Technical Manual

IT3000A

Industrial Weighing Terminal

October 2007

ST.2309.0667

Rev. 4

© SysTec GmbH • Ludwig-Erhard-Str. 6 • D 50129 Bergheim-Glessen

Tel.: 02238 / 9663-0 • Fax.: 02238 / 9663-10

Web: www.systecnet.com • E-Mail: info@systecnet.com

2 Technical Manual IT3000A Rev. 4

Technical Manual IT3000A Rev. 4 3

Technical Manual IT3000A

Date: October 22, 2007

File: IT3000A_THE.DOC

Program Version: 2.41

4 Technical Manual IT3000A Rev. 4

Published By:

SysTec GmbH, Ludwig-Erhard-Str.6, D-50129 Bergheim-Glessen, Germany

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, mechanical, photocopying, recording, or otherwise, without the

prior written permission of SysTec GmbH.

Copyright © 2005 by SysTec GmbH

Terms and product names mentioned in this publication are trademarks, registered trademarks or

service marks of their respective owners. Use of a term should not be regarded as affecting the

validity of any trademark, registered trademark or service mark.

EPSON ESC/P® is a registered trademark of the SEIKO EPSON Corporation.

TOLEDO® is a registered trademark of Mettler-Toledo Inc.

Please Note:

While every precaution has been taken in the preparation of this manual, SysTec GmbH assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

the information contained herein.

The publisher is grateful for any information and/or advice that may contribute to correct errors or

omissions in following editions.

Technical Manual IT3000A Rev. 4 5

Contents

1 Introduction .............................................................................................................9

1.1 General..............................................................................................................9

1.2 Safety Symbols Used In This Manual.....................................................................9

1.3 Safety Advice.....................................................................................................9

1.4 Declaration Of Conformity.................................................................................. 11

2 System Description .................................................................................................12

2.1 Construction.....................................................................................................12

3 Description Of Components .....................................................................................13

3.1 Main Module CPU3000A ...................................................................................13

3.2 Display ............................................................................................................13

3.3 Power Supply 110 - 240 VAC ............................................................................14

3.4 Power Supply 12 - 30 VDC ................................................................................14

4 Installation .............................................................................................................15

4.1 Safety Advice...................................................................................................15

4.2 Setup Of The Instrument....................................................................................15

4.3 Opening Of The Housing .................................................................................... 15

4.4 Connection Of Cables........................................................................................15

4.5 Connection Of Scale.......................................................................................... 16

4.5.1 Analog Understructures And Loadcells ..................................................... 16

4.5.2 Connection Of 1 Scale Base Via ADM...................................................... 16

4.5.3 Connection Of 2 Scale Bases Via Dual-ADM .............................................17

4.5.4 Connection Cables.................................................................................17

4.5.5 Multiple-Range Scale.............................................................................. 18

4.5.6 Multi-Interval Scale ................................................................................19

4.5.7 Adaptation To Scale Environment ............................................................ 20

4.5.8 Setting Of Geo Value .............................................................................20

4.5.9 Weights & Measures Approved Applications .............................................20

4.5.10 Securing Scale Parameters....................................................................21

4.6 Serial Interfaces................................................................................................22

4.6.1 Connection Of Serial Interfaces ...............................................................22

4.6.2 SIM RS485.OPTO..................................................................................22

4.6.3 RS485 Network ....................................................................................23

4.6.4 Cables For Serial Interfaces.....................................................................24

4.7 Connection Of Parallel I/Os................................................................................. 25

4.8 Connection Of 8-Bit Analog Output DAU .............................................................26

4.9 Connection Of 15-Bit Analog Output DAU15........................................................28

4.10 Mains Connection ...........................................................................................30

5 Service Mode ......................................................................................................... 31

5.1 General............................................................................................................31

5.2 Display And Keyboard .......................................................................................32

5.2.1 Multiple Assignment Of Numeric Keypad ..................................................33

5.3 Operator Prompting ...........................................................................................33

5.4 Overview .........................................................................................................34

5.5 Overview Service Mode .....................................................................................36

6 Calibration .............................................................................................................38

6.1 Entering Calibration Mode ..................................................................................38

6.2 Select Group ....................................................................................................39

6.3 Scale Parameters ..............................................................................................40

6.4 Calibration........................................................................................................43

6.5 Linearization .....................................................................................................45

6.6 Zero Adjust ......................................................................................................46

6.7 Adaptation .......................................................................................................47

6.8 High Resolution ................................................................................................49

6.9 Reset Parameters ..............................................................................................50

6.10 Calculate Span................................................................................................51

6.11 W&M Info ......................................................................................................52

6.12 Factory Calibration ..........................................................................................53

6 Technical Manual IT3000A Rev. 4

6.13 Geo Values ....................................................................................................53

7 Interface Configuration............................................................................................ 55

8 Configuration Of Data Entry And Print Format ............................................................ 58

8.1 Configuration Of Fields ...................................................................................... 58

9 Entry Of Parameters................................................................................................ 63

10 Operating Modes .................................................................................................... 69

10.1 Weighing Functions......................................................................................... 69

10.1.1 Tare Memory ...................................................................................... 71

10.2 Tare Functions................................................................................................ 72

10.2.1 Set / Clear Tare................................................................................... 72

10.2.2 Autoclear Tare .................................................................................... 72

10.2.3 Repetitive Tare.................................................................................... 72

10.3 Operating Mode 'BASIC'.................................................................................. 73

10.4 Operating Mode 'COUNT' ................................................................................ 74

10.5 Operating Mode 'TRUCK'................................................................................. 79

10.6 Operating Mode 'FILL 1' .................................................................................. 81

10.7 Operating Mode 'FILL 2' .................................................................................. 83

10.8 Operating Mode 'CHECK'................................................................................. 86

10.9 Operating Mode 'TRUCK ONLINE'..................................................................... 87

10.10 Operating Mode 'BASIC/COUNT' .................................................................... 87

11 Backup.................................................................................................................. 88

12 Restore ................................................................................................................. 88

13 Hardware Test .......................................................................................................89

14 Entry Of Parameters For Analog Output..................................................................... 90

15 Reset .................................................................................................................... 91

16 Online Mode .......................................................................................................... 92

16.1 Structure Of Data Strings ................................................................................ 92

16.2 Overview Commands ...................................................................................... 93

16.3 Read Weights ................................................................................................. 94

16.4 Taring............................................................................................................ 97

16.5 Select Scale ................................................................................................... 98

16.6 Set Scale To Zero ........................................................................................... 99

16.7 Display Of Text And Entries ............................................................................. 99

16.8 Printing........................................................................................................ 104

16.9 Read / Set Digital I/Os ................................................................................... 105

16.10 Key And Error Codes ................................................................................... 107

16.11 Multidrop Connection .................................................................................. 108

16.11.1 Establish And Terminate Connection .................................................. 108

16.11.2 Example (Polling Of Slave 1 And Slave 2)........................................... 109

17 Spervisor Mode .................................................................................................... 110

17.1 Entry of Parameters ...................................................................................... 110

17.2 Data Archive ................................................................................................ 112

17.2.1 View Stored Records ......................................................................... 113

17.2.2 Show Data Archive Info ..................................................................... 113

17.3 Error Report ................................................................................................. 114

18 Configuration Examples ......................................................................................... 115

18.1 Example 'BASIC'........................................................................................... 115

18.2 Example 'COUNT'......................................................................................... 122

18.3 Example 'TRUCK' ......................................................................................... 123

18.4 Example 'FILL'.............................................................................................. 126

18.5 Factory Setting............................................................................................. 127

18.6 Field Length Of System Variables.................................................................... 128

18.7 Form For Print Layouts (80 Columns) .............................................................. 129

18.8 Form For Print Layouts (40 Columns) .............................................................. 130

18.9 Form For Configuration.................................................................................. 131

Technical Manual IT3000A Rev. 4 7

19 Data Transmission ................................................................................................132

19.1 Data Transmission Example 1 .........................................................................133

19.2 Data Transmission Example 2 .........................................................................134

19.3 Data Transmission Example 3 .........................................................................135

19.4 Protocol For Data Transmission....................................................................... 136

19.5 Continuous Output ........................................................................................137

19.5.1 SysTec Protocol ................................................................................137

19.5.2 Flintec Protocol .................................................................................137

19.5.3 Spec 1 Protocol.................................................................................137

19.5.4 Spec 2 Protocol.................................................................................137

19.5.5 Schauf Protocol................................................................................. 137

19.5.6 TOLEDO® Protocol ............................................................................. 138

19.5.7 TOLEDO® TSM Protocol .....................................................................138

20 Transport, Maintenance And Cleaning .....................................................................140

20.1 Transport ..................................................................................................... 140

20.2 Maintenance................................................................................................. 140

20.3 Cleaning.......................................................................................................140

21 Trouble Shooting ..................................................................................................141

21.1 Exchange Of OTPs ........................................................................................ 142

21.2 Error Messages ............................................................................................. 144

22 Technical Data .....................................................................................................147

23 Dimensions .......................................................................................................... 148

24 Service Password .................................................................................................149

8 Technical Manual IT3000A Rev. 4

Technical Manual IT3000A Rev. 4 9

1 Introduction

1.1 General

This manual contains information and Technical Data for installation and operation of the IT3000A

industrial weighing terminal. It is structured in the main chapters:

• Modules and connections

• Calibration

• Service Mode for configuration and settings

• Online mode

• Configuration examples.

1.2 Safety Symbols Used In This Manual

Safety relevant information is shown with corresponding symbols as follows:

W A R N I N G

Failure to observe this precaution could result in serious injuries or fatal accidents. Please make

absolutely sure that these precautions are observed in order to ensure safe operation of the

equipment.

CAUTION

Failure to observe this precaution could result in damage to or destruction of the equipment or

bodily harm! Please make absolutely sure that these precautions are observed in order to ensure

safe operation of the equipment.

Note: This indicates an advice for the designated use of the equipment and/or additional information

to avoid improper handling.

1.3 Safety Advice

W A R N I N G

Disconnect all power to this instrument before opening the housing! Risk of electrical shock!

W A R N I N G

Exercise utmost care when making checks, tests and adjustments that can actuate movable

parts such as feeding devices, gates, flaps, conveyors, etc. Make absolutely sure that nobody

is within reach of movable parts.

W A R N I N G

This unit must not be operated in a potentially explosive atmosphere!

It is the sole responsibility of the user to classify the area of installation and make sure that

absolutely no potentially explosive atmosphere can be present at any time!

CAUTION

Input voltage of the instrument must comply with local mains supply!

10 Technical Manual IT3000A Rev. 4

CAUTION

If the line cord with connector is used as the means to separate the instrument from the mains,

the wall outlet must be installed close to the instrument and must be easily accessible! If a

permanently connected mains cable is used, an easily accessible separator must be included in

the supply circuit!

CAUTION

The power supply unit of the weighing terminal provides SELV voltages in accordance with EN

60950. Make sure that any peripheral device connected to the weighing terminal containing its

own power supply also uses SELV voltages!

CAUTION

This unit must be installed, serviced and operated in strict compliance with all locally applicable

safety regulations and the rules for the prevention of accidents!

CAUTION

When this unit is included as a component part of a system, the resulting system design must

be reviewed by qualified personnel who are familiar with the construction and operation of all

individual components in the system and the potential hazards involved.

CAUTION

If this device is used in an automatic or manual filling cycle, all users must provide a hard wired

emergency stop circuit outside the device circuitry.

CAUTION

This module and its associated equipment must be installed, adjusted and maintained by

qualified personnel only!

Note:

• The unit does not have a mains switch and is operational immediately after connection to the

mains supply!

• Only permit qualified personnel to operate this instrument!

Disconnect all power to this instrument before cleaning and servicing!

• All switch gear connected to the unit and/or installed close to it, such as relays and

contactors, must be fitted with appropriate components (RC-modules, diodes) to suppress

interference.

• In order to avoid static discharge, all metallic parts of a system must be thoroughly grounded.

Movable parts, such as portable scales on plastic wheels, must be grounded with earth clamps

or earth leads of appropriate diameter.

• Keep this manual for future reference!

Technical Manual IT3000A Rev. 4 11

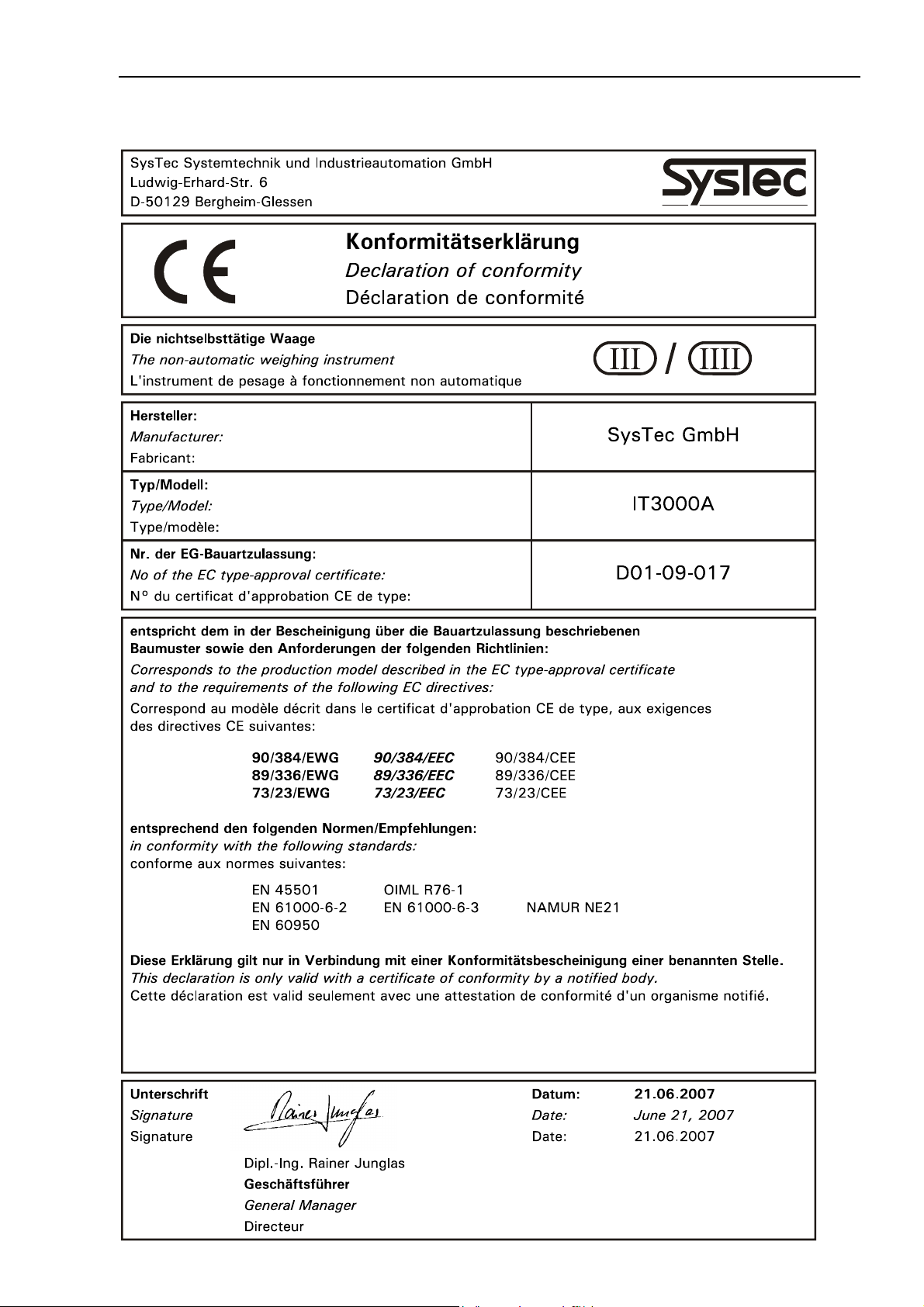

1.4 Declaration Of Conformity

12 Technical Manual IT3000A Rev. 4

2 System Description

The IT3000A is a general purpose weighing terminal for use in a variety of applications such as data

logging, data capturing, parts counting and filling. Depending on the chosen scale interface (ADM or

Dual-ADM) and the selected operating mode, either one or two analog understructures with a total of

up to 16 strain gauge loadcells with an impedance of 350 Ω each can be connected.

The operating modes BASIC, COUNT and ONLINE support the connection of 2 scale bases, whereas

TRUCK, TRUCK/ONLINE, CHECK and FILL are intended for 1 scale base only.

As required for a specific application, plug-on modules for 1 or 2 serial interfaces and 1 module with

2 parallel I/Os or 1 analog output can be added. The integrated clock / RAM module (512kB) provides

powerfail safe date and time function, scale error log, and storage for up to 1000,000 records in a

data archive, 99 first weights (operating mode TRUCK), as well as 9 tare values per scale, 9

reference weights (operating mode COUNT) and 9 product parameters (operating mode FILL).

Power supply through the built-in power supply unit is either for 110 - 240 VAC or 12 - 30 VDC.

Cables of all external components are connected at screw terminals.

Weight and additional information is indicated on a back-lit 20-character LCD, height of characters

14mm. Operation and data entry is made via a sealed membrane keyboard with tactile feedback.

Operation, sequence and printout can be configured for a specific application. All entries required for

the configuration can be made through the keyboard of the terminal. As an alternative, a

comprehensive PC program for configuration and archiving is available.

Instead of operating the terminal locally via keyboard and display, full remote control is possible from

a PC. In applications legal for trade data can also be stored in an approved data archive on the PC's

harddisk.

2.1 Construction

IT3000A is incorporated in a stainless steel housing, protected to IP65, for wall-mount or desk-top

installation. As option, a panel-mount version is available. All cable connections are made at the rear

of the housing through tight cable glands.

See section 'Dimensions' for details.

Technical Manual IT3000A Rev. 4 13

3 Description Of Components

3.1 Main Module CPU3000A

The CPU3000A module is the core of the IT3000A weighing terminal. It contains the microcontroller

with data and program memory. Sockets are provided for the scale interface board ADM (1 scale

base) or Dual-ADM (two scale bases) and the optional installation of 2 serial interfaces (SIM) and 2

parallel I/Os (PIM) or 1 analog output (DAU).

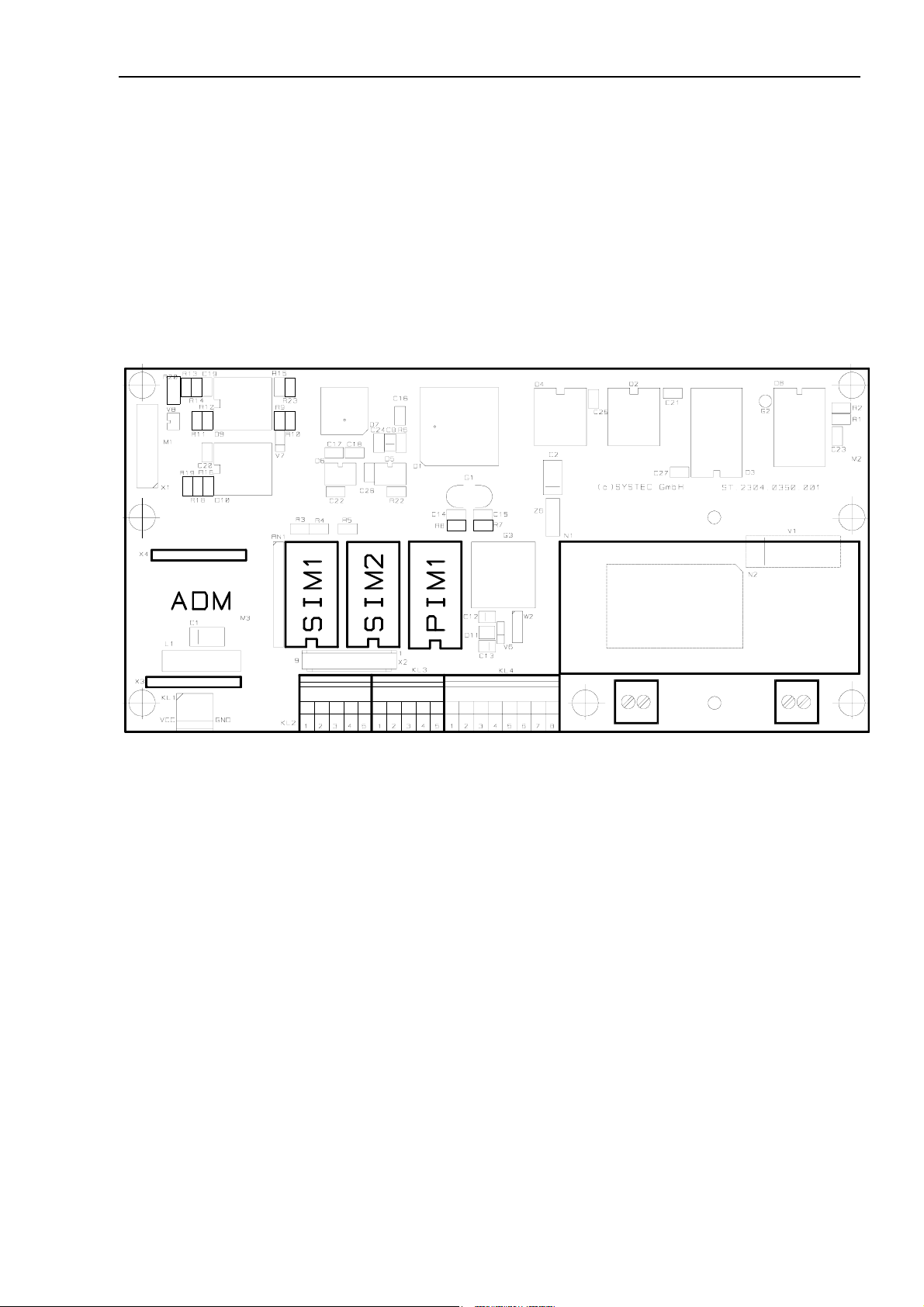

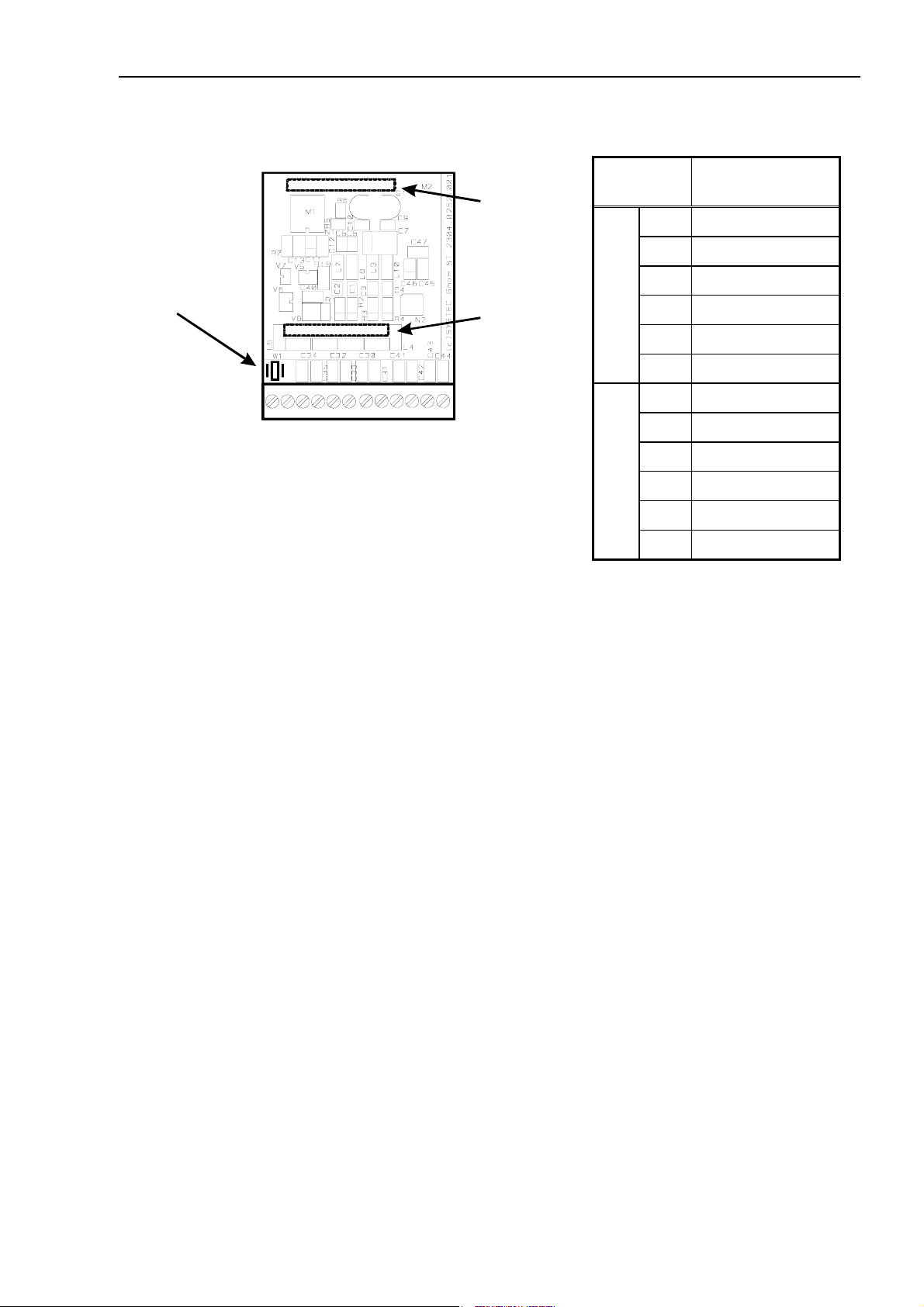

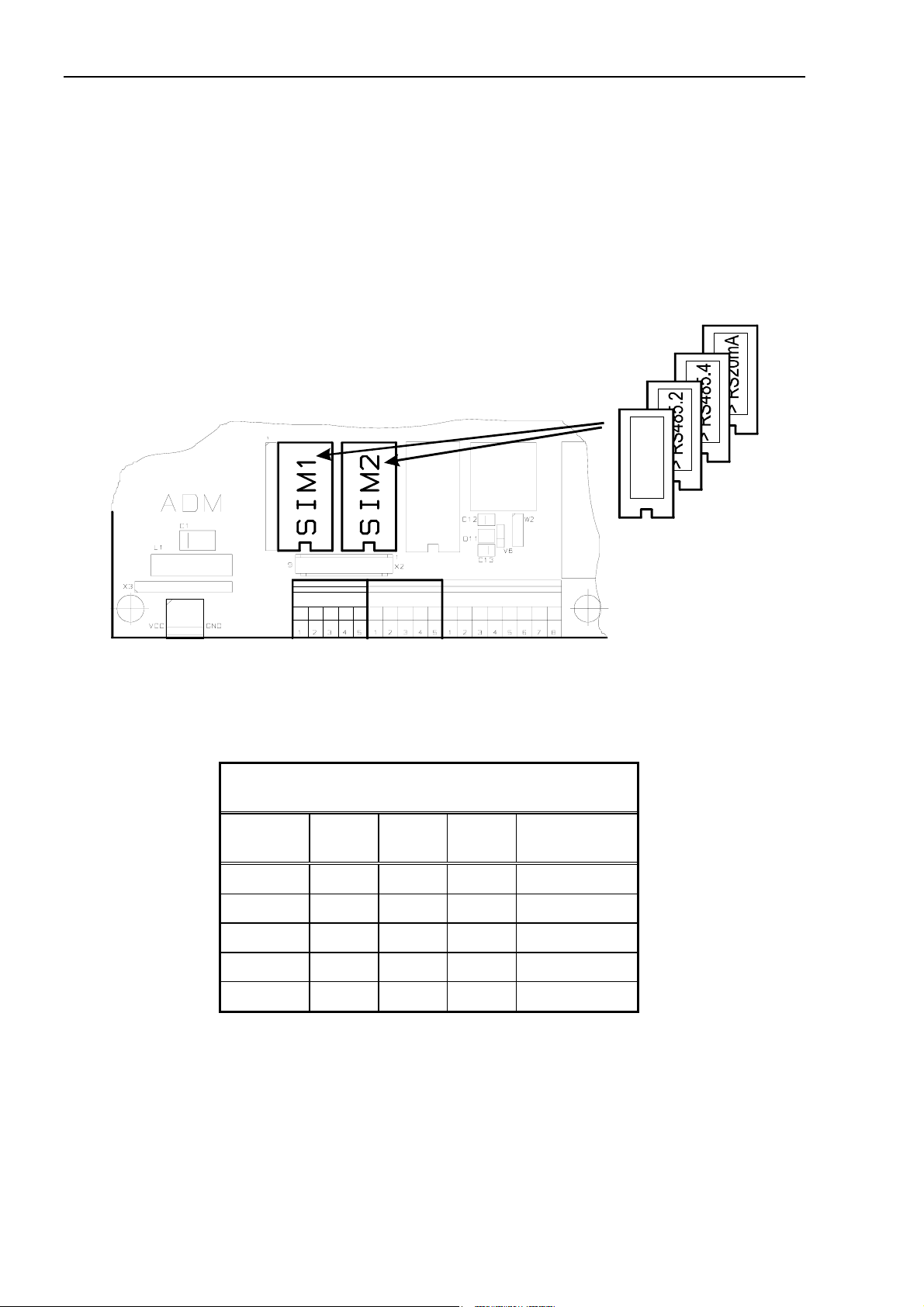

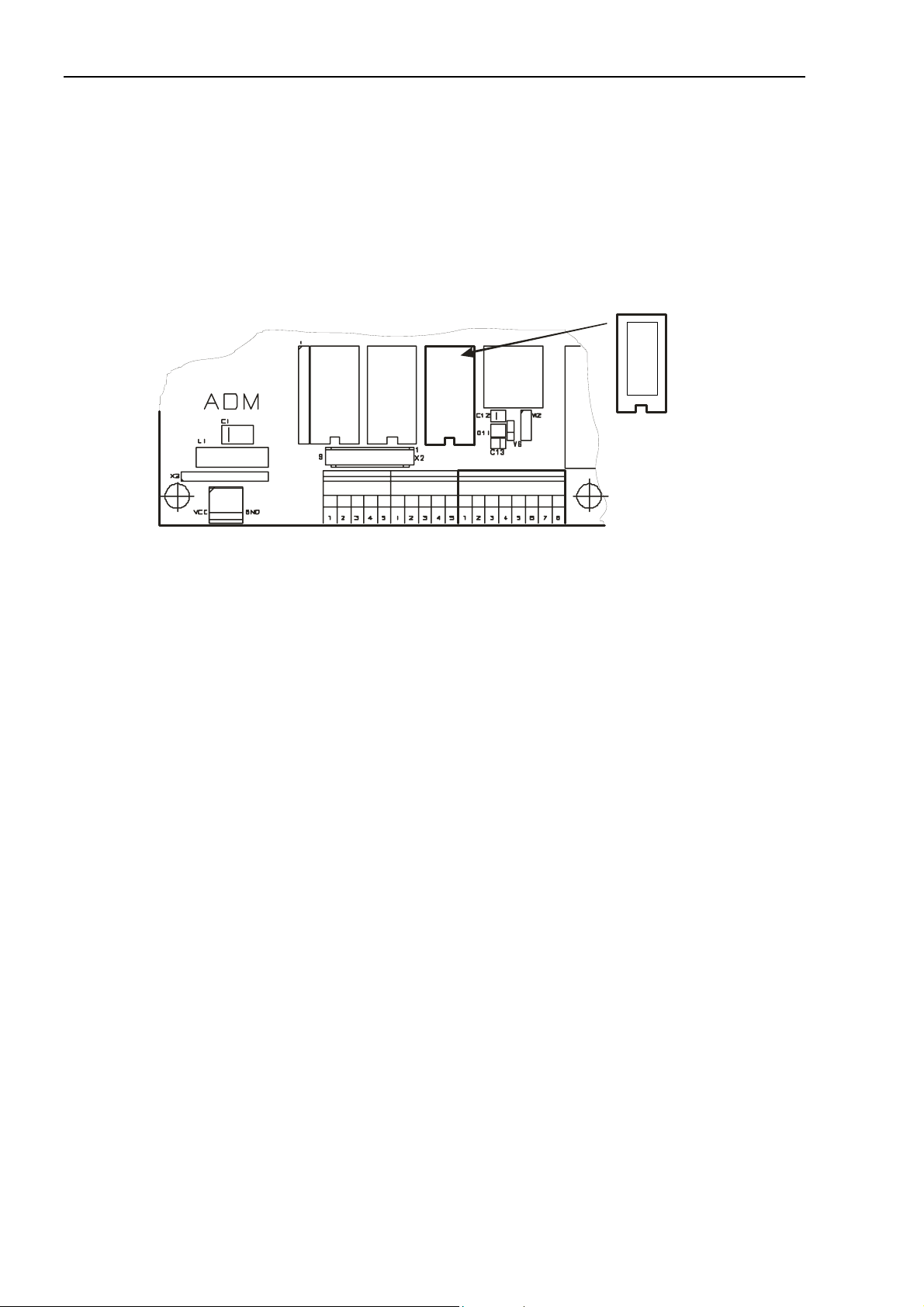

Layout of components on CPU3000A main module:

Power supply unit

Socket for

ADM / Dual-ADM

scale interface

Terminal KL2

interface COM1

Terminal KL3

interface COM2

Terminal KL4

digital inputs/

outputs

Terminal KL6

PE

Terminal KL5

power supply

3.2 Display

To indicate the weight, status information and operator prompts a back-lit 20-character LCD display

is used. The height of characters is 14mm, each character is formed by a matrix of 5x7 dots. The

display is connected at the 16-pin connector X1 on the main module.

By means of the selectable powersave function, backlighting can be switched off after time when the

the terminal is not in use.

14 Technical Manual IT3000A Rev. 4

z

3.3 Power Supply 110 - 240 VAC

The auto sensing switching mode power supply unit operates on an input voltage ranging from 110

Volt (–15%) to 240 Volt (+10%), 50/60 Hz. The output rating is 1A at 5VDC.

W A R N I N G

Parts of the power supply unit are directly connected to dangerously high voltages!

A defective power supply unit can only be replaced. Disconnect all power to the instrument

before servicing!

Position of soldering pins for input and output voltages:

Power supply unit

PE

Terminal KL6

110 V (–15%) to 240 V (+10%),

The power supply has a fused input (2A slow blow).

L1 N

Terminal KL5

50/60H

3.4 Power Supply 12 - 30 VDC

Alternatively, IT3000A is available in a version that operates on 12 V (–15%) to 30 VDC (+10%).

For this version a DC/DC converter is installed on the main module instead of the AC power supply.

The DC version has a fused input (1A slow blow). The output rating of the converter is 5VDC at

600mA.

F1 / 1A

DC/DC

converter

+V 0V

Terminal KL5

12 - 30 VDC

Technical Manual IT3000A Rev. 4 15

4 Installation

4.1 Safety Advice

W A R N I N G

Disconnect all power to the instrument and/or unplug line cord prior to opening the housing!

Failure to observe this precaution could result in bodily injury!

Notes:

• Transport and storage of electronic components such as boards, EPROMs, etc. must only be

made in suitable anti-static ESD bags or cases.

• Shielding measures for the connection of cables must absolutely be adhered to. Insufficient

shielding may cause interference and could result in malfunction of the instrument.

4.2 Setup Of The Instrument

Ambient temperature for operating the unit may range from –10°C to +40°C, at a maximum of

95% relative humidity, without condensation. Exposure to direct sunshine should be avoided.

For wall-mount applications the terminal can be fixed at the wall first, the connection cables can be

fitted later with the lid of the housing removed.

4.3 Opening Of The Housing

To open the housing a size 7mm wrench is required. Please make sure that cables running from the

various modules to display and keyboard are not torn off or damaged when lid is removed.

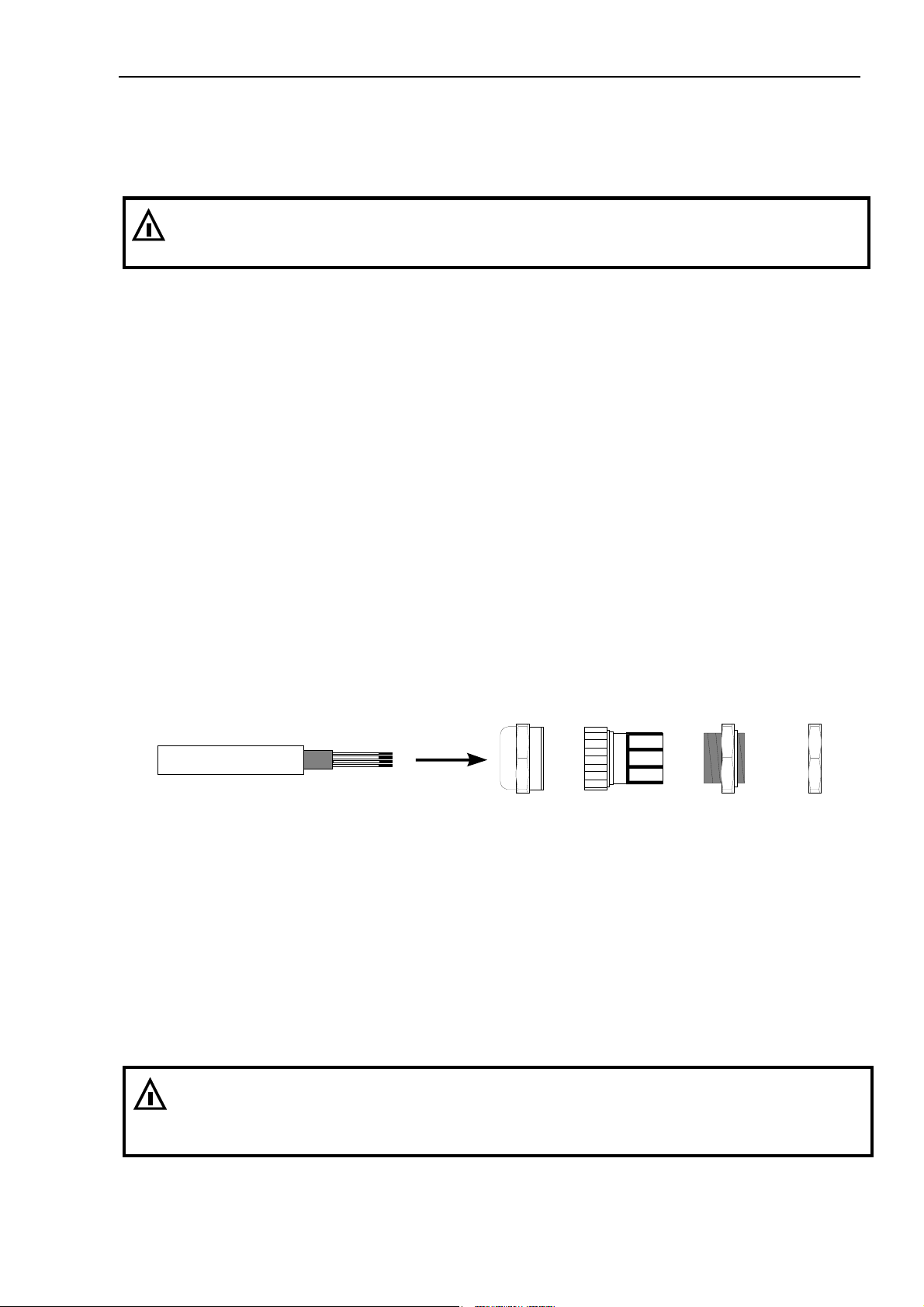

4.4 Connection Of Cables

All cables are led into the housing through cable glands. Required size of wrenches: PG9 → 17mm;

PG11→ 20mm.

Cable jacket Shield Wires Compression nut Plastic insert Bushing Counter nut

Cable connection through cable glands:

1. Slide compression nut over cable jacket;

2. Slide plastic insert (retainer) over cable jacket until inner end is aligned with cut end of jacket;

3. Unravel shield, bend over retainer and push into retaining comb. Cut wires of shield to length of

comb, avoid protruding wires;

4. Insert retainer with cable into bushing;

5. Screw compression nut onto bushing and use wrench to tighten securely.

W A R N I N G

Cut cable ends as short as possible and make sure that they cannot touch any parts (mains

cable, power supply) conducting mains voltage!

Use cable ends on stranded cables and avoid protruding wires!

16 Technical Manual IT3000A Rev. 4

4.5 Connection Of Scale

4.5.1 Analog Understructures And Loadcells

Connection of weighing platforms and loadcells to the IT3000A terminal is made via an ADM or DualADM scale interface as specified below:

• 1 scale base (ADM), 2 scale bases in switching mode (Dual-ADM)

• Max. 16 strain gauge loadcells 350 Ω each

• Overall impedance 21.5 Ω ...4500 Ω

• W&M approved resolution of 6000d at a max. preload of 80%, internal resolution

524,000d

• Smallest permissible input signal for approved applications: 0.33 µV / e

• Update rate 50 updates / second

• Loadcell excitation: 5 V ±5% (gated power supply).

4.5.2 Connection Of 1 Scale Base Via ADM

Terminal assignment on ADM module:

X2

Connection

to X4 on

CPU3000A

Terminal KL1 Assignment

1 + Excitation

Jumper W1

for protection of

calibration data

1

Terminal KL1

scale base with analog

loadcell(s)

Connection of 4-wire loadcell:

To connect loadcells without sense lines (4-wire connection), two jump leads must be connected at

terminal strip KL1 between terminal 1 and 3, and between terminal 2 and 4.

6

X1

Connection

to X3 on

CPU3000A

2 – Excitation

3 + Sense

4 – Sense

5 + Signal

6 – Signal

Technical Manual IT3000A Rev. 4 17

4.5.3 Connection Of 2 Scale Bases Via Dual-ADM

Terminal assignment on Dual-ADM module

Jumper W1

for protection of

calibration data

1166W1 W2

X2

Connection

to X4 on

CPU3000A

X1

Connection

to X3 on

CPU3000A

Terminal

KL1

1 W1 + Excitation

2 W1 – Excitation

3 W1 + Sense

W1

4 W1 – Sense

5 W1 + Signal

6 W1 – Signal

1 W2 + Excitation

Assignment

Terminal KL1

connection for analog

loadcells scale 1 and 2

Connection of 4-wire loadcell:

W2

2 W2 – Excitation

3 W2 + Sense

4 W2 – Sense

5 W2 + Signal

6 W2 – Signal

To connect loadcells without sense lines (4-wire connection), two jump leads each must be

connected at terminal strip KL1 between terminal 1 and 3 as well as 2 and 4 (scale 1 and 2).

For operation with two scales please note:

Connection of 2 scale bases is only supported by the operating modes BASIC, COUNT,

BASIC/COUNT and ONLINE.

The Dual-ADM module has one A/D converter which is either connected to scale 1 or scale 2 and

which does not permit reading of the two scales in parallel (switching mode only). A summing mode

is not possible. On switching from one scale to the other, new measuring values are determined for

digital filtering and the motion detector, thus it takes approx. 1 sec after switching until a stable

weight can be displayed.

The Dual-ADM module provides hardware detection to tell the operating system that now two scales

are connected. Only then the calibration routines for the second scale can be called up.

4.5.4 Connection Cables

For the installation of connection cables for analog weighing platforms please follow the recommendations listed below:

• Only use suitable loadcell cable, (e.g. SysTec order-No. 10KAB211.

4 x 0.75mm² + 2 x 1mm², shielded,)

Nominal voltage of cable ≥250V.

Unsuitable loadcell cable may affect accuracy.

• The shield of the loadcell cable must be connected all around the cable in the cable gland of

the weighing terminal (see also chapter 'Installation' / 'Connection Of Cables'). If an extension

of the loadcell cable is required use only metal junction boxes and cable glands. The shield on

both sides must be connected in the same way as at the terminal. Loadcells and/or weighing

platforms, junction boxes and the terminal must be included in the potential equalization of

the components of a weighing system. Depending on the situation on site this may require

the installation of a separate earth lead of appropriate diameter (e.g. 16mm²) in parallel to the

loadcell cable.

18 Technical Manual IT3000A Rev. 4

• Distance between loadcell cables and power lines: ≥0.5m. Loadcell cables to be installed in

grounded metal conduits, metal hoses or metal cable trays.

• Maximum length of connection cable between weighing platform and IT3000A: 200m

• If tension load is applied to loadcells instead of compression load, connection for +Signal and

–Signal must be switched.

4.5.5 Multiple-Range Scale

Calibration is possible as Single, Dual or Triple Range Scale. The different ranges have different

capacities and scale intervals.

Example: Triple Range Scale with a resolution of 3000 increments for each range:

First range: 0 – 1500kg / 0.5kg

Second range: 0 – 3000kg / 1.0kg

Third range: 0 – 6000kg / 2.0kg

When a Multiple Range Scale is loaded, the scale display changes automatically from a lower to a

higher range. During unloading of the scale, the scale display remains in the higher range. If the scale

was tared (weighing in net mode), on return to gross zero the tare is only cleared when the tare key

is pressed. Only after clearing the tare, the display returns to gross mode and switches back to the

smallest range.

Automatic switching back to the smallest range on reaching zero is only carried out if the scale was

not tared (weighing in gross mode).

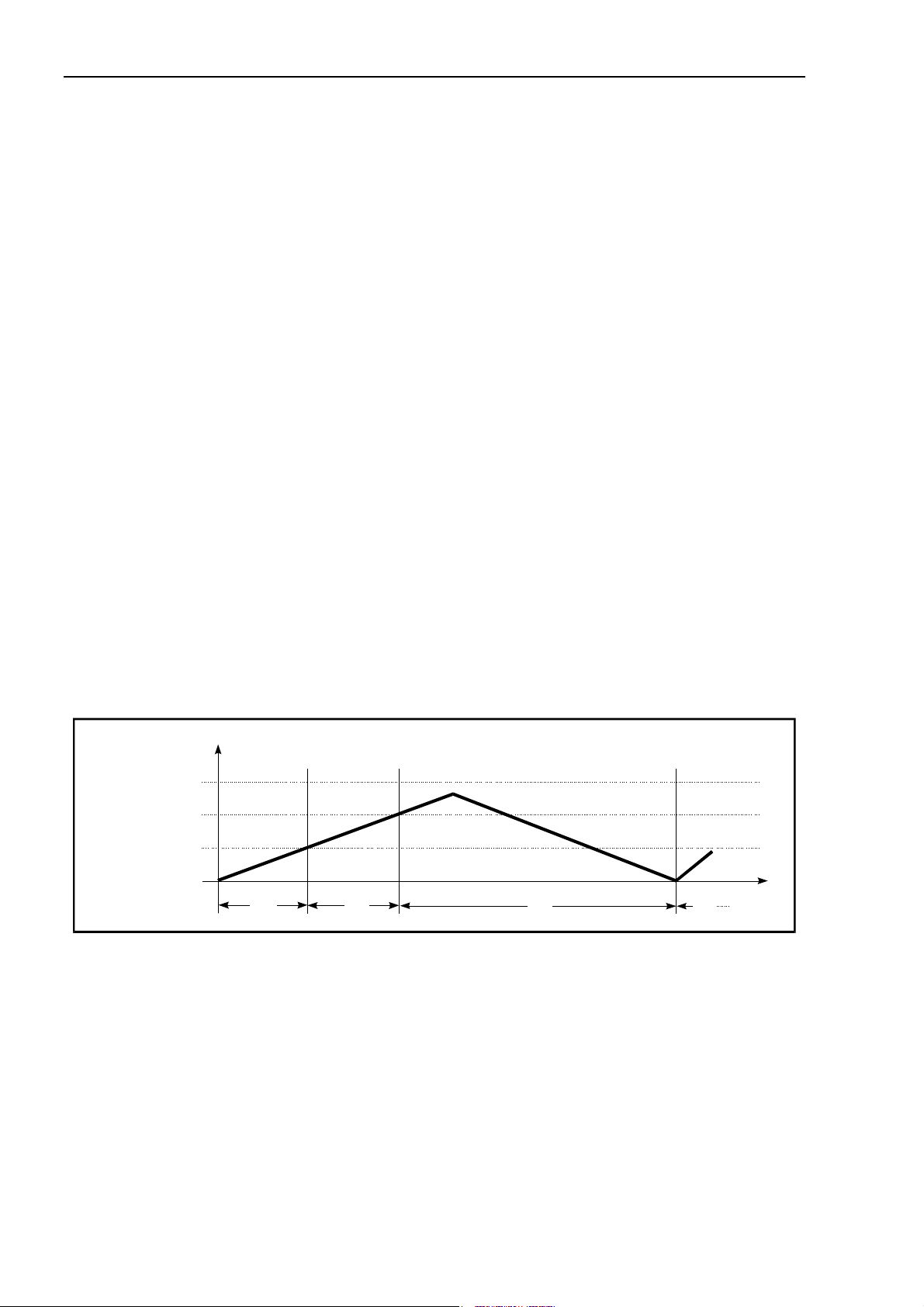

Example of a weight curve for loading and unloading a Multiple Range Scale showing the weight and

the displayed scale interval:

Gross Weight/kg

6000

3000

1500

0

Scale Interval/kg:

0.5 1.0 2.0

0.5

t

When the scale is loaded further after it was tared, the tare weight is rounded automatically to the

next scale interval as soon as the display is switched from one range to the next.

The Multiple Range Scale provides weighing of light and heavy loads on the same scale with a high

degree of accuracy, since each range has a resolution -for instance- of 3000d, inexpensive loadcells

can be used.

For the configuration of a Multiple Range scale all ranges and scale intervals can be chosen freely,

however, the maximum resolution of the loadcells (e.g. 3000d) must not be exceeded in any of the

chosen ranges.

Technical Manual IT3000A Rev. 4 19

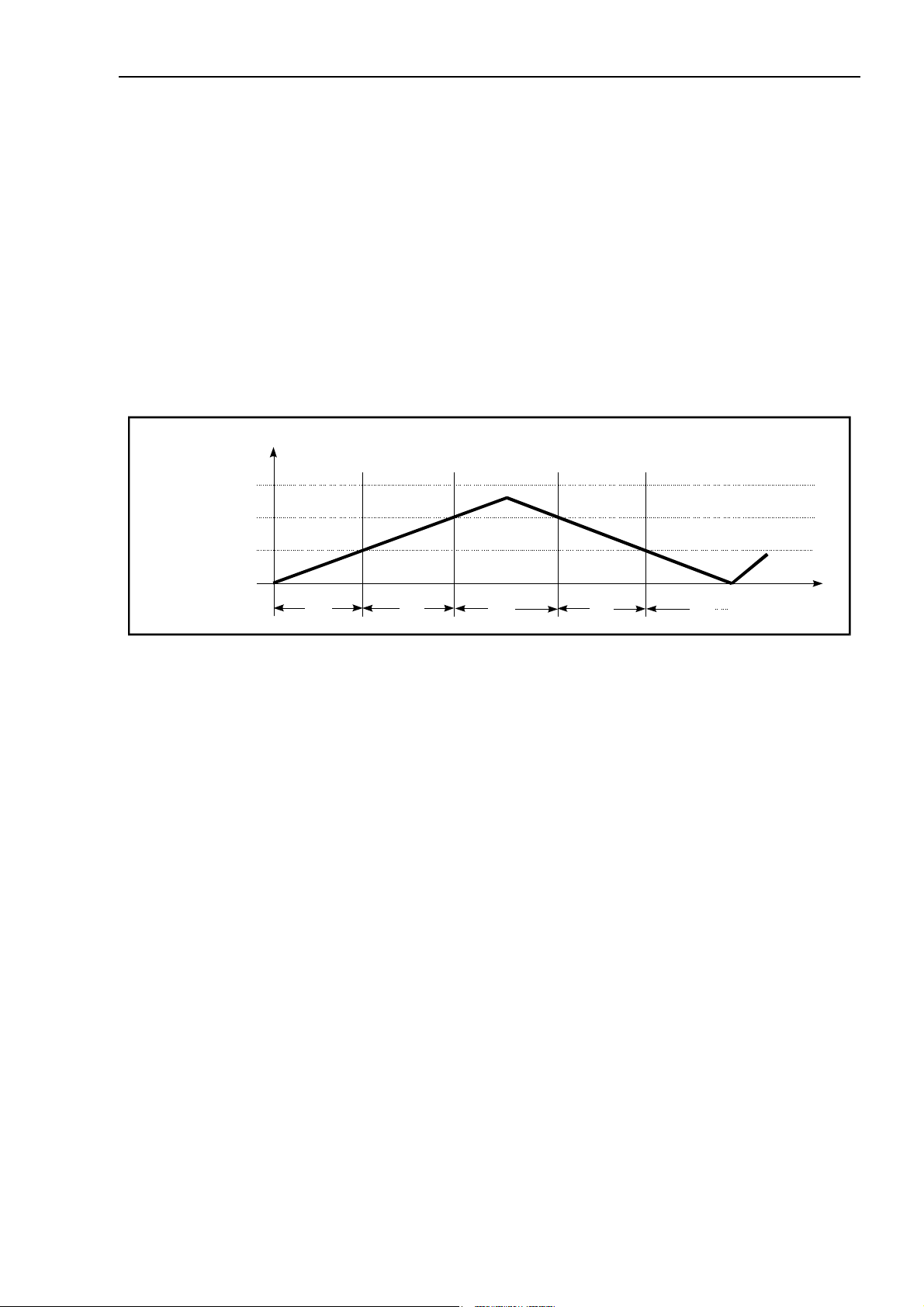

4.5.6 Multi-Interval Scale

A Single Range Scale can be configured as Multi-Interval Scale with two or three different interval

ranges.

Example for a Triple Interval Scale:

First interval range: 0kg – 1500kg / 0.5kg

Second interval range: 1500kg – 3000kg / 1.0kg

Third interval range: 3000kg – 6000kg / 2.0kg

The scale display changes automatically from one interval range to the next during loading and

unloading of the scale.

Example weight curve for loading and unloading a Multi Interval Scale showing the weight and the

scale interval displayed:

Net Weight/kg

6000

3000

1500

0

Scale Interval/kg:

0.5 1.0 2.0

1.0

0.5

t

After taring the scale, the scale display shows the net weight with the smallest scale interval. Small

weights are shown with the highest accuracy, even when the scale is already loaded to a higher

weighing range. Restriction: The max. permitted manually entered tare weight must not exceed the

weight of the range with the smallest interval.

For the configuration of a Multi-Interval scale all ranges and scale intervals can be chosen freely.

20 Technical Manual IT3000A Rev. 4

4.5.7 Adaptation To Scale Environment

The following parameters can be set to obtain optimum weighing results:

• Motion window size and number of measurments for motion detector

• Filter strength of the digital filter for unstable scales

• Auto Zero Range for Auto Zero Function

• Pushbutton Zero Range for Zero-key

• Power Up Zero Range

• Overload Threshold for display blanking.

4.5.8 Setting Of Geo Value

Before calibrating the scale, the Geo Value must be entered, e.g. Great Britain = 21 (see also chapter

Geo Values). If the scale is calibrated at one location and moved to another location later, it is

sufficient to re-enter the Geo Value of the new location.

4.5.9 Weights & Measures Approved Applications

The highest W&M certified resolution (Scale Capacity / Scale Interval) is 6000 increments (with a

max. of 80% deadload).

W&M approved installations require parameter setting in the group 'Adaptation' as follows:

• Motion Window: 0.5d

• Motion Counter: ≥7

• Auto Zero Range: 0.5d

• Pushbutton Zero: ±2%

• Power Up Zero: ±2% or ±10% *)

• Overload: max. 9 d

*) Depending on the application, also the setting 'Off' may be acceptable, e.g. for hopper

scales.

Under menu item 'W&M Info' the conformity of settings with W&M requirements can be checked.

The scale settings are stored in an EEPROM and secured with the jumper W1 which can be sealed by

Weights & Measures with thread and lead seal to prevent unauthorized modification.

Technical Manual IT3000A Rev. 4 21

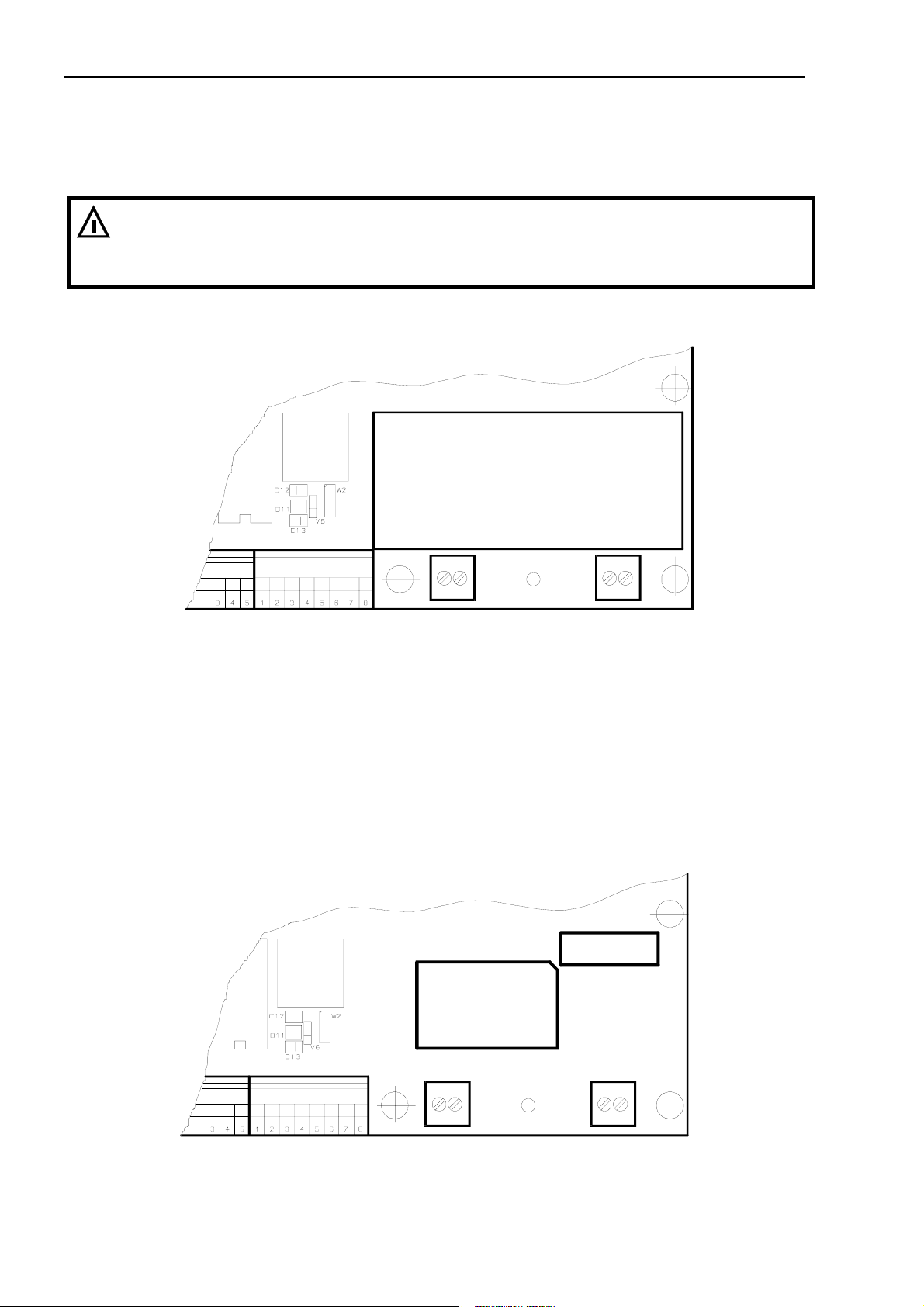

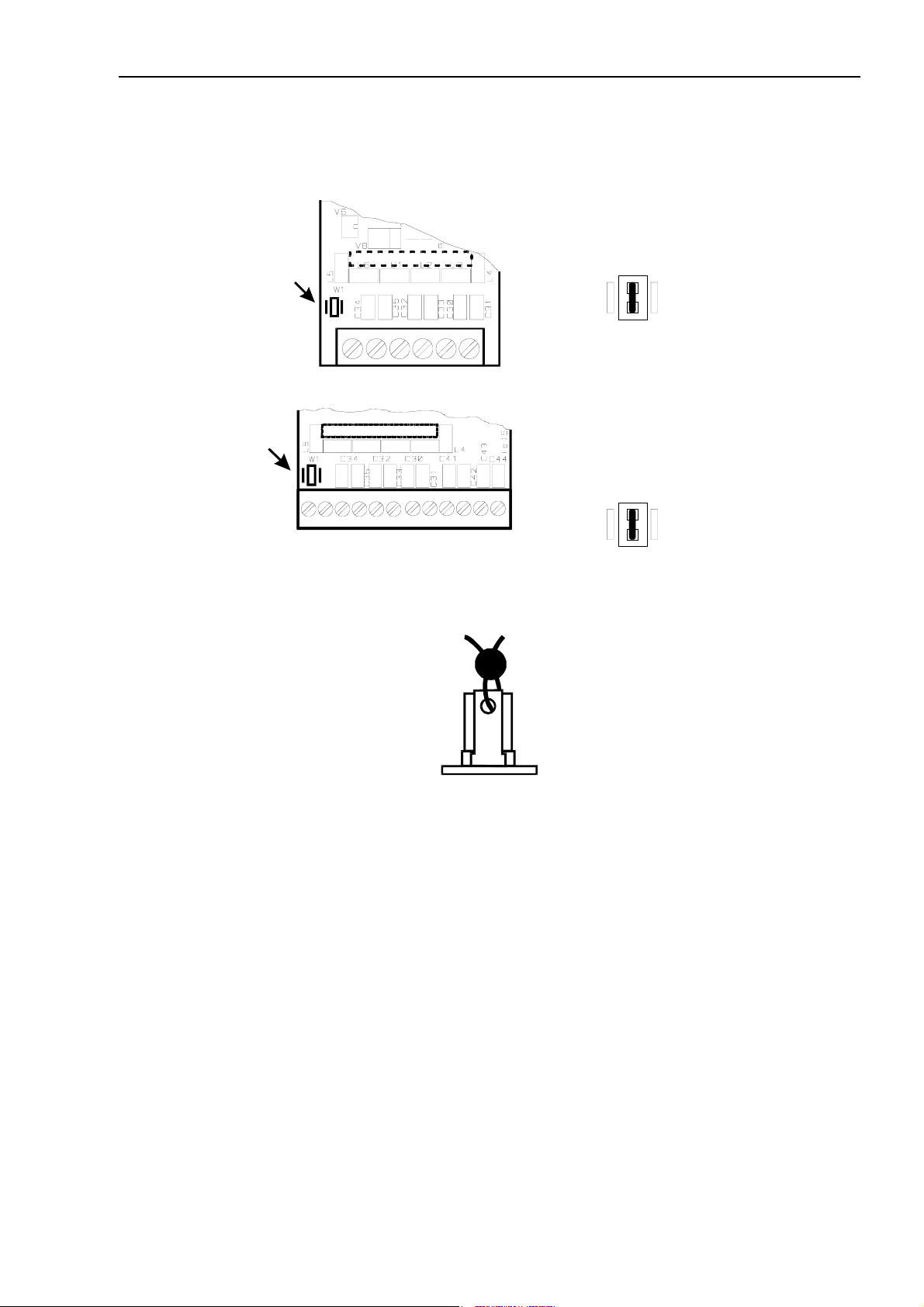

4.5.10 Securing Scale Parameters

The scale parameters are stored in EEPROM and secured with the jumper W1:

ADM

Calibration data secured

W1

1

W1

1

W&M approved applications require that the calibration parameters be protected against unauthorized

modifications. To that effect the jumper can be sealed with thread and lead seal.

6

Dual-ADM

Calibration data of both

scales secured

12

For a description of the scale calibration refer to the respective chapter.

22 Technical Manual IT3000A Rev. 4

4.6 Serial Interfaces

The serial interfaces of the IT3000A terminal can be configured individually by means of plug-on

driver modules as:

RS232 or RS485 2-wire or RS485 4-wire or RS485 2/4-wire optoisolated or 20mA CL (passive).

By default, the interfaces are assigned to: COM1 → PC/EDP, COM2 → printer. The assignment can

be changed in Service Mode to connect other devices such as remote display and reference scale.

4.6.1 Connection Of Serial Interfaces

Connection of serial interfaces on the main module:

> RS232

Terminal strip

KL2

Terminal assignment interface #1 and #2:

Terminal strip KL2: serial interface #1 (COM1)

Terminal strip KL3: serial interface #2 (COM2)

Terminal # RS232 20mA RS485

1 TxD TXIN TxD+ TxD+ / RxD+

2 RTS TXOUT TxD– TxD– / RxD–

3 RxD RXIN RxD+ —

4 CTS RXOUT RxD– —

5 Gnd — — —

Terminal strip

KL3

4-wire

Insert with

notch pointing

to bottom!

RS485

2-wire

4.6.2 SIM RS485.OPTO

The SIM RS485.OPTO interface driver is autosensing and provides both, 2-wire and 4-wire

communication.

Please note: This module cannot be inserted in socket SIM 1 when a Dual-ADM board is installed.

Technical Manual IT3000A Rev. 4 23

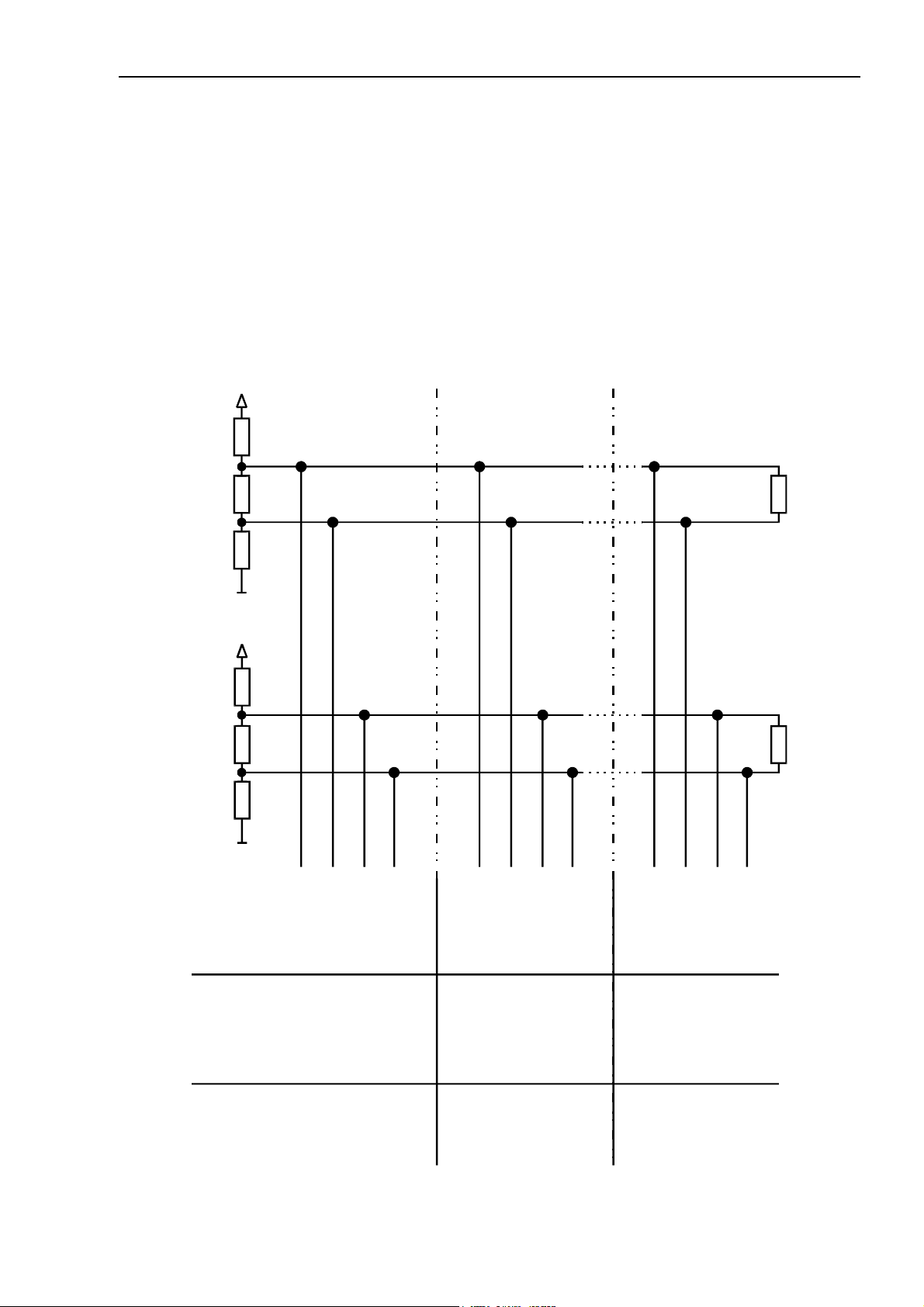

4.6.3 RS485 Network

Terminal assignment: Some manufacturers of components with RS485 interface do not refer to the

terminals TX+ and RX+ as 'A', but 'B' instead (correspondingly, the terminals TX- and RX- are not

referred to as 'B', but 'A').

Termination resistors: In order to prevent reflection (baud rate 19200 Baud or higher, and/or cable

longer than 20m) it is recommended to install termination resistors R

cable. The characteristic impedance of the cable should be approx. 150 Ω.

Pull-up / pull-down resistors: When termination resistors are used, also 390 Ω pull-up and pull-down

resistors must be installed at the master (see also following schematic).

RS 485 network with termination-, pull-up- and pull-down- resistors

V

CC

390

Ω

150

Ω

Term = 150 Ω on both ends of the

150

Ω

390

390

150

390

RS485 4-wire

Ω

Gnd

V

CC

Ω

Ω

Ω

Gnd

−

TxB (Tx )

TxA (Tx+)

−

RxA (Rx+)

RxB (Rx )

−

RxA (Rx+)

RxB (Rx )

−

TxA (Tx+)

TxB (Tx )

RxA (Rx+)

150

Ω

−

RxB (Rx )

−

TxA (Tx+)

TxB (Tx )

RS485 2-wire

A (Tx+ / Rx+)

Master (e.g. PC, PLC or

Process Control System)

Participant

A (Tx+ / Rx+)

Slave 1

− / −

B (Tx Rx )

− / −

A (Tx+ / Rx+)

B (Tx Rx )

Slave n

(Weighing Terminal IT)

− / −

B (Tx Rx )

(Weighing Terminal IT)

24 Technical Manual IT3000A Rev. 4

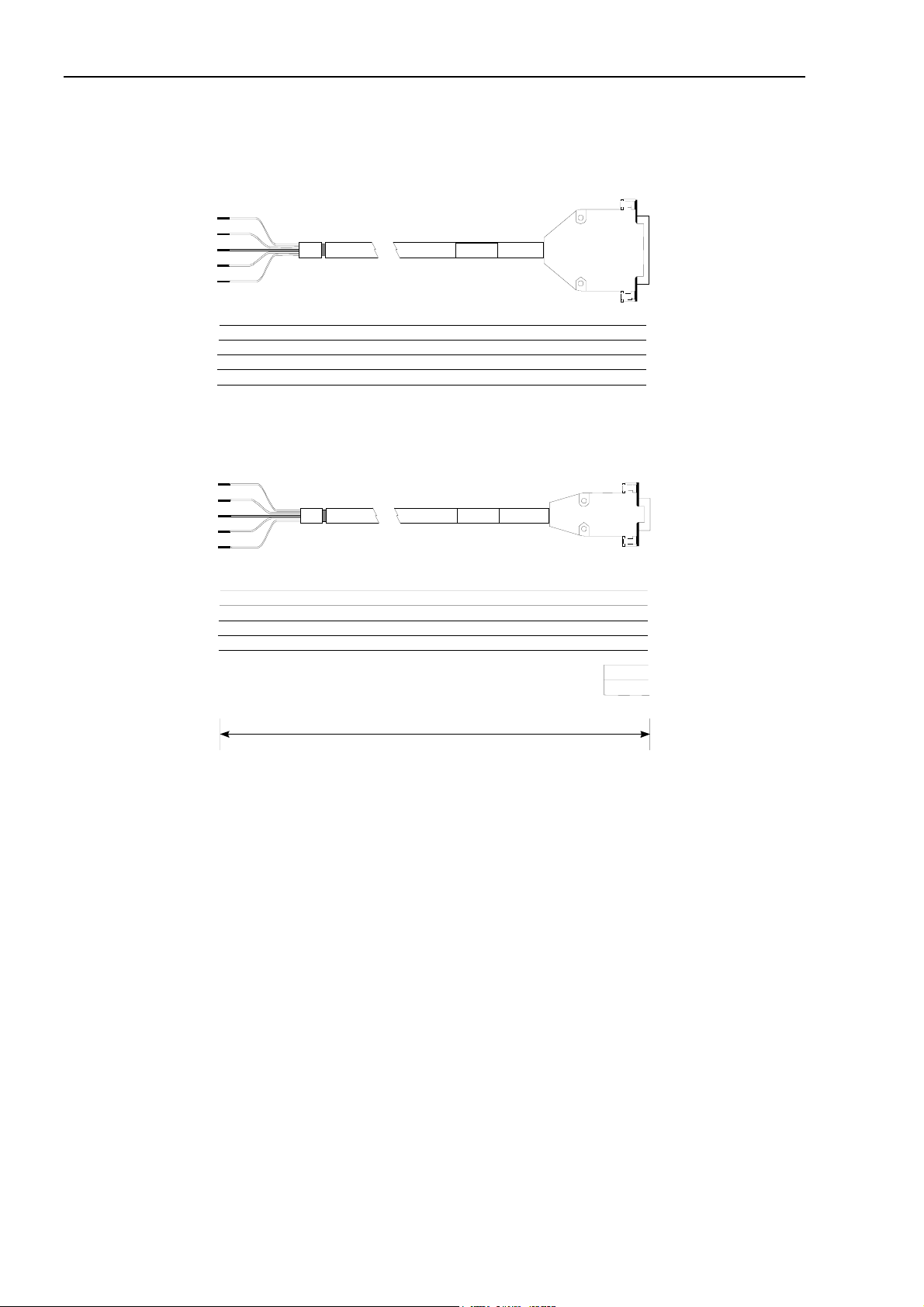

4.6.4 Cables For Serial Interfaces

Standard cables for serial interfaces:

IT3000

TxD 1

RTS 2

RxD 3

CTS 4

Gnd 5

IT3000

TxD 1

RTS 2

RxD 3

CTS 4

Gnd 5

RS232 Printer Cable with 25-pin DSUB connector

Art.-No. 10KAB200

green

yellow

brown

white

gray

RS232 PC Cable with 9-pin male DSUB connector

Art.-No. 10KAB202

green

yellow

brown

white

gray

male

Printer

3 RxD

5 CTS

2 TxD

20 DTR

7 Gnd

PC

2 RxD

8 CTS

3 TxD

7 RTS

5 Gnd

1

4

6

approx. 3m

For the installation of connection cables for serial interfaces please follow the recommendations listed

below:

• Install data cables to prevent capacitive or inductive interference from other cables, machines

and/or electrical devices that could interrupt data transmission and lead to loss of data. If

fluctuation of the earth potential is experienced, this can cause an equalization current flowing

over the shield. In this case a separate earth lead of appropriate diameter for potential equalization

is required.

• Non-factory made cables must comply with the following specification:

3 times twisted pair plus screen, e.g. LIYCY 3 x 2 x 0.14mm² or LIYCY 3 x 2 x 0.25mm²,

For maximum suppression of interference, shield should be grounded on both sides.

Resistance ≤ 125 Ω/km

2

Gauge ≥0.14 mm

up to 200m, ≥0.25 mm2 up to 1200m

Capacitance ≤ 130 nF/km

Length RS232 max. 15m

Length RS485 max. 1200m

Impedance RS485 approx. 150 Ω

Nominal voltage ≥ 250V

Technical Manual IT3000A Rev. 4 25

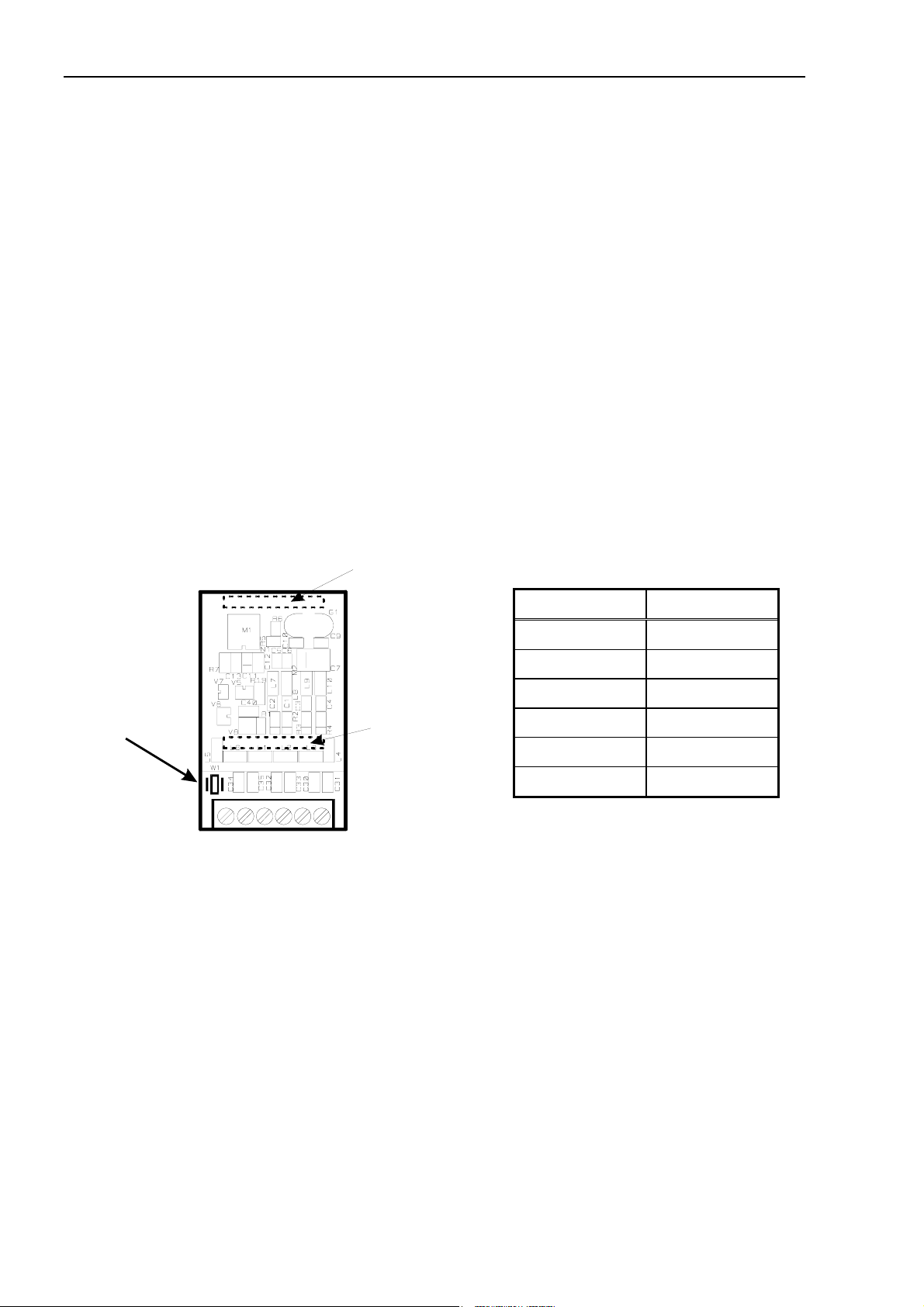

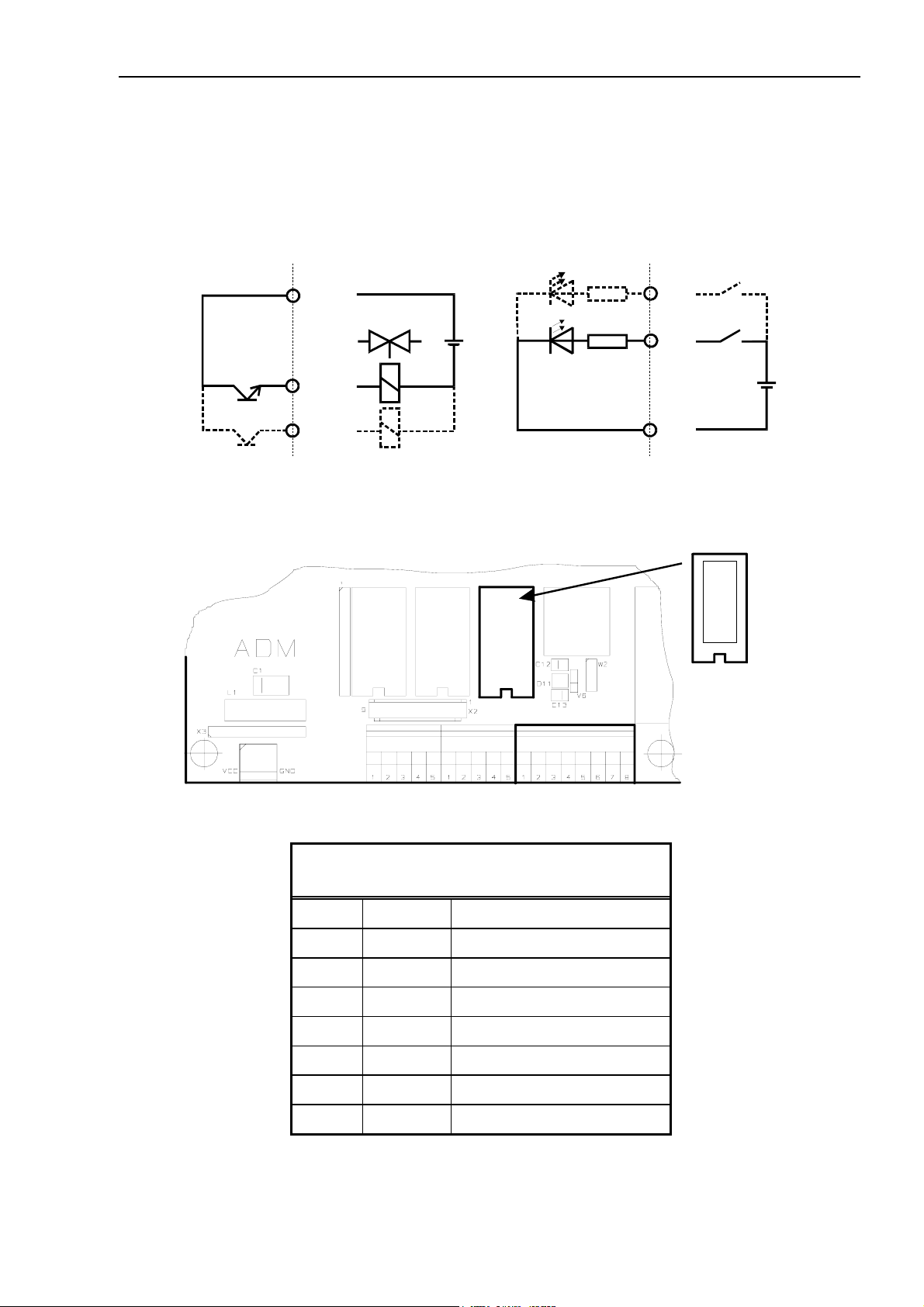

4.7 Connection Of Parallel I/Os

The parallel input/outputs on the CPU3000A can be activated by inserting a plug-on module. The

module provides drivers for two opto-isolated inputs and two opto-isolated outputs.

Rating of outputs: 24VDC, 100mA; rating of inputs: 7mA @ 24VDC.

Principal schematics:

OUT+

+

-

OUT0

OUT1

Parallel output Parallel input

Position and assignment of parallel inputs/outputs on CPU3000A board:

Ri

3K3

IN1

IN0

IN–

PIM

+

-

> PIM

Insert with

notch pointing

to bottom!

Terminal strip KL4

Terminal assignment:

Terminal strip KL4: parallel inputs and outputs

1 OV

2 +10V for external switches only!

3 IN0

4 IN1

5 In– for IN0 - IN1

6 OUT0

7 OUT1

8 OUT+ for OUT0 - OUT1

Note: The internal 10VDC supply (KL4, terminal 2) may be used to connect switches and push

buttons to the digital inputs (15mA max.). The step-up regulator that generates this voltage is short

circuit proof for 1 sec max. External devices connected to the digital outputs must always be

supplied from an external 24VDC power supply.

26 Technical Manual IT3000A Rev. 4

4.8 Connection Of 8-Bit Analog Output DAU

For the output of gross or net weight as analog signal a plug-on module (DAU) can be inserted

instead of a parallel driver module. The output signal has a resolution of 8 bit (256 steps, limits of

operating error = ±4%). The input of the connected device must be electrically isolated and must

not be connected to ground.

Digital inputs/outputs via PIM module and analog output are not possible at the same time.

Position and assignment of analog output on CPU3000A board:

> DAU

PIM1

Insert w ith

notch pointing

to bott om!

Terminal strip KL4

The analog output module can be configured to current output (factory setting) or to voltage output

via solder bridge. Two more solder bridges serve to select internal or external power supply.

Position of solder bridges on DAU:

W1

W3

1

Configuration of DAU via solder bridges W1, W2 and W3.

W1 closed / W2 open W1 open / W2 closed

W3 open Current output 0 - 20 mA

internal power supply

maximum load: 120 Ω

W2

Current output 0 - 20 mA

external power supply 15 - 30 V

maximum load: 750 Ω

W3 closed not allowed! Voltage output 0 - 10 V

Note: Only bridge W1 or W2 may be closed!

external power supply 15 - 30 V

min. input resistance 3.3 kΩ

Technical Manual IT3000A Rev. 4 27

If the analog driver is configured accordingly, the settings in Service Mode, group 'General' 0 - 20

mA or 4 - 20 mA also apply to the voltage output 0 - 10 V or 2 - 10 V.

Terminal assignment:

Terminal strip KL4: analog output DAU

1 must remain free

2 must remain free

3 Uext voltage input when external supply 15 - 30 V is used

4 Gnd ground for exernal supply and voltage output

5 must remain free

6 I– current output

7 I+/U+ current or voltage output

8 must remain free

Example for current output 0 - 20 mA, supply of loop from IT3000A:

3

4

W1 closed

W2

W3 open

> DAU

open

IT3000 KL4

7

+

120 max.

–

6

Example for current output 0 - 20 mA, supply of loop from external power supply:

W1 open

W2 closed

W3 open

> DAU

Gnd

IT3000 KL4

3

4

7

+

–

6

+15 - 30 VDC

external power supply

potential free

0 V

750 max.

Example for voltage output 0 - 10 V, external power supply:

3

4

W1 open

W2 closed

W3 closed

> DAU

Gnd

IT3000 KL4

7

+

6

+15 - 30 VDC

external power supply

potential free

0 V

3.3 k min.

28 Technical Manual IT3000A Rev. 4

4.9 Connection Of 15-Bit Analog Output DAU15

For the output of gross or net weight as analog 15-bit signal a plug-on module (DAU15) can be

inserted instead of a parallel driver module in socket PIM1. The output signal has a resolution of 15

bit (32768 steps). The module can be configured in group 'DAU' of the Service Mode to 0/2 - 10V or

0/4 - 20mA. The output of the DAU15 module is active and potential free.

Digital inputs/outputs via PIM module and analog output are not possible at the same time.

Position and assignment of analog output DAU15 on CPU3000A board:

> DAU 15

PIM1

Insert w ith

notch pointing

to bott om!

Terminal strip KL4

Technical Manual IT3000A Rev. 4 29

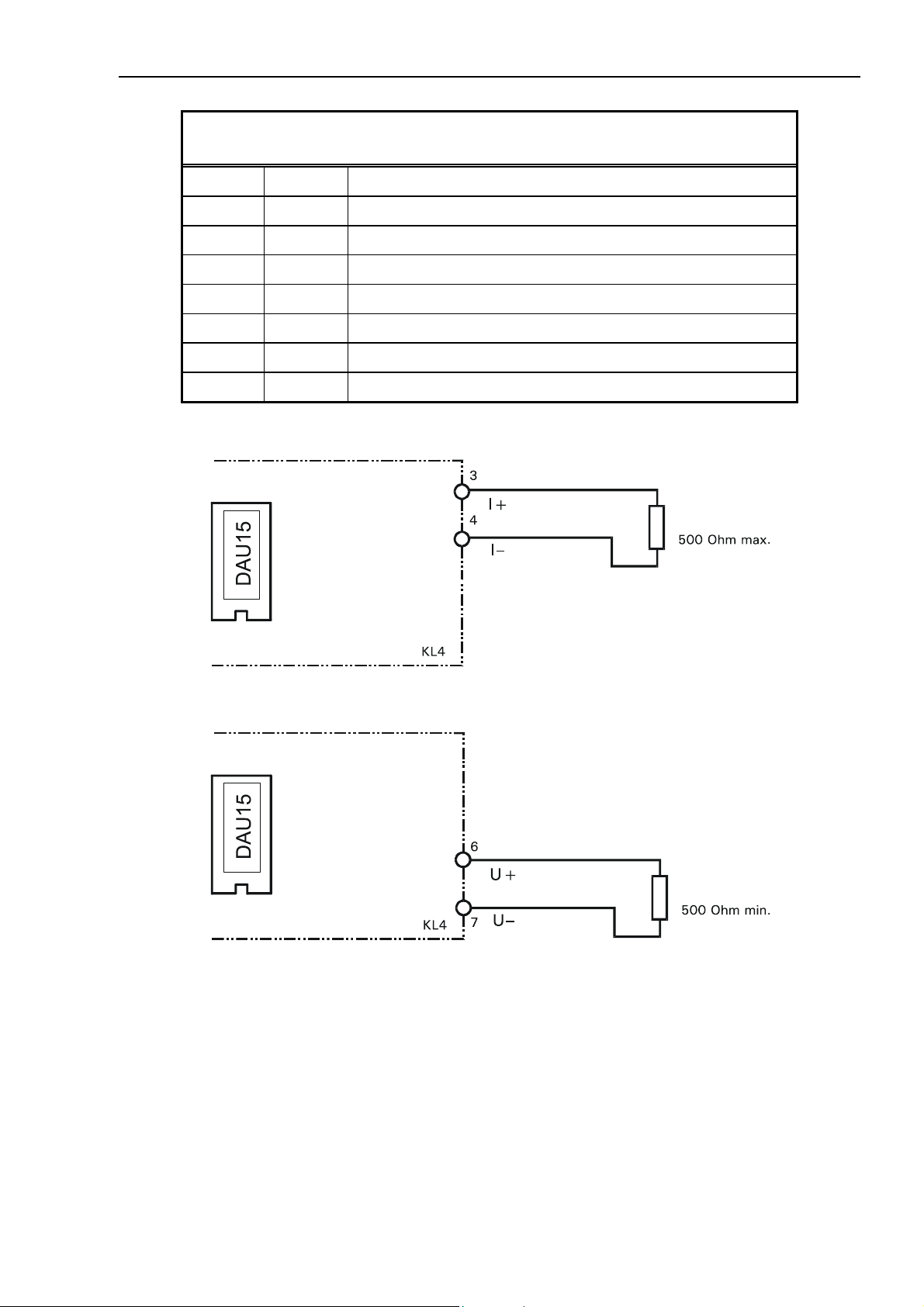

Terminal assignment:

Terminal strip KL4: analog output DAU15

1

2

3 I+ Current output 0/4 - 20mA

4 I– Gnd for current output 0/4 - 20mA

5

6 U+ Voltage output 0/2 - 10V

7 U– Gnd for voltage output 0/2 - 10V

8

Example for current output 0/4 - 20 mA:

Example for voltage output 0/2 - 10 V:

30 Technical Manual IT3000A Rev. 4

4.10 Mains Connection

Before connecting the instrument to power please note:

• Input voltage of the instrument must comply with local mains supply. Factory setting: 110 - 240

V; 50/60Hz, line cord with safety plug firmly connected. The DC version does not have a line

cord and is intended for connection to 12 V to 30V DC.

• Install mains supply for the instrument separate from supply for machines and equipment

generating noise and/or interference (motors, relays, heatings, etc.). Even short spikes and/or

drop-outs may affect the correct function of the instrument and result in defects. If problems of

that nature are encountered, the installation of a voltage stabilizer or an uninterruptable power

supply unit (UPS) may help to overcome the difficulties.

• IT3000A does not have a mains switch and is operational after connection to the mains supply.

Connection to the mains supply is made via the factory installed line cord (length of cable 2.5m).

Make sure that wall outlet is correctly grounded (not applicable to DC version).

• If the line cord with connector is used as the means to separate the instrument from the mains,

the wall outlet must be installed close to the instrument and must be easily accessible! If a

permanently connected mains cable is used, an easily accessible separator must be included in

the supply circuit!

Technical Manual IT3000A Rev. 4 31

5 Service Mode

5.1 General

The Service Mode is a program for configuration, calibration and hardware test of the IT3000A

weighing terminal. In the configuration the operating sequence and the print format are defined. The

following sections give an introduction on how to operate the terminal via keyboard and display and

describe the individual functions of the Service Mode.

Notes:

• IT3000A and its associated equipment must be installed, adjusted and maintained by qualified

personnel only!

• Before accessing the Service Mode all peripheral devices must be installed and configured!

• Access to the Service Mode is protected by the Service Password (see also last page of this

manual).

• Inappropriate changes of Service Mode settings may lead to malfunction and errors in the

operating sequence!

32 Technical Manual IT3000A Rev. 4

5.2 Display And Keyboard

~

F

Gross or net weight or operator prompt and entry

Display line:

Symbol: Scale in gross zero range (±0.2d)

Symbol: Scale in motion

Info Scrolling forward, call up Service Mode in the initial step

Info and scale keys:

F1 – F8

Function keys:

F1 - F2

F0

Taring (Autotare), if scale is tared: clear tare

Set gross weight to zero

Press F-key and numeric key (1 - 8) subsequently to access function

defined in application program;

Switching scale 1 <-> scale 2 when two scales are connected via

Dual-ADM (in the steps defined in the application program).

Switch weight display to tenfold resolution (in the basic step of the

sequence), display falls back to normal mode after approx. 5 sec.

Clr

Numeric entry: press key once → clear entry

Alphanumeric entry: short key stroke → clear last character (can be

repeated several times to clear more than one character); hold key

down for approx. 1 sec → clear the whole entry

Special keys

↑

Return to previous program step

Numeric keypad:

↵

Confirm entry, continue with next program step

Total Display / print totals (if defined in the operating sequence and the

printout)

Entry of numeric data, confirmation 'Yes' (=1) - 'No' (=0) and entry

of alpha characters via multiple key assignment

Technical Manual IT3000A Rev. 4 33

5.2.1 Multiple Assignment Of Numeric Keypad

Where applicable in the application program, an alphanumeric entry is made by selecting the

respective character with a sequence of short keystrokes. If a key is pressed repeatedly within a

period of approx. 0.5 seconds, the display shows the other characters also assigned to this key one

after the other.

Example:

Key pressed: 5 5 5 5 5 5 5 5

Display: 5 M N O m n o 5 etc.

To enter the letter 'n' the key 5 must be pressed six times until 'n' appears on the display. If the

entry is paused for longer than 0.5 sec, the cursor moves on to the next character. If any other key is

pressed, entry continues in the position of the next character immediately.

An incorrect entry can either be corrected by deleting the last character (short key stroke on Clr-key)

or by clearing the complete entry (Clr-key pressed for longer than 0.5 sec). By pressing the Clr-key

repeatedly, it is possible to delete several characters one after the other.

5.3 Operator Prompting

The following sections describe the operating sequence of the weighing terminal with operator

prompts and the requested entries.

The contents of the terminal display is shown in a frame on the left hand side. Next to the display the

possible operator entries are listed, on the right hand side comments and explanations are shown.

Password ????

Prompts or entries that apply only under certain conditions are shown in an extra frame. The

condition is shown in bold face in the upper left hand corner of the frame.

PC not ready:

PC Not Ready !

This message is only displayed when an error occurs.

↵ -key (Enter) and ↑-key

In all program steps, unless otherwise specified, the ↵ -key (Enter) leads to the next step. Pressing

the

↑ -key leads to the previous step.

Entry of 4-character password

↑

Return to normal operation

Error message: PC is not ready for data transmission

Confirmation with Yes (1) or No (0):

A prompt, e.g. 'Save parameters? Y' can be answered by pressing 1 and the

proposed action or by pressing 0 and the

the parameters are not saved.

↵-key to reject the proposal. In this example by entering 0

↵-key to accept the

34 Technical Manual IT3000A Rev. 4

5.4 Overview

After powering the terminal up, the messages with display of program version and date and time are

displayed. By pressing the Info-key while the power up messages are displayed, the Service Mode is

called up. After that the program proceeds to the initial step.

Power up:

Version 9.99 999999

03.09.01 10:41

Application: Count

Display of deviation from calbrated zero, if enabled in Service Mode:

W1 0-Cal. 0.00

Number and date of version,

display for approx. 1.5 sec

Info Call up Service Mode

Date and time,

display for approx. 1.5 sec

Info Call up Service Mode

Selected operating mode,

display for approx. 1.5 sec

Info Call up Service Mode

Show difference between actual and calibrated zero

with tenfold resolution,

display for approx. 1.5 sec

Info Call up Service Mode

Service Mode:

Service Mode

Password ????

Servive Mode menu:

Service: Interface

Service: Format

Display for approx. 1.5 sec.

Entry of 4-character Service Password

↑

Return to normal operation

Configure interfaces;

(see chapter 'Interface Configuration')

Info Use Info-key to scroll through groups

Call up displayed group

↵

Configure operating sequence and printout;

(see chapter 'Configuration Of Data Entry And Print

Formats')

Technical Manual IT3000A Rev. 4 35

Service: General

ADM installed for connection of 1 scale:

Service: Calibrate

Dual-ADM installed for connection of 2 scales:

Service: Calibrate 1

Service: Calibrate 2

Service: Backup

Enter setup parameters (language, format of date,

Calibrate scale;

Calibrate scale 1;

Calibrate scale 2;

Backup of data on PC;

basic sequence, field 33 - 34);

(see chapter 'Entry Of Parameters')

(see chapter 'Calbrate Scale')

(see chapter 'Calbrate Scale')

(see chapter 'Calbrate Scale')

(see chapter 'Backup')

Service: Restore

Service: Test

Service: DAU

Service: Reset

Exit Service Mode:

Saving...

Restore data from PC;

(see chapter 'Restore')

Test hardware;

(see chapter 'Harware Test')

Configure analog output;

(see chapter 'Entry Of Parameters For Analog Output')

Restore factory settings;

(see chapter 'Reset')

Exit Service Mode and store changes, return to normal

↑

operation

36 Technical Manual IT3000A Rev. 4

5.5 Overview Service Mode

Part 1

Technical Manual IT3000A Rev. 4 37

Part 2

38 Technical Manual IT3000A Rev. 4

6 Calibration

6.1 Entering Calibration Mode

Prior to power up the jumper W1 on the ADM or Dual-ADM module must be removed. Only with this

jumper setting can the changed parameters be saved in memory after the calibration.

ADM

Calibration released

W1

1

W1

1

Following below the individual steps of the calibration are described. Additional information is

provided in the chapter 'Scale Connection'.

6

Dual-ADM

Calibration released

12

Technical Manual IT3000A Rev. 4 39

6.2 Select Group

After entering the calibration mode, the first menu item is displayed:

ADM installed for connection of 1 scale:

Service: Calibrate

Dual-ADM installed for connection of 2 scales:

Service: Calibrate 1

Service: Calibrate 2

If jumper W1 is still in position 1 - 2:

Calibration Locked

Select Group 1-9

Calibrate scale;

Calibrate scale 1;

Calibrate scale 2;

Warning: jumper not in calibration position, parameters

↵

Enter number of group or use Info-key to select

1 Scale Parameters

cannot be saved!

Enter calibration mode without saving (e.g. to check

settings)

parameter group:

The parameter setting and calibration follows the sequence of the group numbers (1, 2, 5) as

described in the following chapters. After pressing the ↑-key in step 'Select Group 1

display shows the message:

Save Parameters? Y

2 Calibration

3 Linearization

4 Zero Adjust

5 Adaptation

6 High Resolution

7 Reset Parameters

8 Calculate Span

9 W&M Info

Info Scrolling forward

Save changes and return to menu

↑

Save parameters in EEPROM

-9', the

Info

or

1 / 0

Scrolling

Y(es): Save parameters

N(o): Ignore all changes, do not save data

40 Technical Manual IT3000A Rev. 4

If jumper W1 is still in position 1 - 2:

Error Calibr. Jumper

Error message: jumper not in calibration position,

parameters cannot be saved!

Exit calibration without saving

↵

6.3 Scale Parameters

In this group the weighing ranges, scale intervals and the scale unit are selected. The scale can be

configured as Single Range, Dual Range or Triple Range Scale. A Single Range Scale can be

configured as Multi Interval Scale with two or three different scale intervals.

1 Scale Parameters

1 Scale Parameters

Technical Manual IT3000A Rev. 4 41

Select number of scale ranges:

Single Range

Single Range: Single Range Scale with one, two or

three intervals

Dual Range: Scale with two ranges

Triple Range: Scale with three ranges

If 'Single Range' has been selected:

One Interval

If 'Single Range' and 'One Interval' has been selected:

Capacity 999999

Interval 999999

Info Scroll list

A Single Range Scale can be configured as Single- or

Multi-Interval Scale. Options:

One Interval or

Two Intervals or

Three Intervals or

Additive Tare = Single Range scale with additive tare

(not for W&M approved applications)

Info Scroll list

Single Range capacity entry (6 digits).

Example: 'Capacity 1500'

Single Range scale interval entry (6 digits).

If 'Two Intervals' or 'Three Intervals' has been

selected, entry of the smallest scale interval. (See also

chapter Multi Interval Scale).

Example: 'Interval 0.5000'

Valid entries are:

0.0001, 0.0002, 0.0005, 0.0010, 0.0020, 0.0050,

0.0100, 0.0200, 0.0500, 0.1000, 0.2000, 0.5000,

1.0000, 2.0000, 5.0000, 10.0000, 20.0000,

50.0000, 100.0000, 200.0000, 500.0000.

Incorrect entries are not accepted.

If multiple-range 'Dual Range' or multi-interval 'Two Intervals' has been selected:

High Cap. 999999

High Int. 999.9999

Low Cap. 999999

Low Int. 999.9999

Enter capacity in the higher range (6 digits).

Example: 'High Cap. 6000'

Enter interval in the higher range.

Example: 'High Int. 2.0000'

Enter capacity in the lower range (6 digits).

Example: 'Low Cap. 3000'

Enter interval in the lower range.

Example: 'Low Int. 1.0000'

42 Technical Manual IT3000A Rev. 4

If multiple-range 'Triple Range' or multi-interval 'Three Intervals' has been selected:

High Cap. 999999

High Int. 999.9999

Mid Cap. 999999

Mid Int. 999.9999

Low Cap. 999999

Low Int. 999.9999

Entry of capacity of the highest range

(6 digits)

Example: 'High Cap. 6000'

Entry of interval of the highest range

Example: 'High Int. 2.0000'

Entry of capacity of the medium range (6 digits)

Example: 'Mid Cap. 3000'

Entry of interval of the medium range (6 digits)

Example: 'Mid Int. 1.0000'

Entry of capacity of the lowest range (6 digits)

Example: 'Low Cap. 1500'

Entry of interval of the lowest scale range

Example: 'Low Int. 0.5000'

If 'Single Range' has been selected with 'Additive Tare':

Net Capacity 999999

Capacity 999999

Interval 999.9999

Unit kg

Info Scroll list

Entry of total scale capacity.

Example: 'TotalCapacity 1500'

Entry of weighing range.

Example: 'Capacity 300'

Entry of interval.

Example: 'Interval 0.1000'

Select a unit. Options: kg, g, t, lb

Return to 'Select Group'

↵

Technical Manual IT3000A Rev. 4 43

6.4 Calibration

The zero calibration and maximum load calibration are performed in this group. Instead of calibrating

to maximum load, a calibration with partial load is also possible.

The Geo Value entry permits the calibration at one place even if the scale is to be operated at a

different location. This compensates for the different forces of gravity without recalibration (not for

W&M approved applications). By means of entering the rated signals (mV/V), a scale can also be

precalibrated without test weights (see also chapter 'Precalibration').

2 Calibration

Linearization point(s) already exist:

Fixpoint active

Geo Value 99

Calibrate Zero? Y

Warning: The weight curve is already linearized, and it

might be required to delete existing linearization points

before proceeding.

Display for approx. 2 sec.

Entry of Geo Value. Enter the applicable Geo Value of

the calibration location (see also chapter Geo Values). If Geo Value of place of installation is different, that can be changed later.

Scale Zero Calibration.

Unload the scale and confirm to start the calibration.

Info Scrolling Yes: Calibrate Zero

No: Continue in step 'Zero(mV/V)'

Zero Calibration

↵

Calibrating...

Zero: 9999999

Zero(mV/V): 9999999

Clr Clear value and enter new one

Please note: If Zero calibration parameters are to be stored before the Span calibration, the Setup

must be exited at this point of the sequence (return to step 'Select Group' and answer question

'Save Parameters?' with 'Yes'. After that Group 2 can be entered again to proceed with

calibration, Zero calibration can now be skipped.

Measuring Zero signal.

Message for approx. 6 sec

Displays actual weight with tenfold resolution (for

verification).

Return to step 'Geo Value'

↑

Continue

↵

Display of rated signal

(e.g. 0.23785)

Return to step 'Select Group'

↑

Continue with Span calibration

↵

44 Technical Manual IT3000A Rev. 4

Calibrate Load? Y

Calibr.Weight 999999

Clr Clear displayed default value and enter desired

Calibrating...

Load: 9999999

Load calibration weight on scale.

For best results use the highest possible calibration

load.

Info Scrolling Yes: Calibrate Load

No: Continue in step 'Load(mV/V)'

Return to step 'Calibrate Zero?'

↑

Continue

↵

Default calibration weight

(=weighing range), 6 digits

calibration weight.

Apply load and start calibration

↵

Measuring load signal.

Message for approx. 3 sec.

Displays actual weight with tenfold resolution (for

verification).

Load(mV/V): 999999

Clr Clear value and enter new one

If the internal resolution is insufficient, an error message is displayed:

Resolution Error

To store calibration parameters exit step 'Select Group' and answer question 'Save Parameters' with

'Yes'.

Note: If changes of calibration parameters are to be ignored, setup must be exited and question 'Save

Parameters?' answered with 'No' before any other group of the calibration may be called up.

Return to step 'Calibrate Load?'

↑

Continue

↵

Display of rated signal

(e.g. 0.52243)

Return to step 'Select Group'

↵

The internal resolution should be at least 10 times

higher than the entered resolution.

Check calibration values and repeat calibration if

required.

Return to 'Select Group'

↵

Technical Manual IT3000A Rev. 4 45

6.5 Linearization

Certain weighing inaccuracies are the result of the inherent non-linearity of the load sensor. Up to 6

linearization points can be set freely to compensate this imperfection. Linearization points should be

entered at the points of the weighing curve where the greatest deviations (i.e. max. non-linearity) are

experienced.

Linearization points must be smaller than the max. weighing range. The linearization algorithm

interpretes the sections between two neighboring linearization points as a straight line.

3 Linearization

Linearization points already entered:

Fixpoint n: 999999

Clr Delete existing linearization point (press longer than 1

Clr-key pressed (longer than 1 sec) in step 'Fixpoint n: 999999':

Delete Fixpoint? N

Display of linearization points (1 - max. 6)

Return to previous linearization point or step

↑

'3 Linearization', respectively

Continue with next linearization point

↵

sec)

Info Scrolling Yes: Delete linearization point

No: Do not delete linearization point

Return to previous linearization point or step

↑

'3 Linearization', respectively

On Yes: Proceed to step 'New Fixpoint?'

↵

On No: Continue with next linearization point

After deleting an existing fixpoint, the remaining ones are renumbered in rising order.

After display of the last linearization point or if no fixpoints have been entered yet:

New Fixpoint? N

Enter Fixpoint999999

Calibrate Fixp.? N

Info Scrolling Yes: Enter new fixpoint

No: Do not enter new fixpoint

Return to previous linearization point or step

↑

'3 Linearization', respectively

On Yes: Continue

↵

On No: Return to step 'Select Group'

Press Clr-key and enter linearization weight.

(Before entering a new value, press Clr-Taste for at

least 2 sec).

Are you sure?

46 Technical Manual IT3000A Rev. 4

Linearization..

Lin.Signal 9.99999

Weight: 9999999

A new fixpoint can be inserted between existing ones, after that all fixpoints are renumbered in rising

order.

Measuring the linearization signal

Message appears for approx. 6 sec

Display of rated signal in mV/V (for verification)

Displays measured weight (without correction) with

tenfold resolution (for verification). The linearized

weight can be checked in group 'High Resol.'.

Continue in step 'New Fixpoint?'

↵

6.6 Zero Adjust

In this group the scale's Zero point is readjusted. This feature is usefull when the calibration load was

applied on an auxiliary test rig (e.g. for overhead track scales). After removing the test rig, the

absolute Zero point can be adjusted.

4 Zero Adjust

Linearization point(s) already exist:

Fixpoint active

Unload Scale

Adjusting...

Zero: 9999999

Warning: The weight curve is already linearized, and it

might be required to delete existing linearization points

before proceeding.

Display for approx. 2 sec.

Unload test rig or other loads

Start Zero Adjust

↵

Measuring the Zero signal.

Message appears for approx. 6 sec

Display of the new zero point with tenfold resolution

(for verification)

Return to step 'Unload Scale'

↑

Return to step '4 Zero Adjust'

↵

Technical Manual IT3000A Rev. 4 47

6.7 Adaptation

In this group parameters are entered to adapt the scale to its environment.

5 Adaptation

Motion Window OFF

Info Scroll list

Motion Counter 99

Filter Size OFF

Entry of Motion Window Size.

A stable weight is detected (no motion) when the

number of consecutive weight readings (specified in

the next step) are within this window.

OFF: motion detector off

Window size: 3.0D, 2.0D, 1.0D, 0.5D

(Factory setting: 0.5D)

Entry of number of weight readings for motion

counter.

Specify the number of consecutive weight readings for

no motion detection.

(Factory setting: 20)

Entry of Filter Strength (for digital weight filter).

OFF: filter off

1 to 20: light to strong filtering

(Factory setting: 11)

If the scale is very unstable (e.g. livestock scale) a

strong filtering is recommended.

Info Scroll list

Auto Zero Range 0.5D

Info Scroll list

PbZero (%) + 999

Select range for Automatic Zero Adjust. (E.g. enter

0.5D for a range from −0.5D to +0.5D.)

Zero tracking is enabled within the selected range.

OFF: Disable Zero Adjust

0.5D, 1.0D, 3.0D: zero tracking range

(Factory setting: 0.5D)

Select +range for Pushbutton Zero and Auto Zero

Tracking.

The scale can be set to Zero by pressing the Zero-key

within the specified range.

(Factory setting: 2%)

48 Technical Manual IT3000A Rev. 4

PbZero (%) - 999

PowerUp Zero +/- 10%

Info Scroll list

Overload 99

Select –range for Pushbutton Zero and Auto Zero

Tracking.

The scale can be set to Zero by pressing the Zero-key

within the specified range.

(Factory setting: 2%)

Select range for automatic Zero setting after power

up. (E.g. enter 2% for a range from –2% to +2% of

the scale capacity).

After power up the scale will be automatically set to

Zero if the weight is within the selected range.

OFF: Disable Power Up Zero

±2%, ±10%: range

(Factory setting: Off)

Select the threshold for overload blanking. (E.g. enter

9 to set the limit to capacity + 9d).

The scale display shows '−−−−−−−' when the scale

weight exceeds the selected limit.

(Factory setting: 9)

(For multiple-range scales, 1d corresponds to the

smallest weighing range.)

Incline Sensor? N

*) When an incline sensor is connected and the permissible inclination exceeded (input open), the

display of the indicator is blanked. Instead of the weight only a slash '/' is shown.

Also, external taring via input IN1 is not possible.

NTEP Approval? N

Info Connection of incline sensor for mobile weighing on

parallel input IN1, options:

N = no incline sensor

Y = incline sensor connected *)

Return to step '5 Adaptation'

↵

Set measuring parameters compliant to US regulations

(National Type Evaluation Program) in accordance with

Handbook 44.

Must be set to N(o) for all applications outside the US!

Return to step '5 Adaptation'

↵

Technical Manual IT3000A Rev. 4 49

6.8 High Resolution

In this group the weight is shown with tenfold resolution. Use this group to check the scale accuracy.

6 High Resolution

Weight: 9999999

Info

W1 9999999

Info

AIn (mV/V) 9.99999

Display of the actual weight with tenfold resolution

Display of the weight in normal resolution.

Display of rated signal of loadcell(s) in mV/V = input

↵

(for information only)

In this step the basic weighing functions (zero setting,

x10, taring) are available without leaving the

calibartion mode.

signal of A/D-converter of weighing terminal.

Return to step '6 High Resolution'

50 Technical Manual IT3000A Rev. 4

6.9 Reset Parameters

In this group the scale parameters can be reset to default values. After resetting the parameters the

scale must be reconfigured.

7 Reset

Reset Parameters? N

Info Scroll Y/N

Factory Settings:

Group Parameter Default Calibration

1 (Scale Parameters) Single/Dual/Triple Range Single Range

Capacity 3000

Interval 1

Unit kg

2 (Calibration) Geo Value 20

Zero (mV/V) 0.00000

No: Do not reset parameters

Yes: Reset parameters (see table)

Load (mV/V) 2.00000

4 (Linearization) Fixpoint 1-6 0

5 (Adaptation) Motion Window 0.5D

Motion Counter 20

Filter Size 11

Auto Zero Range 0.5D

Pushbutton Zero (+) 2%

Pushbutton Zero (–) 2%

Power Up Zero OFF

Overload 9D

InclineSensor N

NTEP Approval N

Technical Manual IT3000A Rev. 4 51

6.10 Calculate Span

When the rated output signal of a scale's loadcell(s) is known, calibration can be made without test

weights. This information is available, for instance, for loadcell types D1, C2 and C3 OIML, for which

test reports are issued by the manufacturer stating the rated output in mV/V.

A prerequisite is that the unloaded scale can be calibrated at zero, which is usually the case.

8 Calculate Span

Calibrate Zero? Y

Calibrating...

Zero: 9999999

Zero(mV/V): 9999999

Clr Clear value and enter new one

LC-Cap.(kg) 999999

No.Of LCs 9

mV/V Of LC 1 .99999

Load (mV/V) 9.99999

Calibration without test weights

Scale Zero Calibration.

Unload the scale and confirm to start the calibration.

Info Scrolling Y(es): Calibrate Zero

N(o): Continue in step 'Zero(mV/V)'

Zero Calibration

↵

Measuring Zero signal.

Message for approx. 6 sec

Displays actual weight with tenfold resolution (for

verification).

Display of rated signal

(e.g. 0.23785)

Enter nominal capacity of one loadcell.

Only loadcells with identical capacity may be used in

scale bases with more than one loadcell.

Example: Enter 1000 for a platform with 4 loadcells

with a capacity of 1000kg each.

Enter number of connected loadcells (max. 8)

Enter rated signal of first loadcell.

Continue with next loadcell, after the last loadcell

continue in the next step.

Display of the calculated rated signal at full load.

Please note! The captured values for Zero and Load are automatically entered as calibration values

and can be checked in group 2 'Calibration'.

Return to step '8 Calculate Span'

↵

52 Technical Manual IT3000A Rev. 4

6.11 W&M Info

In this group the setting of parameters can be checked that are relevant for W&M aproved scales.

Any deviation is indicated.

9 W&M Info

If all settings comply with W&M regulations a corresponding message is displayed:

W&M Setup ok

If settings do not comply with W&M regulations a corresponding message is displayed, example:

Error: Overload > 9d

Check parameters for W&M approved scales

(permissible values in brackets):

Motion Window (0.5d)

Motion Counter (≥7)

Autozero Range (0.5d)

Pushbutton Range (≤4%)

Overload (max. 9d)

Value for overload blanking is set to a value greater

than 9d.

Continue

↵

Technical Manual IT3000A Rev. 4 53

6.12 Factory Calibration