Synergy R/C Helicopters Sinery N556 Assembly Manual And Part Reference

ASSEMBLY MANUAL AND PART REFERENCE

WWW.SYNERGYRCHELICOPTERS.COM

VERSION 1.0C

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

2

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

INTRODUCTION

Congratulations on your purchase of the Synergy N556 model helicopter kit!

The Synergy N556 was designed and developed by Matt Botos, a world class competition model helicopter pilot, and is the result of thousands of

hours of research and experience.

Before you proceed please verify you have the latest version of this manual by visiting our website at http://synergyrchelicopters.com/manuals.

If you have any questions during then assembly process or need clarication on anything in this manual please visit our forums at

http://synergyrchelicopters.com/forum where you will nd great tips and expert advice.

THIS RADIO CONTROLLED HELICOPTER IS NOT A TOY. IT IS A SOPHISTICATED PIECE OF EQUIPMENT DESIGNED AND INTENDED FOR

RECREATIONAL USE ONLY. IF NOT PROPERLY ASSEMBLED, MAINTAINED, AND OPERATED, IT IS CAPABLE OF CAUSING PROPERTY

DAMAGE AND BODILY HARM TO BOTH THE OPERATOR AND SPECTATORS. BOTOS DESIGN & DISTRIBUTION, ITS AFFILIATES, AND ITS

AUTHORIZED DISTRIBUTORS ASSUME NO LIABILITY FOR DAMAGE THAT COULD OCCUR FROM THE ASSEMBLY OR USE OR MISUSE OF

THIS PRODUCT. USE THIS PRODUCT AT YOUR OWN RISK.

Operating a model helicopter requires a high degree of diligence and skill. If you are new tomodel helicopters, it is your responsibility to seek help

and guidance from experienced modelers. Having an experienced modeler inspect your model and provide instruction will both

greatly speed up the learning process and make it much safer for you. For those pilots who will be operating their Synergy N556 in the United

States, we strongly recommend joining the AMA. The AMA is a non-prot organization that provides services to the model aircraft pilots. As an

AMA member, you will receive a liability insurance plan to cover against a possible accident or injury. All AMA charter clubs require individuals to

hold a current AMA membership prior to operation of their models at their facility.

For further information, you can contact the AMA at:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(800) 435-9262

https://www.modelaircraft.org

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

3

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

SPECIFICATIONS

• CNC machined 6061-T6 aluminum and Delrin components

• 2mm Carbon Fiber Frame components

• 140mm full head width

• Extra wide head block for quick cyclic response and high stability

• 2450 RPM head speed for maximum performance

• Machined Delrin helical main drive for quiet, efcient power transfer

• Machined Delrin helical tail drive

• One-piece aluminum front tail transmission

• Efcient torque tube tail drive

• Fuel tank located under main shaft for consistent CG

• 10mm main shaft with triple support radial bearings

• 8mm head axle with pivot rocker and solid dampers

• 6mm tail shaft with HD tail hub and HD grips

• Turnbuckle linkages for quick/precise adjustments

FEATURES:

SPECS:

Ofcial Synergy Recommended Equipment*:

• Engine: 55 class nitro engine

• Main Blades: 556mm (stretchable to 606mm)

• Tail Blades: 96mm

• Receiver Battery: 2S 2000-2800mAh

• Cyclic/Tail/Throttle Servos: Full Size

• Main Ratio: 7.44-8.5 (16T included; 7.44:1)

• Tail Ratio: 4.37-4.5:1 (35T included; 4.37:1)

• Main Rotor Diameter 1252mm (with Rail 556mm)

• Tail Rotor Diameter 238mm (with Rail 96mm)

• Fuel Tank Capacity: 14oz

• Cyclic Servos - Futaba BLS272 and MKS 1240

• Tail Servo - Futaba BLS256/BLS276 and MKS HBL980 (760us)

• All HV Servos (no regulator)

• Motor - OS 55HZR

• Mufer - OS PowerBoost III

• Cool Power 30% Nitro Fuel

• FBL System - CGY750 or Vbar

• Main Blades - Rail 556mm

• Tail Blades - Rail 96mm

• Head speed: 2450 RPM

• Receiver Battery: 120g or less

*Exact equipment tested and proven in the Synergy N556, results may

vary if equipment outside of this recommendation is used.

2

1

3

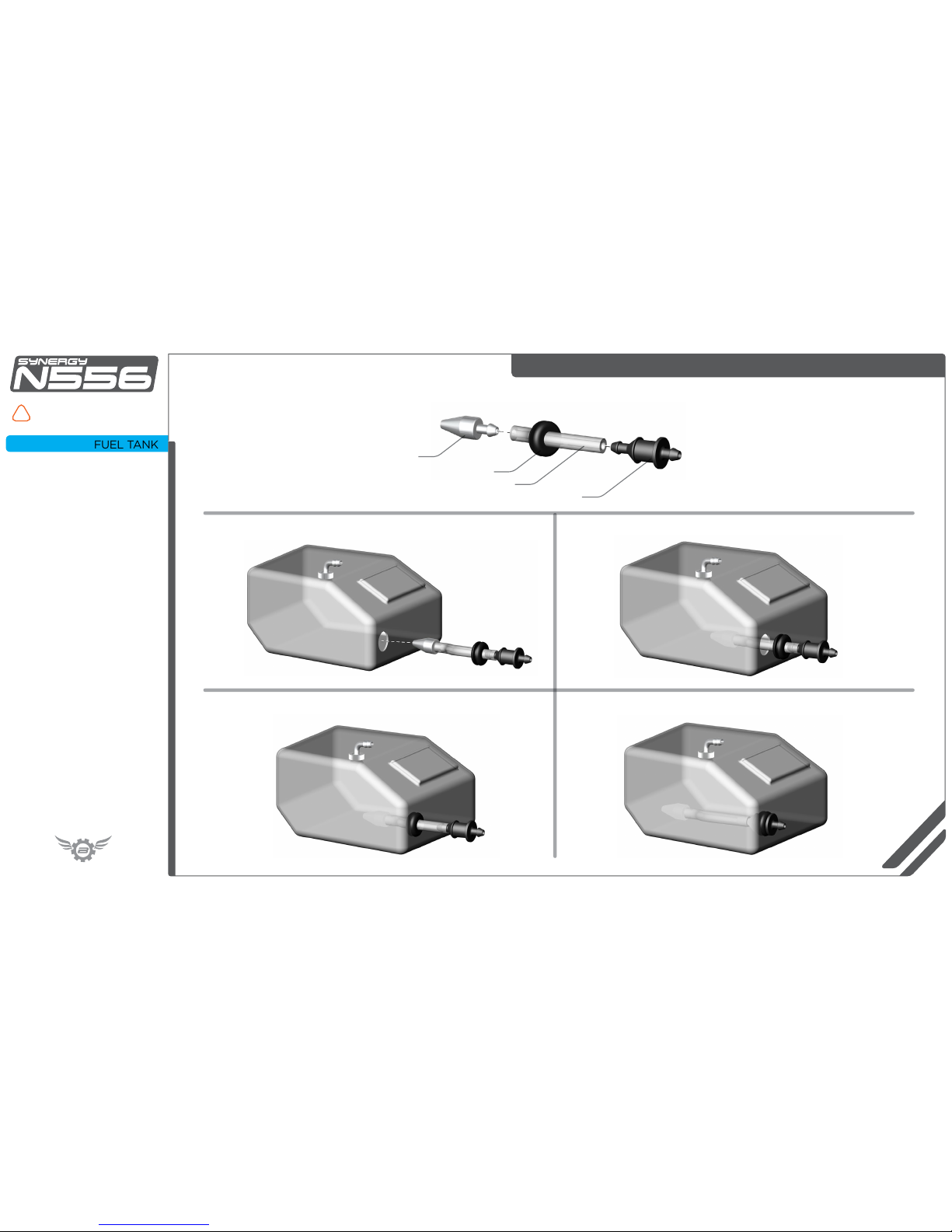

200-414 Vent Assembly

Vent

O-ring

Nut

Nut included in 200-414 Vent Assembly

556-207 N556 Fuel Tank

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

4

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

FUEL TANK

5

4

6

7 8

110-332 Fuel Clunk

106-810 Fuel Tank Stopper Grommet

110-333 Fuel Clunk Tubing

110-331 Fuel Tank Stopper

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

5

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

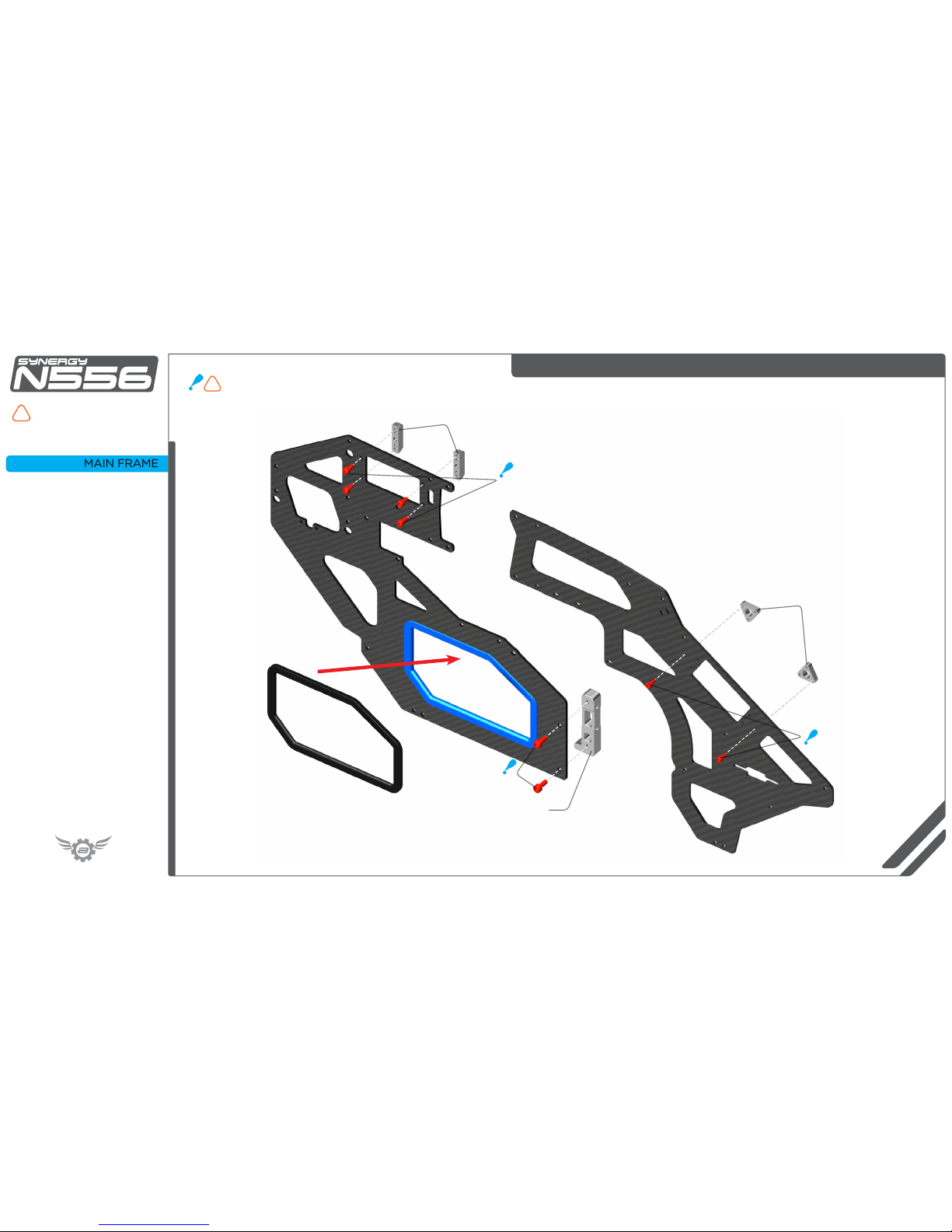

FUEL TANK

100-308 M3x8 Socket Head (2)

556-201 N556 Front Main Frame

556-202 N556 Rear Main Frame

305-112 Elevator Tail Servo Mount (2)

100-206 M2x6 Socket Head (2)

317-601 Fuel Tank Edge Grommet

CUT TO LENGTH

100-268 M2.5x6 Socket Head (4)

556-205 N556 Motor Mount

610-123 Standard Servo Mount (2)

!

APPLY BLUE THREAD LOCK

TO ALL BOLTS

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

6

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

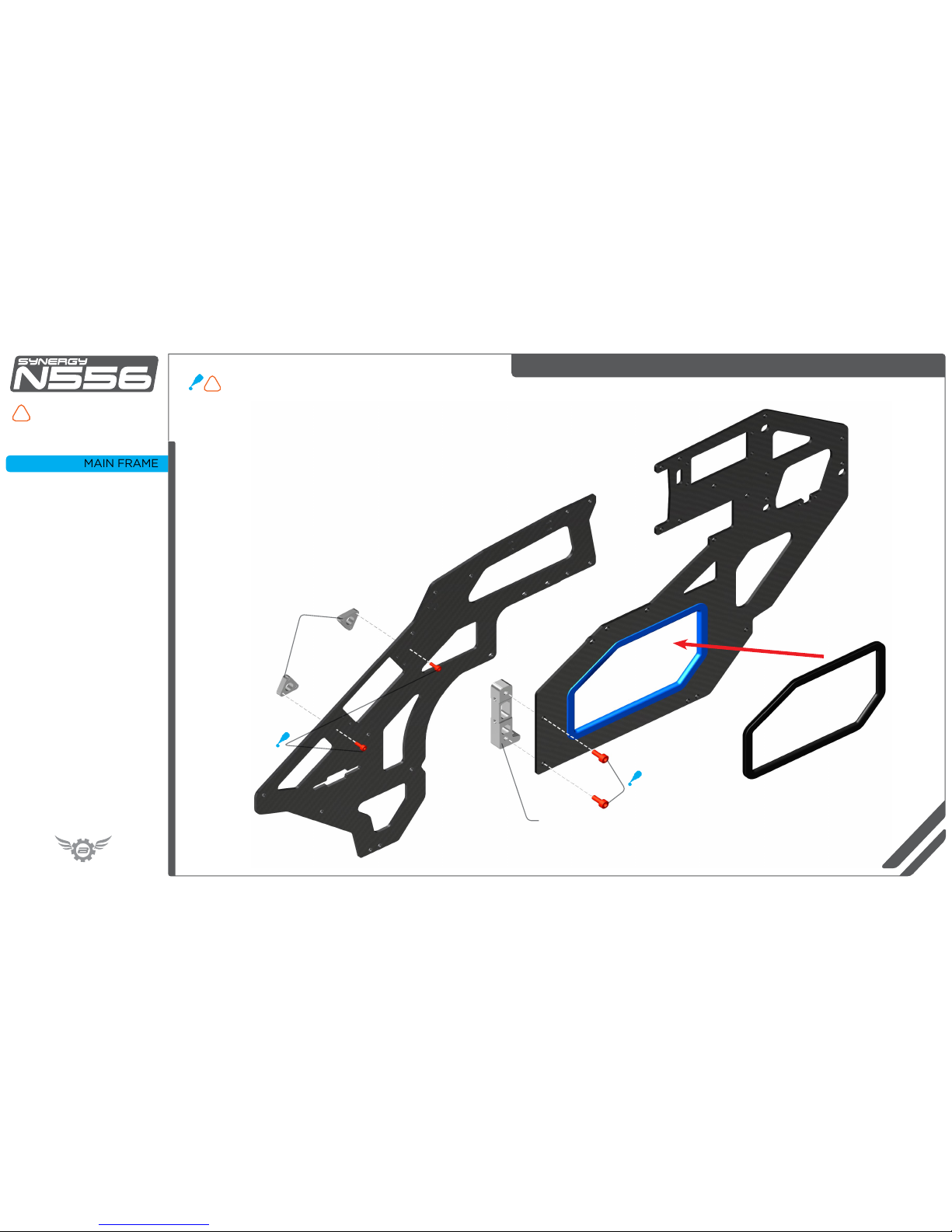

MAIN FRAME

RIGHT SIDE

556-201 N556 Front Main Frame

556-202 N556 Rear Main Frame

100-308 M3x8 Socket Head (2)

!

APPLY BLUE THREAD LOCK

TO ALL BOLTS

556-205 N556 Motor Mount

610-123 Standard Servo Mount (2)

100-206 M2x6 Socket Head (2)

317-601 Fuel Tank Edge Grommet

CUT TO LENGTH

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

7

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

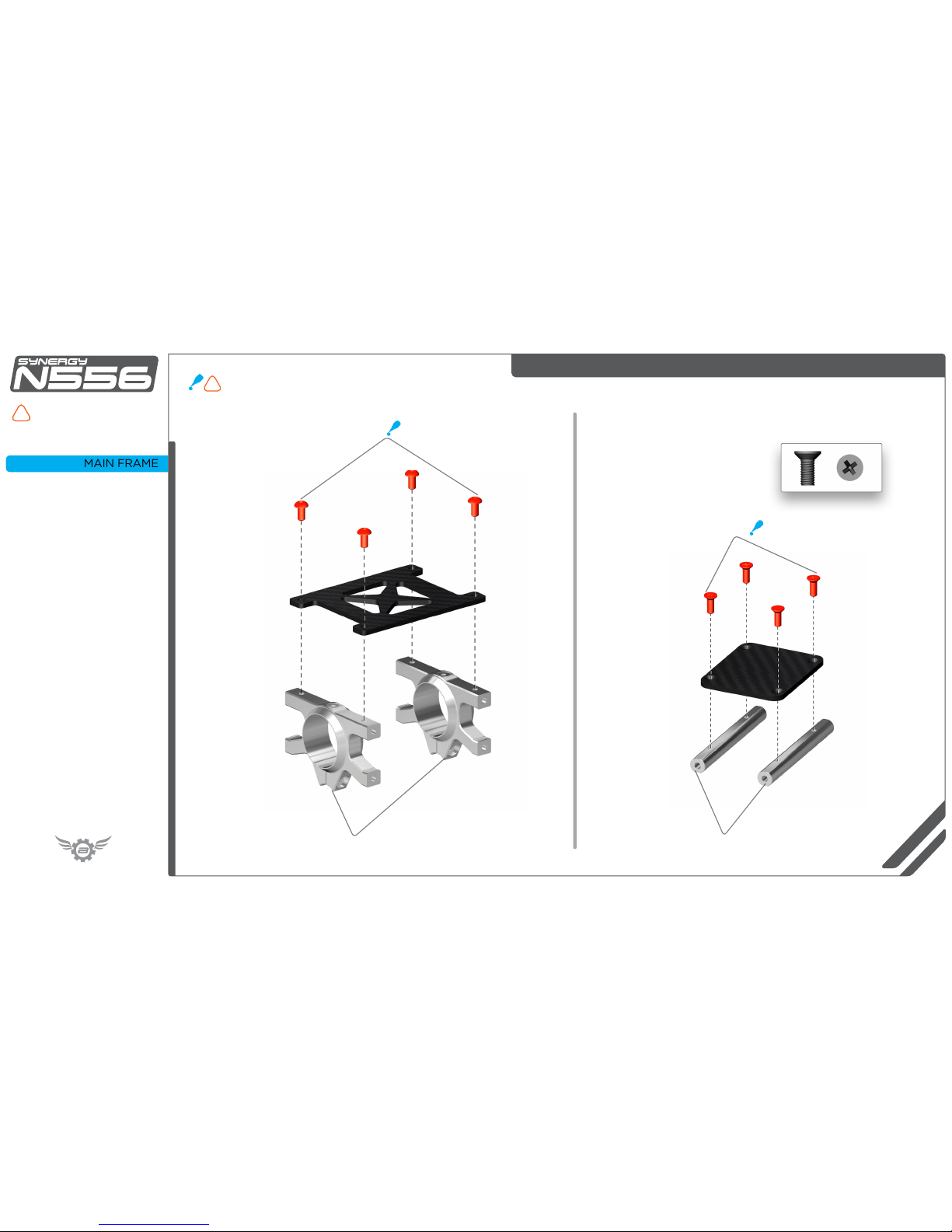

MAIN FRAME

LEFT SIDE

101-306 M3x6 Button Head (4)

305-103 E5 CF Gyro Mount Plate

556-209 N556 Boom Clamp Support Plate

305-111 E5 Main Boom Clamp (2) 305-101 E5 Frame Spacer(2)

103-256 M2.5x6 Type I Cross Recessed (4)

!

APPLY BLUE THREAD LOCK

TO ALL BOLTS

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

8

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

MAIN FRAME

BOOM BLOCKS AND GYRO TRAY

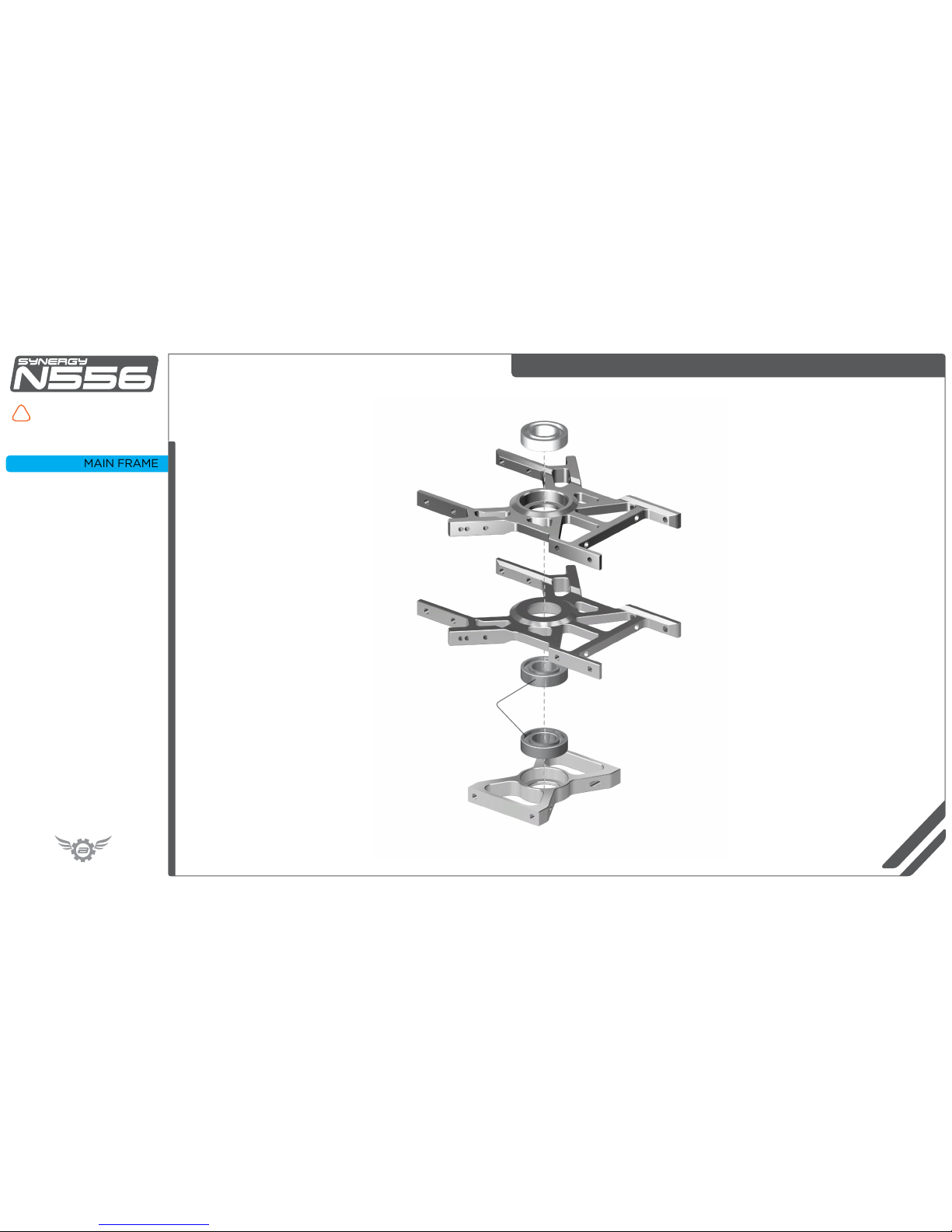

108-105 10x19x5 Radial Bearing

108-105 10x19x5 Radial Bearing

556-206 N556 Main Shaft Bearing Block

556-206 N556 Main Shaft Bearing Block

305-104 E5 Third Main Shaft Bearing Block

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

9

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

MAIN FRAME

MAIN BEARING BLOCKS

NOTE ORIENTATION OF

MAIN SHAFT BLOCKS WHEN

INSTALLING INTO FRAMES

BEARING FACES TOP

BEARING FACES TOP

BEARING FACES BOTTOM

556-210 N556 Radio Plate

305-117 Key Chain Canopy

Mount, Female 17mm

305-117 Key Chain Canopy

Mount, Female 17mm

101-306 M3x6 Button Head

305-106 Break-away Plate

305-106 Break-away Plate

101-306 M3x6 Button Head

305-101 E5 Frame Spacer (2)

103-256 M2.5x6 Type I Cross Recessed (4)

!

APPLY BLUE THREAD LOCK

TO ALL BOLTS

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

10

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

MAIN FRAME

RADIO TRAY AND CANOPY POSTS

1

3

2

4

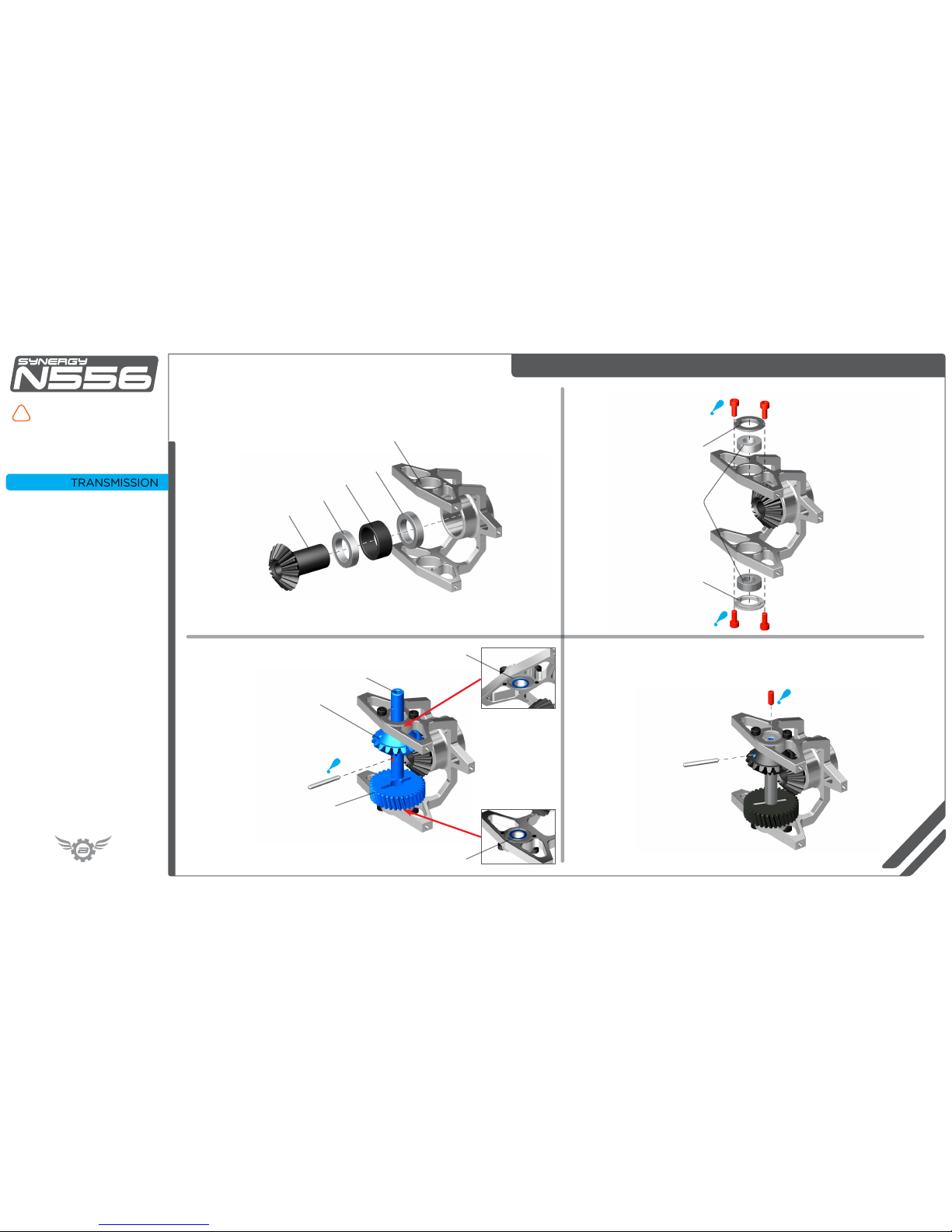

320-218 18T Front Trans

Mushroom Gear

556-403 N556 Bearing Retainer

556-403 N556 Bearing Retainer

100-266 M2.5x6 Socket Head (2)

100-266 M2.5x6 Socket Head (2)

320-406 11mm Bevel Gear Pin

320-406 11mm Bevel Gear Pin

100-366 M3x6 Set Screw

305-518 E5 18T Tail Bevel Gear

556-402 N556 Spur Gear Shaft 6mm

556-035 N556 35T Helical Tail Drive Gear

*OPTIONAL FOR 600 CLASS:

556-034 N556 34T Helical Tail Drive Gear

108-614 6x12x4 Radial Bearing (2)

108-124 12x18x4 Radial Bearing

320-405 Tail Box Bearing Spacer

108-124 12x18x4 Radial Bearing

556-406 N556 Front Tail Transmission Block

BEFORE INSTALLING PIN AND SET SCREW, PRE-THREAD SET

SCREW ALL THE WAY TO CLEAR OUT ANY LEFTOVER BURRS

IMPORTANT:

VERIFY SHIMS ARE

INSTALLED BEFORE

INSTALLING SHAFT

AND GEARS

106-601 6mm Shim

106-601 6mm Shim

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

11

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

TRANSMISSION

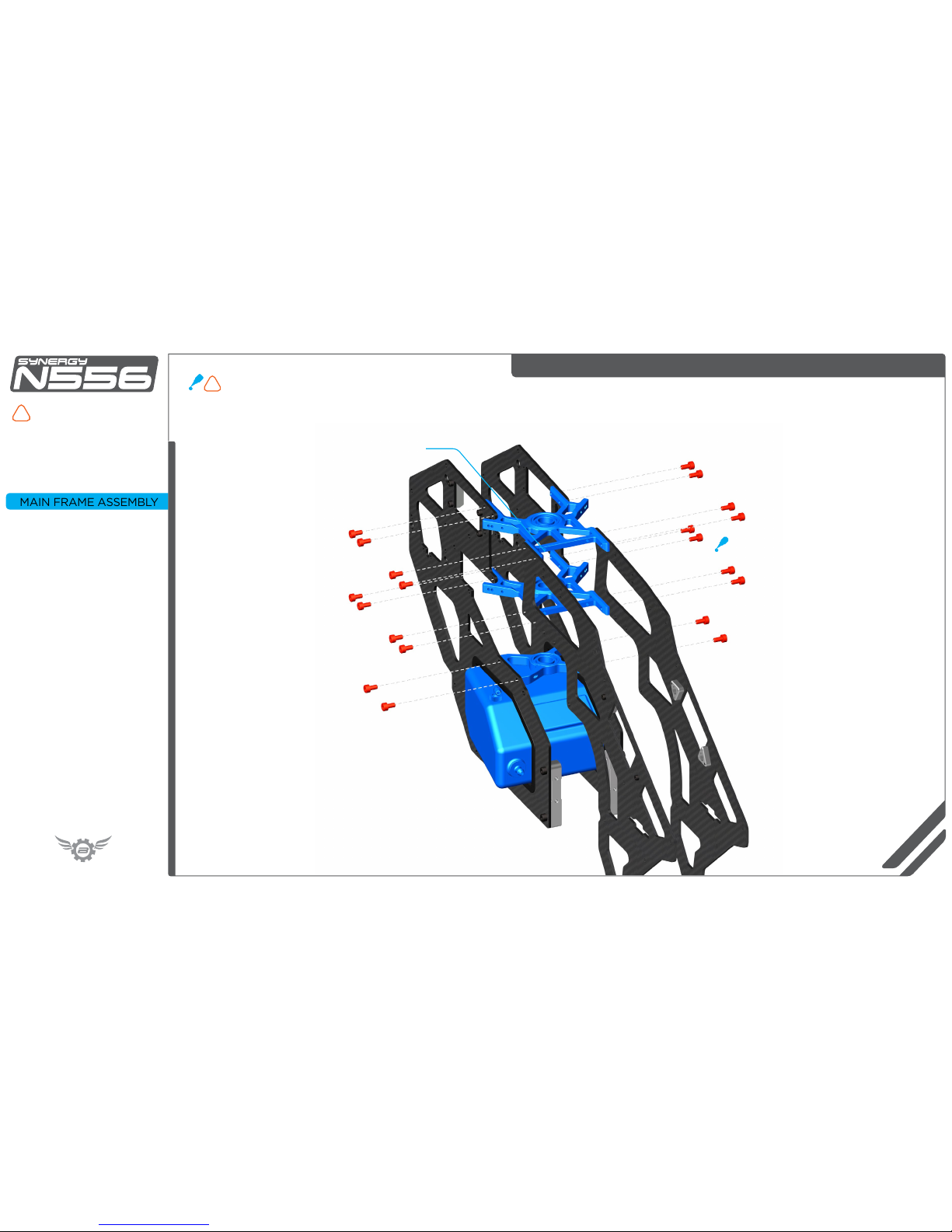

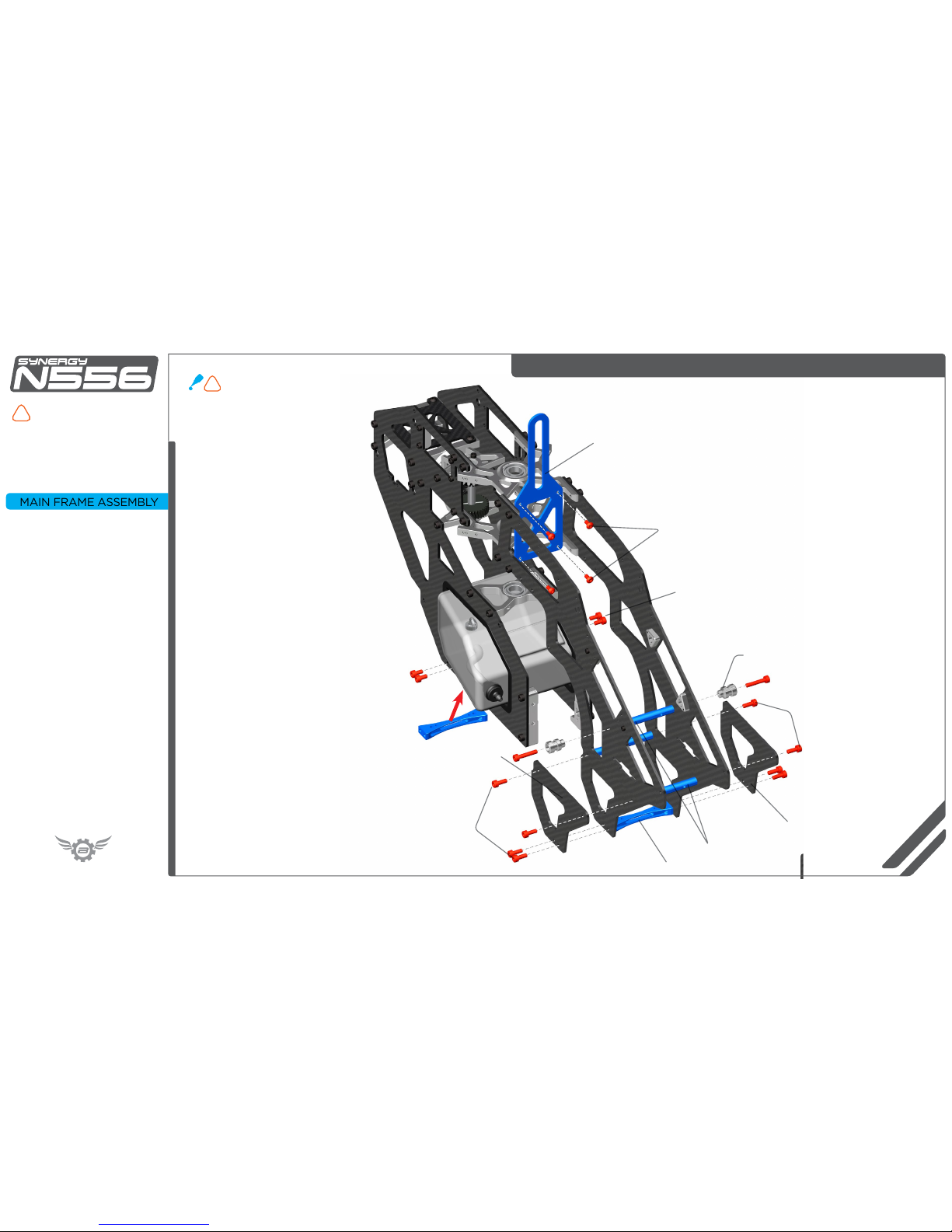

100-306 M3x6 Socket Head (20)

!

APPLY BLUE THREAD LOCK

TO ALL BOLTS

MAIN SHAFT BLOCK ASSEMBLIES

(See page 9)

FUEL TANK ASSEMBLY

(See pages 3-5)

NOTE ORIENTATION OF THE MAIN SHAFT BLOCKS

WHEN INSTALLING INTO FRAMES -- SEE PAGE 9

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

12

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

MAIN FRAME ASSEMBLY

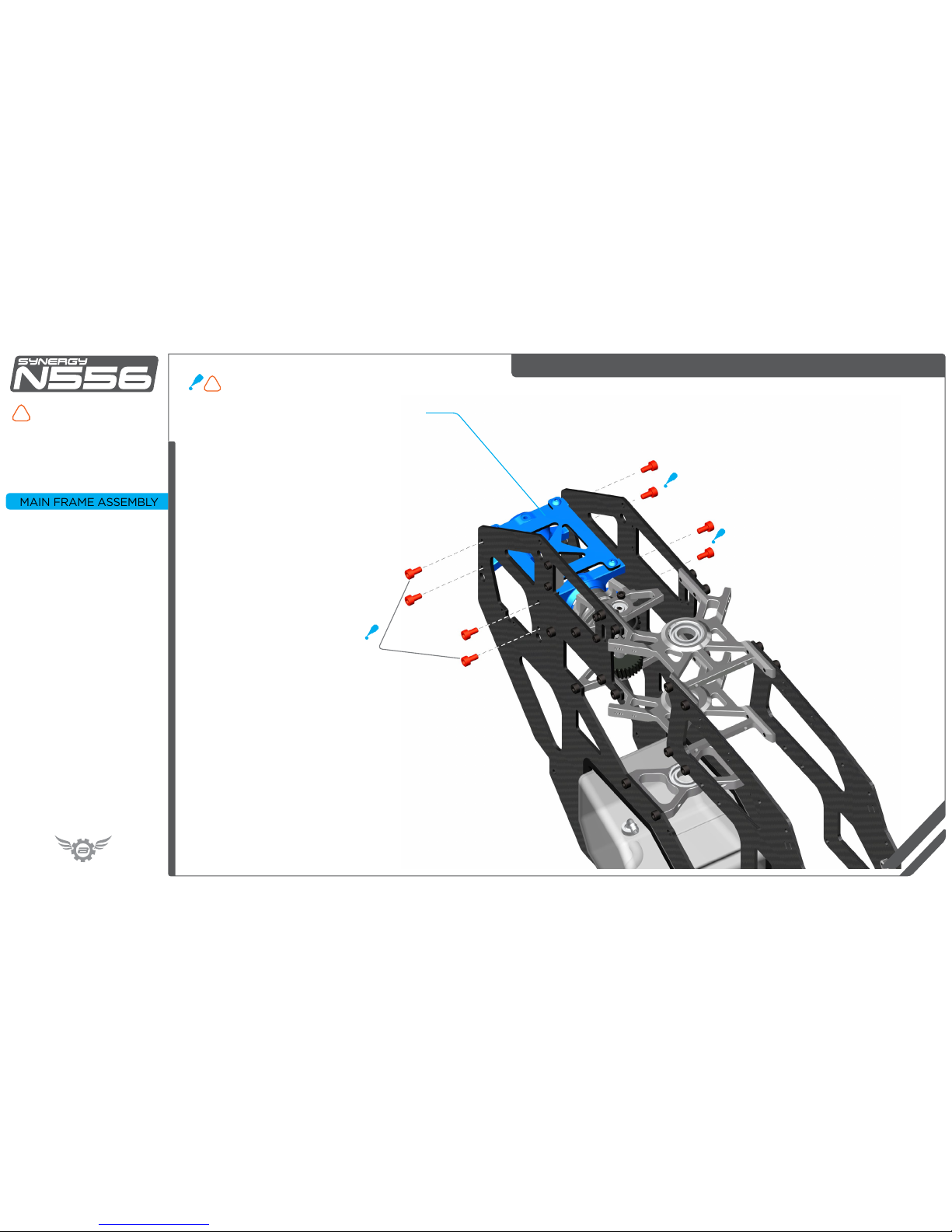

100-306 M3x6 Socket Head (6)

TRANSMISSION ASSEMBLY

(See page 11)

!

APPLY BLUE THREAD LOCK

TO ALL BOLTS

*IMPORTANT: TRANSMISSION

MOUNTING HOLES ARE SLOTTED.

WHEN USING THE STOCK 35T SPUR GEAR,

TRANSMISSION SHOULD BE POSITIONED

TO THE REAR END OF SLOTS.

WHEN USING THE OPTIONAL 34T SPUR GEAR,

TRANSMISSION SHOULD BE POSITIONED TO

THE FRONT END OF SLOTS.

111-101 M3 Dress Washer (6)

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

13

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

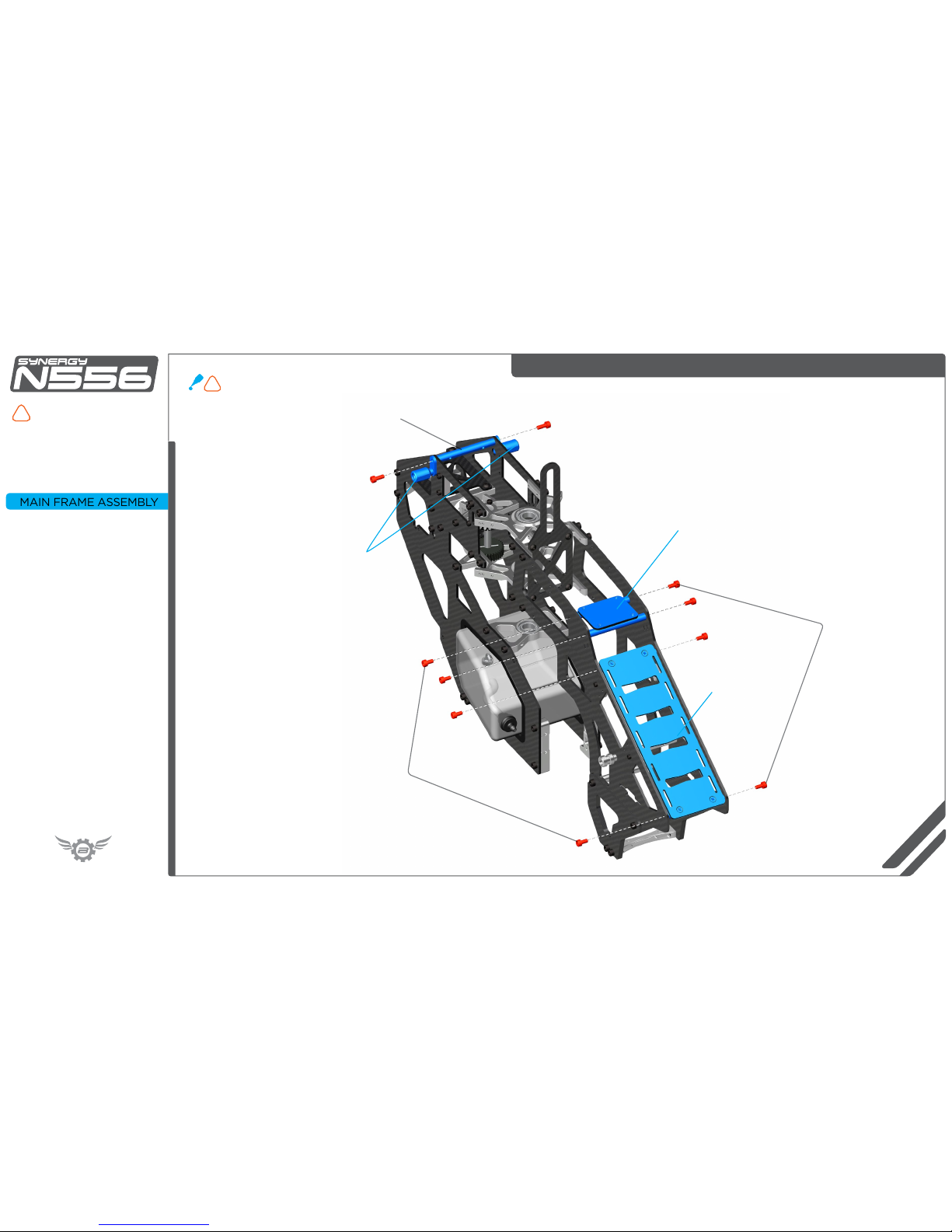

MAIN FRAME ASSEMBLY

100-306 M3x6 Socket Head (8)

BOOM BLOCK ASSEMBLY

(See page 8)

!

APPLY BLUE THREAD LOCK

TO ALL BOLTS

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

14

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

MAIN FRAME ASSEMBLY

100-306 M3x6 Socket Head (2)

100-306 M3x6 Socket Head (2)

100-308 M3x8 Socket Head (4)

556-203 N556 Front Frame Brace

556-203 N556 Front Frame Brace

305-101 E5 Frame Spacers (3)

305-122 E5 Landing Gear Mount

305-122 E5 Landing Gear Mount

100-308 M3x8 Socket Head (4)

305-120 E5 Anti-Rotation Bracket

101-306 M3x6 Button Head (4)

!

APPLY BLUE THREAD LOCK

TO ALL BOLTS

100-312 M2x16 Socket Head (2)

405-101 U-Channel Canopy Post (2)

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

15

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

MAIN FRAME ASSEMBLY

100-308 M3x8 Socket Head

100-306 M3x6 Socket Head (4)

305-101 E5 Frame Spacer

100-306 M3x6 Socket Head (4)

100-308 M3x8 Socket Head

CANOPY MOUNT ASSEMBLIES

(See page 10)

GYRO PLATE ASSEMBLY

(See page 10)

RADIO TRAY

ASSEMBLY

(See page 10)

!

APPLY BLUE THREAD LOCK

TO ALL BOLTS

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

16

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

MAIN FRAME ASSEMBLY

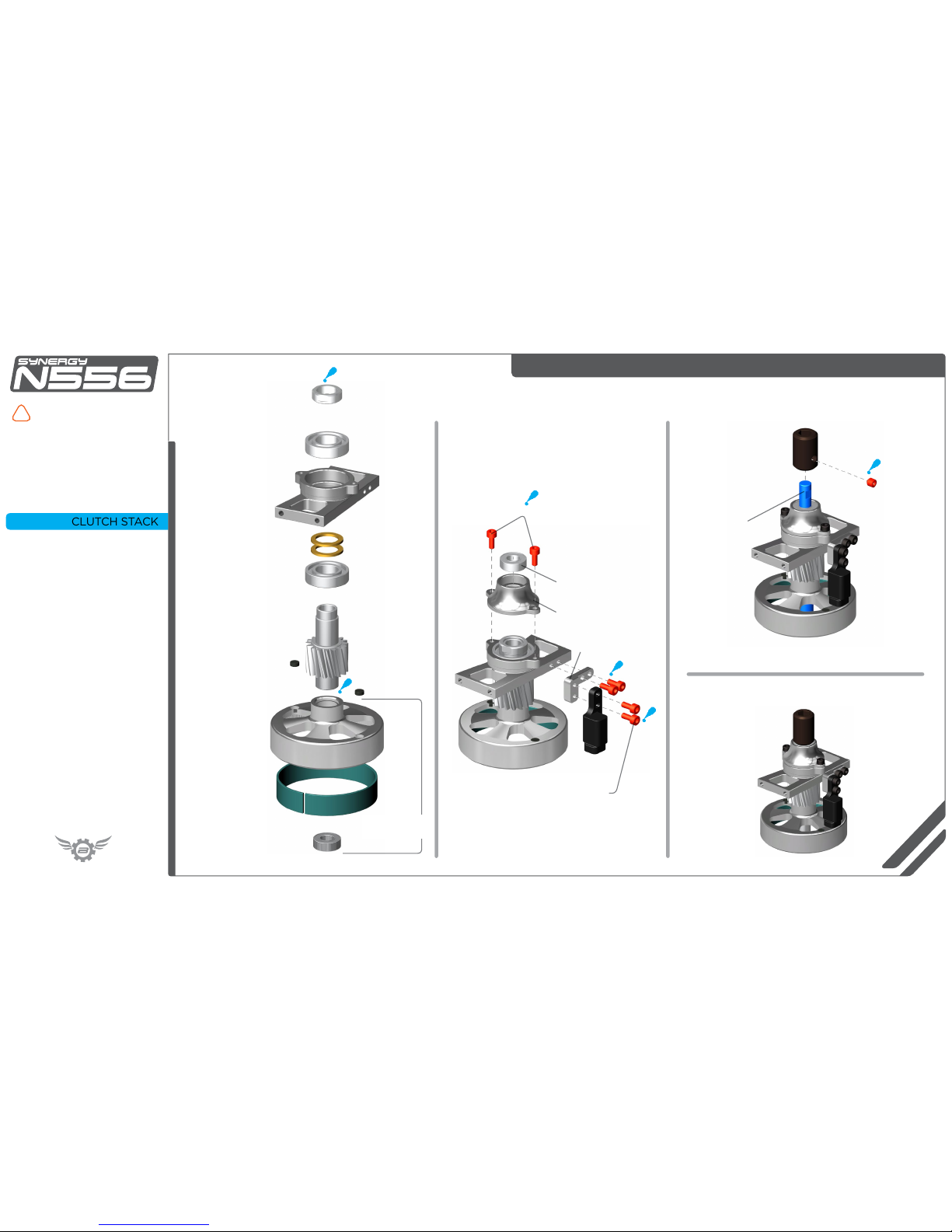

317-203 Pinion Nut

DO NOT OVERTIGHTEN

108-105 10x19x5 Bearing

556-305 N556 Clutch Bell

Bearing Block

100-266 M2.5x6 Socket Head (2)

108-614 6x12x4 Bearing

556-308 N556 Start Shaft

Bearing Block

556-306 N556 Governor

Sensor Mount

100-266 M2.5x6 Socket Head (4)

106-103 10x1.0mm Spacers (2)

108-105 10x19x5 Bearing

556-016 N556 16T Motor Pinion

*OPTIONAL FOR 600 CLASS:

556-014 N556 14T Motor Pinion

Epoxy magnets if using clutch

bell magnetic RPM sensor.

Mount one with N pole facing

upwards and the other with

N pole facing downwards for

equal balance.

610-125L Clutch Bell

317-205 Clutch Liner

108-614 6x12x4 Bearing

COMPLETED CLUTCH STACK ASSEMBLY

100-464 M4x4 Flat

Point Set Screw

317-206 Hex Adapter

610-162 Start Shaft

DO NOT

OVERTIGHTEN

SET SCREW

MAGNETS AND RPM SENSOR NOT INCLUDED

200-508 Clutch Bell,

Lite Assembly v2

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

17

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

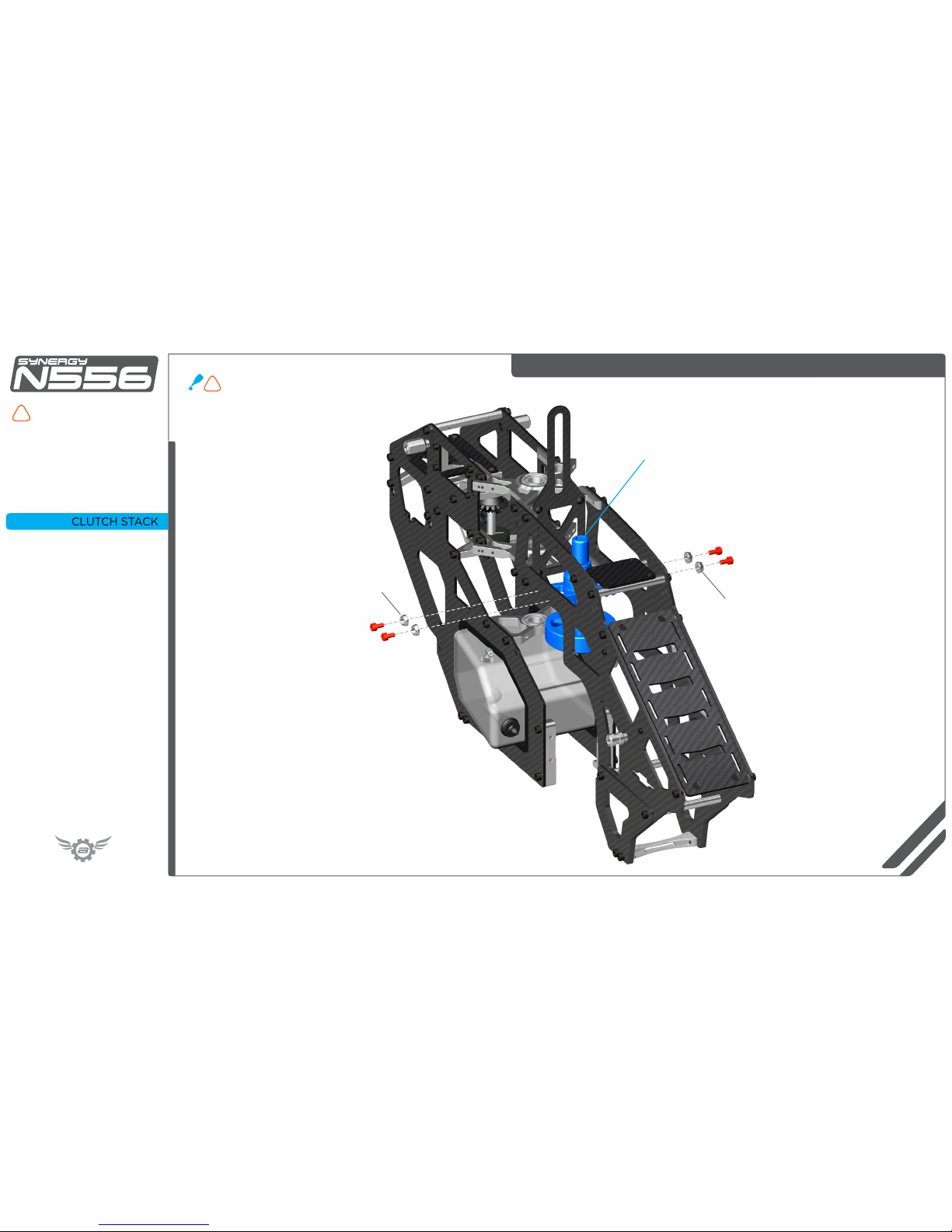

CLUTCH STACK

CLUTCH STACK ASSEMBLY

(See page 17)

100-308 M3X8 Socket Head (2)

111-101 M3 Dress Washer (2)

100-308 M3X8 Socket Head (2)

111-101 M3 Dress Washer (2)

!

APPLY BLUE THREAD LOCK

TO ALL BOLTS

WWW.SYNERGYRCHELICOPTERS.COM

FUEL TANK

MAIN FRAME

TRANSMISSION

MAIN FRAME ASSEMBLY

CLUTCH STACK

ENGINE

LANDING GEAR

MAIN DRIVE UNIT

TORQUE TUBE

BOOM

TAIL ASSEMBLY

SERVO INSTALLATION

SWASH PLATE

CYCLIC LINKAGES

TAIL SERVO

MAIN HEAD

PITCH LINKAGES

BLADE INSTALLATION

CANOPY

SPECIFICATIONS

18

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

VERSION 1.0C

CLUTCH STACK

Loading...

Loading...