SYRUNS SY5000 series User Manual

User Manual of SY5000 series AC Drive Overview

~1~

Chapter 1 Overview

Thank you for choosing SYRUNS SY5000 series AC Drive!

SY5000 series AC Drive is a high-quality, multi-function, low-noise inverter

which is designed, developed and produced according to international standards.

It can meet different needs of industrial conditions. It is applied advanced control

technology of space voltage PWM, with functions of constant voltage control,

power-off restart, dead zone compensation, automatic slip compensation, on-line

modication parameter. It is also with compact structure, easy to install.

For safety, please read the manual thoroughly before using SY5000 series

AC Drive. Meanwhile, please retain the manual and you can use it when regulate,

maintain and inspect the equipment in future.

The manual provides using instruction of SY5000 series AC Drive:

1. SY5000-G series general purpose AC Drive

2. SY5000-P series fan and pump purpose AC Drive

3. SYB-U50, SYB-U100 braking unit

4. Remote control keypad and extention cable

1.1 Purchase verication

Please verify the following items when open the box.

Table 1-1 Verication item

Verication item Verication method

Is it what you order, or not Please watch nameplate on the side of SY5000 AC Drive.

Parts damages or not Please check overall appearance.

Screws loose or not If necessary, use a screwdriver to check it.

If abnormal, please get in touch with the agent.

User Manual of SY5000 series AC Drive Overview

~2~

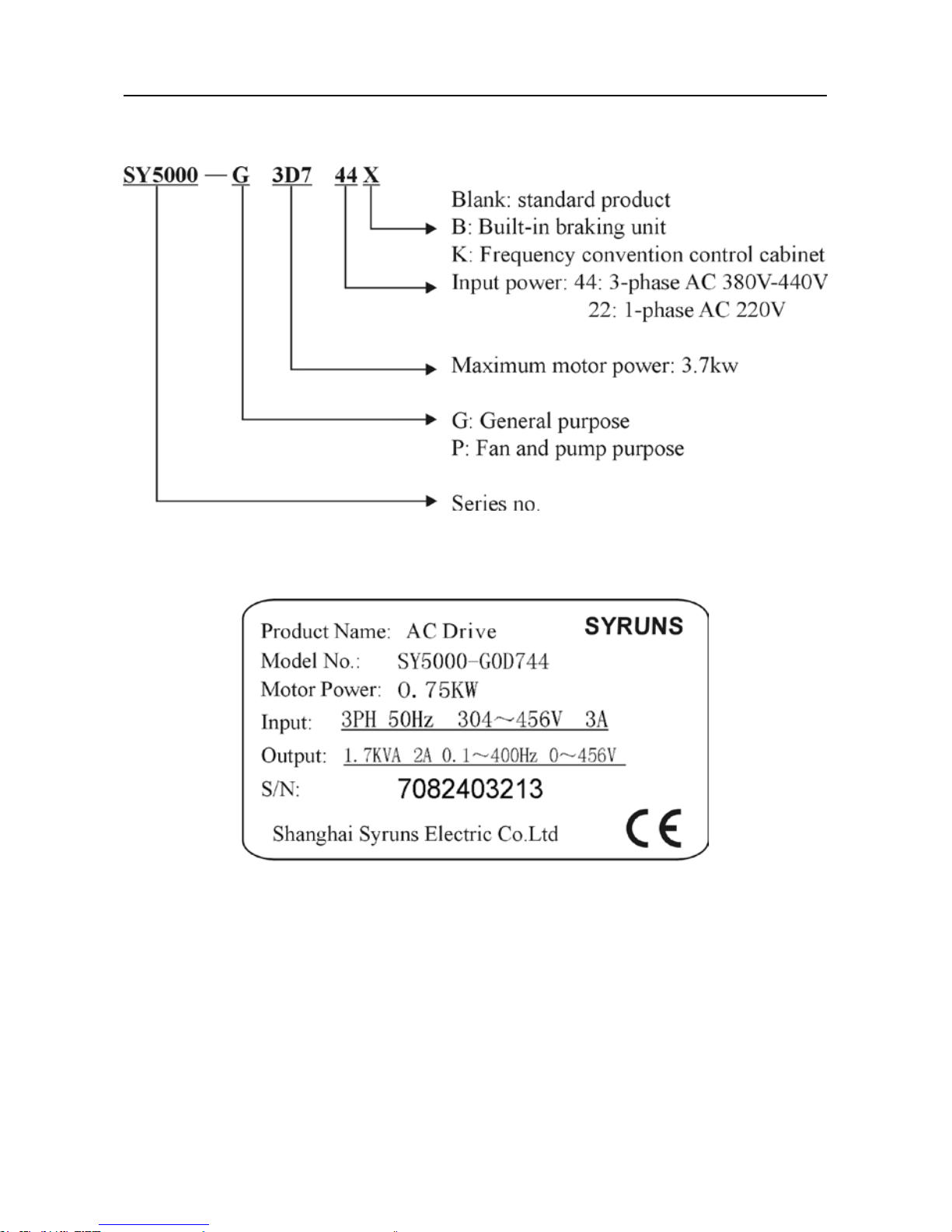

1.2 Instruction of model no.

1.3 Nameplate instruction

User Manual of SY5000 series AC Drive Overview

~3~

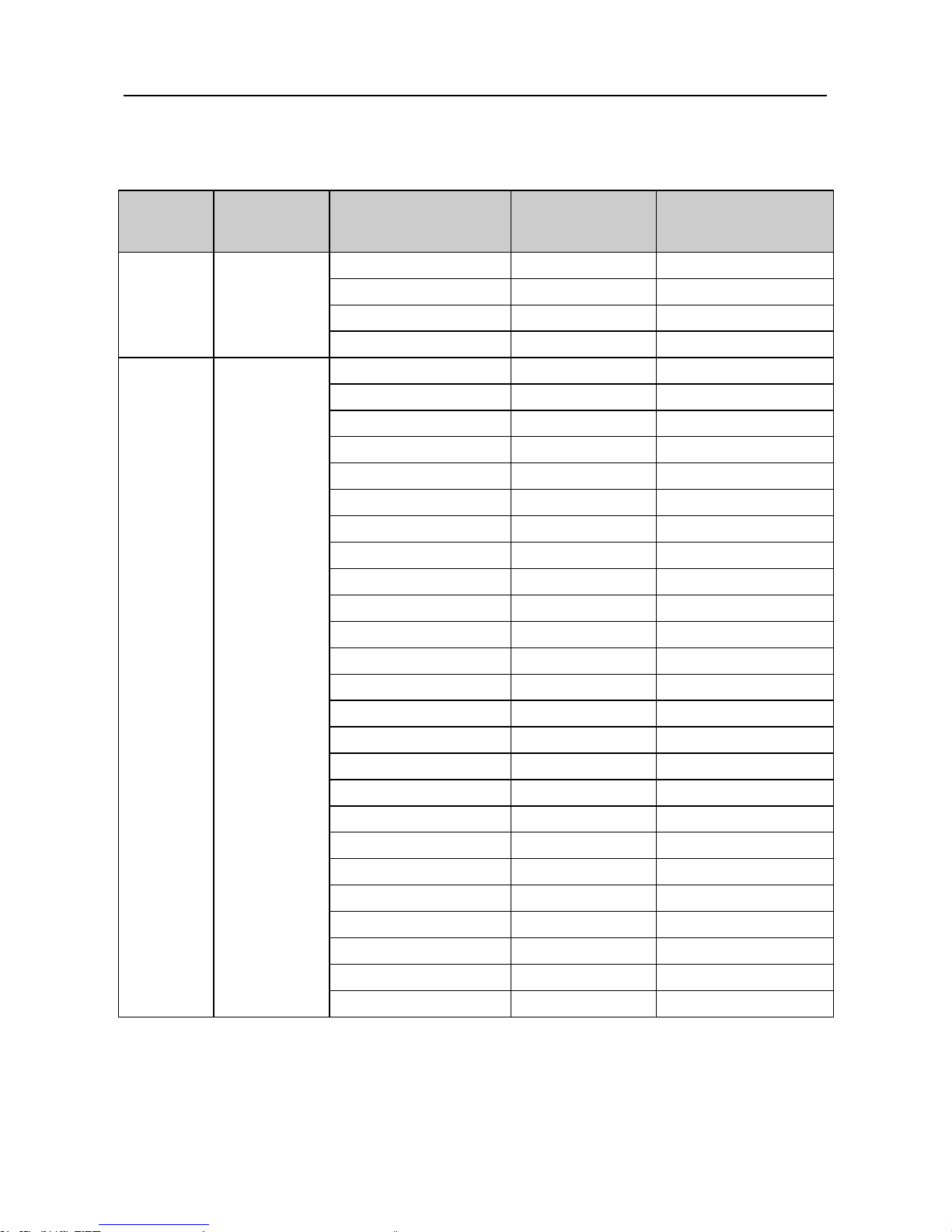

1.4 Specication of SY5000 series AC Drive

Table 1-2 Specication of SY5000 series AC Drive

Voltage

class

Item Model no.

Motor power

(KW)

Rated output

current (A)

Single

phase

220V

General

purpose

SY5000-G0D422 0.4 3

SY5000-G0D722 0.75 4.5

SY5000-G1D522 1.5

7

SY5000-G2D222 2.2 11

Three

phase

380V

General

purpose

SY5000-G0D744 0.75 2

SY5000-G1D544 1.5

4

SY5000-G2D244 2.2 5.5

SY5000-G3D744 3.7 8

SY5000-G5D544 5.5 13

SY5000-G7D544 7.5 17

SY5000-G01144

11 24

SY5000-G01544 15

33

SY5000-G01844 18.5

39

SY5000-G02244 22 44

SY5000-G03044 30 60

SY5000-G03744 37 75

SY5000-G04544 45 90

SY5000-G05544 55 110

SY5000-G07544 75 150

SY5000-G09044 90 175

SY5000-G11044 110 210

SY5000-G13244 132

255

SY5000-G16044 160

305

SY5000-G18544 185

340

SY5000-G20044 200 380

SY5000-G22044 220 425

SY5000-G24544 245 480

SY5000-G28044 280 545

SY5000-G31544 315 615

User Manual of SY5000 series AC Drive Overview

~4~

Three

phase

380V

Fan and

pump

purpose

SY5000-P3D744 3.7 8

SY5000-P5D544 5.5 13

SY5000-P7D544 7.5 17

SY5000-P01144

11 24

SY5000-P01544 15

33

SY5000-P01844 18.5

39

SY5000-P02244 22 44

SY5000-P03044 30 60

SY5000-P03744 37 75

SY5000-P04544 45 90

SY5000-P05544 55 110

SY5000-P07544 75 150

SY5000-P09044 90 175

SY5000-P11044 110 210

SY5000-P13244 132

255

SY5000-P16044 160

305

SY5000-P18544 185

340

SY5000-P20044 200 380

SY5000-P22044 220 425

SY5000-P24544 245 480

SY5000-P28044 280 545

SY5000-P31544 315 615

Table 1-3 Technical specication of SY5000 series AC Drive

Item Specication

Output

Output voltage

Single phase /triple phase corresponding input voltage,

constant voltage control is optional

Output frequency

range

0.10~650.00Hz; highest frequency can set freely between

25.00~650.00Hz

Power

Voltage,

frequency

1PH 220V

±

15%; 3PH 380V±15% 50Hz; 3PH 440V

±

10% 60Hz

Control

function

Control mode

Digital SVPWM space voltage vector control; carrier

frequency 1.0~16.0KHz adjustable continuously

Start frequency 0.00~25.00HZ setting freely

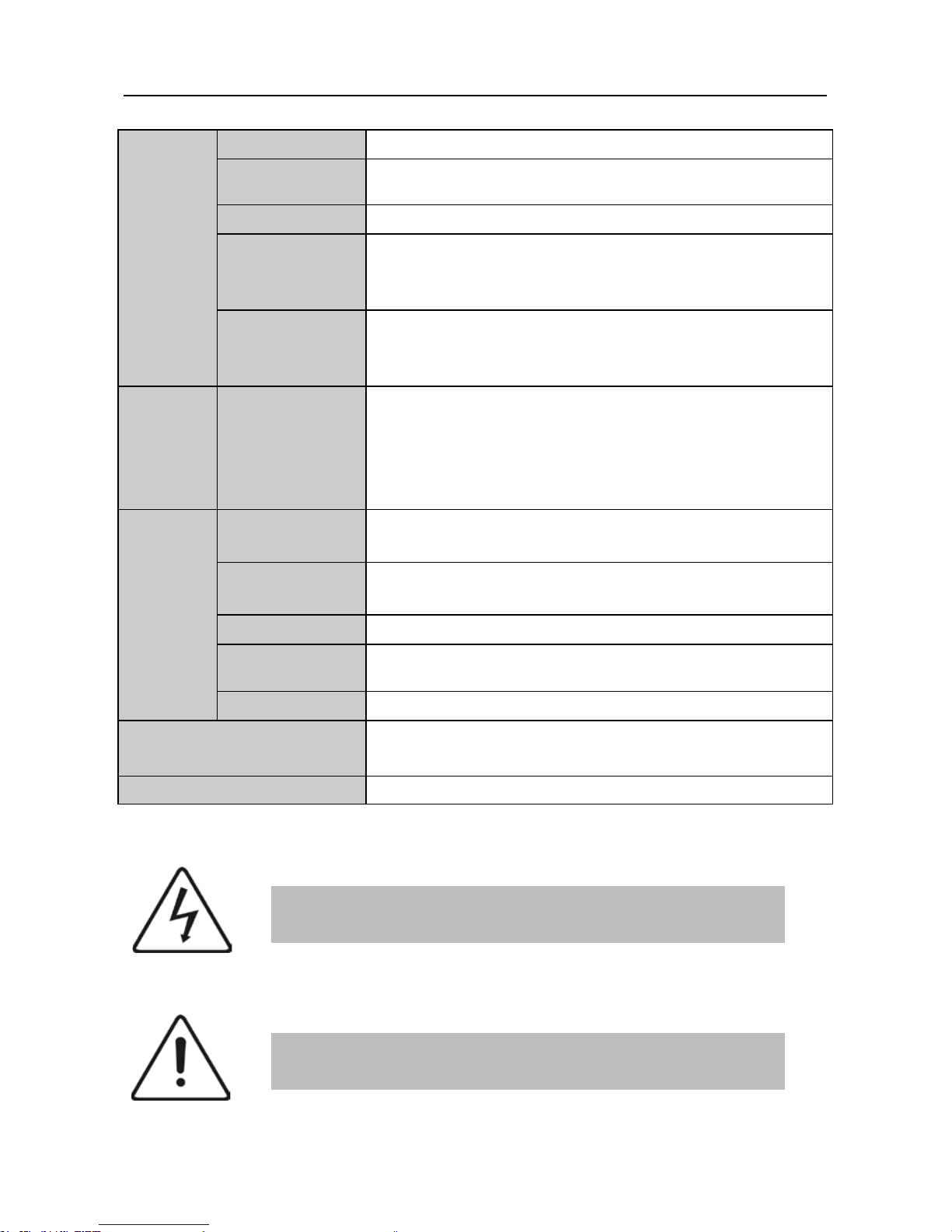

User Manual of SY5000 series AC Drive Overview

~5~

Control

function

Resolution of

output frequency

0.01Hz

Resolution of

frequency setting

Digital setting: under 100Hz:0.01HZ; others: 0.1Hz;

analog input (external terminal) setting: 1% of highest

frequency

V/F feature

Linear V/F: base frequency can be set freely between

25.00~650.00Hz

Torque

compensation

constant torque, 1.2-th power and 1.5-th power decreasing

torque compensation mode selectable, compensation

voltage range: 0~30%

DC braking

Start frequency(0.00~10.00Hz), voltage(0~15%),

duration(0.0~10.0s)can be set freely

Overload

capacity

General purpose: 150% rated current 1minute;

fan and pump purpose: 120% rated current 1 minute

Operation

function

Operation mode

FWD-REV, RUN/FWD-REV, FWD-REV/selfsustaining,3 modes available

Stop mode Deceleration stop/free stop

Frequency

setting

Operation panel▲▼key in, external potentiometer, panel

potentiometer external analog current signal DC4~20mA,

external anolog voltage signal DC0~5V or DC0~10V

Time mode of

accel /decel rate

0.1~6000.0 seconds (accel /decel can be set seperately)

No.1/No.2 accel /decel time, linear /S-curve type accel

/decel modes selectable

Multi-section

speed operation

8-section speed of the external terminal control or

4-section speed of parameters setting (one-cycle or repeat

cycle), each section can be set freely, accel /decel time of

speed, two methods selectable

Jog operation

Frequency(0~highest frequency), accel /decel

time(0.1~6000.0 seconds), accel /decel mode (linear/S

type) can be set freely

Frequency of

upper limit and

lower limit

Upper limit frequency (lower limit frequency~highest

frequency), lower limit frequency (0~upper limit

frequency) setting freely

Other functions

Fault recovery, jog frequency, external analog, input

bias/gain setting, speed display system, slip conpensation,

fault history record (4 times), dynamic parameter (part)

modify, anti-reverse, etc.

User Manual of SY5000 series AC Drive Overview

~6~

Input

output

signal

Operation panel Display: 5 data LED;parameter setting: 6 switches

External terminal

input

4 programmable inputs(PI1~PI4), FWD, REV, EMS,

RES

Fault output IC relay output (AC250V, 1A,resistance load)

Output with open

collector

OUT-COM: Signal in operation/signal of speed arrival

of detection rate/ signal of overload alarm are selectable

(Rated 24V, available output 50mA)

Frequency table

output

DC0~10V (max output current:10mA, resolution

ratio:0.4%), rated output frequency/rated current/rated

voltage are optional

Protection

Protection

function

Overcurrent stalling protection (50~200% of rated

current), overvoltage stalling protection, overvoltage

protection,overcurrent protection, overload protection,

overheat protection, undervoltage protection, emergency

stop,etc.

Working

condition

Installation site

Indoor,altitude of less than 1km,dust free, non-corrosive

gases,no direct sunlight

Application

environment

0℃~+40℃,20%~90%RH (no dew)

Vibration Less than 0.5g

Storage

temperature

-25℃~+65℃

Mounting type Wall-mounted type, oor cabinet type

Protection degree

General purpose:IP20 (

≤

7.5kw); IP10 (≥11kw)

Fanand pump purpose:IP20 (

≤

11kw); IP10 (≥15kw)

Cooling mode Forced air cooling

1.5 Safety symbol instruction

It is very dangerous when use wrongly, possiblely make

people die.

Caution

Danger

It is dangerous if use wrongly, possiblely make people

injury or machine damage.

User Manual of SY5000 series AC Drive Overview

~7~

1.6 Precautions

1. The inverter just applies to general triple-phase AC induction motors or variable

frequency motors. The installation environment should be well ventilated.

2. It is a normal phenomenon that temperature and noise of the motor raise a little

higher than power frequency when use the inverter.

3. General motors can’t work long under low-speed.

4. Output terminal of the inverter cannot be connected with RC absorbing device,

such as capacitor, varistor, etc.

5. If install the contactor between the inverter and the motor, must ensure that the

inverter does not output when the contactor is on-off. Otherwise, it will damage

the inverter.

6. The inverter should be used derating if the altitude is higher than 1000 meters.

Derate 10% when the altitude rises 1500 meters.

7. The inverter is as industrial waste when scrap it. Please be careful:

(1)Inner polymer capacitors probably explode if set it on re.

(2)Plastic pieces may produce toxic gases when burn it.

User Manual of SY5000 series AC Drive Installation

~8~

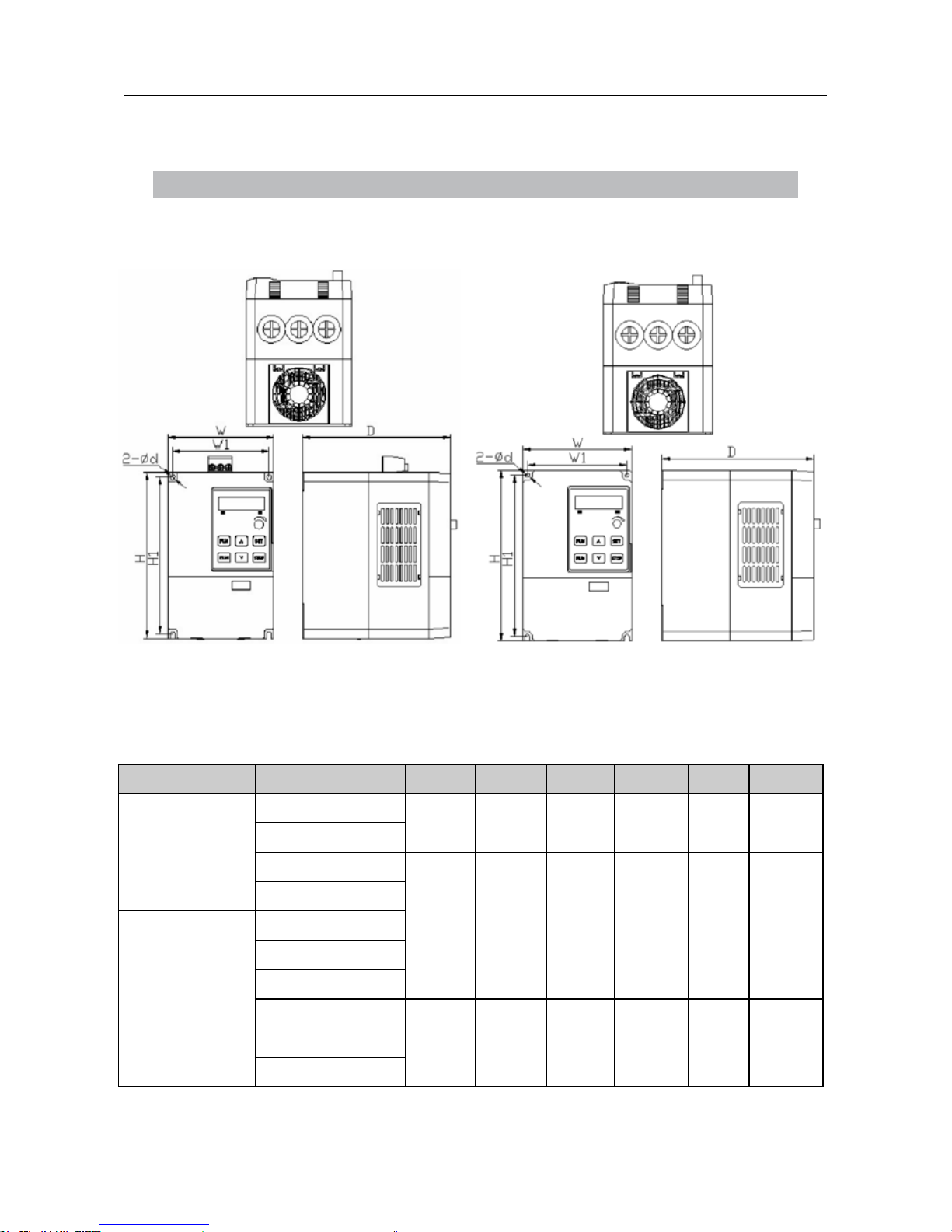

Chapter 2 Installation

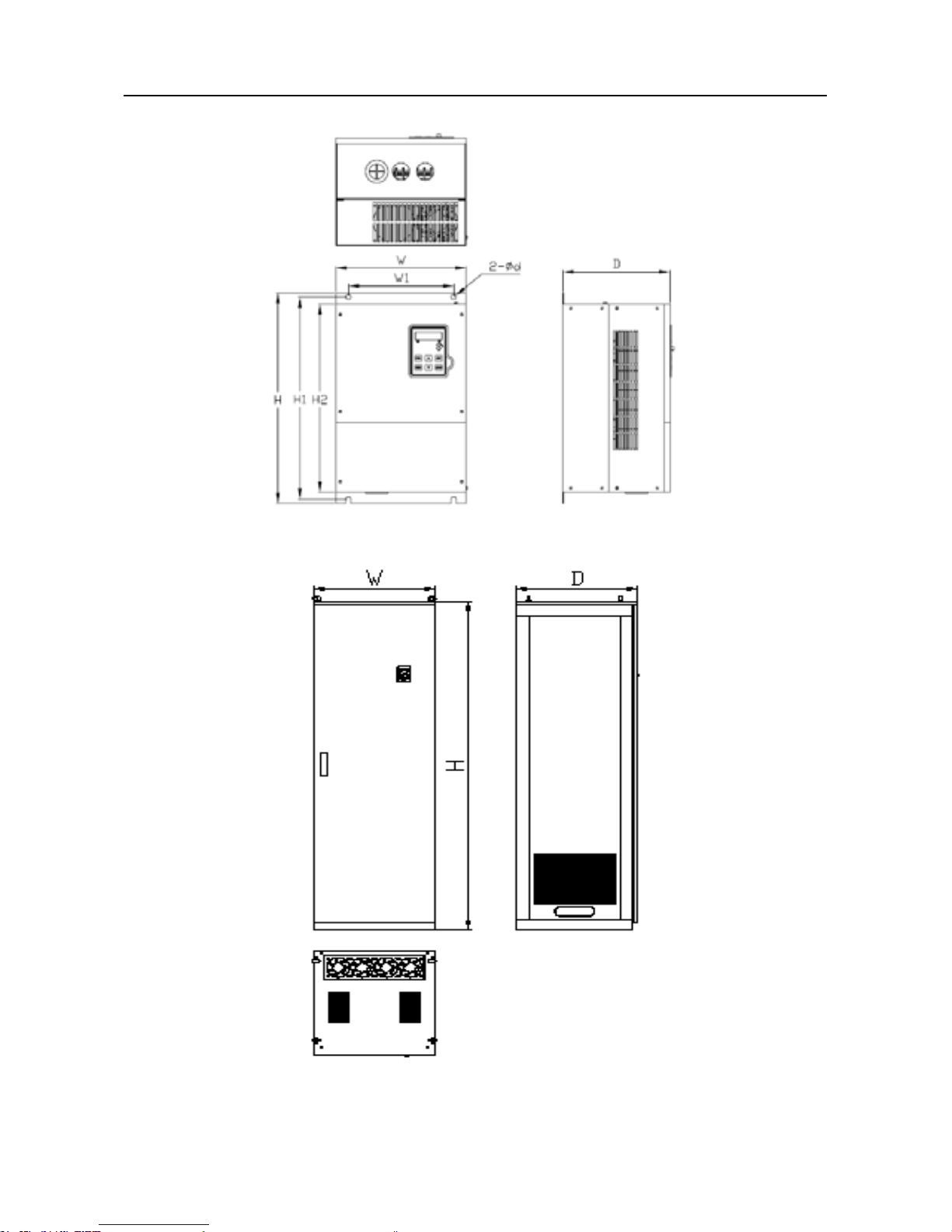

2.1 Overall and installation dimensions

(a) 0.75~2.2KW (b) 3.7~7.5KW

Figure 2-1 Overall of SY5000 series AC Drive

Table 2-1 Overall and installation dimensions of SY5000 series AC Drive

Voltage class Model no. W W1 H H1 D d

Single-phase

220V

SY5000-0D422

85

73 141.5 129.5 113 4.5

SY5000-0D722

SY5000-1D522

115 105 180 170 160 5

SY5000-2D222

Three phase

380V-440V

SY5000-0D744

SY5000-1D544

SY5000-2D244

SY5000-3D744 150 138 235 223 160 5

SY5000-5D544

190 178 300 288 179 6.5

SY5000-7D544

User Manual of SY5000 series AC Drive Installation

~9~

Figure 2-2 (a) 11KW~160KW

Figure 2-2 (b)

≥

185KW

User Manual of SY5000 series AC Drive Installation

~10~

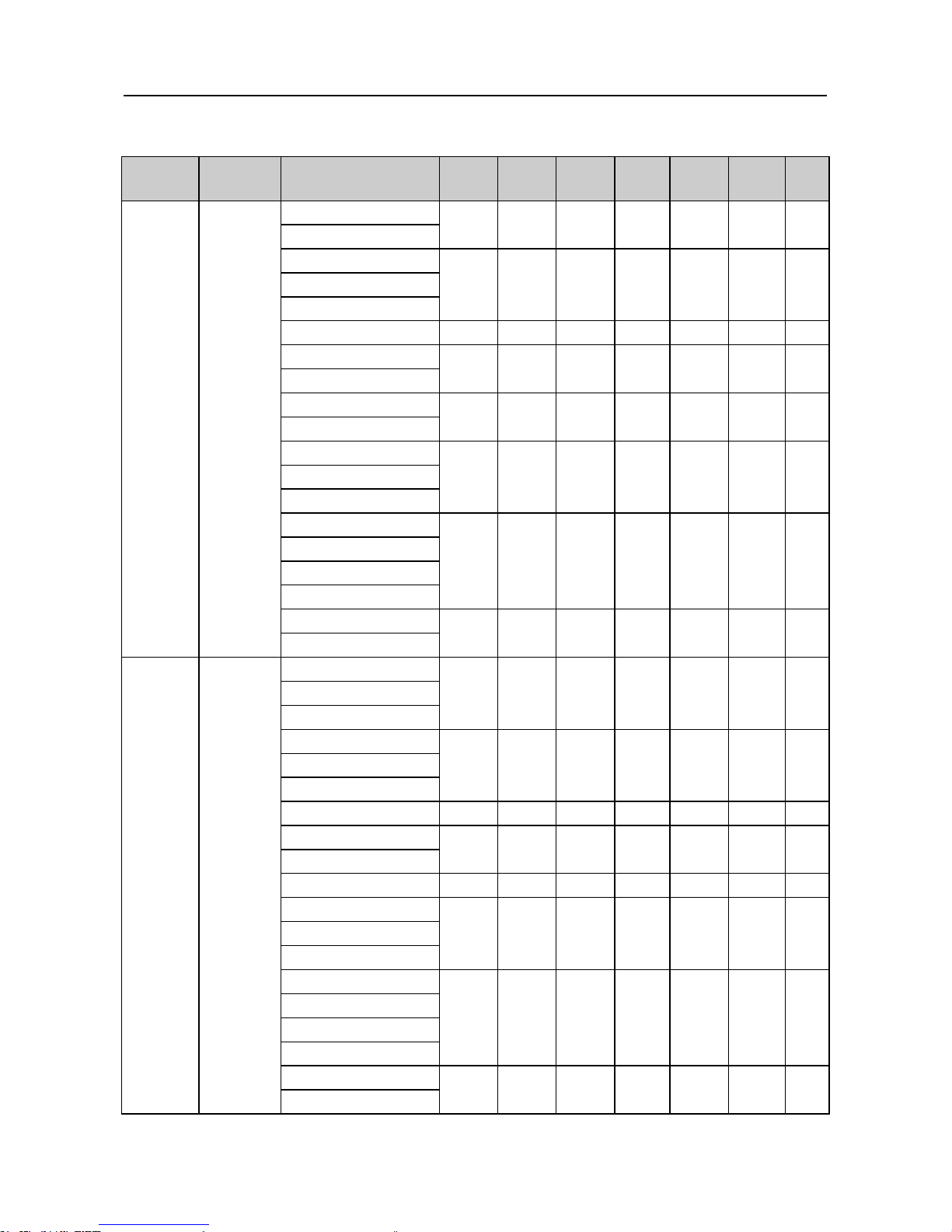

Table 2-2 Overall dimensions(≥11KW)

Voltage

class

Type Model no. W W1 H H1 H2 D d

Three

phase

380V

General

purpose

SY5000-G01144

243 196 392 372 350 185 9.5

SY5000-G01544

SY5000-G01844

293 200 504 484 460 236 9.5SY5000-G02244

SY5000-G03044

SY5000-G03744 307 200 554 534 510 236 9.5

SY5000-G04544

390 300 620 590 560 248 10

SY5000-G05544

SY5000-G07544

430 300 860 800 830 340 12

SY5000-G09044

SY5000-G11044

570 500 900 870 840 375 13SY5000-G13244

SY5000-G16044

SY5000-G18544

610 — 1906 — — 605 —

SY5000-G20044

SY5000-G22044

SY5000-G24544

SY5000-G28044

730 — 2000 — — 605 —

SY5000-G31544

Three

phase

380V

Fan and

pump

purpose

SY5000-P01144

243 196 392 372 350 185 9.5

SY5000-P01544

SY5000-P01844

SY5000-P02244

293 200 504 484 460 236 9.5SY5000-P03044

SY5000-P03744

SY5000-P04544 307 200 554 534 510 236 9.5

SY5000-P05544

390 300 620 590 560 248 10

SY5000-P07544

SY5000-P09044 430 300 860 800 830 340 12

SY5000-P11044

570 500 900 870 840 375 13SY5000-G13244

SY5000-G16044

SY5000-G18544

610 — 1906 — — 605 —

SY5000-G20044

SY5000-G22044

SY5000-G24544

SY5000-G28044

730 — 2000 — — 605 —

SY5000-G31544

User Manual of SY5000 series AC Drive Installation

~11~

2.2 Installation instruction

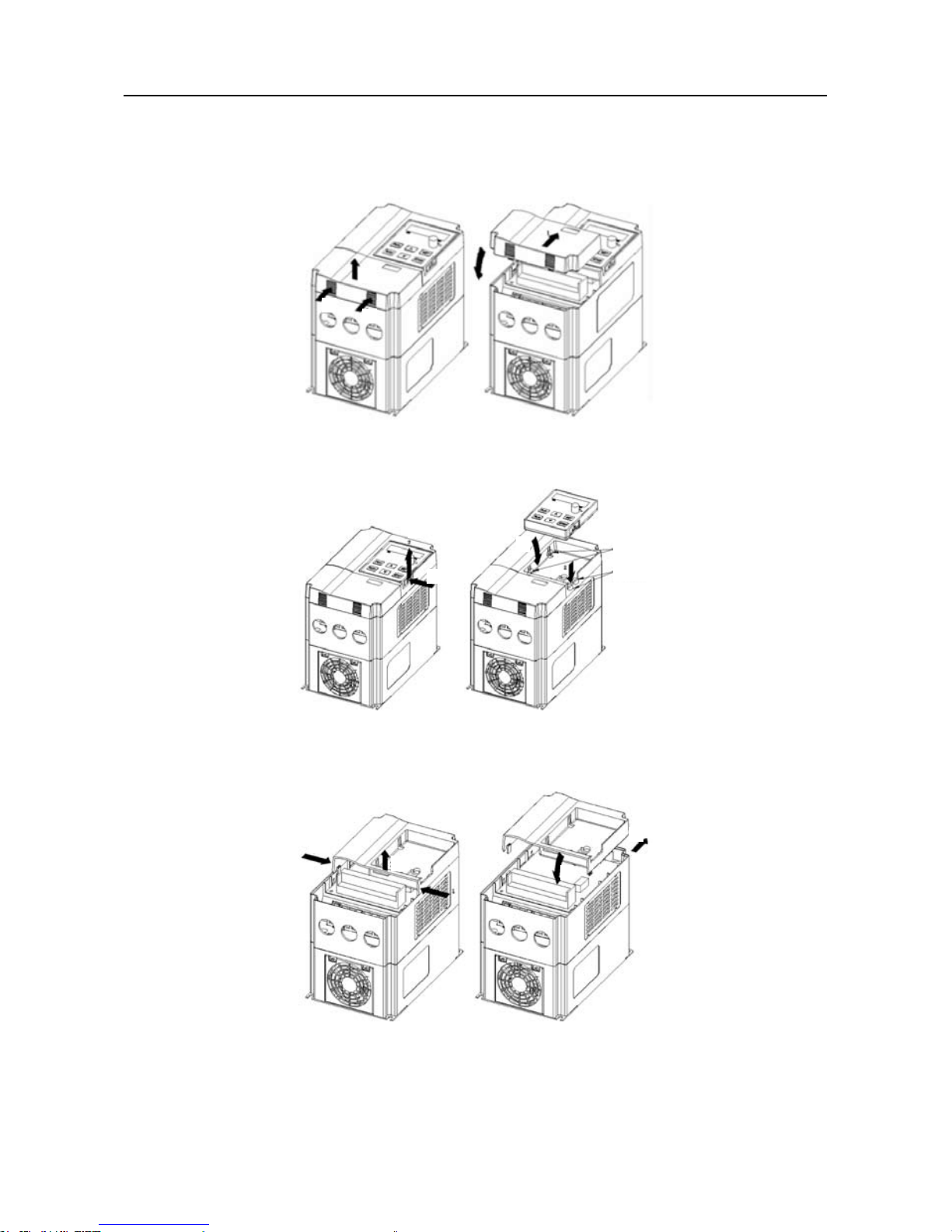

2.2.1 Disassembly and assembly of panel and keypad

(a) (b)

Figure 2-3 Disassembly and assembly of small panel

(a) (b)

Figure 2-4 Disassembly and assembly of keypad

(a) (b)

Figure 2-5 Disassembly and assembly of big panel

Claw locker A

Claw locker B

1

2

1

2

2

1

1

1

2

2

1

User Manual of SY5000 series AC Drive Installation

~12~

1. Disassembly and assembly of small panel (terminal cover)

(1) Disassembly of small panel

As shown in Figure 2-3 (a), press two faces according to direction 1, meanwhile,

lift lower part of small panel according to direction 2.

(2) Assembly of small panel

As shown in Figure 2-3 (b),when assembly,rstly align small panel and big panel,

lean panels forward, embed bayonet shapes of panel in big panel, and then press

down the panels according to direction 2.

2. Disassembly and assembly of keypad

(1) Disassembly of keypad

As shown in Figure 2-4 (a), press the buckle on the side of keypad according to

direction 1, unhook it from big panel, lift it according to direction 2, and then get the

keypad.

(2) Assembly of keypad

As shown in Figure 2-4 (b), stick Digital Console from the 1 directions the claw

locker A(place 2), pressing to keep toward 2 directions immediately after hearing the

“click”voice, stick the claw locker B (place 2).

3. Disassembly and assembly of big panel

(1) Disassembly of big panel

As shown in Figure 2-5 (a), make an effort toward 1 direction to press the two side

of console support, in the meantime, please press 2 directions to lift console support

lower part.

(2) Assembly of big panel

As shown in Figure 2-5 (b) , console support head two cards hang up to block from

the 1 directions the hull body(place 2), press to keep toward 2 directions immediately

after hearing the“click”voice.

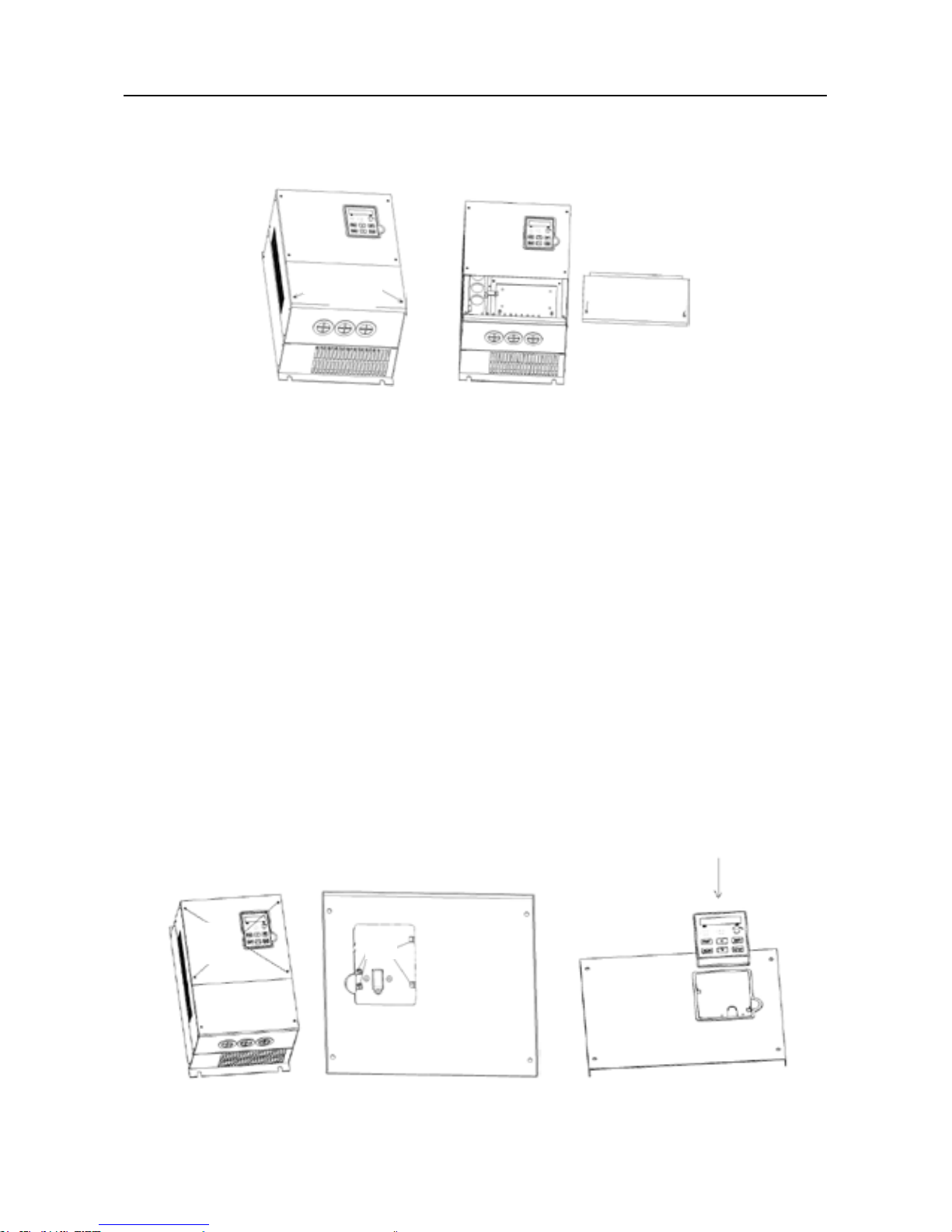

2.2.2 Disassembly and assembly of terminal housing and keypad (≥11 kW)

1. Disassembly and assembly of terminal housing

(1) Disassembly of terminal housing

Use standard No. 1 crosshead screwdriver to take off two M4 screw bolts (as shown

in Figure 2-6 (a)), and then you can remove the terminal housings.

(2) Assembly of terminal housing

Use two M4 × 8 bolts to x terminal housings (The direction is as shown in Figure

User Manual of SY5000 series AC Drive Installation

~13~

2-7(b)), and tighten by using standard No.1 crosshead screwdriver, and tightening

torque is about 5 ~ 8 N • m.

(a) (b)

Figure 2-6 Disassembly and assembly of terminal housing and keypad (≥11 kW)

2. Disassembly and assembly of keypad

(1) Disassembly of keypad

◆ Use standard No.1 crosshead screwdriver to take off four M4 bolts(as shown in

Figure 2-7 (a) );

◆ Disconnect the connection cable of keypad, and remove control panel;

◆ As shown in Figure 2-7 (b), rollover control panel, push out the jaw of keypad,

and remove keypad.

(2) Assembly of keypad

◆ As shown in Figure 2-7 (c), rstly inbed keypad in keypad adapter, and conrm

the correction of inbedding in the slotted hole;

◆ Connect the connection wire of keypad with control circuitboard;

◆ Fix control panel on the box by using four M4×8 bolts, and tighten by using

standard No.1 crosshead screwdriver, and tightening torque is about 5 ~ 8 N • m.

(a) (b) (c)

Figure 2-7 Disassembly and assembly of keypad (≥11kW)

screw hole

screw

hole

clasp

User Manual of SY5000 series AC Drive Installation

~14~

2.3 Requirements and management of installation site

2.3.1 Installation site:

The installation site should meet the following conditions:

Good indoor ventilation

Ambient temperature -10°C~40°C

Humidity less than 90%RH, without dew

Don’t install in the combustibles such as woods

Avoid direct sunlight

No combustible, explosive, corrosive gases and liquids

No ash dust, oil dust, oatable bers and metal particles

strong installed base, no vibration

No electromagnetic interference

Caution

3. Please hold the bottom of AC Drive when carry it.

Risk of feet injury if only holding the panel.

4. Please install in metal board and other nonammable materials.

Risk of re if installing in ammable materials.

5. If install two or more AC Drives in the same cabinet, please set the cooling fan,

and keep the air temperature below 40℃.

Risk of re and other accidents if overheating.

1. In order to avoid being exposed and damaged, don’t use other methods to

disassembly and assembly keypad and panels.

2. Don’t directly install big panel with keypad in the AC Drive, otherwise, it will

bring poor contact.Please separately install big panel in the AC Drive, then

install keypad in the big panel.

Caution

User Manual of SY5000 series AC Drive Installation

~15~

2.3.2 Ambient temperature

To improve operation reality of AC Drive, please install in well-ventilated place.

When used in an enclosed cabinet, install the cooling fan or cooling air-conditioning,

and keep the environment temperature below 40°C.

2.3.3 Precaution

Please put a dust cover on the AC Drive when install. Do not fall metal framents

into AC Drive internal when drill holes. Please remove dust cover after installation

nishes.

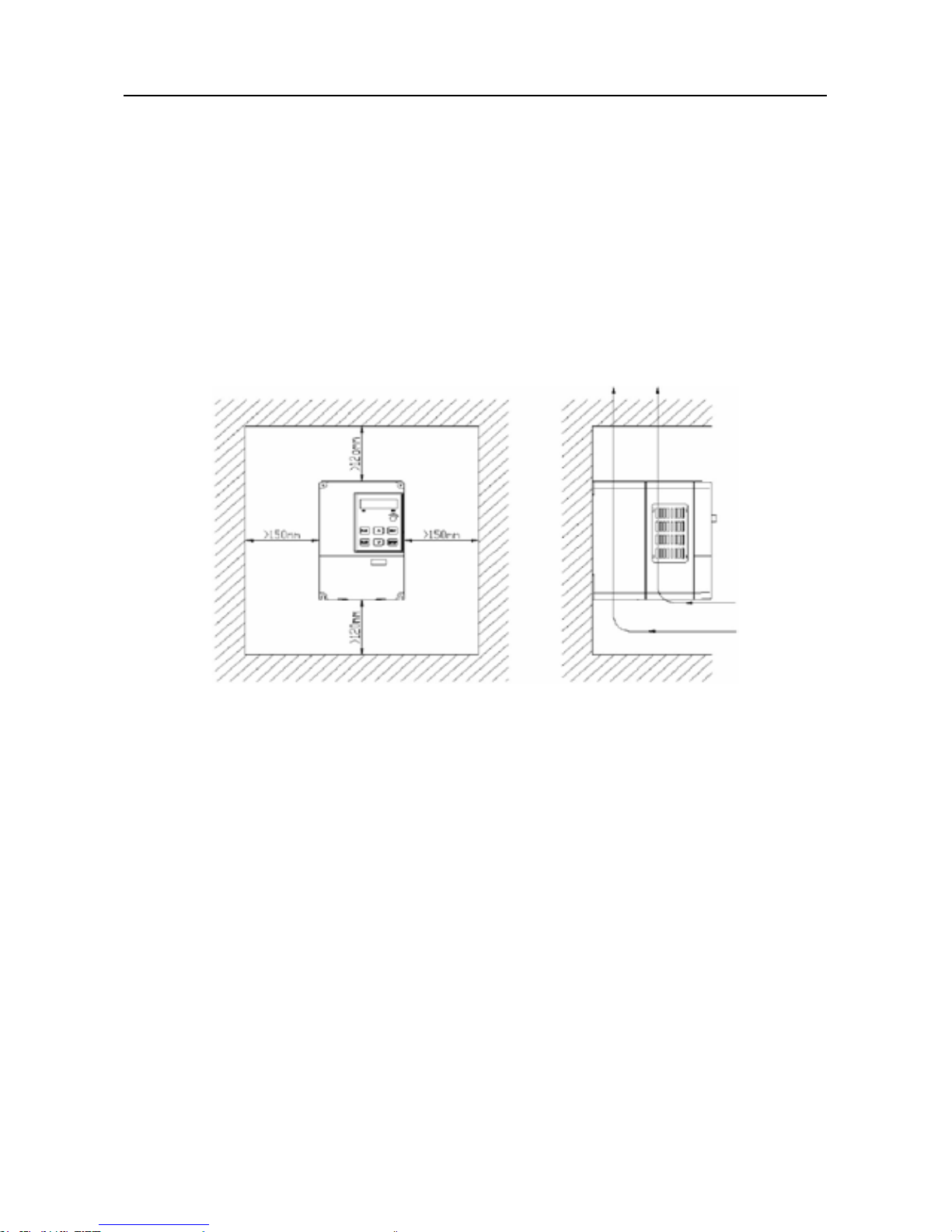

2.3.4 Installation direction and space

Figure 2-8 Installation direction and space of SY5000 series AC Drive

In order to get good effect of cooling cycle, must install the AC Drive in vertical

direction. Please refer to Figure 2-8.

*********************************************************************

Note: When install two AC Drives upper and lower, we should utilize isolating plate.

*********************************************************************

User Manual of SY5000 series AC Drive Wiring

~16~

Chapter 3 Wiring

Danger

Caution

1 Before wiring, please conrm the cut-off of input power supply.

Risk of electric shock and re.

2 Wiring operations must be carried out by electric engineerting specialists.

Risk of electric shock and re.

3 Ground terminal must be reliably grounded.

(380V class:especially the third

ground)Risk of electric shock and re.

4 After connecting with the terminal of emergency stop, be sure to check the

validity of actions.Risk of injury.(The responsibility of wrong wiring is

undertaked by users.)

5 Do not directly touch the output terminals. Do not connect the output terminals of

inverter with the housings. Do not be short circuit between output terminals.

Risk of electric shock and short-circuit.

1 Make sure rated voltages of AC main circuit power supply and inverter are the

same. Risk of injury and electric shock.

2 Do not test withstand voltage of inverter.

It will damage semiconductor components.

3 Please connect braking unit or braking resistor according to wiring diagram.

Risk of re.

4 Please use the specied torque screwdriver fastening terminals. Risk of re.

5 Do not connect the cable of input power supply to output U

、V、W terminals.

It will damage the internal of the inverter if adding voltage onoutput terminals.

6 Do not switch phase-shift capacitor into output circuit. It will damage the internal

of the inverter.

7 Do not switch electric-magnetic switch and electric-magnetic contactor into ouput

circuit. When the inverter is in operation with a load, surge current generated by

electromagnetic switches, electromagnetic contactors will cause the over-current

protection circuit action of inverter.

User Manual of SY5000 series AC Drive Wiring

~17~

3.1 Connection with peripheral equipments

SY5000 series inverter standard connection diagram with peripheral equipments

(As shown in Figure 3-1)

Figure 3-1 Connection diagram with peripheral equipments

User Manual of SY5000 series AC Drive Wiring

~18~

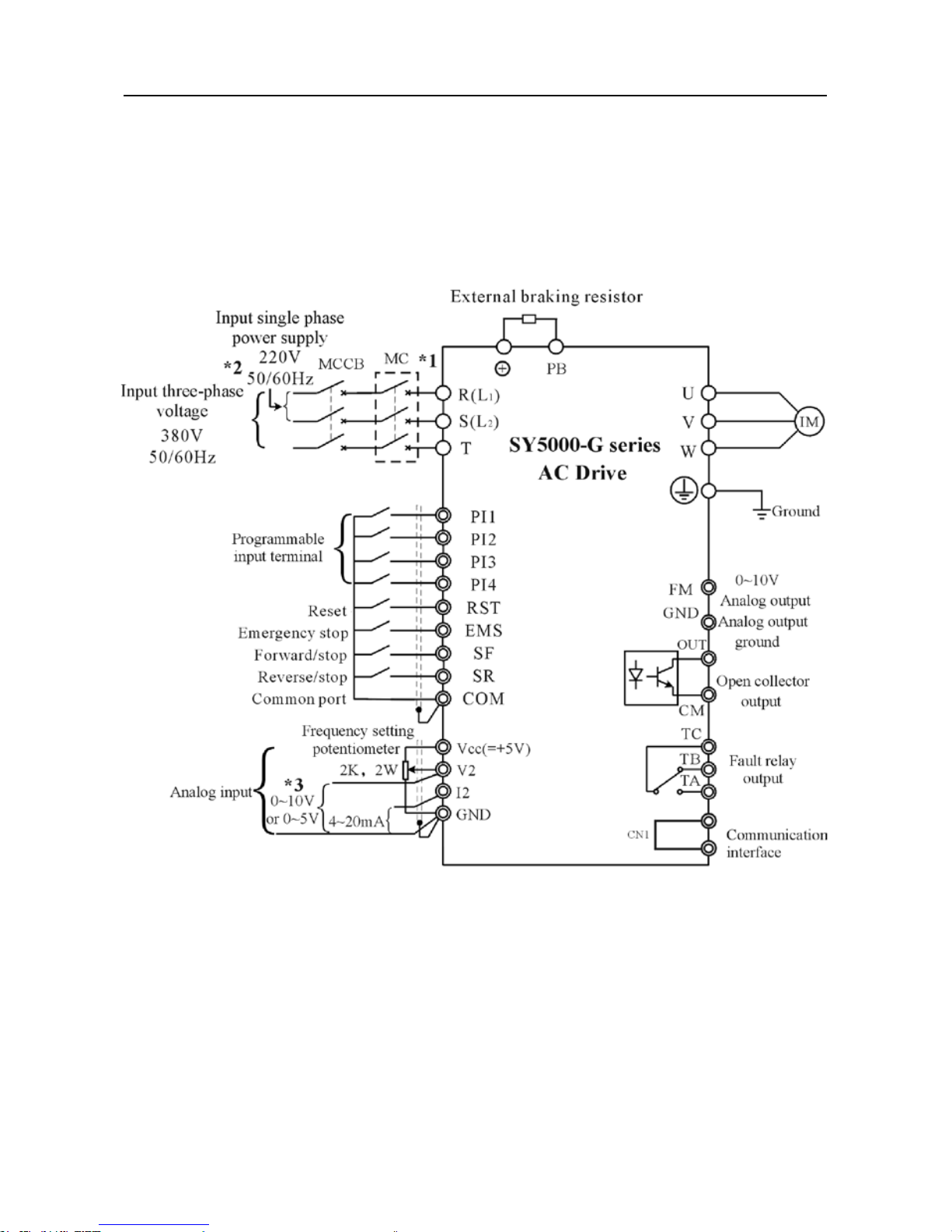

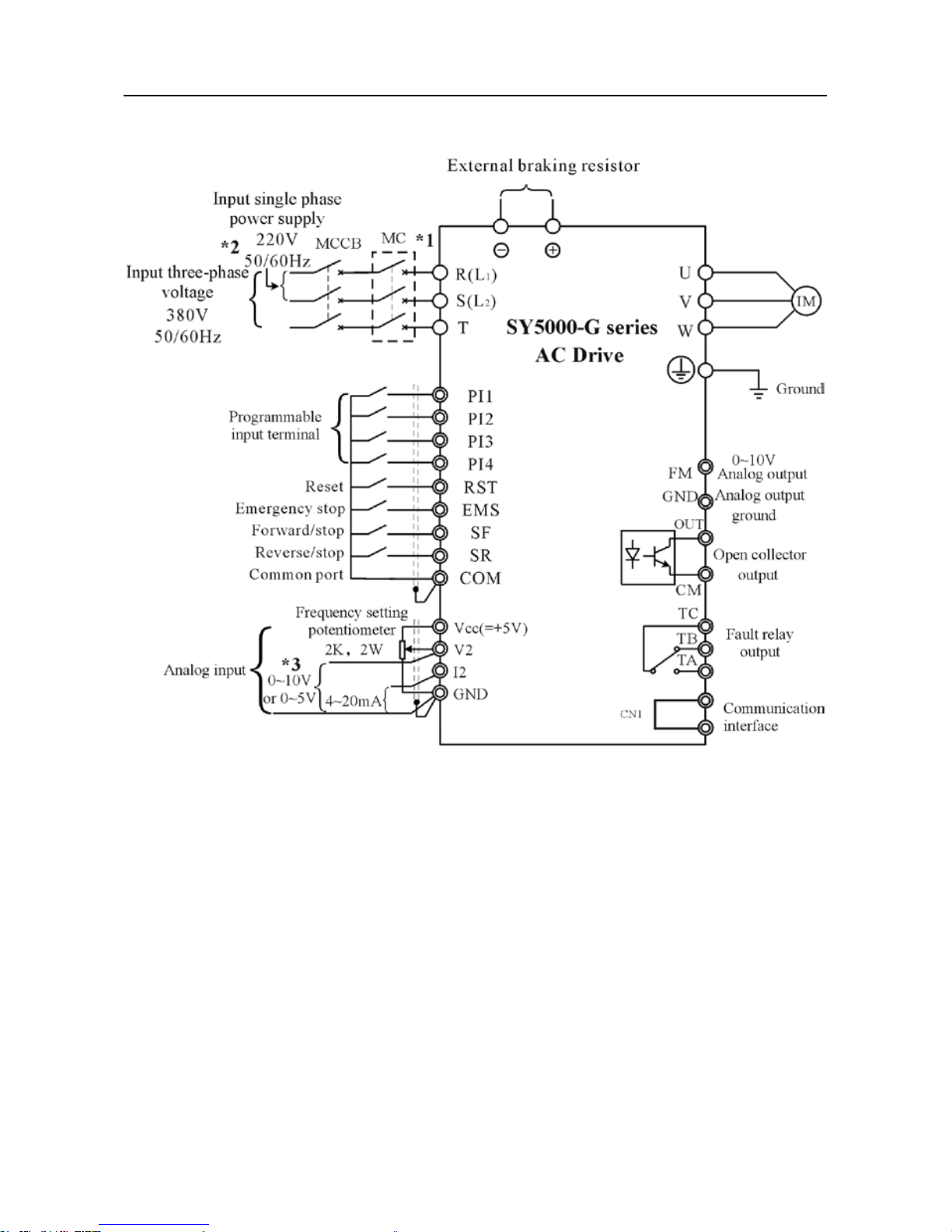

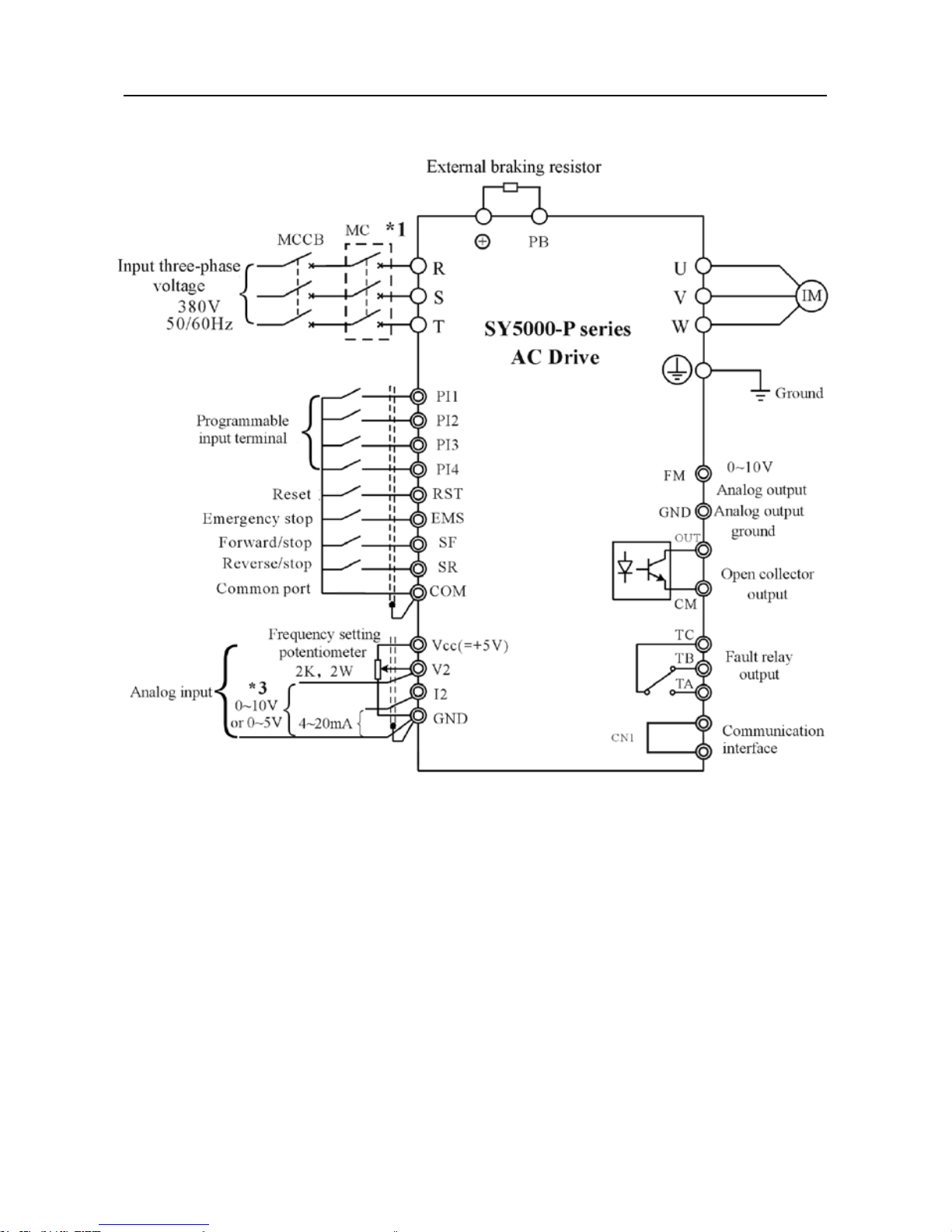

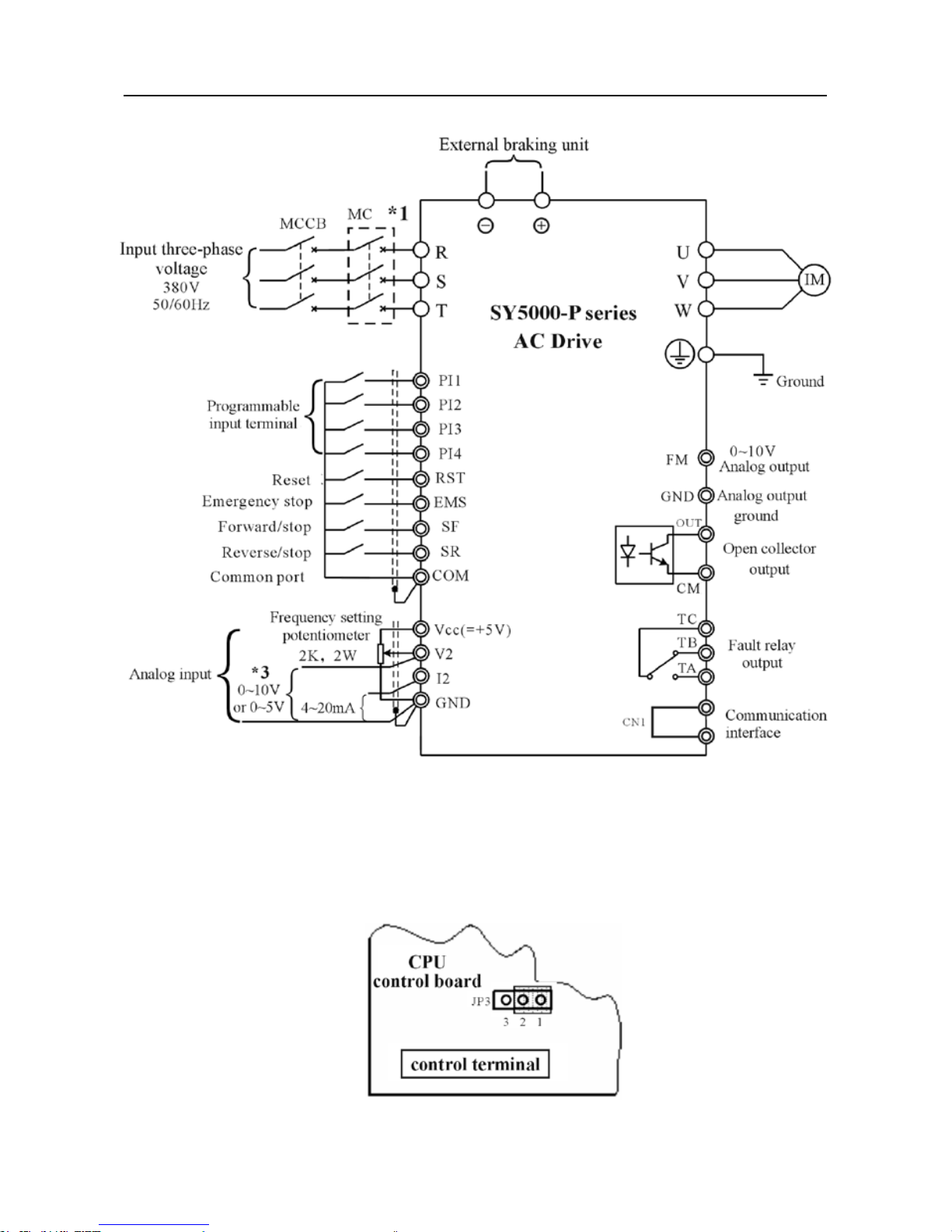

3.2 Connection diagram

Figure 3-2a,3-2b,3-3a,3-3b are connection diagrams of SY5000 series

inverter. When manipulate the inverter by using keyboard of control panel, the electric

motor can work only when connect main circuit.

Figure 3-2a Connection diagram of SY5000-G series (≤15KW)

User Manual of SY5000 series AC Drive Wiring

~19~

Figure 3-2b Connection diagram of SY5000-G series (≥18.5KW)

User Manual of SY5000 series AC Drive Wiring

~20~

Figure 3-3a Connection diagram of SY5000-P series (≤18.5KW)

User Manual of SY5000 series AC Drive Wiring

~21~

Figure 3-3b Connection diagram of SY5000-P series (≥22KW)

Remark:

*1:MC is mainly used to prevent fault re-start or transcient power-cut re-start;

Resistor overheat protection of external braking unit also should be connected to the

control loop of MC.

*2:For 220V series,input power supply switches in L

1,L2

;for 380V, inputpower

User Manual of SY5000 series AC Drive Wiring

~22~

supply switch in R, S, T;

*3:Be decided by JP3 jumpers of CPU board: Located in position 1, input voltage

range of external analog voltage V2 is 0~5V;located in position 3, input voltage

range of V2 is 0~10V. If no special requirements before delivery, JP3 jumper is locaed

in position 1, namely input voltage range of V2 is 0~5V. See above gure。

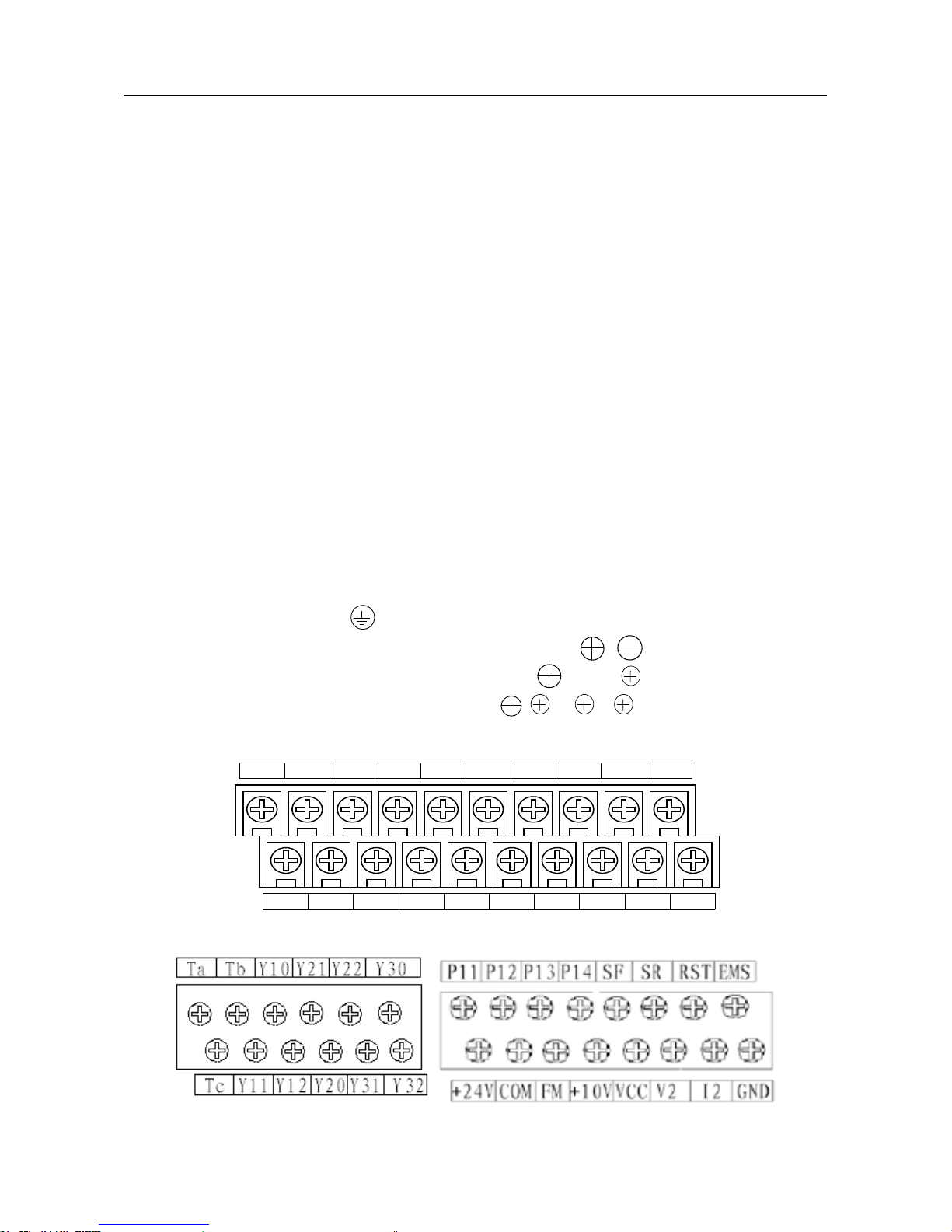

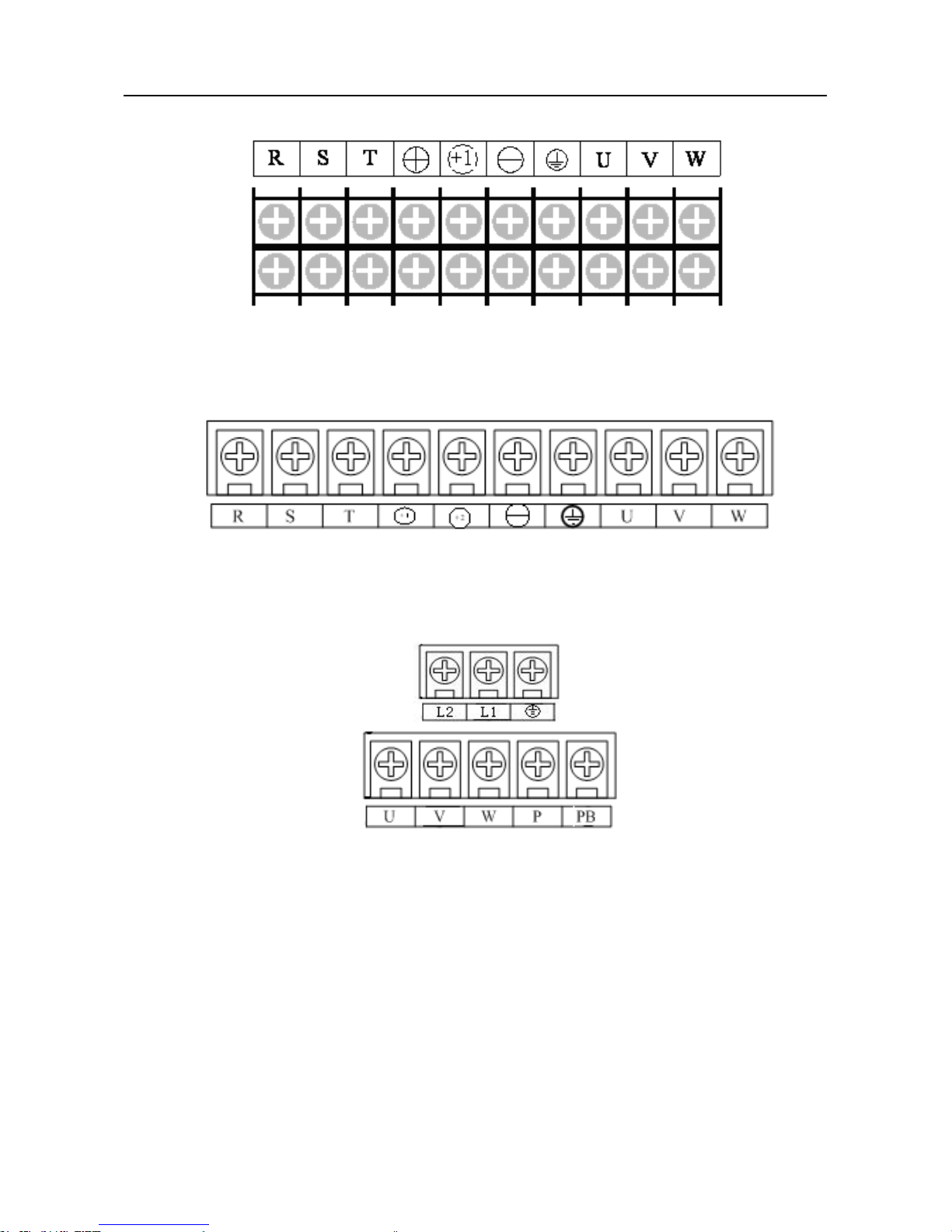

3.3 The composition of terminal blocks

Terminal blocks of SY5000 series inverter include terminal blocks of control

circuit and terminal blocks of main circuit:

Terminal block of general control circuit

1 Analog input:0~5V(0~10V)voltage source V2, 4~20mA current source

I2, GND

2 Digital input:SF, COM, SR, RST, EMS, PI1, PI2, PI3, PI4.

3 Digital output:OUT, TA, TB, TC

4 Analog output:FM

5 Signal of power supply:+5V voltage source Vcc, +24V power supply

Terminal block of main circuit

1 Input power supply

:R(L1), S(L2), T

2 Ground terminal:

3 Connection terminal of external braking unit: ,

4 Connection terminal of braking resistor: , PB和 2, PB

5 Connection terminal of DC reactor

: 1, 1 2

6 Electrical wiring:U, V, W

PI1 PI2 PI3 PI4 SF SR RST EMS FM GND

Ta Tb Tc

COM

OUT VCC V2 I2

GND

+24V

Terminal blocks of SY5000-G series control circuit

Terminal blocks of SY5000-P series control circuit

User Manual of SY5000 series AC Drive Wiring

~23~

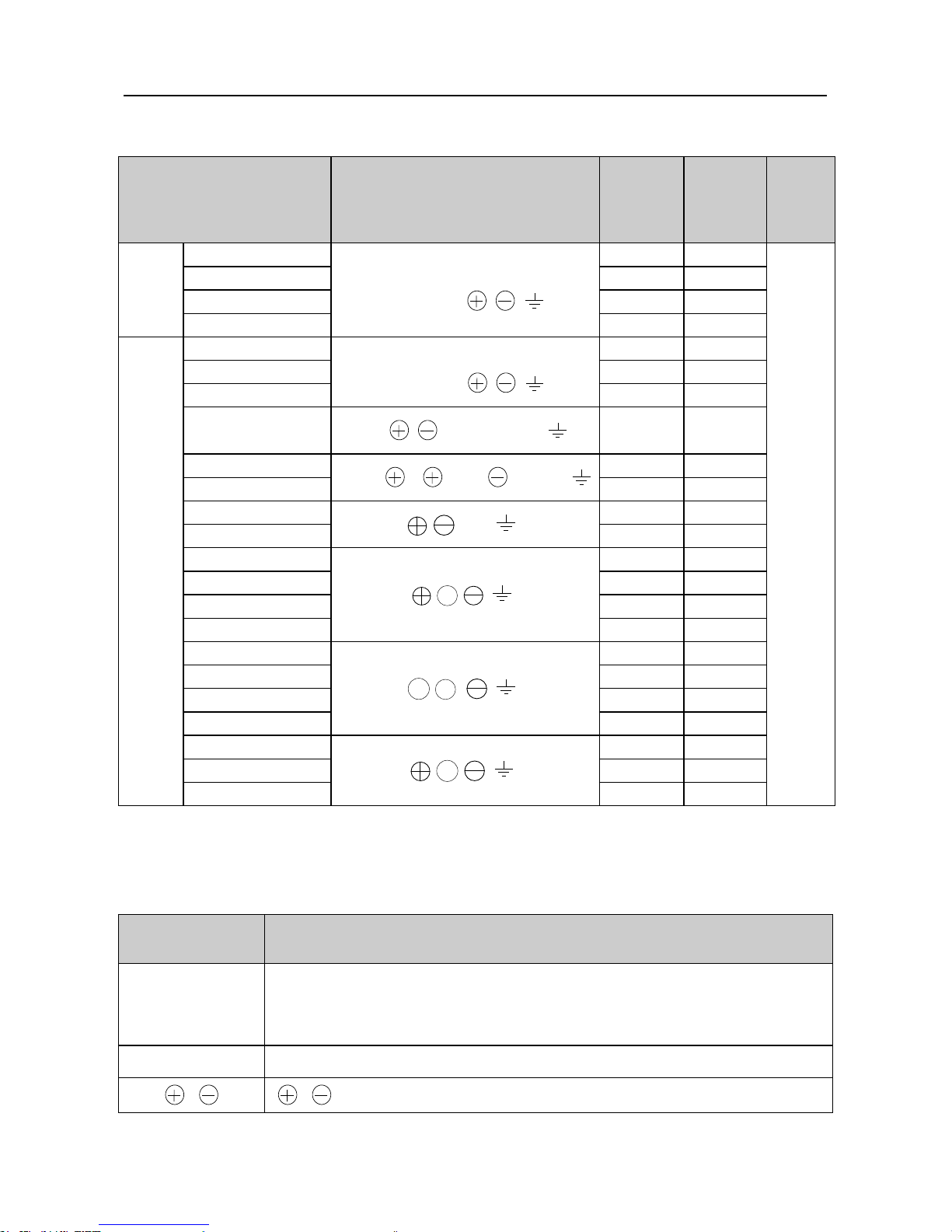

R S T PB U V W

1 2

terminal blocks of main circuit (3PH 380V)

5.5, 7.5KW (SY5000-G series)

7.5, 11KW (SY5000-P series)

R S T

U V W PB

terminal blocks of main circuit (3PH 380V)

0.75~2.2KW (SY5000-G series)

3.7KW (SY5000-P series)

U V W

PB

R S T

terminal blocks of main circuit (3PH 380V)

3.7KW (SY5000-G series)

5.5KW (SY5000-P series)

Terminal blocks of main circuit (3PH 380V)

11KW, 15KW (SY5000-G series)

15KW, 18.5KW (SY5000-P series)

User Manual of SY5000 series AC Drive Wiring

~24~

Terminal blocks of main circuit (3PH 380V)

18.5KW~37KW (SY5000-G series)

22KW~45KW (SY5000-P series)

Terminal blocks of main circuit (3PH 380V)

45KW~90KW (SY5000-G series)

55KW~110KW (SY5000-P series)

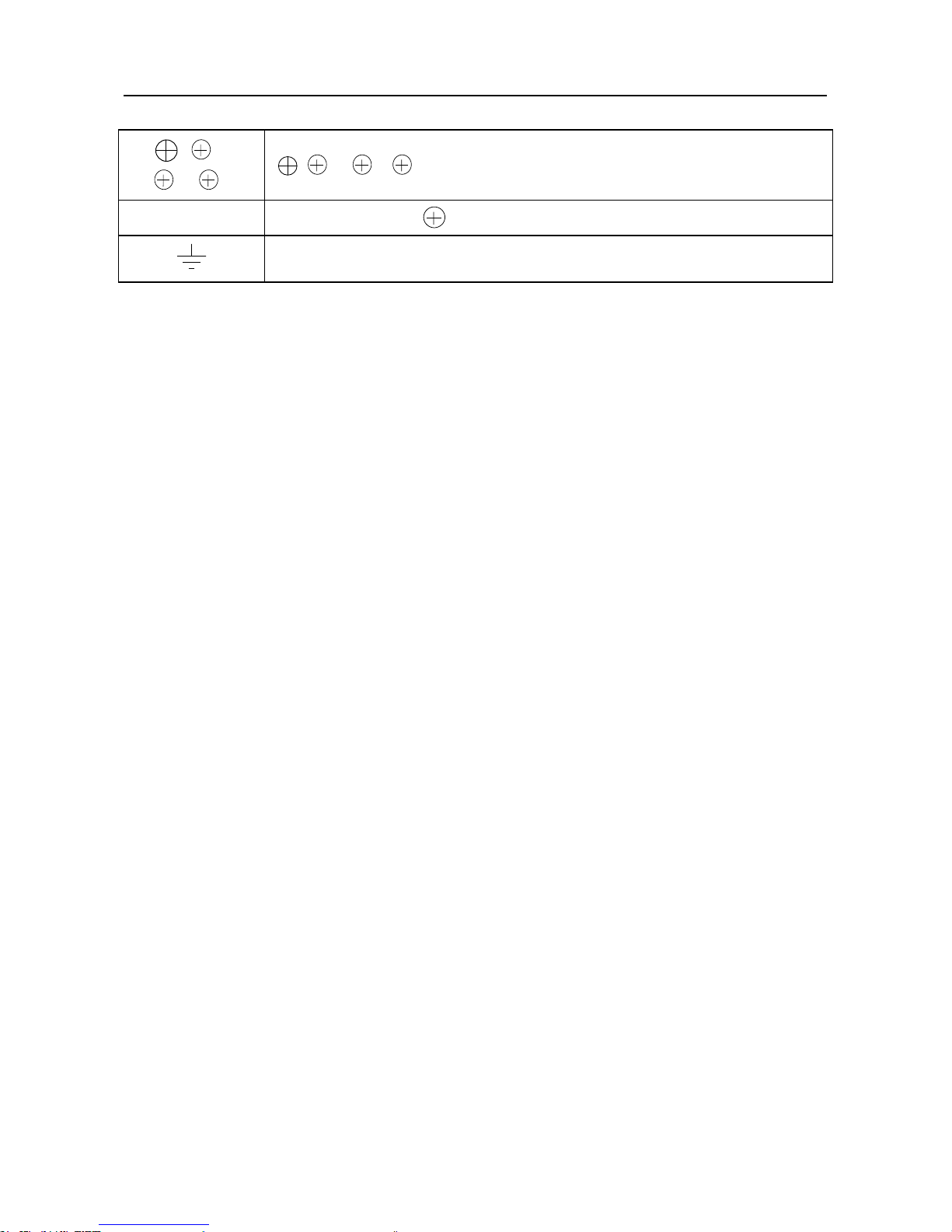

Terminal blocks of main circuit (1PH 220V)

Figure 3-4 Arrangement of terminal blocks of control circuit and main circuit

3.4 Wiring of terminal blocks of main circuit

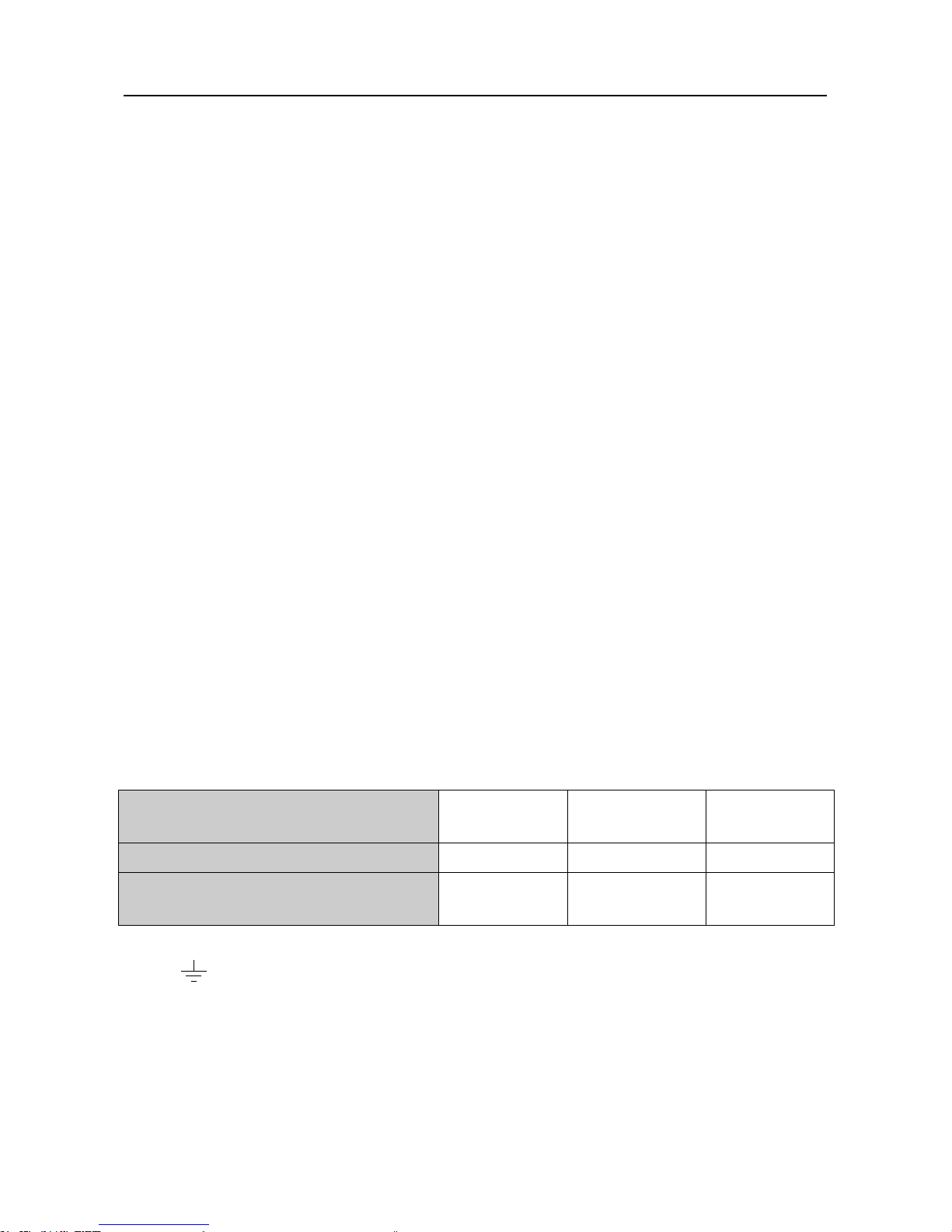

3.4.1 Cable size of main circuit and pressure wire terminals

Cable size and terminal screw size of main circuit, as shown in Figure 3-1

User Manual of SY5000 series AC Drive Wiring

~25~

Figure 3-1 terminal screw size and sectional area of wire

Model no. Terminal symbol

Terminal

screw

Sectional

area of

wire

(mm2)

Wire

species

1PH

220V

SY5000-G0D422

L1,L2

U,V,W,PB, , ,

M2.5 2.5

750V

plastic

cable

SY5000-G0D722

M2.5 2.5

SY5000-G1D522 M4 4

SY5000-G2D222 M4 6

3PH

380V-

440V

SY5000-G0D744

R,S,T,

U,V,W,PB, , ,

M4 2.5

SY5000-G1D544 M4 2.5

SY5000-G2D244 M4 4

SY5000-G3D744

PB, , ,R,S,T,U,V,W,

M4 4

SY5000-G5D544

R,S,T, 1, 2,PB, ,U,V,W,

M5 6

SY5000-G7D544 M5 6

SY5000-G01144

R,S,T, , ,PB , ,U,V,W

M5 8

SY5000-G01544

M5

8

SY5000-G01844

R,S,T, ,+1, , ,U,V,W

M6 16

SY5000-G02244 M6 16

SY5000-G03044

M6 25

SY5000-G03744 M8 25

SY5000-G04544

R,S,T, +1,+2, , ,U,V,W

M8 35

SY5000-G05544

M8 35

SY5000-G07544 M10 60

SY5000-G09044 M10 60

SY5000-G11044

R,S,T, ,+1, , ,U,V,W

M10 60

SY5000-G13244 M12 100

SY5000-G16044 M12 100

3.4.2 Function of main circuit terminal

Terminal function of main circuit, as shown in gure 3-2

Table 3-2 Function of main circuit terminal

Terminal

sign

Function description

R(L1),

S(L2), T

AC power supply input terminal:connect 3PH AC power supply

(R, S, T)(3PH 380V series) or 1PH AC power supply(L1,

L2)(1PH 220V series)

U, V, W Inverter output terminal, which is connected to 3PH AC motor.

, , respectively are anode and cathode of DC bus.

User Manual of SY5000 series AC Drive Wiring

~26~

, 1,

1, 2

1, 1 2 are DC reactor terminals of main circuit

PB

Between PB and is the terminal of built-in braking resistor

Ground terminal,grounding

3.4.3 Precautions of main circuit wiring

1. Installation of ELCB

As the inverter’s output is high-frequency PWM signal, the inverter will generate

high-frequency leakage current, please select Y2 type delay leakage circuit breaker

with above 30mA current sensitivity; if use ordinary ELCB, please select ELCB with

above 200mA current sensitivity.

2. Connection with terminal blocks

The phase sequence of input power supply is irrevelant to R(L1), S(L2), T phase

sequences of terminal block, so it can be any connection.

3. Setting of AC reactor or DC reactor

When the input power is connected with capacitive load, it will generate high peak

current in power grid.

If don’t take appropriate measures, the peak current may damage inverter rectier

and other power modules.

When there is high peak current in power grid, please connect 3PH AC reactor

(optional) on the power input side of inverter, or install DC reactor on the terminal of

DC reactor.

Therefore, it not only suppresses peak current, but also improves power factor.

4. Setting of Surge Protection Device (SPD)

When there is inductive load near the inverter (electromagnetic contactor,

electromagnetic valve, electromagnetic coil, electromagnetic circuit breaker), please

install SPD at two ends of its coil.

5. Wiring of inverter and electric motor

Please check whether rotate forwards when conrm the command of forward.

When the motor is reverse rotation, exchanging any two of U, V, W output

terminals can change rotation direction of the motor.

Use jog function to conrm forward and reverse rotations.

User Manual of SY5000 series AC Drive Wiring

~27~

6. Absolutely prohibit the connection of power supply wire and output terminal

Don’t connect the input power line to the output terminal.

If you input the power at the output terminal, the internal components of inverter

will be damaged.

7. Absolute prohibit short-circuit or grounding of output terminal

Do not directly touch the output terminal. Do not short the output line with inverter

housing. Otherwise, there will be danger of electric shock and short circuit.

In addition, don’t short the output line.

8. Absolutely prohibit the use of phase-shift capacitor

Don’t connect the capacitor in the output circuit. It will cause the damage of the

inverter.

9. Absolutely prohibit the use of electromagnetic switch

Don’t connect electromagnetic switches and electromagnetic contactors.

Otherwise, inverter surge current will cause protection action, and that will damage

interial components when it’s serious.

10. Wiring distance between inverter and motor

The longer wiring distance between the inverter and the motor, the higher high-

harmonic leakage current of the cable.

Leakage current will negatively impack the inverter and near equipments. Then it

should minimize the leakage current.

Wiring distance and carrier frequency are as shown in Table 3-3:

Table 3-3 Wiring distance and carrier frequency between inverter and motor

Wiring distance between inverter

and motor

Below 50m Below 100m Above 100m

Carrier frequency Blow 12KHz Below 10KHz Below 5KHz

Function code of parameter b-026

≤12.0 ≤10.0 ≤5.0

11. Ground connection

①

Ground terminal, please connect the ground.

220V series:type 3 ground(grounding resistance is less than 100Ω)

380V series:special type 3 ground(grounding resistance is less than 10Ω)

②

Don’t share the grounding line with welding machines or power equipments.

③

Please use the grounding wire according to electrical equipments technical

standards. And the distance from the ground is as short as possible.

User Manual of SY5000 series AC Drive Wiring

~28~

④

Don’t form the grounding line to a loop in the place when use two or more

inverters. Correct and wrong grounding methods are as shown in Figure 3-5.

Figure 3-5 Grounding comection

3.5 Wiring of control circuit terminal

In order to reduce interference and attenuation of control signal, wire length of

control signal should be less than 20m. The interval distance between wire length

and power line should be more than 30cm. Control signal line should be twisted-pair

shield cable.

3.5.1 Wire size and line terminal of general control circuit

Table 3-4 Size of terminal and wire and tightening torque of screw

Terminal

screw

Sectional area of wire

(mm2)

Wire type

Tightening torque

of screw(N·m)

M3.5 0.5~2

Multi-unit

shield wire

0.8

Loading...

Loading...