synchronic SB001 Tuning Manual

Synchronic Blow-Off Valve

TUNING MANUAL

2

INDEX

I. SB001 Diagram

II. Installing and Removing the Recirculation Fitting

III. Installing and Removing Mounting Flanges

IV. Filtering the Inlet

V. Connecting to a Vacuum Source

VI. Recirculating the Discharge

VII. Adjusting for Response

VIII. Anti-Stall Valve Kit

IX. Mounting Flange Options

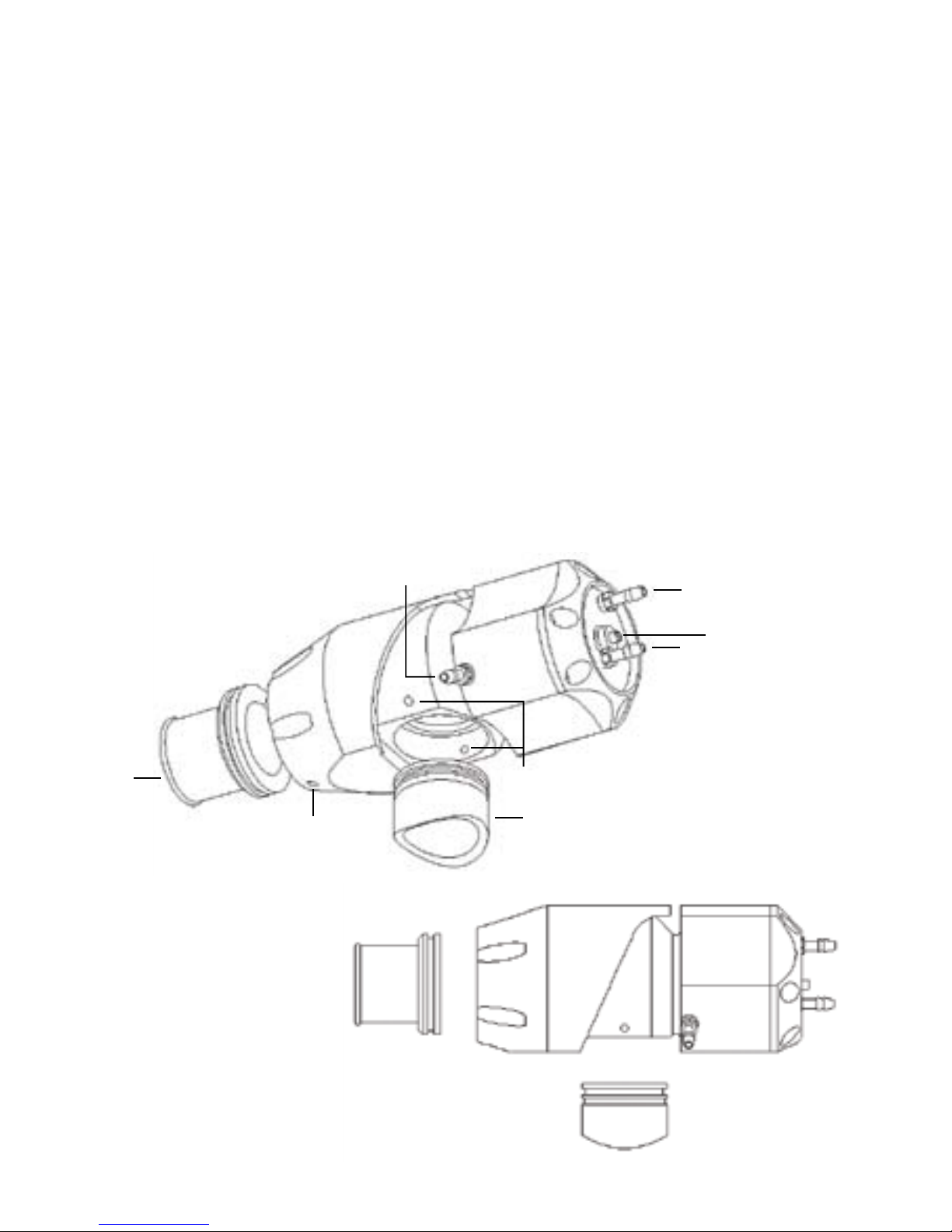

I. PARTS LIST AND DIAGRAM SB001

1. Recirculation Fitting (1.25” OD)

2. Recirculation Fitting Set Screw (M4 x .7)

3. Weld-On Mounting Flange

4. Mounting Flange Set Screws

5. Port A (4-5 mm ID hose)

6. Port B (4-5 mm ID hose)

7. Port C (4-5 mm ID hose)

8. Pre-Load Adjustment

3

1.

2.

3.

4.

5.

6.

7.

8.

4

II. INSTALLING AND REMOVING THE RECIRCULATION FITTING

a. Begin by removing set screw (2) with hex bit size M2. If you

plan on completely removing the Recirculation Fitting, make sure to

remove the set screw and store it away in a safe place for later use.

b. When re-installing the Recirculation Fitting, it is recommended

to apply some motor oil or grease around the o-ring to ease in

installation and aid the o-rings in sealing. You can put a light coat of

RTV silicone to the mating side of the fitting to insure a vacuum seal

for very sensitive MAF systems.

a. Begin by removing the two set screws (4) with bit size M1.5 (1/16).

b. Then, take the stainless steel mounting weld flange (3) that comes

pre-installed and pull it loose. It may be hard to remove if it is the first

time you are removing it. You may need to twist and turn it in order to

get it out. If you plan on using a pair of pliers to remove it, make sure

you tape the ends of the pliers, or use cloth to keep from scratching or

damaging the flange.

c. If you are switching to one of the other alternative mounting flanges,

you will need to transfer the o-ring to the new flange if one is not already

provided for you.

d. Upon reinstallation, you should NOT use grease or oil on the o-rings to

reinstall. Use water instead (not alcohol) to aid in installation.

e. Reinstall set screws, preferably with non-permanent Loctite, and do

not over tighten them.

III. INSTALLING AND REMOVING MOUNTING FLANGES

Loading...

Loading...