Page 1

SYNERGY MFG. 870 INDUSTRIAL WAY, SAN LUIS OBISPO, CA (805) 242-0397

PPM-8056 JK REAR TRACK BAR RELOCATION

BRACKET

Version 1.2

GENERAL NOTES:

• These instructions are also available on our website; www.polyperformance.com.

Check the website before you begin for any updated instructions and additional

photos for your reference.

• The installation of this bracket requires cutting part of the factory track bracket

off.

• You must use a minimum of 3” of rear bump stop extension, PPM-8058 (3”) or

PPM-8076 (4”) to prevent the track bar from contacting the exhaust at full jounce

travel.

1. Remove the factory rear track bar from the axle bracket and loosen the track bar from

the frame bracket to allow the track bar to rotate out of the way. Secure the track bar

up and out of the way with a bungee cord or something similar.

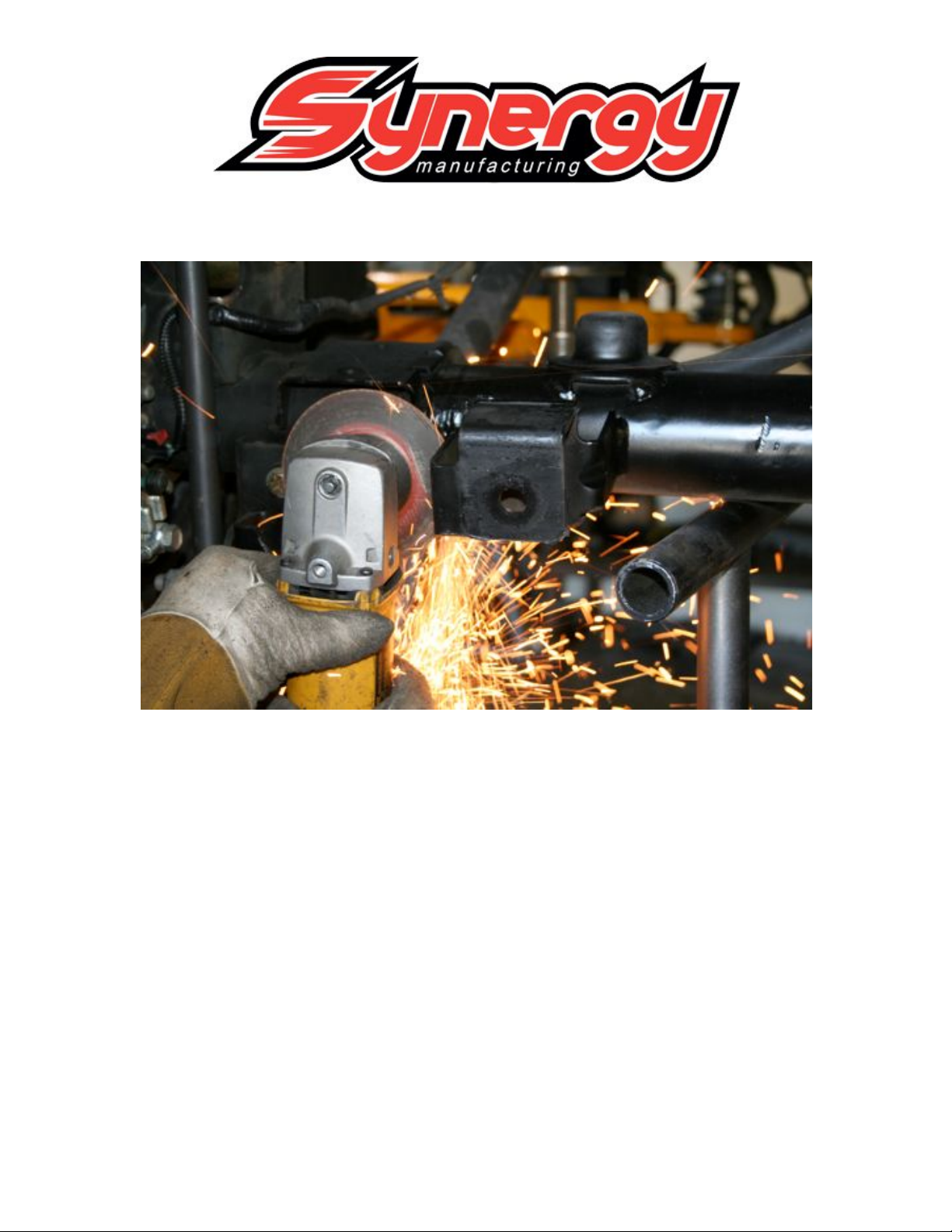

2. Cut part of the factory track bar off as shown in the following pictures. The pictures

show using a 4 ½” grinder with a cut off wheel but a sawzall can also be used.

Page 2

SYNERGY MFG. 870 INDUSTRIAL WAY, SAN LUIS OBISPO, CA (805) 242-0397

Page 3

SYNERGY MFG. 870 INDUSTRIAL WAY, SAN LUIS OBISPO, CA (805) 242-0397

Page 4

SYNERGY MFG. 870 INDUSTRIAL WAY, SAN LUIS OBISPO, CA (805) 242-0397

3. Attach the new track bar relocation bracket to the factory bracket as shown with the

new 9/16” bolt and lock nut; use a flat washer under the bolt head and lock nut.

Page 5

SYNERGY MFG. 870 INDUSTRIAL WAY, SAN LUIS OBISPO, CA (805) 242-0397

4. Install the u-bolts over the axle tube and through the track bar relocation bracket, use

a flat washer and nylock nut to secure the u-bolt. On some rear axle housing there is

a weld along the front of the axle tube opposite of the track bar bracket. Grind the

weld down just were it goes under the u-bolt so that the u-bolt contacts the entire

tube.

5. Torque the 9/16 bolt to 150 ft-lbs, and the

6. Torque the 3/8” u-bolts to 30 ft-lbs.

7. Attach the track bar to the new track bar relocation bracket using the factory nut and

bolt. It helps to have some one push the back of vehicle from side to side to align the

track bar bushing to the hole in the bracket. Tighten the track bar bolt to 125 ft-lbs.

8. The track bar bolt may rub the coil spring on some applications. This is often due to

the coil spring bowing because the pinion angle has increased. Solutions to this are as

follows:

• Trim the end of the bolt sticking through the nut

• Flip the bolt around so the bolt head is adjacent to the spring

• Rotate the spring so the bolts is in between coils

• Cut and rotate the lower spring mounts on the axle

• Install polyurethane lower coil wedges

Page 6

SYNERGY MFG. 870 INDUSTRIAL WAY, SAN LUIS OBISPO, CA (805) 242-0397

Loading...

Loading...