Systec IT8000-DC-W-Ex2/22, IT8000-AC-W-Ex2/22, IT8000-AC-E-Ex2/22, IT8000-DC-E-Ex2/22 Technical Manual

Technical Manual

IT8000-AC-W-Ex2/22

IT8000-DC-W-Ex2/22

IT8000-AC-E-Ex2/22

IT8000-DC-E-Ex2/22

Freely Programmable Weighing Terminal

For Installation In Ex Zone 2 / 22

II 3G Ex ic nA IIC T4 Gc

II 3D Ex ic tc IIIB T50°C Dc IP54

or II 3D Ex ic tc IIIC T50°C Dc IP65

August 2013

ST.2309.1327

Rev. 4

© SysTec Systemtechnik und Industrieautomation GmbH, Bergheim, Germany

2 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 3

Technical Manual IT8000-**-*-Ex2/22

Date: August 30, 2013

File: IT8000_EX222_THE.DOC

Operating System: RTP 7.1 or higher

4 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

Published By:

© SysTec Systemtechnik und Industrieautomation GmbH, Bergheim, Germany

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted

in any form or by any means, mechanical, photocopying, recording, or otherwise, without the prior written

permission of SysTec GmbH.

Terms and product names mentioned in this publication are trademarks, registered trademarks or

service marks of their respecti

ve owners. Use of a term should not be regarded as affecting the validity

of any trademark, registered trademark or service mark.

EPSON ESC/P® is a registered trademark of the SEIKO EPSON Corporation.

TOLEDO® is a registered trademark of Mettler-Toledo Inc.

Please Note:

While every precaution has been taken in the preparation of this manual, SysTec GmbH assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

the information contained herein.

The publisher is grateful for any information and/or advice that may contribute to correct errors or omissions

in following editions.

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 5

Contents

1 Introduction ......................................................................................................................... 7

1.1 About This Manual....................................................................................................... 7

1.2 Safety Symbols Used In This Manual .............................................................................. 7

1.3 Safety Advice ............................................................................................................. 7

1.4 Declaration Of Conformity............................................................................................. 9

2 Marking............................................................................................................................. 10

3 System Description ............................................................................................................. 11

3.1 General .................................................................................................................... 11

3.2 Basic Units And Options ............................................................................................. 11

3.3 Housing.................................................................................................................... 12

3.4 Main Board CPU8000 ................................................................................................. 13

4 Intended Use ..................................................................................................................... 14

5 Assembly .......................................................................................................................... 15

6 Installation......................................................................................................................... 16

6.1 General .................................................................................................................... 16

6.2 Equipotential Bonding ................................................................................................. 16

6.3 Shielding .................................................................................................................. 16

6.4 Connection Of Cables................................................................................................. 17

7 Installation Of External Connections With Type Of Protection 'Ex-nA' ........................................ 18

7.1 Connection Of Power Supply To IT8000-AC-*-Ex2/22 .................................................... 18

7.2 Connection Of Power Supply To IT8000-DC-*-Ex2/22 .................................................... 19

7.3 Connection Of Analog Scale To ADM / ADC .................................................................. 22

7.4 Connection Of IDNet Scale Base To IDN........................................................................ 25

7.5 Connection Of Digital Scale Bases With RS485 Interface To DWM.................................... 27

7.6 Connection Of Serial Interfaces SIM ............................................................................. 30

7.7 Connection Of Parallel I/Os PIM ................................................................................... 34

7.8 Connection Of Fieldbus Module FBM ............................................................................ 37

7.9 Connection Of Profibus DP Module PCM ....................................................................... 38

7.10 Connection Of Ethernet Module ECM .......................................................................... 40

7.11 Connection Of 15-Bit Analog Output DAU15 ............................................................... 42

8 Commissioning................................................................................................................... 44

8.1 General .................................................................................................................... 44

9 Installation Examples........................................................................................................... 45

9.1 Installation Example IT8000-AC-*-Ex2/22 ..................................................................... 45

9.2 Installation Example IT8000-DC-*-Ex2/22 ..................................................................... 46

9.3 Installation Example IT8000-DC-*-Ex2/22 With Akku-Box................................................ 47

10 Service Mode ................................................................................................................... 48

10.1 General................................................................................................................... 48

10.2 Display And Keyboard .............................................................................................. 49

10.3 Operator Prompting .................................................................................................. 50

10.4 Overview ................................................................................................................ 51

10.5 Interface Configuration ............................................................................................. 52

10.6 Header Ident Data .................................................................................................... 56

10.7 Detail Ident Data ...................................................................................................... 57

10.8 Application Setup..................................................................................................... 58

10.9 RAM Data Backup.................................................................................................... 61

6 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

10.10 Hardware Test ....................................................................................................... 62

10.11 S5 Data Block ........................................................................................................ 68

11 Transport, Maintenance And Cleaning .................................................................................. 69

11.1 Transport ................................................................................................................69

11.2 Maintenance ............................................................................................................ 69

11.3 Replacement Of Fuse (Only IT8000-DC-*-Ex2/22)......................................................... 69

11.4 Cleaning.................................................................................................................. 70

11.5 Security Check.........................................................................................................70

11.6 Functional Test ........................................................................................................ 70

11.7 Repair.....................................................................................................................70

11.8 De-Installation..........................................................................................................70

11.9 Disposal ..................................................................................................................70

12 Trouble Shooting............................................................................................................... 71

13 Technical Data.................................................................................................................. 72

13.1 Basic Units .............................................................................................................. 72

13.2 Options................................................................................................................... 73

13.3 Ex-Relevant Electrical Data For Type Of Protection 'Ex-nA' ............................................. 74

14 Annex ............................................................................................................................. 77

14.1 ACK/NAK-Protocol.................................................................................................... 77

14.2 Exchange Of EPROMs ............................................................................................... 78

14.3 Replacing The Battery ............................................................................................... 81

14.4 Combination Of Options ............................................................................................ 83

15 Dimensions ...................................................................................................................... 84

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 7

1 Introduction

1.1 About This Manual

This manual contains information and Technical Data for the use, the installation and the operation of

the weighing terminal IT8000-AC-W-Ex2/22, IT8000-AC-E-Ex2/22, IT8000-DC-W-Ex2/22 and IT8000DC-E-Ex2/22.

Information applicable to all versions refers to 'IT8000-Ex2/22'. Specific information is marked with the

full designation of the respective version, e.g. IT8000-DC-W-Ex2/22.

The weighing terminal must only be operated by trained personnel.

In addition to this manual further information is provided in the following documentation:

ADM / DUAL-ADM / ADM8000-Exi Calibration Manual, Order-No.: ST.2309.0688

MultiRange Calibration Manual, Order-No.: ST.2309.0057

Revere SLC, Calibration Manual, Order-No.: ST.2309.0362

HBM C16i, Calibration Manual, Order-No.: ST.2309.0248

1.2 Safety Symbols Used In This Manual

Safety relevant information is shown with corresponding symbols as follows:

Ex

W A R N I N G

Failure to observe this precaution could result in serious injuries or fatal accidents due to

ignition of an explosive atmosphere. Please make absolutely sure that these precautions are

observed in order to ensure safe operation of the equipment.

W A R N I N G

Failure to observe this precaution could result in serious injuries or fatal accidents. Please make

absolutely sure that these precautions are observed in order to ensure safe operation of the

equipment.

CAUTION

Failure to observe this precaution could result in damage to or destruction of the equipment or

bodily harm! Please make absolutely sure that these precautions are observed in order to ensure

safe operation of the equipment.

Note: This indicates an advice for the designated use of the equipment and/or additional information to

avoid inappropriate handling.

1.3 Safety Advice

Ex

W A R N I N G

Before opening the housing make absolutely sure that all power sources to this instrument are

disconnected and that no potentially explosive atmosphere can be present at any time!

The de-energized state is reached by disconnecting the supply voltages to the instrument and

to all external devices connected to the interfaces of the weighing terminal.

Ex

W A R N I N G

Exercise utmost care when making checks, tests and adjustments that can actuate movable

parts such as feeding devices, gates, flaps, conveyors, etc. Make absolutely sure that nobody

is within reach of movable parts.

8 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

Ex

W A R N I N G

When this unit is included as a component part of a system, the resulting system design must

be reviewed by qualified personnel who are familiar with the construction and operation of all

individual components in the system and the potential hazards involved.

Ex

W A R N I N G

For installation, service and operation of the unit, the ATEX directive as well as all locally

applicable regulations for safety and the prevention of accidents must be observed!

Ex

W A R N I N G

Input voltage of the instrument must comply with local mains supply!

Ex

W A R N I N G

This module and its associated equipment must only be installed, adjusted and maintained by

qualified personnel authorized by SysTec GmbH!

Ex

W A R N I N G

Connection of peripheral devices to IT8000-Ex2/22 is made in compliance with Ex type of

protection 'Ex-nA'. The values of connected load must be observed. Connected peripheral

devices installed in hazardous area must have appropriate Ex protection.

Ex

W A R N I N G

When the instrument is permanently connected to the power supply, an easily accessible

separator must be included in the supply circuit! It must either be located in safe area or -if

installed in Ex area- have appropriate Ex protection for the place of installation.

Ex

W A R N I N G

The weighing terminal must not be installed in areas where electrostatic charging is possible

which may produce spark discharges, brush discharges or propagating brush discharges at the

front panel.

Comment: According to common knowledge, the use of the equipment and the cleaning with a

damp cloth do not produce such a high surface charge density. However, the front panel must

not be wiped with a dry cloth!

W A R N I N G

Risk of electrical shock! When operating electrical devices, parts of this devices are connected

to dangerously high voltages. Inappropriate use of such devices may lead to serious bodily

injuries or substantial damages to property.

W A R N I N G

The power supply unit of the weighing terminal provides SELV voltages in accordance with EN

60950. Make sure that any peripheral device connected to the weighing terminal containing its

own power supply also uses SELV voltages!

Ex

W A R N I N G

This weighing terminal must not be used in Ex-Zone 0, 1, 20 and 21.

It is the sole responsibility of the employer / operating company to classify the area of

installation (zone, group, temperature class). To that effect, the assistance of the Technical

Supervisory Service or any other technical authority may be utilized!

W A R N I N G

The device uses the short-circuit / overcurrent protection of the on-site mains supply.

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 9

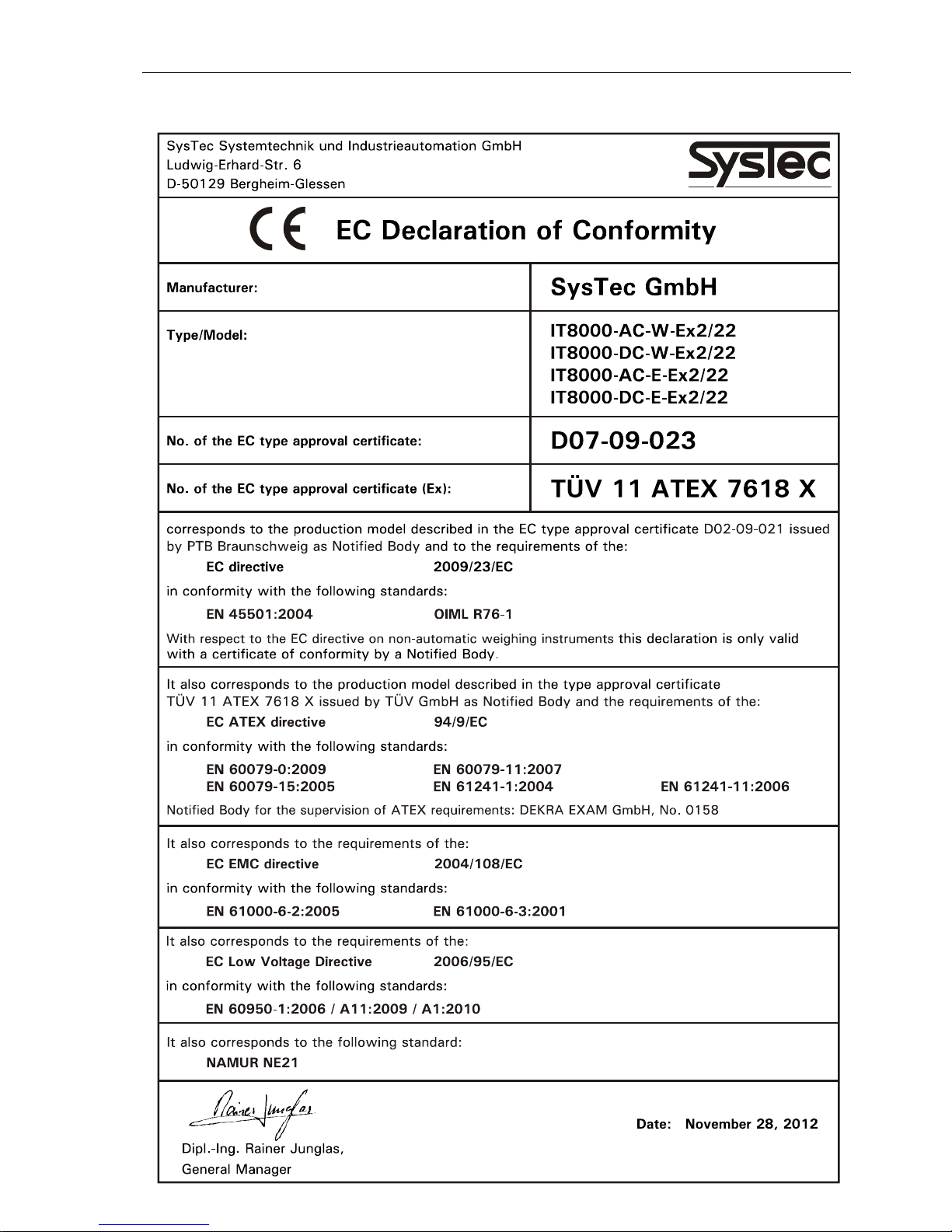

1.4 Declaration Of Conformity

10 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

2 Marking

Systec Systemtechnik und Industrieautomation GmbH

Ludwig-Erhard-Straße 6

Manufacturer

50129 Bergheim-Glessen

IT8000-AC-W-Ex2/22

IT8000-AC-E-Ex2/22

IT8000-DC-W-Ex2/22

Designation

IT8000-DC-E-Ex2/22

Serial-No. Ex yy nnnn (yy=year of construction / nnnn=consecutive number)

Range of ambient temperature –10°C to +40°C

Ex classification

II 3G Ex ic nA IIC T4 Gc

II 3D Ex ic tc IIIB T50°C Dc IP54 or

II 3D Ex ic tc IIIC T50°C Dc IP65

CE marking

Type examination certificate TÜV 11 ATEX 7618 X

Service Only by qualified service personnel authorized by SysTec GmbH

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 11

3 System Description

3.1 General

IT8000Ex is a universal weighing terminal for use in a variety of applications such as data logging, data

capturing and set point control, suitable for installation in Ex zones 2 and 22.

It connects to weighing platforms with analog or digital force transducers. The analog version supports

the connection of up to two understructures with a total of up to 16 strain gauge loadcells with an

impedance of 350 each in any combination. By means of an external extension module it is possible

to connect up to 6 additional understructures.

Alternatively, understructures with digital force transducers can be connected.

With its modular concept, the IT8000-Ex2/22 features in its basic configuration three serial interfaces

as well as four parallel opto-isolated inputs and four opto-isolated outputs for external devices. For

more complex applications several interface extension modules are available, for a fourth serial

interface (FBM), Profibus DP (PCM) or Ethernet communication ECM).

The variable I/O design provides up to 64 digital inputs and 64 digital outputs, plus analog inputs /

outputs.

The IT8000-Ex2/22 is freely programmable, operation and program sequence can be easily adapted to

the specific application. Comprehensive standard software is available for standard applications such as

filling, batching, checkweighing, data logging, truck weighing, etc. The design of custom-specific

programs is possible with the RTG program generator which provides the tools for simple and efficient

programming.

3.2 Basic Units And Options

IT8000-Ex2/22 is available in 4 basic versions:

Type Housing Description Article-No.

IT8000-AC-W-Ex2/22 Wall-mount/

desk-top

Basc unit for wall-mount / desk-top installation

with 2.5m line cord with free ends

to connect to 110 - 240 VAC

X8SYS001

IT8000-AC-E-Ex2/22 Panel-mount Basic unit for panel-mount installation

with 2.5m line cord with free ends

to connect to 110 - 240 VAC

X8SYS011

IT8000-DC-W-Ex2/22 Wall-mount/

desk-top

Basc unit for wall-mount / desk-top installation

with screw terminals

to connect to 12 – 30 VDC

X8SYS005

X8SYS006*

IT8000-DC-E-Ex2/22 Panel-mount Basic unit for panel-mount installation

with screw terminals

to connect to 12 – 30 VDC

X8SYS015

X8SYS016*

* The versions X8SYS006 and X8SYS016 feature the main module CPU8000-NTP-Ex2/22 that

provides low-battery indication for battery operation.

12 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

The following modules are available as options:

Option Description Article-No.

ADM Plug-on weighing module for connection of analog loadcells 13OPT100

ADC Plug-on weighing module for connection of analog loadcells 17OPT100

IDN Plug-on module to connect one digital IDNet platform 17OPT101

DWM Plug-on module to connect one digital platform with RS485 interface 17OPT103

SIM-RS232 Plug-on module with serial RS232 interface 10OPT220

SIM-20mA Plug-on module with serial 20mA interface 10OPT221

SIM-RS485.4 Plug-on module with serial RS485 4-wire interface 10OPT222

SIM-RS485.2 Plug-on module with serial RS485 2-wire interface 10OPT225

SIM-RS485.Opto Plug-on module with opto-isolated serial RS485 interface 10OPT230

DAU15 Plug-on module with analog 0/2-10V or 0/4-20mA output 10OPT231

PIM Plug-on module with two digital inputs/outputs 10OPT300

FBM Plug-on module with socket for fourth serial interface 11OPT301

PCM Plug-on module with Profibus-DP interface 17OPT400

ECM Plug-on module with Ethernet interface

(11OPT304-5/10 incl. 5m/10m Ethernet-Kabel)

11OPT304

3V battery 3V lithium battery Varta CR ½ AA 96ZUB002

3.3 Housing

IT8000-Ex2/22 is incorporated in a stainless steel housing with cable glands to connect cables to

peripheral devices. It is available in two versions:

The housing for desk-top / wall-mount installation (IT8000-**-W-Ex2/22) is protected to IP65.

The housing for panel-mount installation (IT8000-**-E-Ex2/22) is inserted in a suitable cutout of a

switch cabinet and fixed from the rear with 8 mounting brackets. When installed accordingly, the front

of the terminal -in combination with the circumferential gasket between terminal and switch cabinet- is

protected to IP65. When installed in Ex zone 2 (as per II 3G Ex ic nA IIC T4 Gc) and Ex zone 22 with

non-conductive dust (as per II 3D Ex ic tc IIIB T50°C Dc IP54) the surrounding housing must be

protected to IP54 or better.

When installed in Ex zone 22 with conductive dust (as per II 3D Ex ic tc IIIC T50°C Dc IP65) the

surrounding housing must be protected to IP65 or better. The surrounding housing (e.g. switch cabinet)

must conform to the requirements of EN60079-0 section 26.4.

Ex

The housings must be included in the equipotential bonding of the installation.

See section 'Dimensions' for space requirements.

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 13

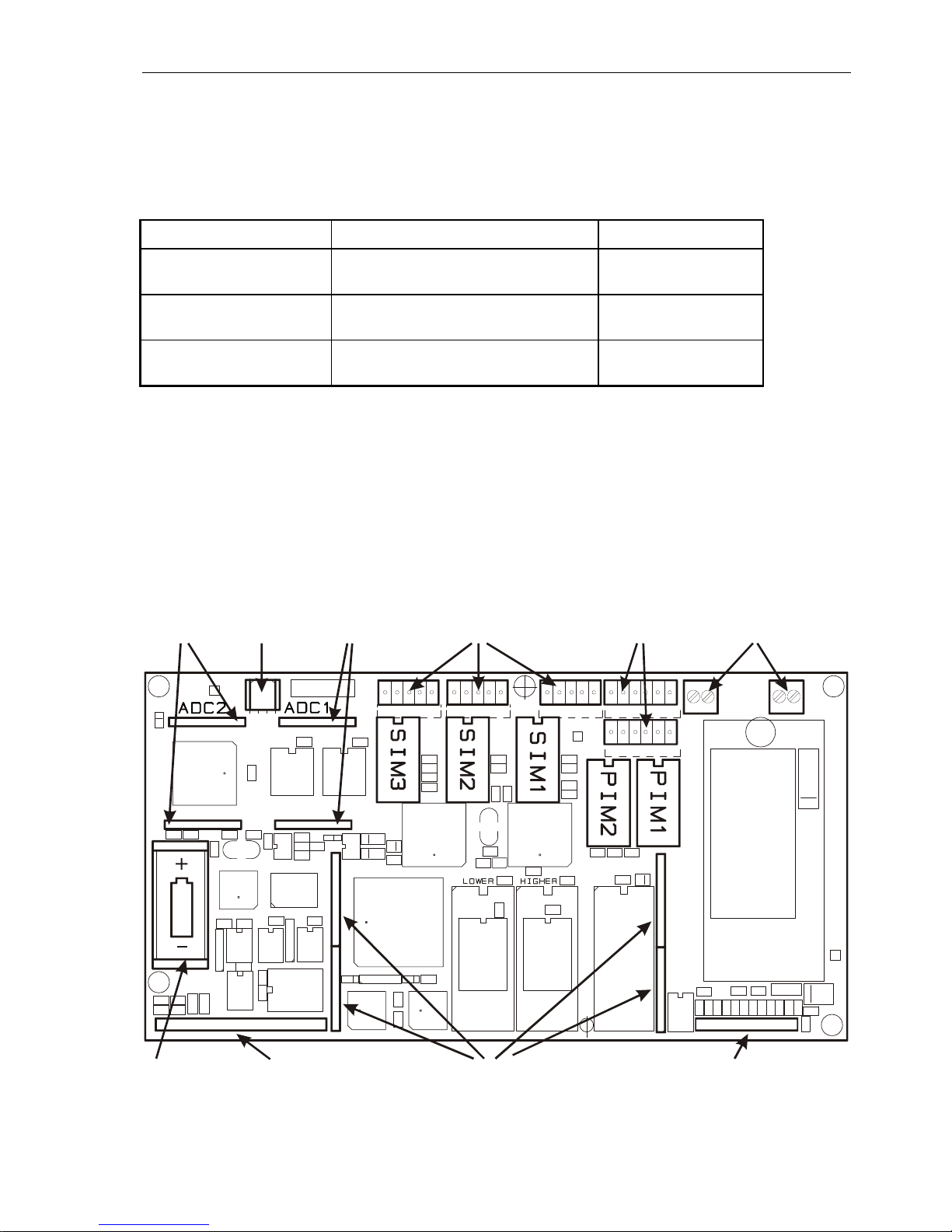

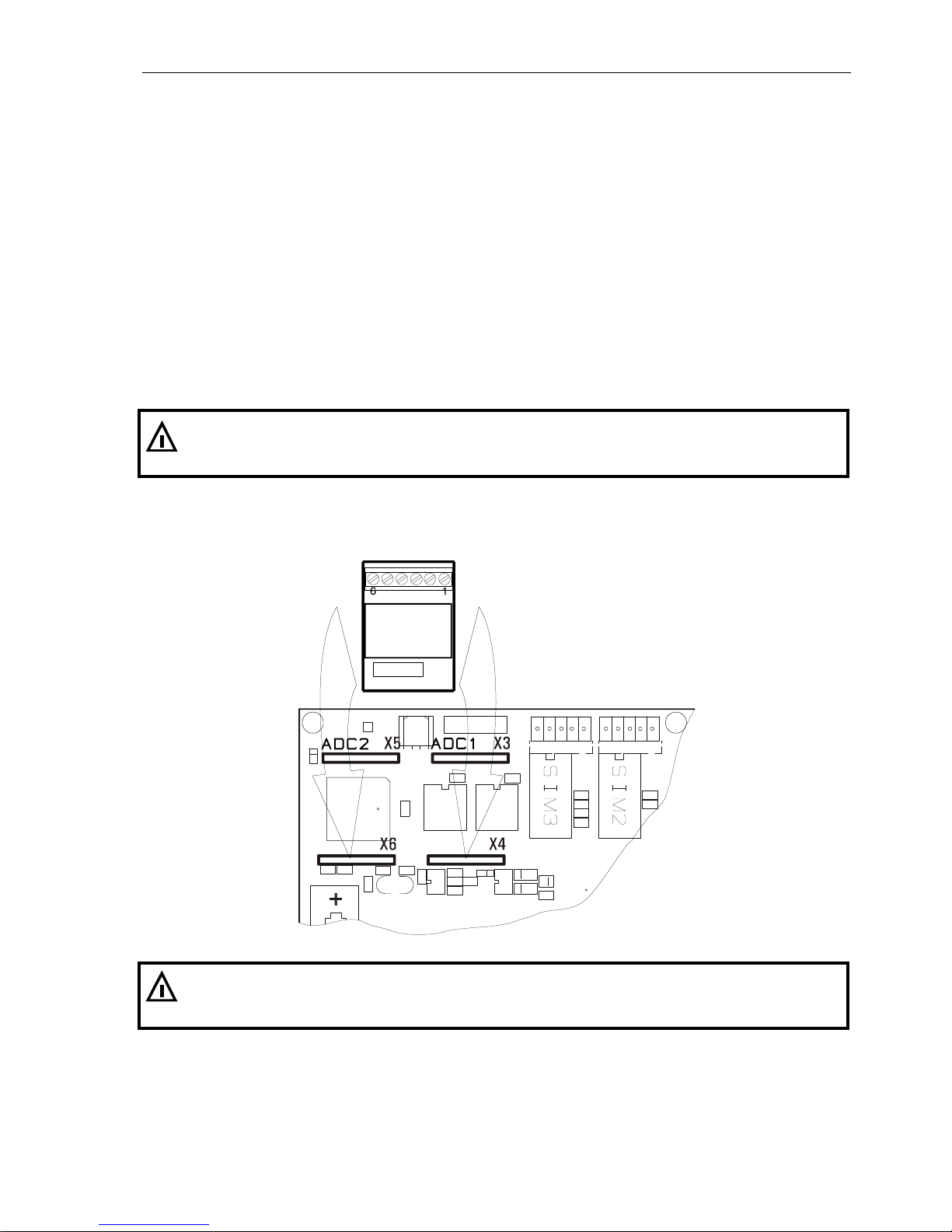

3.4 Main Board CPU8000

The main board contains the Central Processing Unit of the industrial weighing terminal IT8000Ex2/22. It includes the 32bit/16MHz microprocessor 68HC000, 1 MByte battery-backed data,

128 kByte application memory and a battery backed realtime clock..

It is available in three different versions:

Main board Description Used for

CPU8000-230V-Ex2/22 CPU8000 with 110-240 VAC PSU IT8000-AC-*-Ex2/22

Article-No. X8SYS0x1

CPU8000-24VDC-Ex2/22 CPU8000 with 12–30 VDC PSU IT8000-DC-*-Ex2/22

Article-No. X8SYS0x5

CPU8000-NTP-Ex2/22 CPU8000 with 12-30 VDC PSU

and low-bat detection

IT8000-DC-*-Ex2/22

Article-No. X8SYS0x6

Two sockets are provide to insert A/D converters (ADM or ADC) for the connection to understructures

with analog loadcells. Three serial interfaces can be individually configured by means of plug-on

modules (SIM) as RS232, RS485 or 20mA interfaces. Two additional slots can be fitted with plug-on

modules for parallel I/Os (PIM) which contain 2 inputs and two outputs each. For the connection to an

interface expansion board (FBM or PCM) appropriate connectors are available.

Also included on the main board is the wide range power supply, alternatively in AC or DC version.

For information on how to change memory components refer to section 'Changing of EPROMs' in the

annex of this manual.

Position of components on the CPU8000 main board

Socket 2 Connector X2 Socket 1 Terminal KL3/KL2/KL1 Terminal KL4/KL5 Connection AC or

for ADM2 (MFII Keyboard) for ADM1 (SIM3/SIM2/SIM1) (PIM2/PIM1) DC power supply

Lithium Connector X7 Connector X8-X11 Connector X1

battery (Display) (Interface expansion) Keyboard

14 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

4 Intended Use

In compliance with RL 94/9/EG (ATEX 95) appendix I, the weighing terminal IT8000-Ex2/22 is

an apparatus of group II category 3G, that following RL 99/92/EG (ATEX 137), can be used in

zone 2, as well as in gas groups IIA, IIB and IIC, which are at risk of explosion through

combustible substances of temperature classes T1 to T4. The following instructions on the

installation of the IT8000-**-E-Ex2/22 in a surrounding housing must be observed.

IT8000-Ex2/22 is also an apparatus of group II category 3D, that following RL 99/92/EG (ATEX

137) can be used in zone 22 (dust), the maximum surface temperature is 50°C. The following

instructions on the installation of the IT8000-**-E-Ex2/22 in a surrounding housing must be

observed.

Applicable only to IT8000-**-E-Ex2/22: The housing for panel-

mount installation is inserted in a

suitable cutout of a switch cabinet and fixed from the rear with 8 mounting brackets. If

installed accordingly, the front of the terminal -in combination with the circumferential gasket

between terminal and switch cabinet- is protected to IP65. When installed in Ex zone 2 (as per

II 3G Ex ic nA IIC T4 Gc) and Ex zone 22 with non-conductive dust (as per II 3D Ex ic tc IIIB

T50°C Dc IP54) the surrounding housing must be protected to IP54 or better. When installed in

Ex zone 22 with conductive dust (as per II 3D Ex ic tc IIIC T50°C Dc IP65) the surrounding

housing must be protected to IP65 or better. The surrounding housing (e.g. switch cabinet)

must conform to the requirements of EN60079-0 section 26.4.

The weighing terminal must not be installed in areas where electrostatic charging is possible

which may produce spark discharges, brush discharges or propagating brush discharges at the

front panel.

All external connections are designed for type of protection Ex 'nA'. The connection values

shown in chapter 'Installation of external connections with type of protection Ex-nA' must be

observed.

Ex

When installed in hazardous area, all peripheral devices connected to IT8000-Ex2/22 must have

appropriate Ex protection.

The metal housing of the IT8000-Ex2/22 terminal must be integrated at the PA stud into the

equipotential bonding system of the installation. Use serrated washers.

The permissible range of ambient temerature is –10°C to +40°C.

When installing IT8000-**-E-Ex2/22 in a switch cabinet (panel-mount version), this

temperature range also apllies to the inside the switch cabinet.

Furthermore, for use and installation all requirements as per EN 60079-14 must be observed.

Any other but the intended use of the equipment, modifications and extensions must not be

made without the explicit approval of the manufacturer and is deemed not to be intended. Part

of the intended use is observance of this Technical Manual and the adherence to inspection and

maintenance instructions and intervals. The manufacturer does not assume any liability

whatsoever for damages resulting from non-intended use. Any risk resulting from non-intended

use is solely borne by the user.

The weighing terminal and all connected components must be integrated into a common sytem

of equipotential bonding.

Protective covers or other parts covering the housing completely or in part must not be used.

Ex

The housing must be protected against permanent exposure to ultraviolet radiation.

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 15

5 Assembly

Ex

It must be made sure that installation of the weighing terminal is only carried out when all

power to the instrument is disconnected and no potentially explosive atmosphere is present.

The weighing terminal must not be installed in areas where electrostatic charging is possible

which may produce spark discharges, brush discharges or propagating brush discharges at the

front panel.

Installation must be made in compliance with the generally accepted rules of technology. In particular

for all work carried out on electrical installations the specific safety regulations must be observed.

The weighing terminal may be installed in Ex zone 2 or 22. The terminal must not be damaged. The

place of installation must be clean.

The IT8000-**-W-Ex2/22 (wall-mount / desk-top version) has mounting brackets for wall or table-top

installation. They must be fixed with suitable screws which are not part of the supply. All screws must

be tightened securely.

The IT8000-**-E-Ex2/22 (panel-mount version) has screw clamps to fix the terminal in the cutout of

the switch cabinet. To connect the bonding conductor, an M5 stud is provided at the rear or bottom of

the housing. Use serrated washers to prevent the nuts from becoming loose.

The permissible temperature range is –10°C to +40°C at a max. of 95% relative humidity (non

condensing). Direct exposure to ultraviolet radiation must be avoided.

For wall-mount installation the unit can be fixed at the wall first and then the cables can be installed

with the front lid open.

Before the device is put into operation, the housing must be closed and tightened securely with the

hexagonal srews provided. The screws must be tightened with a torque of 1.1Nm.

16 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

6 Installation

6.1 General

This apparatus must only be installed by qualified personnel who are familiar with all regulations

applicable to the different types of protection and the methods of installation, as well as the

general principles for the classification of zones. This level of competence must correspond to

the work that is to be carried out and appropriate training should be provided on a regular basis.

When the weighing terminal is to be installed in Ex zone 2 / 22 the regulations as per

EN 60079-14 must be adhered to.

The weighing terminal must not be installed in areas where electrostatic charging is possible

which may produce spark discharges, brush discharges or propagating brush discharges at the

front panel.

It must be made sure during installation of the weighing terminal that all power to the

instrument is disconnected and that no potentially explosive atmosphere can be present at any

time.

Installation must be carried out in compliance with applicable DIN/VDE regulations. Also, all

country-specific regulations must be observed. Connection of supply volatage must be made in

compliance with VDE 0100 and VDE 0160.

Ex

When the instrument is permanently connected to the power supply, an easily accessible

separator must be included in the supply circuit! It must either be located in safe area or -if

installed in Ex area- have appropriate Ex protection for the place of installation.

All cables are led into the housing through Ex cable glands. Strip cable jacket only as long as

required for the wires to reach the screw terminals. Use wire end ferrules with plastic collar on

stranded cable and avoid protruding wires. When assembling the cable glands make sure that

shield of cable is connected inside the cable gland. Observe instructions in section 'Connection

of cables'.

Ex

Before the device is put into operation, make sure that the housing is closed and tightened

securely with all hexagonal srews provided. The screws must be tightened with a torque of

1.1Nm.

6.2 Equipotential Bonding

Ex

In compliance with EN 60079-14 the apparatus must be integrated into the equipotential

bonding system of the installation. The bonding conductor must have a cross section of min.

4mm². To connect the bonding conductor, an M5 stud with serrated washer is provided at the

rear or bottom of the housing.

6.3 Shielding

Ex

Use only shielded connection cables. The shield must be connected at both sides in the cable

glands. It is mandatory to additionally install equipotential bonding as per EN60079-14

paragraph 12.2.2.3 exception b). The bonding conductor must have a cross section of min.

4mm².

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 17

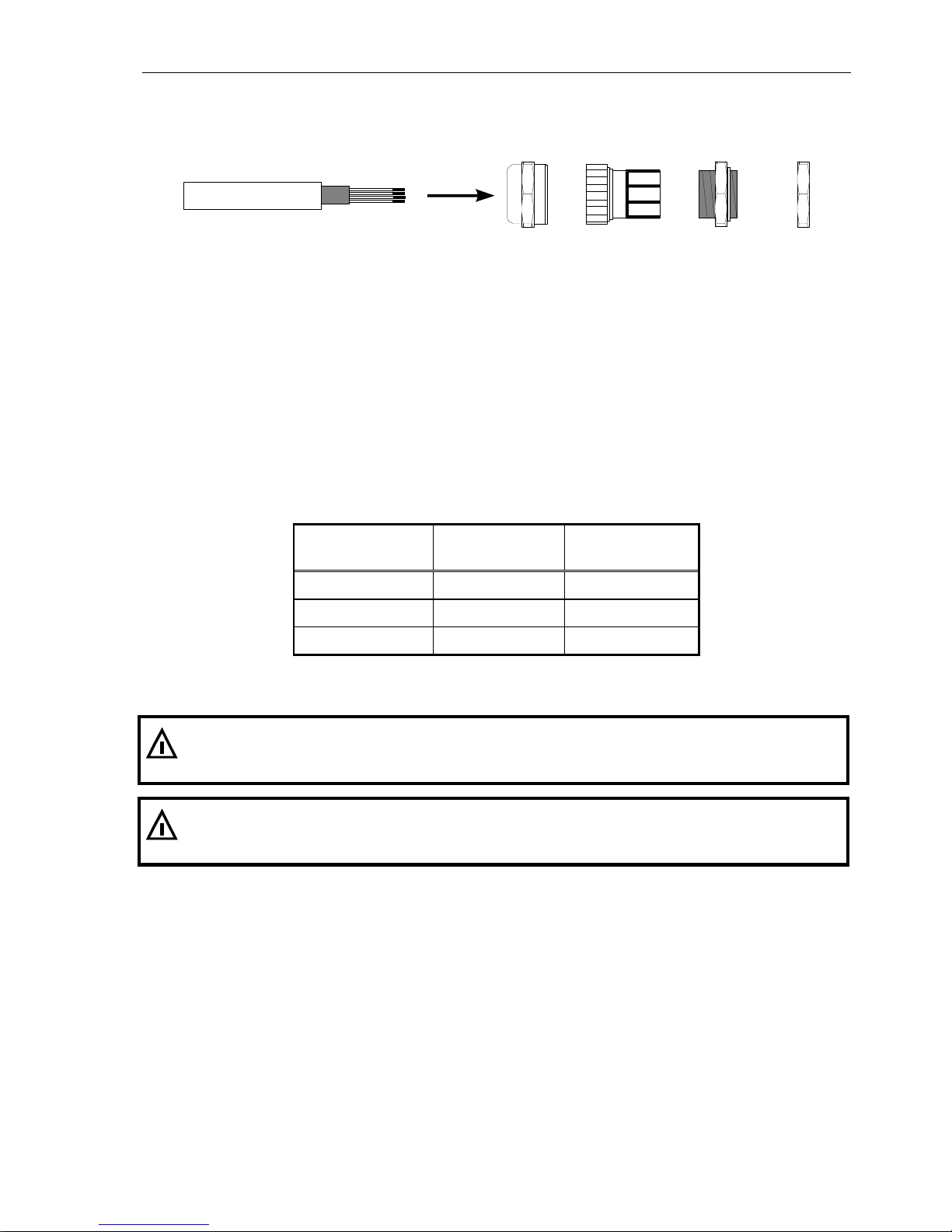

6.4 Connection Of Cables

All cables are led into the housing through cable glands.

Cable jacket Shield Compression nut Plastic insert Bushing Counter nut

Cable connection via cable glands:

1. Slide compression nut over cable jacket;

2. Slide plastic insert (retainer) over cable jacket until inner end is aligned with cut end of jacket;

3. Unravel shield, bend over retainer and push into retaining comb. Cut wires of shield to length of

comb, avoid protruding wires;

4. Insert retainer with cable into bushing;

5. Screw compression nut onto bushing and use wrench to tighten securely.

Permissible diameter of cables and torque for cable glands:

Wrench size of

counter nut

Permissible

diameter of cable

Torque to tighten

counter nut

17 mm 4 – 8 mm 6 Nm

20 mm 5 – 10 mm 5 Nm

22 mm 6 – 12 mm 8 Nm

Contact SysTec service for different cable diameters.

Ex

Use crimped wire end ferrules with plastic collar on stranded cable and avoid protruding wires.

Ex

All connecting cables must be firmly installed to avoid tension load at the cable glands and to

comply with the requirements of EN60079-14 paragraph 9.3.1.

18 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

7 Installation Of External Connections With Type Of

Protection 'Ex-nA'

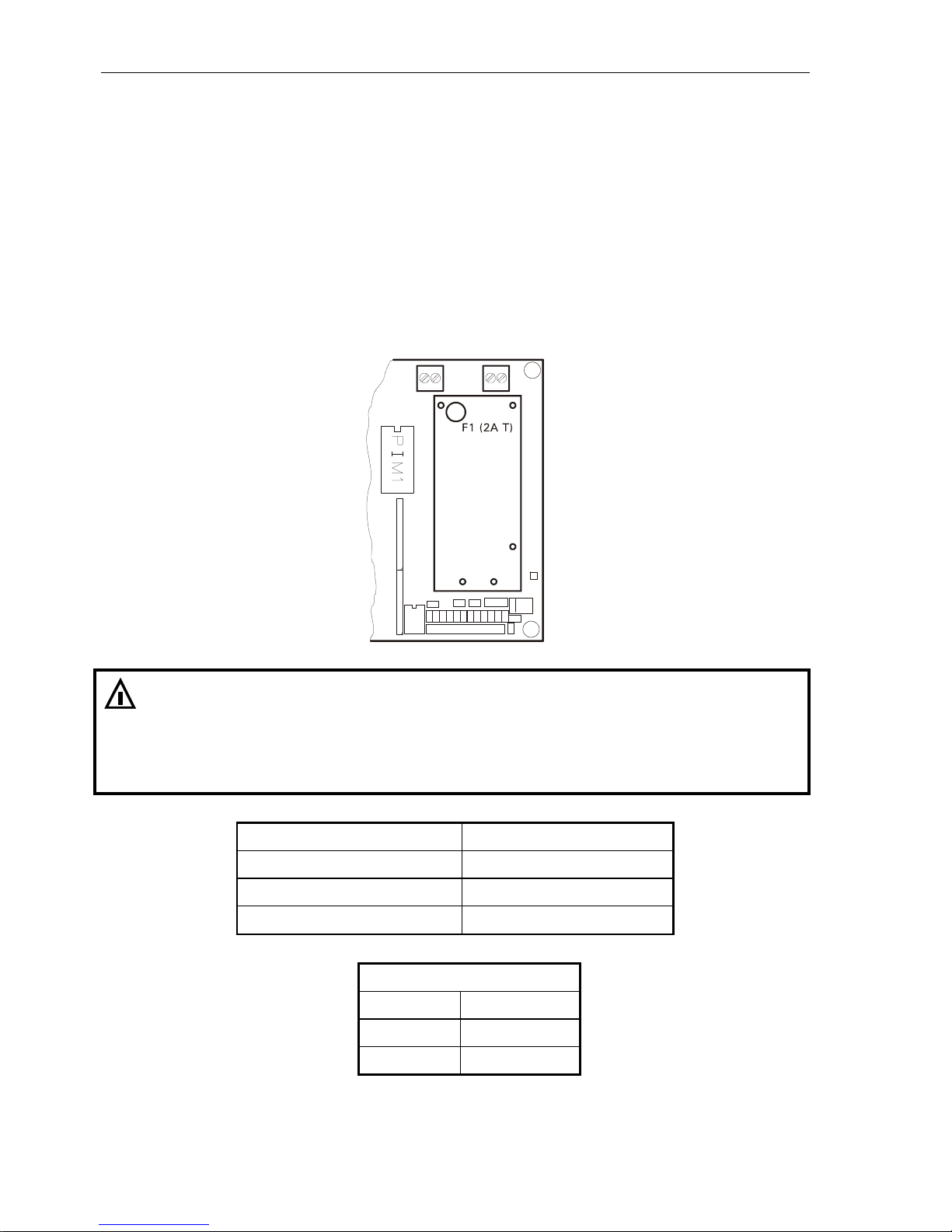

7.1 Connection Of Power Supply To IT8000-AC-*-Ex2/22

IT8000-AC-*-Ex2/22 (article-No. X8SYS0x1) is supplied with a line cord with free ends to connect the

supply voltage.The power supply unit is soldered to the main board CPU8000-230V-Ex2/22. The line

cord is connected to screw terminal KL6 of the CPU8000-230V-Ex2/22.

The power supply has a fused input (2A T). The fuse cannot be replaced.

Terminal KL6

110-240 VAC

PE L1 N

Ex

The connection of the supply voltage at the free cable end of the weighing terminal

IT8000-AC-*-Ex2/22 is designed for type of protection Ex-nA. The listed nominal connection

values must be adhered to.

For the connection of the line cord in hazardous area a suitable method must be chosen in

compliance with EN60079-0 (e.g. Ex-e, Ex-d). A suitable protection against overload and short

circuit in compliance with VDE regulations must be provided.

Nominal voltage UN

110 - 240VAC –15%/+10%

Nominal current IN

300 mA

Frequency range

47 - 63 Hz

Type of protection

Ex-nA

Color code free end of cable

brown L

blue N

green/yellow PE

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 19

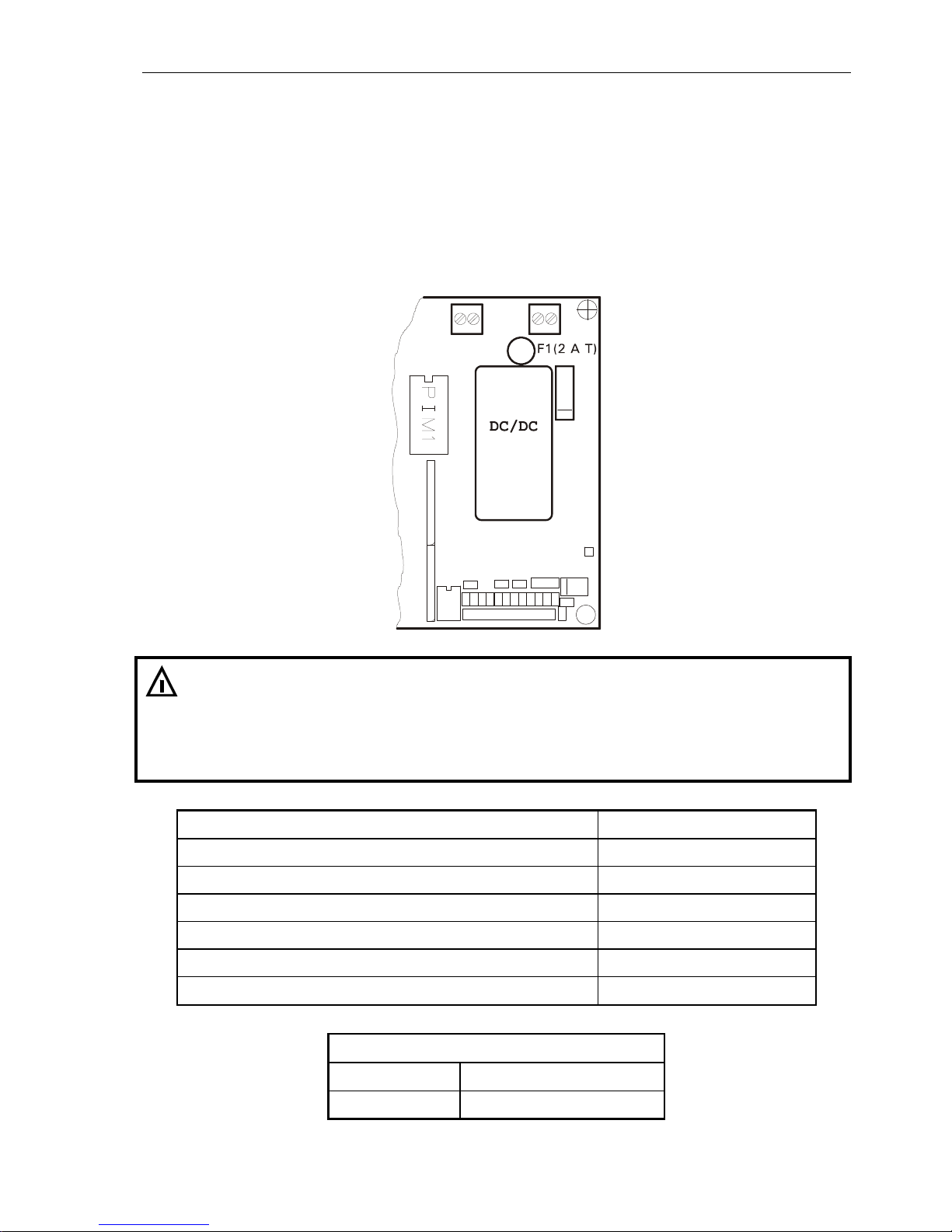

7.2 Connection Of Power Supply To IT8000-DC-*-Ex2/22

The weighing terminal IT8000-DC-*-Ex2/22 is intended for power supply with 12 – 30 VDC. The

connecting terminal KL6 is located on the main board CPU8000-24VDC (for article-No. X8SYS0x5)

and on the CPU8000-NTP-Ex2/22 (for article-No. X8SYS0x6).

A diode is provided as protection against reverse polarity. The power supply of the CPU8000-24VDCEx2/22 has a fused input (2A T). For replacing the fuse see chapter 'Replacing the fuse'.

Terminal KL6

12-30 VDC

PE L1 N

Ex

The connection of the supply voltage to the weighing terminal IT8000-DC-*-Ex2/22 is

designed for type of protection Ex-nA. The listed nominal connection values must be adhered

to.

For the connection of the supply cable in hazardous area a suitable method must be chosen in

compliance with EN60079-0 (e.g. Ex-e, Ex-d). A suitable protection against overload and short

circuit in compliance with VDE regulations must be provided.

Nominal voltage UN: 12 – 30 VDC +10% / –15%

Nominal current IN: 1.5 – 0.5 A

Cross section (rigid wires): 0.75 – 1.5 mm

2

Cross section (flexible wires with insolated wire end ferrule): 0.75 – 1.5 mm

2

Length of stripped insolation: 6 mm

Fastening torque screw terminal: 0.5 – 06 Nm

Ex type of protection: Ex-nA

Terminal assignment CPU8000 terminal KL6

+ V Supply voltage (+)

0 V Supply voltage (—)

20 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

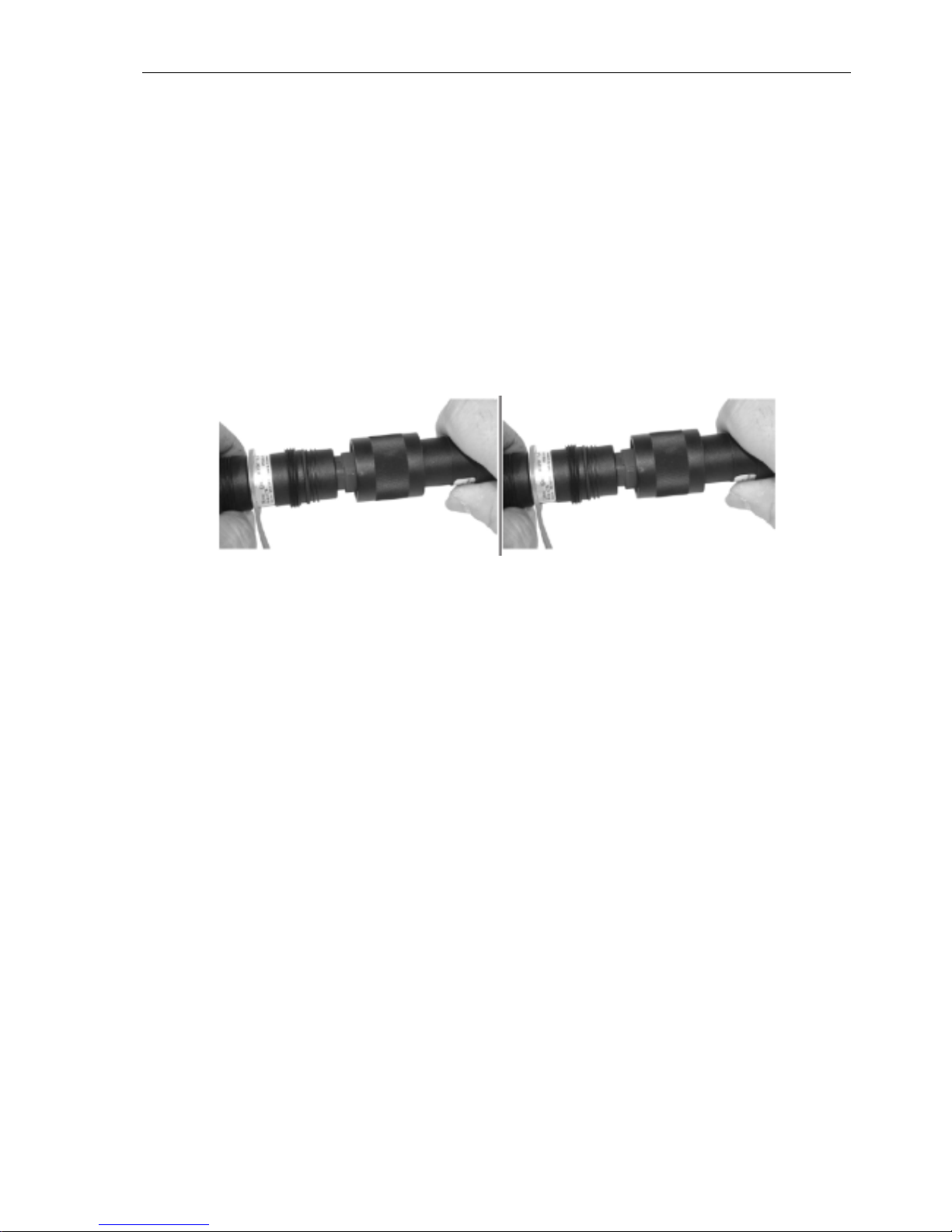

7.2.1 Connecting Cable With Ex Plug For Battery Operation

The weighing terminal IT8000-DC-*-Ex2/22 (article-No. X8SYS0x6) with CPU8000-NTP-Ex2/22 is

suitable for connection to an external rechargeable battery box. To this effect the instrument is

supplied with an assembled connecting cable with ex plug. The following notes must absolutely be

observed:

Absolutely adhere to operating instructions 'Ex-connector mini Clix Reihe 8591'.

Components must have identical coding to avoid damages to connector/socket.

The supply cable to the plug-and-socket connection must be firmly installed and sufficienty

protected against mechanical damage. Cables must comply with the thermic and mechanical

requirements of the location of installation.

When connectors are not connected correctly, protection against risk of explosion is no longer

warranted. Strictly follow the instructions!

After separating, immediately cover components of the plug-and-socket connection conducting

voltage with protective cap!

Ex

For the supply of the weighing terminal the following rechargeable batteries can be used:

1) AkkuBox Ex; 12VDC for use in Ex zone 2 and 22; article-No. E3AKK001

2) Equivalent 12V rechargeable batteries may be used. When a rechargeable battery is used

in hazardous area a suitable type of protection must be provided. Compliance with the

requirements of EN 60079-14 is mandatory.

Observe the operating instructions for the rechargeable battery.

7.2.2 Coding And Pin Assignment Ex Connectors

No. of

pins

Coding Female connector / socket

e.g. AkkuBox Ex

Male connector

IT8000-DC-*-Ex2/22

(article-No. X8SYS0x6)

2 + PE 12 h

Assignment

Pin Voltage

1 12VDC

2 not used

3 GND

PE Shield

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 21

7.2.3 Instructions For Connecting And Separating Coupler

Before plugging in check connectors for any damages.

Align male/female connectors along groove (1).

Push components together up to stop position (2).

Twist right approx. 30° up to stop (3).

Push connectors together completely (4).

Fasten coupling ring tightly (5). This procedure provides for mechanical connection, electrical

contact and IP protection.

Disconnect in reverse order.

22 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

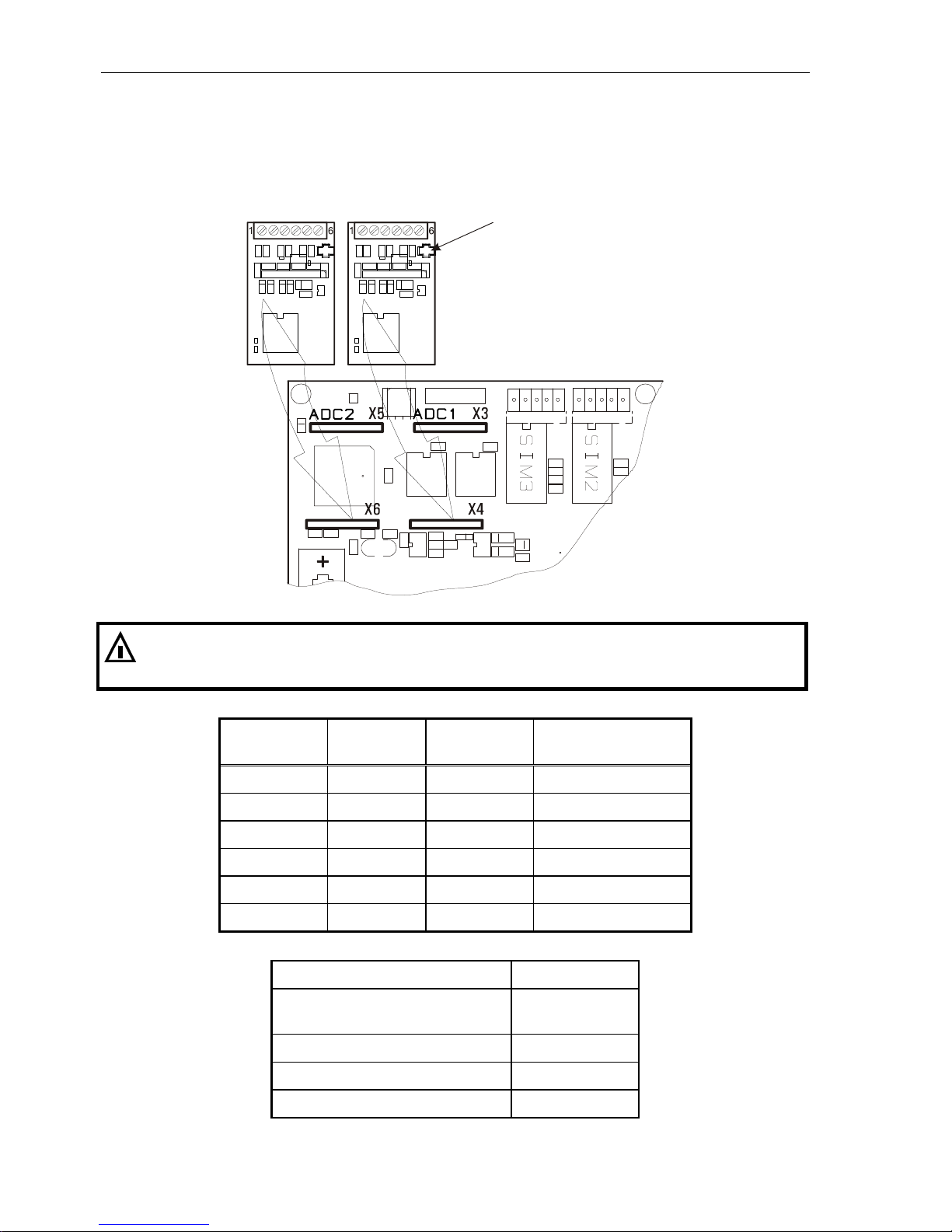

7.3 Connection Of Analog Scale To ADM / ADC

The ADM or ADC provides connection for one weighing platform with strain gauge loadcell(s). A

second weighing platform can be connected using a second ADM or ADC board. The modules are

plugged into sockets ADC1 / ADC2 on the CPU8000 main board.

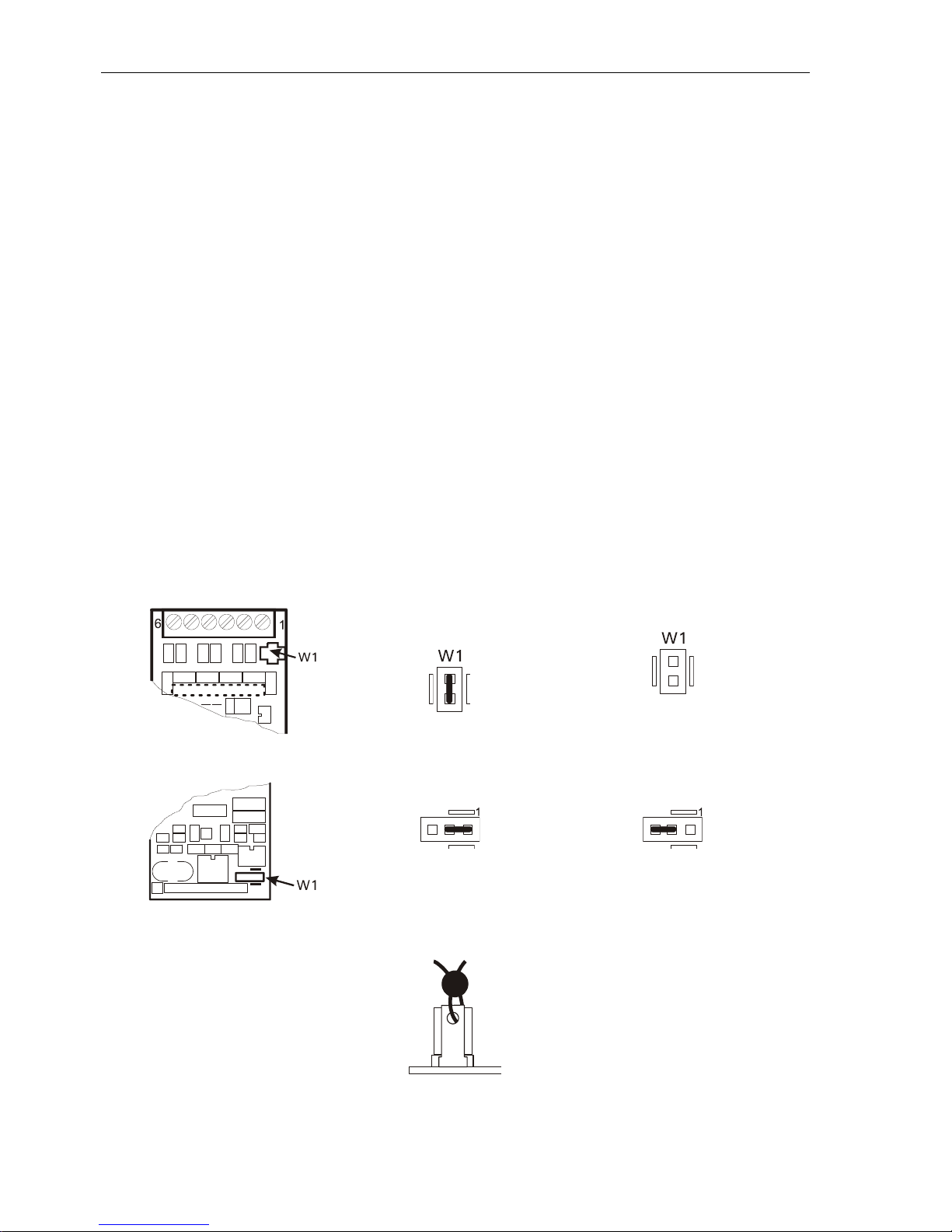

ADM2 ADM1 Jumper W1

Ex

The connection is designed compliant to type of protection 'Ex-nA'. If the loadcell is to be

installed in hazardous area, compliance with the applicable Ex regulations is mandatory. The

following connection values must be observed:

ADM/ADC

Terminal KL1

Signal Description Nominal value

1 +Excitation Output 5 V / 240 mA

2 – Excitation Output 5 V / 240 mA

3 +Sense Input 5 V / 1 mA

4 – Sense Input 5 V / 1 mA

5 +Signal Input 5 V / 1 mA

6 – Signal Input 5 V / 1 mA

Cross section rigid wire: 0.25 – 1.5 mm

2

Cross section flexible wire

with insolated wire end ferrule:

0.25 – 1.5 mm

2

Length of stripped insolation: 6 mm

Fastening torque screw terminal: 0.5 – 0.6 Nm

Ex type of protection: Ex-nA

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 23

Connection of weighing platforms and loadcells is to be made as specified below:

Max. 16 strain gauge loadcells 350 each

Overall impedance 21.5 ...4500

W&M approved resolution of 6000d at a max. preload of 80%, internal resolution 524,000d

Smallest permissible input signal for approved applications: 0.33 µV / e

Update rate 50 updates / second

Loadcell excitation: 5 V ±5%, gated power supply (ADM), DC (ADC)

Connection in 4- or 6-wire mode.

Principal schematics of 6-wire and 4-wire strain gauge loadcell:

6-wire loadcell

4-wire loadcell

Connection of 6-wire loadcell to ADM or ADC:

Terminal Assignment

1 +Excitation

2 – Excitation

3 +Sense

4 – Sense

5 +Signal

6 – Signal

Connection of 4-wire loadcell to ADM or ADC:

To connect loadcells without sense lines (4-wire connection), two jump leads must be connected at

terminal row KL1 between terminal 1 and 3, and between terminal 2 and 4.

Terminal Assignment

1 +Excitation

2 – Excitation

3

4

5 +Signal

6 – Signal

24 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

7.3.1 Connection Cables For Analog Weighing Platforms

For the installation of connection cables for analog weighing platforms please follow the recommendations listed below:

Only use suitable loadcell cable, (e.g. SysTec order-No. 10KAB214 (3 x 2 x 0,75mm², shielded)

Nominal voltage of cable ±250V.

Unsuitable loadcell cable may affect accuracy.

The shield of the loadcell cable must be connected all around the cable in the cable gland of the

weighing terminal (see also chapter 'Installation' / 'Connection Of Cables'). Loadcells, platforms

junction boxes and the weighing terminal must be integrated into the equipotential bonding of

the sytem. Depending on the situation on site this may require the installation of a separate earth

lead of appropriate diameter (e.g. 16mm²) in parallel to the loadcell cable. If the junction box is

installed in hazardous area it must be designed with appropriate type of protection.

To extend the loadcell cable only use metal junction boxes and connect shield of cable on both

sides inside cable gland.

Distance between loadcell cables and power lines min. 0.5m. Loadcell cables to be installed in

grounded metal conduits, metal hoses or metal cable trays.

Maximum length of connection cable between weighing platform and weighing terminal: 200m.

If tension load is applied to loadcells instead of compression load, connection for +Signal

and –Signal must be transposed.

7.3.2 Sealing Of Calibration Parameters

By means of the jumper W1 the calibration parameters stored in EEPROM can be protected against

unauthorized modifications:

ADM in IT8000-Ex2/22 Calibration parameters

protected

Calibration parameters

accessible

ADC im IT8000-Ex2/22 Calibration parameters

protected

Calibration parameters

accessible

If required for W&M approved and stamped systems, the position of the jumper W1 can be sealed with

thread and lead seal:

For a description of the calibration mode refer to the 'Calibration Manual IT8000 ADM and ADC'.

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 25

7.4 Connection Of IDNet Scale Base To IDN

The IDN module (IDNet interface module) permits the connection of one Mettler-Toledo understructure

with IDNet interface. It supports IDNet understructures which operate on 12VDC power supply (e.g.

PikBrick). Understructures which require an additional 32VDC supply cannot be connected.

Only one IDN interface (for 1 understructure) may be installed, which is either inserted in socket ADC1

(if the only scale is an understructure with IDNet interface) or ADC2 (for a mixed setup with digital and

analog scale base). In this case (one ADM/ADC and one IDN) the ADM board must always be installed

in the first socket ADC1, the IDN is then installed in socket ADC2.

In a mixed setup, one analog scale base with up to 8 x 350 loadcells can be connected to the

ADM/ADC interface.

The FBM or ECM module must not be used when an IDN board is in place, because the internal

communication with the IDN module is made via COM4, i.e. this interface is not available for the

fieldbus or Ethernet interface or an additional SIM module.

The IDN module provides a maximum of 12VDC / 150mA as supply for the IDNet scale base.

Ex

W A R N I N G

When an IDN module is installed the the auxiliary voltage (10VDC on CPU8000, terminal KL4)

must not be used.

IDN interface module

IDN

Ex

The connection is designed compliant to type of protection 'Ex-nA'. If the force transducer is to

be installaed in hazardous area, compliance with the applicable Ex regulations is mandatory.

The following connection values must be observed:

26 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

IDN

Terminal KL1

Signal Description Nominal value

1 TxD— — Transmit line 20 mA CL 12 V / 20 mA

2 TxD+ + Transmit line 20 mA CL 12 V / 20 mA

3 RxD— — Receive line 20 mA CL 12 V / 20 mA

4 RxD+ + Receive line 20 mA CL 12 V / 20 mA

5 0 V 0 (12 V) Supply voltage 0 (12 V) / 150 mA

6 +12 V (150mA) +12V Supply voltage 12 V / 150 mA

For a description of the calibration mode refer to the

MultiRange Calibration Manual, Order-No.: ST.2309.0057

Cross section rigid wire: 0.25 – 1.5 mm

2

Cross section flexible wire with insolated wire end ferrule: 0.25 – 1.5 mm

2

Length of stripped insolation: 6 mm

Fastening torque screw terminal: 0.5 – 0.6 Nm

Ex type of protection: Ex-nA

7.4.1 Connection Cables For IDNet Scale Bases

Unsuitable cable may cause loss of data. For the installation of connection cables for IDNet scale bases

please note

Only use suitable connecting cable (data cable), e.g. 6 x 0.25 mm² shielded, SysTec order-No.

10KAB216, or data cable supplied by the manufacturer of the scale base.

Nominal Voltage of cable 250V.

Connect shield of cable at both sides, at cable gland of weighing terminal and at understructure

and/or extension cable. If a difference between potentials is experienced, an appropriate potential

equalization must be installed.

Distance between loadcell cables and power lines: 0.5m. Loadcell cables to be installed in

grounded metal conduits, metal hoses or metal cable trays.

Maximum length of connection cable between weighing platform and weighing terminal: 15m.

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 27

7.5 Connection Of Digital Scale Bases With RS485 Interface To DWM

The DWM module (Digital Weighing Module) permits the connection of digital force transducers

(loadcells) operating on 12VDC power supply and communicating with the IT8000-Ex2/22 via RS485

2-wire or 4-wire network.

Scale bases and loadcells are supported as follows:

Sartorius series IS weighing platforms

Digital HBM series C16i loadcells

Revere series SLC loadcells.

Calibration data can be stored powerfail safe in a serial EEPROM on the DWM module. By means of the

jumper W1 these data can be protected against unauthorized modification.

Only one DWM interface (for 1 understructure) may be installed, which is either inserted in socket

ADC1 (if the only scale is a digital understructure) or ADC2 (for a mixed setup with digital and analog

scale base). In this case (one ADM/ADC and one DWM) the ADM board must always be installed in the

first socket ADC1, the DWM is then installed in socket ADC2.

In a mixed setup one analog scale base with up to 4 x 350 loadcells can be connected to the

ADM/ADC interface.

The FBM or ECM module must not be used when an DWM board is in place, because the internal

communication with the DWM module is made via COM4, i.e. this interface is not available for the

fieldbus or Ethernet communication or an additional SIM module.

The DWM supplies a max. of 12V / 320mA for the digital force transducer(s).

Ex

W A R N I N G

When a DWM module is installed, the following restrictions apply:

The auxiliary voltage (10VDC on CPU8000, terminal KL4) must not be used.

If the current consumption of the digital force transducers exceeds 210mA, the interface

extension socket X8 - X11 must not be used.

If the current consumption exceeds 320mA, an external power supply is required which must

have appropriate type of protection when installed in hazardous area.

DWM Interface module

DWM Jumper W1

28 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

Ex

The connection is designed compliant to type of protection 'Ex-nA'. If the digital scale base is

to be installaed in hazardous area, compliance with the applicable Ex regulations is mandatory.

The following connection values must be observed:

DWM

Terminal

KL1

Assignment

RS485

4-wire

Assignment

RS485

2-wire

Description Nominal value

1 Tx A (Tx+) A (Tx+ / Rx+) + Transmit line RS485 5 V

2 Tx B (Tx—) B (Tx— / Rx—) — Transmit line RS485 5 V

3 Rx A (Rx+) — + Receive line RS485 5 V

4 Rx B (Rx—) — — Receive line RS485 5 V

5 0 V 0 (12 V) Supply voltage 0 (12 V) / 320 mA

6 +12 V (320mA) +12V Supply voltage 12 V / 320 mA

Cross section rigid wire: 0.25 – 1.5 mm

2

Cross section flexible wire with insolated wire end ferrule: 0.25 – 1.5 mm

2

Length of stripped insolation: 6 mm

Fastening torque screw terminal: 0.5 – 0.6 Nm

Ex type of protection: Ex-nA

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 29

7.5.1 Connection Cables For Digital Scale Bases With RS485 Interface

Unsuitable cable may cause loss of data. For the installation of connection cables for digital scale bases

please note:

Only use suitable connecting cable (data cable), e.g. 6 x 0.25 mm² shielded, SysTec order-No.

10KAB216, or data cable supplied by the manufacturer of the scale base.

Nominal Voltage of cable 250V.

Connect shield of cable at both sides, at cable gland of weighing terminal and at understructure

and/or extension cable. If a difference between potentials is experienced, an appropriate potential

equalization must be installed.

Distance between loadcell cables and power lines: 0.5m. Loadcell cables to be installed in

grounded metal conduits, metal hoses or metal cable trays.

The permissible cable length depends on conductor cross section of the chosen data cable and

the current consumption of the connected force transducers. Make sure that excitation voltage

at loadcells does not fall below the minimum excitation voltage as specified by manufacturer.

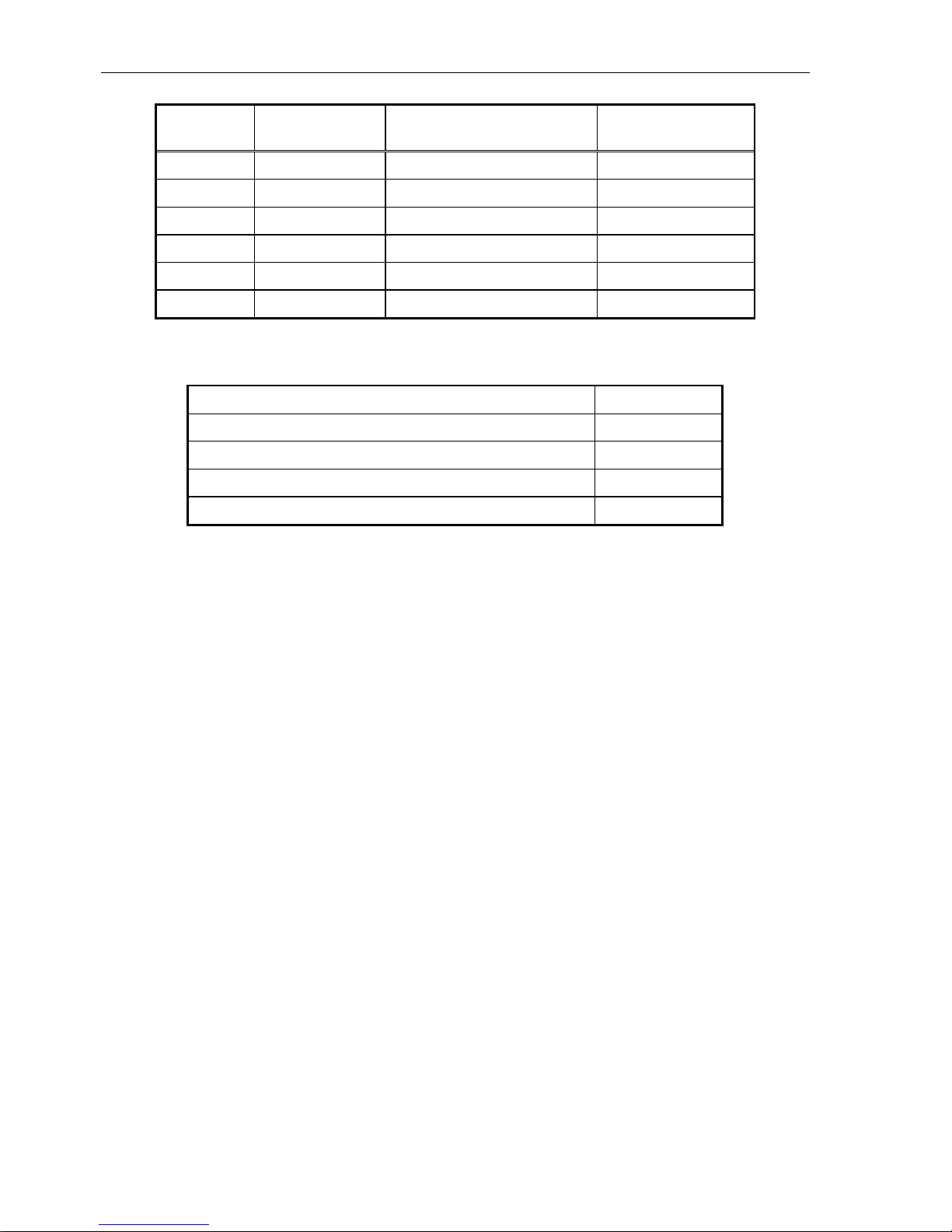

DWM in IT8000-Ex2/22 Calibration parameters

protected

Calibration parameters

accessible

If required for W&M approved and stamped systems, the position of the jumper W1 can be sealed with

thread and lead seal:

30 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

7.6 Connection Of Serial Interfaces SIM

The three serial interfaces on the CPU8000 as well as the fourth interface on the FBM board can be

individually configured as RS232, RS485 4-wire, RS485 2-wire, RS485 2/4-wire optoisolated or 20mA

CL interfaces by means of SIM plug-on modules.

Please note: When a 20 mA CL interface is used, receiver and transmitter of the IT8000 are always

passive, i.e. supply voltage for the current loops must be provided by the connected peripheral device.

Assignment of serial interfaces on the CPU8000

Insert with notch

pointing to top KL3 KL2 KL1

Assignment of serial interfaces on the FBM board

Insert with notch

pointing to right hand side KL1

Ex

Peripheral devices are connected at CPU8000 screw terminals KL1, 2, 3 and FBM module

screw terminal KL1. The connection is designed compliant to type of protection 'Ex-nA'. The

following connection values must be observed:

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 31

SIM-RS232:

CPU8000 Terminal KL1, 2, 3

FBM Terminal KL1

Description Nominal value

1 TxD ±12 VDC

2 RTS ±12 VDC

3 RxD ±12 VDC

4 CTS ±12 VDC

5 GND ±12 VDC

SIM- RS485 2-wire:

CPU8000 Terminal KL1, 2, 3

FBM Terminal KL1

Description Nominal value

1 A (TxD+/ RxD+) 5 VDC

2 B (TxD– / RxD–) 5 VDC

3 A (TxD+/ RxD+) 5 VDC

4 B (TxD– / RxD–) 5 VDC

5 – –

SIM-RS485 4-wire / SIM-RS485 Opto:

CPU8000 Terminal KL1, 2, 3

FBM Terminal KL1

Description Nominal value

1 TxA (TxD+) 5 VDC

2 TxB (TxD–) 5 VDC

3 RxA (RxD+) 5 VDC

4 RxB (RxD–) 5 VDC

5 – –

SIM-20mA:

CPU8000 Terminal KL1, 2, 3

FBM Terminal KL1

Description Nominal value

1 TXIN 12 VDC / 20 mA

2 TXOUT 12 VDC / 20 mA

3 RXIN 12 VDC / 20 mA

4 RXOUT 12 VDC / 20 mA

5 – –

32 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

The following connection values must also be adhered to:

Cross section rigid wire: 0.14 – 1.5 mm

2

Cross section flexible wire with insolated wire end ferrule: 0.25 – 0.5 mm

2

Length of stripped insolation: 7 mm

Fastening torque screw terminal: 0.22 – 0.25 Nm

Ex type of protection: Ex-nA

Principal circuit diagram of the 20mA current loop interface:

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 33

Principal connecting diagram RS485 network:

Terminal assignment: Some manufacturers of components with RS485 interface do not refer to the

terminals TX+ and RX+ as 'A', but 'B' instead (correspondingly, the terminals TX– and RX– are not

referred to as 'B', but 'A').

Termination resistors: In order to prevent reflection (baud rate 19200 Baud or higher, and/or cable

longer than 20 m) it is recommended to install termination resistors RTerm = 150 on both ends of the

cable. Use only twisted pair cables with a characteristic impedance of approx. 150 .

Pull-up / pull-down resistors: When termination resistors are used, also 390 pull-up and pull-down

resistors must be installed at the master (see also following schematic).

Ex

If termination and pull-up / pull-down resistors are to be used in hazardous area, specific

requirements apply. Contact SysTec service for details.

RS485 network with termination, pull-up and pull-down resistors

34 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

For the installation of connection cables for serial interfaces please follow the recommendations listed

below:

Install data cables to prevent capacitive or inductive interference from other cables, machines

and/or electrical devices that could interrupt data transmission and lead to loss of data.

Non-factory made cables must comply with the following specification:

Shielded twisted pair, e.g. LIYCY 3 x 2 x 0.25mm²,

shield to be grounded on both sides.

Resistance

125 /km

Cross section 0.25 mm2- 0.5 mm

2

Capacitance

130 nF/km

Cable length 20mA max. 100 m

Cable length RS232 max. 15 m

Cable length RS485 max. 1200 m

Impedance RS485

ca. 150

Nominal voltage

250 V

7.7 Connection Of Parallel I/Os PIM

The parallel input/outputs on the CPU8000 can be activated by inserting plug-on modules. Each module

provides drivers for two optoisolated inputs and two optoisolated outputs.

Principal schematics

Parallel output Parallel input

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 35

Position and assignment of parallel inputs/outputs on CPU8000 board

Insert with notch

pointing to top KL5 KL4

Ex

Peripheral devices are connected to the CPU8000 at screw terminals KL4 and KL5. The

connection is designed compliant to type of protection 'Ex-nA'. The following connection

values must be observed:

Terminal assignment

KL4 / 5: parallel inputs and outputs 0 - 3

Terminal 4 Terminal 5 Signal Function Nominal value

1 0V 0V Auxiliary voltage 10 VDC / 100 mA

2 +10V +10V Auxiliary voltage 10 VDC / 100 mA

3 IN0 Input 0 24 VDC / 7 mA

4 IN1 Input 1 24 VDC / 7 mA

5 IN2 Input 2 24 VDC / 7 mA

6 IN3 Input 3 24 VDC / 7 mA

1 In– Gnd for inputs 24 VDC / 28 mA

2 OUT0 Output 0 24 VDC / 100 mA

3 OUT1 Output 1 24 VDC / 100 mA

4 OUT2 Output 2 24 VDC / 100 mA

5 OUT3 Output 3 24 VDC / 100 mA

6 OUT+ External supply for

outputs

24 VDC / 400 mA

Note: The internal 10 VDC supply (terminal row KL4, terminal #2) may be used to connect switches

and push buttons to the digital inputs (100 mA max.). If an interface board to connect digital force

transducers (IDN, DWM) is installed, this auxiliary voltage is not available. External devices connected

to the digital outputs must always be supplied from an external 24 VDC power supply. If connected

components are installed in hazardous area, they must comply with appropriate type of protection, e.g.

'Ex-d'.

36 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

The following connection values must also be adhered to:

Cross section rigid wire: 0.14 – 1.5 mm

2

Cross section flexible wire with insolated wire end ferrule: 0.25 – 0.5 mm

2

Length of stripped insolation: 7 mm

Fastening torque screw terminal: 0.22 – 0.25 Nm

Ex type of protection: Ex-nA

For the installation of cables for digital I/Os please note:

Install I/O cables to prevent capacitive or inductive interference from other cables, machines and/or

electrical devices that could affect input/output signals and lead to malfunction and/or dangerous

operational conditions.

Cables must comply with the following specification:

Shielded multicore cables, shield connected to ground on both sides

Flexible wires with wire end ferrules

Resistance 125 /km

Cross section 0.25 mm2bis max. 0.5mm

2

Capacitance 130 nF/km

Nominal voltage 250 V

Legth of cabble max. 15m

Note:

To achieve maximum suppression of all coupled frequencies, the shield should be connected on

both sides.

If fluctuation of the earth potential is experienced, this can cause an equalization current flowing

over the shield. In this case a separate earth lead of appropriate diameter for potential

equalization is required.

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 37

7.8 Connection Of Fieldbus Module FBM

The FieldBus extension Module can be inserted in socket X8-X11 of the main board and provides a

fourth serial interface. To this effect a SIM interface module is plugged into the corresponding socket.

Connection of the serial interface is made at screw terminal KL1 of the FBM board.

Ex

For connection of a serial inteface to SIM4 on the FBM board refer to chapter 'Connection of

serial interfaces'.

Ex

The use of a fieldbus module in the socket 'Fieldbus controller' on the FBM board is not

permitted for IT8000Ex2/22. This socket must remain free.

KL1

FBM SIM4

Main board

38 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

7.9 Connection Of Profibus DP Module PCM

With the Profibus Controller Module the IT8000-Ex2/22 operates as a Profibus DP slave, with an I/O

interface (64 inputs and outputs) or a data interface with 32 input words and 32 output words. The

PCM module is designed for transmission speeds of 12 MBit/s. The definition of the individual data

words depends on the application and is specified in the Installation Instructions pertaining to the

respective product.

The PCM interface is inserted in socket X8-X11 on the main board.

KL1

PCM Profibus DP

Main board

The Profibus address is set in Service Mode, Group 4 'Configure Application' (see also Installation

Instructions of the applicable program). To set parameters of the Profibus master, the GSD file included in the supply- is used.

Data transmission is made over an isolated RS485 interface complying with the Profibus DP

specification. Connections to the Profibus DP interface are made at terminal KL1 on the PCM board.

Correct operation is indicated with the LED on the board.

If the terminal is connected to a physical end of the Profibus DP bus, the jumpers W1, W2 and W3

must be set to terminate the bus.

Ex

The connection of external Profibus DP participants is made at terminal KL1 of the PCM. The

connection is designed compliant to type of protection 'Ex-nA'. The following connection

values must be observed:

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 39

Terminal assignment Profibus DP interface

Terminal KL1: Profibus DP

Terminal # Profibus DP signal Nominal values

1 RTS 5 VDC

2 Gnd 5V 0 (+5 VDC) / 100 mA

3 +5V +5 VDC / 100 mA

4 / 6 B Line 5 VDC

5 / 7 A Line 5 VDC

The following connection values must also be adhered to:

Cross section rigid wire: 0.14 – 1.5 mm

2

Cross section flexible wire with insolated wire end ferrule: 0.25 – 0.5 mm

2

Length of stripped insolation: 7 mm

Fastening torque screw terminal: 0.22 – 0.25 Nm

Ex type of protection: Ex-nA

Function of jumpers

Jumper Profibus DP interface

W1 Pull-up resistor

W2 Termination resistor

W3 Pull-down resistor

The line is terminated when the jumpers are closed.

For the configuration of the Profibus master, a GSD file is required that you can download from our

website 'www.systecnet.com'.

Follow the link 'Service' and from there to 'download software'.

Download the file 'GSD.ZIP' (click right on the link and choose 'Save Target As...).

Unpack the ZIP file on your hard disk.

40 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

7.10 Connection Of Ethernet Module ECM

With the Ethernet Controller Module the IT8000-Ex2/22 terminal can be connected to Ethernet

networks. The ECM module is plugged into sockets X8-X11 on the CPU8000 board. Connection to the

LAN is made via a prefabricated cable.

The ECM module supports the TCP/IP protocol. Data can be transferred from the nework to the serial

interface COM4 via the port #1234 without change of contents.

The ECM module is configured with the PC program EtherPort Tool which is used to identify the

module in the network and to assign an IP address with the pertaining parameters. Each ECM board

has its unique MAC address which is printed on the side of the Xport module.

IT8000 Service Mode settings for COM4 are as follows: 9600 Baud, format 8N, no handshake (---).

The choice of the transmission protocol depends on the application program on the PC.

The ECM module must not be used when an IDN or DWM board is in place, because these modules

use COM4 for the internal communication with the CPU8000, i.e. COM4 is not available for the

Ethernet interface.

RJ45 connector

ECM for network cable

Main board

Ex

The connection is designed compliant to type of protection 'Ex-nA'. The connection values of

the Ethernet standard (IEEE 802.3) must be adhered to:

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 41

ECM

RJ45 socket

Signal Description Nominal values (Ex-nA)

1 Tx+ Transmit Data + IEEE 802.3

2 Tx- Transmit Data - IEEE 802.3

3 Rx+ Receive Data + IEEE 802.3

4 Rx- Receive Ata - IEEE 802.3

5 Not used Not used IEEE 802.3

6 Not used Not used IEEE 802.3

7 Not used Not used IEEE 802.3

8 Not used Not used IEEE 802.3

Shield Chassis Ground Chassis Ground IEEE 802.3

The 'EtherPort Tool' can be downloaded from our website 'www.systecnet.com'.

Follow the link 'Service' and from there to 'download software'.

Download the file 'EtherPort_Tool.ZIP' (click right on the link and choose 'Save as...).

Unpack the ZIP file on your harddisk. Start 'Setup.exe'.

7.10.1 Ethernet Cable With RJ45 Connector

IT8000-Ex2/22 with ECM module is supplied ex factory with a firmly connected Ethernet cable of 5 m

or 10 m length with RJ45 connector to connect to a local area network.

Ex

If the RJ45 connector of the Ethernet cable is to be connected to the network inside the

hazardous area, an appropriate method of protection in compliance with EN60079-0 (e.g. Ex-e,

Ex-d) must be chosen for the connection. The RJ45 connector itself does not have any Ex

protection and must not be connected/disconnected when a potentially explosive atmosphere is

present!

42 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

7.11 Connection Of 15-Bit Analog Output DAU15

For the output of gross or net weight as analog 15-bit signal a plug-on module (DAU15) can be

inserted instead of a parallel driver module in the PIM socket. The output signal has a resolution of 15

bit (32768 steps). The module can be configured in group 4 'Configuration Of DAU15 Analog Output'

of the Service Mode to 0/2 - 10V or 0/4 - 20mA. The output of the DAU15 module is active and

potential free.

Position and assignment of analog output module DAU15 on CPU8000 board

Insert with notch

pointing to top KL5 KL4

Ex

Peripheral devices are connected to the CPU8000 at screw terminals KL4 and KL5. The

connection is designed compliant to type of protection 'Ex-nA'. The following connection

values must be observed:

Terminal assignment KL4 and KL5:

DAU15 plugged into socket PIM1 or PIM2

KL4 KL5 Signal Description Socket Nominal values

1 -

2 -

3 I+ + Current output 0/4 - 20mA PIM1 10 V / 20 mA

4 I— — Current output 0/4 - 20mA PIM1 10 V / 20 mA

5 I+ + Current output 0/4 - 20mA PIM2 10 V / 20 mA

6 I— — Current output 0/4 - 20mA PIM2 10 V / 20 mA

1 -

2 U+ + Voltage output 0/2 - 10V PIM1 10 V / 20 mA

3 U— — Voltage output 0/2 - 10V PIM1 10 V / 20 mA

4 U+ + Voltage output 0/2 - 10V PIM2 10 V / 20 mA

5 U— — Voltage output 0/2 - 10V PIM2 10 V / 20 mA

6 -

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 43

The following connection values must also be adhered to:

Cross section rigid wire: 0.14 – 1.5 mm

2

Cross section flexible wire with insolated wire end ferrule: 0.25 – 0.5 mm

2

Length of stripped insolation: 7 mm

Fastening torque screw terminal: 0.22 – 0.25 Nm

Ex type of protection: Ex-nA

Example for current output 0/4 - 20 mA (DAU15 in socket PIM1):

Example for voltage output 0/2 - 10 V (DAU15 in socket PIM2):

44 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

8 Commissioning

8.1 General

Prior to start up follow the check list below:

Check to make sure that during commissioning no potentially explosive atmosphere can be

present.

Check whether the conditions concerning the intended use are fulfilled (see section 'Intended

use').

Check assembly as described in 'Assembly'.

Check of installation (equipotential bonding, connection of external components) as described

in chapter 'Installation'.

Check installation as to compliance with EN 60079-14.

Check whether housing is thoroughly closed with all hexagonal srews tightly fastened.

Check to make sure that the components connected to the outputs and interfaces (valves,

movable parts) cannot cause any damage.

Switch on supply voltage.

Configure weighing terminal (interface parameters...) in the Service Mode as described in

section 'Service Mode'.

Calibrate scale as described in Calibration Instructions.

Ex

Test inputs/outputs, serial interface and scale function in Service Mode as described in

section 'Hardware Test'.

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 45

9 Installation Examples

Shown below are three typical system configurations with the weighing terminal IT8000-Ex2/22.

These are principal schematics depicting the options to connect peripheral devices and the connections

in hazardous area as well as in safe area. All devices installed in hazardous area must be designed

compliant to an appropriate type of protection. All sections of this manual and the installation standard

EN 60079-14 must be complied with in full detail.

9.1 Installation Example IT8000-AC-*-Ex2/22

46 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

9.2 Installation Example IT8000-DC-*-Ex2/22

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 47

9.3 Installation Example IT8000-DC-*-Ex2/22 With Akku-Box

48 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

10 Service Mode

10.1 General

The Service Mode is a program for the configuration and the hardware test of the IT8000-Ex2/22

weighing terminal. Additionally, a tool is implemented to back up and restore data when connected to a

PC. The following sections give an introduction on how to operate the terminal via keyboard and

display and describe the individual functions of the Service Mode.

Notes:

IT8000-Ex2/22 and its associated equipment must be installed, adjusted and maintained by

qualified personnel only!

Before accessing the Service Mode all peripheral devices must be installed and configured!

Access to the Service Mode is protected by the Service Password.

Inappropriate changes of Service Mode settings may lead to malfunction and errors in the

operating sequence!

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 49

10.2 Display And Keyboard

Upper display line: Gross or net weight or headline of special functions *)

Lower display line: Prompts, left justified, or parameter entry, right justified *)

Info Forward scrolling

Backwards scrolling

Info

Access to Service Mode

Pressed simultaneously with alpha key: upper case letter

Pressed simultaneously with alpha key: lower case letter

Press three times: activate contrast adjustment, increase contrast

Special keys:

Press three times: activate contrast adjustment, reduce contrast

F1 - F4 Functions depending on application program

F5 (Print) Print F6 (Find) Search entry

Function keys:

F7 (Delete) Delete entry F8 (Esc) Abort function

Clr Clear entry

Clear keys:

Delete last character

Cursor key:

Return to previous program step

Enter key:

Confirm entry, continue with next program step

X Show net weight with tenfold resolution for 5 sec (only in tare

step of operating mode Simple Weighing, if enabled in Service

Mode)

Automatic taring, if scale is tared: clear tare

Set selected scale to zero

Scale keys:

Select scale (applicable only if two scales installed)

*) Depending on the application program the display may be subdivided in a different way (e.g. 4

lines).

50 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

10.3 Operator Prompting

The following sections describe the operating sequence with operator prompts and the requested

entries. In the Service Mode only two out of the maximum of 4 lines are used.

The content of the terminal display is shown in a frame on the left hand side. Next to the display the

possible operator entries are listed, on the right hand side comments and explanations are shown.

Example:

Service Mode

Password ????

Entry of the 4-character service password

Return to normal operation

Prompts or entries that apply only under certain conditions are shown in an extra frame. The condition

is shown in bold face in the upper left hand corner of the frame.

Example:

If detail ident data is specified:

Detail Ident Data

Delete after print Y

1,Y

0,N

ID is cleared after printing.

ID data is not cleared.

This display appears only if ID has been specified.

Enter Key and -Key

In all program steps, unless otherwise specified, the Enter-key leads to the next step. Pressing the key leads to the previous step.

Parameter Choice, e.g. 'Product No. 99':

In program steps that require the selection of a parameter, the options can be displayed by means of

the Info-key (scrolling). By pushing the Enter-key the displayed parameter is selected. The selection

can be exited via the -key.

Select Functions, e.g. 'Select Function 1-2':

In program steps that require the selection of a function, the options can be displayed by means of the

Info-key (scrolling). By pressing the Enter-key the displayed function is selected. Alternatively, the

function can also be started directly by entering the corresponding number in the step 'Select

function'. Function selection can be exited by pressing the -key.

Confirmation with Y (1) or N (0):

A prompt such as 'Save parameters? Y' is confirmed by pressing the key #1 and subsequently the key. By pressing key #0 and -key the proposed action is rejected and in this example the parameters

are not saved.

Numeric Entries (Numerals Only):

A requested numeric entry is depicted by '99999'. The length of the string corresponds to the

maximum length of the entry, (e.g.: 99 = 2 digits, numeric).

Numeric entries are made from right to the left. As defined in the program, entry of decimal point and

minus sign may be accepted. Fixed point data entries already show the right number of decimals.

Technical Manual IT8000-**-*-Ex2/22 Rev. 4 51

Alphanumeric Entry (Letters and Numerals):

A requested alphanumeric entry is depicted by 'XXXXXXX'. The number of x characters corresponds

to the length of the entry. Alphanumeric data entry is made from left to right. If the number of

characters to be entered is greater than the number of characters that can be shown on the display,

the content of the display is shifted to the left by one position for every newly entered character. By

pressing the key the entry can be scrolled to the left - simultaneously pressing the and keys

scrolls the entry to the right.

Adjusting the contrast of the display:

As of version RTP 6.06 of the operating system and IT8000-CPU Index 006, the contrast of the

display can be adjusted via the keyboard. Press the key or three times to activate the adjustment.

Then press the or key again to increase or reduce the contrast in steps. Press any other key to exit

adjustment.

10.4 Overview

After the power up messages with display of program version, date and time, the scale is started and

the program proceeds to the initial step.

W1 0 kg

IT8000 XXXXX V9.99

While program name and version number is displayed

Service Mode can be accessed by simultaneously

pressing the shift and Info keys.

Info Call up Service Mode

Service Mode

Password ????

Entry of the 4-character service password

Return to normal operation

Service Mode

Select Group 1-7

1 Interface configuration

2 Header ident data

3 Detail ident data

4 Application setup

5 Data backup

6 Hardware test

7 S5 Data block

Info Scrolling

F5 Print Setup and configuration data

Backwards scrolling

Return to normal operation

When Service Mode is exited, the entered or modified parameters are stored. Parameters of the groups

1 and 4 (and the factory setting of the device assignment) are stored in Flash-EPROM, whereas all

other parameters are stored in RAM. While Flash-EPROM is updated, a corresponding message is

displayed:

Storing Parameters

Please Wait...

Display while Flash-EPROM is updated

52 Technical Manual IT8000-**-*-Ex2/22 Rev. 4

CAUTION

By no means switch off power during this operation, because that will inevitably destroy the

contents of the Flash-EPROM and thus the program.

Note: If the Info-key is pressed on power up, the version and the checksum of the RTP operating

system are temporarily displayed.

RTP7.2 ID:9999999999

Version and checksum of RTP operating system.

10.5 Interface Configuration

Service Mode

Select Group 1-7

1 Interface configuration

Serial In

terfaces

Scale 1 ADC

Select scale driver for first scale

ADC = Analog L/C connected to ADM/ADC

Mettler = Mettler IDNet protocol

1

)

Sartorius = MC1 compatible protocol (SBI)

2

)

Summing = Summing scale ADM1 + ADM2

or ADC1 + ADC2

IS Scale = Sartorius IS platform

HBM C16i = Digital HBM loadcell

REVERE SLC= Digital Revere SLC loadcell

Disabled = Scale temporarily out of operation

off = No scale

F1 ADC selected: Adapt Mode provides options to

optimize the digital filtering of the captured weight,

refer to the ADM / DUAL-ADM / ADM8000-Exi

Calibration Manual, Order-No.: ST.2309.0688

1

) Intended for Mettler-Toledo scale bases with IDNet interface and 12VDC power supply.

2

) Parameters of the Sartorius scale must be set to: