Page 1

May 23, 2008

SECTION 4 ADJUSTMENT

4.1 Flow Cell Disassembly ......................................................... 1

4.2 Optical Alignment (Rough) ................................................... 3

4.2.1 Laser Diode Adjustment........................................................... 4

4.2.2 Installing Condenser Lens Unit No.6........................................6

4.2.3 Flow Cell Position Adjustment.................................................. 9

4.2.4 Beam Stopper Position adjustment.........................................11

4.2.5 Florescence light adjustment (rough)..................................... 12

4.2.6 Preparation of Optical Alignment (fine)..................................13

4.2.7 Procedure for Optical Axis Adjustment Procedure................. 15

4.3 Optical Axis Alignment (Fine) ............................................. 16

4.3.1 Front Scattered Light (Fine)................................................... 16

4.4 Electric Adjustment............................................................. 22

4.4.1 PCB No.1260 ......................................................................... 22

4.4.2 PCB No.6365 ......................................................................... 24

4.5 Sensitivity Adjustment ........................................................ 25

4.6 HGB Blank Convert Value Adjustment ............................... 27

4.7 RBC Clog Level Adjustment............................................... 27

4.8 CP Unit Position Adjustment............................................... 28

4.9 CP Piercer Position Adjustment..........................................30

4.10 Sensitivity Adjustment Procedure (Europe only)..................36

4.10.1 Introduction .............................................................................36

4.10.2 Sensitivity Adjustment for DIFF channel.................................37

4.10.3 Sensitivity Adjustment for WBC/BASO channel......................38

4.10.4 Sensitivity Adjustment for RET channel..................................39

4.11 Count Calibration Procedure (Europe only).........................40

4.11.1 Introduction..............................................................................40

4.11.2 Calibration Overview...............................................................40

4.11.3 Calibration Procedure..............................................................43

4.12 Maintenance Check List......................................................46

4.13 DP Volume Verification........................................................47

4.13.1 SLS DP ...................................................................................47

4.13.2 HGB DP ..................................................................................47

4.13.3 DIFF DP..................................................................................48

4.13.4 RET Diluent DP.......................................................................49

4.13.5 BASO DP................................................................................50

4.12.6 RBC DP...................................................................................50

4.13.7 DIFF Dye DP...........................................................................51

4.13.8 RET Dye DP............................................................................52

XT Series S/M

Page 2

May 23, 2008

4.14 Sensitivity Adjustment for XT-2000iV/XT-1800iV ................ 53

4.14.1 Changed contents .................................................................. 53

4.14.2 Added RET (FSC) discrete setting.......................................... 53

4.14.3 Added Animal frame in DIFF-CH sensitivity screen................ 53

4.14.4 Sensitivity Adjustment procedure (same as XT-2000i/XT-1800i)

........................................................................................................... 54

4.14.5 RET (FSC) discrete setting..................................................... 55

4.15 Rinse Cup Height Adjustment............................................. 56

4.16Adjustment after installing XT RET master .......................... 57

4.16.1 Confirmation of RET channel sensitivity................................. 57

4.16.2 Confirmation of RBC and Hgb by use of SCS-1000............... 57

4.16.3 Confirmation and calibration of RET-He................................. 57

4.17 Position Adjusting of SRV ................................................... 59

XT Series S/M

Page 3

May 23, 2008

SECTION 4 ADJUSTMENT

4.1 Flow Cell Disassembly

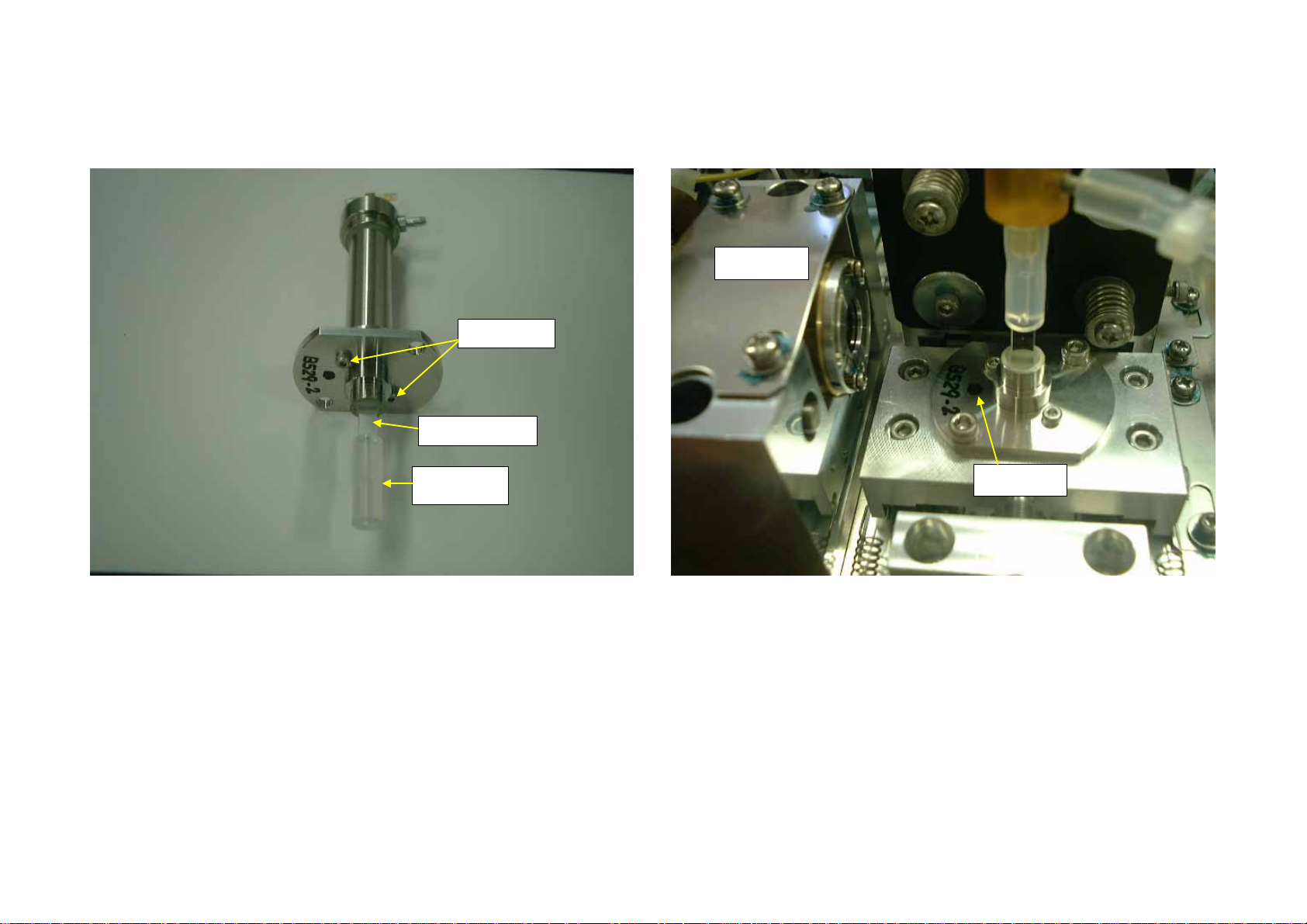

(2) Carefully disconnect lower tubing of the flow cell unit while holding the

T joint because T joint is easily broken. Remove Nipple No.9.

A reference movie for optical alignment has been made as a service

material. This tool is designed to visually show the XT optical alignment

FCM Detector Block

steps from disassembly to optical alignment. To view the movie, click

HERE.

To prevent electrostatic discharge damage, touch the chassis to est ablish

a ground before servicing Optical Unit No.22.

(1) Loosen locking screws and locking nut of the Flow Cell Unit No.10.

Turn Flow Cell adjustment screw CCW so that the Flow Cell can be

easily removed. Remove fixing screws of the Flow Cell Unit No.10.

Nipple

No.9

T Joint

Flow cell unit

No.10

Tubing

Fixing screws

(3) Carefully remove the Flow Cell Unit No.10 from FCM Detector Block.

Locking nut

Flow cell

adjustment screw

Locking Screws

XT Series S/M 4-1

Page 4

May 23, 2008

(4) Remove two fixing screws of the flow cell unit. Cut the Tube Silicone

1.5 X 6 when replacing Flow Cell No.22.

Fixing Screws

Flow Cell No.22

(5) After installing new Flow Cell No.22, install the Flow Cell Unit No.10

facing the black dot to laser diode. After installing, connect tubing as

figure in the previous page.

Laser Diode

Tube Silicone

1.5 X6

Black dot

XT Series S/M 4-2

Page 5

(4) Remove two fixing screws of the flow cell unit. Cut the Tube Silicone

1.5 X 6 when replacing Flow Cell No.22.

Fixing Screws

Flow Cell No.22

(5) After installing new Flow Cell No.22, install the Flow Cell Unit No.10

facing the black dot to laser diode. After installing, connect tubing as

figure in the previous page.

Laser Diode

Tube Silicone

1.5 X6

Black dot

XT Series S/M 4-2 December 13, 2007

Page 6

4.2 Optical Alignment (Rough)

Turn on the laser by selecting Menu -> Controller -> Service ->Laser

Power.

Adjust the pin hole position by turning Pin Hole Adjustment Screw so that

the pin hole is center of the Photo Diode.

Pin hole adjustm ent screw

Pin hole

Remove Condenser Lens Unit No.6 by loosening fixing screws.

Fixing

Screws

Condenser Lens Unit No.6

XT Series S/M 4-3 December 13, 2007

Page 7

4.2.1 Laser Diode Adjustment

(1) Adjust the cylinder depth (height) by turning Laser Diode adjustment

Screw so that the cylinder corner and base are same level.

AdjustthecylinderheightbyturningLaserDiodeadjustmentScrew

sothatthecylindercornerandbasearesamelevel..(Ifnot,adjustit.)

LaserDiode

AdjustmentScrew

ReflectionfromFlowCell

Hex-socketscrewdriver

LaserBeamfromLDunit

Flow ce

No.1

ll unit

0

LaerDiode

LensHolder

(2) Turn on the laser by selecting Menu -> Controller -> Service ->Laser

Power. Place the Hex-socket driver between the Flow Cell and the LD

unit as shown in the below figure. If the flow cell angle is correct,

Laser beams from the LD unit and reflection from the Flow Cell

surface are in line on the Hex-socket driver. If not, turn flow cell by

loosening fixing screws of the Flow Cell Unit No.10. After flow cell

angle adjusted, tighten the fixing screws alternately. Turn off the laser

to press OK in the Laser power screen.

Fixing screws

Flow cell

adjustment screw

Hex-socket socket driver

XT Series S/M 4-4 December 13, 2007

Page 8

Double-click the above image to see the movie.

XT Series S/M 4-5 December 13, 2007

Page 9

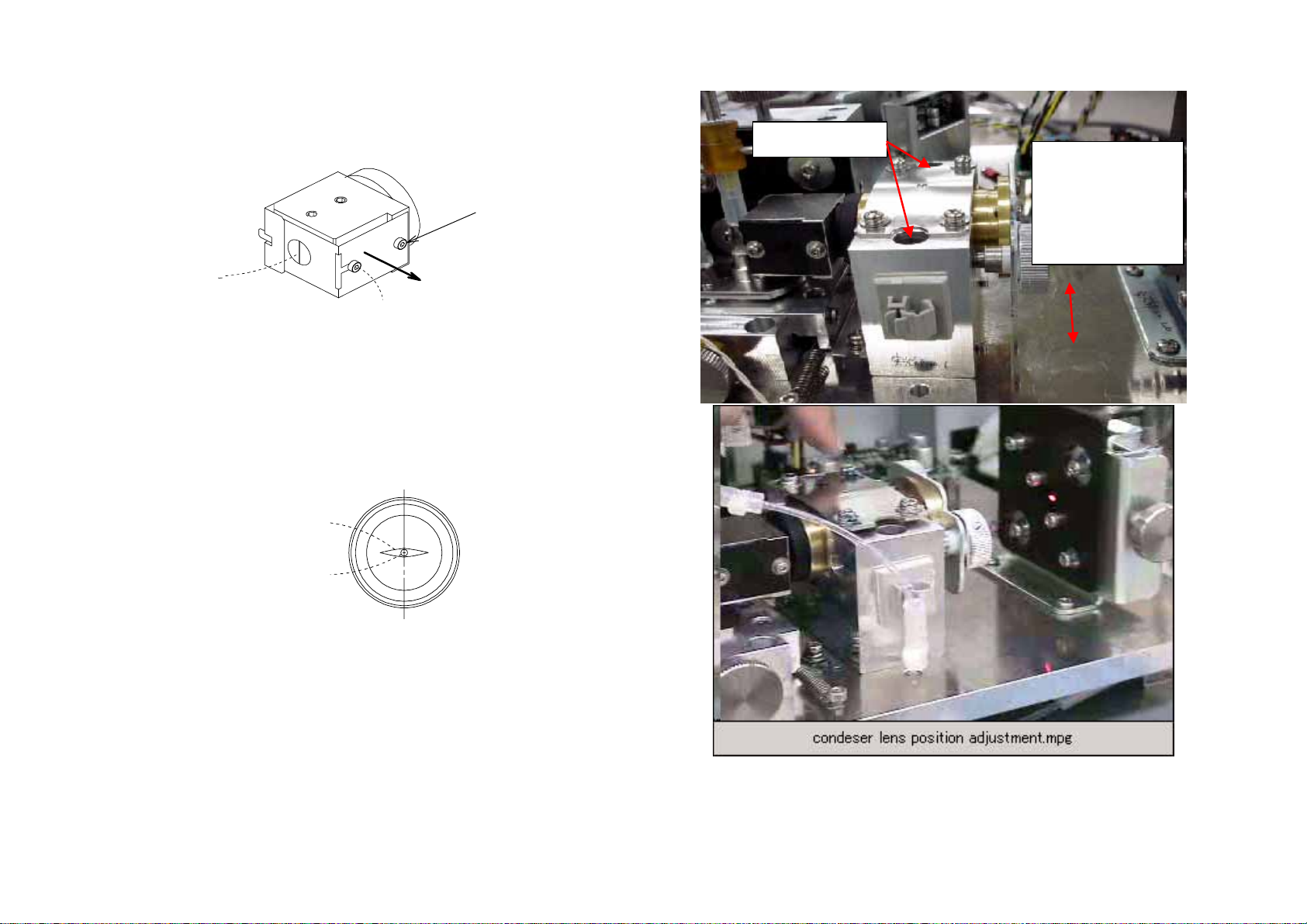

4.2.2 Installing Condenser Lens Unit No.6

Fixing

Screws

Dowel pins

Condenser Lens Unit No.6

(1) Adjusting Condenser Lens Unit No.6 Position

1) Loosen fixing screw. Adjust the edge of the Lens Holder No.39

and edge of Mirror Tube No.14 is 2-3mm as below by turning

Condenser Adjustment Screw. Install the Condenser Lens Unit

No.6 while pressing to the dowel pins and tighten the fixing screw

temporary.

2-3 mm

Fixing Screws

Condenser Adjustment Screw

2) Turn on the laser by selecting Menu -> Controller -> Service

->Laser Power

3) Loosen locking nut of Flow Cell Adjustment screw and locking

screws for flow cell stage.

Locking Screws

Locking Nut

Flow Cell Adjustment Screw

XT Series S/M 4-6 December 13, 2007

Page 10

4) Turn Flow Cell Adjustment Screw CCW so that the laser beam is

out of the flow cell. Turn Beam stopper adjustment screw so that

the laser beam is out of the beam stopper.

Do not turn this screw

Fixing Screws

Move Condeser

Len Unit No.6

side to side

while pushing

the dowel pins.

Beam Stopper

Beam Stopper Adjustment Screw

5) Move Condenser Lens from side to side while pushing the

Condenser Lens Unit No.6 to the dowel pins so that the center of

the laser beam is in the center of the Photo Detector No.20. If the

vertical position of the laser beam is not correct, adjust the pin hole

adjusting screw to fit the height, then adjust it side to side. Tighten

two fixing screws of Condenser Lens Unit No.6.

Laser

Beam

Pin

Hole

Double-click the above image to see the movie.

XT Series S/M 4-7 December 13, 2007

Page 11

6) Turn Flow Cell Adjustment screw CW so that the laser beam is in

the flow cell. Adjust the laser beam position so that the beam is out

of the flow cell center . A djust the Condenser Lens screw so that the

laser beam on the Photo Diode No.20 is lowest. Adjust the vertical

pin hole adjustment screw so that the laser beam is center of the

pin hole. Do not adjust the horizontal pin hole adjust screws.

XT Series S/M 4-8 December 13, 2007

Page 12

4.2.3 Flow Cell Position Adjustment

(1) Adjust the Flow Cell Adjustment Screw so that the pin hole is in the

center of the flow cell sample path (The distance between flow cell

stage and fixing metal is approx. 8 mm.).

(2)

8 mm

Flow Cell

Adjustment Screw

(2) Observe the laser beam image on the Photo Detector Unit No;20.

When the sample path of the flow cell is not seen clearly, place a

magic mending tape (frosted tape) between flow cell and laser diode

unit. Place white paper in front of the Photo Diode for clear view.

Pin Hole

Laser Beam

Sample Path of the Flow Cell

XT Series S/M 4-9 December 13, 2007

Page 13

Sample Path

Pin Hole

(3) Confirm that the edges of the Flow Cell Sample Path are symmetrical

in image thickness. This will confirm that the flow cell rotation position

adjustment was performed correctly in section 4.1.1.

Double-click the above image to see the movie.

Good Symmetry Poor Symmetry

XT Series S/M 4-10 December 13, 2007

Page 14

4.2.4 Beam Stopper Position adjustment

(1) Turn Beam Stopper Adjustment Screw to find the shadow of the

Beam Stopper. Move Beam Stopper Fixture so that the image of the

flow cell sample path and Beam Stopper are parallel. To see image

clearly, place white paper in front of the Photo Detector No.20To see

image clearly, place a piece of magic mending tape (frosted tape)

between flow cell and laser diode. To see image clearly, turn off the

light.

(2) Turn Beam Stopper Adjustment Screw so that the center of the Beam

Stopper Image and pin hole are same.

Laser Beam on

the Beam St opper

Beam Stopper

Adjustment Screw

Pin hole

Sample Path of

the Flow Cell

Image of the

Beam Stopper

Beam Stopper

Fixture fixi ng

screws

Push Beam Stopper

Fixture lightly to this

direction while

tightening the screws

Image of

Beam Stopper

(3) Remove white paper in front of the Photo Detector No.20. Remove

the mending tape between flow cell and laser diode.

(4) Turn off the laser to press OK in the Laser power screen.

Move Beam

Stopper Fixture

Too much

tightening sti f fen

beam stopper

Beam Stopper

Adjustment Scr ew

XT Series S/M 4-11 December 13, 2007

Page 15

4.2.5 Florescence light adjustment (rough)

(1) Turn Condenser Lens Unit No.7 adjustment screw (B/F) so that

distance between condenser lens and flow cell is approx. 1mm. Do

not touch the lens to flow cell. Adjust the Condenser Lens No.7 so

that the lens position is as below. Loosen locking screws to move

Condenser Lens Unit No.7.

Locking Screws

Condenser

Lens Unit No.7

Locking Nut

Flow Cell Adjustment Screw

Condenser Lens Position

Adjustment Screw (F/B)

The edge of the lens is

same height of the top

of the flow cell.

XT Series S/M 4-12 December 13, 2007

Page 16

4.2.6 Preparation of Optical Alignment (fine)

(1) Adjusting laser power

1) Turn Flow Cell Adjustment Screw CCW so that the laser beam is

out of flow cell.

2) Turn VR1 on PCB No2161 CCW fully.

3) Start the IPU with factory maintenance mode.

4) Turn on the laser by selecting Service ->Laser Power

5) Adjust the laser power by turning VR1 on PCB No.2161 so that 3.4

+/- 0.1mW is observe on the power meter (wave length: 633 nm).

6) Press Back -> Menu to display measurement window.

(2) Priming Reagent

1) Press start switch and confirm that no leakage is occurred.

2) Run Air Bubble Removal by selecting

Menu->Controller->Maintenance->Air Bubble Removal.

3) Press Cancel to display measurement window.

4) Press Start Switch without aspirating sample to confirm that RET#

is less than 0.3 X 10^4/uL.

5) After one cycle, observe no bubble at the flow cell.

(3) Settings of the Oscilloscope

CH1: Side Florescence light (SFL) Connect to TP21 (SFL) and TP24

(A GND) on PCB No.2158.

CH2: Front Scattered light (FSC) Connect to TP15 (FSC) and TP24

(A GND) on PCB No.2158.

[Settings]

VOL TS/DIV CH1: 20-50 mV, CH2: 20-50 mV, TIME/DIV 0.2-0.5 us/div

TRIGGERING SOURCE: SFL: CH1, FSC: CH2, (INV ON, SLOPE

OFF)

[PMT voltage setting]

Set Side Florescence light (SFL) voltage 300 +/- 50 V.

PCB No.2161 Drawing

XT Series S/M 4-13 December 13, 2007

Page 17

SFL(TP21)

SSC(TP18)

FSC(TP15)

PCB No.2158 Drawing

XT Series S/M 4-14 December 13, 2007

Page 18

May 23, 2008

4.2.7 Procedure for Optical Axis Adjustment Procedure

(1) Preparing Latex for Optical Alignment

Fixing

Screws

1) Latex for FSC

Dilute 2 drops of latex SS

-071-P with CELLPACK 30mL.

Dilute 6 drops of latex particles 4207A with CELLPACK 30mL.

NOTE) Produced latex for FSC is usable only one day. Do not use

after the day.

2) Latex for SFL

Dilute 2 drops of latex A-7312 with CELLPACK 50mL.

NOTE) Produced latex for FSL is usable within three hours.

Do not use after that.

(2) Select Menu->Controller->Service-> Service Sequence->Optical Axis

Adjustment (Rough).

(4) Press Start switch to aspirate Latex for FSC from the manual

aspiration pipette.

Condenser Lens Unit No.6

(3) Loosen fixing screws for Laser Diode and Condenser lens unit for

adjusting optical alignment.

Fixing Screws

Laser Diode Unit

XT Series S/M 4-15

Page 19

4.3 Optical Axis Alignment (Fine)

4.3.1 Front Scattered Light (Fine)

Adjust each adjustment screws so that the wave height is highest and

uniform.

(1) Provisional Adjustment

When the latex wave is disorder or low, run Optical Axis Alignment

two or three times to adjust temporary. Adjust the position of laser

diode, condenser lens and flow cell to observe the wave easily.

Adjust so that the wave is

V

t

Before Provision Adjus tment After Provision A djustment

V

(2) Laser diode adjustment

1) Adjust laser diode adjustment screw so that the wave width is

narrowest and wave height is highest and uniformed.

uniformed to be easily observed

t

V

Tighten sc r ews

alternately

t

W

Laser Diode

Adjustment Screw

2) Tighten screws on the Laser Diode not to widen the wave width.

Tighten screws alternately not to move the laser diode. Adjust the

pin hole position of the Photo Detector Unit No.20 so that the laser

beam is center of the pin hole by adjusting vertical adjustment

screw. Do not adjust the horizontal pin hole adjustment screws.

3) If the wave height is lowered or disordered, adjust pin hole height

and flow cell side to side position.

Shadow of

Beam Stopper

Pin hole

Reflect from the sample

path of the flow cell

XT Series S/M 4-16 December 13, 2007

Page 20

May 23, 2008

(3) Condenser Lens No.6 Adjustment (Fine)

1) Adjust adjustment screw of the Condenser Lens No.6 so that the

wave height is highest.

2) Tighten fixing screws on the Condenser Lens No.6 alternately.

3) If the wave height is lowered or disordered after tightening fixing

screws, adjust pin hole height and flow cell side to side position Do

not adjust the horizontal pin hole adjustment screws.)

(4) Photo Detector No.20 Adjustment (Fine)

1) Adjust vertical adjustment screw adjustment screw of the Photo

Detector No.20 so that the wave height is highest and uniformed.

2) Tighten four fixing screws of Photo Detector Unit No.20 in order of

a-d-b-c.

a

c

(5) Flow cell adjustment

1) Select Optical Axis Adjustment (Fine).

2) Adjust flow cell adjustment screw so that the wave height is

highest and uniformed.

3) Confirm below values.

FSC(W) is 0.16 or less

4) Confirm that the FSC(X) is 130±50 in the Optical Axis Adjustment

(Fine) screen. If the value is not within the range, enter a value in

the FSC Gain box so that the FSC(X) is 130 ± 50.

5) Adjust flow cell adjustment screw and pinhole horizontal

adjustment screws so that the wave height is highest and

uniformed. When flow cell adjustment screw is moved, be sure to

adjust pinhole horizontal screws.

b

d

6) Confirm that the pinhole is in the center of the beam stopper

shadow. If the pinhole is not in the right position, adjust beam

stopper position. Do not touch beam stopper position after this

adjustment.

(6) Flow Cell Adjustment

1) Adjust flow cell adjustment screw so that the wave height is

highest and uniformed again.

2) Then tighten locking nut of the flow cell adjustment screw by 30 or

40 degrees using a tool. During this tightening, hold the flow cell

adjustment screw by fingers not to move. After tightening, confirm

that the FSC(W)< 0.180.

3) Tighten locking screws.

4) Reconfirm below values.

FSC(W) is 0.16 or less

5) Reconfirm that the FSC(X) is 130 ± 50.

(7) Confirmation of Flow Cell Adjustment

1) Run latex SS-071-P (diluted 10 times with CELLPACK) as a

patient in the manual mode. Confirm the WBC/BASO scattergram

is concentrated as shown below. If the scattergram is not good,

perform the optical alignment from section 4.1.1 Adjust Flow Cell

Angle.

Good example Bad example

XT Series S/M 4-17

Page 21

Good Example (e-CHECK Level 2)

Good Example FSC (Latex)

XT Series S/M 4-18 December 13, 2007

Page 22

Locking Screws

Condenser

Lens Unit No.7

Locking Nut

Flow Cell Adjustment Screw

(6) Side florescence adjustment (Fine)

1) Select Optical Axis Adjustment (Rough).

2) Press Start switch to aspirate Latex for SFL from the manual

aspiration pipette.

3) Adjust each adjustment screws so that the wave height is highest

and uniform.

4) Adjust Condenser Lens Unit No.7 vertical adjustment screws so

that the wave height is highest and uniform.

5) Adjust Condenser Lens Unit No.7 horizontal adjustment screws so

that the wave height is highest and

Vertical adjustment screw

Horizontal

adjustment screw

Condenser

Lens Unit No.7

uniform.

6) Adjust Condenser Lens Unit No.7 Forward/Backward adjustment

screws so that the wave height is highest and uniform.

Condenser

Lens Unit No.7

Condenser Lens

Fowared/Backward

Adjustment Screw

XT Series S/M 4-19 December 13, 2007

Page 23

7) Repeat step 3) – 5) so that the wave height is highest and uniform.

8) Adjust Socket unit direction so that the wave height is highest and

uniform. When Socket unit is tuned fully, adjust PMT socket

direction.

Socket Assembly

When fixing screw is

loosened, adj ust the

Socket assembly while

pulling up the socket .

Locking Screw

Vertical

Adjustment Screw

Photo Detector

No.22

Locking Screw

Fixing Screw

Photo Detector No.21

9) Select Optical Axis Adjustment (Fine). Confirm that the SFL(X) is

130 +/- 50. If the SFL(X) is not within the range, enter a value in the

SFL Gain so that the SFL(X) is 130 +/- 50.

10) Examine below values.

SFL(W)< 0.410

(7) Side Scattered adjustment (Fine)

1) Change the CH1 probe as follows. CH2 remained same.

CH1: Side Scattered (SSC) TP18 (SSC: signal) and TP24 (A

GND): signal on PCB No2158 (Setting remain unchanged.)

2) Loosen fixing screw of Photo Detector Unit No.22 and Optical

base.3) Loosen locking screws.

Optical Base

Fixing Screw

4) Select Optical Axis Adjustment (Rough).

5) Press Start switch to aspirate Latex for SFL from the manual

aspiration pipette.

6) Adjust Photo Detector side to side position so that the wave height

is highest and uniform as follows.

a) Mark a line of the position of Photo Detector No.22 and Optical

Base with an extrafine-pointed pen when Photo Detector No.22 is

moving to the left and the waveform becomes out of order.

Assume that the mark on the Photo Detector No.22 is A and the

mark on Optical Base is B.

b) Mark a line of the position of Photo Detector No.22 and Optical

Base with a extrafine-pointed pen when Photo Detector No.22 is

moving to the right and the waveform becomes out of order.

Assume that the mark on the Optical Base is C. The distance

between B and C will be approximately 2 mm.

)

c) Adjust the Photo Detector left/right position so that the A is the

center of the B and C.

After adjusting the position, tighten the fixing screws.

XT Series S/M 4-20 December 13, 2007

Page 24

7) Adjust Photo Detector vertical position so that the wave height is

highest and uniform as follows.

a) Mark a line of the position of Photo Detector Mounting Plate

No.3-A and Detector Mounting Plate No.3-B with an

extrafine-pointed pen when Photo Detector No.22 is moving to the

up and the waveform becomes out of order. Assume that the mark

on the Photo Detector Mounting Plate No.3-B is D and mark on

the Photo Detector Mounting Plate No.3-A is E.

b) Mark a line of the above D and Photo Detector Mounting Plate

No.3-A with an extrafine-pointed pen when Photo Detector No.22

is moving to the down and the waveform becomes out of order.

Assume that the mark on the Photo Detector Mounting Plate

No.3-A is F. The distance between E and F will be approximately 2

mm.

c) Adjust the Photo Detector up/down position so that the D is the

center of the E and F.

d) After adjusting the position, tighten the fixing screws for up/down

position.

8) Adjust forward/backward adjustment screw of Condenser lens unit

No.7 so that the wave height is highest and uniform.

9) Repeat step 1) to 3) to get the wave height is highest and

uniformed.

10) After adjustment, tighten locking screws and fixing screws of

Photo Detector Unit No.22.

11) Tighten locking screws.

12) Tighten nut of the forward /backward adjustment screw.

13) Examine below values.

SFL(W)< 0.410

14) Confirm that the SFL(MFV) is 130 +/- 50.

15) Select Optical Axis Adjustment (Fine). Examine below values.

SSC(W)< 0.410

SSC(X)>30

Good Example SFL (Latex)

XT Series S/M 4-21 December 13, 2007

Page 25

4.4 Electric Adjustment

4.4.1 PCB No.1260

(1) Jumper pin settings

[Synchronous serial settings]

Synchronous serial signal can be used with multiple PCB. When

additional PCB is added subsequently, jumper setting should be

changed as follows.

Connector 1-2 Short circuit 2-3 Short circuit

J19 No Additional PCB Additional PCB added

On XT-2000i, set to 1-2 short circuited.

[Voltage setting of Constant voltage drive motor]

The voltage of constant voltage drive motor can be switch 12V or 5V.

Connector 1-2 Short circuit 2-3 Short circuit

J25 Motor Driven Voltage 5V Motor Driven Voltage

12V

On XT-2000i, set to 1-2 short circuited.

(2) Adjusting Blood Sensor

1) Confirm that SNS23 is red without placing a test tube in front of the

blood sensor. Place 15 mm diameter test tube with 2 mL water to a

Rack and shift it to blood sensor position.

2) If SNS23 is gray (or D34 is fully lit), Jump to step 3). If SNS 23 is

red, turn VR1 on PCB No.1260 CCW so that SNS23 turns to gray.

3) Place empty 15 mm diameter test tube to a rack and confirm that

SNS23 is red (or D34 is dimly lit) when the test tube is in front of

the blood sensor. (Use empty 12 mm diameter test tube if the

customer uses this type of test tube.)

4) If SNS23 does not turn red (or D34 is not dimly lit), turn VR1 on

PCB No.1260 CW so that SNS23 turns to red.

5) Repeat above steps for verification.

NOTE: With 2 mL test tube: Gray, With empty test tube: Red

XT Series S/M 4-22 December 13, 2007

Page 26

(3) LED and Test Point

[LED]

LED Indication Function

D 1 R-5 Reagent Prism Sensor (EPK)

D 2 R-4 Reagent Prism Sensor (FBT)

D 3 R-3 Reagent Prism Sensor (FFD)

D 4 R-2 Reagent Prism Sensor (SLS)

D 5 R-1 Reagent Prism Sensor (RED)

D 13 PUMP-E Blood sensor (Whole Blood pump side) error: lit

D 14 B-P2 Blood sensor (Whole blood pump side level: H)

D 15 B-P1 Blood sensor (Whole blood pump side level: L)

D 16 CP-E Blood sensor (CP side) error: lit

D 17 B-CP2 Blood sensor (CP side level: H)

D 18 B-CP1 Blood sensor (CP side level: L)

When thermistor wire broken (sheath reagent t emperatur e

D 19 FCM-E

D 20 ENV-E

D 21 REAC-E

D 22 HAET-E

D 23 FMT-E

D 27 HEAT When reaction chamber heater on: lit

D 28 REAC When reagent heater on: lit

D 29 FMT When PMT heater on: lit

D 34 T-BLOOD When blood detection sensor detects sample: lit

detection): lit

When thermistor wire broken (ambient temperature

detection): lit

When thermistor wire broken (reagent heater temperature

detection): lit

When thermistor wire broken (reaction chamber

temperature detection): lit

When thermistor wire broken (PMT temperature

detection): lit

D13 and D16: Blood sensor level H: When a bubble(s) passed: lit

(Sensor monitors just before aspirating sample. The sensor is

automatically adjusted using EPK.)

D14, D15, D17 and D18: Blood sensor level L: When sample

passes: lit (Sensor monitors just before rotating the SRV.)

[Test Points]

Indication Function

TP 1 PUMP Blood sensor (Whole blood pump side) voltage

TP 2 CP Blood sensor (CO side) voltage

TP 3 12V-A Voltage for analog signal: 12V

TP 4 A.GND A.GND

TP 5 ENV AD converter for ambient temperature thermister input voltage

TP 6 SEATH AD converter for sheath reagent thermistor input volage

TP 7 REAC AD converter for reagent heater thermister input voltage

TP 8 HEAT AD converter for reaction chamger thermister input voltage

TP 9 FMT AD converter for PMT thermister input voltage

TP 10 T-BLOOD Blood detection sensor input signal

TP 11 VCC Voltage Vcc

TP 12 D.GND D.GND

TP 13 12V Voltage 12V

TP 14 24V Voltage 24V

XT Series S/M 4-23 December 13, 2007

Page 27

4.4.2 PCB No.6365

(1) Dip Switch

bit ON OFF Default

1 Connect Conveyer Not Connect Conveyer OFF

2 Sampler connected Not Sampler connected ON

3 Zero padding for HST Not Zero padding for HST OFF

4 Connect Bar Code

Reader

5 Initialize setting data in

EEPROM at power ON

6 Output debugger

Not output debugger

informaion

Not Connect Bar Code

Reader

Not Initialize setting data in

EEPROM at power ON

information

7 XT-1800i XT-2000i OFF

8 Initialize counters in

EEPROM at power ON

Not Initialize counter in

EEPROM at power ON

OFF

OFF

OFF

OFF

XT Series S/M 4-24 December 13, 2007

Page 28

4.5 Sensitivity Adjustment

(1) Select Mode by selecting Menu->Controller->Service->Mode and

mark control 3 in the Analytical Mode.

(2) Select Manual from tool bar, CBC+DIFF+RET in discrete and select

Manual mode, then press OK.

(3) Run Auto rinse. After Auto rinse is over, confirm that no background

error occurs.

(4) Analyze e-CHECK (level 2) in manual mode.

(5) After analysis completes, select Sensitivity by selecting

Menu->Controller->Service-> Sensitivity.

(6) Confirm that the analyzed values are in the below table range.

(7) If the analyzed value is not within the range, change the value in the

sensitivity screen as below steps.

Parameters Target value: Parameter to be adjusted

RBC-X Assayed value +/- 1ch RET(SFL)

RBC-Y Assayed va lue +/- 3ch RET(FSC)

DIFF-X Assayed value +/- 3ch DIFF(SSC)

DIFF-Y Assayed value +/- 2ch DIFF(SFL)

BASO-X Assayed value +/- 3ch BASO(SSC)

BASO-Y Assayed value +/- 2ch BASO(FSC)

(MCV) Assayed value +/- 1 fl RBC gain

(MPV) Assayed value +/- 1fL PLT gain

Blank 20.00 +/- 2.0 HGB Blank

Sample Assayed value +/- 0.2 g/dL HGB span

*Check the value in the data browser screen.

XT Series S/M 4-25 December 13, 2007

Page 29

Measured Value

The value of digital

potentiometer

2175

*2

*2

*2

*2

135

135

1680

*2

*1

*2

*1

*1

*1

(8) For RBC-Y, BASO-Y, MCV and P-MFV, enter target value in the *1 box and press “>>>”, then digital potentiometer is automatically calculated.

Press Send to reflect the digital potentiometer.

(9) For RBC-X, DIFF(SSC), DIFF(SFL), BASO(SSC), HGB blank and HGB span, enter values in the *2 boxes for digital potentiometer to change the

sensitivity. Press Send to reflect the sensitivity.

(10) If the values are not in the range of table above repeat step (8) or step (9).

XT Series S/M 4-26 December 13, 2007

Page 30

4.6 HGB Blank Convert Value Adjustment

(1) Confirm that 30 minutes past after turning on the main unit.

(2) Select Sensitivity by selecting Menu->Controller->Service->

Sensitivity.

(3)Change the value in the HGB Blank box so that the blank value be

20.00 +/-5.0.

1) Enter appropriate value in the HGB Blank box and press Send.

2) Repeat above step so that the Blank value be in the range.

(Default value: 160)

4.7 RBC Clog Level Adjustment

(1) Select RBC Clogs by selecting Menu->Controller->Service->RBC

Clogs, RBC clog level is displayed in real time.

(2) Enter “100” in the target then press “>>>” and Send.

(3) Repeat above step so that the clog level be in the range of 98 –

102.

XT Series S/M 4-27 December 13, 2007

Page 31

4.8 CP Unit Position Adjustment

(1) Remove CP Cover by loosening two thumb screws.

(2) Remove front lower cover by removing four screws. (Loosen two

screws in dashed circles.)

(3) Place a sample rack with Alignment Tool A at the position 1.

Alignment Tool A

(4) Feed in the rack by selecting Menu

Æ Controller Æ Maintenance Æ

Rack Feed in.

(5) Shift the rack three steps by operating “Rack Feed in” three times to

move the Alignment Tool A in front of the hand clipper.

(6) Move the hand clipper toward you by selecting Menu

Service

Æ CP Æ Front. Place Alignment Tool B at the hand clipper

so that the two Alignment tools touch.

Alignment Tool B

(7) Loosen 6 fixing screws on the CP Unit.

Æ Controller Æ

XT Series S/M 4-28 December 13, 2007

Page 32

(8) Adjust CP position so that the tips of the two Alignment tools are

exactly aligned. Move the CP Unit chassis so that the CP Unit

chassis is parallel to the Main Unit chassis.

(9) After competing adjustment, tighten 6 fixing screws loosened in step

7.

(10) Move the hand clipper toward you by selecting Menu

Æ Controller

Æ Service Æ CP Æ Front. Adjust the position of the Sample Tube

Flicking Metal No.3 so that it comes center of the hand clippers.

Sample Tube Flicking Metal No.3

Mount the Front lower cover.

(11)

Mount the CP cover. If the CP cover touches to the front cover,

(12)

adjust the Cover Mounting Plate No.46 right and left position.

Cover Mounting Plate No.46

XT Series S/M 4-29 December 13, 2007

Page 33

4.9 CP Piercer Position Adjustment

(1) Remove CP cover by loosening two upper thumb screws.

(2) Place an empty blood collection tube at the position 1 of a rack as

shown.

XT Series S/M 4-30 December 13, 2007

Page 34

(3) Shift the rack manually to the leftward so that the blood collection

tube is in front of the hand clipper.

(4) Run “Rotate” by selecting service

Æ CP.

(5) Place a ruler at the piercer needle and confirm that the needle is in

the center of the tube and parallel.

XT Series S/M 4-31 December 13, 2007

Page 35

(6) If the needle is not proper position, adjust the needle position by

loosening three screws so that the needle is center and parallel to the

tube as shown.

(7) Return the tube to the initial position by selecting “Initial Position”.

Affix an adhesive tape on the opening of the tube and run “Clamp &

Piercer”.

XT Series S/M 4-32 December 13, 2007

Page 36

(8) Return the tube to the initial position by selecting “Initial Position”.

Check the pierced hole is in the center of the tube. If it is not in the

center, adjust it again.

(9) If the position of the pierced hole is not center in a back-and-forth

direction, follow the procedures below to adjust piercer position.

1) Remove Cover Mounting Metal No.49 by loosening screws as

shown.

XT Series S/M 4-33 December 13, 2007

Page 37

2) Loosen four screws as shown.

3) Remove Hgb Detector block by removing one thumb screw.

XT Series S/M 4-34 December 13, 2007

Page 38

4) Loosen two M4 hex screws and adjust the piecer unit position so

that the piecing position is in the center of the tube. Fix the hex

screws temporally after adjustment.

(10) After adjustment, affix an adhesive tape on the opening of the tube

again, and confirm that the pierce hole is in the center of the tube by

selecting “Clamp & Piercer. ” When the pierced hole is in the center

of the tube, tighten all fixing screws.

XT Series S/M 4-35 December 13, 2007

Page 39

4.10 Sensitivity Adjustment Procedure (Europe only)

4.10.1 Introduction

During installation, after Optical Axis Alignment and in case of poor

sensitivity control blood data, sensitivity adjustment should be performed

for XT-2000i field analysers with the following procedures. These

procedures are mostly in accordance to section 4.2.1 Service Manual.

However this procedure as it is described here uses human blood

samples for three parameters (NEUT-Y, WBC/BASO-Y and RBC-X), as

these are not stable enough for use with control blood adjustment.

Following optical sensitivity parameters need to be adjusted:

a) DIFF-X (X-axis of DIFF channel)

b) NEUT-Y (Y-axis of DIFF channel)

c) BASO-X (X-axis of WBC/BASO channel)

d) BASO-Y (Y-axis of WBC/BASO channel)

e) RBC-X (X-axis of RET channel)

f) RBC-Y (Y-axis of RET channel)

(1) First, using fresh whole blood samples, the following 3 sensitivity

parameters are to be adjusted.

a) NEUT-Y (Y-axis of DIFF channel)

b) WBC/BASO-Y (Y-axis of WBC/BASO channel)

c) RBC-X (X-axis of RET channel)

(2) The other 3 sensitivity parameters are to be adjusted using e-CHECK

(Level 2).

(You can find the value in the NPP / Assay Sheets)

a) DIFF-X (X-axis of DIFF channel)

b) BASO-X (X-axis of WBC/BASO channel)

c) RBC-Y (Y-axis of RET channel)

The fresh whole blood samples used for adjustment purpose, should

meet the following specifications:

a) Criteria for fresh whole blood samples

HGB: 120 - 160 g/l

PLT: 150 – 450 x 10

MCV: 85 - 105 fl

WBC: 5.5 – 9.5 x 10

9

/l

9

/l

Neut: 55 – 78%

Lymph: 20 – 30%

Mono: 2 – 10%

Eo: 0 – 5%

Baso: 0 – 2%

No WBC-Suspect Flags

Retics in normal range

b) Anti-coagulant: EDTA-2K or EDTA-3K should be used.

c) No turbidity should be observed.

Concerning the name of each sensitivity parameter, refer to

corresponding channel parameters as displayed in the Service Menu.

Concerning the detailed procedures, perform sensitivity adjustment

according to adjustment protocol as printed in the Service Manual.

For efficient adjustment procedure, perform it in the following order:

DIFF

Æ WBC/BASO Æ RET channel

Note: Some values marked with * differ from the acceptable limit

ranges as printed in the Service Manuals

XT Series S/M 4-36 December 13, 2007

Page 40

4.10.2 Sensitivity Adjustment for DIFF channel

4.10.2.1 Fresh Whole Blood Samples

(1) Prepare 20 fresh whole blood samples according to the criteria written

in the introduction above.

(2) Run 20 fresh whole blood samples consecutively (once per sample)

within four hours after collection and calculate the truncated Mean

(M1) and SD (SD) for the following parameter: (Human blood has to

be measured with the profile "other1" in case XT-2000iV/XT-1800iV

software is installed.)

NEUT-Y (Y-axis of DIFF channel)

(3) Remove the data showing outside Mean+/- 1.5SD and re-calculate

the Mean (M2).

(4) Verify if the M2 for NEUT-Y is within the following ranges:

Parameter Target Value (ch) Acceptable Range (ch)

NEUT-Y 43.5 +/- 2.0

(5) If the fresh whole blood samples data are outside the above range,

perform the pre-adjustment with

e-CHECK (Level 2). (Refer to XT-2000i S/M section 4.4 for detailed

procedures, change to CTRL3 mode)

Channel

DIFF channel

Y-axis

Sensitivity Parameter

e-CHECK Whole Blood

DIFF-Y NEUT-Y Value in Sensitivity

Samples

Adjustment Point

screen

Note: The purpose of the pre-adjustment with e-CHECK is to keep the

adjustment practicable.

(6) After pre-adjustment with e-CHECK, run the whole blood samples

again (repeat steps 2 - 4.)

(7) Verify that data of NEUT-Y are within the specified limits. If it fails,

repeat step 5 - 7 until it meets the specs.

4.10.2.2 e-CHECK (Level 2)

(1) Prepare one vial of e-CHECK (Level 2).

(2) Run e-CHECK 5 times consecutively and calculate the Mean (M1)

and SD (SD) for DIFF-X.

(3) Remove the data showing outside Mean+/- 1.5SD and re-calculate

the truncated Mean (M2).

(4) Verify if the M2 meets the following criteria of the XT-2000i assay

sheet:

Parameter Target Acceptable Range

DIFF-X XT-2000i assay data +/- 3.0 (ch)

(5) If it fails, perform the sensitivity adjustment for DIFF-X according to

the S/M section 4.4.

XT Series S/M 4-37 December 13, 2007

Page 41

4.10.3 Sensitivity Adjustment for WBC/BASO channel

4.10.3.1 Fresh Whole Blood Samples

(1) Prepare 20 fresh whole blood samples according to the criteria written

in the introduction above.

(2) Run 20 fresh whole blood samples in Normal Open Mode

consecutively (once per sample) within four hours after collection and

calculate the truncated Mean (M1) and SD (SD) for the following

parameter

WBC/BASO-Y (Y-axis of BASO channel). Remove outliers from

the data set before the calculation of the mean Baso-Y value.

(3) Remove the data showing outside Mean+/- 1.0 SD and re-calculate

the Mean (M2).

(4) Verify if the M2 for WBC/BASO-Y is within the following ranges:

Parameter Target Value (ch) Acceptable Range (ch)

WBC/BASO-Y 72.0 +/- 3.5

(5) If the fresh whole blood samples data are outside the above range,

perform the pre-adjustment with e-CHECK (Level 2). (Refer to

XT-2000i S/M section 4.4 for detailed procedures, change to CTRL3

mode.)

Sensitivity Parameter Channel

e-CHECK Whole Blood

Samples

WBC/BASO

BASO-Y WBC/BASO-Y Value in Sensitivity

Y-axis

Note: The purpose of the pre-adjustment with e-CHECK is to keep

the adjustment practicable

.

Adjustment Point

screen

(6) After pre-adjustment with e-CHECK, run the whole blood samples

again (repeat steps 2 - 4.)

(7) Verify that data of WBC/BASO-Y are within the specified limits. If it

fails, repeat step 5 - 7 until it meets the specs.

4.10.3.2 e-CHECK (Level 2)

(1) Prepare one vial of e-CHECK (Level 2).

(2) Run e-CHECK (Level 2) 5 times consecutively and calculate the

Mean (M1) and SD (SD) for BASO-X.

(3) Remove the data showing outside Mean +/- 1.0 SD and re-calculate

the Mean (M2).

(4) Verify if the M2 are within the following criteria of the XT-2000i assay

sheet:

Parameter Target Acceptable Range

BASO-X XT-2000i assay data +/- 2.0 (ch)

(5) If it fails, perform the sensitivity adjustment for BASO-X according to

the S/M section.

XT Series S/M 4-38 December 13, 2007

Page 42

4.10.4 Sensitivity Adjustment for RET channel

4.10.4.1 Fresh Whole Blood Samples

(1) Prepare 20 fresh whole blood samples according to the criteria written

in the introduction above.

(2) Run 20 fresh whole blood samples consecutively (once per sample)

in Normal Open Mode and calculate Mean (M1) and SD (SD) for the

following parameter:

RBC-X (X-axis of RET channel)

(3) Remove the data showing outside Mean +/- 1.5 SD and re-calculate

the truncated Mean (M2).

(4) Verify if the M2 for RBC-X is within the following ranges:

Parameter Target Value (ch) Acceptable Range (ch)

RBC-X 17.7 +/- 1.0

(5) If the fresh whole blood sample data are outside the above range,

perform the pre-adjustment with e-CHECK (Level 2). (Refer to

XT-2000i S/M for detailed procedures, change to CTRL3 mode.)

Sensitivity Parameter Channel

RET channel

X-axis

e-CHECK

(Level 2)

RBC-X RBC-X Value in

Whole Blood Samples

Note: The purpose of the pre-adjustment with e-CHECK is to

keep the adjustment practicable.

(6) After doing pre-adjustment with e-CHECK (Level 2), run the whole blood

samples again (repeat step 2-4)

Adjustment

Point

Sensitivity

screen

(7) Verify that the data (RBC-X) are within the above specifications. If it

fails, repeat step 5 - 7 until it meets the specs.

4.10.4.2 e-CHECK (Level 2)

For RBC-Y

(1) Prepare one vial of e-CHECK (Level 2).

(2) Run e-CHECK (Level 2) 5 times consecutively, and calculate Mean

(M1) and SD (SD) for the following parameter:

RBC-Y (Y-axis of RET channel)

(3) Remove the data showing outside Mean +/- 1.0SD and re-calculate

the truncated Mean (M2).

(4) Verify if the M2 are within the following criteria:

Parameter Target Acceptable Range

RBC-Y XT-2000i assay data +/- 2.0 (ch)

(5) If it fails, perform the sensitivity adjustment for RBC-Y according to

the 4.4 Sensitivity Adjustment.

XT Series S/M 4-39 December 13, 2007

Page 43

4.11 Count Calibration Procedure (Europe only)

4.11.1 Introduction

The XT -2000i uses two different channels, which yield a tot al WBC count,

two channels with RBC, and PLT counts and three different

measurement modes (Manual Open Mode, Sampler Mode and Capillary

Mode) which need to be cross calibrated for correct analytical results.

The correct calibration of different channel results is essential for correct

flagging, as it indirectly influences the sensitivity of certain flags.

4.11.2 Calibration Overview

Following calibration steps are to be performed during installation

procedure and upon requirement when instrument performs out of

controls or major components have been replaced for service purpose.

4.11.2.1 Master Mode Calibration (Open Manual Mode)

(1) CBC Calibration

The master mode calibration is the basic calibration and used as

primary basis for all following calibration steps. It is applicable to the

CBC parameters and reference count channels, wherever same cell

types are counted in different channels (e.g. WBC).

There are two possibilities (materials) to perform the master mode

calibration, one is the use of fresh blood samples using reference

methods and/or counters, which might be very labour intensive and

time consuming. The other more practicable method is to use

SCS-1000, the Sysmex Calibrator System material, which is

traceable to reference methods.

The following table lists all parameters and materials to be used for

the master mode calibration.

Parameter Device Material Method Person Comment

HGB IPU

HCT

HGB IPU

RBC IPU

PLT IPU

WBC IPU

IPU SCS-1000/

Cal-File

Cal-File

Cal-File

Cal-File

SCS-1000/

fresh blood

samples

fresh blood

samples

SCS-1000 SCS-1000 Service

SCS-1000 SCS-1000 Service

SCS-1000 SCS-1000 Service

SCS-1000 SCS-1000 Service

SCS-1000/

reference

methods

SCS-1000/

reference

methods

User Calibration check

User Calibration check

technician

technician

technician

technician

to be done

routinely

to be done

routinely

Primary

HGB-calibration

During installation

During installation

During installation

The first two calibration procedures can be performed through the user .

Calibration status should be checked routinely by means of reference

methods SCS-1000.

Count calibration check has to be performed during installation and

after certain service maintenance procedure, which might have impact

to the count calibration status of the analyser (e.g. changing the whole

blood aspiration tube, or SRV). You can get in IPU_INI,

[IPU_System_Setting], Calibrator_Calibration=1 (0=initial), to perform

calibration of these parameter automatically.

XT Series S/M 4-40 December 13, 2007

Page 44

(2) WBC-count calibration

After analyses of fresh blood samples for the mode-to-mode

calibration, the WBC count of WBC/BASO channel represents the

WBC reference result of XT-2000i and is printed on the report. As

there is another channel which also give a WBC total result, this have

to be cross-calibrated to the reference count as obtained during

master mode calibration.

The table shows the details for the WBC-channel calibration.

Parameter Device CAL

Material Reference Comment

Name

WBC#(DIFFch) IPU

Cal-File

DIFF_CAL Fresh blood WBC# During

installation

Note: All calibration procedures are to be performed by experienced

technical specialists!

(3) Calibration of Optical Parameters

The RBC and PLT count of the HDF Impedance channel represent

the RBC/PLT reference results of XT-2000i and these are printed on

the report (in some particular cases, PLT-O is reported instead of

PLT-I). As there is another channel, which also gives RBC and PLT

total results, the RET-channel, these results have to be

cross-calibrated to the respective reference counts as obtained

during master mode calibration.

The table shows the details for the calibration of the optical

parameters.

Parameter Device CAL Name Material Reference Comment

RBC-O# IPU

Cal-File

PLT-O IPU

Cal-File

RBCO_CAL Fresh blood RBC During

installation

PLTO_CAL Fresh blood PLT During

installation

Note: All calibration procedures are to be performed by experienced

technical specialists!

(4) Calibration of other Parameters

There are several other parameters, which could be calibrated as they

are listed in the calibration file of the IPU. However, the calibration of

these parameters should generally

not be changed as it might have an

impact to the overall WBC differential and flagging performance of the

analyser. In any case the calibration should only be changed after

consultation of the responsible product specialist and in accordance

with the respective customer’s requirements. The following table shows

the parameters and details of the calibration methods to be used.

Parameter Device CAL Name Material Reference Comment

RET IPU

CD n.a. CD_CAL n.a. n.a. n.a.

LFR/MFR IPU

LYMPH,

MONO, EO,

BASO

MONO_B IPU

RET_CAL Fresh blood Manual or

Cal-File

Cal-File

IPU

Cal-File

Cal-File

LFR_CAL

MFR_CAL

L YMPH_CAL

MONO_CAL

EO_CAL

BASO_CAL

MONO_B_C

AL

Fresh blood n.a. Calibration

Fresh blood

(for EO and

BASO see

comment)

n.a. n.a. User Mode

flowcytometric

RET counting

methods

Manual or

flowcytometric

counting

methods

During

installation or

upon

customer

inquiry

can not be

done, as

there is no

reference

method

available

For

practicable

reasons EO

and BASO

might be

calibrated

using control

blood

calibration

factor for

Monocyte

counting.

Note:

Changing

this factor

does not

influence the

QC results

.

Note: All calibration procedures are to be performed by experienced

technical specialists!

XT Series S/M 4-41 December 13, 2007

Page 45

4.11.2.2 Mode to Mode Calibration

The mode-to-mode calibration is necessary and required during the

installation procedure, as this is not done during production process in Japan.

This calibration ensures the identical performance of the analyser in all

analytical modes.

(1) Sampler Mode Calibration

Sampler mode calibration is applicable for all parameters including

Optical-, DIFF (total)-parameters. The WBC differential count

parameters do not need to be specifically calibrated in the sampler

mode.

The following table lists all parameters and details of the calibration

procedures.

Parameter Device Material Reference

Comment

Method

RBC, PLT,

HGB, WBC,

RET, RBC-O,

PLT-O, DIFF

IPU Cal-File Fresh blood

samples

Master (open)

mode results

During installation.

Sampler mode

parameters are

indicated by

“PARAM”_SM_CAL

Note: “PARAM” stands for the respective parameter (e.g.

WBC_SM_CAL.).

(2) Capillary Mode Calibration

Capillary mode calibration is applicable for all parameters including

optical parameters, but not the HPC, as this is measured exclusively

in the manual open mode. The WBC differential counts are not

reportable parameters in the capillary mode.

The following table lists all parameters and details of the calibration

procedures.

Parameter Device Material Reference

Comment

Method

RBC, PLT,

HGB, WBC,

RET,

RBC-O,

PLT-O

IPU

Cal-File

Fresh

blood

samples

Master (open)

mode results

During installation. Sampler

mode parameters are

indicated by

“PARAM”_CAP_CAL

Note: “PARAM” stands for the respective parameter (e.g.

WBC_SM_CAL).

XT Series S/M 4-42 December 13, 2007

Page 46

4.11.2.3 RBC-Gain adjustment

RBC_GAIN adjustment is not a count calibration, but a RBC-sensitivity

adjustment procedure to adjust the MCV of the analyser using control

blood. The factor to adjust the RBC-Gain is also included in the CAL-file

and has to be set for each mode separately. Please refer to the following

table.

Parameter Device Material Reference

Comment

Value

RBC_GAIN,

RBC_SM_GAIN,

RBC_CAP_GAIN

IPU

Cal-File

Control

Blood

Control Blood

assay values

During installation

and sometimes

during service

maintenance

procedures

4.11.3 Calibration Procedure

4.11.3.1 SCS-1000 calibration procedures

For SCS-1000 calibration procedures, please follow the instructions

given as package insert of SCS-1000.

4.11.3.2 Fresh blood calibration procedures

First perform cross-calibration of manual mode WBC data from

DIFF-channel as well as the calibration of manual open mode of optical

parameters (RBC-O and PLT-O).

The mode-to-mode calibration of sampler and capillary mode should

always follow this first step.

Perform the fresh blood calibration according to following procedure:

(1) Prepare 10 or more normal fresh blood samples (within 4 hours after

blood collection) which meet following criteria:

<Criteria for fresh whole blood samples>

CBC data

HGB : 120 - 160 g/l

PLT: 150 – 450 x 10

MCV: 85 - 105 fl

WBC: 5.5 – 9.5 x 10

PLT: 150 - 350 x 10

9

/l

9

/l

9

/l

Anti-coagulant: EDTA-2K or EDTA-3K should be used.

No turbidity should be observed.

(2) Analyse each sample twice and record the 20 results of each

parameter’s reference and the results to be calibrated from the

analysis result screen and the respective service screen

(3) Calculate the deviation factor (e.g. WBC / WBC#(DIFFch)) of each

sample analyses separately and use these values to calculate the

total deviation factor (calculated as mean of all deviation factors.)

XT Series S/M 4-43 December 13, 2007

Page 47

(4) If the total deviation factor is bigger than 1.01 or smaller than 0.99 (>

+/- 1.0 %), please change the respective calibration factor in the

XT-2000i^XXXXX.CAL file.

(5) Verify the calibration by single analysis and re-calculation of deviation

factors.

(6) If any parameter does not meet the acceptable deviation limits, repeat

steps 1-5.

(7) Finally multiply the new deviation factor with the existing current

number of the calibration file and overwrite this number by the new

one.

4.11.3.3 Example

The following table shows an example of such calibration procedure for

one parameter (here using 10 single measurements for demonstration

purpose):

(1) Step: Manual Mode (calibration of WBC#(DIFFch))

WBC#(DIFFch) WBC Deviation

Factor

3,489 3.39 0.971

7,779 7.95 1.022

12,819 1.95 1.010

8,009 8.7 1.008

13,016 12.7 0.989

7,137 7.8 1.006

6,734 6.7 0.9905

10,829 10.7 1.0130

6,027 6.0 0.9955

Total deviation factor

1.0006

(mean)

Since the deviation of 0.0006 is less than ± 1.0 %, a change of

calibration factor is not necessary.

XT Series S/M 4-44 December 13, 2007

Page 48

(2)-a Step: Sampler Mode (WBC-SM calibration)

WBC_ SM WBC Deviation Factor

4.06 3.39 0.8350

8.73 7.95 0.9107

1.69 12.95 0.8254

9.04 8.07 0.8927

14.45 12.87 0.8907

7.54 7.18 0.9523

7.36 6.67 0.9063

12.15 10.97 0.9029

6.74 6.00 0.8902

8.75 7.72 0.8823

Total deviation factor (mean) 0.8888

Since the total deviation factor of 0.8888 showed that sampler counts

were significantly higher than in manual mode (11.12 % > 1%), we

had to change the WBC_SM calibration factor by applying following

formula:

Current cal_factor * total deviation factor = new cal_factor (1000 *

0.8888 = 888.8)

The old factor was 1000 and was changed to 889.

Note:

These dummy sample data were taken for demonstration

purpose. Samples with such values would have of course not

been used for calibration, as they did not fulfil sample

requirements.

(2)-b Step: Sampler Mode (WBC-SM control after calibration)

WBC_ SM WBC Deviation Factor

3.64 3.39 0.9313

7.78 7.95 1.0219

1.68 12.95 0.9466

8.11 8.07 0.9951

12.64 12.87 1.0182

6,2 7.18 1.0846

6.39 6.67 1.0438

10.59 10.97 1.0359

6.04 6 0.9934

7.71 7.72 1.0013

Total deviation factor (mean) 1.0072

Since the deviation factor was now 1.0072 (0.72% < 1%) the

calibration setting was confirmed.

XT Series S/M 4-45 December 13, 2007

Page 49

4.12 Maintenance Check List

Item Action

Pneumatic

Unit

Main Unit

Hydraulics

(1) Compressor Leaf Valve/Filter Check/Clean

(2) Compressor Piston Ring Replace every 2

(3) Relief V alv e Adjust

(4) Tubing Check/Replace

(5) Trap Chamber Check/Clean

(1) 0.25 MPa Regulator Adjust

(2) 0.16 MPa Regulator Adjust

(3) 0.07 MPa Regulator Adjust

(4) Bellows Unit No.7 (0.04 MPa) Check/Adjust/

(5) Tubing Check/Replace

(1) Waste Chambe rs and Trap

Chamber

(2) Waste Chambe r Drain Line Tubing

Replace

(3) Rinse Cup Check/Clean

(4) SRV (include Tray) Check/Clean

(5) Sample Aspiration Pipe Check/Clean

(6) SRV Drive Mechanism Check

(7) WBC Flow Cell/RBC Transducer Check/Clean

(8) Reaction Chamber Mixing Mech.

(Mixing motor RPM/Belt)

(9) Charging Line T ubing Replace every 2

(10) FCM Sheath Syringe Seal No.18/

O-RING NO.12

(11) RBC Sheath Syringe (check for

leakage)

year or every

60,000 cycles

Clean

Check/Clean

Replace every 2

year or every

60,000 cycles

Check

year or every

60,000 cycles

Replace every 2.5

years or 142,500

cycles

Check

(1) HGB Unit Check/Clean Electronics

(2) Power input/ output Check

Others

(1) Data V erifi cation Check

(2) Piercing Position Check/Adjust

(3) HGB Spa n Check/Adjust

(4) WBC Optical Axis Check/Adjust

(5) Sensitivity of WBC, RBC and PLT Check/Adjust

(6) Outer Cover Clean

(7) QC Check

(8) Supplied parts check

Check

XT Series S/M 4-46 December 13, 2007

Page 50

4.13 DP Volume Verification

4.13.1 SLS DP

(1) Disconnect the upper tubing on MV2-1 of Valve Unit No.165.

(2) Connect a tube Teflon 0.8 X1.8 (length: 180 mm) using Rubber Joint

No.22 instead.

(3) Place the other side of the Teflon tube into a Micro tube or equivalent.

(4) Select “Service”

(5) Repeat step (4) so that there is no bubble in the Teflon tubing.

(6) Place a Micro tube onto electric weigh device. Reset the scale to

“zero”.

(7) Repeat steps (3) and (4).

Æ “Diaphragm Pump” to activate DP once.

(8) Weigh the Micro tube with solution and confirm the measure value is

within the following range.

0.4904 – 0.5104 g

(9) If the value is not within the range, replace the diaphragm pump.

4.13.2 HGB DP

(1) Disconnect the upper tubing on MV3-1 of Valve Unit No.165.

(2) Connect a tube Teflon 0.8 X1.8 (length: 180 mm) using Rubber Joint

No.22 instead.

(3) Place the other side of the Teflon tube into a Micro tube or equivalent.

(4) Select “Service”

Æ “Diaphragm Pump” to activate DP once.

(5) Repeat step (4) so that there is no bubble in the Teflon tubing.

XT Series S/M 4-47 December 13, 2007

Page 51

(6) Place a Micro tube onto electric weigh device. Reset the scale to

“zero”.

(7) Repeat steps (3) and (4).

(8) Weigh the Micro tube with solution and confirm the measure value is

within the following range.

0.9754 – 1.0144 g

(9) If the value is not within the range, replace the diaphragm pump.

4.13.3 DIFF DP

(1) Disconnect the upper tubing on MV12-1 of Valve Unit No.166.

(4) Select “Service”

Æ “Diaphragm Pump” to activate DP once.

(5) Repeat step (4) so that there is no bubble in the Teflon tubing.

(6) Place a Micro tube onto electric weigh device. Reset the scale to

“zero”.

(7) Repeat steps (3) and (4).

(8) Weigh the Micro tube with solution and confirm the measure value is

within the following range.

0.9754 – 1.0144 g

(9) If the value is not within the range, replace the diaphragm pump.

(2) Connect a tube Teflon 0.8 X1.8 (length: 180 mm) using Rubber Joint

No.22 instead.

(3) Place the other side of the Teflon tube into a Micro tube or equivalent.

XT Series S/M 4-48 December 13, 2007

Page 52

4.13.4 RET Diluent DP

(1) Disconnect the upper tubing on MV13-1 of Valve Unit No.166.

(8) Weigh the Micro tube with solution and confirm the measure value is

within the following range.

2.050 – 2.200 g

(9) If the value is not within the range, adjust the volume as shown below.

(2) Connect a tube Teflon 0.8 X1.8 (length: 180 mm) using Rubber Joint

No.22 instead.

(3) Place the other side of the Teflon tube into a Micro tube or equivalent.

(4) Select “Service”

Æ “Diaphragm Pump” to activate DP once.

(5) Repeat step (4) so that there is no bubble in the Teflon tubing.

(6) Place a Micro tube onto electric weigh device. Reset the scale to

“zero”.

(7) Repeat steps (3) and (4) two times.

XT Series S/M 4-49 December 13, 2007

Page 53

4.13.5 BASO DP

(1) Disconnect the upper tubing on MV14-2 of Valve Unit No.166.

(8) Weigh the Micro tube with solution and confirm the measure value is

within the following range.

0.9754 – 1.0144 g

(9) If the value is not within the range, replace the diaphragm pump.

4.12.6 RBC DP

(1) Disconnect the upper tubing on MV14-3 of Valve Unit No.166.

(2) Connect a tube Teflon 0.8 X1.8 (length: 180 mm) using Rubber Joint

No.22 instead.

(3) Place the other side of the Teflon tube into a Micro tube or equivalent.

(4) Select “Service”

(5) Repeat step (4) so that there is no bubble in the Teflon tubing.

(6) Place a Micro tube onto electric weigh device. Reset the scale to

“zero”.

(7) Repeat steps (3) and (4).

Æ “Diaphragm Pump” to activate DP once.

(2) Connect a tube Teflon 0.8 X1.8 (length: 180 mm) using Rubber Joint

No.22 instead.

(3) Place the other side of the Teflon tube into a Micro tube or equivalent.

(4) Select “Service”

Æ “Diaphragm Pump” to activate DP once.

(5) Repeat step (4) so that there is no bubble in the Teflon tubing.

XT Series S/M 4-50 December 13, 2007

Page 54

(6) Place a Micro tube onto electric weigh device. Reset the scale to

“zero”.

(7) Repeat steps (3) and (4).

(8) Weigh the Micro tube with solution and confirm the measure value is

within the following range.

1.90 – 2.10 g

(9) If the value is not within the range, replace the diaphragm pump.

4.13.7 DIFF Dye DP

(1) Disconnect the upper tubing on MV34-3 of Valve Unit No.168.

(5) Repeat step (4) so that there is no bubble in the Teflon tubing.

(6) Place a Micro tube onto electric weigh device. Reset the scale to

“zero”.

(7) Repeat steps (3) and (4).

(8) Weigh the Micro tube with dye solution and confirm the measure

value is within the following range.

19.000 – 21.500 mg

(9) If the value is not within the range, adjust the volume as shown below.

(2) Connect a tube Teflon 0.8 X1.8 (length: 180 mm) using Rubber Joint

No.22 instead.

(3) Place the other side of the Teflon tube into a Micro tube or equivalent.

(4) Select “Service”

Æ “Diaphragm Pump” to activate DP once.

XT Series S/M 4-51 December 13, 2007

Page 55

4.13.8 RET Dye DP

(1) Disconnect the upper tubing on MV33-1 of Valve Unit No.168.

(2) Connect a tube Teflon 0.8 X1.8 (length: 180 mm) using Rubber Joint

No.22 instead.

(3) Place the other side of the Teflon tube into a Micro tube or equivalent.

(4) Select “Service”

Æ “Diaphragm Pump” to activate DP once.

(5) Repeat step (4) so that there is no bubble in the Teflon tubing.

(6) Place a Micro tube onto electric weigh device. Reset the scale to

“zero”.

(7) Repeat steps (3) and (4).

(8) Weigh the Micro tube with dye solution and confirm the measure

value is within the following range.

19.000 – 21.500 mg

(9) If the value is not within the range, adjust the volume as shown below.

XT Series S/M 4-52

December 13, 2007

Page 56

4.14 Sensitivity Adjustment for XT-2000iV/XT-1800iV

4.14.1 Changed contents

The sensitivity adjustment for XT-2000iV/XT-1800iV differs from

XT-2000i/XT-1800i as follows.

(1) RET (FSC) discrete setting is added.

(2) Animal frame is added in DIFF-CH sensitivity setting screen. (This is

reserved. Currently, the frame does not function and entering a value

will not affect the result.) Human blood has to be measured with the

profile "Other (for North America, “Human”)" in case

XT-2000iV/XT-1800iV software is installed.

4.14.2 Added RET (FSC) discrete setting

RET (FSC) discrete setting became available to avoid missing smaller

PLTs.

(1)The range of setting: 1 - 4

The default value is “4” for the XT-2000i/XT-1800i. Change the value

to “1” when installing XT-2000iV/XT-1800iV software. (Refer to

installation procedure)

Both [Human] and [Animal] frames must be set as “1”.

4.14.3 Added Animal frame in DIFF-CH sensitivity screen.

This frame is currently reserved for future functional expansion. The

frame of (Human) must be used (not the frame for animal) for the setting.

(The animal frame in DIFF-CH does not affect to any results.)

Figure 4.13.3: Sensitivity setting screen

XT Series S/M 4-53 December 13, 2007

Page 57

4.14.4 Sensitivity Adjustment procedure (same as

XT-2000i/XT-1800i)

(1) Select “Menu”

Æ “Controller” Æ “Service” Æ “Mode”, and check

“Control 3” in Analytical Mode. Then press OK.

(2) Press [Manual] and select “CBC+DIFF+RET” for discrete and

“Manual” for [Mode]. Press [OK] button.

(3) Press [Auto-Rinse] to run rinse sequence.

(4) Confirm that no background error appears after Auto-Rinse.

(5) Analyze e-CHECK (level 2) in manual mode.

(6) Confirm all parameters below falls within the range.

Parameter Target value Parameter to be

adjusted

RBC-X Assayed value +/- 1 CH RET(SFL)

RBC-Y Assayed value +/- 3 CH RET(FSC)

DIFF-X Assayed value +/- 3 CH DIFF(SSC)

DIFF-Y Assayed value +/- 2 CH DIFF(SFL)

BASO-X Assayed value +/- 3 CH BASO(SSC)

BASO-Y Assayed value +/- 2 CH BASO(FSC)

(MCV) Assayed value +/- 1 fL RBC gain

(MPV) Assayed value +/- 1fL PLT gain

Blank 20.00 ± 2.0 HGB Blank

Sample Assayed value +/- 0.2 g/dL HGB Span

Check the value in the data browser screen.

Table 4.13.4.1: Adjustment range

(7) If there are parameters which do not falls within the range, change the

value in the sensitivity screen as below steps.

(8) Select Menu

Æ Controller Æ Service Æ Sensitivity.

*2

*1

*3

*2

*2

*2

*1

*1

*1

*2

*2

Figure 4.13.4.1: Sensitivity adjustment window

(9) Enter the target values in

*1 boxes for RBC-Y, BASO-Y, MCV and

MPV, then press “>>>” button to calculate the digital volume

automatically. Then press “Send” button to reflect the changed

digital volume value.

(10) Enter values of digital volume in

*2 boxes directly for RET (SFL),

DIFF(SSC), DIFF(SFL), BASO(SSC), HGB blank and HGB span.

Then press “Send” button to reflect the digital volume value.

XT Series S/M 4-54 December 13, 2007

Page 58

(11) Analyze e-CHECK (level 2) again and if the values do not fall within

the target value of Table 4.13.4.1, repeat the steps of (9) through

(11).

4.14.5 RET (FSC) discrete setting

(1) Enter value “1” in

button. (

Both [Human] and [Animal] frames must be set as “1”.

*3 box in the Figure 4.13.4.1 and press “Send”

The scattergram location is not affected by changing the value in the

RET (FSC) discri for Human and Animal.)

This setting must be performed when installing XT-2000iV/XT-1800iV

software.

XT Series S/M 4-55 December 13, 2007

Page 59

4.16 Rinse Cup Height Adjustment

(1) Select Rinse Cup Motor “Down” test by entering “Service”

Cup Motor”

Æ “Down”.

(2) The rinse cup descent in lower position.

(3) Verify the pipette tip is located between gap A.

(4) If adjustment is necessary, adjust the Rinse Cup height by loosening

two fixing screws shown below so that the pipette end will be between

the gap A.

A

Æ “Rinse

Rinse Cup No.35

XT Series S/M 4-56 December 13, 2007

Page 60

4.17 Adjusting Sensitivity and Calibration for XT RET master

XT RET master needs more accurate adjusting sensitivity

and calibration than ordinal XT-2000i in order to increase

accuracy of RET-He.

4.17.1 Adjusting RET channel sensitivity

(1) Required material: e-CHECK (Level 2)

(2) The number of times for measurement: More than five times for

each sample

(3) Procedure

1) Start the IPU program. After starting the IPU program, start the

main unit in service mode. Run e-CHECK more than five times in

CTRL3 mode.

2) Calculate RBC-Y mean value.

NOTE:

To calibrate the RET-He, use the XT.ini not the

XT-2100i*****.CAL (***** stands for instrument ID). To take

effect the changed XT.ini, restart both the main unit and IPU

program. Make sure that editing theXT.ini after quitting the

IPU program.

3) Adjust the volume so that the RBC-Y is within +/-2ch of RBC-Y

value on e-CHECK assay value.

Refer to

Service Manual for detailed procedure.

4.17.2 Confirmation and calibration of RET-He

Perform this step after above

completed.

(1) Required material: e-CHECK (Level 2)

(2) The number of times for measurement: More than five times for

each sample

(3) Procedure

1) Start the IPU program. After stating the IPU program, start the

2) Calculate RET-He mean value.

3) When the value is within +/-1pg compared with e-CHECK

4) Calculate the correction factor so that the RET-He result is within

5) Turn off the XT-2000i Main Unit and quit the IPU program. Log-on

6) Open C:¥WINDOWS¥XT.ini (Windows XP) or C:¥WINNT¥XT.ini

7) Start the IPU program. After stating the IPU program, start the

8) Calculate the mean value of RBC-He and confirm that the value is

main unit in service mode. Run e-CHECK more than five times in

CTRL3 mode.

(RET-He) value, complete the operation. When the value is

higher than +/-1pg,follow the step (4) and after.

+/-1pg of the e-CHECK assay value as follows.

(Example)

e-CHECK assay value: 26.2pg

Mean value obtained step (2): 27.3pg

The correction factor will be (26.2/27.3)X1000=960 (rounded).

to Windows as “Administrator”. When IPU program starts, quit it.

(Windows 2000) using Explorer. Locate HE_SRV_CAL=1000

and change the value to correction factor calculated in step (4).

Save the file by overwriting it.

main unit in service mode. Run e-CHECK more than five times in

CTRL3 mode.

within +/- 1pg of the assay value.

1. Adjusting RET channel sensitivity is

XT Series S/M 4-57 December 13, 2007

Page 61

May, 22, 2008

4.17 Position Adjusting of SRV

NOTE: Tools Needed: Pin gauge( 0.8mm drill bit)

(1) Pass pin gauge through adjusting hole while air cylinder is up.

(2) Adjust the position of lower Adjustment Plate No.17 to touch the

arm of SRV Rotor Valve No.22 and fully tighten Screw

Hex-Socket Bolt.

Adjustment Hole

SRV Fixed Valve No.33

Adjustment Plate No.17

Arm of SRV Rotor Valve No.22

(3) Pass Pin gauge through adjusting hole while air cylinder is

down.

(4) Adjusting the position of upper Adjusting Plate No.17 to fit the

arm of SRV Rotor Valve No.22 and fully tighten Screw

Hex-Socket Bolt.

Adjustment Hole

SRV Fixed Valve No.33

Adjustment Plate No.22

Screw Hex Socket Bolt

M3XM6 (SUS)

XT Series S/M 4-59

Loading...

Loading...