Scalibur – Modular Controllers

SCA-340 / SCA-340-L

Manual

Rev.22

Disclaimer / Impressum

This manual is intended to provide support for installation and usage of the device. The

information is believed to be accurate and reliable. However, SysMik GmbH Dresden

assumes no responsibility for possible mistakes and deviations in the technical

specifications. SysMik GmbH Dresden reserves the right to make modifications in the

interest of technical progress to improve our modules and software or to correct mistakes.

We are grateful to you for criticism and suggestions. Further information (device description,

available software) can be found on our homepage www.sysmik.de. Please ask for latest

information.

SysMik disclaims all warranties in case of improper use or disassembly and software

modifications not described in this document or when using improper or faulty tools.

Commissioning and operation of the device by qualified personnel only. All applicable

regulations have to be observed.

SysMik

All other trademarks mentioned in this document are registered properties of their owners.

These and further trademarks are used in this document but not marked for better

readability.

No part of this document may be reproduced or modified in any form without prior written

agreement with SysMik GmbH Dresden.

Copyright © 2018 by SysMik GmbH Dresden

SysMik GmbH Dresden Tel + 49 (0) 351 – 4 33 58 – _0

Bertolt-Brecht-Allee 24 Fax + 49 (0) 351 – 4 33 58 – 29

01309 Dresden E-Mail (Sale) sales@sysmik.de

E-Mail (Support) service@sysmik.de

Germany Homepage https://www.sysmik.de

®

and the SysMik logo are registered trademarks of SysMik GmbH Dresden.

2 sysmik.de Manual SCA-340 / SCA-340-L

Contents

Contents

1. Introduction 6

2. Device and System Overview 7

2.1 Hardware 7

2.1.1 Functional Overview 7

2.1.2 Processor Core 7

2.1.3 Ethernet 7

2.1.4 Serial Ports 8

2.1.5 USB 8

2.1.6 LON 8

2.1.7 Inline Local Bus Interface / Modular IO Terminals 8

2.2 Software Overview 9

2.2.1 Scalibur System Shell 9

2.2.2 IO Server 9

2.2.3 Commissioning Web Server 9

2.2.4 Sedona Virtual Machine 9

2.2.5 Niagara Framework 10

3. Installation and Commissioning 11

3.1 Assembly 11

3.1.1 Dimensions 11

3.1.2 Mounting 12

3.1.3 Adding Inline Terminals 13

3.2 Connections 14

3.2.1 Connectors 14

3.2.2 Power Supply 15

3.2.2.1 How to Connect Power 15

3.2.2.2 Power Dissipation Calculations for a Scalibur Controller 17

3.2.2.3 Current Consumption Calculation for a Scalibur Station (with Terminals) 18

3.2.2.4 Derating of Terminal and USB Supply 18

3.2.2.5 Protective Devices of 24 V Main and Segment Supply UM and US 20

3.2.3 RS-485 and LON 20

3.2.4 Ethernet 21

3.2.5 USB-OTG for local Access 22

Manual SCA-340 / SCA-340-L sysmik.de 3

Contents

3.2.6 USB 23

3.3 Operating Elements 24

3.3.1 Overview 24

3.3.2 Inline Supply LEDs “US”, “UM”, “UL” 24

3.3.3 Process Status LEDs “PL”, “ST”, “SE” 24

3.3.4 IO Status LED “IO” 25

3.3.5 Communication LEDs “COM1”, “COM2”, “LON” 25

3.3.6 Service Button and LED “SV” 26

3.3.7 Ethernet Status LEDs 26

3.3.8 RS-485 Termination 27

4. Software 28

4.1 Configuration Tools 28

4.1.1 SCA System Shell 29

4.1.2 Commissioning Website 29

4.1.3 File Access via FTP 30

4.2 Commissioning Scalibur 30

4.2.1 IP Addressing 31

4.2.2 Time and Time Zone 31

4.2.3 Hardware Data Point Test 31

4.3 Ethernet Switch for Flexible Network Topologies 33

4.3.1 Assignment of IP Interfaces to External Ethernet Ports 33

4.3.2 Ethernet Ring Monitoring 35

4.3.3 Rapid-Spanning-Tree-Protocol (RSTP) 35

4.3.4 Port Status Informations 36

4.3.5 Broadcast Storm Protection 36

4.4 Real-Time Control with Scalibur and Sedona 37

4.4.1 IO Access 37

4.4.2 Modbus 37

4.4.3 Platform Service 38

4.5 Integration with Scalibur and Niagara Framework 39

4.5.1 Local IO Access 39

4.5.2 Serial Interfaces 41

4.5.3 IO Remote Control 43

4.5.4 Sedona Integration 43

4 sysmik.de Manual SCA-340 / SCA-340-L

Contents

4.6 Concurrent Access to the IO Terminals 44

5. Best Practices and Troubleshooting 46

5.1 Performance and Resource Management 46

5.2 Reliability of Nonvolatile Memory 47

5.3 Diagnosis and Troubleshooting 47

5.3.1 SCA System Shell / Commissioning Website is not accessible 48

5.3.2 IP Address unknown 48

5.3.3 No IP Communication 48

5.3.4 Unknown Niagara Platform Access Credentials 48

5.3.5 No Platform Connection to Device - Platform Daemon is not starting 49

5.3.6 Sedona Virtual Machine is not Starting 49

5.3.7 IO Errors 49

6. Technical Data 50

7. Order Information 53

7.1 Scalibur and Accessories 53

7.2 Supported Inline Automation Terminals 54

8. Glossary 56

9. Third-Party Software 57

10. Bibliography 58

Manual SCA-340 / SCA-340-L sysmik.de 5

Introduction

1. Introduction

Scalibur is a powerful modular controller for Niagara and Sedona. Scalibur stands

for scalability, a major characteristic of this controller. Scalability comprises several

aspects:

1) Scalable IO

A Scalibur station consists of the Scalibur controller and up to 63 terminals of the

modular Inline system. The terminals are available in a wide variety of types:

digital and analog inputs and outputs with different numbers of channels as well

as functional terminals for DALI light control, pulse metering, MBUS or serial

interfaces.

2) Scalable software

Scalibur has been developed primarily for the Niagara framework. Niagara

applications are built with the software tool Niagara Workbench. While Niagara

is very powerful, it is not very well suited for specific real-time applications. In

order to realize such applications with Scalibur too, the controller has the

Sedona framework in parallel to Niagara. Sedona applications run with fixed

cycle times in the millisecond range and are created with the

Niagara Workbench. Beside the separate exclusive use of either framework, the

parallel use of Niagara and Sedona is supported. The Niagara and Sedona

application can communicate to each other with a Sedona driver for Niagara.

3) Scalable licensing

The license model for Scalibur is very flexible: a license comprises a certain

number of data points which can be integrated with Scalibur. These license

packs are available as first-time license (250/500/1250/5000/10000 data points)

or as upgrade license (500/1250/2500 data points). Sedona, as open source

project, doesn’t have any license fees.

4) Scalable IP network

Scalibur contains two logically separated IP interfaces and an integrated

Ethernet switch with four external ports. The configurable assignment of the

Ethernet ports to the separate IP interfaces and the usage of the spanning-treeprotocol allow flexible topologies like daisy-chain and redundant ring-structures

for both the backbone and the local control network.

6 sysmik.de Manual SCA-340 / SCA-340-L

2. Device and System Overview

2.1 Hardware

2.1.1 Functional Overview

Device and System Overview

Fig. 2.1.1.1: SCA-340-L basic circuit diagram

2.1.2 Processor Core

Processor: ARM® Cortex® A8 / 1 GHz

DDR3 SDRAM: 1 GB RAM (512 MiB for hardware version < 06 – see serial label)

eMMC Flash: 1,8 GB

NVRAM: 512 KiB / (buffered for a power failure of 5 days)

RTC: buffered for a power failure of 5 days

The internal Flash memory can be extended with a microSD card.

2.1.3 Ethernet

The integrated Ethernet switch has 4 external ports, which can be assigned

independently to one of the two separate IP interfaces. If at least two ports belong to

an IP interface, then redundant communication paths can be established, for

example by connecting several devices in a ring. The Ethernet switch supports the

Rapid Spanning Tree Protocol (RSTP), as well as a ring monitoring function to

automatically switch off redundant paths, and a broadcast storm protection function.

Factory default: eth0 is assigned to LAN3/LAN4, eth1 is assigned to LAN1/LAN2,

and RSTP and ring monitoring are deactivated.

Manual SCA-340 / SCA-340-L sysmik.de 7

Device and System Overview

2.1.4 Serial Ports

Both RS-485 ports have switches for bias and terminating resistors, and are

galvanically isolated from each other and the rest of the circuit.

Further serial interfaces may be added using modular IO terminals (M-Bus, RS-232,

RS-485, RS-422).

2.1.5 USB

USB 1 is a USB-OTG port with Mini-USB socket, and is used for installation and

maintenance. Connected to a PC, it allows to control the device via console and to

access the internal installation web site for device configuration and data point test.

The second USB port (USB 2) allows to connect USB end-devices.

2.1.6 LON

The SCA-340-L has a LON interface according to the CEA-709 standard, to connect

directly to LonMark TP/FT-10 networks.

2.1.7 Inline Local Bus Interface / Modular IO Terminals

The local bus interface allows to connect up to 63 modular IO terminals. This

interface comprises the communication channel to the IO terminals as well as the

power supply of these terminals and their connected sensors and actuators.

Scalibur is a controller for the Inline IO system and unlocks the rich pool of Inline IO

terminals for building automation.

Inline is a modular IO system by Phoenix Contact, to flexibly and quickly build up

space-saving automation stations. An Inline station consists of a bus controller and

a set of IO terminals, chosen freely in terms of numbers, type, and sequential

arrangement. The bus controller runs the Inline station and has interfaces to the

higher level controller. Up to 63 IO terminals can be connected to a bus controller.

There are IO terminals for almost any purpose:

digital inputs and outputs with 1, 2, 4, 8, 16, or 32 channels per terminal

Triac and relay outputs for switching signals or for higher loads

analog inputs for measuring voltage, current, resistance, or temperature

with 2, 4, or 8 channels per terminal

analog outputs for voltage or current with 2, 4, or 8 channels per terminal

function terminals for complex IO operations or gateway functions (DALI,

M-Bus, S0 pulse metering, serial interface)

supply and support terminals , e.g. to realize separated voltage domains

within an Inline station

The overall width of the Inline extension terminals is 1, 2 or 4 DU (1 DU, division

unit = 12.2 mm or approx. 0.48 in.).

Inline terminals are provided with a pluggable wiring level enabling pre-wiring and

easy module exchange.

The mechanics of the system also allows exchanging terminals without complete

dismantling of the station.

Scalibur determines type and function of all supported terminals automatically, thus

certain in- and output functions can also be created without a previous configuration

of the station, which is especially helpful for commissioning tests.

8 sysmik.de Manual SCA-340 / SCA-340-L

2.2 Software Overview

Scalibur is using a Linux operating system, which runs several applications in

parallel.

Device and System Overview

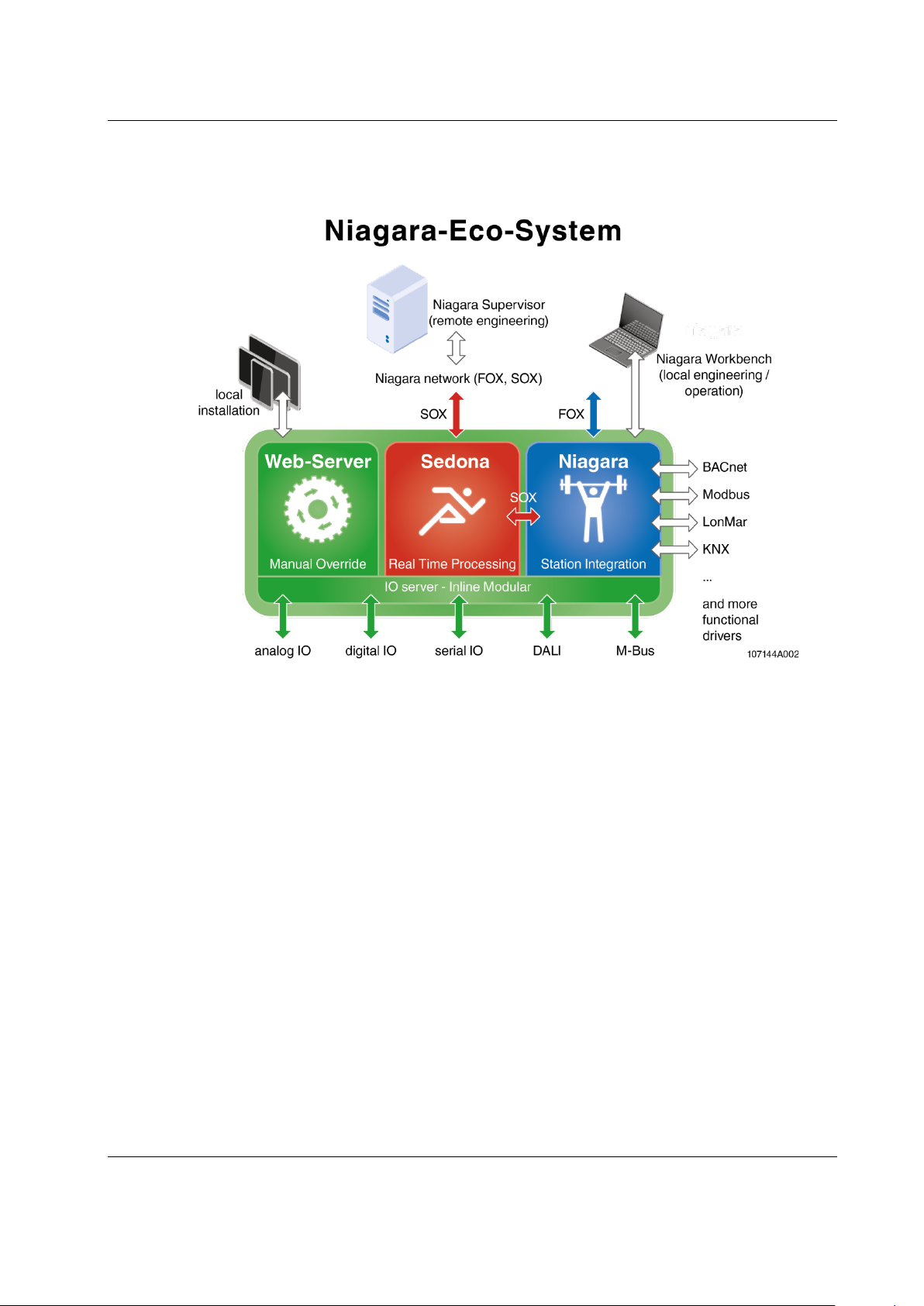

Fig. 2.1.7.1: Scalibur software structure

2.2.1 Scalibur System Shell

The Scalibur System Shell is accessible only via the local USB-OTG port, and is

used during commissioning to configure basic settings like IP address, or as

maintenance access if IP address or passwords have been lost.

2.2.2 IO Server

The IO server controls the modular Inline terminals of the Scalibur station and

manages concurrent accesses to the hardware data points. Niagara and the IO

server communicate via an TCP connection. This allows to control IOs remotely

from another Niagara station. The remote access can be limited or disabled by the

setting of the IP address of the controlling station.

2.2.3 Commissioning Web Server

The commissioning web server is exclusively accessible via the local USB-OTG

port. It presents web pages to commission the device: setting IP addresses and time

zone, reading state of inputs and setting output states of the data points of the local

IO terminals for test purposes.

2.2.4 Sedona Virtual Machine

The Sedona virtual machine (SVM) runs the Sedona application in real-time with

configurable cycle time. The Niagara Workbench connects to the SVM to modify the

application, load updates, or create backups of the application. Platform specific kits

provide access to the IO terminals, and also to system settings like IP addresses

Manual SCA-340 / SCA-340-L sysmik.de 9

Device and System Overview

and Modbus settings. A Modbus TCP server and a Modbus TCP client/Modbus RTU

master are integrated and are used to exchange data with other Sedona controllers.

Also, Niagara can be deactivated here.

2.2.5 Niagara Framework

Scalibur can be parameterized with Niagara Workbench and a platform connection

to the Niagara daemon. This includes loading of software updates and of a station

(Niagara application), which can be run automatically by the Niagara daemon.

A Workbench connection to a station is used to modify the station. All features of the

Niagara framework are available:

data point integration over a plethora of open automation protocols (LON,

BACnet, KNX, M-Bus, Modbus, and others) with data normalization

system functions (scheduler, alarming, trend log)

web visualization

enterprise interfaces (oBIX, data bases) and many more

10 sysmik.de Manual SCA-340 / SCA-340-L

3. Installation and Commissioning

3.1 Assembly

3.1.1 Dimensions

Width x Height x Depth:

80 mm x 119,8 mm x 71,5 mm (3.15 inch x 4.72 inch x 2.81 inch)

Installation and Commissioning

Fig. 3.1.1.1: Scalibur dimensions

Manual SCA-340 / SCA-340-L sysmik.de 11

Installation and Commissioning

3.1.2 Mounting

Preferred mounting position is horizontal (i.e. on a horizontal DIN rail which is

attached to a vertical wall). For all other mounting positions, a derating has to be

observed (see chapter 6).

Note: The air vents have to be kept free with a sufficient spacing to other components, to

ensure optimal air ventilation.

The device is designed for easy snap in mounting on 35 mm x 7.5 mm

DIN EN 60715 rails (formerly DIN EN 50022).

Note: The DIN rail should be attached to a mounting plate or an even back plane for best

stability.

Suitable fixtures, like end clamps or grounding terminals have to be used at both

ends of the station, to prevent sliding off the rail.

Note: To ensure easy unlocking of the Ethernet connectors, use only clamps at the bus

controller side of the station that do not protrude more than 30 mm from the rail.

Note: Only use clean and corrosion free mounting rails in order to ensure a safe contact

between the FE terminals.

12 sysmik.de Manual SCA-340 / SCA-340-L

3.1.3 Adding Inline Terminals

6452B010

An Inline station is assembled by plugging the individual components to each other,

thus establishing the potential and bus signal connection between the individual

components of the station. Figure 3.1.3.1 shows the procedure of mounting a

terminal.

Disconnect power to the entire station.

Mount the electronics base onto the rail (A). Adjacent terminals are

interlocked by their feather keys / keyways (B).

First insert the feather keys of the local bus into the keyways of the

preceding terminal (B1).

Guide the feather keys along the keyways until they lock appropriately

(B2).

Ensure that the feather keys are properly connected (C2). C1 shows the

common mistake that the feather keys are not inside their keyways.

After mounting all electronics bases install the connectors onto their

respective bases. First insert the front detent (D1). Then push the

connector onto the electronics base until the rear detent locks properly

(D2).

Installation and Commissioning

Figure 3.1.3.1: Installation on the mounting rail (A), connection of Inline components to each other (B),

connection check (C), plugging of the wiring level (D)

Note: While connecting the components to each other and to the mounting rail later, please

make sure that all feather keys and latches are properly snapped in!

Note: Please consult the User Manual with regard to configuration and installation of the

Inline product family (see [1]).

Manual SCA-340 / SCA-340-L sysmik.de 13

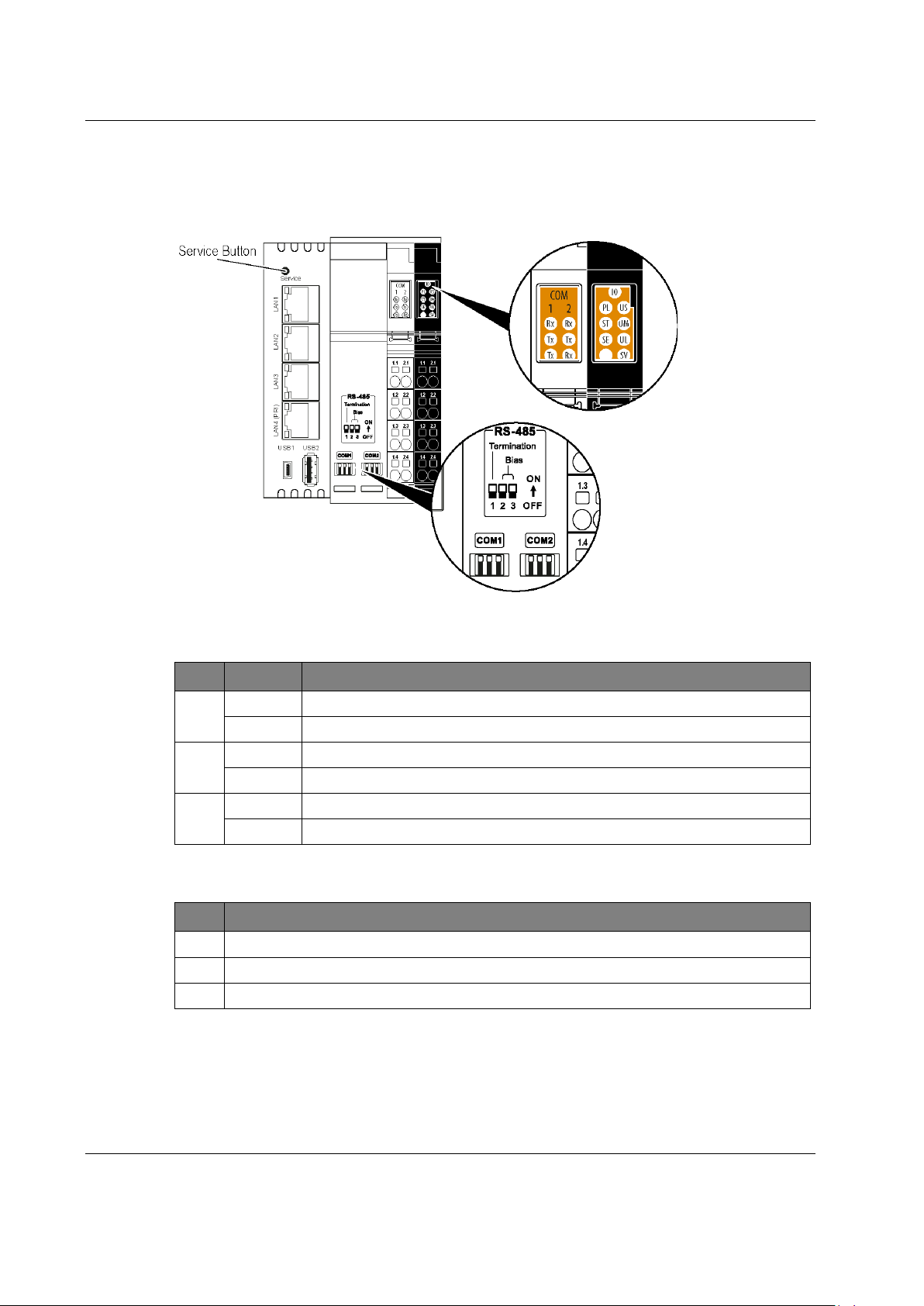

Installation and Commissioning

1

Micro-SD card slot

8

Switches for RS-485 termination / bias

2

Type label with device-specific

information

9

Service interface

3

Service button

10

Bus interface connector

4

Ethernet (4x 10/100BaseT)

11

Supply connector

5

FE connector *)

12

Labeling field (2x)

6

USB 1 (mini USB, USB-OTG)

13

Diagnostic indicators

7

USB 2

14

End plate

*) … The FE connector is placed at the rear side of the connector – it is not visible in the

sketch.

3.2 Connections

3.2.1 Connectors

Fig. 3.2.1.1: Overview device connections

14 sysmik.de Manual SCA-340 / SCA-340-L

3.2.2 Power Supply

3.2.2.1 How to Connect Power

The bus controller is operated with 24 V DC. The bus controller is powered from this

source and it generates the logic voltage for the logic circuit and the analog voltage

for the analog circuit. The logic circuit supplies the internal bus including the

communication chips of all connected automation I/O terminals. The analog circuit

provides an auxiliary supply for analog signals.

Note: While connecting the automation terminals please observe the derating of the logic

voltage, the supply of the analog terminals, and the maximum ampacity of the terminals.

Furthermore the bus controller includes connections for the supply of the mains and

segment voltage of the Inline station.

Fig 3.2.2.1 shows the basic circuit for the connections of the power supply.

Installation and Commissioning

Fig. 3.2.2.1: Supply of U

Note: If UBK/UM and US are to be supplied from a common source, the fuse protection of the

individual sections with regard to their supply requirements has to be observed.

/ UBK and US from different sources (A) and from a common source (B)

M

Note: The current passing through terminals and potential routing contacts must not exceed

8 A.

Manual SCA-340 / SCA-340-L sysmik.de 15

Installation and Commissioning

The Functional Earth ground FE is connected to the potential routing contacts and is

automatically grounded if the bus controller is snapped on a grounded mounting rail.

The function of FE is to discharge interferences.

Note: Functional earth ground (1.4 and. 2.4) has to be connected additionally via 1.5 mm²

wire (AWG 15) and grounding terminal to the mounting rail (see Fig. 3.2.2.2).

Fig. 3.2.2.2: Connecting functional earth ground (FE) of Scalibur

16 sysmik.de Manual SCA-340 / SCA-340-L

Terminal

point

Name Function

24 V DC segment supply (segment circuit); The supplied voltage

contacts.

UBK: 24 V DC bus controller supply, logic supply (UL) and analog

contacts

Reference ground for the internal bus and automation terminals

(main and segment circuit).

Functional ground; Connecting the functional ground to this

contact at the back side of the enclosure.

Installation and Commissioning

1.1 US

2.1

1.2, 2.2

1.3, 2.3 GND

1.4, 2.4 FE

Table 3.2.2.1.1: Terminal assignment of supply connector

U

/ UM

BK

is lead to the automation terminals via the potential routing

supply (U

UM: 24 V DC main voltage (main circuit); The supplied voltage is

lead to the automation terminals via the potential routing

(logic and analog circuit) and for the main and segment supply

terminal point is mandatory (see above). The terminal point is

internally connected to the potential routing contacts and the FE

ANA

)

3.2.2.2 Power Dissipation Calculations for a Scalibur Controller

The power dissipation of the bus controller equals the sum of the power

requirements of the bus controller itself and the power loss of the internal power

supply for the whole Inline station:

P

SCA

= PO+ P

P

SCA

P

O

USB

+ P

PERI

power dissipation of the bus controller

power requirements for operating the bus controller without

terminals and any external load (4.1 W)

P

power dissipation of the bus controller caused by the load on

USB

USB1 and USB2 (max. 500 mA each)

P

= 0.7 V × ( I

USB

P

power dissipation of the bus controller caused by the Inline IO

PERI

USB1

+ I

USB2

)

terminals

P

= 1.0 V × I

PERI

L

IL current consumption of UL

Note: The factors 1.1 V und 0.7 V result from the electrical efficiency of the internal power

supply unit.

Sample calculation: Power dissipation of a Scalibur in case of the maximum

possible current drawn from U

consumption.

P

= 4.1 W + 0.7 V × 0.1 A + 1.0 V × 2.0 A

SCA

P

= 4.1 W + 0.07 W + 2.0 W

SCA

P

= 6.17 W

SCA

Manual SCA-340 / SCA-340-L sysmik.de 17

and a USB memory stick with 0.1 A current

L

Installation and Commissioning

3.2.2.3 Current Consumption Calculation for a Scalibur Station (with Terminals)

To find a suitable external power supply, the current consumption of the entire

Scalibur station has to be considered:

= I

I

IS

SCA

+ I

USB

+ IK + I

AS

IIS current consumption of the entire Scalibur Inline station

I

current consumption of the Scalibur

SCA

I

current consumption of connected USB devices

USB

I

current consumption of connected terminals

K

I

current consumption of sensors and actuators, fed by the Inline station

AS

The current consumption of a Scalibur (without terminals) is maximum 170 mA.

I

= 0.17 A

SCA

Please consult the manual of the connected USB device to find out the actual

current draw from USB.

The respective USB currents IUSB1 and IUSB2 are weighted by a factor of 0.24,

resulting in the equation:

I

USB

= (I

USB1

+ I

USB2

) × 0.24

The current consumption of the connected terminals can be found in their manuals.

The following rules of thumb apply:

The current provided by U

The current provided by U

influences the total current directly.

ANA

applies to the total current with a factor of 0.36.

L

The following formula applies:

I

= IA + IL × 0.36

K

IA current from U

I

current from UL (max. 2.0 A)

L

(max. 500 mA)

ANA

See the according datasheets in order to determine the current consumption of the

connected actuators and sensors.

For an estimation it is often sufficient to check, whether the supply can be provided

completely by the Scalibur, that is without power or boost terminals.

Without power and boost terminals and regardless of the circuits U

und US, the

M

maximum current consumption of the Scalibur with connected terminals is 1.7 A.

In addition there are the current requirements of the sensors and actuators, whereas

the current through feather keys and keyways is limited to a maximum of 8 A.

Note: When selecting an external power supply, plan sufficient reserves. also into account

that it could come to a current increase to a multiple of the rated current in the moment of

turn-on caused by input capacities. Power supplies with over current shut-down must have a

sufficient response delay to avoid start-up problems.

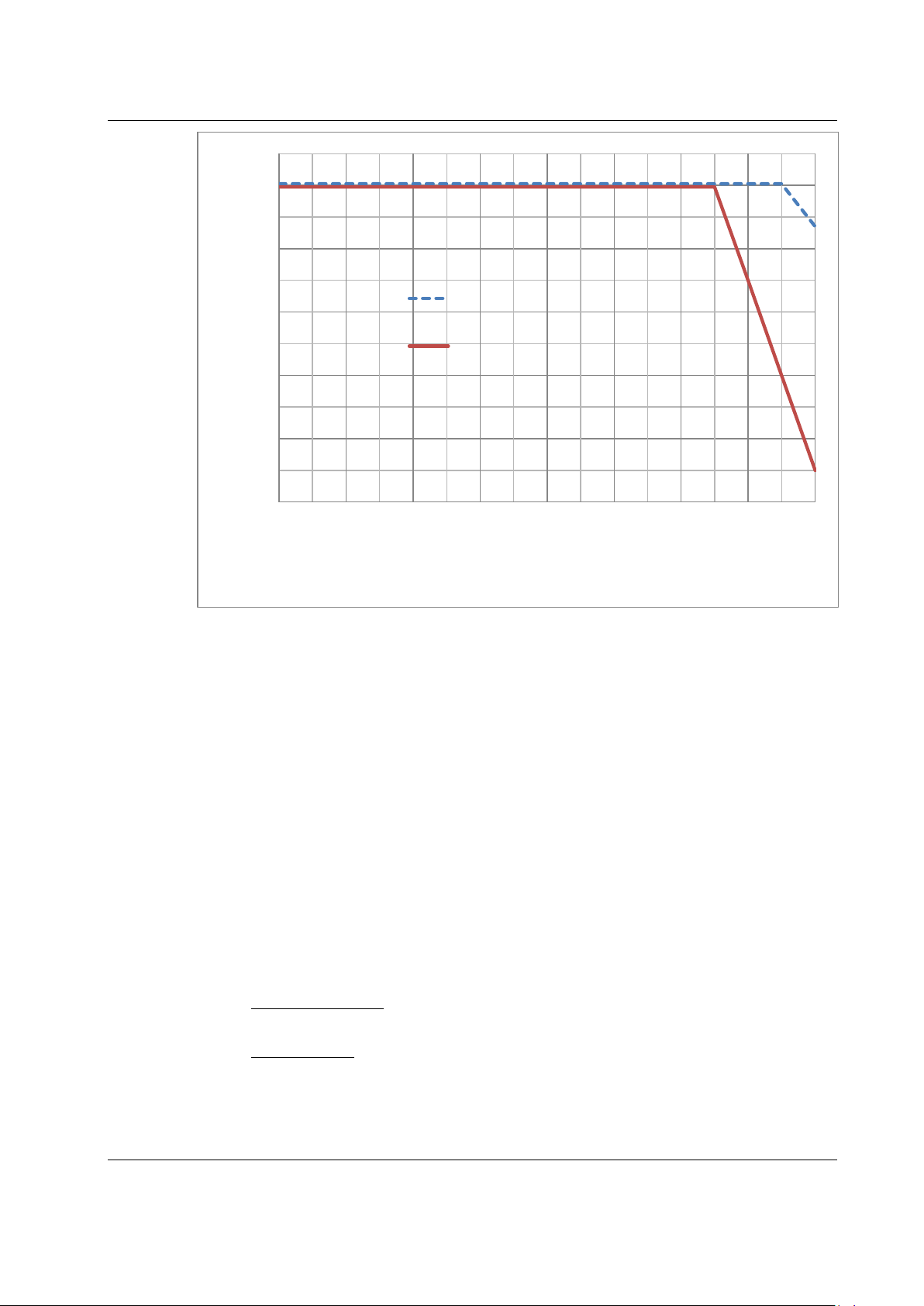

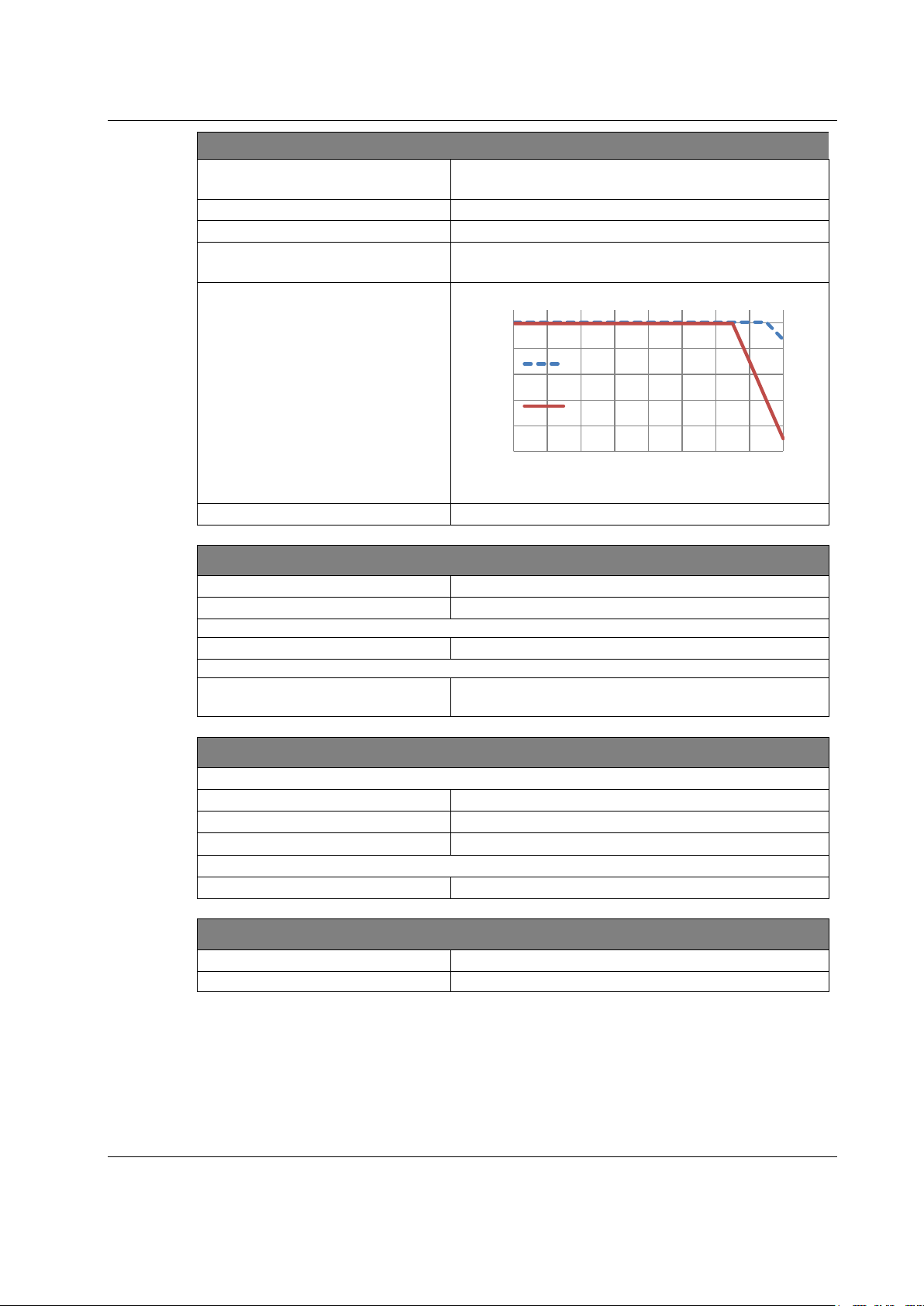

3.2.2.4 Derating of Terminal and USB Supply

Because USB and the Inline terminals are supplied by Scalibur’s internal power

supply unit, an increased load there increases Scalibur’s internal power dissipation.,

Therefore, a derating has to be observed, which is depending on the mounting

position (see Fig. 3.2.2.4). The recommended mounting position (with least derating)

is horizontally (that is, clipped to a horizontal DIN rail on the wall).

The internal power dissipation caused by USB loads (P

terminals (P

18 sysmik.de Manual SCA-340 / SCA-340-L

) is calculated according to chapter 0.

PERI

) and the connected Inline

USB

Pv [%]

T

env

[°C] environmental temperature in °C

100

80

Installation and Commissioning

60

40

20

0

-25 -15 -5 5 15 25 35 45 55

Pv [%] Power dissipation of internal Scalibur supply in %

Fig. 3.2.2.3: Derating diagram of maximum internal power dissipation

horizontal mounting

other mounting positions

T

env

[°C]

Please refer to the manuals of the Inline terminals to find out the load of the logic

supply.

Maximum load on the logic supply (2 A) and on USB (2 x 500 mA) leads to a 100%

power dissipation of 2.7 W:

P

= 1.0 V × IL + 0.7 V × I

V

P

= 1.0 V × 2.0 A + 0.7 V × 1.0 A = 2.7 W

V

USB

This power dissipation can be maintained up to a maximum environmental

temperature of 40 °C (104 °F). For higher temperatures, the load (P

PERI

and P

USB

must be reduced according to Fig. 3.2.2.3.

)

Example 1: Horizontal mounting position

For an environmental temperature of 55 °C (131 °F) and horizontal mounting, the

power dissipation is limited to 87 %, which means 2.35 W. Supposed I

loaded with the max. allowed 2 A, then the USB ports can support a maximum of

0,5 A:

I

USB

0.87 P

=

– 1 V × I

V

0.7 V

L

2.35 W – 2 W

I

USB

=

0.7 V

= 0.5 A

Manual SCA-340 / SCA-340-L sysmik.de 19

is fully

L

Installation and Commissioning

Example 2: Other mounting positions

For an environmental temperature of 45 °C (113 °F) and non-horizontal mounting,

using additionally a USB device with 200 mA, the power dissipation is limited to

70 %, i.e. 1.89 W. Therfore, the max. current from U

0.7 P

I

=

L

– 0.7 V × I

V

1.89 W – 0.14

I

=

L

1 V

1 V

USB

W

= 1.75 A

is:

L

3.2.2.5 Protective Devices of 24 V Main and Segment Supply U

Surge / overvoltage: Input protective diodes (can be destroyed by permanent

overload).

Polarity reversal: Parallel diodes. In case of wrong polarity a high current is flowing

which is blowing the external fuses.

Segment supply and main supply are related to the same ground potential.

Note: Each 24 V voltage supply must be fused externally. The power supply unit must be

capable of supplying a current four times the nominal value of the external fuse to reliably

blow the fuses in case of an error.

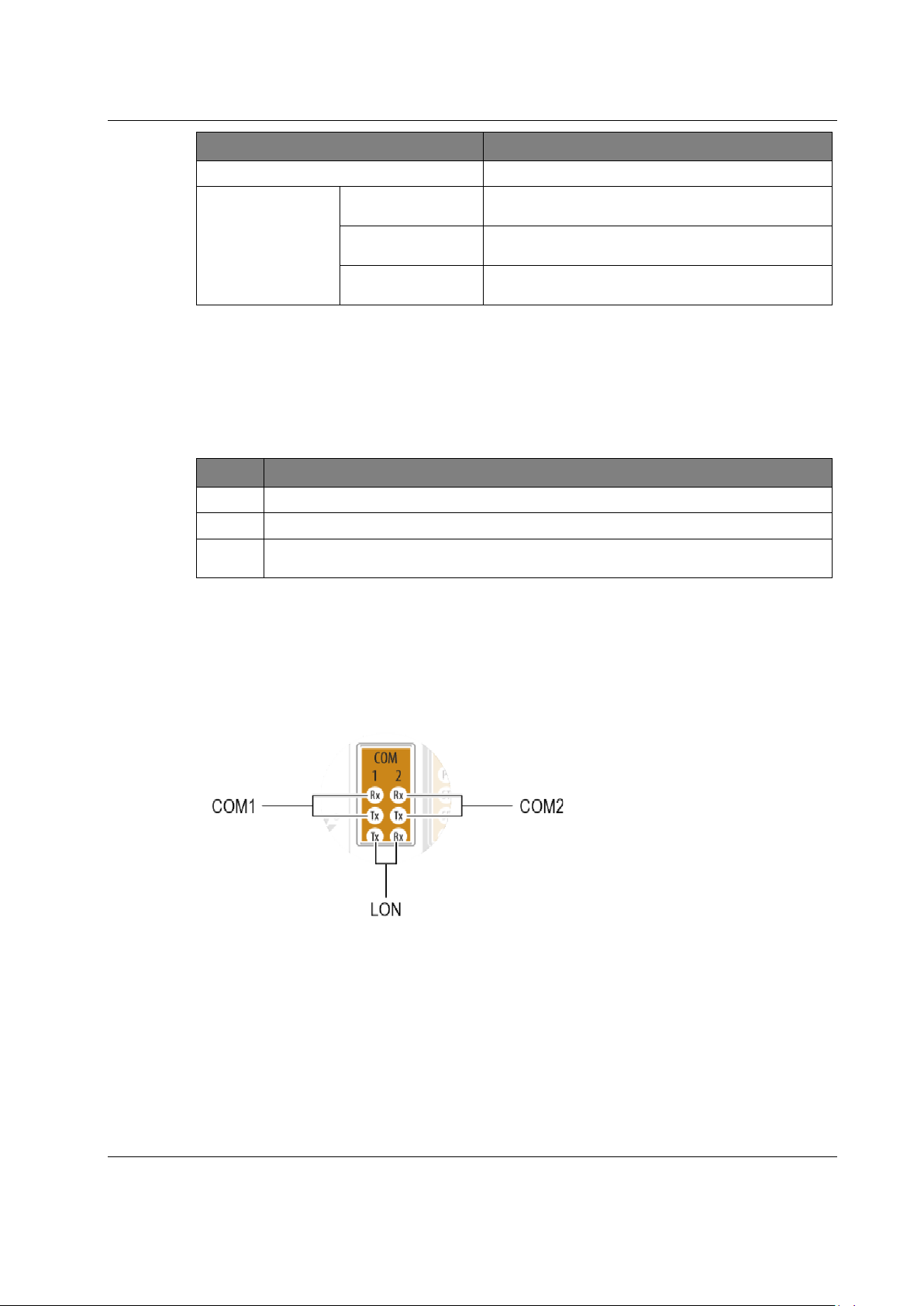

3.2.3 RS-485 and LON

The interface connector provides terminals for both RS-485 interfaces and (for

SCA-340-L only) the LON TP/FT-10 interface.

and US

M

Fig. 3.2.3.1: RS-485/LON Interface terminal connections

20 sysmik.de Manual SCA-340 / SCA-340-L

Installation and Commissioning

Terminalpoint

1.1

COM1 +

COM1 RS-485 data signal + positive

1.2

COM1 -

COM1 RS-485 data signal - negative

1.3

SH1

COM1 shield

2.1

COM2 +

COM2 RS-485 data signal + positive

2.2

COM2 -

COM2 RS-485 data signal - negative

2.3

SH2

COM2 shield

1.4

NT1

2.4

NT2

Name Function

LON TP/FT-10 (SCA-340-L only), polarity independent

Fig. 3.2.3.2: Terminal assignment of interface connector

For RS-485 the proper polarity has to be observed, and bias and termination

resistors have to be chosen properly. Scalibur has fitting built-in-resistors, which can

be used via DIP switches. The shield connections are internally capacitive

connected to FE (functional earth).

The connection is pluggable and includes two terminal points connected inside the

plug for each bus line. Thus the TP/FT-10 bus can be wired in one line without

additional terminals and the ICS can be removed without bus interruption.

While connecting L

ONWORKS technology based devices to the bus, the LONMARK

wiring guidelines [3] must be observed. According to the network topology one or

two network terminators such as SysMik ACC-BT have to be attached. If shielded

cables are used, the shield can be connected to the SH connector in order to avoid

electrostatic charging. The data bus is polarity independent. More detailed

information can be found in the manual of the used transceiver [2].

3.2.4 Ethernet

The Scalibur provides four Ethernet ports with built-in switch and the following

properties:

shielded RJ45 connectors

10/100BaseT, automatic detection

automatic MDI/MDI-X crossover detection

Figure 3.2.4.1: Terminal assignment of Ethernet port

Manual SCA-340 / SCA-340-L sysmik.de 21

Installation and Commissioning

The 10/100BaseT-Ports are able to recognize and to correct an interchanged

receive path pair (RD+/RD-). Thus either crossover or patch cable can be used, no

matter if the remote station is another end device, a switch or a hub.

Note: The maximum distance of 100 m between Ethernet devices can only be achieved

using cables from category 5 on.

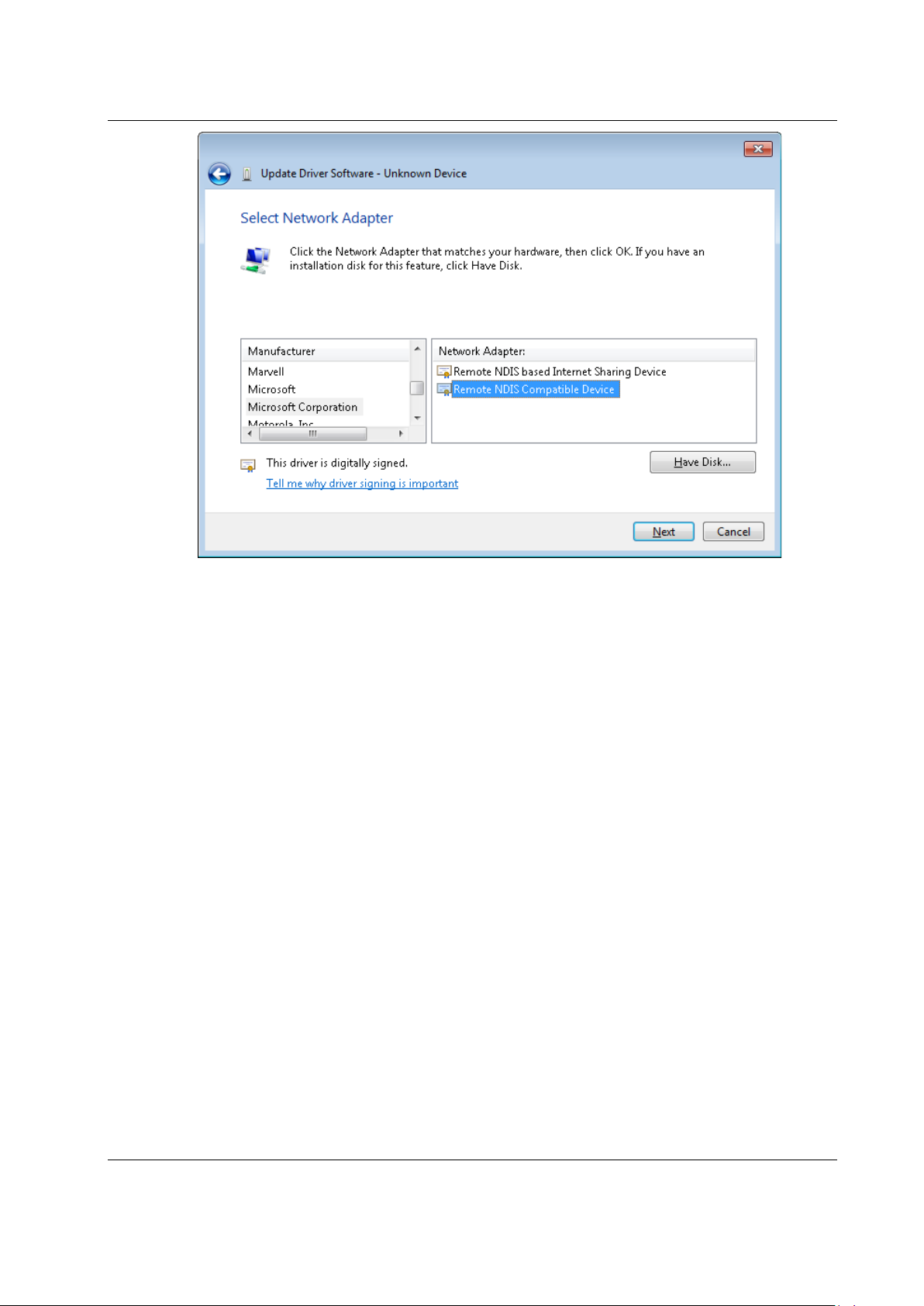

3.2.5 USB-OTG for local Access

The local access is a connection between Scalibur and a PC, which works

regardless of the device settings (especially IP address). Simply connect a Windows

PC to the Scalibur with a standard Mini USB cable.

Installation of PC driver

With Scalibur Operating System 1.01.0 or newer, the PC driver software is

automatically installed (Windows 8.1, Windows 10).

For older Scalibur Operating Systems or when using Windows 7, the proper driver

has to be selected manually as follows:

If you connect the Scalibur to your PC for the first time, Windows detects a new

device and shows this in the Device Manager as “RNDIS/Ethernet Gadget” below

“Other devices”.

select “Update driver software…” in the local menu of the device entry

chose “Browse my computer for driver software”

chose “Let me pick from a list of device drivers on my computer”

select “Network adapters” as device type

select “Microsoft Corporation” as manufacturer and “Remote NDIS

Compatible Device” as network adapter and click “Next”

pass warning “Update driver warning” with “Yes”

close the notification window after successful device driver installation

1

1

If the device is detected as a serial COM device instead, we recommend a firmware

upgrade of the Scalibur. If that is not feasible, please contact SysMik for an alternative

solution of the driver installation.

22 sysmik.de Manual SCA-340 / SCA-340-L

Fig. 3.2.5.1: Selecting device driver

Installation and Commissioning

The Scalibur is now located under „Network adapter“ as „RNDIS/Ethernet Gadget“.

This acts as additional network interface, which provides a local network access to

the Scalibur.

3.2.6 USB

The USB type A socket accepts USB end devices according to the standard

USB 1.0 and USB 2.0. Beside this, the device must also be supported by software

(esp. driver).

Manual SCA-340 / SCA-340-L sysmik.de 23

Installation and Commissioning

3.3 Operating Elements

3.3.1 Overview

Fig. 3.3.1.1: Front view with display and operating element s

3.3.2 Inline Supply LEDs “US”, “UM”, “UL”

LED State Description

US

UM

UL

Table 3.3.2.1: Inline supply LEDs

green voltage at segment circuit (+24 V DC)

off no voltage at segment circuit

green voltage at main circuit (+24 V DC)

off no voltage at main circuit

green U

off UBK, UL not OK

(24 V supply), UL (logic supply) OK

BK

3.3.3 Process Status LEDs “PL”, “ST”, “SE”

LED Description

PL status of Niagara Platform

ST status of Niagara station

SE status of Sedona Virtual Machine, incl. IO-server

Table 3.3.3.1: Process status LEDs

In normal operation, all three LEDs are using the same signalizing method.

24 sysmik.de Manual SCA-340 / SCA-340-L

Installation and Commissioning

The process is running and needs less than

10 % of processor time.

The process is running and needs between 10 %

and 50 % processor time.

The process is running and needs more than

50 % processor time.

Communication with the Inline Terminals is not working. Possibly, there are no

terminals attached or the terminals are not snapped-in properly.

LED status Description

off The process has not been started.

10 % on time

blinking yellow

(2 s period)

Table 3.3.3.2: Process status LED behavior

50 % on time

90 % on time

During a software update, the process status LEDs signalize the programming

process as a running light.

3.3.4 IO Status LED “IO”

The communication state of the IO terminals is signalized by a dual colored “IO”

LED, located at the supply connector.

State Description

off The IO server is not running.

green Communication with Inline terminals is OK.

red

Table 3.3.4.1: IO status LED

3.3.5 Communication LEDs “COM1”, “COM2”, “LON”

Located at the interface connector, the Scalibur has LEDs which signalize the data

transmission of their respective interface. The layout of the LEDs resembles the

layout of the terminals: COM1 upper left, COM2 upper right, and LON below (only

SCA-340-L).

Fig. 3.3.5.1: COM LEDs

Manual SCA-340 / SCA-340-L sysmik.de 25

Installation and Commissioning

LED state

Description

Time slice of about 2 s after booting; allows manual reset of IP

address and Niagara Platform access credentials to state of delivery.

Time slice of about 2 s after red blinking; allows manual reset of

Sedona application and kits to state of delivery.

LED State Description

COM1 Rx green Data are being received via COM1.

COM1 Tx yellow Data are being sent via COM1.

COM2 Rx green Data are being received via COM2.

COM2 Tx yellow Data are being sent via COM2.

LON Rx green Data are being received via LON (only SCA-340-L).

LON Tx yellow Data are being sent via LON (only SCA-340-L).

Table 3.3.5.1: Inline supply LEDs

3.3.6 Service Button and LED “SV”

off normal operation and for about 7 s after power-on

red booting, approx. 7 s

blinking red 5 Hz

blinking green 5 Hz

Table 3.3.6.1: Service LED

How to reset IP address, access credentials, and Sedona

The Service button can be used in interaction with the Service LED to manually

reset IP address, Niagara Platform access credentials, Daemon HTTP Port,

Daemon HTTPS Port, and Sedona to the state of delivery.

If the Service button is pressed when the Service LED is blinking red, and is held

pressed for at least 3 s, the IP address of eth0 and the Niagara Platform credentials

are reset to the state of delivery.

If the Service button is pressed when the Service LED is blinking green, and is held

pressed for at least 3 s, the Sedona app and Sedona kits are reset to the state of

delivery.

3.3.7 Ethernet Status LEDs

Each Ethernet port has two LEDs to signalize its link and communication state.

Fig. 3.3.7.1: Ethernet status LEDs

26 sysmik.de Manual SCA-340 / SCA-340-L

LED State Description

Installation and Commissioning

Speed

Link

Table 3.3.7.1: Ethernet port LEDs

yellow 100 Mbps

off 10 Mbps (if link is active)

green electrical connection to network

short off packet transmission

permanent off no electrical connection to network

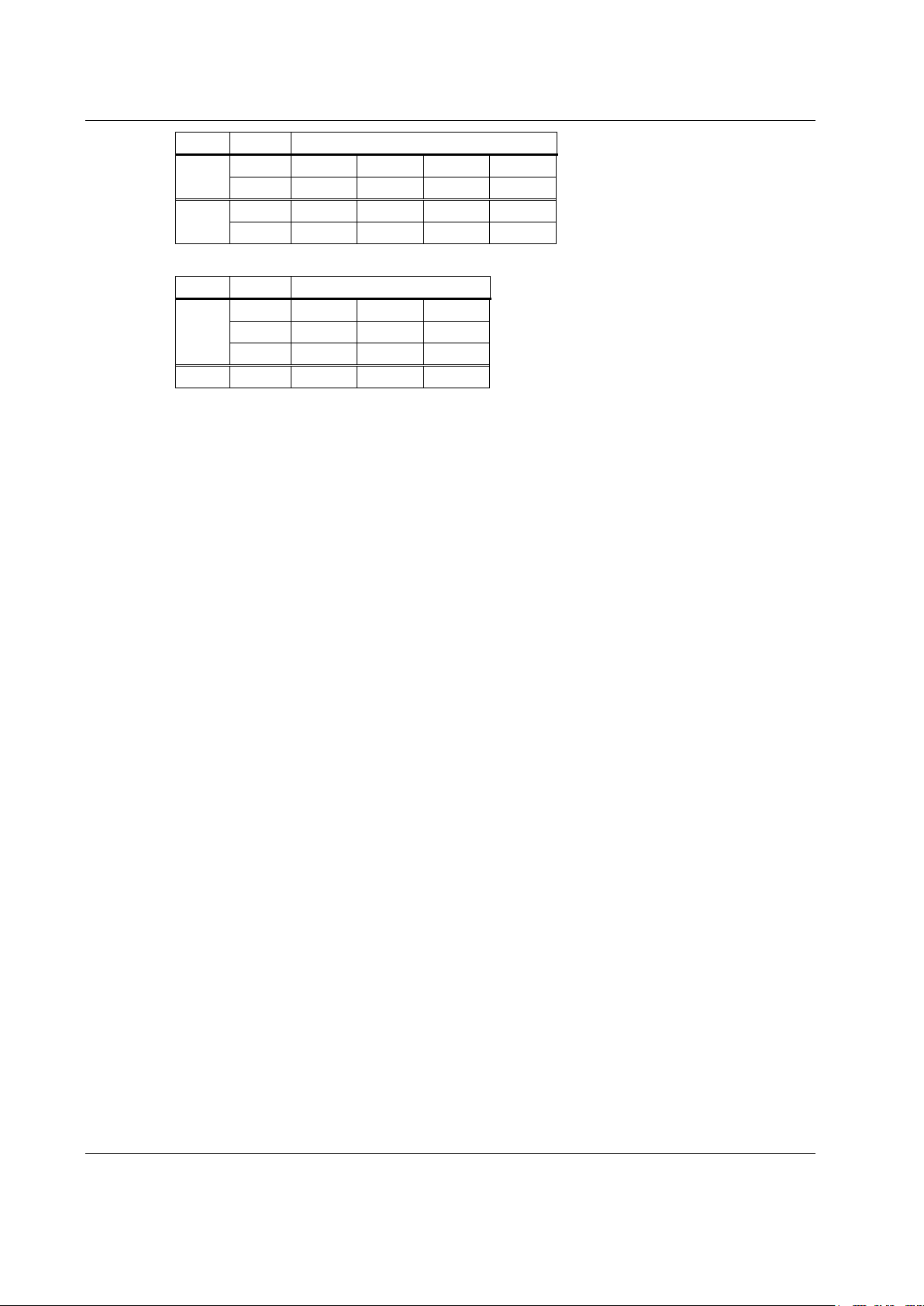

3.3.8 RS-485 Termination

RS-485 networks are using bus topology and are terminated at both ends with a

termination resistor. Additionally, the data lines are pulled once with bias resistors to

a defined idle state. The Scalibur has built-in resistors for termination (120 Ω) and

biasing (510 Ω) of COM1 and COM2, according to the BACnet MS/TP specification.

Each resistor can be separately activated via DIP switches.

Fig. 3.3.8.1: Assignment of DIP switches to RS-485 termination

Manual SCA-340 / SCA-340-L sysmik.de 27

Software

4. Software

Note: Scalibur factory defaults

Ethernet eth0 – LAN3 / LAN4: 192.168.1.1 / subnet mask 255.255.255.0

eth1 – LAN1 / LAN2: disabled

Platform-Credentials: sysmik / intesa

Sedona-Credentials: admin / no password (after Sedona activation)

Fig. 9.1: Login

4.1 Configuration Tools

Fundamental device settings are vital to the device operation and should be

protected carefully. To prevent unwanted accesses from the network while offering a

stable configuration access, which is independent of the current IP settings, the

Scalibur offers a local access via USB-OTG (see chapter 3.2.5).

The connected PC is getting another virtual network adapter, which is connected to

the Scalibur and is automatically receiving IP settings from the Scalibur DHCP

server. The IP address of the Scalibur is 172.16.0.10 in this virtual network.

28 sysmik.de Manual SCA-340 / SCA-340-L

The local access offers several services and protocols to the PC for configuration

and diagnosis.

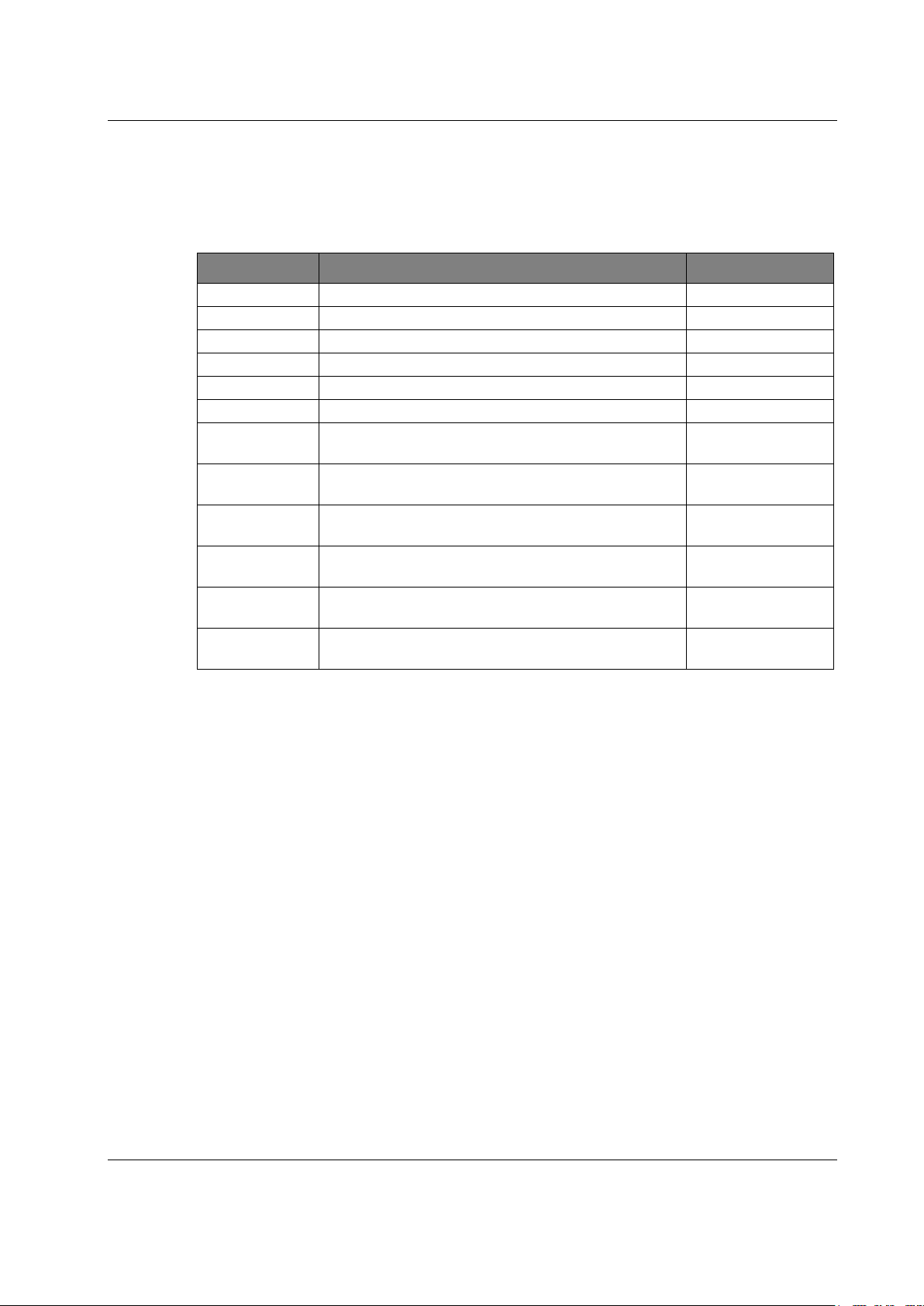

Protocol Port PC-Software Application

Telnet 23 Telnet client SCA system shell

HTTP 8080 Web browser commissioning website

Table 4.1.1: Protocols of local access

4.1.1 SCA System Shell

The SCA System Shell allows to configure fundamental settings of the Scalibur. To

this end, the PC is connected via USB-OTG to the Scalibur and then a Telnet client

is used on the PC to establish a Telnet session with the Scalibur (address

172.16.0.10 / port 23).

The SCA System Shell shows host ID, version information of several software

components, the current time, and the IP addresses of the Scalibur. A numberbased menu allows to perform different actions:

1. Update System Time configure current system time

2. Update IPv4 Settings configure IP addresses

3. Update IPv6 Settings configure IPv6 addresses

4. Switch Configuration configure the Ethernet switch (Ethernet

5. Ping IPv4 Host ping an IP address from the Scalibur

6. SSH/SFTP usage start/stop SSH/SFTP server

7. Sedona/Niagara Enable activate/deactivate Niagara and Sedona

8. IO Server configure IO server (port number,

9. Sedona Factory Default reset Sedona app and Sedona kits to

10. Reset Platform Credentials reset Platform credentials to default

11. Reboot reboot Scalibur

x. Exit exit Telnet session

Software

port assignment to IP interface, RSTP,

ring monitoring, broadcast storm

protection)

remote address)

state of delivery

(user sysmik / password intesa /

Daemon HTTP Port 3011 / Daemon

HTTPS Port 5011)

4.1.2 Commissioning Website

The commissioning website allows to configure the Scalibur and to access data

points of connected IO terminals.

To this end, a PC is connected via USB-OTG to the Scalibur and the following URL

is entered in the address field of the web browser:

172.16.0.10:8080

Manual SCA-340 / SCA-340-L sysmik.de 29

Software

The page Overview shows host ID and version information of several software

components.

Page Settings allows to configure several settings:

Network to configure IP addresses

Webserver to configure the port at which the restricted webserver (without

device settings) is accessible

Date/Time to configure current time and time zone

IO Server to configure the IO server (port number, remote access)

Run to activate/deactivate Niagara and Sedona

Switch to configure the Ethernet switch (Ethernet port assignment, RSTP,

ring monitoring, broadcast storm protection)

On the page Terminals, the data points of the connected IO terminals can be

observed and manually overridden (see 4.2.3).

The webserver hosts further web pages, which are alternatively also available via

Ethernet:

DALI configurator to assign addresses to DALI ballasts (connected via

DALI terminals) and configure them

User defined visualization pages, which are created using Sedona

programming [4].

4.1.3 File Access via FTP

The Scalibur has an SFTP server to access the file system. This can be used to

load software updates from the PC to the Scalibur. The SFTP server can only be

activated and deactivated from the SCA System Shell (see chapter 4.1.1). A

password for the user “sftpuser” can be defined.

In parallel to SFTP an SSH server can be activated. It can be used for command

line based diagnosis of the controller by the manufacturer only.

4.2 Commissioning Scalibur

Scalibur comes with a default configuration and settings like IP addresses, time,

time zone, and others have to be specifically configured.

The following Scalibur functions are active:

The SCA System Shell expects input.

The IO server detects the connected IO terminals and opens its interface

for commissioning website, Sedona, and Niagara.

The commissioning webserver hosts the commissioning website.

The Niagara daemon is ready for a Platform connection with Workbench

(user sysmik / password intesa). Though there is no station running – these

can be loaded later during the Niagara commissioning.

Changing IP addresses or time zone becomes effective only after reboot.

30 sysmik.de Manual SCA-340 / SCA-340-L

4.2.1 IP Addressing

Scalibur’s default IP address of the primary IP interface (eth0) is 192.168.1.1, the

subnet mask 255.255.255.0. The secondary IP interface (eth1) is deactivated by

default. There are several ways to configure the IP settings:

SCA System Shell (see 4.1.1)

Commissioning website via Settings/Network (see 4.1.2)

Workbench via Platform connection with the Niagara daemon under TCP/IP

Configuration

4.2.2 Time and Time Zone

The internal time is derived from a buffered RTC. At delivery the buffer capacitor is

usually discharged and the time at the first start of the Scalibur is set to midnight

2000-01-01. Time and time zone (default Central European Time CET or Central

European Summer Time CEST) can be configured in several ways:

SCA System Shell (see 4.1.1)

Commissioning website via Settings

Workbench via Platform connection with the Niagara daemon under

Platform Administration

4.2.3 Hardware Data Point Test

Usually, the electrical connection and the software integration of control stations are

done by different persons and at different times. Ideally, the electrical installation

(mounting and cabling) should be finished with a data point test and its according

documentation. This is supported by the commissioning webserver, which clearly

visualizes all input and output signals of the IO terminals. If required, output

channels and also their configuration, like measuring ranges, can be manually

overridden. Thus, a data point test doesn’t need any application software. By leaving

the commissioning page (either manually or by timeout), all overrides are reverted.

Date/Time (see 4.1.2)

Change Date/Time

Software

Manual SCA-340 / SCA-340-L sysmik.de 31

Software

Table 4.2.1: Testing data points via commissioning webpage

32 sysmik.de Manual SCA-340 / SCA-340-L

4.3 Ethernet Switch for Flexible Network Topologies

LAN1

LAN2

LAN3

LAN4

LAN1

eth1

LAN2

LAN3

LAN4

The integrated Ethernet switch with four external and two internal ports, allows

Ethernet cabling without additional switches. It supports:

free assignment of IP interfaces to external Ethernet ports

ring monitoring with automatic port deactivation

Rapid Spanning Tree Protocol (RSTP) to manage redundant Ethernet

topologies

throtteling of Ethernet traffic to prevent multicast and broadcast storms

The Ethernet switch can be configured here:

SCA System Shell (see 4.1.1)

Commissioning Website (see 4.1.2)

WorkPlace via Fox connection with Niagara Station under

Config

(SysmikScaSwitchCfgView)

When using ring monitoring or RSTP, the status of the respective ports (activated,

deactivated) is changed automatically. The port status information shows the state

of the redundant topology. The state of the external Ethernet ports is provided in the

Niagara Station, in the Sedona Application, and on the Commissioning Website.

Factory default:

RSTP deactivated

ring monitoring deactivated

Broadcast/Multicast throtteling: 1Mbps

eth1on ports LAN1, LAN2

eth0 on ports LAN3, LAN4

DriversSysmikScaIoNetworkLocalPlatformEthSwitch

Software

4.3.1 Assignment of IP Interfaces to External Ethernet Ports

The Ethernet Switch connects the two internal IP interfaces eth0 and eth1 with the

external Ethernet ports. Fig. 4.3.1.1 to Fig. 4.3.1.4 show the possible combinations.

eth0

Fig. 4.3.1.1: LAN1-4 on eth0, eth1 deactivated

eth0

Fig. 4.3.1.2: LAN2/3/4 on eth0, LAN1 on eth1

Manual SCA-340 / SCA-340-L sysmik.de 33

Software

LAN1

LAN2

LAN3

LAN4

LAN1

LAN2

LAN3

LAN4

eth0

eth1

eth0

Fig. 4.3.1.3: LAN3/4 on eth0, LAN1/2 on eth1 (factory default)

eth1

Fig. 4.3.1.4: LAN4 on eth0, LAN1/2/3 on eth1

If an IP interface has more than one Ethernet port assigned to it, the IP interface is

accessible on each of these ports. Also, Ethernet traffic is forwarded between these

ports, so that several devices can be linked in a line-topology (see Fig. 4.3.1.5).

Between Ethernet ports that do belong to different IP interfaces there is no Ethernet

traffic (i.e. these ports are completely separated at Ethernet level).

Fig. 4.3.1.5: Example of Ethernet wiring

34 sysmik.de Manual SCA-340 / SCA-340-L

4.3.2 Ethernet Ring Monitoring

eth

LAN

RSTP configurations

1

A)

2

A)

3

B)

4

B)

eth

LAN

RSTP configurations

1 1 0 2

3

4

Ethernet ports LAN3 and LAN4 allow to build an Ethernet ring, provided both ports

belong to eth0. The Ethernet ring connects Ethernet field devices with integrated

unmanaged switch (with at least two Ethernet ports, like SysMik's SCC devices) and

ensures Ethernet communication even when one connection in the ring is broken

(see Fig. 4.3.1.5).

If the ring is completely closed and the involved switches are unmanaged ones, a so

called broadcast storm is likely to occur: because broadcast and multicast

messages are always forwarded, they circulate in the ring and create high traffic

load. The Ethernet ring monitoring observes always the state of the ring and

deactivates LAN4 when the ring is faultless. If the ring connection is broken at one

point, LAN4 is activated.

Note: The time for complete recovery of the communication in the ring is defined by the

aging-time of the switches in the ring.

4.3.3 Rapid-Spanning-Tree-Protocol (RSTP)

The Rapid-Spanning-Tree-Protocol allows to build arbitrary redundant Ethernet

structures, also beyond simple ring structures, by detecting redundant paths in the

system and disabling them as long as they are not needed. As soon as a connection

is broken it will be replaced by a redundant path (provided there is one). RSTP

needs just a few seconds to re-establish a broken connection.

Software

Note: Inside an RSTP structure, all involved Ethernet switches must support RSTP and must

be adequately configured.

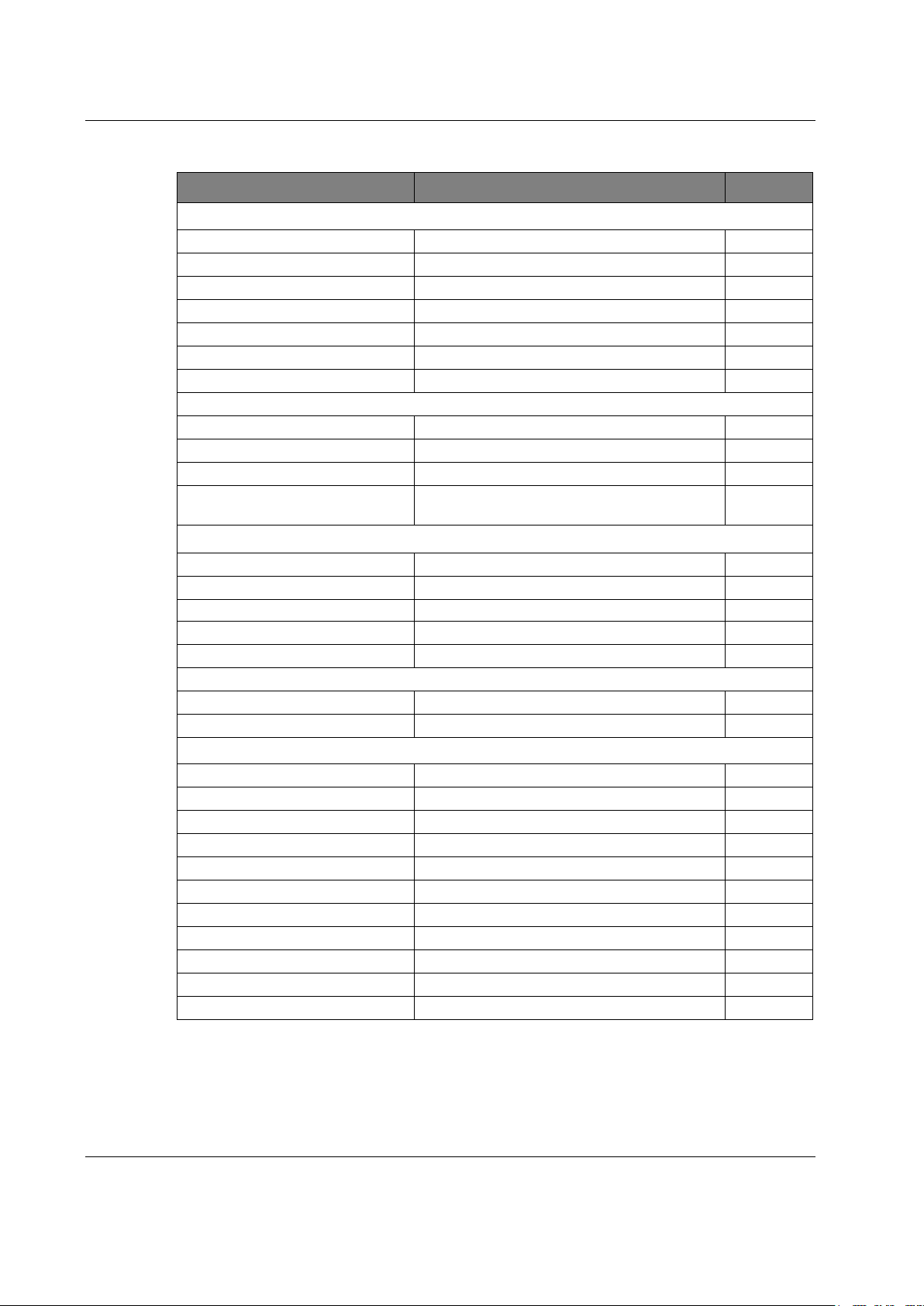

Tables 4.3.3.1 to Table 4.3.3.4 show the possible combinations regarding RSTP. A

LAN port can be configured for RSTP if there is at least one further LAN port

assigned to the same IP interface.

0

A), B)

RSTP topologies independent of each other

Table 4.3.3.1: LAN1-4 at eth0, eth1 deactivated

Table 4.3.3.2: LAN2/3/4 at eth0, LAN1 at eth1

Manual SCA-340 / SCA-340-L sysmik.de 35

Software

eth

LAN

RSTP configurations

1

2

3

4

eth

LAN

RSTP configurations

1

2

3

0 4

1

0

Table 4.3.3.3: LAN3/4 at eth0, LAN1/2 at eth1 (factory default)

1

Table 4.3.3.4: LAN4 at eth0, LAN1/2/3 at eth1

4.3.4 Port Status Informations

If ring monitoring or RSTP is active, then the state of the external Ethernet ports is

available in the Niagra station, the Sedona application, and the Commissioning

Website. This allows to check whether the redundancy of a topology is still intact.

When a path gets disconnected, formerly inactive ports will be activated, which can

be signalized.

Sedona PlatformService Lan1State…Lan4State: Boolean

true = FORWARDING

false = BLOCKING

null = no current information available (RSTP or loop not active)

Niagara Station Config

Lan1State…Lan4State: Status Boolean

true {ok} = FORWARDING

false {ok} = BLOCKING

xxx {stale}: no current information available (RSTP or loop not active)

xxx {disabled}: status check disabled (configurable via

Config

DriversSysmikScaIoNetworkLocalPlatformEthSwitch.Enabled)

DriversSysmikScaIoNetworkLocalPlatformEthSwitch

4.3.5 Broadcast Storm Protection

36 sysmik.de Manual SCA-340 / SCA-340-L

Broadcast storm protection limits the traffic rate for multicast and broadcast packets.

Configurable values are 0.032 / 0.05 / 0.1 / 0.5 / 1 (factory default) / 2 / 5 / 10 / 20

Mbps. This setting applies to all four ports.

Even with ring monitoring and RSTP, redundant paths can't be completely avoided.

From detecting a topology change it takes several seconds until the reorganization

is completed. In this period a broadcast storm can develop, which might interfere

with the management messages for the reorganization, thus effectively preventing a

proper reorganization. The broadcast storm protection function limits the traffic load

of broadcast and multicast messages and terminates broadcast storms.

4.4 Real-Time Control with Scalibur and Sedona

Sedona allows to program control applications, which run with configurable cycle

times. Sedona must first be activated from the SCA system shell (s. 4.1.1) or the

commissioning website (s. 4.1.2). Niagara Workbench is used as engineering tool.

The programming follows a component-based approach: The application consists of

components, which are parameterized and connected with each other. With the

textual programming language Sedona (similar to C++ and Java), it is even possible

to create own Sedona components. An introduction to Sedona offers [4], while

further, more detailed information can be found in [6].

4.4.1 IO Access

Hardware data points can be accessed via the terminal components of the

SysMikScaIo kit. There is a component for each terminal type with its specific slots,

that allow to access inputs and outputs and to parameterize the terminal.

The component ScaIo works as folder, into which the hardware related components

are added. Furthermore, it provides an Action Restart IO to restart the IO server.

Each terminal component has a property Terminal, which defines the terminal

position. The first terminal directly at the Scalibur has position 1, and so on. Some

terminal components contain further parameters (e.g. measuring ranges for analog

input terminals) or actions (e.g. counter initialization of pulse metering terminals).

Software

Table 4.4.1: PropertySheet view of a terminal component

4.4.2 Modbus

Via Platform Service, a Modbus TCP server can be started for the Sedona Virtual

Machine, which hosts the following data points:

10,000 coils (digital outputs)

10,000 discrete inputs (digital inputs)

10,000 holding registers (analog outputs)

10,000 input registers (analog inputs)

The Sedona application has access to these data points via components of the kit

SysMikModbusServer.

Additionally, with components of the kit SysMikModbusClient, the Sedona

application can act as Modbus TCP client or Modbus RTU master to read and write

data points of remote Modbus devices.

Manual SCA-340 / SCA-340-L sysmik.de 37

Software

4.4.3 Platform Service

The platform service (SedonaAppserviceplat) is a mandatory element of any

Sedona application and allows device specific configurations:

Timezone – time zone, e.g. Europe/Berlin

IP-Addressing

- Ip Addressing – static or DHCP

- Ip Address

- Ip Net Mask – subnet mask

- Ip Gateway – gateway address

- Ip Dns1, Ip Dns2, Ip Dns3 – Domain Name Server

Sntp Address – SNTP server address

Modbus TCP server

- Modbus Port (0 to deactivate Modbus server)

- Unit-ID

Modbus RTU

- Modbus Rtu Enabled

- Modbus Rtu Baud

- Modbus Rtu Parity

- Modbus Rtu Stop Bits

Niagara enabled – in case the parallel operation of Niagara and Sedona is

not wanted, Niagara can be deactivated or again be enabled

IoPort – TCP port number of the IO server

IoRemoteAddr – to prevent an unwanted remote control of Scalibur IOs by

other Niagara stations, a remote control address can be configured. Default

is empty which blocks remote control completely. It is possible to allow

remote control only for a specific IP address by setting the entry to this

specific IP address. 255.255.255.255 allows remote control from any IP

address..

All configurations require a restart of the Scalibur to become effective.

38 sysmik.de Manual SCA-340 / SCA-340-L

4.5 Integration with Scalibur and Niagara Framework

The Niagara framework contains many communication protocols, which are

automatically available in the Scalibur, too:

BACnet IP, BACnet MS/TP (only at COM1 and COM2), LonWorks IP852, LonMark

TP/FT-10 (only SCA-340-L), Modbus TCP, Modbus RTU, M-Bus, KNX/IP, SNMP,

oBIX, Sedona and many more. Data points from different sources can be integrated

and connected using these communication protocols. Niagara offers a rich set of

processing and system functions, like trend log, alarming, scheduling, web

visualization, report generators, and interfaces to e-mail, SMS, data bases and

other. All the engineering is done with a single tool – Workbench.

4.5.1 Local IO Access

The components of the module sysmikScaIo allow to access the IO terminals. This

follows consequently the approach of the Niagara Driver Framework (Network –

Device – Point): SysMikScaNetwork – Terminals – Data points (IO channel).

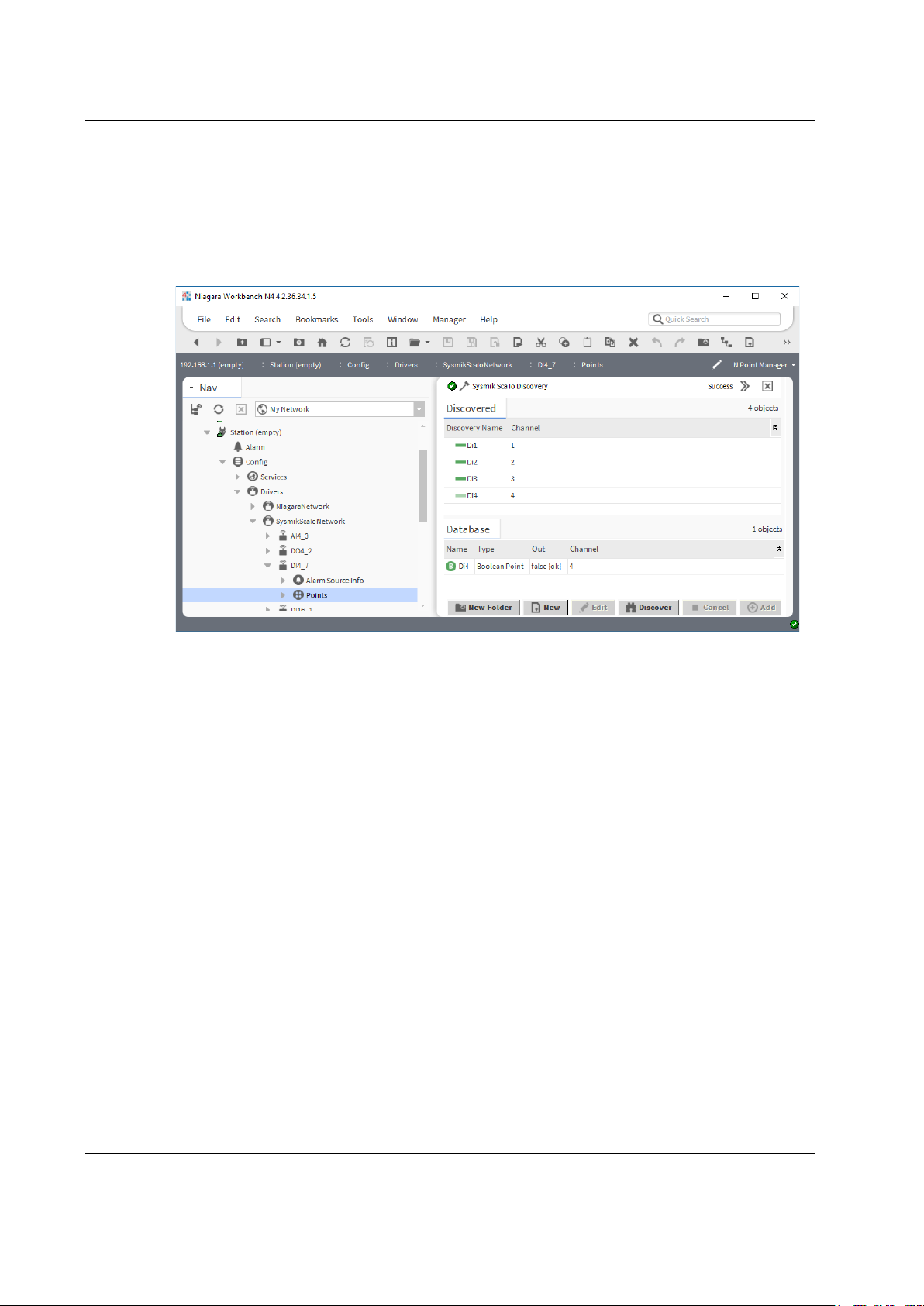

From the Driver Manager, the default view of Station

SysmikScaIoNetwork is created via New.

In the N Device Manager, the default view of the SysmikScaIoNetwork, the

connected terminals can be detected via Discover. The detected terminals can be

inserted to the station via Add.

ConfigDrivers, a

Software

Fig. 4.5.1.1: N Device Manager of the SysmikScaIoNetwork

Manual SCA-340 / SCA-340-L sysmik.de 39

Software

In the N Point Manager, the default view of the points folder, the available IO

channels can be displayed via Discover. These can be inserted as proxy points to

the station via Add. Some data points have specific functions:

Measurement ranges of the analog input terminals can be configured with

the additional property Ai Type of the proxy extension.

Counter values of the pulse metering terminal can be initialized with the

action Init Counter of the proxy extensions.

Fig. 4.5.1.2: N Point Manager of a terminal component

40 sysmik.de Manual SCA-340 / SCA-340-L

4.5.2 Serial Interfaces

The Scalibur has two serial RS-485 interfaces, that are available as COM1 and

COM2 for any serial protocols. All relevant baud rates equal or above 200 baud are

supported.

Further serial interfaces can be added via IO terminals. Universal serial terminals of

type IB IL RS UNI support the interface types RS-232, RS-485, and RS-422, which

can be configured with Workbench via their associated terminal component in

SysmikScaNetwork. IB IL RS 232-ECO and IB IL RS 485-ECO support serial

interfaces types regarding their names. The serial interfaces of the IO terminals can

be used as master for serial protocols except BACnet MS/TP. The supported baud

rates are documented in the data sheets of the terminals.

Terminals of type IB IL MBUS extend the Scalibur by serial interfaces according to

the M-Bus standard for connection of up to 30 M-Bus slaves and are controlled with

the Niagara M-Bus driver.

The interface names of the serial terminals are assigned according to their position,

starting with COM3.

A summary of all serial interfaces, including their current use (owner) is available at

Station/Config/Services/PlatformServices/SerialPortPlatformServiceNpsdk.

Example:

The screenshot shows an overview for a Scalibur controller with 4 serial ports total –

two from the controller itself and two added via serial terminals:

COM1: The first built-in RS-485 interface is used by the MS/TP port of the

BacnetNetwork.

COM2: The second built-in RS-485 interface is assigned to the

ModbusSlaveNetwork.

COM3: The IB IL MBUS terminal at Inline position 7 is used as interface for

the MbusNetwork.

COM4: The IB IL RS UNI terminal at Inline position is used by the

ModbusAsyncNetwork. To this end the property RsType of the terminals

PropertySheet in SysmikScaNetwork is set to RS-485.

Software

Manual SCA-340 / SCA-340-L sysmik.de 41

Software

Fig. 4.5.2.1: SerialPortPlatformServiceNpsdk

Fig. 4.5.2.2: Interface configuration of IB IL RS UNI

42 sysmik.de Manual SCA-340 / SCA-340-L

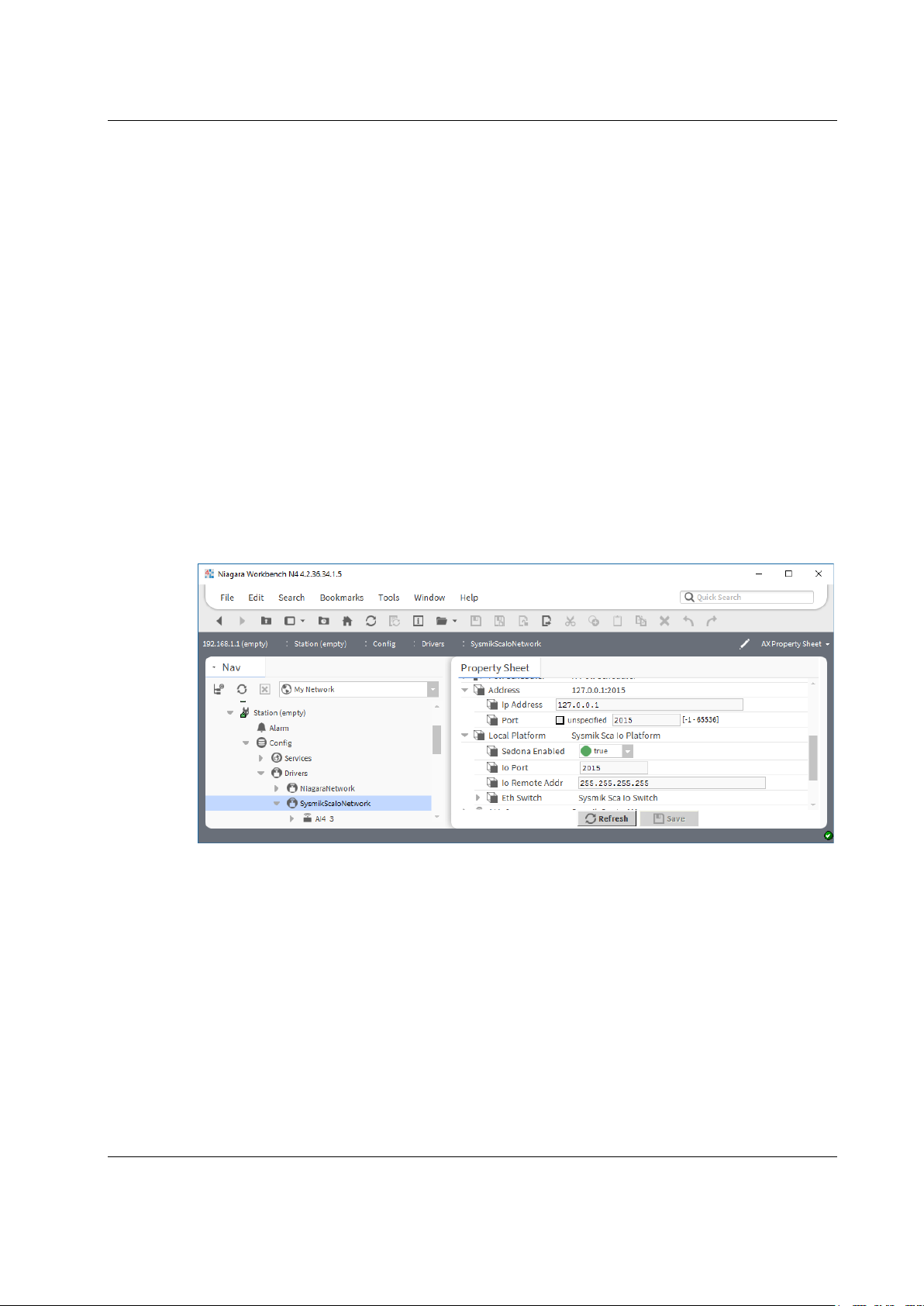

4.5.3 IO Remote Control

The SysmikScaNetwork sets up a TCP connection to an IO server, to access the IO

terminals. The property Address defines address and port of this server. Default is

the local address 127.0.0.1:2015, which establishes contact to the local IO

server. But it is also possible to connect to an IO server of a different device by

configuring its address here.

Fig. 4.5.3.1: Configuration of the IO server to be contacted

To do so the remote access must be activated first. In Workbench an allowed

remote control address can be configured via

Station

ConfigDriversSysmikScaIoNetworklocalPlatformIoRemoteAddr

Software

Address setting Description

invalid address (empty string) remote control deactivated (default)

valid IP address IO server accepts only accesses from this IP address

255.255.255.255 any IP address can access the IO server

Table 4.5.3.1: Address settings for IO server access

Furthermore, the port number of the IO server can be defined via

Station

Fig. 4.5.3.2: Configuration of IO server

ConfigDriversSysmikScaIoNetworklocalPlatformIo Port

4.5.4 Sedona Integration

Data points of the local Sedona application can be added to Niagara via the Sedona

driver. If a parallel operation of Niagara and Sedona is not desired, Sedona can be

deactivated via

Station

ConfigDriversSysmikScaIoNetworklocalPlatformSedonaEnabled

Manual SCA-340 / SCA-340-L sysmik.de 43

Software

Analog output,

DALI-control, float

4.6 Concurrent Access to the IO Terminals

Several software components can access the IO terminals of the Inline system. For

reading input data, this poses no problems. For outputs and configuration however,

the different program parts could work against each other. In order to achieve a

predictable behavior of the IOs, there is a channel-wise priority control.

Each source can set a value with its source-specific priority, or release its access.

This release is using technology specific values:

Type

Digital output, bool auto null null

Measuring range, enum auto auto auto

Table 4.6.1: Release values of priority control

If several sources try to access the same IO channel, the following ranking applies:

Rank Component

1 Commissioning website (i.e. manual override in test mode)

2 Sedona

3 Niagara local access

4 Niagara remote access

Table 4.6.2: Ranking of priority sources

The commissioning website has highest priority. Manual override is always possible

regardless of the other program components. By leaving the commissioning page,

all overrides are automatically released.

Sedona and Niagara components do by default release their priority. Only if they are

configured or connected to other components, the priority is actually used.

Note: Deleting or re-addressing components does not automatically release the

priority of this channel. Of course, a priority could be manually released by setting

explicitly to the release value. Restarting the Scalibur re-initializes (releases) the

complete internal priority array.

Commissioning

website

auto nan (not a number) null

Sedona Niagara

44 sysmik.de Manual SCA-340 / SCA-340-L

Software

Depending on the data point type, the following default values apply if all priorities

are released (that is, no software component accesses this channel):

Type of data point Default value

Digital output – output signal off

Analog output – output signal 0.0 V

DALI control - ballast 0.0 %

Analog input – measurement range 0..10 V, if applicable

Table 4.6.3: Default values of priority control

Some actions have command character. These do not change the priority level, but

are processed in their order of occurrence (or suppressed completely in case of

insufficient priority). Such commands are:

Initialization of counter values of the pulse metering terminal

DALI lighting control commands

Initialization, read and write operations of serial terminals

For these cases it is up to the application programmer to prevent unwanted

concurrent accesses from different sources.

Manual SCA-340 / SCA-340-L sysmik.de 45

Best Practices and Troubleshooting

5. Best Practices and Troubleshooting

5.1 Performance and Resource Management

All software processes share the common resources (processor time, memory).

Besides the complexity of the application itself, the interface definitions, especially

the connected I/O terminals have an important impact on ressource usage. While

each data point needs ressources just by its existence, it is usually also processed

within the application, thus enlarging the application.

Note: All quantitative information given in this chapter are not guaranteed. They may help

you to estimate the load caused by I/O terminals.

I/O terminals

Scalibur can handle up to 63 I/O and function terminals. This is a rather theoretical

limit, which gets relativated by the geometrical size of the station. In general,

stations with more terminals need more time to transfer data between controller and

terminals. Digital input and putput terminals have the least performance impact.

If you connect 63 digital I/O terminals with 32 channels each, the station has 2016

I/O datapoints, while being more than 9 ft. wide. Supply and segment terminals

might enlarge the stations width even further.

IB IL DALI/PWR, IB IL DALI, IB IL DALI/MM

A DALI terminal can adress up to 81 data points (64 short addresses, 16 group

addresses, one broadcast). The ressource demand depends on the number of DALI

ballasts and how they are controlled:

addressing via broadcast (one data point, no status), maybe using scenes

group addressing (some data points, which are written on change only, no

status)

individual addressing (many data points, which are written on change only)

individual addressing with evaluation of ballast status (many data points,

which are polled periodically)

individual or group addressing with additional use of DALI sensors

While e.g. broadcast addressing needs little ressources and would allow the

maximum number of 63 DALI terminals, for a higher load on the DALI terminals no

more than 8 DALI terminals should be used. Especially when using DALI sensors,

the desired reaction time is an important criterion.

IB IL RS UNI, IB IL MBUS, IB IL RS 232-ECO, IB IL RS 485-ECO

These terminals are serial interfaces which can have 30 (MBus) or more slave

devices. The limiting factor is here the required poll rate or reaction time. The hard

limit is 16 serial terminals, but then no other terminals could be added. We

recommend to use 8 terminals at the most.

With Modbus RTU, the max. number of about 4-5 messages per second can be

achieved with one connected terminal IL IL RS UNI. When 8 such terminals are

connected, the poll rate drops to about 2 messages per second (for each terminal).

46 sysmik.de Manual SCA-340 / SCA-340-L

Diagnosis

The available resources can be shown in Workbench using all accesses:

Platform: Platform Administration

Station: Views

Sedona: App

Note: The system load should be below 100 %, because otherwise the relevant timing (cycle

times) can’t be ensured. Optimize in this case your application, i.e. by increasing Sedona

task cycle time or intervals of the Niagara station (e.g. poll intervals). Please be aware that

every kind of communication creates processor load, too – so leave a margin for that.

Resource Manager

serviceplat (see [4])

5.2 Reliability of Nonvolatile Memory

Scalibur contains a highly integrated Flash memory for use in the industrial

temperature range. Physically caused, the reliability is depending on the number of

writes and the environmental temperature: frequent writing of large data blocks

wears out the memory and a high environmental temperature reduces the

guaranteed data retention time.

The stress on the memory depends heavily on the application. Occasional write

accesses due to programming and software upgrades cause writing of large data

blocks to the Flash. However, these are almost negligible in comparison to the

amount of data which is written in regular intervals, like logging of history data or

StationSave.

The write load caused by history data can be shown via

Station

Size and write frequency of history data should be configured in such a way, that

writing of a data recovery block happens less than once a minute.

StationSave should be performed much less than once per hour.

Regarding the environmental temperature, the defined maximum values in chapter

Fehler! Verweisquelle konnte nicht gefunden werden. must not be exceeded

and the mounting position has to be observed (see chapter 3.1.2).

ConfigServicesPlatformServicesDataRecoveryService.

Best Practices and Troubleshooting

5.3 Diagnosis and Troubleshooting

Scalibur is a very complex device with many functions and interfaces. This

complexity leads to many possible misconfigurations in practical use. Most mistakes

arise from connections with other devices or components. Therefore the controller

should not be diagnosed isolated, but in context with the complete system.

Several tools allow to locate possible reasons for failures:

power LEDs (see 3.3.2)

software status LEDs (see 3.3.3)

IO status LED (see 3.3.4)

communication LEDs (see 3.3.5)

diagnosis LEDs of the connected IO terminals

Service LED (see 3.3.6)

Ethernet status LEDs (see 3.3.7)

Manual SCA-340 / SCA-340-L sysmik.de 47

Best Practices and Troubleshooting

Additionally, Niagara provides powerful tools to analyze the communication in

connected automation networks.

Before starting a detailed analysis, make sure that the device is properly wired,

supplied and has finished booting. Check especially

if all IO terminals are properly interlocked and connected by their feather

keys/keyways

if the mounting rail is properly grounded

if the functional earth connector of the device is connected using a 1.5 mm²

(AWG ) wire with the mounting rail via a earthing clamp

if the LEDs UM, US, UL are permanently on

if the power supply voltage is within the allowed tolerance range

A good indicator are the tree software status LEDs (see 3.3.3). Only if they

are regularly blinking, the boot process has finished.

5.3.1 SCA System Shell / Commissioning Website is not accessible

Both of these need an USB cable from the PC USB port to the Mini USB port of the

Scalibur.

Please verify that the cable is not damaged and is properly plugged into both

sockets.

Check if the Device Manager shows the device Remote NDIS Compatible Device is

shown as Network adapter. If not, re-install the device driver (see 3.2.5).

5.3.2 IP Address unknown

The IP addresses of the Scalibur can be shown and modified via the SCA System

Shell or the commissioning website. Both accesses work independent of the current

IP settings via a local USB connection (see 4).

5.3.3 No IP Communication

The command ping allows to test the Ethernet connection between two devices. The

SCA System Shell provides a ping function.

Please check first the proper connection of the Scalibur to the Ethernet using the

Ethernet status LEDs.

Then, the IP addresses and subnet masks of all devices that shall communicate with

each other. Especially ensure unique IP addresses and proper subnet settings.

5.3.4 Unknown Niagara Platform Access Credentials

If the access credentials are lost, they can be reset to their default value (user

sysmik / password intesa) with the Service button (see 3.3.6). The Scalibur has to

be restarted and the Service button must be pressed at the right moment.

48 sysmik.de Manual SCA-340 / SCA-340-L

Best Practices and Troubleshooting

logic voltage ok, error at interface between blinking and previous terminal

(e.g. loose contact, defective terminal, hot-plugging of terminal)

5.3.5 No Platform Connection to Device - Platform Daemon is not starting

If the Platform daemon doesn’t start, it's not possible to connect to the Niagara

Platform of the device. This can be identified by looking at the PL LED (see Table

3.3.3.1): it doesn't blink or ceases to blink about one minute after the start. Possible

reasons and measures:

Daemon HTTP Port is doubly used

The Daemon HTTP Port must not be used by any other system component (e.g. by

the IO server).

Check with the SCA System Shell (see 4.1.1) or the Commissioning Website (see

4.1.2), that there is no other software component (webserver, IO server) is using the

Daemon HTTP Port (default: standard 3011 / secure 5011).

The Daemon HTTP Port can be reset to its default value using the Service button

(see 3.3.6) or the SCA System Shell.

RTC date in invalid range

If the device has no power supply for several days, eg. when in storage, the RTC

can loose its date, which is then set to a random value at start. A date outside the

range of June, 6

Platform daemon.

Set the date with the SCA System Shell to a value inside the above mentioned

range. Check the Operating System version with the SCA System Shell or the

Commisioning Website. If the version is ≤ 1.0.1.2, then the device software needs to

be upgraded. Versions from 1.0.1.3 on will automatically fix a date outside of this

range.

th

2015 to December, 29th 2020 prevents starting the Niagara

5.3.6 Sedona Virtual Machine is not Starting

Sedona must be activated from the SCA system shell (s. 4.1.1) or the

commissioning website (s. 4.1.2). If the Scalibur Sedona files (app.sab and

kits.scode) are corrupted or inconsistent, the SVM cannot start. In this case, a

device connection from Niagara Workbench to the Sedona controller is not possible.

Consequently, Sedona tools cannot be used to fix this situation.

Instead, the Service button offers a way to overwrite these files with default files

(see 3.3.6). The Scalibur has to be restarted and the Service button must be

pressed at the right moment.

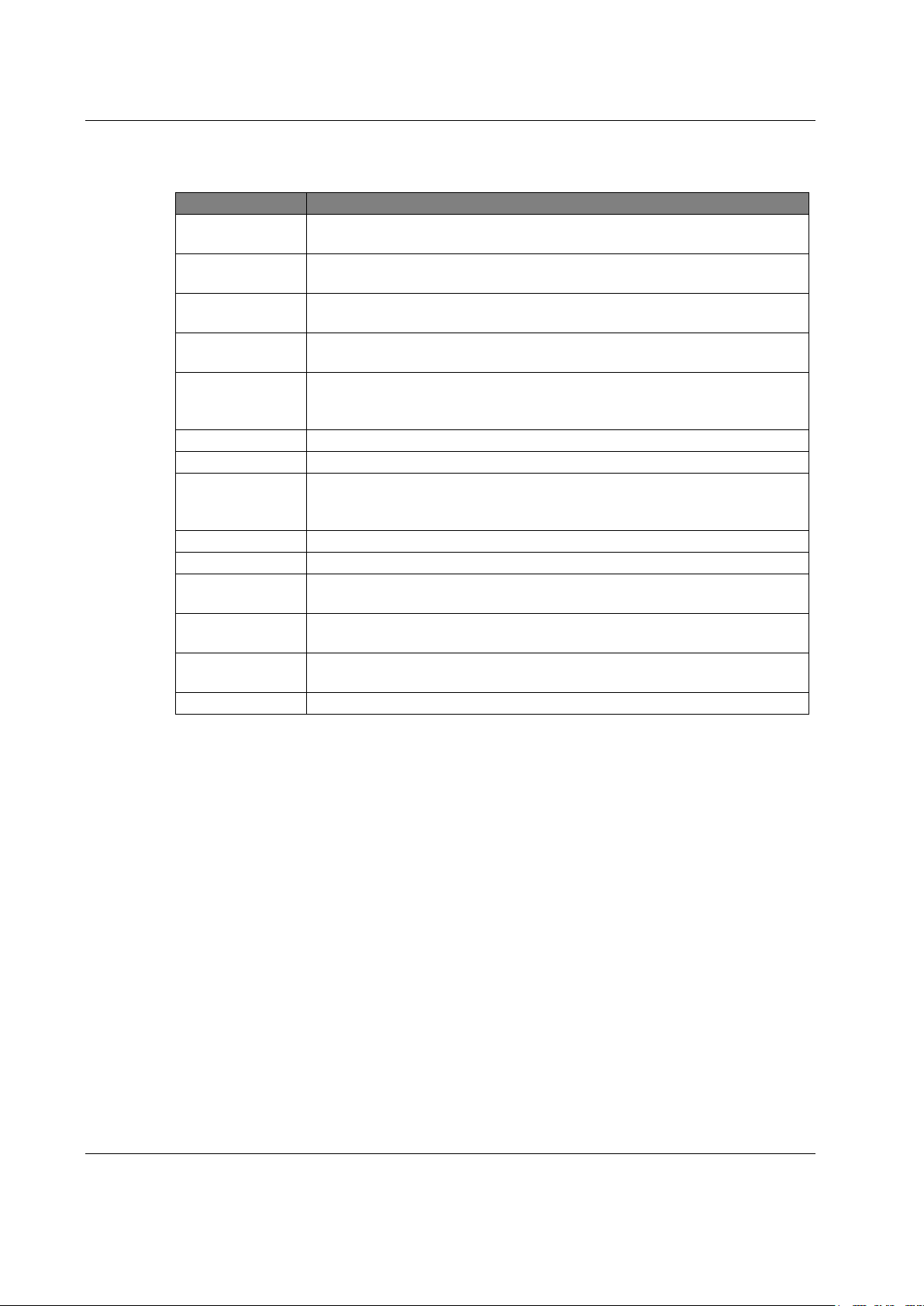

5.3.7 IO Errors

Important indicators for the state of the IO terminals are Scalibur’s IO LED and the

diagnosis LEDs of the Inline terminals (labelled “D”).

State Description

off no logic voltage

on logic voltage ok, local bus active

blinking 0.5 Hz logic voltage ok, local bus not running

blinking 2 Hz logic voltage ok, peripheral error (see manual of specific terminal)

blinking 4 Hz

Table 5.3.7.1: Behavior of diagnosis LED D

Manual SCA-340 / SCA-340-L sysmik.de 49

Technical Data

Processing unit

Processor / clock

ARM® Cortex® A8 32 bit RISC processor 1 GHz

1 GB

(512 MiB for hardware version <06 – see serial label)

eMMC

1.8 GB

NVRAM

512 KiB buffered for 5 days

RTC

buffered for 5 days

Ethernet switch

Connections

4 x 10/100BaseT

MDI/MDI-X crossover

automatic

Aging time

default 330 s

Isolation

LAN1/2/3/4 vs. module

test voltage 1500 V AC, 1 min 1)

LAN vs LAN

test voltage 1500 V AC, 1 min 1)

RS-485 (COM1, COM2)

Max. number of bus devices

256 (1/8 unit load)

Max. data rate

200 kbps

Isolation

RS-485 vs. module

test voltage 500 V AC, 50 Hz, 1 min 1)

RS-485 Port 1 vs. RS-485 Port 2

test voltage 500 V AC, 50 Hz, 1 min 1)

LON TP/FT-10 (twisted pair bus connection for free topology)

Transceiver

TP/FT-10

Isolation

LON vs. module

test voltage 250 V AC, 50 Hz, 1 min 2)

6. Technical Data

DDR3 SDRAM

50 sysmik.de Manual SCA-340 / SCA-340-L

Connecting Inline automation terminals

Max. number of I/O terminals per

Inline station

Max. load of logic supply (UL)

2 A

Max. load of analog supply (U

ANA

)

0.5 A

Max. ampacity of potential routing

contacts UM, US, and GND

Isolation

none

General electrical data

Supply voltage UBK

24 V DC

Absolute limits

19.2 V to 30 V DC

Current drain at nominal voltage without local bus terminals

IBK

≤ 170 mA

Current drain at nominal voltage with local bus terminals (without UM and US)

≤ 1.5 A (7.5 V logic supply loaded with 2 A and 24 V

analog supply with 0.5 A, no USB devices)

Connections

Supply, RS-485, TP/FT-10

Type

Spring-cage terminals

Rated cross section

0.08 mm2 to 1.5 mm2, 24 - 16 AWG

Ampacity

8 A

Ethernet

Type

RJ45, shielded

Enclosure

Width x height x depth

80 mm x 119,8 mm x 71,5 mm

Weight

approx. 230 g / 8 oz

PV [%]

env

63

8 A

100

80

Derating of logic supply and USB

supply, depending on mounting

position