Page 1

VISUAL

HEADLAMP ALIGNMENT

SYSTEM

ASSEMBLY

OPERATION

CALIBRATION

Safety by Design

524 S.E. Transport Drive

Lees Summit, MO 64081

888-884-8182

816-525-9263 FAX: 816-525-9283

www.symtechcorp.net

Page 2

INDEX

1. GENERAL Pg. 3

1.1 “SCA 1 ISOColor ” INTRODUCTION

1.2 SYSTEM COMPONENTS

1.3 LASER WARNING

1.4 WARNING, EXPOSURE TO DIRECT SUNLIGHT

2. ASSEMBLY Pg. 4

2.1 BASE / WHEEL ATTACHMENT

2.2 MAST / GLIDE PLATE / ROTATIONAL MAST MOUNT

2.3 OPTICAL ALIGNMENT HEAD

2.4 SIGHTING UNIT

2.5 SIGHTING UNIT CALIBRATION

2.6 FLOOR SLOPE LASER

3. OPERATION Pg. 6

3.1 ALIGNMENT BAY(s) PREPARATION

3.2 FLOOR SLOPE MEASUREMENT

3.3 VEHICLE PREPARATION, Prior to Alignment

4. HEADLAMP ALIGNMENT PG. 7

4.1 ALIGNMENT of OPTICAL HEAD TO VEHICLE

4.2 CENTERING on the HEADLAMP

4.3 SELECTING HEADLAMP PATTERN

4.4 ALIGNMENT of HEADLAMP PROCEDURE

5. LASER CALIBRATION / MAINTENANCE Pg. 8

5.1 LASER CALIBRATION

5.2 MAINTENANCE

6. FREQUENTLY ASKED QUESTIONS Pg. 9

WARRANTY Pg. 10

CUSTOMER SERVICE

888-884-8182

Page 3

1. GENERAL

t

1.1 INTRODUCTION

The Model “SCA 1 ISOColor” Visual Headlamp Alignment System is an economical optical alignment

tool that functions under the same principle for accuracy and dependability of an aiming screen, with the

added benefit of Symtech Corporation’s “ISOColor” technology, without the excessive use of valuable

shop space and the confusion of vertical and horizontal lamp placement. System design and operation has

been engineered with the technician in mind. The “SCA 1” features “ISOColor” technology that

facilitates headlamp alignment, with profitability and customer satisfaction as the end result.

The Model “SCA 1” is designed, manufactured and serviced by Symtech Corporation, Lees Summit,

Missouri, the industry leader in headlamp alignment technology to the service and body repair industries,

the architect of the Model “LCA 2 EZ” Visual, “CVA 3 EZ ISOColor” Visual and the ”HBA 5” Electronic

Headlamp Alignment systems along with the “AIM 200” Headlamp Intensity meter.

We are confident that the “SCA 1 ISOColor” will provide you with years of exceptional service. Thank

you for selecting a Symtech “Safety by Design” product to address your headlamp alignment needs.

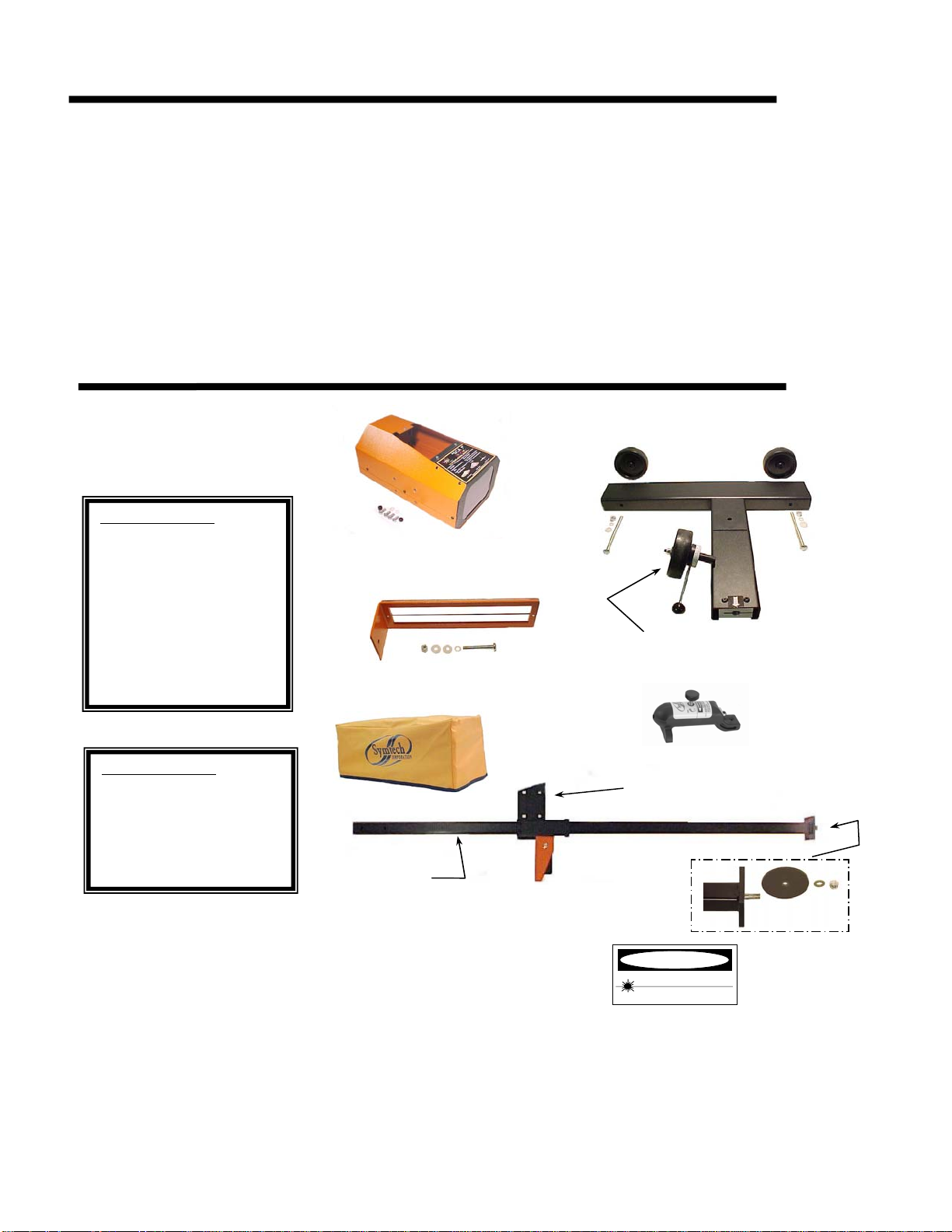

1.2 SYSTEM COMPONENTS

Small Parts Package

2 Large Nylon Washers

5

2

/16” Nylon Washers

1

2 ¼” x

2 ¼” x 3/16” (BLACK)Nylon

2 5/16” Self-Locking Nuts

4 ¼” x 20 Machine Screws

1 3/8” Self Locking Nut

1

/8” (WHITE)Nylon

3

/8” Flat Washer

Spacers

Spacers

Large Parts Package

2 5/16” x 5 ½” Carriage Bolts

1 Floor Slope Handle

2 Wheels

1 Wheel w/Floor Slope

Eccentric

1 3” Rotational Bearing

1.3 LASER WARNING

1.4 WARNING, EXPOSURE TO DIRECT SUNLIGHT

AVOID LOOKING DIRECTLY INTO LASER

LIGHT – POSSIBLE EYE INJURY CAN

OCCUR.

DO NOT PLACE OR POSITION “SCA 1” SO THAT DIRECT SUNLIGHT ENTERS

FRONT LENS. DOING SO WILL CAUSE DAMAGE TO ISOColor SCREEN AND

VOID WARRANTY. Front lens acts like an enlarged magnifying glass which will

concentrate direct sunlight into a destructive high intensity beam on the aim screen.

OPTICAL HEAD

SIGHTING UNIT

MAST

BASE & WHEELS

FLOOR SLOPE

AXEL

FLOOR SLOPE

OPTIONAL

DUST COVER

P/N: 01016000

GLIDE PLATE

LASER

Exploded

View

Rotational

Moun

DANGER

AVOID DIRECT EYE EXPOSURE

PEA K P OW ER < 5m W

WA V ELE N G T H 400-700nm

CLASS IIIA LASER PRODUCT

LASER RADIATION

3

Page 4

2. ASSEMBLY

Inspect all components of the SCA 1 ISOColor system to assure that no damage has occurred during shipment, compare

contents of package with that of the exploded view to make sure that no component has been inadvertently left out of

packaging. If a component is missing, contact our customer service department at 888-884-8182 for an immediate

replacement.

2.1 BASE / WHEEL ATTACHMENT

Place base of system on floor, or table with channel facing

downward.

Insert a 5/16” x 5 1/2” carriage bolt into each of the holes noted,

making sure that the square carriage bolt head seats securely into the

square hole placement.

Complete wheel assembly by placin g in order a large nylon washer,

wheel, small nylon washer and self-locking

bolt.

5

/16” nut on carriage

Tighten self-locking nut snug against wheel, but not so tight as to

hinder free wheel movement.

Insert floor slope eccentric and wheel into mounting block on base

(rear wheel). Tighten friction bolt until floor slope eccentric can be

moved, but not loose enough to move by itself.

2.2 MAST / GLIDE PLATE / ROTATIONAL MAST MOUNT

The Mast and Glide Plate are packaged as an assembly.

Place rotation bearing over mast stud and insert rotational mast stud

into base. Secure mast to base with

locking nut. Tighten nut securely then back-off

mast rotates freely with minor resistance.

3

/8” flat washer and 3/8” self-

1

/8 turn, or until

Move glide plate up and down the mast through its full motion, by

depressing handle.

2.3 OPTICAL ALIGNMENT HEAD

Remove optical alignment head from shipping carton.

Inspect for any damage that may have occurred during

shipment i.e. lens, case, etc..

Attach optical alignment head to the mast glide plate by

aligning mounting holes of glide plate with the holes in

the optical head. Insert ¼” x 20 x ¾” phillips machine

screw through glide plate, place a ¼” x

1

/8” (WHITE)

nylon spacer on each upper attachment screw, place a ¼”

x 3/16” (BLACK) nylon spacer on each lower attachment

screw and tighten securely.

Remove protective paper covering from viewing window

on top of optical head.

Move optical head through the full range of movement to

assure of smooth operation.

2.4 SIGHTING UNIT

Sighting unit is the “L” bracket assembly enclosed

in the accessories box.

NOTE: Mount sighting unit so that unit is

located directly over the optical head.

Insert the 5/16” x 2.5” phillips head machine screw

with thin

5

/16” nylon washer into the sighting unit.

Optical

Head

Front of Base

ROTATIONAL

BEARING

¼” x 20 x ¾”

Phillips Machine Screws

¼” x 1/8”

Nylon Spacers

(WHITE)

Glide

Plate

¼” x 3/16”

Nylon Spacers

(BLACK)

Tighten

this Bolt

4

Page 5

Place a thick nylon bushing on the screw and insert

screw through the holes provided at the top of the

mast, place a thick nylon bushing on screw and selflocking nut.

Tighten to a tension that allows for movement of

sighting unit, but provides sufficient friction to hold

unit in place when unattended.

NOTE: The mast has two sight unit mounting positions, mount in

the position that is most comfortable for the technician to

sight through

Sighting unit must be calibrated to the optical head prior

to alignment of headlamps.

2.5 SIGHTING UNIT CALIBRATION

Calibration of sighting unit must be performed prior to alignment of

headlamps.

Raise optical head of SCA 1 ISOColor to the approximate center of

mast.

Turn the sighting unit until you can see the front edge of the optical

head while looking through the sighting unit lens. Line on lens

should line up with the front edge of the optical head.

If line does not line up with the front edge of optical head, loosen

the thumbscrews on the lens and move the lens into alignment.

Tighten thumbscrews.

It is important that periodical checking of calibration of the sighting

unit be performed, to assure proper calibration.

NOTE: When technicians of differing heights are using the SCA 1

ISOColor and the sighting unit is relocated to the optional

mounting position for better viewing, the sight unit must be

checked for calibration and adjustment made accordingly.

2.6 FLOOR SLOPE LASER

The floor slope laser assembly is factory calibrated, DO

NOT turn the level adjustment set screw.

The laser is used for floor slope measurement only. Remove

laser after floor slope measurements have been recorded.

Remove floor slope laser from packaging and insert front

fixture placement pin into hole on top and at front of the

rear area of the optical head, also there is an indentation

provided for the height adjustment screw to rest within.

Activate the laser by turning ON/OFF knob clockwise

(CAUTION: Excessive turning may damage laser

ON/OFF mechanism) to assure of functionality, turn off

laser. No further adjustment is required.

NOTE: Should calibration of the laser become necessary in

the future, Refer to “LASER CALIBRATION”.

Calibration, Section 5.1, Pg. 9.

Laser Battery Replacement

Unscrew back of laser and replace batteries with three (3), LR 44

button batteries or equivalent. Reverse process for assembly.

After battery replacement, CALIBRATION COULD BE REQUIRED.

Adjustment

IN

Calibration

On / Off

Knob

Optical

Head

OUT of

Calibration

Optical

Head

ON/OFF

Knob

Fixture

Placement Pin

Thumb Screws

Level Adjuster

Set Screw

5

Page 6

3. OPERATION PROCEDURES

3.1 PREPARATION, ALIGNMENT BAY(s)

Prior to any headlamp alignment using the SCA 1 ISOColor, the floor slope of the bay, or bays must be

determined, this is done by using the floor slope laser assembly and noting the position of the rear floor slope

wheel.

If the correct floor slope of the bay is not adjusted prior to any headlamp alignment, the technician will align

the headlamps in a higher, or lower position than what is correct. The SCA 1 ISOColor must be on the same

plain as the vehicle that is to be aligned, if the vehicle is positioned on a floor that has an upward slope

running from fore to aft of vehicle, then the SCA 1 ISOColor must be adjusted to have the same slope.

3.2 FLOOR SLOPE MEASUREMENT

Tool Required: Tape Measure or Ruler

Move the SCA 1 ISOColor to the service bay to be used for headlamp alignment and place the SCA 1

ISOColor at the front of the vehicle, off to one side. If multiple bays are to be used, procedure for

determining floor slope will need to be performed in each bay and recorded.

Lower the optical head to the bottom of the mast. Adjust optical head by rotating eccentric wheel at rear of

base until level vial registers level. Turn the laser on with the thumbscrew on the front of the laser assembly.

MEASURE

At the center point of the front wheel of the vehicle measure the distance from the floor to the point where the

laser strikes the tape measure, RECORD.

Move to the center point of the rear wheel of vehicle and measure the point where the laser strikes the tape

measure, RECORD.

If the measurements at the front and rear wheels are not equal, the

bay has a slope.

Rotate the floor slope handle on rear wheel until equal

measurements are registered at the front and rear wheels.

NOTE: When rotating eccentric axle on SCA 1 ISOColor, both

measurements will change at front and rear vehicle wheels,

to achieve equal measurements, more than one eccentric

Note the number on the floor slope gauge and record that number

along with the bay designate on floor slope sticker provided. Repeat

procedure for other bays and record.

NOTE: After measurements have been taken, remove laser and

3.3 VEHICLE PREPARATION

• Remove ice or mud from under the fenders.

• Set the tire inflation to the values recommended by the manufacturer.

• See that there is no load in the vehicle unusual to normal driving conditions.

• Check vehicle springs for sag or broken leafs.

• Check function of any automatic leveling systems and specific manufacturers instructions pertaining to

• Clean lenses (foggy and or yellowed lens can lessen the lamp intensity by up to 80%), check for bulb

• Stabilize suspension by rocking vehicle sideways.

axle adjustment may be required.

store in a secure place

vehicle preparation for headlamp alignment.

burnout, broken mechanical aiming pads, moisture in lens and proper beam switching.

MEASURE

FLOOR SLOPE REGISTRY

Bay# Slope Date Bay# Slope Date

_____ _____ ______ _____ _____ ______

_____ _____ ______ _____ _____ ______

_____ _____ ______ _____ _____ ______

_____ _____ ______ _____ _____ ______

6

Page 7

4. HEADLAMP ALIGNMENT

R

4.1 ALIGNMENT OF OPTICAL HEAD TO VEHICLE

Place the SCA 1 ISOColor in front of the first headlamp to be

aligned. Once the SCA 1 ISOColor is in place, the lens of the

optical head should be approximately 12 inches (+/- 6 inches) from

the face of the headlamp.

Set the floor slope of the eccentric wheel for the bay in which the

vehicle has been parked.

Rotate the sighting unit so that the front of the vehicle can be seen

through the sighting unit. Locate two (2) common points on or

under the hood to align the line in the sighting unit on.

NOTE: Points can be hood stops, radiator support (s), points

While looking through the sighting unit, align the line of the

sighting unit on the two common points by rotating the optical head

of the machine.

The SCA 1 ISOColor is now aligned with the vehicle. Repeat the

alignment process for each lamp.

4.2 CENTERING on the HEADLAMP

Turn headlamps on. Move optical head up, or down to the center of the

headlamp. Position of center of the headlamp is approximate; a ± 1.5”

allowance is acceptable.

TRICK: A method of determining if position is greater than 1.5” is by

observing the illumination that appears on the front of the optical lens

housing when moving the optical head left/right and up/down.

4.3 SELECTING HEADLAMP PATTERN

Not all headlamps are created alike and different vehicles

may have different design patterns. To be certain of the

lamp pattern, a designate is located on the lamp at the

bottom of the lens. Patterns of lamps that may be aligned

with the SCA 1 ISOColor are;

• SAE HIGH BEAM: All high beam lamps. Highest

Position aimer until illumination is of equal proportion around lens.

intensity point is centered on the Horizontal /

Vertical axis.

• SAE LOW BEAM: All low beam lamps

manufactured prior to 1999, selective manufacture

after 1999. The high intensity area is located in the

lower right hand quadrant.

• FOG/DRIVING LAMPS: All fog/driving lamps the

top of the high intensity area is located 4” down and

centered on the Vertical axis.

• SAE LOW BEAM “

Right): Low beam lamps manufactured after

1999, some vehicles. The high intensity area is

located in the lower right hand quadrant and

the beam pattern is aligned by placing the right

upper portion of the beam pattern on the

Horizontal axis.

of fender, etc.

VOR” (Visual Optical

7

H

H

US Low Beam

V

US Low Beam

V

Aim Area

VO

Common Points

V

H

High Beam

V

H

Fog / Driving

Lamp

Page 8

• SAE LOW BEAM “VOL” (Visual Optical Left):

Low beam lamps manufactured after 1999, some

vehicles. The high intensity area is located in the

lower right hand quadrant and the beam pattern is

aligned by placing the left upper portion of the beam

pattern on the .4 Degree (2.096”) Down Horizontal

axis.

• HID (High Intensity Discharge / Xenon) Lamps

Some HID / Xenon lamps (bright and bluish in appearance) generate

minimal Infrared emission to activate the ISOColor screen, visual

appearance of pattern on screen may have only one color and possibly

no color. However, a representative visual alignment is achieved by

observing the lamp pattern as depicted on the screen and aligning it to

the appropriate position. In the event of only one, or two colors

appearing on screen, the center of the inner most color represents the

hot spot.

4.4 ALIGNMENT OF HEADLAMP PROCEDURE

1. Locate SCA 1 ISOColor approximately 12 inches from in

front of the lamp to be aligned. Placement can be 6” to 18”

without jeopardizing alignment.

2. Position SCA 1 ISOColor in front of first lamp to be

aligned. Centering of system on headlamp is very

forgiving, as the fresnel lens provides a ± 1.5” widow for

centering.

3. Align SCA 1 ISOColor to vehicle by sighting through the

sighting unit and rotating optical head until line in sighting

unit intersects the two common points selected.

4. Headlamps should be switched on to low beam as this is

the primary driving lamp.

a. In compound lamps, where the Low Beam and

the High Beam are in the same lamp, you only

align one pattern, as by law, the other patte r n

must be within 1.5” of perfect alignment.

5. While viewing aim screen, adjust headlamp to position that

appears as graphic illustration of headlamp pattern selected.

The most inner portion of color is the high intensity zone

and this is what you center over the white dot designated

for the lamp pattern selected.

i. NOTE: Graphics on aiming screen

denote position of lamp position in

inches.

ii. Outer box denotes 8 inches, inner box

denotes 4 inches. Each hash mark

denotes 1 inch increment.

6. Repeat steps for remaining lamps.

5. LASER CALIBRATION / MAINTENANCE

5.1 FLOOR SLOPE LASER CALIBRATION

“LASER IS CALIBRATED AT THE FACTORY PRIOR TO SHIPMENT”

Aim Area

V

H

.4 Degree Down

(2.096 Inches)

US Low Beam

VOL

Headlamp Alignment Procedure

1. Position “SCA 1” in Front of first

lamp to be Aligned.

2. Adjust Floor Slope to Recorded

Bay Setting.

3. Square SCA 1 to Vehicle by

Looking Trough Sighting Unit.

4. Aligning Two Common Points with

5. Select Lamp Beam Type. While

6. Move SCA 1 to Next Lamp and

Line in Sighting Mirror.

viewing Lamp Patten, Adjust

Lamp to Pictorial Position

Repeat Steps 3 Through 5.

8

Page 9

Calibration Required ONLY if Rear- LASER Adjustment Set Screw has

“

been tampered with”

Tools Required: Elevated Surface (wheel alignment, frame machine, etc.)

Level (carpenters level or other means)

6‘ Straight Edge (board or other means)

5/64” Allen Wrench

Locate an elevated surface and lay the straight edge on surface facing away from

optical head. Check straight edge for level, shim if necessary.

Move SCA 1 ISOColor to end of straight edge, turn on the laser and adjust

height of optical head so that the mounted laser will shoot down the straight edge.

Adjust the rear floor slope wheel until the level in the optical head is centered. Readjustment of

height of optical block may be necessary.

Adjust the rear height adjustment set screw of the laser assembly (Lock Tight has been installed

on screw at factory, minor pressure should break seal) till laser is viewed at both ends of straight

edge equally.

Laser is now calibrated, installing lock tight or other adhesive to adjustment screw is

recommended.

5.2 MAINTENANCE

The SCA 1 ISOColor will provide years of trouble free operation with minimum maintenance, however,

care should be taken in the day-to-day usage of this service instrument. Following are areas that should be

periodically checked and serviced;

• Check wheel axles nuts for tightness, minor lubrication is

recommended.

• Check the optical head mounting bolts for tightness and tighten as

required.

• Check all other mounting screws, bolts and nuts for tightness.

• Clean the mast area where the brake rides with a mild detergent to

assure of secure holding.

• Clean the front lens, sighting unit and viewing window with a mild

detergent being careful to use a non-abrasive soft cloth.

• Visually inspect alignment screen for burn holes that could have been

caused by exposure to direct sunlight. Caution should always be

exercised in storing of SCA 1, a placement of a dust cover (P/N:

01016000) on unit is recommended during storage.

6. FREQUENTLY ASKED QUESTIONS

Question: Level in optical head is not centered during alignment procedure?

Answer: Level vial is used ONLY when checking the calibration of the FLOOR SLOPE LASER.

Question: The high intensity (hot spot) area of one headlamp is of a different color than

the other lamp?

9

Page 10

Answer: All lamps are legislated to be created equal, but this has proven not to be the case. Lamp intensities

will vary from lamp to lamp. The intensity of the lamp will determine the color of the high intensity

zone.

Question: Do I have to check for floor slope every time I perform a headlamp

alignment?

Answer: Floor slope need only be performed one time in each bay that the SCA 1 ISOColor is to be used.

When determining the floor slope, record the reading of the rear eccentric wheel on the sticker

provided, Each time you are in that bay, refer to the sticker and adjust the rear eccentric to that

measurement.

Question: Must I re-calibrate the Sighting Unit when I move the mounting of the sighting unit for taller,

or shorter technicians?

Answer: YES. It is good operating procedure to always check the Sight Unit calibration prior to all headlamp

alignments. When different height technicians are using the system, re-calibration is sometimes

required when moving the mounting of the sight unit from a high to low position and vice-versa.

Question: I cannot attain equal readings at the front wheel and the rear wheel areas when determining the

floor slope.

Answer: The only time that this can occur is when the shop bay has an abnormally excessive angle of slope.

The most frequent problem with determining floor slope is patience in adjusting until the

measurements are equal. A TRICK to assist in making this measurement is to first measure the height

of the laser at the optical head. Then turn the eccentric wheel until the laser reading matches the

measurement of the optical head at the rear wheel area. Check readings at front and rear wheel areas

and make, if any, minor adjustments to equal measurements. RECORD READING OF ECCENTRIC

WHEEL FOR FUTURE REFERENCE.

Question: What do I use as reference when squaring the SCA 1 ISOColor to the vehicle and do I need to

square again when moving from one lamp to another?

Answer: It is always recommended to check the alignment of the sight unit to the vehicle for every lamp to be

aligned. Some reference points that are prominent on most vehicles are the grill, hood line, radiator

support, hood bumpers, strut tower bolts and common assembly point bolts. Always pick two points

Question: Why is the aim screen not as colorful when I align Xenon headlamps?

that are of equal proportion.

Answer: Xenon lamps do not generate the IR (infra-red) of incandescent lamps and therefore less color will

appear on screen. In most instances, a minimal amount of color will appear and that is the high

intensity zone (hot spot) of the lamp. If no color appears at all, then alignment should be performed

by viewing the overall pattern of the lamp and positioning it as the illustration of lamp patterns notes

on pages 7. and 8..

WARRANTY

All Symtech Corporation products are warranted to be free from defects in material and workmanship under

normal user service for a period of one year after the sale of the product. Exception to this policy will be

individually evaluated and must be approved by Symtech Corporate. The sole obligation under this warranty shall

be to repair, or replace any defective products or parts thereof, which upon examination are deemed to the

seller’s satisfaction to be defective.

The warranty shall not apply to any product, which has been subject to misuse, negligence, or accident. The

seller shall not be responsible for any special or consequential damages and the warranty as set forth is in lieu

of all other warranties, either expressed or implied. However, the seller makes no warranty of merchantability in

respect to any products for any particular purpose other than that stated in literature and any applicable

manufacturer shop or service manuals referred to therein, including any subsequent service bulletins.

All Symtech Corporation Optical Headlamp Alignment Systems have been tested by an AMECA accredited

independent laboratory and found to comply with the Society of Automotive Engineers (SAE) recommended

practices prescribed in standards j599, j600, j1383 and j1735.

The seller makes no claims or warranties of any kind that the Symtech Corporation Optical Headlamp

Alignment Systems will align headlamps that do not conform to Society of Automotive Engineers recommended

practices described in j599, j600, j1383, and j1735.

Safety by Design

10

Loading...

Loading...