SYRUNS SY6000-Z, SY6000-Z01140Y, SY6000-Z02240Y, SY6000-Z03040Y, SY6000-Z01540Y Series Manual

...Page 1

Contents

PREFACE...............................................................................................1

CHAPTER 1 PRINCIPLE OF ENERGY SAVING...............................2

CHAPTER 2 FEATURES ......................................................................4

2.2 INSTRUCTION OF MODEL NO. ............................................................4

2.3 SPECIFICATIONS ................................................................................4

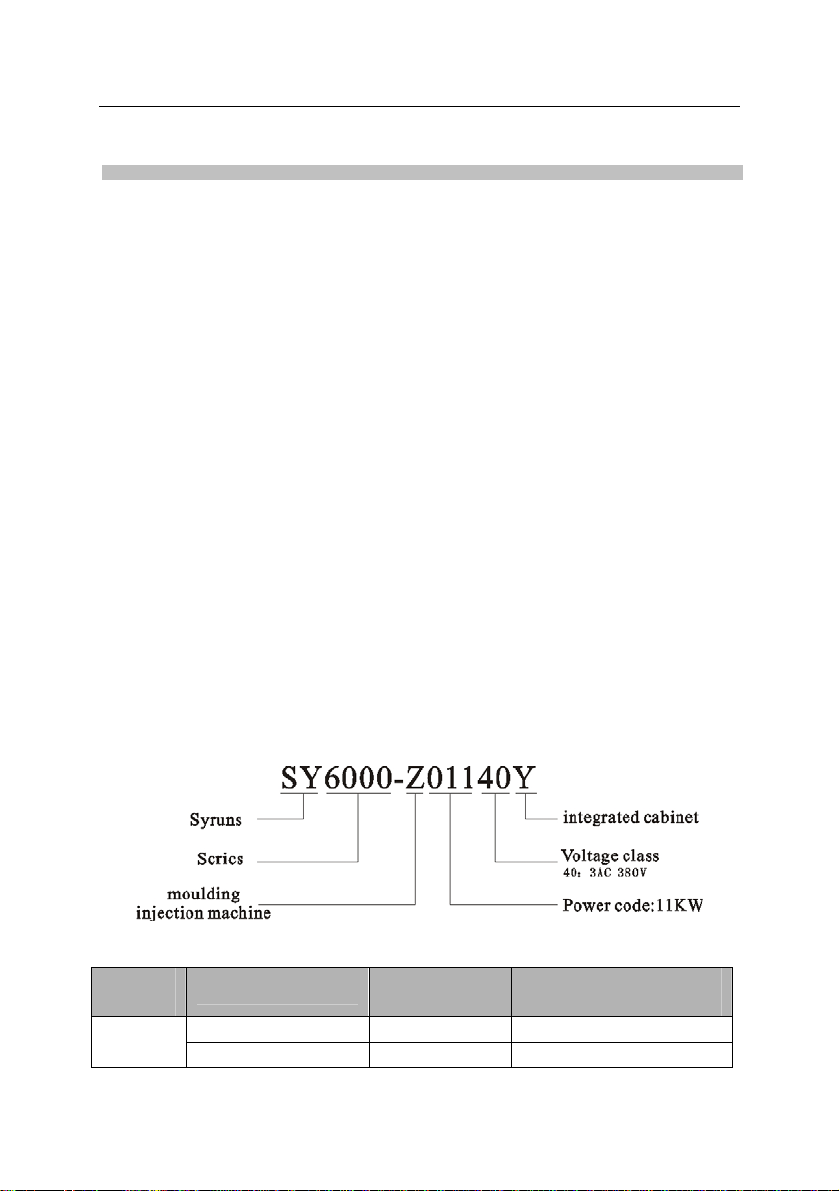

2.4 OVERALL DIMENSIONS......................................................................5

CHAPTER 3 INSTALLATION..............................................................6

3.1 INSTALLATION SITE...........................................................................6

3.2 PRECAUTIONS:..................................................................................6

3.3 MAIN CIRCUIT AND CONTROL CIRCUIT .............................................7

CHAPTER 4 OPERATION....................................................................8

4.1 SWITCHOVER BETWEEN POWER FREQUENCY AND ENERGY-SAVING .8

4.1.1 Running at energy-saving switching to power frequency......8

4.1.2 Running at power frequency switching to energy saving......8

4.2 TESTING STAGE OF THE CABINET......................................................9

4.3 NORMAL USING STAGE......................................................................9

4.4 KEYPAD OPERATION .................................................................10

4.4.1 KEYPAD FUNCTION ......................................................................10

4.4.2 KEYPAD BASIC OPERATION ..........................................................10

4.4.2.1 Direct display status..........................................................10

4.4.2.2 Switchover of display parameter.......................................10

CHAPTER 5 PARAMETERS..............................................................12

CHAPTER 6 TROUBLESHOOTING.................................................18

6.1 FAULT CODE AND REASON ANALYSIS ..............................................18

6.2 ADJUSTMENT OF DEFECTIONS.........................................................20

CHAPTER 7 MAINTENANCE...........................................................22

7.1 DAILY INSPECTION..........................................................................22

7.2 REGULAR MAINTENANCE................................................................22

7.3 PERIODIC MAINTENANCE................................................................23

7.4 STORAGE.........................................................................................23

0

Page 2

User Manual of SY6000-Z series Preface

PREFACE

Thanks for choosing SY6000-Z series moulding injection

energy saving cabinet.

SY6000-Z series cabinet is high quality moulding injection

energy saving drive which is designed according to

IEC618000/IEC610000. The cabinet owns protection functions of

phase-loss, over voltage, under voltage, over current, etc.

SY6000-Z series cabinet is suitable for kinds of moulding

injection machine with hydraulic control proportional pump. It

controls output power of motor according to pressure signal and

flow signal of moulding injection machine to reach the objective

of energy saving. The energy saving rate may get 25%~65%.

SY6000-Z series cabinet can work for pump motors which

power ratings are from 11KW~55KW. It also can apply for one

moulding injection machine with multiple pump motors.

Before using SY6000-Z series cabinet, in order to keep

people in safe and acquire better energy-saving effect, please read

the manual thoroughly. If you meet with tough problems when

using, please contact us in time.

Please retain this manual and you will use it if necessary in

future.

1

Page 3

User Manual of SY6000-Z series Principle of energy-saving

Chapter 1 Principle of energy saving

Power consumption of moulding injection machine

mainly in the following sections:

① Power consumption of hydraulic pump system;

② Power consumption of heaters;

③ Power consumption of circulating cooling water pump

Electricity consumption of hydraulic pump accounts for

80% energy consumption of the injection molding machine, so

reducing the power consumption is the key to save energy for

molding injection machine.

The pressure and flow are changing when molding

injection machine is in matching mould, cross locking,

injection, material storing, cooling and other stages.

When oil need of the injection molding machine changes,

the relief valve in pump outlet will adjust pressure and flow of

the load, while the output motor power is the same, thus results

in waste of energy.

According to requirements of pressure and speed at the

current work status of moulding injection machine, such as

stages of mold, lock cross, shooting rubber, material storage

and cooling, SY6000-Z series cabinet can adjust automatically

the pump speed the fuel supply to make actual fuel supply be

consistent with actual load flow at any working stage.

Thus it eliminates overflowing of hydraulic oil, reduces

pump output, and saves electricity consumption of pump motor,

so as to achieve the best energy-saving state of moulding

injection machine.

2

Page 4

User Manual of SY6000-Z series Principle of energy-saving

3

Page 5

User Manual of SY6000-Z series Features

Chapter 2 Features

2.1 SY6000-Z series cabinet is suitable for quantitative pump

moulding injection machine. Its features are as follows:

z Adopt advanced space voltage vector PWM control algorithm, with

advanced technology and low output current harmonic content, without

power supply pollution

z With timing functions, cumulative working time can be recorded

under energy saving state.

z Adopt high-quality imported components, product quality assured

z Excellent fault management and protection features make cabinet and

motor away from damage under no circumstance

z Large capacity of instantaneous impact current, up to 250%; overload

capacity 180% per minute

z No trip when the moulding injection machine is under high pressure

plastic injection and heavy load, so as do not affect production, ensure

product quality

z Advanced integrated cabinet, with switchover of power frequency /

energy saving, with dedicated air channel, compact structure, easy to

install

2.2 Instruction of model no.

2.3 Specifications

Voltage

class

380V

Model no.

SY6000-Z01140Y 11.0 24 3PH

SY6000-Z01540Y 15.0 33

Power rating

(kW)

4

Rated output current

(A)

Page 6

User Manual of SY6000-Z series Features

Voltage

class

Model no.

Power rating Rated output current

(kW) (A)

SY6000-Z01840Y 18.5 39

SY6000-Z02240Y 22.0 44

SY6000-Z03040Y 30.0 60

SY6000-Z03740Y 37.0 75

SY6000-Z04540Y 45.0 90

SY6000-Z05540Y 55.0 110

2.4 Overall dimensions

Installation dimensions of SY6000-Z series AC Drives (unit: mm)

Voltage

class

Model no. W H H1 D D1

SY6000-Z01140Y

SY6000-Z01540Y

320 630 660 200 225

SY6000-Z01840Y

3PH

380V

SY6000-Z02240Y

SY6000-Z03040Y

390 780 810 300 325

SY6000-Z03740Y

SY6000-Z04540Y

500 850 880 350 375

SY6000-Z05540Y

5

Page 7

User Manual of SY6000-Z series Installation

Chapter 3 Installation

3.1 Installation site:

In order to get good performance and long lifespan, the installation

site should meet the following conditions:

z Good indoor ventilation.

z Ambient temperature-10 ~40 .℃℃

z Humidity less than 90%RH, without dew.

z Don’t install in the combustibles such as woods.

z Avoid direct sunlight.

z No combustible, explosive, corrosive gases and liquids.

z No ash dust, oil dust, floatable fibers and metal particles.

z Strong installation base, no vibration.

z No electromagnetic interference.

3.2 ★ Precautions:

1. The cabinet applies for injection equipment which is dragged by

general three-phase AC induction motor or inverter motor. Motor

insulation class is B or above.

2. General three phase induction motor, which is driven by the

cabinet, can not run in long term at low speed.

3. Capacitor, VDR and other RC absorbing devices are not allowed

to connect with output terminals of the cabinets.

4. If there are contactors between the cabinet and the motor, must

ensure that the cabinet doesn’t output when the contact switches,

otherwise the cabinet may be damaged.

5. Installation environment should be well ventilated.

6. The cabinet should be used derating if the altitude is higher

than1000 meters. Derate using 10% when the altitude rises 1500 meters.

7. Compare with running at power frequency, temperature rise and

noise of the motor will increase slightly when use the cabinet. This is

6

Page 8

User Manual of SY6000-Z series Installation

normal phenomenon.

8. The cabinet will be as industrial waste when scrap it, so please

be careful:

(1) Inner polyester capacitors probably explode if set it on fire.

(2) Plastic pieces may produce toxic gases when burn it.

3.3 Main circuit and control circuit

7

Page 9

User Manual of SY6000-Z series Operation

Chapter 4 Operation

4.1 Switchover between power frequency and energy-saving

4.1.1 Running at energy-saving switching to power frequency

1. The cabinet runs at the state of energy-saving, and the indicator lights.

2. Turn off pump motor of moulding injection machine, and make sure

the motor has stopped.

3. Rotate changeover switch, the indicator of power frequency running

lights at this time, then the cabinet starts running at the state of power

frequency running.

4. Start main motor of moulding injection machine, and start normal

operation

4.1.2 Running at power frequency switching to energy saving

1. The cabinet runs at the state of power frequency, and the indicator of

power frequency running lights.

2. Turn off pump motor of moulding injection machine, and make sure

the motor has stopped.

3. Rotate changeover switch, the indicator of energy saving running

lights at this time, then the cabinet starts running at the state of energy

saving running.

4. Start main motor of moulding injection machine, and start normal

operation.

★Key point:

Turn off the motor of moulding injection motor before switchover

between power frequency and energy saving running, then start switching

between power frequency and energy-saving.

8

Page 10

User Manual of SY6000-Z series Operation

4.2 Testing stage of the cabinet

Under circumstance of same mould and raw material, measure

electricity consumptions of moulding injection machine at two running

states of power frequency and energy saving during the same time, and

calculate energy saving rate.

When switch power frequency and energy saving, technician should

adjust timely parameters of moulding injection machine and the cabinet

until it produces qualified products.

For some types injection molding machines, don’t need change

parameters of moulding injection machine after adjustment of the cabinet,

as switchover between power frequency and energy saving doesn’t effect

product quality.

4.3 Normal using stage

After installation and adjustment of the cabinet, please run the cabinet

at the state of energy saving in normal use.

When users need replace moulds, technician only need adjust the

parameters of flow and pressure until it produces qualified produ cts.

Precautions: ★

1. Shunting changeover switch is forbidden during running. Otherwise

it will cause malfunction to the cabinet.

2. Do not convert running of power frequency/ energy saving, so as to

avoid protection action of the cabinet.

Warning:★

Do not connect AC power supply to output terminals (U, V, W),

otherwise will lead to damage the cabinet, and even cause fires!

9

Page 11

User Manual of SY6000-Z series Operation

4.4 Keypad operation

4.4.1 Keypad function

Control panel keypad of SY6000-Z series energy saving cabinet

consists of LED digital monitor, LED indicator, operation keys and panel

potentiometer, as shown in Figure 4-1.

Figure 4-1 Name and instruction of keypad

4.4.2 Keypad basic operation

4.4.2.1 Direct display status

Direct display status of SY6000-Z series cabinet refers to initial

display mode after power on, which is used for displaying output

frequency of the cabinet.

4.4.2.2 Switchover of display parameter

In the status of direct display, we can view or modify function

10

Page 12

User Manual of SY6000-Z series Operation

parameters by keypad operations.

Figure 4-2 Operation procedure of parameter setting

11

Page 13

User Manual of SY6000-Z series Parameters

Chapter 5 Parameters

Basic functions of molding injection machines

Function

code

Description Setting range Default Model No.

Group F0 Basic function

0:keypad running

F0.00

F0.01

F0.02

F0.03

F0.04

F0.05

F0.06

F0.07 Rated current 0.0~760.0A

Running setting

selection

Max output

frequency

Upper limit

frequency

Lower limit

frequency

Acceleration time

0

Deceleration time

0

Rated power

rating

1:terminal running

2:communication

running

F0.02~600.00Hz 50.00Hz ◎ 1

F0.03~F0.01 50.00Hz ◎ 2

0.00 Hz~F0.02 0.00Hz ◎ 3

0.1~3600.0s

0.1~3600.0s

1.5~400.0kW

0 ◎ 0

Depend

on models

Depend

on models

Depend

on models

Depend

on models

○ 4

○ 5

● 6

● 7

F0.08

F1.00

Parameter

initiation

Group F1 Frequency setting

Keypad setting

frequency

0: No operation

1: Restore default

2: Clear fault record

0.00 Hz~F0.01 50.00Hz

12

0 ◎ 8

○

9

Page 14

User Manual of SY6000-Z series Parameters

Function

code

Description Setting range Default Model No.

F1.01

F1.02

F1.03

F1.04

F1.05

Main frequency

command

Auxiliary

frequency

command

Auxiliary

frequency

reference

Frequency

command

selection

UP/DOWN

setting

0: Keypad

1: AI1

2: AI2

3: HDI

4: Simple PLC

5: Multi-step speed

6: PID

7: Communication

8: Potentiometer

0: AI1

1: AI2

2: HDI

0: Max output

frequency

1: Main frequency

command

0: Main

1: Auxiliary

2: Main + auxiliary

3: Max (main,

auxiliary)

0: Valid, save

UP/DOWN value

when power off

1: Valid, do not save

UP/DOWN value

when power off

2: Invalid

○

0

10

○

0

11

○

0

12

○

0

13

0 ○ 14

F2.06 Stop mode

F2.12

Lower limit

frequency mode

Group F2 Start/stop control

0: Coast to stop

1: Free stop

0: Run at lower limit

frequency

13

0 ○ 28

0 ◎ 34

Page 15

User Manual of SY6000-Z series Parameters

p

Function

code

Description Setting range Default Model No.

F2.15

F6.10

F6.11

FA.14

FA.15

(valid when

frequency lower

limit >0)

Power-on terminal

running protection

Group F6 enhanced function

No. of fault auto

reset

Interval time of

fault auto reset

Group FA enhanced function

Third latest fault

type

Second latest fault

type

1: Stop

2: Sleep standby

0: Disabled when

power on

1: Enabled when

0 ○ 37

power on

0~9 0

0.1~100.0s 1.0s

0: No failure

1:Inverter unit

rotection (FLT)

2: Reserved

3: Reserved

● 212

4: Acc over-current

(OC1)

5: Dec over-current

(OC2)

6: Constant speed

over-current (OC3)

7: Acc over voltage

(OE1)

8: Dec over voltage

(OE2)

9: Constant speed over

● 213

voltage (OE3)

10:Bus under-voltage

failure (Uv)

○

○

117

118

14

Page 16

User Manual of SY6000-Z series Parameters

Function

code

Description Setting range Default Model No.

11:Motor overload

(OL1)

12: Over load (OL2)

13: Reserved

14: Output phase

failure (SPO)

15: Over heat (Ot)

16: Reserved

17: External fault (EF)

18:Communication

error (CE)

19:Current detection

error (ItE)

● 214

FA.16

Latest fault

Purpose

20: Motor

self-learning error (tE)

21: EEPROM

operation error (Err)

22:PID feedback

disconnection error

(PIDE)

23: Braking unit fault

(bCE)

24: Reserved

Group Fd Molding injection

Fd.00 Model selection

Max input of

Fd.01

Fd.02

proportional flow

control valve

Max input

frequency of

proportional flow

0: G purpose

1: P purpose

2: Molding injection

0 ◎ 238

purpose

0.0%~100.0% 100.0% ◎ 239

0.00Hz~F0.01 50.00Hz ◎ 240

15

Page 17

User Manual of SY6000-Z series Parameters

Function

code

Description Setting range Default Model No.

control valve

Min input current

Fd.03

of proportional

0.0%~Fd.01 0.0% ◎ 241

flow control valve

Min input

Fd.04

frequency of

proportional flow

0.00Hz~F0.01 0.00Hz ◎ 242

control valve

Input current

weighting

Fd.05

coefficient of

0.00~1.00 0.10 ◎ 243

proportional flow

control valve

Fd.06 Reserved 244

Fd.07 Reserved 245

Fd.08 Reserved 246

Fd.09 Reserved 247

Fd.10 Reserved 248

Max input current

Fd.11

of proportional

0.0%~100.0% 100.0% ◎ 249

flow control valve

Max input

Fd.12

frequency of

proportional flow

0.00Hz~F0.01 50.00Hz ◎ 250

control valve

Min input of

Fd.13

proportional flow

0.0%~Fd.11 0.0% ◎ 251

control valve

Fd.14

Min input

frequency of

0.00Hz~F0.01 0.00Hz

16

◎

252

Page 18

User Manual of SY6000-Z series Parameters

Function

code

Description Setting range Default Model No.

proportional flow

control valve

Input weighting

Fd.15

coefficient of

proportional flow

0.00~1.00 0.90

◎

253

control valve

Fd.16 Reserved 254

Fd.17 Reserved 255

Fd.18 Reserved 256

Fd.19 Reserved 257

Fd.20 Reserved 258

For more details, please reference to Chapter 5 of User Manual of

SY5000 series AC Drives.

17

Page 19

User Manual of SY6000-Z series Troubleshooting

Chapter 6 Troubleshooting

6.1 Fault code and reason analysis

The protection circuit and fault output relay activates, and stop the

machine and show failure, after the cabinet detects abnormal situations.

Make sure to find the failure causes and countermeasures, and run the

cabinet after troubleshooting.

The cabinet will record last 3 times causes of the malfunction. After

fault reset, you can check records any time in group E in viewing

functional parameters (Parameters FA.14~FA.16). For fault codes

description, please check Table 6-1.

Table 6-1 Fault name and reason analysis

Fault

code

oC1

oC2

oC3

oC2

oC3

oE1

oE3

Name Reason Troubleshooting

Please identify reasons,

Over-current

in operation

Over-current

in accel

Over-current

in decel

Over-voltage

in accel

Over-voltage

in operation

Output short circuit

or mutation load

1. The setting value

of accel time is too

small; 2. Torque

compensation

voltage value is set

in an error.

1. The setting value

of decel time is too

small;

2. Output short or

load mutation.

1.Power voltage is

too high; 2.load

speed has fluctuated

and reset after taking

approximate measures. If

this is still on, please ask

for technical support.

1. increase accel time

value;

2. increase or decrease

torque compensation

voltage value

1. increase decel time

value;

2. eliminate short-circuit or

load mutation

1.Make sure that the power

voltage is in the normal

range;

2. Decrease fluctuation of

load speed.

18

Page 20

User Manual of SY6000-Z series Troubleshooting

1. To change the decel time

oE2

Over-voltage

in decel

Load inertia

(GD2) is too big

so that it is suitable for the

load inertia;

2. connect braking unit

1. Short-circuit

FLt

Intelligent

power

module

(IPM)

protection

happens in the

upper and lower

bridge arms of IPM;

2. Other reason

causes oversized

Please identify reasons,

and reset after taking

approximate measures. If

this is still on, please ask

for technical support.

transient current.

Transient

Poff

power-cut or

under-voltage

fault

ot

Over-heat of

inverter

oL Over load

The power voltage

declines or transient

power failure

Please check power status

and wiring of input side.

occurs in operation.

1. Cooling fan is

abnormal; 2.

Ambient

temperature is too

high; 3. Air vent is

blocked

1. motor over-load;

2. V/F feature or

torque

compensation

capacity is

1. Check fan operation;

2.Make inverter operating

environment meet the

requirements;

3. Eliminate dust of the air

vent.

1. Decrease load or replace

larger capacity inverter;

2. Increase or decrease

torque compensation

voltage

uncertain.

Please store this parameter

Err

E2PROM

write data

error

Errors happen when

E2PROM stores

data.

again by using SET key, or

initialize by using E-059

parameter, cut off the

power and then power on.

EF

Emergency

stop

Terminal input,

EMS acts

Confirm the signal

connection.

Remark: E2PROM errors of wiring data, just display anomaly and don’t trip.

19

Page 21

User Manual of SY6000-Z series Troubleshooting

6.2 Adjustment of defections

Table 6-2 Adjustment of defections

Defections Related reasons Adjustment

Reasons of raw material,

Processed

products are

deficient

material temperature, mould

Injection pressure is too low Increase injection pressure

Injection speed is too slow Increase injection speed

Injection time is too short Increase injection time

Processed

products are

over edge

Reasons of raw material,

material temperature, mould

Injection pressure is too big;

clamping force is insufficient

Reasons of raw material and

Processed

products

have bubbles

Injection speed is too quick Decrease injection speed

Reasons of raw material and

Processed

products

have sinking

Injection speed is too quick Decrease injection speed

Pressure maintaining time is

Reasons of raw material and

Welding

mark

Injection speed is too slow Increase injection speed

Injection pressure is too low Increase injection pressure

Filamentary

silver and

ripple

Size of

Reasons of raw material,

ma

Injection pressure is too low Increase injection pressure

Reasons of raw material, Adjust parameters of

mould temperature

Injection pressure is too

small

mould temperature

Injection pressure is not

enough

too short

material temperature

terial temperature, mould

Adjust parameters of

moulding injection

machine

Adjust parameters of

moulding injection

machine

Decrease injection pressure

Adjust parameters of

moulding injection

Increase injection pressure

Adjust parameters of

moulding injection

machine

Increase injection pressure

Increase corresponding

time

Adjust parameters of

moulding injection

machine

Adjust parameters of

moulding injection

machine

20

Page 22

User Manual of SY6000-Z series Troubleshooting

Defections Related reasons Adjustment

material temperature, mould moulding injection

processed

products is

unstable

Injection pressure is too low Increase injection pressure

Pressure maintaining time is

Increase corresponding

not enough

machine

time

Electric and hydraulic system of

Processed

products

stick the

moulding

moulding injection machine are

unstable

Reasons of raw material and

mould temperature

Ask for technical support

Adjust parameters of

moulding injection

machine

Injection pressure is too high Decrease injection pressure

Increase corresponding

time

Adjust corresponding

temperature

Increase corresponding

time

Adjust parameters of

moulding injection

machine

Increase corresponding

time

Adjust corresponding

temperature

Increase corresponding

speed

Decrease corresponding

time

Adjust parameters of

moulding injection

machine

Adjust corresponding

temperature

Inlet stick the

moulding

Cold block

or rigid block

in processed

products

Processed

products

fades

Processed

products

intensity

decreases

Injection time is too short

Material temperature is too

high

Cooling time is too short

Reasons of raw material and

mould temperature

Moulding time is too short

Material temperature is too

high

Injection pressure is too high Decrease injection pressure

Injection speed is too quick

Pressure maintaining time is

too long

Reasons of raw material,

material temperature, mould

Moulding temperature is too

low

21

Page 23

User Manual of SY6000-Z series Maintenance

Chapter 7 Maintenance

7.1 Daily inspection

z Hearing and touching the housing, check if there are abnormal heating,

noise and vibration from the cabinet and motor.

z Check if ambient temperature and humidity exceeds the manual

provision by using thermometer and hygrometer.

z Load current is in the range of rated value or not.

z Cooling fan runs normally or not.

7.2 Regular maintenance

Start to check after no displaying of the monitor and turning off of the

main circuit power indicator.

Inspection contents are as shown in Table 7-1.

Table 7-1 Regular inspection contents

Inspection items Inspection contents Abnormal countermeasure

Main circuit terminal,

screw of control

circuit terminal

Heat sink Dust or not

PCB Dust or not

Cooling fan

Power components Dust or not

Aluminum capacitor

Loosening of screws

or not

Abnormal noise,

abnormal vibration,

or total running time

up to 20,000 hours.

Discoloring,

off-favor, bubbling,

or not

Tighten with a screwdriver

User4~6kg/cm2 pressure

dry compressed air to blow

off

User4~6kg/cm2 pressure dry

compressed air to blow off

Replace cooling fan

User4~6kg/cm2 pressure

dry compressed air to blow

off

Replace aluminum capacitor

22

Page 24

User Manual of SY6000-Z series Maintenance

7.3 Periodic maintenance

Operational lifespan of electronic components are closely related to

using environment, using condition and maintenance situation.

Lifespan of vulnerable parts under normal using conditions are as

shown in Table 7-2.

Table 7-2 Replacement time of components

Component name Lifespan

Cooling fan 2~3 years

Capacitor 4~5 years

PCB 5~8 years

Periodic service conditions of above components are:

1. Ambient temperature: 10~35℃;

2. Load coefficient: 85% below;

Users determine replacement period according to actual situation.

7.4 Storage

1. Store cabinets in well-ventilated places, and avoid high

temperature, humidity and dustiness;

2. Long time storage will lead to deterioration of electrolytic

capacitors. So ensure connection the cabinet to power supply at least

once in two years. And input voltage slowly raises rated value by the

voltage regulator.

23

Loading...

Loading...