Page 1

BRIGHT SOLUTIONS

PROFESSIONAL SERIES Kit

HEADLAMP Resurfacer / Protector

Thank you for purchasing BRIGHT SOLUTIONS

PROFESSIONAL SERIES Kit, this is a 3 or 4 STEP process

that takes approximately 10~15 MINUTES to perform per

headlamp dependent upon severity of damage of lamp lens. By

applying the patented Preserver, your headlamp cleaning will be

preserved for more than two years.

Can Be Used on

Turn Signal Lights Reflective Lens Covers

: Headlamps Taillights

KEEP OUT OF THE REACH OF CHILDREN

DO NOT ALLOW PRODUCT TO FREEZE

WHEN APPLYING PRODUCT IN TEMPERATURES

o

BELOW 60

, TURN LAMPS ON TILL WARM.

DO NOT APPLY SHINE RESTORER/ PROTECTOR IN

DIRECT SUNLIGHT

READ INSTRUCTIONS IN ENTIRETY BEFORE USE.

USE ENCLOSED GLOVES TO PROTECT HANDS.

FIRST determine the extent of damage that has occurred over time to

your headlamp lens.

IF

Headlamp lens is slightly fogged and or yellowed, without

visible hairline scratches or crazing, in most cases, the lamp

can be simply cleaned clear without the use of sandpaper.

Steps 1, 3 and 4

IF

Headlamp lens has extensive yellowing, scratches, crazing,

and/or pits, sanding is necessary to obtain a successful

result. Regardless of damage, using sandpaper during

cleaning will speed the process dramatically.

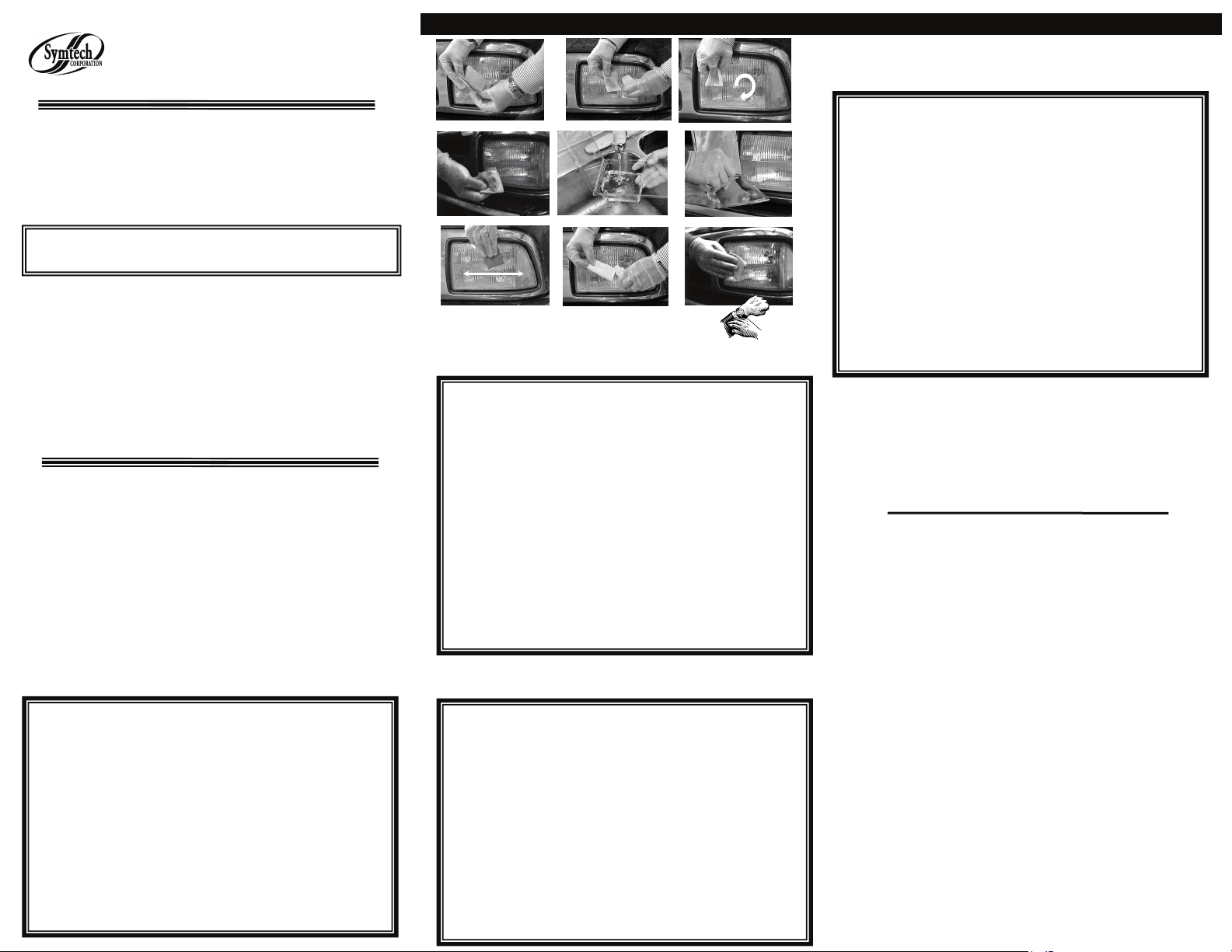

STEP 1

CLEANING

Remove all contents from package.

Select one of the towels and fold in quarters (1).

Thoroughly shake the BRIGHT SOLUTIONS Water Based

Pretreatment before applying to towel.

Open the specially formulated BRIGHT SOLUTIONS Water

Based Pretreatment, saturate the towel (2), and begin cleaning

the entire lens with a circular motion (3).

Continue cleaning, changing the towel surface and adding more Water

Based Pretreatment as towel becomes discolored (4) with dirt

and oxidation film of lamp lens.

When dirt and decolonization ceases to be removed from lens,

Proceed to

STEP 2 or 3

.

Steps 1, 2 ,3

PAGE 1

2

5

8

Five Minutes

Drying Time

STEP 2

1

4

7

SANDING

Fill cavity of package with water (5), start with 1500 grit sandpaper,

dampen with water and begin sanding the entire surface of the

lens, wetting sandpaper (6) as needed to prevent buildup of particles.

Note: ALWAYS sand in a straight motion (7), DONOT use

a circular motion.

Continue sanding till all discolored plastic has been removed from

lamp surface and residue of sanding is white in appearance.

Sanding is complete when lamp lens is uniform in appearance.

Take the 2000 grit sandpaper, dampen with water and sand the entire

surface of the lens, wetting sandpaper (6) as needed. This process will reduce the sanding lines .

Note: ALWAYS sand in the same direction as previous step

and in a straight motion (7), DONOT use a circular

Proceed to

motion.

STEP 3

STEP 3

POLISHING

Select one of the towels and fold in quarters (1).

Thoroughly shake the BRIGHT SOLUTIONS HEADLAMP

CLEANER/POLISH before applying to towel. Shake the

container frequently throughout the cleaning process.

Open the specially formulated BRIGHT SOLUTIONS

HEADLAMP CLEANER/POLISH, saturate a small area of

the towel (2), and begin cleaning the entire lens with a circular

motion (3).

Continue polishing and adding more HEADLAMP CLEANER/

POLISH as necessary to polish the entire lamp lens.

When lens has achieved a highly polished appearance, wipe off all

polish residue with Water Based Pretreatment

Proceed to

STEP 4

.

STEP 4

SHINE RESTORER/PRESERVER

3

6

9

Select one of the towels and fold in quarters (1).

NOTE:

Apply SHINE RESTORER/ PROTECTOR out

of direct sunlight. WHEN APPLYING PRODUCT

IN TEMPERATURES BELOW 60

Safety by Design

ON TILL WARM

o

, TURN LAMPS

Apply a liberal amount of the SHINE RESTORER/

PROTECTOR to a clean lint-free paper towel (8) and apply it

smoothly across the plastic surface (9), avoiding any runs or

bubbling. Do not wipe till dry or tacky, wipe on wet, stand back

and let dry

To remove SHINE RESTORER/PROTECTOR from other

surfaces when wet, rinse with water and wipe off with a dry

towel.

Multiple coats of SHINE RESTORER/PROTECTOR are

recommended to increase the shine and protection properties.

Plastic surface must be dry to the touch prior to each application of

PROCESS FOR

POLICE / EMERGENCY VEHICLE

LIGHT BAR COVERS:

Select one of the towels, fold in quarters (1) and saturate towel with

1.

Water Based PRETREATMENT (2).

Apply Water Based PRETREATMENT to entire surface

of lamp lens with a circular motion (3) Repeat process until

all dirt is removed and towel no longer turns black or yellow

(4). Cover may turn hazy. This is normal and will be removed with the final steps.

Select one of the towels, fold in quarters (1) and saturate towel with

2.

HEADLAMP

CLEANER/POLISH (2).

Apply HEADLAMP CLEANER/POLISH to entire surface

of lamp lens with a circular motion (3) with mild to moderate

pressure.

CLEANER/POLISH as necessary to polish the entire lamp lens.

When lens has achieved a highly polished appearance,

Continue polishing and adding more

residue of HEADLAMP CLEANER/POLISH with WA-

TERBASED PRETREATMENT. It is very important that

all HEADLAMP CLEANER/POLISH is removed in order

to obtain a secure bond of the Deep Fill Restorer & the Shine

Restorer / Protector in Steps 3 & 4.

Remove all

Page 2

PAGE 2

** NOTE: DO NOT sand Police / Emergency light bar covers

unless absolutely necessary, such as excessive breakdown of plastics. This plastic tends to scratch easily,

if you feel it is needed, use the highest grade sandpaper as possible (2000 or 2500 grit). Wet the sand paper

and use a Back and Forth Motion in the same direction.

Before applying Deep Fill Restorer, be sure lens is completely clean and dry. Use only WATERBASED Pretreat-

ment for this. Look at the lens while the Pretreatment is

wet, this will give you an idea of how the lens will look once

the final step is done, and will also let you know if more

cleaning is needed.

Apply a small amount of DEEP FILL RESTORER to a lint

3.

free paper towel and apply it pressing firmly, starting at the

top of the light and wiping from left to right with firm pressure

so you are pushing it into the plastic. Wipe over the area second time with the wet part of the paper towel to remove any

excess. Move down the light in the same manner Do

over a covered area more than twice as this product dries

quickly and will build up leaving the light with a streaked

appearance. Allow to dry completely, if you step back about

3-4 feet from the vehicle, the sand scratches should not be

obvious.

Apply SHINE RESTORER/PROTECTOR with lint free

4.

paper towel and wipe it smoothly over the lens cover as if

painting. Lightly touch up drips and always wait for the coats

to dry before adding the next coat. We recommend at least 3

coats of SHINE RESTORER/PROTECTOR for added

protection.

Not go

NOTES:

As with any repair versus replacement, some items will not

achieve like new results. If directions are followed, significant

improvement in the appearance of the items will be achieved. As

we are unable to supervise the application process, user assumes all

risks. The manufacturer and its distributors are not liable for any

damages incurred by the use of this product. If you are unsure as

to the application process or compatibility of the item you would

like to resurface, please contact the manufacturer or distributor for

advice on how to proceed.

Safety by Design

524 S.E. Transport Drive

Lee’s Summit, Missouri 64081

816-525-9263 FAX: 816-525-9283

www.symtechcorp.net

Manufactured for Symtech Corporation

by Coliance Corporation.

REVISED 10/2008

Loading...

Loading...