SYRUNS SY6000-Z, SY6000-Z01140Y, SY6000-Z02240Y, SY6000-Z03040Y, SY6000-Z01540Y Series Manual

...

Contents

PREFACE...............................................................................................1

CHAPTER 1 PRINCIPLE OF ENERGY SAVING...............................2

CHAPTER 2 FEATURES ......................................................................4

2.2 INSTRUCTION OF MODEL NO. ............................................................4

2.3 SPECIFICATIONS ................................................................................4

2.4 OVERALL DIMENSIONS......................................................................5

CHAPTER 3 INSTALLATION..............................................................6

3.1 INSTALLATION SITE...........................................................................6

3.2 PRECAUTIONS:..................................................................................6

3.3 MAIN CIRCUIT AND CONTROL CIRCUIT .............................................7

CHAPTER 4 OPERATION....................................................................8

4.1 SWITCHOVER BETWEEN POWER FREQUENCY AND ENERGY-SAVING .8

4.1.1 Running at energy-saving switching to power frequency......8

4.1.2 Running at power frequency switching to energy saving......8

4.2 TESTING STAGE OF THE CABINET......................................................9

4.3 NORMAL USING STAGE......................................................................9

4.4 KEYPAD OPERATION .................................................................10

4.4.1 KEYPAD FUNCTION ......................................................................10

4.4.2 KEYPAD BASIC OPERATION ..........................................................10

4.4.2.1 Direct display status..........................................................10

4.4.2.2 Switchover of display parameter.......................................10

CHAPTER 5 PARAMETERS..............................................................12

CHAPTER 6 TROUBLESHOOTING.................................................18

6.1 FAULT CODE AND REASON ANALYSIS ..............................................18

6.2 ADJUSTMENT OF DEFECTIONS.........................................................20

CHAPTER 7 MAINTENANCE...........................................................22

7.1 DAILY INSPECTION..........................................................................22

7.2 REGULAR MAINTENANCE................................................................22

7.3 PERIODIC MAINTENANCE................................................................23

7.4 STORAGE.........................................................................................23

0

User Manual of SY6000-Z series Preface

PREFACE

Thanks for choosing SY6000-Z series moulding injection

energy saving cabinet.

SY6000-Z series cabinet is high quality moulding injection

energy saving drive which is designed according to

IEC618000/IEC610000. The cabinet owns protection functions of

phase-loss, over voltage, under voltage, over current, etc.

SY6000-Z series cabinet is suitable for kinds of moulding

injection machine with hydraulic control proportional pump. It

controls output power of motor according to pressure signal and

flow signal of moulding injection machine to reach the objective

of energy saving. The energy saving rate may get 25%~65%.

SY6000-Z series cabinet can work for pump motors which

power ratings are from 11KW~55KW. It also can apply for one

moulding injection machine with multiple pump motors.

Before using SY6000-Z series cabinet, in order to keep

people in safe and acquire better energy-saving effect, please read

the manual thoroughly. If you meet with tough problems when

using, please contact us in time.

Please retain this manual and you will use it if necessary in

future.

1

User Manual of SY6000-Z series Principle of energy-saving

Chapter 1 Principle of energy saving

Power consumption of moulding injection machine

mainly in the following sections:

① Power consumption of hydraulic pump system;

② Power consumption of heaters;

③ Power consumption of circulating cooling water pump

Electricity consumption of hydraulic pump accounts for

80% energy consumption of the injection molding machine, so

reducing the power consumption is the key to save energy for

molding injection machine.

The pressure and flow are changing when molding

injection machine is in matching mould, cross locking,

injection, material storing, cooling and other stages.

When oil need of the injection molding machine changes,

the relief valve in pump outlet will adjust pressure and flow of

the load, while the output motor power is the same, thus results

in waste of energy.

According to requirements of pressure and speed at the

current work status of moulding injection machine, such as

stages of mold, lock cross, shooting rubber, material storage

and cooling, SY6000-Z series cabinet can adjust automatically

the pump speed the fuel supply to make actual fuel supply be

consistent with actual load flow at any working stage.

Thus it eliminates overflowing of hydraulic oil, reduces

pump output, and saves electricity consumption of pump motor,

so as to achieve the best energy-saving state of moulding

injection machine.

2

User Manual of SY6000-Z series Principle of energy-saving

3

User Manual of SY6000-Z series Features

Chapter 2 Features

2.1 SY6000-Z series cabinet is suitable for quantitative pump

moulding injection machine. Its features are as follows:

z Adopt advanced space voltage vector PWM control algorithm, with

advanced technology and low output current harmonic content, without

power supply pollution

z With timing functions, cumulative working time can be recorded

under energy saving state.

z Adopt high-quality imported components, product quality assured

z Excellent fault management and protection features make cabinet and

motor away from damage under no circumstance

z Large capacity of instantaneous impact current, up to 250%; overload

capacity 180% per minute

z No trip when the moulding injection machine is under high pressure

plastic injection and heavy load, so as do not affect production, ensure

product quality

z Advanced integrated cabinet, with switchover of power frequency /

energy saving, with dedicated air channel, compact structure, easy to

install

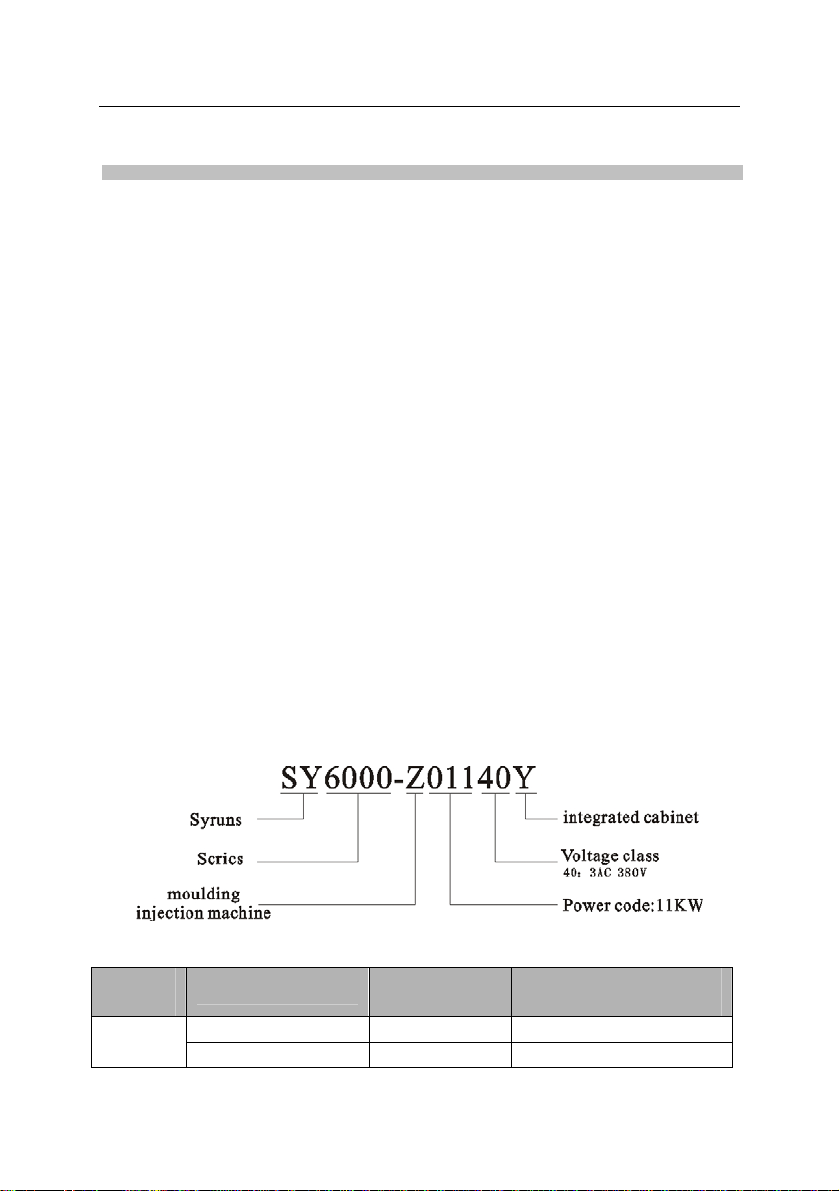

2.2 Instruction of model no.

2.3 Specifications

Voltage

class

380V

Model no.

SY6000-Z01140Y 11.0 24 3PH

SY6000-Z01540Y 15.0 33

Power rating

(kW)

4

Rated output current

(A)

User Manual of SY6000-Z series Features

Voltage

class

Model no.

Power rating Rated output current

(kW) (A)

SY6000-Z01840Y 18.5 39

SY6000-Z02240Y 22.0 44

SY6000-Z03040Y 30.0 60

SY6000-Z03740Y 37.0 75

SY6000-Z04540Y 45.0 90

SY6000-Z05540Y 55.0 110

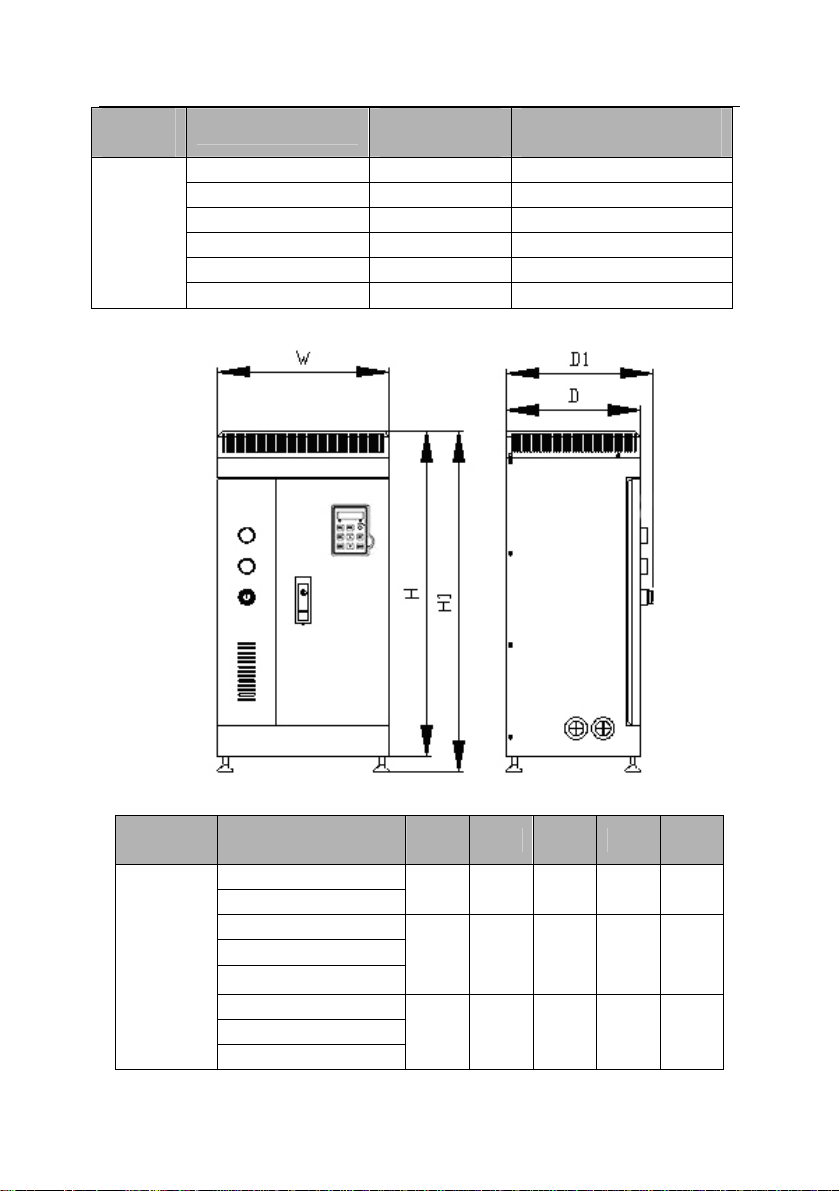

2.4 Overall dimensions

Installation dimensions of SY6000-Z series AC Drives (unit: mm)

Voltage

class

Model no. W H H1 D D1

SY6000-Z01140Y

SY6000-Z01540Y

320 630 660 200 225

SY6000-Z01840Y

3PH

380V

SY6000-Z02240Y

SY6000-Z03040Y

390 780 810 300 325

SY6000-Z03740Y

SY6000-Z04540Y

500 850 880 350 375

SY6000-Z05540Y

5

User Manual of SY6000-Z series Installation

Chapter 3 Installation

3.1 Installation site:

In order to get good performance and long lifespan, the installation

site should meet the following conditions:

z Good indoor ventilation.

z Ambient temperature-10 ~40 .℃℃

z Humidity less than 90%RH, without dew.

z Don’t install in the combustibles such as woods.

z Avoid direct sunlight.

z No combustible, explosive, corrosive gases and liquids.

z No ash dust, oil dust, floatable fibers and metal particles.

z Strong installation base, no vibration.

z No electromagnetic interference.

3.2 ★ Precautions:

1. The cabinet applies for injection equipment which is dragged by

general three-phase AC induction motor or inverter motor. Motor

insulation class is B or above.

2. General three phase induction motor, which is driven by the

cabinet, can not run in long term at low speed.

3. Capacitor, VDR and other RC absorbing devices are not allowed

to connect with output terminals of the cabinets.

4. If there are contactors between the cabinet and the motor, must

ensure that the cabinet doesn’t output when the contact switches,

otherwise the cabinet may be damaged.

5. Installation environment should be well ventilated.

6. The cabinet should be used derating if the altitude is higher

than1000 meters. Derate using 10% when the altitude rises 1500 meters.

7. Compare with running at power frequency, temperature rise and

noise of the motor will increase slightly when use the cabinet. This is

6

User Manual of SY6000-Z series Installation

normal phenomenon.

8. The cabinet will be as industrial waste when scrap it, so please

be careful:

(1) Inner polyester capacitors probably explode if set it on fire.

(2) Plastic pieces may produce toxic gases when burn it.

3.3 Main circuit and control circuit

7

Loading...

Loading...