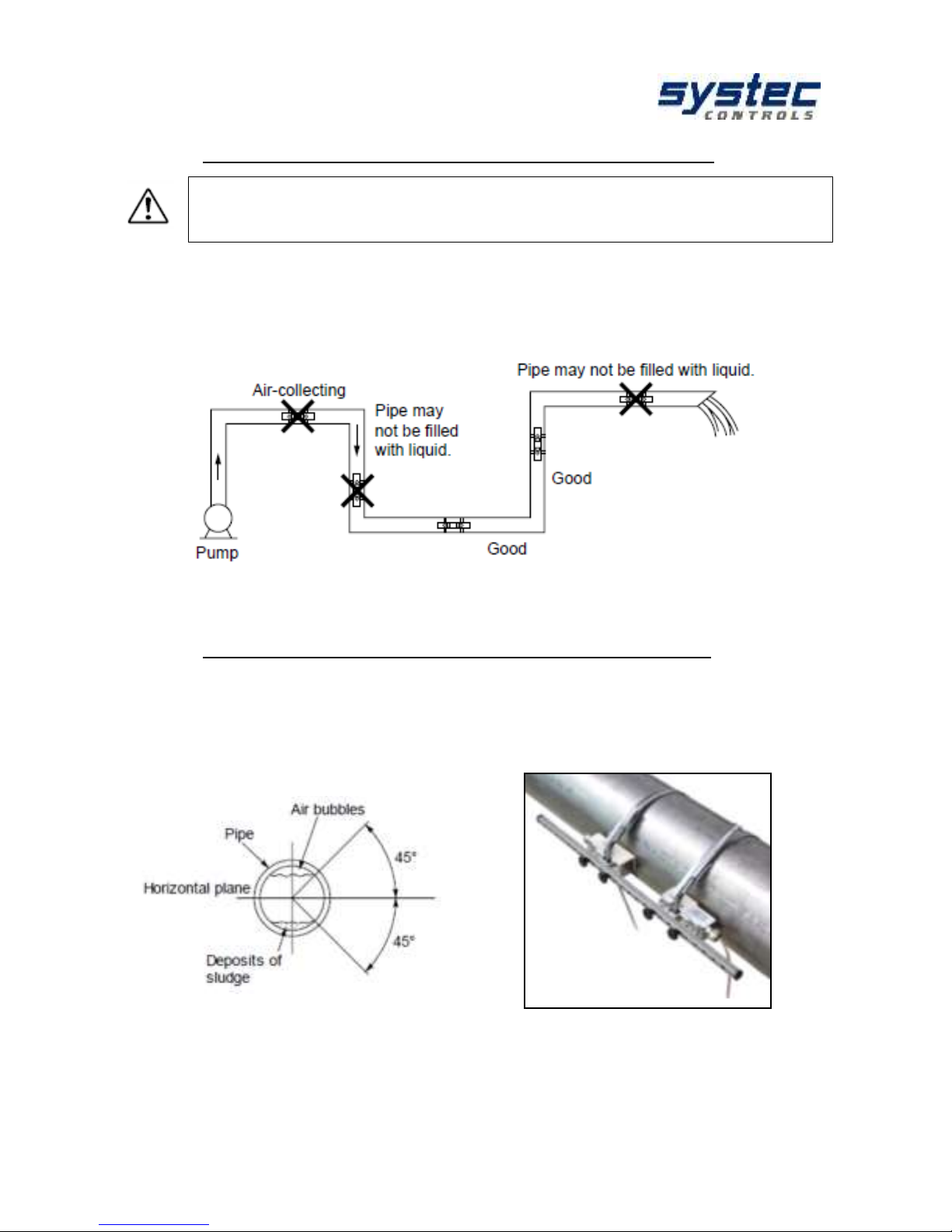

8.1.2 Basic principles for ultrasonic transducer assembly

The pipe always has to be completely filled at the mounting positions

of the ultrasonic transducers!

Measurement of partially filled pipes is not possible!

The ultrasonic transducers can be mounted vertically or horizontally or in any other

position. This is conditional on compliance with the possible mounting positions

shown below:

Figure 4: Preferable mounting positions for ultrasonic transducers (1)

8.1.3 Ultrasonic sensor Mounting on horizontal pipelines

On horizontal piping, it is recommended to mount the transducer with an offset of

approx. +/-45% to the horizontal plane. This is based on the fact that there is a risk

of the accumulation of bubbles in the upper section and sedimentation in the lower

section of the pipe.

Figure 5: Preferable mounting positions for ultrasonic transducers (2)

Page 24

deltawaveC-F/P

Manual

24 systec Controls Mess- und Regeltechnik GmbH

Note on deposits in the pipeline, e.g. Lime:

The flow rate calculation of the deltawaveC-F / P is based on the following formula.

The red-marked term can be seen that the deltawaveC-F/P the entire pipe crosssection includes in the calculation. Your deltawaveC-F/P calculates the pipe crosssection based on the parameterized values from your tube circumference or tube

diameter and wall thickness. If lime scale deposits occur within the pipeline, they

reduce the measurable cross-section through which the fluid flows. This will add an

additional measurement uncertainty.

Especially if the pipe is unknown and/or the documentation of the

application is missing, measuring the thickness of the pipe wall can be

reasonable. In this case, systec Controls offers you the precise pipe wall

thickness measuring device deltawaveC-WD.

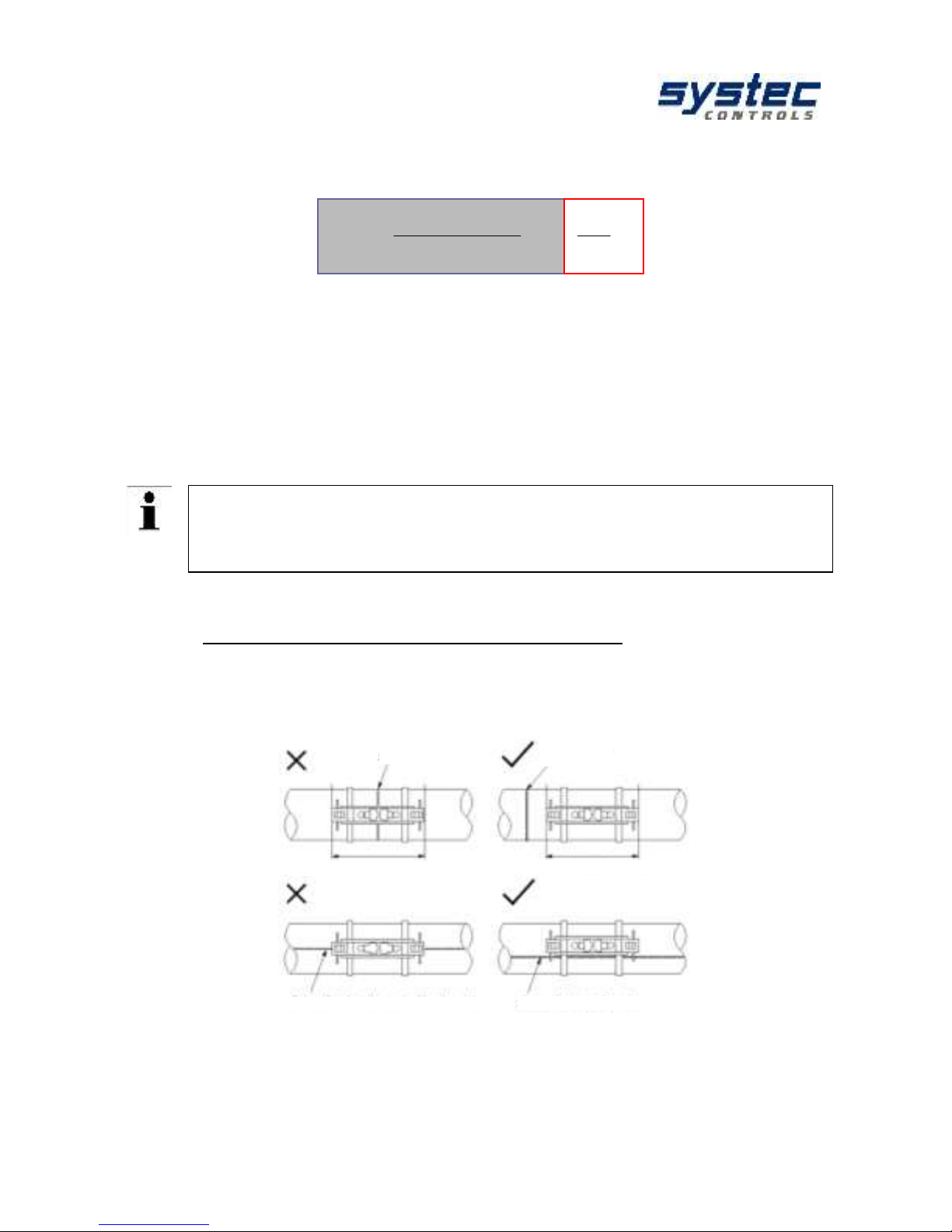

8.1.4 Ultrasonic transducer on uneven surfaces

Avoid mounting the sensors on uneven surfaces such as welds or deformations.

For pipes with thick and uneven protective paint, remove it as far as possible at the

points on which the ultrasonic transducers are mounted.

Figure 6: Preferable mounting positions for ultrasonic transducers (3)

welded joint

welded joint

welded joint outside

welded joint in measurement area

welded joint outside

welded joint partly in measurement area

4cos2

)(

2

Re

12

D

k

tt

t

LQ

Page 25

deltawaveC-F/P

Manual

25 systec Controls Mess- und Regeltechnik GmbH

8.2 Fundamentals of parameterization

The Parameterization chapter defines the input of all data that is necessary for flow

measurement.

1. „QUICK SETUP“: The Quick Setup guide offers step-by-step instructions on the

essential tasks you have to complete for deltawaveC-F/P parameterization. This

Quick Setup is quite sufficient for handling most applications and gets you started

with fast and efficient parameterization in no time at all.

2. „CMPL SETUP“: The complete setup function enables access to all options and

expert settings. Here, you can also directly access individual parameters via the

main menu.

What needs to be parameterized?

1. The pipe's outer diameter or circumference.

2. The wall thickness of the pipe. The material and thickness of the pipe

lining, if such lining exits.

3. The pipe material

4. The medium

5. The type of ultrasonic transducers

6. The mounting mode for the ultrasonic transducers

Ultrasonic measurement is based on the signal transit time process. The

ultrasonic signals penetrate the piping and the medium. In order to

calculate the signal transit time, each medium, piping material and existing

lining will be assigned a sonic speed value, as well as the pipe diameter or

circumference value.

The deltawaveC-F/P has stored tables in which the sound velocities of

materials and media are stored. If the material or medium is not listed in the

tables, its sound velocity must be entered manually. At the end of this

manual you will find tables with additional sound velocities for different

substances.

Page 26

deltawaveC-F/P

Manual

26 systec Controls Mess- und Regeltechnik GmbH

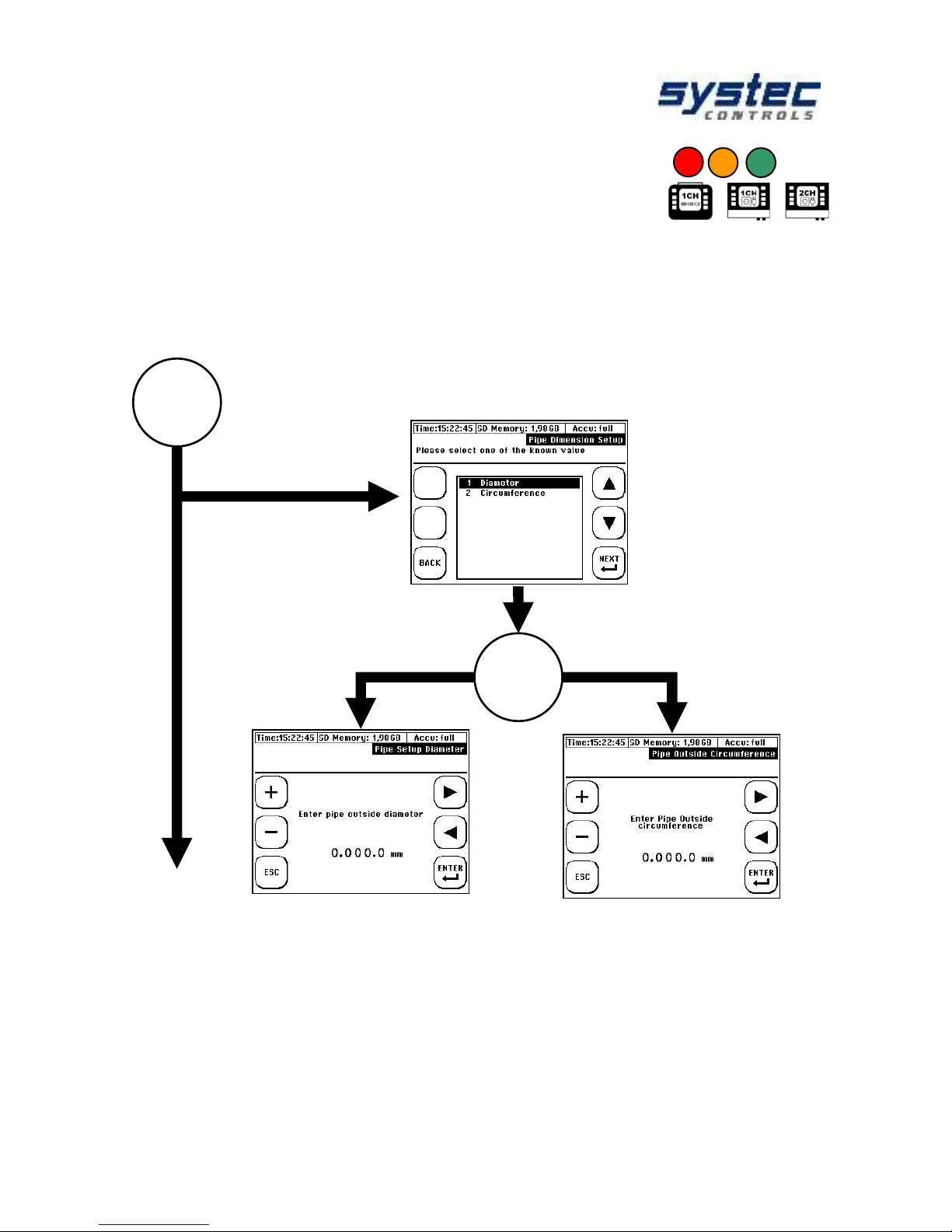

8.3 Parameterization with the Quick Setup

How to access the parameterization dialog:

After power on: Select „Setup“ „Quick Setup“

In the primary measuring window "Flow 1": Select "Setup" "Quick "Setup".

1

Specify whether to enter the pipe circumference or outer

diameter:

or

Enter the outside diameter

Enter the diameter

Page 27

deltawaveC-F/P

Manual

27 systec Controls Mess- und Regeltechnik GmbH

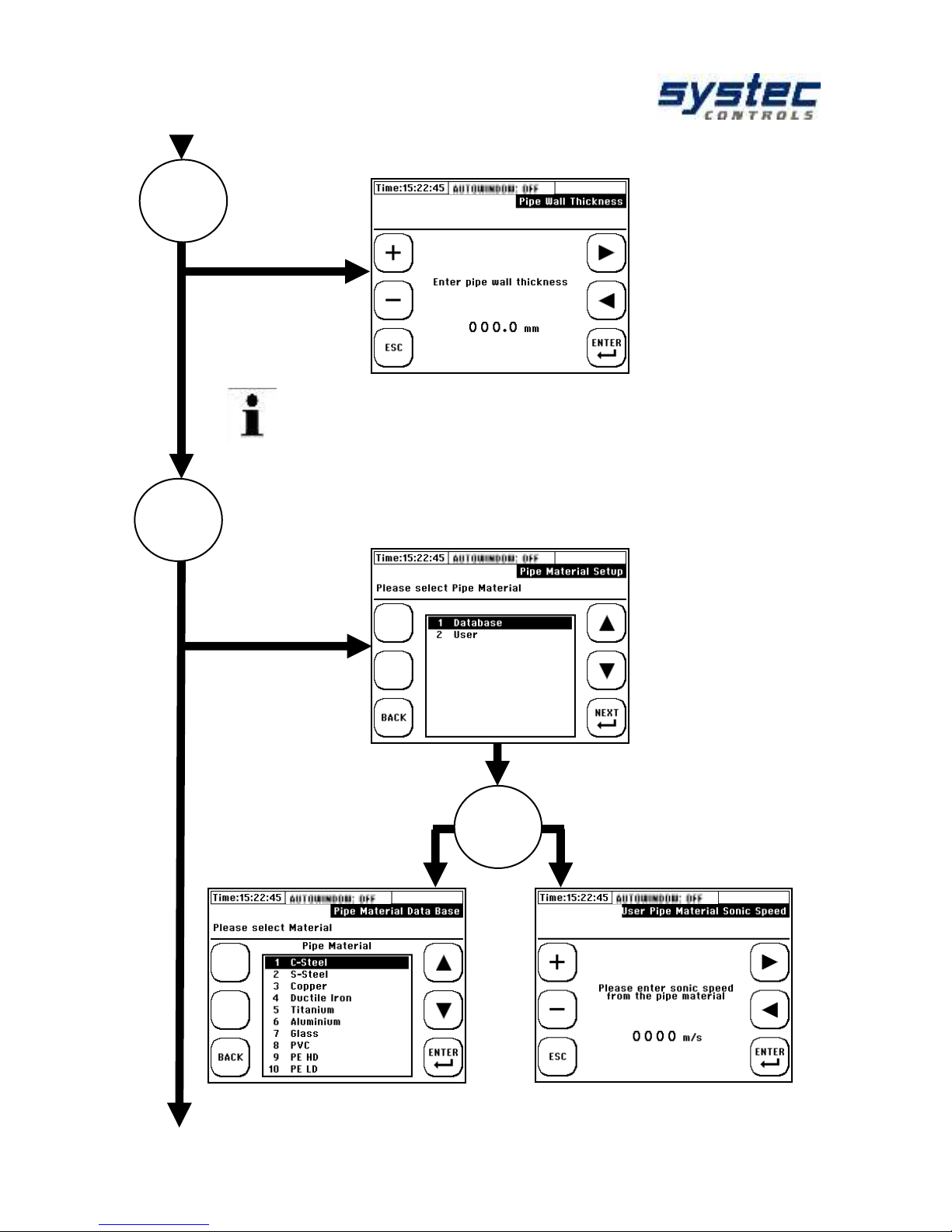

OR

Enter the pipe's wall thickness:

Choose pipe material:

Choose the pipe material Enter the sonic speed

from the database from the pipe material

Database from: manually:

It is advisable to use a wall thickness meter if you do not

know this parameter.

2

3

Page 28

deltawaveC-F/P

Manual

28 systec Controls Mess- und Regeltechnik GmbH

OR

Does the pipe have a Coating

NO

Enter the thickness of the YES

pipe

Select the database,

or user input if material

is not listed in the database

4

5

Page 29

deltawaveC-F/P

Manual

29 systec Controls Mess- und Regeltechnik GmbH

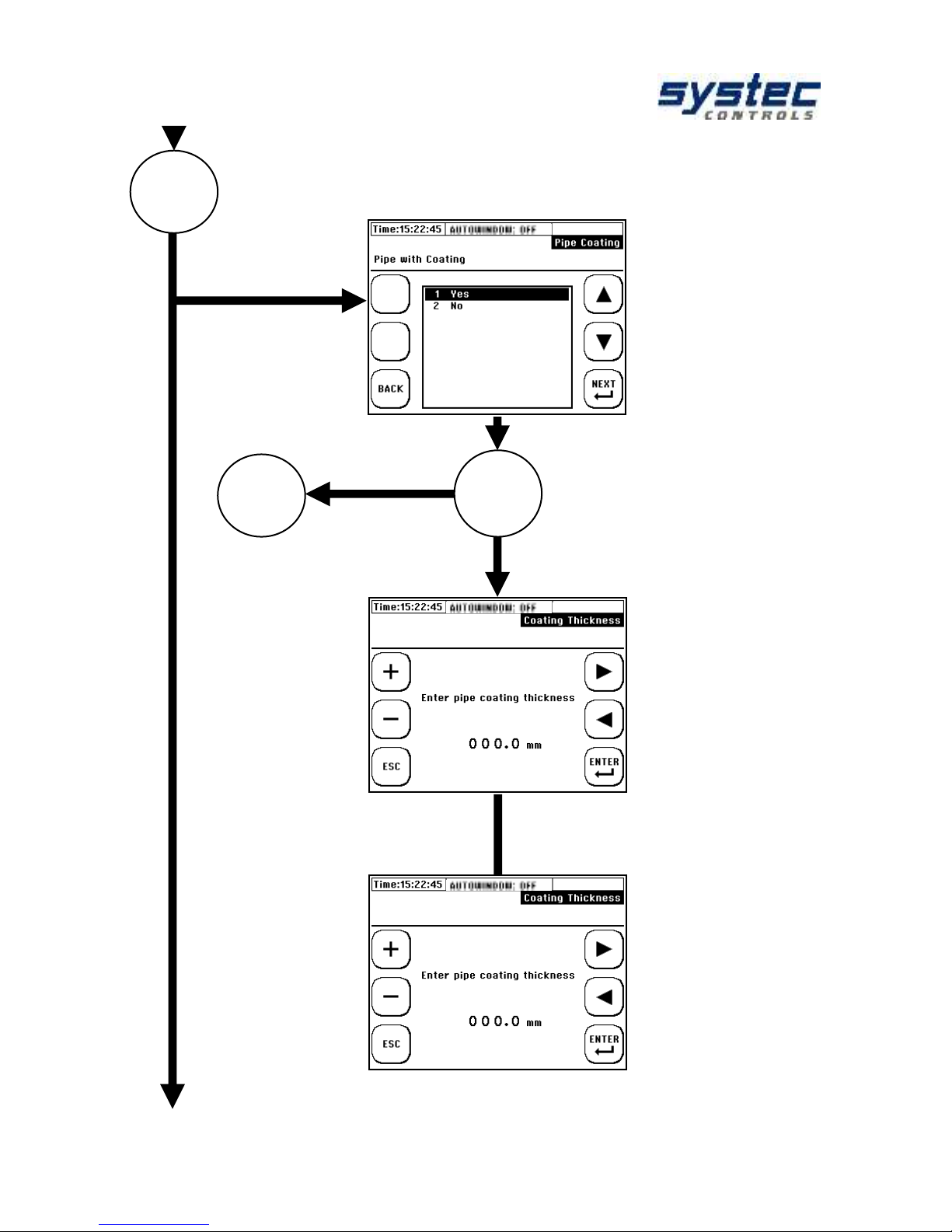

Select the medium:

5

Select the database, for

coating material

Enter the coating sonic

speed of the material

OR

Select the fluid, from the

database

Enter the fluid sonic

speed manually

OR

Page 30

deltawaveC-F/P

Manual

30 systec Controls Mess- und Regeltechnik GmbH

Enter the kinematic

viscosity of the

medium:

Enter the thermal

capacity of the

medium

Enter the density of

the medium

Page 31

deltawaveC-F/P

Manual

31 systec Controls Mess- und Regeltechnik GmbH

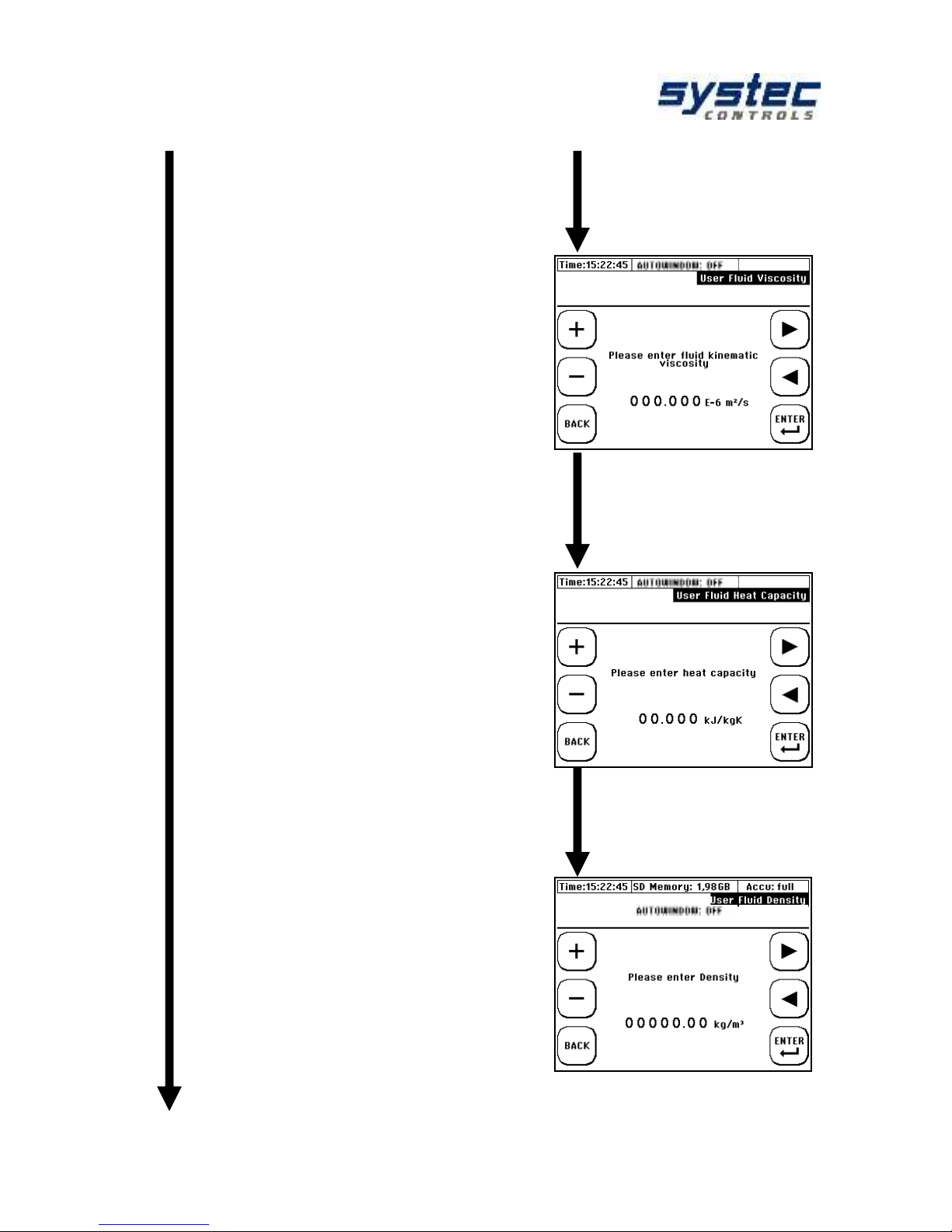

Select a suitable ultrasonic transducer:

Select a suitable mounting mode

For information on suitable transducers for specific pipe

dimensions, refer to chapter "deltawaveC-F/P and

components“.

6

7

Page 32

deltawaveC-F/P

Manual

32 systec Controls Mess- und Regeltechnik GmbH

Output of the distance between the ultrasonic transducers:

END

Important!

Please do always take care which mounting bar for transducers is

displayed. The displayed one bar must be used:

Short = 25cm, hole distance 7,5mm, (XUC-FW F21)

Long = 40cm, hole distance 15mm, (XUC-FW F10, F20)

The sensor distance in millimetres is always the distance between

the front edge of the ultrasonic transducer 1 (UP) to the front edge

of ultrasonic transducer 2 (DOWN) independent from the chosen

method of mounting.

The standard mounting type is "V-mounting".

Information on the mounting types can be found in the

chapter "Preparation for measurement".

Before you start

measuring we

highly

recommend a

zero setup (if

possible)

8

Page 33

deltawaveC-F/P

Manual

33 systec Controls Mess- und Regeltechnik GmbH

8.4 Sensor assembly / Sensor distance

The distance between the ultrasonic transducers is always measured between their

opposing surfaces in all mounting modes. Once you have completed the

parameterization of the measuring point, the flow transmitter displays the distances

that have to be set up using a measuring tape. When using a spacer bar in the socalled V-mode, you can position the transducers conveniently by means of the

spacer bar.

8.4.1 Introduction to the installation of ultrasonic transducers

Principle composition of the ultrasonic transducers:

Ultrasonic transducers (F05, F10 and F20/F21) is beige and made of plastic

(PEEK).

deltawaveC-F

deltawaveC-P

Figure 7: Principle composition of the ultrasonic transducers: 1: basic body, 2: cover, 3:

connection cable (RG316), 4: knurled screws for fixing on the mounting rail, 5: knurled screw

(variation of contact pressure), 6: support housing ("portable" type), 7: BNC connector (RG58,

female, "portable" type), 8: projection of the acoustic transmission surface

1 2 3 4 8

2

7

1

6

4 5 7

8

Page 34

deltawaveC-F/P

Manual

34 systec Controls Mess- und Regeltechnik GmbH

8.4.2 Mounting ultrasonic transducer

This chapter informs you of the possibilities for mounting the ultrasonic transducers.

The V-mode is standard for most applications.

V-Mounting

V-mounting results in a measurement in most

applications and is often the best compromise

achievable signal quality and accuracy.

W- Mounting

W-Mounting assembly is used when a

measurement result which is as exact as

possible and/or a high resolution is to be

achieved.

In the case of small pipe sizes, this mounting

type can also be useful due to the signal sensor

separation

Z- Mounting

Z-Mounting assembly is due to the minimal

signal path typically for large pipes or very dirty

or gas-loaded media with high signal

attenuation or signal dispersion for use

contaminants.

NO MOUNTING BAR

In some cases Z-mounting results in successful measurements on small pipe

diameters (< 20 mm) as well: if the received signals (pipe wall/V/W) can no longer

be unambiguously unselected or when the correct reception signals in the

measurement window cannot be uniquely positioned (look at 14.2.3)

Figure 8: Z-mounting example, only possible

without mounting rail (XUC-FW)

Figure 9: V- and W-mounting example

with mounting rail (XUC-FW)

Page 35

deltawaveC-F/P

Manual

35 systec Controls Mess- und Regeltechnik GmbH

8.4.3 Correct selection of transducer types

Below you will find a guide for the correct ultrasonic transducer selection, which has

proven to be successful in practice.

Pipe diameter

Transducer

Systematic

Comment

D < 35 mm

F21 Transducer

( ** )

35 mm > D < 110 mm

F10 Transducer

F21 Transducer

( ** )

( * )

110 mm > D < 250 mm

F10 Transducer

( ** )

250 mm > D < 400 mm

F10 Transducer

F05 Transducer

( ** )

( * )

D > 400 mm

F05 Transducer

( ** )

Systematic: ( ** ) –Best selection; ( * ) second best selection

8.4.4 Correct selection of mounting options

Below you will find a guide for the correct choice of mounting options, which has

proven to be successful in practice.

Pipe diameter

Mounting option

Systematic

Comment

D < 40 mm

W- Mounting

V- Mounting

Z- Mounting

( ** )

( * )

( * )

40 mm > D < 130 mm

W- Mounting

V- Mounting

Z- Mounting

( ** )

( ** )

( * )

If the SNR good

Disturbed signal

130 mm > D < 400 mm

V- Mounting

Z- Mounting

( ** )

( * )

D > 400 mm

V- Mounting

Z- Mounting

( ** )

( * )

If the SNR good

Systematic: (**) highest accuracy; (*) higher signal strength

Page 36

deltawaveC-F/P

Manual

36 systec Controls Mess- und Regeltechnik GmbH

8.4.5 Mounting of the Transducer in V-Mode or W-Mode

After the parameterization of the measuring point, the transmitter shows the

distance of the transducers in mm and the number of holes. The number of holes is

a reference quantity of the distance with simultaneous application of the mounting

rails for the ultrasonic transducers F10, F20 and F21.

There are two different lengths of mounting bars with different grid dimensions:

Short Bar = 40cm, hole distance 15mm (only for F10 and F20 Transducer)

Long Bar = 25cm, hole distance 7,5mm (only for F21Transducer)

For example: The whole number is „3“, this corresponds to the number of holes

between the ultrasonic sensors plus the position at which the thumbscrew of the

opposing transducer is mounted. Mount the sensors on the rail as shown. Fix the

transducers to the rail using the knurled screws (B).

deltawaveC-F

Example of the number of holes 3

deltawaveC-P

Example of the number of holes 5

If the wrong mounting rail is used or the wrong hole distance, the

measurement does not work or incorrect values are displayed!

0 1 2 3 4

5

0 1 2

3

Page 37

deltawaveC-F/P

Manual

37 systec Controls Mess- und Regeltechnik GmbH

deltawaveC-F

deltawaveC-P

For the long-term installation of transducers

only the coupling pads are recommended.

Place one acoustic coupling pad between

the acoustic transmission surface of the

transducer and the pipeline for each

ultrasonic transducer.

Do not use any additional coupling media

such as gels or pastes!

Make sure that the coupling pads lie flat on

the complete sensor surface.

Turn the thumbscrew max out, so that the

transducer base is located below the lower

edge of the sensor carrier (V-profile)

Apply a peanut-sized drop of ultrasonic

coupling gel (Magnalube) to the acoustic

transmission surface (offset downwards) and

rub it slightly.

Figure 10: XUC-FW F10 with acoustic

coupling pad

Figure 11: Transducer with an approx.

peanut-sized drop of coupling gel

The coupling gel allows a significantly better signal quality than the acoustic

coupling pads. However, high temperature signal, the coupling gel may run

and the acoustic signal coupling can be lost.

In this case a thermally stable coupling gel or acoustic coupling pad can be

used - contact systec Controls.

The coupling pads are stable long-term and allow for a sufficiently good

signal quality in most cases when used correctly. Use acoustic coupling foil

exclusively for ultrasonic transducers for fixed installation.

For optimum signal coupling, a higher contact pressure is necessary, which

usually cannot be produced with the mounting means of the portable

measuring device.

In rare cases it may happen that the use of an acoustic coupling gel proves

to be more appropriate than the acoustic coupling pads:

- Pipe surface with high roughness

- rapid flow of the coupling gel at high thermal loads

Page 38

deltawaveC-F/P

Manual

38 systec Controls Mess- und Regeltechnik GmbH

deltawaveC-F

deltawaveC-P

The ultrasonic transducers are attached by

stainless steel band on the pipeline. The

stainless steel tensioning band is designed

for the maximum diameter of the tube to be

used for your ultrasonic transducer and

tensioned via the tensioning buckle.

The tensioning band can be shortened

easily for smaller pipes.

To attach the ultrasonic transducers (with

or without the mounting rail), use the

stainless steel chains or hook-and-loop

bands.

The knurled screw is tightened in a

clockwise direction until a slight pressure

is applied

Figure 12: Mounting of XUC-PW with

stainless steel chains; 1: tension spring, 2:

hook for fastening

Figure 13: Mounting of XUC-FW with

stainless steel band; 1: clamping tool, 2:

clamping lock, 3: clamping band.

8.4.6 Mounting the ultrasonic transducers based on the Z method

Use a plastic or paper template to mark the mounting positions.

1. Wrap the plastic template once around the pipe at the mounting position of the

first ultrasonic transducer. Using a felt tip pen, draw a line on the pipe along the

template (corresponds with the pipe circumference)

Figure 14: Attaching the template tape

Figure 15: Mark the circumference

2

1

1

2

3

Page 39

deltawaveC-F/P

Manual

39 systec Controls Mess- und Regeltechnik GmbH

2. • On successful completion of parameterization, your deltawaveC-P/F

displays the axial distance between the ultrasonic transducers (transducer

distance). Measure the transducer distance based on the value displayed on your

deltawaveC-P/F, starting from the first line drawn to the position at which the

second line is to be drawn.

Figure 16: Mark the distance between

transducer

Figure 17: Mark the circumference for the

second transducer.

3. On the circumference lines, select

two exactly opposite positions.

4. Mount the first sensor to the centre

of mark 1.

5. Measure out the half of the pipe

circumference along the circumference

line from mark 2 and apply marking 3.

Figure 18: Opposed marks 1 & 2 at the

circumference lines

2

2

21

r

U

6. Mount the second sensor to the centre of the sensor front (not the sensor) at

mark 2 (see Figure 19 & Figure 20). The sensors are now exactly opposite.

1

2

Page 40

deltawaveC-F/P

Manual

40 systec Controls Mess- und Regeltechnik GmbH

Figure 19: Mark the position of the second

transducer at half circumferential distance

Figure 20: Mounted transducer, Z-mounting

8.4.7 Mounting the ultrasonic transducers at two

crossed measuring paths

The mounting type of both pairs of transducers must be the same (V-mounting, Wmounting or Z-mounting). It is not possible to combine different mounting methods.

For Z-mounting the transducers of the respective pair must be offset by 180 °. For V

and W mounting, the transducers of the respective pair are mounted on the same

side of the tube. Installation instructions for the exact alignment at 180 ° offset can

be found in the Z-type mounting aid (8.4.6).

3 1 2

3 1 2

Page 41

deltawaveC-F/P

Manual

41 systec Controls Mess- und Regeltechnik GmbH

8.5 Zero Setting

Before starting the measurement, we recommend performing a zero calibration.

Prerequisites for zero-point calibration are:

- that the device is configured correctly and that both ultrasonic

transducers are mounted properly on the pipe and electrically

connected to the transmitter

- the line is completely filled

- the flow rate is zero

If all prerequisites are fulfilled, perform a zero-point calibration, otherwise,

do not perform a zero-point calibration!

An incorrect zero point adjustment will have a more negative impact on the

measurement result than no zero adjustment!

Procedure:

1) Ensure zero flow

2) Navigation after switching on:

„Setup“ „Zero- Setup“

From the measuring window "Flow 1" outgoing:

„Setup“ „Zero Setup“

From the main menu "COMPL. SETUP"

outgoing: „Miscellaneous“ „Zero“ „Set Zero“

3) The zero point adjustment starts automatically.

Wait until the counter reaches the value "0" again.

4) After confirming (ENTER) the time correction of

the zero point adjustment, you are returned to the

"Setup" window.

Typical values for the zero point adjustment are generally in single-digit

range.

If you receive a "time correction" in two-digit range (and more), you can

assume that a (residual) flow was present during the zero-point adjustment.

The zero point will be automatically deleted when relevant parameters

(parameters pipe, parameter medium and parameter converter) have

been edited again.

Page 42

deltawaveC-F/P

Manual

42 systec Controls Mess- und Regeltechnik GmbH

You can check the detected zero point by navigating from the "Flow 1"

measurement window to the diagnostic window. In the measurement window, select

“Flow 1“ „DIAG“

The zero point remains stored in the device until it is automatically

overwritten with a new zero offset or has been removed manually by

"Delete zero".

The time correction value of the zero point adjustment is an essential part

of the parameter structure (see 11.1 Saving/Loading parameter data).

The zero point will be automatically deleted when relevant parameters

(parameters pipe, parameter medium and parameter converter) have been

edited again

For zero-point calibration, your deltawaveC-F/P determines the run-time

difference at zero flow, which can arise between the sensors and, if

necessary, a flow which is still present.

This determined time (dt ZERO) is automatically compensated in the flow

measurement. This increases the accuracy of your flow measurement. dt

ZERO is sign-loaded - a subsequent exchange of up- and downtransducers would thus double the error. The ultrasonic sensors are paired

at the factory and have a very low zero point error (typically <2 ns).

A zero flow rate cannot be guaranteed at every position of the pipeline

system. When installed carefully, this error is in the range of 0.00-0.03 m /

s flow velocity. The larger the pipeline is, the smaller is usually the zero

point error.

9 Heat measurement

Page 43

deltawaveC-F/P

Manual

43 systec Controls Mess- und Regeltechnik GmbH

The integrated heat quantity measurement allows you to determine the heating or

cooling power in your application using with the optionally available Pt100.

9.1 Introduction

The Pt100 No. 1 is mounted on the input side (T1 = Tin), Pt100 No. 2 at the output

of the process section (T2 = Tout). The placement of the ultrasonic sensors is

irrelevant as long as the volume flow is equal. There should be a pipe section to be

selected with optimal inflow / outflow (look at chapter 8.1.1).

Figure 21: Scheme of heat quantity measurement

The deltawaveC-F/P shows you the heat output and the accumulated heat quantity.

Calculating thermal output

The cross-sectional area of the pipe's inner diameter [A] is multiplied by the flow

velocity [v] and specific thermal capacity of the medium [c], as well as the

or

deltawaveC-F

deltawaveC-P

heat / power

volume / volume flow

Pt100

T2

Pt100

T1

outlet

temperature

inlet

temperature

ultrasound

transducer

Q… volume flow

Pin

P

out

determination of

heat quantity

Page 44

deltawaveC-F/P

Manual

44 systec Controls Mess- und Regeltechnik GmbH

dtQQ

TTcvAQ

coldhotw

)(

differential temperature of both Pt100, [Tout – Tin]. The product defines thermal

output [Q] in W units.

)( inoutw TTcvAQ

][kWQ

Calculating heat (quantity)

The heat quantity is derived as a function of thermal output over time.

]/,[ hkWJQ

9.2 Installing the Pt100

The Pt100 are mounted on the pipeline using the supplied stainless steel tapes.

Figure 22: At pipe mounted Pt100

It is irrelevant whether you attach the Pt100 to the pipeline with the longer

or shorter side of the housing.

For the determination of the heat quantity the determination of the correct

temperature difference is important (relative measurement). This means

that the temperature readings can deviate absolutely relative to a reference

(for example, against an immersion thermometer).

It is important to calibrate both Pt100 and to ensure that both Pt100 show

the same measured value in a volume of the same temperature (the

difference between the Pt100 before the installation on the pipeline should

be zero degree).

The thermal insulation or the use of thermal grease during assembly of the

Pt100 can significantly reduce the measurement uncertainties when

determining the temperature difference.

Page 45

deltawaveC-F/P

Manual

45 systec Controls Mess- und Regeltechnik GmbH

9.3 Parameterization of the Pt100 for the

heat quantity measurement

Before installing the temperature sensors on the pipeline, the temperature

difference between both Pt100 should be approximately zero degree in a volume of

thermal equilibrium.

We recommend that both temperature sensors be immersed in a tube with liquid for

approx. 2...5 minutes (the liquid should be at room temperature) before the tubes

are mounted on a pipeline. Avoid touching the probes in advance of the calibration.

To check the calibration, please use the display in "Measuring window 3", "Heat

quantity", as the temperature difference between T2-T1 is displayed in this

measuring window. After calibration, the temperature difference should not be > 0.2

° C (2 / 10K). If the temperature difference is higher, repeat the calibration

procedure.

Further information on the parameterization of the Pt100 can be found in the

chapters 11.9.2, 11.9.3 and 11.10.1.

In addition to the zero adjustment, the individual temperature readings can be offset

(adjustment to reference value / compensation of deviations).

Example: In the pipeline there is a resistance thermometer which shows

80°C. However, your deltawaveC-F/P contact resistance thermometer

Pt100 shows only 78.5 ° C. The difference can be corrected manually. In

this case, you specify a default value of 80 ° C. The default value is an

absolute value and no offset.

The parameterized clamped value is valid for both Pt100. The temperature

measurement is clamped with one second (average value formation). For low

measuring dynamics and small temperature differences between Pt100 No. 2 and

No. 1, it is recommended to increase the Pt100 clamping value. An increase in the

clamping has a positive effect on the stability of the temperature difference

measurement.

Page 46

deltawaveC-F/P

Manual

46 systec Controls Mess- und Regeltechnik GmbH

10 Measuring windows deltawaveC-

F/P

10.1 Headline

The header is the same for each of

the three measurement windows and

displays basic values and status

messages:

1) General information

2) General measurement values

3) Name of the UI window

4) Status display

5) Status display for communication

Display

Explanation

Gen. Inform.

Time

Format: hh:mm:ss

AUTOWINDOW

ON / OFF

Auto window function

IOE

Indicates that the memory for the pulse output is full and the pulse

output is disabled (look at chapter 11.5.4).

Battery condition :

Battery is charging ; 50-100%; 25-49%; 10-25%; <10%

Value

s

Vs

Sound velocity of medium in m/s

SigQ

Signal quality (percentage of valid signals)

T1 / T2

Temperature values of the Pt100

Communication

MODBUS ON

MODBUS OFF

Status for the MODBUS communication.

Priority over SER SST. status.

SER. SST. ON

SER. SST. OFF

Status display for serial communication.

Priority over LOGGER status.

LOGGER ON

LOGGER OFF

Status display for the data loggers.

Priority over USB status.

USB ON

Indicates that the USB interface is connected to an external master.

QLOGGER ON

Indicates that the Quick Logger is active.

Measurement

OK

Everything OK. Valid signals are evaluated.

NO SIG

No valid signals present.

Error

Problems with the ultrasound board. Possible reasons: defective, DSP

update necessary.

VS ERR

0.8 * Vs parameterized <Vs> 1.2 * Vs parameterized

Possible reasons: wrong signal (W instead of V, V instead of W)

VP / VL ERR

Error in the calculation of the signal propagation.

1 2 3

4

5

Page 47

deltawaveC-F/P

Manual

47 systec Controls Mess- und Regeltechnik GmbH

10.2 Measuring window "Flow 1"

In the flow measurement window 1 you get all the important information, compactly

summarized for your flow, heat output and heat quantity measurement.

Navigation in the User-Interface:

1) Approximately 10 seconds after

switching on, it will automatically switch

from the home screen to the central

measuring window "Flow 1".

2) From the main menu, starting:

Select "ESC" then "MEASURE."

Display

Explanation

FLOW

Displays the current volume flow

TOTAL

FLOW

Totalizer flow = flow meter

(Summed up volume)

Parameterizable types: Sum counter (+), negative counter

(-), absolute counter (+/- sum), difference counter (+/- diff)

POWER

Displays the current heat output.

HEAT

TOTAL

Totalizer heat quantity = heat quantity counter

(Summed heat quantity)

Parameterizable types: Sum counter (+), negative counter

(-), absolute counter (+/- sum), difference counter (+/- diff)

Password activated/

deactivated

Status of password protection.

Switch to the setup window

ONLY portable: activates

the Quick-Logger

Sets the totalizer (flow and heat

quantity) to zero.

Change to measuring window

"Flow 2".

Switch to diagnostic window.

Switch to the oscilloscope

window.

Page 48

deltawaveC-F/P

Manual

48 systec Controls Mess- und Regeltechnik GmbH

10.3 Measuring window "Flow 2"

In the flow measurement window 2 you get all the important information, compactly

summarized for your flow measurement (without heat measurement).

Navigation in the User-Interface:

From the main measurement window

"Flow 1" outgoing: Select "Flow 2"

Display

Explanation

FLOW

Displays the current volume flow

Fluid

VELOCITY

Indication of the flow velocity of the medium in the pipe

TOTAL

FLOW

Totalizer flow = flow meter

Parameterizable types: Sum counter (+), negative counter

(-), absolute counter (+/- sum), difference counter (+/- diff)

Password activated/

deactivated

Status of password protection.

Switch to the setup window

Change to measuring window

"Flow 1".

Sets the totalizer (flow and heat

quantity) to zero.

Change to measuring window

"heat quantity".

Switch to diagnostic window.

Switch to the oscilloscope

window.

Page 49

deltawaveC-F/P

Manual

49 systec Controls Mess- und Regeltechnik GmbH

10.4 The measuring window "heat quantity"

In the "Heat quantity" measurement window, you get all the important information,

compactly summarized for your heat quantity measurement.

Navigation in the User-Interface:

From the main measurement window

"Flow 1" outgoing: Select "Flow 2" then

„Heat“

Display

Explanation

FLOW

Displays the current volume flow

POWER

Displays the current heat output

HEAT

TOTAL

Totalizer heat quantity = heat quantity counter

Parameterizable types: Sum counter (+), negative counter

(-), absolute counter (+/- sum), difference counter (+/- diff)

DIFF.

TEMPERATURE

Displays the currently measured temperature difference

Password activated/

deactivated

Status of password protection.

Switch to the setup window

Change to measuring window

"Flow 2".

Sets the totalizer (flow and heat

quantity) to zero.

Switch to the password window

(Activation / deactivation)

Switch to diagnostic window.

Switch to the oscilloscope

window

Page 50

deltawaveC-F/P

Manual

50 systec Controls Mess- und Regeltechnik GmbH

10.5 Password protection

The deltawaveC-F/P is equipped with password protection. After enabling

password protection, it is only possible to switch between the measurement

windows and the password display. Parameters or totalizers cannot be

changed when password protection is activated.

Activation of the password:

To access the password display, navigate to the last measurement window.

The following screen is the password window.

Please select "Activate password" or "Deactivate password" and confirm

the function with the "Enter" key.

Edit the number code by using the arrow

(navigation), as well as "+" and "-" (zoom in /

out) buttons. Press "ENTER" to confirm the

entered password. For security reasons, a

second password request is made. Re-Enter

the code and confirm. After that the

password protection is activated or

deactivated depending on the function

selected.

If you have lost/forgotten your password and you can´t deactivate

password protection then please contact systec Controls.

Page 51

deltawaveC-F/P

Manual

51 systec Controls Mess- und Regeltechnik GmbH

10.6 The measurement windows of the 2channel deltawaveC-F

Navigation in the User-Interface:

1) Approximately 10s after power-up the

screen automatically switches from the

start screen to the central measurement

window "CH1 / CH2".

2) From the main menu: Choose

"ESC" then "MEASURE."

CH1/CH2

CH1&CH2

(CH1+CH2)/2

The individual results are shown in the individual measurement windows in

terms of flow velocity, volume flow, totalizer (volume and heat quantity) and

power. Either for the individual channel or according to the illustrated

calculation (sum, difference or mean value)

Switch to the setup window

Switch to the password window

(Activation / deactivation)

Sets the totalizer (flow and heat

quantity) to zero.

Switch the measurement

channel „CH1&CH2“

Switch the measurement

channel „CH1/CH2“

Switch the measurement

channel „(CH1+CH2)/2“

Switch to diagnostic window.

(after CH-Selection)

Switch to the oscilloscope

window

Page 52

deltawaveC-F/P

Manual

52 systec Controls Mess- und Regeltechnik GmbH

11 The main menu (complete menu)

11.1 Loading, saving and managing

parameter data

Navigation in the User-Interface:

From the main measurement window "Flow 1":

select „SETUP“ then „COMPL SETUP“ select

„Save/Load Site Param“

Your deltawaveC-F/P offers you the possibility to

save, load and display all relevant parameters. This

saves time when you need to perform

measurements of recurring measuring points.

Via the "file access", up to 9 parameter sets can

be stored and made available as a parameter file "*

.PAR" on the SD card. The format corresponds to a

text file ("* .txt") and can be visualized and edited at

any time via a text editor or a spreadsheet program.

To select a parameter set, use the arrow keys to

select a memory location and confirm with "Next".

You now have the option to check all parameters

before saving. The parameter data is distributed

over 7 measurement windows. To switch between

the parameter data, use the arrow key.

IMPORTANT

The parameter overview shows the current contents

of the PAR file. To ensure that the content matches

the current parameters, the current parameter set

must first be saved in the corresponding file.

Page 53

deltawaveC-F/P

Manual

53 systec Controls Mess- und Regeltechnik GmbH

Resetting the PAR file name and

content

Save the current parameter data

Switch between the overview

windows

Switch to edit file name

Back to file list

Loading the PAR content

Edit the file name:

1) Use the arrow keys to select characters that

correspond to the PAR file name (max. 7

characters)

2) Press "ENTER" to confirm the selection of a

character

3) "DEL" clears the last character.

4) Exit by navigating to "DONE" and confirm with

"ENTER“

The new name is only accepted when the "Save" function is activated in

Overview 1.

The "Default.PAR" file is regularly overwritten with the current parameters

(cyclical saving of the current settings) so that this memory space should

not be used.

The parameter data are stored from firmware 1.33.x on the device-internal

SD memory card and can be exported via USB.

The copying / saving of parameter files from the device-internal SD card are only

possible via the USB interface. As soon as the transmitter is connected to a PC via

USB, the SD card is recognized as an external data memory and data can be

exchanged.

The system only registers "known" PAR files.

If a parameter file is to be transferred from a deltawaveC-F/P (device 1) to

a different device (device 2) via USB, it must be ensured that the name of

the PAR file is assigned to one of the names from the list of Device 2 (see

file access, e.g.: FILE1.PAR). The file (device 2) can then be directly

replaced / overwritten.

Systec Controls recommends storing and backing up parameter sets of

important or recurring applications. This saves time and enables fast,

efficient assistance in cases support where support is needed

During the year 2017, a software tool will be available that allows

convenient creation and editing of parameter files. If you are interested,

please contact systec Controls.

Page 54

deltawaveC-F/P

Manual

54 systec Controls Mess- und Regeltechnik GmbH

11.2 The pipe parameters

Navigation in the User-Interface:

From the main measurement window "Flow 1":

select „SETUP“ then „COMPL SETUP“ select

„Pipe Setup“

The pipe parameters are part of the Quick Setup

(mandatory parameters), but can also be edited

individually via the main menu.

Pipe Setup

outside diameter

outside Circumference

or

Enter

outside diameter

Enter

outside Circumference

Enter wall thickness

Pipe material

from data base

User defined

pipe material

or

Does the pipe have an internal liner?

YES

NO

or

Thickness of liner

Liner material

Liner material

User defined

or

E N D

Page 55

deltawaveC-F/P

Manual

55 systec Controls Mess- und Regeltechnik GmbH