Page 1

Using the ModelSource

640-pin Generic Device

Adapter

To search the entire manual

set, press this toolbar button.

For help, refer to intro.pdf.

Release R3.6b

November 2001

Page 2

The ModelSource 640-pin Adapter

Copyright © 2001 Synopsys, Inc.

All rights reserved.

Printed in USA.

Information in this document is subject to change without notice.

Synopsys and the Synopsys logo are registered trademarks of Synopsys, Inc. For a list

of Synopsys trademarks, refer to this web page:

http://www.synopsys.com/copyright.html

All company and product names are trademarks or registered trademarks of their

respective owners.

2 Synopsys, Inc. November 2001

Page 3

The ModelSource 640-pin Adapter Contents

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About This Application Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Typographical and Symbol Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

The Synopsys Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Comments? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Describing a 640-pin Logic Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Procedural Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2

Building the Daughterboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Daughterboard Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connector Pin Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connectors J1 and J3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connectors J2, J4, J5 and J6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Routing Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 3

Connecting the Daughterboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adapter Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 4

Developing the Shell Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

User-Generated Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Files Provided by Synopsys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

November 2001 Synopsys, Inc. 3

Page 4

The ModelSource 640-pin Adapter Contents

Chapter 5

Completing the Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Mounting the Adapter onto the ModelSource Modeling Systems . . . . . . . . . . . . . 25

Labeling the Daughterboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Verifying the Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unmounting the Adapter from the ModelSource Modeling Systems . . . . . . . . . . . 27

Appendix A

J1–J6 Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

November 2001 Synopsys, Inc. 4

Page 5

The ModelSource 640-pin Adapter Preface

Preface

About This Application Note

This application note describes the features and use of the ModelSource 640-pin

Generic Device Adapter (hereafter referred to as the “Adapter”), which allows you to

model a 640-pin device using ModelSource modeling systems.

This application note assumes that you are familiar with model-building procedures as

described in these Synopsys documents:

●

Logic Model Development Manual

●

Shell Software Reference Manual

●

ModelSource User’s Manual

●

LM-family Modeler Manual

Related Documents

To see a complete listing, refer to the Guide to Hardware Modeling Documents.

Manual Overview

This manual contains the following chapters and appendixes:

Preface Describes the application note and lists the

typographical conventions and symbols used in it; tells

how to get technical assistance.

Chapter 1

Describing a 640-pin Logic

Model

November 2001 Synopsys, Inc. 5

Describes the hardware and software needed to create a

Logic Model using the 640-pin Generic Device Adapter.

Page 6

Preface The ModelSource 640-pin Adapter

Chapter 2

Building the Daughterboard

Chapter 3

Connecting the Daughterboard

Chapter 4

Developing the Shell Software

Chapter 5

Completing the Model

Provides specifications for building the 640-pin Adapter

Daughterboard.

Describes the Adapter and provides a procedure for

connecting it and the Daughterboard.

Briefly outlines software development tasks and

provides references.

Describes mounting the Adapter onto the Modeling

Systems; labeling the Daughterboard; verifying the

model; and unmounting the Adapter.

Appendix A

Provides a pinout listing for J1-J6 connectors.

J1–J6 Connector Pinouts

Typographical and Symbol Conventions

● Default UNIX prompt

Represented by a percent sign (

● User input (text entered by the user)

%).

Shown in

bold type, as in the following command line example:

% cd $LMC_HOME/hdl

● System-generated text (prompts, messages, files, reports)

Shown as in the following system message:

No Mismatches: 66 Vectors processed: 66 Possible

● Variables for which you supply a specific value

Shown in italic type, as in the following command line example:

% setenv LMC_HOME prod_dir

In this example, you substitute a specific name for prod_dir when you enter the

command.

● Command syntax

Choice among alternatives is shown with a vertical bar ( | ) as in the following

syntax example:

-effort_level low | medium | high

In this example, you must choose one of the three possibilities: low, medium, or

high.

6 Synopsys, Inc. November 2001

Page 7

The ModelSource 640-pin Adapter Preface

Optional parameters are enclosed in square brackets ( [ ] ) as in the following

syntax example:

pin1 [pin2 ... pinN]

In this example, you must enter at least one pin name (pin1), but others are optional

( [pin2 ... pinN]).

Getting Help

If you have a question while using Synopsys products, use the following resources:

1. Start with the available product documentation installed on your network or located

at the root level of your Synopsys CD-ROM. Every documentation set contains

overview information in the intro.pdf file.

Additional Synopsys documentation is available at this URL:

http://www.synopsys.com/products/lm/docs

Datasheets for models are available using the Model Directory:

http://www.synopsys.com/products/lm/modelDir.html

2. Visit the online Support Center at this URL:

http://www.synopsys.com/support/lm/support.html

This site gives you access to the following resources:

❍ SOLV-IT!, the Synopsys automated problem resolution system

❍ product-specific FAQs (frequently asked questions)

❍ lists of supported simulators and platforms

❍ the ability to open a support help call

❍ the ability to submit a delivery request for some product lines

3. If you still have questions, you can call the Support Center:

North American customers:

Call the Synopsys Eaglei and Logic Modeling Products Support Center hotline at

1-800-445-1888 (or 1-503-748-6920) from 6:30 AM to 5 PM Pacific Time, Monday

through Friday.

International customers:

Call your local sales office.

November 2001 Synopsys, Inc. 7

Page 8

Preface The ModelSource 640-pin Adapter

The Synopsys Website

General information about Synopsys and its products is available at this URL:

http://www.synopsys.com

Comments?

To report errors or make suggestions, please send e-mail to:

doc@synopsys.com

To report an error that occurs on a specific page, select the entire page (including

headers and footers), and copy to the buffer. Then paste the buffer to the body of your

e-mail message. This will provide us with information to identify the source of the

problem.

8 Synopsys, Inc. November 2001

Page 9

The ModelSource 640-pin Adapter Chapter 1: Describing a 640-pin Logic Model

1

Describing a 640-pin Logic Model

This chapter describes the necessary components and provides a procedural summary

for building a 640-pin Logic Model.

Hardware Requirements

To build a complete 640-pin Logic Model using the 640-pin Adapter, you need the

following hardware:

● The device you want to model, henceforth referred to as the device under test

(DUT). The DUT can have up to 640 input, output, and I/O signals, exclusive of

supply voltage and auxiliary signals. The DUT can include more than one physical

package, as long as the components fit within an area approximately 6” x 6”.

● One 640-pin Generic Device Adapter Daughterboard, henceforth referred to as the

“Daughterboard”, to which you attach the DUT.

● Four ModelSource modeling systems, either 4 MS3200 units or 4 MS3400 units.

You cannot mix these two types of units.

● One 640-pin Adapter, which provides the interface between the modeling systems

and the Daughterboard.

November 2001 Synopsys, Inc. 9

Page 10

Chapter 1: Describing a 640-pin Logic Model The ModelSource 640-pin Adapter

Software Requirements

To support the 640-pin Logic Model, you need the following software:

● User-created Shell Software files, described in the Shell Software Reference

Manual.

● The product-specific Shell Software files GEN640.ADP and GEN640.PKG,

provided by Synopsys and described in later text.

● R3.3b or later of the Runtime Modeler Software.

● The lm utility, R3.3b or later, for labeling the Daughterboard.

Procedural Summary

The steps in building a 640-pin Logic Model are as follows:

1. Build the Daughterboard and attach the DUT to it.

2. Connect the Daughterboard to the Adapter.

3. Develop the model Shell Software.

4. Mount the Adapter onto the ModelSource modeling systems.

5. Label the Daughterboard.

6. Verify the model.

Steps 1, 2 and 4 are described in detail in this application note. Steps 3, 5, and 6 are

summarized here; for more details, refer to the Logic Model Development Manual.

10 Synopsys, Inc. November 2001

Page 11

The ModelSource 640-pin Adapter Chapter 2: Building the Daughterboard

2

Building the Daughterboard

This chapter describes the specifications you must meet when building the

Daughterboard.

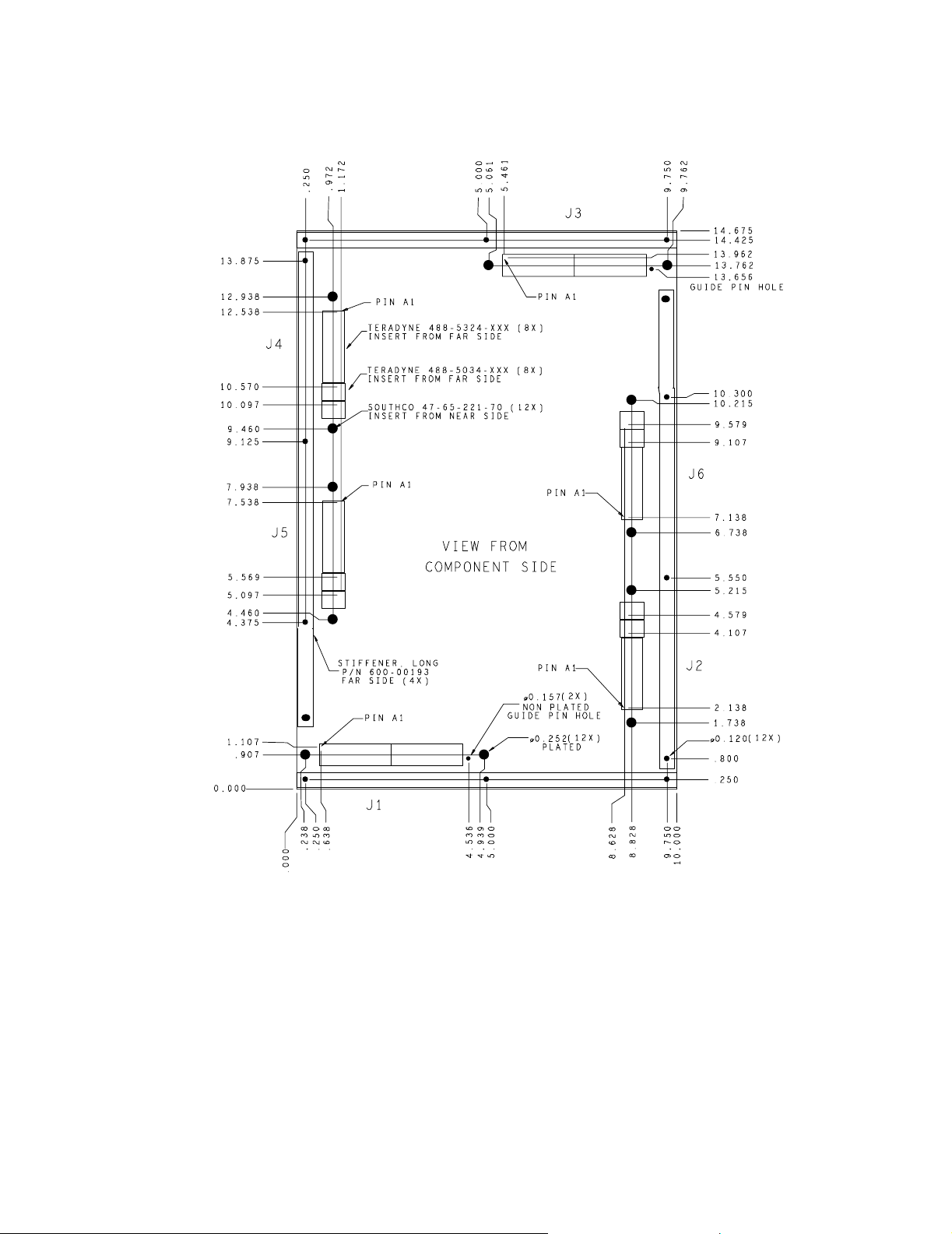

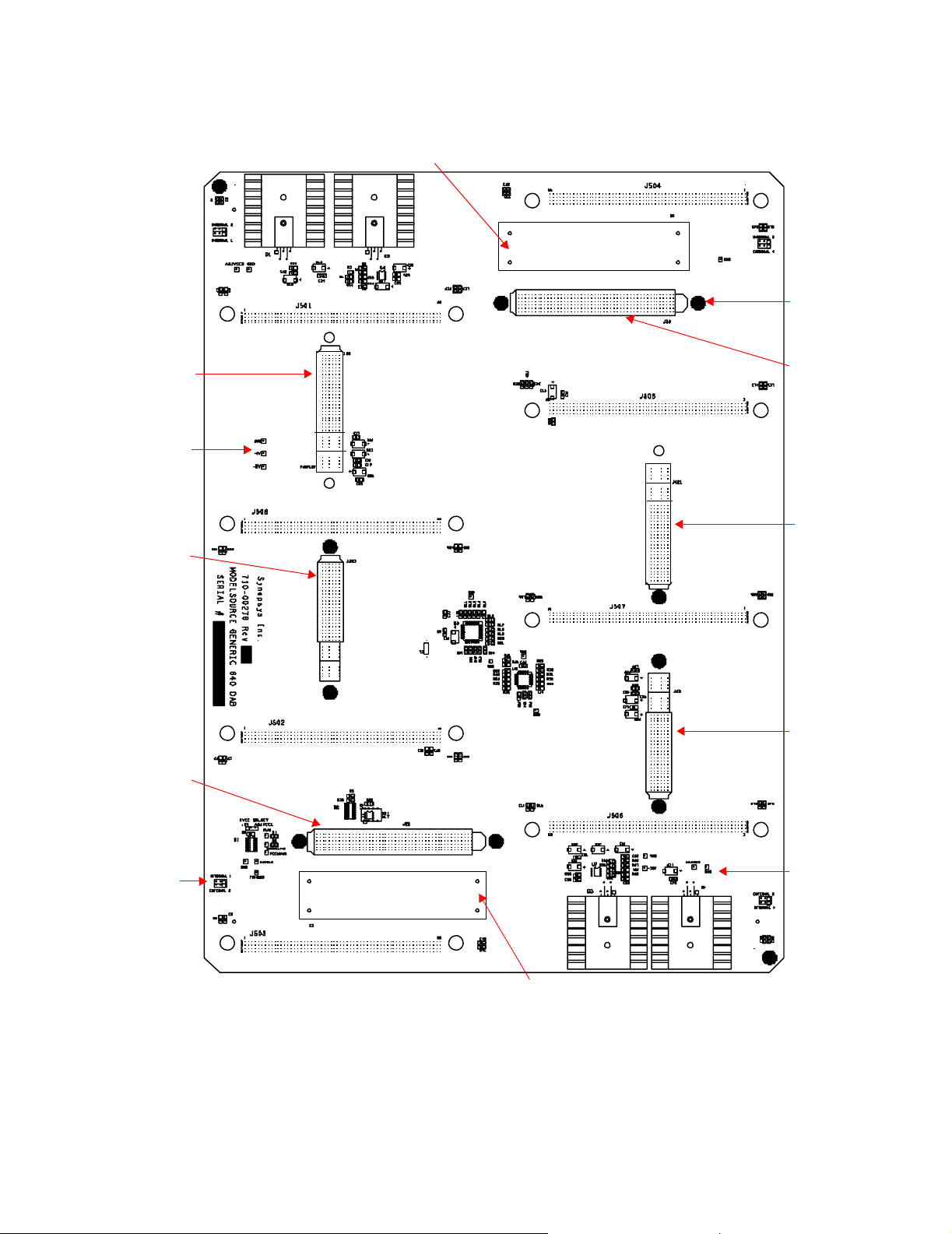

Daughterboard Description

Figure 1 shows the physical specifications of the Daughterboard from the component

side. The Daughterboard is designed to have a footprint area in excess of 10” by 14”,

allowing for a multi-chip DUT.

Following are descriptions of some of the items shown on the drawing. All connectors

are to be installed from the far side.

● Guide pin holes: These are designed to mate with the guide pins on the Adapter to

ensure correct orientation when attaching the Daughterboard to the Adapter.

● Board stiffeners: Four (two long and two short) are required around the perimeter of

the Daughterboard to reinforce it. Fabrication drawings for compatible long and

short stiffeners are provided in Figure 3 on page 15.

● Connectors J1-J6: These are to be installed from the far side, and are designed to

mate with corresponding connectors on the Adapter. The location of Pin A1 of each

connector is indicated on the drawing. Details of the connector pins are provided in

text that follows.

November 2001 Synopsys, Inc. 11

Page 12

Chapter 2: Building the Daughterboard The ModelSource 640-pin Adapter

Figure 1: 640-pin Adapter Daughterboard

12 Synopsys, Inc. November 2001

Page 13

The ModelSource 640-pin Adapter Chapter 2: Building the Daughterboard

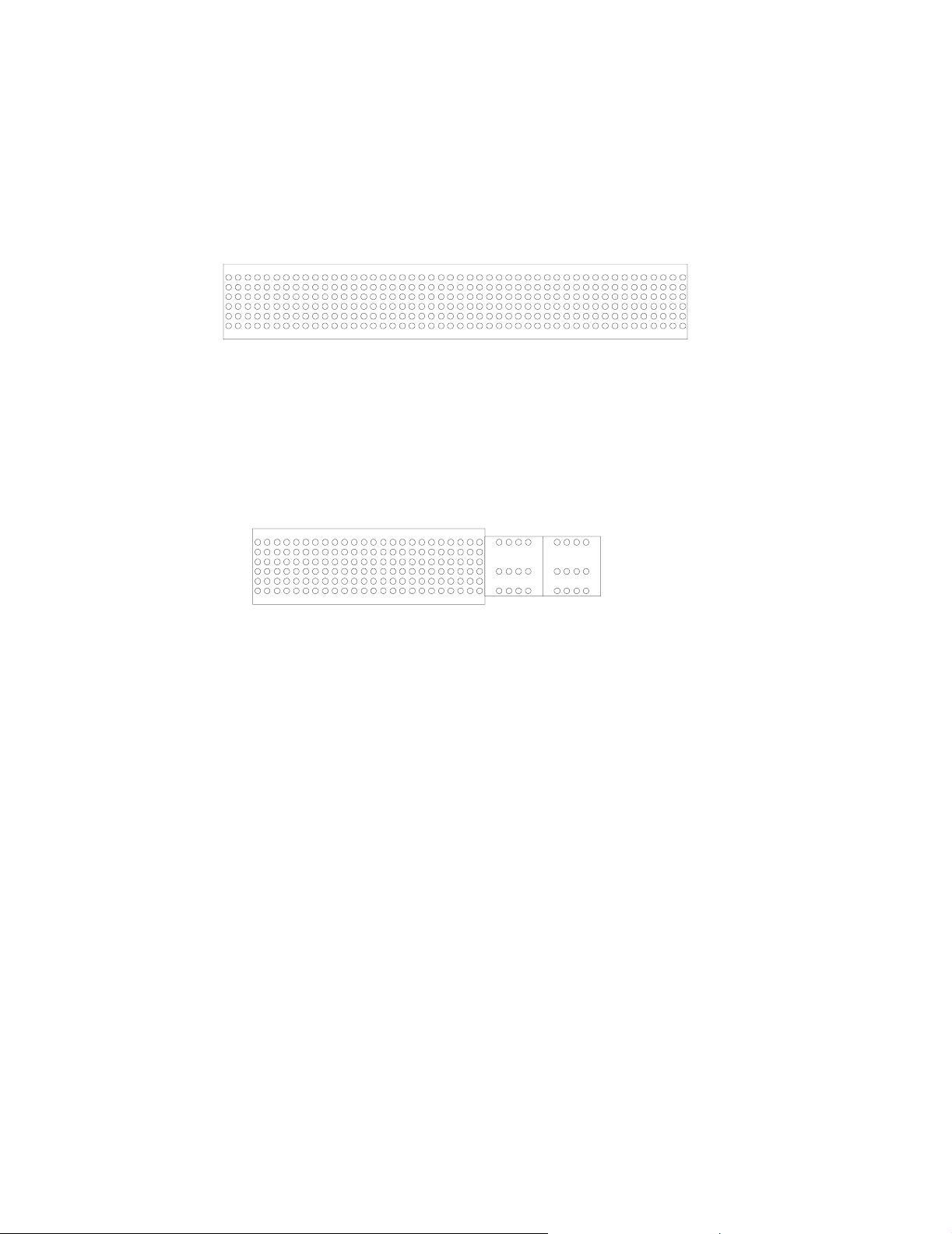

Connector Pin Detail

Connectors J1–J6 include the connections (DUT1–DUT640) between the DUT and the

Adapter through the Daughterboard and, in addition, supply voltage, ground

connections, and various auxiliary signals. Figure 2 shows details of J1–J6 connector

pins, from the component side. Pinouts are listed in “J1–J6 Connector Pinouts” on

page 29.

Connectors J1 and J3

These connectors include two each of Teradyne signal modules, and have 6 rows of 48

pins each. You will notice in Appendix A that no connections are listed for Rows B and

E; these are exclusively ground.

Connectors J2, J4, J5 and J6

These connectors include one each of Teradyne signal modules (A1–F24, at the left of

the figure) and two each of Teradyne power modules (AP1–FP4 and AP5–FP8, at the

right of the figure). As with connectors J1 and J3, the left (signal module) side has rows

B and E exclusively connected to ground. The right (power module) side has no rows B,

C, or E.

November 2001 Synopsys, Inc. 13

Page 14

Chapter 2: Building the Daughterboard The ModelSource 640-pin Adapter

Connectors J1 and J3

One Teradyne

Signal Module

1242448

A

B

C

D

E

F

Rows B and E are connected to ground

Connectors J2, J4, J5 and J6

One Teradyne

Signal Module

1

A

B

C

D

E

F

Rows B and E are

connected to ground do not exist

One Teradyne

Signal Module

Two Teradyne

Power Modules

AP1 AP8

DP1 DP8

FP1 FP8

Rows B, C, and E

Figure 2: Connector Pin Detail, Shown from Component Side

Parts List

The required parts are as follows:

● Eight Teradyne HDM signal modules, 488-5324-XXX. These are available either as

press fit or solder tail, in a variety of tail lengths. The last three digits (XXX) of the

part number depend on which type you choose; for specific part numbers, see the

Teradyne product documentation.

● Eight Teradyne HDM power modules, 437-5034-500. These are currently available

only as solder tail.

● Twelve Southco retractable screw fasteners, 47-65-221-70.

● To mount the stiffeners:

❍ Fourteen 4-40 1/4” pan head Phillips screws

14 Synopsys, Inc. November 2001

Page 15

The ModelSource 640-pin Adapter Chapter 2: Building the Daughterboard

❍ Fourteen #4 lock washers

❍ Fourteen #4 flat washers

● One EEProm, Catalyst semiconductor CAT93C86.

Note

The above does not include the package type designation; that is up to the

model designer.

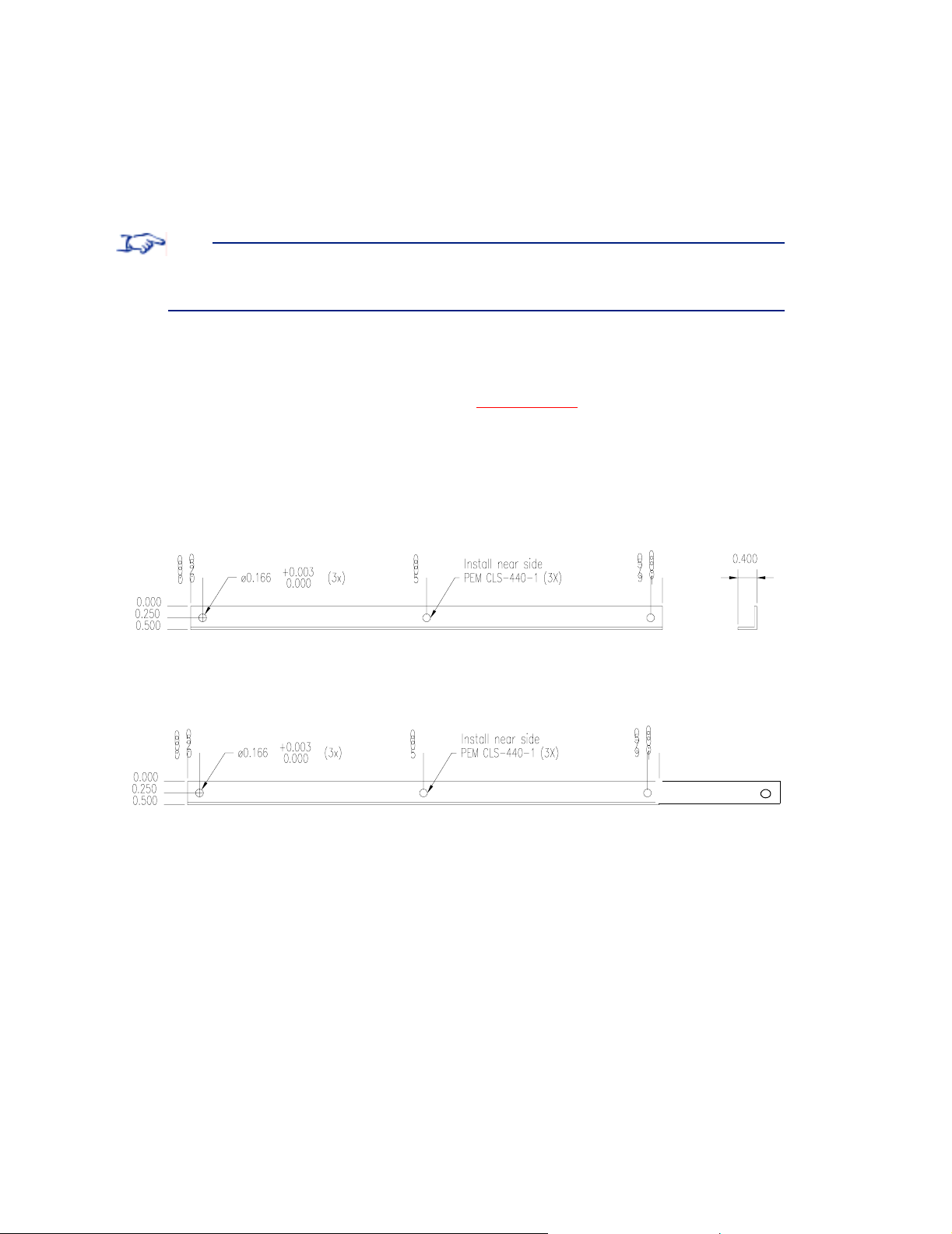

● Two Synopsys board stiffeners (short), 600-00193 (or build according to

specifications).

● Two Synopsys board stiffeners (long), 600-00XXX (or build according to

specifications).

Figure 3 shows a drawing of the short and long board stiffeners.

Short Stiffener

Long Stiffener

Figure 3: Fabrication Drawing of Board Stiffeners

Requirements

● You must locate the connectors and guide pin holes exactly as shown in Figure 1 on

page 12, so that the Daughterboard will fit onto the Adapter.

● The height of the DUT above the Daughterboard must not exceed 2.25 inches.

November 2001 Synopsys, Inc. 15

Page 16

Chapter 2: Building the Daughterboard The ModelSource 640-pin Adapter

● The DUT signal traces (DUT1 through DUT640) are controlled impedance, and

must be 93 ohms ± 10%. (All other signals are uncontrolled but will function

correctly at 93 ohms.)

● You must make the following specific connections:

❍ J1-A1 to J1-F48 (SEAT1)

❍ J2-A1 to J2-F24 (SEAT2)

❍ J3-A1 to J3-F48 (SEAT3)

❍ J4-A1 to J4-F24 (SEAT4)

❍ J5-A1 to J5-F24 (SEAT5)

❍ J6-A1 to J6-F24 (SEAT6)

(These connections pass a daisychain signal through all four J connectors to allow

the ModelSource system to detect whether or not the Adapter is seated correctly.)

● You must provide a series termination of 4.7 ohms within 1 inch of the DUT’s signal

pins. Use as small a surface mount package as can practically be mounted.

Routing Guidelines

Provide connections for your DUT device(s) on the Daughterboard. Route the DUT

signals (DUT1 through DUT640) and other appropriate signals to the J connector pins

according to the pinout listing in “J1–J6 Connector Pinouts” on page 29.

The following are some guidelines:

● For optimal pattern clock rates, ensure that all DUT signals are the same length, or

nearly so (within 0.5 inch).

● Use either microstrip (preferred) or stripline for the signal layers, but do not mix

them, because their propagation velocities are different. Use microstrip if the signal

routing fits on two layers; use stripline if the signal routing requires more than two

layers.

● For ease of testing, create test points for the following signals:

❍ J1-D17 (KEEPALIVE)

❍ J1-A15 (TRIGGER)

❍ J1-A19 (PLAY)

❍ J1-A17 (SAMPLE)

❍ Any voltages used by the DUT

16 Synopsys, Inc. November 2001

Page 17

The ModelSource 640-pin Adapter Chapter 2: Building the Daughterboard

❍ J4-FP5–J4-FP8 (FANP12V), if used

❍ DUT signal used for DUT clock

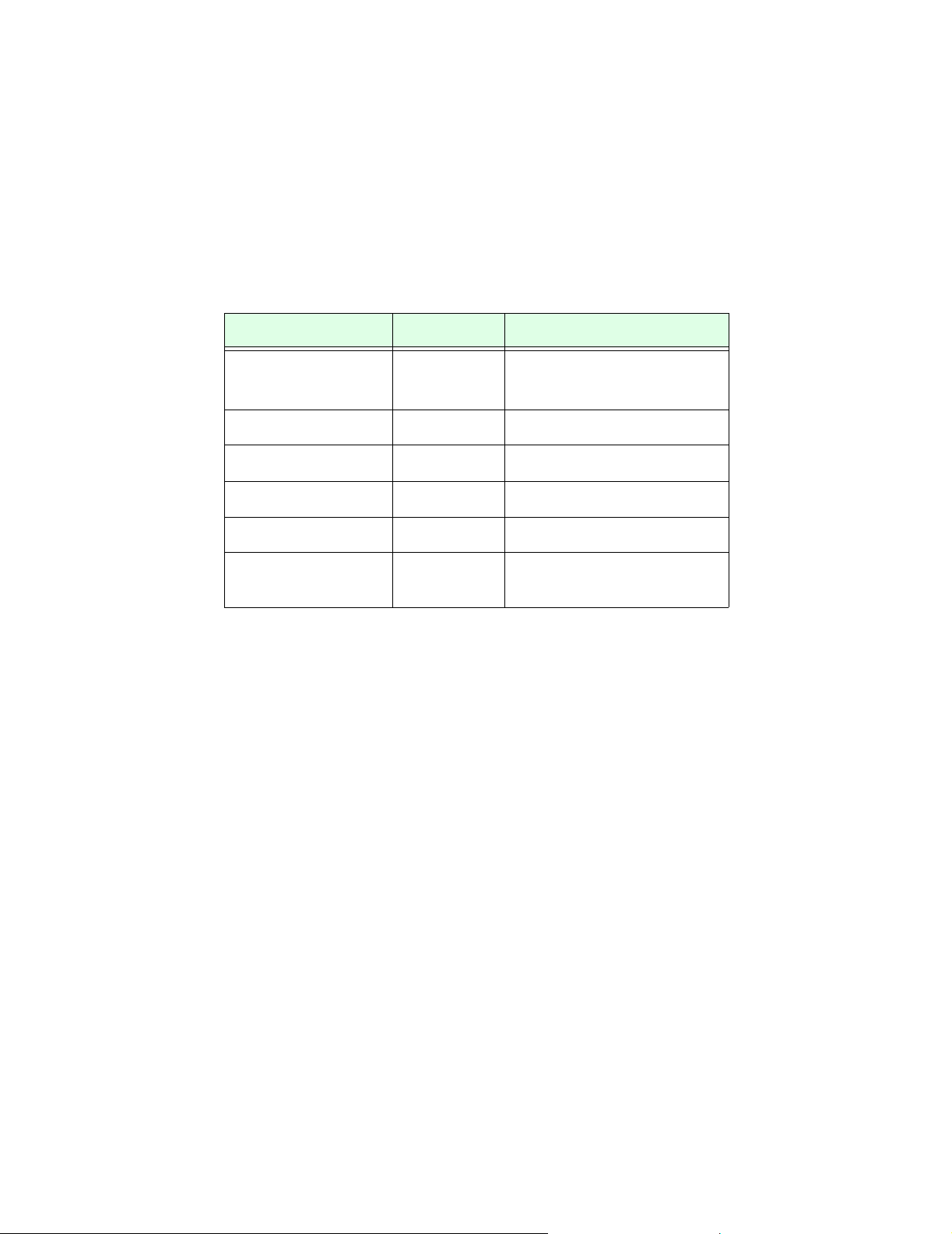

● You can connect to any of the available power supplies listed in Table 1. Do not

interconnect different power supplies.

Table 1: Available Power Supplies

Pins Signal Power Supply

J2-AP5–J2-AP8

P5V +5V DC, 6A max

J4-AP5–J4-AP8

J2-AP1–J2-AP4 ADJVCC1 +3-5V DC, 6A max

J4-AP1–J4-AP4 ADJVCC2 +3-5V DC, 6A max

J4-FP1–J4-FP4 M5V -5.2V DC, 400mA max

J2-FP5–J2-FP8 P12V +12V DC, 400mA max

J4-FP5–J4-FP8 FANP12V +12V DC, 400mA max (for

fan/heat sink only)

● For bypass/decoupling capacitors, follow the DUT manufacturer’s

recommendations, if provided; otherwise, use the following guidelines:

❍ For each supply of P5V, ADJVCC1 or ADJVCC2, provide 47µF, 16V tantalum

(use two of these, if space permits).

❍ For each supply of P12V, M5V, provide 10µF, 16V tantalum.

❍ For bypass, for every 25 signal pins, place a pair of 0.1µF and 0.01µF high

frequency X7R or NPO capacitors directly underneath the device, if possible, or

around the perimeter of the device.

November 2001 Synopsys, Inc. 17

Page 18

Chapter 2: Building the Daughterboard The ModelSource 640-pin Adapter

18 Synopsys, Inc. November 2001

Page 19

The ModelSource 640-pin Adapter Chapter 3: Connecting the Daughterboard

3

Connecting the Daughterboard

This section describes the Adapter and gives instructions for interconnecting it and the

Daughterboard.

Adapter Description

Figure 4 shows a drawing of the Adapter. The items of interest to the user are as follows:

● Connectors that mate with Daughterboard connectors J1–J6

● Ejectors for disconnecting the Daughterboard from the Adapter

● Guide pins that fit the Daughterboard guide pin holes to ensure correct orientation

● Test points for the signals TRIGGER, KEEPALIVE, PLAY, FEEDBACK,

SAMPLE, ADJVCC1, +5V, -5V, and GND

November 2001 Synopsys, Inc. 19

Page 20

Chapter 3: Connecting the Daughterboard The ModelSource 640-pin Adapter

2

6

3

Ejector

Guide

Pin

Mates

with J4

Test

Points

Mates

with J5

Mates

with J1

Mates

with J

Mates

with J

Mates

with J

Test

Points

Ejector

Test

Points

Figure 4: The 640-pin Generic Device Adapter

20 Synopsys, Inc. November 2001

Page 21

The ModelSource 640-pin Adapter Chapter 3: Connecting the Daughterboard

Procedures

Caution

Do not connect or disconnect the Daughterboard to or from the Adapter

while the Adapter is mounted on the ModelSource modeling systems.

To connect the Daughterboard to the Adapter, follow these steps:

1. Remove the lid from the Adapter.

2. Set the Daughterboard on the Adapter, engaging the guide pins through the guide

pin holes.

3. Push firmly to seat.

4. Hand-tighten each of the Southco retractable screw fasteners.

5. Replace the Adapter lid.

To disconnect the Daughterboard from the Adapter, follow these steps:

1. Remove the lid from the Adapter.

2. Loosen the Southco retractable screw fasteners.

3. Push the ejectors on the Adapter.

4. Carefully lift the Daughterboard from the Adapter.

5. Replace the Adapter lid.

November 2001 Synopsys, Inc. 21

Page 22

Chapter 3: Connecting the Daughterboard The ModelSource 640-pin Adapter

22 Synopsys, Inc. November 2001

Page 23

The ModelSource 640-pin Adapter Chapter 4: Developing the Shell Software

4

Developing the Shell Software

The Shell Software file requirements for a 640-pin Logic model are similar to those for

standard Logic Models, and are summarized here. For more information, see the Shell

Software Reference Manual.

User-Generated Files

As for all Generic Device Adapters, you must create one or more Shell Software files

that contain DUT-specific information, such as pinouts, device names, propagation

delays, timing checks.

Files Provided by Synopsys

● The Adapter Mapping (.ADP) file, GEN640.ADP: This file provides signal

mapping between the Adapter and the ModelSource modeling system. You should

be able to use this file without modification.

● A template Package Mapping (.PKG) file, GEN640.PKG: The .PKG file provides

signal mapping between the Daughterboard and the DUT; the template file contains

Daughterboard pin names mapped to duplicate pin names, for those pins used for

DUT signals. You create the custom .PKG file by editing the template and replacing

the duplicate pin names with your DUT pin names.

November 2001 Synopsys, Inc. 23

Page 24

Chapter 4: Developing the Shell Software The ModelSource 640-pin Adapter

Figure 5 shows part of the template GEN640.PKG file provided by Synopsys.

{*******************************************************************}

{* Copyright (c) 2001by Synopsys, Incorporated *}

{*All rights reserved. *}

{*******************************************************************}

{* Logic Model PACKAGE map file for Generic 640 Device Adapter. *}

{*******************************************************************}

{ package_map_revision A *}

{*******************************************************************}

package_mapping

J1A2 = J1A2

J1A3 = J1A3

J1A4 = J1A4

J1A5 = J1A5

J1A6 = J1A6

J1A7 = J1A7

J1A8 = J1A8

J1A9 = J1A9

J1A10 = J1A10

J1A11 = J1A11

J1A12 = J1A12

J1A13 = J1A13

J1A21 = J1A21

J1A22 = J1A22

J1A23 = J1A23

J1A24 = J1A24

J1A25 = J1A25

Figure 5: Partial GEN640.PKG File

T o customize this file for your DUT, you replace the first name on each line with the

name of the appropriate signal on your DUT.

For example, you change the first line

J1A2 = J1A2

to

DUTpname = J1A2

24 Synopsys, Inc. November 2001

Page 25

The ModelSource 640-pin Adapter Chapter 5: Completing the Model

5

Completing the Model

This chapter describes the tasks needed to complete the model: mounting the Adapter

onto the Modeling Systems, labeling the Daughterboard, and verifying the model. It also

describes how to unmount the Adapter from the Modeling Systems.

Mounting the Adapter onto the ModelSource Modeling Systems

To mount the Adapter onto the ModelSource modeling systems, follow these steps:

1. Make a stack of four MS3200 or four MS3400 modeling systems (do not mix these

two modeling systems). Connect the modeling systems together as described in

“Chapter 2: Installation” in the ModelSource User’s Manual.

Note

Do not stack the modelings systems more than four high. Ensure that the

surface on which the modelers are stacked is flat and rigid.

2. Place the base of the Adapter against the front of the sets of four connected

modeling systems, hanging the Adapter’ s hook receptacles on the positioning hooks

of the modeling systems. Pull the Adapter gently towards you to make sure that it is

securely balanced on the hooks.

3. Seat the modeling boards in the ModelSource modeling systems onto the Adapter as

described in the following paragraph.

Each modeling system has a knob on the right and on the left side for moving the

top and bottom modeling boards, respectively, backwards and forwards. Turn each

knob individually counterclockwise to bring each modeling board forward to

connect with the Adapter.

November 2001 Synopsys, Inc. 25

Page 26

Chapter 5: Completing the Model The ModelSource 640-pin Adapter

Labeling the Daughterboard

After you have completed the Shell Software and mounted the Adapter and

Daughterboard onto the ModelSource modeling systems, you must verify the

Daughterboard’s label and update it if necessary.

Note

Ensure that the Daughterboard is seated on the Adapter before you verify

and update the label. If the daughterboard is not seated, the software will

report the label as “GEN640”, the label of the Adapter itself.

If it is necessary to update the Daughterboard’s label, use the lm Label Device Adapter

utility to change the adapter’s label to the device_name used in the model’s Shell

Software. For more details, refer to “Label Device Adapter“ in the ModelSource User’s

Manual.

Verifying the Model

After you have developed the model, you must verify it. For more information, see the

ModelSource User’s Manual and the Logic Model Development Manual.

Note

The pattern memory available for simulation is limited to the smallest

amount of available memory on any one of the eight modeling boards in the

four modelers.

26 Synopsys, Inc. November 2001

Page 27

The ModelSource 640-pin Adapter Chapter 5: Completing the Model

Unmounting the Adapter from the ModelSource Modeling Systems

To remove the Adapter from the ModelSource modeling systems, follow these steps:

1. Ensure that the Adapter is not currently in use (that is, the In Use LEDs are not

illuminated).

2. Turn each knob individually clockwise, to unseat each modeling board connector

from the Adapter.

3. Verify that the “Seated LED” on each modeling board is no longer illuminated.

4. Push the Adapter so that it is flush against the front panel of the modeling system

assembly, and slide it up as far as you can.

5. Pull the Adapter straight out and away from the modeling system assembly.

November 2001 Synopsys, Inc. 27

Page 28

Chapter 5: Completing the Model The ModelSource 640-pin Adapter

28 Synopsys, Inc. November 2001

Page 29

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

A

J1–J6 Connector Pinouts

The pinouts for connectors J1 through J6 of the 640-pin Adapter and the Daughterboard

are listed in Table 2. Do not use pins that are labeled RESERVED.

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J1 A1 SEAT1

J1 A2 DUT171

J1 A3 DUT173

J1 A4 DUT170

J1 A5 DUT169

J1 A6 DUT168

J1 A7 DUT167

J1 A8 DUT166

J1 A9 DUT165

J1 A10 DUT164

J1 A11 DUT163

J1 A12 DUT162

J1 A13 DUT161

J1 A14 NC

J1 A15 TRIGGER

November 2001 Synopsys, Inc. 29

Page 30

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J1 A16 NC

J1 A17 SAMPLE

J1 A18 NC

J1 A19 PLAY

J1 A20 NC

J1 A21 DUT198

J1 A22 DUT197

J1 A23 DUT196

J1 A24 DUT202

J1 A25 DUT194

J1 A26 DUT193

J1 A27 DUT192

J1 A28 DUT191

J1 A29 DUT190

J1 A30 DUT189

J1 A31 DUT188

J1 A32 DUT187

J1 A33 DUT186

J1 A34 DUT185

J1 A35 DUT226

J1 A36 DUT225

J1 A37 DUT224

J1 A38 DUT223

J1 A39 DUT222

J1 A40 DUT221

30 Synopsys, Inc. November 2001

Page 31

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J1 A41 DUT220

J1 A42 DUT219

J1 A43 DUT218

J1 A44 DUT217

J1 A45 DUT237

J1 A46 DUT215

J1 A47 DUT214

J1 A48 DUT213

J1 C1 NC

J1 C2 DUT172

J1 C3 DUT174

J1 C4 DUT175

J1 C5 DUT176

J1 C6 DUT177

J1 C7 DUT178

J1 C8 DUT179

J1 C9 DUT180

J1 C10 DUT181

J1 C11 DUT182

J1 C12 DUT183

J1 C13 DUT184

J1 C14 NC

J1 C15 NC

J1 C16 NC

J1 C17 TEMP

November 2001 Synopsys, Inc. 31

Page 32

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J1 C18 NC

J1 C19 NC

J1 C20 NC

J1 C21 DUT199

J1 C22 DUT200

J1 C23 DUT201

J1 C24 DUT195

J1 C25 DUT203

J1 C26 DUT204

J1 C27 DUT205

J1 C28 DUT206

J1 C29 DUT207

J1 C30 DUT208

J1 C31 DUT209

J1 C32 DUT210

J1 C33 DUT211

J1 C34 DUT212

J1 C35 DUT227

J1 C36 DUT228

J1 C37 DUT229

J1 C38 DUT230

J1 C39 DUT231

J1 C40 DUT232

J1 C41 DUT233

J1 C42 DUT234

32 Synopsys, Inc. November 2001

Page 33

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J1 C43 DUT235

J1 C44 DUT236

J1 C45 DUT216

J1 C46 DUT238

J1 C47 DUT239

J1 C48 DUT240

J1 D1 DUT11

J1 D2 DUT13

J1 D3 DUT10

J1 D4 DUT9

J1 D5 DUT8

J1 D6 DUT7

J1 D7 DUT6

J1 D8 DUT5

J1 D9 DUT4

J1 D10 DUT3

J1 D11 DUT2

J1 D12 DUT1

J1 D13 NC

J1 D14 NC

J1 D15 FEEDBACK

J1 D16 NC

J1 D17 KEEPALIVE

J1 D18 NC

J1 D19 NC

November 2001 Synopsys, Inc. 33

Page 34

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J1 D20 DUT38

J1 D21 DUT37

J1 D22 DUT36

J1 D23 DUT42

J1 D24 DUT34

J1 D25 DUT33

J1 D26 DUT32

J1 D27 DUT31

J1 D28 DUT30

J1 D29 DUT29

J1 D30 DUT28

J1 D31 DUT27

J1 D32 DUT26

J1 D33 DUT25

J1 D34 DUT66

J1 D35 DUT65

J1 D36 DUT64

J1 D37 DUT63

J1 D38 DUT62

J1 D39 DUT61

J1 D40 DUT60

J1 D41 DUT59

J1 D42 DUT58

J1 D43 DUT57

J1 D44 DUT77

34 Synopsys, Inc. November 2001

Page 35

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J1 D45 DUT55

J1 D46 DUT54

J1 D47 DUT53

J1 D48 NC

J1 F1 DUT12

J1 F2 DUT14

J1 F3 DUT15

J1 F4 DUT16

J1 F5 DUT17

J1 F6 DUT18

J1 F7 DUT19

J1 F8 DUT20

J1 F9 DUT21

J1 F10 DUT22

J1 F11 DUT23

J1 F12 DUT24

J1 F13 NC

J1 F14 EEOUT

J1 F15 EEIN

J1 F16 EECLK

J1 F17 EEPE

J1 F18 EESEL

J1 F19 EEVCC

J1 F20 DUT39

J1 F21 DUT40

November 2001 Synopsys, Inc. 35

Page 36

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J1 F22 DUT41

J1 F23 DUT35

J1 F24 DUT43

J1 F25 DUT44

J1 F26 DUT45

J1 F27 DUT46

J1 F28 DUT47

J1 F29 DUT48

J1 F30 DUT49

J1 F31 DUT50

J1 F32 DUT51

J1 F33 DUT52

J1 F34 DUT67

J1 F35 DUT68

J1 F36 DUT69

J1 F37 DUT70

J1 F38 DUT71

J1 F39 DUT72

J1 F40 DUT73

J1 F41 DUT74

J1 F42 DUT75

J1 F43 DUT76

J1 F44 DUT56

J1 F45 DUT78

J1 F46 DUT79

36 Synopsys, Inc. November 2001

Page 37

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J1 F47 DUT80

J1 F48 SEAT1

J2 A1 SEAT2

J2 A2 DUT160

J2 A3 DUT159

J2 A4 DUT158

J2 A5 DUT136

J2 A6 DUT156

J2 A7 DUT155

J2 A8 DUT154

J2 A9 DUT153

J2 A10 DUT152

J2 A11 DUT151

J2 A12 DUT150

J2 A13 DUT149

J2 A14 DUT148

J2 A15 DUT147

J2 A16 DUT132

J2 A17 DUT131

J2 A18 DUT130

J2 A19 DUT129

J2 A20 DUT128

J2 A21 DUT127

J2 A22 NC

November 2001 Synopsys, Inc. 37

Page 38

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J2 A23 NC

J2 A24 NC

J2 C1 NC

J2 C2 DUT133

J2 C3 DUT134

J2 C4 DUT135

J2 C5 DUT157

J2 C6 DUT137

J2 C7 DUT138

J2 C8 DUT139

J2 C9 DUT140

J2 C10 DUT141

J2 C11 DUT142

J2 C12 DUT143

J2 C13 DUT144

J2 C14 DUT145

J2 C15 DUT146

J2 C16 DUT105

J2 C17 DUT106

J2 C18 DUT107

J2 C19 DUT108

J2 C20 DUT109

J2 C21 DUT110

J2 C22 NC

J2 C23 NC

38 Synopsys, Inc. November 2001

Page 39

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J2 C24 NC

J2 D1 NC

J2 D2 DUT91

J2 D3 DUT93

J2 D4 DUT90

J2 D5 DUT89

J2 D6 DUT88

J2 D7 DUT87

J2 D8 DUT86

J2 D9 DUT85

J2 D10 DUT84

J2 D11 DUT83

J2 D12 DUT82

J2 D13 DUT81

J2 D14 DUT118

J2 D15 DUT117

J2 D16 DUT116

J2 D17 DUT122

J2 D18 DUT114

J2 D19 DUT113

J2 D20 DUT112

J2 D21 DUT111

J2 D22 NC

J2 D23 NC

J2 D24 NC

November 2001 Synopsys, Inc. 39

Page 40

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J2 F1 NC

J2 F2 DUT92

J2 F3 DUT94

J2 F4 DUT95

J2 F5 DUT96

J2 F6 DUT97

J2 F7 DUT98

J2 F8 DUT99

J2 F9 DUT100

J2 F10 DUT101

J2 F11 DUT102

J2 F12 DUT103

J2 F13 DUT104

J2 F14 DUT119

J2 F15 DUT120

J2 F16 DUT121

J2 F17 DUT115

J2 F18 DUT123

J2 F19 DUT124

J2 F20 DUT125

J2 F21 DUT126

J2 F22 NC

J2 F23 NC

J2 F24 SEAT2

J2 AP1 ADJVCC1

40 Synopsys, Inc. November 2001

Page 41

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J2 AP2 ADJVCC1

J2 AP3 ADJVCC1

J2 AP4 ADJVCC1

J2 AP5 P5V

J2 AP6 P5V

J2 AP7 P5V

J2 AP8 P5V

J2 DP1 GND

J2 DP2 GND

J2 DP3 GND

J2 DP4 GND

J2 DP5 GND

J2 DP6 GND

J2 DP7 GND

J2 DP8 GND

J2 FP1 NC

J2 FP2 NC

J2 FP3 NC

J2 FP4 NC

J2 FP5 P12V

J2 FP6 P12V

J2 FP7 P12V

J2 FP8 P12V

J3 A1 SEAT3

November 2001 Synopsys, Inc. 41

Page 42

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J3 A2 DUT640

J3 A3 DUT639

J3 A4 DUT638

J3 A5 DUT616

J3 A6 DUT636

J3 A7 DUT635

J3 A8 DUT634

J3 A9 DUT633

J3 A10 DUT632

J3 A11 DUT631

J3 A12 DUT630

J3 A13 DUT629

J3 A14 DUT628

J3 A15 DUT627

J3 A16 DUT612

J3 A17 DUT611

J3 A18 DUT610

J3 A19 DUT609

J3 A20 DUT608

J3 A21 DUT607

J3 A22 DUT606

J3 A23 DUT605

J3 A24 DUT604

J3 A25 DUT603

J3 A26 DUT595

42 Synopsys, Inc. November 2001

Page 43

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J3 A27 DUT601

J3 A28 DUT600

J3 A29 DUT599

J3 A30 NC

J3 A31 RESERVED (AD13)

J3 A32 RESERVED (AD7)

J3 A33 RESERVED (AD5)

J3 A34 RESERVED (AD0)

J3 A35 RESERVED (-ACK)

J3 A36 NC

J3 A37 DUT584

J3 A38 DUT583

J3 A39 DUT582

J3 A40 DUT581

J3 A41 DUT580

J3 A42 DUT579

J3 A43 DUT578

J3 A44 DUT577

J3 A45 DUT576

J3 A46 DUT575

J3 A47 DUT574

J3 A48 DUT572

J3 C1 NC

J3 C2 DUT613

J3 C3 DUT614

November 2001 Synopsys, Inc. 43

Page 44

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J3 C4 DUT615

J3 C5 DUT637

J3 C6 DUT617

J3 C7 DUT618

J3 C8 DUT619

J3 C9 DUT620

J3 C10 DUT621

J3 C11 DUT622

J3 C12 DUT623

J3 C13 DUT624

J3 C14 DUT625

J3 C15 DUT626

J3 C16 DUT585

J3 C17 DUT586

J3 C18 DUT587

J3 C19 DUT588

J3 C20 DUT589

J3 C21 DUT590

J3 C22 DUT591

J3 C23 DUT592

J3 C24 DUT593

J3 C25 DUT594

J3 C26 DUT602

J3 C27 DUT596

J3 C28 DUT597

44 Synopsys, Inc. November 2001

Page 45

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J3 C29 DUT598

J3 C30 NC

J3 C31 RESERVED (AD11)

J3 C32 RESERVED (AD12)

J3 C33 RESERVED (AD6)

J3 C34 RESERVED (AD2)

J3 C35 RESERVED (-WR)

J3 C36 NC

J3 C37 DUT561

J3 C38 DUT562

J3 C39 DUT563

J3 C40 DUT564

J3 C41 DUT565

J3 C42 DUT566

J3 C43 DUT567

J3 C44 DUT568

J3 C45 DUT569

J3 C46 DUT570

J3 C47 DUT573

J3 C48 DUT571

J3 D1 DUT480

J3 D2 DUT479

J3 D3 DUT478

J3 D4 DUT456

J3 D5 DUT476

November 2001 Synopsys, Inc. 45

Page 46

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J3 D6 DUT475

J3 D7 DUT474

J3 D8 DUT473

J3 D9 DUT472

J3 D10 DUT471

J3 D11 DUT470

J3 D12 DUT469

J3 D13 DUT468

J3 D14 DUT467

J3 D15 DUT452

J3 D16 DUT451

J3 D17 DUT450

J3 D18 DUT449

J3 D19 DUT448

J3 D20 DUT447

J3 D21 DUT446

J3 D22 DUT445

J3 D23 DUT444

J3 D24 DUT443

J3 D25 DUT435

J3 D26 DUT441

J3 D27 DUT440

J3 D28 DUT439

J3 D29 NC

J3 D30 RESERVED (AD10)

46 Synopsys, Inc. November 2001

Page 47

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J3 D31 RESERVED (AD9)

J3 D32 RESERVED (AD3)

J3 D33 RESERVED (AD4)

J3 D34 RESERVED (-RD)

J3 D35 NC

J3 D36 DUT424

J3 D37 DUT423

J3 D38 DUT422

J3 D39 DUT421

J3 D40 DUT420

J3 D41 DUT419

J3 D42 DUT418

J3 D43 DUT417

J3 D44 DUT416

J3 D45 DUT415

J3 D46 DUT414

J3 D47 DUT412

J3 D48 NC

J3 F1 DUT453

J3 F2 DUT454

J3 F3 DUT455

J3 F4 DUT477

J3 F5 DUT457

J3 F6 DUT458

J3 F7 DUT459

November 2001 Synopsys, Inc. 47

Page 48

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J3 F8 DUT460

J3 F9 DUT461

J3 F10 DUT462

J3 F11 DUT463

J3 F12 DUT464

J3 F13 DUT465

J3 F14 DUT466

J3 F15 DUT425

J3 F16 DUT426

J3 F17 DUT427

J3 F18 DUT428

J3 F19 DUT429

J3 F20 DUT430

J3 F21 DUT431

J3 F22 DUT432

J3 F23 DUT433

J3 F24 DUT434

J3 F25 DUT442

J3 F26 DUT436

J3 F27 DUT437

J3 F28 DUT438

J3 F29 NC

J3 F30 RESERVED (AD14)

J3 F31 RESERVED (AD8)

J3 F32 RESERVED (AD1)

48 Synopsys, Inc. November 2001

Page 49

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J3 F33 RESERVED (AD15)

J3 F34 RESERVED (-AS)

J3 F35 NC

J3 F36 DUT401

J3 F37 DUT402

J3 F38 DUT403

J3 F39 DUT404

J3 F40 DUT405

J3 F41 DUT406

J3 F42 DUT407

J3 F43 DUT408

J3 F44 DUT409

J3 F45 DUT410

J3 F46 DUT413

J3 F47 DUT411

J3 F48 SEAT3

J4 A1 SEAT4

J4 A2 DUT560

J4 A3 DUT559

J4 A4 DUT558

J4 A5 DUT536

J4 A6 DUT556

J4 A7 DUT555

J4 A8 DUT554

November 2001 Synopsys, Inc. 49

Page 50

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J4 A9 DUT553

J4 A10 DUT552

J4 A11 DUT551

J4 A12 DUT550

J4 A13 DUT549

J4 A14 DUT548

J4 A15 DUT547

J4 A16 DUT532

J4 A17 DUT531

J4 A18 DUT530

J4 A19 DUT529

J4 A20 DUT528

J4 A21 DUT527

J4 A22 NC

J4 A23 NC

J4 A24 NC

J4 C1 NC

J4 C2 DUT533

J4 C3 DUT534

J4 C4 DUT535

J4 C5 DUT557

J4 C6 DUT537

J4 C7 DUT538

J4 C8 DUT539

J4 C9 DUT540

50 Synopsys, Inc. November 2001

Page 51

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J4 C10 DUT541

J4 C11 DUT542

J4 C12 DUT543

J4 C13 DUT544

J4 C14 DUT545

J4 C15 DUT546

J4 C16 DUT505

J4 C17 DUT506

J4 C18 DUT507

J4 C19 DUT508

J4 C20 DUT509

J4 C21 DUT510

J4 C22 NC

J4 C23 NC

J4 C24 NC

J4 D1 NC

J4 D2 DUT491

J4 D3 DUT493

J4 D4 DUT490

J4 D5 DUT489

J4 D6 DUT488

J4 D7 DUT487

J4 D8 DUT486

J4 D9 DUT485

J4 D10 DUT484

November 2001 Synopsys, Inc. 51

Page 52

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J4 D11 DUT483

J4 D12 DUT482

J4 D13 DUT481

J4 D14 DUT518

J4 D15 DUT517

J4 D16 DUT516

J4 D17 DUT522

J4 D18 DUT514

J4 D19 DUT513

J4 D20 DUT512

J4 D21 DUT511

J4 D22 NC

J4 D23 NC

J4 D24 NC

J4 F1 NC

J4 F2 DUT492

J4 F3 DUT494

J4 F4 DUT495

J4 F5 DUT496

J4 F6 DUT497

J4 F7 DUT498

J4 F8 DUT499

J4 F9 DUT500

J4 F10 DUT501

J4 F11 DUT502

52 Synopsys, Inc. November 2001

Page 53

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J4 F12 DUT503

J4 F13 DUT504

J4 F14 DUT519

J4 F15 DUT520

J4 F16 DUT521

J4 F17 DUT515

J4 F18 DUT523

J4 F19 DUT524

J4 F20 DUT525

J4 F21 DUT526

J4 F22 NC

J4 F23 NC

J4 F24 SEAT4

J4 AP1 ADJVCC2

J4 AP2 ADJVCC2

J4 AP3 ADJVCC2

J4 AP4 ADJVCC2

J4 AP5 P5V

J4 AP6 P5V

J4 AP7 P5V

J4 AP8 P5V

J4 DP1 GND

J4 DP2 GND

J4 DP3 GND

J4 DP4 GND

November 2001 Synopsys, Inc. 53

Page 54

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J4 DP5 GND

J4 DP6 GND

J4 DP7 GND

J4 DP8 GND

J4 FP1 M5V

J4 FP2 M5V

J4 FP3 M5V

J4 FP4 M5V

J4 FP5 FANP12V

J4 FP6 FANP12V

J4 FP7 FANP12V

J4 FP8 FANP12V

J5 A1 SEAT5

J5 A2 DUT400

J5 A3 DUT399

J5 A4 DUT398

J5 A5 DUT376

J5 A6 DUT396

J5 A7 DUT395

J5 A8 DUT394

J5 A9 DUT393

J5 A10 DUT392

J5 A11 DUT391

J5 A12 DUT390

54 Synopsys, Inc. November 2001

Page 55

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J5 A13 DUT389

J5 A14 DUT388

J5 A15 DUT387

J5 A16 DUT372

J5 A17 DUT371

J5 A18 DUT370

J5 A19 DUT369

J5 A20 DUT368

J5 A21 DUT367

J5 A22 NC

J5 A23 NC

J5 A24 NC

J5 C1 NC

J5 C2 DUT373

J5 C3 DUT374

J5 C4 DUT375

J5 C5 DUT397

J5 C6 DUT377

J5 C7 DUT378

J5 C8 DUT379

J5 C9 DUT380

J5 C10 DUT381

J5 C11 DUT382

J5 C12 DUT383

J5 C13 DUT384

November 2001 Synopsys, Inc. 55

Page 56

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J5 C14 DUT385

J5 C15 DUT386

J5 C16 DUT345

J5 C17 DUT346

J5 C18 DUT347

J5 C19 DUT348

J5 C20 DUT349

J5 C21 DUT350

J5 C22 NC

J5 C23 NC

J5 C24 NC

J5 D1 NC

J5 D2 DUT331

J5 D3 DUT333

J5 D4 DUT330

J5 D5 DUT329

J5 D6 DUT328

J5 D7 DUT327

J5 D8 DUT326

J5 D9 DUT325

J5 D10 DUT324

J5 D11 DUT323

J5 D12 DUT322

J5 D13 DUT321

J5 D14 DUT358

56 Synopsys, Inc. November 2001

Page 57

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J5 D15 DUT357

J5 D16 DUT356

J5 D17 DUT362

J5 D18 DUT354

J5 D19 DUT353

J5 D20 DUT352

J5 D21 DUT351

J5 D22 NC

J5 D23 NC

J5 D24 NC

J5 F1 NC

J5 F2 DUT332

J5 F3 DUT334

J5 F4 DUT335

J5 F5 DUT336

J5 F6 DUT337

J5 F7 DUT338

J5 F8 DUT339

J5 F9 DUT340

J5 F10 DUT341

J5 F11 DUT342

J5 F12 DUT343

J5 F13 DUT344

J5 F14 DUT359

J5 F15 DUT360

November 2001 Synopsys, Inc. 57

Page 58

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J5 F16 DUT361

J5 F17 DUT355

J5 F18 DUT363

J5 F19 DUT364

J5 F20 DUT365

J5 F21 DUT366

J5 F22 NC

J5 F23 NC

J5 F24 SEAT5

J5 AP1 RESERVED

J5 AP2 RESERVED

J5 AP3 RESERVED

J5 AP4 RESERVED

J5 AP5 RESERVED

J5 AP6 RESERVED

J5 AP7 RESERVED

J5 AP8 RESERVED

J5 DP1 GND

J5 DP2 GND

J5 DP3 GND

J5 DP4 GND

J5 DP5 GND

J5 DP6 GND

J5 DP7 GND

J5 DP8 GND

58 Synopsys, Inc. November 2001

Page 59

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J5 FP1 RESERVED

J5 FP2 RESERVED

J5 FP3 RESERVED

J5 FP4 RESERVED

J5 FP5 RESERVED

J5 FP6 RESERVED

J5 FP7 RESERVED

J5 FP8 RESERVED

J6 A1 SEAT6

J6 A2 DUT320

J6 A3 DUT319

J6 A4 DUT318

J6 A5 DUT296

J6 A6 DUT316

J6 A7 DUT315

J6 A8 DUT314

J6 A9 DUT313

J6 A10 DUT312

J6 A11 DUT311

J6 A12 DUT310

J6 A13 DUT309

J6 A14 DUT308

J6 A15 DUT307

J6 A16 DUT292

November 2001 Synopsys, Inc. 59

Page 60

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J6 A17 DUT291

J6 A18 DUT290

J6 A19 DUT289

J6 A20 DUT288

J6 A21 DUT287

J6 A22 NC

J6 A23 NC

J6 A24 NC

J6 C1 NC

J6 C2 DUT293

J6 C3 DUT294

J6 C4 DUT295

J6 C5 DUT317

J6 C6 DUT297

J6 C7 DUT298

J6 C8 DUT299

J6 C9 DUT300

J6 C10 DUT301

J6 C11 DUT302

J6 C12 DUT303

J6 C13 DUT304

J6 C14 DUT305

J6 C15 DUT306

J6 C16 DUT265

J6 C17 DUT266

60 Synopsys, Inc. November 2001

Page 61

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J6 C18 DUT267

J6 C19 DUT268

J6 C20 DUT269

J6 C21 DUT270

J6 C22 NC

J6 C23 NC

J6 C24 NC

J6 D1 NC

J6 D2 DUT251

J6 D3 DUT253

J6 D4 DUT250

J6 D5 DUT249

J6 D6 DUT248

J6 D7 DUT247

J6 D8 DUT246

J6 D9 DUT245

J6 D10 DUT244

J6 D11 DUT243

J6 D12 DUT242

J6 D13 DUT241

J6 D14 DUT278

J6 D15 DUT277

J6 D16 DUT276

J6 D17 DUT282

J6 D18 DUT274

November 2001 Synopsys, Inc. 61

Page 62

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J6 D19 DUT273

J6 D20 DUT272

J6 D21 DUT271

J6 D22 NC

J6 D23 NC

J6 D24 NC

J6 F1 NC

J6 F2 DUT252

J6 F3 DUT254

J6 F4 DUT255

J6 F5 DUT256

J6 F6 DUT257

J6 F7 DUT258

J6 F8 DUT259

J6 F9 DUT260

J6 F10 DUT261

J6 F11 DUT262

J6 F12 DUT263

J6 F13 DUT264

J6 F14 DUT279

J6 F15 DUT280

J6 F16 DUT281

J6 F17 DUT275

J6 F18 DUT283

J6 F19 DUT284

62 Synopsys, Inc. November 2001

Page 63

The ModelSource 640-pin Adapter Appendix A: J1–J6 Connector Pinouts

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J6 F20 DUT285

J6 F21 DUT286

J6 F22 NC

J6 F23 NC

J6 F24 SEAT6

J6 AP1 RESERVED

J6 AP2 RESERVED

J6 AP3 RESERVED

J6 AP4 RESERVED

J6 AP5 RESERVED

J6 AP6 RESERVED

J6 AP7 RESERVED

J6 AP8 RESERVED

J6 DP1 GND

J6 DP2 GND

J6 DP3 GND

J6 DP4 GND

J6 DP5 GND

J6 DP6 GND

J6 DP7 GND

J6 DP8 GND

J6 FP1 NC

J6 FP2 NC

J6 FP3 NC

J6 FP4 NC

November 2001 Synopsys, Inc. 63

Page 64

Appendix A: J1–J6 Connector Pinouts The ModelSource 640-pin Adapter

Table 2: Pinouts for Connectors J1-J6

Connector Pin Signal

J6 FP5 RESERVED

J6 FP6 RESERVED

J6 FP7 RESERVED

J6 FP8 RESERVED

64 Synopsys, Inc. November 2001

Loading...

Loading...