Systec IT1000-AC-W-Ex2/22, IT1000-BATT-W-Ex2/22, IT1000-DC-W-Ex2/22, IT1000-BATT-E-Ex2/22, IT1000-AC-E-Ex2/22 Technical Manual

...

Technical Manual

IT1000-AC-W-Ex2/22

IT1000-DC-W-Ex2/22

IT1000-BATT-W-Ex2/22

IT1000-AC-E-Ex2/22

IT1000-DC-E-Ex2/22

IT1000-BATT-E-Ex2/22

Industrial Weighing Terminal

For Installation In Ex Zone 2 / 22

II 3D Ex ic tc IIIB T50°C Dc IP54

or II 3D Ex ic tc IIIC T50°C Dc IP65

II 3G Ex ic nA IIC T4 Gc

December 2017

ST.2309.1312

Rev. 9

© SysTec Systemtechnik und Industrieautomation GmbH, Bergheim, Germany

2 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 3

Technical Manual IT1000-**-*-Ex2/22

Date: December 01, 2017

File: IT1000_EX222_THE.DOC

Program Version: IT1000 as of 2.25

4 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

Published By:

©

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted

in any form or by any means, mechanical, photocopying, recording, or otherwise, without the prior written

permission of SysTec GmbH.

Terms and product names mentioned in this publication are trademarks, registered trademarks or

service marks of their respective owners. Use of a term should not be regarded as affecting the validity

of any trademark, registered trademark or service mark.

EPSON ESC/P® is a registered trademark of the SEIKO EPSON Corporation.

TOLEDO® is a registered

Please Note:

While every precaution has been taken in the preparation of this manual, SysTec GmbH assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

th

The publisher is grateful for any information and/or advice that may contribute to correct errors or omissions

in following editions.

SysTec Systemtechnik und Industrieautomation GmbH, Bergheim, Germany

trademark of Mettler-Toledo Inc.

e information contained herein.

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 5

Contents

1 Introduction ........................................................................................................................... 9

1.1 About This Manual ......................................................................................................... 9

1.2 Safety Symbols Used In This Manual ............................................................................... 9

1.3 Safety Instructions ......................................................................................................... 9

1.4 Marking ...................................................................................................................... 11

2 System Description ............................................................................................................... 12

2.1 General ....................................................................................................................... 12

2.2 Basic Units And Options ............................................................................................... 13

2.3 Housing ...................................................................................................................... 14

2.4 Description Of Components .......................................................................................... 15

3 Intended Use ........................................................................................................................ 17

4 Assembly ............................................................................................................................ 18

5 Installation ........................................................................................................................... 19

5.1 General ....................................................................................................................... 19

5.2 Equipotential Bonding ................................................................................................... 19

5.3 Shielding ..................................................................................................................... 19

5.4 Connection Of Cables ................................................................................................... 20

6 Installation Of External Connections With Type Of Protection 'Ex-nA' ......................................... 21

6.1 Connection Of Power Supply To IT1000-AC-*-Ex2/22 ..................................................... 21

6.2 Connection Of Power Supply To IT1000-DC-*-Ex2/22 And IT1000-BATT-*-Ex2/22 ............ 22

6.3 Operation Of IT1000-BATT-*-Ex2/22 ............................................................................. 23

6.4 Connection Of Analog Scale To ADM ............................................................................. 26

6.5 Connection Of Serial Interface SIM ................................................................................ 29

6.6 Connection Of Parallel I/Os PIM ..................................................................................... 34

6.7 Connection Of Parallel I/Os IOM .................................................................................... 36

6.8 Connection Of 15-Bit Analog Output DAU15 .................................................................. 38

7 Commissioning ..................................................................................................................... 40

8 Installation Examples ............................................................................................................. 41

8.1 Installation Example IT1000-AC-*-Ex2/22 ....................................................................... 41

8.2 Installation Example IT1000-DC-*-Ex2/22 ....................................................................... 42

8.3 Installation Example IT1000-BATT-*-Ex2/22 With Akku-Box ............................................. 43

9 Service Mode ....................................................................................................................... 44

9.1 General ....................................................................................................................... 44

9.2 Display And Keyboard .................................................................................................. 45

9.3 Operator Prompting ...................................................................................................... 46

9.4 Weighing Functions ...................................................................................................... 48

9.5 Power Up ................................................................................................................... 49

9.6 Overview Service Mode ................................................................................................ 50

10 Calibrate Scale ................................................................................................................... 52

10.1 Entering Calibration Mode ........................................................................................... 52

10.2 Capacity & Interval .................................................................................................... 53

10.3 Span Adjust .............................................................................................................. 56

10.4 Linearization .............................................................................................................. 58

10.5 Zero Adjust ............................................................................................................... 59

10.6 Adaptation ................................................................................................................ 59

6 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

10.7 Show X10 ................................................................................................................. 61

10.8 Reset Calibration Parameters........................................................................................ 62

10.9 Calculate Span ........................................................................................................... 63

10.10 W&M Info ................................................................................................................ 64

10.11 Factory Calibration .................................................................................................... 65

10.12 Geo Values .............................................................................................................. 65

10.13 Configuration Of Scale Interface Module ...................................................................... 67

11 Adapt Mode ........................................................................................................................ 70

12 Interface Configuration ......................................................................................................... 71

13 Configuration Of Print Format (Format) .................................................................................. 73

13.1 Configuration Of Fields ................................................................................................ 73

14 General .............................................................................................................................. 74

15 Hardware Test .................................................................................................................... 78

16 Settings For Analog Output DAU ........................................................................................... 79

17 Reset General Parameters ..................................................................................................... 80

18 Protocol ............................................................................................................................. 81

19 Supervisor Mode ................................................................................................................. 82

20 Operating Modes ................................................................................................................. 84

20.1 Operating Mode 'BASIC' ............................................................................................. 84

20.2 Operating Mode 'COUNT' ............................................................................................ 85

20.3 Operating Mode 'FILL' ................................................................................................. 87

20.4 Operating Mode 'CHECK' ............................................................................................ 89

21 Online Mode SysTec Standard .............................................................................................. 91

21.1 Structure Of Data Strings ............................................................................................ 91

21.2 Summary Of Commands ............................................................................................. 91

21.3 Read Weight .............................................................................................................. 92

21.4 Taring ....................................................................................................................... 96

21.5 Select Scale ............................................................................................................... 97

21.6 Set Scale To Zero ....................................................................................................... 98

21.7 Error Codes ................................................................................................................ 98

22 Online Mode MP85 .............................................................................................................. 99

22.1 Interface Parameters ................................................................................................... 99

22.2 Structure Of Data Strings ............................................................................................ 99

22.3 Overview On Commands ............................................................................................. 99

22.4 Read Weights........................................................................................................... 100

22.5 Taring ..................................................................................................................... 100

22.6 Set Scale To Zero ..................................................................................................... 101

22.7 Status Bytes ............................................................................................................ 102

23 Online Mode BDI ............................................................................................................... 103

23.1 Interface Parameters ................................................................................................. 103

23.2 Structure Of Data String ............................................................................................ 103

23.3 Initialization ............................................................................................................. 103

23.4 Overview On Commands ........................................................................................... 104

23.5 Read Weights........................................................................................................... 105

23.6 Taring ..................................................................................................................... 107

23.7 Set Scale To Zero ..................................................................................................... 108

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 7

23.8 Error Codes ............................................................................................................. 108

23.9 Weight Status ......................................................................................................... 108

24 Multidrop Connection ........................................................................................................ 109

24.1 Establish And Terminate Connection .......................................................................... 109

24.2 Example (Polling Of Slave 1 And Slave 2) ................................................................... 110

25 Remote Display ................................................................................................................ 111

25.1 Interface Parameters ................................................................................................ 111

25.2 Connection To ITx000 .............................................................................................. 111

25.3 Connection To IT1000 ............................................................................................. 112

26 Multi-Remote-Display (Remote Display For IT2000P) ............................................................. 112

26.1 Interface Parameters ................................................................................................ 112

26.2 Connection Of IT2000P To IT1000 ............................................................................ 113

26.3 IT1000 Key Assignment ........................................................................................... 113

27 Configuration Example ....................................................................................................... 114

27.1 Factory Setting ........................................................................................................ 114

27.2 Example 'COUNT' .................................................................................................... 116

27.3 Field Length Of System Variables ............................................................................... 117

27.4 Form For Print Layouts (80 Columns) ......................................................................... 118

27.5 Form For Print Layouts (40 Columns) ......................................................................... 119

27.6 Form For Configuration ............................................................................................. 120

28 Data Transmission ............................................................................................................ 121

28.1 Protocol For Data Transmission ................................................................................. 121

28.2 Continuous Output ................................................................................................... 122

29 Transport, Maintenance And Cleaning ................................................................................. 126

29.1 Transport ................................................................................................................ 126

29.2 Maintenance ........................................................................................................... 126

29.3 Replacing The Battery (Realtime Clock DS1687-5) ....................................................... 126

29.4 Cleaning ................................................................................................................. 127

29.5 Security Check ........................................................................................................ 127

29.6 Functional Test ........................................................................................................ 127

29.7 Repair ..................................................................................................................... 127

29.8 De-Installation ......................................................................................................... 127

29.9 Disposal .................................................................................................................. 127

30 Trouble Shooting .............................................................................................................. 128

30.1 Error Messages ........................................................................................................ 128

31 Technical Data ................................................................................................................. 130

31.1 General Data ........................................................................................................... 130

31.2 Ex-Relevant Electrical Data For Type Of Protection 'Ex-nA' ........................................... 130

32 Dimensions ...................................................................................................................... 133

8 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 9

Ex

bodily harm! Please make absolutely sure that these precautions are observed in order to ensure

Ex

Ex

1 Introduction

1.1 About This Manual

This manual contains information and Technical Data for the use, the installation and the operation of

the industrial weighing terminals IT1000-AC-W-Ex2/22, IT1000-AC-E-Ex2/22, IT1000-DC-W-Ex2/22

and IT1000-DC-E-Ex2/22, IT1000-BATT-W-Ex2/22 and IT1000-BATT-E-Ex2/22.

Information applicable to all versions refers to IT1000-Ex2/22. Specific information is marked with the

full designation of the respective version, e.g. 'IT1000-AC-W-Ex2/22'.

The weighing terminal must only be operated by trained personnel. For simple weighing transactions to

be carried out by the enduser the Operating Instructions IT1000 (ST.2309.0603) are available.

1.2 Safety Symbols Used In This Manual

Safety relevant information is shown with corresponding symbols as follows:

W A R N I N G

Failure to observe this precaution could result in serious injuries or fatal accidents due to

ignition of an explosive atmosphere (gas and/or dust). Please make absolutely sure that these

precautions are observed in order to ensure safe operation of the equipment.

W A R N I N G

Failure to observe this precaution could result in serious injuries or fatal accidents. Please make

absolutely sure that these precautions are observed in order to ensure safe operation of the

equipment.

CAUTION

Failure to observe this precaution could result in damage to or destruction of the equipment or

safe operation of the equipment.

Note: This indicates an advice for the designated use of the equipment and/or additional information to

avoid inappropriate handling.

1.3 Safety Instructions

W A R N I N G

Before opening the housing make absolutely sure that all power sources to this instrument are

disconnected and that no potentially explosive atmosphere can be present at any time!

The de-energized state is reached by disconnecting the supply voltages to the instrument and

to all external devices connected to the interfaces of the weighing terminal.

W A R N I N G

Exercise utmost care when making checks, tests and adjustments that can actuate movable

parts such as feeding devices, gates, flaps, conveyors etc. Make absolutely sure that nobody is

within reach of movable parts.

W A R N I N G

For installation, service and operation of the unit, the ATEX directive as well as all locally

applicable regulations for safety and the prevention of accidents must be observed!

10 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

Ex

Ex

Ex

Ex

Ex

Ex

Ex

W A R N I N G

This weighing terminal must not be used in Ex-Zone 0, 1, 20 and 21.

It is the sole responsibility of the employer / operating company to classify the area of

installation (zone, group, temperature class). To that effect, the assistance of the Technical

Supervisory Service or any other technical authority may be utilized!

W A R N I N G

When this unit is included as a component part of a system, the resulting system design must

be reviewed by qualified personnel who are familiar with the construction and operation of all

individual components in the system and the potential hazards involved.

W A R N I N G

Input voltage of the instrument must comply with local mains supply!

W A R N I N G

This module and its associated equipment must only be installed, adjusted and maintained by

qualified personnel authorized by SysTec GmbH!

W A R N I N G

Connection of peripheral devices to IT1000A-Ex2/22 is made in compliance with Ex type of

protection 'Ex-nA'. The connection values must be observed. Connected peripheral devices

installed in hazardous area must have appropriate Ex protection.

W A R N I N G

When the instrument is permanently connected to the power supply, an easily accessible

separator must be included in the supply circuit! It must either be located in safe area or -if

installed in Ex area- have appropriate Ex protection for the place of installation.

W A R N I N G

The weighing terminal must not be installed in areas where electrostatic charging is possible

which may produce spark discharges, brush discharges or propagating brush discharges at the

front panel.

Comment: According to common knowledge, the use of the equipment and the cleaning with a

damp cloth do not produce such a high surface charge density. However, the front panel must

not be wiped with a dry cloth!

W A R N I N G

Risk of electrical shock! When operating electrical devices, parts of this devices are connected

to dangerously high voltages. Inappropriate use of such devices may lead to serious bodily

injuries or substantial damages to property.

W A R N I N G

The power supply unit of the weighing terminal provides SELV voltages in accordance with EN

60950. Make sure that any peripheral device connected to the weighing terminal containing its

own power supply also uses SELV voltages!

W A R N I N G

The device uses the short-circuit / overcurrent protection of the on-site mains supply.

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 11

1.4 Marking

Systec Systemtechnik und Industrieautomation GmbH

Manufacturer

Ludwig-Erhard-Straße 6

50129 Bergheim-Glessen

IT1000-AC-W-Ex2/22

IT1000-AC-E-Ex2/22

IT1000-DC-W-Ex2/22

Designation

IT1000-DC-E-Ex2/22

IT1000-BATT-W-Ex2/22

IT1000-BATT -E-Ex2/22

Serial-No. Ex yy nnnn (yy=year of construction / nnnn=consecutive number)

Range of ambient temperature –10 °C to +40 °C

II 3G Ex ic nA IIC T4 Gc

Ex classification

II 3D Ex ic tc IIIB T50°C Dc IP54 or

II 3D Ex ic tc IIIC T50°C Dc IP65

CE marking

Type examination certificate TÜV 11 ATEX 7618 X

Service

Only by qualified service personnel authorized by SysTec GmbH

Addresses on request

12 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

2 System Description

2.1 General

IT1000-Ex2/22 is a general purpose weighing terminal for use in a variety of applications such as data

logging, data capturing, parts counting, setpoint control and filling, suitable for installation in Ex zones

2 and 22.

The weighing module ADM is used to connect one scale base with strain gauge loadcells with an

overall impedance of 21 Ω to 4500 Ω. In addition a battery-backed realtime clock can be installed.

Power supply through the built-in wide-range power supply unit is either for 110–240 VAC or 12–

30 VDC or 10–24 VDC (battery-powered version). Housings are available for both, desk-top/wallmount and panel-mount installation. Cables of all external components are connected at screw

terminals.

Weight and additional information is indicated on a back-lit 13-character LCD, height of characters

14mm. Operation is made via a sealed membrane keyboard with 5 keys.

Instead of operating the terminal locally via keyboard and display, full remote control is possible from a

PC. In applications legal for trade data can be stored in an approved data archive on the PC's harddisk.

This option requires the installation of the realtime clock in the weighing terminal and the PC program

PC COM+.

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 13

2.2 Basic Units And Options

IT1000-Ex2/22 is available in 4 basic versions:

Type Housing Description Article-No.

IT1000-AC-W-Ex2/22 Wall-mount/

desk-top

Basic unit for wall-mount / desk-top installation

with 2.5 m line cord with free ends

to connect to 110–240 VAC

IT1000-AC-E-Ex2/22 Panel-mount Basic unit for panel-mount installation

with 2.5 m line cord with free ends

to connect to 110–240 VAC

IT1000-DC-W-Ex2/22 Wall-mount/

desk-top

Basic unit for wall-mount / desk-top installation

with screw terminals

to connect to 12–30 VDC

IT1000-DC-E-Ex2/22 Panel-mount Basic unit for panel-mount installation

with screw terminals

to connect to 12–30 VDC

IT1000-BATT-WEx2/22

Wall-mount/

desk-top

Basic unit for wall-mount / desk-top installation

with screw terminals

to connect to 12–30 VDC

IT1000-BATT-EEx2/22

Panel-mount Basic unit for panel-mount installation

with screw terminals

to connect to 12–30 VDC

The following modules are available as options:

Option

Description Article-No.

X1SYS001

X1SYS011

X1SYS005

X1SYS015

X1SYS006

X1SYS016

ADM Plug-on weighing module for connection of analog loadcells 13OPT100

SIM-RS232 Plug-on module with serial RS232 interface 10OPT220

SIM-20mA Plug-on module with serial 20mA interface 10OPT221

SIM-RS485.4 Plug-on module with serial RS485 4-wire interface 10OPT222

SIM-RS485.2 Plug-on module with serial RS485 2-wire interface 10OPT225

SIM-RS485.Opto Plug-on module with opto-isolated serial RS485 interface 10OPT230

DAU15 Plug-on module with analog 0/2–10 V or 0/4–20 mA output 10OPT231

PIM Plug-on module with two digital inputs/outputs 10OPT300

IOM Plug-on module with one digital input and 3 digital outputs 10OPT302

RTC DS1687-5 Plug-on module DS1687-5 with realtime clock, RAM and battery

13OPT500

backup

14 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

Ex

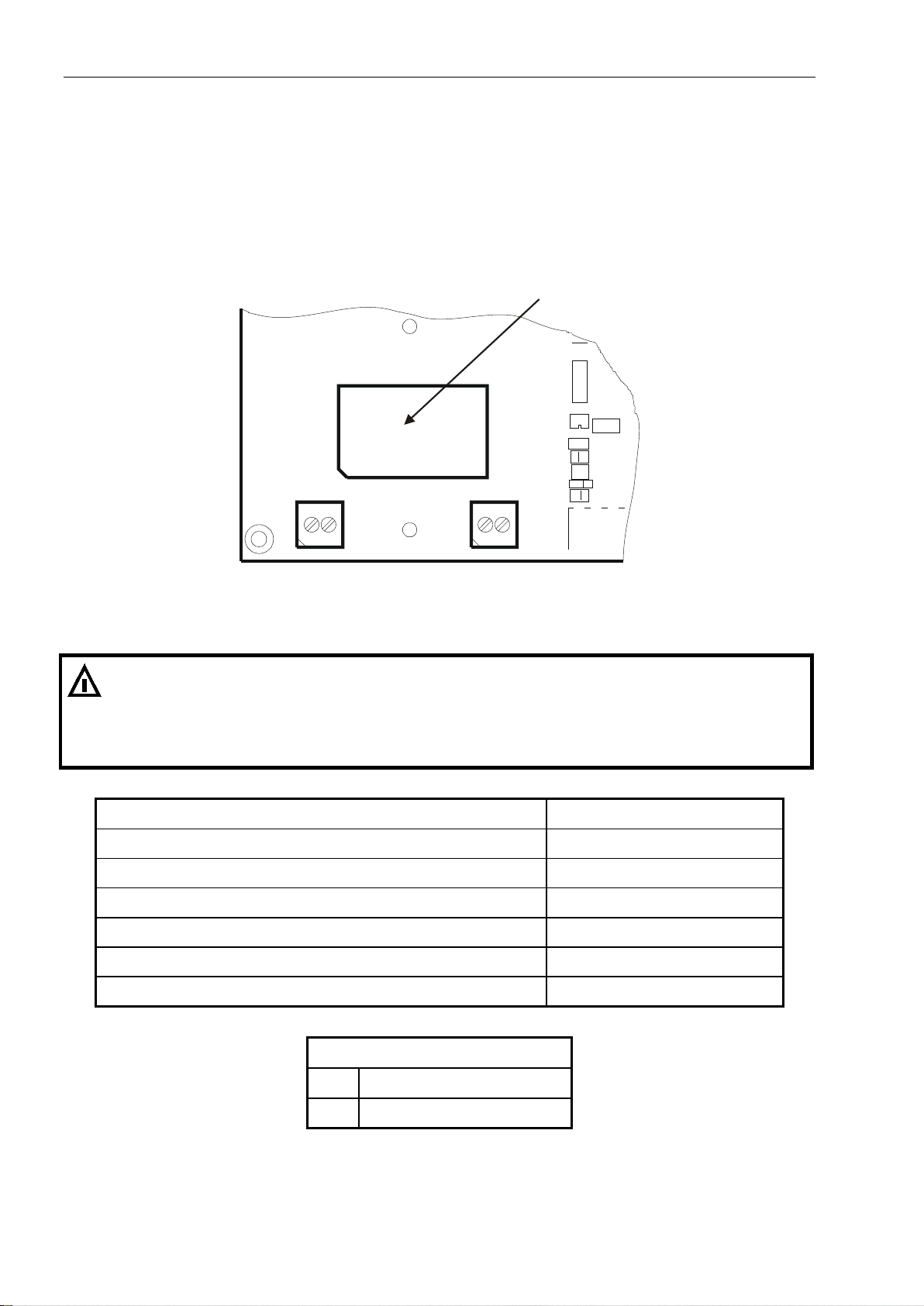

2.3 Housing

IT1000-Ex2/22 is incorporated in a stainless steel housing with cable glands to connect cables to

peripheral devices. It is available in two versions:

The housing for desk-top / wall-mount installation (IT1000-**-W-Ex2/22) is protected to IP65.

The housing for panel-mount installation (IT1000-**-E-Ex2/22) is inserted in a suitable cutout of a

switch cabinet and fixed from the rear with 6 mounting brackets. When installed accordingly, the front

of the terminal -in combination with the circumferential gasket between terminal and switch cabinet- is

protected to IP65.

When installed in Ex zone 2 (as per II 3G Ex ic nA IIC T4 Gc) and Ex zone 22 with non-conductive dust

(as per II 3D Ex ic tc IIIB T50°C Dc IP54) the surrounding housing must be protected to IP54 or better.

When installed in Ex zone 22 with conductive dust (as per II 3D Ex ic tc IIIC T50°C Dc IP65) the

surrounding housing must be protected to IP65 or better.

The surrounding housing (e.g. switch cabinet) must conform to the requirements of EN60079-0 section

26.4.

See section 'Dimensions' for space requirements.

The housings must be included in the equipotential bonding of the installation.

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 15

2.4 Description Of Components

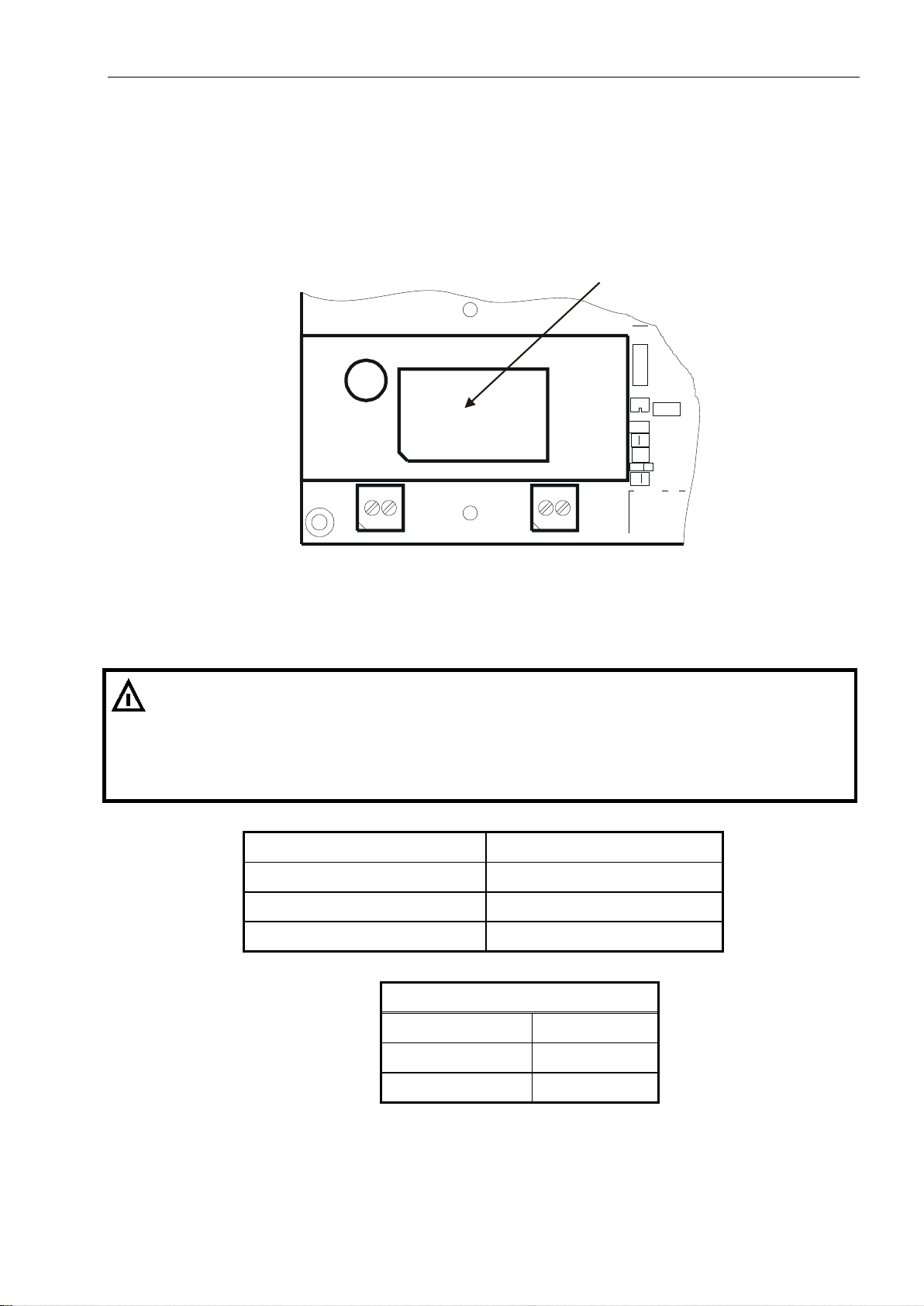

2.4.1 Main Module CPU1000

The CPU1000 is the main module of the IT1000-Ex2/22 weighing terminal. It contains the

microcontroller, the power supply and the display. It also has a sockets to plug on the weighing module

ADM and a battery-backed realtime clock. An additional socket is provided that can be used

alternatively for a serial interface (SIM) or two digital I/Os (PIM) or an analog output (DAU15).

The following versions are available:

Main board Description Used for

CPU1000-230V-Ex2/22 CPU1000 with 110–240 VAC PSU IT1000-AC-*-Ex2/22

Article-No. X1SYS0x1

CPU1000-24VDC-Ex2/22 CPU1000 with 12–30 VDC PSU IT1000-DC-*-Ex2/22

Article-No. X1SYS0x5

CPU1000-NTA-Ex2/22 CPU1000 with 12–30 VDC PSU

and low-bat detection

Layout of components on CPU1000 main module

Realtime clock Power supply

IT1000-DC-*-Ex2/22

Article-No. X1SYS0x6

X3 / X4

Socket for

ADM weighing

module

Terminal KL1 Terminal KL2 Terminal KL3 Keyboard

power supply PE I/O interface

16 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

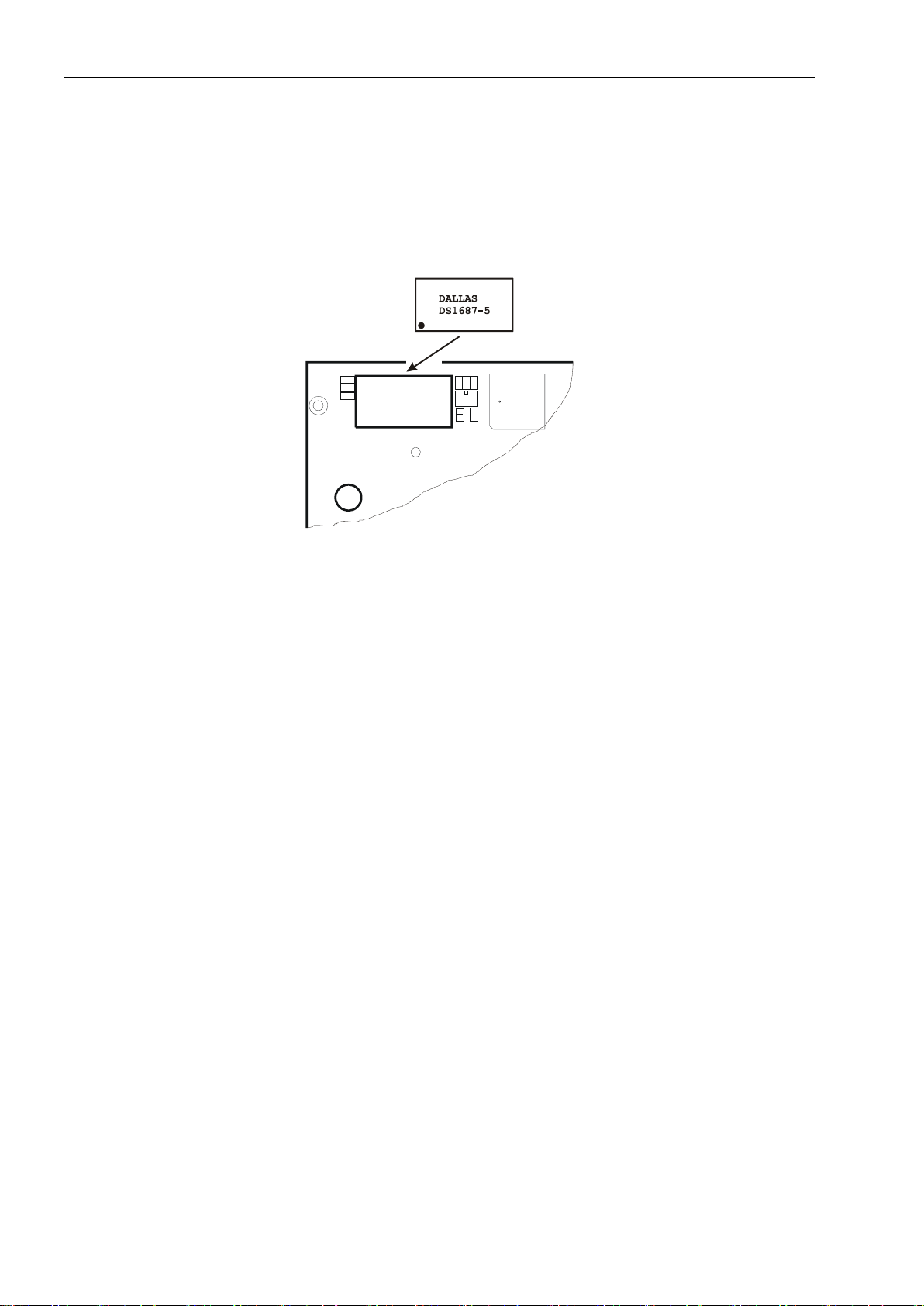

2.4.2 Battery-Backed Realtime Clock RTC DS1687-5

As an option a module with realtime clock and 240 bytes of battery backed memory (e.g. for totals)

can be installed. The integrated lithium battery has a lifetime of approx. 10 years.

The realtime clock is required for applications using the external data archive on PC harddisk because

the ident-No. (which in conjunction with the date serves to identify a record in the archive) is stored in

the memory of the module.

Insert with mark pointing to the left

Notes:

• For the storage of volatile data the module of the optional realtime clock contains a lithium battery.

Dispose of used batteries as indicated by manufacturer.

• If no realtime clock is installed, entry of date and time is required on power up!

• For replacing the module observe the instructions in section 'Replacing the battery'!

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 17

Ex

Ex2/22 is also an apparatus of group II category 3D, that following RL 99/92/EG (ATEX

Ex2/22 must have

Ex

of the intended use is observance of this Technical Manual and the adherence to inspection and

3 Intended Use

In compliance with RL 2014/34/EU appendix I, the weighing terminal IT1000-Ex2/22 is an

apparatus of group II category 3G, that following RL 99/92/EG (ATEX 137), can be used in

zone 2, as well as in gas groups IIA, IIB and IIC, which are at risk of explosion through

combustible substances of temperature classes T1 to T4. The following section 'Installation of

'IT1000-**-E-Ex2/22 in switch cabinet' must be observed.

IT1000-

137) can be used in zone 22 (dust), the maximum surface temperature is 50°C. The following

instructions on the installation of the IT1000-**-E-Ex2/22 in a surrounding housing must be

observed.

Installation of 'IT1000-**-E-Ex2/22 in switch cabinet: The housing for panel-mount installation

is inserted in a suitable cutout of a switch cabinet and fixed from the rear with 6 mounting

brackets. If installed accordingly, the front of the terminal -in combination with the

circumferential gasket between terminal and switch cabinet- is protected to IP65. When

installed in Ex zone 2 (as per II 3G Ex ic nA IIC T4 Gc) and Ex zone 22 with non-conductive

dust (as per II 3D Ex ic tc IIIB T50°C Dc IP54) the surrounding housing must be protected to

IP54 or better. When installed in Ex zone 22 with conductive dust (as per II 3D Ex ic tc IIIC

T50°C Dc IP65) the surrounding housing must be protected to IP65 or better. The surrounding

housing (e.g. switch cabinet) must conform to the requirements of EN60079-0 section 26.4.

The weighing terminal must not be installed in areas where electrostatic charging is possible

which may produce spark discharges, brush discharges or propagating brush discharges at the

front panel.

All external connections are designed for type of protection Ex 'nA'. The connection values

shown in chapter 'Installation of external connections with type of protection Ex-nA' must be

observed.

When installed in hazardous area, all peripheral devices connected to IT1000appropriate Ex protection.

The metal housing of the IT1000-Ex2/22 terminal must be integrated at the PA stud into the

equipotential bonding system of the installation. Use suitable serrated washers.

The permissible range of ambient temperature is –10 °C to +40 °C.

When installing IT1000-**-E-Ex2/22 in a switch cabinet (panel-mount version), this

temperature range also applies to the inside the switch cabinet.

Furthermore, for use and installation all requirements as per EN 60079-14 must be observed.

Any other but the intended use of the equipment, modifications and extensions must not be

made without the explicit approval of the manufacturer and is deemed not to be intended. Part

maintenance instructions and intervals. The manufacturer does not assume any liability

whatsoever for damages resulting from non-intended use. Any risk resulting from non-intended

use is solely borne by the user.

The weighing terminal and all connected components must be integrated into a common

system of equipotential bonding.

Protective covers or other parts covering the housing completely or in part must not be used.

The housing must be protected against permanent exposure to ultraviolet radiation.

18 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

Ex

4 Assembly

It must be made sure that installation of the weighing terminal is only carried out when all

power to the instrument is disconnected and no potentially explosive atmosphere is present.

The weighing terminal must not be installed in areas where electrostatic charging is possible

which may produce spark discharges, brush discharges or propagating brush discharges at the

front panel.

Installation must be made in compliance with the generally accepted rules of technology. In particular

for all work carried out on electrical installations the specific safety regulations must be observed.

The weighing terminal may be installed in Ex zone 2 or 22. The terminal must not be damaged. The

place of installation must be clean.

The IT1000-**-W-Ex2/22 (wall-mount / desk-top version) has mounting brackets for wall or table-top

installation. They must be fixed with suitable screws which are not part of the supply. All screws must

be tightened securely.

The IT1000-**-E-Ex2/22 (panel-mount version) has screw clamps to fix the terminal in the cutout of

the switch cabinet. To connect the bonding conductor, an M5 stud is provided at the rear or bottom of

the housing. Use serrated washers to prevent the nuts from becoming loose.

The permissible temperature range is –10 °C to +40 °C at a max. of 95% relative humidity (non

condensing). Direct exposure to ultraviolet radiation must be avoided.

For wall-mount installation the unit can be fixed at the wall first and then the cables can be installed

with the front lid open.

Before the device is put into operation, the housing must be closed and tightened securely with the

hexagonal nuts provided. The nuts must be tightened with a torque of 1.1 Nm.

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 19

Ex

This apparatus must only be installed by qualified personnel who are familiar with all regulations

Ex

Ex

Ex

5 Installation

5.1 General

applicable to the different types of protection and the methods of installation, as well as the

general principles for the classification of zones. This level of competence must correspond to

the work that is to be carried out and appropriate training should be provided on a regular basis.

When the weighing terminal is to be installed in Ex zone 2 / 22 the regulations as per

EN 60079-14 must be adhered to.

The weighing terminal must not be installed in areas where electrostatic charging is possible

which may produce spark discharges, brush discharges or propagating brush discharges at the

front panel.

It must be made sure during installation of the weighing terminal that all power to the

instrument is disconnected and that no potentially explosive atmosphere can be present at any

time.

Installation must be carried out in compliance with applicable DIN/VDE regulations. Also, all

country-specific regulations must be observed. Connection of supply voltage must be made in

compliance with VDE 0100 and VDE 0160.

When the instrument is permanently connected to the power supply, an easily accessible

separator must be included in the supply circuit! It must either be located in safe area or -if

installed in Ex area- have appropriate Ex protection for the place of installation.

All cables are led into the housing through Ex cable glands. Strip cable jacket only as long as

required for the wires to reach the screw terminals. Use wire end ferrules with plastic collar on

stranded cable and avoid protruding wires. When assembling the cable glands make sure that

shield of cable is connected inside the cable gland. Observe instructions in section 'Connection

of cables'.

Before the device is put into operation, make sure that the housing is closed and tightened

securely with all hexagonal nuts provided (torque: 1.1 Nm).

5.2 Equipotential Bonding

In compliance with EN 60079-14 the apparatus must be integrated into the equipotential

bonding system of the installation. The bonding conductor must have a cross section of min.

4 mm². To connect the bonding conductor, an M5 stud with serrated washer is provided at the

rear or bottom of the housing.

5.3 Shielding

Use only shielded connection cables. The shield must be connected at both sides in the cable

glands. It is mandatory to additionally install equipotential bonding as per EN60079-14

paragraph 'additional requirements for the type of protection i-intrinsic safety' / section

'grounding of conductive shields' / exception b). The bonding conductor must have a cross

section of min. 4 mm².

20 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

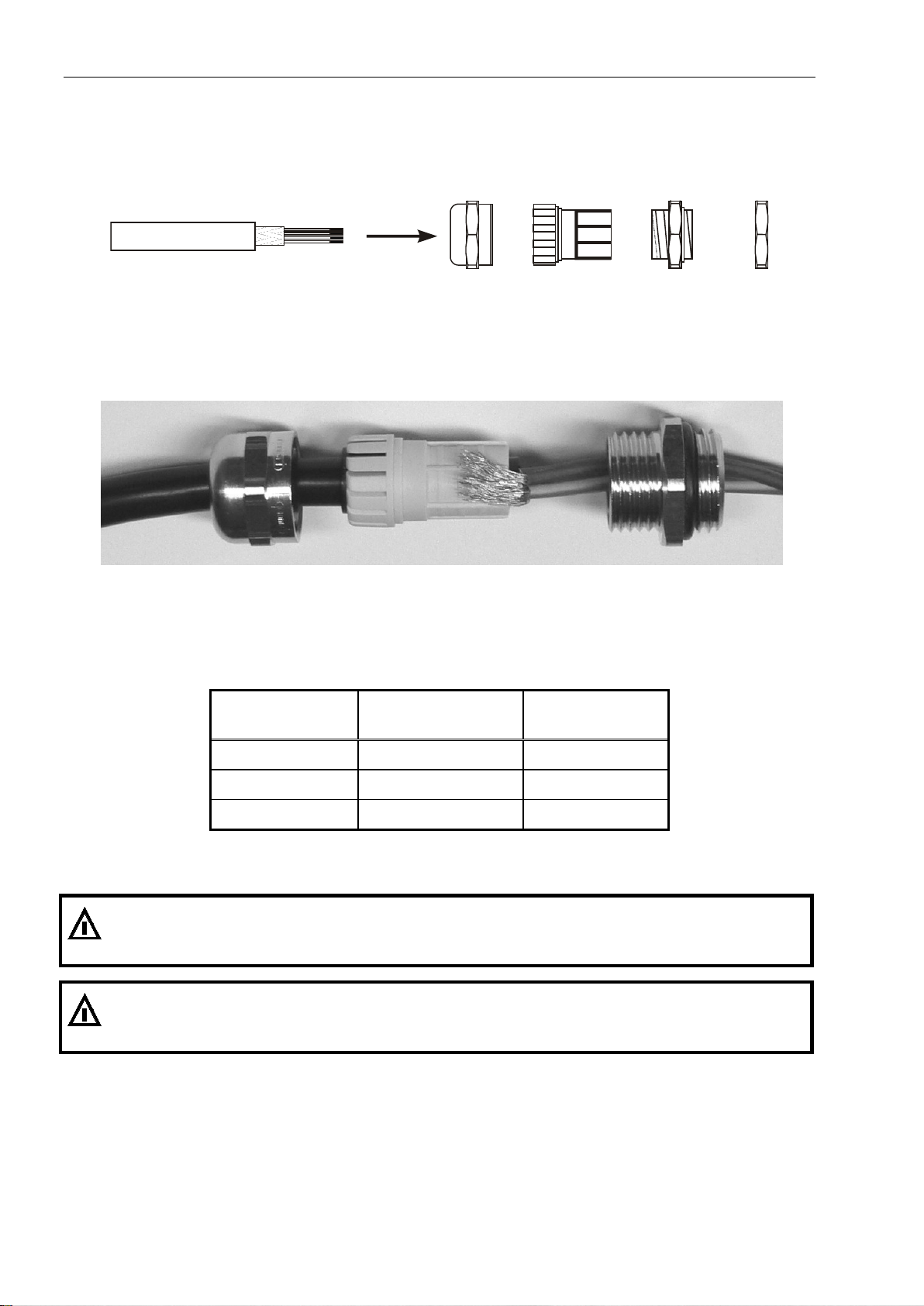

Cable jacket

Shield

Compression nut

Plastic insert

Bushing

Counter nut

Ex

Ex

5.4 Connection Of Cables

All cables are led into the housing through Ex cable glands.

1. Slide compression nut over cable jacket;

2. Slide plastic insert (retainer) over cable jacket until inner end is aligned with cut end of jacket;

3. Unravel shield, bend over retainer and push into retaining comb to ensure good conductive contact

with housing. Cut wires of shield to length of comb, avoid protruding wires that would endanger

tightness of cable gland;

4. Insert retainer with cable into bushing;

5. Screw compression nut onto bushing and use wrench to tighten securely.

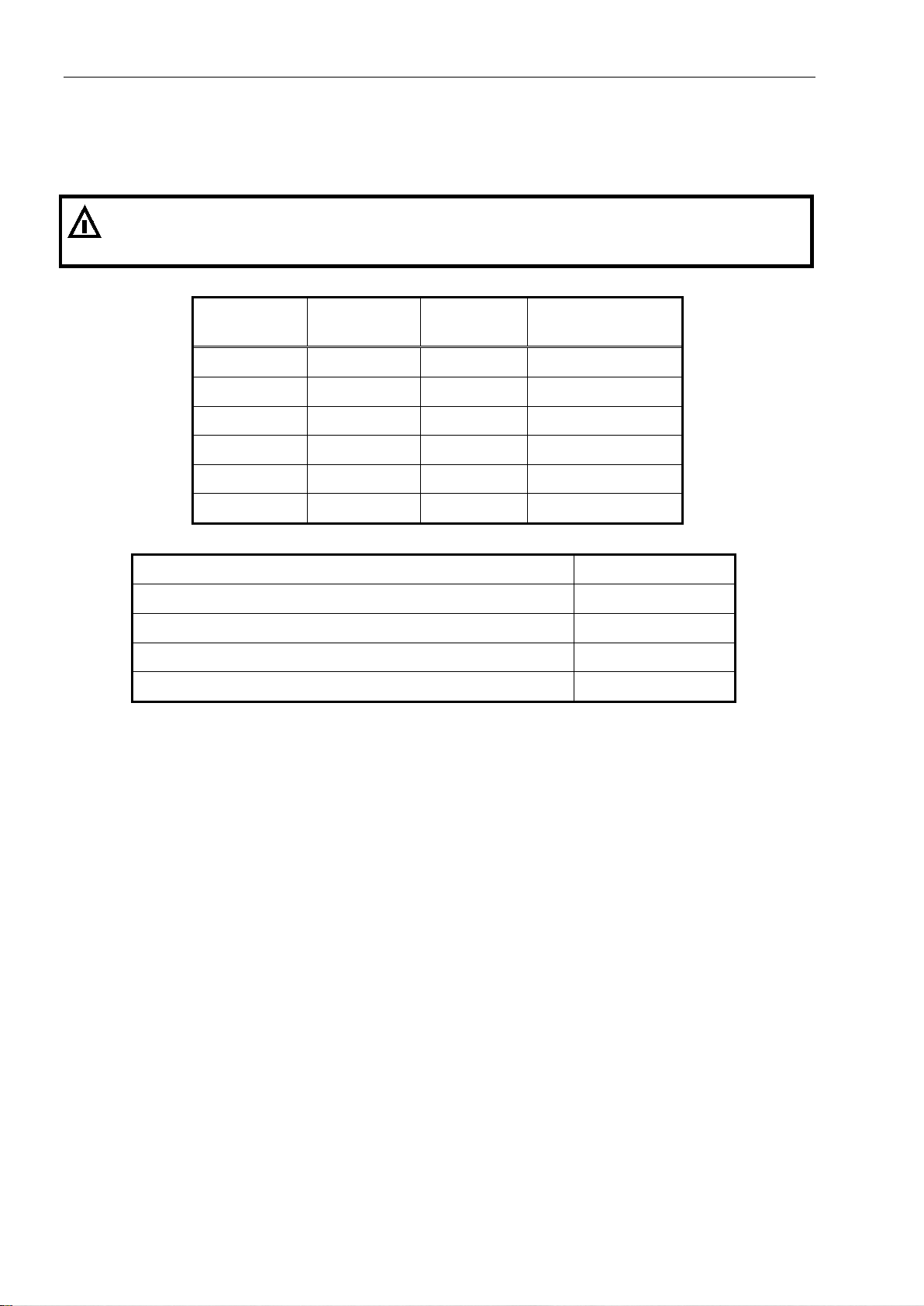

Permissible diameter of cables and torque for cable glands:

Wrench size of

counter nut

Permissible diameter

of cable

Torque to tighten

counter nut

17 mm 4–8 mm 6 Nm

20 mm 5–10 mm 5 Nm

22 mm 6–12 mm 8 Nm

Contact SysTec service for different cable diameters.

Use crimped wire end ferrules with plastic collar on stranded cable and avoid protruding wires.

All connecting cables must be firmly installed to avoid tension load at the cable glands and to

comply with the requirements of EN60079-14 paragraph 'cables and lines for permanent

installation'.

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 21

Ex

6 Installation Of External Connections With Type Of

Protection 'Ex-nA'

6.1 Connection Of Power Supply To IT1000-AC-*-Ex2/22

IT1000-AC-*-Ex2/22 (article-No. X1SYS0x1) is supplied with a line cord with free ends for the supply

voltage.

Power supply unit

L1 N PE

Terminal KL1 Terminal KL2

110 V (–15%) to 240 V (+10%),

50/60Hz

The connection of the supply voltage at the free cable end of the weighing terminal IT1000-AC*-Ex2/22 is designed for type of protection Ex-nA. The listed nominal connection values must

be adhered to.

For the connection of the line cord in hazardous area a suitable method must be chosen in

compliance with EN60079-0 (e.g. Ex-e, Ex-d). A suitable protection against overload and short

circuit in compliance with VDE regulations must be provided.

Nominal voltage U

Nominal current IN

N 110–240 VAC –15 %/+10 %

100 mA

Frequency range 47–63 Hz

Type of protection

Ex-nA

Color code free end of cable

brown L

blue N

green/yellow PE

22 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

Ex

6.2 Connection Of Power Supply To IT1000-DC-*-Ex2/22 And IT1000-BATT-*-Ex2/22

The supply voltage for the weighing terminal IT1000-DC-*-Ex2/22 is connected at screw terminal KL1

of the CPU1000-24VDC-Ex2/22 (article-No. X1SYS0x5).

The supply voltage for the weighing terminal IT1000-BATT-*-Ex2/22 is connected at screw terminal

KL1 of the CPU1000-NTA-Ex2/22 (article-No. X1SYS0x6).

DC/DC converter

+V 0 V PE

Terminal KL1 Terminal KL2

12–30 VDC

The connection of the supply voltage to the weighing terminal IT1000-DC-*-Ex2/22 is designed

for type of protection Ex-nA. The listed nominal connection values must be adhered to.

For the connection of the supply cable in hazardous area a suitable method must be chosen in

compliance with EN60079-0 (e.g. Ex-e, Ex-d). A suitable protection against overload and short

circuit in compliance with VDE regulations must be provided.

Nominal voltage U

N: 12–30 VDC +10 % / –15 %

Nominal current IN: 330–100 mA

Cross section (rigid wires): 0.75–1.5 mm2

Cross section (flexible wires with insolated wire end ferrule): 0.75–1.5 mm2

Length of stripped insolation: 6 mm

Fastening torque screw terminal: 0.5–0.6 Nm

Ex type of protection: Ex-nA

Terminal assignment KL1

+ V Supply voltage (+)

0 V Supply voltage (—)

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 23

6.3 Operation Of IT1000-BATT-*-Ex2/22

During the power up sequence the current charge state of the battery pack is briefly displayed,

followed by program version, date and time. If the indicator is not fitted with a realtime clock module,

data and time must be entered anew everytime the unit is switched on. The charge state can also be

viewed during running operation. To call up this function briefly press F / Up key three times.

The indicator is switched on by pressing the Print / Enter key once, to switch it off press F / Up key for

approx. 3 sec.

Battery life of a new, fully charged battery pack is max. 40 hours, depending on the connected

loadcells and the use of the backlighting. Charge time of a discharged battery pack is approx. 3 hours.

Battery life also depends on several other factors such as ambient temperature, number of charge

cycles and hardware configuration of the IT1000 terminal.

Note: When the IT1000-BATT terminal is supplied from an external battery, under '\ Service Menu \

General \ Batt' the respective type must be chosen, this choice affects the automatic power off

switching when battery is low:

Battery symbol lights

up at approx.

24Pb 24 V lead battery 23 V 22 V

Switching off

at approx.

12Pb 12 V lead battery 11.5 V 11 V

Line mains operation 10 V 9 V

When battery is low, this is indicated with a flashing symbol at the right hand side of the display. The

operator should then recharge the battery.

The charging of the rechargeable battery is indicated by a flashing triangle (version 2.29 or higher).

To avoid deep discharge of the battery, the IT1000-BATT is automatically switched off when the

voltage falls below the min. value. Before this happens, the message 'Low Battery' is shown for

approx. 2 min. If the unit is switched on again, 'Low Battery' is shown for approx. 2 minutes and then

the terminal is automatically switched off again to avoid deep discharge damage to the battery.

24 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

Ex

6.3.1 Connecting Cable With Ex Plug For Battery Operation

The weighing terminal IT1000-BATT-*-Ex2/22 (article-No. X1SYS0x6) with CPU1000-NTA-Ex2/22 is

suitable for connection to an external rechargeable battery box. To this effect the instrument can be

supplied with an assembled connecting cable (E3KAB003) with ex plug. This cable must be ordered

separately.

The following notes must absolutely be observed:

Absolutely adhere to the operating instructions 'DXN' provided by Marechal

Components must have identical coding, or damages to connector / socket cannot be ruled

out.

The connector cable must be firmly installed in a suitable way to protect it against

mechanical damage. An appropriate type of cable must be chosen that complies with the

thermal and mechanical requirements at the place of installation.

If connectors are not connected correctly, protection against risk of explosion is no longer

ensured. Strictly follow the instructions!

Immediately after disconnecting, cover voltage-conducting components with protective cap!

The following rechargeable batteries can be used for the supply of the weighing terminal:

1) AkkuBox Ex; 12 VDC for use in Ex zone 2 and 22

Article-No. E3AKK002 / E3AKK003

2) The use of alternative 12 V batteries is possible. However, when used in hazardous

area they must have appropriate ex protection. The requirements of EN 60079-14 must

be observed.

The operating instructions of the rechargeable battery must be observed.

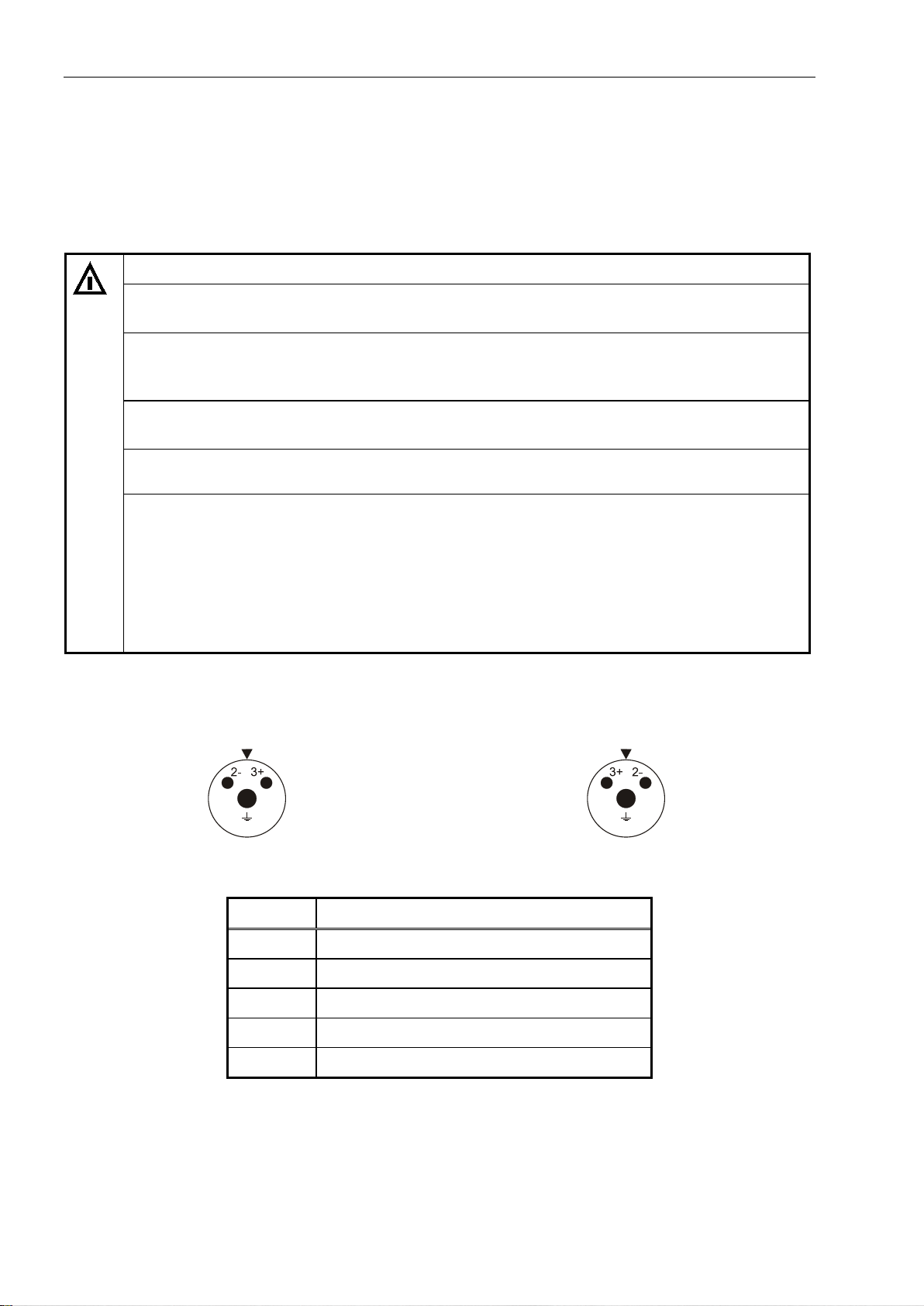

6.3.2 Assignment DXN1 Connector

Top view socket Top view connector

DXN1 Pin Assignment

1

2–

3+

PE

N

not used

GND

+12 VDC

Shield

not used

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 25

6.3.3 Instructions For Connecting And Separating Connectors

1. Open protective caps before plugging and check connector/socket for damages.

2. Align male/female connectors along red arrows and insert into groove.

1)

2)

3. Turn connector/socket right by approx. 45° to stop.

4. Plug in connector/socket until they click into place and are held by the blue hook.

3)

4)

Disconnect in reverse order.

26 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

Ex

6.4 Connection Of Analog Scale To ADM

The Analog Digital Module ADM is plugged into the socket ADM on the CPU1000. It provides

connection for one analog scale base.

The connection is designed compliant to type of protection 'Ex-nA'. If the loadcell is to be

installed in hazardous area, compliance with the applicable Ex regulations is mandatory. The

following connection values must be observed:

ADM

Signal Description Nominal value

Terminal KL1

1 +Excitation Output 5 V / 240 mA

2 – Excitation Output 5 V / 240 mA

3 +Sense Input 5 V / 1 mA

4 – Sense Input 5 V / 1 mA

5 +Signal Input 5 V / 1 mA

6 – Signal Input 5 V / 1 mA

Cross section rigid wire: 0.25–1.5 mm

2

Cross section flexible wire with insolated wire end ferrule: 0.25–1.5 mm2

Length of stripped insolation: 6 mm

Fastening torque screw terminal: 0.5–0.6 Nm

Ex type of protection: Ex-nA

Connection of weighing platforms and loadcells is to be made as specified below:

• Max. 16 strain gauge loadcells 350 Ω each

• Overall impedance 21.5 Ω ...4500 Ω

• W&M approved resolution of 6,000 e at a max. preload of 80%, internal resolution 524,000 d

• Smallest permissible input signal for approved applications: 0.33 µV / e

• Update rate 50 updates / second

• Loadcell excitation: 5 V ±5 %, gated power supply

• Connection in 4- or 6-wire mode.

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 27

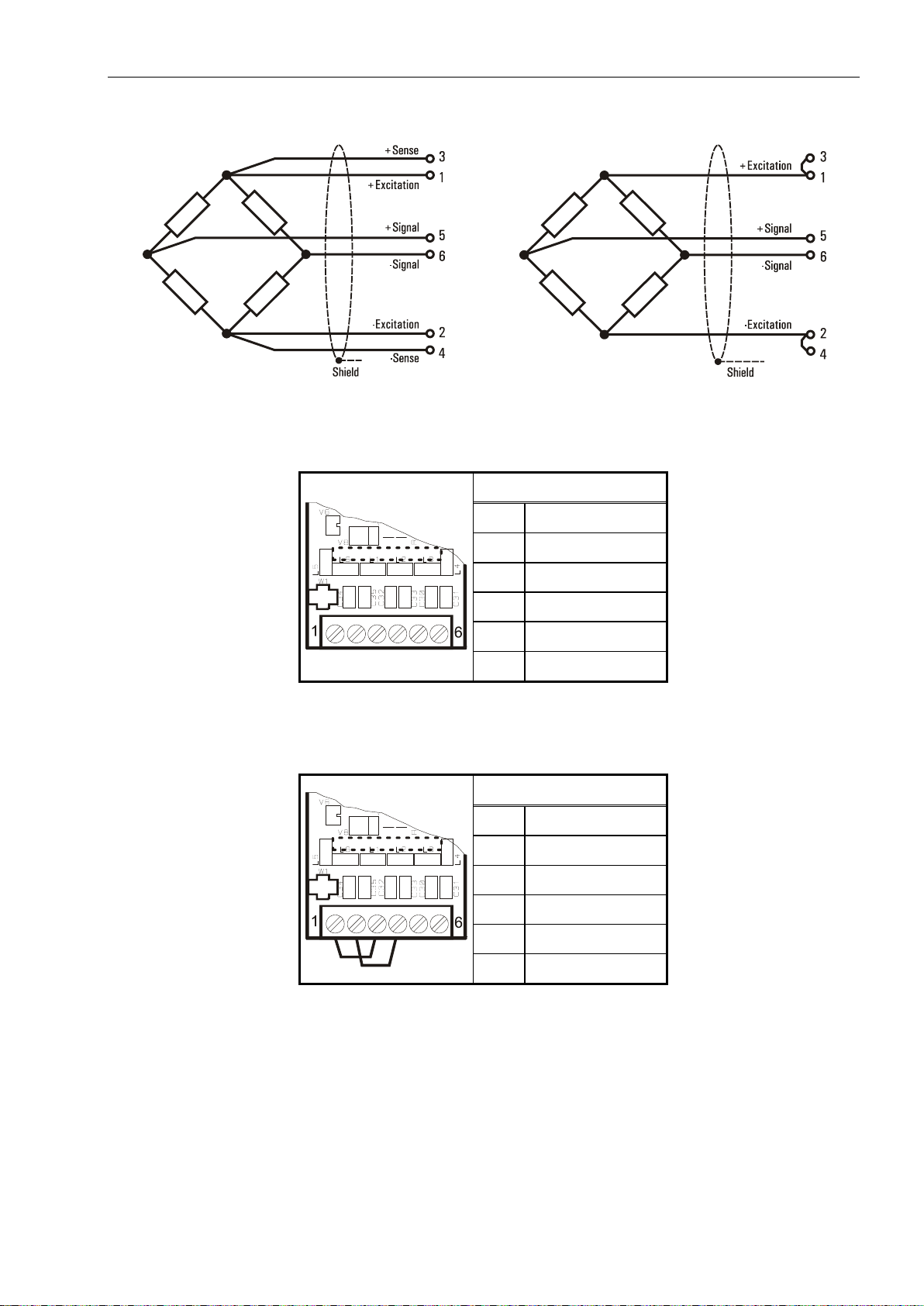

Principal schematics of 6-wire and 4-wire strain gauge loadcell

6-wire loadcell

4-wire loadcell

Connection of 6-wire analog loadcell(s) to the ADM module:

Terminal Assignment

1 +Excitation

2 – Excitation

3 +Sense

4 – Sense

5 +Signal

6 – Signal

Connection of 4-wire analog loadcell(s) to the ADM module:

To connect loadcells without sense lines (4-wire connection), two jump leads must be connected at

terminal strip KL1 between terminal 1 and 3, and between terminal 2 and 4.

Terminal Assignment

1 +Excitation

2 – Excitation

3

4

5 +Signal

6 – Signal

28 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

6.4.1 Connection Cables For Analog Weighing Platforms

For the installation of connection cables for analog weighing platforms please follow the

recommendations listed below:

• Only use suitable loadcell cable,

(e.g. SysTec cable 10KAB214, 3 x 2 x 0.75 mm², shielded)

Nominal Voltage of cable ≥250 V.

Unsuitable loadcell cable may affect accuracy.

• The shield of the loadcell cable must be connected all around the cable in the cable gland of the

weighing terminal (see also chapter 'Installation' / 'Connection Of Cables'). If an extension of the

loadcell cable is required use only metal junction boxes and cable glands. The shield on both sides

must be connected in the same way as at the terminal. Loadcells and/or weighing platforms,

junction boxes and the terminal must be included in the potential equalization of the components of

a weighing system. Depending on the situation on site this may require the installation of a separate

earth lead of appropriate diameter (e.g. 16 mm²) in parallel to the loadcell cable.

• Distance between loadcell cables and power lines: ≥0.5 m. Loadcell cables to be installed in

grounded metal conduits, metal hoses or metal cable trays.

• Maximum length of connection cable between scale base and weighing terminal: 200 m.

• If tension load is applied to loadcells instead of compression load, connection for +Signal and

–Signal must be transposed.

6.4.2 Securing Scale Parameters

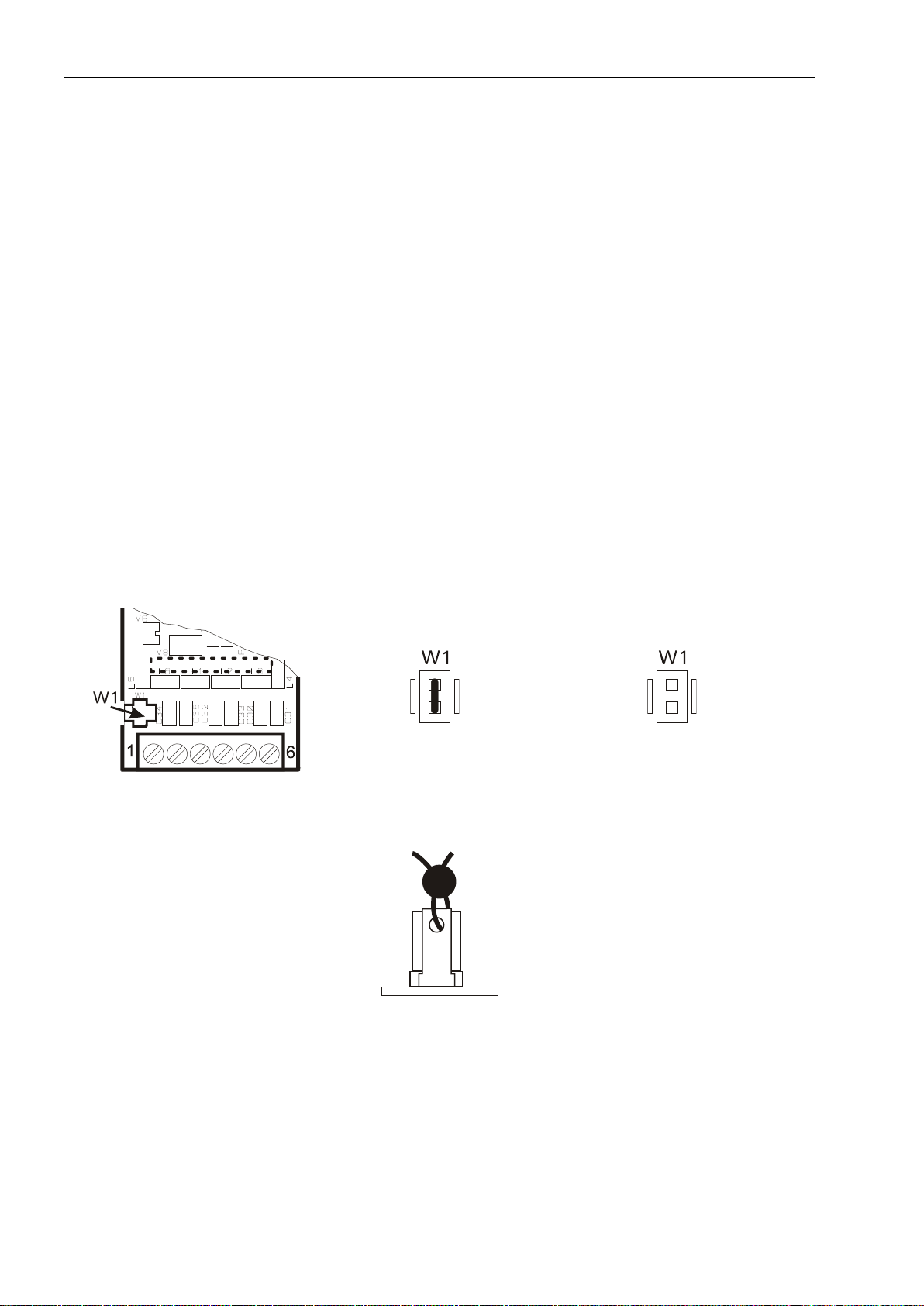

The scale parameters are stored in EEPROM and secured with the jumper W1:

Calibration data secured

W&M approved applications require that the calibration parameters be protected against unauthorized

modifications. To that effect the jumper can be sealed with thread and lead seal or adhesive label.

For a description of the scale calibration refer to the respective chapter.

Calibration and storing released

Technical Manual IT1000-**-*-Ex2/22 Rev. 9 29

Ex

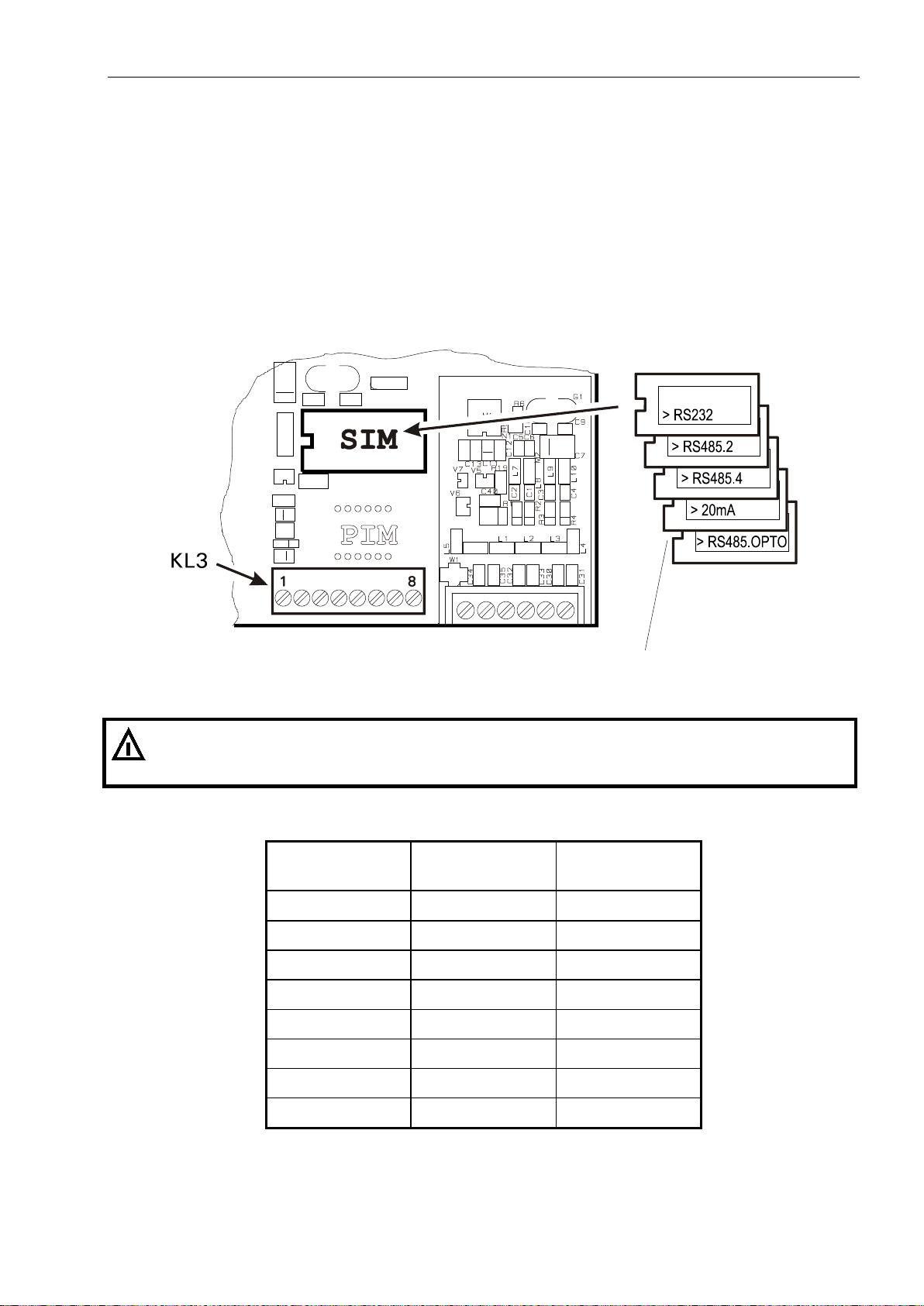

6.5 Connection Of Serial Interface SIM

In the SIM socket one of the following interface modules (SIM) can be inserted:

• SIM-RS232

• SIM-RS485 2-wire

• SIM-RS485 4-wire

• SIM-RS485.OPTO 2/4-wire opto isolated

• SIM-20mA CL (passive).

Note: If an interface module is installed in the SIM socket, the PIM socket must remain free!

Position of serial interface on CPU1000 board

Insert with notch

pointing to the left!

Peripheral devices are connected at CPU1000 screw terminal KL3. The connection is designed

compliant to type of protection 'Ex-nA'. The following connection values must be observed:

SIM-RS232:

CPU1000

Description Nominal value

Terminal KL3

1 GND ±12 VDC

2 — not used

3 — not used

4 — not used

5 TxD ±12 VDC

6 RTS ±12 VDC

7 RxD ±12 VDC

8 CTS ±12 VDC

30 Technical Manual IT1000-**-*-Ex2/22 Rev. 9

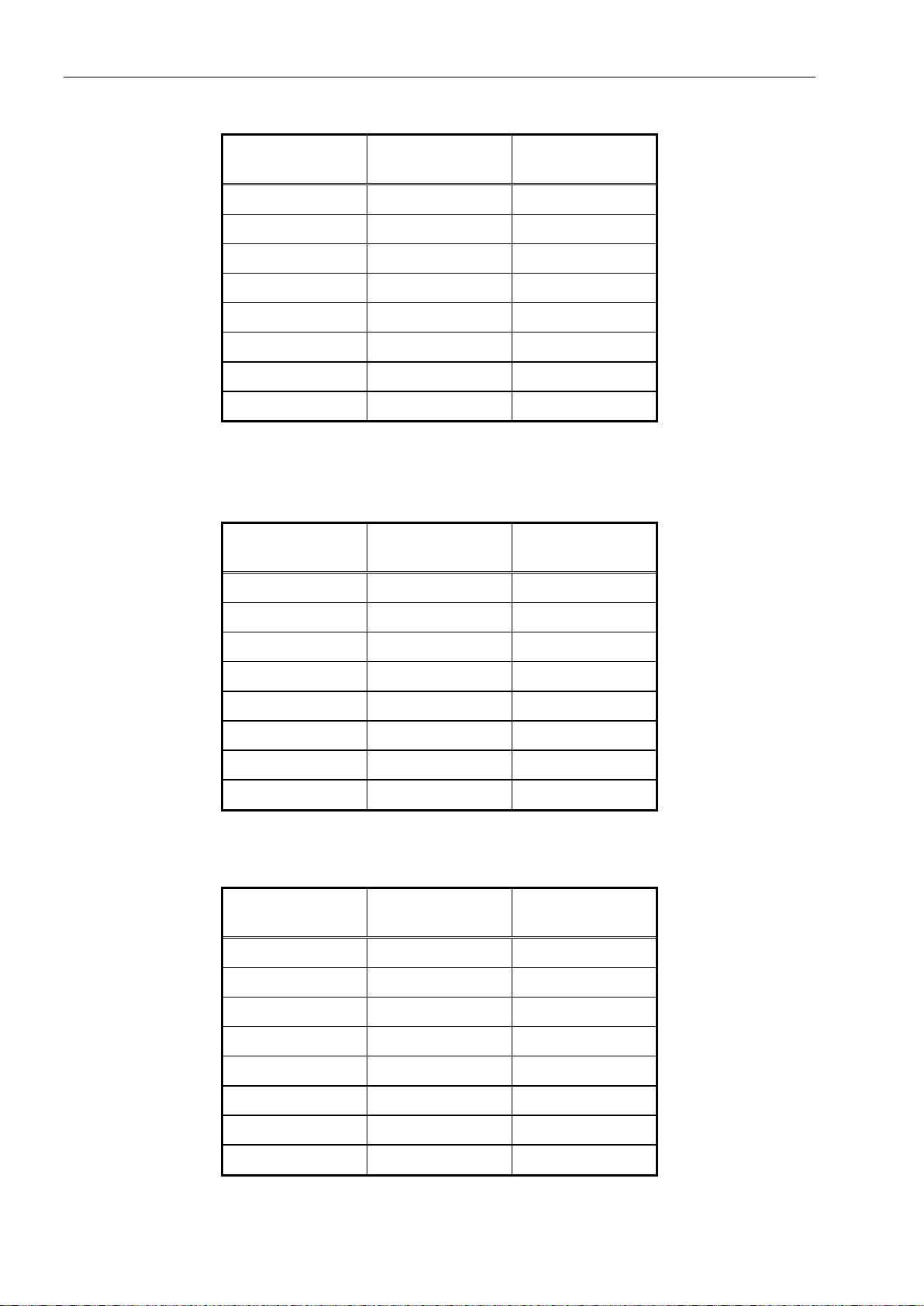

SIM-RS485-2-wire:

SIM-RS485-4-wire:

SIM-RS485-OPTO:

CPU1000

Description Nominal value

Terminal KL3

1 — not used

2 — not used

3 — not used

4 — not used

5 A (TxD+/ RxD+) 5 VDC

6 B (TxD– / RxD–) 5 VDC

7 A (TxD+/ RxD+) 5 VDC

8 B (TxD– / RxD–) 5 VDC

CPU1000

Description Nominal value

Terminal KL3

1 — not used

SIM-20mA:

2 — not used

3 — not used

4 — not used

6 TxD+ 5 VDC

7 TxD– 5 VDC

8 RxD+ 5 VDC

9 RxD– 5 VDC

CPU1000

Description Nominal value

Terminal KL3

1 — not used

2 — not used

3 — not used

4 — not used

6 TXIN 12 VDC / 20 mA

7 TXOUT 12 VDC / 20 mA

8 RXIN 12 VDC / 20 mA

9 RXOUT 12 VDC / 20 mA

Loading...

Loading...